Patents

Literature

103results about How to "Precise shape control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of metal nanostructure

InactiveCN103668130AAvoid influencePrecise shape controlLiquid/solution decomposition chemical coatingUltraviolet lightsNanostructure

The invention discloses a preparation method of a metal nanostructure. The preparation method comprises the steps of (1) manufacturing a mask plate; (2) providing a clean and dry base plate, uniformly coating a positive ultraviolet photoresist on the base plate, and pre-baking to ensure that the positive ultraviolet photoresist is solidified to form a photoresist base plate; (3) overlapping the mask plate on the photoresist base plate, and performing exposure, development, residual adhesive removal and hardening under ultraviolet light to obtain a forming mold with shape grooves of a nanostructure graph; (4) depositing a metal in the forming mold by adopting a chemical synthetic method; (5) soaking the forming mold deposited with the metal in an acetone solution, and performing ultrasonic adhesive removal to obtain the metal nanostructure of the nanostructure graph. The preparation method disclosed by the invention is simple in process and high in efficiency; the shape, size and position of the prepared metal nanostructure can be accurately controlled, and the light extraction efficiency and light absorption efficiency of a metal nanostructure material are effectively improved.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

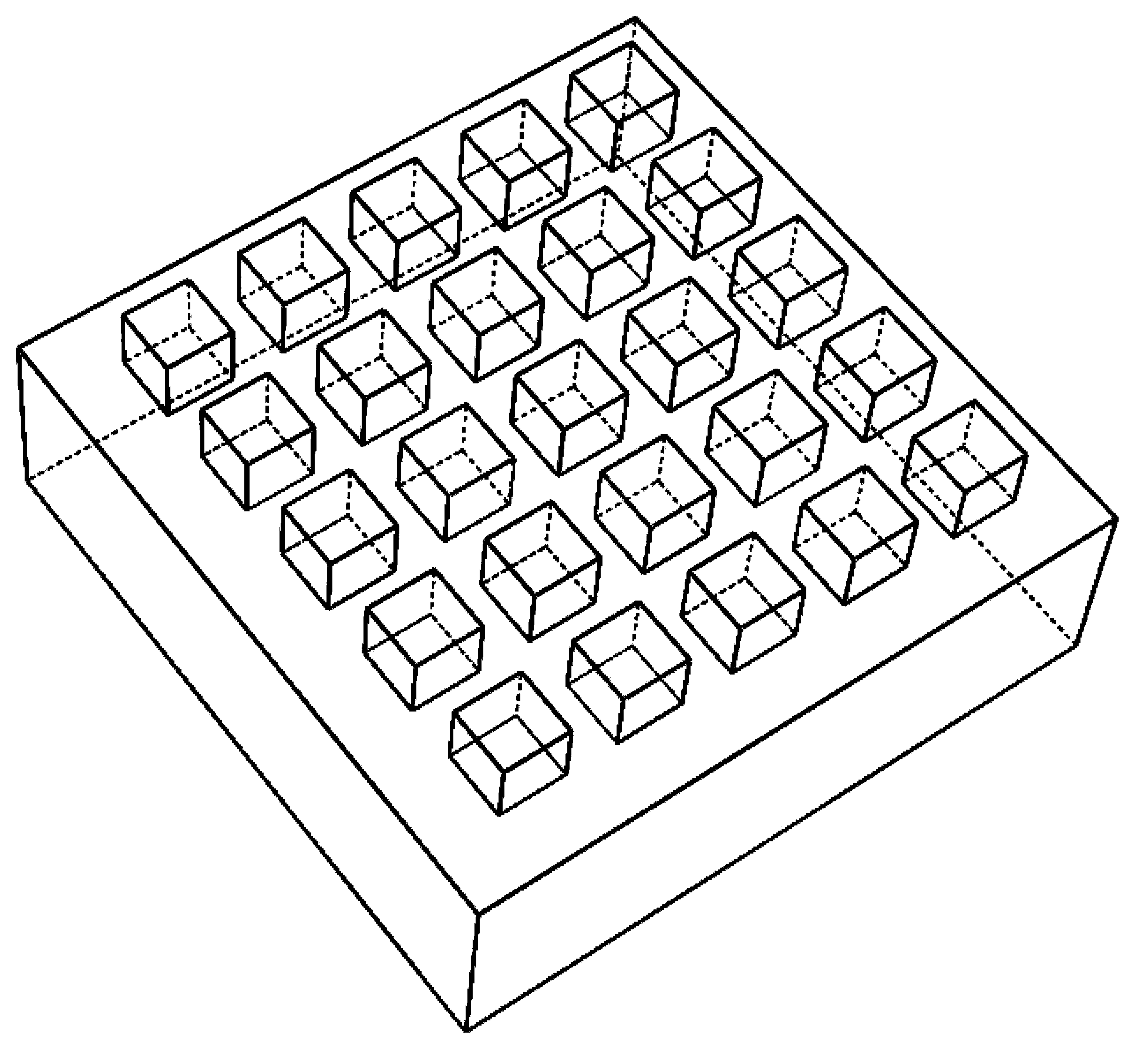

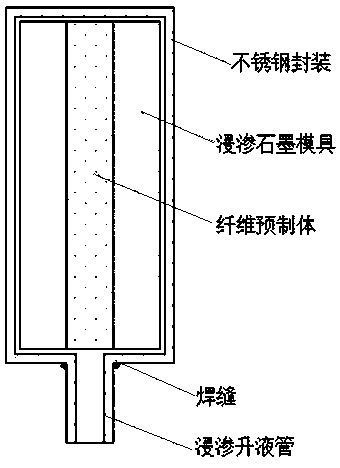

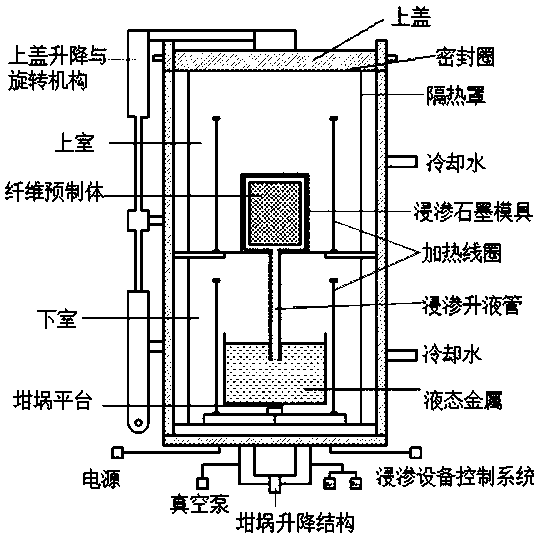

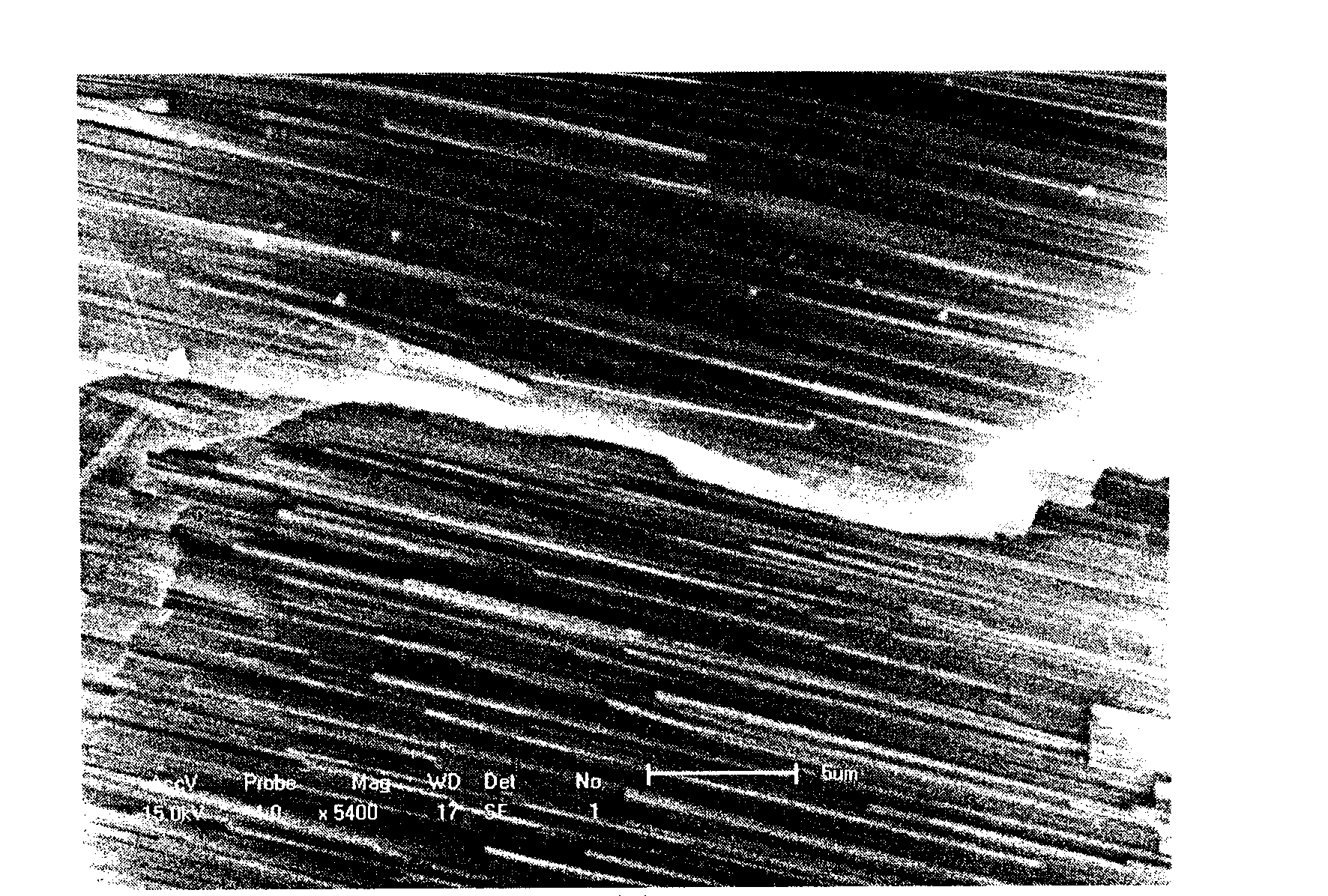

Near-net forming method of 3D braided fiber reinforced metal-based composite material

The invention discloses a near-net forming method of the 3D braided fiber reinforced metal-based composite material, and belongs to the technical field of advanced composite materials. The method is characterized in that a vacuum air pressure infiltration preparation technology based on a liquid binder is adopted to assist in accurately controlling the shape and the size of a 3D braided fiber preform structure; in the 3D weaving process of the fiber preform, a liquid binder is adopted to accurately fix and shape the 3D braided fiber preform, then the size precision of the 3D braided fiber reinforced metal-based composite material is accurately controlled through the impregnated graphite mold of the embedded fiber preform, and deformation and local fiber polarization of the 3D braided fiberpreform in the infiltration process are prevented. The prepared 3D braided fiber reinforced metal-based composite material has high dimensional accuracy and excellent mechanical properties, the near-net forming of the 3D braided fiber reinforced metal-based composite material is realized, batch industrial production can be realized, the near-net forming method has a wide application prospect in the fields of aerospace, national defense, military and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

Lithium battery and electrode for same, and preparation method of solid electrolyte film

ActiveCN103268930ASimple equipmentReduce manufacturing costFinal product manufactureCell electrodesLaser printingCurrent collector

The invention relates to a lithium battery and an electrode for the same, and a preparation method of a solid electrolyte film, and belongs to the technical field of materials, and solves the problems of the film electrode prepared by the traditional method that the requirement on equipment is high, the process is complicated, the energy consumption is high and the pollution of organic solvent exists. A computer laser printing technology is used for preparing the electrode, the solid electrolyte film, the lithium battery and a full-solid lithium battery on a printing substrate or a current collector through electrode active substances and solid electrolyte materials. The method not only can conveniently and precisely control the shape, the size and the thickness of the electrode and the battery and can be environment-friendly and simple in equipment, but also can realize the mass production, can greatly reduce the production cost of the battery and can reduce the environmental pollution of the organic solvent.

Owner:HARBIN INST OF TECH

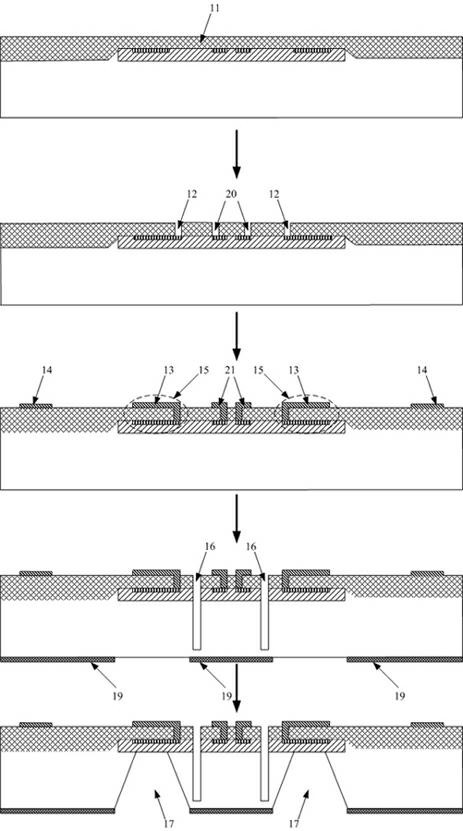

Heat-type wind-speed and wind-direction sensor with heat insulation structure and preparation method thereof

InactiveCN102095888AEnsure consistencyImprove consistencySemiconductor/solid-state device detailsSolid-state devicesBonding processHeat capacity

The invention discloses a heat-type wind-speed and wind-direction sensor with a heat insulation structure, comprising a silicon chip and a ceramic substrate, wherein the silicon chip is positioned above the ceramic substrate; four heating elements and four heat-sensing temperature-measuring elements are symmetrically distributed on the four edges of the upper surface of the silicon chip; a heat insulating groove is arranged between each heating element and each heat-sensing temperature-measuring element; heat insulating cavities are arranged below the heat-sensing temperature-measuring elements at the back of the silicon chip; and a ceramic gold-plating layer and a silicon gold-plating layer are arranged between the silicon chip and the ceramic substrate and are connected by adopting a gold-gold bonding process so as to be used for the heat connection between the silicon chip and the ceramic substrate. In the whole preparation process of the sensor, a standard CMOS (complementary metal-oxide-semiconductor) process is used, the after-treatment process is simple, and the prepared heat-insulating groove and the heat insulating cavities can be used for increasing the sensitivity of the chip effectively, reducing the heat conduction loss of the chip and the heat capacity of the sensor, and reducing the response time of the sensor.

Owner:SOUTHEAST UNIV

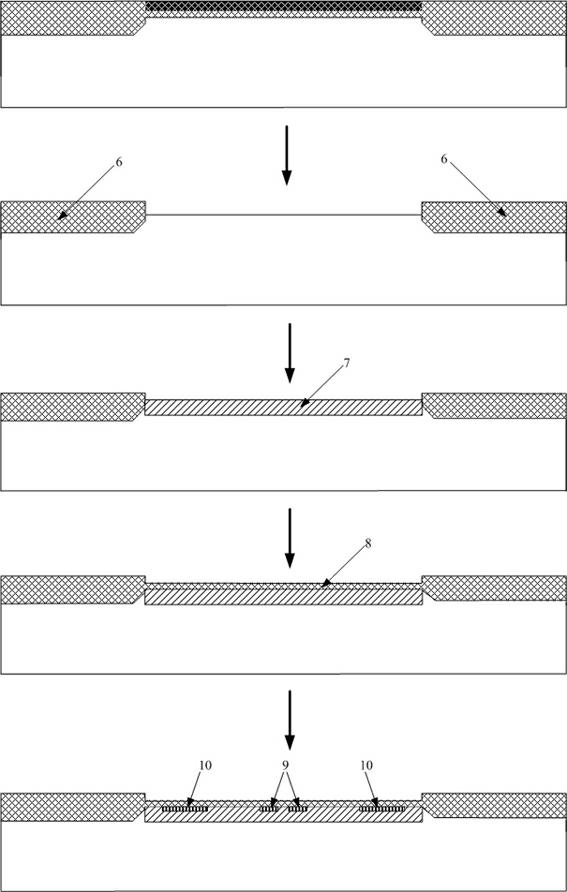

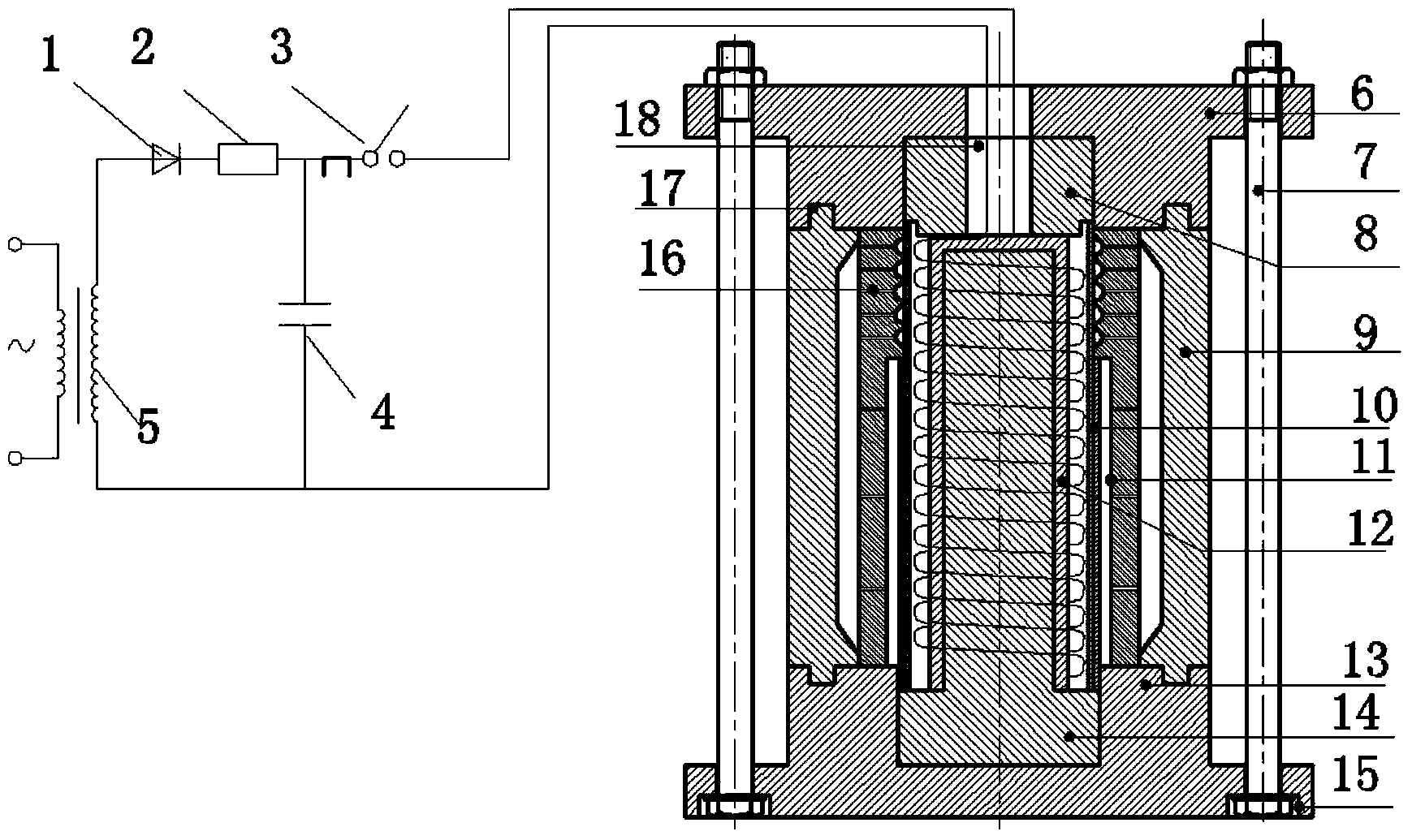

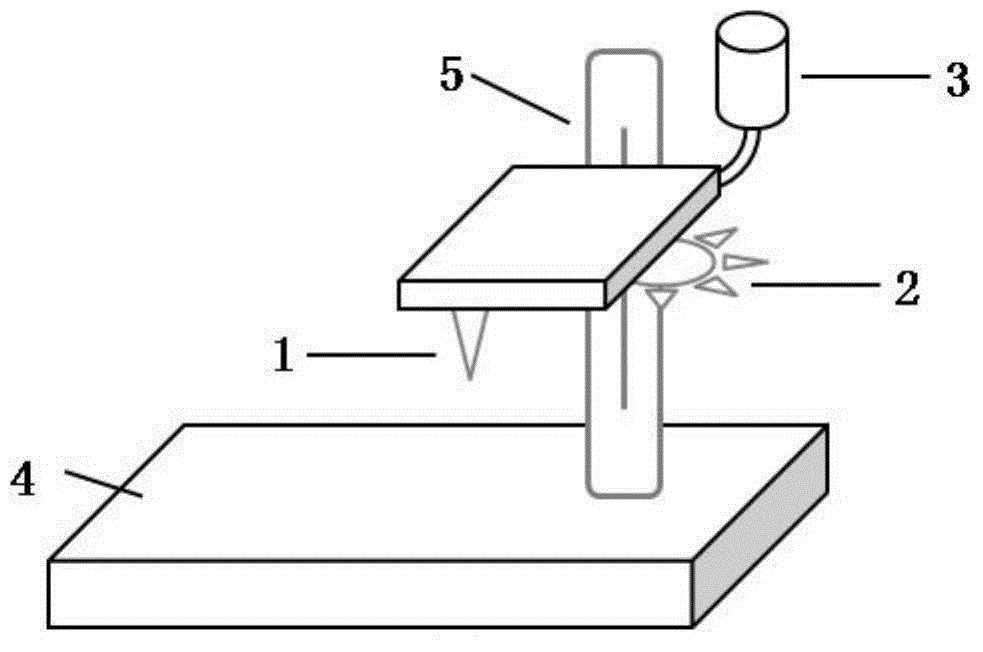

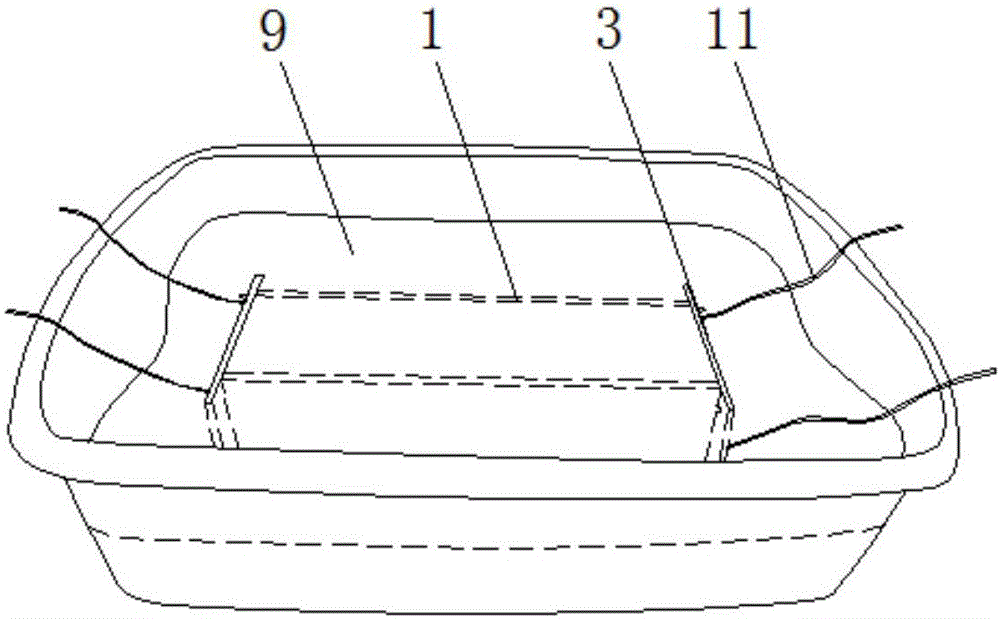

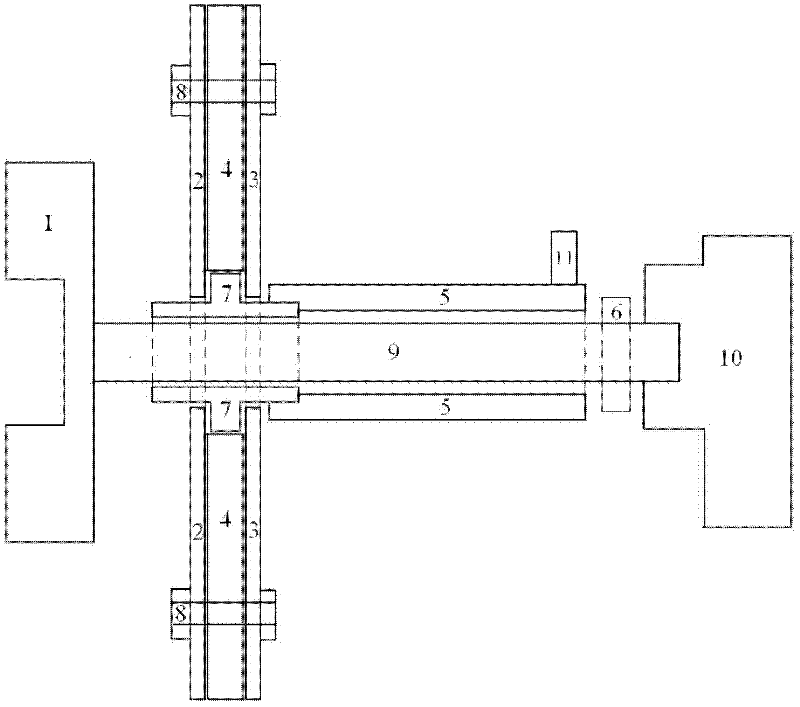

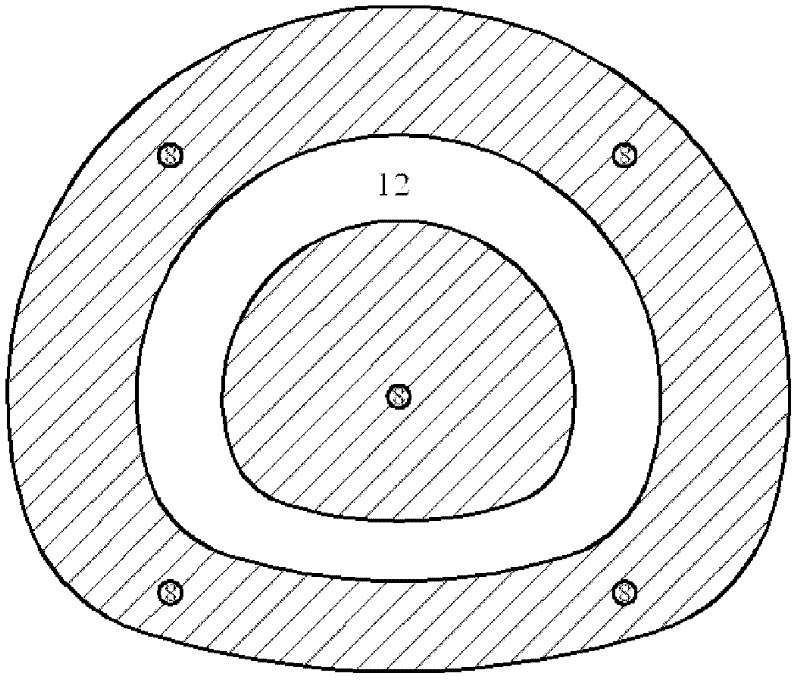

Device and method for machining composite energy absorption tube

The invention discloses a composite energy absorption tube machining device which comprises a rectifier (1), a resistor (2), a switch (3), a capacitor (4), a boosting transformer (5), an upper fixing plate (6), a fixing bolt (7), a pressing block (8), a mould frame (9), a constraint mould (11), a coil (12), a lower fixing plate (13), a T-shaped platform (14), an exhaust vent (16), a fixing groove (17) and a wire hole (18). Compared with a hydraulic forming method and a mechanical bulging method, a composite metal energy absorption forming method based on the electromagnetic forming principle and used in the composite energy absorption tube machining device is high in machining efficiency and high in the pipe fitting forming speed and enables composite metal tubes to be formed under the high strain rate; due to the fact that the high strain deformation process can be used for forming metal materials which are deformed difficultly through a conventional method, the plasticity of the metal materials is greatly improved, and the yield strength of the materials is greatly improved. Different wave forms and reinforcing ribs can be formed by changing the shape of the constraint mould in a mould body, and the machining flexibility is high.

Owner:HUNAN UNIV

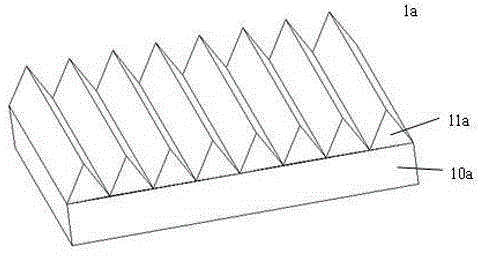

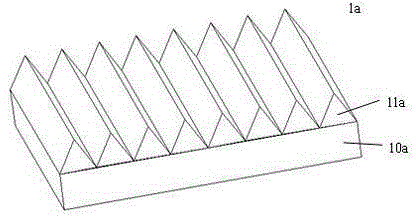

3D printing-based prism film preparation method and device thereof

The invention relates to a 3D printing-based prism film preparation method which comprises the following steps: 1, a three-dimensional digital model of a prism film is established and converted to work instructions of 3D printing equipment, and the work instructions contain a first instruction for printing a substrate layer and a second instruction for printing a prism layer; 2, a first raw material for printing the substrate layer is put into a charging cavity and converted to a liquid state; and the 3D printing equipment sprays the first liquid raw material onto a molding area according to the first instruction, the sprayed first raw material is solidified quickly, a print head reciprocates translationally to print and an entity of the substrate layer is formed by piling up the first raw material layer upon layer; and 3, the second raw material for printing the prism layer is put into the charging cavity and converted to a liquid state; and the 3D printing equipment sprays the second liquid raw material onto the molding area according to the second instruction, the sprayed second raw material is solidified quickly to form a single prism column, and the print head continues to print according to a certain regulations so as to form an entity of the prism layer. By the method and the device, the preparation technology of the prism film can be simplified, and production efficiency can be enhanced.

Owner:FUZHOU UNIV

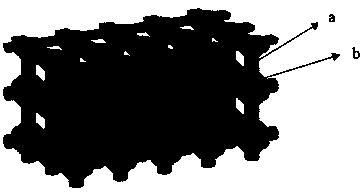

Three-dimensional shell ceramic skeleton-metal matrix composite and preparation method thereof

ActiveCN108396165AReduce manufacturing costLow costAdditive manufacturing apparatusAdditive manufacturing processesSpherical shapedMetal matrix composite

The invention discloses a three-dimensional shell ceramic skeleton-metal matrix composite and a preparation method thereof, and belongs to the field of metal matrix composites. According to the structure of the three-dimensional shell ceramic skeleton-metal matrix composite, the inside and outside of a three-dimensional shell ceramic skeleton is filled with a metal matrix, the whole three-dimensional shell ceramic skeleton is of a hollow shell structure, interpenetrating column pitch points are in a spherical, cylindrical or square shape, and the wall thickness of the three-dimensional shell ceramic skeleton is 0.5-3mm. According to the preparation method, the difficulty of infiltration of metal liquid and ceramic reinforcement is improved effectively, the inside and outside of the shell is wrapped with a pure matrix, and the plastic toughness of the composite is not lost while good wear resistance is achieved. The shape of the pitch points of the skeleton is in a spherical, cylindrical and square shape, the pitch points of the skeleton are distributed periodically, certain connection strength during sintering can be provided, and the synergistic effect of the skeleton structure and the matrix is brought maximally. The three-dimensional shell ceramic skeleton-metal matrix composite is expected to be used in the field of friction and abrasion working conditions.

Owner:KUNMING UNIV OF SCI & TECH

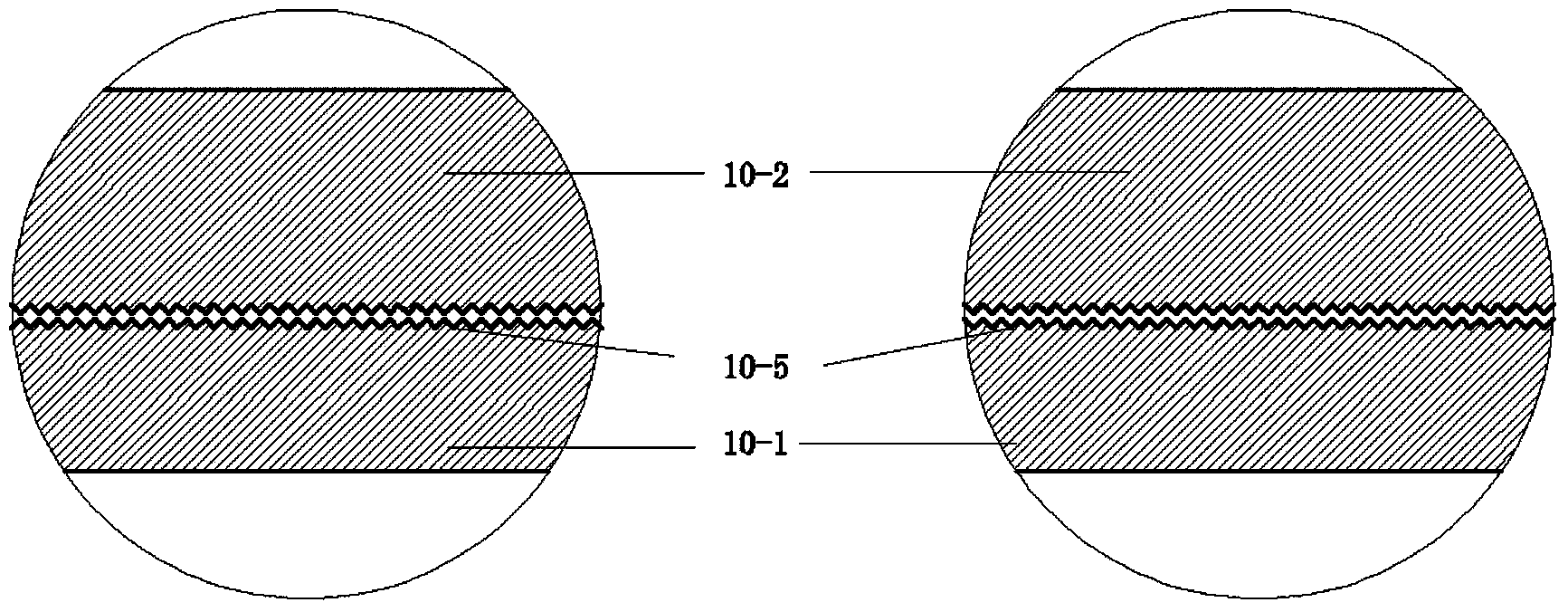

Method for preparing discharge plasma of metal laminated composite material

The invention provides a method preparing discharge plasma of a metal laminated composite material and belongs to the technical field of the preparation of metal laminated composite materials. In the method, two or more types of bulk metals, of which the surfaces are simply treated, are used as raw materials to be combined, under conditions of vacuum or inert atmosphere and reasonably matched discharge plasma preparation process parameters and under an action of inverted high-speed flow of discharge shock waves generated by impulsive discharge, electrons and ions in electric fields, the surfaces to be combined of the bulk metals are punctured to a certain degree to make the surfaces to be combined quickly purified and activated and the metallurgical combination performed between the interfaces to be combined of the laminated bulk metals to make the bulk metals quickly combined and formed at a smaller pressure and at the low temperature, so that the metal laminated composite material with flat and straight interface, high combined strength and accurately controlled shape and size of products can be directly obtained. The method has the advantages of low requirement on the surface cleanliness of the metals to be combined, energy conservation and environmental protection, easy operation, strong repeatability, short flow and cycle and low cost.

Owner:UNIV OF SCI & TECH BEIJING

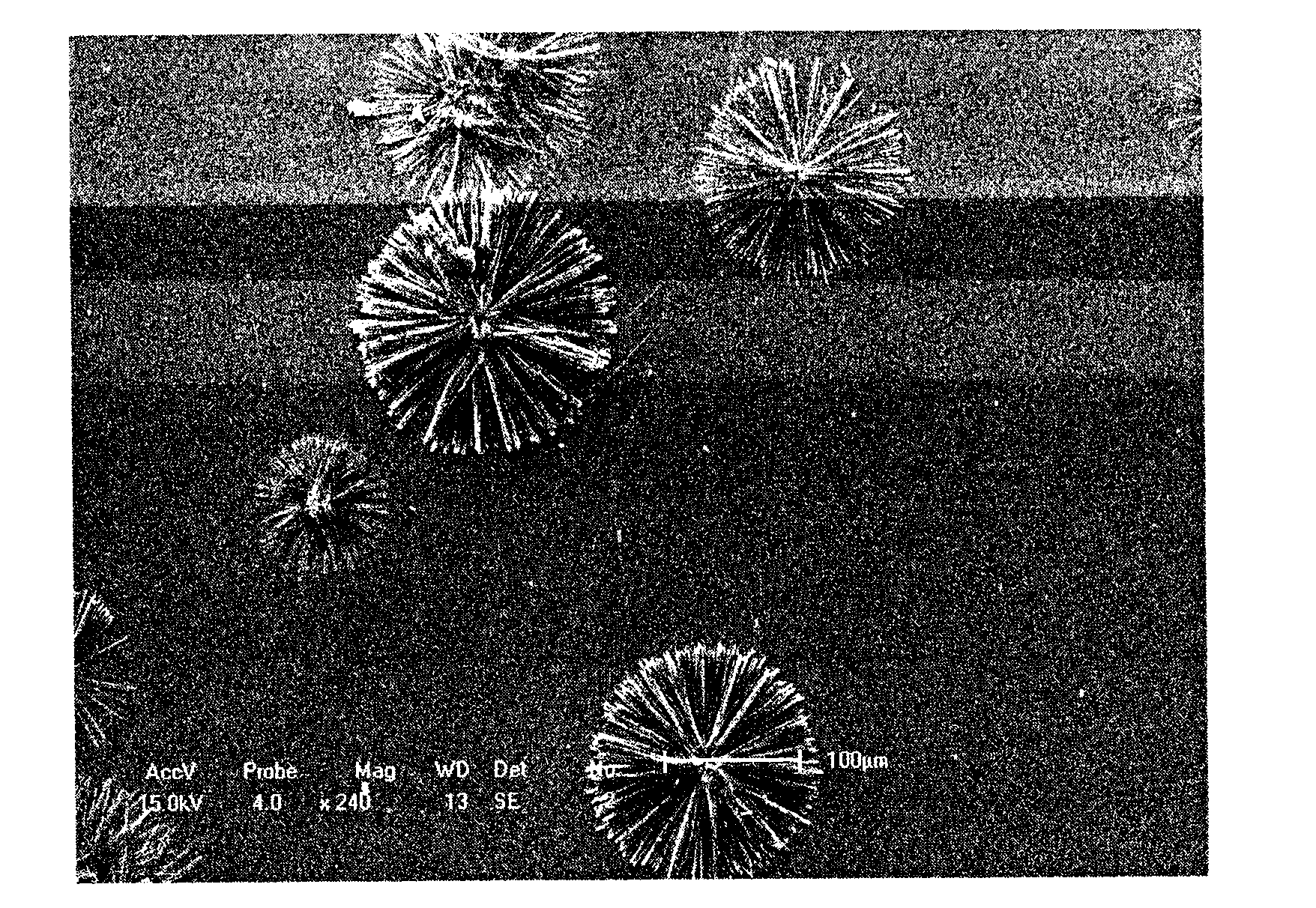

C60 nano monocrystal assembly materials in different shapes and preparation method thereof

InactiveCN101649482APrecise shape controlEasy to operatePolycrystalline material growthFrom normal temperature solutionsShape controlVertical array

The invention relates to C60 nano monocrystal assemblies in different shapes and a preparation method thereof, belonging to the technical field of preparation of monocrystal materials. The C60 nano monocrystal assembly materials are in shapes of a micron pipe, a micron rod, a nano flower cluster, a nano besom, a nano rod parallel array or micron pipe vertical array and have face-centered cubic structures. A saturated C60 methylbenzene solution is used as a mother liquor, meta-Xylene is used as a shape control agent, and different ambient temperatures and volatilization time times are adjustedso as to control the shapes of the materials. The C60 nano monocrystal assemblies in various shapes can be prepared, the shape of a product can be controlled, the method is simple to operate, and theproduct provides an effective way for the application of a nano device and has favorable application prospect.

Owner:JILIN UNIV

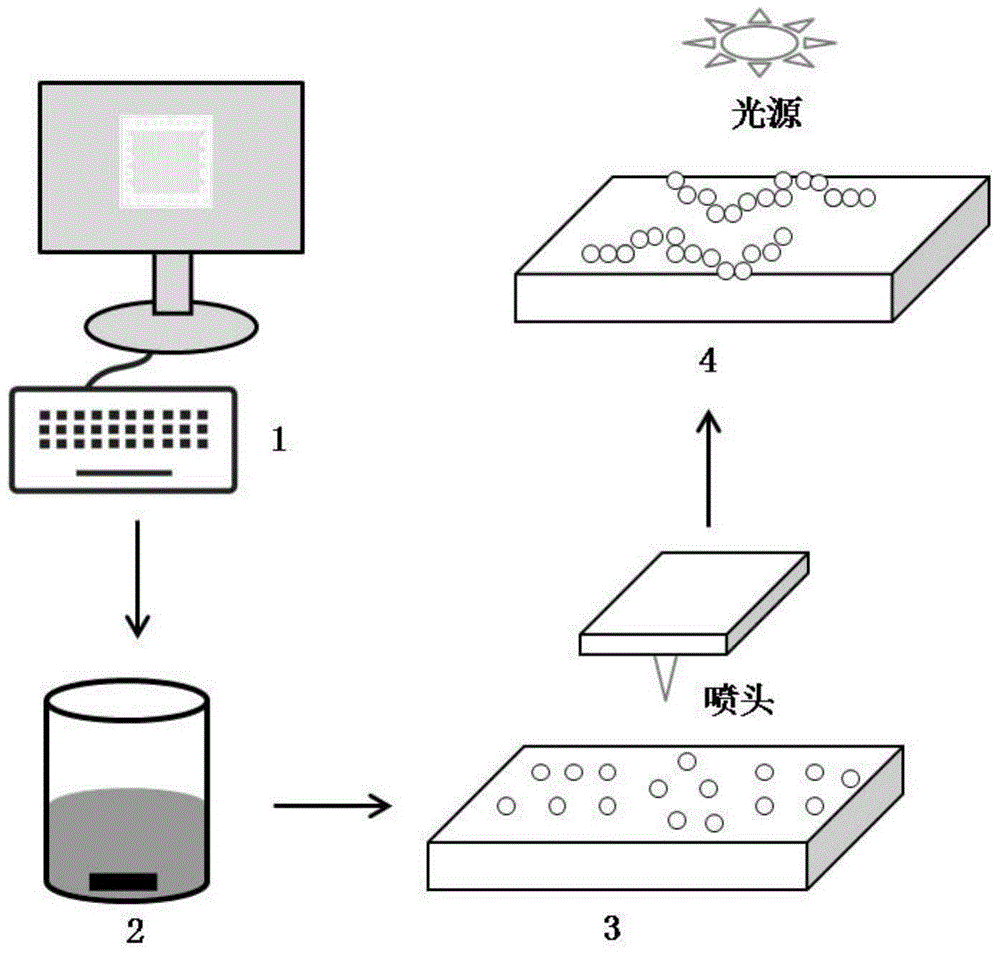

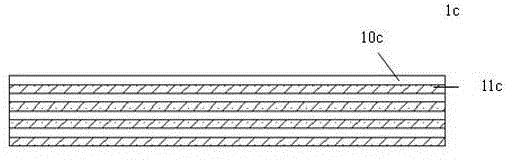

Method for preparing organic separating membrane through three-dimensional molding technology

InactiveCN105643931APrecise shape controlPrecise thickness controlAdditive manufacturing apparatusChemistryLight source

The invention relates to a method for preparing a membrane through a three-dimensional molding technology, in particular to a method for preparing an organic separating membrane through the three-dimensional molding technology. The method comprises the steps that firstly, a three-dimensional separating membrane model is prepared through three-dimensional cartographic software and then is converted into a format capable of being recognized by a 3D printer; secondly, photocuring material systems of the organic separating membrane are mixed and subjected to filtering and degassing; processed photocuring material liquid is injected to a cavity of the 3D printer, the separating membrane is printed in a spraying layer-by-layer mode, and the separating membrane is formed by combination with a light source polymerization curing reaction; and finally the separating membrane is obtained. The obtained organic separating membrane can be applied to the industries such as environmental protection, chemical engineering, separation and pharmacy. The organic separating membrane is prepared by means of the spraying type photocuring 3D printing for the first time, the preparation method and design structure are novel, the shape, thickness and surface structure of the separating membrane can be accurately controlled, the uniformity and selection separability of the separating membrane are improved, the production efficiency of the preparation process is improved, and compared with a traditional organic separating membrane, the spraying type photocuring 3D printing membrane has the characteristics of being high in curing rate and low in volume shrinkage rate.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

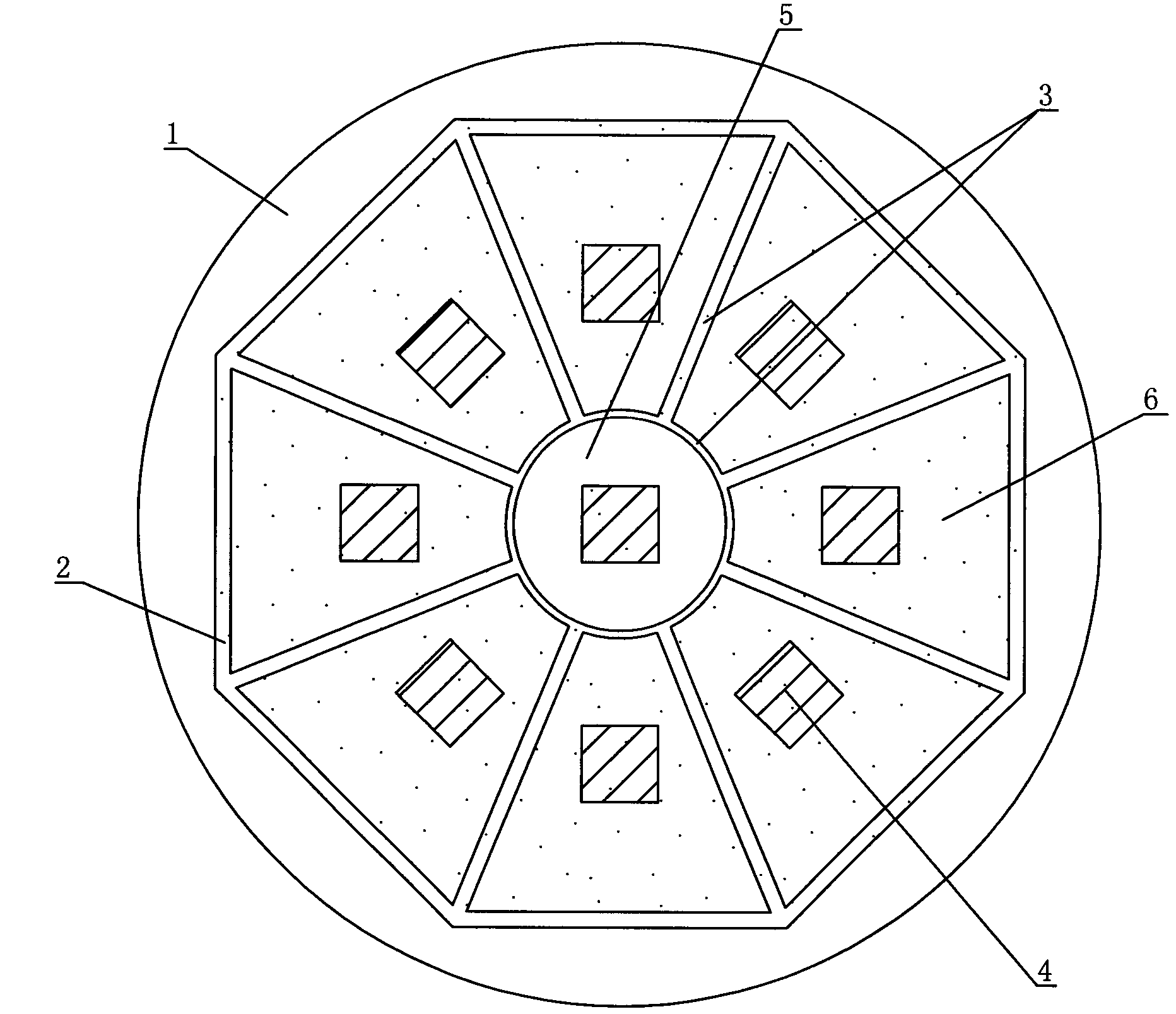

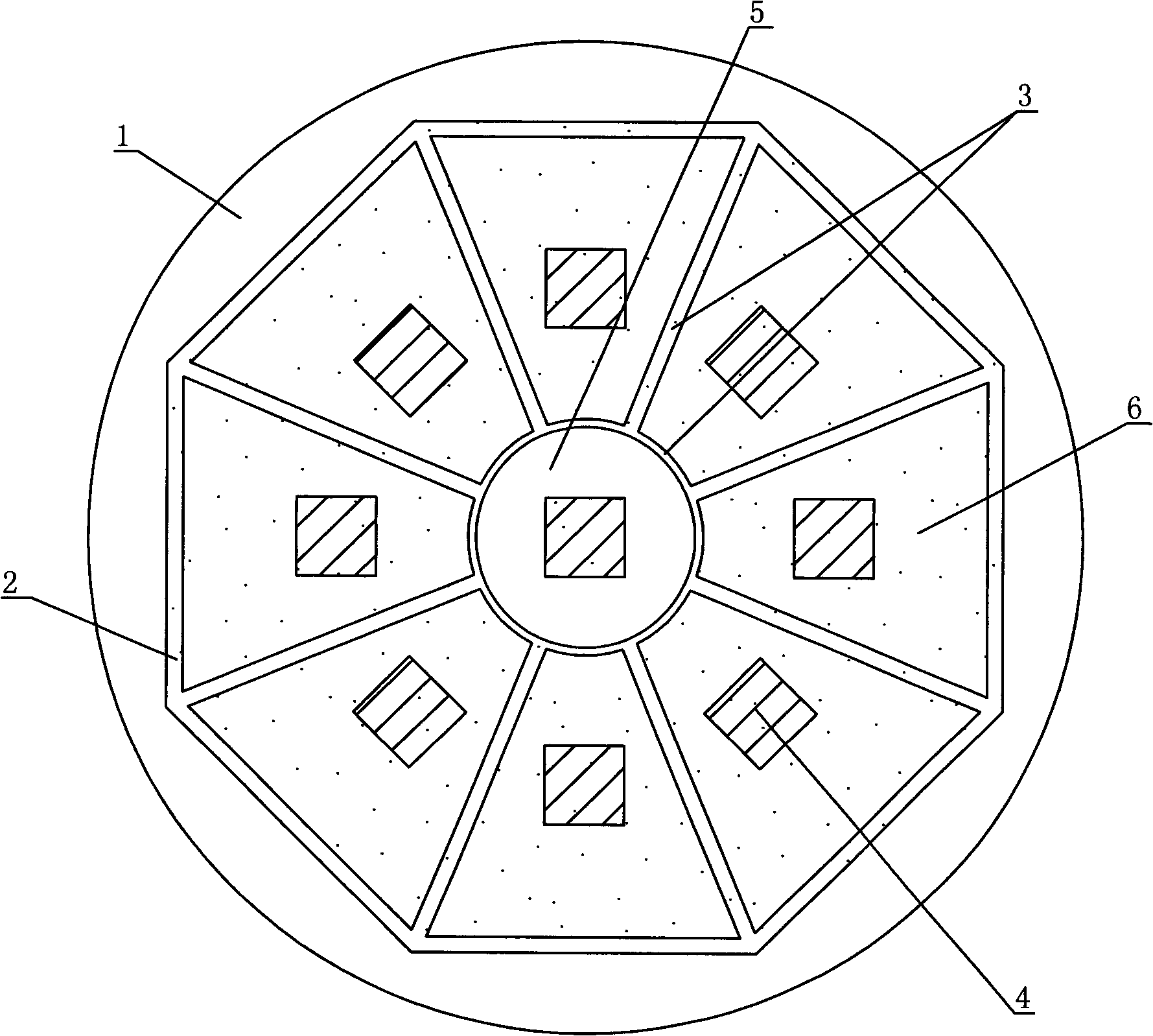

Chip scale integration packaging process and light emitting diode (LED) device

ActiveCN102097549AEfficient use ofReduce lossesSolid-state devicesSemiconductor devicesGratingPhosphor

The invention discloses a chip scale integration packaging process and a light emitting diode (LED) device. The packaging process sequentially comprises the following steps of: processing a surface plate substrate, fixing LED chips, coating phosphor glue to form box dam shapes, coating transparent glue to form grating plate shapes, curing the phosphor glue and the transparent glue to form box dams and grating plates, dispensing the phosphor glue in the box dam and drying the phosphor glue. The LED device comprises the surface plate bracket, wherein the surface plate bracket is divided into a central area and more than two peripheral areas outside the central area; the LED chips are fixed in the central and peripheral areas; the phosphor glue box dams are arranged on the surface plate bracket outside the peripheral areas; the grating plates formed by the transparent glue are arranged between the central and peripheral areas and between every two adjacent peripheral areas; and the phosphor glue is packaged in each area. The LED device molded by the packaging process has low optical energy loss, and emits light with uniform light color and high color rendering.

Owner:HONGLI ZHIHUI GRP CO LTD

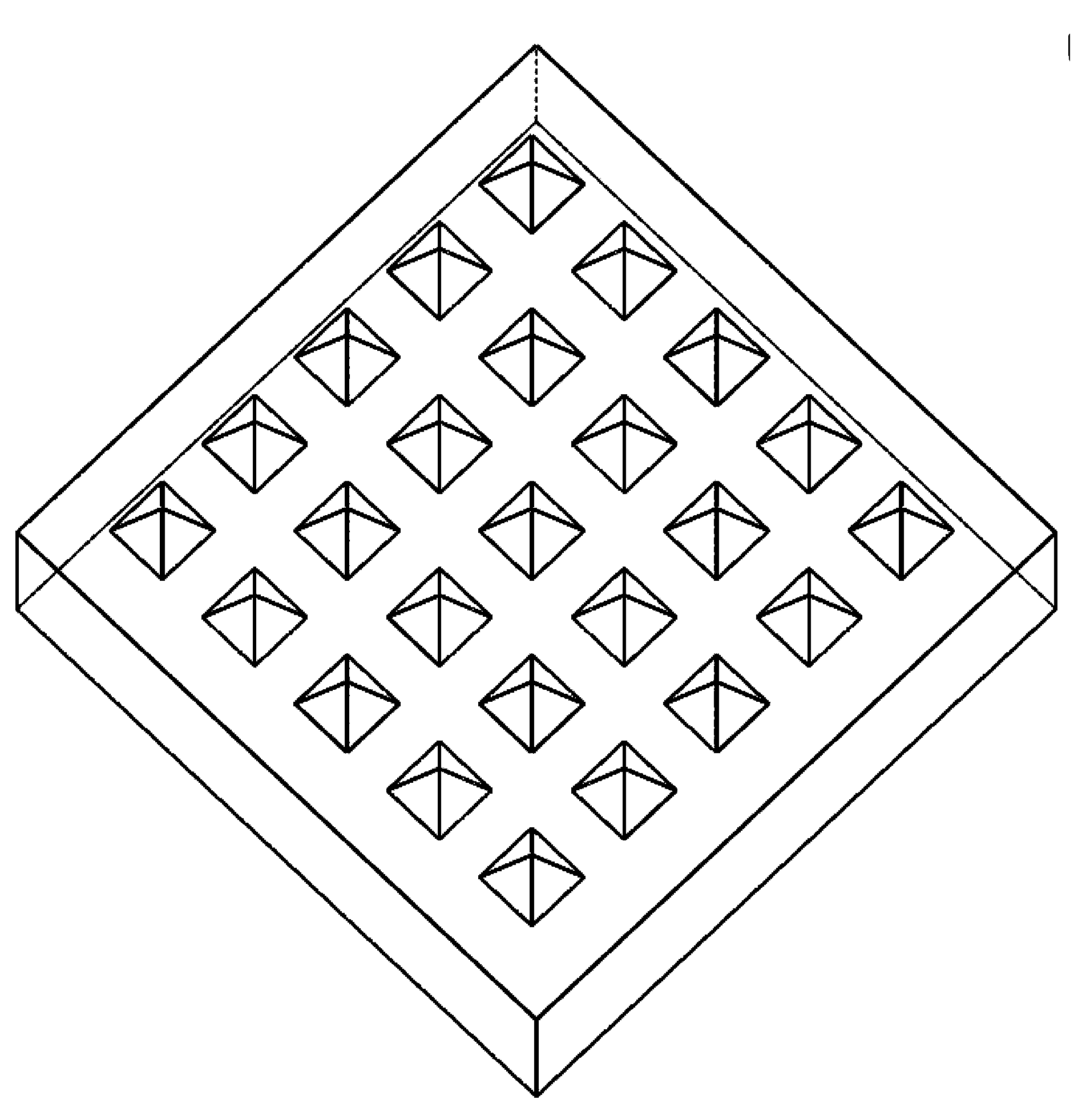

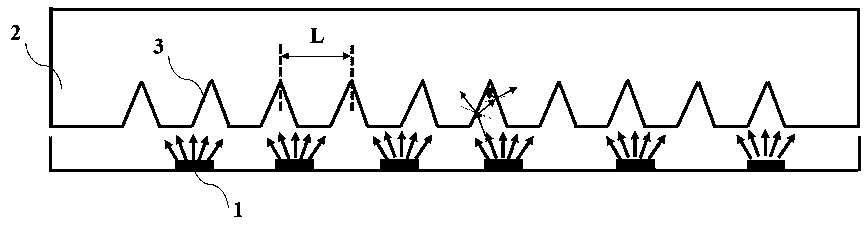

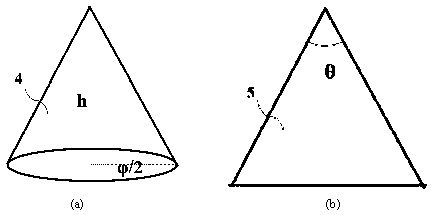

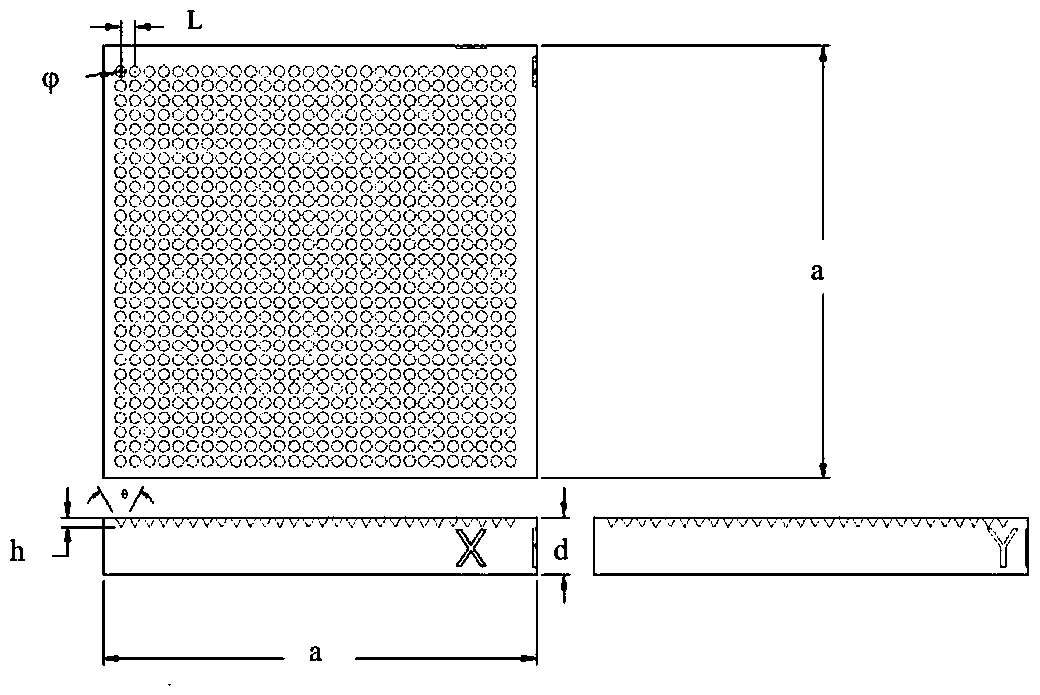

Fluorescent ceramic with surface light trap structure enhanced illumination and preparation method thereof

InactiveCN108530070AHigh light conversion efficiencyEasy to captureAdditive manufacturing apparatusLuminescent compositionsMetallurgyFluorescence

The invention provides a fluorescent ceramic with surface light trap structure enhanced illumination and a preparation method thereof. Conical micro-structured light traps are constructed on the surface of the fluorescent ceramic in order, and have parameters as follows: phi is more than or equal to 10 microns and less than or equal to 100 microns, h is more than or equal to 8.6 microns and less than or equal to 100 microns, L is more than or equal to 10 microns and less than or equal to 150 microns, and theta is more than 0 and less than or equal to 60 degrees, where phi is the diameter of the bottom surface of the cone, h is the height of the cone, L is the distance between the circle centers of the bottom surfaces of each two adjacent cones, and theta is twice of the angle between the generatrix and the height of each cone.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

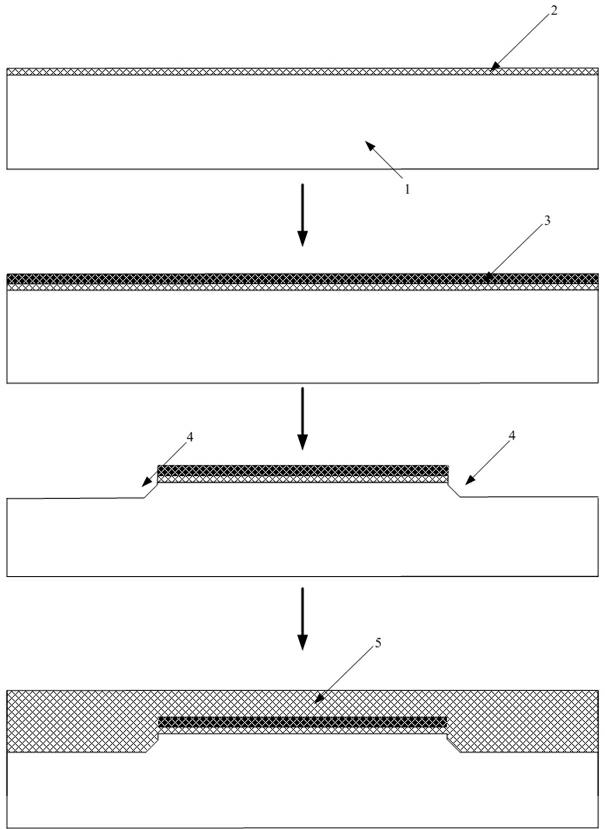

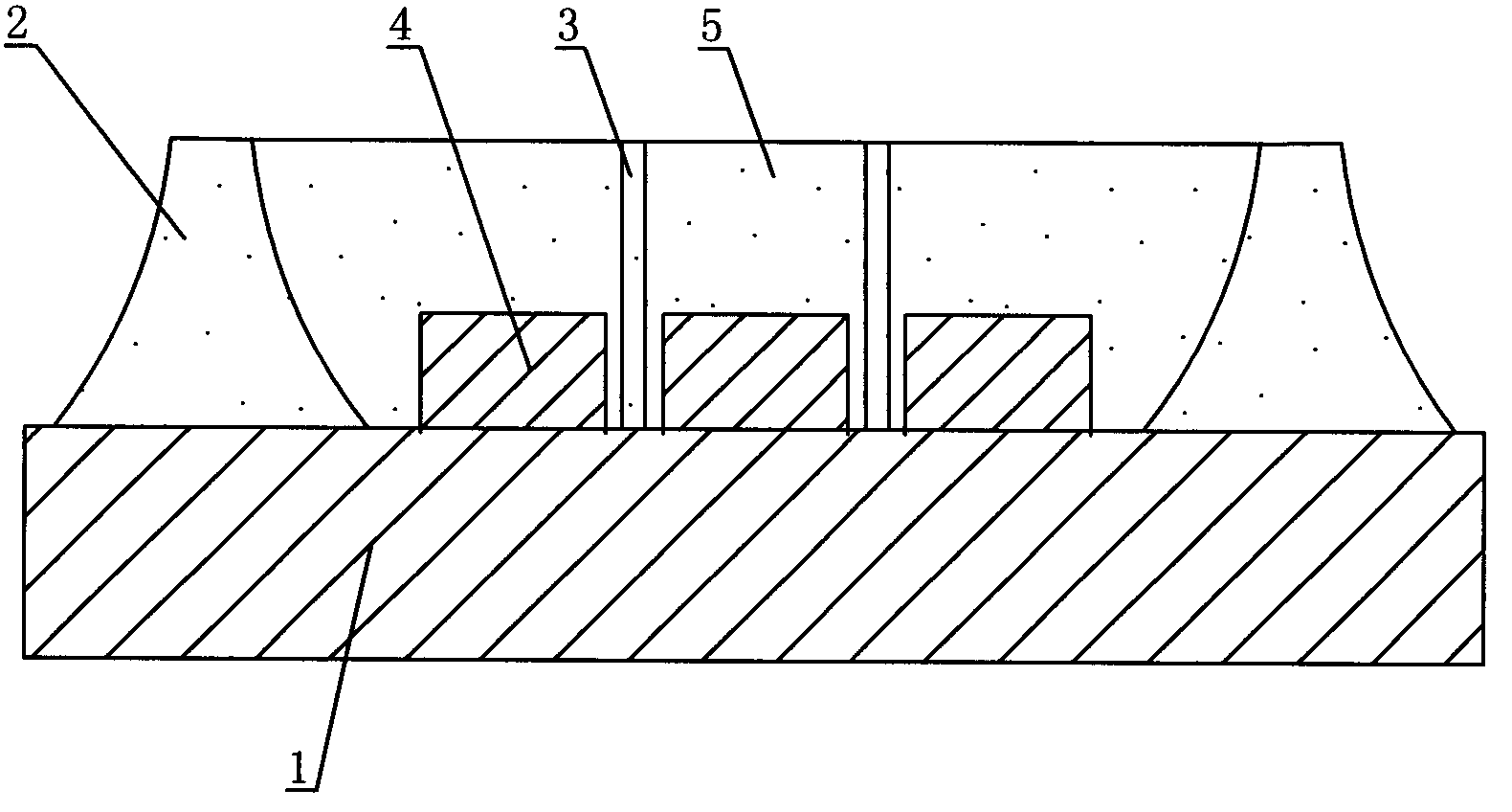

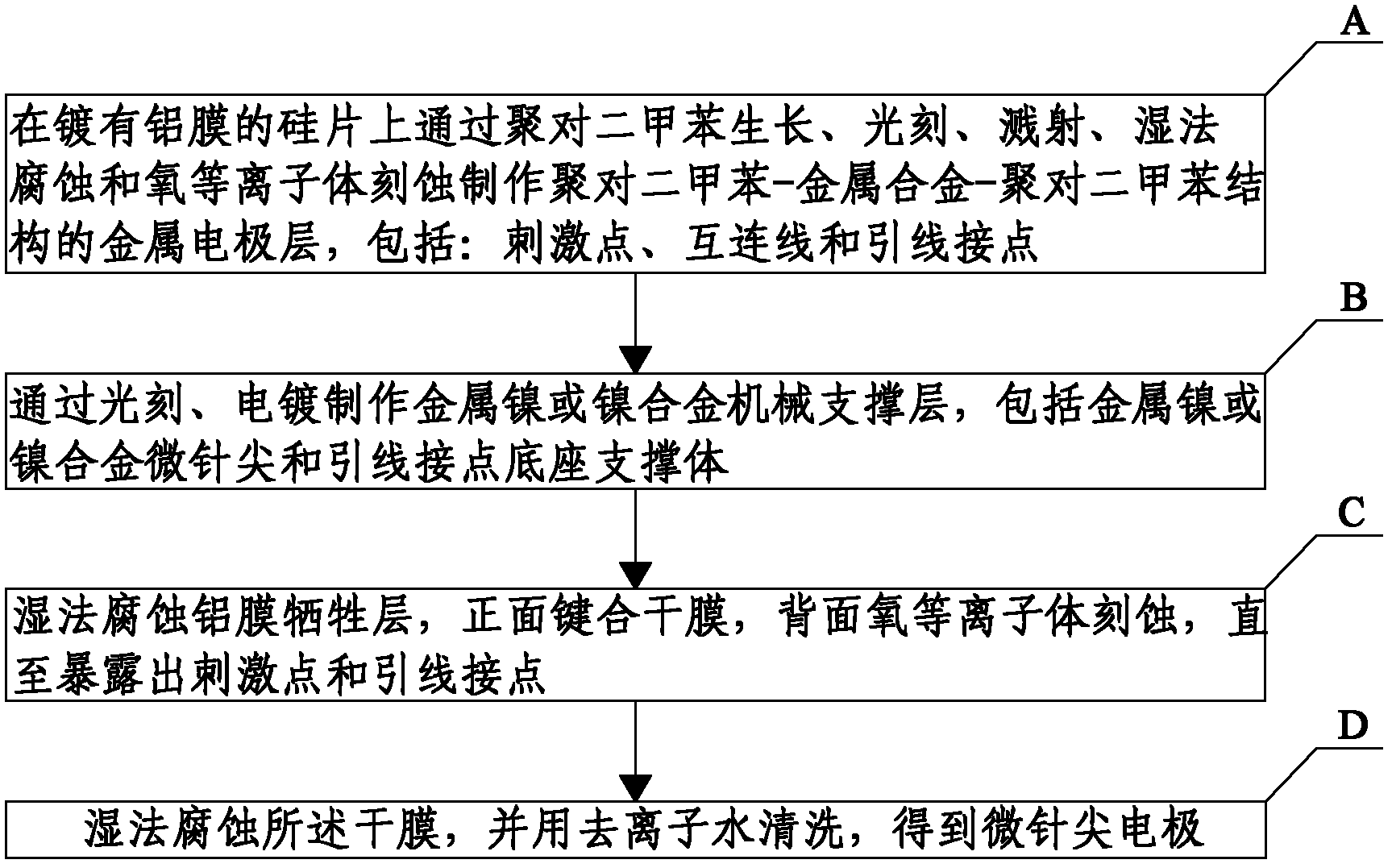

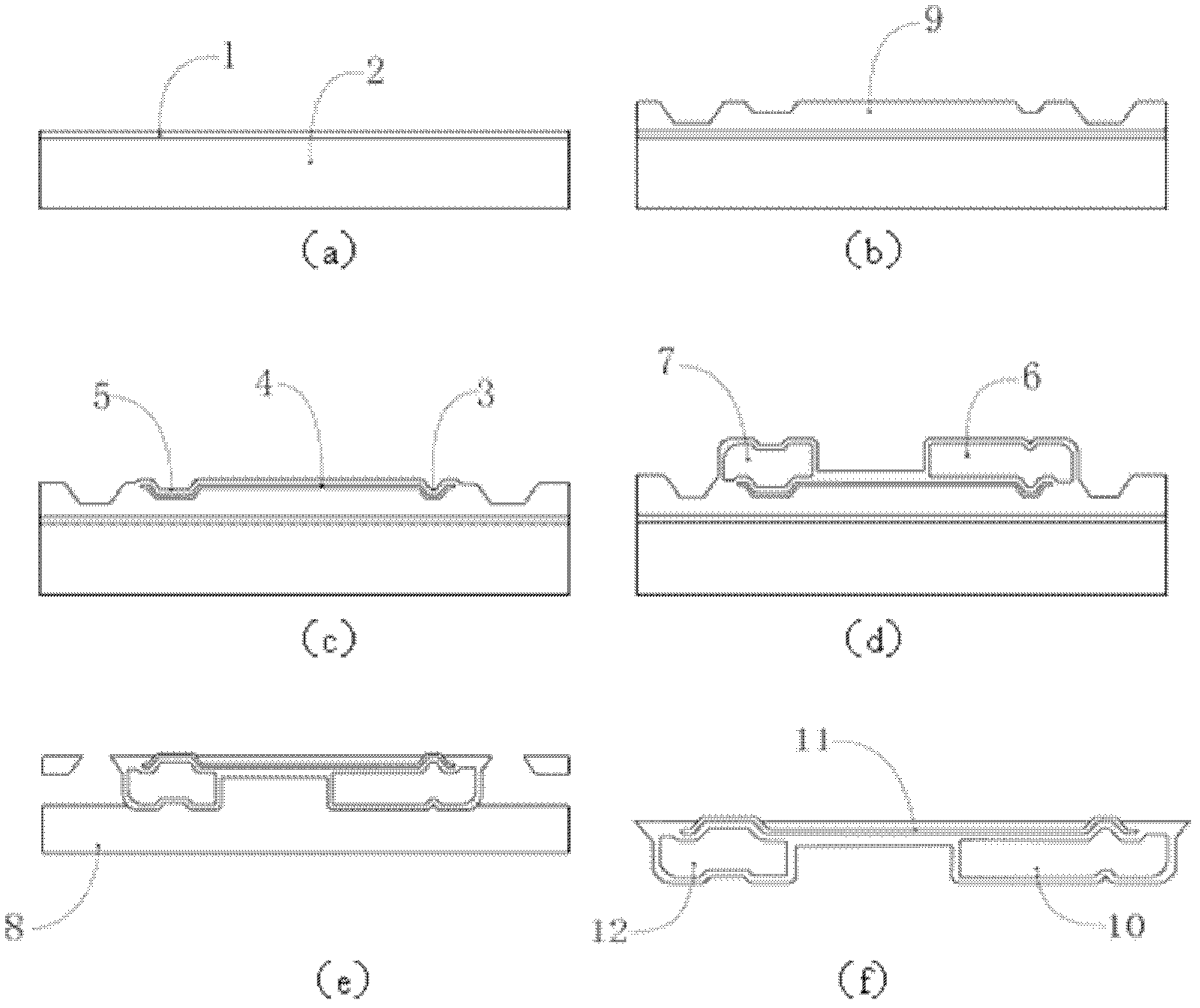

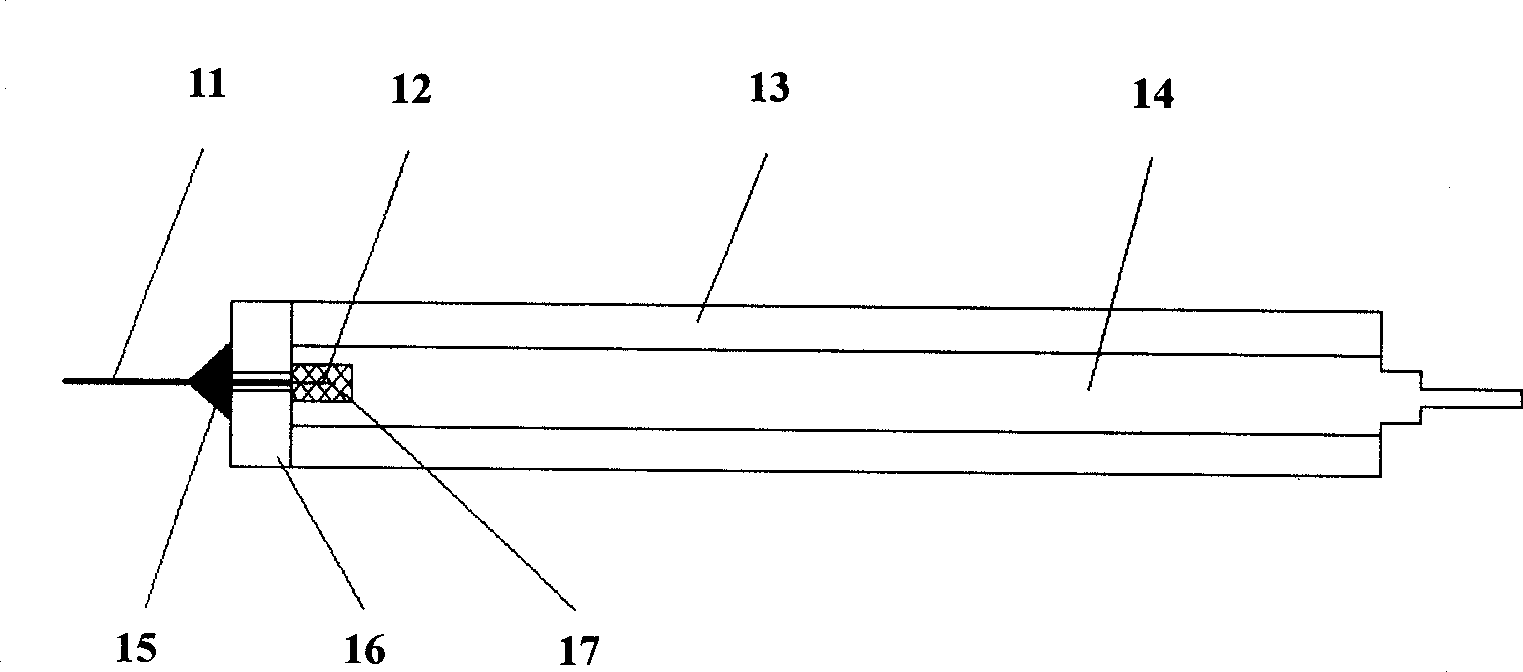

Implantable microneedle tip electrode and manufacturing method thereof

ActiveCN102289148AControllable thicknessReduce process costDecorative surface effectsInternal electrodesAluminiumMetallic Nickel

The invention discloses an embedded micro-pinpoint electrode and a manufacturing method thereof, which relates to the technical field of micro-electronic mechanical systems and embedded micro-electrodes. The method comprises the following steps: A: manufacturing a metal electrode layer of a parylene-metal alloy-parylene structure on a silicon piece (2) coated with an aluminum film (1), wherein the metal electrode layer comprises an exciting point (3), an interconnection line (4) and a lead connecting line (5); B: manufacturing a nickel metal or nickel alloy mechanical supporting layer by photoetching and plating, wherein the mechanical supporting layer comprises a nickel metal or nickel alloy micro pinpoint (6) and a base supporting body of the lead connecting point (7); C: eroding an aluminum film victimization layer by a wetting method; bonding a dry film (8) on a front surface; etching an oxygen plasma on a back surface until an exciting point and a lead connecting point are exposed; and D: eroding the dry file by the wetting method and cleaning by using deionized water to obtain the micro-pinpoint electrode. The invention has the characteristics of high mechanical performance,good biological compatibility, convenient embedding, light damage to tissue, accurate and controllable size, high sensibility and high reliability.

Owner:析芒(宁波)生物微系统有限公司

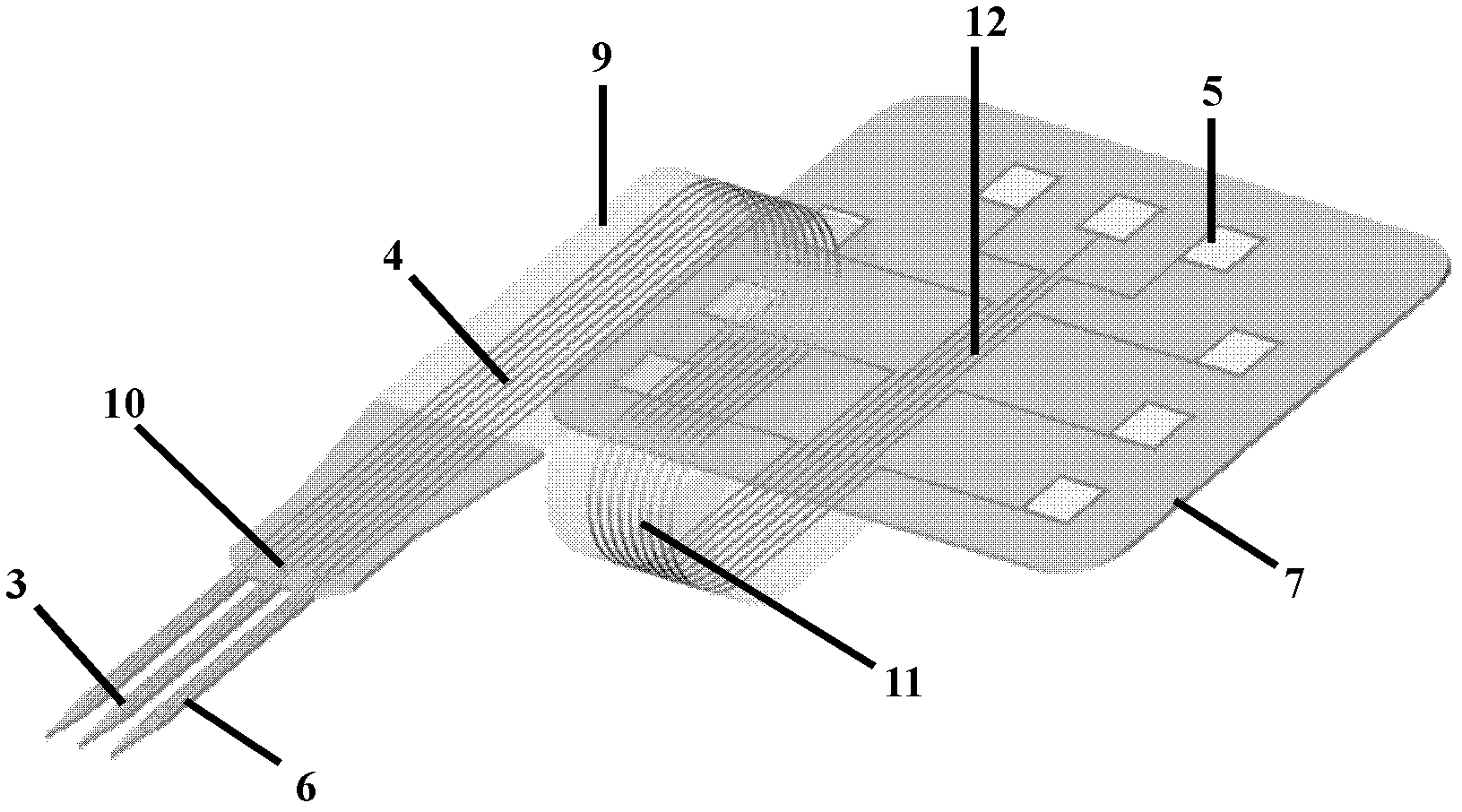

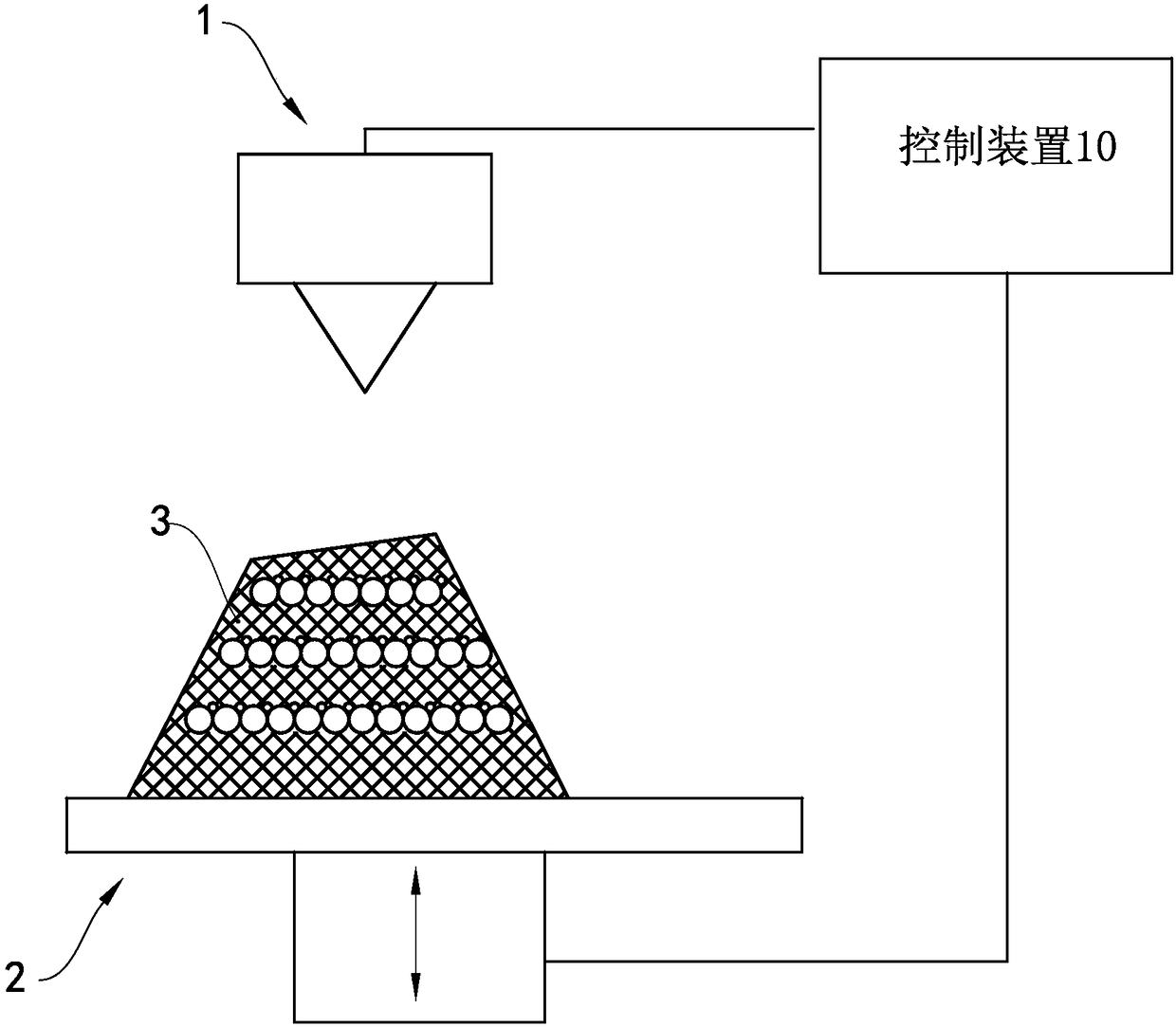

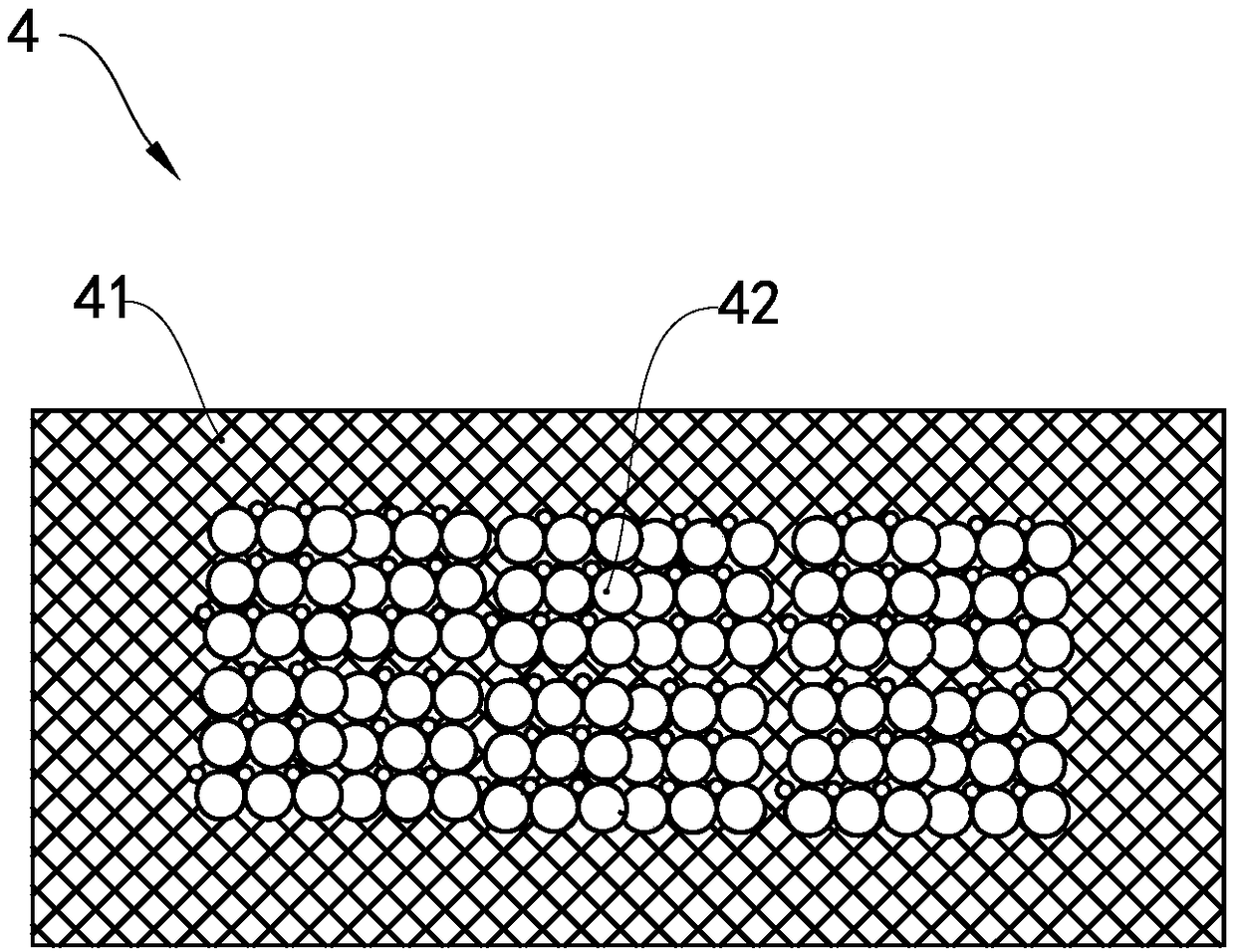

Three-dimensional printer, molding method of three-dimensional printer, and metal three-dimensional object

PendingCN108067619AReduce porosityPrecise shape controlAdditive manufacturing apparatusSpray nozzleMaterial supply

The invention provides a metal three-dimensional object, a three-dimensional printer and a molding method of the three-dimensional printer. The three-dimensional printer comprises a printing head component, a printing platform and a sinter-molding chamber; the printing head component comprises a metal wire material supply passage, a metal powder supply passage and at least one printing nozzle; themetal wire material supply passage communicates with one printing nozzle; the metal powder supply passage communicates with one printing nozzle; the metal wire material supply passage is used for supplying a metal-wire-like first printing material; the metal powder passage is used for supplying a second printing material which at least contains metal powder; the printing head component is used for extruding out the first printing material and the second printing material; the printing platform is used for bearing primarily-solidified objects formed by the first printing material and the second printing material which are extruded out by the printing head component; each primarily-solidified object comprises at least one molded layer; and each molded layer comprises an outer layer and an inner layer. The metal three-dimensional object molded by the three-dimensional printer is compact, high in strength and also good in mechanical properties.

Owner:PRINT RITE UNICORN IMAGE PROD CO LTD

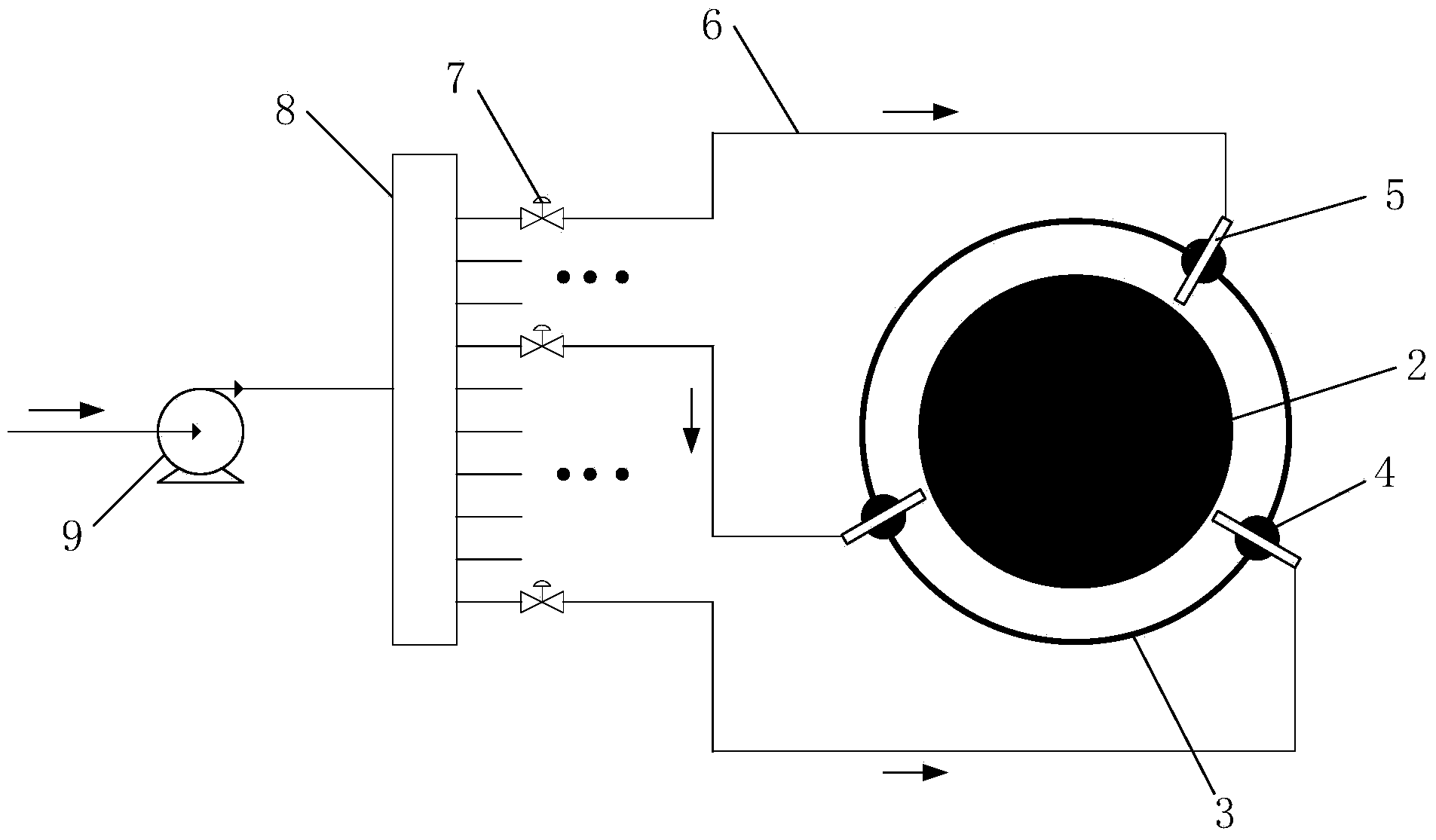

Ultrasonic cavitation cloud control device and ultrasonic cavitation cloud control method

InactiveCN103831271AAccurate shapeAccurate locationEnergy based chemical/physical/physico-chemical processesCleaning using liquidsUltrasonic cavitationSpray nozzle

The invention relates to an ultrasonic cavitation cloud control device and an ultrasonic cavitation cloud control method. The ultrasonic cavitation cloud control device comprises an energy converter, a diverter, a regulating valve, a branch pipe and a nozzle. The energy converter is used for converting electric energy into ultrasonic waves, and a sound field is formed through the ultrasonic waves via the radiant surface of the energy converter. The diverter is used for diverting the received water flow comprising gas nuclei. The regulating valve is communicated with the diverter and used for adjusting the flow rate of the water flow diverted by the diverter. The branch pipe is communicated with the regulating valve and used for conveying the water flow. The nozzle is communicated with the branch pipe and used for spraying the water flow to the radiant surface. Cavitation bubbles are formed by the gas nuclei in the water flow under the action of the sound field, and cavitation cloud is formed through cavitation bubble gathering. The nozzle is used for controlling the shape of the calvitation cloud by adjusting the flow rate and direction of the water flow sprayed to the radiant surface. The ultrasonic cavitation cloud control device and the ultrasonic cavitation cloud control method can precisely control the ultrasonic cavitation cloud easily and conveniently.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

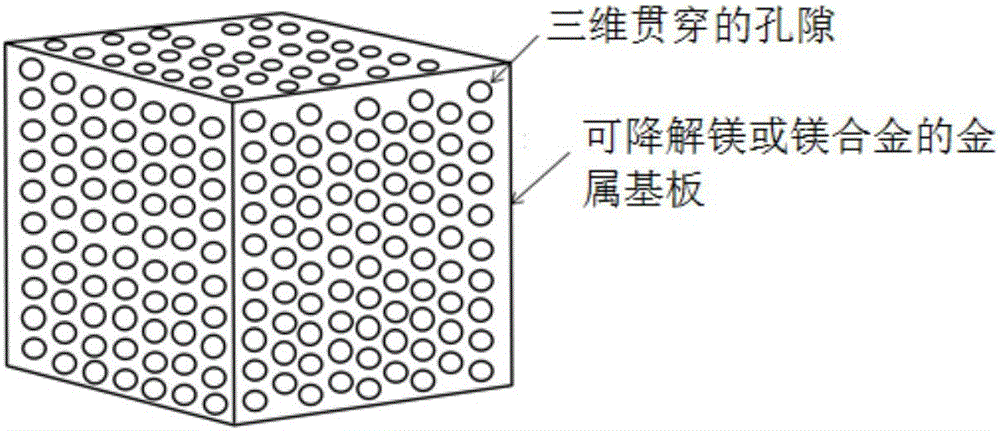

Preparation method of degradable magnesium alloy and degradable polymer composite

InactiveCN106421891ASatisfy fixed clinical needsImprove mechanical propertiesTissue regenerationProsthesisPorosityDrug biological activity

The invention provides a preparation method of a degradable magnesium alloy and degradable polymer composite. Degradable magnesium or a degradable magnesium alloy is taken as a metal substrate and processed, and three-dimensional through pores in different shapes and with different porosity are densely formed in the metal substrate adopting the degradable magnesium or the degradable magnesium alloy. The degradable magnesium or the degradable magnesium alloy is taken as a substrate material and tightly combined with a degradable polymer through the crossed through three-dimensional pores, the overall mechanical properties of the composite are far higher than those of a single degradable polymer, the composite can meet requirements of most applications such as bone filling, bone repair, bone transplantation and the like, the medical magnesium or the medical magnesium alloy is degraded in a human body fluid corrosion environment, calcium deposition and osteocyte formation can be promoted, bone healing can be accelerated, and the biological activity is improved; the composite can form porous tissue automatically in a degradation process, ingrowth of new bone tissue and propagation of osteocytes are facilitated, and rehabilitation time of bone tissue is shortened.

Owner:FOSHAN UNIVERSITY

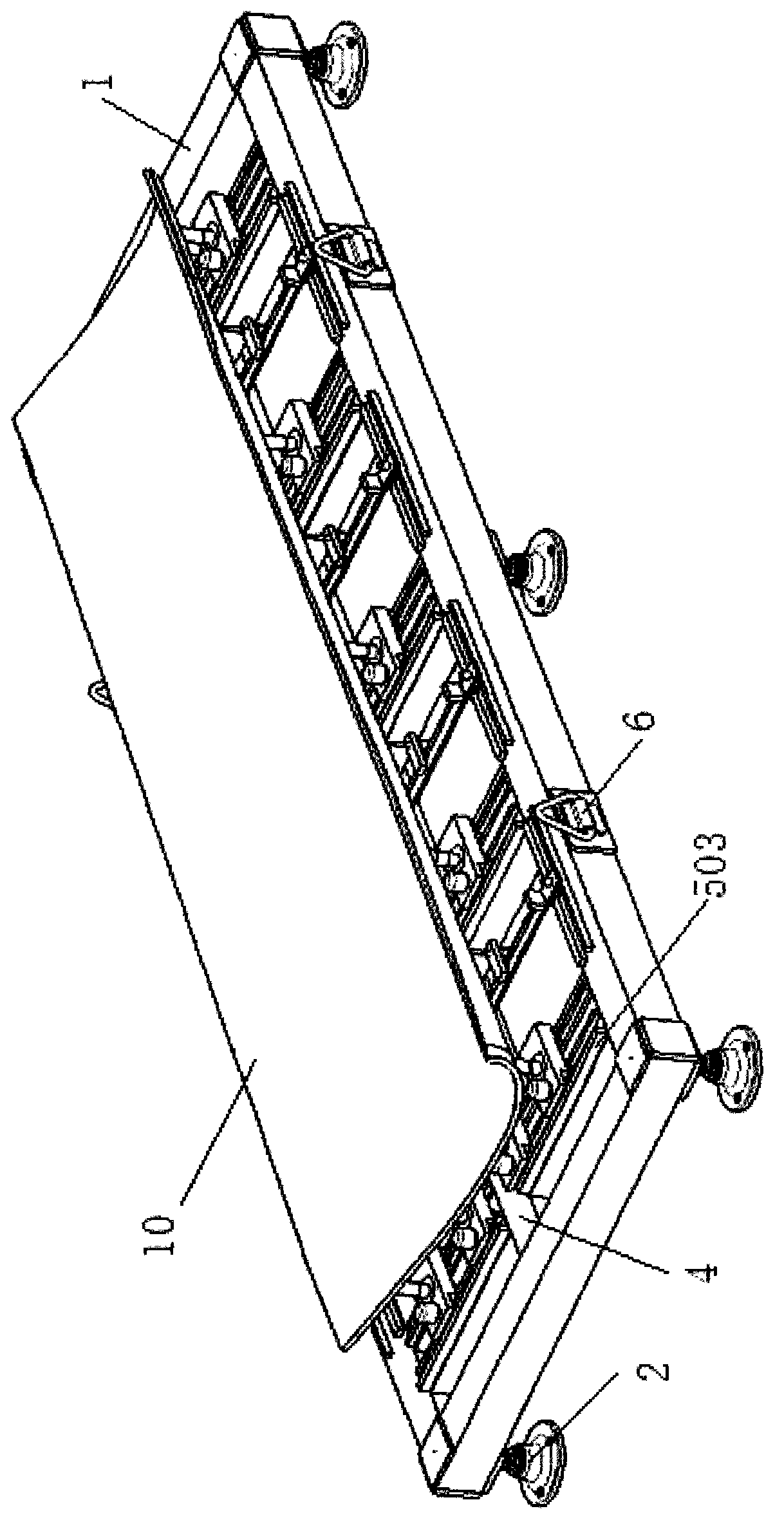

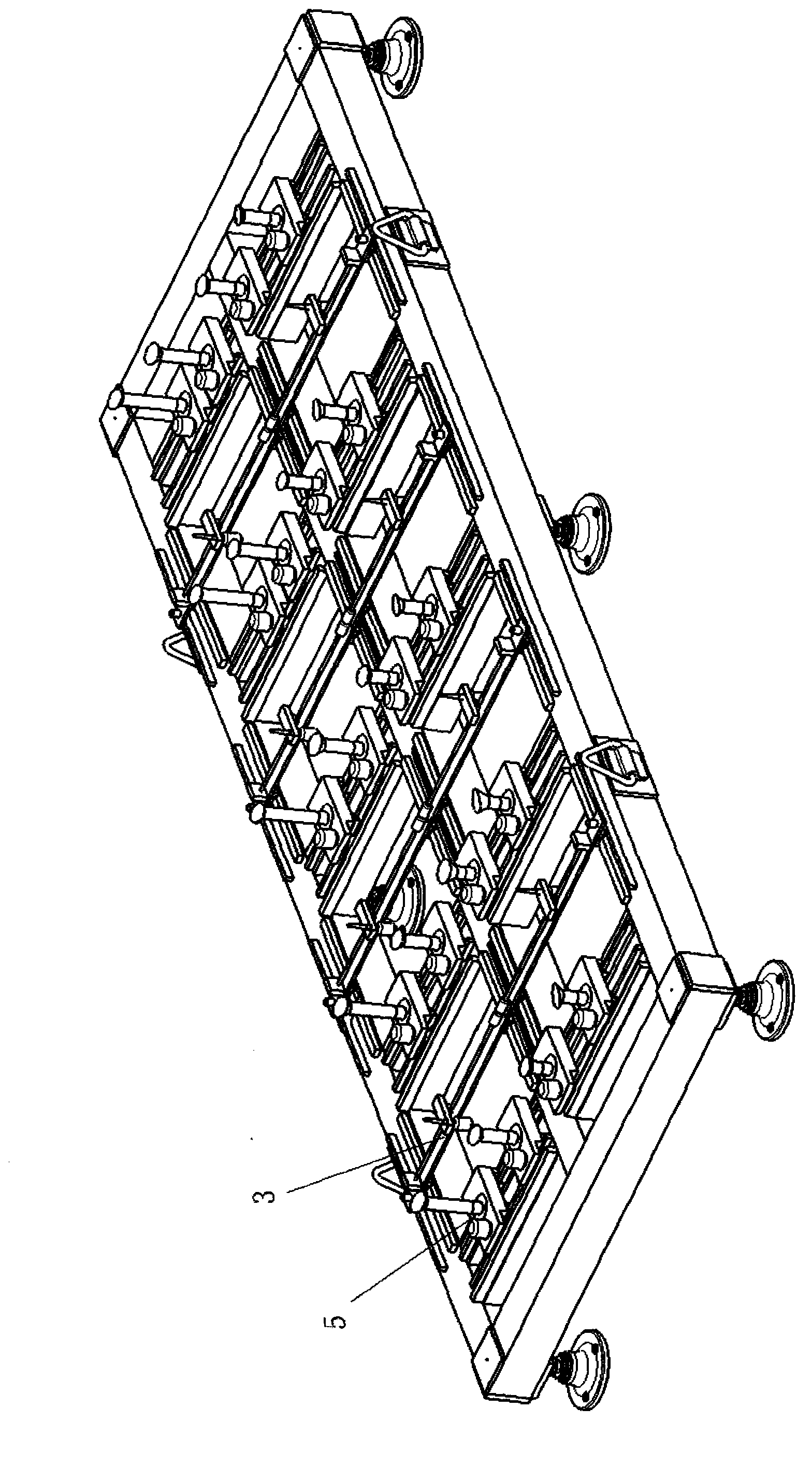

Wallboard part detecting device

InactiveCN103542818AGuaranteed accuracyAchieve quantificationUsing optical meansBraced frameMechanical engineering

The invention relates to a wallboard part detecting device which comprises a frame, vertical support columns, a detecting part, at least one middle crossbeam and a support device. The frame comprises a rectangular structure formed by two parallel first lateral edges and two parallel second lateral edges vertical to the first lateral edges. The vertical support columns for supporting the frame are fixed on the four lateral edges. The detecting part for detecting to-be-detected parts is fixed on the frame. The detecting part is vertically disposed between the two first lateral edges. The middle crossbeams vertical to the second lateral edges are evenly disposed between the first lateral edges. Two ends of each middle crossbeam are fixedly connected to the second lateral edges. The support device for supporting the to-be-detected parts is fixed on the frame. The support device is parallel with the detecting part and disposed between the two second lateral edges. By the wallboard part detecting device, detecting modes of traditional rigid detecting tools are changed, a large amount of tool research cost and time are saved, and detecting speed is increased.

Owner:XIAN LIANZONG AVIATION PRECISION MFG

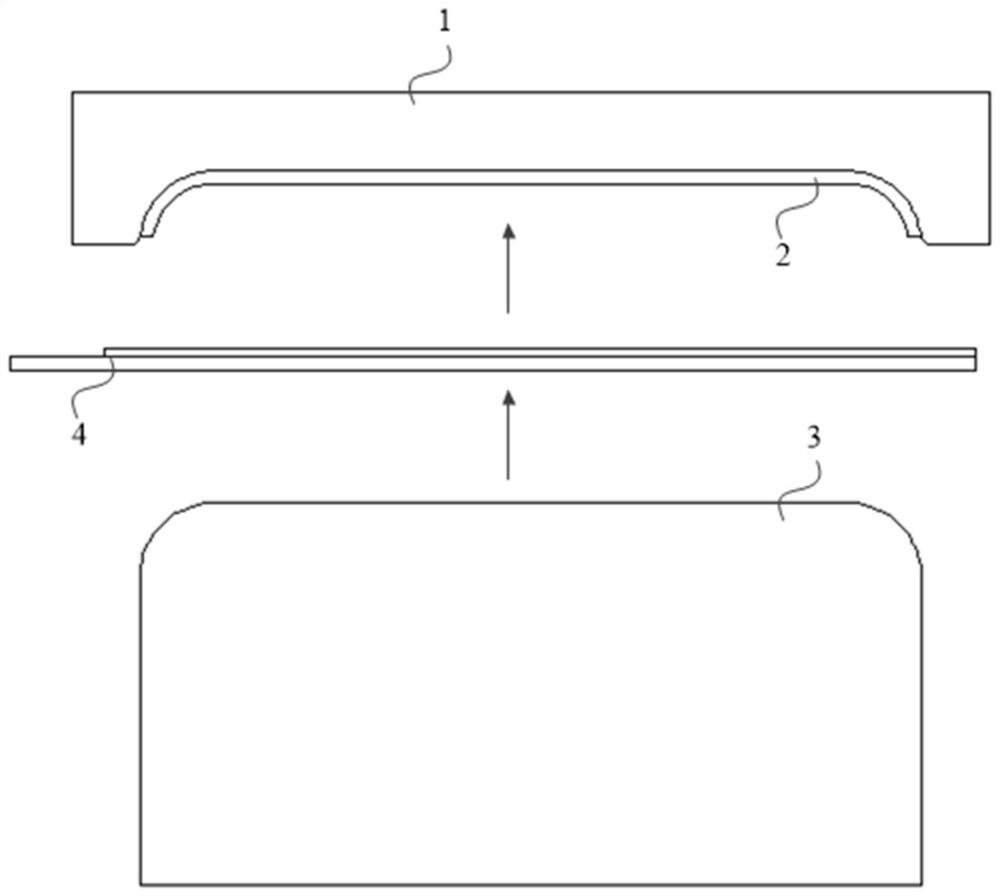

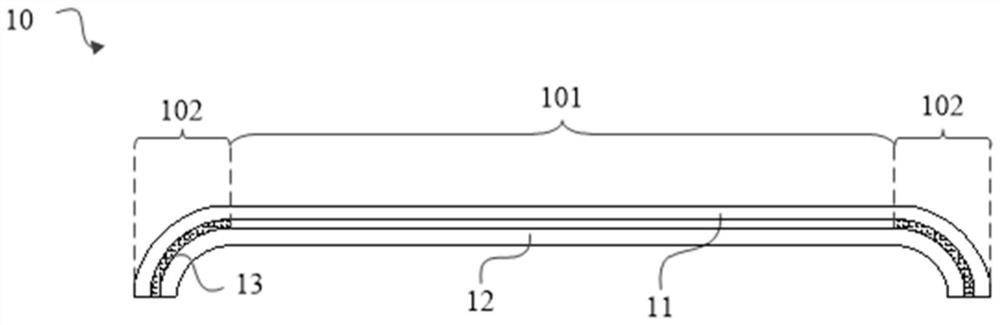

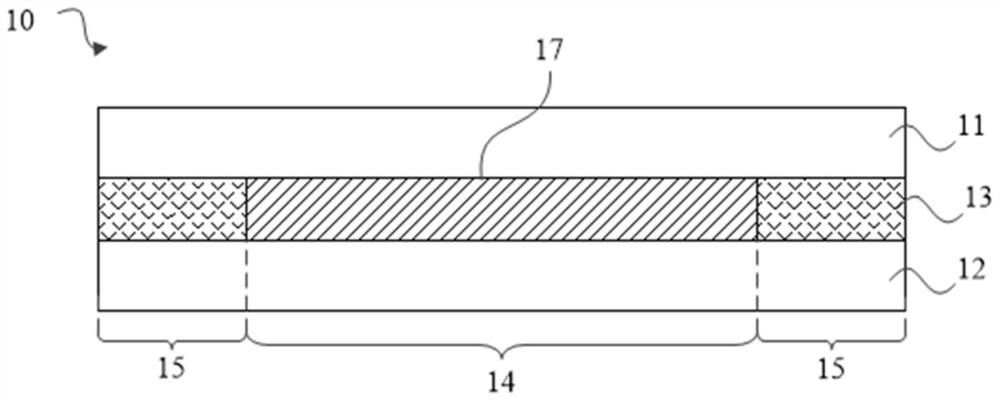

Cover plate, display panel and preparation method of display panel

ActiveCN113362722APrecise shape controlEasy to usePhotovoltaic energy generationIdentification meansStructural engineeringHot melt

The invention provides a cover plate, a display panel and a preparation method of the display panel, and relates to the technical field of display, in order to solve the technical problem that an existing curved surface cover plate is poor in attachment, the cover plate is applied to the display panel, the display panel is provided with a plane area and a curved surface area which are connected with each other, and the cover plate is provided with a plane part and a to-be-bent part which are connected with each other. The cover plate comprises at least two layers of flexible cover bodies which are mutually overlapped, and a hot melt adhesive layer is arranged between every two adjacent flexible cover bodies; and the hot melt adhesive layer at least covers the flexible cover body in the to-be-bent part. According to the invention, the cover plate and the display module can be tightly attached, and the use performance of the display panel is improved.

Owner:YUNGU GUAN TECH CO LTD

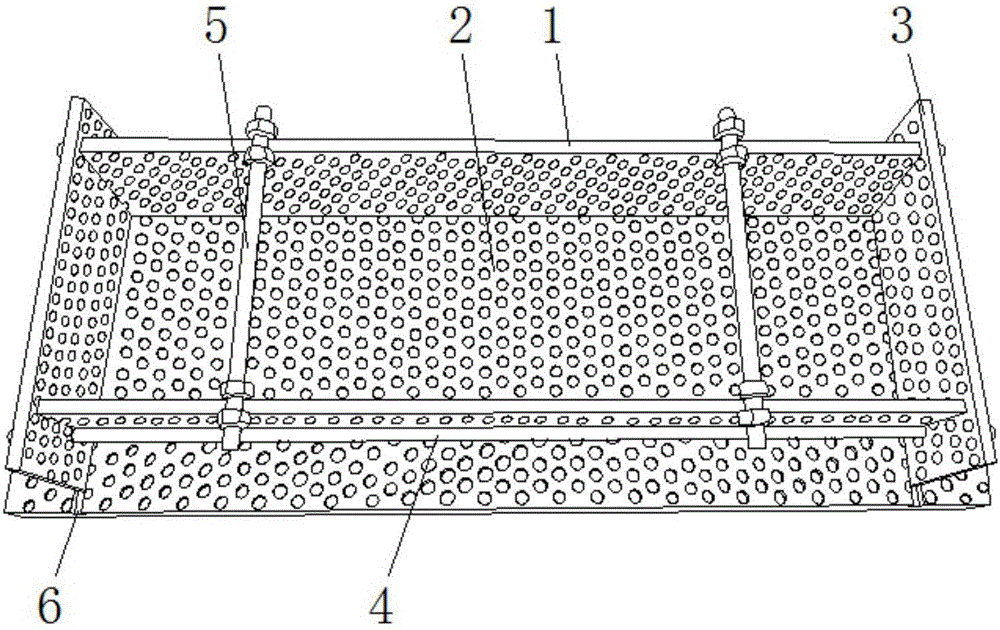

Manufacturing method of biological soil fixation test beam used for constructional engineering

InactiveCN105806688AImprove permeabilityLow costPreparing sample for investigationChemical solutionFixation test

The invention discloses a manufacturing method of a biological soil fixation test beam used for constructional engineering.The manufacturing method includes the following steps that materials are prepared, wherein the materials comprise longitudinal side plates, a bottom plate and end plates; 2, the longitudinal side plates, the bottom plate and the end plates are assembled; 3, a lightweight mold needed for cutting of geotechnical cloth is manufactured, and the geotechnical cloth is cut according to the size; 4, two transverse screws are detached; 5, the cut geotechnical cloth is placed in a rectangular model cavity, and sandy soil is added to a cavity defined by the geotechnical cloth; 6, the distance between the two longitudinal side plates is fixed through the two transverse screws; 7, bacteria are poured into a test piece, and the whole mold is placed in a chemical solution; 8, the rectangular biological soil fixation beam is formed after the reaction is completed.A large number of mechanical performance tests such as the anti-bending performance test need to be conducted on the beam which is produced through the method and needed for building a house before practical engineering application, basic data and scientific reference are provided for practical application of the technology, and safety and reliability of an infrastructure and the house are guaranteed.

Owner:重庆市綦江区全兴建筑工程有限公司

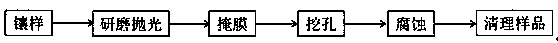

Metal surface local region precise corrosion method

The invention relates to the field of detection, in particular to a metal surface local region precise corrosion method. The method is characterized in that by aiming at the corrosion on a metal material, after sample embedding, and a to-be-corroded surface is ground and polished, anti-corrosion mask treatment is performed; a local mask region in a polishing surface mask position is removed; the local region of a metal surface is exposed; a natural corrosion or accelerated corrosion method is used for corroding the exposed local metal region; all masks are removed to obtain local corrosion samples. Any surface of samples of any shape is corroded; the local corrosion region can be a point, a line or a surface; the number, the size, the shape, the position and the corrosion depth of the local corrosion region can be precisely controlled; a series of standard samples with consistency can be prepared.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

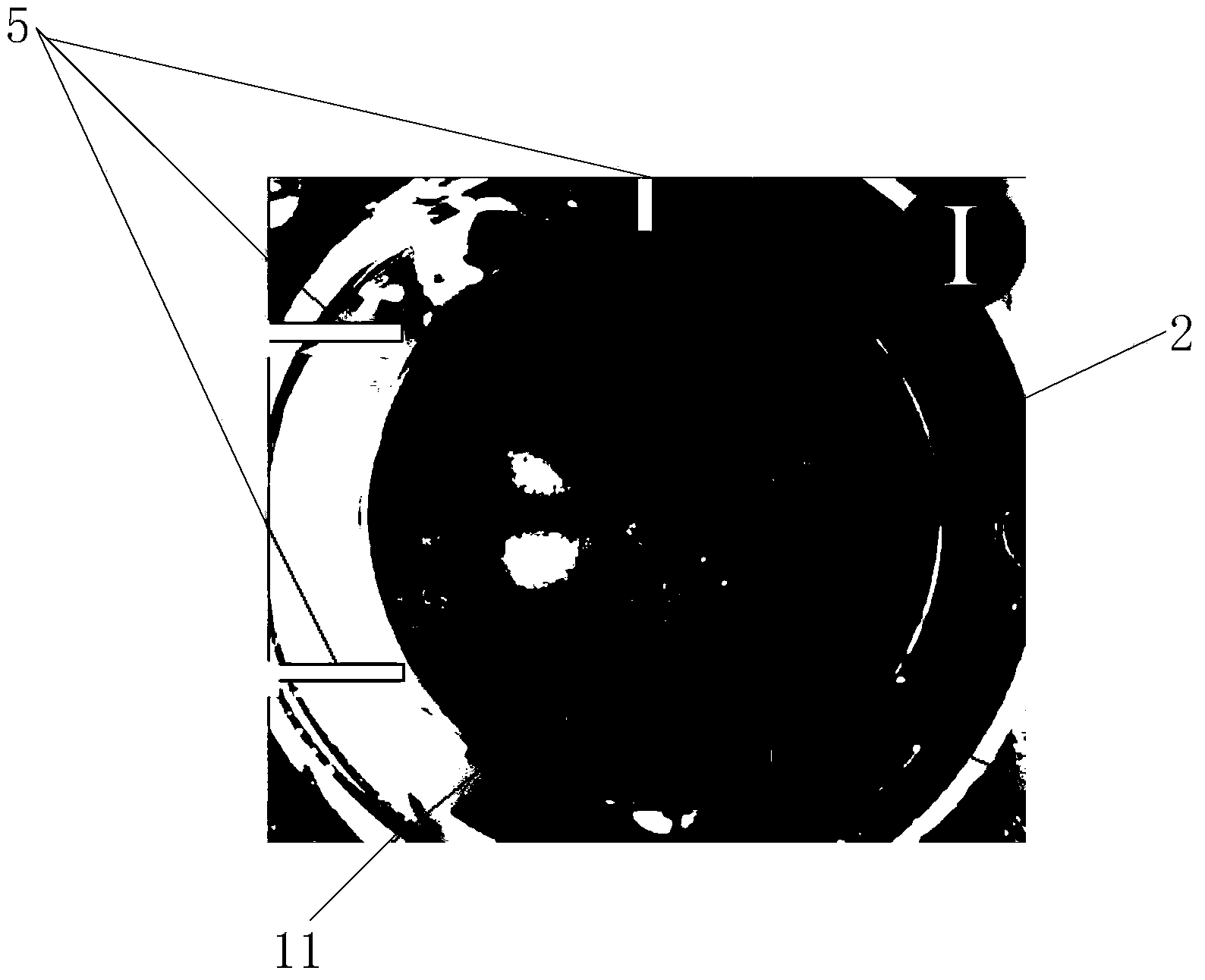

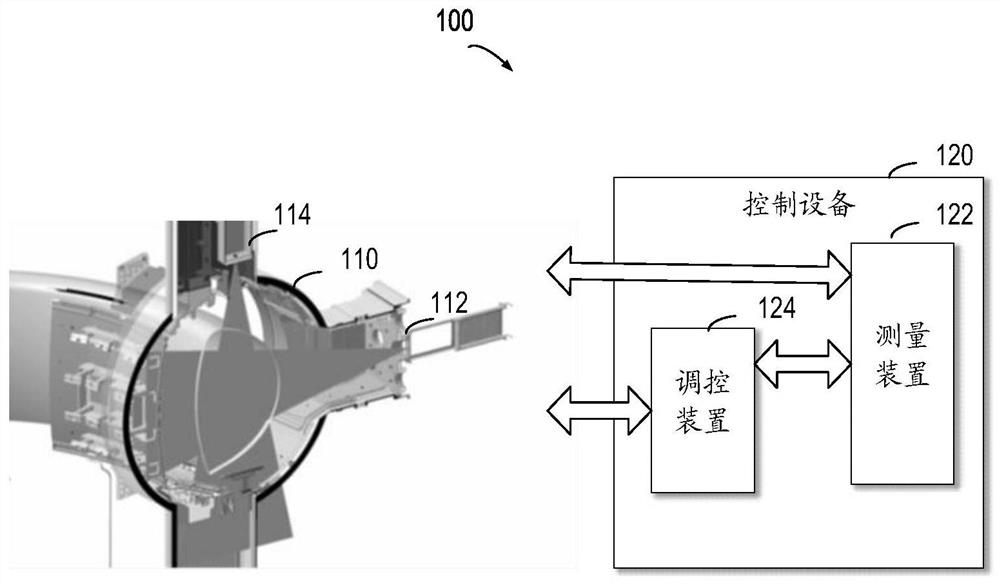

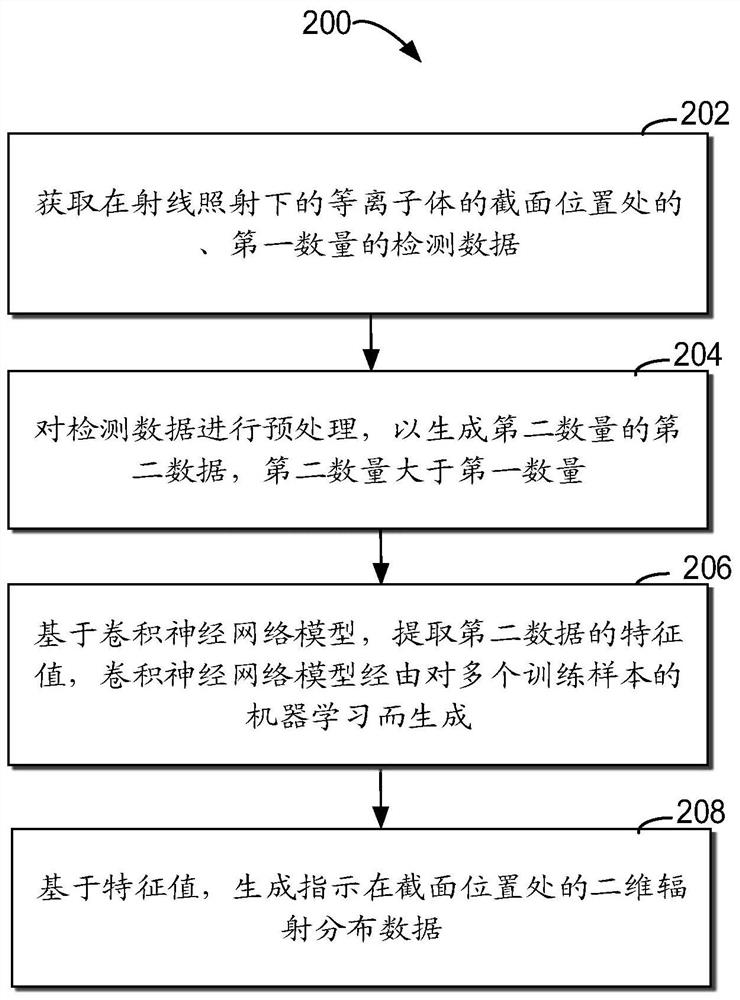

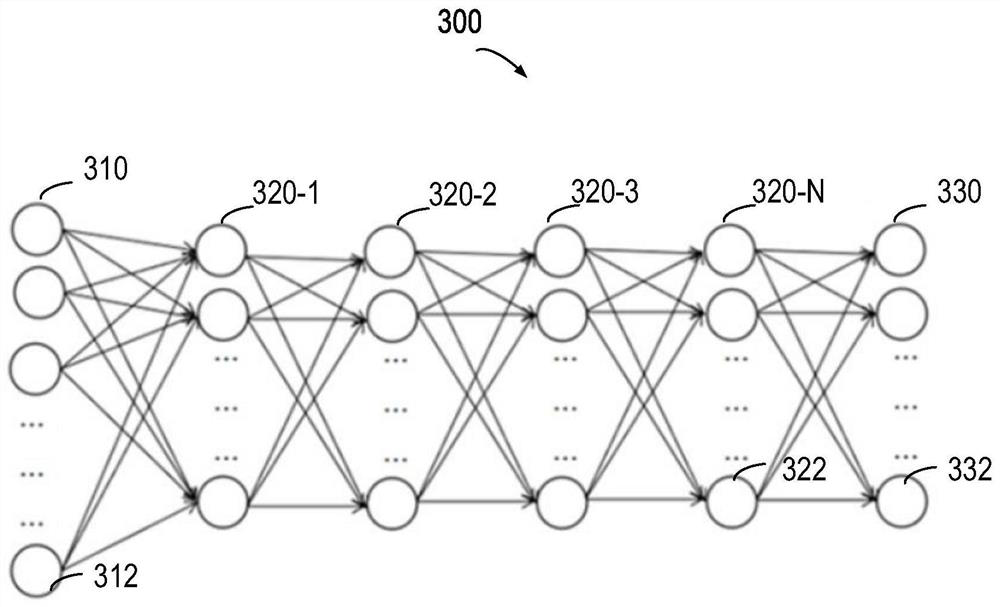

Method and apparatus for measuring plasma state

ActiveCN111935892APrecise shape controlNuclear energy generationPlasma techniquePhysicsFeature (machine learning)

The invention provides a method and apparatus for measuring a plasma state, a method and apparatus for controlling plasma discharge, and a computer readable storage medium. The method for measuring the plasma state comprises the following steps: acquiring a first quantity of detection data at a cross section position of plasma under ray irradiation; preprocessing the detection data to generate a second quantity of second data, the second quantity being greater than the first quantity; extracting a feature value of the second data based on a convolutional neural network model, the convolutionalneural network model being generated by machine learning of the plurality of training samples; and generating, based on the feature value, two-dimensional radiation distribution data indicative of the cross section position. The scheme for measuring the state of the plasma and controlling the discharge of the plasma can accurately deduce and / or control the state of the plasma.

Owner:CHINA SCI INTELLICLOUD TECH CO LTD

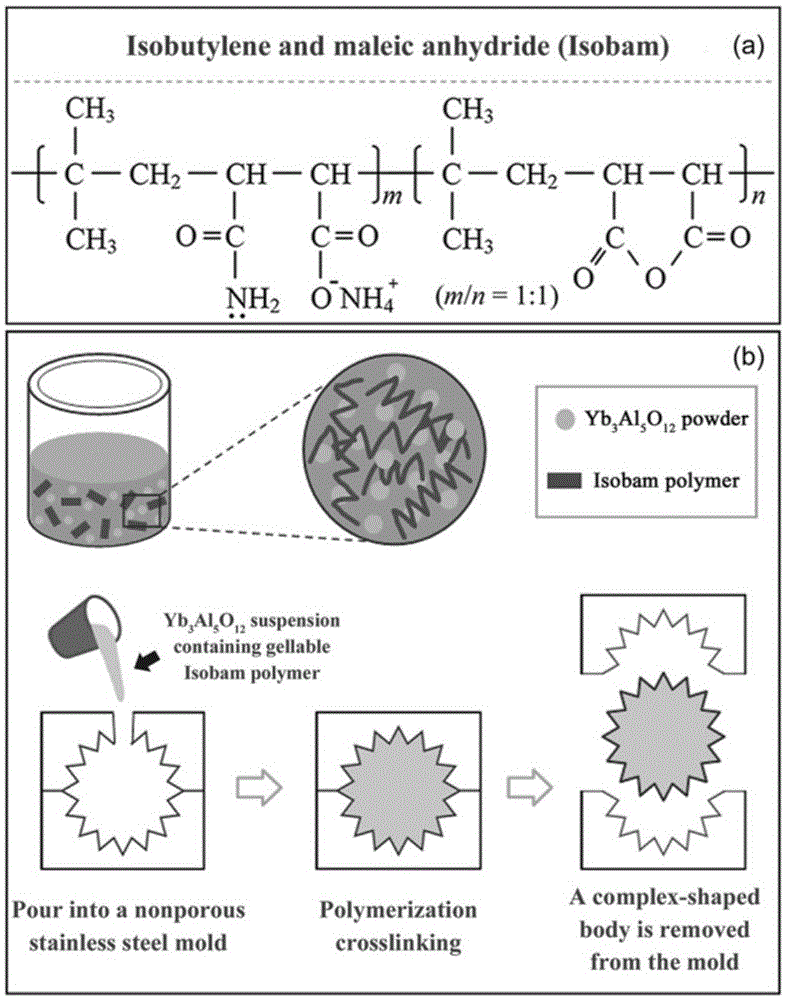

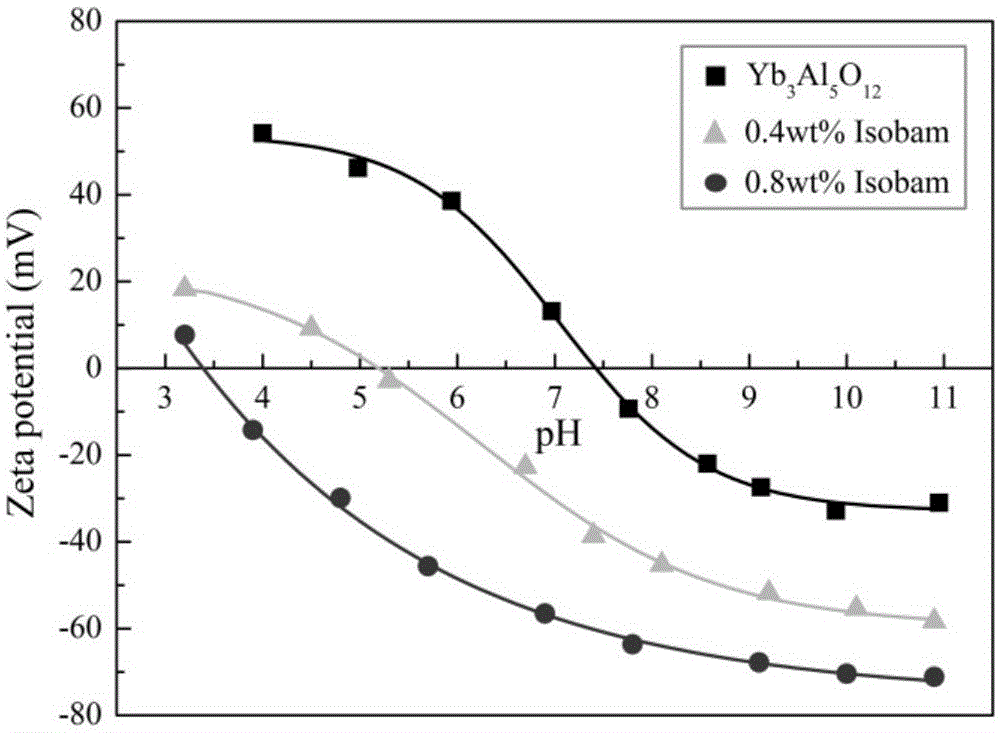

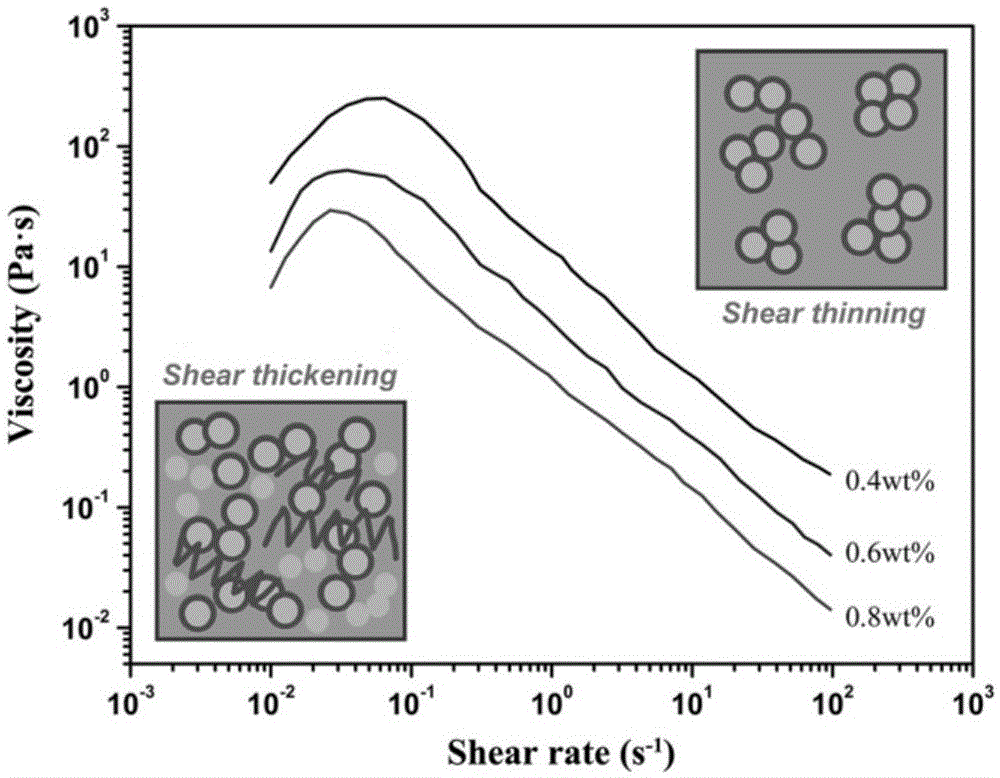

Method for preparing ultra-high-temperature thermal-insulation Yb3Al5O12ceramic component

The present invention provides a method for preparing an ultra-high-temperature thermal-insulation Yb3Al5O12ceramic component. The method comprises: (1) carrying out a high temperature solid phase reaction on raw materials such as Yb2O3 powder and Al2O3 powder to obtain Yb3Al5O12 ceramic powder; (2) mixing the Yb3Al5O12 ceramic powder, water and an isobutylene-maleic anhydride copolymer to form a stable Yb3Al5O12 ceramic water-based slurry, and carrying out room temperature curing cross-linking to obtain a Yb3Al5O12 ceramic green; and (3) finally sintering for 1-4 h at a temperature of 1450-1680 DEG C so as to obtain the compact and complex-shape ultra-high-temperature thermal-insulation Yb3Al5O12ceramic component, wherein the sintering atmosphere is Ar gas or air. According to the present invention, the preparation method has characteristics of simple process, no requirement of high pressure equipment, easy achieving, and strong practicality.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

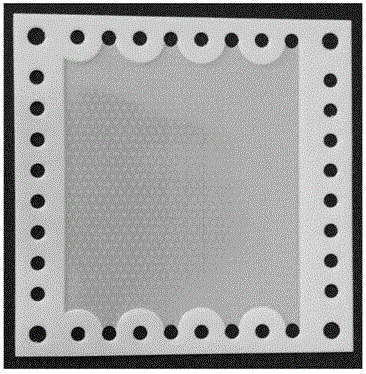

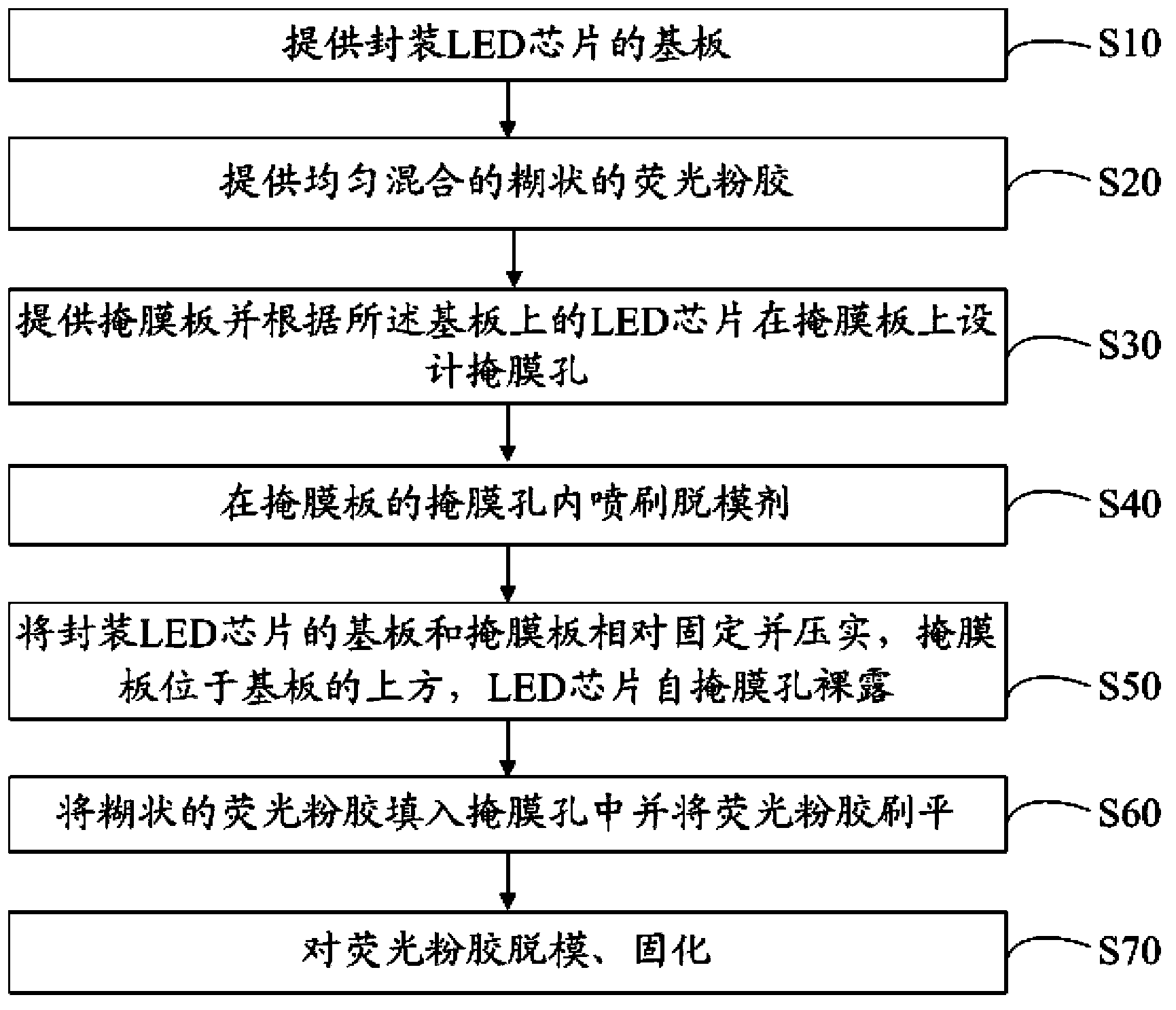

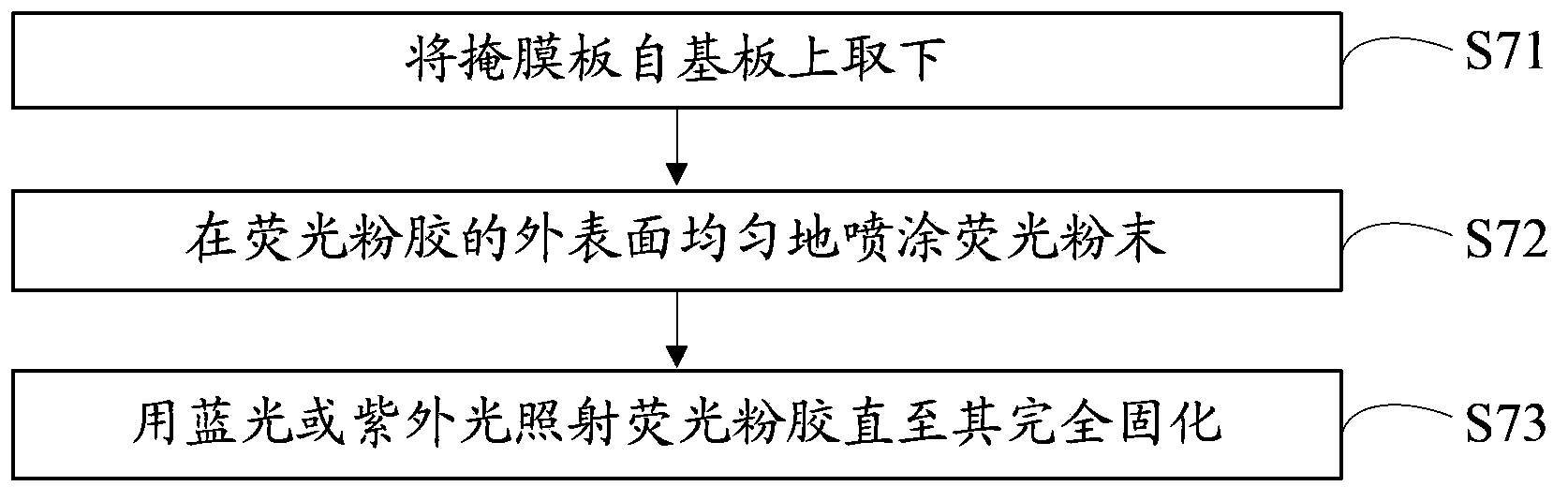

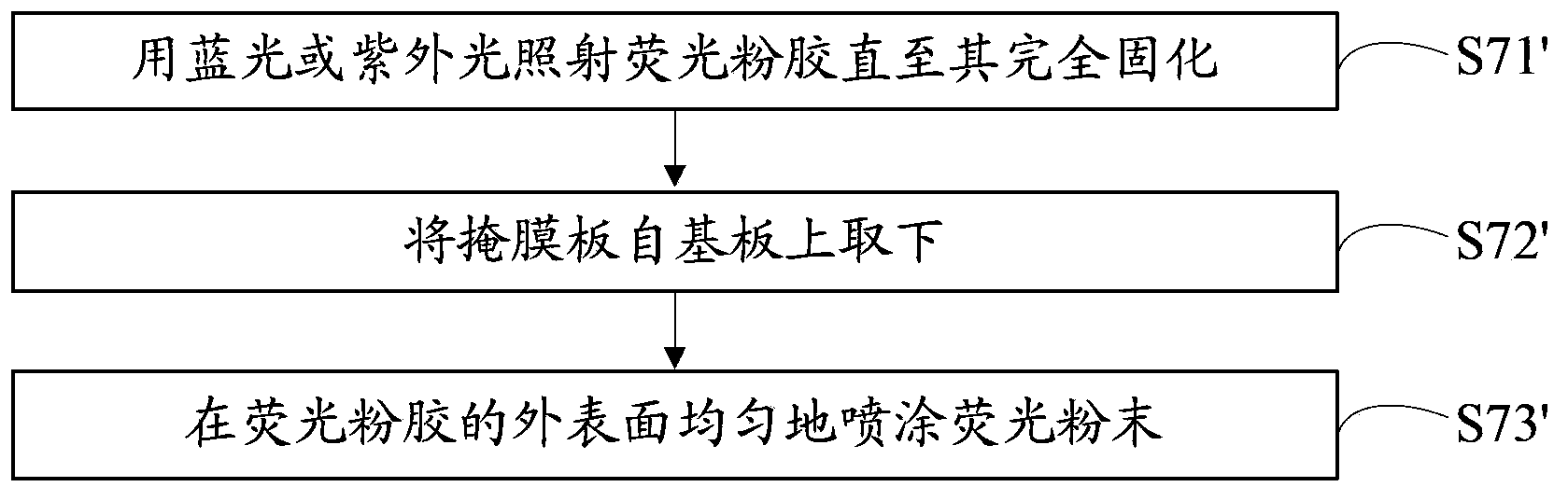

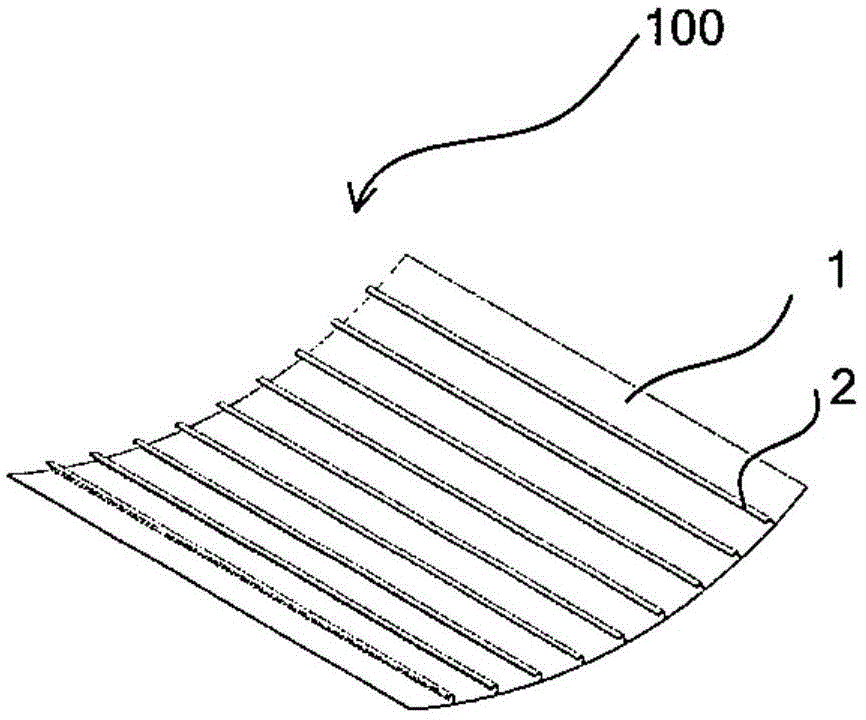

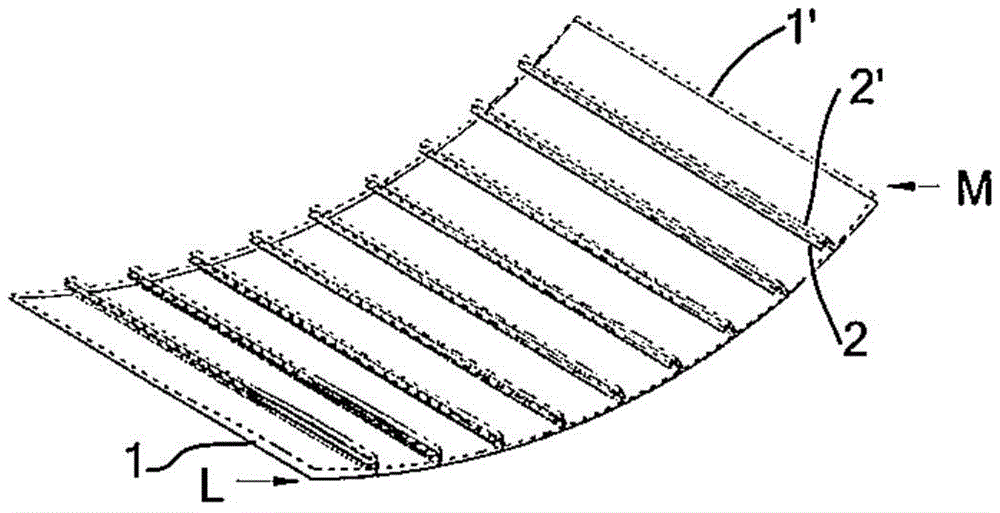

Phosphor coating method and LED device

ActiveCN104300074APrecise shape controlPrecise thickness controlSemiconductor devicesPhosphorFluorescence

The invention discloses a phosphor coating method and an LED device. The phosphor coating method comprises the steps that pasty-state phosphor glue which is mixed uniformly is provided; a masking plate is provided and mask holes are designed in the masking plate according to LED wafers in a substrate; the substrate that packages LED wafers is fixed and compressed relative to the masking plate, the masking plate is positioned over the substrate, and the LED wafers are exposed of the mask holes; the pasty-state phosphor glue is filled into the mask holes and flattened via brushing; and the phosphor glue is demolded and solidified. The shape and thickness of a phosphor layer can be accurately controlled via the phosphor coating method, a uniform optical field can be obtained, and LED devices in the same batch are unified in light color.

Owner:SHENZHEN UNIV

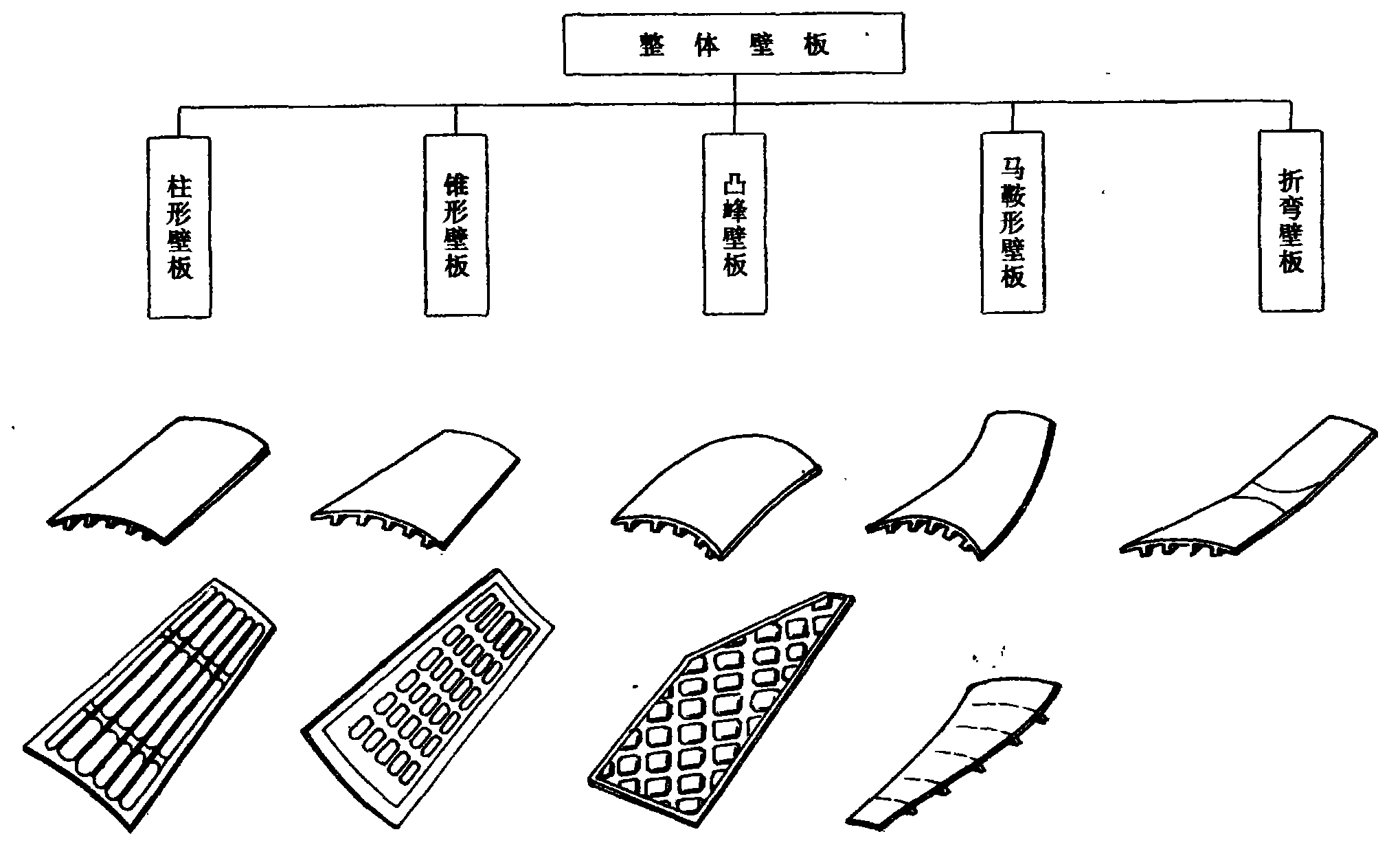

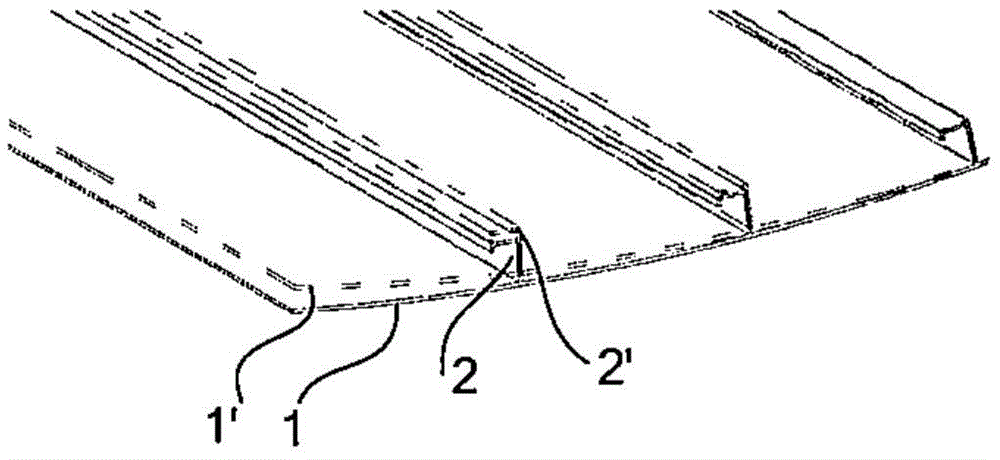

Laser Shock Shape Calibration Method for Welded Integral Wall Panel

ActiveCN103752651BHigh control precisionImprove work efficiencyOptoelectronicsUltimate tensile strength

The invention relates to a laser shock shape-correcting method for welded integral panels. The laser shock shape-correcting method includes: S1) measuring deformation and residual stress; S2) determining a shape correcting amount and a shape correcting route by a computer; S3) determining strength of laser shock shape correcting by the computer; S4) performing laser shock shape correcting on the welded integral panel by laser shock equipment according to the strength and the shape correcting route determined by the computer; S5) performing shape correction detecting on the welded integral panel, if a film pasting interval is over a preset interval, sequentially repeating the steps S1, S2, S3 and S4 to enable the film pasting interval to approach to the preset interval, and stopping repeating until the film pasting interval is smaller than or equal to the preset interval. Compared with a conventional mechanical shape correcting method, the laser shock shape-correcting method has the advantages of high control accuracy and working efficiency, wide application range and the like, and meets standards of high requirement of aeronautical parts.

Owner:SHANGHAI AIRCRAFT MFG

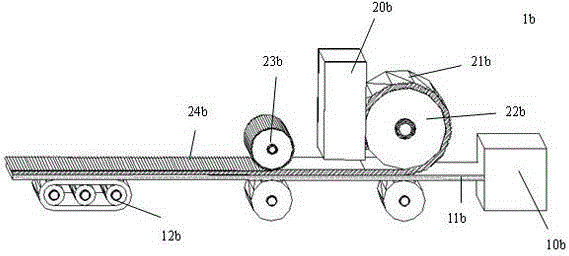

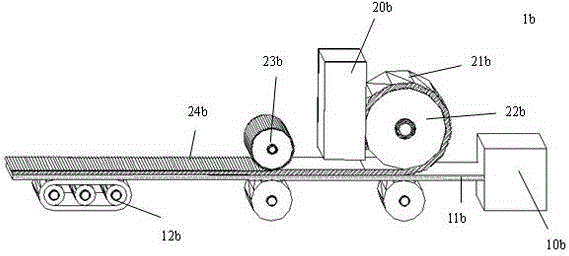

3D printing-based reflective polarizing film preparation method and device thereof

ActiveCN104401003APrecise shape controlPrecise thickness controlFlat articlesLiquid stateRefractive index

The invention relates to a 3D printing-based reflective polarizing film preparation method which comprises the following steps: 1, a three-dimensional digital model of a reflective polarizing film is established and converted to work instructions for controlling operation of 3D printing equipment, and the work instructions contain a first instruction for printing a first refractive index film of the reflective polarizing film and a second instruction for printing a second refractive index film of the reflective polarizing film; 2, a first raw material and a second raw material are respectively put into a charging cavity of the 3D printing equipment to be converted to a liquid state; and 3, the 3D printing equipment alternately executes the first instruction and the second instruction, a print head alternately sprays a first liquid raw material and a second liquid raw material onto a molding area, the sprayed raw materials are solidified quickly, and the reflective polarizing film having hundreds of the alternately-tiered first and second refractive index films is finally formed by spraying and solidifying the refractive index films layer upon layer. By the method and the device, the preparation technology of the reflective polarizing film can be simplified, and production efficiency can be enhanced.

Owner:FUZHOU UNIV

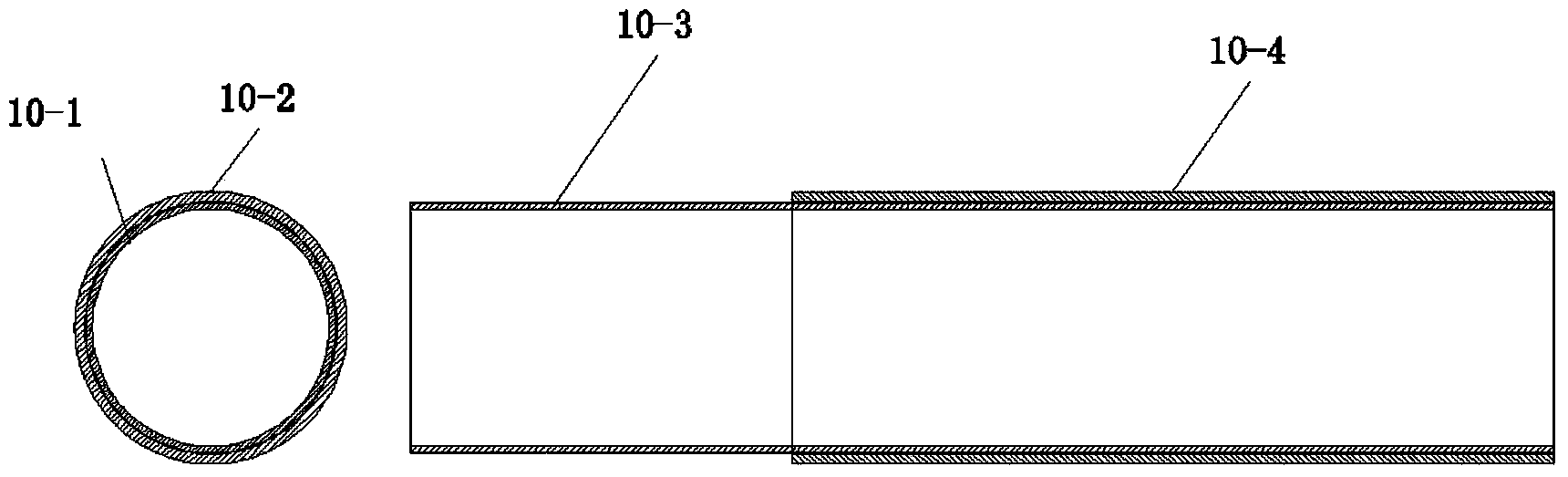

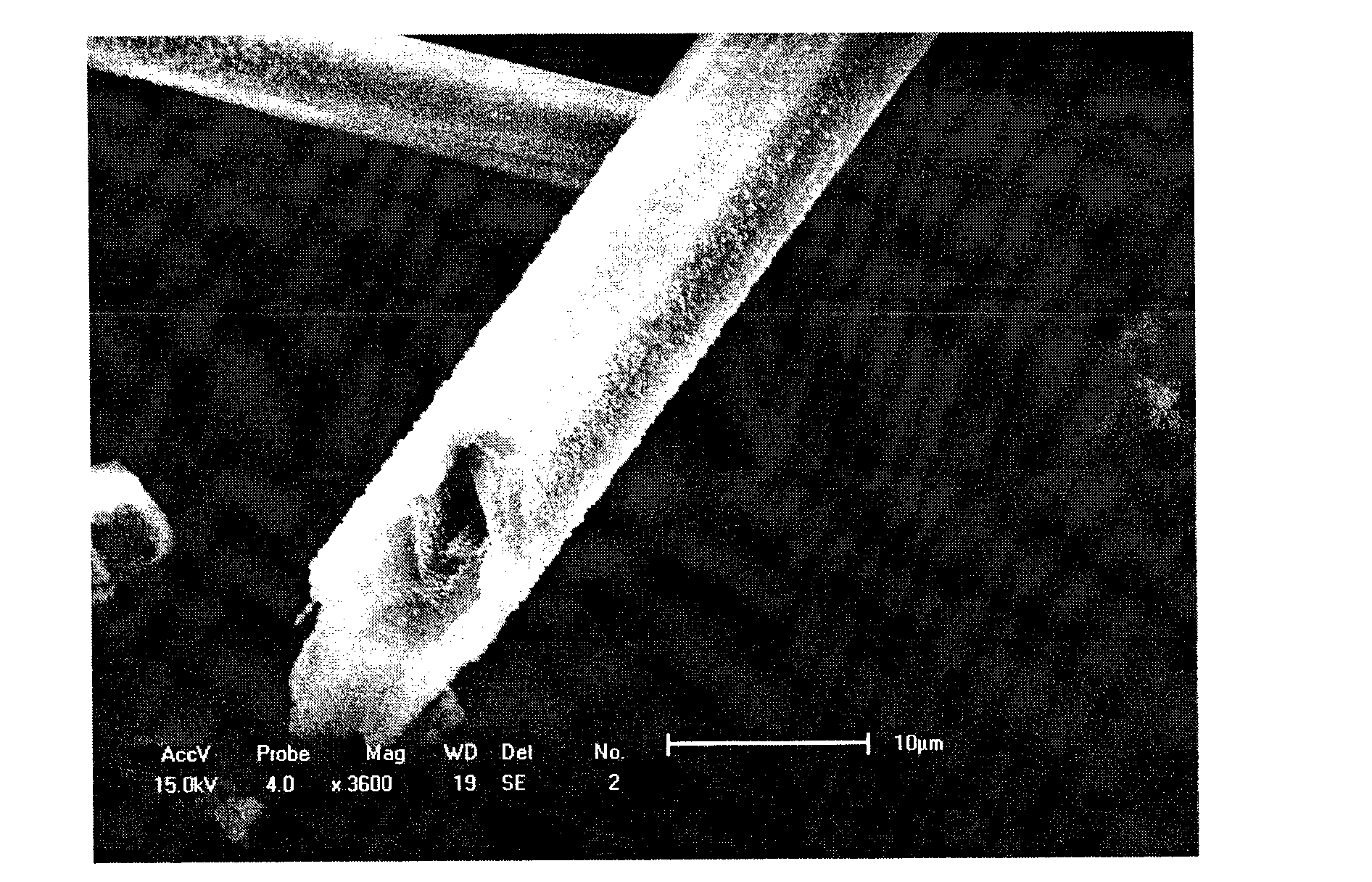

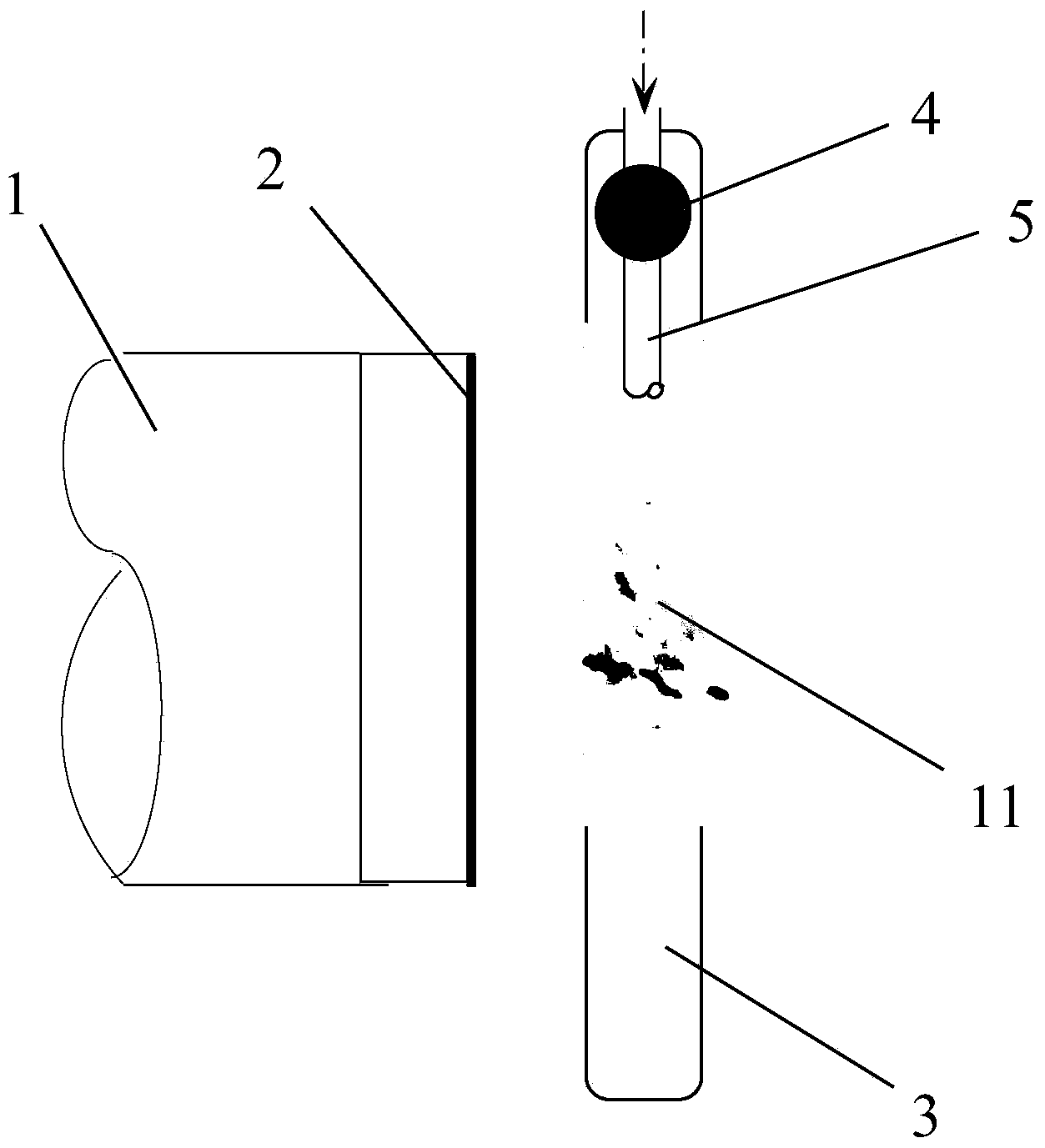

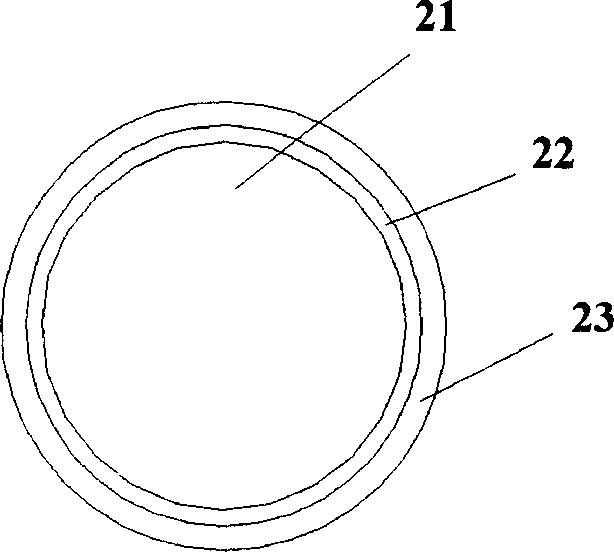

Ultra-micro ring electrode and preparation method thereof

InactiveCN1789997AMiniaturizableRealize mass productionMaterial electrochemical variablesElectrodesHydrofluoric acidFluohydric acid

The invention discloses a super-microring electrode and preparing method, which comprises the following steps: first, taking the naked optical fiber as the filamentary insulation substrate of super-microring electrode; adapting RF magnetic sputtering technology to deposit a layer of metal film as electrode film on the optical fiber surface; second, adapting plasma reinforced chemical gas-phase deposition technology to deposit silica film as electrode insulation film on the metal film; then, corroding the silica film on one end of optical fiber through fluohydric acid to make the optical fiber covered by metal film only; adapting aluminum powder conductive glue to connect the optical fiber and copper lead; finally, assembling the copper lead of super-microring electrode in the plastic liner; adapting optical fiber knife pen to cut the super-microring electrode surface on the other end of optical fiber covered by metal film and silicon nitride film.

Owner:XI AN JIAOTONG UNIV

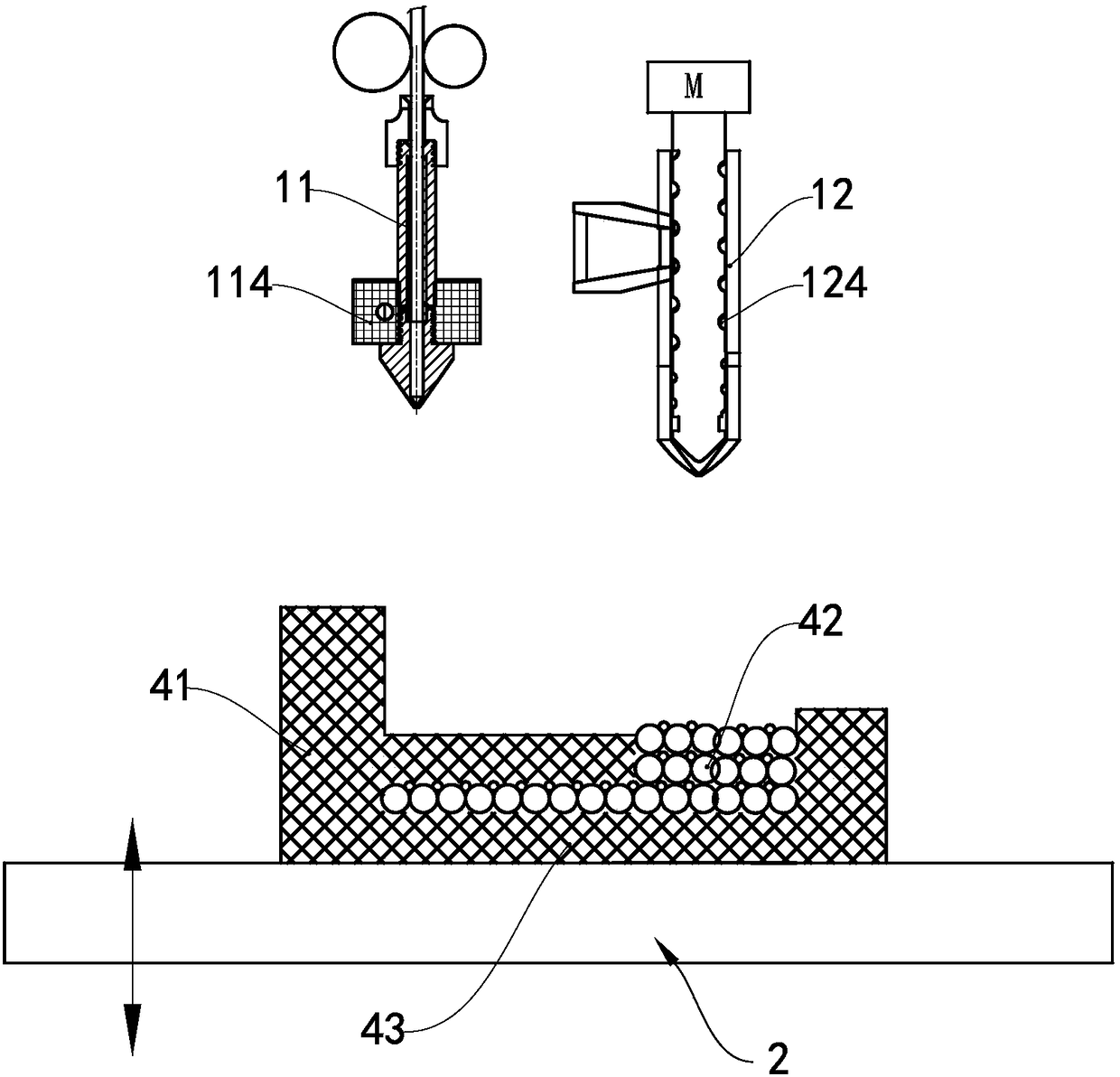

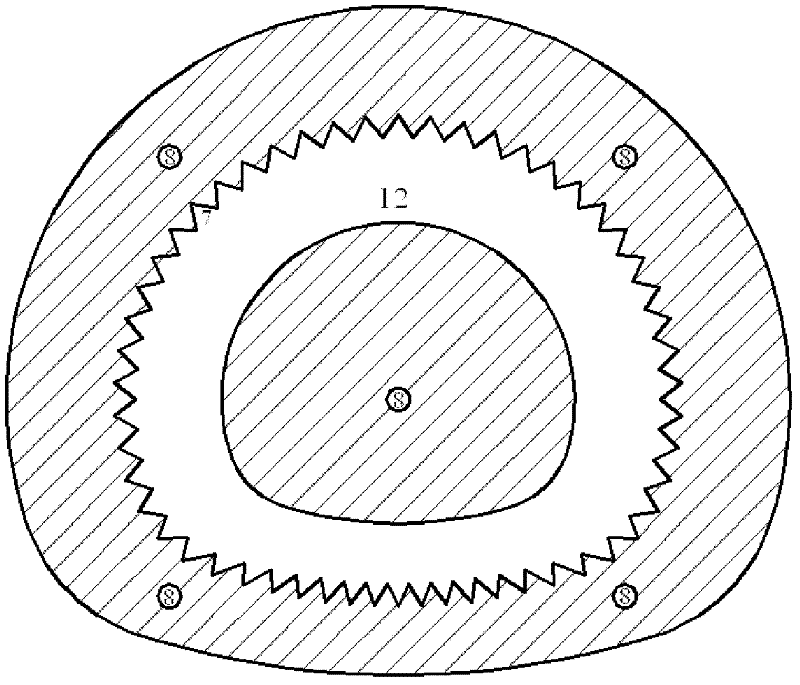

Accurate automatic excavating device for model test

InactiveCN102359136APrecise control of tunneling depthPrecisely control the shape of the excavation sectionSoil-shifting machines/dredgersEngineeringModel test

The invention relates to an accurate automatic excavating device for a model test. The excavating device is favorable for improving the similarity of the model test and an actual project, realizing automation of the model test excavating process and reducing the artificial disturbance influence of manual excavation on a model, so that the monitoring data of the model test are more accurate, and the law in the test is closer to the actual project. The excavating device comprises a cutter, the front side and the periphery of which are used for simultaneously cutting low-strength similar materials; the cutter is connected with a power system through a transmission rod; a hole-type control device is arranged at the rear part of the cutter and at the front part of the transmission rod, the hole-type control device is provided with an arc cutter moving track with toothed edges, the transmission rod is arranged in the cutter moving track and engaged with the inner toothed edge of the cutter moving track through a gear, the gear is also connected with a sleeve sleeved on the transmission rod, the sleeve is provided with scales, and a penetration positioning ring is arranged at the rear part of the sleeve; and meanwhile, a cutter rotating control handle for controlling the rotating speed of the cutter is arranged at the tail end of the sleeve.

Owner:SHANDONG UNIV

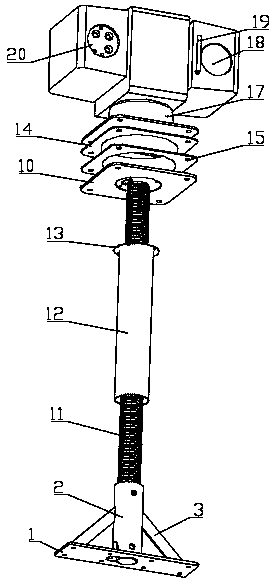

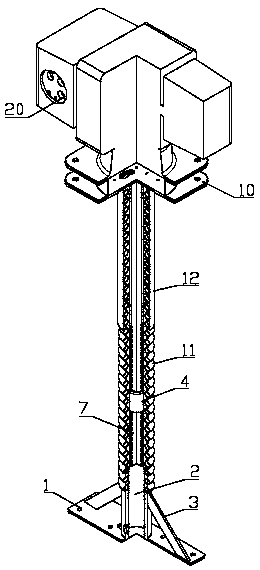

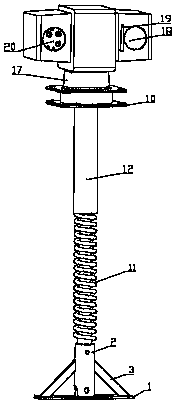

Multi-degree of freedom adjustment structure for security robot

PendingCN108189080AAffect normal workNormal transmissionManipulatorMulti degree of freedomDrive motor

The invention relates to a multi-degree of freedom adjustment structure for a security robot, and belongs to the field of security robots. The multi-degree of freedom adjustment structure for the security robot comprises a fixing support seat, an electronic push rod, a spring wire, a sleeve, a shock absorption platform, a cloud platform and a camera, and the electronic push rod includes a drivingmotor, a driving motor supporting tube, a worm, a lifting screw rod and a stroke switch. The invention provides the multi-degree of freedom adjustment structure for the security robot, and the multi-degree of freedom adjustment of the camera of the security robot is achieved to meet different working requirements; the drive motor drives the screw rod to move up and down, the stroke control is moreprecise, and the lifting reaction speed is faster; the conditions that the camera can be powered and video signal transmission is normal can be ensured while the lifting mechanism moves up and down,and the case that the disconnection of a wire caused by the movement of the push rod affects the normal operation of the security robot is avoided.

Owner:中山火炬高新企业孵化器有限公司

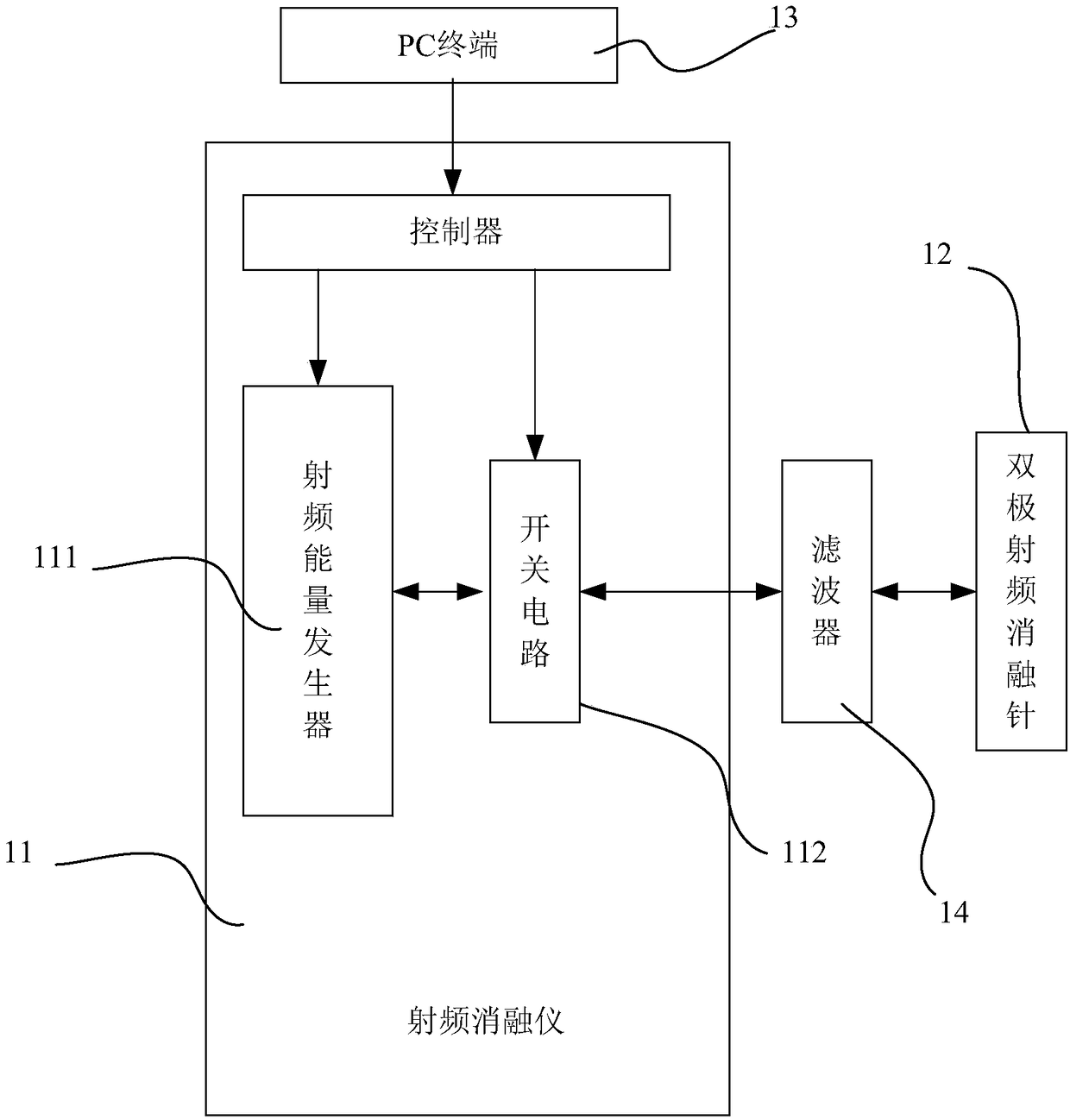

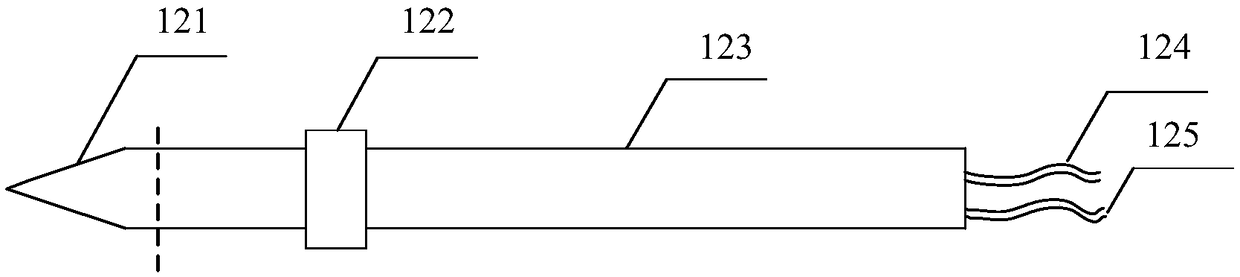

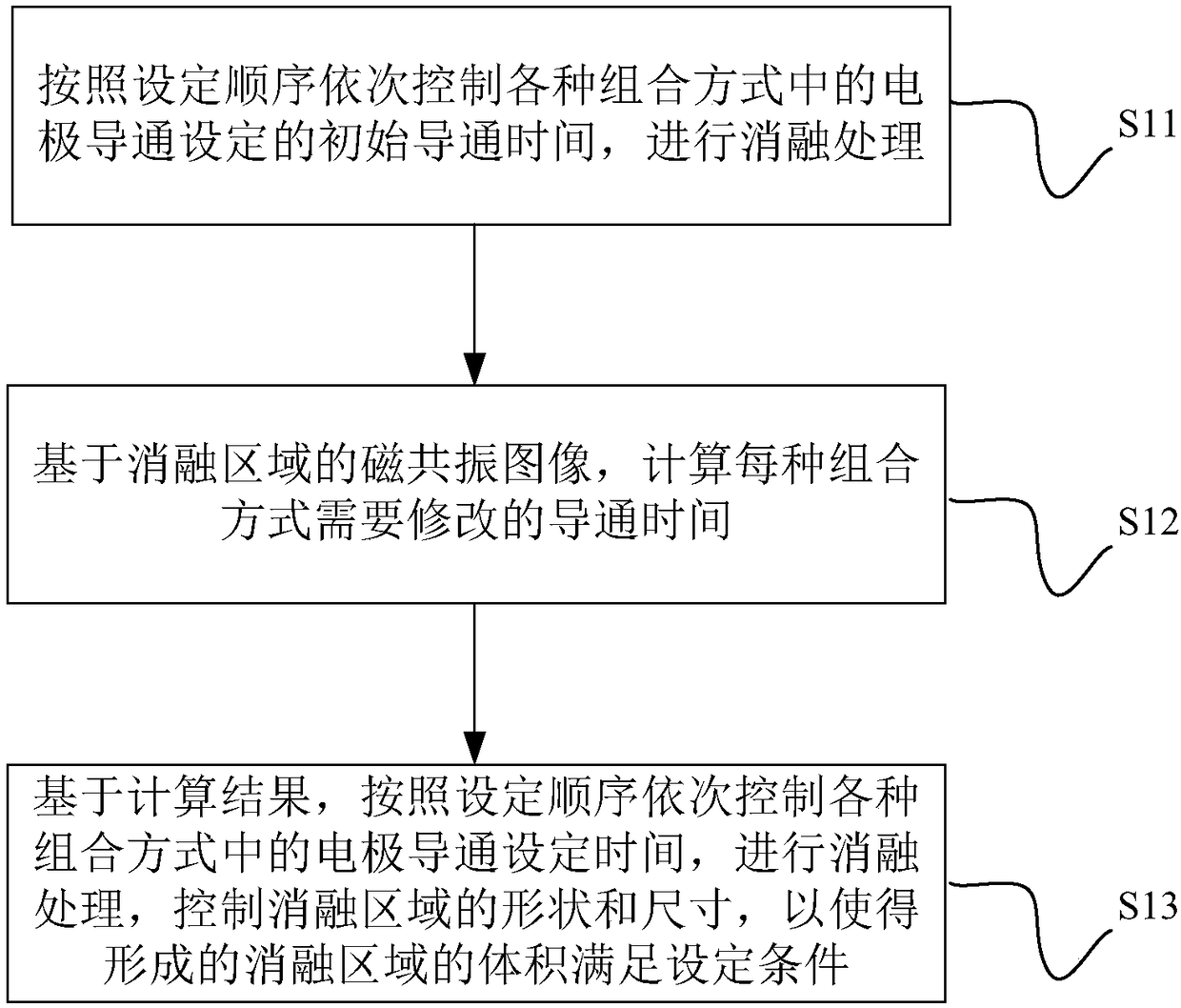

Radio frequency ablation system and control method thereof

PendingCN108354665APrecise shape controlDiagnosticsSurgical instruments for heatingRadio frequency energyRadiofrequency ablation device

The invention discloses a radio frequency ablation system and a control method thereof. The radio frequency ablation system comprises a radio frequency ablatograph for generating radio frequency energy on the basis of set ablation parameters, and a plurality of bipolar radio frequency ablation needles, wherein each bipolar radio frequency ablation needle comprises a first electrode and a second electrode for outputting the radio frequency energy; the radio frequency ablatograph comprises a radio frequency energy generator and a switching circuit; the radio frequency energy generator is used for generating radio frequency energy; the switching circuit is used for controlling the on-off states between each first electrode, each second electrode and the radio frequency energy generator. According to the technical scheme, the on-off states between each first electrode, each second electrode and the radio frequency energy generator can be independently controlled through the switching circuit, the size of the radial ablation region can be obtained through one first electrode and one second electrode, and the shape of the ablation region can be accurately controlled by controlling the on-off states of each first electrode and each second electrode.

Owner:安徽硕金医疗设备有限公司

Ultrathin carrier cell sheet and preparation method thereof

ActiveCN106924817AHigh mechanical strengthTrait controlCoatingsProsthesisMacromolecular drugUltimate tensile strength

The invention discloses an ultrathin carrier cell sheet and a preparation method thereof. The preparation method comprises the following steps of (1) spreading a gel material solution onto a substrate, and condensing into a solid state; (2) generating an ion polymer layer which has opposite polarity with the gel material on the substrate spread with the gel material, generating an ion polymer layer which has opposite polarity with the upper ion polymer layer, on the upper ion polymer layer, and repeating the operation, so as to form a layered self-assembly film; (3) planting a target cell into the substrate obtained in step (2), and conventionally culturing; (4) in the culture process, enabling the layered self-assembled film loaded with the cell to disengage from the substrate, so as to form the cell sheet. Compared with the traditional preparation method of the cell sheet, the preparation method has the advantages that the character control or decomposing step of a supporter material is not needed, the mechanical strength of the cell sheet is obviously improved, and macromolecular medicines, such as protein, polypeptide, antibody and nucleic acid, can be loaded.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com