Preparation method of titanium alloy three-dimensional lattice sandwich structure

A technology of three-dimensional lattice and sandwich structure, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of high surface roughness, high cost, and poor design of the upper and lower panels, and achieve good interlayer bonding and high bonding Strength, performance and the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] The preparation process scheme of the three-dimensional lattice structure of TC4 titanium alloy is as follows:

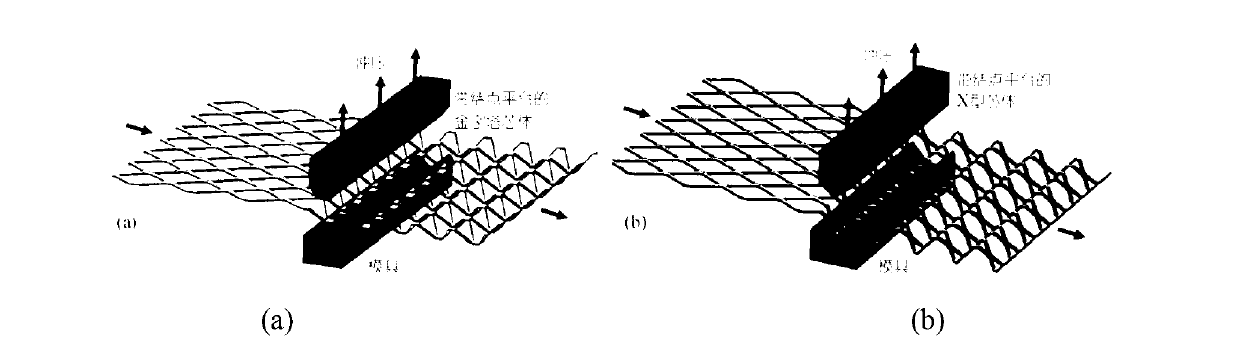

[0044] (1) Process the hollowed-out grid structure of the core plate. The TC4 titanium alloy plate is processed into a hollowed-out grid structure by high-pressure water cutting or CNC machining, and the thickness of the core plate is 0.8mm;

[0045] (2) Process the panel. The TC4 titanium alloy plate is processed into a flat plate suitable for the shape and size of the core plate by high-pressure water cutting or numerical control machining. The thickness of the panel is 2.0mm;

[0046] (3) Surface chemical cleaning to remove the oxide layer on the surface of the core board and the panel. The surface cleaning solution used is a mixed solution of nitric acid, hydrofluoric acid and water, and the volume ratio is: 10%:5%:85%;

[0047] (4) Solder stop flux coating, apply solder stop flux on the hollow grids on the two surfaces of the core board, the principle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com