Three-dimensional printer, molding method of three-dimensional printer, and metal three-dimensional object

A three-dimensional printer and molding method technology, applied in the direction of additive processing, etc., can solve the problems of low powder spreading work efficiency, reduced work efficiency, large energy consumption, etc., to achieve good mechanical properties, avoid poor molding accuracy, and reduce material looseness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The first embodiment of the three-dimensional printer

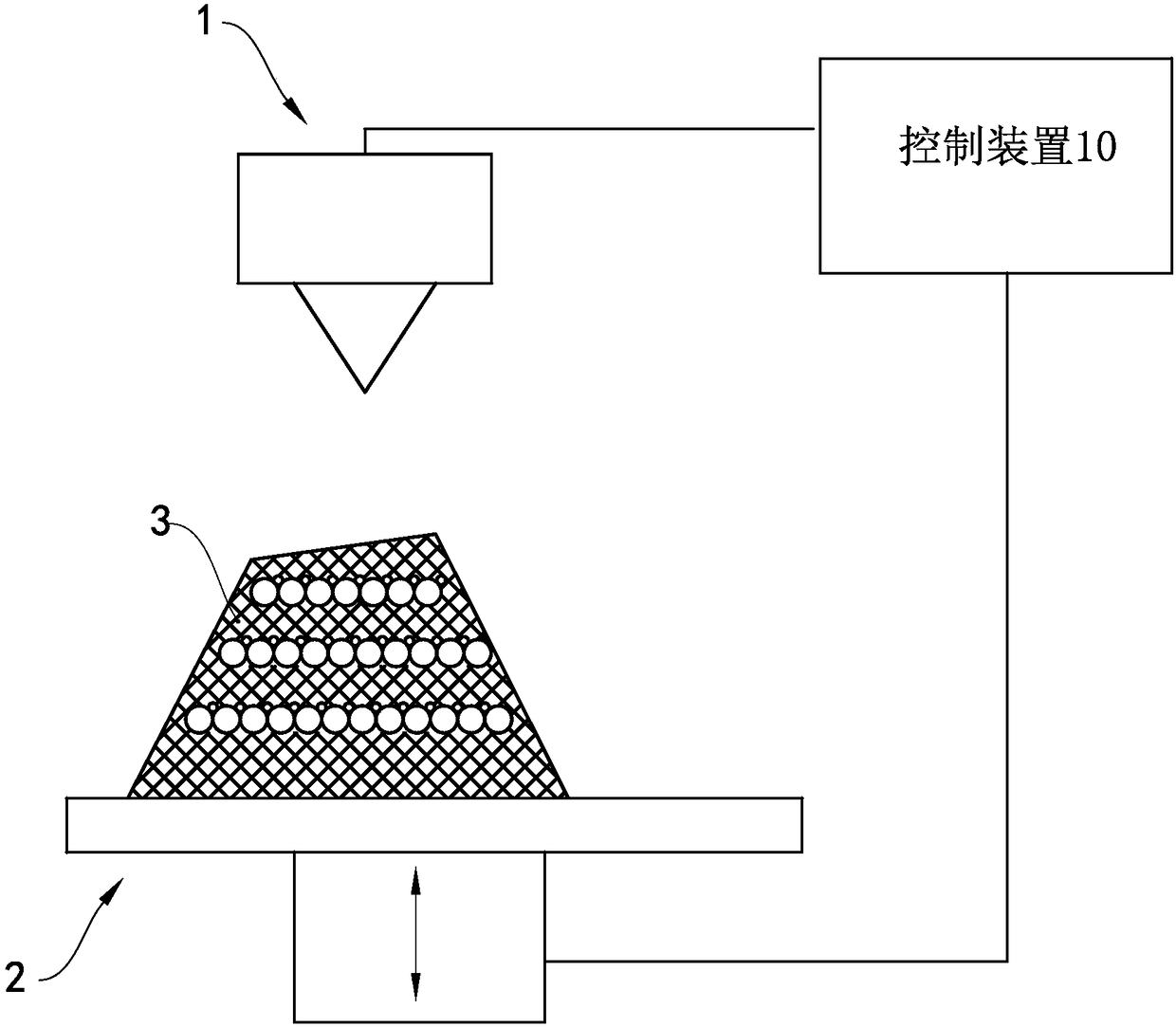

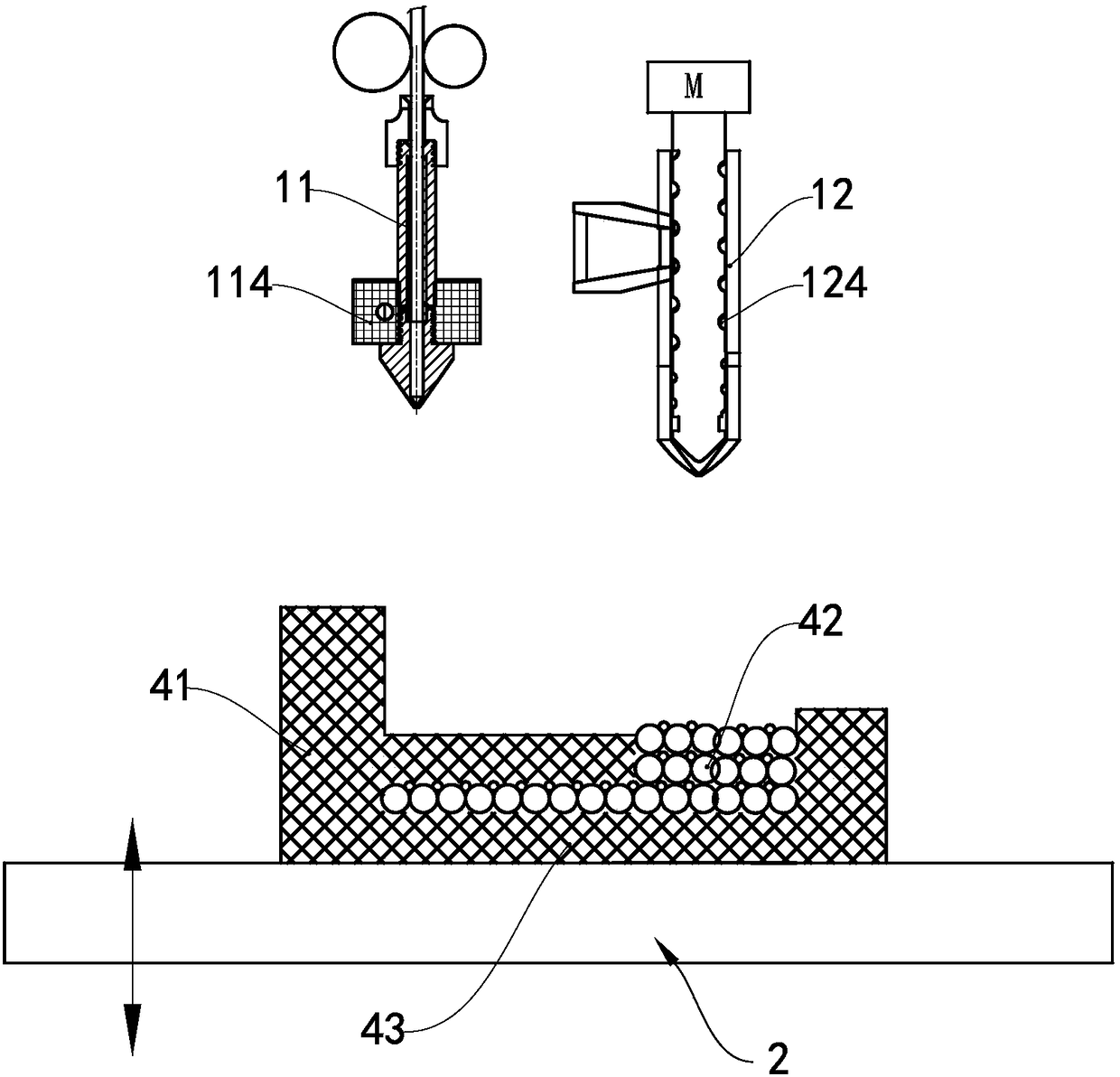

[0030] see figure 1 , the three-dimensional printer of this embodiment includes a print head assembly 1, a printing platform 2, a control device 10 and a sintering molding chamber, and the interior of the sintering molding chamber is a vacuum environment or an inert gas environment.

[0031]The sintering molding chamber is used for sintering and molding the preliminary solidified object 3. The temperature of the sintering step is preferably controlled at 1350°C to 1380°C. The high-temperature sintering process is relatively common in the molding process of powder metal, and its main purpose is to enhance the structure of the three-dimensional object In terms of strength, those skilled in the art can select a suitable temperature for different types of metal powder materials to sinter and shape the initially solidified object.

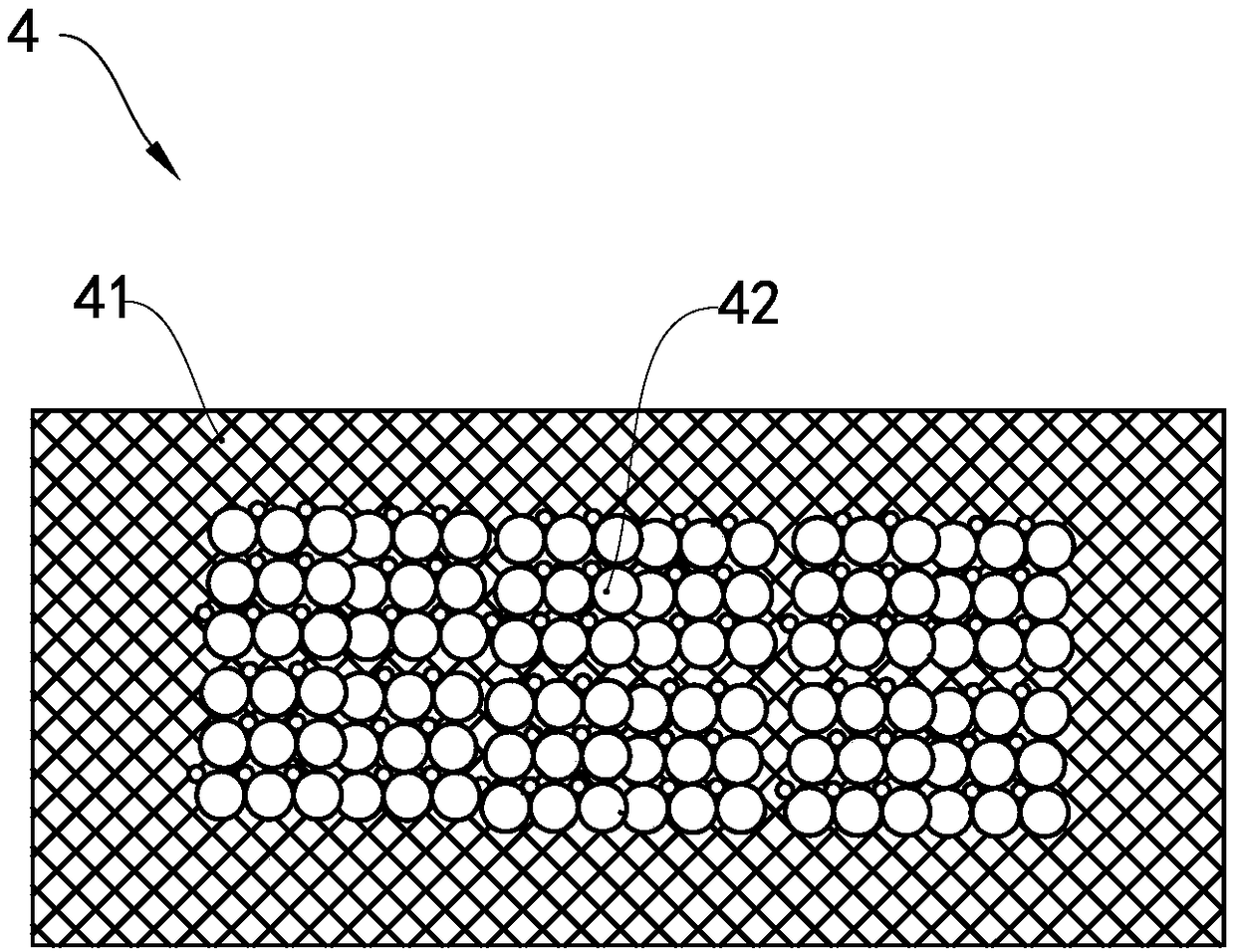

[0032] see figure 2 and image 3 , the preliminary cured object obtained by printing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com