Patents

Literature

238results about How to "Refine grain size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for smithing GH4169 alloy plate shaped forgeable piece in air at an approximately equal temperature

ActiveCN101036931AGrain refinementHigh strengthForging/hammering/pressing machinesWheelsRoughcastCrystallite

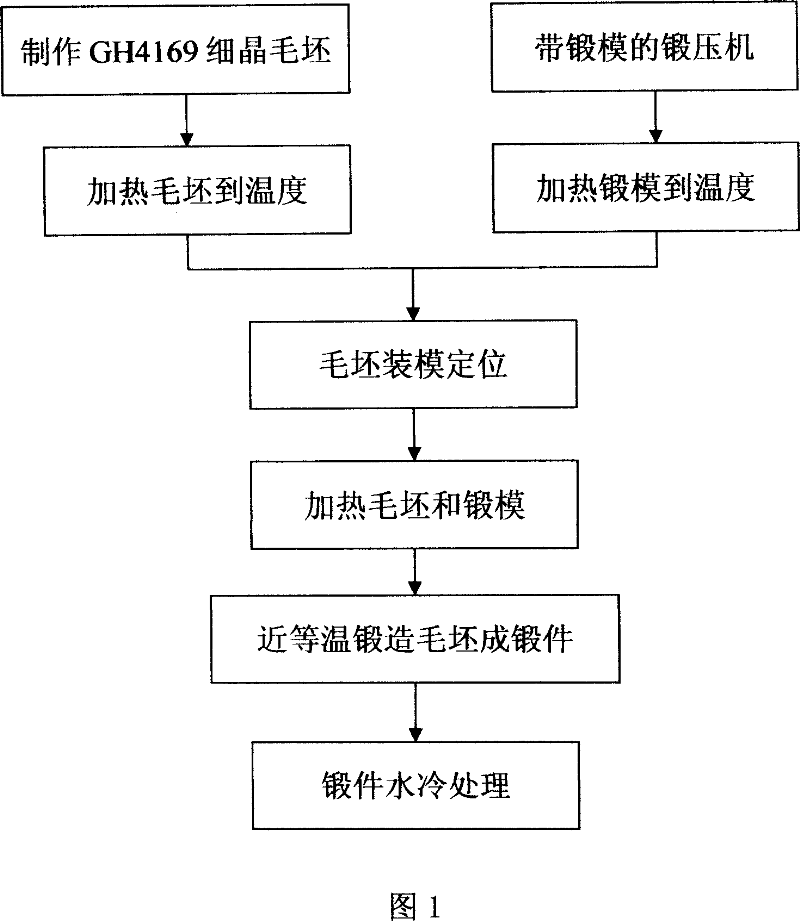

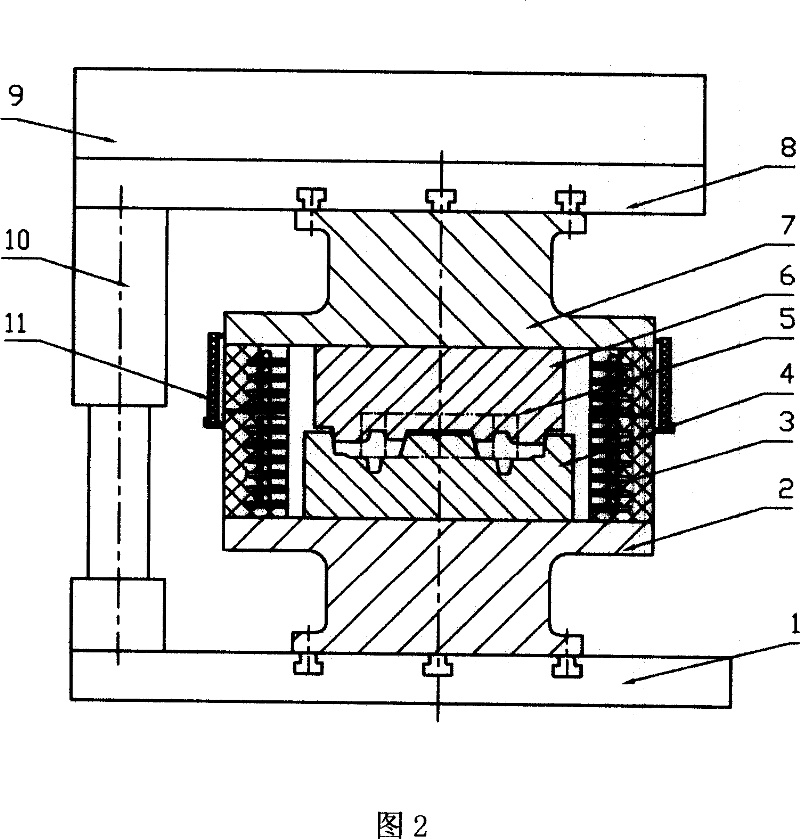

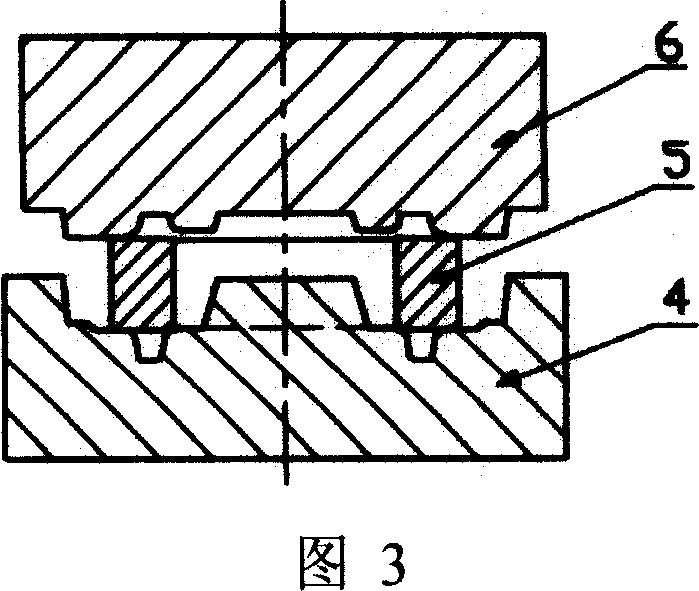

The invention discloses a close isothermal forging method of GH4169 alloy tray-shaped forging in the air, the technological process is that: making GH4169 finegrain roughcast adopting method of upsetting, punching and rolling after heating GH4169 alloy original rod material to 995-1005 DEG C; respectively heating the finegrain roughcast to 995-1005 DEG C and forging die to 950-965 DEG C; diefilling and positioning the finegrain roughcast; while heating finegrain roughcast and forging die to keep the heating warm humidity; forging die and forging press the finegrain roughcast forming under the 55MN to 65MN forging pressure and 0.01s-1 to 0.05s-1 strain rate; obtaining the tray-shaped forging; water-cool processing the tray-shaped forging. Adopting forging method of the invention can realize forming of the GH4169 alloy material tray-shaped forging difficult to deform and obtain the GH4169 alloy tray-shaped forging with weensy crystal grain, high intensity and complicated shape.

Owner:GUIZHOU ANDA AVIATION FORGING

Translucent alumina sintered body and a process for producing the same

InactiveUS6482761B1Improve corrosion resistanceEasy to provideImpression capsArtificial teethAlkaline earth metalTransmittance

A translucent alumina sintered body wherein the total content of an alkali metal element and an alkaline earth metal element is 50 ppm or less, and the linear transmittance of a light having a wavelength of 600 nm is 40% or more at a thickness of the sintered body of 0.85 mm.

Owner:SUMITOMO CHEM CO LTD

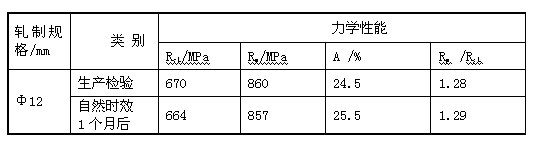

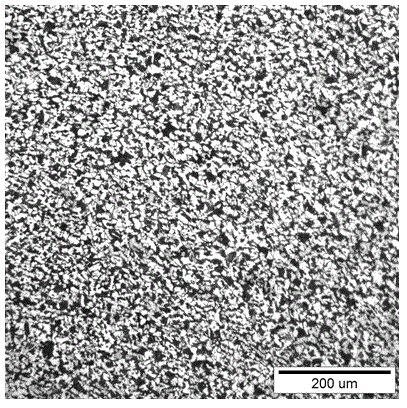

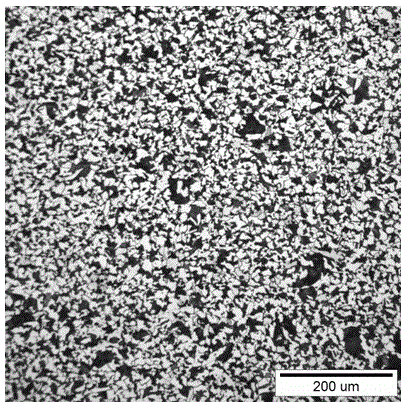

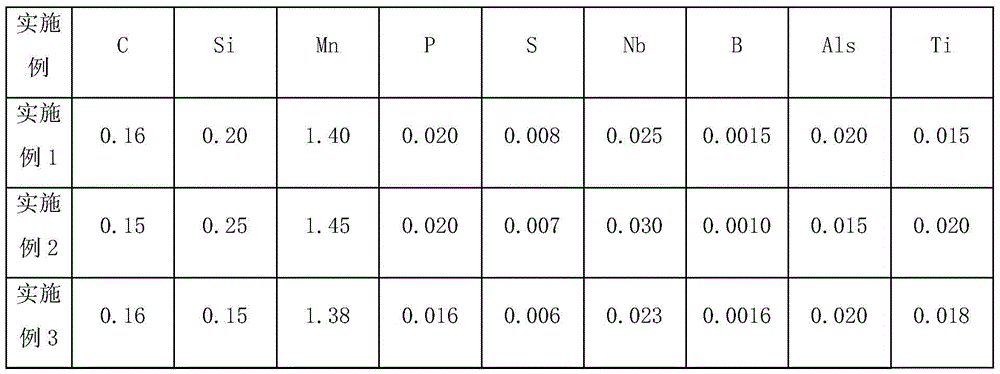

Niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production thereof

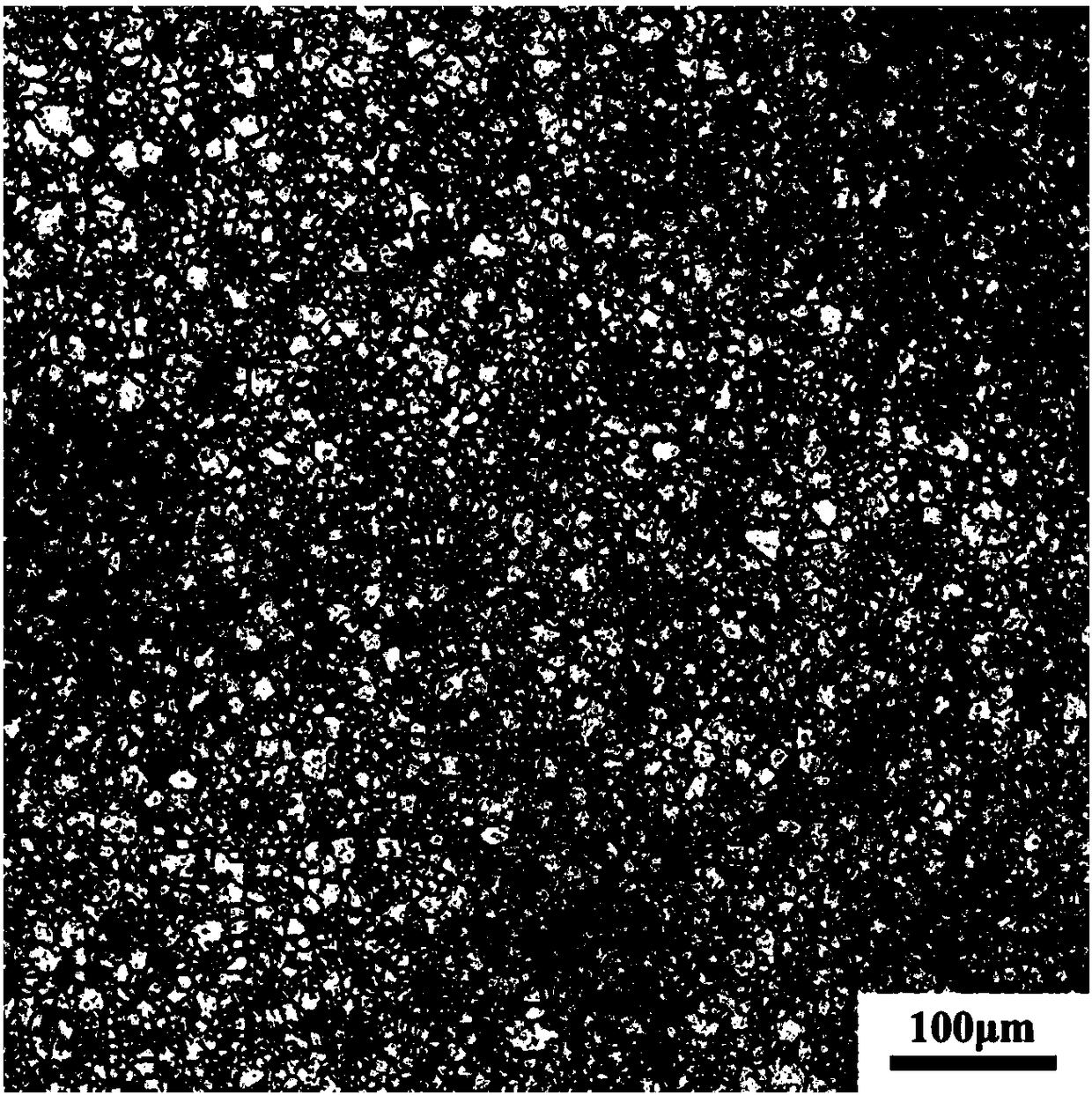

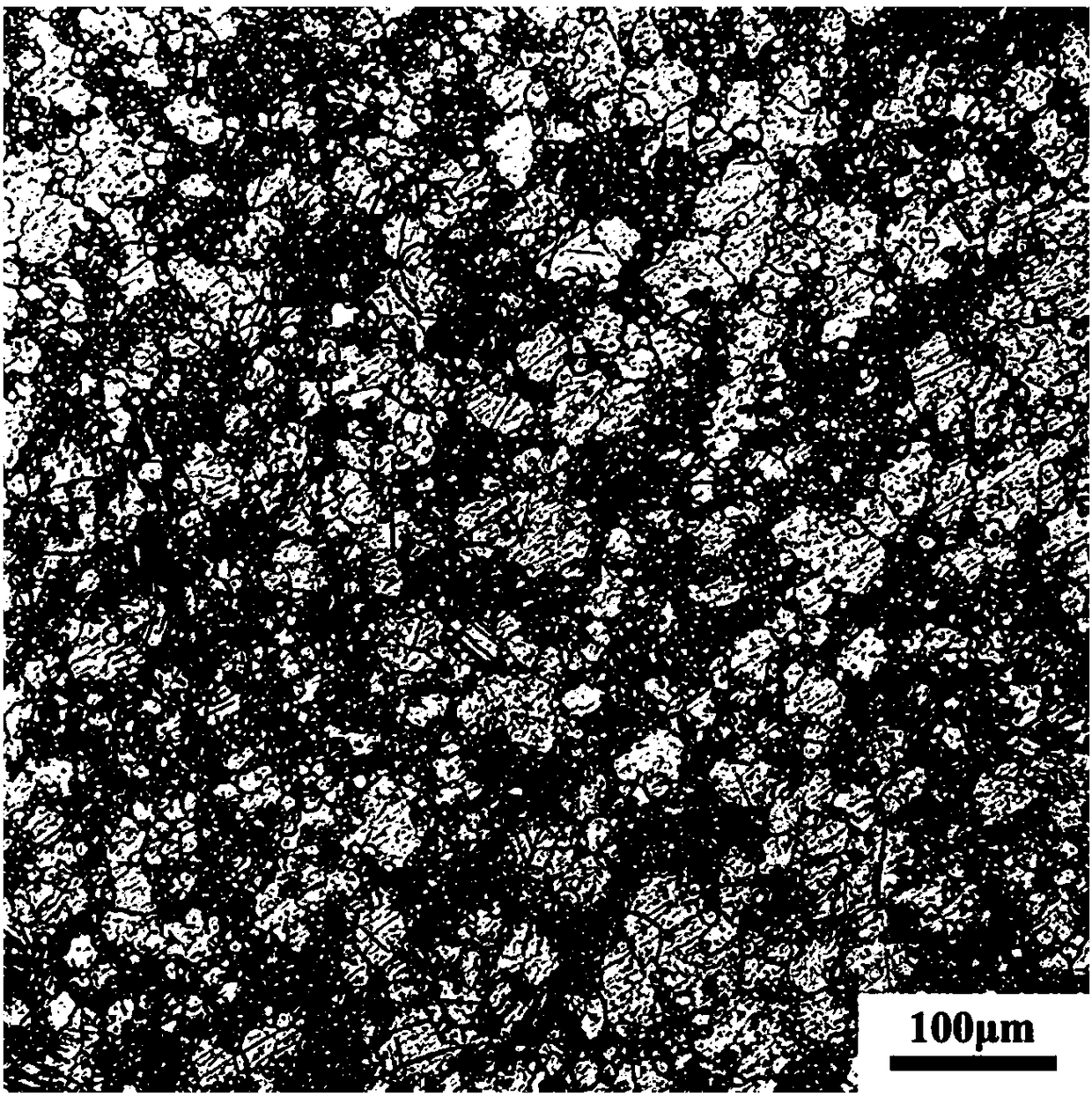

ActiveCN102796962ALow strain agingIncreased strain agingProcess efficiency improvementNiobiumTitanium

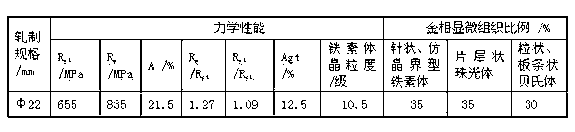

The invention provides a niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar and production of the niobium, titanium and boron microalloy hot-rolled ribbed bar (HRB) 600 high-performance aseismic reinforcing bar. Through molten steel smelting, molten steel casting, billet controlled rolling and controlled cooling, the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar is produced and comprises the following chemical constituents according to mass ratio: 0.14-0.18% of C, 0.30-0.50% of Si, 0.50-0.75% of Mn, 0.50-0.70% of Cr, 0.030-0.050% of Nb, 0.0015-0.0030% of B, 0.020-0.040% of Ti, no more than 0.045% of S, no more than 0.045% of P and the balance of Fe and unavoidable impurities. The niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcing bar has the characteristics of low production cost, technological applicability, strong controllability and the like, the steel microstructure is uniformly distributed and has good form, the refining effect of ferrite is obvious, and the niobium, titanium and boron microalloy HRB600 high-performance aseismic reinforcement has good low-strain timeliness, high strength, good toughness, good welding performance, excellent aseismic performance and excellent combination property.

Owner:WUKUN STEEL

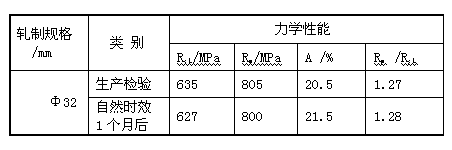

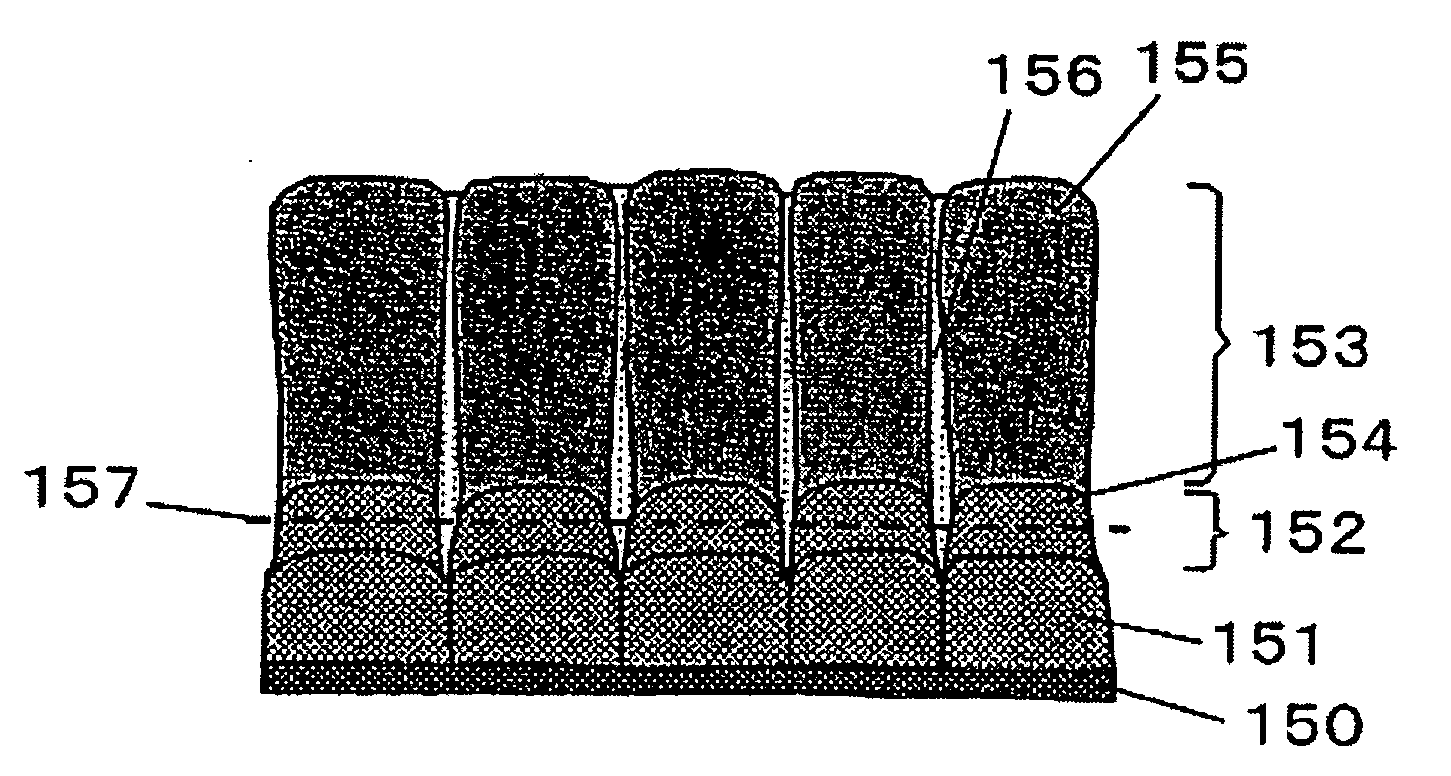

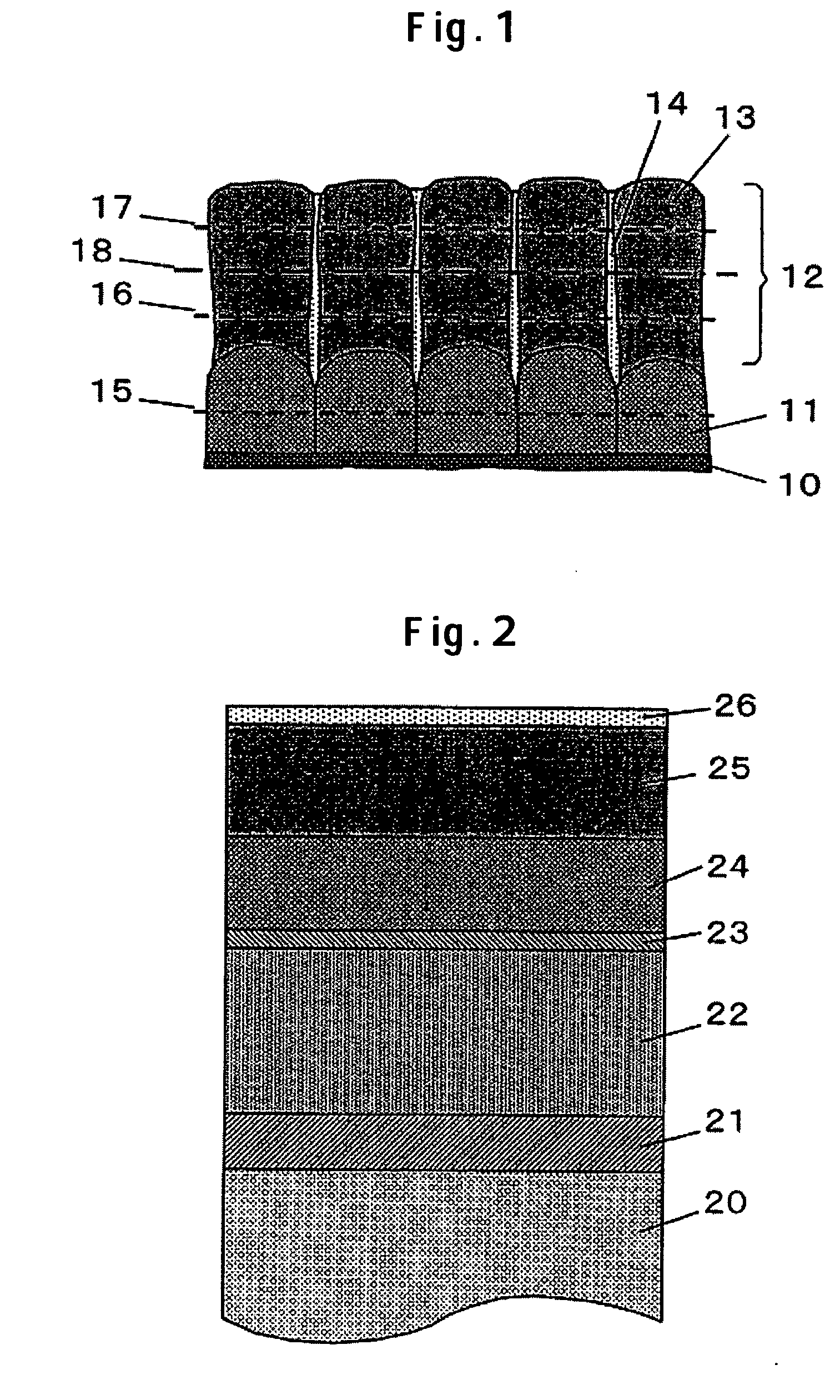

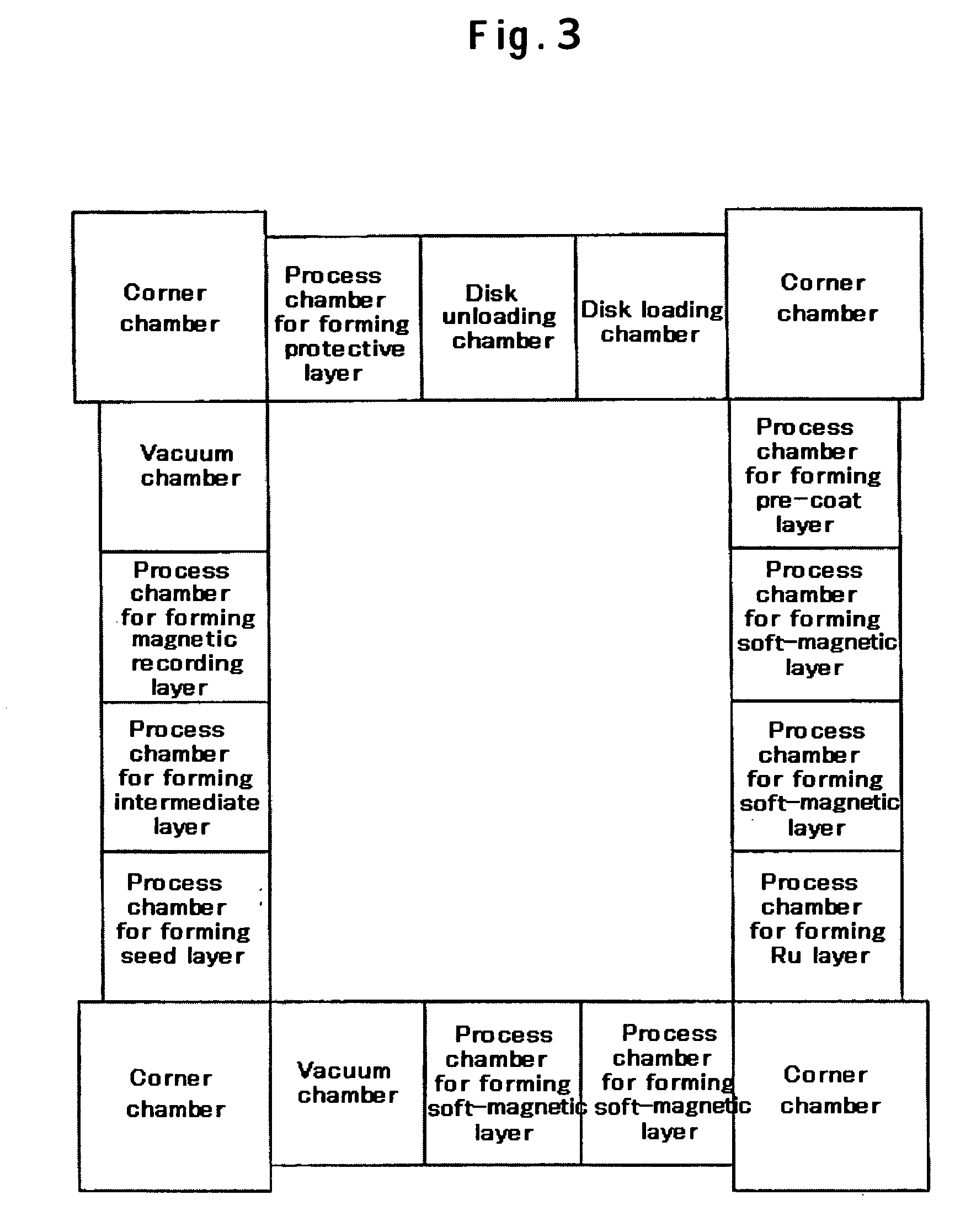

Perpendicular magnetic recording medium with granular structured magnetic recording layer, method for producing the same, and magnetic recording apparatus

InactiveUS20060088737A1Secure durabilitySecure flyabilityVacuum evaporation coatingSputtering coatingRecording layerProtection layer

Embodiments of the invention provide a perpendicular magnetic recording medium having a granular structured magnetic recording layer including many columnar grains, and grain boundary layers containing oxide, wherein a high medium S / N ratio is obtained while securing head flyability and durability. In an embodiment, the perpendicular magnetic recording medium includes a granular structured magnetic recording layer having many columnar grains, as well as grain boundary layers including oxide respectively. Assuming that the columnar grains are divided equally in the film thickness direction into a protective layer side portion and an intermediate layer side portion, and the diameter of the protective layer side portion is larger than that of the intermediate layer side portion.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Hot-rolling transformation-induced plasticity steel plate and preparation method thereof

A hot-rolling transformation-induced plasticity steel plate and a preparation method thereof belong to the field of metallurgical technology. The steel plate comprises the following components by weight percentage: 0.18 to 0.20 percent of C, 1.30 to 1.45 percent of Mn, 0.60 to 0.70 percent of Si, 0.50 to 0.60 percent of Al, 0.009 percent or less than 0.009 percent of P, 0.007 percent or less than 0.007 percent of S, 0 to 0.040 percent of Nb and the balance of Fe. The preparation method thereof comprises the steps of: smelting low-silicon and low-carbon steel into steel ingot; heating the steel ingot to 1200 plus / minus 10 DEG C to obtain billet through forging; loading the billet into a heating furnace, heating the billet to 1200 plus / minus 10 DEG C and keeping temperature for 1 to 2 hours; carrying out rough rolling and precision rolling; air cooling till the temperature reaches 700 to 760 DEG C; accelerating cooling at a speed of reducing 40 to 50 DEG C per second; and adopting a reeling machine for reeling. The hot-rolling transformation-induced plasticity steel plate prepared by the method has high intensity of tension and better impact ductility.

Owner:NORTHEASTERN UNIV

Lithium-enriched manganese-based material precursor as well as preparation method, lithium-enriched manganese-based anode material and preparation method thereof, lithium battery

ActiveCN108557905AEnough grain boundary fusionActive enoughCell electrodesSecondary cellsChemistryVoltage

The invention relates to a lithium-enriched manganese-based material precursor which is a lithium-enriched manganese-based carbonate precursor of a lamellar morphology, the particle size of the precursor is 1-7mu m, and the specific surface area of the precursor is 8-50m<2> / g. By adopting the lithium-enriched manganese-based carbonate precursor of the lamellar morphology, a lithium-enriched manganese-based anode material of a high single crystallization degree can be easily prepared. The invention further relates to a preparation method of the lithium-enriched manganese-based carbonate precursor of the lamellar morphology, and a preparation method and the application of the lithium-enriched manganese-based anode material of a single crystal morphology. Therefore, the mechanical strength, the stability, the compaction density, the capacity and the first efficiency of the micro structure of the anode material can be improved, and the voltage attenuation of the material can be inhibited.

Owner:桑德新能源技术开发有限公司 +1

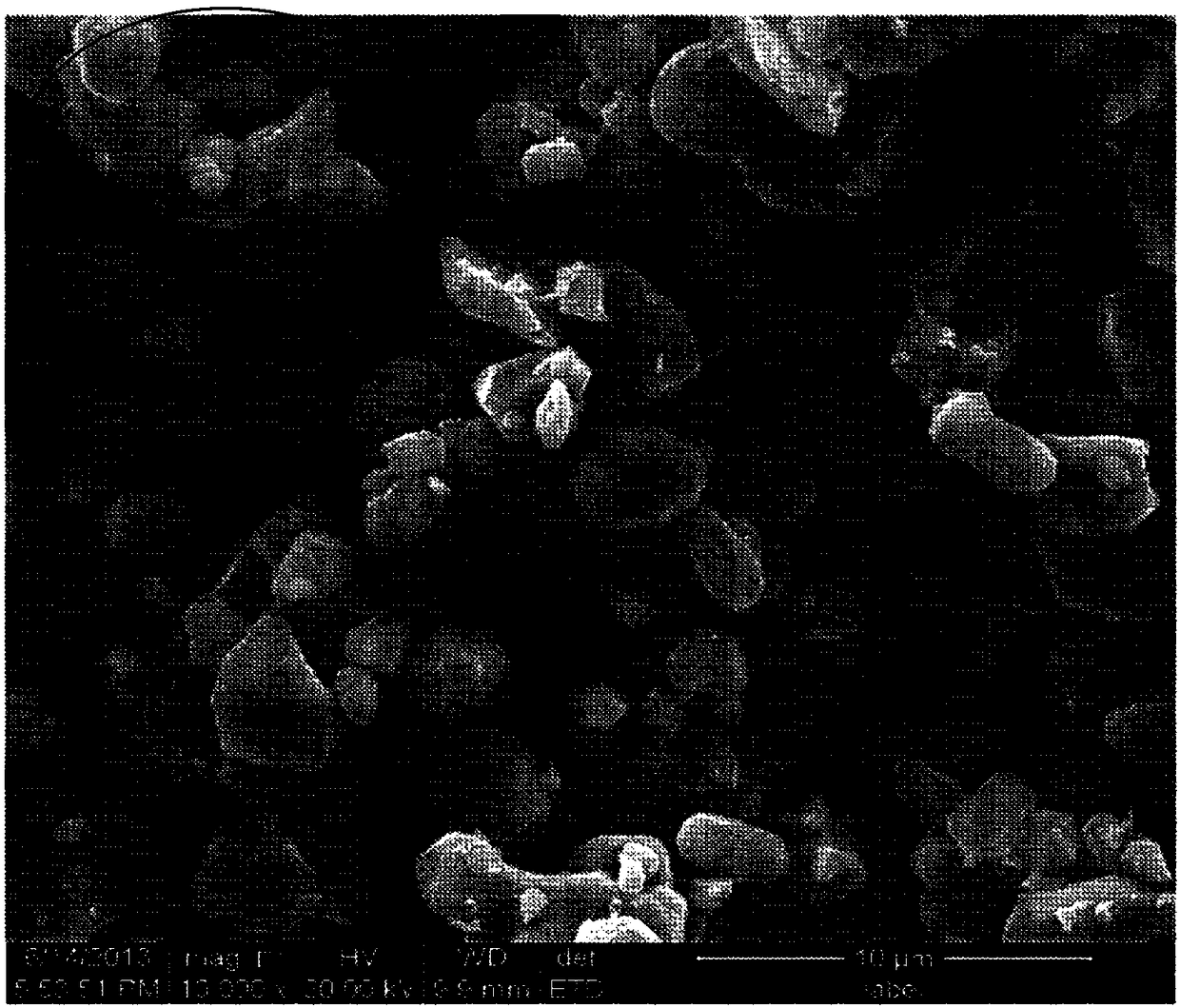

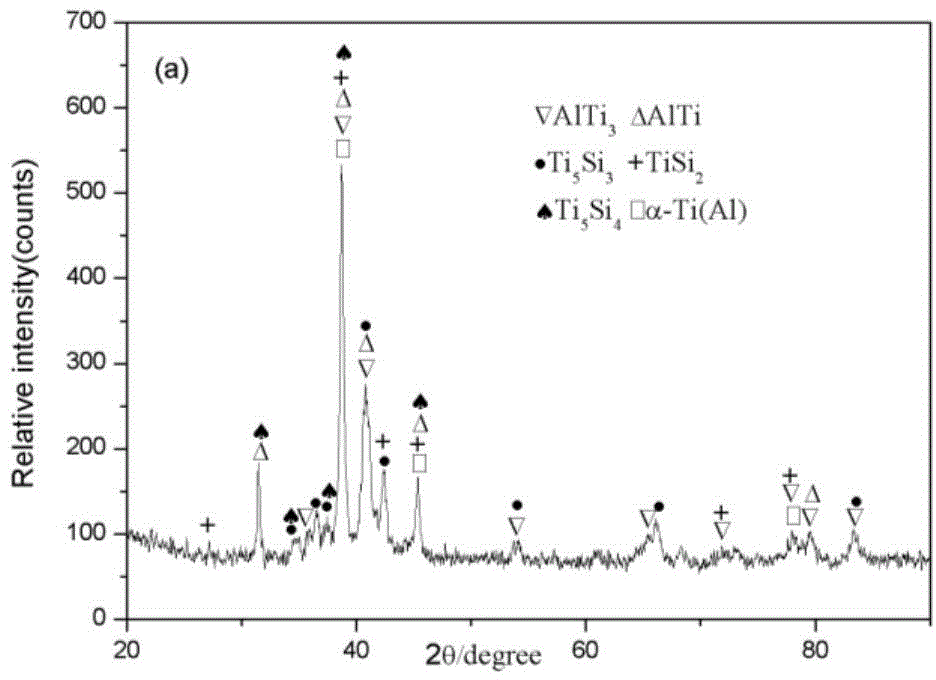

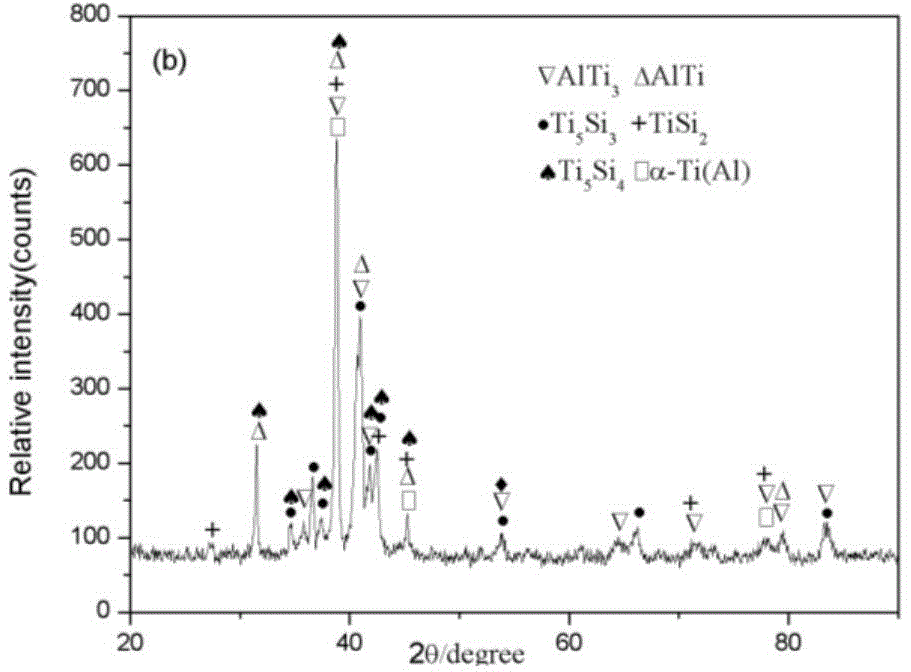

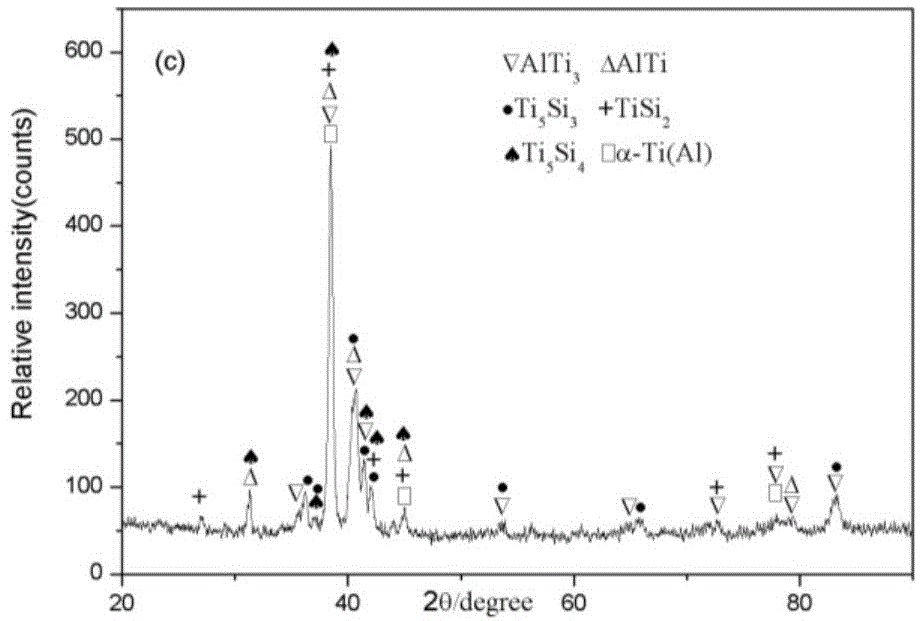

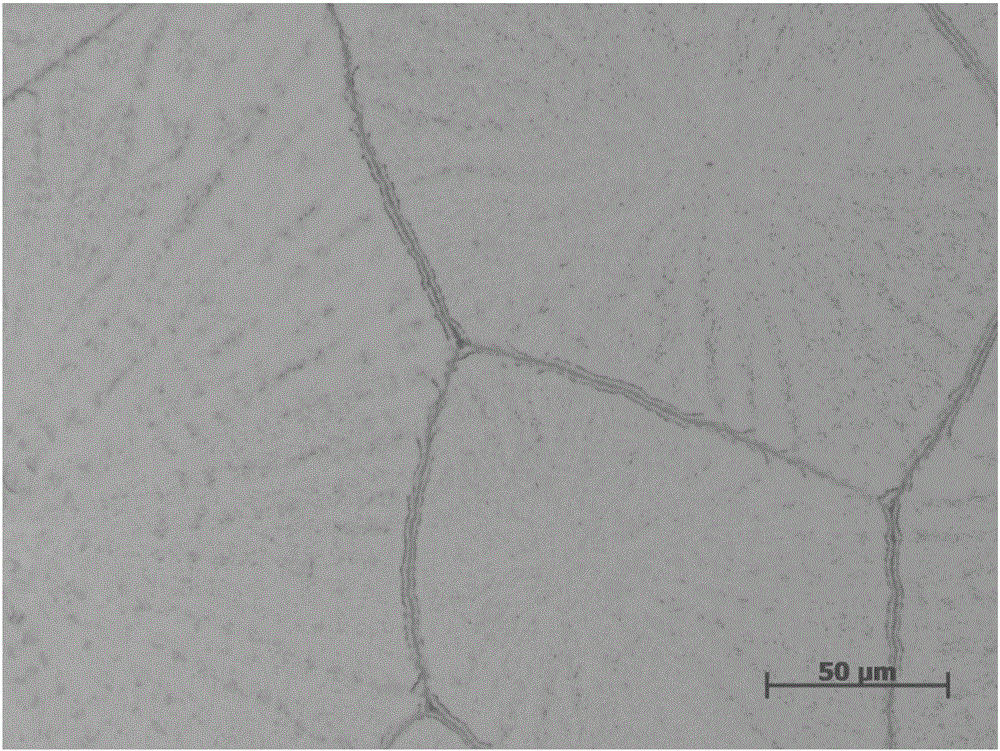

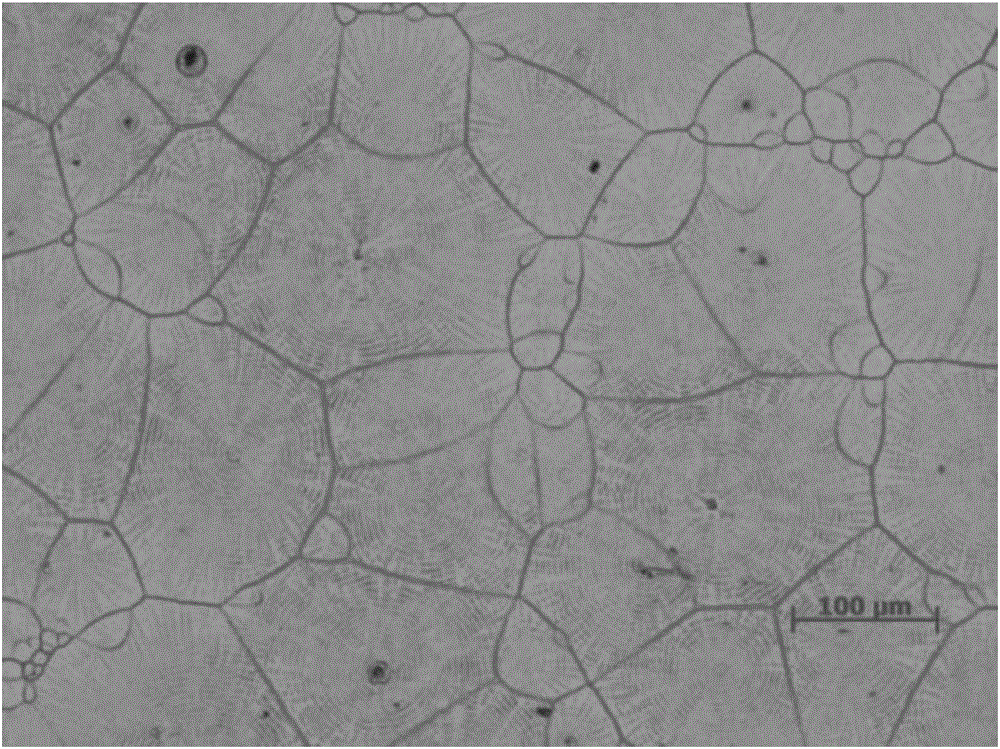

Preparation technology of intermetallic compound based ceramic composite coating on surface of titanium alloy

ActiveCN104152895AHigh hardnessGood metallurgical bondMetallic material coating processesCeramic compositeShielding gas

The invention discloses a preparation technology of an intermetallic compound based ceramic composite coating on the surface of a titanium alloy. The preparation technology comprises the following steps of: (1) uniformly mixing cladding material powder, preparing mixed powder into paste with a water glass solution, uniformly coating the surface of the titanium alloy with the paste with the coating thickness of 0.5-1.0mm, carrying out airing, and (2) carrying out laser cladding on the coating on the surface of the titanium alloy with the laser power of 800-1200W and the laser scanning speed of 2.5-7.5mm / s, and blowing argon for shielding with the shielding gas pressure of 0.2-0.4MPa, wherein a laser spot diameter is fixed at 4mm.The mixed cladding material powder comprises the following ingredients by mass percentage: 25-65% of Ti, 20-60% of Al, 5-30% of Si and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 2-40% of B4C and 0-3% of Y2O3, or 25-65% of Ti, 20-60% of Al, 5-30% of Si, 5-40% of TiC, and 0-3% of Y2O3. The composite coating prepared by the technology can significantly increase microhardness of the titanium alloy, improve wear resistance of titanium alloy components, and extend an application scope of titanium alloy spare parts.

Owner:SHANDONG UNIV

Large grain organic and inorganic hybrid perovskite film preparation method

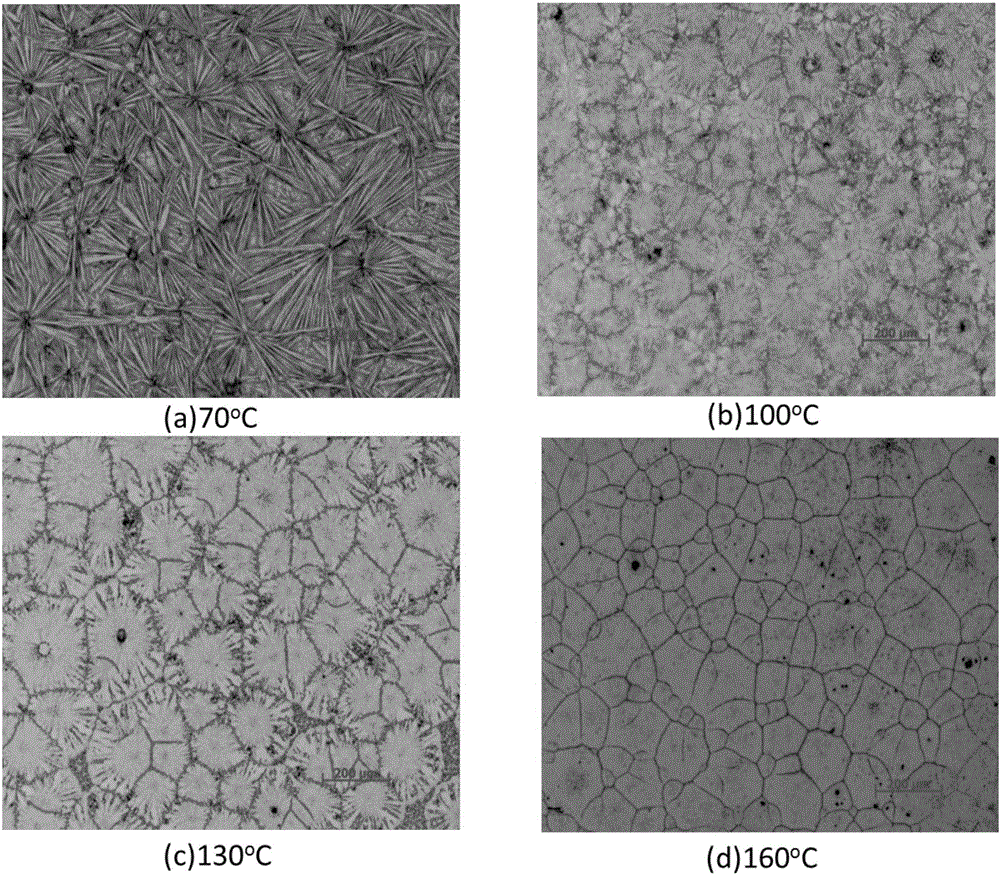

ActiveCN106159088AEasy to controlEasy preparation of controlled substrate temperatureSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisSolar battery

The invention discloses a large grain organic and inorganic hybrid perovskite film preparation method, belonging to the perovskite type solar battery and correlated photoelectric semiconducting material field, and can prepare a uniform and compact large grain film through the steps of configuration of an organic and inorganic hybrid perovskite precursor solution, stirring and heating, spin coating, annealing, etc. The method requires no spin coating in a multistep approach, ca easily control the temperature of a room temperature substrate, has no strict requirements on an annealing and cooling rate, and can manufacture a film efficiently. The method realizes virtual grain film growth through adjusting the grain dimension of a perovskite light-absorption layer, thereby reducing grain inner defects, and increasing the carrier transport efficiency; in addition, the method controls grain boundary defects, greatly improves perovskite crystal film environment stability, and enhances perovskite thin-film device performances. A perovskite type virtual monocrystalline film prepared in the low temperature solution method can assemble hysteresis free, efficient and stable perovskite type solar batteries and correlated film transistor, electroluminescent and laser emission photoelectric semiconductor devices.

Owner:NANJING UNIV OF TECH

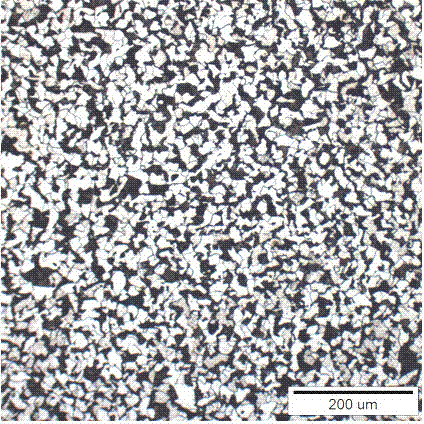

Production method for non-annealed medium carbon cold heading steel hot-rolled wire rod

ActiveCN104759469AIncrease weightRefine the grain sizeTemperature control deviceMetal rolling arrangementsTemperature controlWire rod

The invention discloses a production method for a non-annealed medium carbon cold heading steel hot-rolled wire rod. The production method includes steps that (1) smelting molten steel, and continuously casting to form a billet; (2) slowly cooling the billet to release stress; (3) heating the slowly cooled hot-rolled billet to 1150 to 1190 degrees centigrade, preserving the heat for 110 to 140 minutes, and dephosphorizing through high pressure water; (4) carrying out rough intermediate rolling, pre-precision rolling and finish rolling on the dephosphorized hot-rolled billet, wherein the finish rolling temperature is 965 to 995 degrees centigrade, the coiling temperature is controlled at 960 to 980 degrees centigrade after finishing finish rolling, and the dimensional precision is performed with negative common difference; (5) feeding a hot-rolled steel wire rod to a cooling line, closing a fan and a heat holding cover, and keeping the steel wire rod in the heat holding cover for at least 40 minutes to obtain the hot-rolled wire rod. The production method for the non-annealed medium carbon cold heading steel hot-rolled wire rod enables the drawing amount to be reduced, avoids the hardness increase due to large drawing amount, meets the non-annealing production demand of the downstream user, enables the cost to be reduced, avoids the environment pollution due to annealing, and is featured with energy saving, environment friendliness and low cost.

Owner:XINGTAI IRON & STEEL

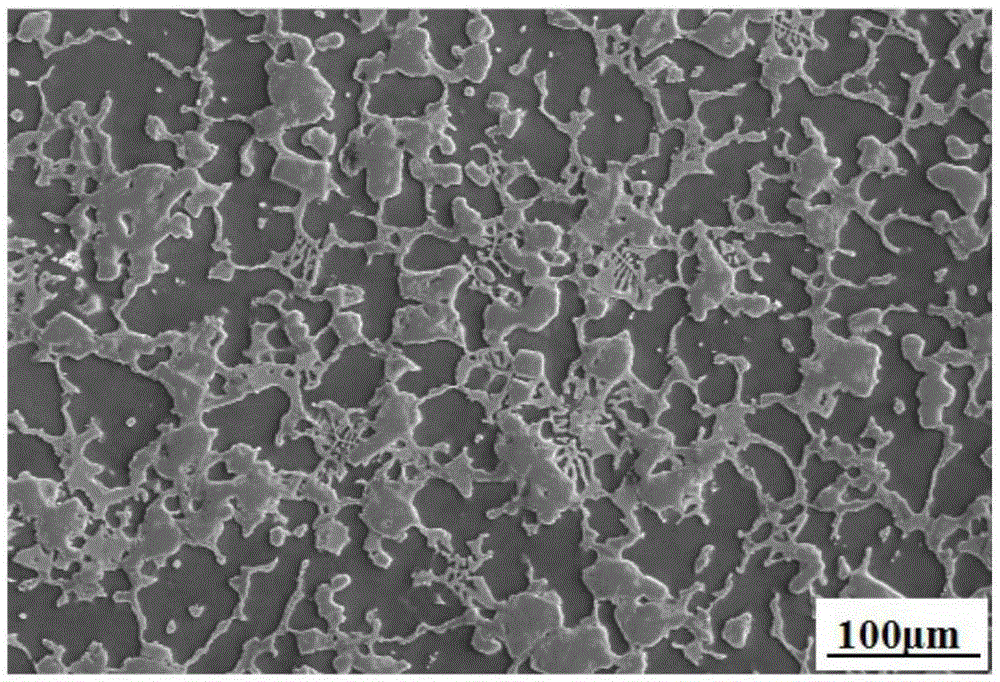

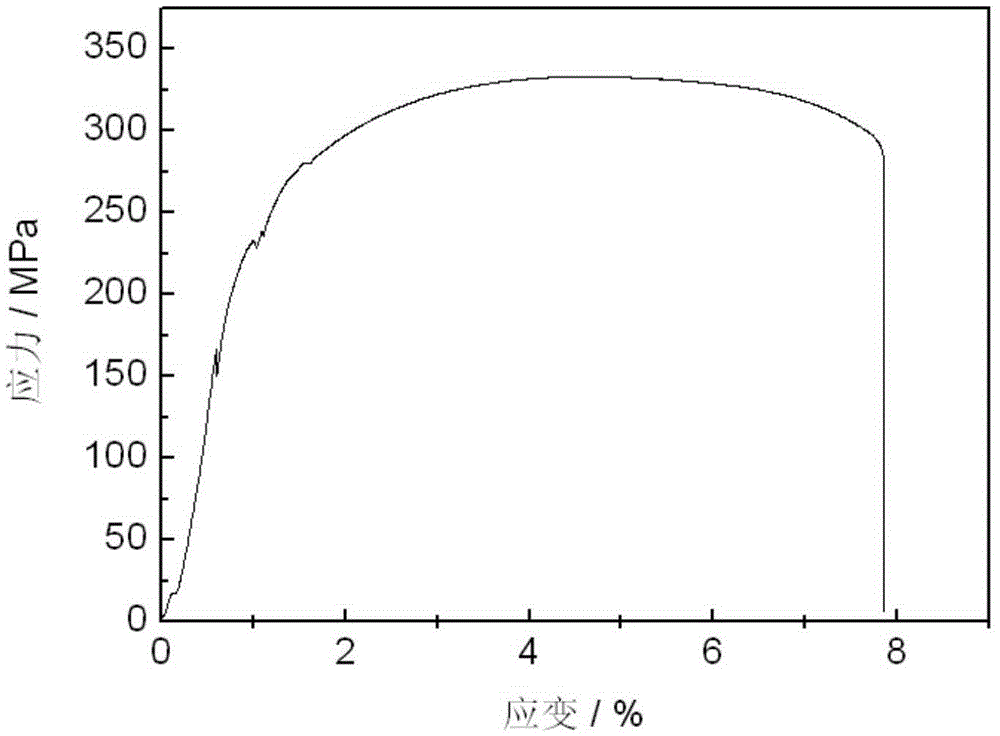

Heated and reinforced high-strength cast magnesium alloy and preparation method thereof

The invention provides a heated and reinforced high-strength cast magnesium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 8.0-10.0 of Zn, 1.0-5.0 of Al, 1.0-5.0 of Sn, 0.1-1.0 of Cu, 0.3-0.8 of Mn, 0.3-0.5 of Ca, and the balance of Mg and inevitable impurity elements. According to the high-strength cast magnesium alloy, under a room-temperature stretch test, the tensile strength reaches 320-350 MPa, and the yield strength reaches 220-260 MPa. A heat treatment process of the magnesium alloy comprises solution treatment by 4-8 hours at a temperature of 330-380 DEG C, air cooling, aging by 8-16 hours at a temperature of 150-220 DEG C and obtaining of the high-strength cast magnesium alloy. The heat treatment process of the alloy is simple and easy to realize; and the aging treatment can form a lot of nanoscale strengthening phases in an alloy structure, so that the alloy strength can be prominently improved. The alloy contains no such noble metal as rare earth, and is an alloy system with low cost and wide applicability.

Owner:山东山科智镁新材料科技有限公司

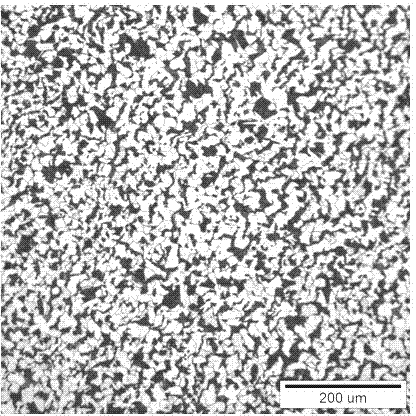

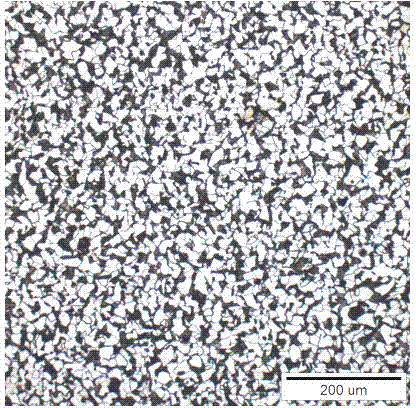

Non-annealed cold forging steel hot-rolled wire rod and production method thereof

The invention discloses a non-annealed cold forging steel hot-rolled wire rod and a production method thereof. The method comprises the steps of continuous casting, heating, rolling, spinning and cooling. The non-annealed cold forging steel hot-rolled wire rod comprises 0.29-0.38wt% of C, 0.15-0.30wt% of Si, 0.70-0.90wt% of Mn, 0.03wt% or less of P, 0.03wt% or less of S, 0.30wt% or less of Cr, 0.0008-0.0050wt% of B, and the balance of Fe and residual elements. In the heating step, continuous cast billets are heated to 1100-1190DEG C; in the rolling step, the initial finish rolling temperature is 965-995DEG C; in the spinning step, the spinning temperature is 960-990DEG C; and in the cooling step, the cooling speed is 0.5-1.5DEG C / s. The method realizes production of the non-annealed cold forging steel hot-rolled wire rod through optimally designing chemical components, controlling the heating temperature, the initial finish rolling temperature, the spinning temperature and the cooling speed and controlling the amount and the grain size of ferrite by using present devices and technologies without increasing investment or production cost, so the non-annealing production and cost reduction demands of downstream users are met, and pollution of annealing to environment is avoided.

Owner:XINGTAI IRON & STEEL

Low rare earth high strength magnesium lithium alloy and preparation method thereof

InactiveCN101787471AHigh strengthImprove plastic deformation abilityRare earthVolumetric Mass Density

The invention discloses a low rare earth magnesium lithium alloy, composed of the following components by weight percent: 5.5-11% of Li, 1-5% of Zn, 1-5% of Ca, 0-2% of RE, balance Mg. Vacuum-pumping and argon protection method is adopted to cast alloy, then the obtained as cast magnesium alloy ingot is subject to heat treatment under the protection of gas, and finally the alloy is extruded or rolled and subject to texturing processing, thus obtaining magnesium alloy after texturing processing. The invention provides a magnesium lithium alloy with low rare earth content and density less than 1.6g / cm3; the magnesium lithium alloy not only has high strength but also has higher plasticity and toughness and can meet the requirement of room temperature texturing processing thin plate on performance indexes of strength and plasticity.

Owner:XIAN UNIV OF TECH

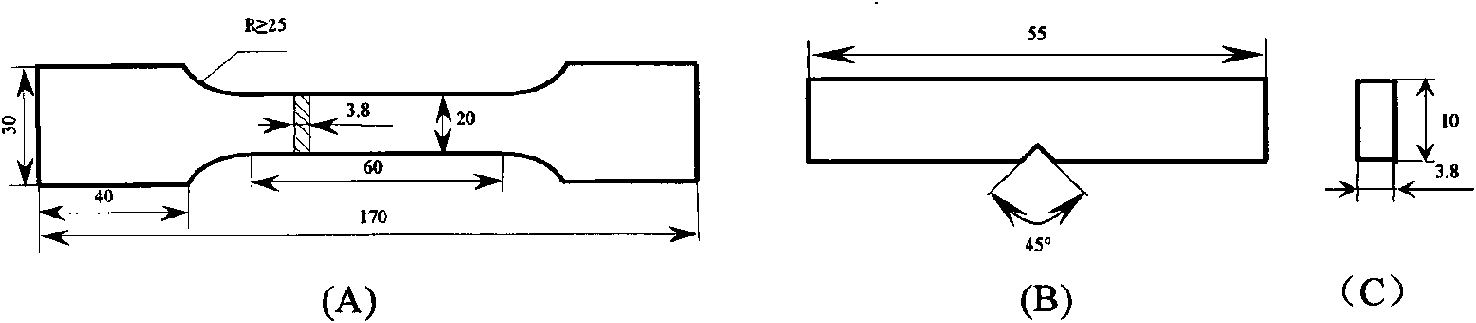

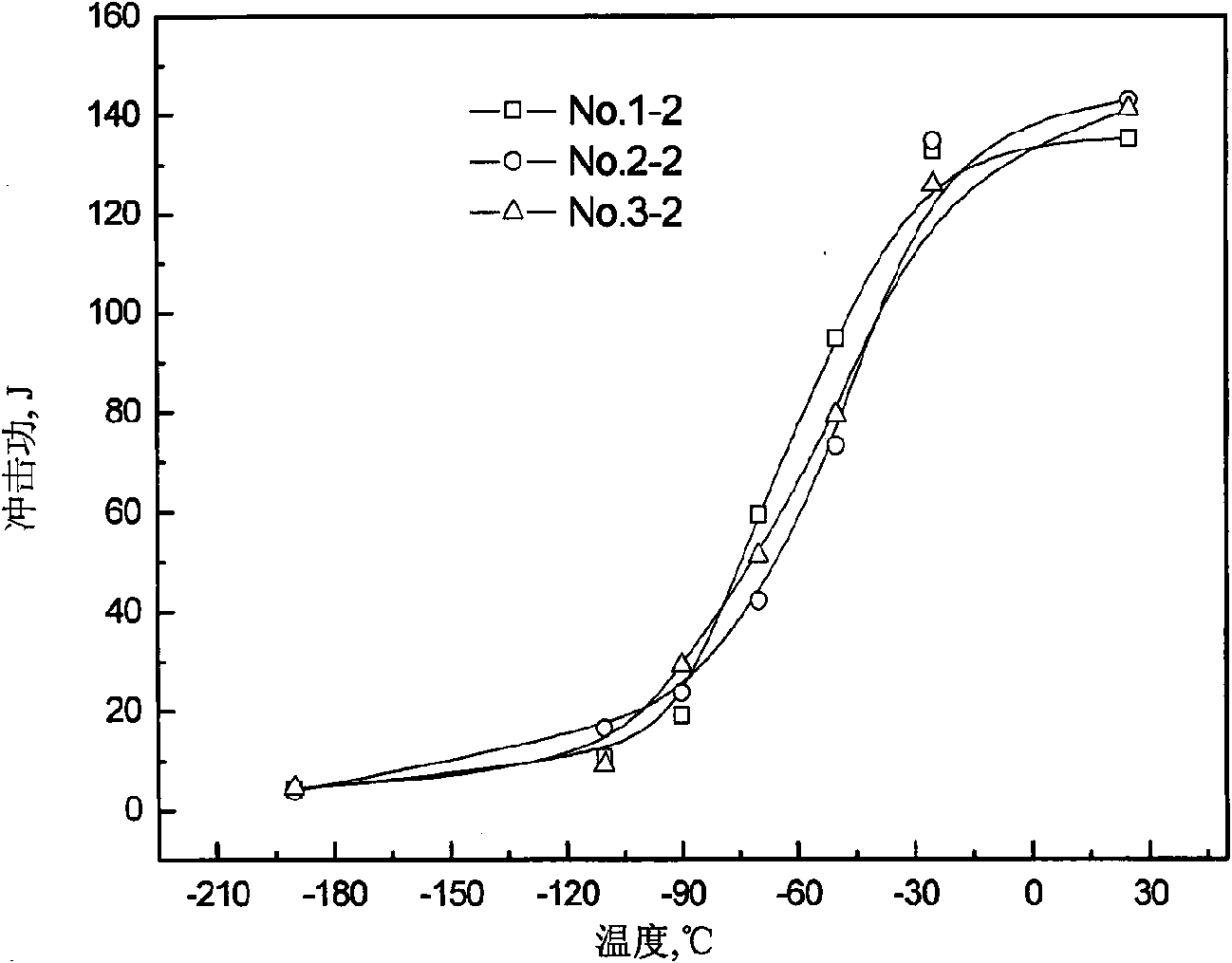

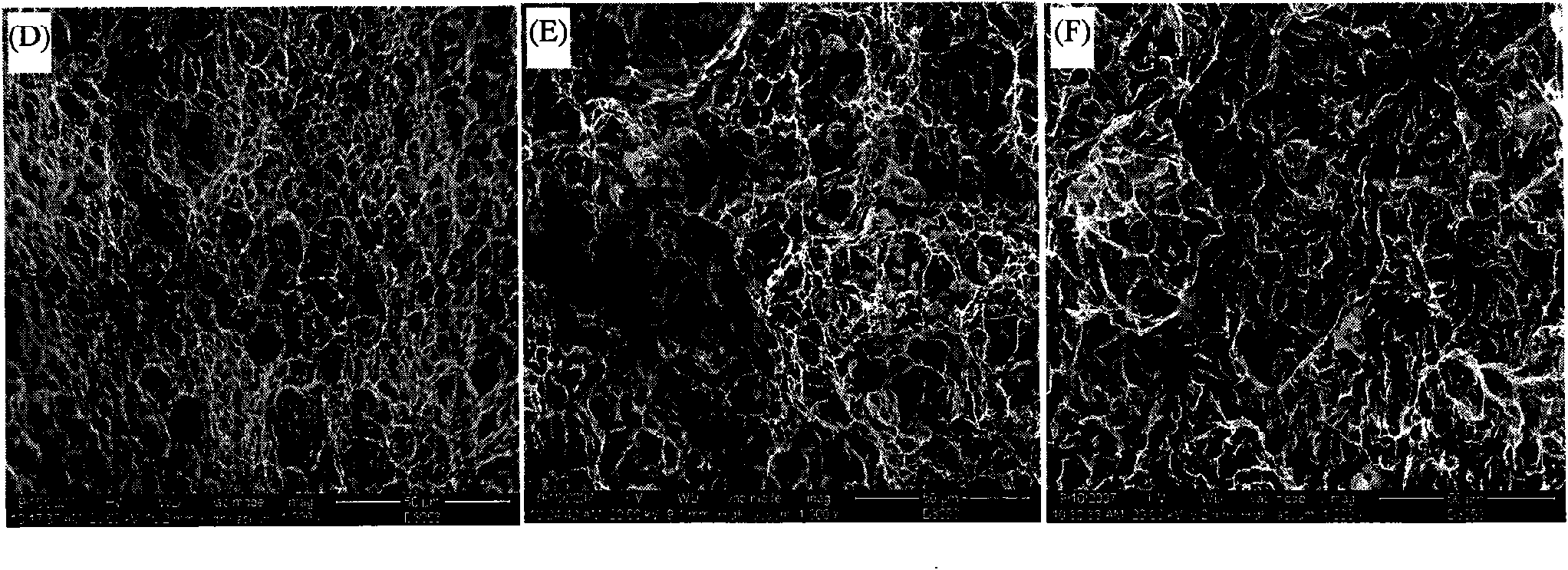

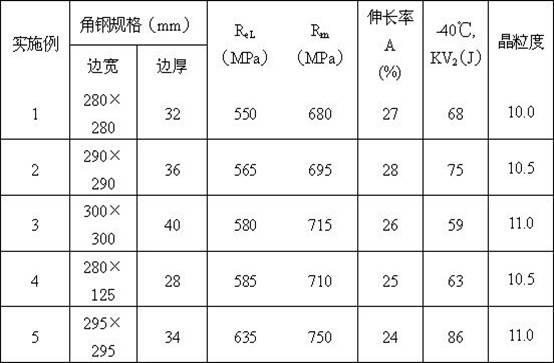

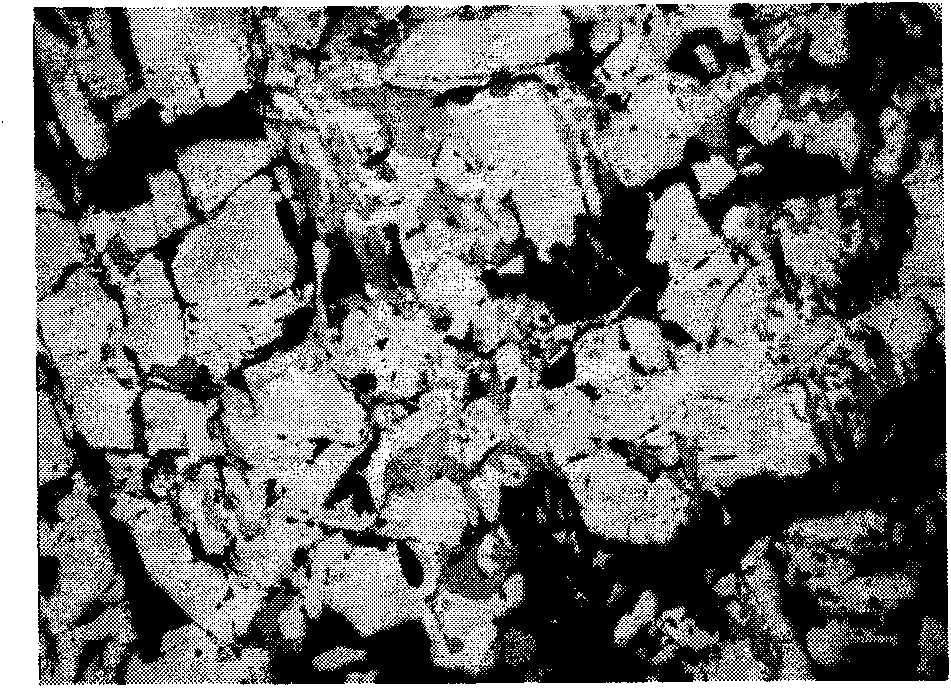

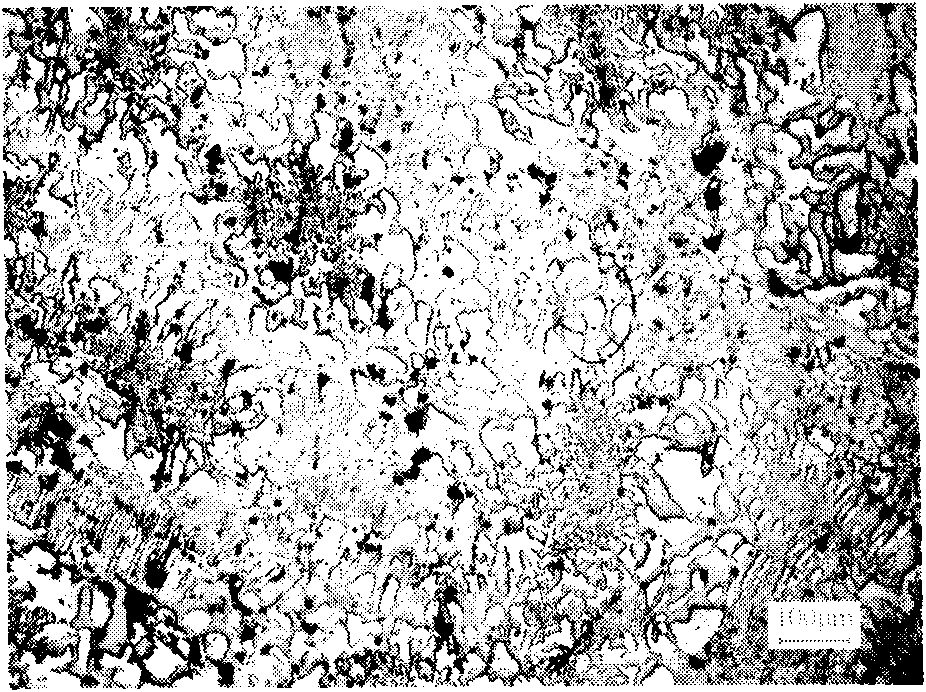

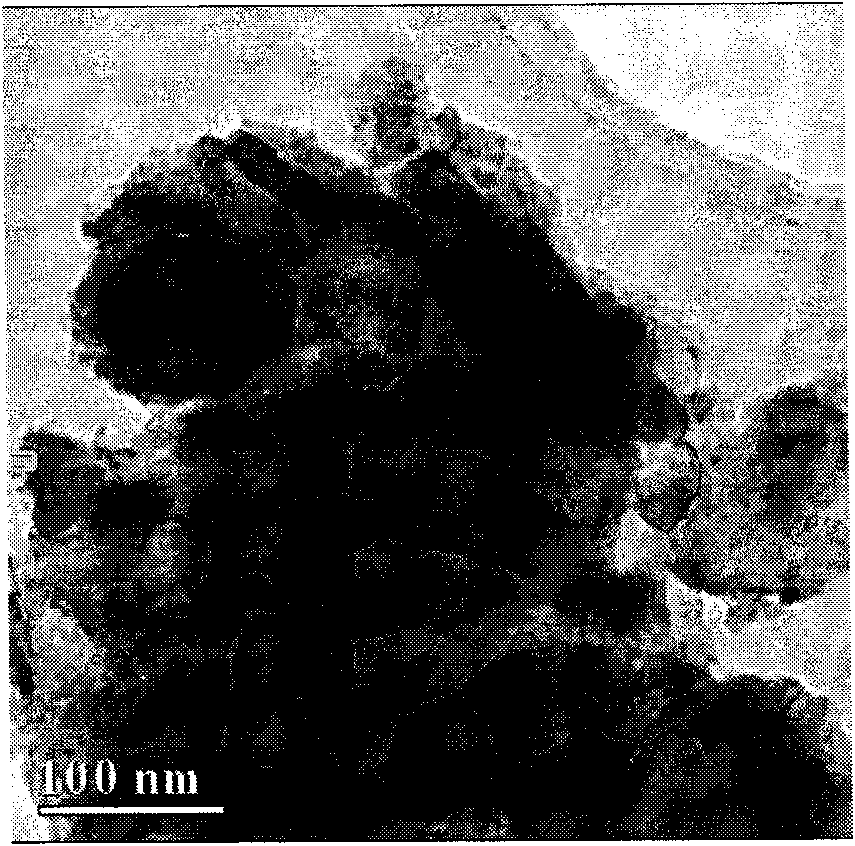

Cold-resistant high-strength hot-rolled angle steel and production method thereof

InactiveCN102676921AMeet the requirements of the constructionHigh strengthMetal rolling arrangementsUltra high pressureNiobium

The invention relates to a cold-resistant high-strength hot-rolled angle steel and a production method thereof. The angle steel contains, by weight, 0.06%-0.20% of carbon (C), 0.20%-0.50% of silicon (Si), 1.10%-1.50% of manganese (Mn), phosphorus (p), sulphur (s), 0.030%-0.070% of vanadium(V), 0.015%-0.050% of niobium (Nb), and 0.10%-0.60% of nickel (Ni), wherein p <=0.015% and s <=0.010%. Carbon equivalent (CEV) =C+Mn / 6+ (Cr+Mo+V) / 5+ (Ni+Cu) / 15<=0.40%. The process includes smelting, slagging, argon blowing, continuous casting, heating of casting blank, hot rolling and cooling to a room temperature. According to the cold-resistant high-strength hot-rolled angle steel and the production method thereof, requirements for a power transmission tower at -40 DEG C can be completely satisfied, the yield strength of the angle steel is larger than 550 MPa, the tensile strength of the angle steel is larger than or equal to 680 MPa, the elongation after fracture of the angle steel is larger than or equal to 24%, the Charpy impact energy at -40 DEGC is larger than or equal to 55J, and the grade of the prior austenite grain size is greater than or equal to 10 grade. The cold-resistant high-strength hot-rolled angle steel has the advantages of being high in strength, fine in grains and good in toughness, the production method can be used for producing the angle steel for an ultrahigh pressure power transmission tower, and the side width of the angle steel can be kept to be 280mm or more.

Owner:武汉钢铁有限公司

Nanocrystalline high-chromium cast-iron composite nucleating agent for engineering machinery as well as preparation method and application method thereof

The invention relates to a nanocrystalline high-chromium cast-iron composite nucleating agent for engineering machinery as well as a preparation method and an application method thereof and relates to chromium-contained cast-iron alloys. The nanocrystalline high-chromium cast-iron composite nucleating agent is a sheet nanocrystalline high-chromium cast-iron composite nucleating agent for the engineering machinery containing nanocrystalline rear-earth silicoferrite and Fe-Ti-B, comprises an Fe-Ce-Si-Ca interalloy and a Fe-Ti-B interalloy in a mass ratio of 100: (6.67-10.0), has a nanocrystalline grain size smaller than 100 nm and is prepared by adopting a centrifugal quenching and flinging method. Grains and texture of the high-chromium cast-iron alloys for the engineering machinery are produced and thinned by the nanocrystalline high-chromium cast-iron composite nucleating agent by a metal melting die-casting method so that substrate grains and a cementite phase of the high-chromium cast-iron alloys are remarkably thinned, cementite layered sheets and particles are further thinned, and the distribution is evener. In-situ generated TiB2 particles in high-chromium cast-iron liquid also take the action of enhancing a substrate, thereby obviously improving the comprehensive mechanical performance of the high-chromium cast-iron alloys for the engineering machinery.

Owner:天津万石科技发展有限公司

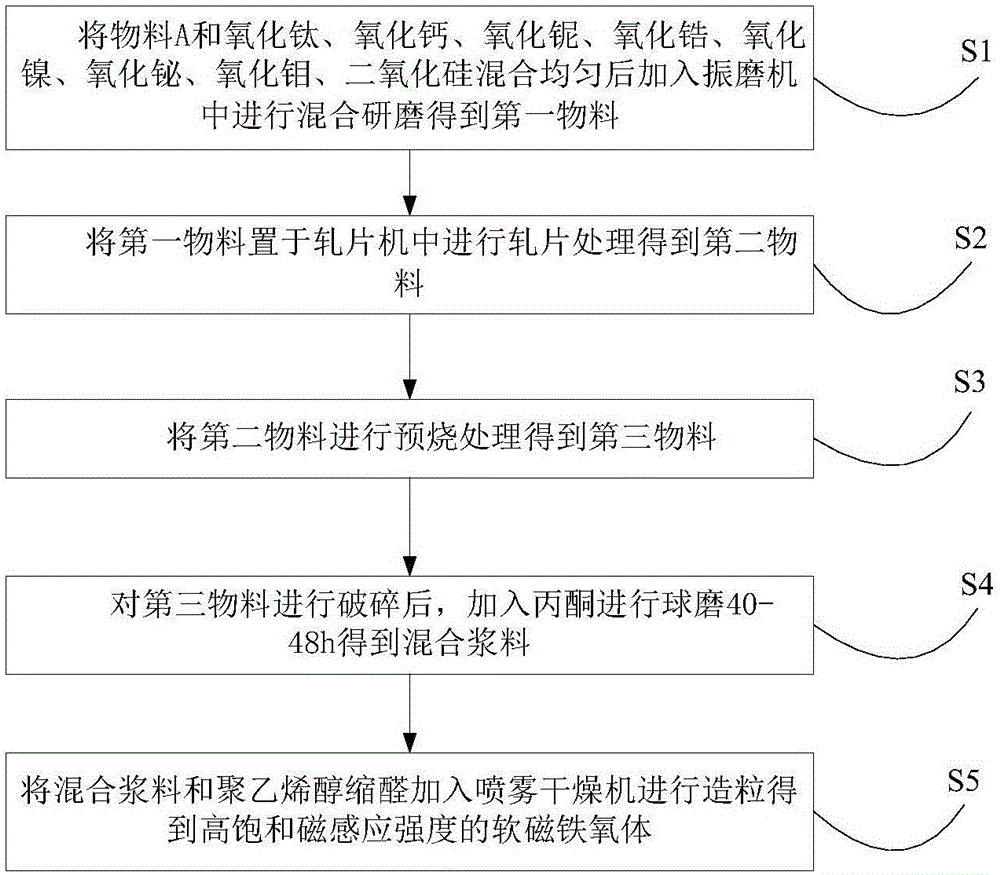

Soft-magnetic ferrite with low loss and high saturation flux density and preparation method therefor

The invention discloses a soft-magnetic ferrite with low loss and a high saturation flux density. The raw materials comprise materials A and materials B. The materials A comprise, by mole, 56-60 parts of iron oxide, 40-45 parts of manganese oxide, 7-10 parts of zinc oxide and 2-4 parts of copper oxide. With the total weight of the materials A as a base, the materials B comprise 2500-3000ppm, 300-700ppm of calcium oxide, 100-300ppm of niobium oxide, 400-800ppm of zirconium oxide, 1500-2000ppm of nickel oxide, 300-800ppm of bismuth oxide, 300-500ppm of molybdenum oxide, 200-500ppm of silicon oxide and 2000-2500ppm of bonding agents. The invention also discloses a preparation method for the soft-magnetic ferrite with low loss and a high saturation flux density.

Owner:ZHONGDE ELECTRONICS

Preparation method of catalyst for improving yield of gasoline produced by catalytic cracking

ActiveCN104275206AHigh yieldRefine grain sizeCatalytic crackingMolecular sieve catalystsSodium silicateMolecular sieve

The invention discloses a preparation method of a catalyst for improving the yield of gasoline produced by catalytic cracking. The preparation method comprises the following steps: with a mixture of kaolin and diatomite subjected to acid treatment as a raw material, adding chemical water, structural auxiliaries, a dispersing agent and / or a reinforcing agent into the mixture, and performing mixed pulping and spraying to obtain microspheres; roasting the sprayed microspheres, mixing the roasted microspheres with a guiding agent, sodium silicate and sodium hydroxide in a certain ratio, and performing a crystallization reaction under hydrothermal conditions, thereby obtaining a crystallization product with a pore structure and excellent abrasion resistance and with a 30%-60% NaY molecular sieve, wherein the crystallization product, namely the in-situ crystallized microspheres, can be taken as a precursor for preparing the catalytic cracking catalyst; and exchanging the in-situ crystallized microspheres with ammonium salt and rare earth to obtain the catalytic cracking catalyst for improving the yield of gasoline.

Owner:PETROCHINA CO LTD

High-strength beryllium-copper alloy bar and preparation process thereof

ActiveCN113174509AHigh strengthGrain refinementFurnace typesHeat treatment furnacesRare-earth elementVanadium atom

The invention discloses a high-strength beryllium-copper alloy bar, and particularly relates to the technical field of beryllium-copper alloys. The high-strength beryllium-copper alloy bar comprises the following elements: Be, Si, Ni, Co, Zr, Ti, V, rare earth elements, and the balance of Cu and inevitable impurities. According to the produced high-strength beryllium-copper alloy bar, nickel, cobalt, zirconium, titanium, vanadium and rare earth elements are added, the addition of nickel and cobalt can refine crystal grains in an alloy material and improve the uniformity of an internal structure, so that the beryllium-copper alloy material has good mechanical properties, zirconium can improve the softening temperature of the beryllium-copper alloy and refine recrystallized crystal grains, and titanium can effectively enhance the strength of the beryllium-copper alloy, the vanadium can purify, deteriorate and refine crystal grains and can improve the wear resistance of the beryllium-copper alloy bar, and the rare earth elements can refine the crystal grains to make the crystal grains uniform and can effectively improve the strength and corrosion resistance of the beryllium-copper alloy bar. The practicability of the beryllium-copper alloy bar can be improved, and the beryllium-copper alloy bar can meet the use requirements of people.

Owner:江阴金湾合金材料有限公司

Smelting preparation method of heat insulation aluminum alloy profile

InactiveCN103103416AImprove performanceHigh strengthMetallic material coating processesChromium carbideAluminium preparations

The invention discloses a smelting preparation method of a heat insulation aluminum alloy profile. The smelting preparation method comprises the following operation steps: (1) configuring an aluminum alloy melt: mixing the following raw materials in parts by weight: 50-60 parts of aluminum ingot, 30-40 parts of waste aluminum product, 5-10 parts of chromium carbide and 5-7 parts of glass slag powder, adding the raw materials into a smelting furnace, heating till a furnace charge is softened and collapses, and scattering a layer of covering agent on the surface of metal for covering; and properly stirring the melt after the furnace charge is completely molten so as to enable the temperature in a melting bath to be uniform and consistent and finally adding a magnesium ingot into the melt. The waste aluminum material is added into the raw materials for mixing so as to be conductive to stabilizing the performances of the aluminum profile and reducing the possibility of affecting the quality of the aluminum profile due to the appearance of the non-detected materials during the smelting of aluminum liquid; the formula is further optimized so as to increase the strength and the hardness of an aluminum alloy and be conductive to improving the comprehensive properties of the aluminum alloy profile; and the surface of the aluminum alloy profile is chromized, so that the anti-corrosion capability of an oxide film on the surface of the aluminum alloy profile and the bonding force between the aluminum alloy profile and a coating are improved.

Owner:东莞市旺美铝制品有限公司

Precipitation-enhanced high-entropy alloy without sigma-phase precipitation tendency and preparation method of precipitation-enhanced high-entropy alloy

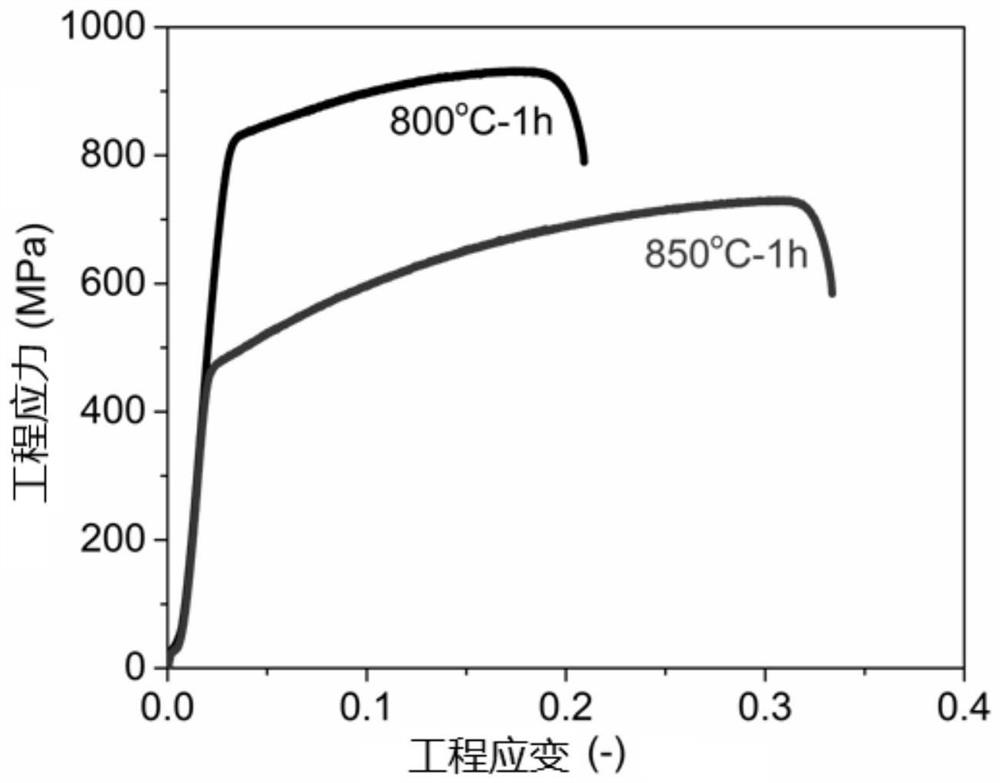

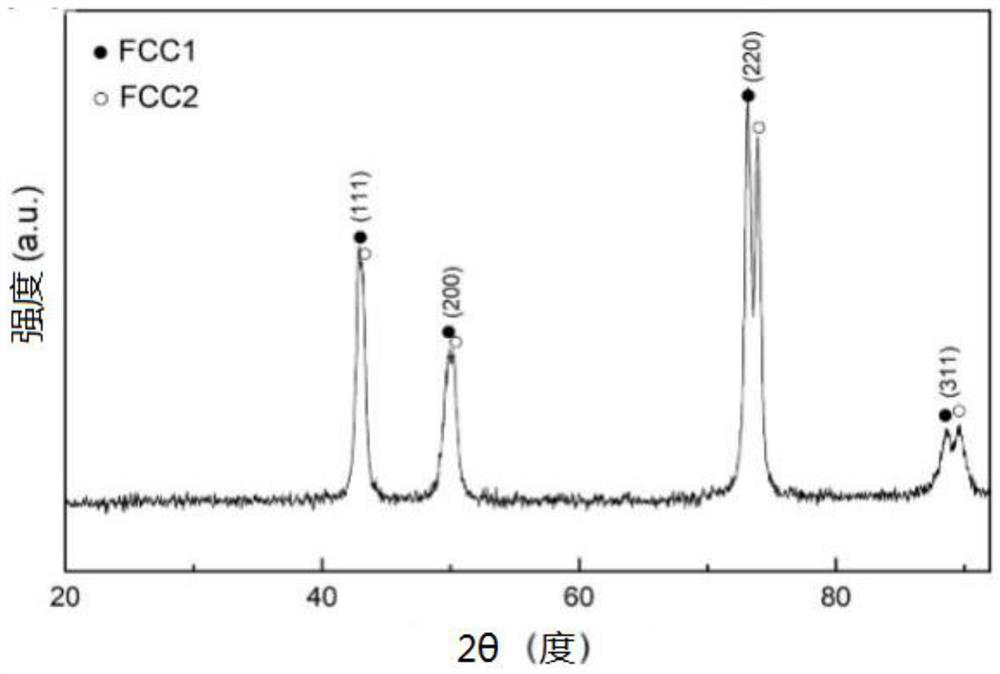

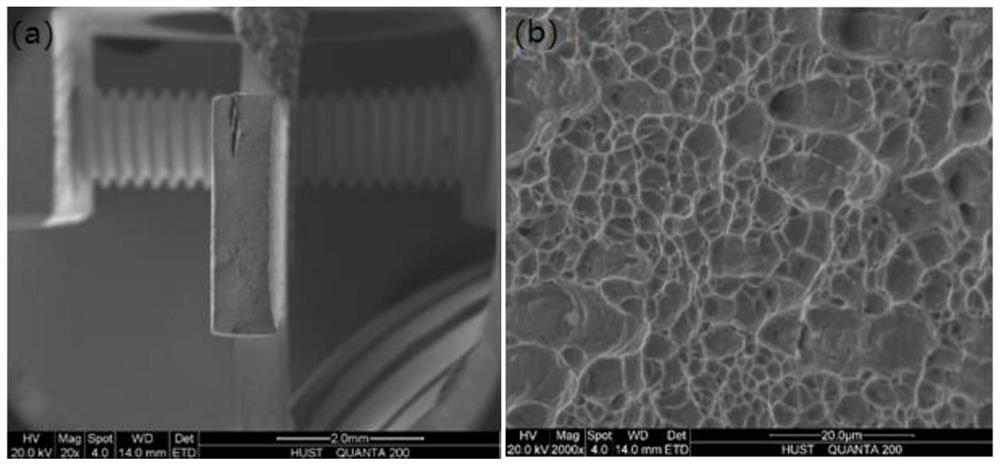

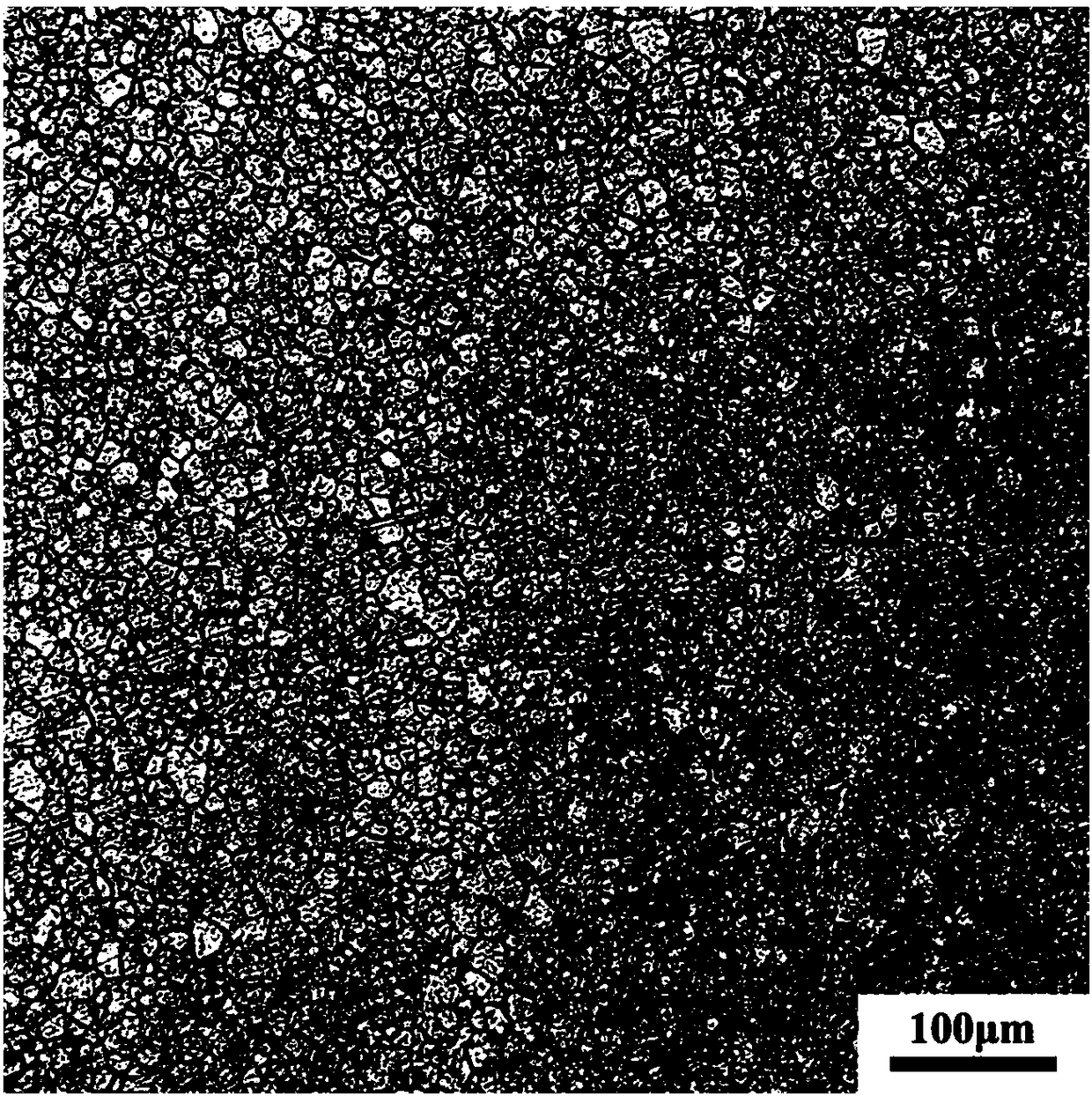

ActiveCN111826573AImprove mechanical propertiesEliminate precipitation tendencyElectric arc furnaceHigh entropy alloys

The invention discloses a precipitation-enhanced high-entropy alloy without a sigma-phase precipitation tendency and a preparation method of the precipitation-enhanced high-entropy alloy, and belongsto the field of high-entropy alloys. The precipitation-enhanced high-entropy alloy is composed of such four elements as Fe, Ni, Mn and Cu at a molar ratio. According to the preferred preparation method of the precipitation-enhanced high-entropy alloy, the prepared raw materials are smelted in an electric-arc furnace under the protection of vacuum argon gas at first, and then the precipitation-enhanced high-entropy alloy without the sigma-phase precipitation tendency is obtained through the steps of drop casting, homogenization annealing, cold rolling and aging. The precipitation-enhanced high-entropy alloy without the sigma-phase precipitation tendency has the beneficial effects that the optimal values of the room temperature yield strength and the tensile strength can reach 825 MPa and 933 MPa correspondingly; the elongation can be higher than 15%; and the mechanical performance indexes can be adjusted by utilizing aging parameters. Furthermore, the precipitation-enhanced high-entropyalloy without the sigma-phase precipitation tendency has the excellent comprehensive mechanical performance at room temperature.

Owner:HUAZHONG UNIV OF SCI & TECH

Drive gear and preparation method thereof

ActiveCN104195452ALow costImprove corrosion resistanceFurnace typesHeat treatment furnacesTemperingGear wheel

The invention discloses a drive gear and a preparation method thereof. The drive gear consists of the following chemical components in percentage by weight: C, Si, Mn, Cr, Ni, Nb, V, Cu, P, S, lanthanide-series rear earths and the balance of Fe. The preparation method for the drive gear comprises the following steps: preparing a blank by adopting a casting mode; then, carrying out thermal treatment on the blank, a cutting process on rough-turning gear ring gear blank, a rough-milling gear-hobbing process, carburizing and nitriding treatment, tempering, hardening and tempering thermal treatment; and finally, carrying out a finish turning process and finish-milling gear-hobbing process and then inspecting, packaging and storing. The drive gear is high in strength, hardness and abrasive resistance, good in corrosion resistance and oxidization resistance, high in yield strength and tensile strength; and the gear processing method is simple, low in cost and good in molding performance.

Owner:南京航迅机电有限公司

Low-cost high-compression-strength wrought magnesium alloy and preparation method thereof

InactiveCN108118225ANo significant increase in preparation costsRich varietyElemental compositionCu element

The invention relates to a low-cost high-compression-strength wrought magnesium alloy and a preparation method thereof. The magnesium alloy material is composed of six elements, namely Mg, Zn, Mn, Sn,Ca and Cu, wherein the content of the Zn element is 4.0%-8.5%, the content of the Mn element is 0.1%-0.4%, the content of the Sn element is 0.1%-0.4%, the content of the Ca element is 0.1%-0.4%, thecontent of the Cu element is 0.1%-0.4%, the content of inevitable impurities is less than or equal to 0.15%, and the balance is the Mg; and compared with a traditional commercial grade magnesium alloymaterial, high compressive yield strength can be obtained after the magnesium alloy material is subjected to a conventional extrusion treatment, and the compressive yield strength of the alloy is obviously higher than tensile yield strength. The magnesium alloy material does not contain precious alloy elements, and is simple in preparation process and low in cost, has very important practical value for manufacturing a pressed magnesium alloy component.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

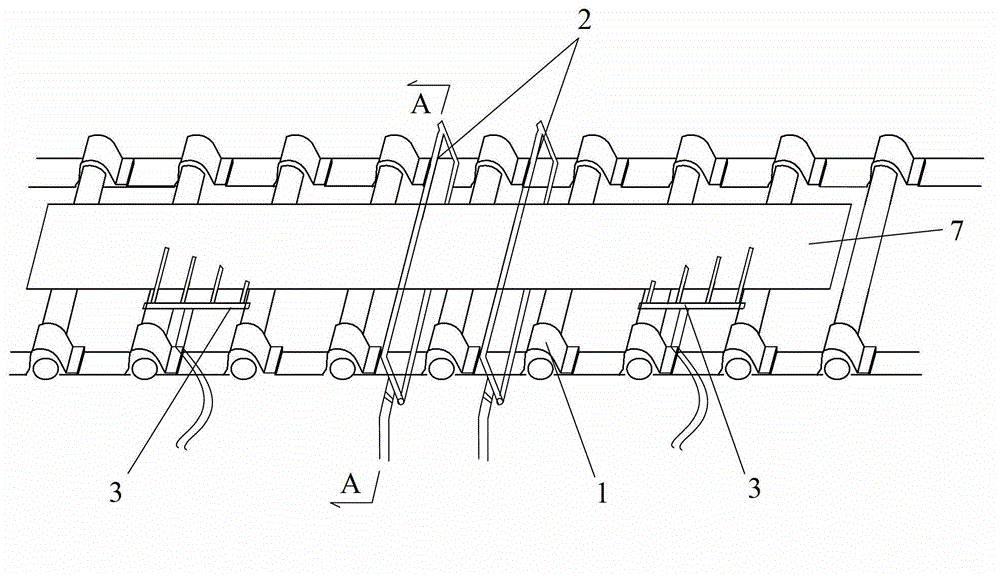

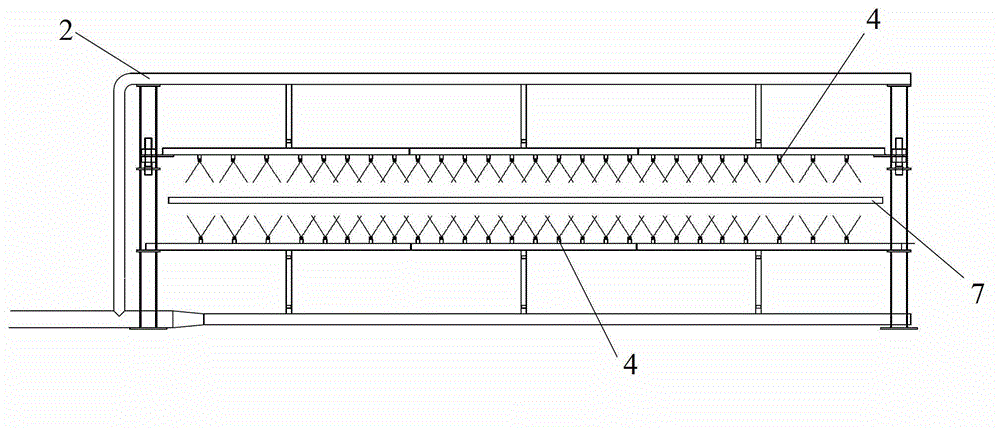

Method and cooling system for improving comprehensive mechanical property of normalized steel plate

ActiveCN102912091AImprove comprehensive mechanical propertiesAvoid austenite grain growthFurnace typesHeat treatment process controlThermal insulationSteel plates

The invention discloses a method for improving the comprehensive mechanical property of a normalized steel plate. The running time of the steel plate in a heating region in a normalizing furnace is reasonably prolonged and the running time of the steel plate in a thermal insulation region in the normalizing furnace is reasonably shortened, so that the austenite grain growth is avoided to provide favorable conditions for subsequent accelerated cooling. The steel plate is quickly cooled to be 600-700 DEG C from the normalizing temperature in a way of normalizing, atomizing and cooling, so that the mist cooling with higher heat exchange efficiency increases the supercooling degree of the structural transformation of the steel plate and effectively prevents the austenite grain growth; and grains are refined, so that the effect of improving the strength by structure refinement in the heat treatment process of the steel plate is given full play. The invention further provides a cooling system for improving the comprehensive mechanical property of the normalized steel plate. Therefore, the equipment is simple, the investment is low, the surface quality of the steel plate can be improved, and the practicality is better.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

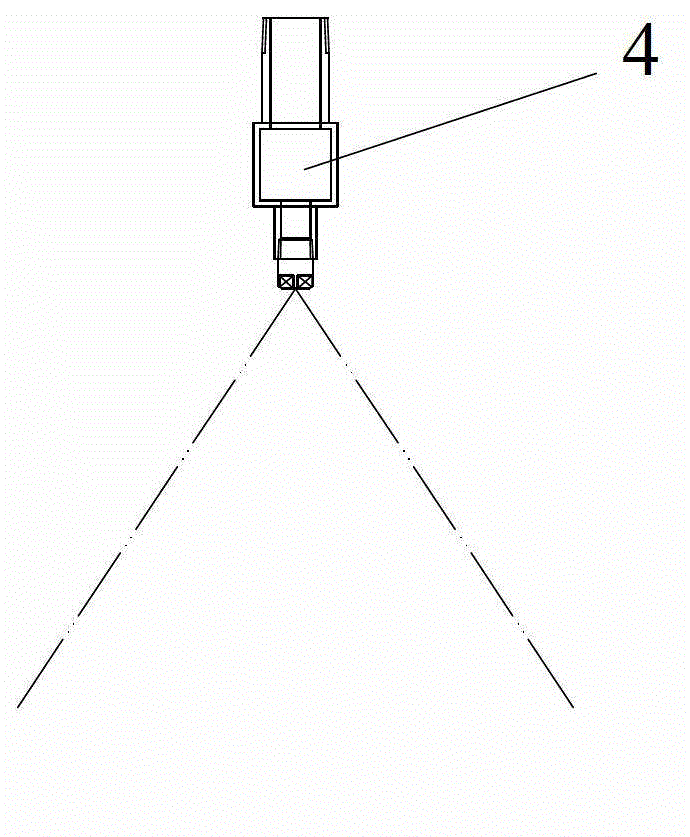

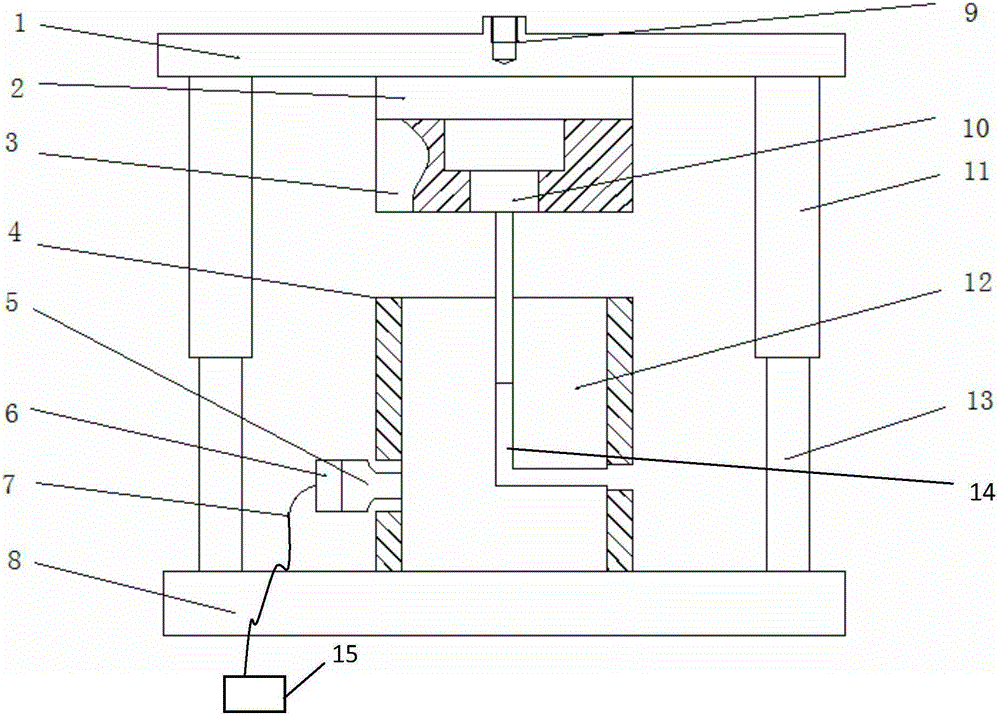

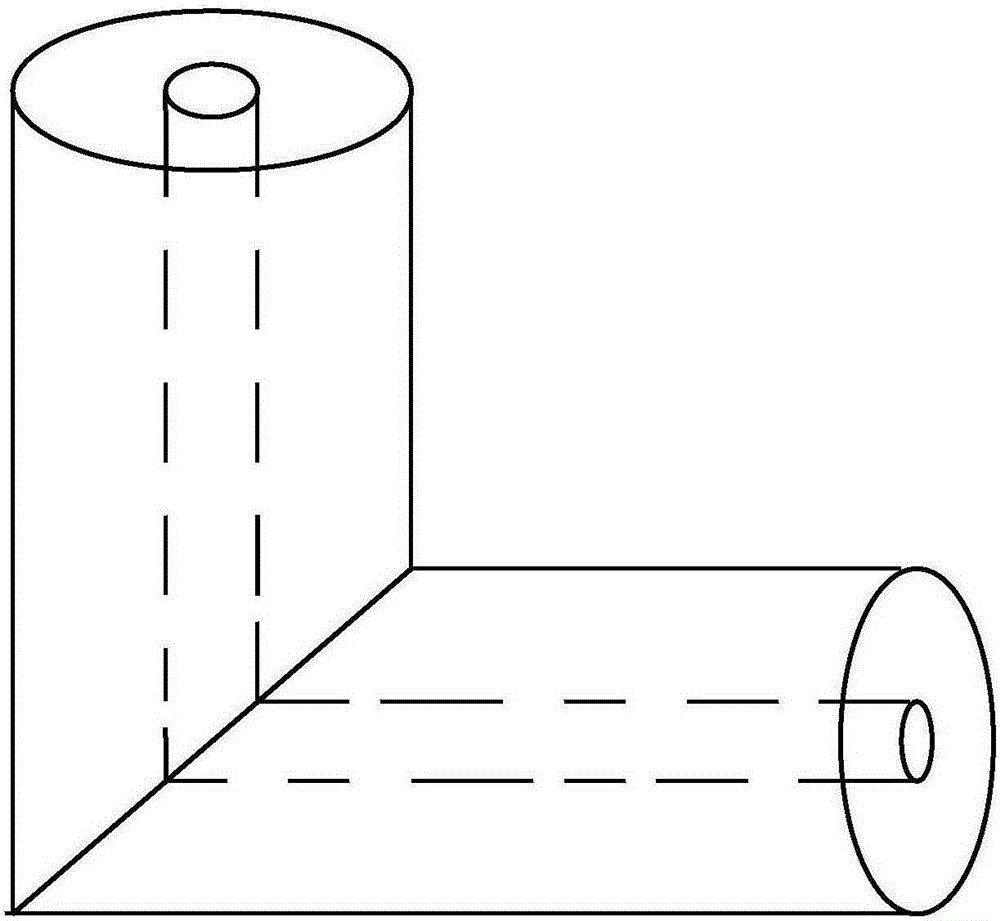

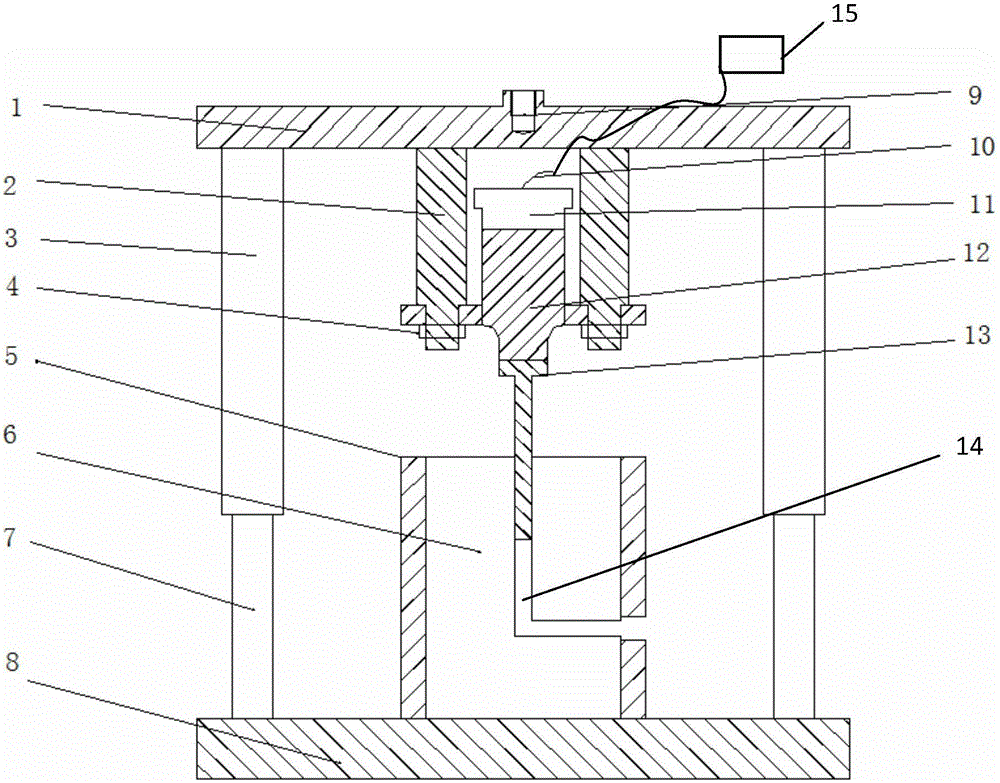

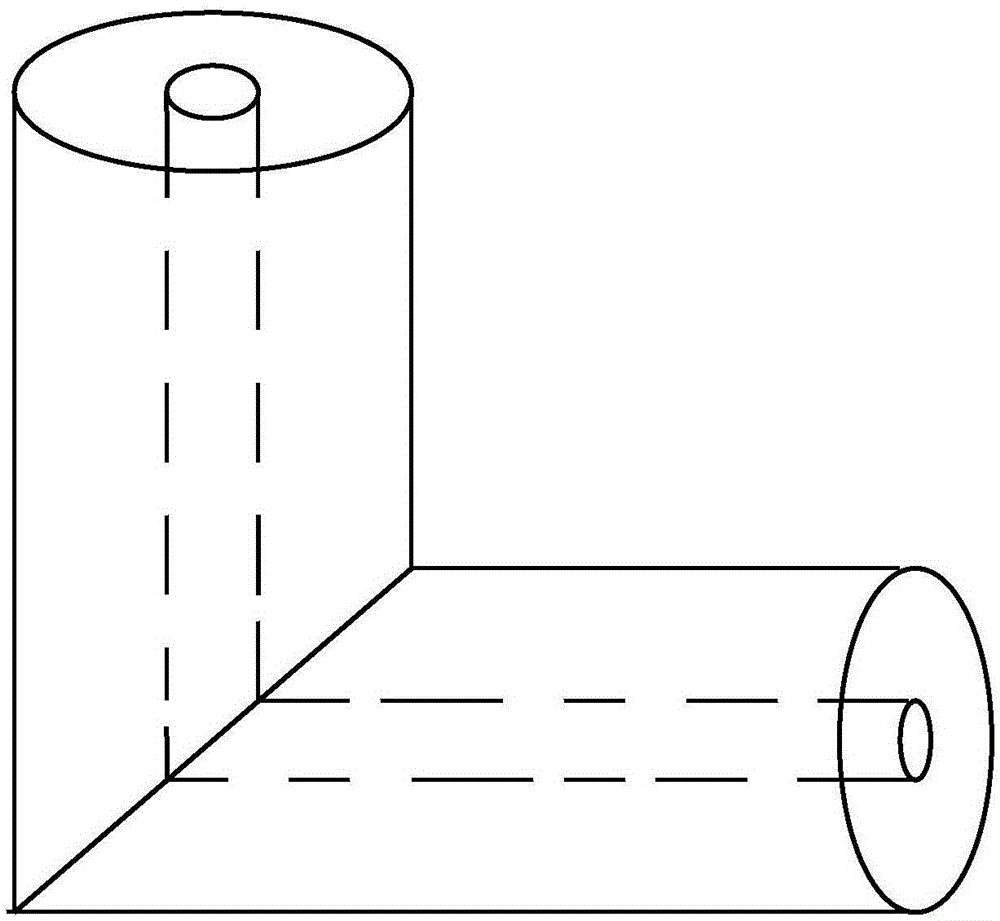

Equal channel angular extrusion device of ultrasonic vibration female die

InactiveCN105170681AIncrease the dislocation densityReduce internal frictionExtrusion diesMechanical vibrations separationEngineeringUltrasound

The invention provides an equal channel angular extrusion device of an ultrasonic vibration female die. The equal channel angular extrusion device is composed of an upper template and a lower template. A threaded hole in the upper end of the upper template is connected with a hydraulic plunger on a hydraulic machine. The upper end of a cushion block is connected with the upper template. The lower end of the cushion block is connected with a male die. The male die is fixed in a blocking ring. The upper end of the blocking ring is fixedly connected with the cushion block. The upper end of a guide sleeve is fixedly connected with the upper template. The lower end of the guide sleeve is connected with the upper end of a guide column. The lower end of the guide column is fixedly connected with the lower template. The lower end of the female die is fixed to the lower template. The side face of the female die is fixed through a split stress ring. An ultrasonic vibration device is fixedly connected to the side face of the female die. High-strength ultrasonic waves are input into the female die, high-frequency periodic vibration displacement is generated on the surface of the female die, grain uniformizing and refining of an extrusion piece are improved, and the problems that an equal channel angular extrusion die is nonuniform in grain refining, and cracks exist on the extrusion piece are solved effectively.

Owner:GUANGXI UNIV

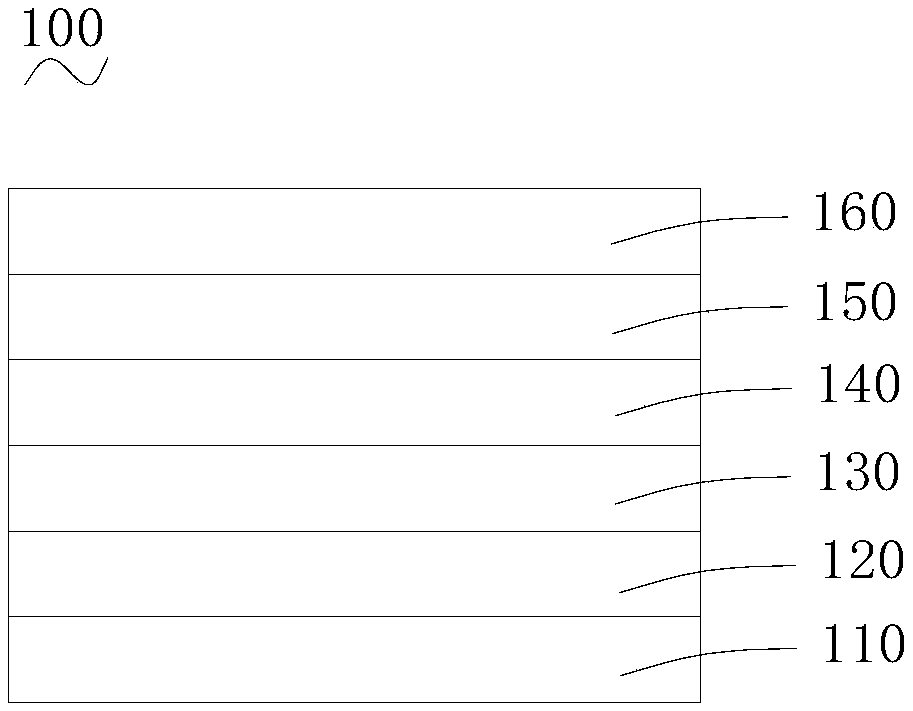

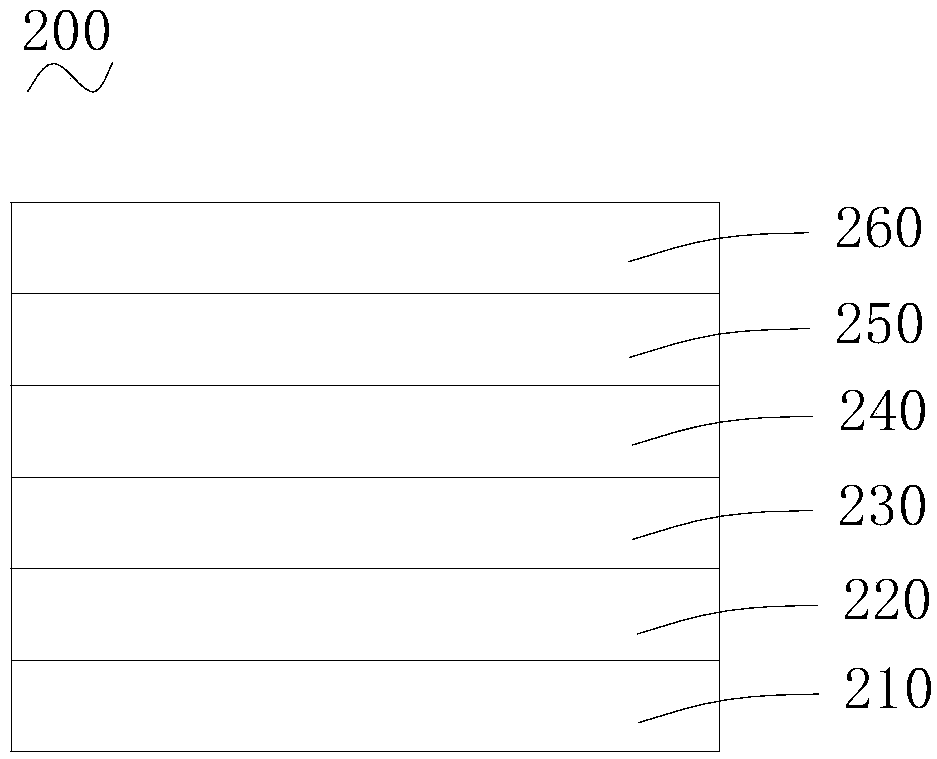

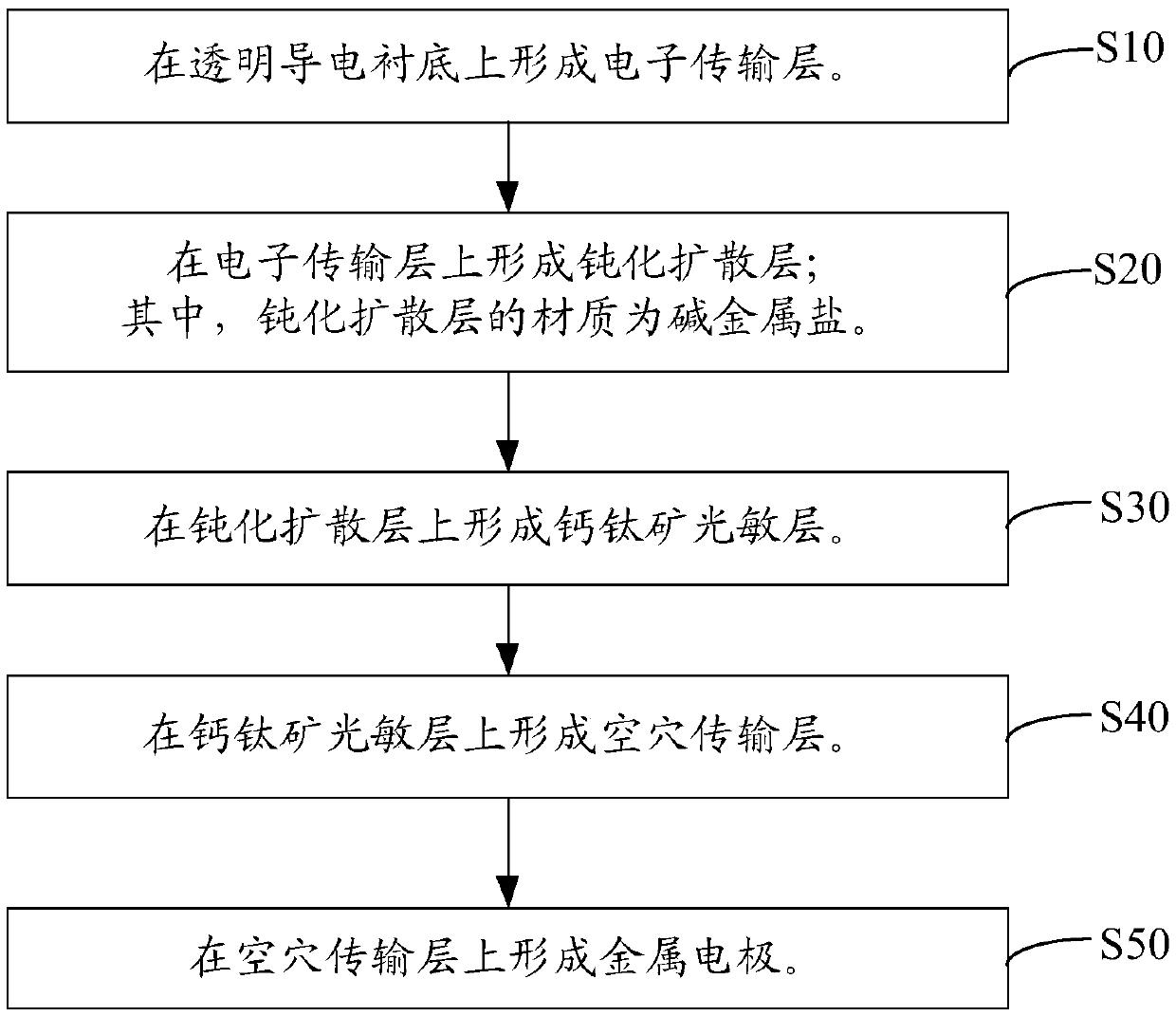

Perovskite solar cell and preparation method thereof

ActiveCN109686843AReduce loadGuaranteed stabilitySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellCharge carrier

The invention relates to a perovskite solar cell and a preparation method thereof. The perovskite solar cell comprises a transparent conductive substrate, an electron transport layer, a passivation diffusion layer, a perovskite photosensitive layer, a hole transport layer and a metal electrode which are sequentially laminated, or the perovskite solar cell comprises a transparent conductive substrate, a hole transport layer and a passivation diffusion layer, a perovskite photosensitive layer, an electron transport layer and a metal electrode which are sequentially laminated; wherein the material of the passivation diffusion layer is alkali metal salt. According to the perovskite solar cell, the alkali metal salt is used as the passivation diffusion layer, and the passivation diffusion layeris positioned at one side of the perovskite photosensitive layer; on one hand, the alkali metal salt can diffuse into the perovskite photosensitive layer, the crystalline grains are larger, internaldefects are reduced, so that the stability of the device is maintained, on the other hand, the passivation diffusion layer can passivate the interface of the grain boundary, reduce the load of carriers and maintain the stability of the device. The method entirety can improve the efficiency of the perovskite device.

Owner:KUNSHAN GCL OPTOELECTRONIC MATERIAL CO LTD

Smelting preparation method for anti-cracking aluminum alloy section bar

InactiveCN103103400AImprove performanceHigh strengthSolid state diffusion coatingAluminium preparationsSmelting process

The invention discloses a smelting preparation method for an anti-cracking aluminum alloy section bar. The smelting preparation method comprises the following operation steps: (1) preparing aluminum alloy melt, wherein the aluminum alloy melt is prepared from the following materials in parts by weight: 55-65 parts of 3003 aluminum ingots, 32-42 parts of waste aluminum products, 5-10 parts of boron carbide and 5-10 parts of nanometer quartz sand powder; adding the materials to a smelting furnace; scattering a layer of covering agent to the surface of the melt to cover the melt when the furnace materials are heated up to be softened and collapsed, wherein the covering agent comprises the following components in parts by weight: 10-20 parts of CaO, 10-25 parts of Al2O3, 35-45 parts of SiO2, 12-30 parts of C and 12-23 parts of coal ashes. According to the smelting preparation method disclosed by the invention, the waste aluminum materials are added to the material ingredients, and the waste aluminum materials are smelted by one step and stable in components, and so the waste aluminum waste materials added to the ingredients are beneficial to stabilizing the performances of the aluminum section bar and reducing the possibility that the quality of the aluminum section bar is affected by undetected materials during the smelting process of the melt. The dosage proportion of the relevant ingredients in the aluminum section bar formula is adjusted, so that the formula is further optimized.

Owner:WUHU HENGKUN AUTO PARTS

Method for reducing surface cracks of boron containing steel continuous casting sheet billet

The invention discloses a method for reducing surface cracks of a boron containing steel continuous casting sheet billet. Firstly, a boron containing steel component is controlled in an optimized manner, ferroboron is added under the situation that molten steel oxygen removing is good, the boron recycling rate is increased, and the control stability of the boron component is guaranteed; and titanium is utilized for capturing nitrogen needed for forming boron nitride, precipitation of boron nitride particles is restrained, thermoplasticity of boron containing steel is improved, and titanium nitride is high in stability, low in high-temperature solubility, not prone to roughing and capable of refining grains. Furthermore, optimal control is carried out on the continuous casting technology, the secondary cooling area specific water flow, the sheet billet outlet straightening area temperature, the throwing pressure and the front and rear roller smooth arc deviation are controlled, the crack defect ratio of the boron containing steel sheet billet is greatly reduced to be below 1.5% from the original 9.3%, the surface quality of the continuous casting sheet billet is improved, and accordingly the quality of final products is improved.

Owner:SHANDONG IRON & STEEL CO LTD

Equal channel angular pressing device of ultrasonic vibration male die

InactiveCN105080992AIncrease the dislocation densityReduce internal frictionExtrusion diesHydraulic ramHigh intensity

Provided is an equal channel angular pressing device of an ultrasonic vibration male die. The upper ends of pressure columns of the device are fixed to an upper die plate. A threaded hole in the upper end of the upper die plate is connected with a hydraulic plunger on a hydraulic machine. The upper ends of guide sleeves are fixedly connected with the upper die plate. The lower ends of the guide sleeves are connected with guide columns. The lower ends of the guide columns are fixedly connected with a lower die plate. The side face of a female die is fixed through a stress ring. An ultrasonic vibration device is fixedly connected between the upper end of the male die and the upper die plate. According to the device, high-intensity ultrasonic waves are input into the male die, high-frequency periodic vibration displacement is generated on the surface of the male die, uniformity of extruded elements is improved, crystal particles are refined, and the problems that according to an equal channel angular pressing die, the crystal particles are not uniform in refining and the extruded elements have cracks are solved.

Owner:GUANGXI UNIV

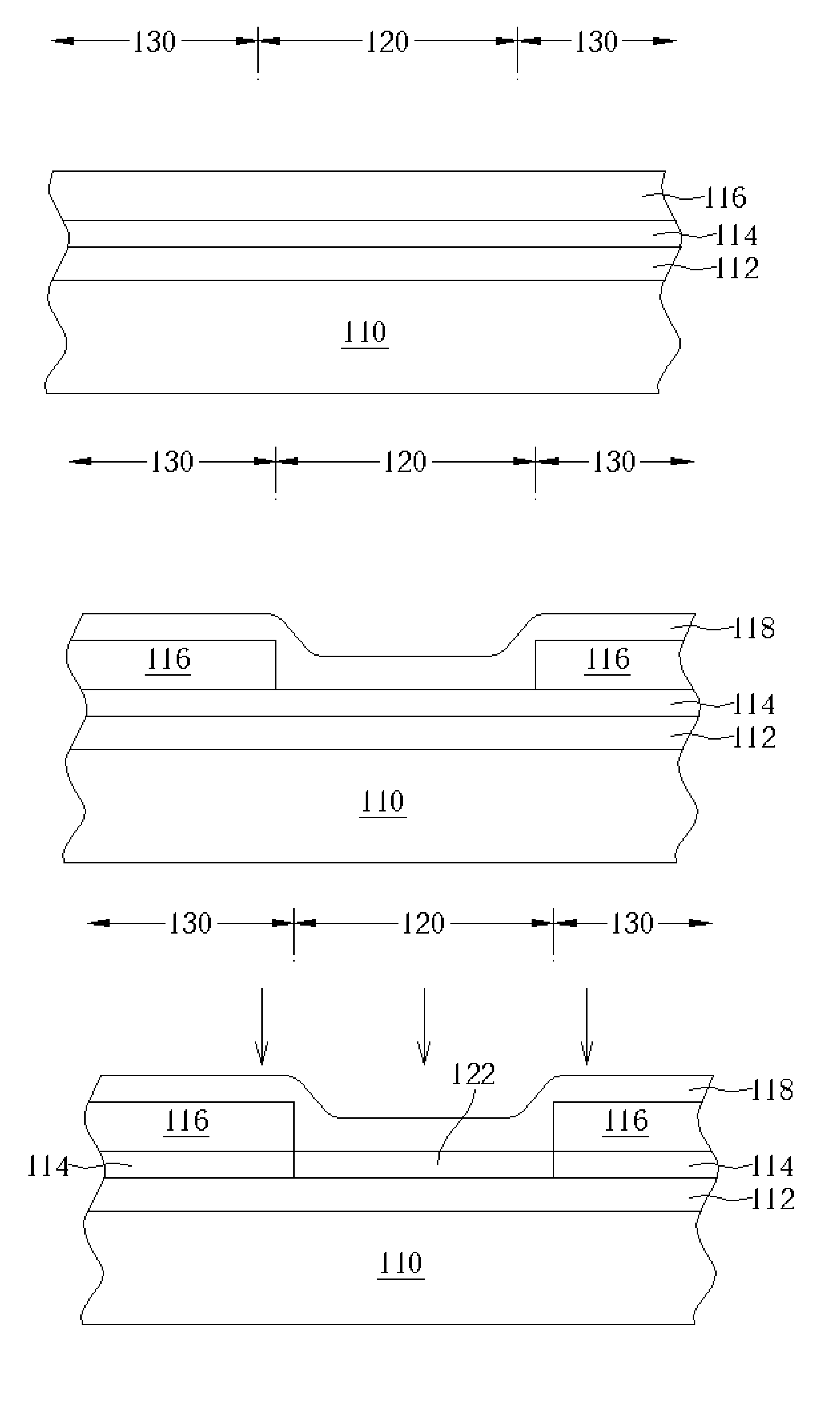

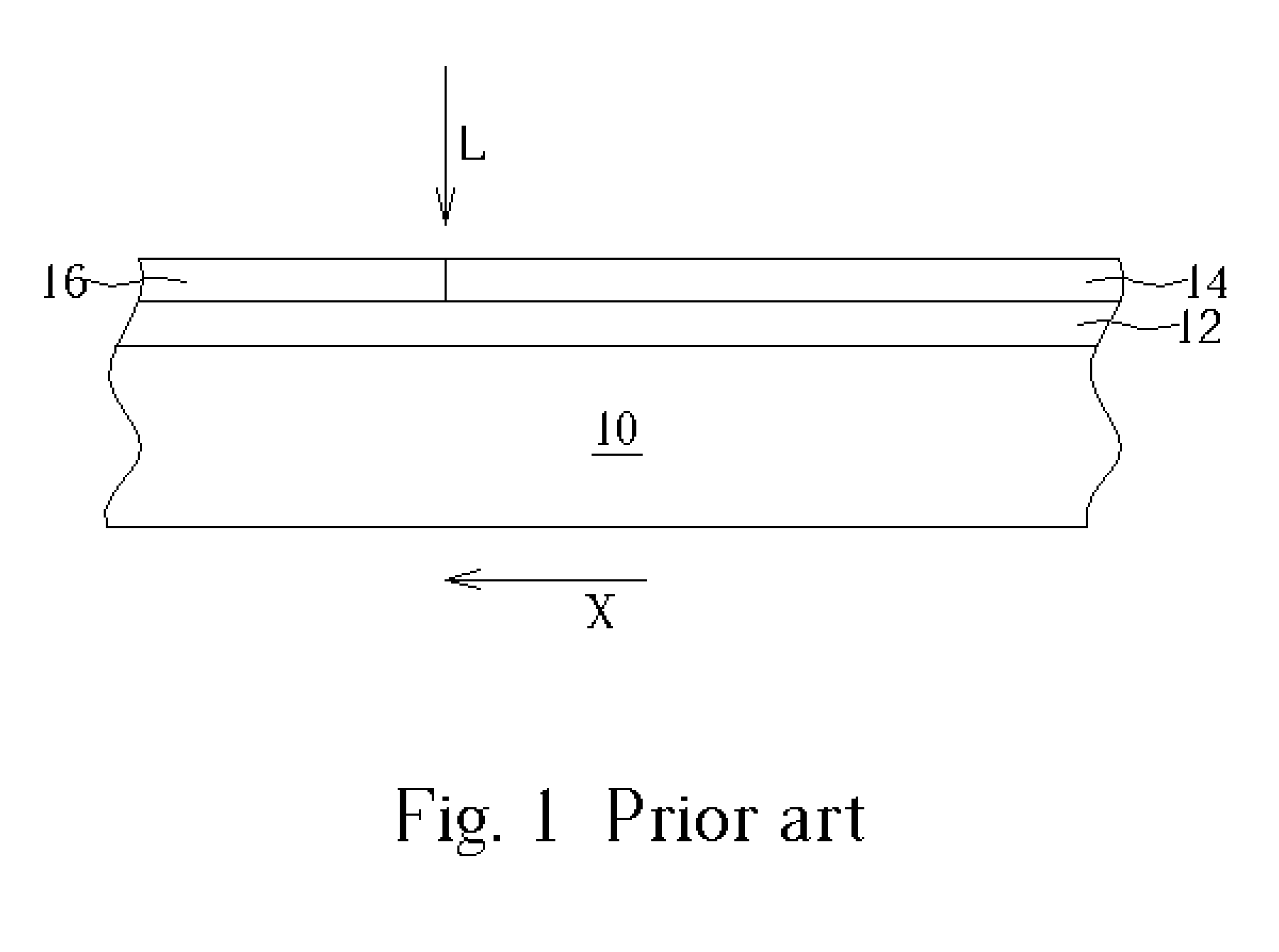

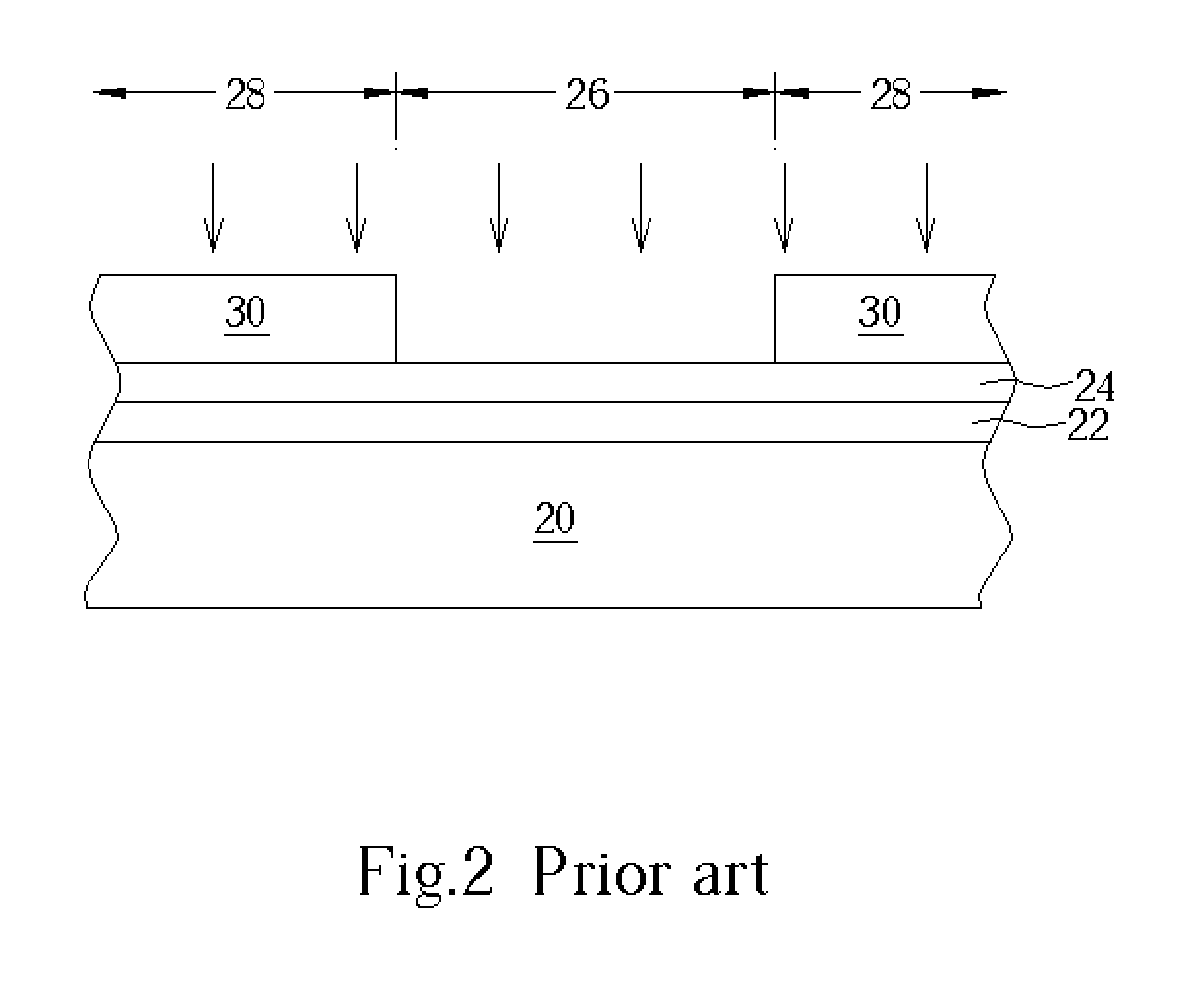

Method of fabricating polysilicon film by excimer laser crystallization process

ActiveUS7071083B2Refine grain sizeImprove display qualityCoupling device detailsSemiconductor/solid-state device manufacturingExcimer laser crystallizationOptoelectronics

A method of fabricating a polysilicon film by an excimer laser crystallization process. First, a substrate comprising a first region and a second region is provided. An amorphous silicon layer and a mask layer are formed on the substrate in sequence. Then, a photo-etching process is performed to remove the mask layer in the first region. A heat-retaining capping layer is formed on the mask layer and the amorphous silicon layer. After that, an excimer laser crystallization process is performed so that the amorphous silicon layer in the first region is crystallized into a polysilicon film.

Owner:CHINA STAR OPTOELECTRONICS INT HK

Manufacturing method for aluminum targets

ActiveCN105624591AImprove thermal conductivityUniform grainVacuum evaporation coatingSputtering coatingIngotHeat treated

Owner:合肥江丰电子材料有限公司

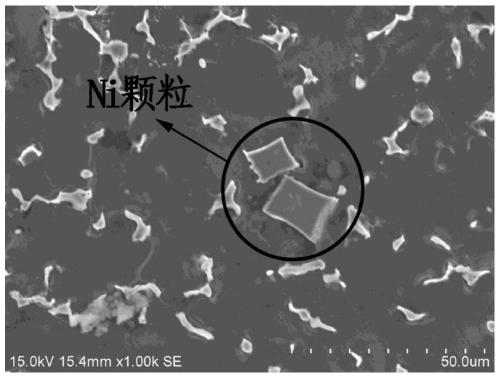

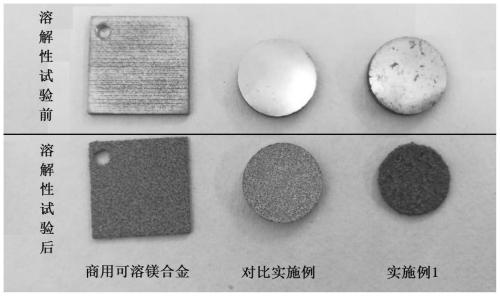

High-ductility low-temperature quick-degraded magnesium alloy and preparation method thereof

The invention relates to a high-ductility low-temperature quick-degraded magnesium alloy and a preparation method thereof, and belongs to the technical field of magnesium alloy materials. The alloy comprises the following components in percentage by mass: 5.0-6.5% of Gd, 0.1-0.25% of Ni, 0.05-0.5% of Zr and / or 0.4-1.0% of Mn, inevitable impurity not more than 0.3%, and the balance of Mg. The effects of various alloy elements are considered; the synergistic effect of the alloy elements is used for obtaining the magnesium alloy with high plasticity and higher low-temperature degrading speed; thealloy is few in element type, low in element adding quantity and low in cost, so that the alloy preparation cost is not obviously increased; and compared with a commercial magnesium alloy, the magnesium alloy is small in change of the preparation process and suitable for mass production.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com