Forging method for improving anisotropism of 6XXX aluminum alloy forge piece

An anisotropic, aluminum alloy technology, applied in the field of aluminum alloy thermal processing, can solve the problems of low strength and anisotropy of 6XXX aluminum alloy free forgings, and achieve the effect of improving comprehensive mechanical properties, reducing anisotropy, and being easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The forging blank is φ360mm×480mm 6082 aluminum alloy. The specific forging steps are as follows:

[0029] 1) High-temperature forging: use the homogenized 6082 aluminum alloy forging billet for forging, the initial forging temperature of high-temperature forging is 460°C, the final forging temperature is 440°C, and the forging ratio is 8.4;

[0030] 2) Low-temperature forging: the initial forging temperature of low-temperature forging is 250°C, the final forging temperature is 235°C, and the forging ratio is 2.8;

[0031] 3) Solution treatment: solution temperature 550°C, holding time 4h, water quenching at room temperature.

[0032] 4) Forging at room temperature: the forging temperature at room temperature is 25°C, the final forging temperature is 20°C, rough deformation forging is carried out along the height direction, and the deformation amount is 20%. Forging size: φ700mm×90mm

Embodiment 2

[0034] The forging blank is φ300mm×670mm 6061 aluminum alloy. The specific forging steps are as follows:

[0035] 1) High-temperature forging: use homogenized 6061 aluminum alloy forging billets for forging, the initial forging temperature of high-temperature forging is 480°C, the final forging temperature is 468°C, and the forging ratio is 8;

[0036] 2) Low-temperature forging: the initial forging temperature of low-temperature forging is 240°C, the final forging temperature is 220°C, and the forging ratio is 2.6;

[0037] 3) Solution treatment: solution temperature is 550°C, holding time is 6h, water quenching at room temperature.

[0038] 4) Forging at room temperature: the forging temperature at room temperature is 23°C, the final forging temperature is 18°C, rough deformation forging is carried out along the height direction, and the deformation amount is 25%. Forging size: 500mm×450mm×150mm

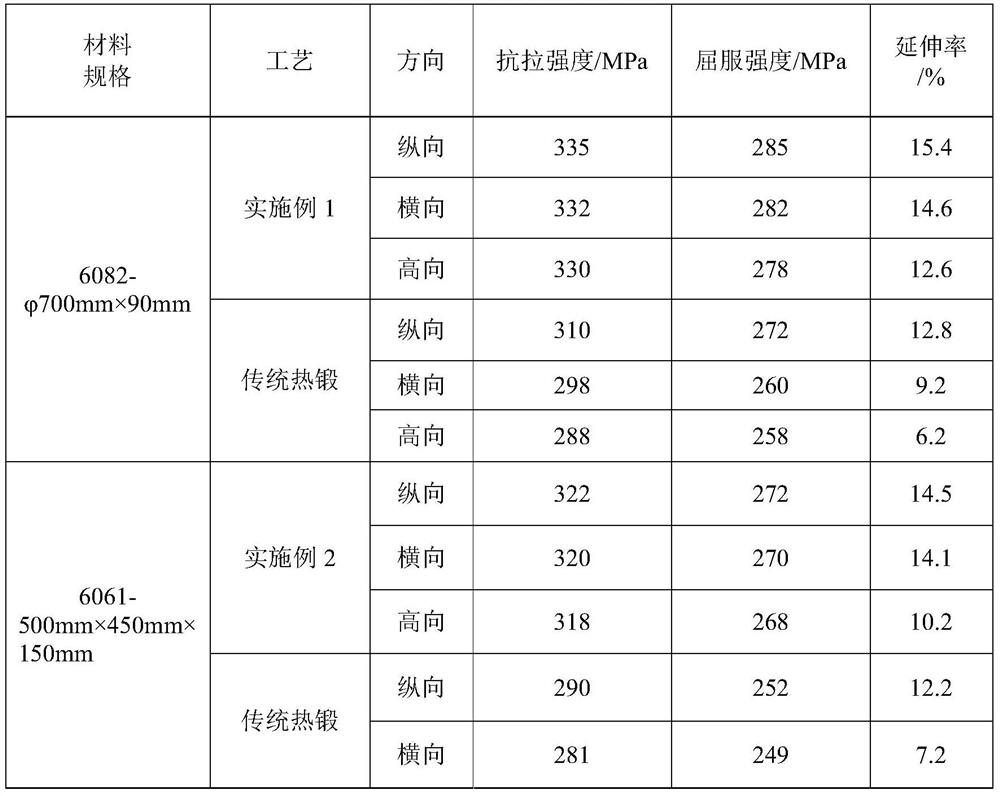

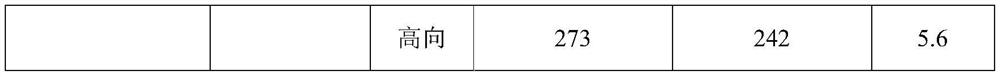

[0039] The above-mentioned two embodiments are carried out T652 heat treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com