Patents

Literature

54results about How to "Improve comprehensive mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of magnesium alloy hub

ActiveCN103203602AImprove comprehensive mechanical propertiesDense tissueMetal-working apparatusSqueeze castingThermal treatment

A production method of a magnesium alloy hub is characterized by including the steps of first, smelting; second, squeeze-casting; third, homogenizing; fourth, forging; fifth, thermal treatment; and sixth, subsequent treatment. Compared with the prior art, the production method has the advantages that the production method combines advantages of magnesium alloy hub production by casting and forging, and the magnesium alloy hub is made by squeeze-casting and forging according to the features of squeeze casting technology; the magnesium alloy hub is imparted with excellent comprehensive performance, the production process is simple, and the production cost is low.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

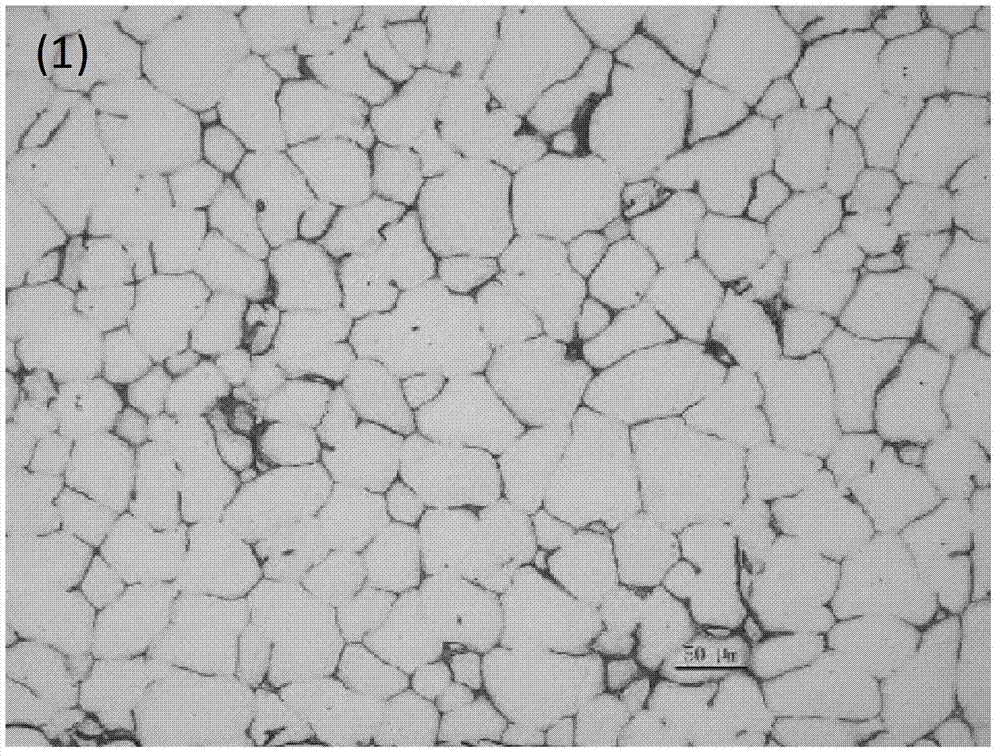

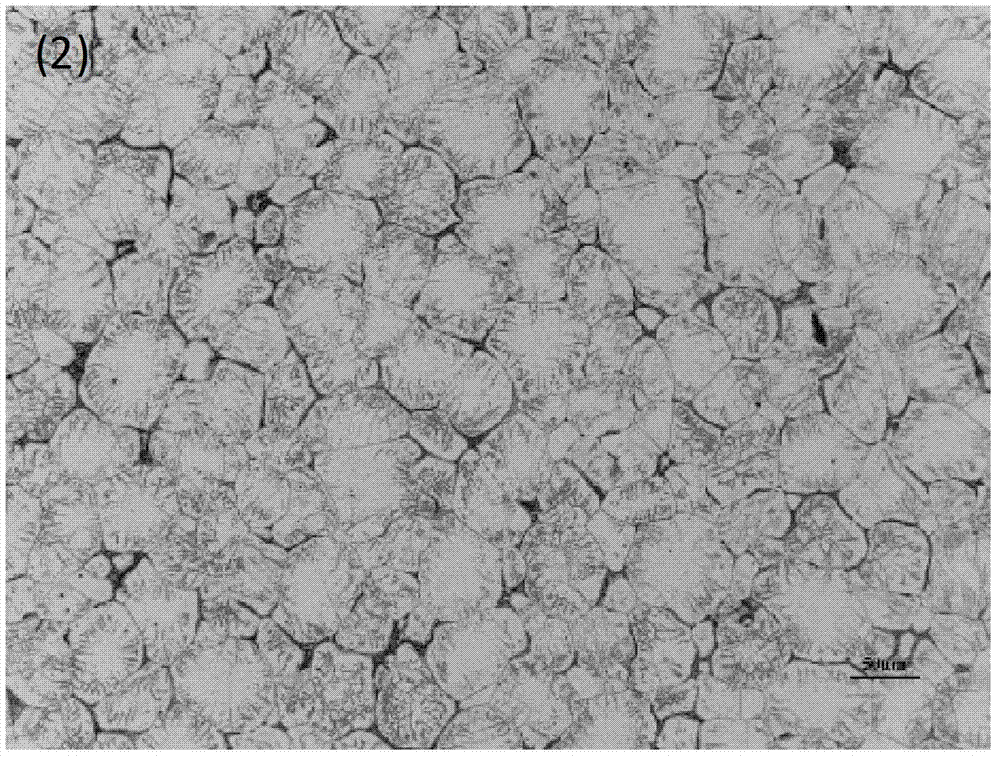

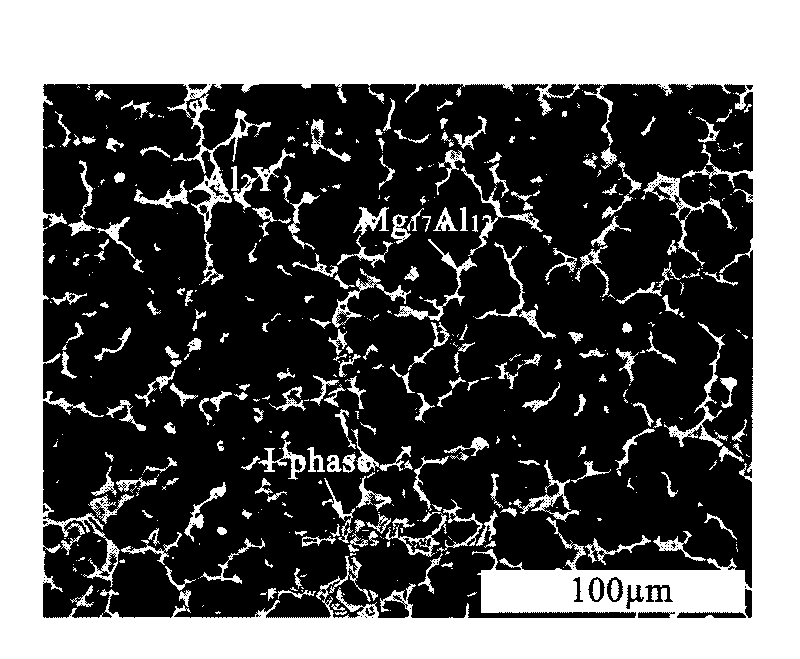

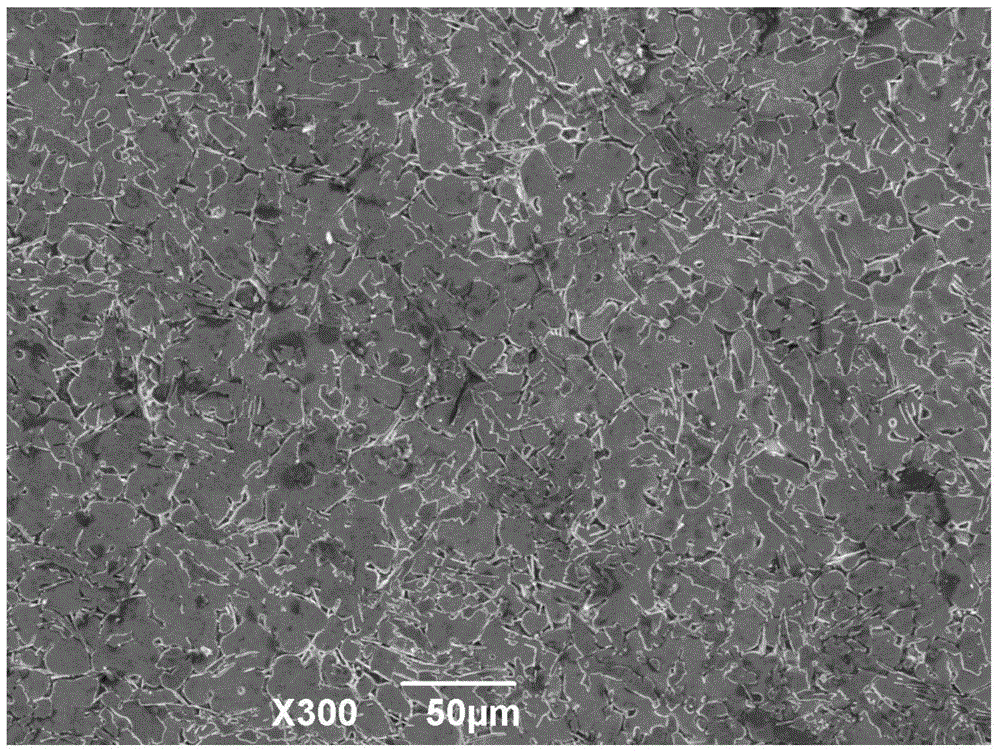

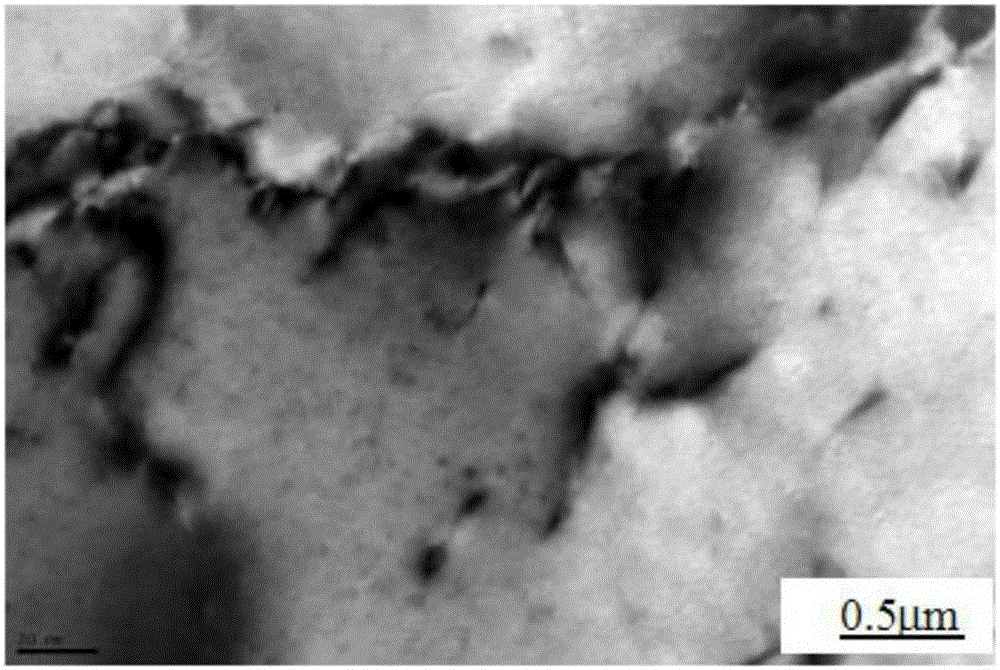

Quasicrystal reinforced magnesium alloy and semisolid preparation method thereof

InactiveCN101713042AImprove comprehensive mechanical propertiesSimple processInjection mouldingInterfacial bond

The invention discloses a quasicrystal reinforced Mg-Zn-Y-Al alloy and a semisolid preparation method thereof, belonging to the industrial magnesium alloy and the manufacturing field thereof. The quasicrystal reinforced magnesium alloy comprises the following components in percentage by weight: 4-15% of Zn, 0.5-3.5% of Y, 3-10% of Al and the balance of Mg. A hot extrusion method is adopted to extrude the Mg-Zn-Y-Al alloy into bars, and an electromagnetic induction heating device is adopted to heat the extrude bar into semisolid to carry out semisolid injection moulding. The fine texture of the quasicrystal reinforced Mg-Zn-Y-Al alloy of the invention contains fine quasicrystal reinforced phase which has favorable interfacial bond strength with a matrix so as to obviously improve the comprehensive mechanical properties of magnesium alloy. The semisolid preparation technology thereof is suitable for producing high-performance magnesium alloy parts with complex shape, is simple, has high yield, energy saving and environment protection, lowers cost and can be widely applied to industrial production.

Owner:DALIAN JIAOTONG UNIVERSITY

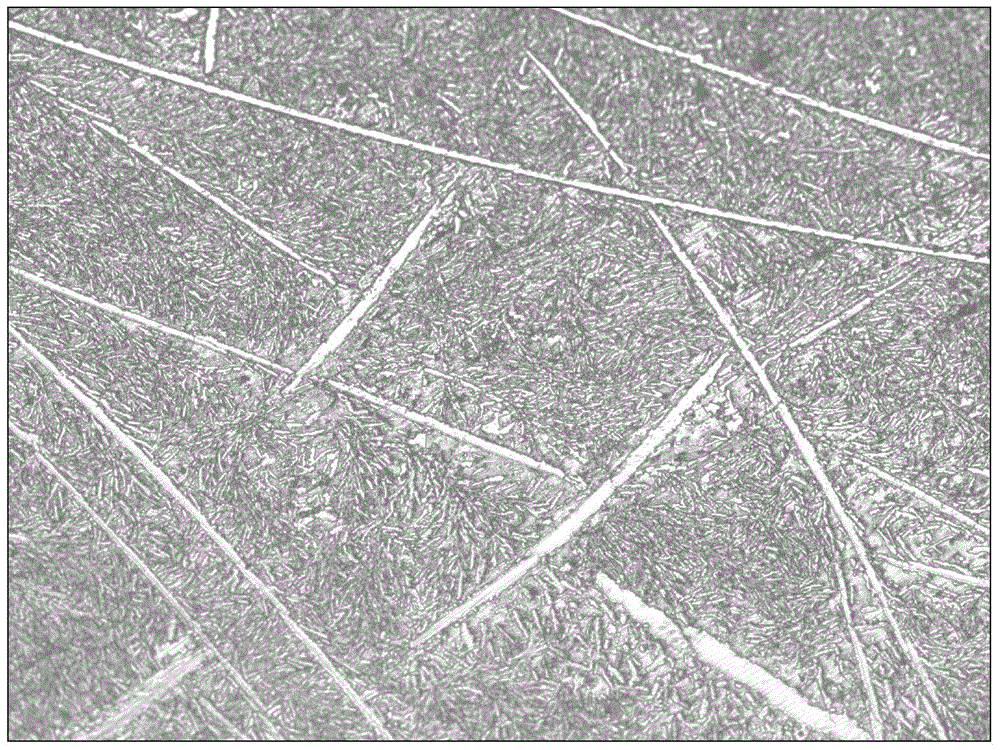

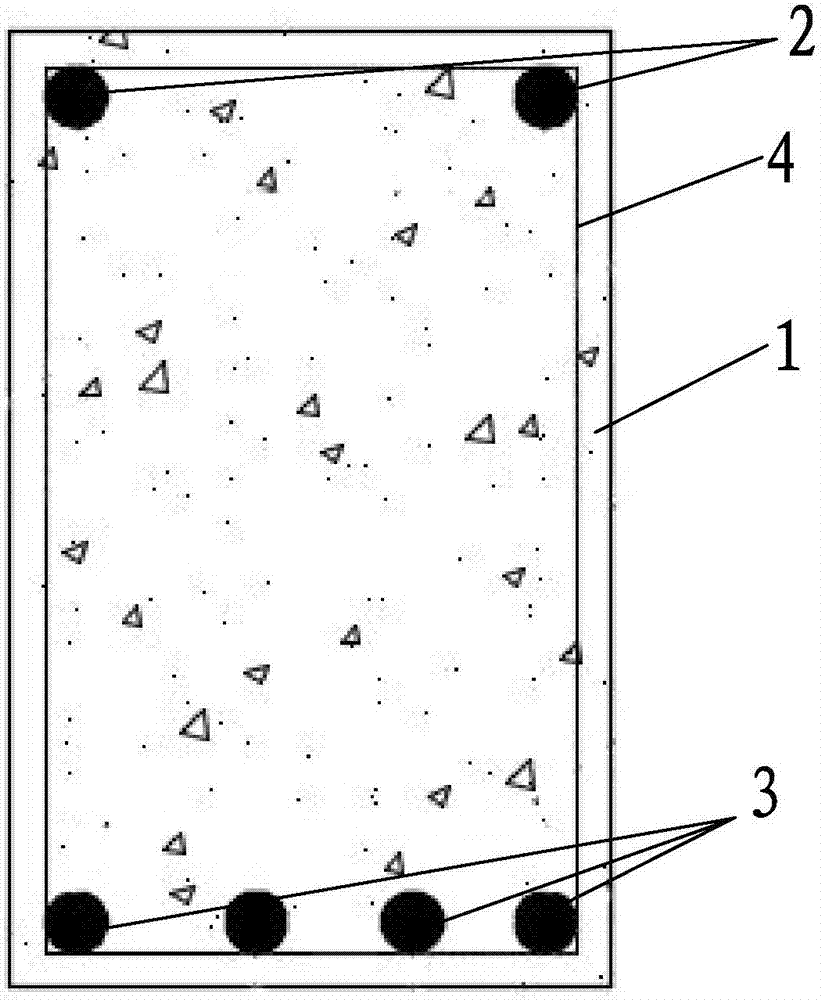

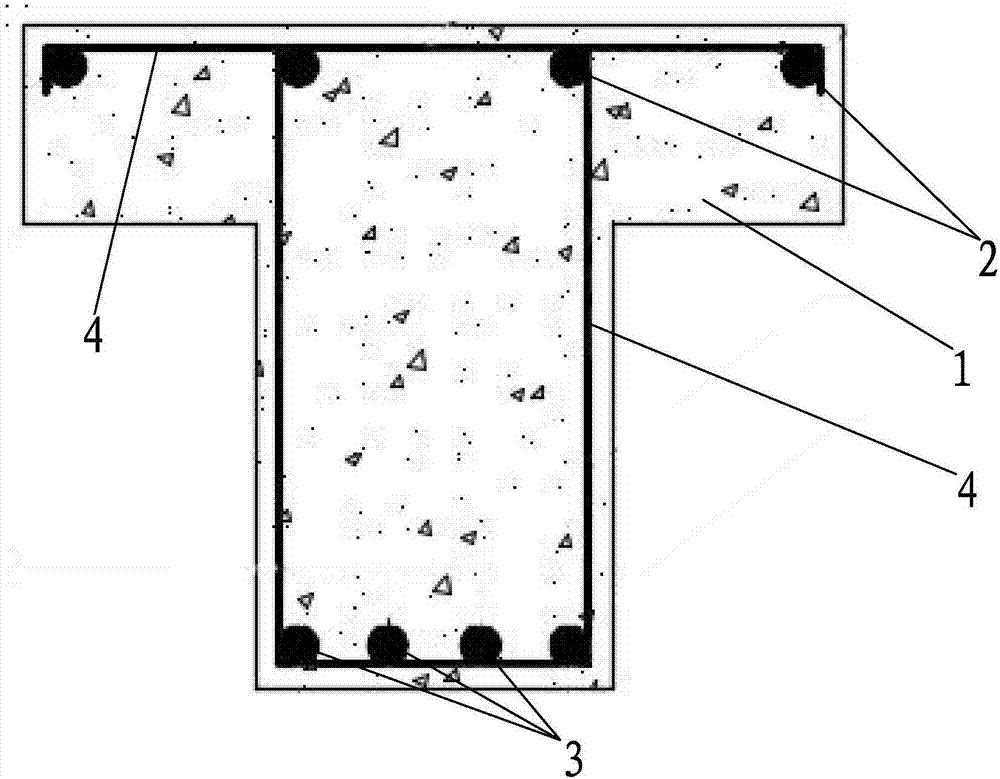

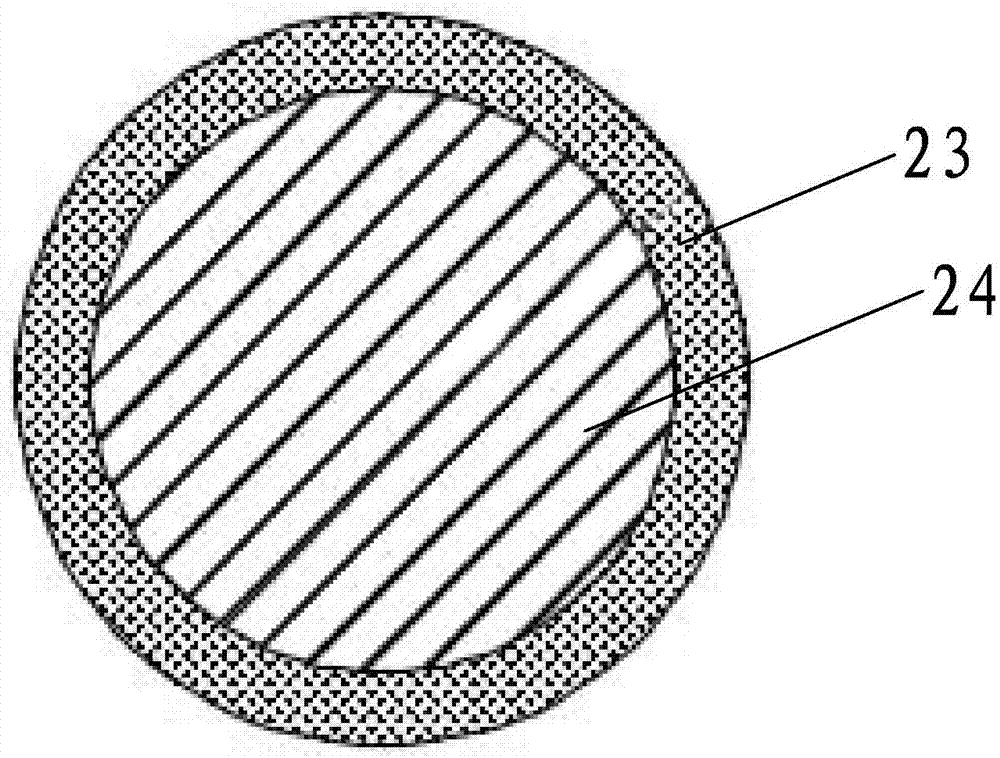

Method for continuously casting titanium alloy near single-crystal ingot by using electromagnetic cold crucible

InactiveCN101121999AImprove comprehensive mechanical propertiesImprove mechanical propertiesPulling actionDirectional solidification

A method of continuously founding the titanium alloy to be close to an single crystal ingot with a magnetic field belongs to a method of making the titanium alloy to be close to the single crystal ingot. The method solves the problem that the container material is easy to pollute the alloy and thus affect the physical and mechanical performances of the single crystal alloy during preparation of single crystal in the current directional solidification methods. The procedures of the invention are as follows: 1. vacuum pumping is conducted in a furnace (4), and then argon is re-charged. 2. induction coils (3) are arranged out of a water-cooled copper crucible (2), and spread on the outer surface of the water-cooled copper crucible (2). 3. a material rod (3) enters into the induction coils (3), the titanium alloy charge enters into the cavity of the water-cooled copper crucible (2), and the diameter of the upper part of the charge is small. 4. After heating, pulling is conducted, the feeding speed must strictly match with the pulling action; a rod enters into a crystallizer (9); the material rod forms close single crystal after pulling, and obtains the single crystal ingot after processing the outer layer. The invention realizes high-grade, high-efficiency, safety, special and low-cost single crystal preparation method for the titanium alloy material.

Owner:HARBIN INST OF TECH

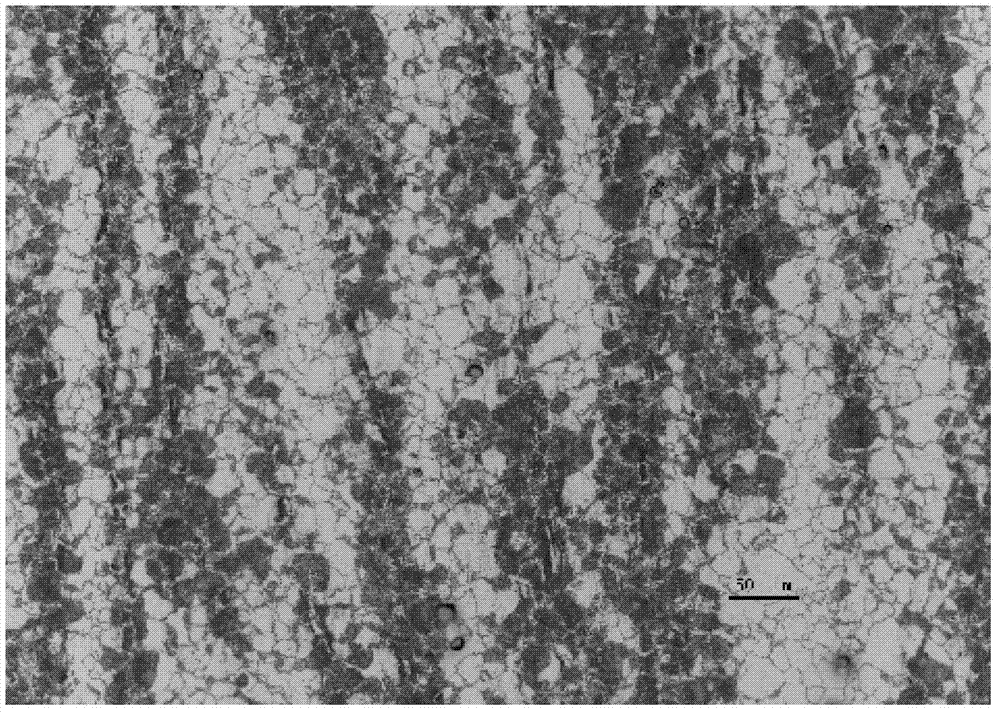

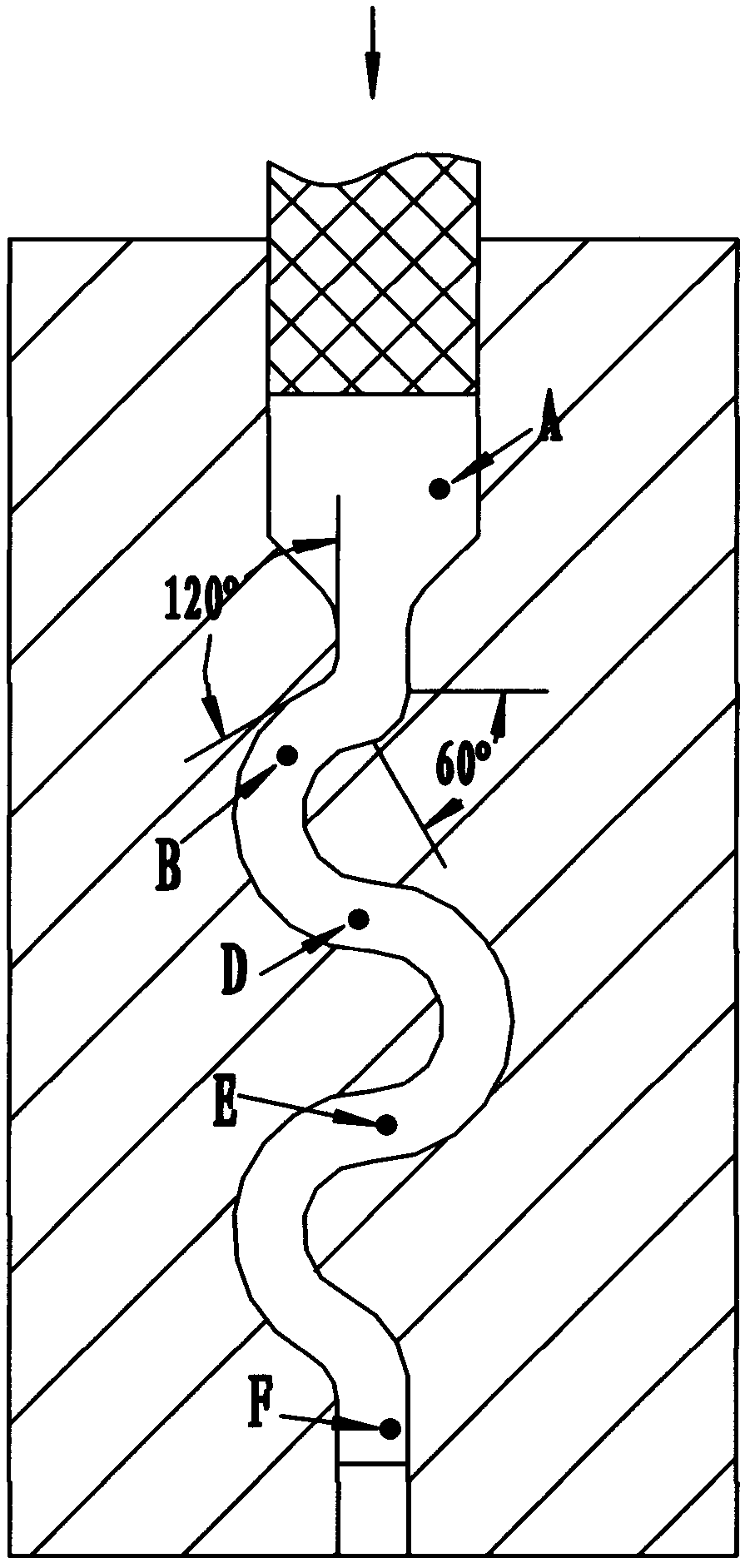

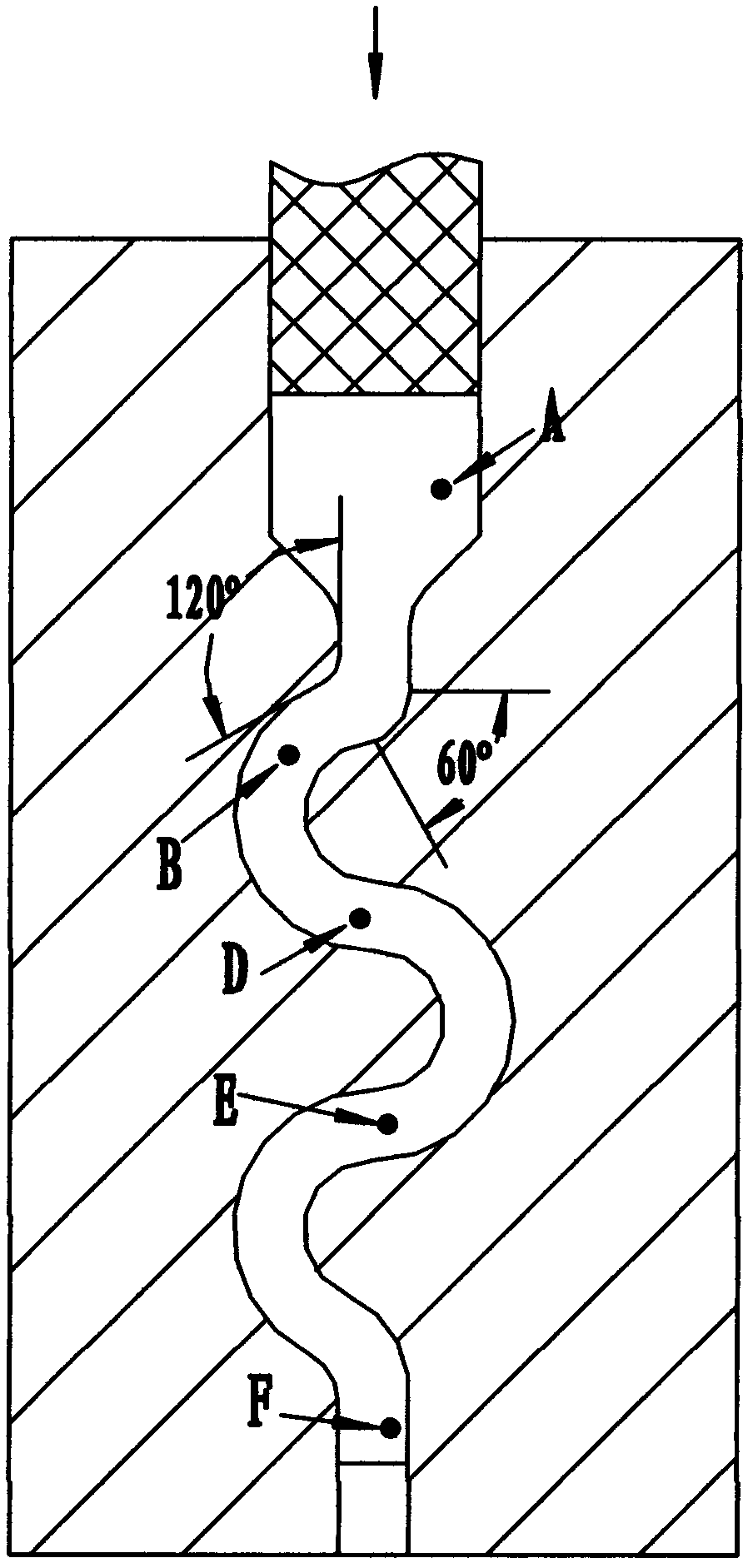

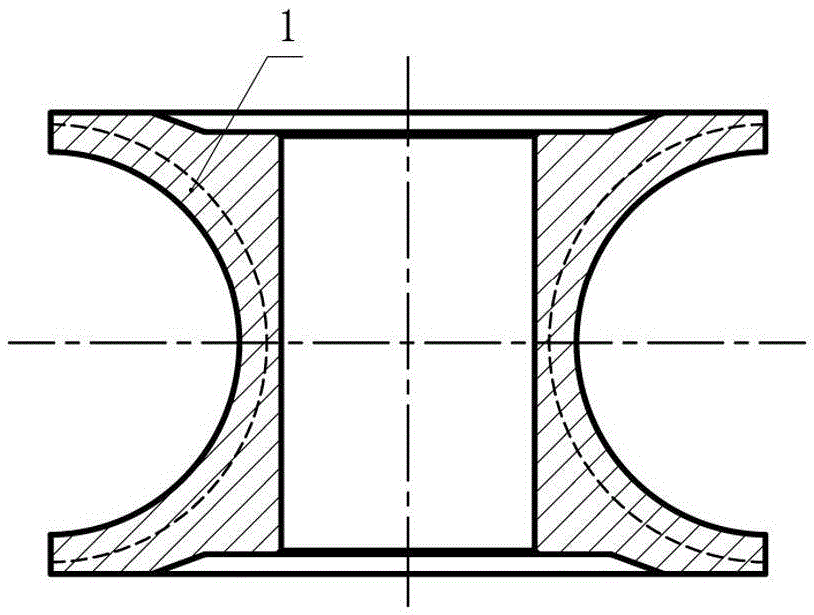

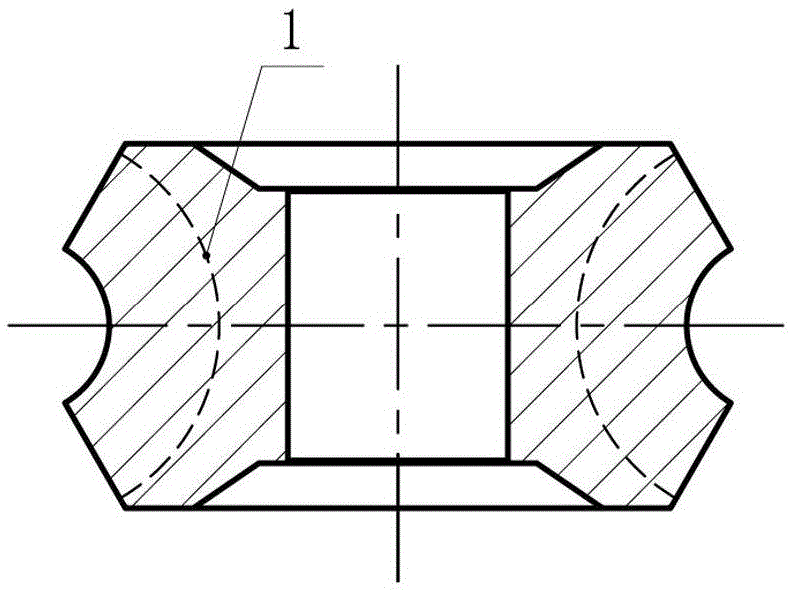

Coextrusion processing method of magnesium alloy

InactiveCN102601141AImprove refinementImprove comprehensive mechanical propertiesExtrusion diesMaterial flowMagnesium alloy

The invention discloses a coextrusion processing method of a magnesium alloy. According to the method, a coextrusion mould is adopted, wherein the coextrusion mould comprises an upper end vertical extrusion channel. The method comprises the following steps of: step one, carrying out homogenization treatment on a magnesium alloy casting blank material; step two, heating the coextrusion mould, wherein the temperature of the coextrusion mould is 10 DEG C-30 DEG C lower than that of the magnesium alloy blank material, and a lubricating agent is uniformly coated on extrusion channel of the coextrusion mould after being heated; and step three, heating the magnesium alloy blank material subjected to homogenization treatment to 250 DEG C-400 DEG C, carrying out one-way uniform speed extrusion from the upper end of the magnesium alloy blank material so as to ensure that the magnesium alloy blank material flows and is subjected to compressional deformation towards an S type channel from the vertical channel. According to the coextrusion processing method provided by the invention, the coextrusion deformation technology is adopted, thus refinement effect of magnesium alloy grains is greatly improved, the comprehensive mechanical property of a magnesium alloy material is improved, and heat treatment gate and a complicated compressional deformation working procedure in the compressional deformation process are reduced.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

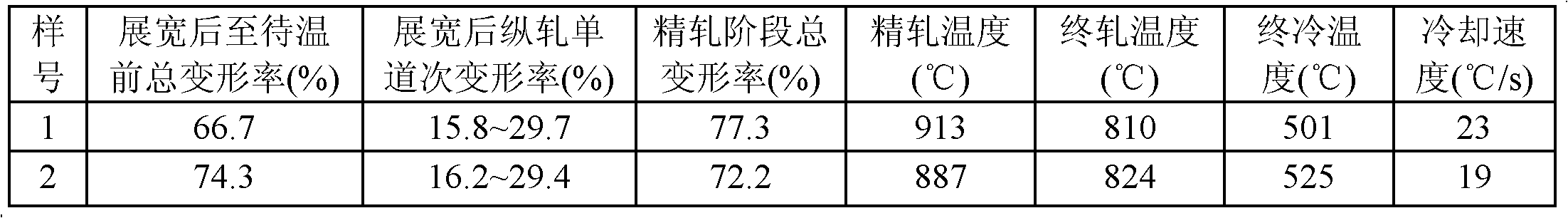

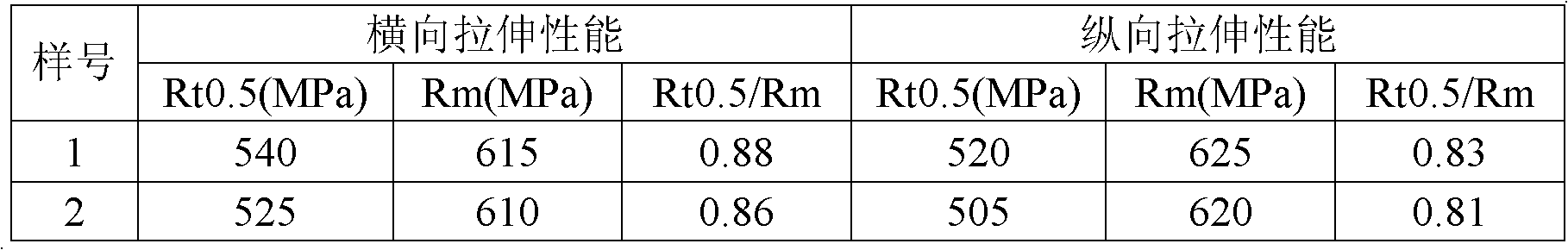

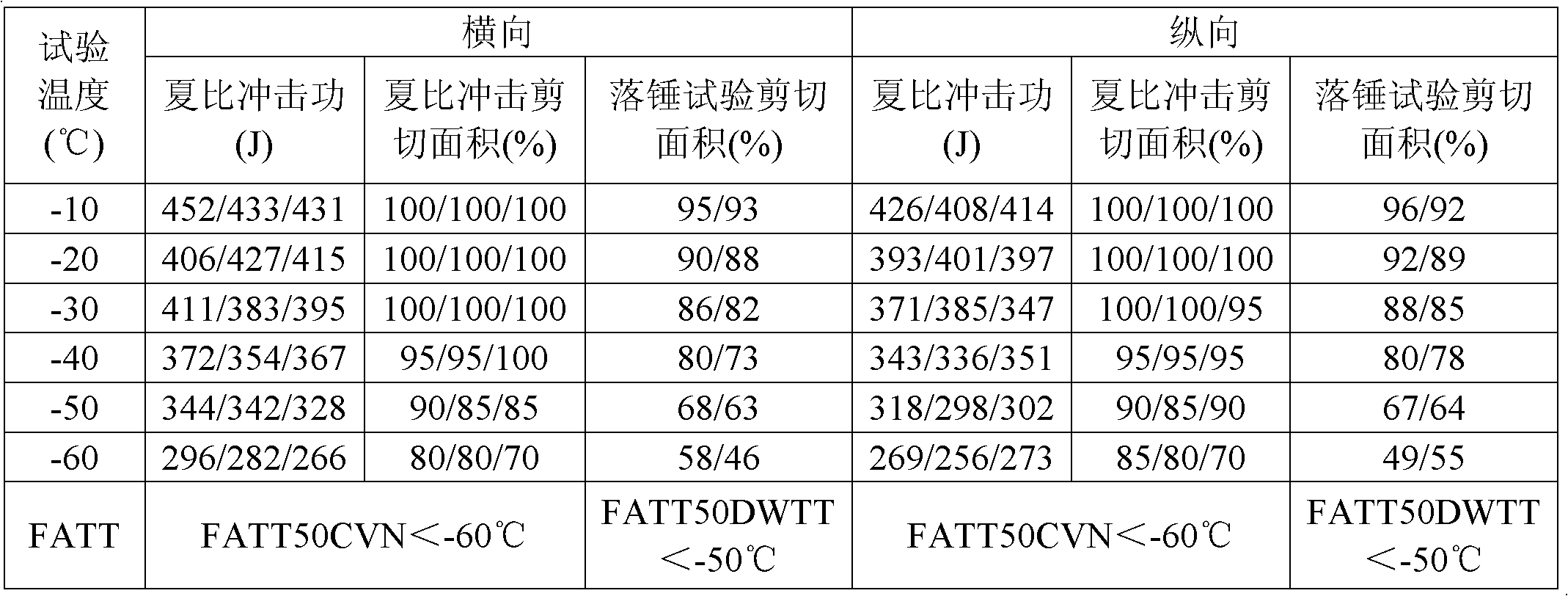

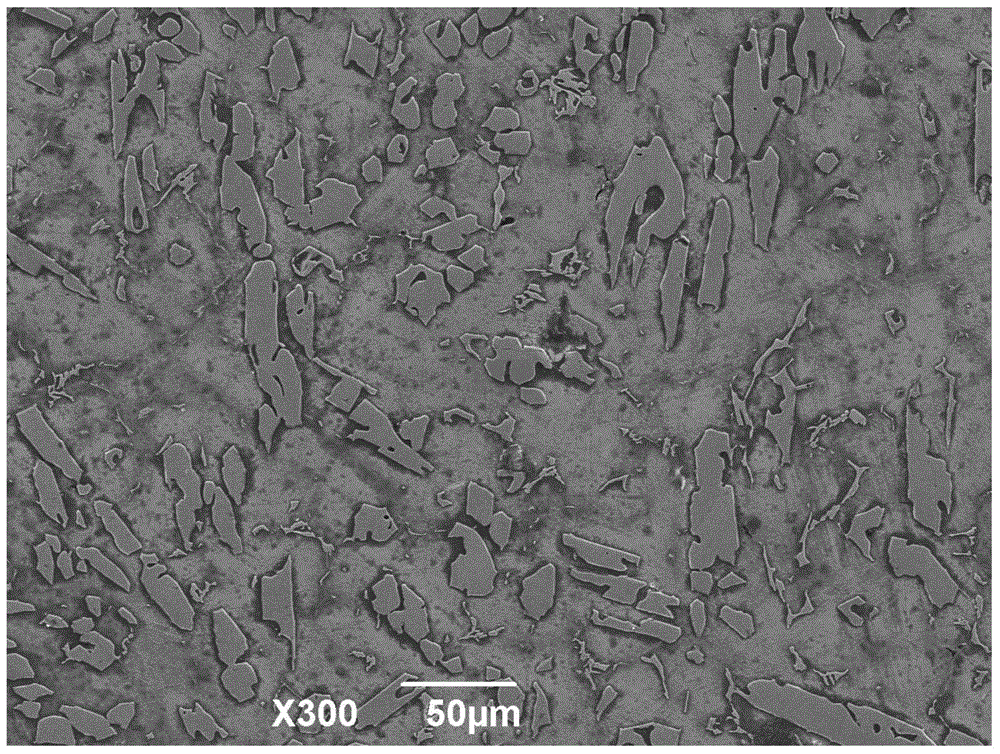

Production method of X70 hot-rolled medium plate for submerged pipeline

ActiveCN102181796AImprove transverse and longitudinal strength and low temperature toughnessImprove comprehensive mechanical propertiesSteel platesAlloy element

The invention provides a production method of an X70 hot-rolled medium plate for a submerged pipeline. The medium plate comprises the following components in percentage by weight: 0.035 to 0.07 percent of C, 0.10 to 0.35 percent of Si, 1.40 to 1.85 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.0035 percent of S, 0.01 to 0.06 percent of Alt, 0.035 to 0.07 percent of Nb, 0.008 to 0.020 percent of Ti, 0.10 to 0.30 percent of Mo, 0.10 to 0.25 percent of Ni, 0.10 to 0.25 percent of Cr, 0.10 to 0.25 percent of Cu and the balance of Fe and inevitable impurity elements. In the steel plate manufacturing process, the effects of the alloy elements and the potential of an excavation thermo-mechanical control process are fully exerted through an optimized blank type design, a strict heating schedule and a reinforced thermo-mechanical control process in coordination with an appropriate amount of Ni, Cr and Cu alloy elements, so that an organization form based on a uniform fine acicular ferrite is obtained on a steel plate with the whole wall thickness, and the medium plate has relatively high horizontal and longitudinal tensile strength and high low-temperature toughness, and completely meets the requirements of high performance of steel for a deepwater submerged pipeline.

Owner:SHOUGANG CORPORATION

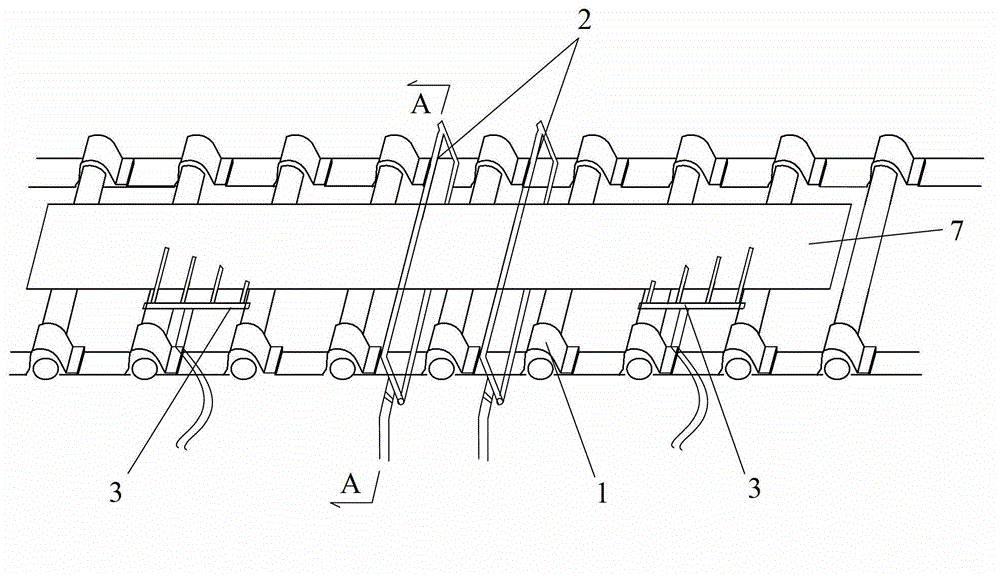

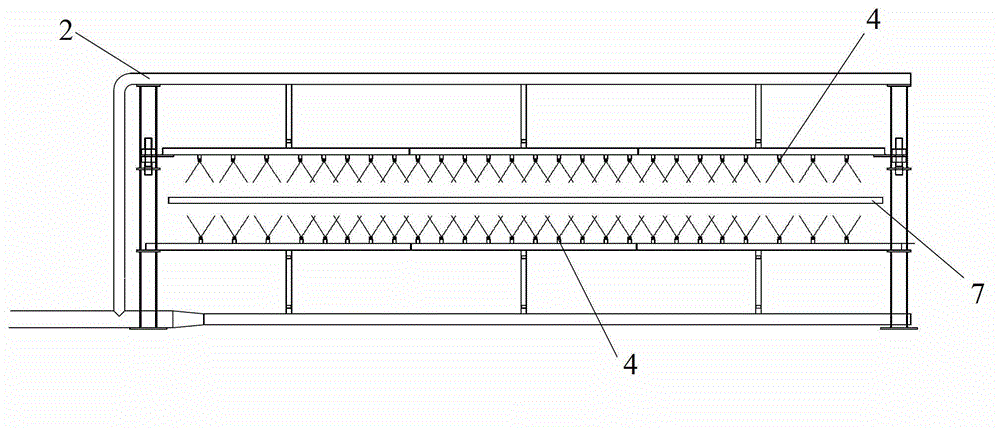

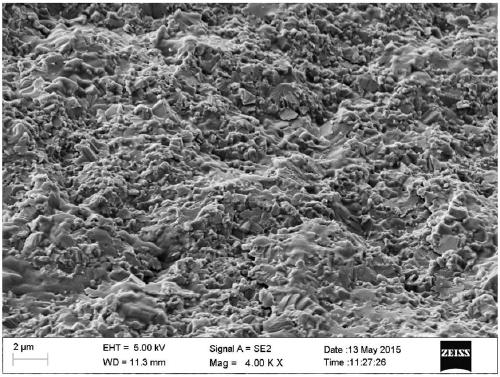

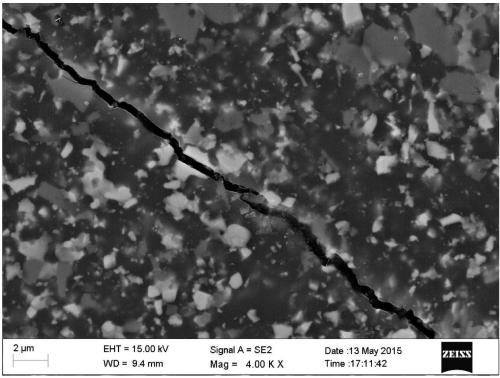

Controlled cooling method after H-shape steel rolling

InactiveCN1583305AImprove mechanical propertiesImprove comprehensive mechanical propertiesWork treatment devicesMetal rolling arrangementsCrystalliteCooling methods

A controlled cooling method for the rolled H-shaped steel features that the just rolled H-shaped steel is cooled by the aerosolizing mode in a controllable cooler and its cooling speed is more than 50 deg.C / s.

Owner:NORTHEASTERN UNIV

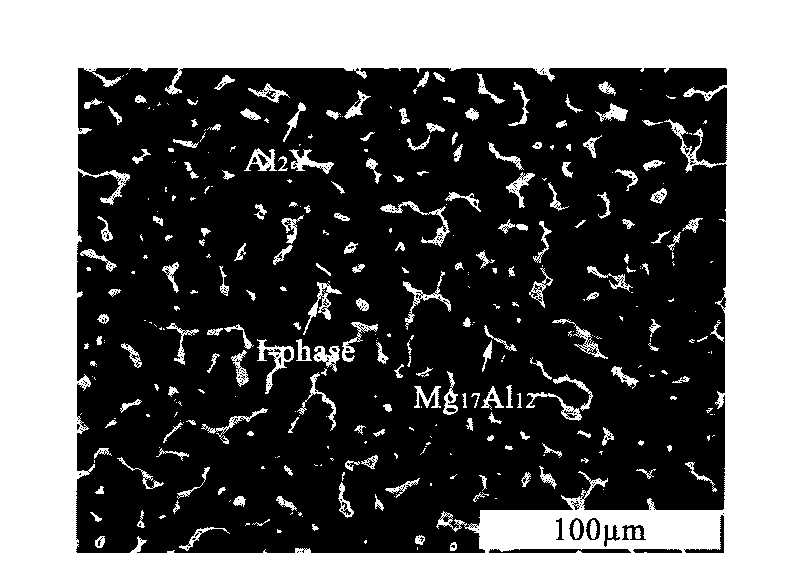

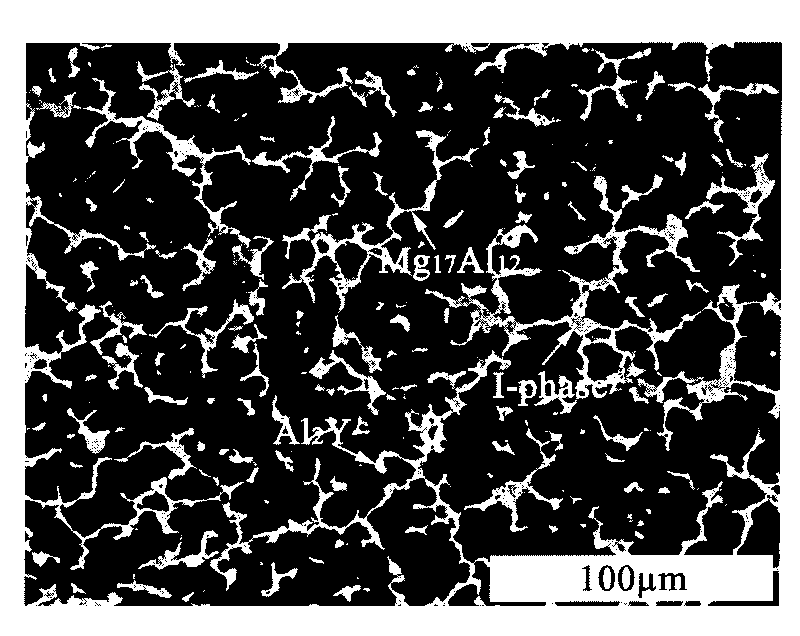

Quasi-crystal reinforced multi-element magnesium alloy and preparation method thereof

InactiveCN104372224AImprove comprehensive mechanical propertiesGood comprehensive mechanical propertiesMulti elementMagnesium alloy

The invention discloses a quasi-crystal reinforced multi-element magnesium alloy and a preparation method thereof, belonging to the field of industrial magnesium alloys and manufacturing thereof. The quasi-crystal reinforced multi-element magnesium alloy comprises the following components in percentage by mass: 6.0-16% of Zn, 1.4-3.6% of Y, 0.1-0.5% of Ho, 0.1-0.5% of Er, 0.05-1.2% of Mn, 0.02-1.6% of Ti, 0.05-1.8% of Zr, and the balance of Mg. The quasi-crystal reinforced multi-element magnesium alloy disclosed by the invention has relatively good comprehensive mechanical properties namely relatively high tensile strength and relatively high elongation percentage, and particularly has relatively high yield strength.

Owner:SOUTHWEST JIAOTONG UNIV

Method for improving toughness of boracic high-entropy alloy by adding rare earth

ActiveCN104451351APromotes toughening effectImprove comprehensive mechanical propertiesRare-earth elementHigh entropy alloys

The invention discloses a method for improving the toughness of a boracic high-entropy alloy by adding rare earth, belonging to the technical field of alloy materials. According to the component design idea of the invention, a boron element with the mole fraction of 0.1-8% is added into a high-entropy alloy consisting of five or more than five elements, and meanwhile 0.1-4% of a rare earth element such as Y or Ce is added together. Due to addition of the rare earth elements, the gap solid solution reinforcement effect of the small atom boron element in the high-entropy alloy is improved, and the separation content, the morphology and the distribution of rigid boride hard phase are improved, so that the strength and the toughness of the boracic high-entropy alloy are synchronously improved.

Owner:江苏康柏斯机械科技有限公司

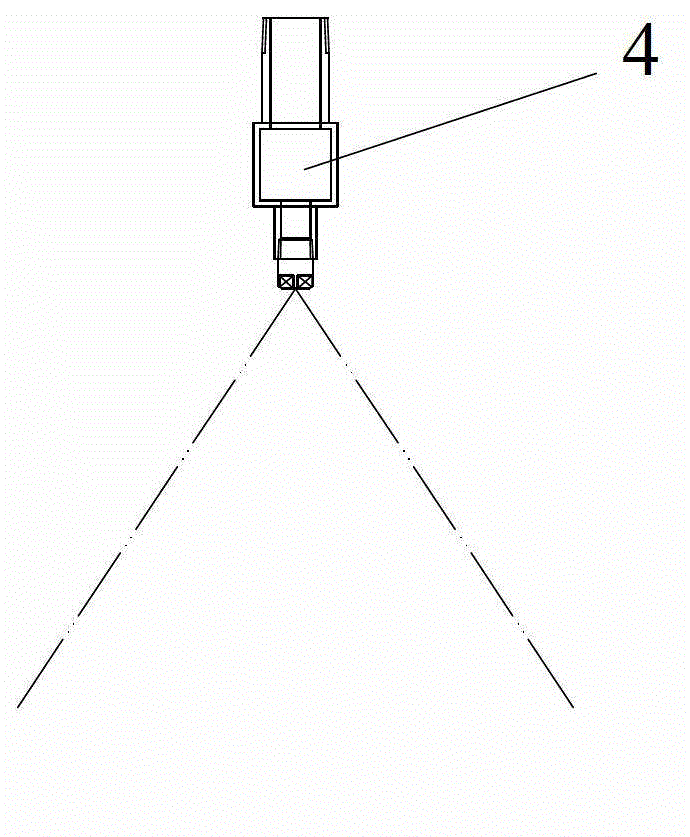

Method and cooling system for improving comprehensive mechanical property of normalized steel plate

ActiveCN102912091AImprove comprehensive mechanical propertiesAvoid austenite grain growthFurnace typesHeat treatment process controlThermal insulationSteel plates

The invention discloses a method for improving the comprehensive mechanical property of a normalized steel plate. The running time of the steel plate in a heating region in a normalizing furnace is reasonably prolonged and the running time of the steel plate in a thermal insulation region in the normalizing furnace is reasonably shortened, so that the austenite grain growth is avoided to provide favorable conditions for subsequent accelerated cooling. The steel plate is quickly cooled to be 600-700 DEG C from the normalizing temperature in a way of normalizing, atomizing and cooling, so that the mist cooling with higher heat exchange efficiency increases the supercooling degree of the structural transformation of the steel plate and effectively prevents the austenite grain growth; and grains are refined, so that the effect of improving the strength by structure refinement in the heat treatment process of the steel plate is given full play. The invention further provides a cooling system for improving the comprehensive mechanical property of the normalized steel plate. Therefore, the equipment is simple, the investment is low, the surface quality of the steel plate can be improved, and the practicality is better.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

High performance alumina composite ceramic cutting tool material and preparation method thereof

InactiveCN108947495AImprove comprehensive mechanical propertiesImprove mechanical propertiesTitanium carbonitrideBall mill

The invention relates to a high performance alumina composite ceramic cutting tool material and a preparation method thereof. The preparation method includes the following steps: 1) preparing raw materials; 2) pouring 50-70 parts by weight of alumina powder with particle sizes being 0.5-1.5 [mu]m, 15-25 parts by weight of titanium carbonitride powder with particle sizes being 0.5-1.5 [mu]m and 15-25 parts by weight of titanium tungsten carbide powder with particle sizes being 0.5-1.5 [mu]m into a mixing bucket, adding absolute ethanol as a medium, performing ball milling on a ball mill for 43-53 h so that the mixing of all phase materials can be more uniform, obtaining composite ceramic material powder with good dispersion through vacuum drying and sieving, and packaging for later use; and3) performing charging and sintering. The defects of the limitation of single particle addition on enhancing the mechanical properties of materials can be overcome, and the comprehensive mechanical properties of ceramic cutting tool materials can be effectively improved.

Owner:SHANDONG UNIV

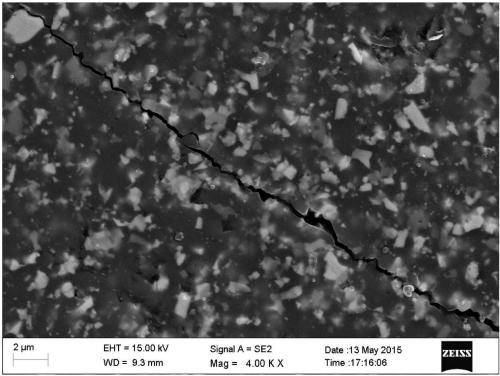

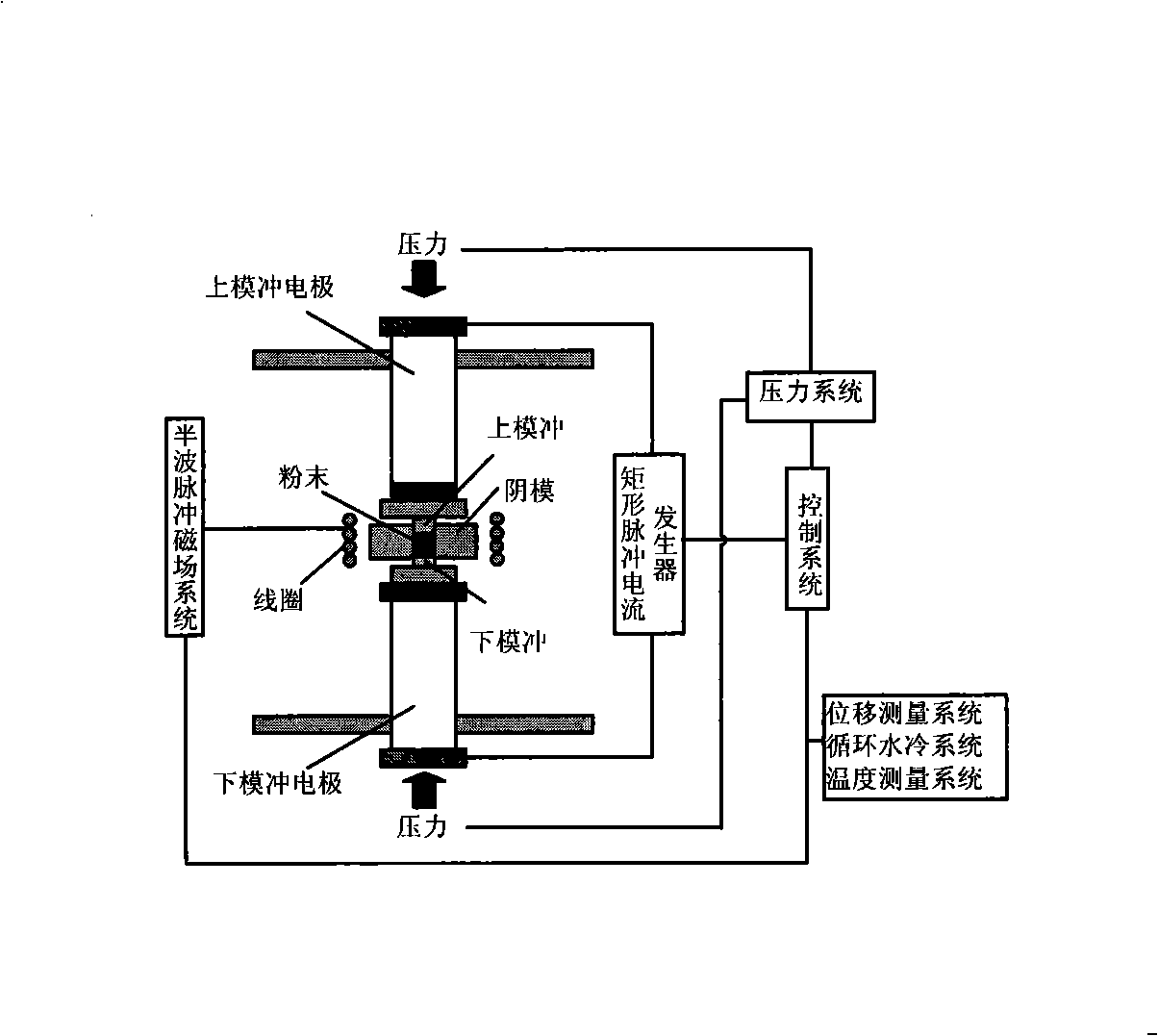

Method for preparing nanocrystalline block iron-base alloy material by four-field coupling sintering

InactiveCN101323917AImprove uniformityImprove comprehensive mechanical propertiesPeak valueIron based alloy

The invention provides a method for preparing a bulk nano iron matrix composite by four-field coupling sintering. The four-field coupling adopted by the method refers to simultaneously applying rectangular pulse current and axial semi-wave pulse magnetic field and sintering pressure, wherein, the sintering pressure of positive and negative electrodes applied to power is 10MPa to 50MPa and time for sintering is 1 to 6 minutes. The peak value, base value, frequency, duty ratio of the rectangular pulse current and the strength of the additional axial semi-wave pulse magnetic field increase with the increasing of the size of sintering material. The method significantly improves the uniformity of the axial temperature field of sintering, promotes the comprehensive mechanical performance of iron matrix alloy in sintering state and prepares the bulk iron matrix composite that is characterized by being nearly completely compact, high strength and nanocrystal. The method obviously reduces the requirements for equipment, shortens period, improves efficiency, is especially beneficial to the domestic production of the bulk nano iron matrix composite and has good prospect of promotion and application.

Owner:SOUTH CHINA UNIV OF TECH

ABS/carbon fiber composite material suitable for 3D printing

InactiveCN106380801AIncreased material compatibilityImprove comprehensive mechanical propertiesMaleic anhydrideMethyl methacrylate

The invention discloses a composite material suitable for 3D printing, wherein the composite material comprises the following components in parts by weight: 40-45 parts of polylactic acid (PLA), 40-45 parts of acrylonitrile-butadiene-styrene (ABS), 10-20 parts of carbon fibers, 4-8 parts of a toughening agent, 0.2-5.0 parts of a compatilizer, and 0.1-2.0 parts of an auxiliary agent. The toughening agent comprises styrene-acrylonitrile-butadiene rubber (ABS high glue powder); the compatibilizer comprises a maleic anhydride grafted polymer, and one or two compatibilizers of a ternary copolymer formed by copolymerizing methyl methacrylate, butadiene and a styrene copolymer and a ternary copolymer (SAG) formed by copolymerizing styrene, acrylonitrile and glycidyl methacrylate are in compatibility use. The prepared 3D printing composite material has the advantages of superior comprehensive performance, broad market prospect and application value.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Composite particle reinforced roller of hot-rolling seamless steel pipe sizing mill or reducing mill and preparation method thereof

ActiveCN105618485AImprove ball effectImprove comprehensive mechanical propertiesFurnace typesRollsQuenchingSizing

The invention discloses a composite particle reinforced roller of a hot-rolling seamless steel pipe sizing mill or reducing mill and a preparation method thereof. Composite particles are composed of hardening particles, active wetting agents and matrix reinforcing agents. The composite particle reinforced roller of the sizing mill or reducing mill is cast after nodular cast iron matrix molten metal is reinforced; and the high-strength and high-toughness composite particle reinforced roller is obtained by conducting isothermal quenching and machining on the roller. The composite particle reinforced roller is resistant to abrasion and impact; the service life of the roller is prolonged by over two times; the production cost is lowered; the production efficiency of a steel pipe production enterprise is improved, and economic benefits of the steel pipe production enterprise are increased.

Owner:SHANDONG SIFANG STEEL PIPE EQUIP MFG

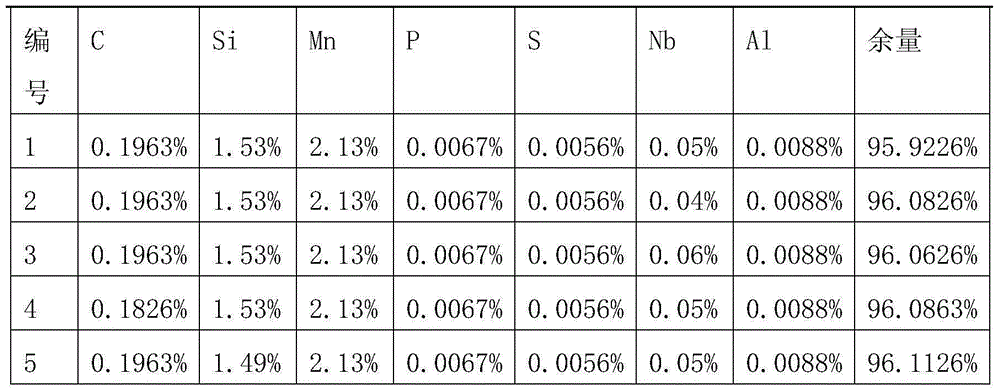

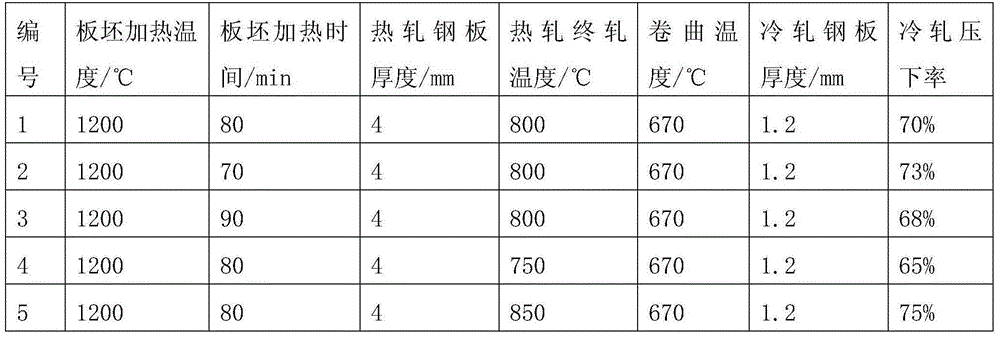

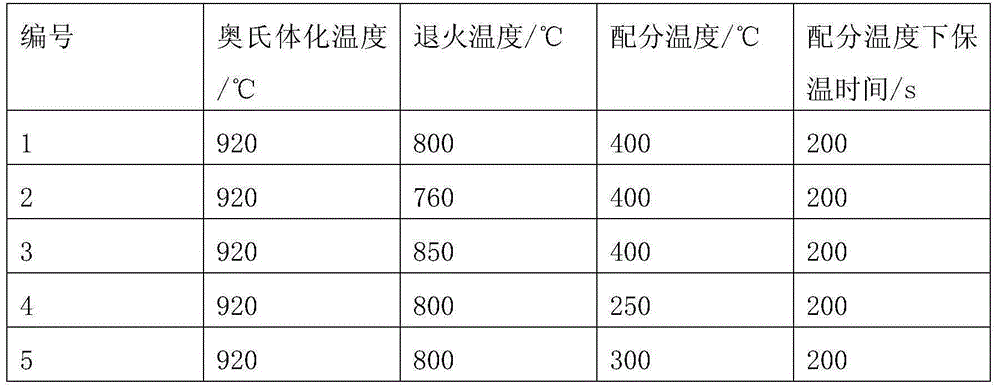

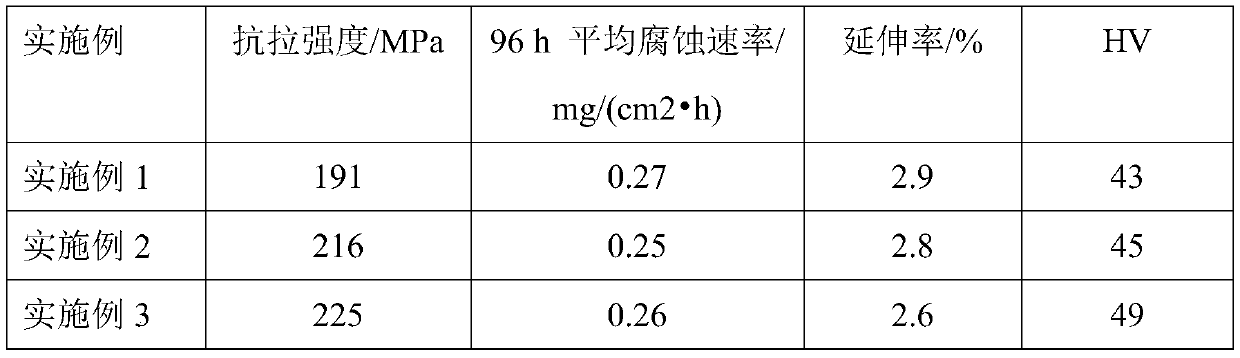

Niobium alloying TAM steel and preparing method thereof

ActiveCN105039847AImprove toughnessImprove comprehensive mechanical propertiesSteel platesChemical composition

The invention relates to niobium alloying TAM steel and a preparing method thereof, and belongs to the technical field of metal component designing and thermal machining. The niobium alloying TAM steel comprises, by weight percentage, 0.18-0.21% of C, 1.48-1.55% of Si, 1.90-2.20% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.015% of S, 0.04-0.06% of Nb, smaller than or equal to 0.04% of Al, and the balance Fe and other inevitable impurities. An appropriate amount of niobium is added in a niobium alloying manner, the toughness of the TAM steel is improved through precipitation of carbide of niobium and the like, and therefore the comprehensive mechanical performance of the niobium-containing TAM steel is improved, and a steel plate has high strength and plasticity and especially has the superior hydrogen resisting and induced delaying fracture performance. According to the production of the niobium-containing TAM steel, the steel organization performance is more stable through the new technology-Q&P technology.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Environment-friendly flame-retardant cable material and preparation method thereof

InactiveCN108102210AImprove flame retardant performanceImprove comprehensive mechanical propertiesPlastic/resin/waxes insulatorsEPDM rubberPlasticizer

The invention discloses an environment-friendly flame-retardant cable material and a preparation method thereof. The cable material comprises, by weight, 30-40 parts of an ethylene-vinyl acrylate copolymer, 10-20 parts of an EPDM rubber, 7-15 parts of modified talcum powder, 22-30 parts of a flame retardant, 3-10 parts of whisker, 2-8 parts of an antioxidant and 0.5-5.5 parts of a plasticizer. Thepreparation method comprises (1) weighing: weighing components according to the specified ratio, (2) mixing, (3) mixing: mixing the raw materials in a kneader at a temperature of 140 to 160 DEG C for25min, and (4) extrusion granulation: adding the raw materials into a twin-screw extruder and carrying out extrusion granulation at a processing temperature of 200-220 DEG C. The environment-friendlyflame-retardant cable material has good flame retardant performances and excellent comprehensive performances. The preparation method has simple processes and high processing efficiency and can meetthe needs of large-scale industrial production.

Owner:HEFEI ANLI ELECTRIC POWER ENG CO LTD

Novel Mg-Y-Nd-(La+Ce)-Zr biodegradable magnesium alloy and manufacturing method thereof

ActiveCN110468319AImprove comprehensive mechanical propertiesGood processing performanceSurgeryBiocompatibility TestingCorrosion

The invention discloses an Mg-Y-Nd-(La+Ce)-Zr biodegradable magnesium alloy and a manufacturing method thereof. The Mg-Y-Nd-(La+Ce)-Zr biodegradable magnesium alloy is characterized in that the magnesium alloy is manufactured from the following components in percentage by mass: 3.0-4.5% of Y, 2.0-3.5% of Nd, 0.3-1.0% of Zr, 0.05-0.5% of lanthanum cerium composite rare earth, and the balance beingmagnesium and inevitable impurities, wherein the impurity content is less than or equal to 0.1%, and lanthanum content and cerium content in the lanthanum cerium composite rare earth each account for50%; and the manufacturing method comprises the steps: batching, casting, annealing, extruding, and obtaining finished products. According to the magnesium alloy and the manufacturing method, a multi-element and small-amount design method is adopted, the proportion is scientific and reasonable, the manufacturing process is simple, the manufactured magnesium alloy is high in compactness, reliable in quality, excellent in mechanical property and corrosion resistance, controllable in degradation speed and excellent in biocompatibility, meanwhile, a cardiovascular stent made of the magnesium alloycannot be damaged for deformation and can be well matched with human tissues, and therefore the magnesium alloy has wide application prospects in the medical field.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

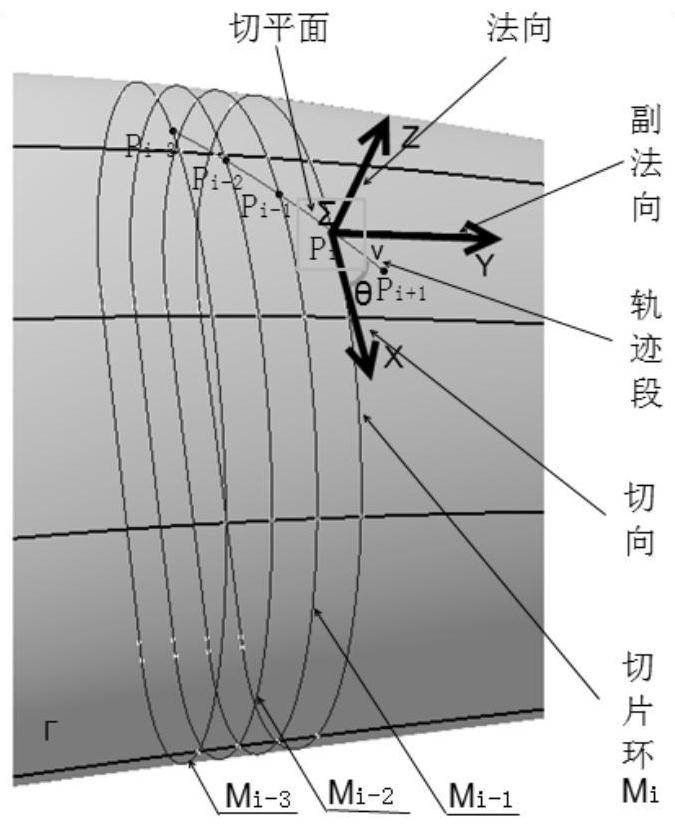

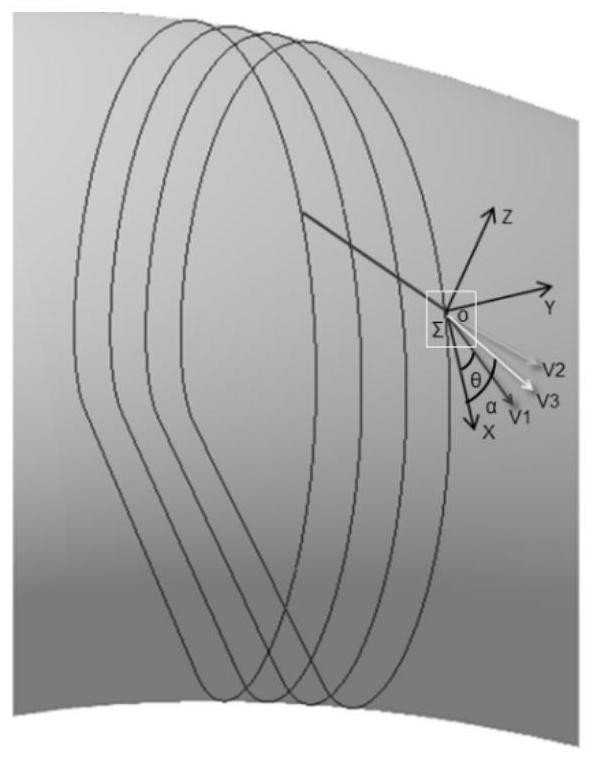

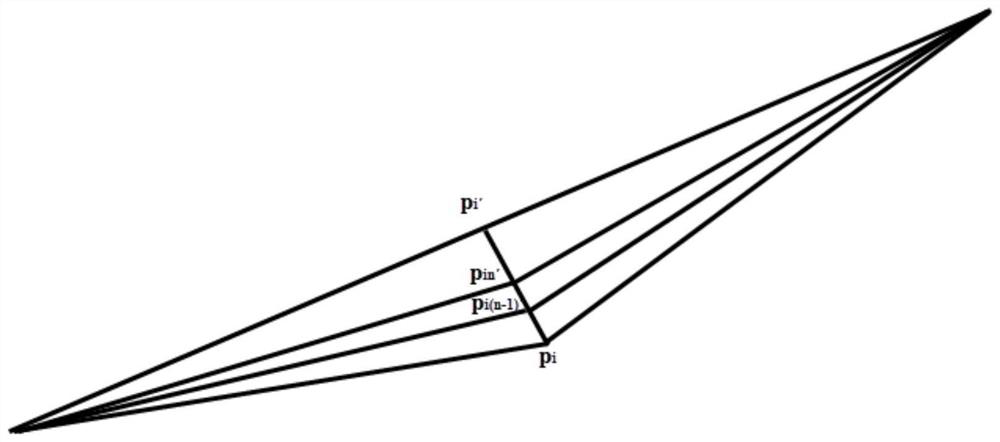

Method for optimizing track of complex revolved body and system

PendingCN112348233AImprove efficiencyImprove comprehensive mechanical propertiesForecastingDesign optimisation/simulationEngineeringStructural engineering

The invention discloses a method for optimizing a track of a complex revolved body and a system capable of realizing the method. According to the method, an initial track is generated according to a component laying angle and a material curvature requirement, then an offset track is generated by adopting equidistant offset, and the track is optimized by adopting an automatic fiber laying path optimization method adopting local adjustment and global optimization. According to the method, the variable curvature algorithm is fully utilized to generate the initial trajectory, the advantage of highefficiency of the equidistant bias algorithm is fully utilized on the basis of considering the structural design requirement and the fiber placement manufacturability requirement, the bottleneck thatthe manufacturability of the complex revolving body fiber placement trajectory is difficult to meet the design requirement is broken through, therefore, high-performance, high-efficiency and high-precision laying forming of the complex revolved body continuous fiber reinforced composite material can be achieved. Based on the optimized track, the manufacturability requirement and the structural requirement are met, and the comprehensive mechanical property of the component can be remarkably improved.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP +1

Heat-proof cast magnesium alloy

InactiveCN108315622AImprove heat resistanceImprove comprehensive mechanical propertiesBismuthAluminium

The invention discloses a heat-proof cast magnesium alloy. The heat-proof cast magnesium alloy comprises, by weight, 0.5-2% of silicon, 2.5-5.5% of aluminum, 5-8% of zinc, 0.2-0.5% of bismuth, 0.1-0.5% of manganese, 3-5% of gadolinium, 0.2-1.5% of calcium, below 0.02% of impurities, and the balance of magnesium. The heatproof property of the magnesium alloy is effectively improved by optimizing the composition and the ratio of the alloy, and the comprehensive mechanical properties of the high-strength cast magnesium alloy in the invention are significantly higher than those of currently reported cast magnesium alloys.

Owner:FOSHAN GAOMING LIGANG PRECISION CASTING CO LTD

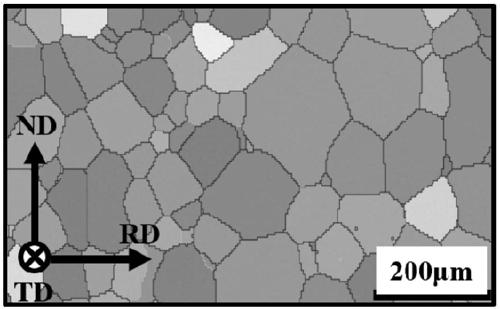

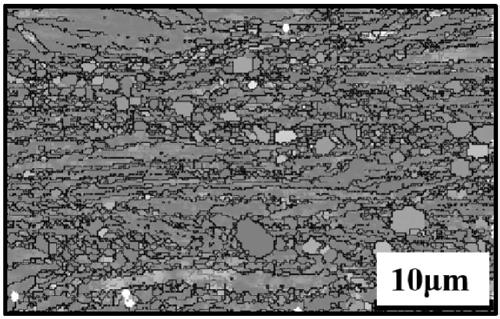

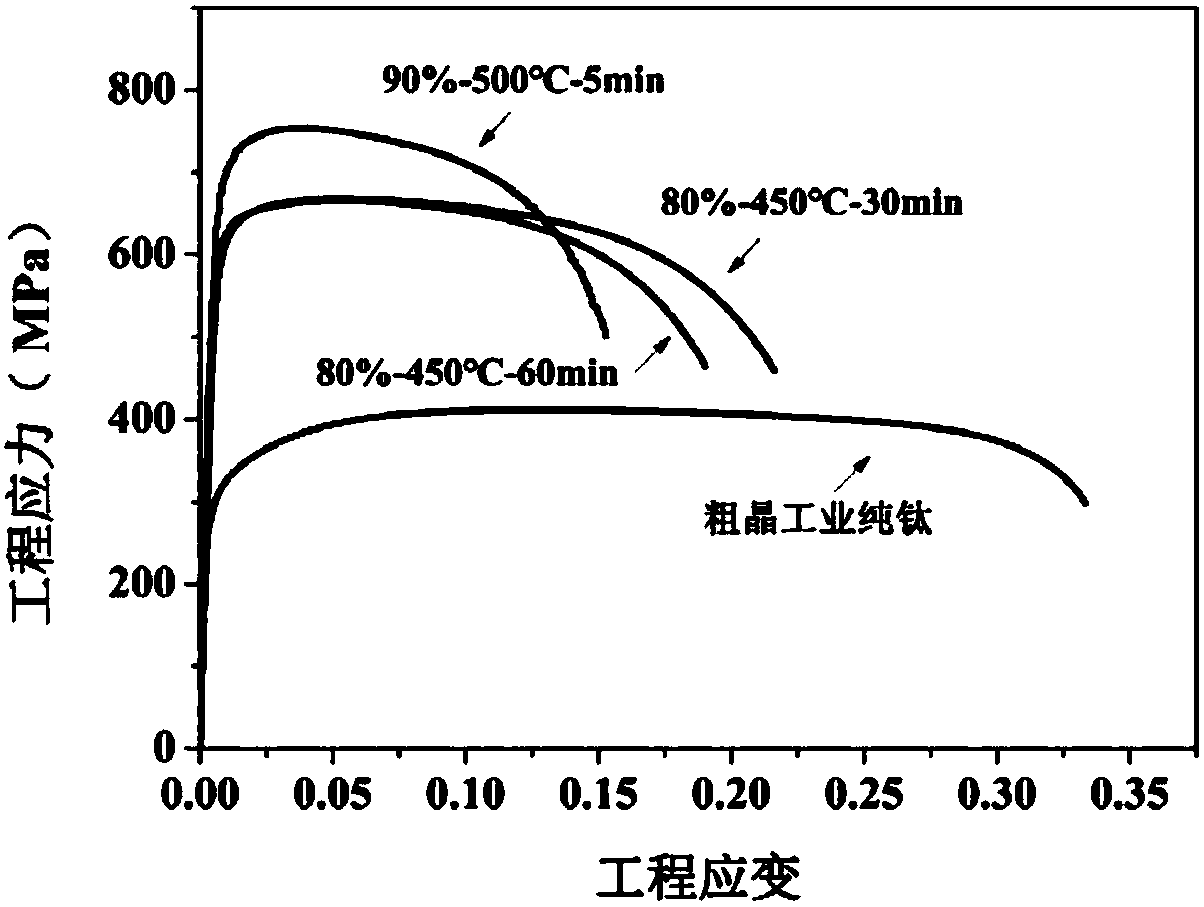

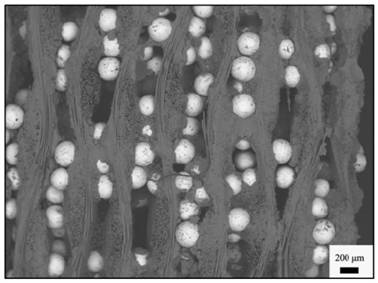

Preparation method of non-homogeneous layered-structure commercial pure titanium

ActiveCN109825785AImprove comprehensive mechanical propertiesSimple process conditionsLayered structureDuctility

The invention discloses a preparation method of non-homogeneous layered-structure commercial pure titanium, and belongs to the field of commercial pure titanium manufacturing. The method comprises thesteps that homogenized annealing treatment is conducted on the commercial pure titanium with the thickness of 10-15 mm to obtain homogeneous tissues with the average grain size of 70 microns; 80-90%of cold rolling treatment is conducted on the commercial pure titanium to form traditional belt-shaped coll-rolling tissues; incomplete recrystallization annealing cold rolling treatment is conductedon the commercial pure titanium at the temperature of 450-500 DEG C for 5-60 min to finally prepare the non-homogeneous layered-structure commercial pure titanium. Mechanical experiment results show that the commercial pure titanium with the structure has the buckling strength of 550-660 MPa and the tensile strength of 630-750 MPa, particularly the uniform elongation can be greater than or equal to 4%, and the elongation at break can be greater or equal to 15%. The non-homogeneous layered-structure commercial pure titanium has the advantages that the problem of lower commercial pure titanium strength is solved, the non-homogeneous layered-structure commercial pure titanium can be allowed to have better extendability and plasticity, and the strength and plasticity matching performance of the non-homogeneous layered-structure commercial pure titanium is improved to make industrial application production convenient.

Owner:NANJING UNIV OF SCI & TECH +1

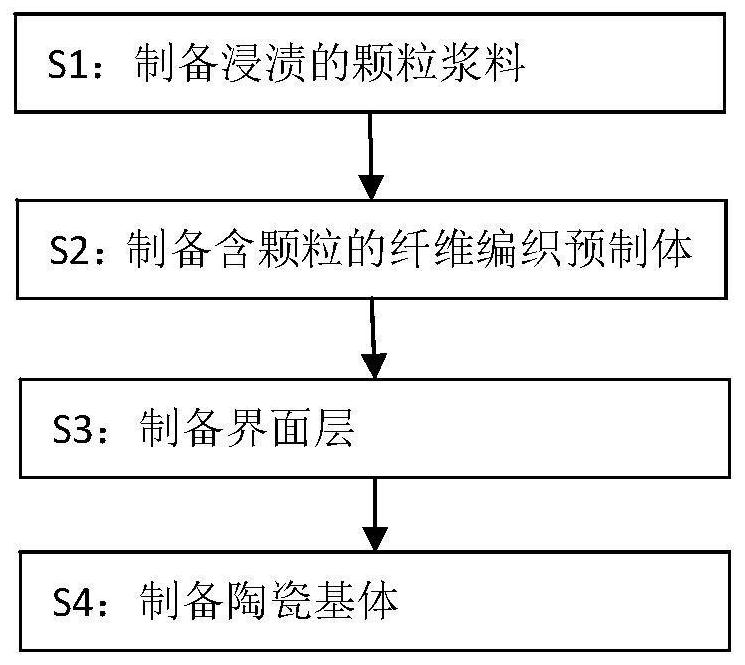

Particle-reinforced fiber-woven composite material and preparation method thereof

PendingCN113896555AImprove comprehensive mechanical propertiesImprove uniformityCompositermesBraided composite

The invention discloses a particle-reinforced fiber-woven composite material and a preparation method thereof, and relates to a fiber-woven composite material. A fiber cloth layer as a basic element is impregnated with particle slurry, a fiber cloth layer containing particle slurry is laminated on the fiber cloth layer containing particle slurry, impregnating and laminating are repeated to form a particle-containing fiber woven preform blank, an interface layer is deposited on the particle-containing fiber woven preform blank, and a ceramic matrix is densified in the preform blank containing the interface layer to form the particle reinforced fiber woven composite material. The method comprises the following steps of: (1) preparing impregnated particle slurry; (2) preparing a fiber woven preform containing particles; (3) preparing an interface layer; and (4) preparing a ceramic matrix to obtain the particle-reinforced fiber woven composite material. The uniformity of the particle-containing fiber woven preform can be improved, the pore defects in the preform can be reduced, the density can be improved, the material performance can be improved, the preparation steps can be simplified, the production energy consumption can be reduced, and the production efficiency can be improved.

Owner:XIAMEN UNIV

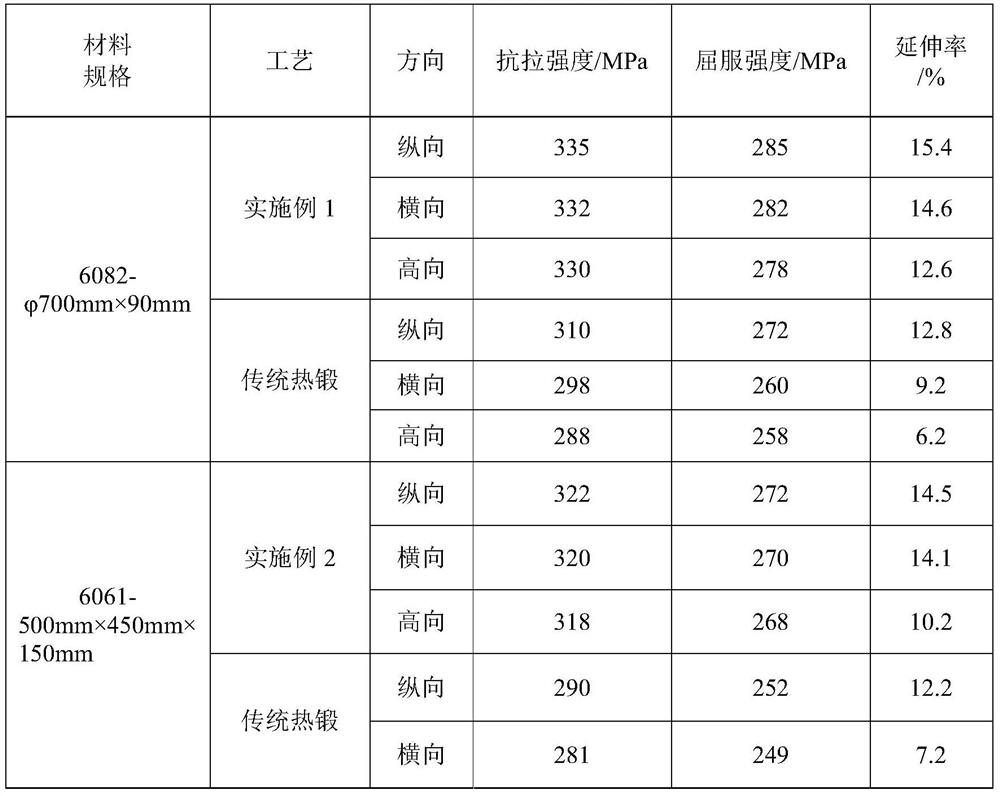

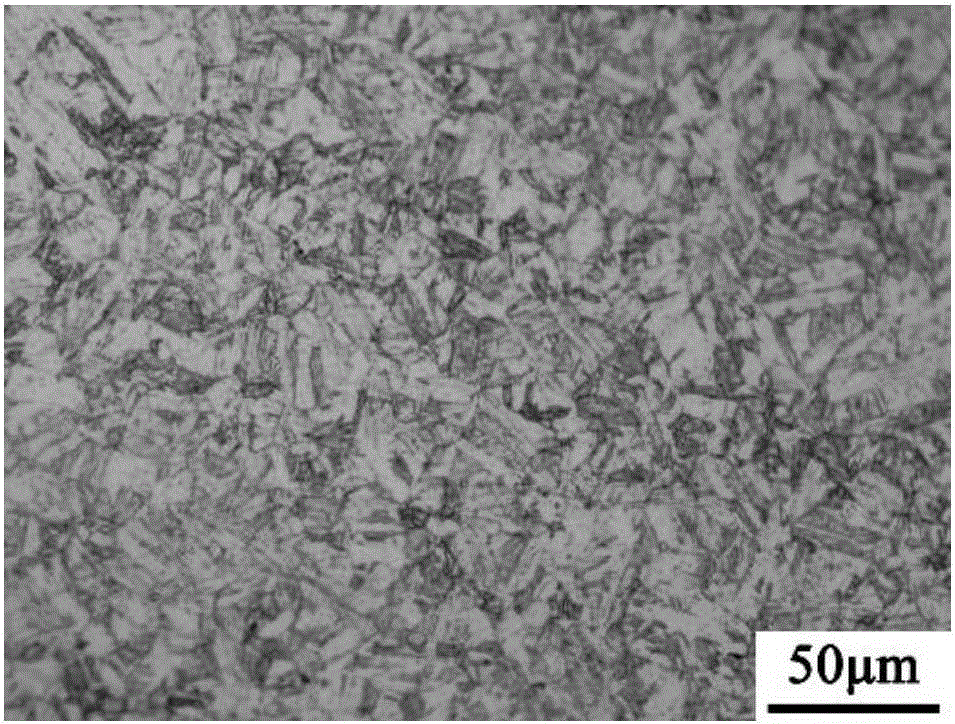

Forging method for improving anisotropism of 6XXX aluminum alloy forge piece

ActiveCN111945086AImprove alloy strengthImprove comprehensive mechanical propertiesMechanical properties of carbon nanotubesSolution treatment

The invention belongs to the technical field of design of mechanical structures, and relates to a forging method for improving the anisotropism of a 6XXX aluminum alloy forge piece. The forging methodcomprises the following specific forging formation steps of high-temperature forging, low-temperature forging, solution treatment and room-temperature cold deformation. The forging method for improving the anisotropism of the 6XXX aluminum alloy forge piece, disclosed by the invention, increases the recrystallization degree of the 6XXX aluminum alloy forge piece, reduces the strength and toughness difference among the longitudinal direction, the transverse direction and the height direction of the forge piece, improves the strength and the comprehensive mechanical properties of the 6XXX aluminum alloy free forge piece, and is suitable for manufacturing the 6XXX aluminum alloy free forge piece of which the thickness is 60 mm or above.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

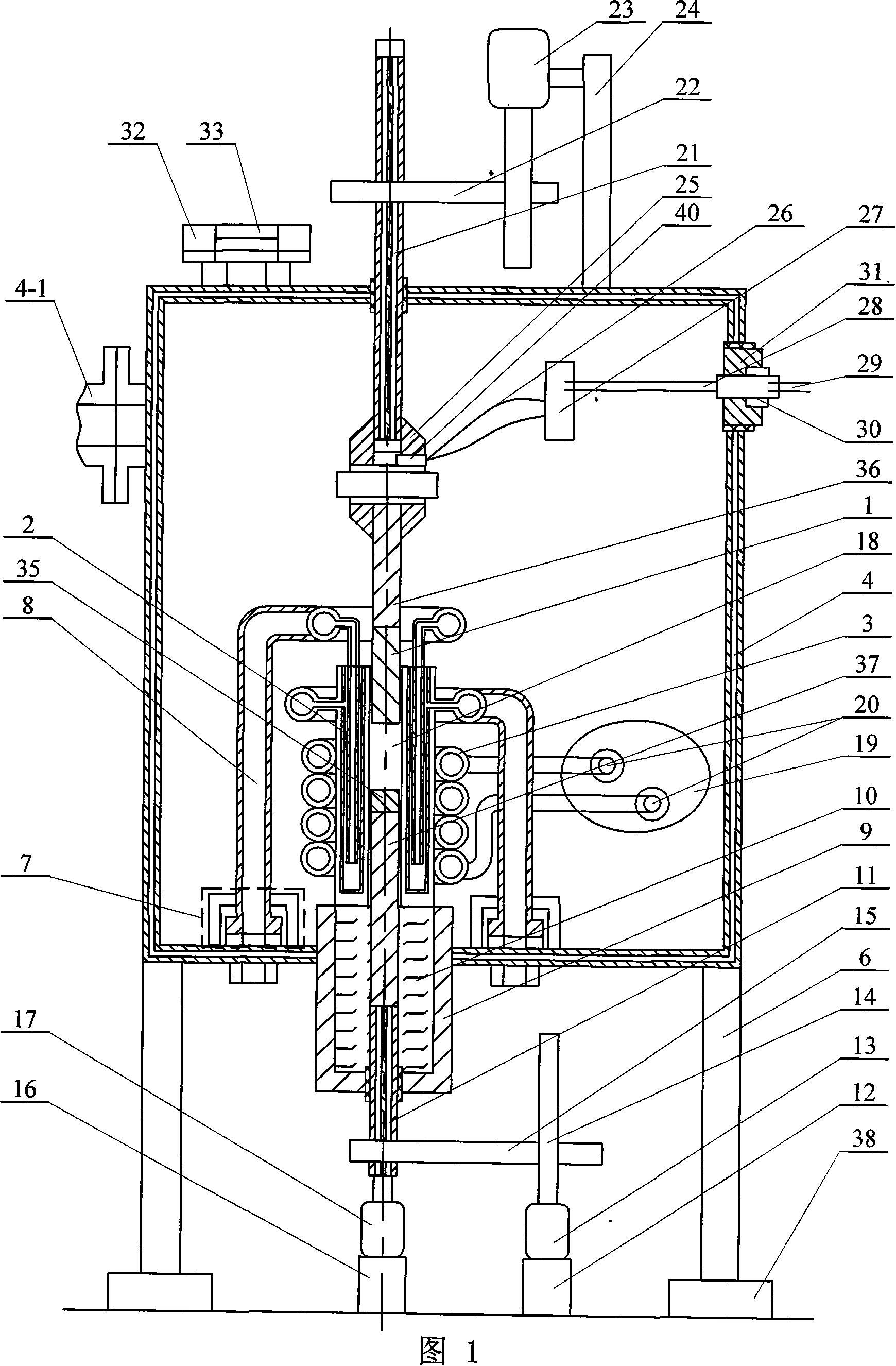

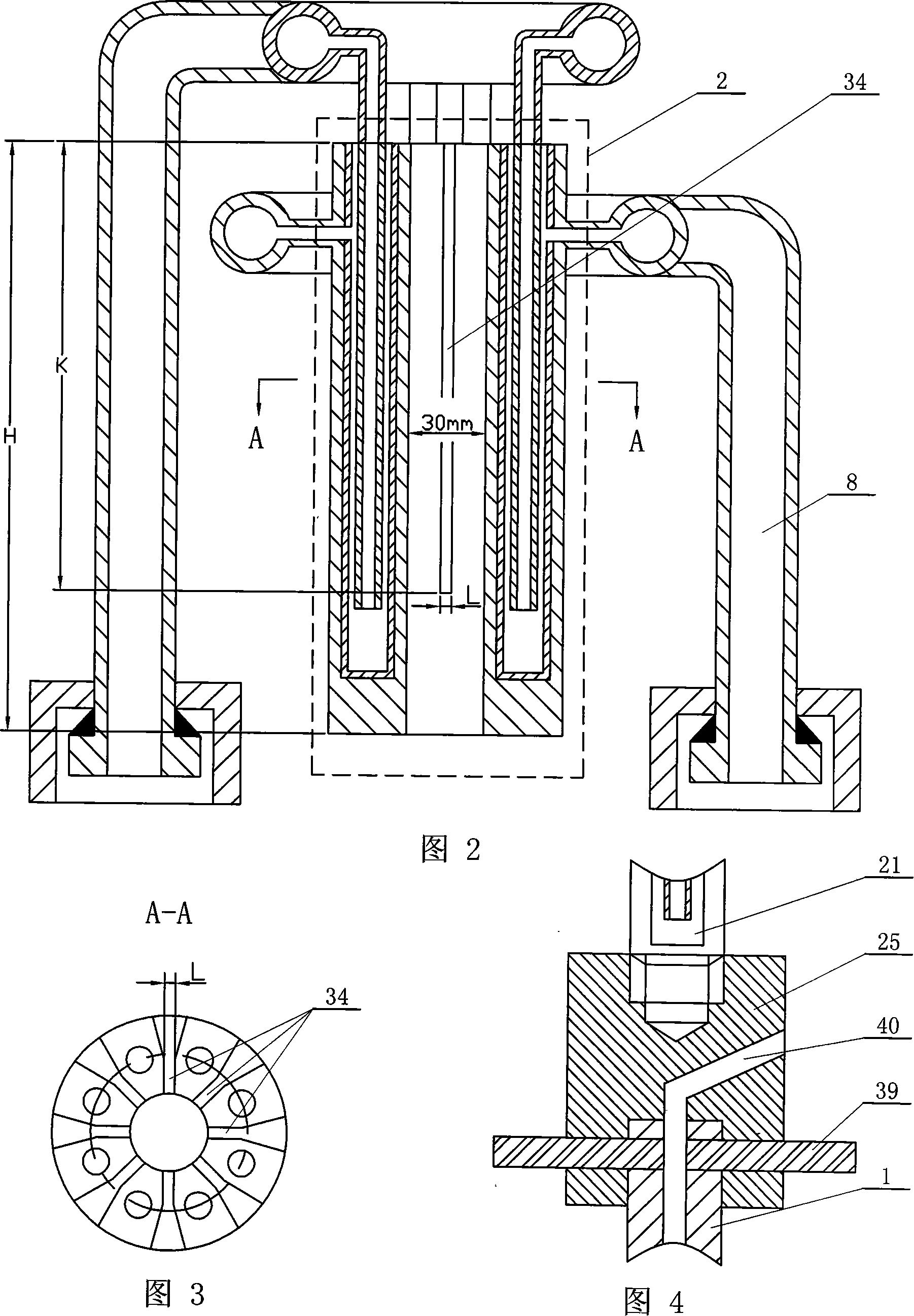

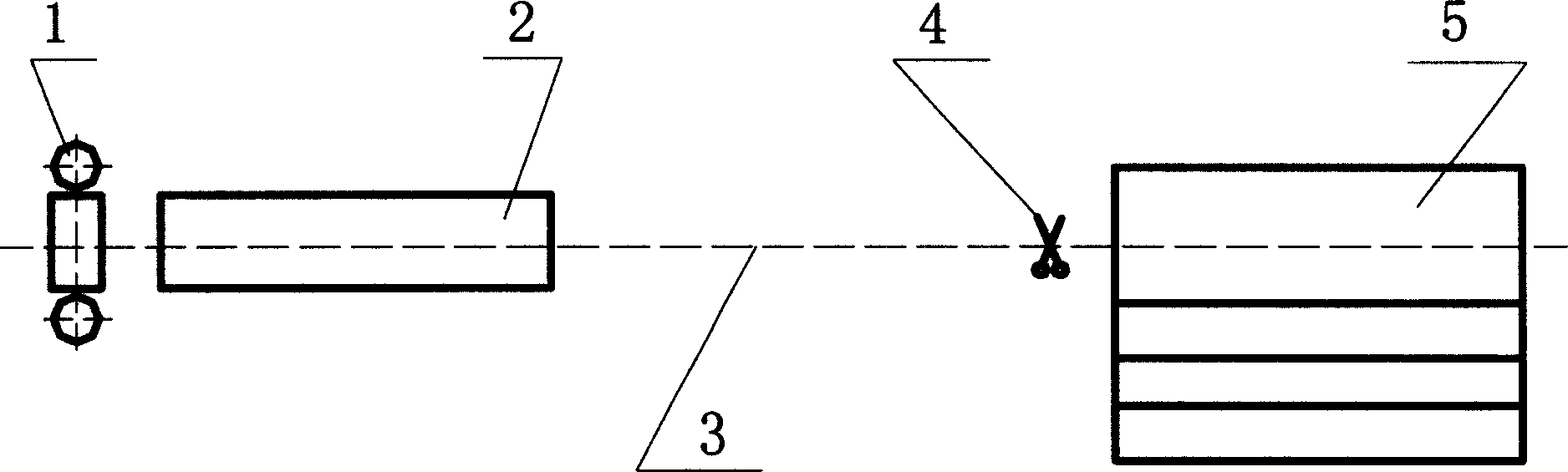

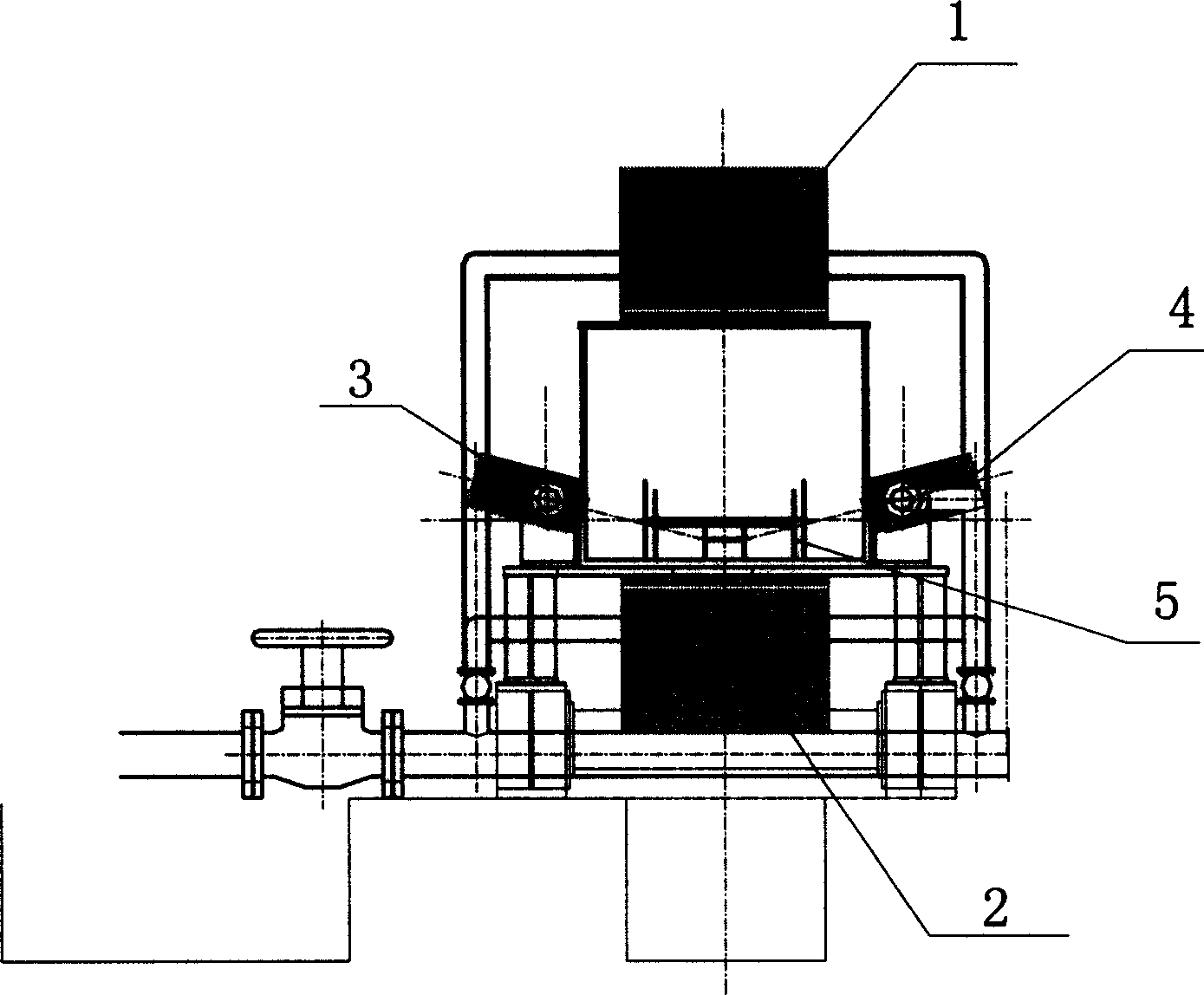

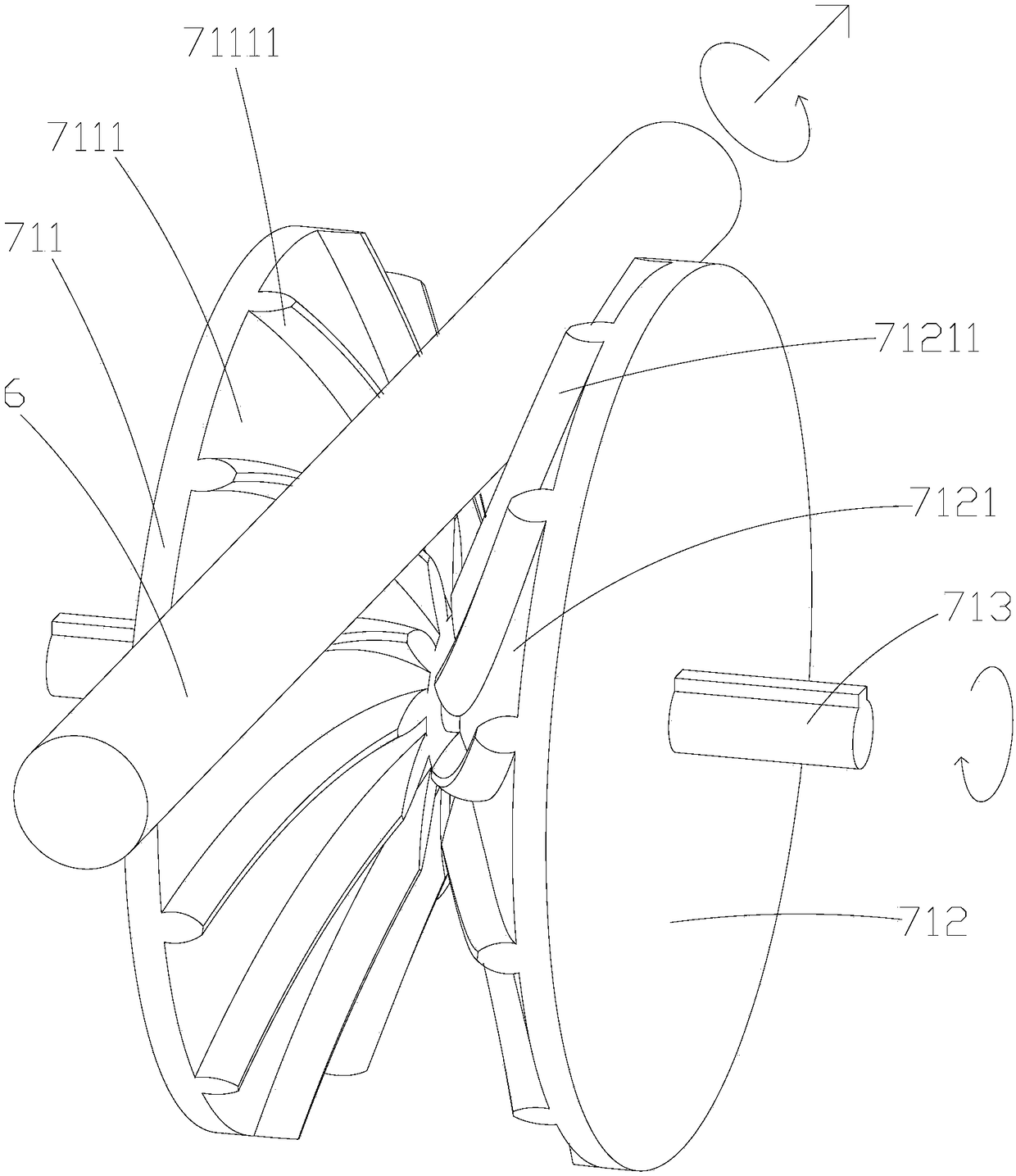

Secondary quenching treatment device and rod-shaped workpiece processing method

ActiveCN109295286AImprove comprehensive mechanical propertiesThe structure of the transmission mechanism is simpleIncreasing energy efficiencyFurnace typesQuenchingTreatment quality

The invention discloses a secondary quenching treatment device and a rod-shaped workpiece processing method. The quenching treatment device comprises a primary induction heater assembly, a primary quenching assembly, a secondary induction heater assembly, a secondary quenching assembly and a transmission mechanism. In the process of processing and treating an automobile anti-collision rod, the rod-shaped workpiece can sequentially pass through the primary induction heater assembly, the primary quenching assembly, the secondary induction heater assembly and the secondary quenching assembly through the transmission mechanism, so that different heat treatments can be respectively carried out on the core layer and the surface layer of the rod-shaped workpiece section by section on the same production line to improve the comprehensive mechanical properties of the rod-shaped workpiece; and the transmission mechanism is simple in structure, convenient to assemble and efficient and stable in transmission, so that the rod-shaped workpiece can spin while advancing in the length direction of the rod-shaped workpiece and can be evenly heated and quenched while being processed and treated, andthe heat treatment quality of products can be improved.

Owner:JIMEI UNIV

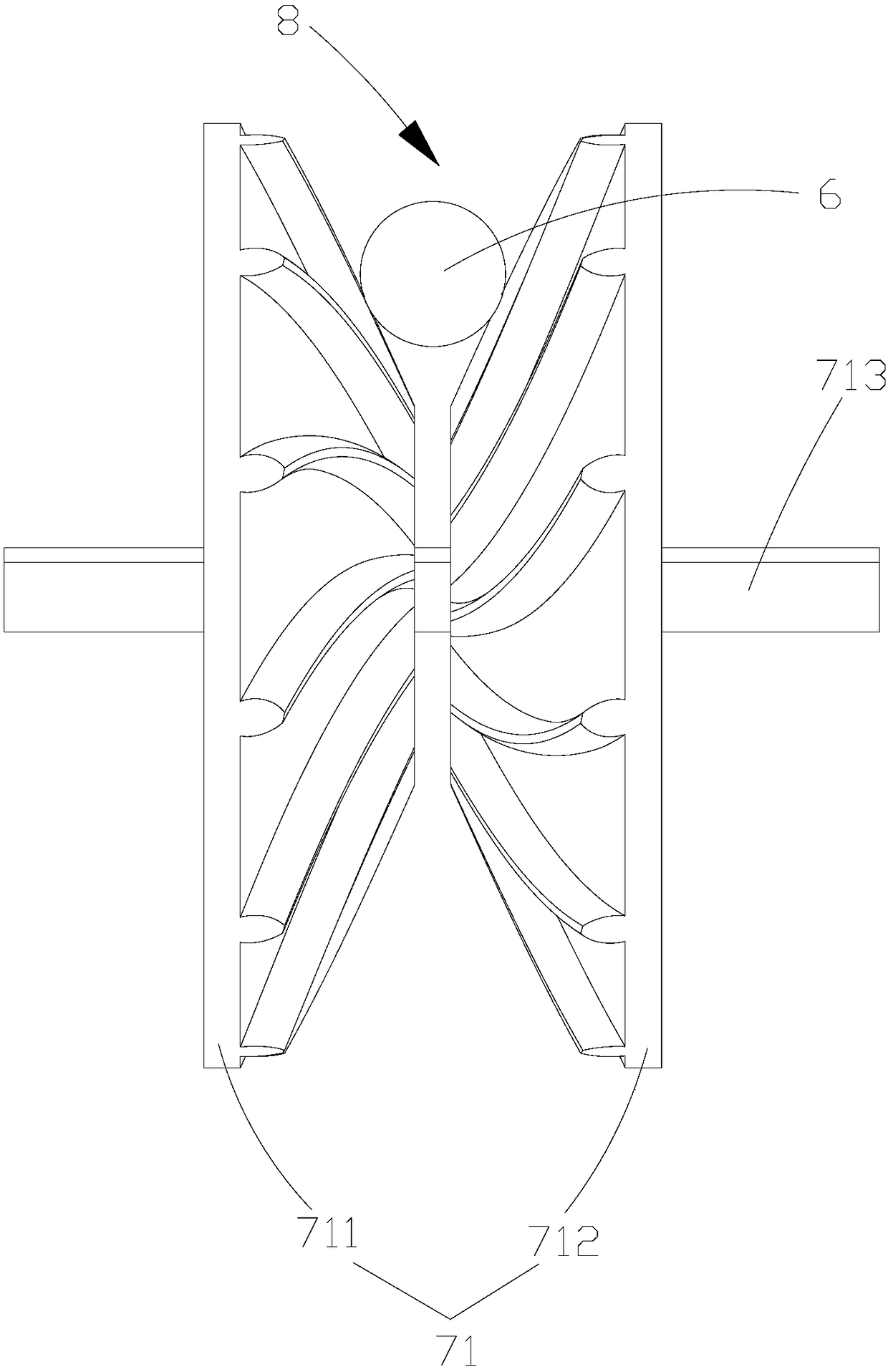

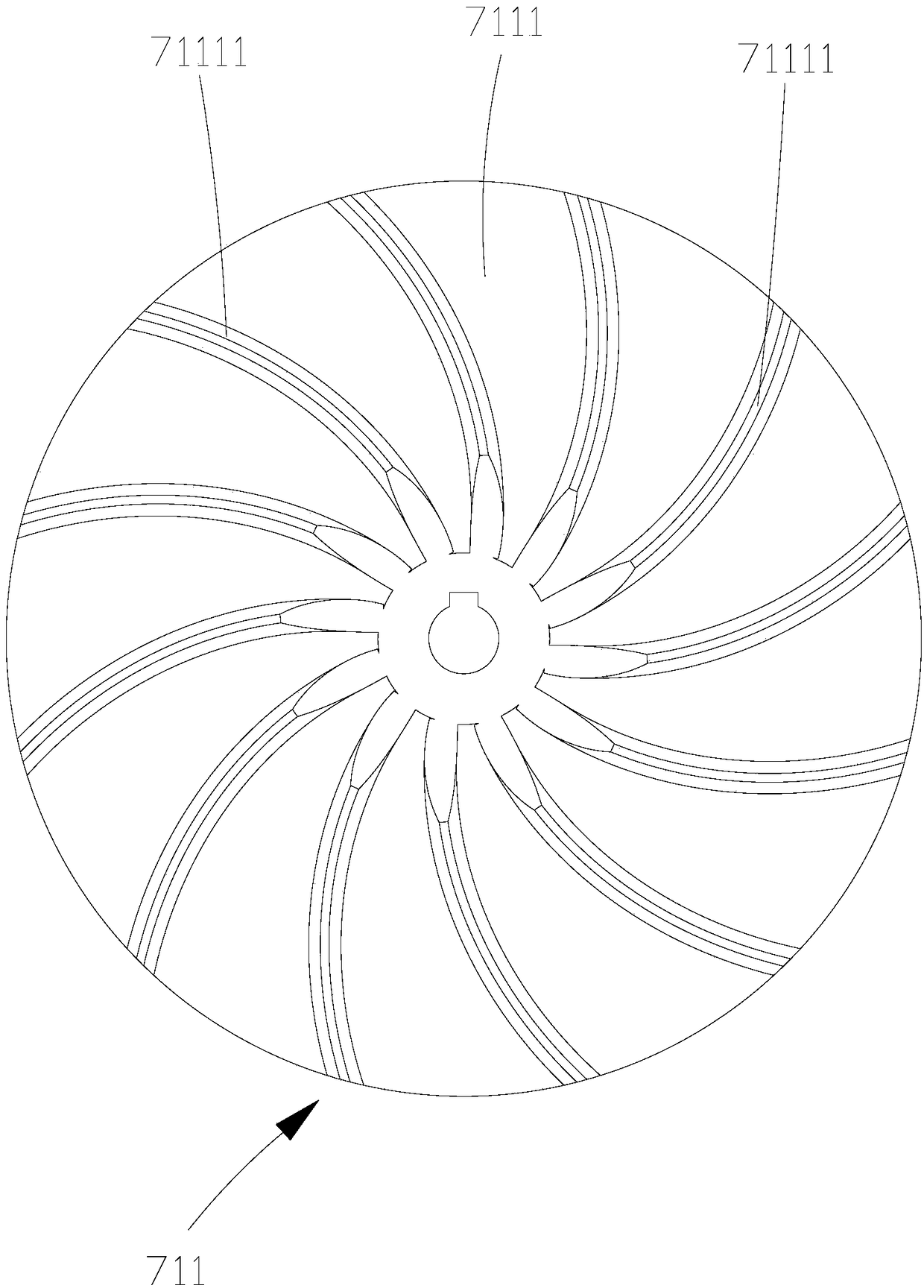

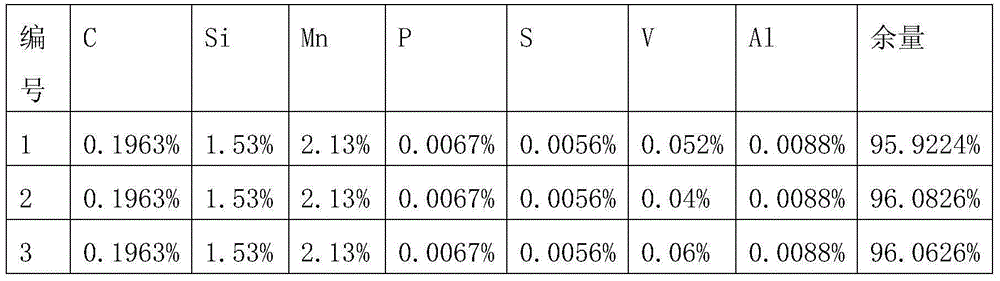

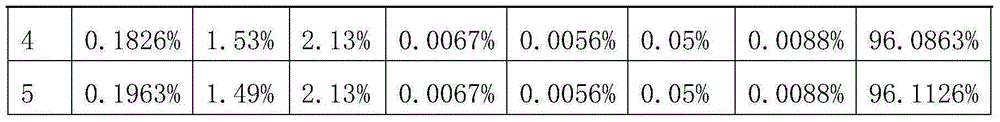

Vanadium-contained TAM steel and manufacturing method thereof

InactiveCN105039844AImprove toughnessImprove comprehensive mechanical propertiesSteel platesChemical composition

The invention relates to vanadium-contained TAM steel and a manufacturing method thereof, and belongs to the technical field of metal composition design and heat machining. The vanadium-contained TAM steel comprises, by weight percentage, 0.18%-0.21% of C, 1.48%-1.55% of Si, 1.90%-2.20% of Mn, not larger than 0.020% of P, not larger than 0.015% of S, 0.04%-0.06% of V, not larger than 0.04% of Al and the balanced Fe and inevitable impurities. An appropriate amount of vanadium is added in a vanadium alloying manner, the obdurability of the TAM steel is improved through precipitation of carbide of the vanadium and the like, and the comprehensive mechanical property of the vanadium-contained TAM steel is improved; and a steel plate has the higher strength and the higher plasticity, and the vanadium-contained TAM steel particularly has the excellent hydrogen-embrittlement-resistant delay breakage performance. A new technology, namely a Q&P process, is adopted in production of the vanadium-contained TAM steel, and therefore the steel structure property is more stable.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Zirconium-oxide-based nanocomposite ceramic die material and preparation method thereof

InactiveCN107602117AImprove comprehensive mechanical propertiesLower sintering temperatureCemented carbideMagnesium

The invention provides a zirconium-oxide-based nanocomposite ceramic die material and a preparation method thereof. Raw materials of the die material include zirconium oxide, silicon carbide, aluminumoxide, lanthanum oxide, zinc oxide, titanium oxide, molybdenum, nickel and magnesium oxide. The preparation method of the zirconium-oxide-based nanocomposite ceramic die material comprises the steps:firstly, adding zirconium oxide, silicon carbide and aluminum oxide into ethanol to prepare a suspension A; then, adding lanthanum oxide, zinc oxide, titanium oxide, molybdenum, nickel and magnesiumoxide into ethanol to prepare a suspension B; next, mixing the suspension A with the suspension B, pouring the mixed suspension into a ball milling tank to carry out ball milling by utilizing a hard alloy ball machine, carrying out vacuum drying on a grinding liquid at 100 DEG C, and after sieving the obtained composite powder, carrying out hot pressing and sintering to obtain the zirconium-oxide-based nanocomposite ceramic die material. The composite ceramic die material provided by the invention is better in comprehensive mechanical property and excellent in antifriction and wear-resistant properties.

Owner:SUZHOU HAOYAN PRECISION MOLD CO LTD

Method for eliminating cracks in additive manufacturing metal material

PendingCN112846233AImprove comprehensive mechanical propertiesImproves tensile strength and elongationAdditive manufacturing apparatusIncreasing energy efficiencyCrazingMetallic materials

The invention relates to a method for eliminating cracks in an additive manufacturing metal material. The elimination method comprises the following steps of heating the additive manufacturing metal material with the cracks, preserving heat, then carrying out isostatic pressing treatment at the preserving temperature, and performing cooling to obtain the additive manufacturing metal material with the cracks eliminated. According to the elimination method, an intercrystalline liquid film is formed by a trace remelting method, the cracks are backfilled to form a solid-liquid two-phase coexistence state, then the re-solidification rate is controlled to realize uniform solidification shrinkage of the material, isostatic pressure can be applied in the process to inhibit the generation of shrinkage cavities, finally, crack healing and component densification are realized, and meanwhile, the comprehensive mechanical property of the component can be improved.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

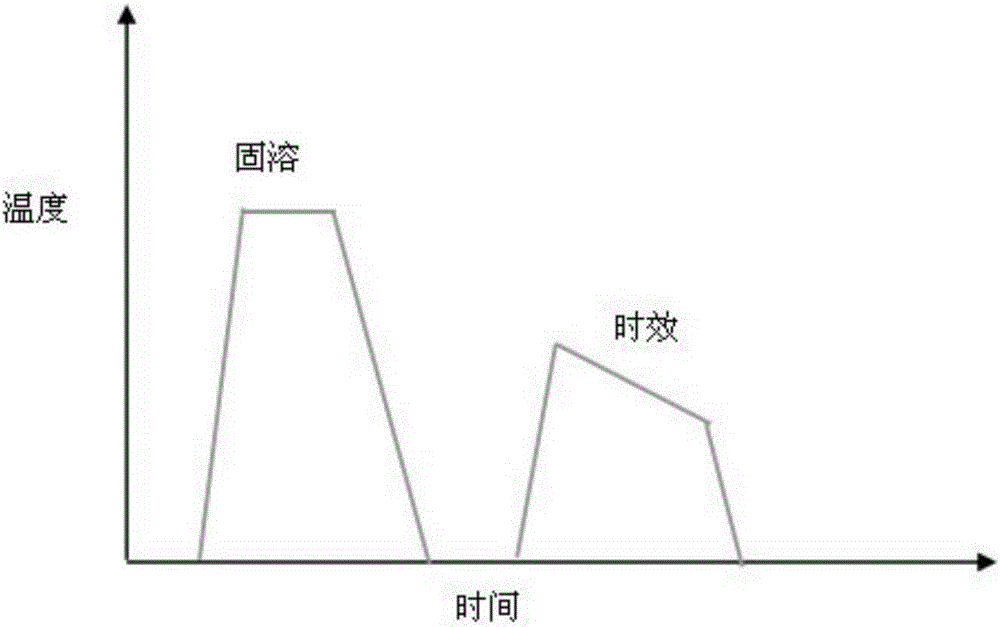

Precipitation hardening stainless steel PH17-4 negative temperature gradient aging heat treatment method

InactiveCN105349747AImprove comprehensive mechanical propertiesRaise Strength IndexNegative temperatureSolution treatment

The invention relates to an aging heat treatment method, in particular to a precipitation hardening stainless steel PH17-4 negative temperature gradient aging heat treatment method. The method aims at solving the problem that when a traditional heat treatment technology is used for treating precipitation hardening stainless steel PH17-4, the good comprehensive mechanical property of the steel cannot be sufficiently exerted. The method comprises the steps that when the precipitation hardening stainless steel is subjected to solution treatment, a sample is heated to 400 DEG C to 650 DEG C, aging treatment is carried out for 1-5 h in a manner that the negative aging temperature change gradient ranges from 16 DEG C / h to 80 DEG C / h, air cooling or wind cooling to the room temperature is carried out, and the method is completed. After the negative temperature gradient aging treatment of the PH17-4 steel, the tensile strength of the steel reaches 1162 MPa to 1512 MPa, the yield strength ranges from 1140 MPa to 1447 MPa, the elongation rate ranges from 10% to 14%, and the shrinkage rate of a section ranges from 55% to 65%.

Owner:HARBIN INST OF TECH

High-wearproof antioxidant fishing net

InactiveCN105778236AImprove comprehensive mechanical propertiesImprove interface compatibilityMonocomponent polyolefin artificial filamentArtifical filament manufactureChemistryPowder mixture

The invention discloses a high-wearproof antioxidant fishing net. The high-wearproof antioxidant fishing net comprises propylene carbonate, polynorbornene, HDPE (high-density polyethylene) resin, erucyl amide, polyvinylidene chloride, a lac resin and nylon 6 mixture, a polytetrafluoroethylene powder and talcum powder mixture, nano aluminium hydroxide, nano silicon carbide and compound plasticizer. The high-wearproof antioxidant fishing net has the advantages that the HDPE resin is modified and is matched with the propylene carbonate, the polynorbornene,, the erucyl amide, the polyvinylidene chloride, the lac resin and nylon 6 mixture, the polytetrafluoroethylene powder and talcum powder mixture, the nano aluminium hydroxide and the nano silicon carbide, so that the obtained fishing net has good processing performance and mechanical performance, high strength, tenacity and impact strength and excellent antioxidation; particularly, tensile strength, wear resistance and antioxidation are improved greatly; the fishing net is applicable to extensive water areas and low in loss.

Owner:巢湖市强力渔业有限责任公司

Hybrid FRP (Fiber Reinforced Plastics)-steel composite bar sea sand concrete beam

InactiveCN107217786AGood ductilityImprove comprehensive mechanical propertiesGirdersJoistsRebarBasalt fiber

The invention discloses a hybrid FRP (Fiber Reinforced Plastics)-steel composite bar sea sand concrete beam, which comprises sea sand concrete, and a plurality of upper composite bars, a plurality of lower composite bars and a plurality of hoops fixedly arranged in the sea sand concrete. The hoops are uniformly fixed and tied on the outer surfaces of the upper composite bars and the lower composite bars along length directions of the upper composite bars and the lower composite bars; the upper composite bars and the lower composite bars are respectively arranged on the upper end and the lower end of the bar sand concrete, and comprise reinforcing steel bars and FRP fiber cloth coating the outer surfaces of the reinforcing steel bars; the FRP fiber cloth of each upper composite bar is made of the same material or different materials; the FRP fiber cloth of the plurality of lower composite bars adopts at least two materials; the FRP fiber cloth is adhered with the sea sand concrete; the FRP fiber cloth of the lower composite bars comprises at least two of carbon fiber cloth, glass fiber cloth, basalt fiber cloth and aramid fiber cloth. The hybrid FRP-steel composite bar sea sand concrete beam provided by the invention has no need to desalt sea sand, and has good strength and a bearing performance.

Owner:GUANGDONG UNIV OF TECH

Multifunctional ABS composite material

InactiveCN104371257AHigh flame retardant efficiencyImprove comprehensive mechanical propertiesCarbon blackAnoxomer

The invention provides a multifunctional ABS composite material, which is characterized being composed of the following components in parts by weight: 60 to 90 parts of ABS resin, 10 parts of ABS-g-MAH, 5 to 10 parts of alkali-free chopped glass fiber, 0.5 to 1.0 part of ferroferric oxide, 2 to 3 parts of composite carbon black, 0.5 to 0.8 part of lubricant, 5 to 10 parts of phosphorus flame retardant, 5 to 10 parts of nitrogen flame retardant, 0.5 to 1.0 part of silicon synergist, 2 to 3 parts of antistatic agent, and 0.5 to 1.0 part of antioxidant 1010. The phosphorus flame retardant and nitrogen flame retardant or the phosphorus flame retardant and silicon synergist are used together to generate a synergetic effect so as to improve the flame retardant efficiency, moreover, the toxic gas released during the burning process is reduced, and the provided ABS composite material has the advantages of low smoke and toxicity. Furthermore, the ABS composite material has a good mechanical property and a good electromagnet shielding performance, and has the advantages of rapid heat radiation, high electromagnet shielding efficiency, long-lasting antistatic effect, high mechanical strength, and easiness for flow processing. The application range of the ABS composite material is enlarged.

Owner:QINGDAO BOYANDA IND TECH RES INST GENERAL PARTNERSHIP

Novel high-performance polymer material

InactiveCN109021418ALow priceImprove comprehensive mechanical propertiesHigh performance polymerCorrosion

The invention discloses a novel high-performance polymer material. The novel high-performance polymer material mainly comprises, by weight, 40-45 parts of synthetic plastic, 5-9 parts of titanium powder, 3-6 parts of epoxy resin, 2-5 parts of nitrile butadiene rubber, 7-8 parts of algal oil, 3-4 parts of chromium, 11-13 parts of a stabilizer, 14-16 parts of a filler, 12-15 parts of zinc borate powder, 17-19 parts of ceramic fibers, 1-2 parts of an anti-aging agent, 20-25 parts of shale fibers, and the balance of a polymer material. The synthetic plastic material is selected, the scientific distribution proportion of the polymer material is optimized, and materials adopted in the invention have low prices and certain practical values, and can enhance the comprehensive mechanical properties,the high temperature resistance, the corrosion resistance and the impact resistance of the polymer material.

Owner:太仓金凯特新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com