Niobium alloying TAM steel and preparing method thereof

A technology of niobium alloying and chemical composition, which is applied in the field of metal composition design and thermal processing, can solve problems such as unsatisfactory requirements, and achieve the effects of improving comprehensive mechanical properties, promoting sustainable development of the national economy, and improving strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of niobium alloyed TAM steel specifically includes traditional mechanical rolling process smelting, hot rolling, cold rolling and new process Q&P process:

[0030]a. Mechanical rolling process: Smelting and casting steel billets into slabs, heating at 1150-1250°C for 70-90 minutes, then hot-rolling them into 3-5mm thick hot-rolled steel plates, and then cold-rolling them to 1- 1.5mm, the cold rolling reduction rate is 65-75%, and the ferrite + pearlite structure is obtained; among them, the hot rolling finishing temperature is 750-850°C, and the coiling temperature is 650-700°C;

[0031] b. Q&P process: heat the cold-rolled sheet obtained in step a to the austenitizing temperature of 900-920°C at 10°C / s, keep it warm for 600s, then cool it down to room temperature at 50°C / s; then heat it at 10°C / s s Reheat to annealing temperature of 760-850°C, hold for 600s, then cool down to partition temperature of 150-450°C at 50°C / s, hold for 50-200s, and fin...

Embodiment 1

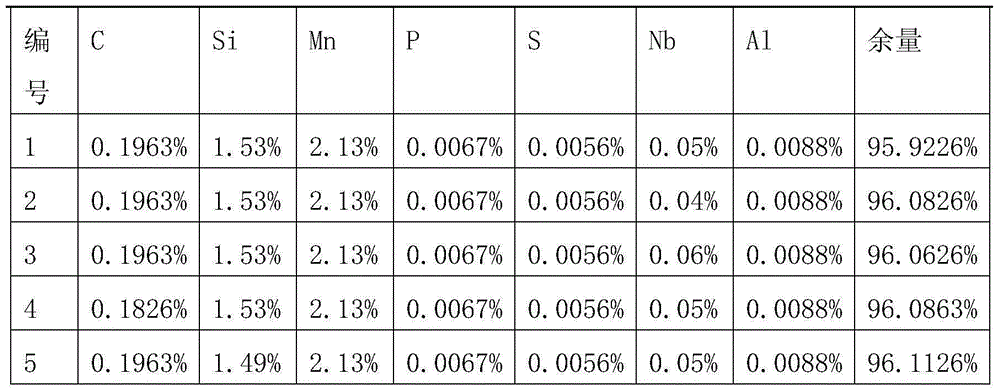

[0039] The composition percentage of each component of the niobium alloyed TAM steel of the present invention is shown in Table 1 with reference to:

[0040] Table 1 Composition percentage of niobium alloyed TAM steel

[0041]

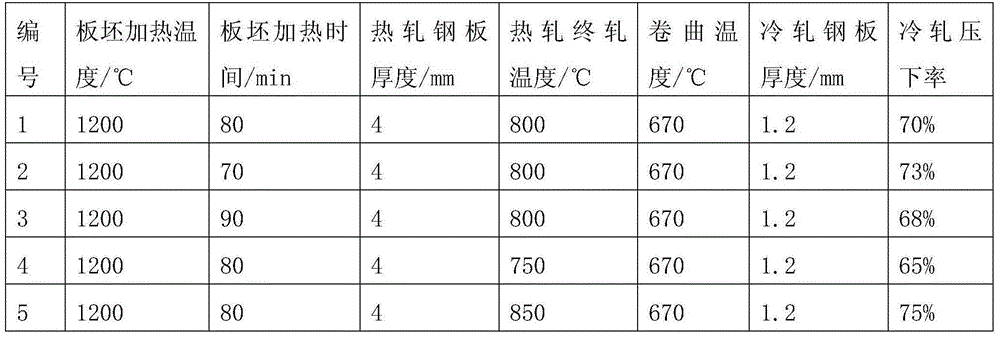

[0042] The traditional mechanical rolling process smelting, hot rolling, cold rolling and new process Q&P process are carried out according to the composition percentages of the various components of the niobium alloyed TAM steel in Table 1. The specific process parameters of the traditional mechanical rolling process are shown in Table 2:

[0043] Table 2 The specific process parameters of the mechanical rolling process

[0044]

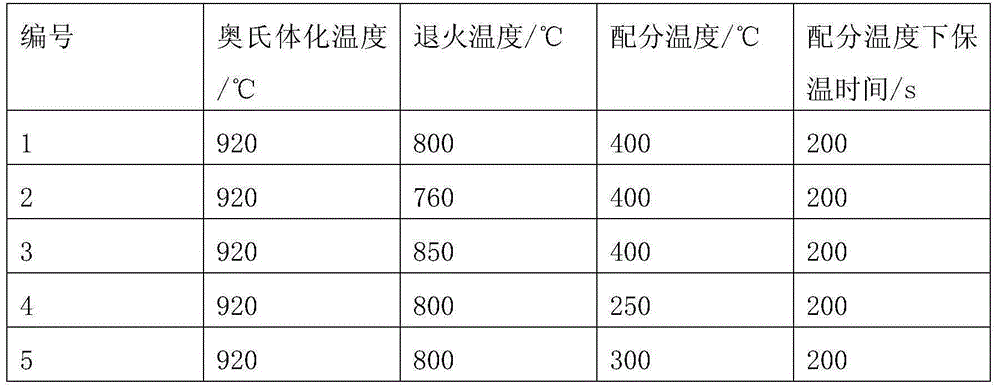

[0045] The specific process parameters of the new process Q&P process are shown in Table 3:

[0046] Table 3 Q&P process specific process parameters

[0047]

[0048] According to the composition percentages of the niobium alloyed TAM steel in Table 1 and the mechanical rolling process in Table 2 and the Q&P proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Strong plastic product | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com