Cold-resistant high-strength hot-rolled angle steel and production method thereof

A high-strength, angle steel technology, applied in metal rolling and other directions, can solve the problems of low strength and poor toughness of angle steel, and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

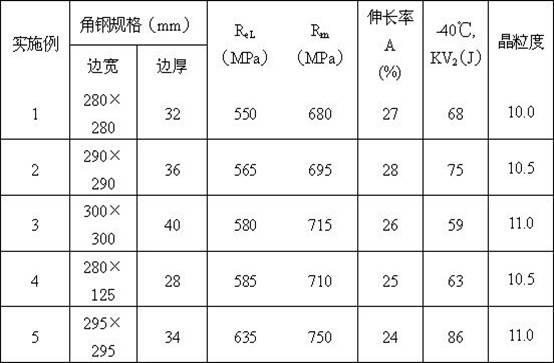

Examples

Embodiment 1

[0029] Production of equilateral angle steel with a side length of 280 mm, its composition and weight percentage content: C: 0.06%, Si: 0.20%, Mn: 1.50%, P: 0.0148%, S: 0.010%, V: 0.030%, Nb : 0.015%, Ni: 0.60%, the rest is Fe and unavoidable impurities, and satisfies CEV= C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15=0.356%≤0.40 %.

[0030] Its production steps:

[0031] 1) For smelting, the superheating degree of molten steel is 15°C; when the outflow of molten steel is 1 / 4, Ni is added in a set amount at one time;

[0032] 2) Carry out slagging, and control the alkalinity of slag at 3.6;

[0033] 3) Perform argon blowing for 4.5 minutes;

[0034] 4) Carry out continuous casting, control the pouring temperature at 1530-1535°C, and stir evenly with electromagnetic;

[0035] 5) Heating the slab, the heating temperature is 1220-1225°C;

[0036] 6) Carry out hot rolling, the starting rolling temperature is 1150-1155°C, the deformation is controlled at 850°C to 75%, and the final rolling te...

Embodiment 2

[0039] Production of equilateral angle steel with a side length of 290 mm, its composition and weight percentage content: C: 0.081%, Si: 0.28%, Mn: 1.420%, P: 0.0146%, S: 0.0096%, V: 0.042%, Nb : 0.026%, Ni: 0.22%, the rest are Fe and unavoidable impurities, and satisfy CEV= C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15=0.34%≤0.40 %.

[0040] Its production steps:

[0041] 1) For smelting, the superheating degree of molten steel is 12°C; when the outflow of molten steel is 1 / 4, Ni is added in a set amount at one time;

[0042] 2) Carry out slagging, and control the alkalinity of slag at 3.8;

[0043] 3) Perform argon blowing for 5 minutes;

[0044]4) Carry out continuous casting, control the pouring temperature at 1540-1545°C, and stir evenly with electromagnetic;

[0045] 5) Heating the billet at a temperature of 1230-1235°C;

[0046] 6) Carry out hot rolling, the starting rolling temperature is 1160-1165°C, the deformation is controlled at 885°C to 78%, and the final rolling temperatur...

Embodiment 3

[0049] Production of equilateral angle steel with a side length of 300 mm, its composition and weight percentage content: C: 0.11%, Si: 0.36%, Mn: 1.35%, P: 0.0142%, S: 0.009%, V: 0.051%, Nb : 0.033%, Ni: 0.48%, the rest is Fe and unavoidable impurities, and satisfies CEV= C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15=0.377%≤0.40 %.

[0050] Its production steps:

[0051] Production of equilateral angles with a side length of 300 mm,

[0052] 1) For smelting, the superheated degree of molten steel is 13°C; when the outflow of molten steel is 1 / 4, Ni is added in a set amount at one time;

[0053] 2) Carry out slagging, and control the alkalinity of slag at 4.0;

[0054] 3) Perform argon blowing for 6 minutes;

[0055] 4) Carry out continuous casting, control the pouring temperature at 1535-1540°C, and stir evenly with electromagnetic;

[0056] 5) Heating the billet, the heating temperature is 1245~1250℃;

[0057] 6) Carry out hot rolling, the starting rolling temperature is 1172-1177°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com