Patents

Literature

62results about How to "Organization performance is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

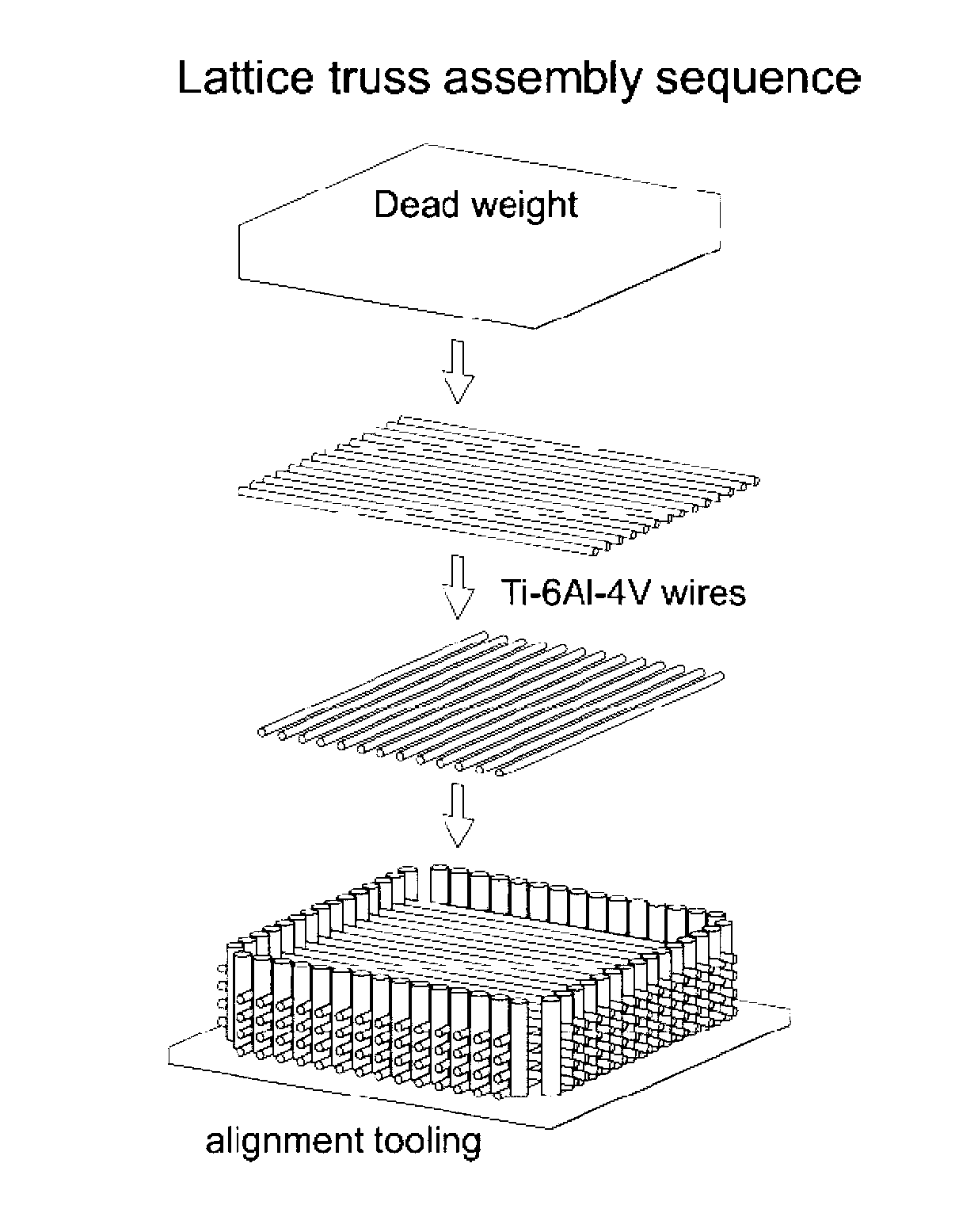

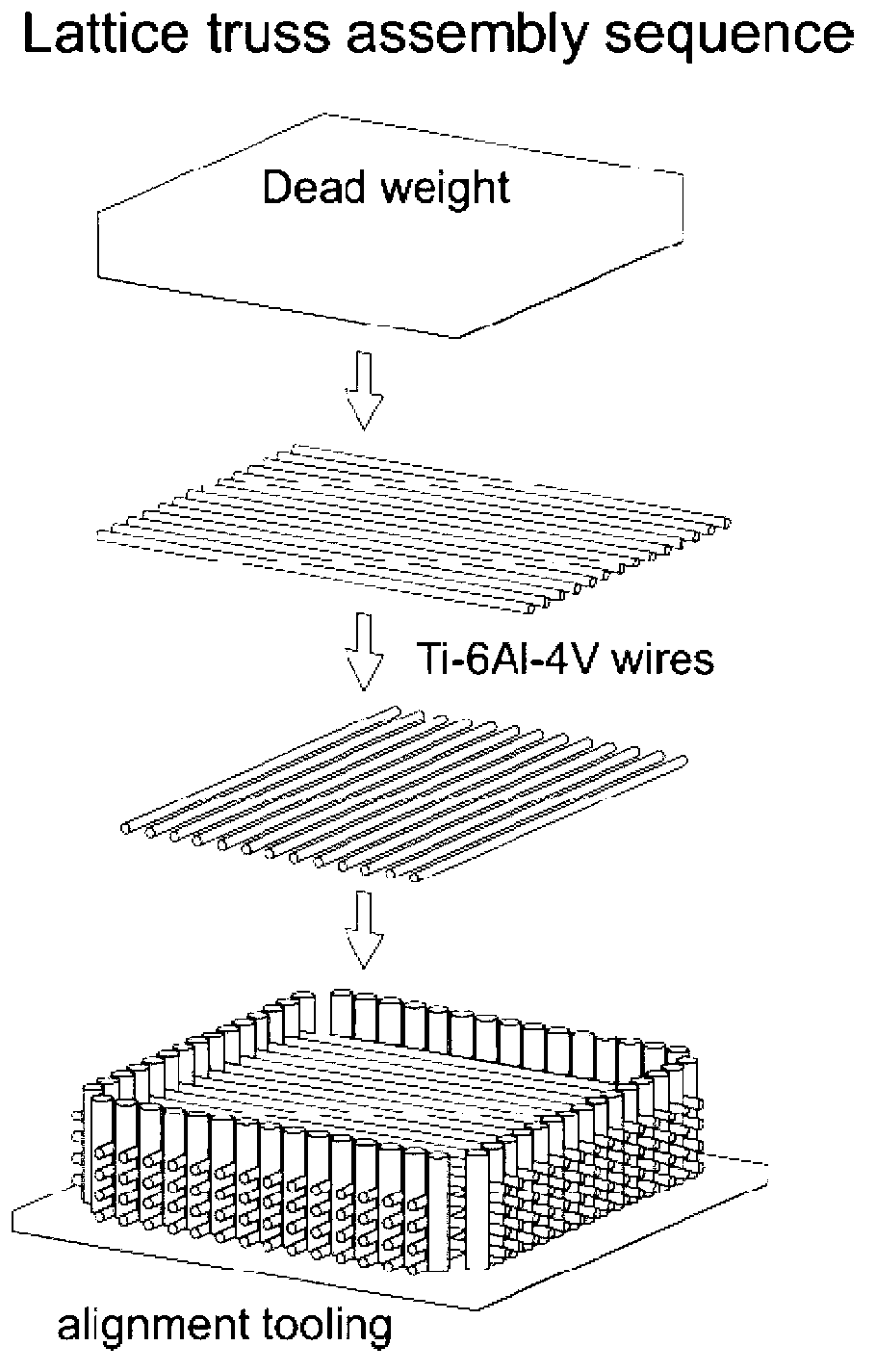

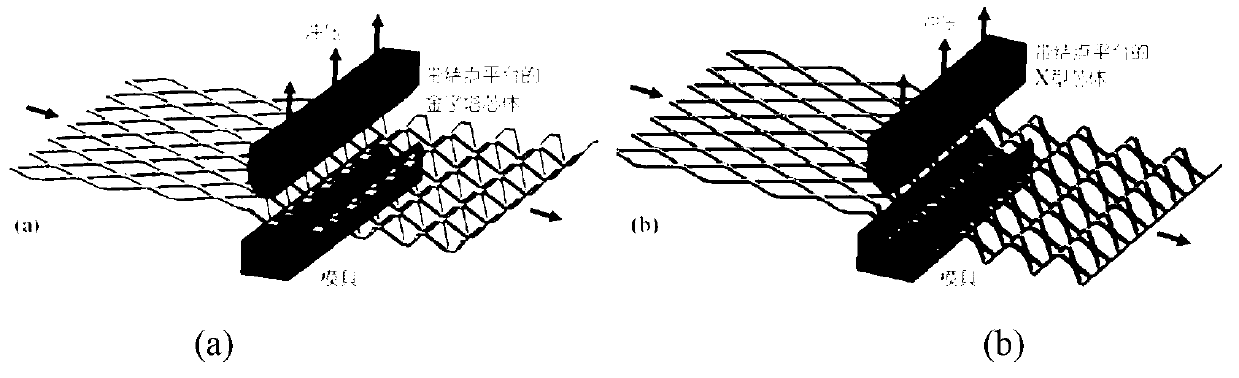

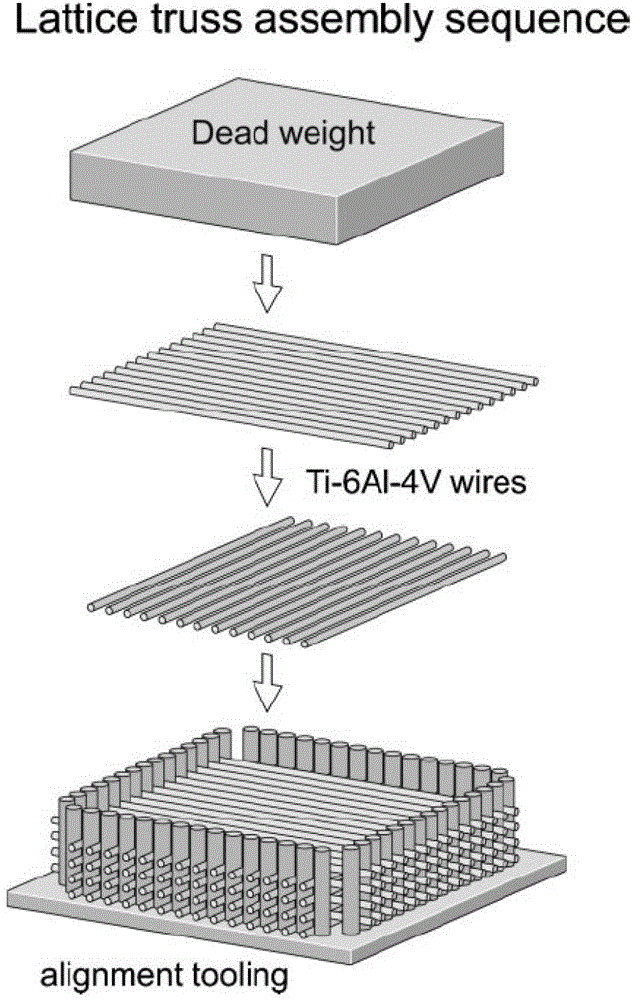

Preparation method of titanium alloy three-dimensional lattice sandwich structure

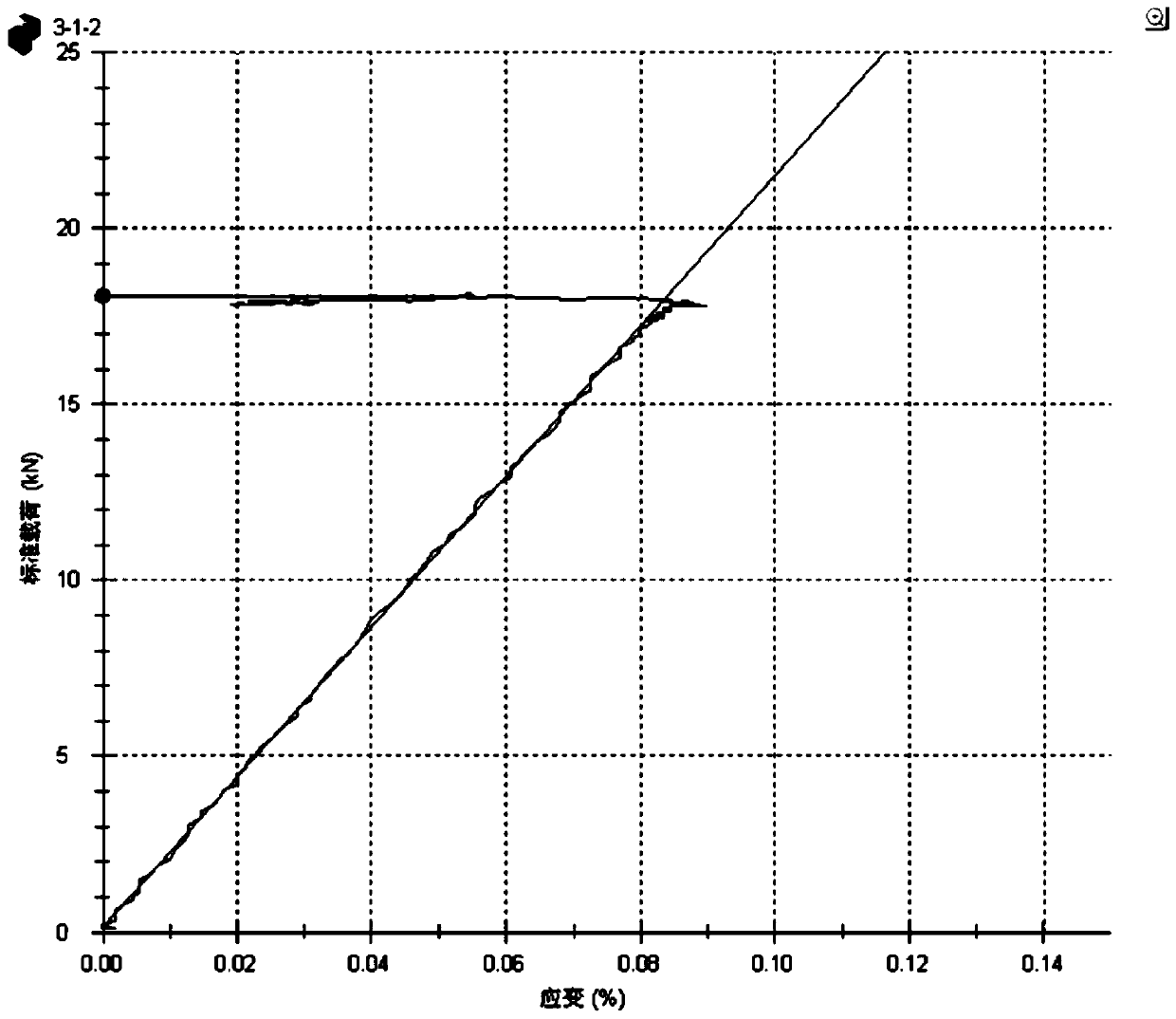

ActiveCN102990300AImprove performanceImprove interlayer bonding performanceNon-electric welding apparatusUltimate tensile strengthTitanium alloy

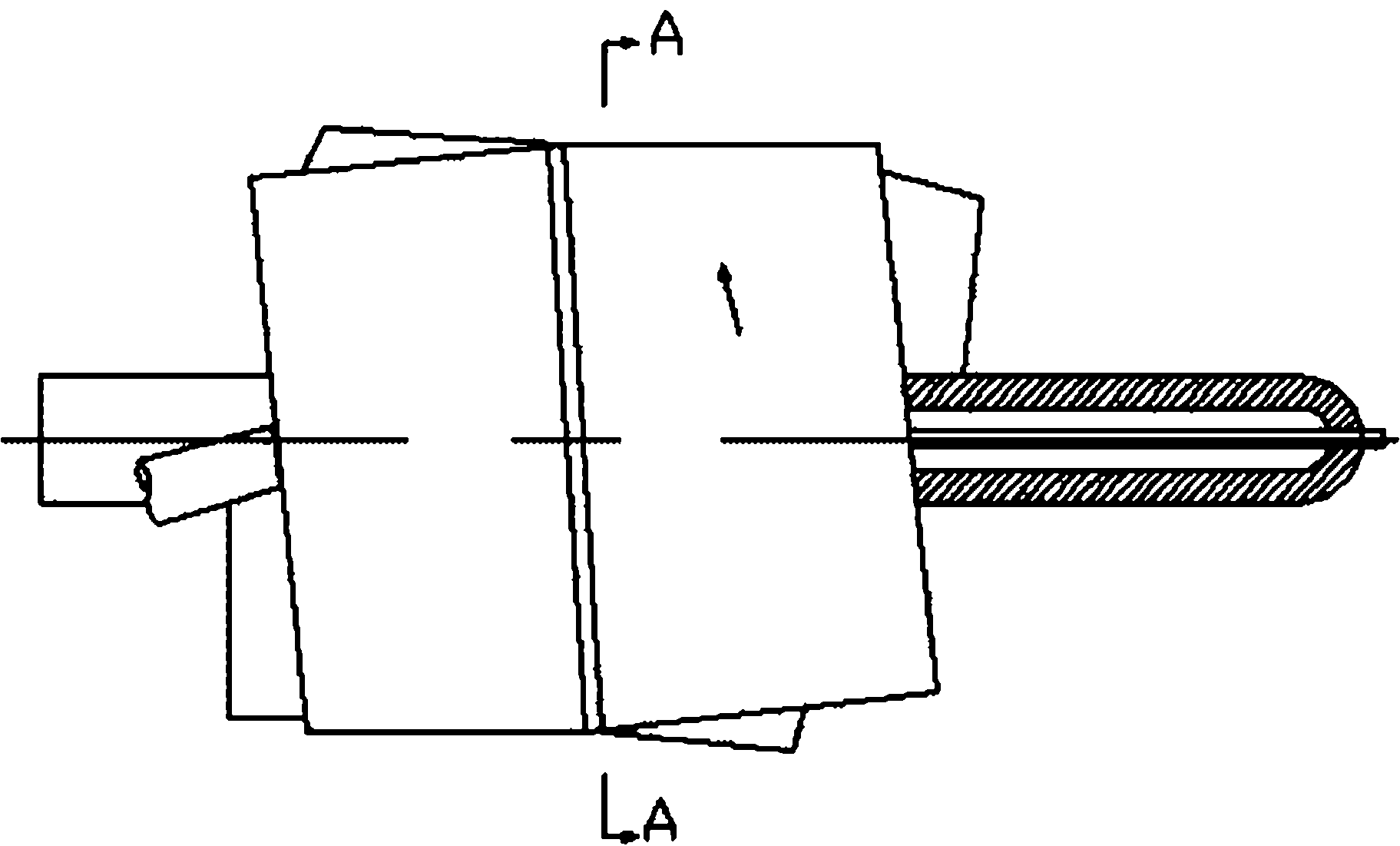

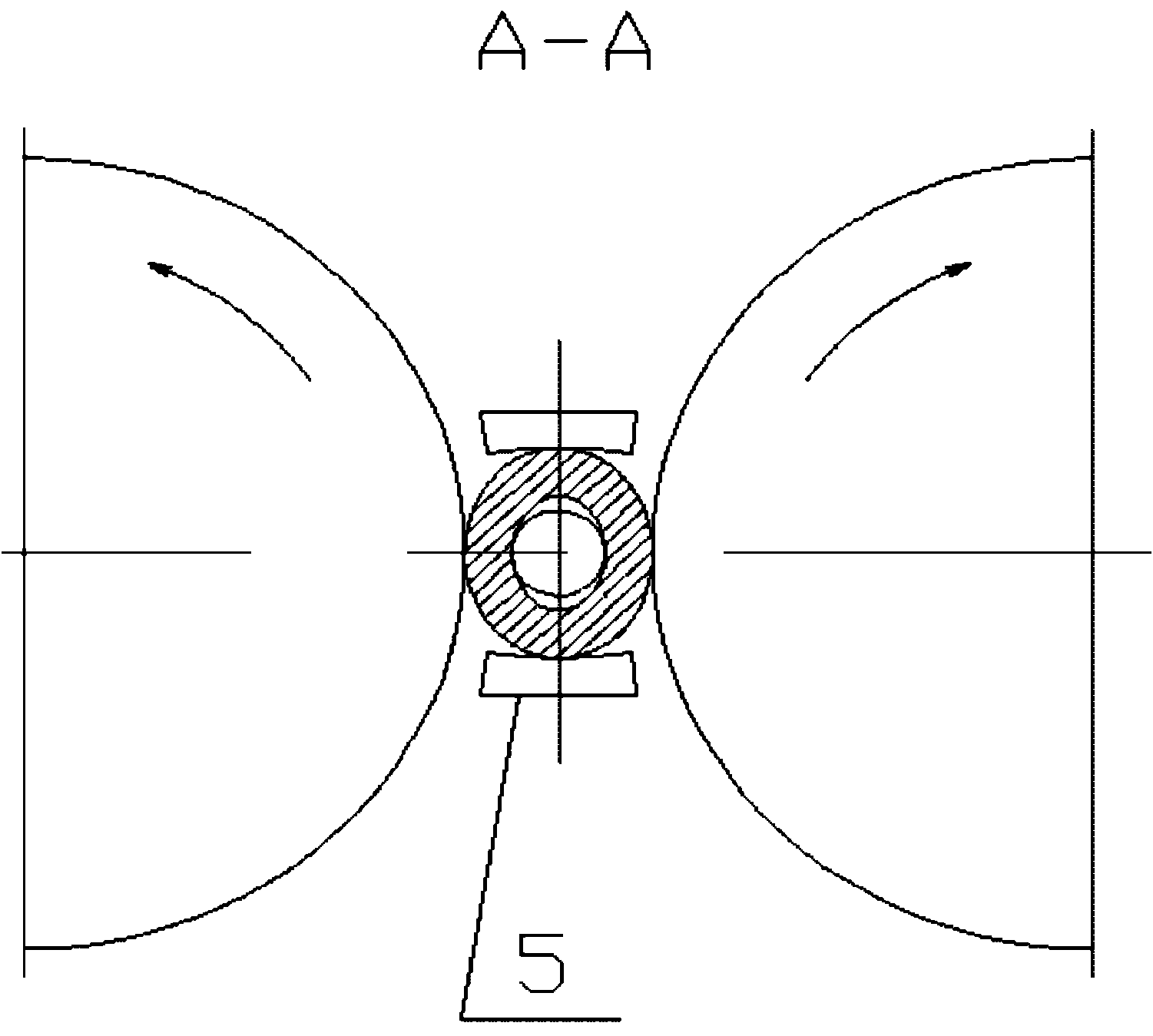

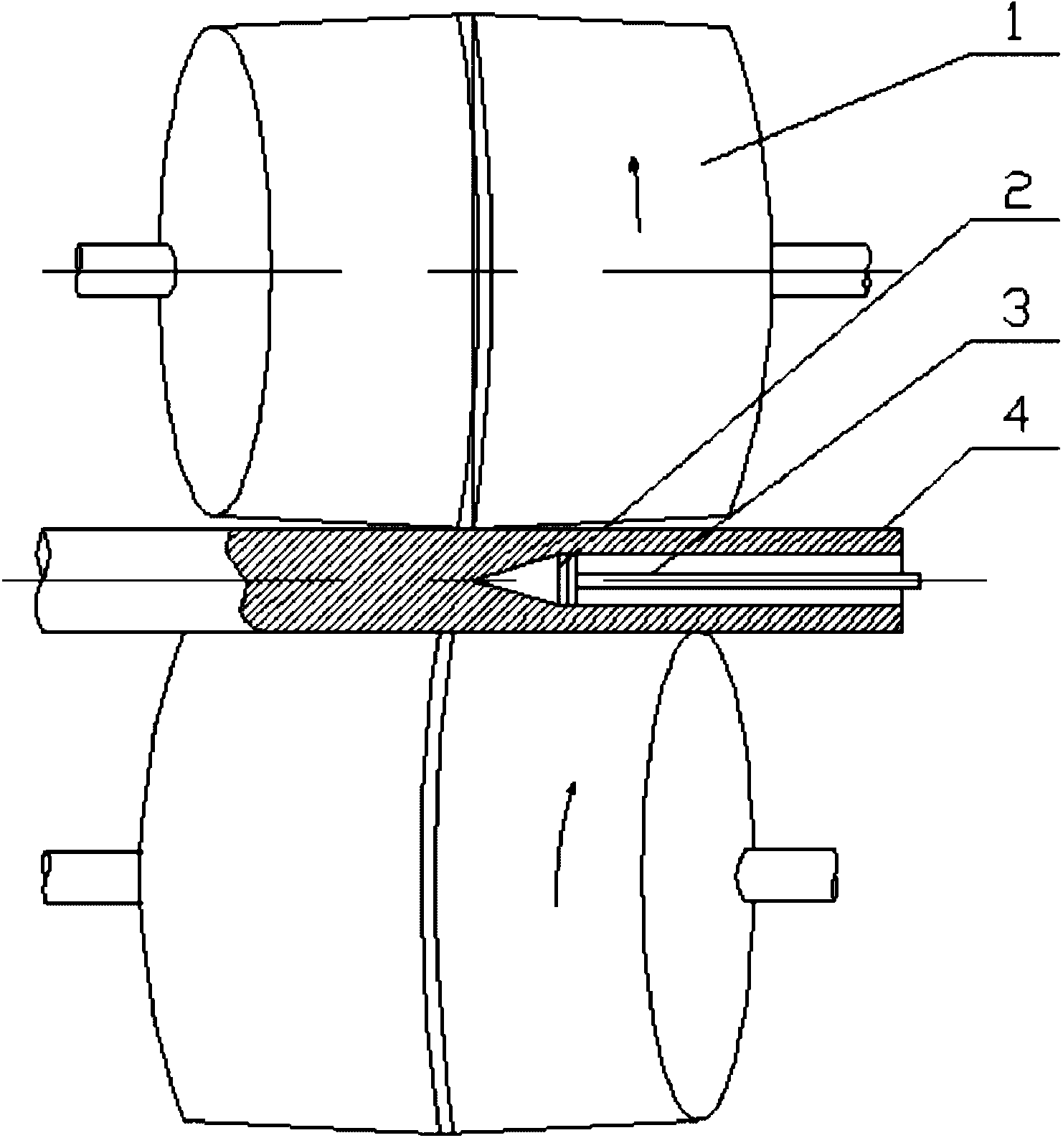

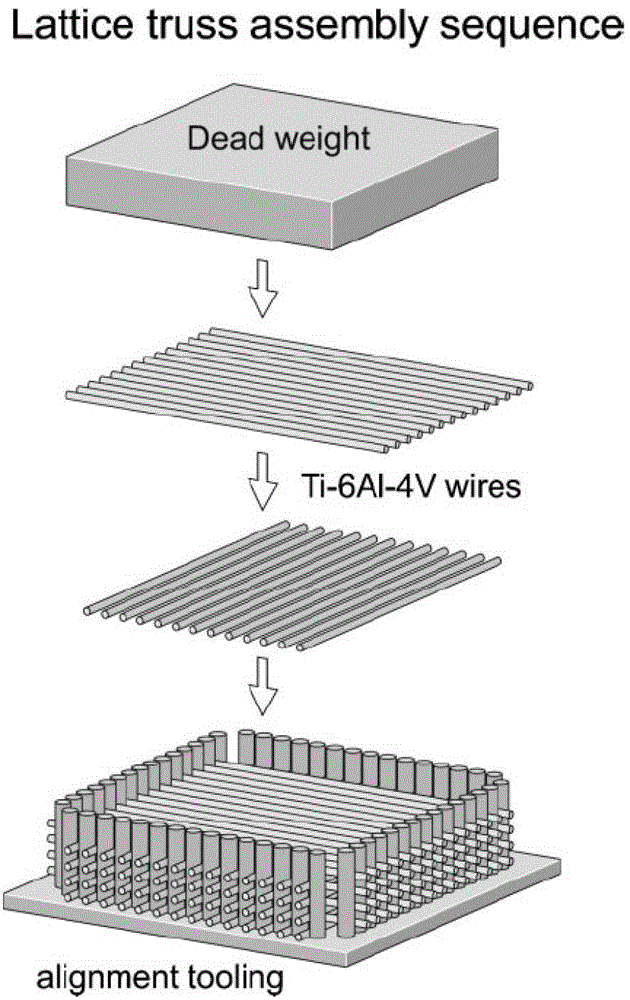

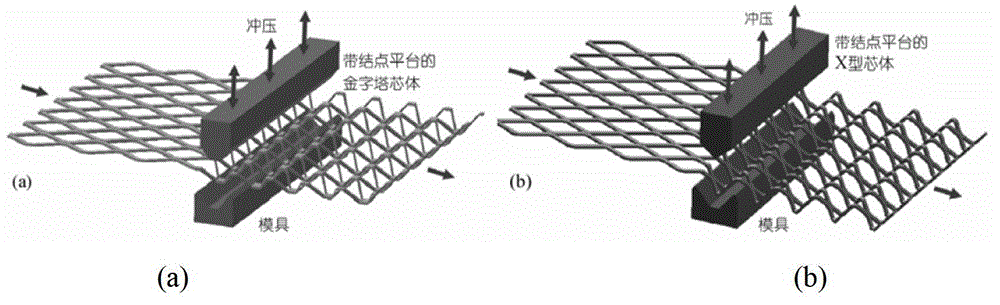

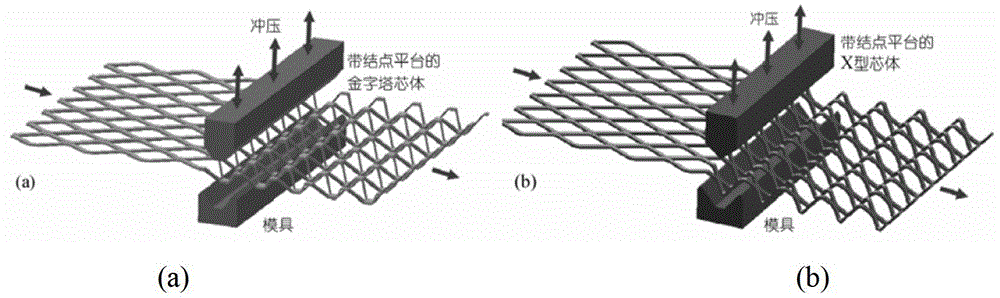

The invention belongs to a titanium alloy structure forming technology, and in particular relates to a preparation method of a titanium alloy three-dimensional lattice sandwich structure. According to the invention, a titanium alloy three-dimensional lattice sandwich member is prepared by adopting a superplastic forming method, and the method of preparing the titanium alloy three-dimensional lattice sandwich structure by adopting a superplastic forming / diffusion connection process is proposed for the first time, therefore on one hand, the shape of a formed part, in particular to the titanium alloy three-dimensional lattice structure with a complex shape, can be accurately controlled, and on the other hand, the technical problem that a titanium alloy three-dimensional lattice sandwich layer is difficult to form is solved. The structure which is prepared by superplastic forming / diffusion connection has higher bonding strength because the three-dimensional lattice sandwich layer and upper and lower panels are bonded together by a diffusion connection method.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

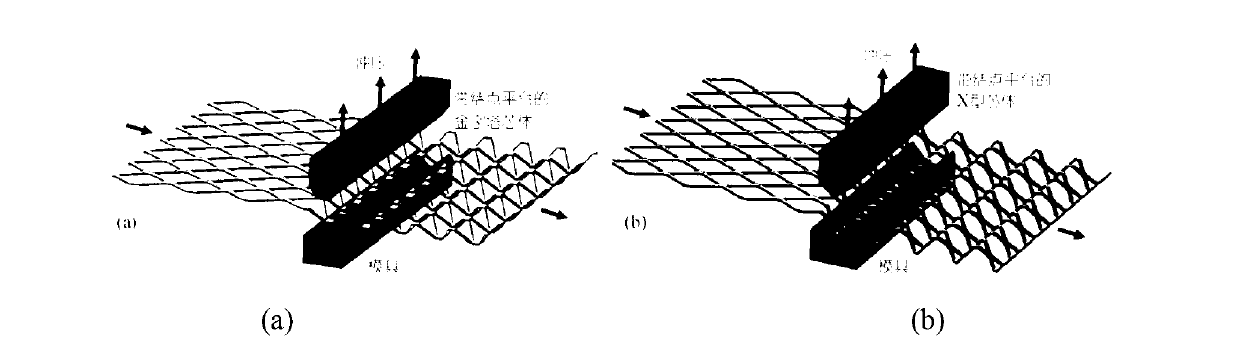

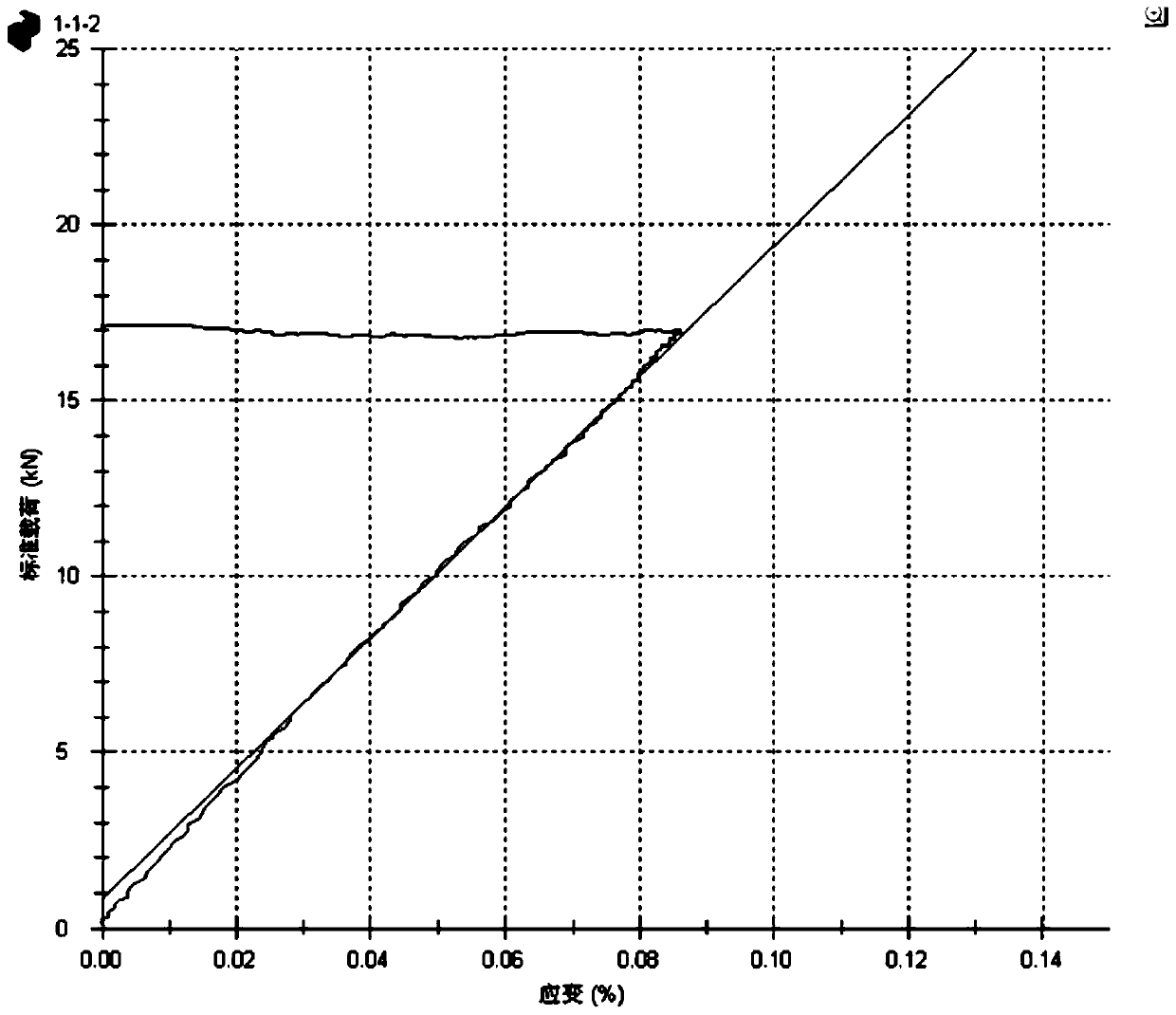

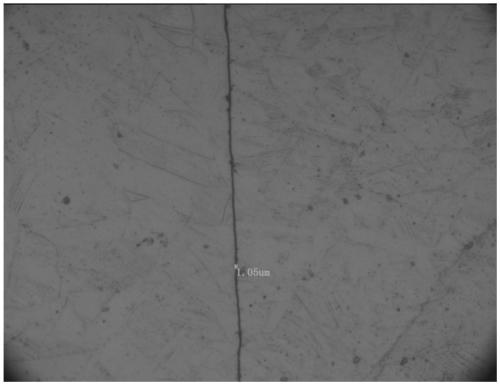

Preparation method for X-type titanium alloy three-dimensional lattice sandwich structure

ActiveCN102990299AImprove performanceImprove interlayer bonding performanceNon-electric welding apparatusMetallurgyUltimate tensile strength

The invention belongs to the titanium alloy structure forming technology and relates to a method for preparing an X-type titanium alloy three-dimensional lattice sandwich structure by superplastic forming / diffusion connection. An X-type titanium alloy three-dimensional lattice sandwich member is prepared by adopting the superplastic forming method; and the X-type titanium alloy three-dimensional lattice sandwich structure is prepared by adopting the superplastic forming / diffusion connection process for the first time, so that on one hand, formed parts, especially the X-type titanium alloy three-dimensional lattice sandwich structures with complex shapes can be accurately controlled in shape, and the technical difficult problem of low possibility of formation of an X-type titanium alloy three-dimensional lattice sandwich is solved at the same time. The structure prepared by adopting the superplastic forming / diffusion connection process is higher in bonding strength as the three-dimensional lattice sandwich is connected with upper and lower panels through the diffusion connection method.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

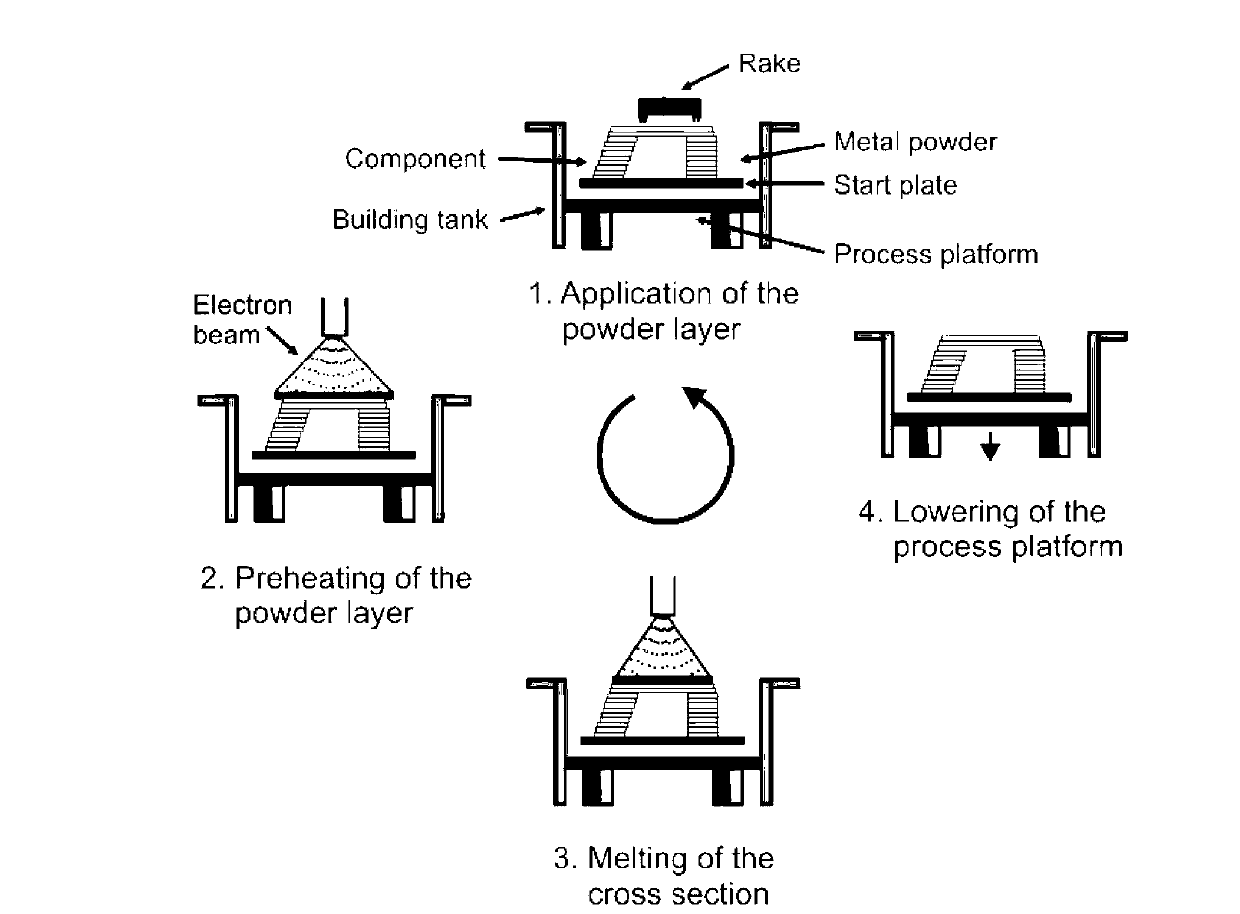

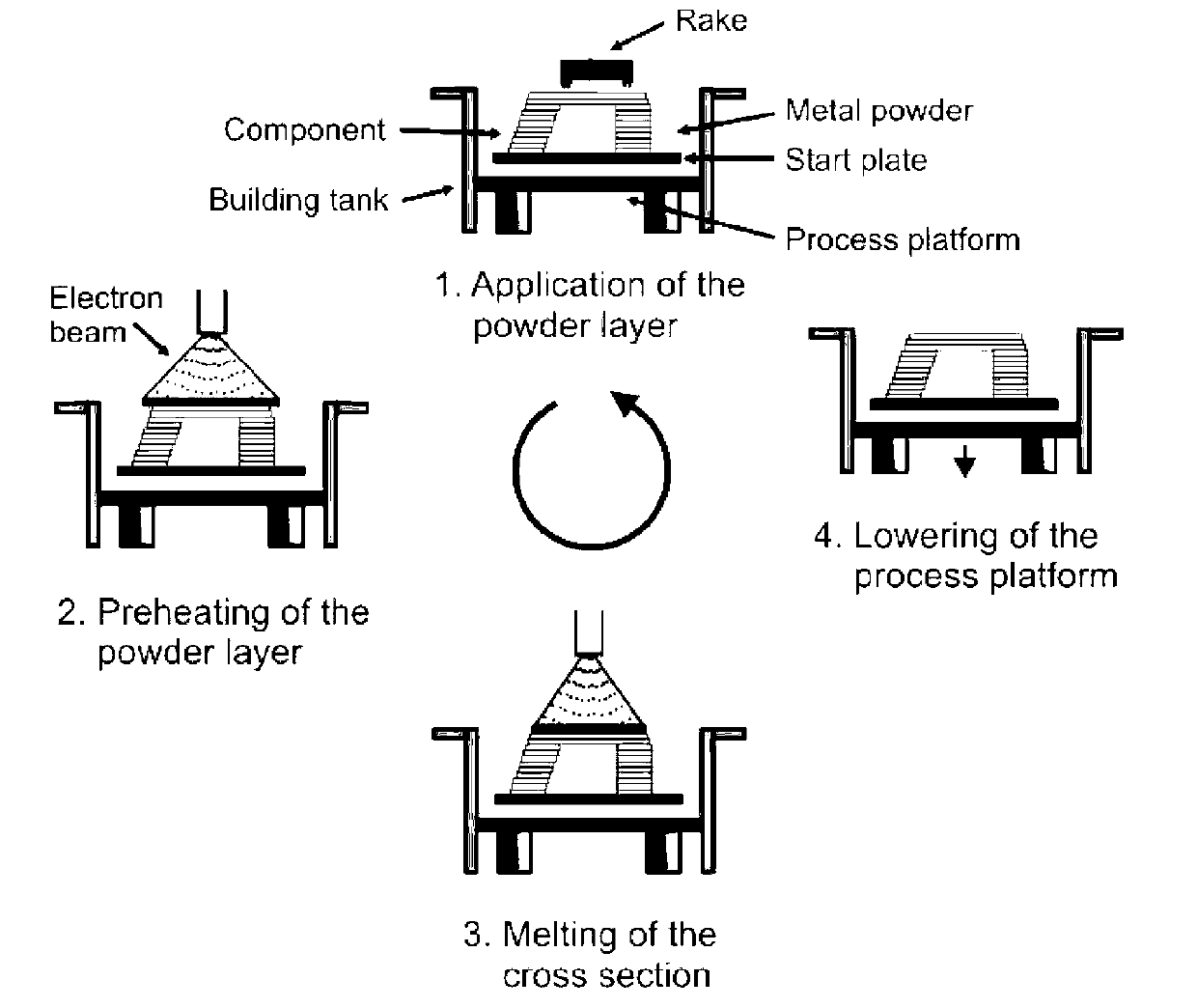

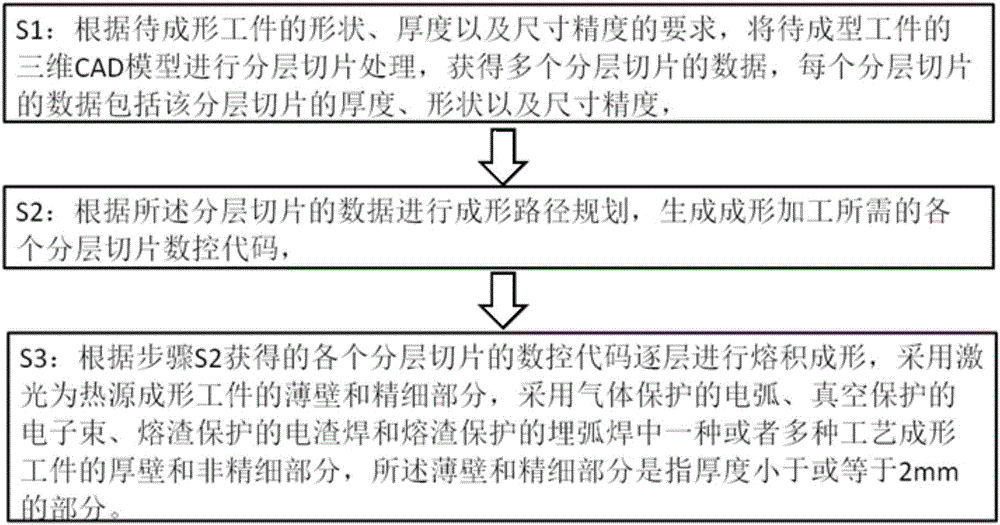

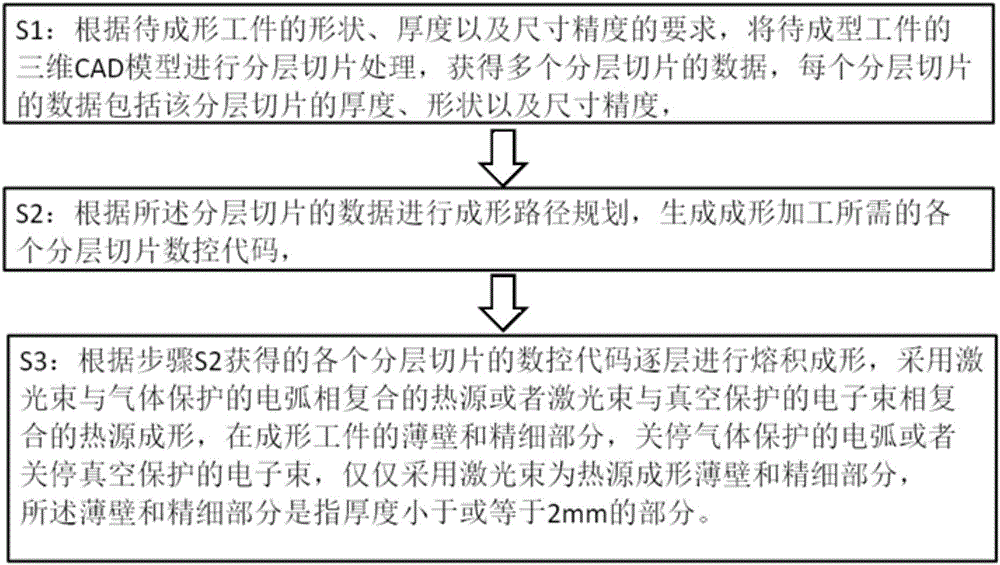

Deposition forming manufacturing method of parts and molds

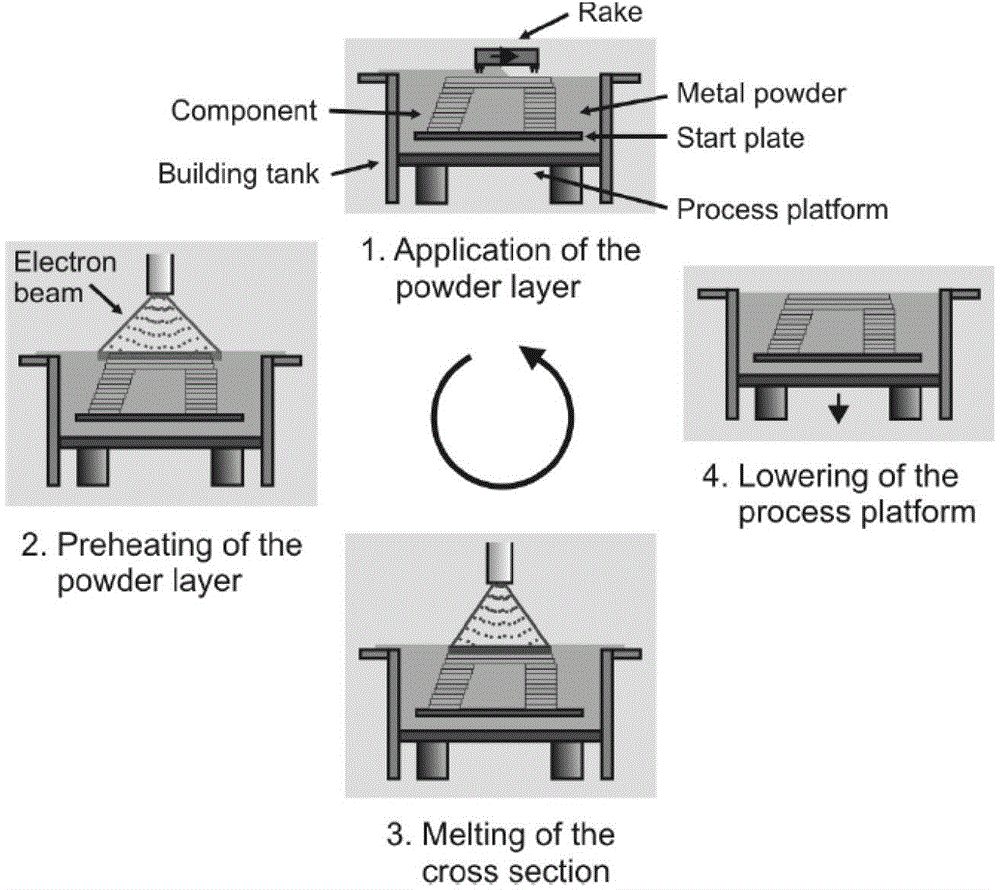

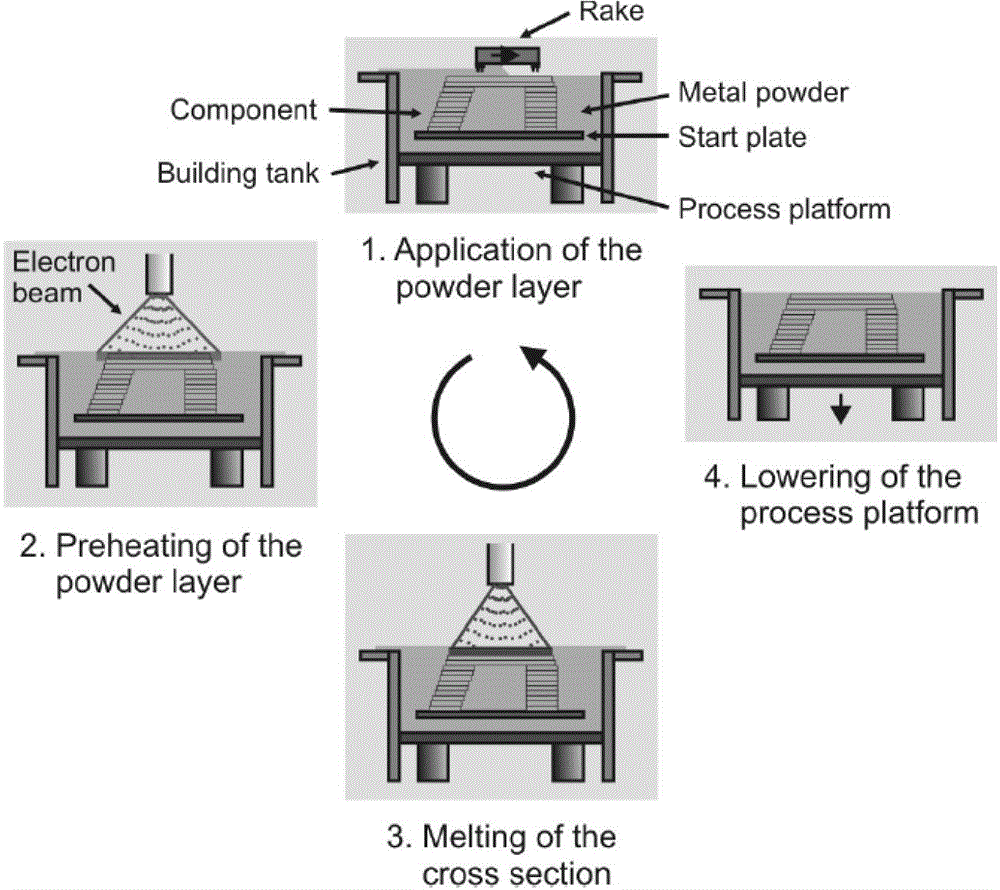

ActiveCN105945281AImprove mechanical propertiesImprove metallurgical qualityAdditive manufacturing apparatusIncreasing energy efficiencyElectricityStructure property

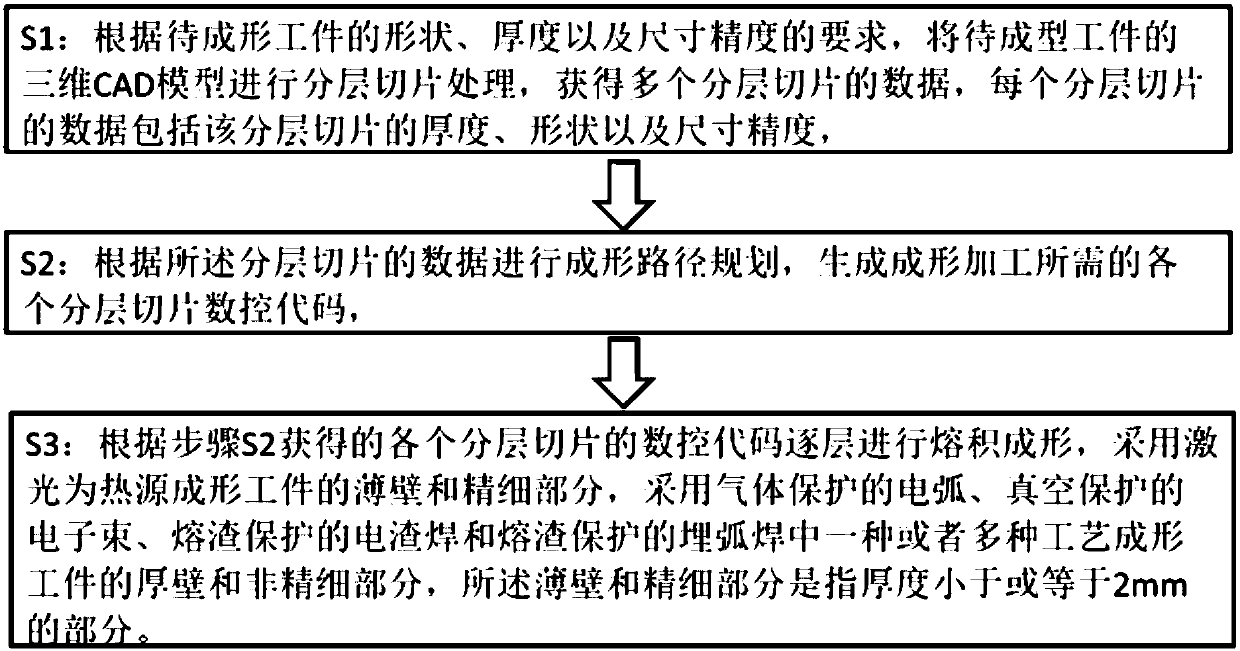

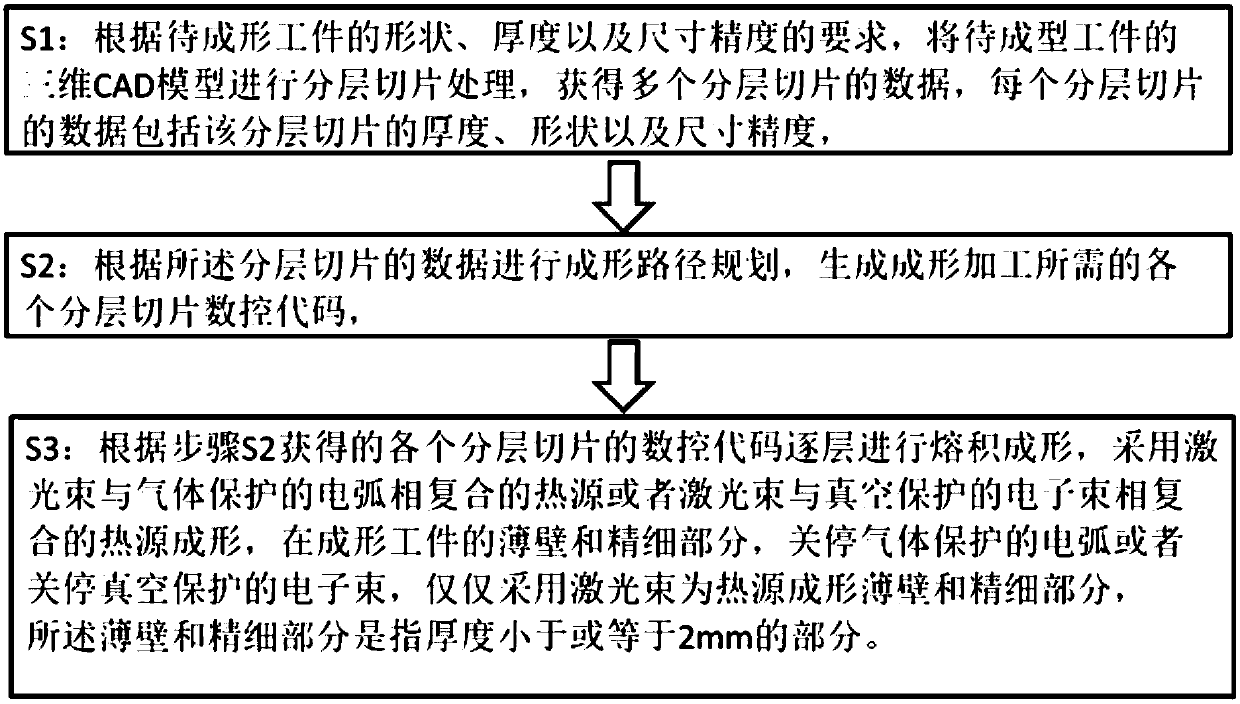

The invention discloses a deposition forming manufacturing method of parts and molds, and belongs to the field of non-mold growing manufacturing and remanufacturing. The method comprises the following steps that S1, the three-dimensional CAD model of a workpiece to be formed is subjected to hierarchical slicing; S2, the CNC codes of all hierarchical slices are acquired; S3, deposition forming is conducted layer by layer according to the CNC codes of all the hierarchical slices, the fine portions of the workpiece are formed by laser, and one or more technologies in electric arc welding, electron beam welding, electroslag welding and submerged-arc welding is or are adopted to form the thick wall and the non-fine portions of the workpiece; or in the S3, a heat source which is compounded by laser beams and gas protection electric arcs or a heat source which is compounded by the laser beams and vacuum protection electronic beams is adopted for forming the thin wall and the fine portions of the workpiece, and the gas protection electric arcs or the vacuum protection electron beams are shut down. According to the deposition forming manufacturing method, direct deposition forming can be achieved to obtain parts and molds which are stable in structure property and high in manufacturing precision and are provided with thin walls or fine portions.

Owner:HUAZHONG UNIV OF SCI & TECH

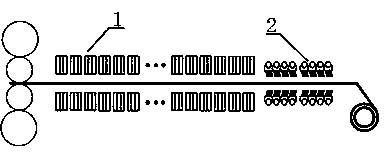

Pipe mold manufacturing process adopting continuous-casting blank to forge and roll rough blank periodically

InactiveCN102179681AHigh yieldLow costMetal rolling arrangementsStructure propertyEnergy consumption

The invention relates to a pipe mold manufacturing process adopting a continuous-casting blank to forge and roll a rough blank periodically, belonging to the technical field of pipe mold manufacture. The manufacturing process comprises the process steps of: smelting of the continuous casting blank in a blast furnace, reinspecting, blanking, heating in a ring-shaped furnace, mannesmann piercing, periodically rolling a pipe, straightening, detecting flaws with magnetic powder, cutting the head and the tail, roughly processing, boring, carrying out ultrasonic flaw detection, thermally treating, sampling and reinspecting, finish processing, carrying out surface strengthening treatment, inspecting, spraying and printing, weighing and warehousing. The pipe mold manufacturing process has the advantages that the continuous casting blank replaces the mold casting blank adopted by the existing process, the characteristics that the yield is high, the cost is low, the energy consumption is less, the structure property is stable and the like are fully exerted, and the cost is reduced in the two aspects of the process and raw materials; in addition, the forging and rolling of a Pilger type rolling machine and the structure characteristics of a classic T-shaped pipe mold are effectively combined, the condition that the pipe mold blank forged and rolled by the process periodically has the performance close to the forged blank of the traditional pipe mold is guaranteed, and the Pilger head which needs to be cut in rolling is fully utilized simultaneously, so that the production efficiency is improved greatly.

Owner:邯郸市鑫泽天然气科技有限公司

High-strength wear-resistant complex brass for automotive synchronizing ring

The invention discloses a high-strength wear-resistant complex brass for an automotive synchronizing ring, which comprises the following components in percentage by weight: 59-65% of Cu, 1.7-3.7% of Al, 2.2-3.8% of Mn, 0.5-1.3% of Si, 0.07-0.27% of Cr, 0.2-0.6% of Ni, less than or equal to 0.6% of Fe, less than or equal to 0.18% of Pb, and the balance of Zn and less than 0.05% of impurities. The complex brass has good plasticity and toughness under the conditions of high strength, high hardness and high wear resistance.

Owner:苏州撼力合金股份有限公司

Low-alloy heat-resistant steel plate and manufacturing method thereof

InactiveCN103320696AGood tensile properties at room temperatureOrganization performance is stableManufacturing convertersManganeseWorking temperature

The invention belongs to the technical field of alloy material manufacturing, and especially relates to a manufacturing method of a low-alloy heat-resistant steel plate and a manufacturing method thereof. According to the low-alloy heat-resistant steel plate and the manufacturing method thereof, the steel plate comprises the following components, by weight, 0.08-0.16% of carbon, 0.15-0.40% of silicon, 0.40-0.70% of manganese, no more than 0.015% phosphorus, no more than 0.010% of sulfur, 0.90-1.20% of chromium, 0.20-0.35% of molybdenum, 0.15-0.30% of vanadium, and balance of iron and unavoidable impurities. The steel plate is produced through the processes of converter smelting, LF+VD or RH out-furnace refining, slab continuous casting, slab stacking and slow cooling, re-heating, high pressure water phosphorus removing, slab rolling, steel plate stacking and slow cooling, normalizing+ tempering, and the like. The steel plate provided by the invention has good normal temperature and high-temperature properties, and the like, such that steel plate application safety under high-temperature environment is ensured. The steel plate is mainly used for manufacturing steel structural parts with a working temperature of 540-640 DEG C in a power plant boiler, such as end cap, lug, header, gas-saving device beam, steam pipe, superheater, reheater tube, and the like.

Owner:JIGANG GRP

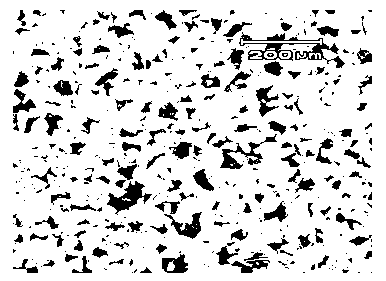

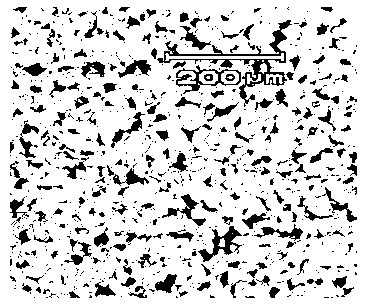

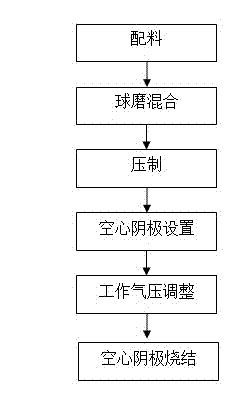

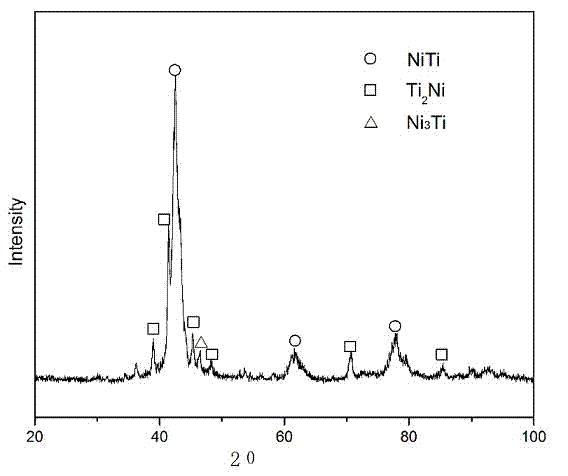

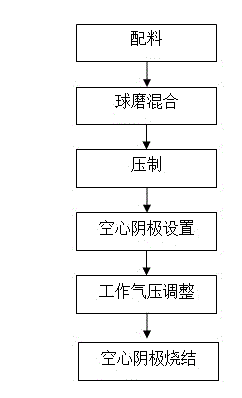

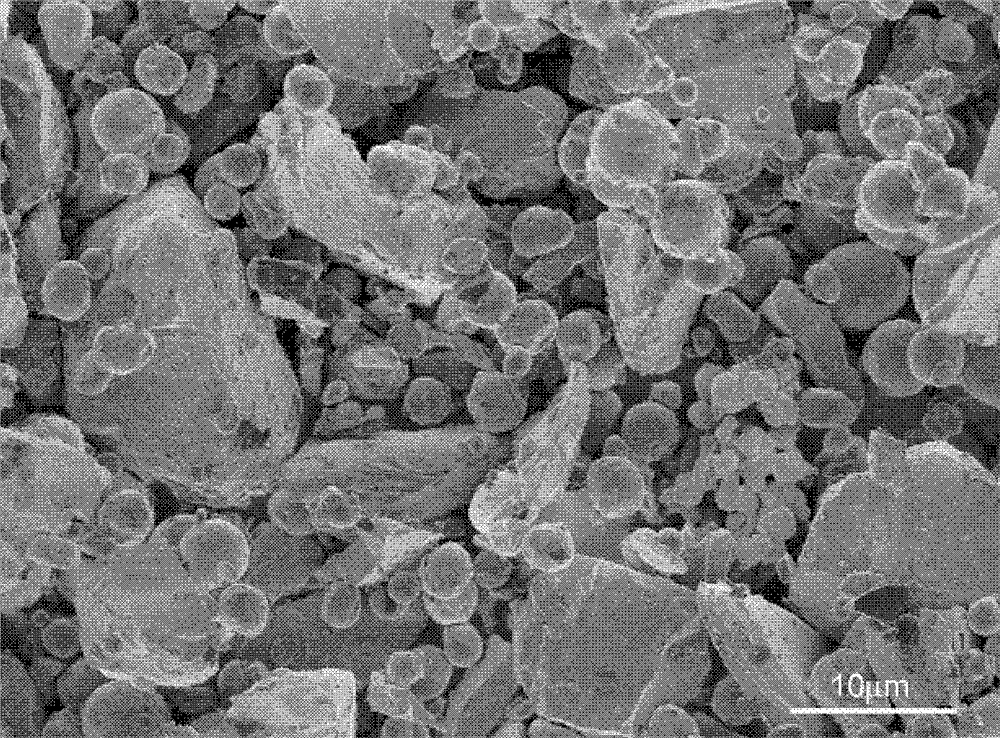

Titanium-nickel-aluminum alloy material and preparation technique thereof

A titanium-nickel-aluminum alloy material is of a hollow cathode plasma sintered body and consists of the following components in percentage by atom weight, 47-9% of titanium, 45-47% of nickel and the balance of aluminum, wherein the content of the titanium is 1-3% more than the content of the nickel. The preparation technique comprises the following steps of: batching according to the atom percentage of all the components, mixing by a ball mill, screening and carrying out compression molding to obtain a compact; forming a hollow cathode by the compact and a graphite plate reflection screen, carrying out high-temperature fast sintering on the compact by using a hollow cathode plasma sintering method, and cooling to finally obtain the alloy material. The titanium-nickel-aluminum alloy material prepared by the invention has the advantages of excellent plasticity and strength, even sintered body crystal size, compact tissue and low cost. The hollow cathode plasma sintering preparation process is simple, the difficulty of high demand of smelting casting technique equipment is solved, the preparation temperature is significantly lowered, the material use ratio is increased, and the energy consumption and the cost are reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

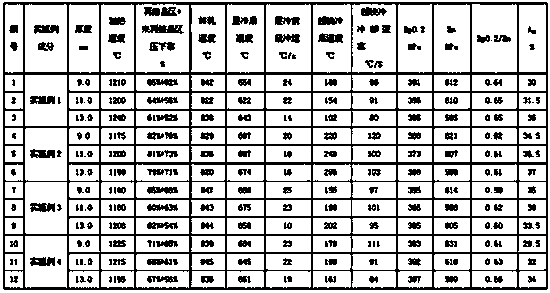

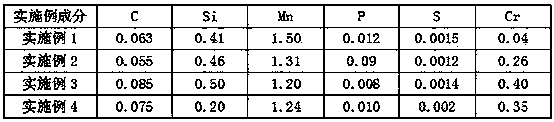

Thick-specification hot-rolled dual-phase steel plate and manufacturing method thereof

The invention discloses a low-cost thick-specification uniform-structure hot-rolled dual-phase steel plate based on a post ultra-fast cooling technique and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by weight: 0.055-0.085% of C, 0.20-0.50% of Si, 1.20-1.50% of Mn, at most 0.40% of Cr, at most 0.012% of P, at most 0.002% of S, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: (1) heating a casting blank, and carrying out controlled rolling; (2) after hot rolling, cooling to a ferrite phase-change zone in a forepart centralized laminar cooling mode; and (3) cooling to martensitic phase-change temperature below by using a post ultra-fast cooling system, and coiling. The production mode, which uses the post ultra-fast cooling technique as the core, is utilized to lower the dependence of the thick-specification high-strength hot-rolled dual-phase steel on alloy elements; and the thick-specification high-strength hot-rolled dual-phase steel has the advantages of cheap components, uniform structure and excellent and stable performance, and is suitable for mass industrial production.

Owner:NORTHEASTERN UNIV

Titanium nickel aluminium molybdenum alloy material and preparation process thereof

The invention relates to a titanium nickel aluminium molybdenum alloy material which is of a hollow cathode plasma sintering body and comprises the following components in atomic percent: 47-48.5% of titanium, 45-46.5% of nickel, 0.5-1% of molybdenum and the balance of aluminium, wherein the titanium content is 1-3% higher than the nickel content. A preparation process of the titanium nickel aluminium molybdenum alloy material comprises the following steps of: weighing titanium powder with certain granularity, nickel powder, aluminium powder and prealloy powder with the molybdenum content of 20wt% in the atomic percent of each component, carrying out ball milling, mixing, sieving, and obtaining a compacted blank by virtue of compression moulding; and forming a hollow cathode by virtue of the compacted blank and a graphite plate reflecting screen, realizing high-temperature rapid sintering on the compacted blank by adopting a hollow cathode plasma sintering method, and cooling, so that the alloy material is obtained. The titanium nickel aluminium molybdenum alloy material provided by the invention has good plasticity and strength, grains of the sintering body are uniform, the structure is compact, and the cost is low. The hollow cathode plasma sintering preparation process is simple, the problem that requirement on smelting and casting technological equipment is high is solved, the preparation temperature is obviously reduced, the material utilization is improved, the energy consumption is reduced, and the cost is saved.

Owner:CHANGSHU LIONY METALS

Moderate-intensity high-conductivity electrical aluminum wire material and preparation method thereof

ActiveCN103556016AHigh strengthImprove performanceMetal/alloy conductorsEconomic benefitsVolumetric Mass Density

The invention relates to a moderate-intensity high-conductivity electrical aluminum wire material and a preparation method thereof. A method for optimizing the alloy components and combining processes of extruding, preparing and aging is adopted, so that an Al-Mg-Si alloy wire is high in density, fewer in defects and high in yield. The problem that the conductivity and intensity of the Al-Mg-Si alloy wire prepared by a traditional method cannot be considered simultaneously is solved. The conductivity of the Al-Mg-Si alloy wire prepared by the method disclosed by the invention is over 62 percent IACS (International Annealed Copper Standard), the tensile strength is over 220MPa, and the alloy wire is easy to implement and low in cost and has obvious social and economic benefits and wide application prospects.

Owner:SHENYANG POLYTECHNIC UNIV

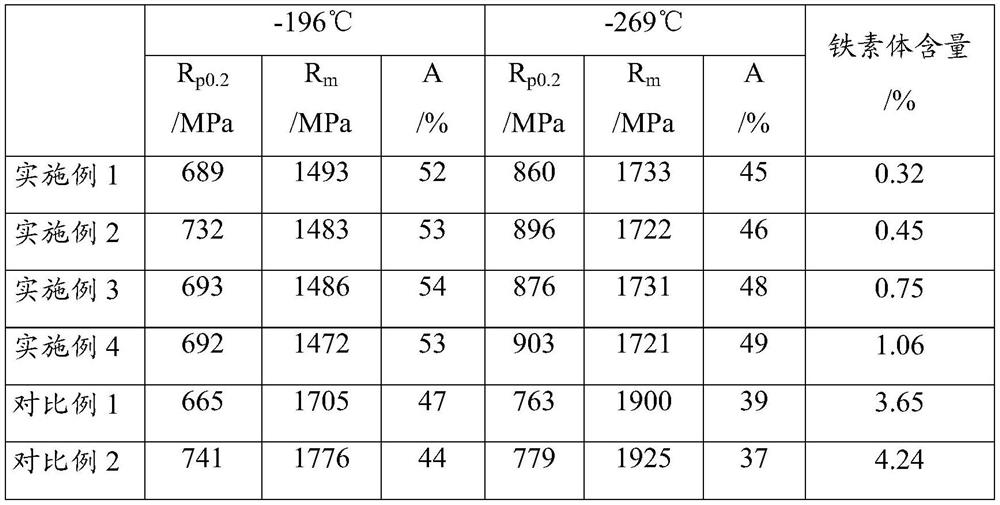

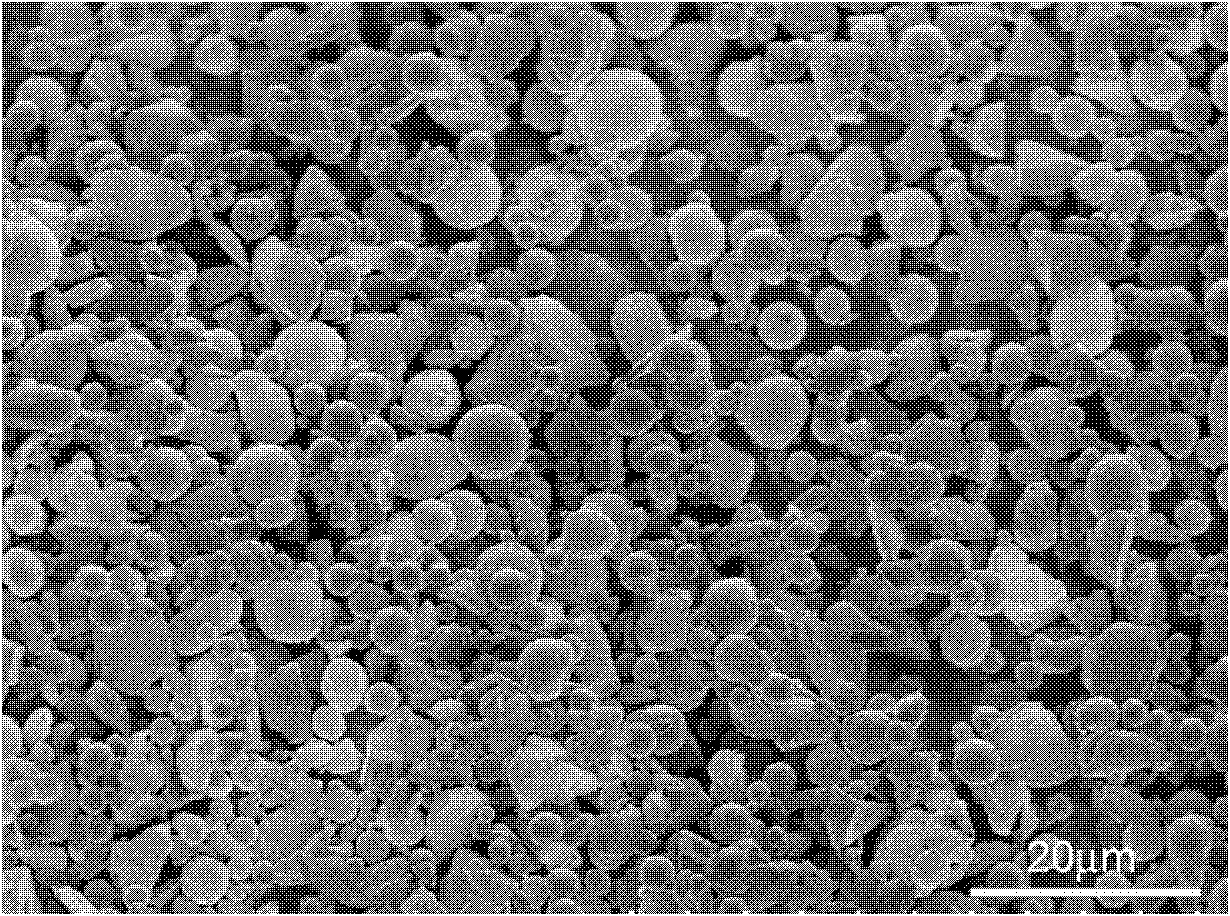

Austenitic stainless steel, preparation method thereof and application of austenitic stainless steel in hydrogen storage pressure vessel

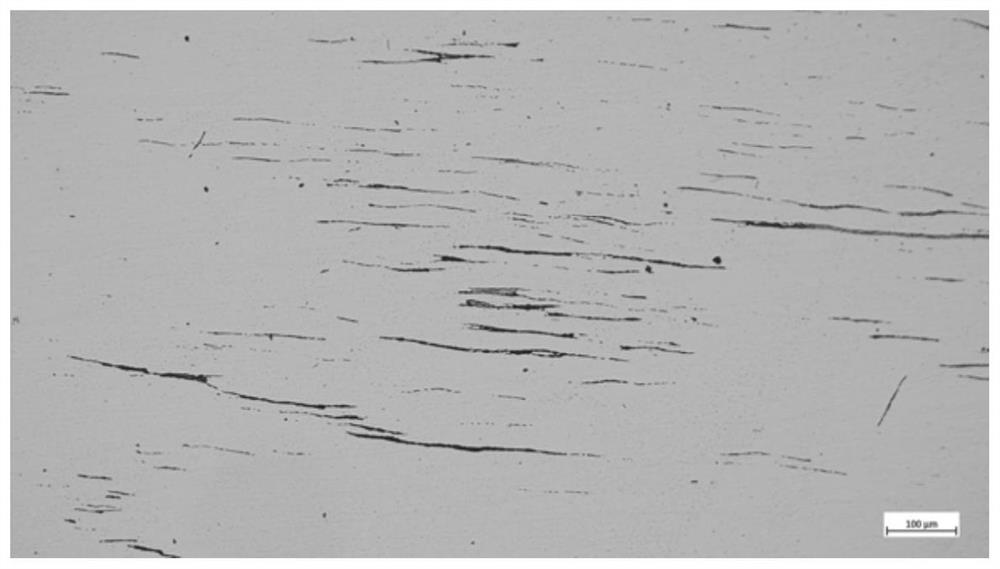

ActiveCN114351051AReasonable design of ingredientsReduced ferrite contentFixed capacity gas holdersMetal rolling arrangementsMetallurgySS - Stainless steel

The invention belongs to the technical field of steel smelting, and relates to austenitic stainless steel, a preparation method thereof and application of the austenitic stainless steel in a hydrogen storage pressure container. The austenitic stainless steel provided by the invention comprises the following components in percentage by weight: 0.010%-0.030% of C, 0.40%-0.75% of Si, 1.3%-2.0% of Mn, 17.5%-18.0% of Cr, 13.05%-14.00% of Ni, 2.5%-3.0% of Mo, less than or equal to 0.030% of P, less than or equal to 0.002% of S, less than or equal to 0.06% of N, less than or equal to 0.5% of Cu, 0.002%-0.005% of B, 28.5%-35% of Nieq, and the balance of Fe and inevitable impurities. The austenitic stainless steel is stable in structure performance, low in ferrite content and good in hydrogen embrittlement resistance, the development requirement of a hydrogen storage pressure container of a hydrogen refueling station is met, and the austenitic stainless steel has important practical significance on safe and efficient development of the hydrogen energy storage technology.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Manufacturing method of 23CrNi3Mo alloy steel seamless pipe for drilling tool

InactiveCN108127003AHigh hardnessMeet cold rolling processing requirementsFurnace typesHeat treatment furnacesSurface oxidationAcid washing

The invention discloses a manufacturing method of a 23CrNi3Mo alloy steel seamless pipe for a drilling tool. The method comprises the following steps of (1) peeling and cutting round steel; (2) performing perforation by a hot perforation machine; (3) performing acid washing to remove scales at the acid washing temperature of 45 to 70 DEG C, wherein the acid washing time is 90 to 150min; (4) performing spheroidization heat treatment on the steel pipe subjected to acid washing, wherein the heat treatment temperature is 680 to 690 DEG C, and the heat insulation time is 4 to 6h; (5) performing acid washing again on the steel pipe subjected to heat treatment for removing surface scales, wherein the acid washing temperature is 45 to 70 DEG C, and the acid washing time is 90 to 150min; (6) performing cold rolling treatment with the feeding quantity of 1 to 2mm per time; (7) performing spheroidization heat treatment again on the steel pipe subjected to cold rolling treatment, wherein the heattreatment temperature is 680 to 690 DEG C, and the heat insulation time is 4 to 6h; (8) performing acid washing on the steel pipe subjected to heat treatment, wherein the acid washing temperature is 45 to 70 DEG C, and the acid washing time is 90 to 150min; (9) performing straightening; (10) performing finished product value management detection and surface inspection; performing packaging and warehouse entering after the constant cutting and marking on qualified products.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

7, 000-series alloy material for automobile bumpers, and production method thereof

The invention discloses a 7, 000-series alloy material for automobile bumpers. The 7, 000-series alloy material for the automobile bumpers is characterized in that the aluminum alloy comprises the alloy ingredients of Zn, Mg, Cu, Zr, Ti, Sn, Mn, Ag, Co, Sc, Yb, B, Cr4 and the balance aluminum and unavoidable impurities, wherein the ratio of Mg to Zn ranges from 0.17 to 0.19, the ratio of Cu to Mgranges from 0.43 to 0.53, the ratio of Cu to Ti ranges from 1.5 to 1.8, the content of one single impurity is smaller than or equal to 0.005%, the total content of the impurities is smaller than or equal to 0.1%, the average grain diameter of aluminum alloy grains ranges from 20 microns to 40 microns. When the alloy is observed through SEM and TEM, the area percentage of the strengthening phase MgZn2 ranges from 1% to 1.6% while the average size of the MgZn2 ranges from 50 nanometers to 60 nanometers, the area percentage of the strengthening phase Mg2Sn ranges from 0.3% to 0.6% while the average size of the Mg2Sn ranges from 30 nanometers to 50 nanometers, the area percentage of the strengthening phase Al6Mn ranges from 0.3% to 0.4% while the average size of the Al6Mn ranges from 20 nanometers to 30 nanometers, the area percentage of the strengthening phase Al3Ti ranges from 0.5% to 0.8% while the average size of the Al3Ti ranges from 20 nanometers to 30 nanometers, the yield strengthranges from 580 MPa to 650 Mpa, the tensile strength ranges from 670 MPa to 720 MPa, and the elongation ranges from 18% to 23%.

Owner:温州市赢创新材料技术有限公司

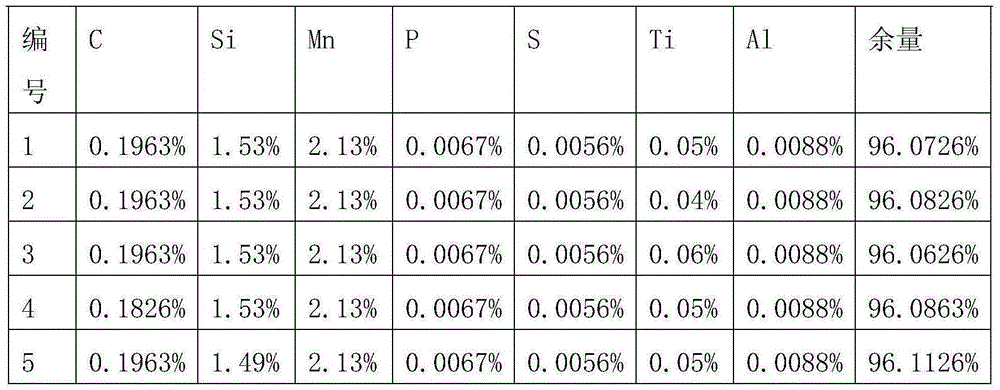

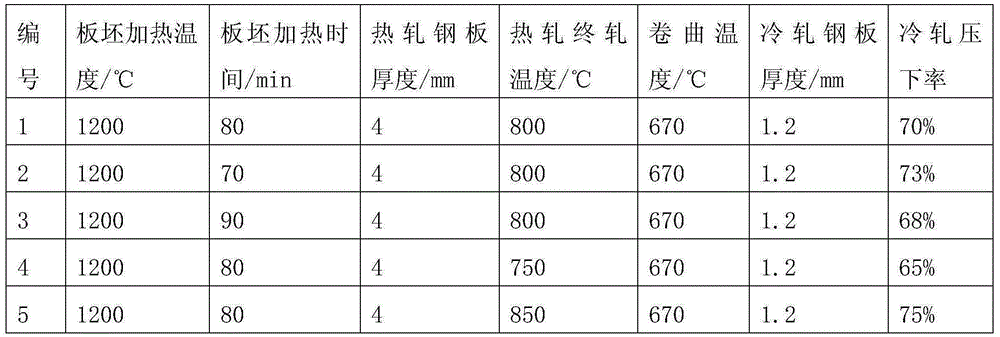

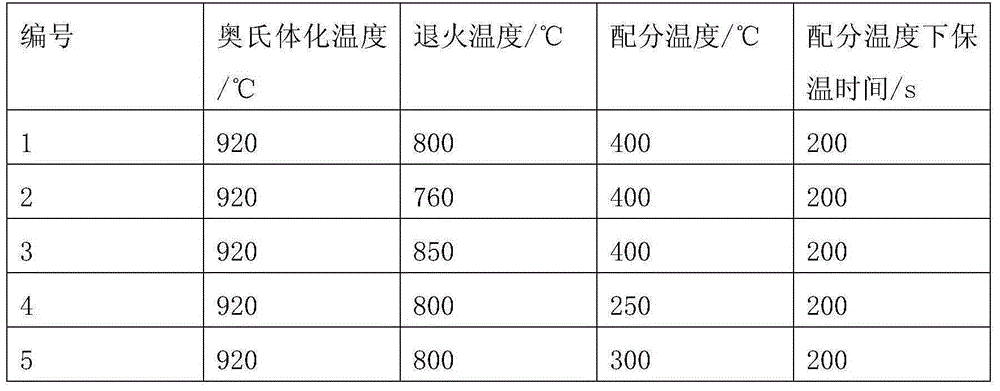

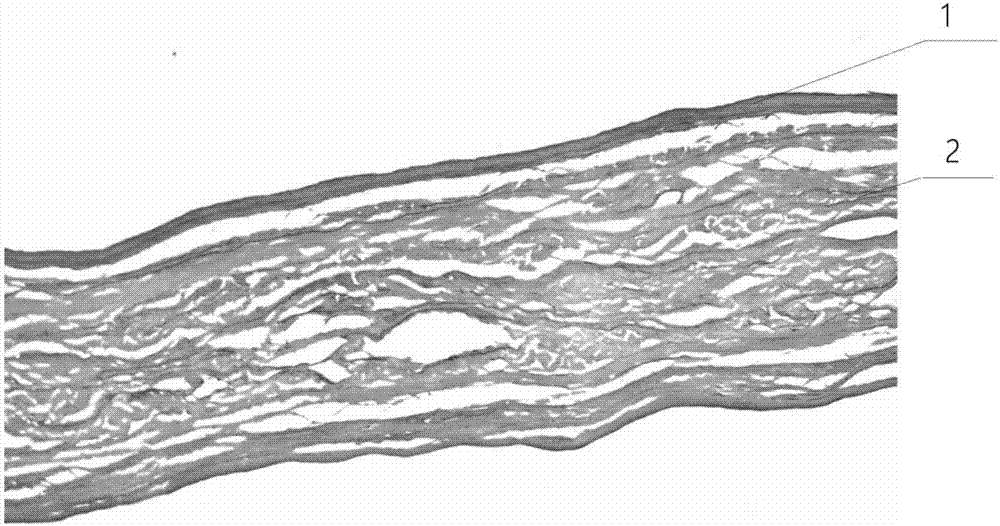

Titanium alloyed TAM steel and manufacturing method thereof

The invention relates to titanium alloyed TAM steel and a manufacturing method thereof and belongs to the technical field of design and thermal processing of metal ingredients. The titanium alloyed TAM steel disclosed by the invention comprises the following chemical ingredients in weight percentage: 0.18-0.21 percent of C, 1.48-1.55 percent of Si, 1.90-2.20 percent of Mn, smaller than or equal to 0.020 percent of P, smaller than or equal to 0.015 percent of S, 0.04-0.06 percent of Ti, smaller than or equal to 0.04 percent of Al and the balance Fe and inevitable impurities. According to the titanium alloyed TAM steel disclosed by the invention, a suitable amount of titanium is added in a titanium alloying way; the toughness of the TAM steel is improved by precipitation of carbides and the like of titanium, so that the comprehensive mechanical properties of the titanium-containing TAM steel are improved, and a steel plate is enabled to have relatively high strength and plasticity and is especially excellent in hydrogen induced delay cracking resistance. The titanium-containing TAM steel disclosed by the invention is produced by adopting a novel process, i.e., a Q and P process, so that steel tissues are more stable in performance.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Artificial biological cardiac and vascular valve on basement membrane component surface layer and preparation method thereof

PendingCN107412871ABarrier depositionIsolation toxicityPharmaceutical delivery mechanismTissue regenerationSurface layerCalcification

The invention relates to an artificial biological cardiac and vascular valve on a basement membrane component surface layer and a preparation method thereof. The artificial biological cardiac and vascular valve comprises a biovalve material and the basement membrane component surface layer tightly covering the biovalve material. On the basis that the good strength and toughness of a crosslinking biovalve are reserved, rapid endothelialization of the smooth and dense basement membrane component surface layer can be achieved, and calcium salt deposition can be obstructed, so that cytotoxicity and immunogenicity reducing which are caused by calcification and isolation crosslinking of the biovalve are prevented, and the service life of the artificial biological cardiac and vascular valve is prolonged.

Owner:EXCELLENCE MEDICAL TECH SUZHOU CO LTD +1

Austenitic stainless steel medium plate for liquid hydrogen container and preparation method of austenitic stainless steel medium plate

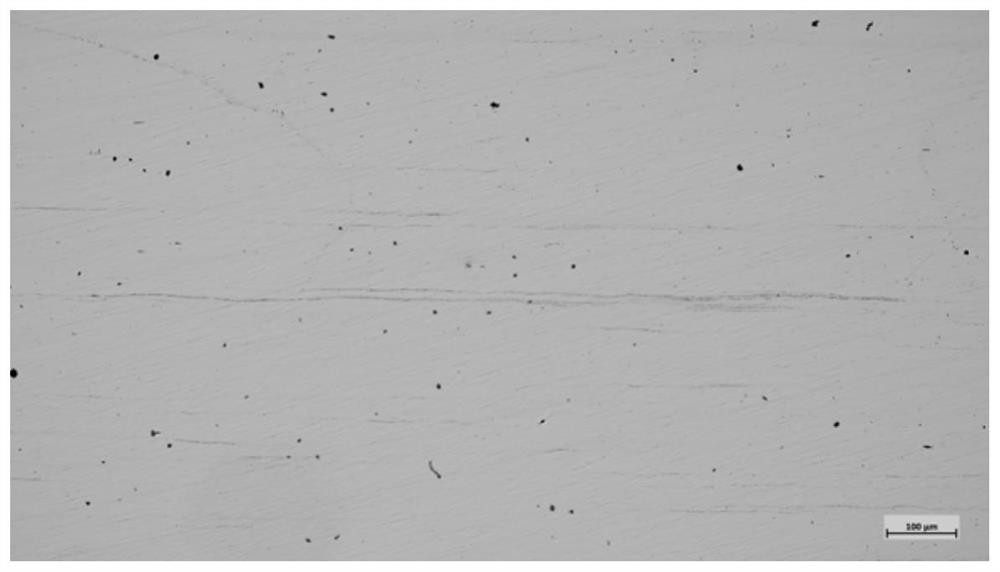

ActiveCN114774797AOrganization performance is stableReduced ferrite contentVessel wallsFurnace typesSolution treatmentSS - Stainless steel

The invention provides an austenitic stainless steel medium plate for a liquid hydrogen container. The austenitic stainless steel medium plate comprises, by weight, 0.050%-0.080% of C, 0.40%-0.75% of Si, 1.0%-1.7% of Mn, 16.0%-17.0% of Cr, 10.5%-11.50% of Ni, 2.0%-2.5% of Mo, smaller than or equal to 0.030% of P, smaller than or equal to 0.002% of S, 0.06%-0.100% of N, 0 < = Cu < = 0.3%, 0 < = Co < = 0.5% and the balance Fe and inevitable impurities. The invention further provides a preparation method of the austenitic stainless steel medium-thickness plate for the liquid hydrogen container. The preparation method comprises the steps of continuous casting billet heating, hot rolling and solution treatment. The stainless steel medium-thickness plate is stable in structure performance and low in ferrite content, has good plasticity and toughness under the low-temperature condition, and can well meet the requirement of a liquid hydrogen container for a stainless steel material.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Low-heat-expansion high-intensity alumina-silicon-aluminum (AlN-Si-Al) mixed composite material and preparation method thereof

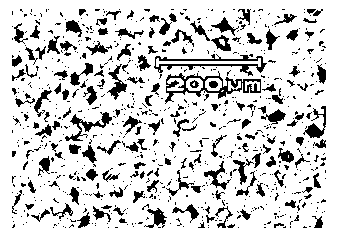

ActiveCN103160716AHigh-strength machining process performanceGood machining performanceAluminum matrix compositesPowder metallurgy

The invention relates to a low-heat-expansion high-intensity alumina-silicon-aluminum (AlN-Si-Al) mixed composite material and a preparation method thereof. The AlN-Si-Al mixed composite material comprises 10wt% to 25wt% of AlN, 40 wt% to 45 wt% of Si and 30 wt% to 50 wt% of Al, wherein the AlN and the Si are used as reinforcing materials and distributed in a continuous aluminum substrate in the form of particles in a dispersive mode, so that a reinforced aluminium base composite material mixed with AlN particles and Si particles is formed. The AlN-Si-Al mixed composite material is prepared by adoption of a powder metallurgy preparation process. The low-heat-expansion high-intensity AlN-Si-Al mixed composite material has low heat expansion and high intensity. The composite material is uniform in microstructure, completely compact and of a good machining process performance. The AlN-Si-Al mixed composite material is expected to be a substitute material of a high-silicon-content Si / Al packaging material and a substitute material of high-silicon-carbide (SiC)-content SiC / Al packaging material.

Owner:有研金属复材技术有限公司

Economical hot die-casting die steel and preparation method thereof

The invention discloses economical hot die-casting die steel. The economical hot die-casting die steel comprises the following chemical components of, in percentage by weight, 0.25-0.45% of C, 1.0-5.0% of Si, less than or equal to 1.0% of Mn, less than or equal to 2.0% of Cr, less than or equal to 1.5% of Mo, less than or equal to 0.035% of P, less than or equal to 0.035% of S, less than or equalto 0.035% of AL, and the balance Fe and other inevitable impurities. When the hot die-casting die steel is produced, slag charge is added, wherein the slag charge comprises 5% or less of MnO2, 5% or less of Ti02, 5% or less of boric acid, 2% or less of industrial soda ash, 5%-15% of Na2O or K2O, 65%-70% of SiO2, 15%-30% of AL2O3, 10% or less of CaF2 and 10% or less of CaO. The invention further discloses a preparation method of the hot die-casting die steel, and on the basis that the die steel has the advantages of being high in strength, resistant to creep deformation, good in fracture toughness, stable in structure performance and the like, the production and manufacturing cost of the hot die-casting die steel is remarkably reduced.

Owner:朱文清

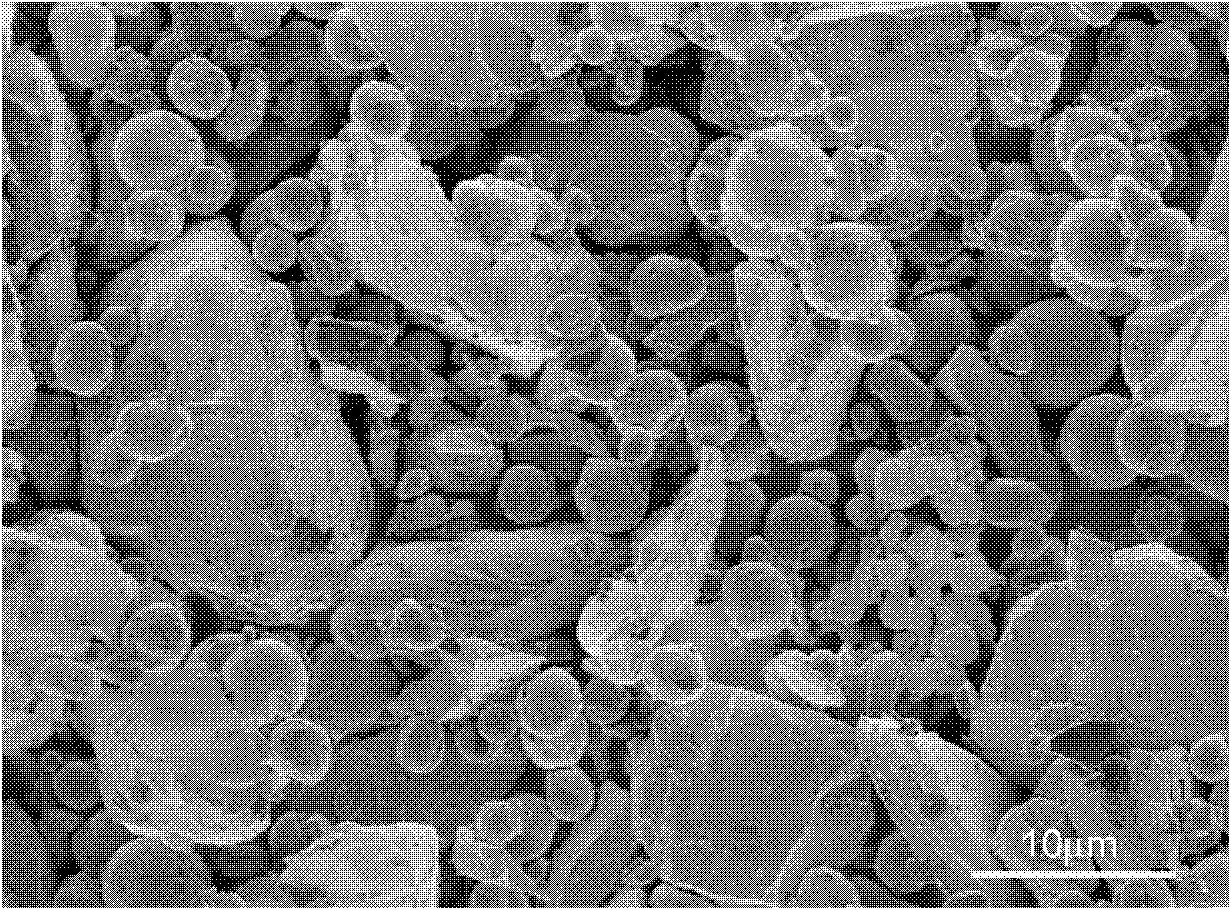

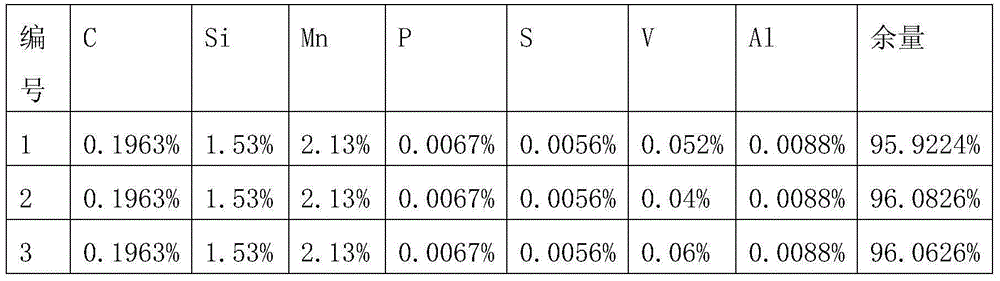

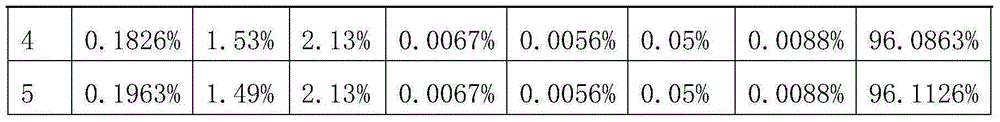

Vanadium-contained TAM steel and manufacturing method thereof

InactiveCN105039844AImprove toughnessImprove comprehensive mechanical propertiesSteel platesChemical composition

The invention relates to vanadium-contained TAM steel and a manufacturing method thereof, and belongs to the technical field of metal composition design and heat machining. The vanadium-contained TAM steel comprises, by weight percentage, 0.18%-0.21% of C, 1.48%-1.55% of Si, 1.90%-2.20% of Mn, not larger than 0.020% of P, not larger than 0.015% of S, 0.04%-0.06% of V, not larger than 0.04% of Al and the balanced Fe and inevitable impurities. An appropriate amount of vanadium is added in a vanadium alloying manner, the obdurability of the TAM steel is improved through precipitation of carbide of the vanadium and the like, and the comprehensive mechanical property of the vanadium-contained TAM steel is improved; and a steel plate has the higher strength and the higher plasticity, and the vanadium-contained TAM steel particularly has the excellent hydrogen-embrittlement-resistant delay breakage performance. A new technology, namely a Q&P process, is adopted in production of the vanadium-contained TAM steel, and therefore the steel structure property is more stable.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

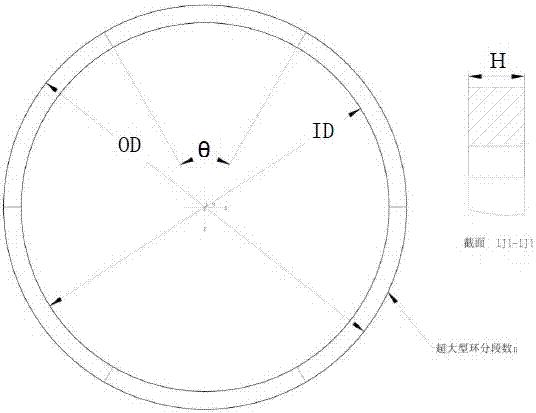

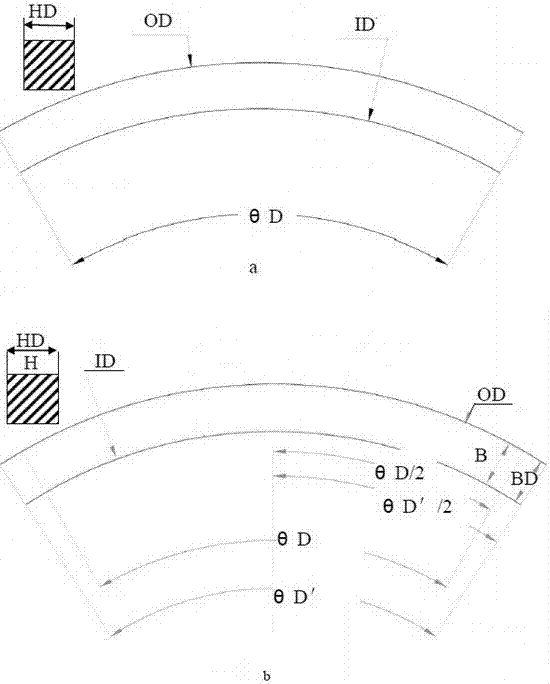

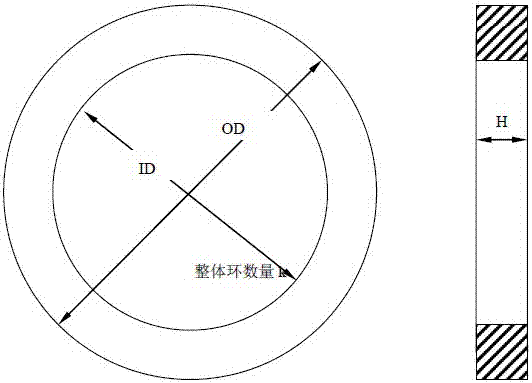

Manufacturing technology for ultra-large split ring piece

ActiveCN107414428AAvoid duplication of investmentKeep Metal Fiber StreamlinedManufacturing technologySplit ring

The invention discloses a manufacturing technology for an ultra-large split ring piece. The manufacturing technology comprises the steps that the number, size and allowance design of a whole ring piece and the manufacturing technology of the whole ring piece are determined according to the subsection number, cross section characteristics and detection requirements of the ultra-large split ring piece, lifting technology excess materials and other elements, the whole ring piece is cut according to the designed number of split ring sections and then subjected to shaping machining through a special tool, the shaped ultra-large ring sections are marked out according to the finally designed ring section shape and size and then subjected to cutting machining, and finally, the cut ring sections are machined according to the size and shape of a final product. In this way, through the manufacturing technology for the ultra-large split ring piece, the split ring piece with the any split ring section number and the ultra-large diameter can be manufactured, the allowance design and production efficiency are better than those of a traditional free forging technology, limitation to the equipment is small, and the manufacturing technology has the advantages of being obvious low in cost, high in efficiency and capable of being easily applied and popularized to existing common ring rolling equipment, and is suitable for production of various ultra-large split ring piece products.

Owner:AVIC EXCELLENCE FORGING WUXI

Operation method for preventing sintering machine from generating large blocks due to stopping

The invention provides an operation method for preventing a sintering machine from generating large blocks due to stopping. The method comprises the following steps that 1), the fuel ratio before stopping the sintering machine is controlled; 2), the conveying quantity before stopping the sintering machine is controlled; 3), the distribution before stopping the sintering machine is controlled; and4), technical pumping stopping and air volume control are performed. By the adoption of the method, when the sintering machine is stopped, the situation that sintering ore forms large blocks due to pumping stopping and subsequent equipment accidents such as hopper blockage are caused can be avoided, so that the stability and continuity of sintering production are improved, and the transportation cost of sintering production is reduced.

Owner:ANYANG IRON & STEEL

Preparation method for X-type titanium alloy three-dimensional lattice sandwich structure

ActiveCN102990299BImprove performanceImprove interlayer bonding performanceNon-electric welding apparatusUltimate tensile strengthTitanium alloy

The invention belongs to the titanium alloy structure forming technology and relates to a method for preparing an X-type titanium alloy three-dimensional lattice sandwich structure by superplastic forming / diffusion connection. An X-type titanium alloy three-dimensional lattice sandwich member is prepared by adopting the superplastic forming method; and the X-type titanium alloy three-dimensional lattice sandwich structure is prepared by adopting the superplastic forming / diffusion connection process for the first time, so that on one hand, formed parts, especially the X-type titanium alloy three-dimensional lattice sandwich structures with complex shapes can be accurately controlled in shape, and the technical difficult problem of low possibility of formation of an X-type titanium alloy three-dimensional lattice sandwich is solved at the same time. The structure prepared by adopting the superplastic forming / diffusion connection process is higher in bonding strength as the three-dimensional lattice sandwich is connected with upper and lower panels through the diffusion connection method.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

A medium-strength and high-conductivity electrical aluminum wire material and its preparation method

ActiveCN103556016BHigh strengthImprove performanceMetal/alloy conductorsHigh densityEconomic benefits

Owner:SHENYANG POLYTECHNIC UNIV

High-strength wear-resistant complex brass for automotive synchronizing ring

The invention discloses a high-strength wear-resistant complex brass for an automotive synchronizing ring, which comprises the following components in percentage by weight: 54-56% of Cu, 3.0-4.5% of Al, 0.5-1.0% of Fe, 6.0-7.5% of Ni, 2.0-2.5% of Si, and the balance of Zn and less than 0.05% of impurities. The complex brass also has good plasticity and toughness under the conditions of high strength, high hardness and high wear resistance.

Owner:苏州撼力合金股份有限公司

Low-heat-expansion high-intensity alumina-silicon-aluminum (AlN-Si-Al) mixed composite material and preparation method thereof

The invention relates to a low-heat-expansion high-intensity alumina-silicon-aluminum (AlN-Si-Al) mixed composite material and a preparation method thereof. The AlN-Si-Al mixed composite material comprises 10wt% to 25wt% of AlN, 40 wt% to 45 wt% of Si and 30 wt% to 50 wt% of Al, wherein the AlN and the Si are used as reinforcing materials and distributed in a continuous aluminum substrate in the form of particles in a dispersive mode, so that a reinforced aluminium base composite material mixed with AlN particles and Si particles is formed. The AlN-Si-Al mixed composite material is prepared by adoption of a powder metallurgy preparation process. The low-heat-expansion high-intensity AlN-Si-Al mixed composite material has low heat expansion and high intensity. The composite material is uniform in microstructure, completely compact and of a good machining process performance. The AlN-Si-Al mixed composite material is expected to be a substitute material of a high-silicon-content Si / Al packaging material and a substitute material of high-silicon-carbide (SiC)-content SiC / Al packaging material.

Owner:有研金属复材技术有限公司

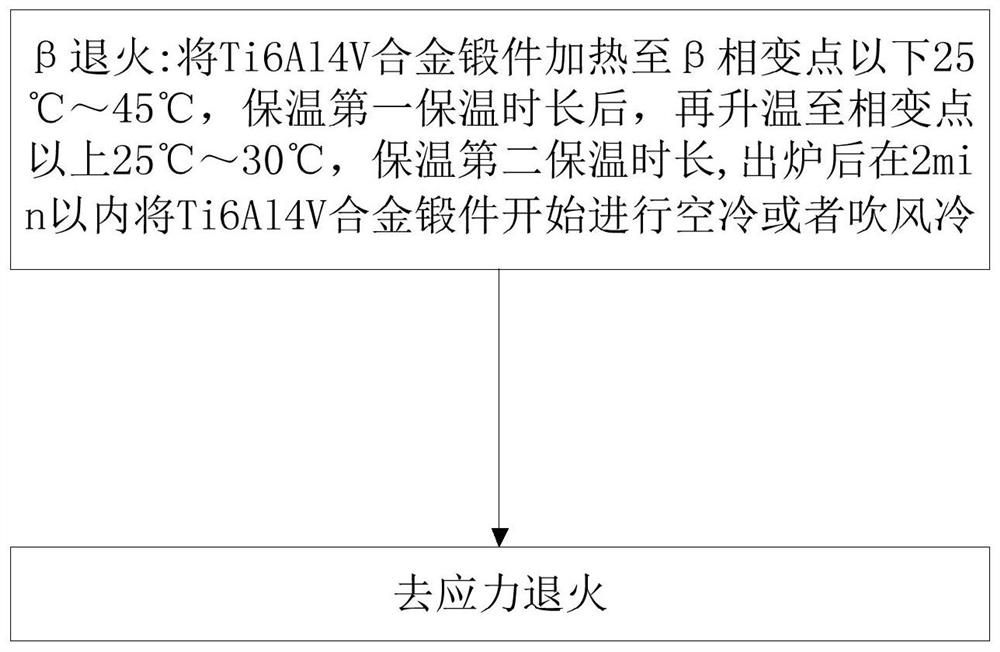

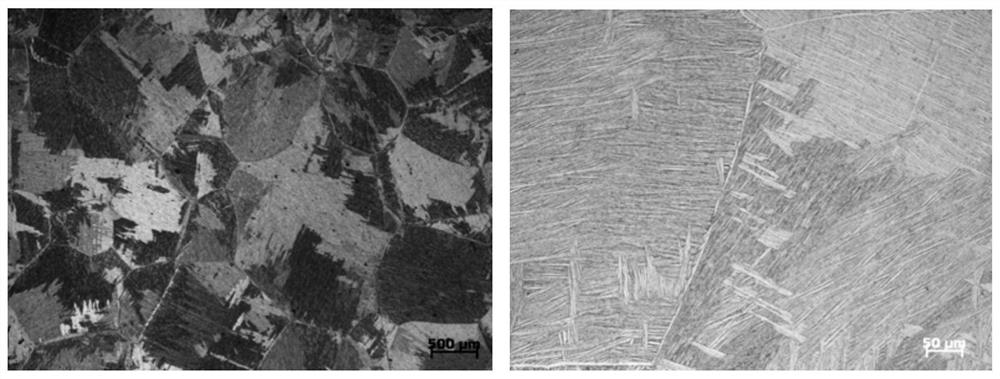

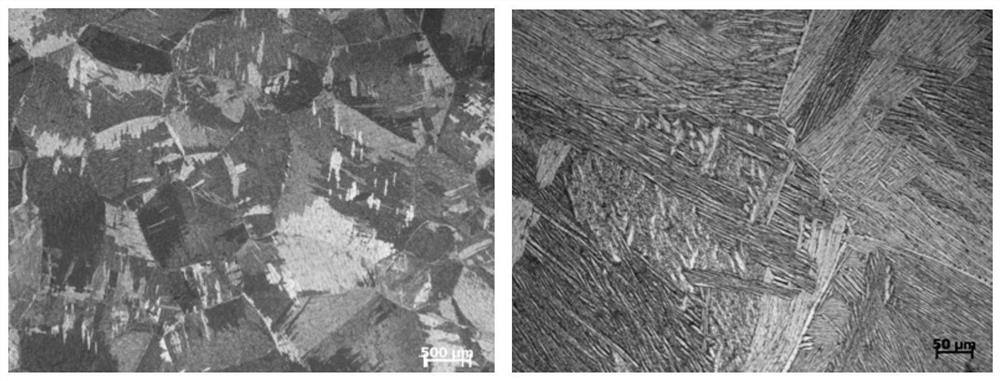

Beta annealing heat treatment method for Ti6Al4V alloy forge piece

The invention provides a beta annealing heat treatment method for a Ti6Al4V alloy forge piece. The beta annealing heat treatment method comprises the following steps of 1, beta annealing, specifically, heating the Ti6Al4V alloy forge piece to 25-45 DEG C below a beta phase transformation point, keeping the temperature for a first heat preservation duration, heating to 25-30 DEG C above the phase transformation point, keeping the temperature for a second heat preservation duration, and starting air cooling or air cooling on the Ti6Al4V alloy forge piece within 2 minutes after furnace discharging; and 2, stress relief annealing. By means of the beta annealing heat treatment method for the Ti6Al4V alloy forge piece, the high strength, plasticity and fracture toughness and the low fatigue crack propagation rate which meet the specification requirements can be obtained, the process is simple and stable, operation is convenient, and the beta annealing heat treatment method is suitable for industrial production.

Owner:SHAANXI HONGYUAN AVIATION FORGING

Fusion deposition forming manufacturing method of parts and molds

ActiveCN105945281BImprove forming efficiencyImprove manufacturing precisionAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgyElectroslag welding

The invention discloses a manufacturing method for fusion deposition forming of parts and moulds, and belongs to the field of moldless growth manufacturing and remanufacturing. It includes the following steps: S1 performs layered slicing processing on the 3D CAD model of the workpiece to be formed, S2 obtains the NC codes of each layered slice, S3 performs fusion deposition and forming layer by layer according to the NC codes of each layered slice, and uses the laser to form the workpiece Fine parts, using one or more processes of arc, electron beam, electroslag welding and submerged arc welding to form thick-walled and non-fine parts of the workpiece, or S3 using a heat source or laser beam combined with a laser beam and a gas-shielded arc Combined heat source forming with vacuum shielded electron beam, shut down the gas shielded arc or shut down the vacuum shielded electron beam in the thin wall and delicate parts of the formed workpiece. The method of the invention can directly form the parts and molds with thin walls or fine parts with stable structure and performance and high manufacturing precision.

Owner:HUAZHONG UNIV OF SCI & TECH

High-strength wear-resistant complex brass for automotive synchronizing ring

The invention discloses a high-strength wear-resistant complex brass for an automotive synchronizing ring, which comprises the following components in percentage by weight: 54-56% of Cu, 3.0-4.5% of Al, 0.5-1.0% of Fe, 6.0-7.5% of Ni, 2.0-2.5% of Si, and the balance of Zn and less than 0.05% of impurities. The complex brass also has good plasticity and toughness under the conditions of high strength, high hardness and high wear resistance.

Owner:苏州撼力合金股份有限公司

A kind of manufacturing method of double-layer composite seamless pipe of the same steel type

ActiveCN108746243BGuaranteed dimensional accuracyGuaranteed stabilityMachining deformationDouble-walled pipe

The invention discloses a manufacturing method of same-steel double-layer composite seamless pipe. The manufacturing method comprises the following steps: (1) peeling and cutting round steel; (2) punching the round steel by using a thermal puncher, thus obtaining capillary pipes; (3) carrying out acid pickling on the capillary pipes; (4) carrying out cold rolling on the capillary pipes, then carrying out thermal treatment, and repeating the step until reaching specifications before an inner pipe is combined with an outer pipe; (5) sleeving the outer pipe obtained in step (4) outside the innerpipe, carrying out compounding and cold drawing, and then carrying out bright heat treatment; (6) straightening an obtained pipe; (7) carrying out finished product straight pipe physicochemical detection and surface examination on the obtained steel pipe, and packaging and storing qualified products in a warehouse after cutting the qualified products in fixed length and identifying the qualified products. According to the manufacturing method disclosed by the invention, by stipulating the final cold machining deformation, the thermal treatment mode, the thermal treatment system and the composite deformation technology of a mother pipe before combining, a double-layer pipe which is high in size accuracy, good in surface quality, stable in structure property and strong in practicability canbe produced, the problems of larger pipe seam clearance and poorer pulling resistance of a double-layer composite pipe are solved, and the limit of a machining mode of the double-layer composite pipeis also broken through.

Owner:JIANGSU YINHUAN PRECISION STEEL TUBE CO LTD

Preparation method of titanium alloy three-dimensional lattice sandwich structure

ActiveCN102990300BImprove performanceImprove interlayer bonding performanceNon-electric welding apparatusUltimate tensile strengthTitanium alloy

The invention belongs to a titanium alloy structure forming technology, and in particular relates to a preparation method of a titanium alloy three-dimensional lattice sandwich structure. According to the invention, a titanium alloy three-dimensional lattice sandwich member is prepared by adopting a superplastic forming method, and the method of preparing the titanium alloy three-dimensional lattice sandwich structure by adopting a superplastic forming / diffusion connection process is proposed for the first time, therefore on one hand, the shape of a formed part, in particular to the titanium alloy three-dimensional lattice structure with a complex shape, can be accurately controlled, and on the other hand, the technical problem that a titanium alloy three-dimensional lattice sandwich layer is difficult to form is solved. The structure which is prepared by superplastic forming / diffusion connection has higher bonding strength because the three-dimensional lattice sandwich layer and upper and lower panels are bonded together by a diffusion connection method.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com