Method for preparing contact wires and pole blanks

A technology for contacting wires and wire rods, which is applied in the direction of metal rolling, manufacturing extensible conductors/cables, root rods/rods/wires/strip conductors, etc., which can solve the problem of large volume and weight, high price, The problem of long contact wires and other issues can be achieved to simplify heat treatment problems, high mechanical strength, and maintain the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

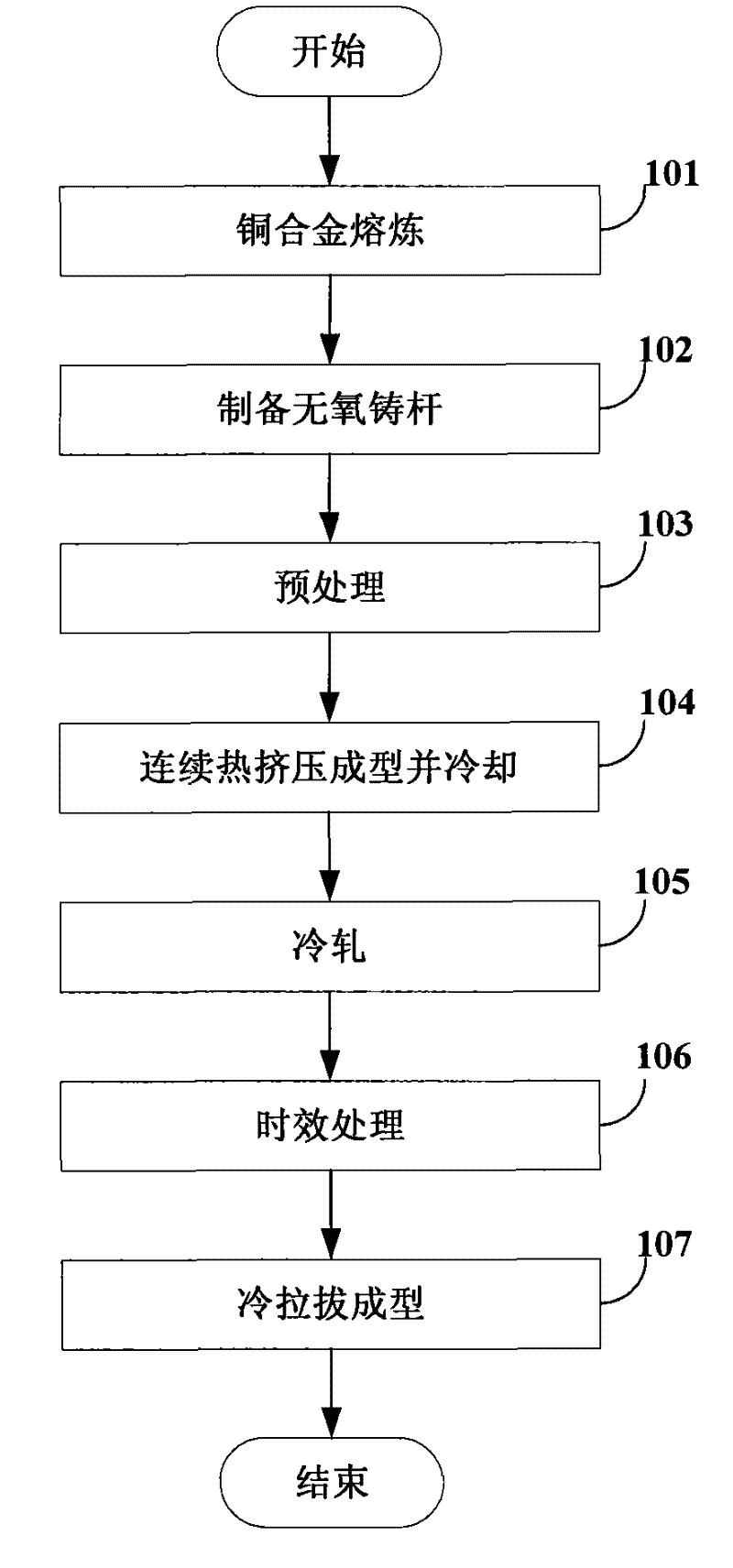

[0026] Such as figure 1 as shown, figure 1 It is a schematic flow chart of the preparation method of the contact wire according to the present invention, which may specifically include the following steps:

[0027] Step 101: Smelting copper alloys (for example, copper-chromium-zirconium alloys, copper-silver-chromium alloys, etc.); various appropriate smelting methods can be used, and the content of impurities such as oxides should be as low as possible.

[0028] Step 102: preparing an oxygen-free casting rod; the oxygen-free casting rod can be prepared by means of vacuum melting method, shielding gas melting method, upward continuous casting or horizontal continuous casting.

[0029] Step 103: pretreatment; performing necessary cleaning or diameter reduction on the anaerobic cast rod.

[0030] Step 104: sending the billet rod into the extrusion machine for continuous hot extrusion, and rapidly cooling the extruded contact wire rod billet. The as-cast structure of the alloy...

Embodiment 1

[0036] 1) Non-vacuum melting copper-chromium-zirconium alloy. Copper-chromium alloy and copper-zirconium alloy are added in the form of master alloy. In the furnace, chromium element accounts for 0.6% of the total weight, zirconium accounts for 0.1%, magnesium accounts for 0.05%, and the rest is copper. Argon protection.

[0037] 2) Horizontal continuous casting to prepare oxygen-free casting rods.

[0038] 3) Clean the surface of the billet rod.

[0039] 4) Send the connected billet rods into the Kangfu extruder for continuous hot extrusion and cooling to obtain the contact wire rod billet.

[0040] 5) The billet is cold-rolled with a deformation of 45%.

[0041] 6) Carry out aging treatment at a temperature of 550° C. and keep warm for 2 hours.

[0042] 7) Cold drawing forming, multi-pass cold drawing according to the cross-sectional size of the contact wire, the deformation amount is 50%, and the tensile strength of the contact wire can reach more than 580MPa, and the e...

Embodiment 2

[0044] 1) Non-vacuum melting copper-silver-chromium alloy. Among them, the copper-chromium alloy is added in the form of an intermediate alloy, and the chromium element in the furnace accounts for 0.6% of the total weight, silver accounts for 0.1%, magnesium accounts for 0.05%, and the rest is copper.

[0045] 2) Horizontal continuous casting to prepare oxygen-free casting rods.

[0046] 3) Clean the surface of the billet rod.

[0047] 4) Send the connected billet rods into the Kangfu extruder for continuous hot extrusion and cooling to obtain the contact wire rod billet.

[0048] 5) The billet is cold-rolled with a deformation of 45%.

[0049] 6) Carry out aging treatment at a temperature of 480° C. and keep warm for 2 hours.

[0050] 7) Cold drawing forming, multi-pass cold drawing according to the cross-sectional size of the contact wire, the deformation amount is 45%, and the tensile strength of the contact wire can reach more than 580MPa, and the conductivity can reach...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com