Method for preparing grain-refining preferred tropism Bi2Te3 thermoelectric materials

A technology for preferentially oriented and thermoelectric materials, which is applied in the preparation process of ion sintering and the preparation of Bi2Te3 thermoelectric materials with fine-grain preferred orientation, achieves the effects of low sintering temperature, simple process, and short synthesis and molding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

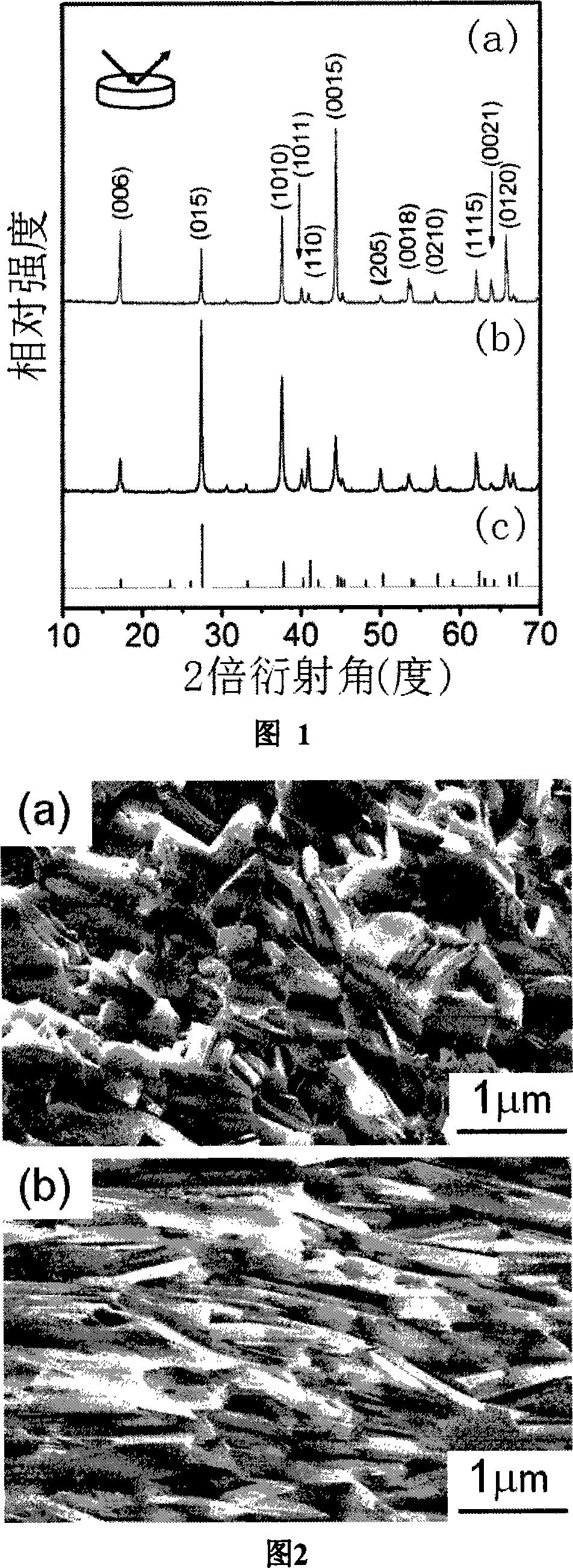

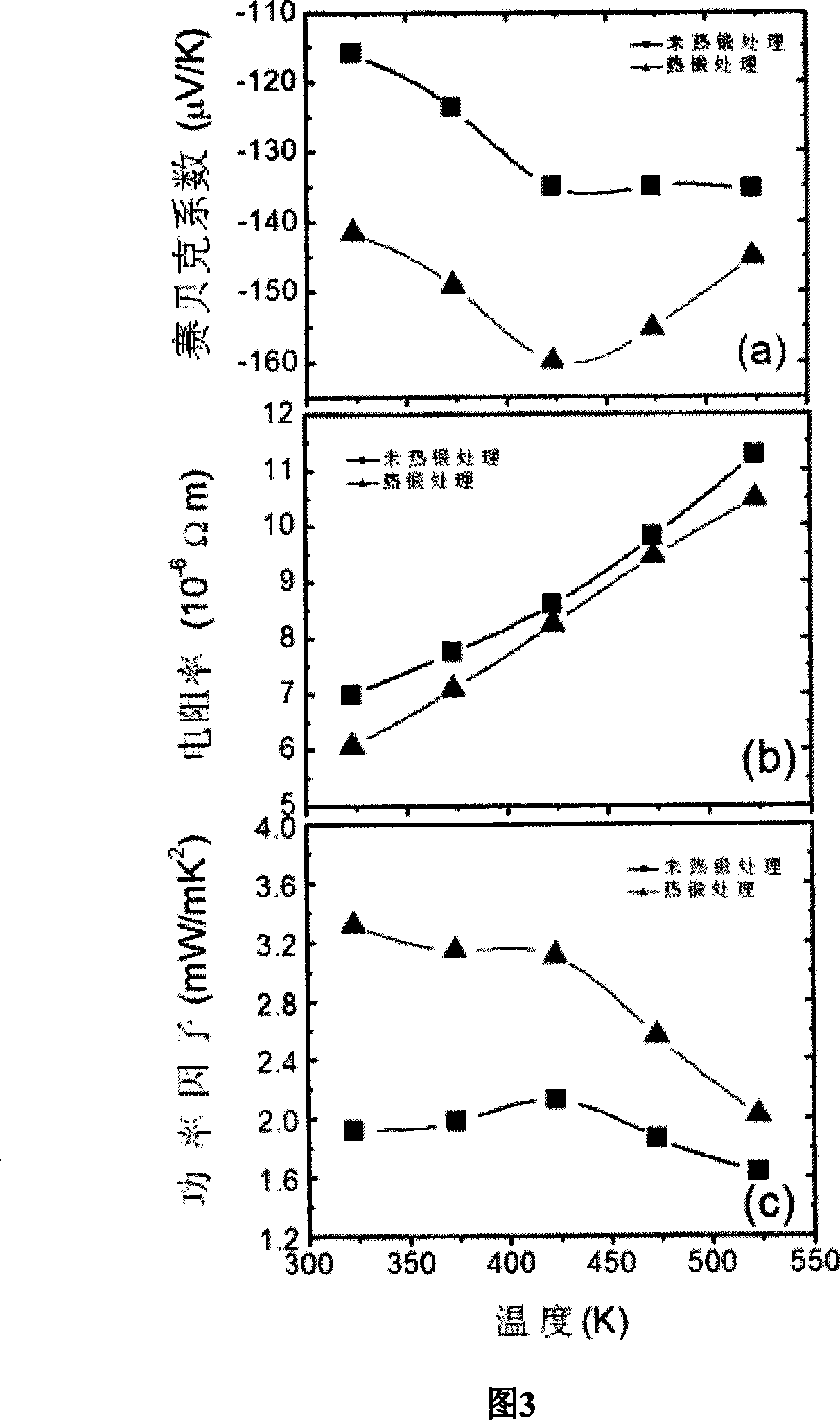

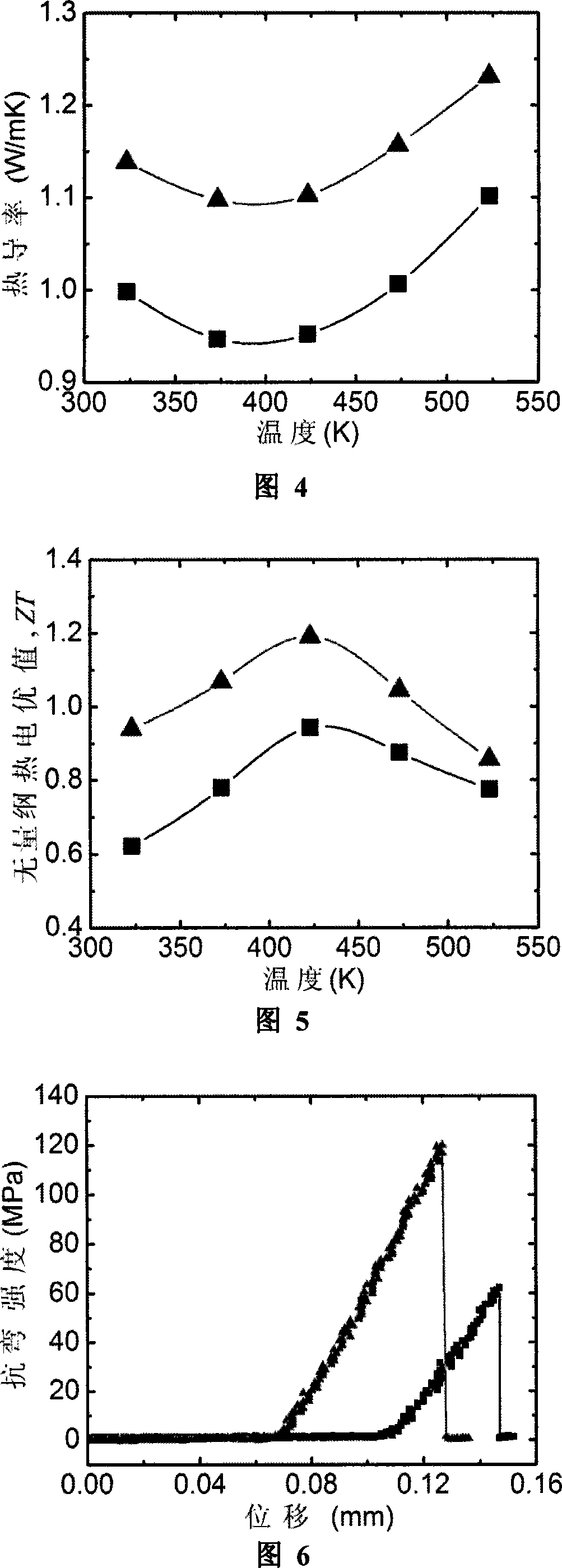

[0028] First, the mechanical alloying method (MA) was used to prepare Bi 2 Te 3 Precursor fine powder. The method is to mix the high-purity Bi and Te elemental powders according to the atomic ratio of 2:3, put them together into a planetary high-energy ball mill for mechanical alloying under the protection of an inert gas, dry-mill the synthetic compound, then carry out wet-milling, and finally bake Do it Bi 2 Te 3 The fine powder of the base material, and then the Bi 2 Te 3 The powder is sintered into a block. The bulk material is mainly prepared by two-step spark plasma sintering: the first step is sintering to obtain dense and fine-grained Bi 2 Te 3 For the block, the sintering temperature is 200-500°C, the holding time is 2-8min, and the pressure is 20-60MPa. The second step adopts discharge plasma technology to conduct hot forging treatment to obtain the texture, the temperature is 200-500°C, the holding time is 2-8min, and the pressure is 30-60MPa.

[0029] Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com