Patents

Literature

4014results about How to "Discharge in time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Selective laser melting forming device and method of medical magnesium alloy metal part

ActiveCN101856724ASatisfies complex spatial shape requirements with high degrees of freedomMeet complex space shape requirementsSelective laser meltingOptoelectronics

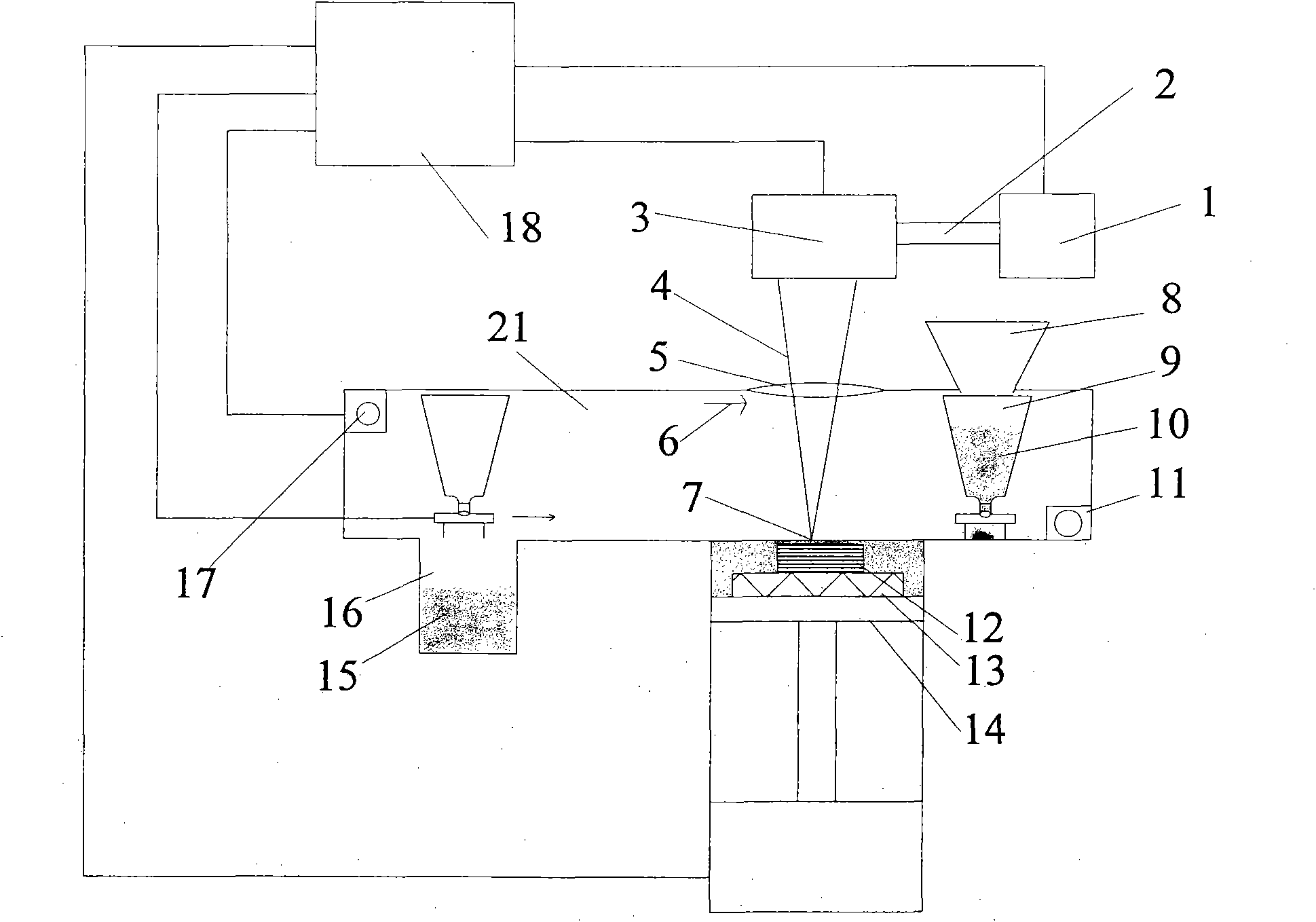

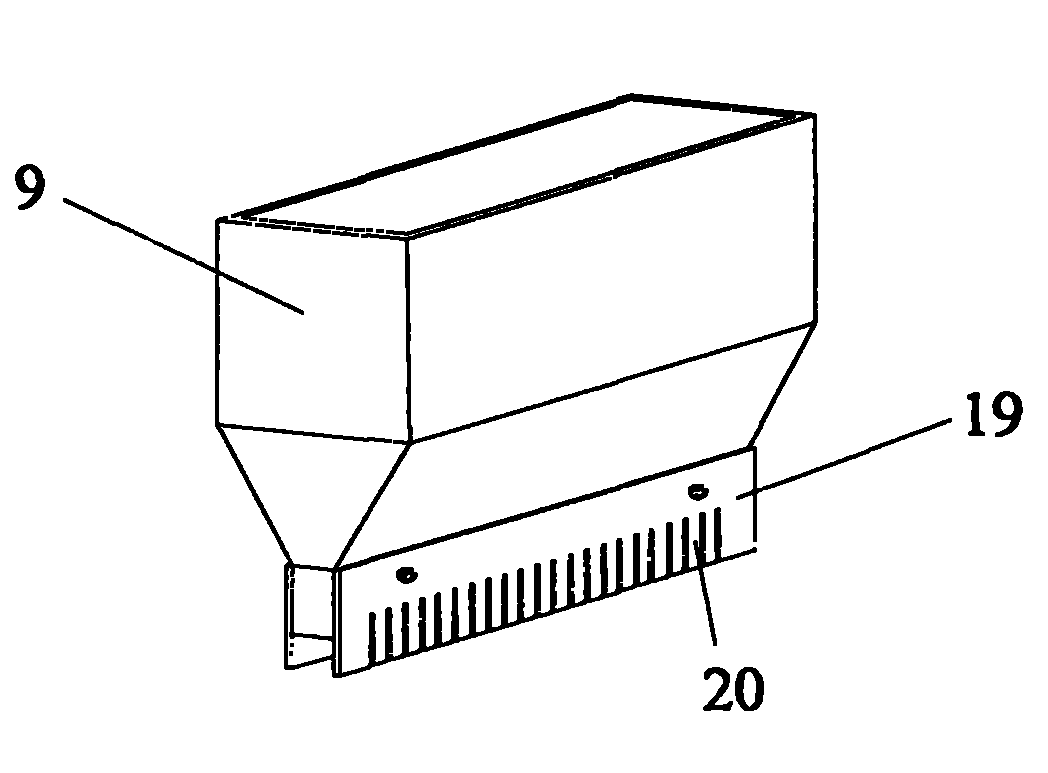

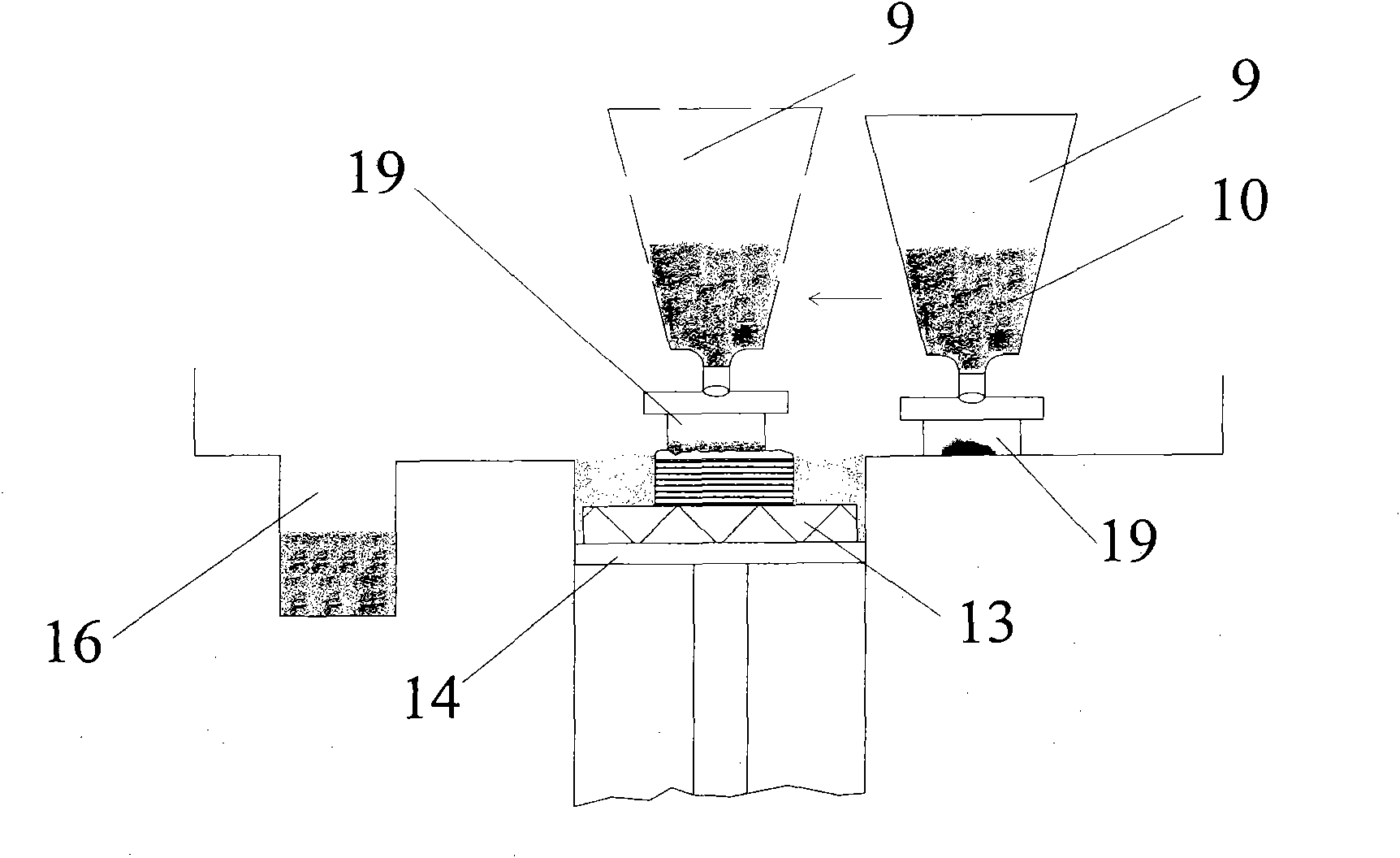

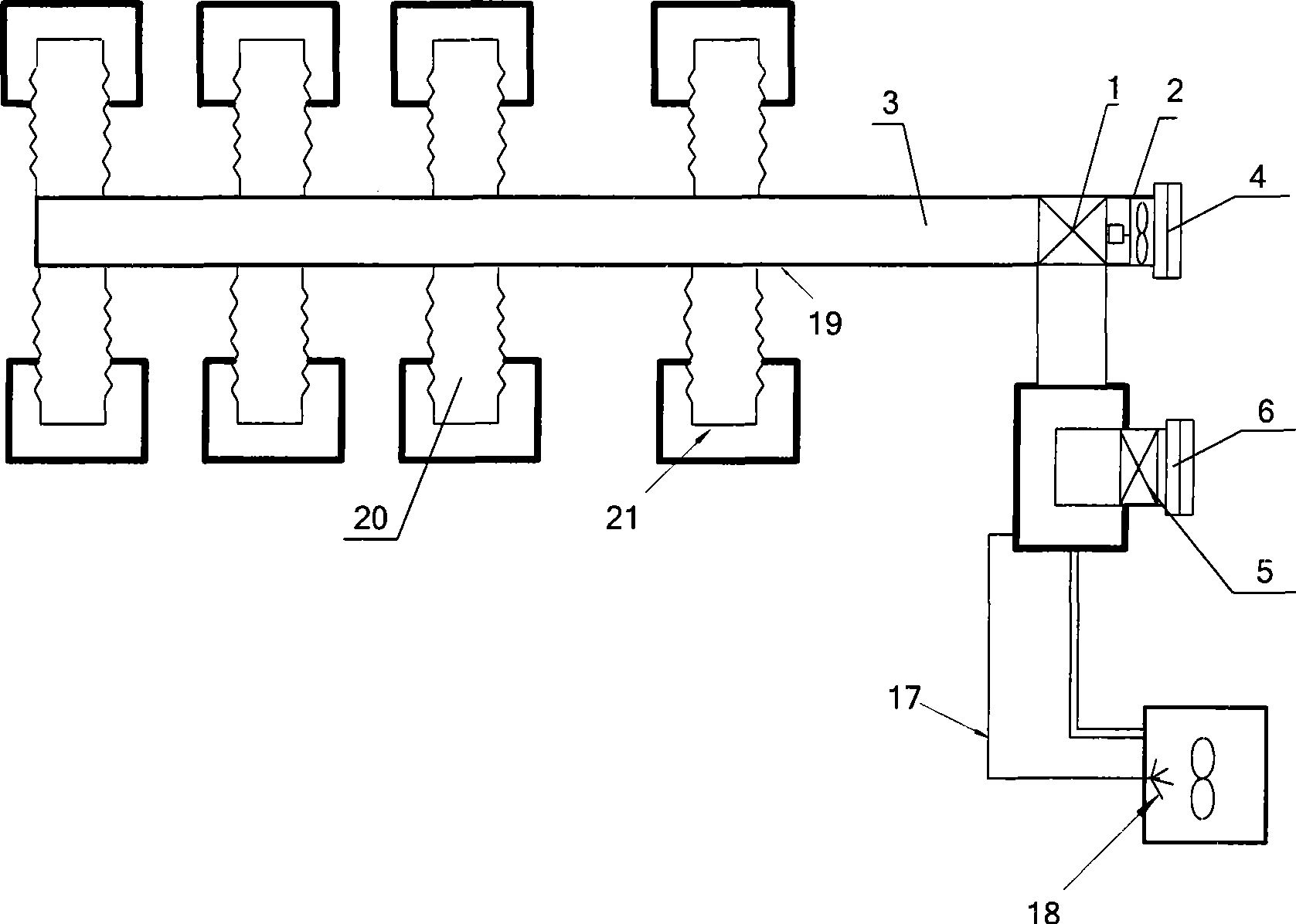

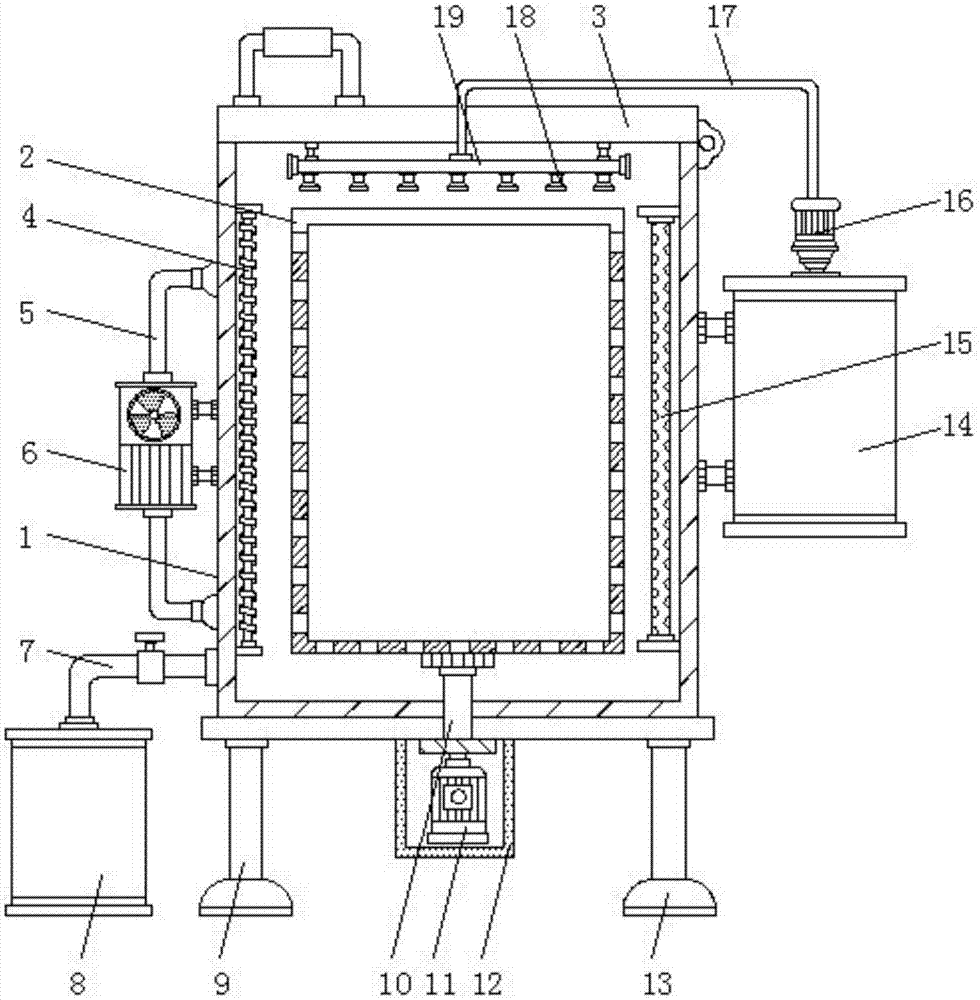

The invention provides a selective laser melting forming device of a medical magnesium alloy metal part, which comprises a control device, a powder delivering and spreading device, a laser transmission mechanism, an air purification device and a closed forming chamber, wherein the powder delivering and spreading device comprises a hopper and powder spreading brushes arranged on two sides below the hopper, the upper part of the hopper is arranged in a way of corresponding to a feeding opening on the upper part of the forming chamber, and the lower parts of the powder spreading brushes horizontally correspond to the upper surface of a forming cylinder; the laser transmission mechanism is arranged outside and above the forming chamber and is arranged in a way of corresponding to the forming cylinder; the side wall of the forming chamber is provided with an air inlet and an air outlet, and the air purification device is connected with the air inlet and the air outlet respectively; and the control device is connected with the powder delivering and spreading device, the laser transmission mechanism, the forming cylinder and the air purification device respectively. The invention also provides a selective laser melting forming method of the medical magnesium alloy metal part. The device and the method can manufacture parts which have complex shapes required in the medical field directly, and have the advantages of high forming efficiency and the like.

Owner:SOUTH CHINA UNIV OF TECH

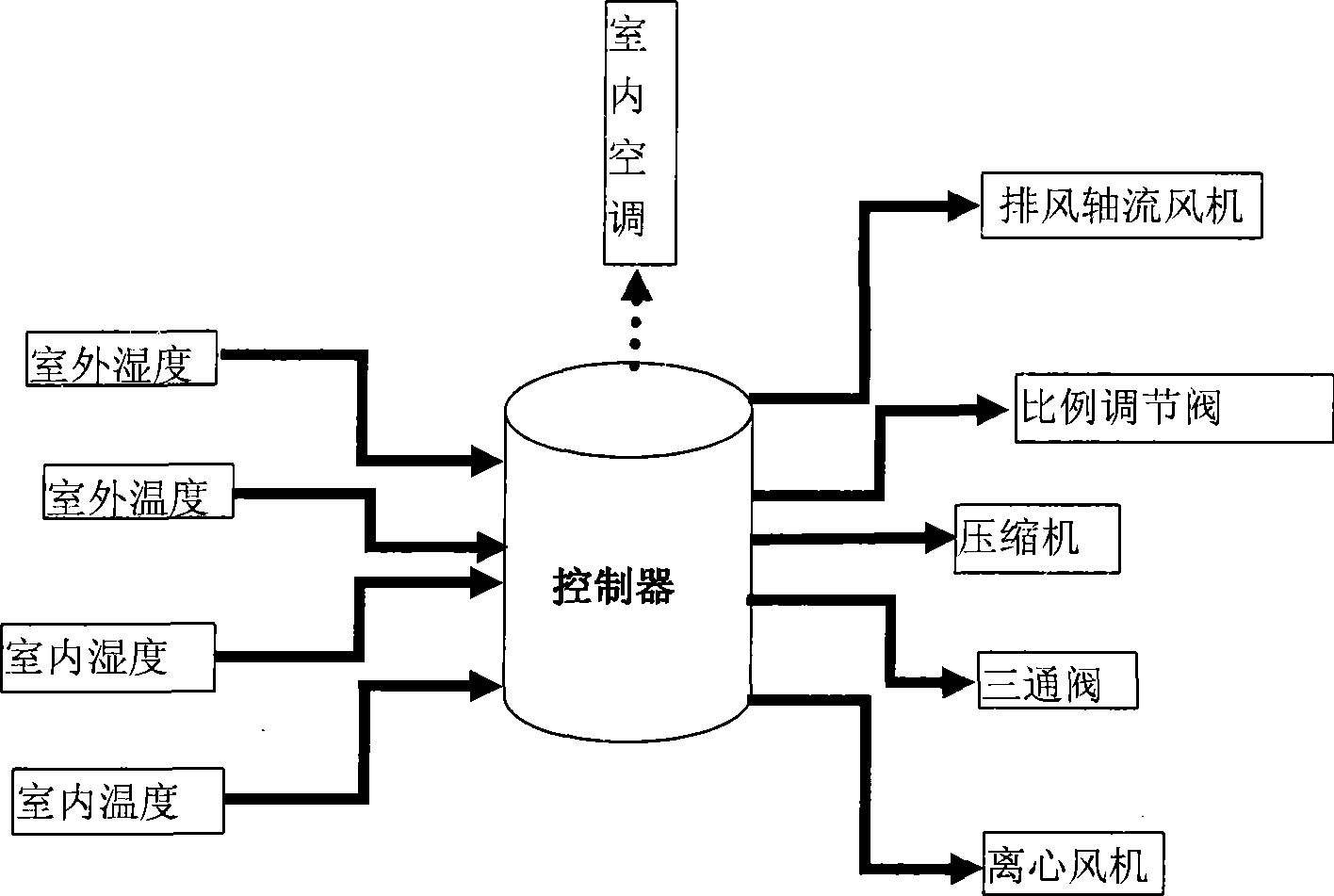

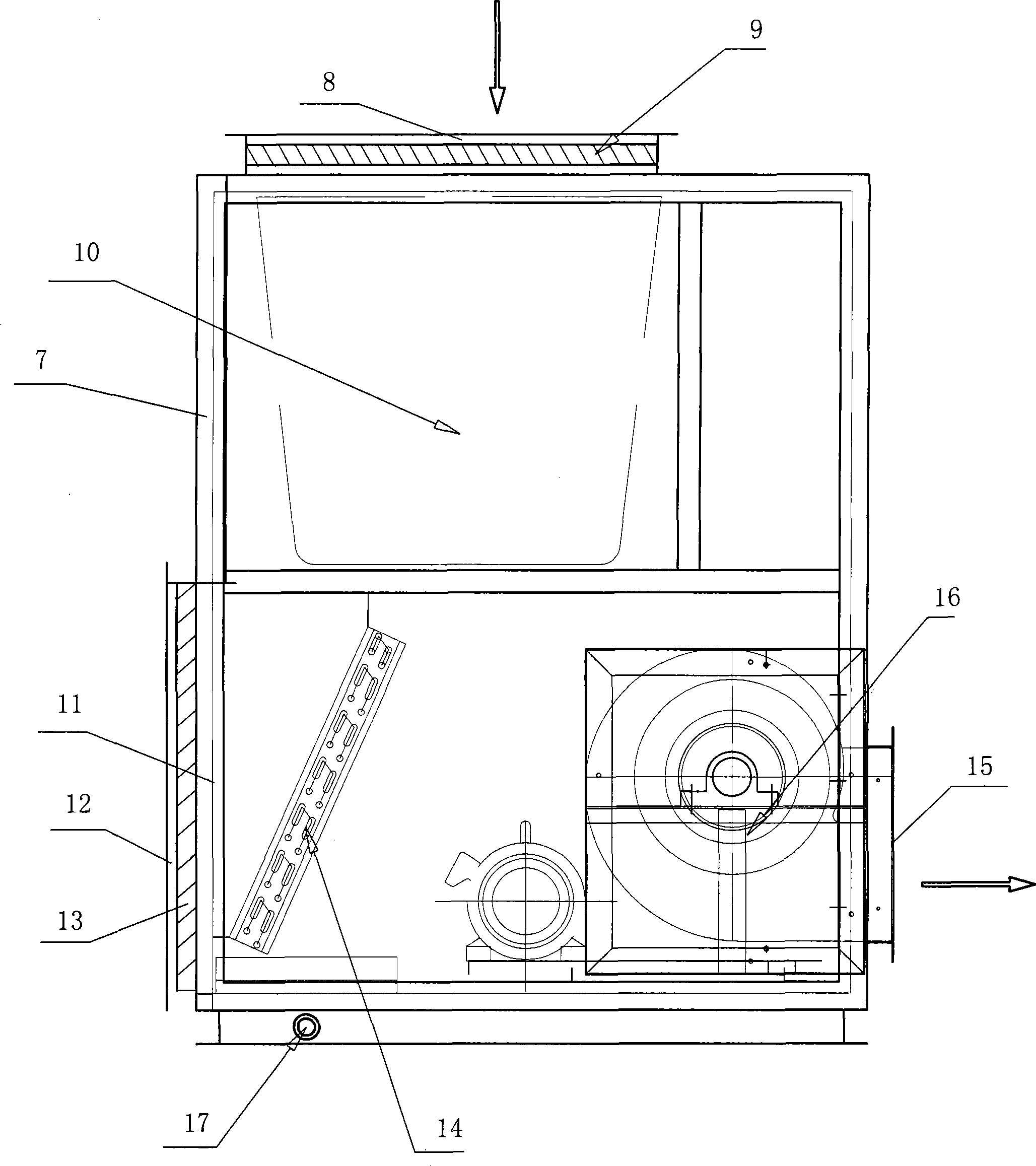

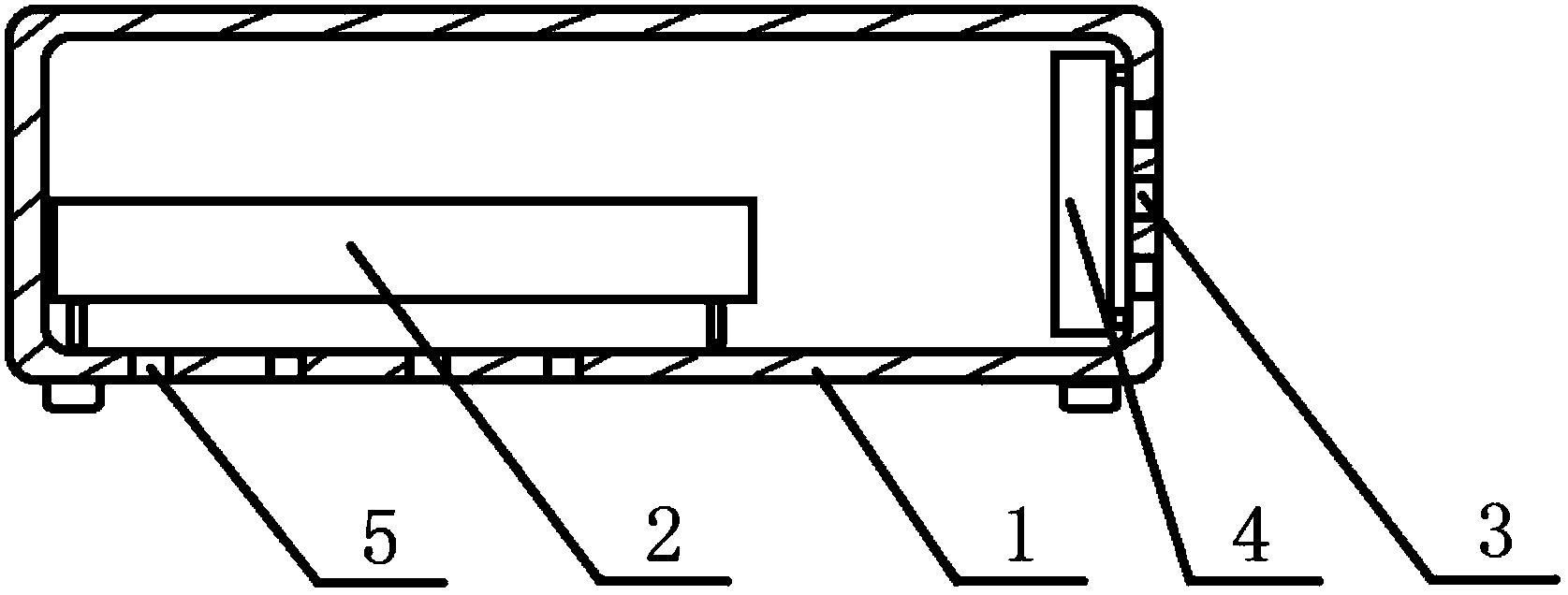

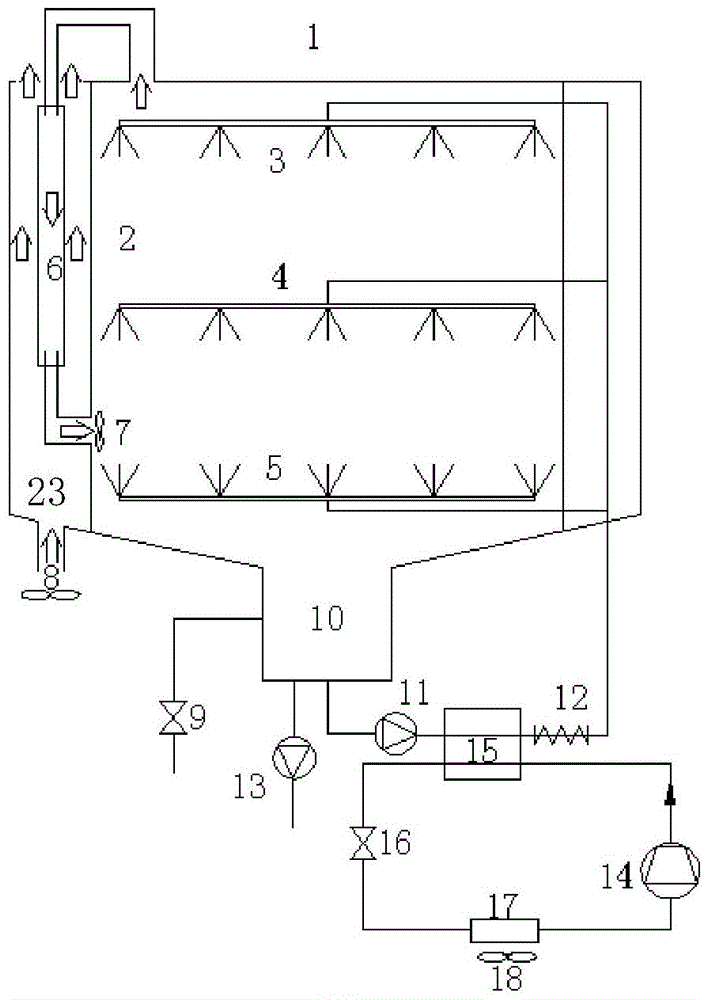

Communication base station energy-saving air conditioner unit and airflow regulating method thereof

InactiveCN101440984AReduce energy consumptionMaintain humidityMechanical apparatusSpace heating and ventilation safety systemsAirflowEngineering

The present invention discloses a communication base station energy-saving air-conditioning unit, which comprises a compressor formed a circulating system, a fresh air system for feeding fresh air, a constant temperature and humidity indoor machine unit for processing the fresh air and the return air, a three-way valve (1), an air exhausting axial fan (2) and a first air return opening (3), wherein the three-way valve (1) is connected with an air inlet (6), the present invention also comprises a temperature sensor for detecting air temperature of the base station and outside air temperature, a temperature sensor for detecting the air humidity of the base station and outside air, and a controller for controlling the air exhausting axial fan (2), the three-way valve (1), a proportion regulating valve (5), the constant temperature and humidity indoor machine unit and the compressor according to the information of the temperature sensor and the humidity sensor. The present invention can effectively reduce the energy-consumption of the air-conditioning unit by reasonably using air flow organization and distribution.

Owner:SUN YAT SEN UNIV

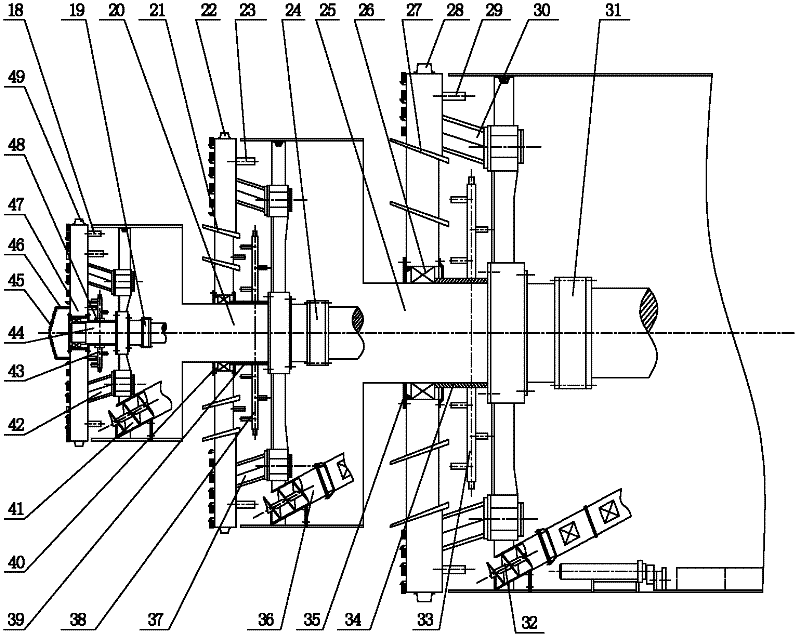

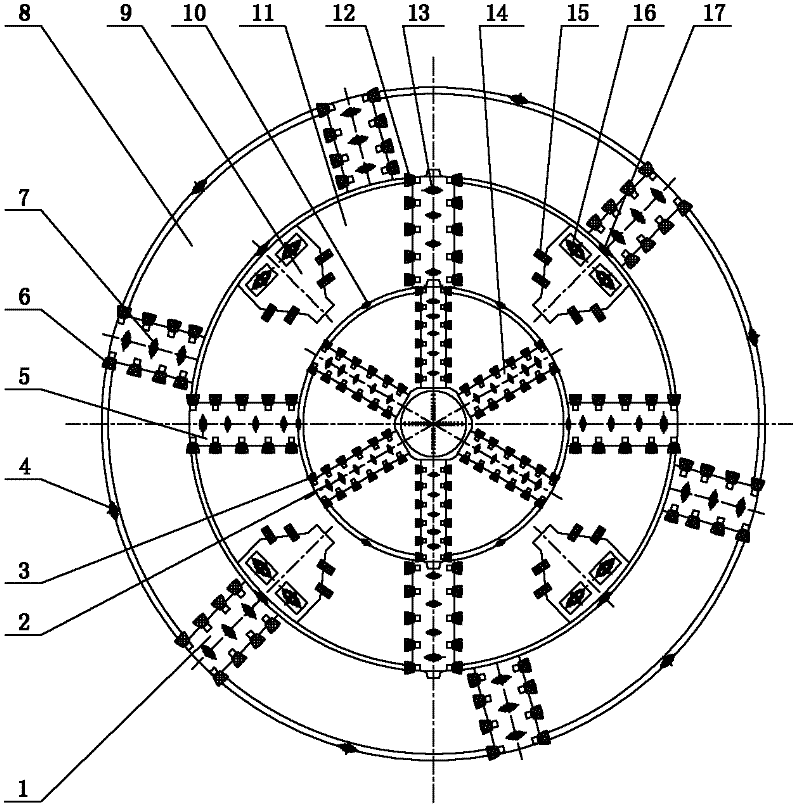

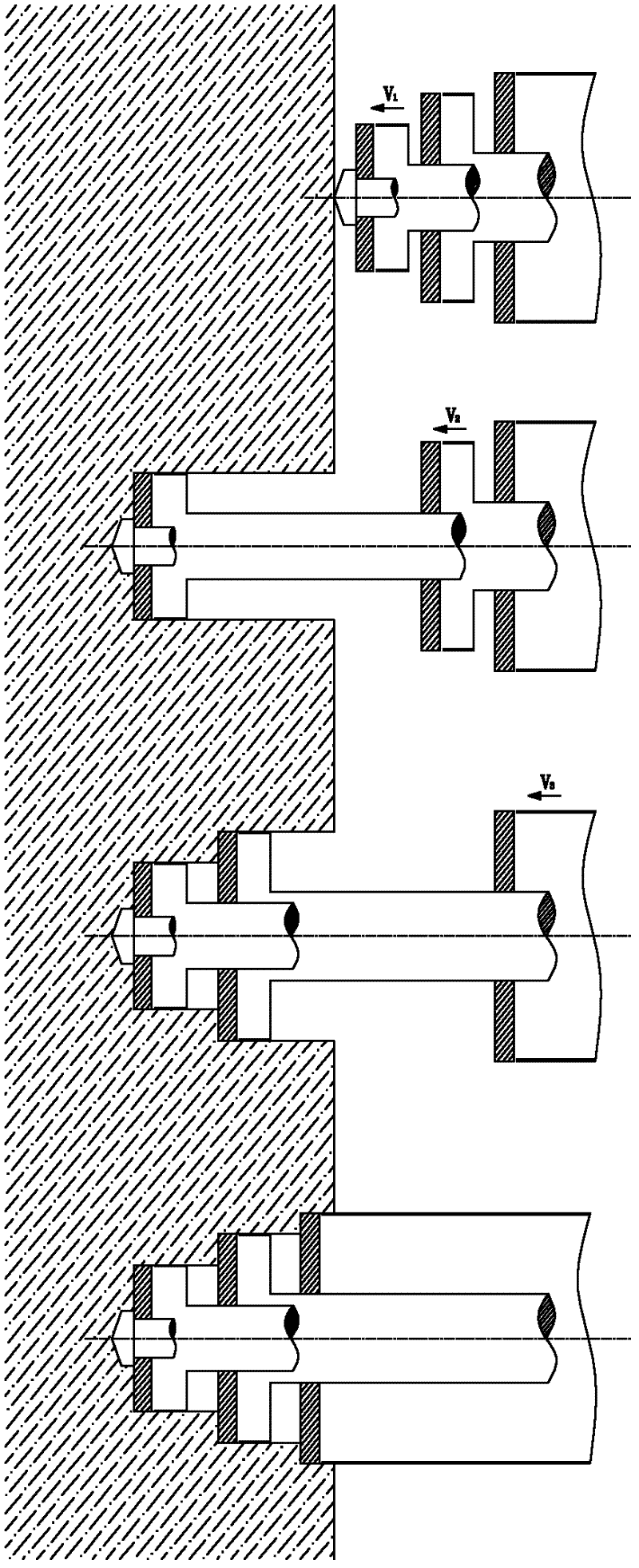

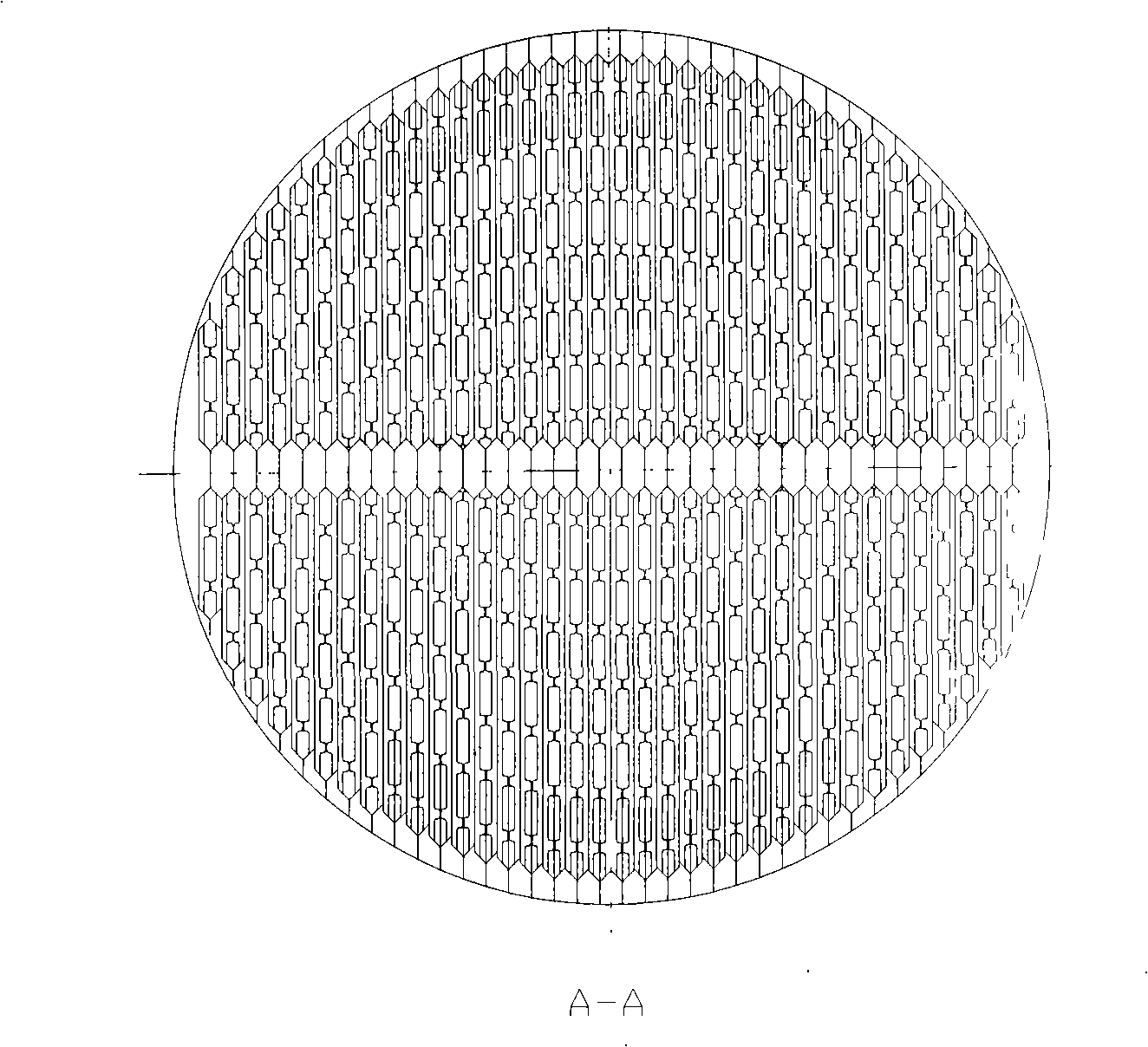

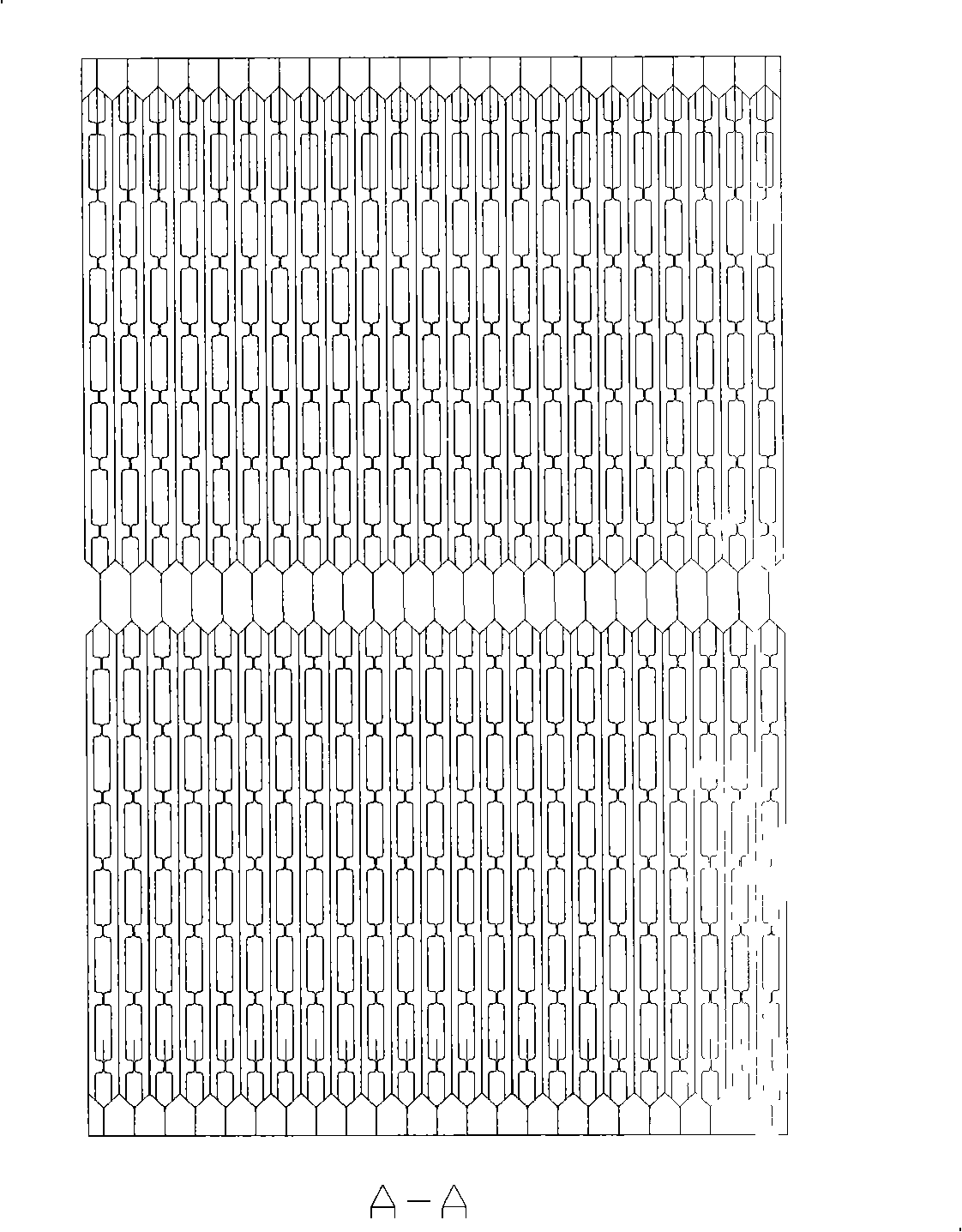

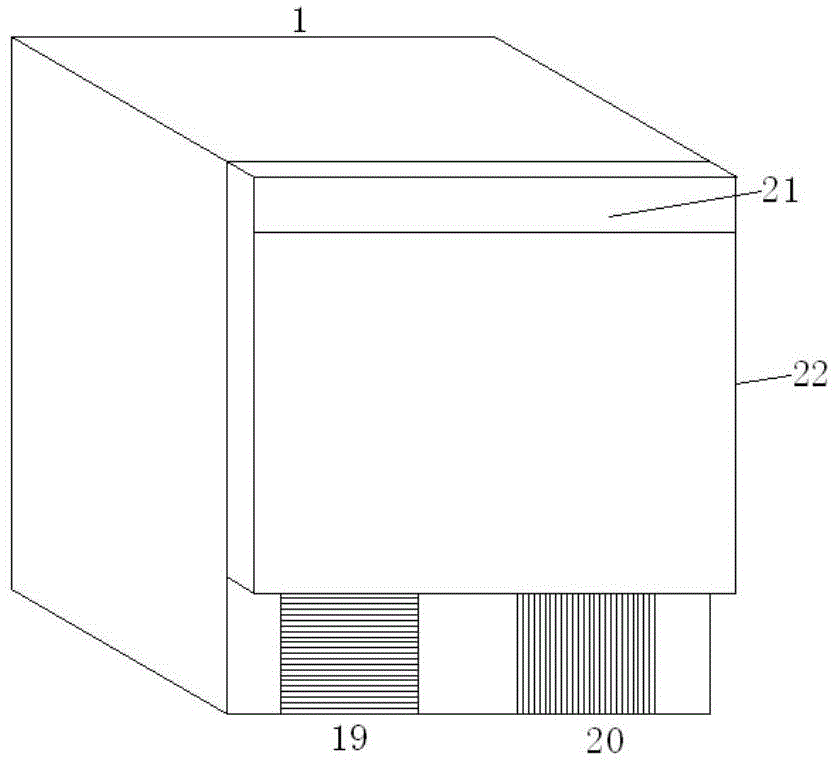

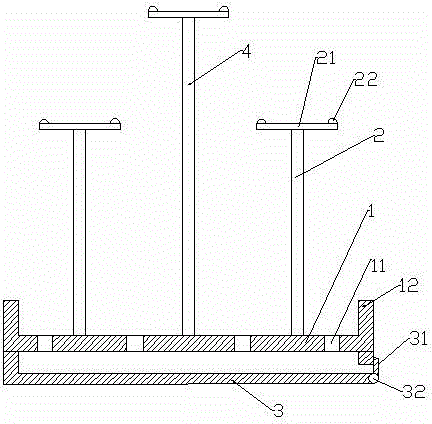

Multistage-separation progressive shield cutter head

InactiveCN102536254ASpeed up the flowEasy control of earth pressure balanceTunnelsEngineeringShield tunneling

The invention discloses a multistage-separation progressive shield cutter head which comprises a plurality of flexible shield cutter heads. During the work, a central shield cutter head primary rotation shaft clutch is closed; a power main shaft drives a primary cutter head to rotate to cut rocks; and at the same time, a rear hydraulic device pushes a central cutter head to tunnel ahead. When a certain distance is tunneled, a primary clutch is separated; after partial components are reassembled, a secondary clutch is closed and a secondary cutter head starts to tunnel ahead; and repeatedly, the multistage cutter head progressive excavation is realized. Cutter heads of a shield tunneling machine of a multistage-separation progressive structure share the same power main shaft and are respectively provided with a central stirring device and an auger delivery chip removal device; and material bulks cut by the cutter heads are crushed and conveyed into a chip removal guiderail at the center of the shield machine.

Owner:XIAN RUITE RAPID MFG ENG +1

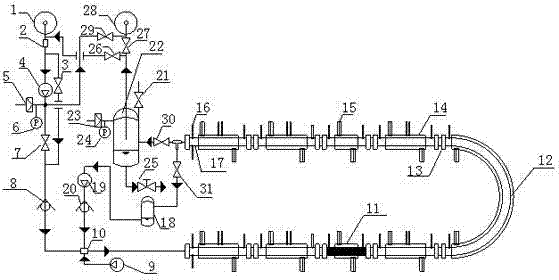

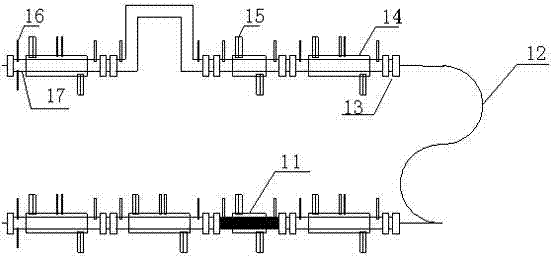

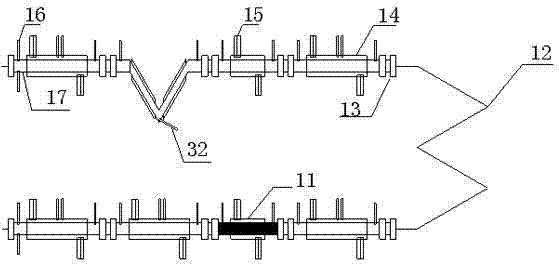

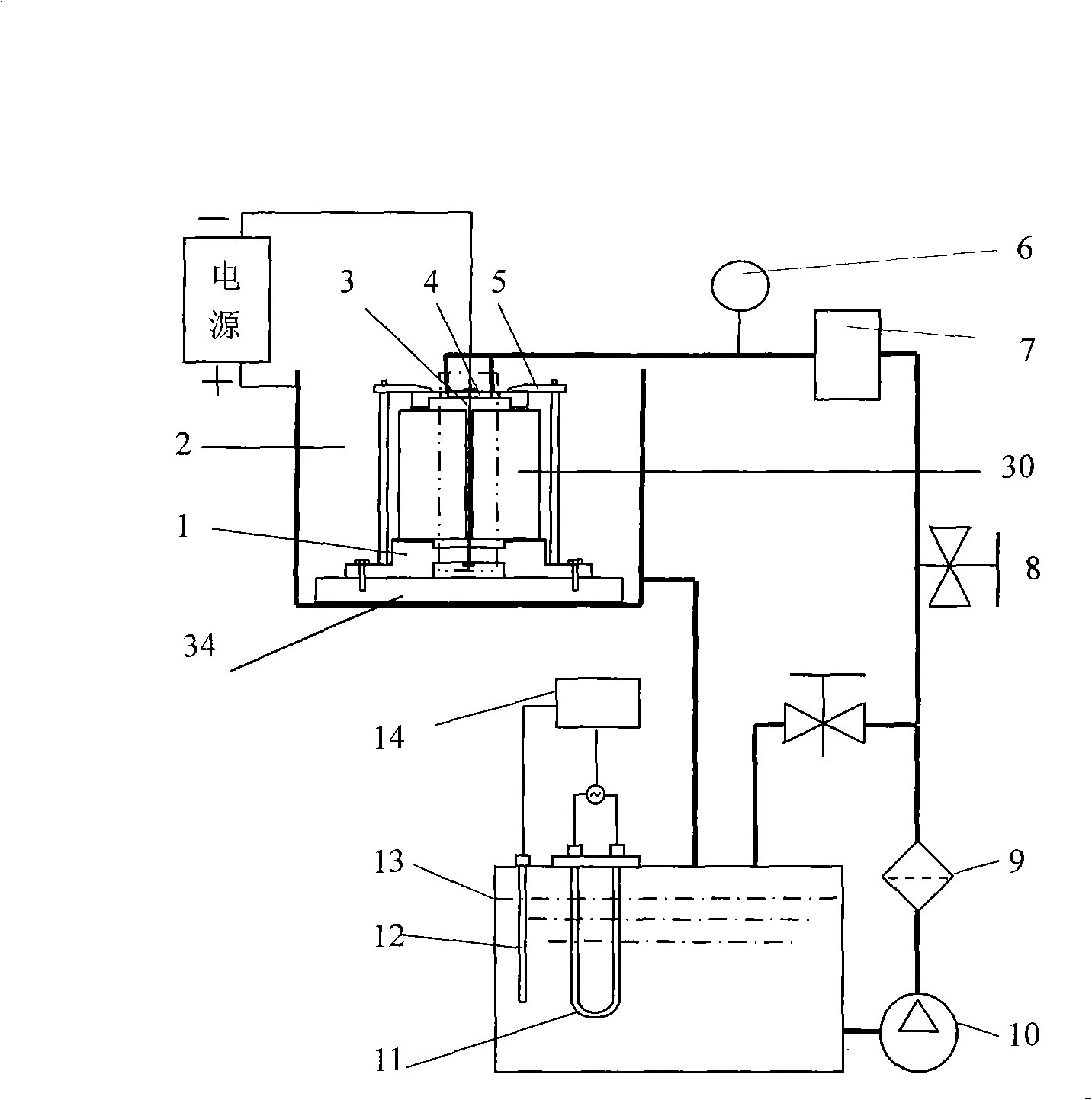

Simulating device for fluid flow safety evaluation of oil-gas pipelines

The invention discloses a simulating device for fluid flow safety evaluation of oil-gas pipelines. The device comprises a multiphase flow circulating system, a separating system, a fluid injecting system and a waste gas recovery system. The device disclosed by the invention emerges on the basis of fully considering the current fluid flow safety hotspot problem and is capable of simulating a low-temperature high-pressure environment to carry out the fluid flow safety evaluation of the oil-gas pipelines, wherein the evaluation content comprises oil-gas pipeline blockage caused by problems such as hydrate and wax deposit and the oil-gas transmission safety problem caused by pipeline corrosion. The device disclosed by the invention is not limited to the evaluation content and can also be used for exploring the research on the evaluation of multi-phase fluid flow regularity, hydrate inhibitor performance and the like. The device disclosed by the invention has the characteristics of reasonable structure, ingenious design, operational flexibility, accuracy in measurement and the like.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of nylon powder for selective laser sintering

ActiveCN104497323ADestroy the regularity of the shapeRegular shapeSelective laser sinteringOrganic solvent

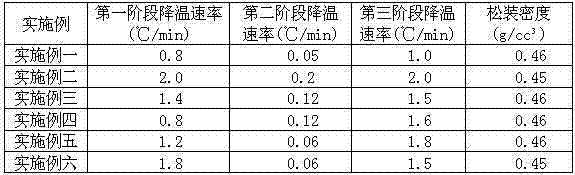

The invention provides a preparation method of nylon powder for selective laser sintering. The preparation method comprises the steps of adopting a precipitation method, and finally separating out solid powder through the processes of dissolution, cooling and precipitation. The method is characterized by being carried out under the condition of the presence of an organic solvent, wherein the cooling process is carried out in three phases, and rapid cooling is carried out to achieve a temperature which is 10 DEG C below than the separation temperature in the first phase; slow cooling is carried out to achieve the separation temperature in the second phase; rapid cooling is carried out to achieve a normal temperature in the third phase. The method is simple and feasible, low in cost, and capable of preparing the nylon powder with regular morphology, good part performance and suitable for SLS sintering.

Owner:HUNAN FARSOON HIGH TECH CO LTD

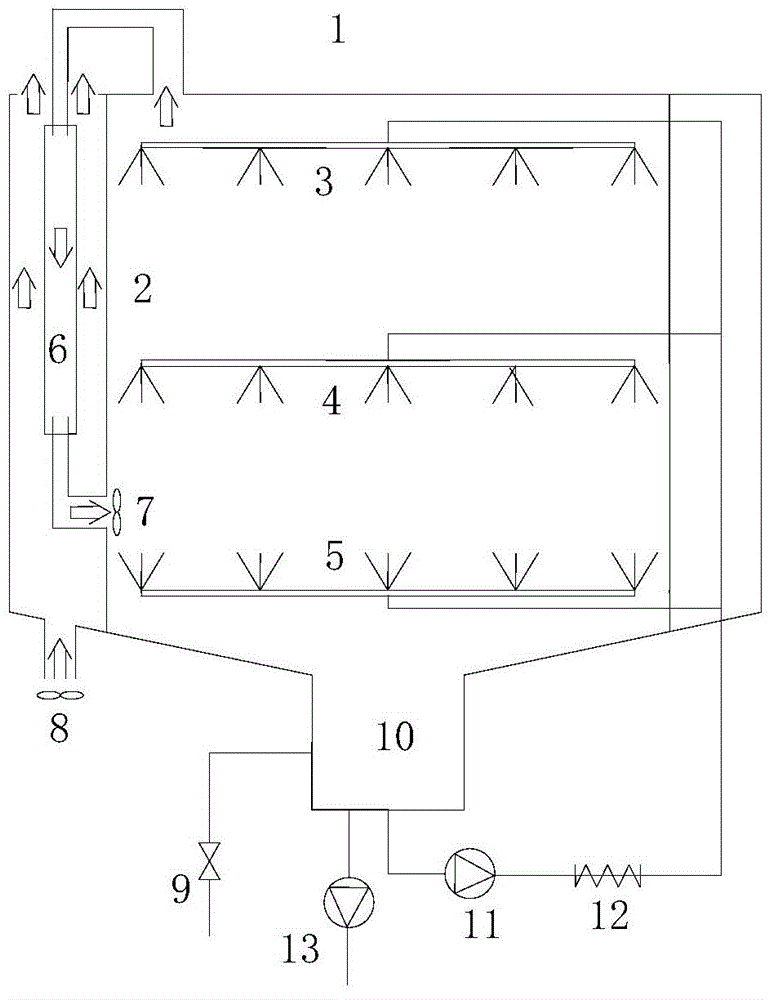

Photobioreactor

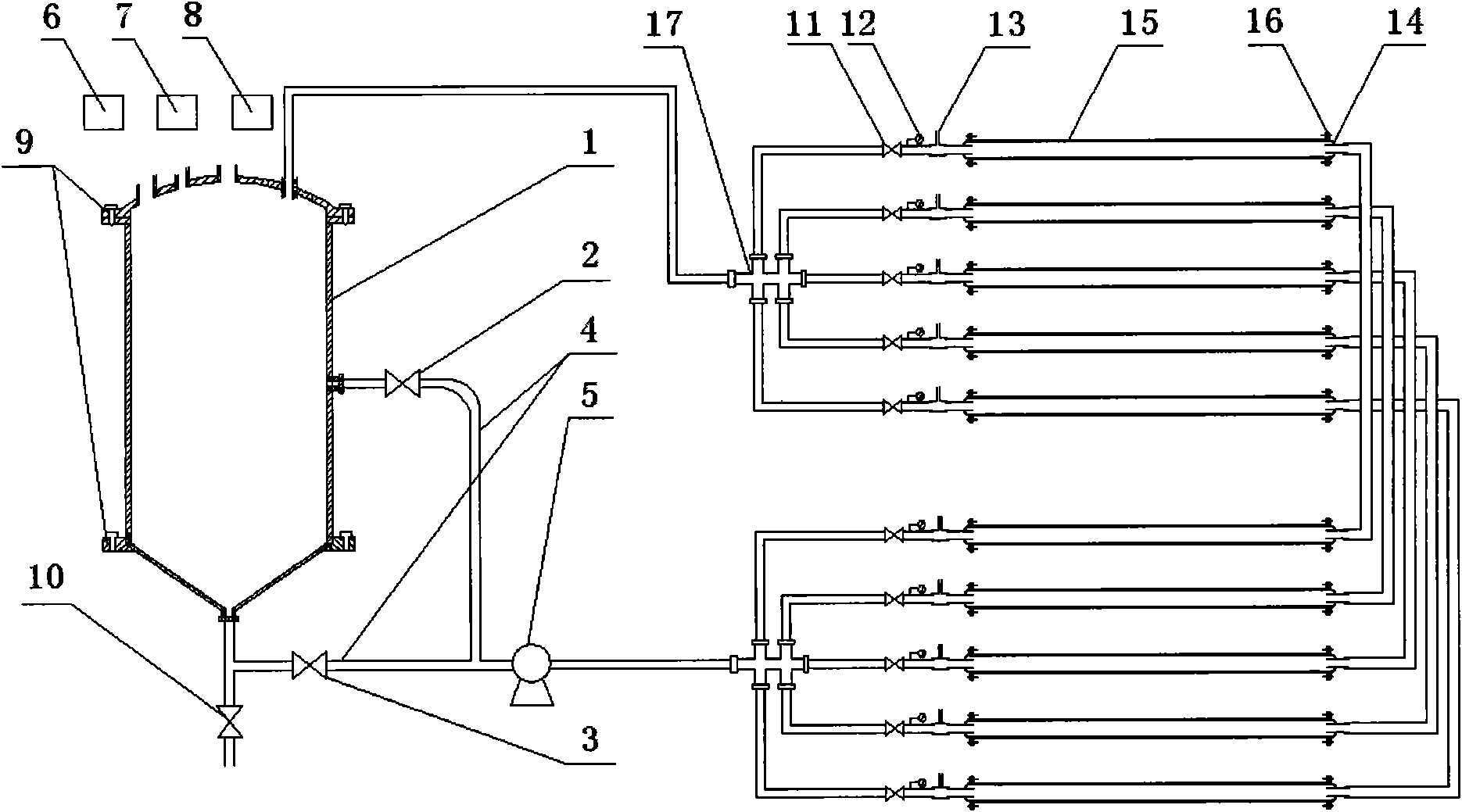

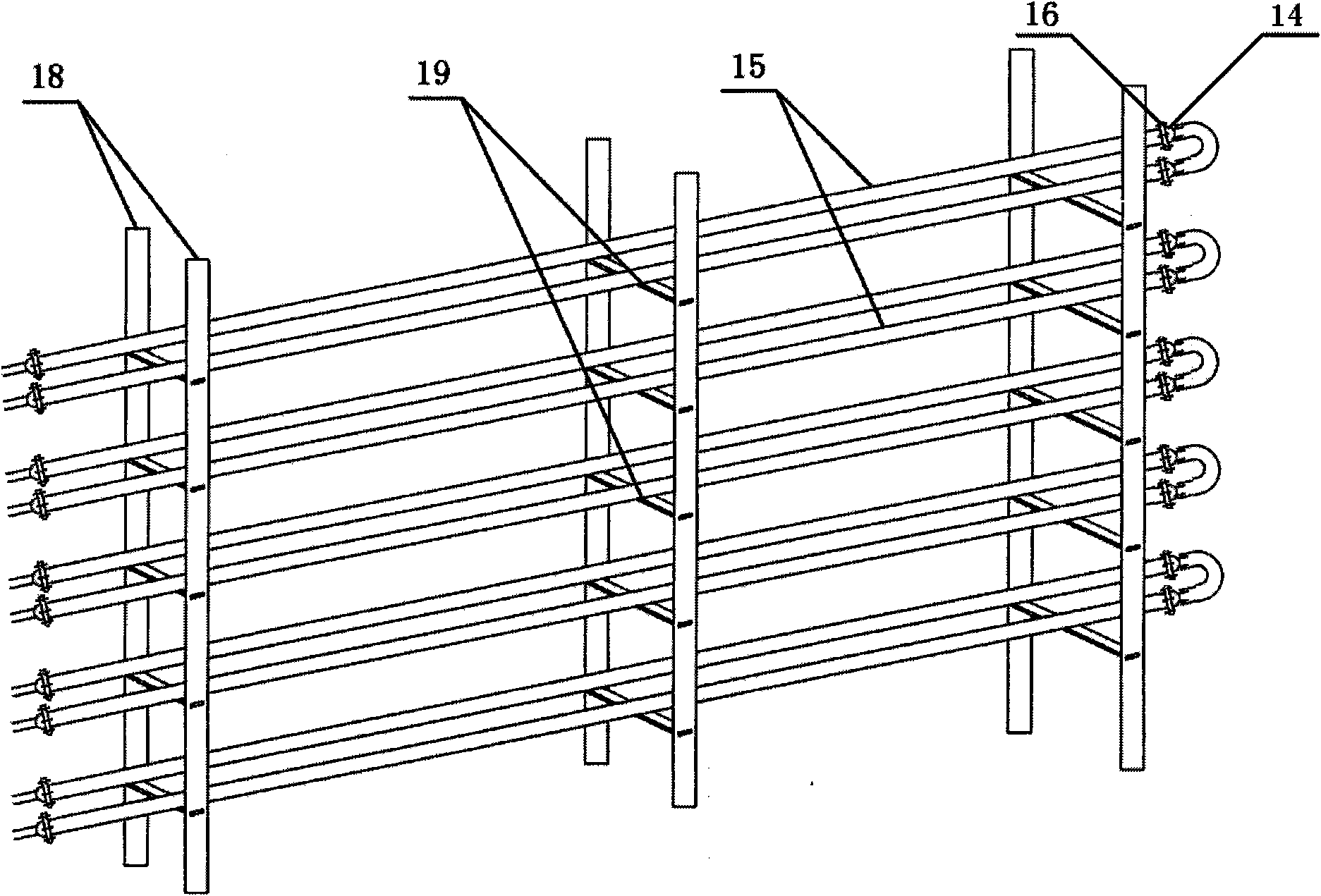

ActiveCN101597567AFacilitate observation of cultivation and collectionAvoid harmBioreactor/fermenter combinationsBiological substance pretreatmentsPhotobioreactorPeristaltic pump

The invention discloses a photobioreactor which aims at providing a set of solution scheme for cultivating microalgae with simple production, convenient disassembly and high efficiency. The photobioreactor comprises a buffer / gathering system, a detecting device, a reaction region and a gas exchange device, wherein the buffer / gathering system is a transparent drum with a taper-shaped bottom and is connected with two pipelines respectively used for cycle cultivation and microalgae collection; the detecting device is introduced from the upper part of the buffer / gathering system; the reaction region comprises a plurality of circular transparent photoreaction tubes; and the gas exchange device is connected with the inner part of the reaction region. The photobioreactor realizes the circulation of a cultivation system through a peristaltic pump, adjusts the ventilation of each photoreaction tube through a gas pump and a plurality of gas valves, has simple and convenient operation and high mass transfer efficiency, and is suitable for fast cultivation of microalgae with a large number.

Owner:ENN SCI & TECH DEV

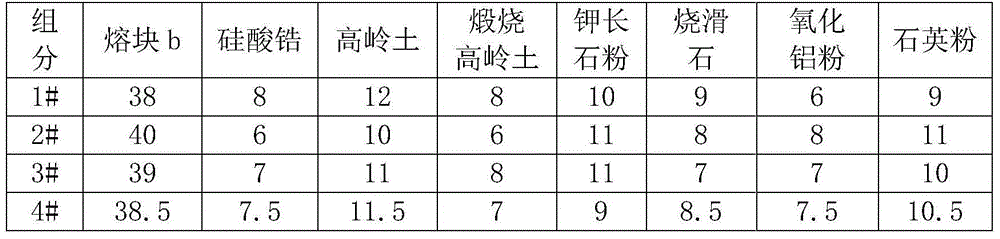

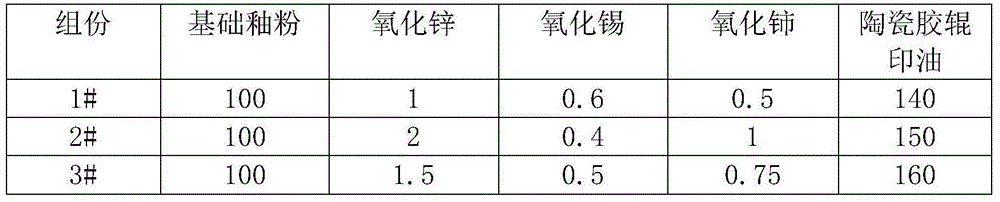

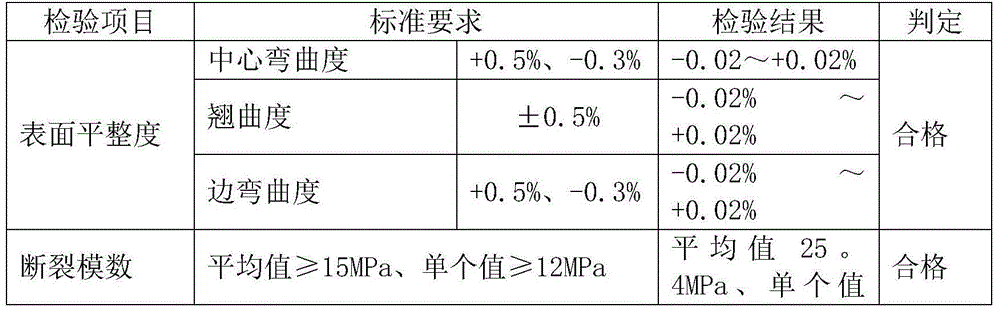

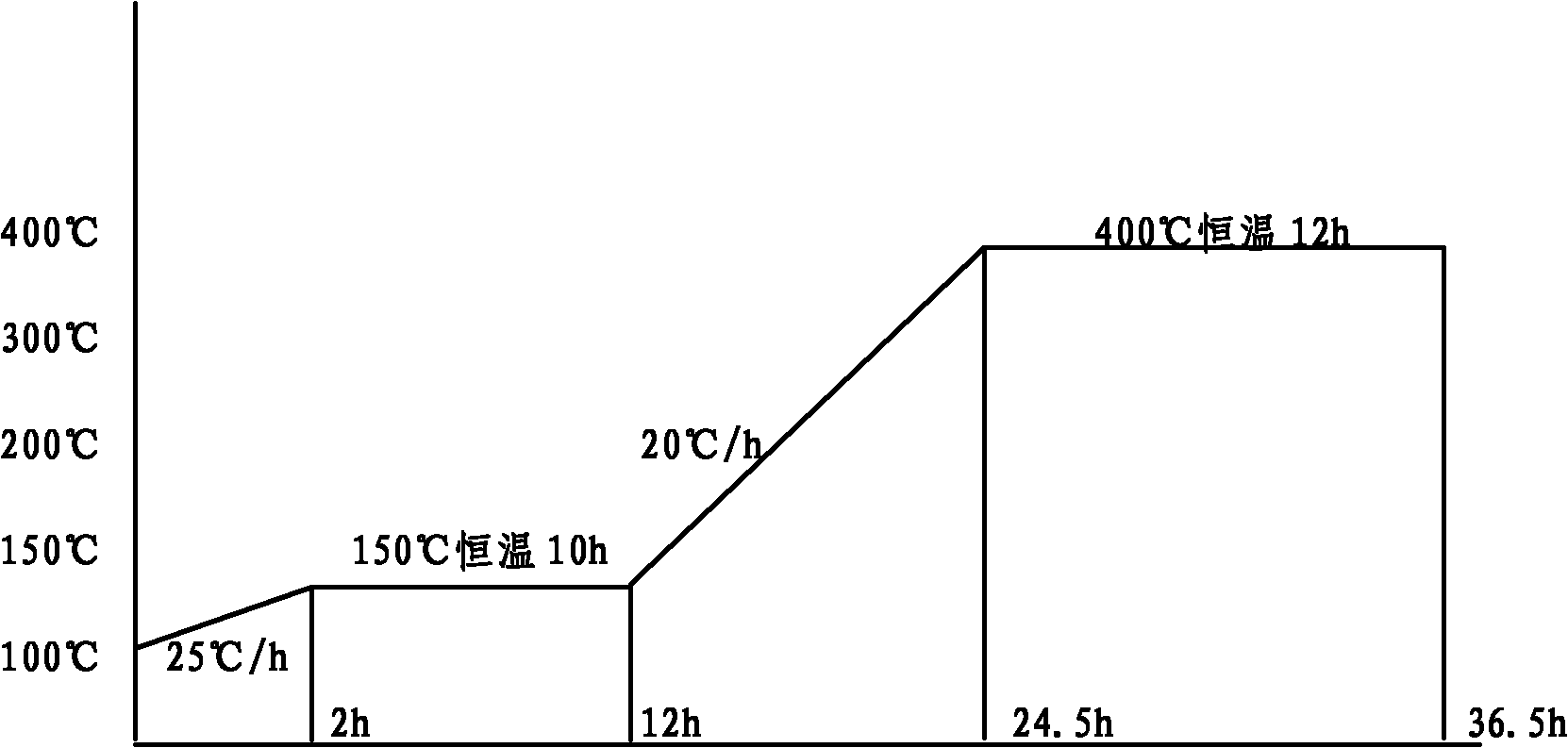

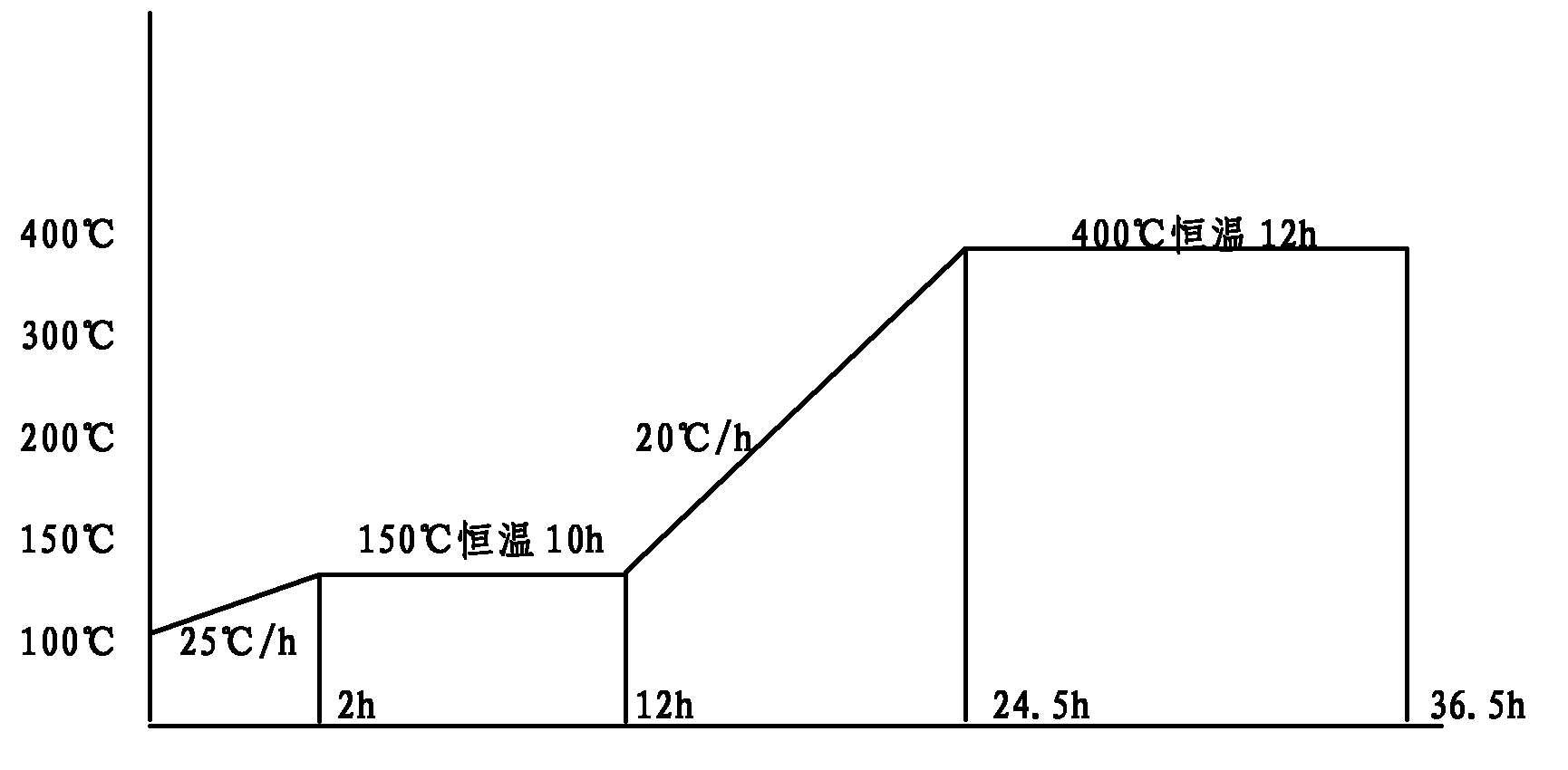

Glaze and preparation of embossment phantom glazed brick

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

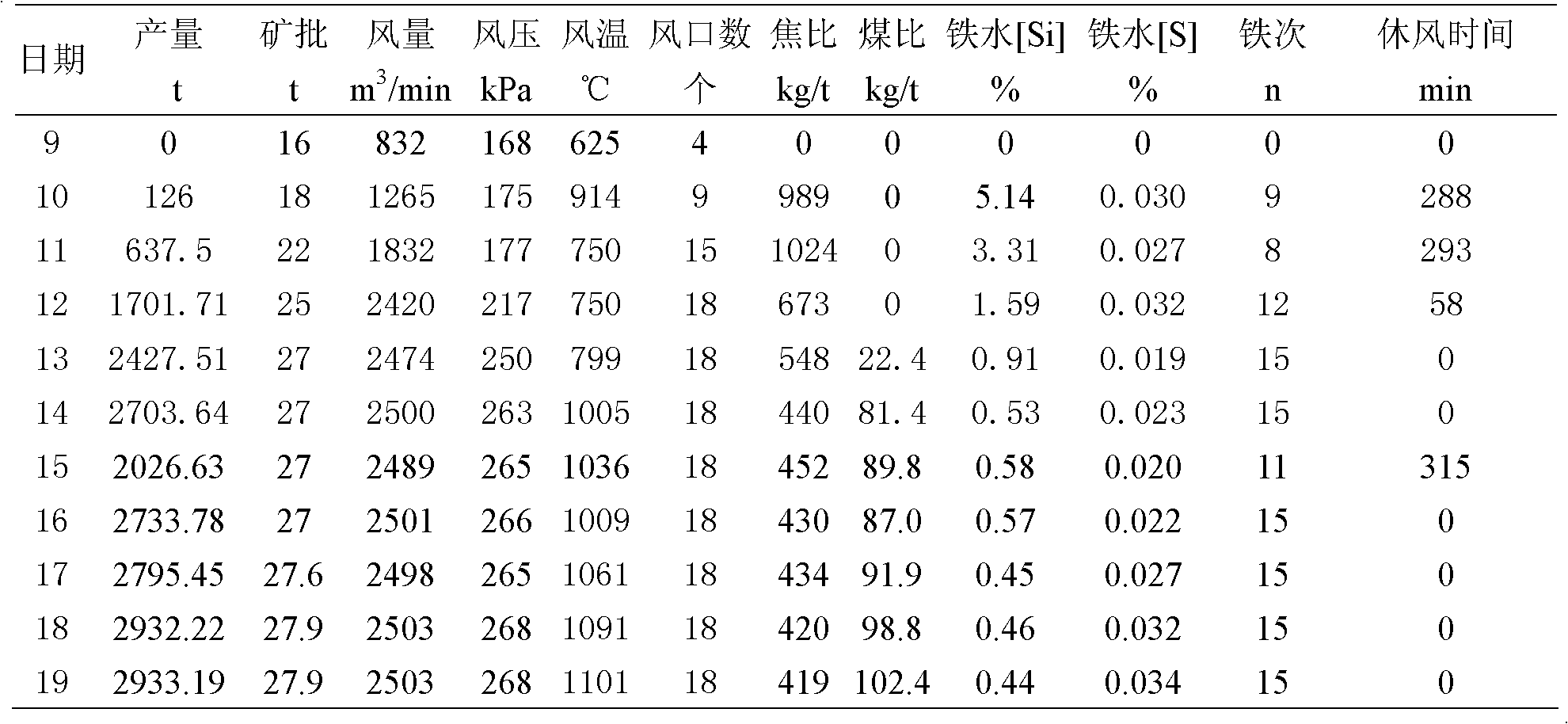

Method capable of rapidly reaching yield after small and medium maintenance of blast furnace

InactiveCN101818221ADischarge in timeOpen the furnace smoothlyBlast furnace componentsBlast furnace detailsSlagEconomic benefits

The invention relates to a method capable of rapidly reaching a yield after the small and medium maintenance of a blast furnace, mainly comprising the steps of adjusting a furnace condition before stopping the furnace, selecting relevant technological parameters in the process of running the furnace, and the like. The invention discharges iron slag in time and realizes the purpose of smooth furnace running and rapid yield reaching of the blast furnace through establishing a scientific furnace running scheme and sufficient preparation and adopting a reasonable air supply and loading system, and the yield reaching schedule achieves a satisfactory purpose. The whole production process of the invention is safe, sequential, scientific and high-efficient, the utilization factor of the blast furnace can achieve 2.253t / m3.d within 5 days, and in the whole process of furnace-running yield reaching, the blast furnace has the advantages of favorable iron slag fluidity, satisfactory quality of molten iron and less unplanned blast stoppage, greatly saves manpower and physical resources and obtains favorable effects and economic benefits.

Owner:CHONGQING IRON & STEEL CO LTD

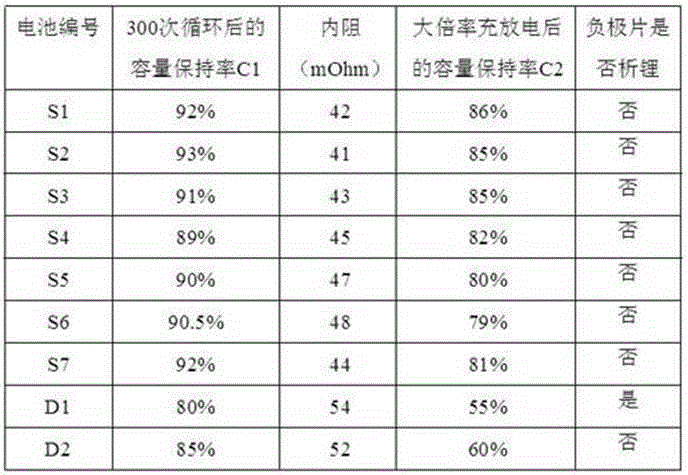

First-time charging forming method for lithium-ion secondary battery

InactiveCN103151565AImprove cycle performanceImprove high rate discharge performanceFinal product manufactureSecondary cells charging/dischargingHigh rateElectrical battery

The invention belongs to the technical field of lithium-ion secondary batteries, and in particular relates to a first-time charging forming method for a lithium-ion secondary battery. The method comprises the following steps that: carrying out aging treatment on the lithium-ion secondary battery poured with electrolyte, then gradually increasing the charging current to carry out a sectional charge formation on the battery in the state of negative pressure, and sealing the battery when the voltage reaches 3.6 volts; and carrying out aging treatment on the battery, carrying out constant-current charging to 3.8-4.0 volts at a rate of 0.5 C-1 C, then carrying out constant-current charging to 4.2 volts at a rate of 0.2 C-0.5 C, and carrying out constant-voltage charging in the state of 4.2 volts at last. Compared with the prior art, the invention adopts the method of sectional charge formation to charge the battery to 3.6 volts firstly, so as to exhaust the harmful gas produced in the process of forming SEI (solid electrolyte interface), ensure the migration of Li<+> better, enable the formed SEI to be more uniform, stable and compact, and thus improving the cycling performance and high rate discharging performance.

Owner:湖北力莱科技有限公司

Router

InactiveCN103685042AExtended service lifeEasy to cool downData switching networksCooling/ventilation/heating modificationsWorking temperatureComputer engineering

The invention provides a router. The router comprises a housing and a circuit board, wherein the circuit board is located in the housing and fixedly connected with the housing. The router is characterized in that ventilation holes are formed in the side wall of the housing; a fan is arranged on the inner side of the side wall; the fan is fixedly connected with the inner side wall of the housing. The router has the beneficial effects that the added ventilation holes and the fan can exhaust hot air in the housing in time to cool the circuit board, keep the circuit board at proper working temperature, and prolong the service life of the circuit board; air holes are added under the circuit board, and thus the air can be introduced in the housing through the air holes, which is convenient to cool the circuit board.

Owner:TIANJIN XINYUN NETWORK TECH

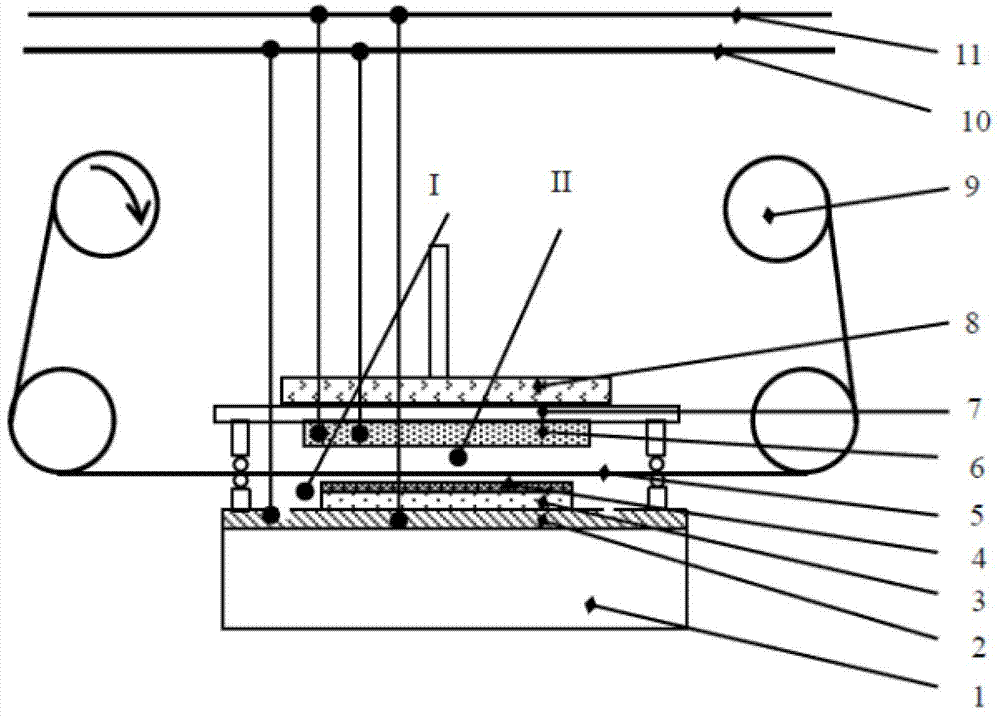

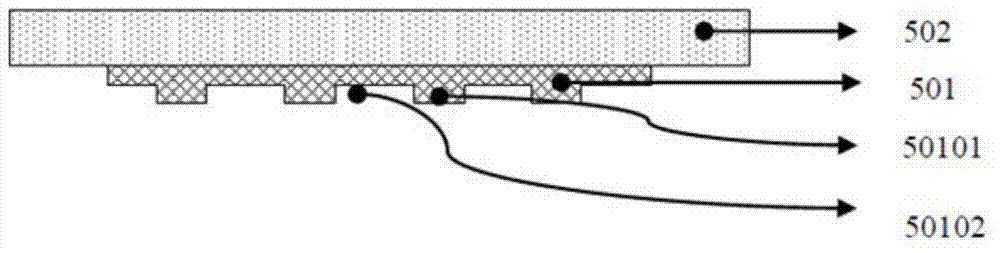

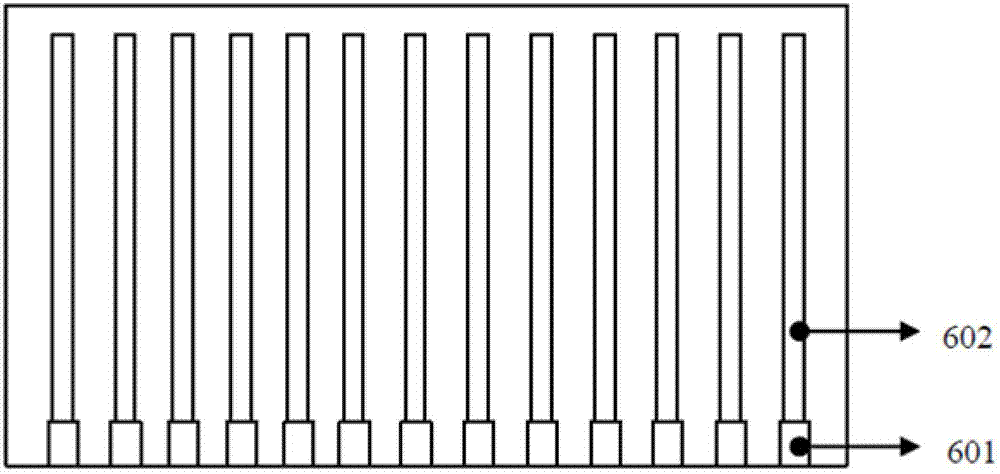

Nanometer impression device and nanometer impression method for high-brightness light-emitting diode (LED) graphics

ActiveCN102866582AReduce defectsGood removal effectNanoinformaticsPhotomechanical exposure apparatusSolubilityGraphics

The invention discloses a nanometer impression device and a nanometer impression method for high-brightness light-emitting diode (LED) graphics. The nanometer impression device comprises a wafer bearing platform, a vacuum sucking disc, a substrate, a ultraviolet light cured nanometer impression slushing compound and the like. A die is a thin film elastic composite flexible die and comprises a graphical layer and a supporting layer, wherein the graphical layer has the characteristics of water solubility, thin-film structure, elasticity and high transparency, and the die is manufactured by adopting a rolling impression process. The nanometer impression method for achieving high-brightness LED graphics based on the device comprises the steps of (1) pre-processing, (2) impression, (3) curing, (4) demoulding, (5) post-processing and (6) transferring of impression graphics. By means of the nanometer impression device and the nanometer impression method, a large-area, high-aspect-ratio micro-nanometer structure is efficiently manufactured on an unsmooth surface or a curved surface substrate or a fragile substrate with low cost. The nanometer impression device and the nanometer impression method are suitable for large-scale manufacture of optical devices, three-dimensional miniature batteries, micro-electromechanical system (MEMS) devices, photovoltaic devices, anti-reflecting layers, self-cleaning surfaces and the like and are especially suitable for the LED graphics and industrial-grade large-scale production of wafer-level splicing-free micro-optical devices.

Owner:兰红波

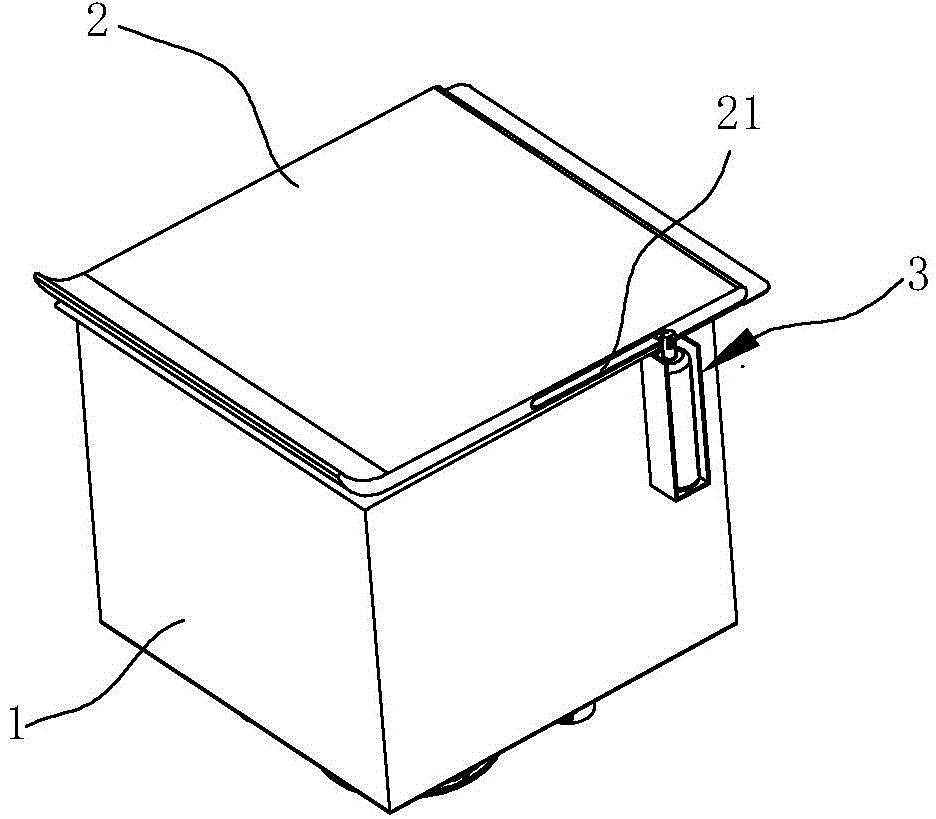

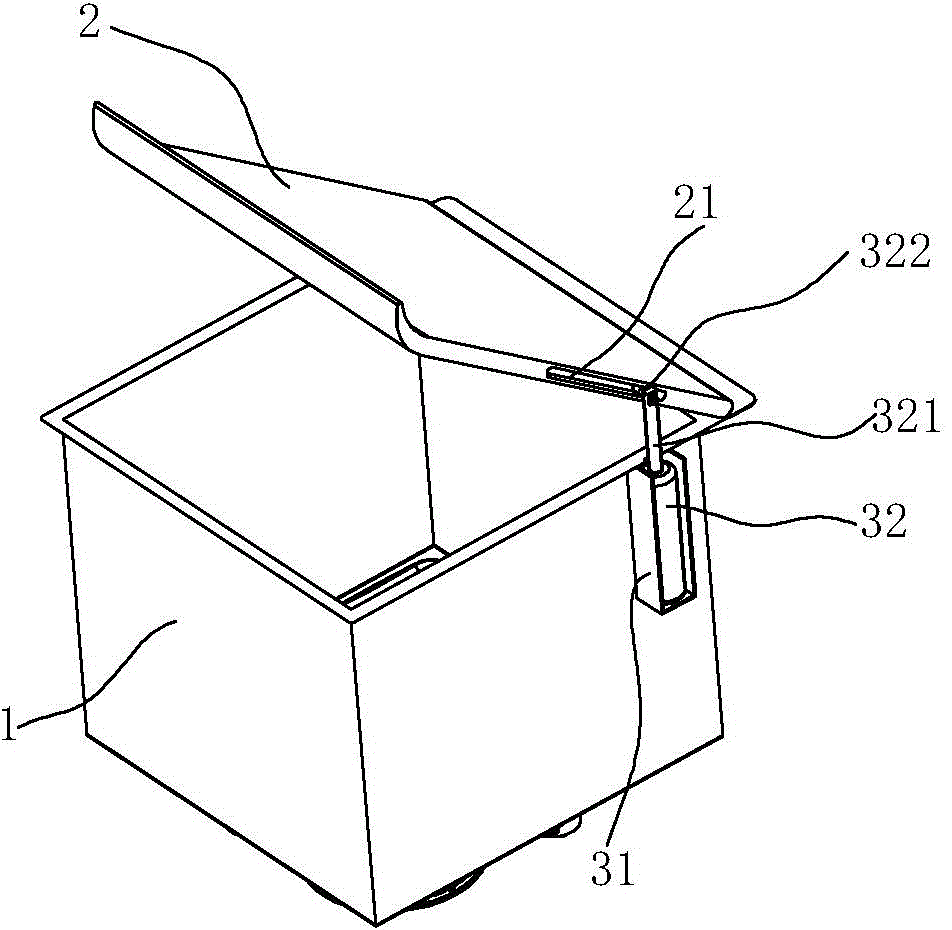

Opening and closing control method of cover plate of water tank type cleaning machine

ActiveCN104545752AFast dryingImprove securityTableware washing/rinsing machine detailsAutomatic controlAgricultural engineering

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Traditional Chinese medicine composition for treating cardiovascular and cerebrovascular diseases

InactiveCN106729432AImprove blood weightImprove blood vessel elasticityHeavy metal active ingredientsHydroxy compound active ingredientsAcute hyperglycaemiaCervical spondylosis

The invention discloses a traditional Chinese medicine composition for treating cardiovascular and cerebrovascular diseases. The traditional Chinese medicine composition is mainly prepared from 81 kinds of traditional Chinese medicine such as radix panacis quinquefolii, placenta hominis, radix salvia miltiorrhizae, herba rhodiolae, fructus schisandrae, head of Chinese angelica, rhizoma chuanxiong, radix polygalae, hirudo, radix notoginseng, fried semen ziziphi spinosae, herba cistanches and radix rehmanniae through mutual matching. The traditional Chinese medicine composition is capable of improving general blood circulation, blood weight and blood vessel elasticity within a shorter time, and meanwhile, damp cold in a body and outer walls of blood vessels can be eliminated and removed out of the body in time; the traditional Chinese medicine composition has the function of repairing internal organs such as the liver, the kidney, the lung and the spleen and is capable of increasing the immunity and the disease resistance of the body in time; the traditional Chinese medicine composition has an obvious treatment or auxiliary treatment rehabilitation function on heart disease, cerebral thrombosis, serious insomnia, astriction, hypertension, hyperglycemia, hyperlipidemia, insufficiency of cerebral blood supply, tinnitus, cervical spondylosis and lumbar spondylosis.

Owner:贾庭山

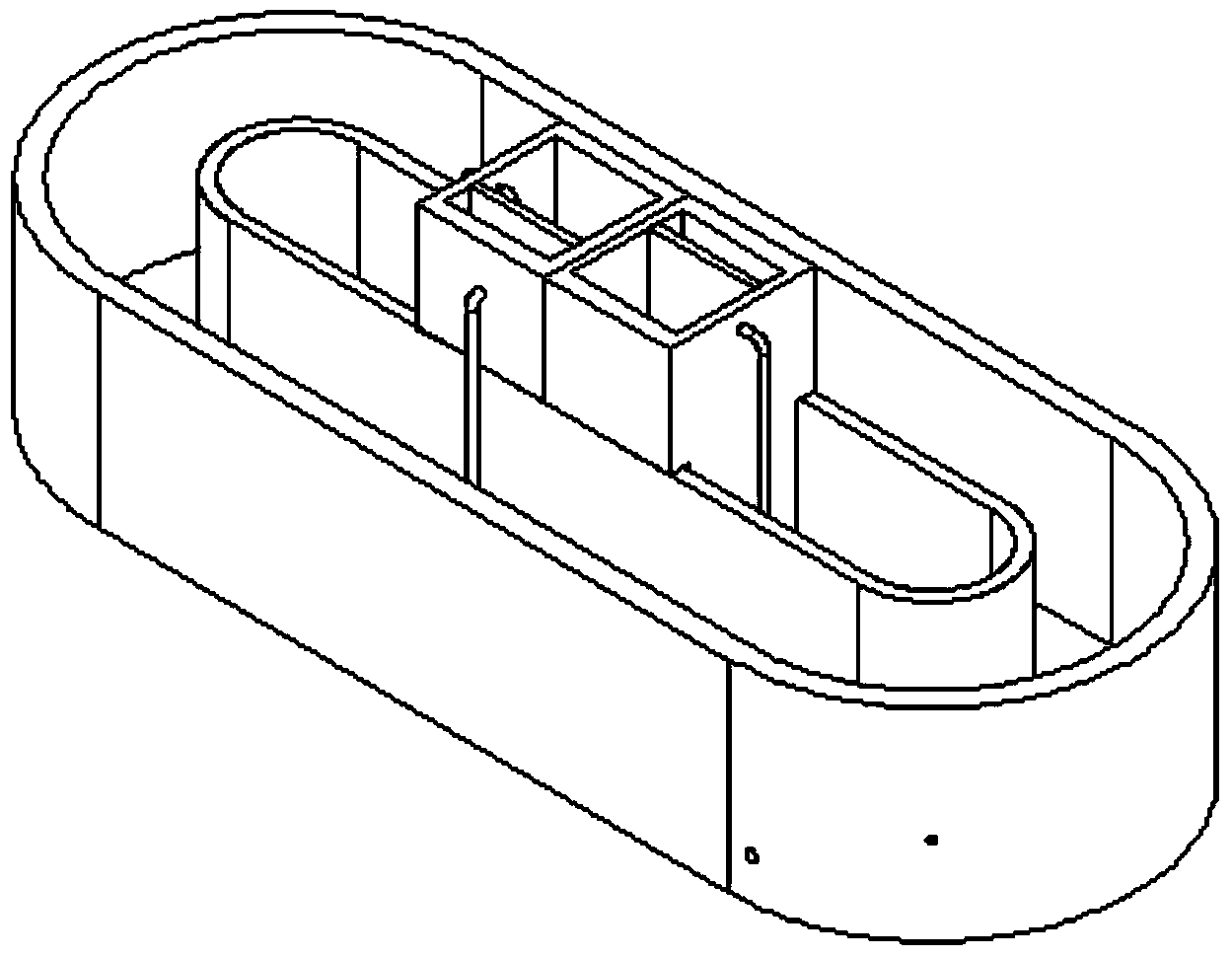

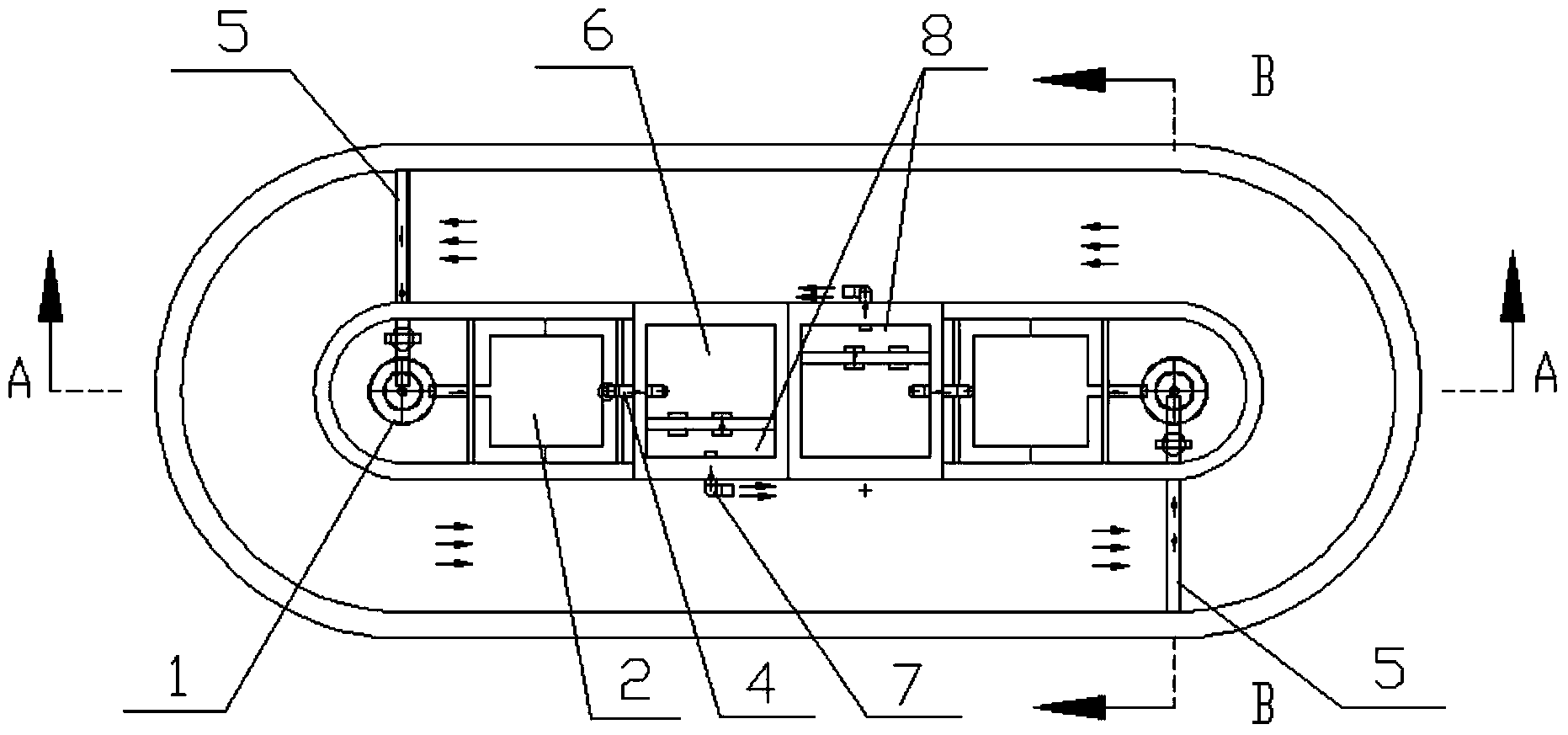

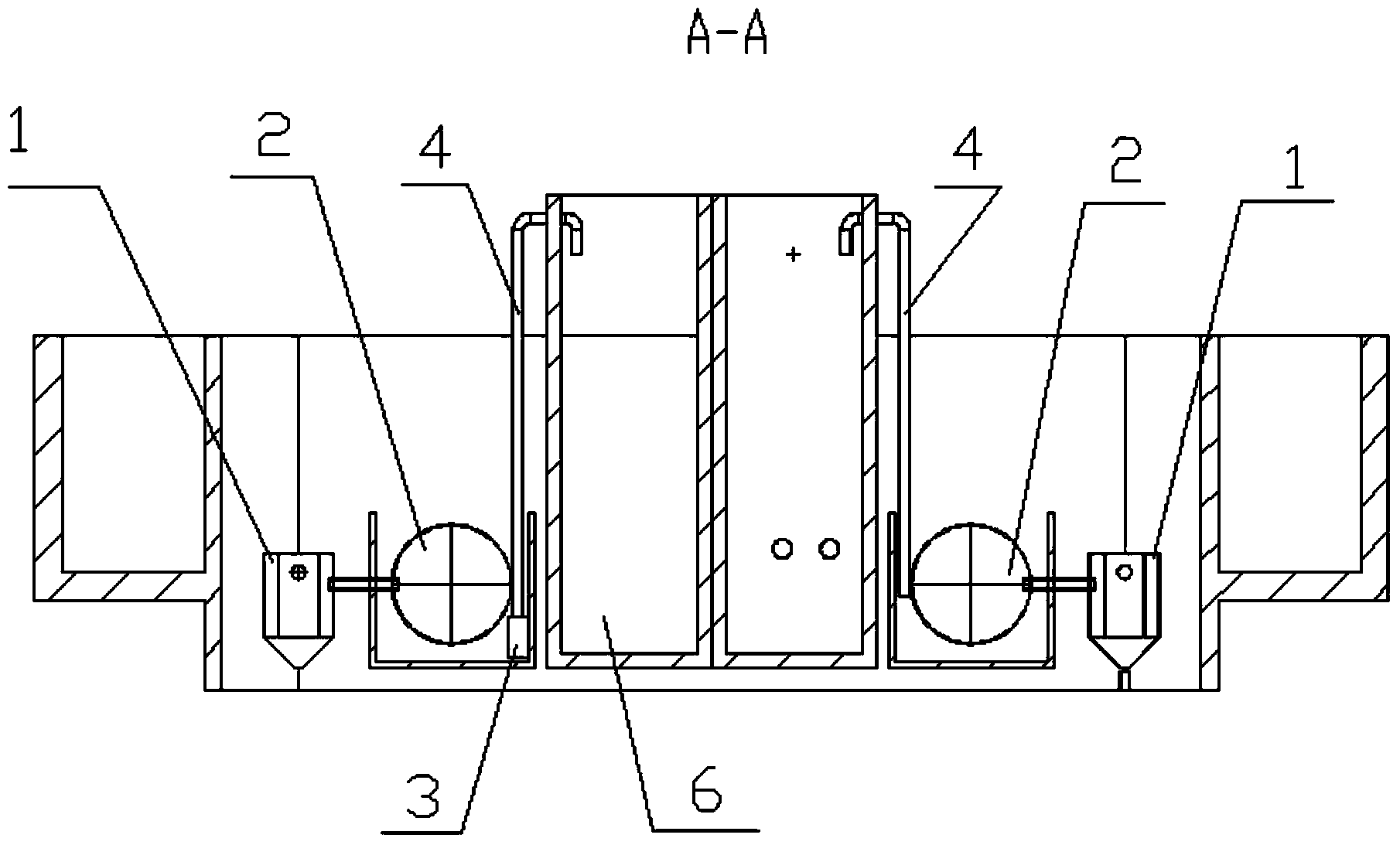

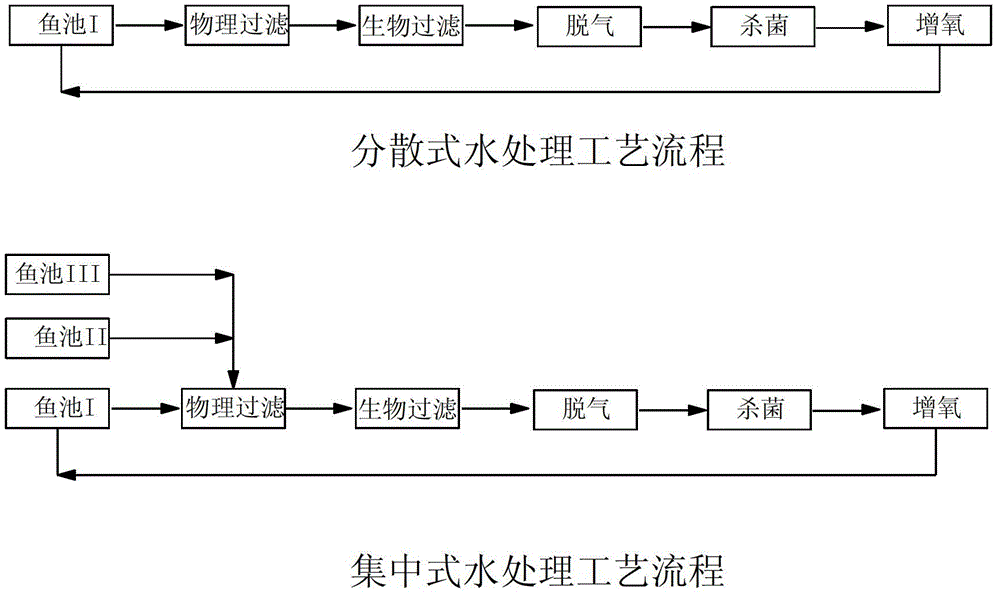

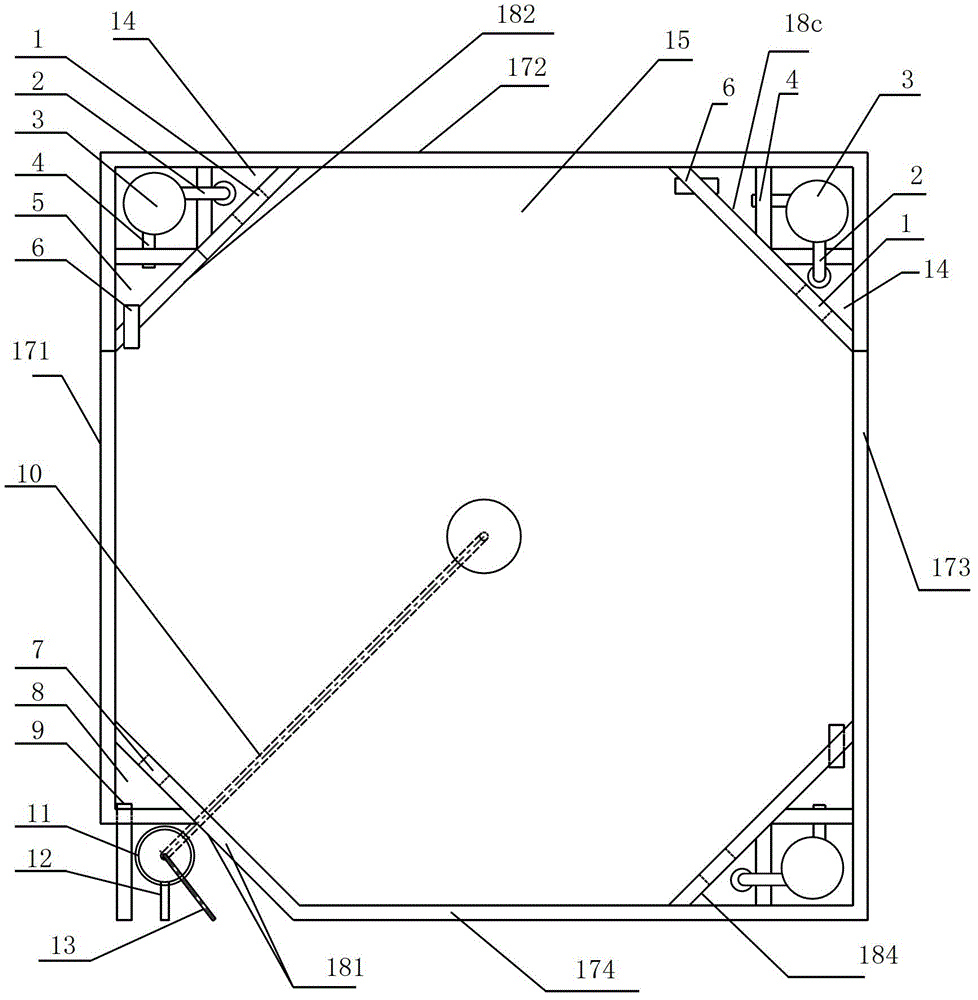

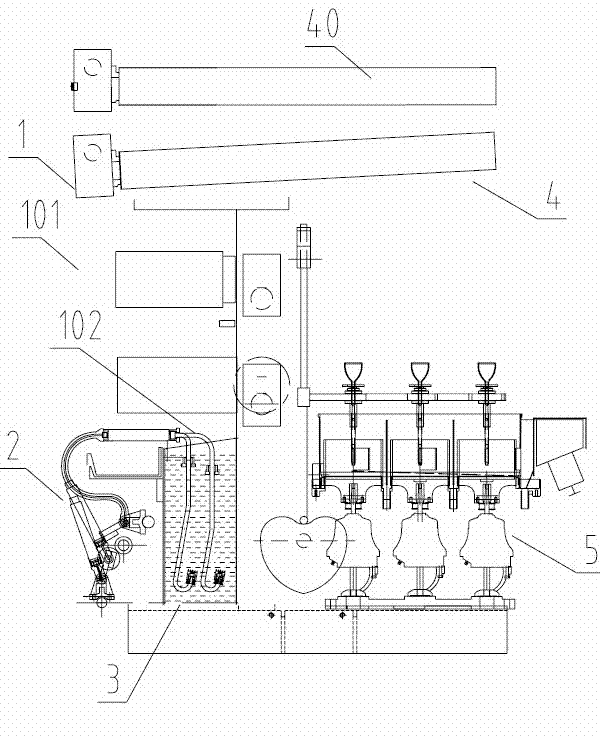

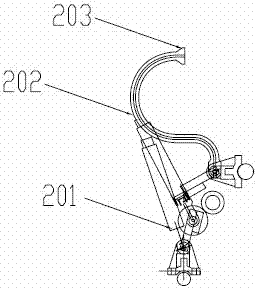

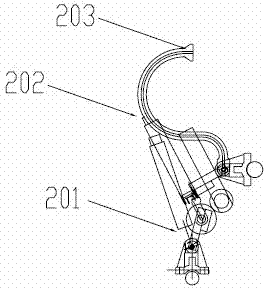

Circuit-type fishpond breeding system integrating circulating water treatment process

The invention relates to a circuit-type fishpond breeding system integrating a circulating water treatment process. The circuit-type fishpond breeding system integrating the circulating water treatment process comprises a fishpond shaped like an annular runway, and sewage treatment systems arranged in an inner ring of the fishpond. Each sewage treatment system comprises a vertical flow type solid-liquid separator (1), wherein a sewage discharging groove (5) perpendicular to the water flow direction is formed in the bottom of the fishpond and communicated with an inlet of the vertical flow type solid-liquid separator (1), an outlet of the vertical flow type solid-liquid separator (1) is communicated with a micro-filtration machine (2), outlet water of the micro-filtration machine (2) adopts a water pump (3) and a water lifting pipe (4) for water lifting and is injected into a biological filter (6), the biological filter (6) is separated from an aeration oxygenation pond (8) through a separation plate and is communicated with the aeration oxygenation pond (8) through a through hole in the lower portion of the separation plate, a water falling pipe (7) is arranged on the lateral wall of the aeration oxygenation pond (8) and communicated with the fishpond, and the water outlet direction at the bottom of the water falling pipe (7) is the same as the water flow direction of the fishpond. The number of the sewage treatment systems is two, and the sewage treatment systems are evenly distributed in the inner ring of the annular fishpond in a central symmetry mode.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

Tea cleaning and drying device

InactiveCN107965989ARealize the function of cleaning and removing impuritiesSpeed up the flowPre-extraction tea treatmentDrying gas arrangementsWater resourcesAgricultural engineering

The invention discloses a tea cleaning and drying device which comprises a drying box, a rotating tube and a seal cover. The bottom of the drying box is provided with a rotating motor, the rotating motor is connected with the rotating tube through a rotating shaft, two inner walls, close to the rotating tube, of the drying box are provided with a heating pipe and an ultraviolet ray lamp pipe correspondingly, the outer wall, close to the heating pipe, of the drying box is provided with an air blower, the bottom of one side of the drying box is connected with a waste water treatment box througha pollution discharge pipe, the top of the seal cover is provided with an air exhaust fan, and the bottom of the seal cover is provided with a water spray pipe. By means of the tea cleaning and dryingdevice, before agricultural and sideline products are dried, cleaning and impurity removing functions performed on the agricultural and sideline products can be realized, and the quality of dried products is improved; by means of the arrangement of the waste water treatment box, the waste water after cleaning can be filtered and purified, and the recycling of water resources is facilitated; and the tea cleaning and drying device is simple in structure, the efficiency of drying performed on the agricultural and sideline products is high, and the drying is performed more thoroughly.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

Method for quickly forming soft power lithium-ion cell

ActiveCN107579302AHelps to formImprove conductivitySecondary cells charging/dischargingElectricityLithium

The invention discloses a method for quickly forming a soft power lithium-ion cell. The method comprises the following steps: (S1) supplying a heat source for heating a cell by using a heating plate;(S2) driving a pressurizing plate to pressurize the cell by using a servo motor; (S3) performing gradient charging on the cell; and (S4) charging the cell till reaching high charge state. According tothe invention, a stable, compact and uniform SEI film is formed on a cathode surface, the performance of the lithium-ion cell is greatly promoted, the early failure of the lithium-ion cell in the circulating process is avoided, the yield of the cell is increased, the cell quality is optimized, the forming time of the cell is shortened, the large-scale production of the cell is realized and the method has wide application prospect.

Owner:CAMEL GRP NEW ENERGY BATTERY CO LTD

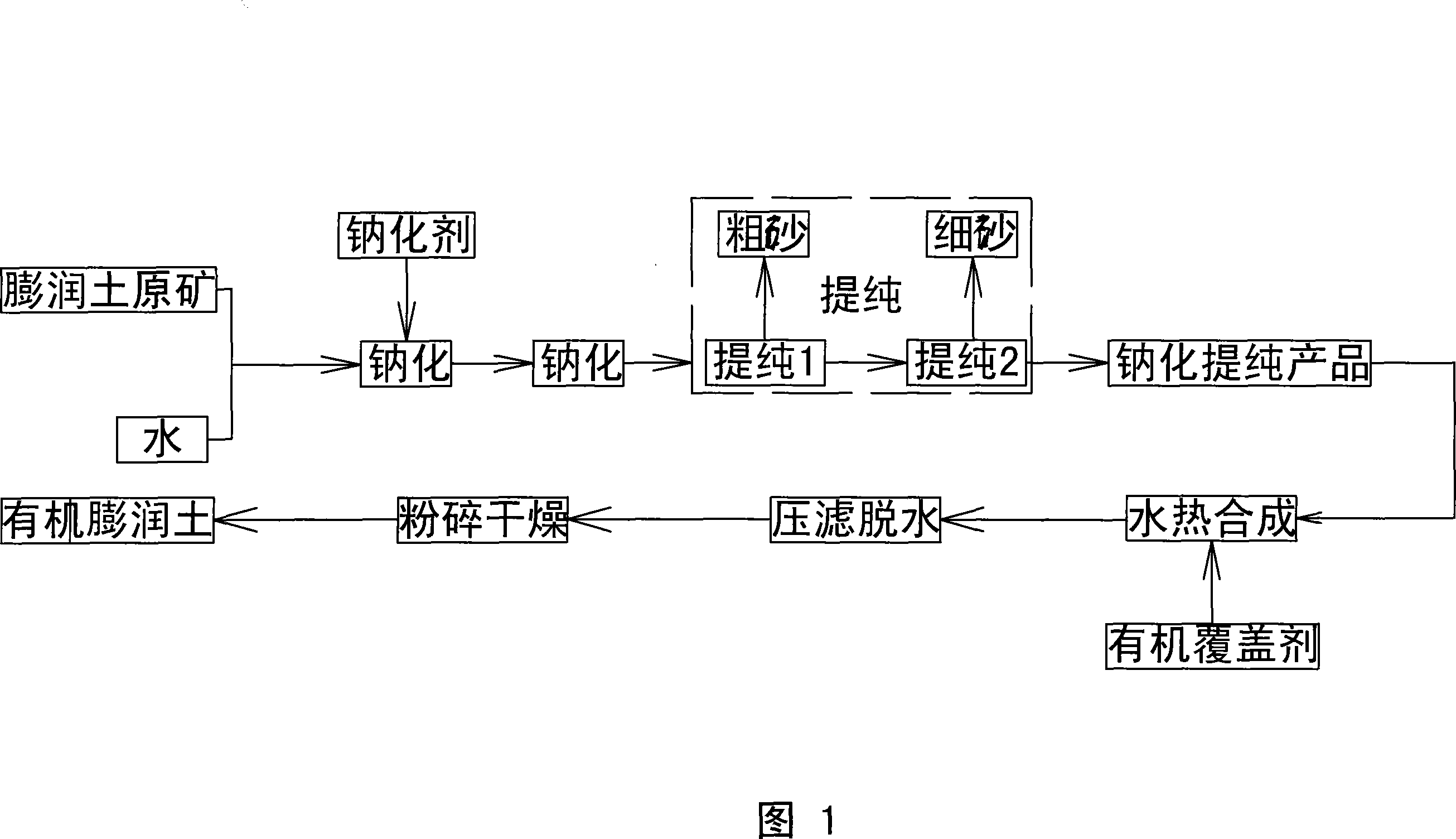

Method for preparing heavy-viscous organophilic bentonite

InactiveCN101224894AContinuously workingImprove stabilityPigmenting treatmentSilicon compoundsSodium BentonitePrinting ink

The invention provides a method for preparing high viscosity organophilic bentonite, which carries out steps of sodium treatment, purification, hydrothermal synthesis, dewatering by filter pressing, crashing and drying operation to bentonite raw ore to obtain the high viscosity organophilic bentonite. The invention can be directly applied to oil paint, printing ink, petroleum drilling slurry and heavy polymer and so on as a thickening suspension agent, a fluid deformation agent and an anti-sagging agent. Through systematic study on technologies of the sodium treatment modification, purification, organic compound and so on of the bentonite, the invention prepares organophilic bentonite jelly glue with stable product quality and excellent performance and determines a proper technical process flow and technical parameters.

Owner:苏州中材非金属矿工业设计研究院有限公司

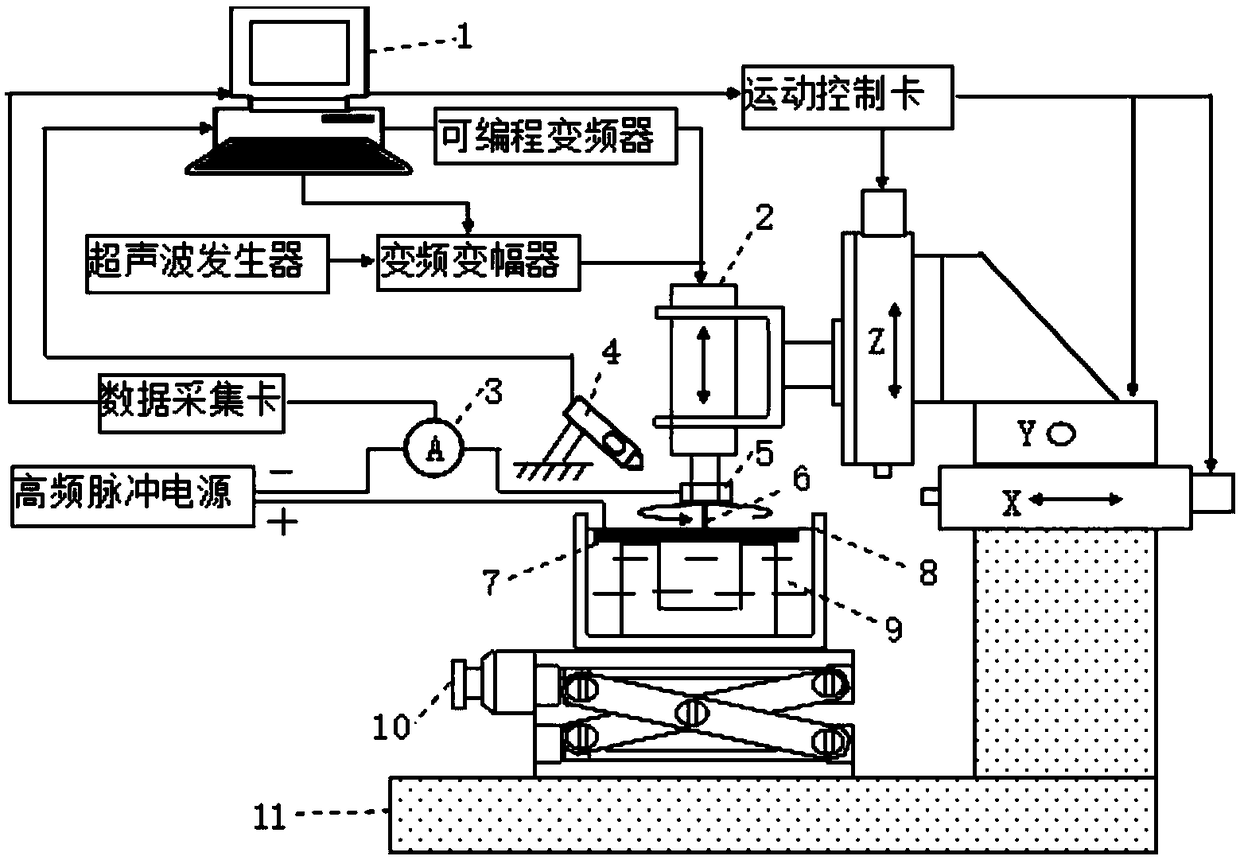

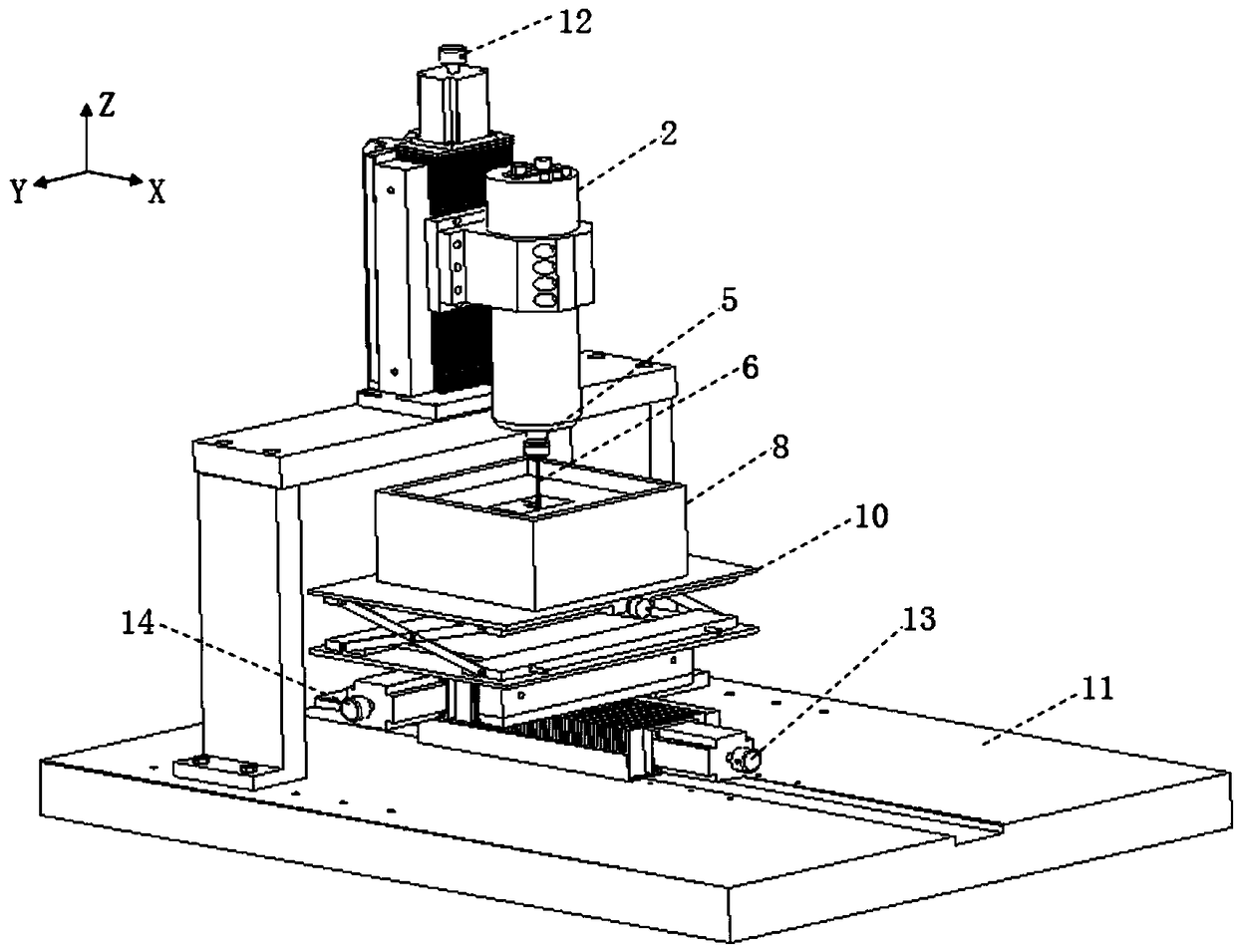

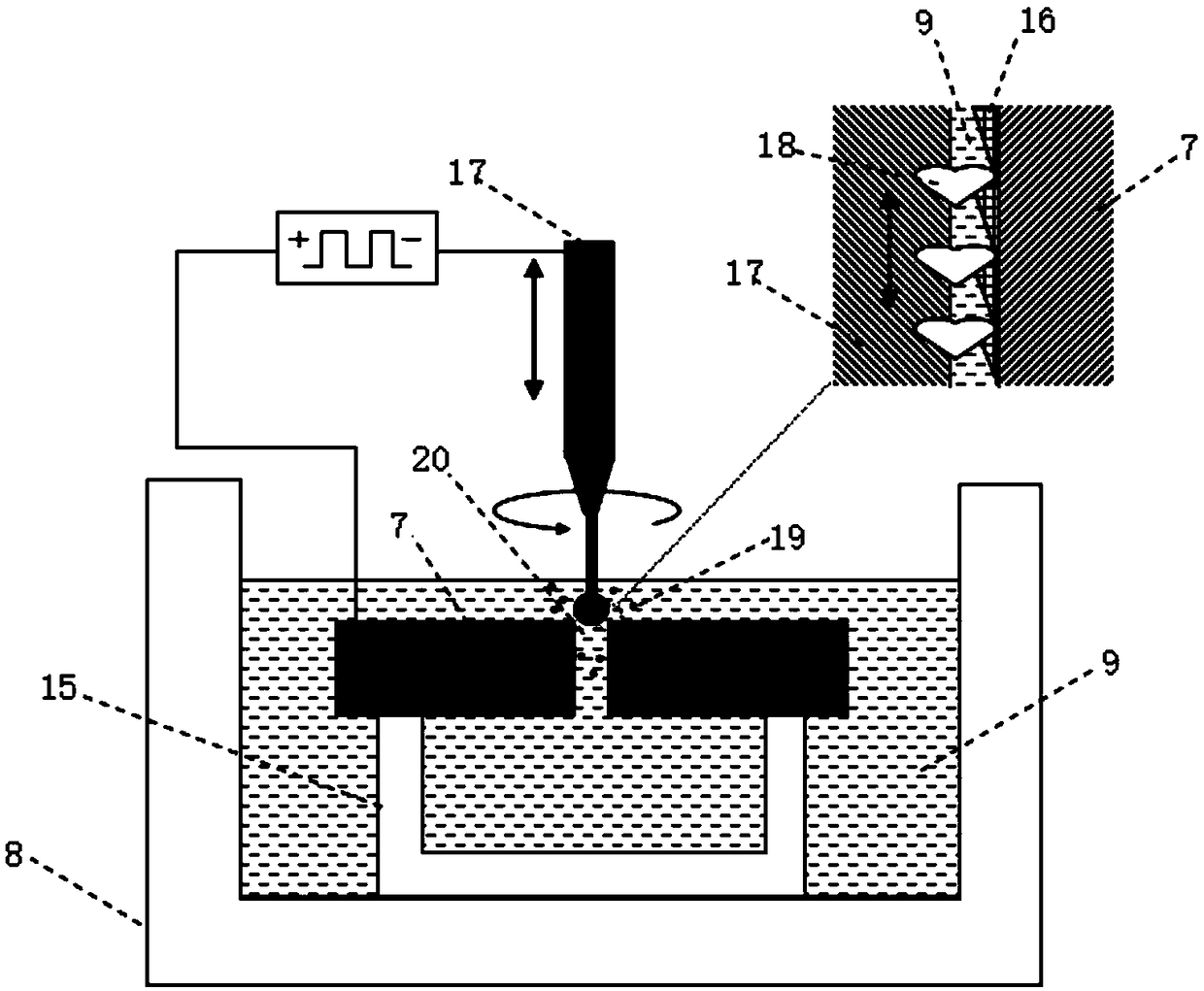

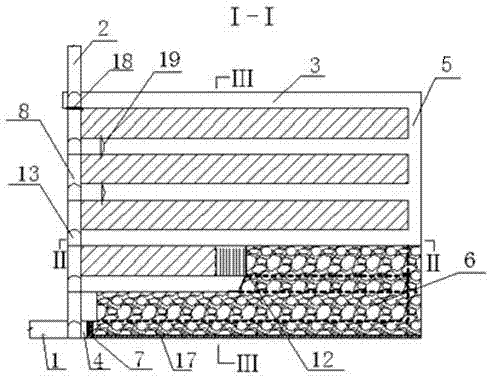

Rotary ultrasonic-assisted fine electrolytic grinding and broaching device and method

InactiveCN108705164AEfficient processingHigh precision machiningElectrical-based auxillary apparatusElectrolysisEngineering

The invention provides a rotary ultrasonic-assisted fine electrolytic grinding and broaching device and method. According to the rotary ultrasonic-assisted fine electrolytic grinding and broaching device and method, on the basis that a pre-formed hole is obtained through electrolytic drilling and grinding by a fine electrolytic machine tool, online tool-changing operation is conducted on the machine tool to avoid positioning errors, axial ultrasonic vibration is applied to a rotary spindle of the machine tool, and electrolytic grinding and broaching are conducted on the pre-formed hole througha high-frequency pulse power supply. An electrolyte is disturbed through the cavatition and enhanced mass transfer effect of ultrasonic vibration to promote separated-out gas and other electrolytic products in a machining area to be discharged in time, so that the gas flow field and the gap electric field are more uniform, and the machining efficiency, the repeated machining precision and the surface machining quality are improved. Slight removal of workpieces is achieved through the high-frequency pulse power supply, so that the machining locality and the dimension controllability are improved, and precise adjustment of matching between electrolytic machining and mechanical grinding is facilitated. By adoption of the rotary ultrasonic-assisted fine electrolytic grinding and broaching device and method, the small hole machining precision and the surface machining quality are improved while the machining efficiency is ensured.

Owner:SHANDONG UNIV

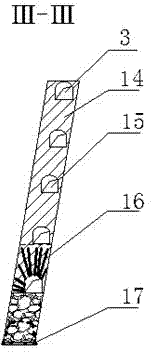

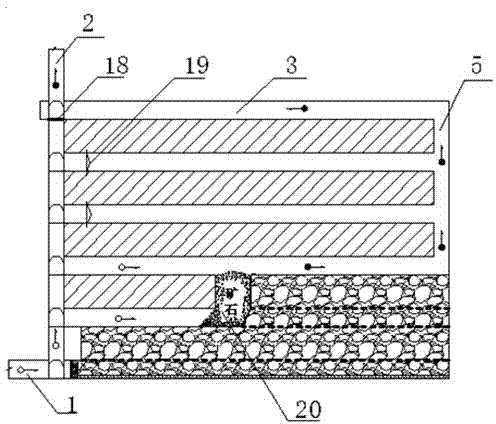

Mining method of thin minor ore body

ActiveCN104847356AAvoid lostImprove recovery rateUnderground miningSurface miningMining engineeringCircular economy

The invention discloses a mining method of a thin minor ore body, which comprises the steps of ore recovery and goaf filling, which are alternatively circularly performed from bottom to top in a horizontal layering manner, propelling is performed along with a work surface, lime, loess, dead rock and the like are adopted and mixed layer by layer to fill a goaf, a filling body supports hanging wall and heading wall surrounding rocks, and serves as a work platform of upper layering recovery and ore removal, the ore is conveyed to an ore chute with a mechanical method, spallation ore removal of each recovery spallation step length and the filling procedure of the goaf are performed alternatively, when the uppermost horizontal layer of a chamber is recovered, mechanical and manual fill tightening are performed. The method solves the problem of discharge of tunneled dead rocks, effectively processes the goaf, prevents surface subsidence, accords with requirements of circular economic development and green ore construction. Compared with a shallow hole shrinkage method, the mining method has the advantages of improving ore recovery rate, reducing ore dilution rate and improving ore removal grade and ore removal efficiency through production practice.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

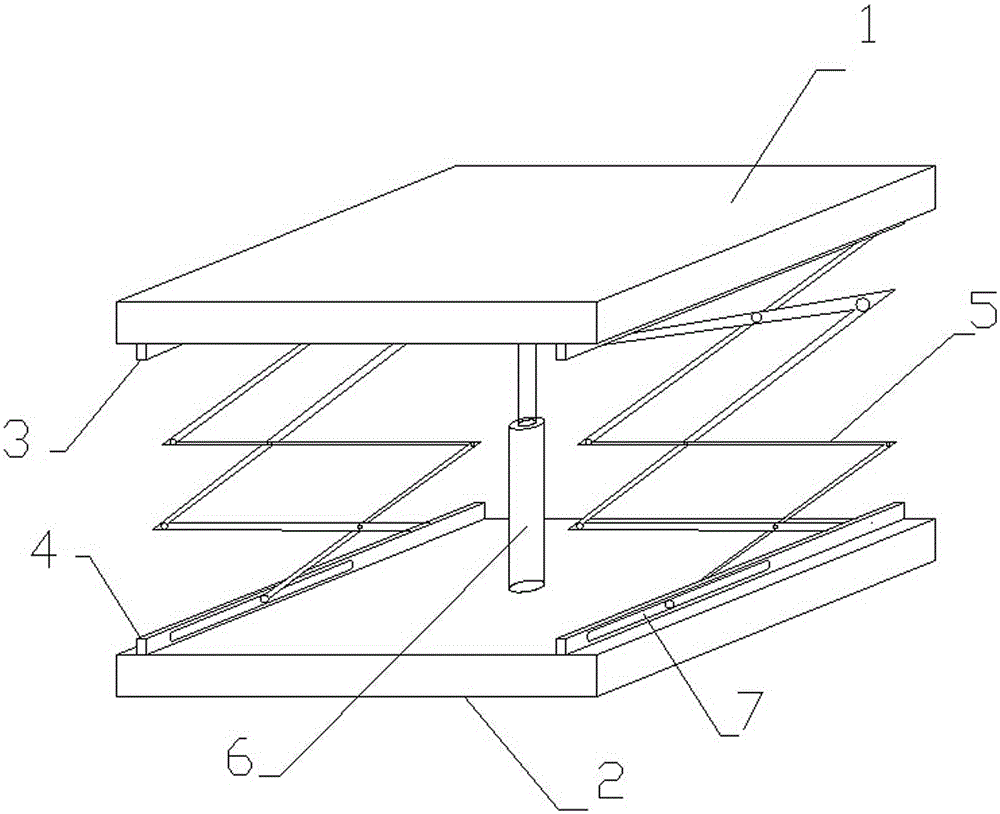

Solar automatic lifting system for rainwater grate

InactiveCN105133722ADischarge in timeAvoid Waterlogging ProblemsSewerage structuresSewage drainingAutomatic controlEngineering

The invention discloses a solar automatic lifting system for a rainwater grate; the solar automatic lifting system comprises a lifting device and a control mechanism which are arranged below the rainwater grate, and a solar power supply device which is externally arranged, wherein a mounting frame is detachably arranged on the sidewall of a drain well below the rainwater grate; the lifting device is composed of two shear arms which are relatively arranged and a linear motor; two ends of the shear arms are respectively arranged in the rainwater grate and a rail on the mounting frame in a sliding mode; the linear motor is arranged between the rainwater grate and the mounting frame; the control mechanism comprises an external rainfall sensor and a controller; and the controller is arranged inside the well wall of the sewer. The lifting system disclosed by the invention can be used for automatically lifting the rainwater grate according to rainfall, so as to solve the problem that rainwater cannot be removed timely in weathers of heavy rain and rainstorm since the cover of a conventional drain well cannot be opened timely.

Owner:HENAN UNIV OF SCI & TECH

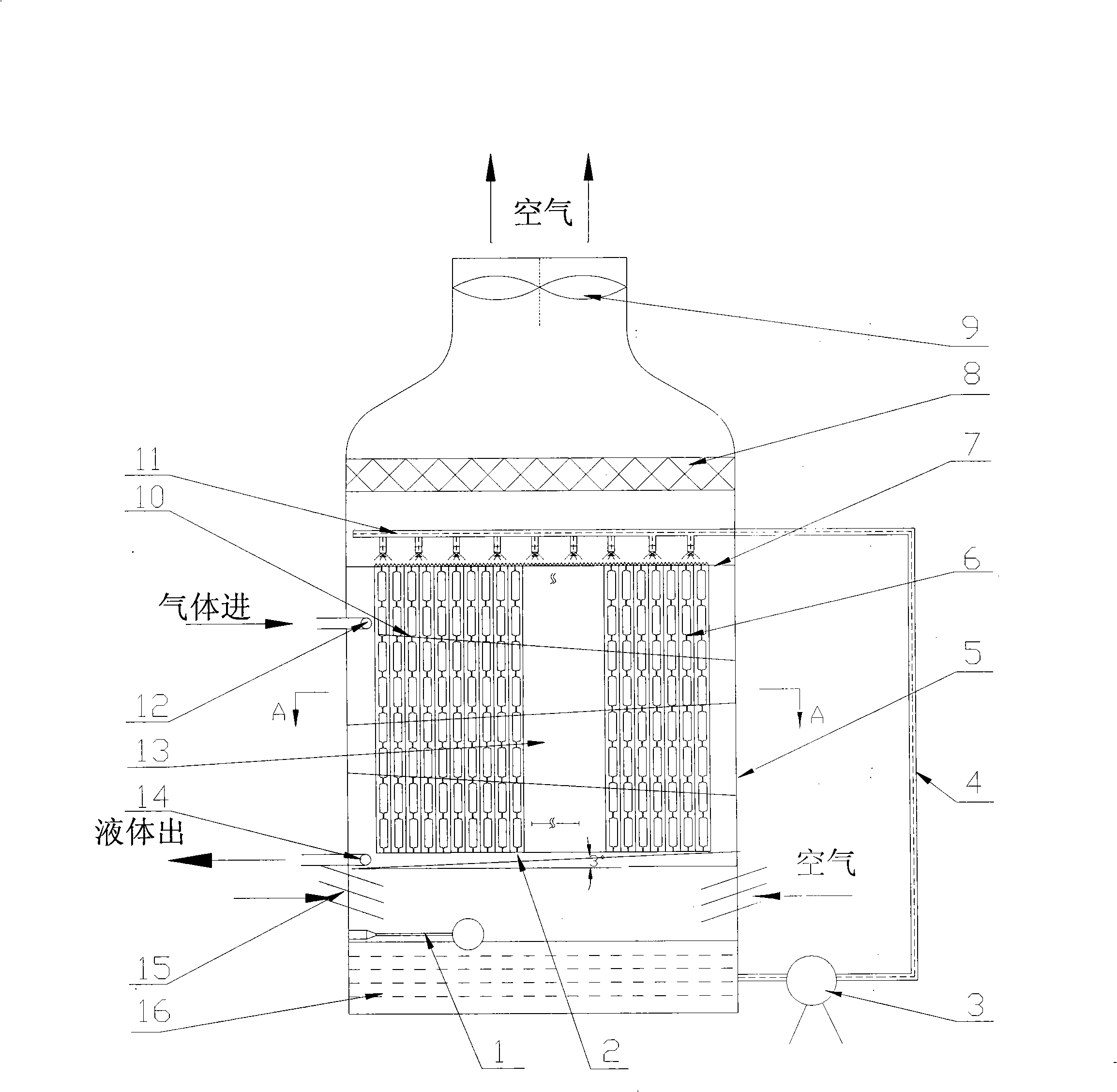

Plate shell-type nonsaturated evaporation condensing plant

InactiveCN101256043AIncrease settling velocityHigh speedEvaporators/condensersSteam/vapor condensersHeat resistanceEvaporation

The invention discloses a plate-shell type nonsaturated evaporation condensing device comprising an upper housing body, a plate-shell type heat exchanger, and a lower housing body. The upper housing body is connected with the lower housing body by a water pump, and the heat exchange main body is the plate-shell type heat exchanger which is connected with the upper housing body and the lower housing body respectively. The plate-shell type heat exchanger comprises an upper tube plate, a lower tube plate, heat exchange plate bundles, a housing, a baffle, a gas-distributing pipe and a collector tube. The upper tube plate is provided horizontally, the lower tube plate declines in the direction of the flowing hot fluid, the plate type heat exchanger gets through holes in the upper tube plate and the lower tube plate with a in-line modus, and the baffle is disposed among the heat exchange plate bundles. The inventive device is provided with a large effective heat transfer area, even aqueous film allocation, rapid settling velocity, quick transfer of nonsaturated evaporation heat and moisture, anabatic liquid membrane fluctuation, enhanced turbulent flow, an attenuated liquid membrane laminar sublayer, decreased heat resistance, a small condensing resisting force and a remarkable condensing effect. Deposit and erosion are reduced, a mall floor space is provided, and the inventive device is suitable for condensing and cooling field.

Owner:SOUTH CHINA UNIV OF TECH

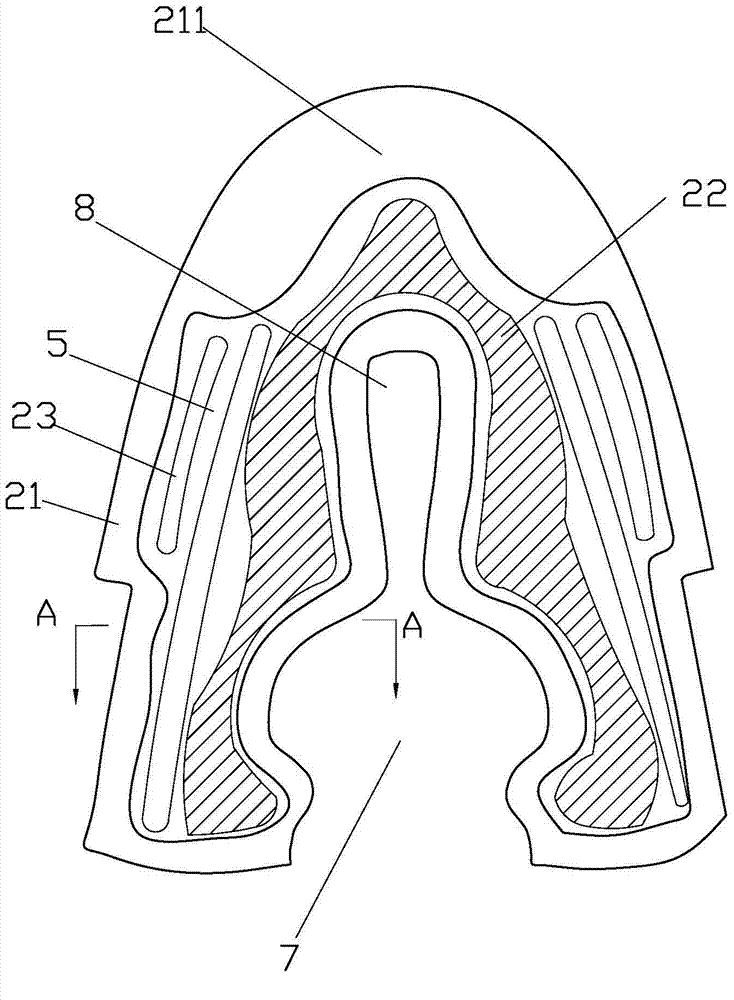

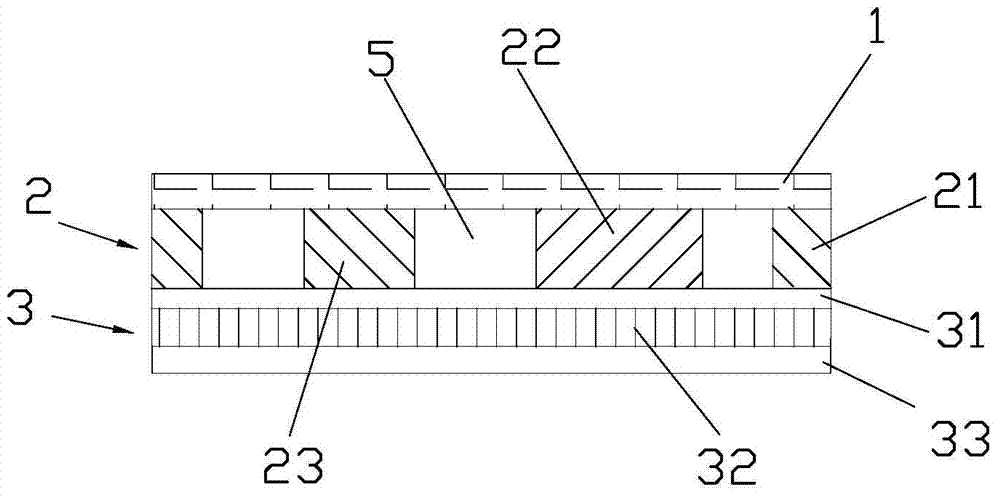

4D breathable vamp and shoe

ActiveCN104273799AImprove comfortSoft and comfortable to wearUpperBootlegsBiomedical engineeringSurface layer

The invention provides a 4D breathable vamp which comprises a vamp body. The 4D breathable vamp is characterized in that the vamp body comprises a surface layer, a lining layer and a bottom layer which integrally adhered, the whole surface layer is made screen cloth, the density of the lining layer is larger than that of the surface layer and the bottom layer, the lining layer is made of knitted fabric with single-color or colorful printings, the surface, with the printings, of the lining layer faces the surface layer, the lining layer is 1.5-3mm in thickness and comprises a plurality of components, the lining layer are respectively adhered to the surface layer and the bottom layer, the whole bottom layer is made of sandwich screen cloth, and the sandwich screen cloth comprises an upper layer, a connecting layer and a lower layer. The invention further provides a shoe made by vamp body. The 4D breathable vamp has the advantages that vamp is light and breathable and has certain hardness, shoe shape can be kept, wearing comfortableness is achieved, the feet of a wearer are less prone to bruising, diversified decorating patterns can be designed on the vamp, a three-dimensional effect is achieved, vamp design freedom is achieved, and the vamp is convenient to produce and attractive in appearance.

Owner:SINCETECH FUJIAN TECH CO LTD

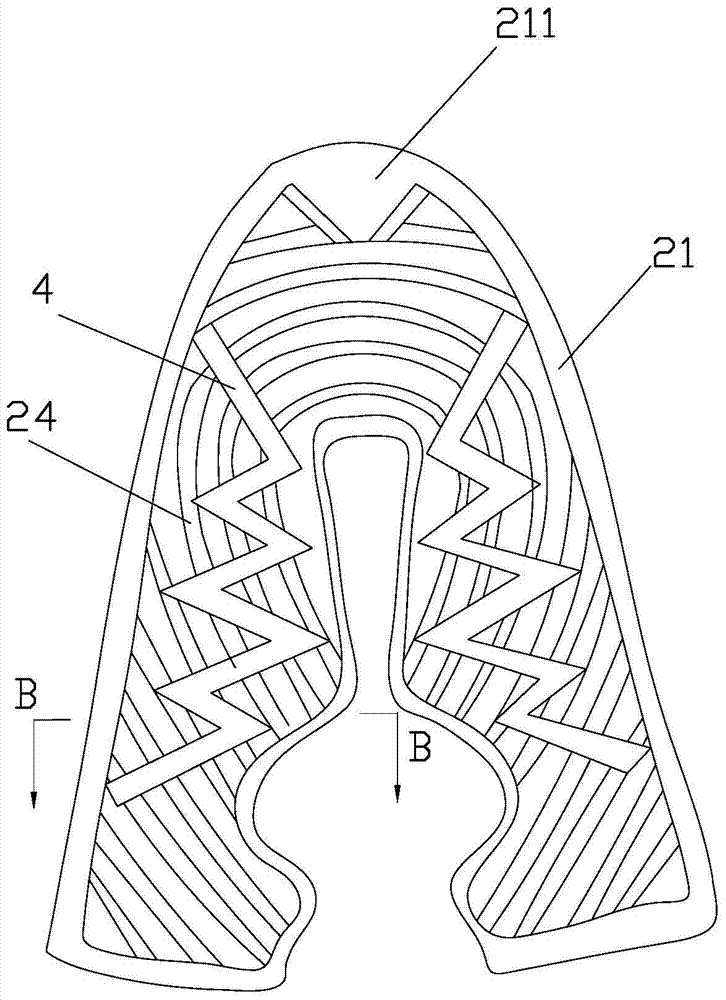

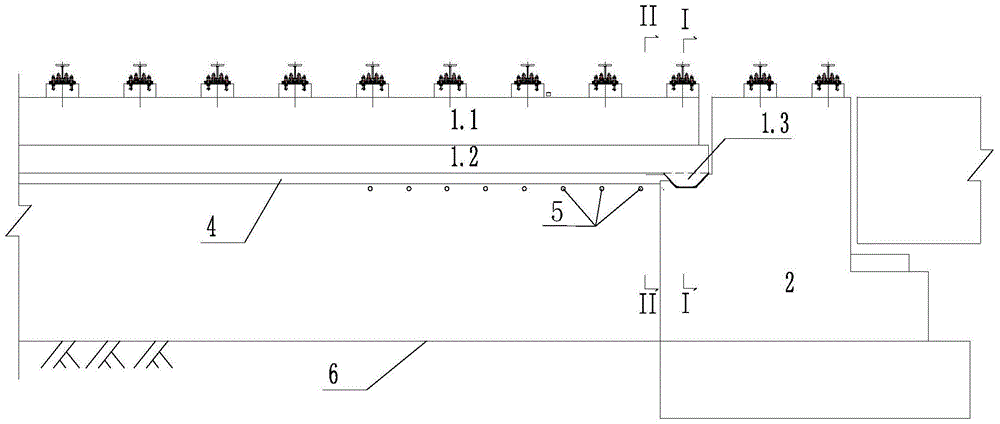

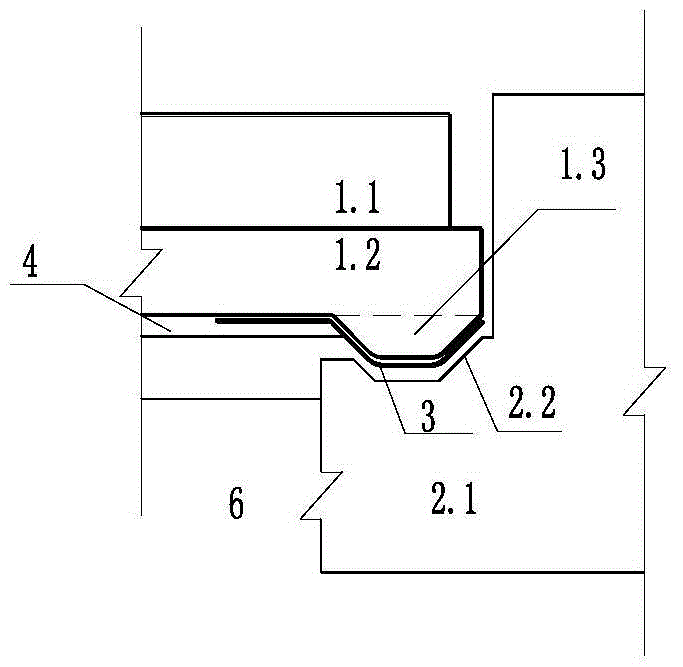

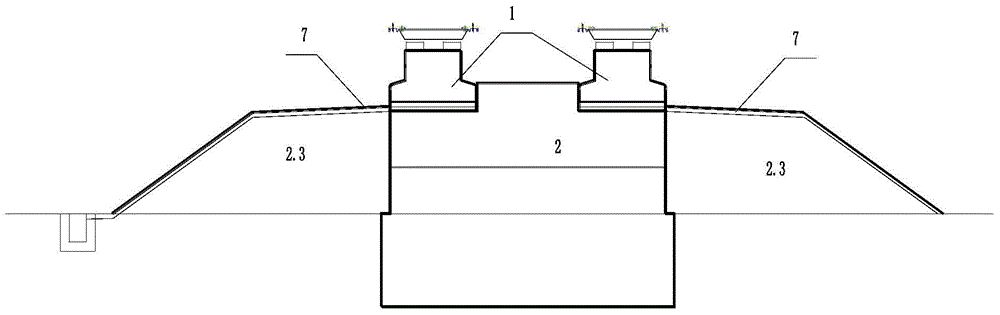

Bearing-rail beam low track and viaduct transition section structure of medium-low-speed magnetic suspension traffic engineering

ActiveCN105672067AError will not occurAchieving smoothness requirementsRailway tracksBridge structural detailsLow speedAbutment

The invention discloses a bearing-rail beam low track and viaduct transition section structure of medium-low-speed magnetic suspension traffic engineering. The structure comprises a roadbed, a bridge abutment, bearing-rail beams, a plurality of grouting pipes and drainage ditches. The bridge abutment comprises an abutment back body and abutment cones. Each bearing-rail beam comprises a bottom slab and an upper structure arranged on the bottom slab, and the bottom slab is buried in the roadbed and extends downwards to form tenons corresponding to tenon grooves. Each tenon is placed in the corresponding tenon groove, and round corners are arranged on the tenons and the tenon grooves so that the tenons can rotate in the tenon grooves. The grouting pipes are arranged in the roadbed. According to the bearing-rail beam low track and viaduct transition section structure, the bearing-rail beams of a low track are in lap joint with the tenon grooves of a viaduct, so that settlement and slab staggering, caused by different foundation treatment measures, between the low track and the viaduct are avoided, the effect that settlement and slab staggering of a magnetic levitation F rail at the junction of the low track and the abutment are avoided is guaranteed, and the requirement for smoothness of the F rail at the transition section between a viaduct structure and the low track of the magnetic suspension traffic engineering is effectively met.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

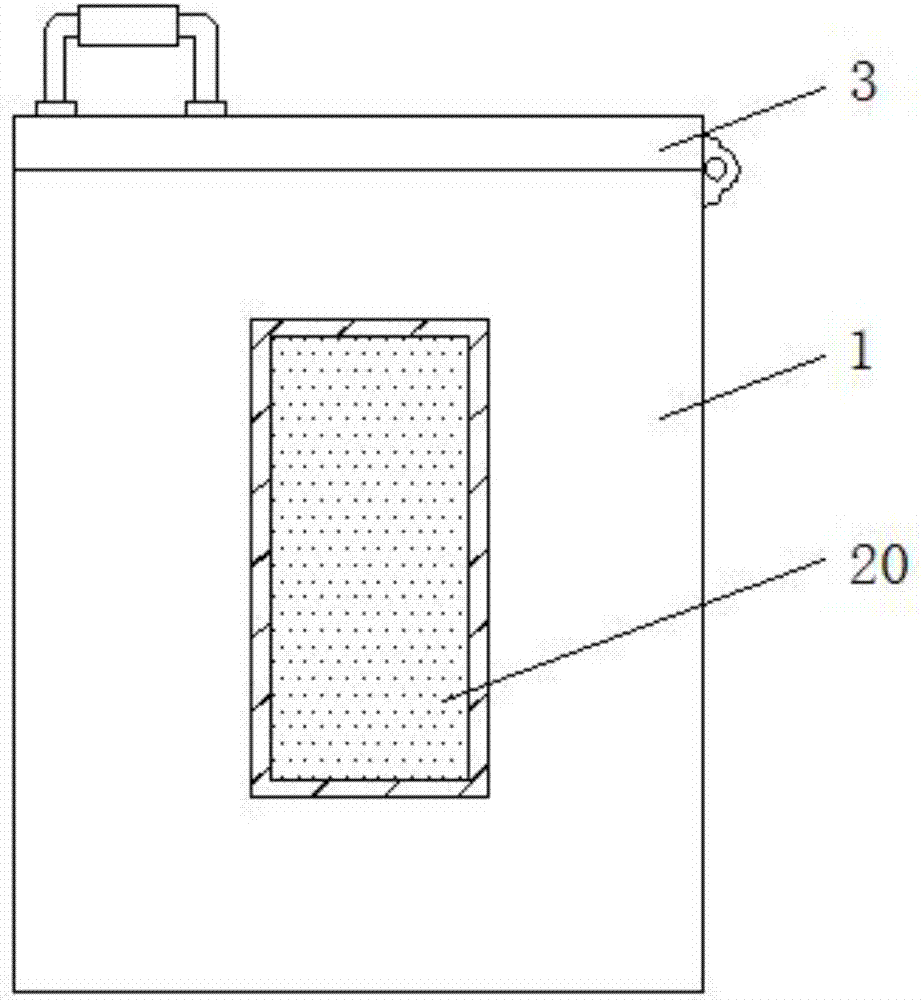

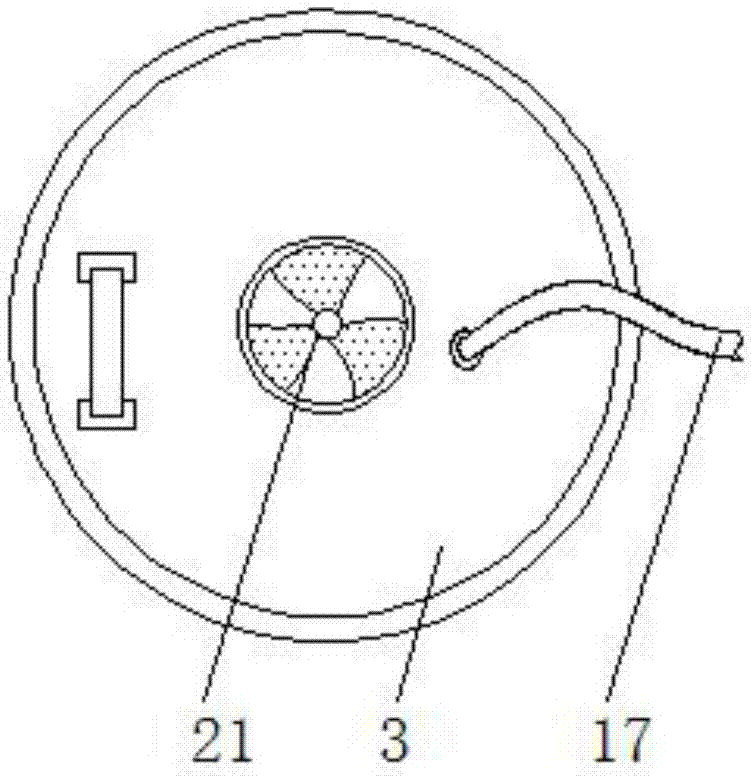

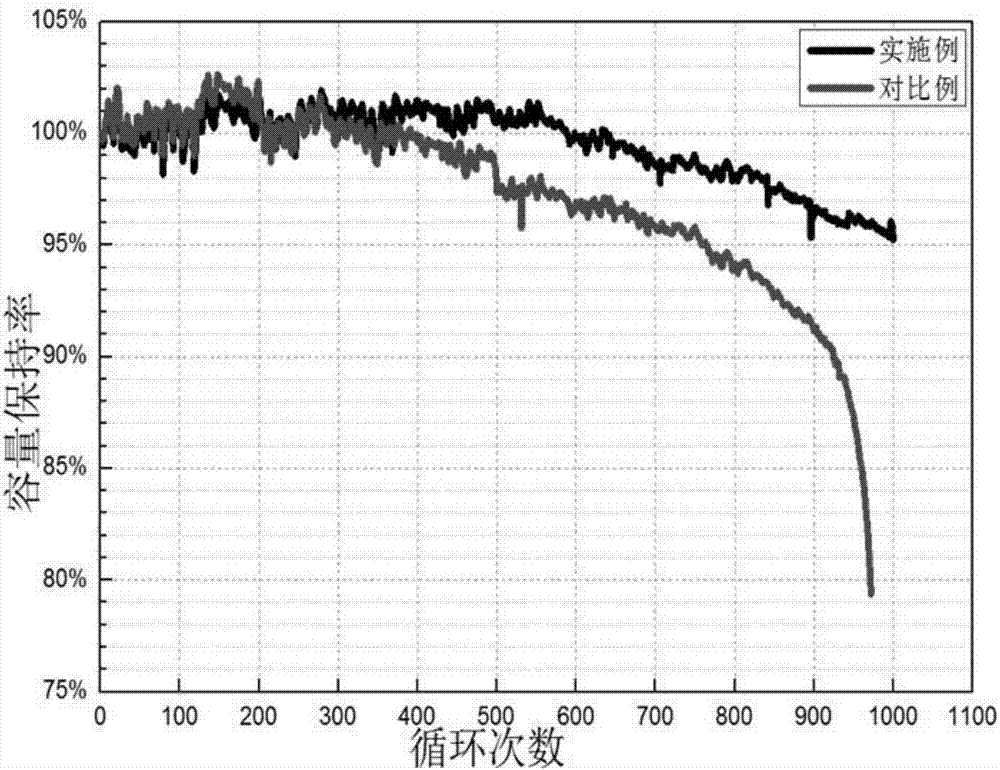

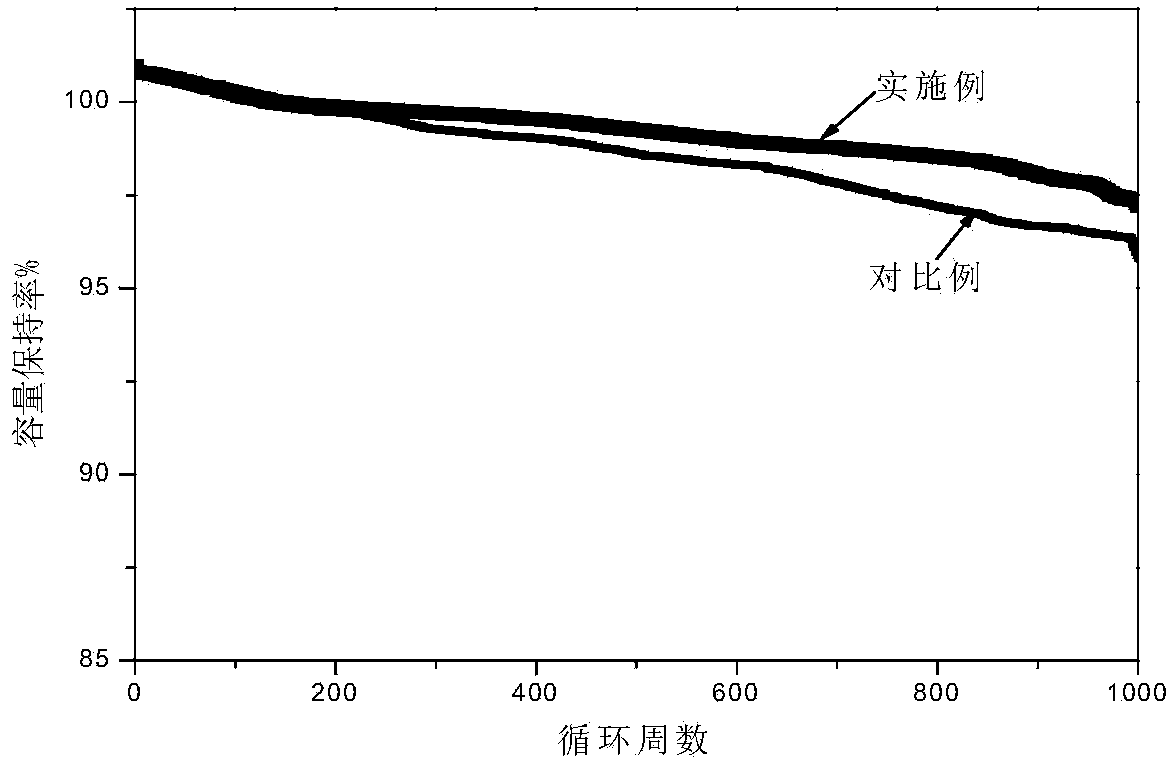

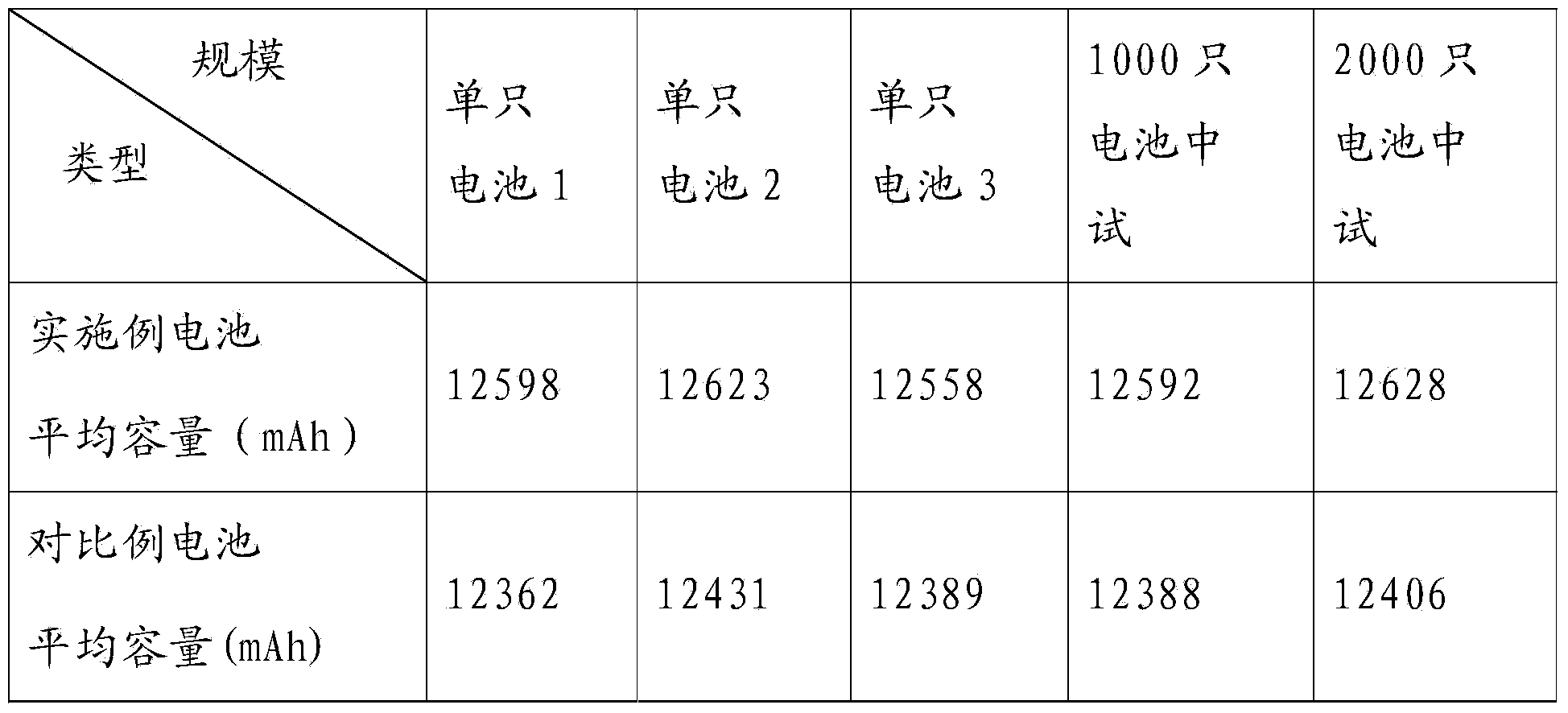

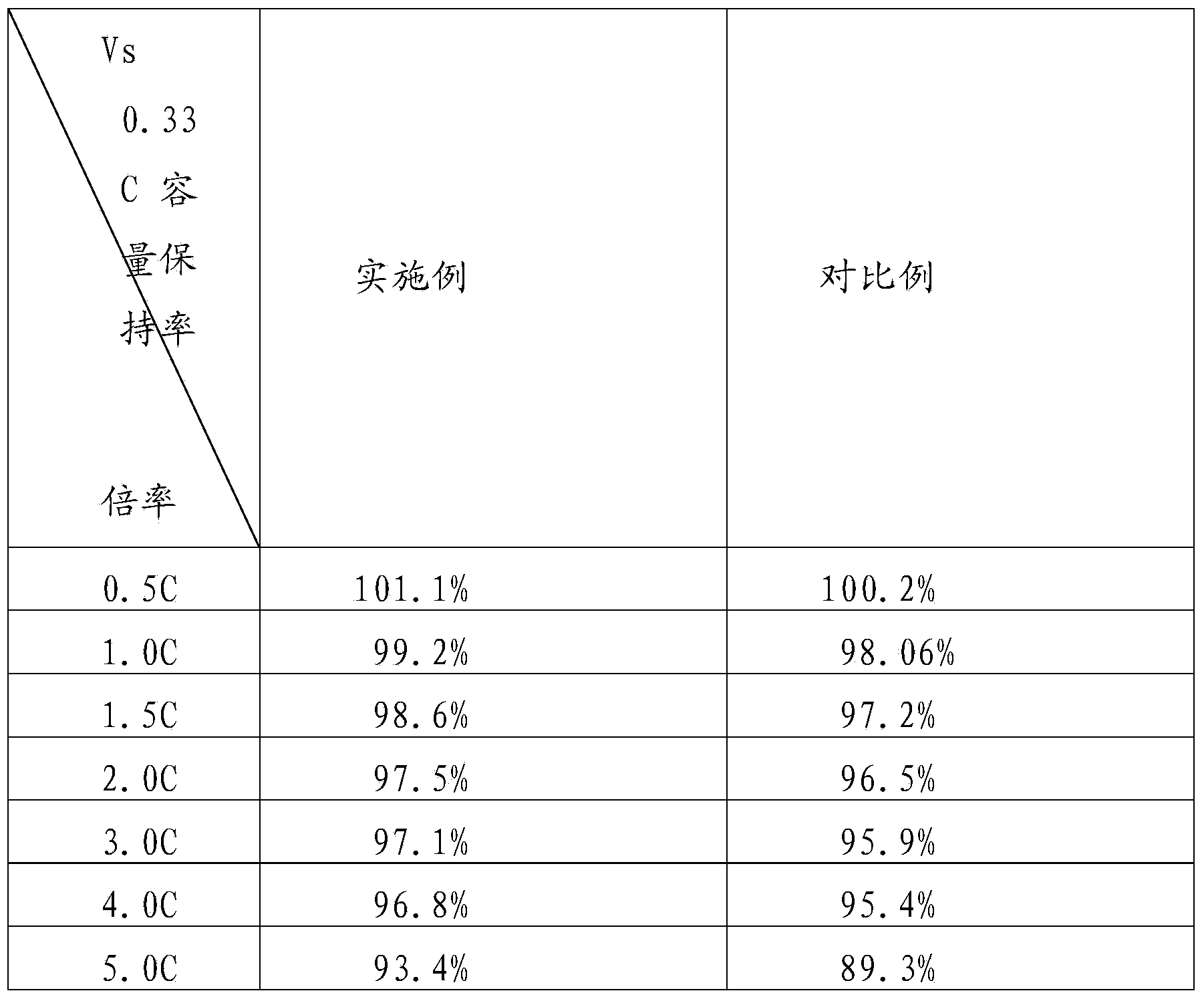

Formation method of lithium ion battery

InactiveCN104037464ADischarge in timeAvoid overflowSecondary cells charging/dischargingElectrolyte accumulators manufactureLithium electrodeEngineering

The invention discloses a formation method of a lithium ion battery. The formation method comprises the following steps: (1) carrying out constant-current charging with a 0.04C-0.2C current; (2) carrying out the constant-current charging with a 0.2C-1.0C current; (3) placing; (4) carrying out the constant-current discharging to a cut-off voltage with a 0.2C-0.6C discharging current; (5) placing; (6) carrying out the constant-current charging with a 0.5C-1.0C current; (7) carrying out the constant-current charging to the cut-off voltage with a 0.04C-0.2C current, and then converting into constant-voltage charging; and (8) maintaining a micro-vacuum state with the pressure being -0.03MPa-0.01MPa all the time in the lithium ion battery during the whole formation stage. The formation method disclosed by the invention has the advantages that in formation, gas generated in the battery can be exhausted in time, so that the lower capacity of the battery caused by bubbles adhered onto the surface of a negative pole piece is avoided; the phenomenon of overflowing of the electrolyte with the gas in the formation is avoided, so that the condition that the inventory of the electrolyte meets the process requirement is guaranteed; the discharging step is added after the charging step, so that the circulating performance and the rate capability of the prepared battery are respectively improved to a certain extent.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Heat pump type tableware washer and control method thereof

ActiveCN105476584AImprove energy efficiencyFast heatingTableware washing/rinsing machine detailsFluid circulation arrangementDecreased energyEngineering

The invention provides a heat pump type tableware washer and a control method thereof. The washer is added with a heat pump device comprising a compressor, a condenser, a throttle device, an evaporator and an evaporator fan. The condenser is disposed on a line where a circulating water pump is located; a heating heat-exchange passage is also disposed between a housing and a treatment chamber, the evaporator and the evaporator fan of the heat pump device are received in the heating heat-exchange passage, and both an air inlet and an air outlet of the heating heat-exchange passage are arranged in the front of the housing. The heat pump device provides hot water in a washing stage, decreasing energy consumption; both the air inlet and the air outlet are arranged in the front of a body, enabling air to circulate more smoothly, avoiding the problem that unsmooth air circulation in a cupboard where the washer is mounted may cause poor heat dissipation of a chamber of the compressor; a guarantee is given to both timely discharge of heat of the chamber of the compressor and reduction of exhaust temperature, thus prolonging life of the compressor.

Owner:HANGZHOU SANHUA RES INST CO LTD

Draining cup support

Owner:SUZHOU CITY WUZHONG DISTRICT XUKOU FENGSHOU MACHINERY PARTS FACTORY

Electrolytic machining technique and device for small bore diameter inner wall surface fine groove

InactiveCN101259549AFast curingImprove curing effectMachining electrodesMachining working mediaElectrolysisEngineering

The invention discloses an electrolytic machining technique of a micro-groove on an inner wall surface of a small aperture and a device. The technique is that: a cathode of a forming tool of a variable cross-section structure which is provided with insulation sections and conductive sections at intervals and is made of conductive metal wires of 200 to 1000 mum is positioned in an unthreaded hole of a workpiece which is processed in advance by utilizing the electrolytic machining device of the invention, the workpiece is taken as an anode, then electrolytic solution is radially flowed along an electrode wire, the electrolytic machining is carried out in the unthreaded hole, the pressure of the electrolytic solution is maintained at 1 to 5 MPa, and the micro-groove structure is obtained at the inner wall surface of the unthreaded hole by flushing the products after the processing. The diameter size of the cathode of the forming tool which is prepared by adopting the ultra-violet light masking solidification technology and the electroforming process can be as small as a few hundred microns, and a rib cooling hole structure with the hole diameter size of about 1mm can be obtained by combining the electrolytic machining technique. The adopted technical process of the invention is easy to master and has small investment, the minimal hole diameter which can be processed is small, and the processing precision is high.

Owner:ZHEJIANG UNIV OF TECH

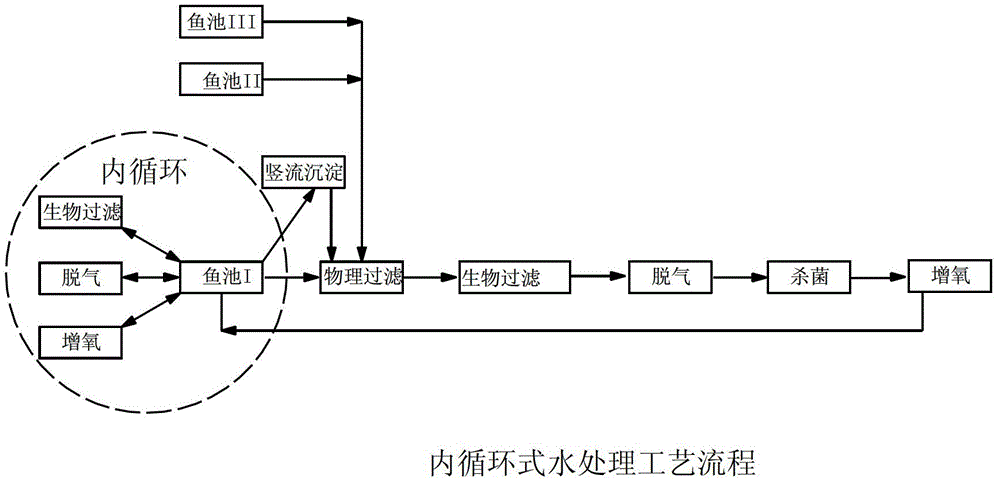

Internal circulation fishpond and circulating water treatment process

The invention relates to the technical field of aquaculture, and discloses an internal circulation fishpond and a circulating water treatment process. According to the internal circulation fishpond and the circulating water treatment process, an air striping device, a physical filtration device and a biological filtration device are arranged in vacant regions, such as corners of the fishponds; multiple functions, such as plug flow, oxygenation, degassing, solid filtration and biological filtration, are integrated in the design of the fishpond; through arranging an air stripping pump, a moving bed biofilter and a vertical flow precipitator and the like, the water treatment function of the fishpond is perfected and enhanced, and the fishpond has the functions of oxygenation, degassing, physical filtration and biological filtration; the circulating speed of a water body is reduced while the solid utilization rate is improved; through reducing the treatment load amount of a water treatment system, the circulating speed of the water body and the operating energy consumption of a circulating water pump are reduced.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

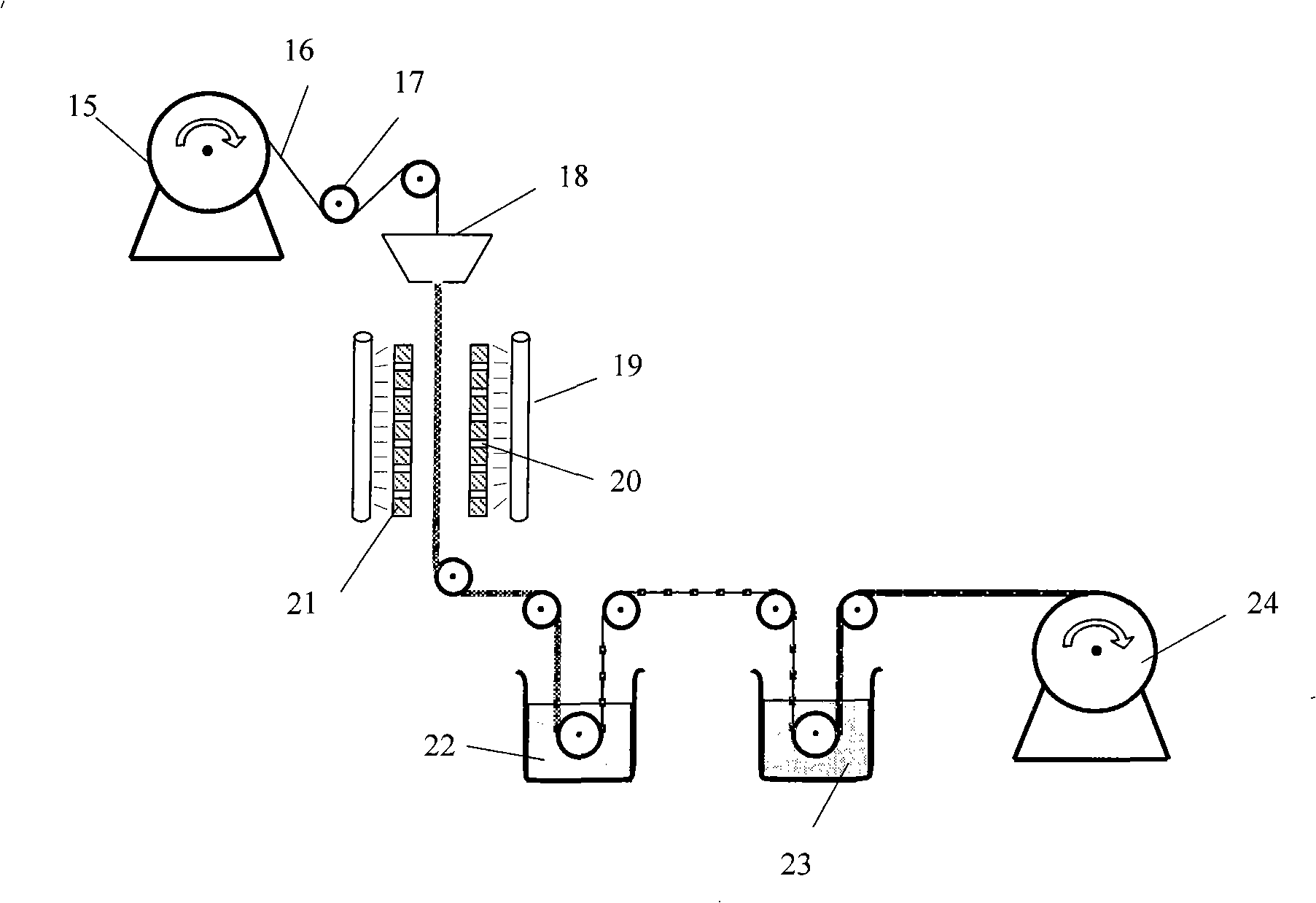

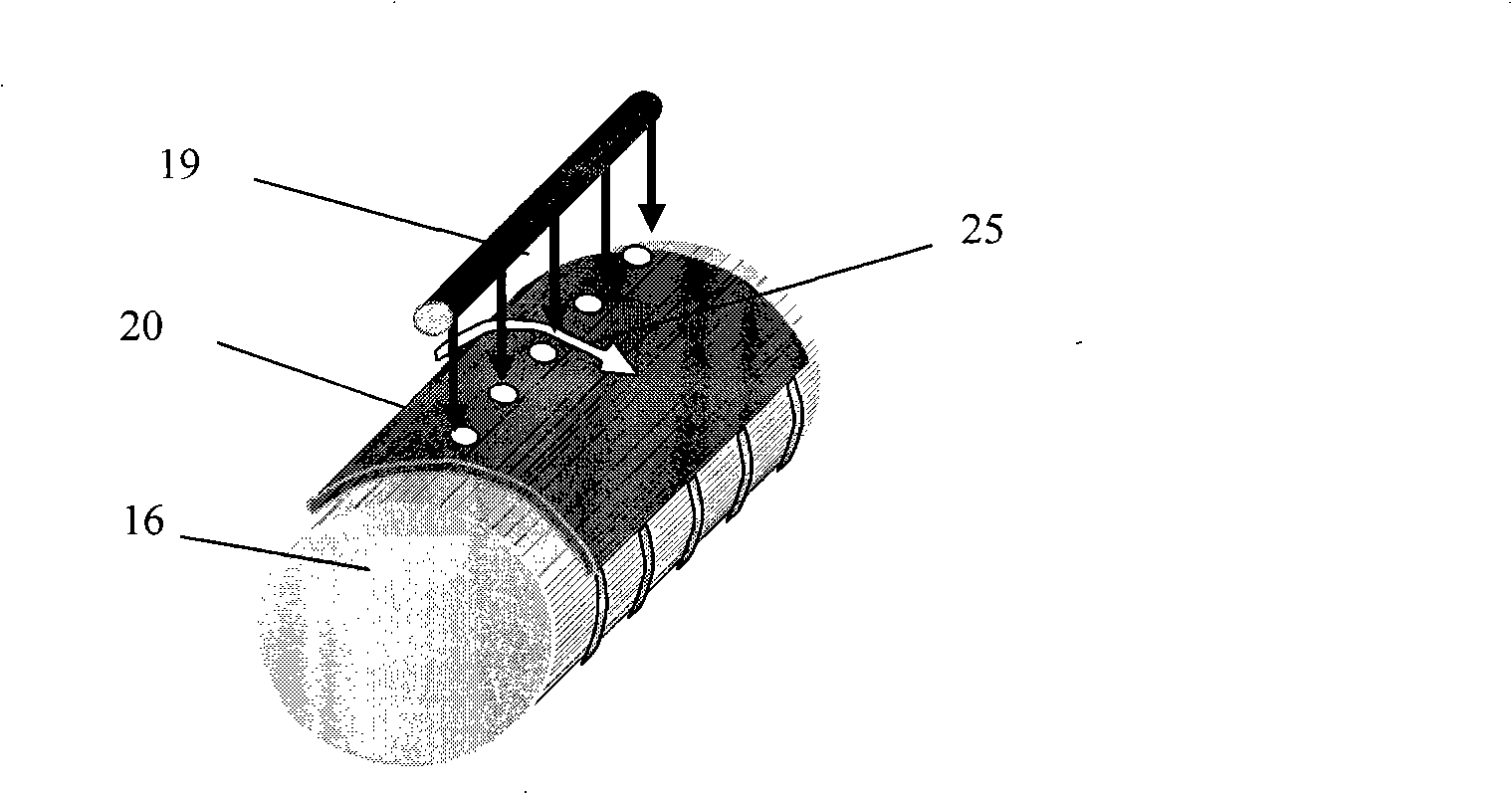

Spinning process of bamboo-like flat filaments produced by semi-continuous high-speed spinning machine

ActiveCN103290495AEasy maintenanceLow cost of spinningArtificial thread manufacturing machinesArtificial filaments from viscoseFrequency changerPolymer science

The invention relates to a spinning process of bamboo-like flat filaments produced by a semi-continuous high-speed spinning machine and belongs to the technical field of spinning of semi-continuous spinning machines. The spinning process comprises glue supply, filament strip forming, spinning and winding. The spinning process is characterized in that the glue supply is achieved through a glue supply device which comprises a metering pump, a glue supply tube and a filter; the metering pump is connected with a frequency converter which is used for controlling the amount of the glue supply of the metering pump; the frequency converter controls the metering pump to perform intermittent glue supply; the spinning is achieved through a spinning device which comprises at least one spinning roller which is horizontally arranged relative to an operating surface of a spinning surface; and filament strips surround the spinning roller to achieve drafting, solidification and deacidification in the spinning processes under the rotation of the spinning roller. The spinning process of the bamboo-like flat filaments produced by the semi-continuous high-speed spinning machine has the advantages of solving the problems that the filament strips of the semi-continuous spinning machines are inadequate in response, so that the spinning speed cannot be improved and the production efficiency and product quality cannot be integrated, enabling the arrangement direction of the spinning roller to be changed to enable the spinning speed of the spinning machine to be improved and enabling the high quality bamboo-like flat filaments to be spun out.

Owner:YIBIN HIEST FIBER +2

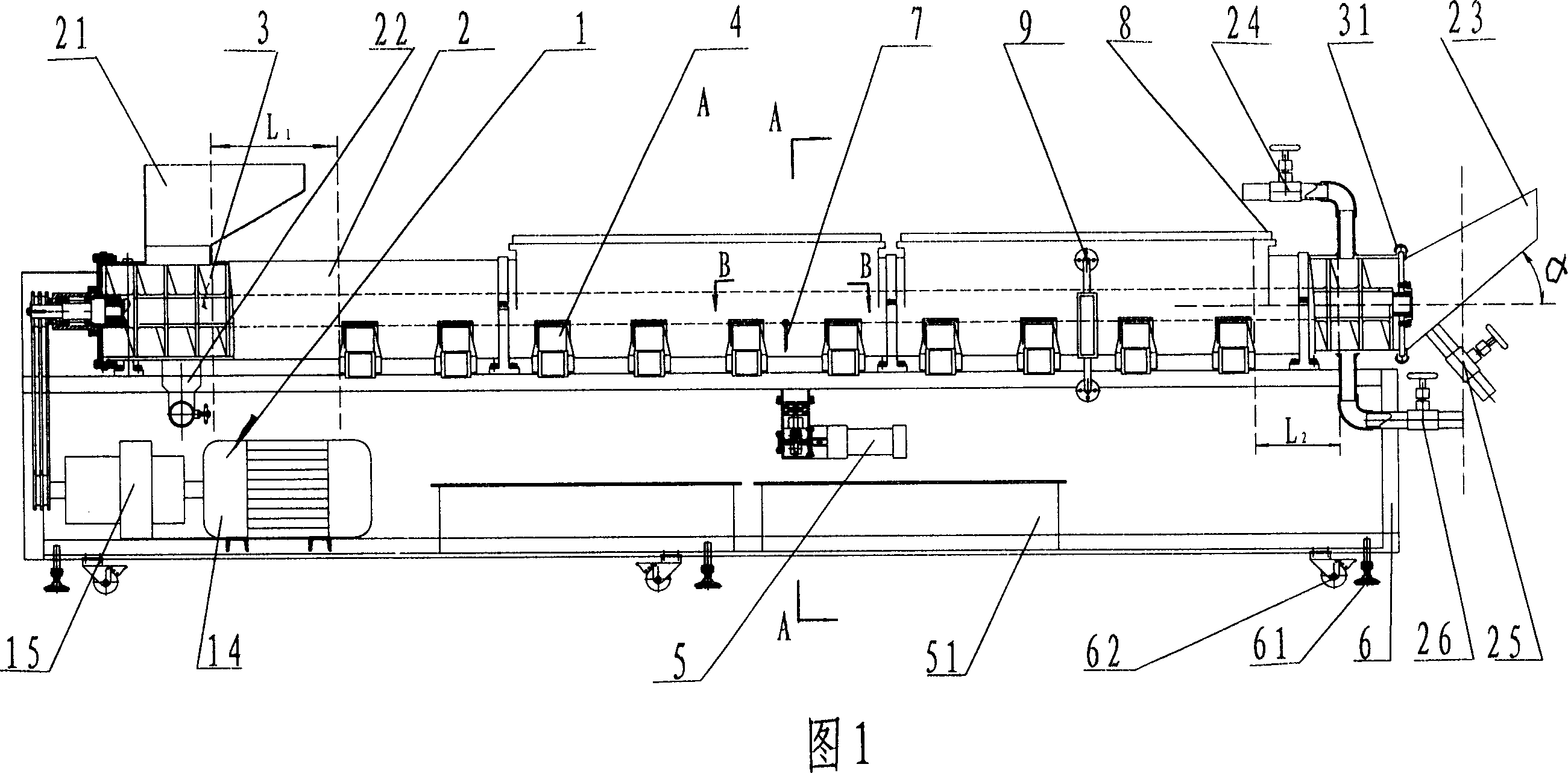

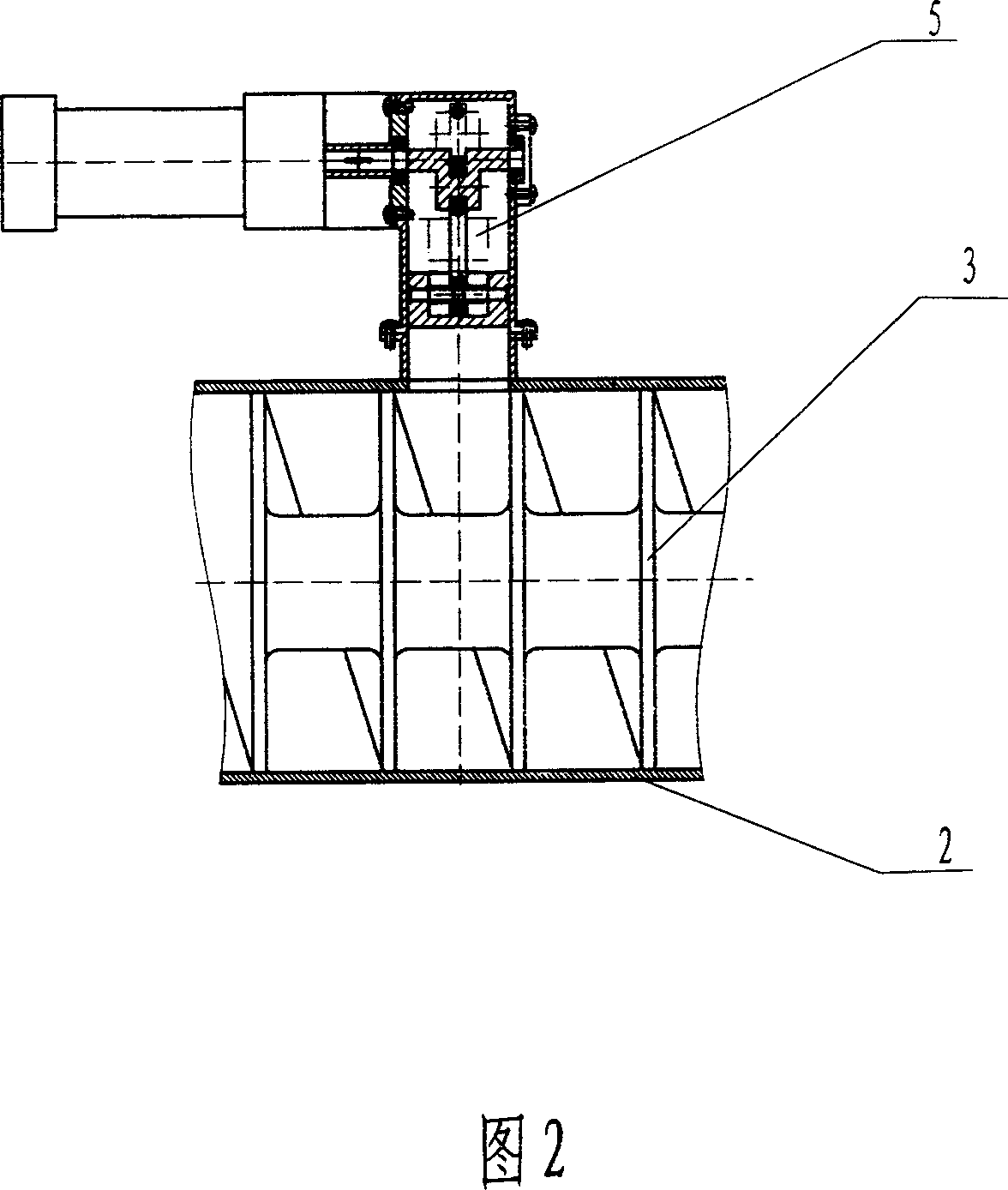

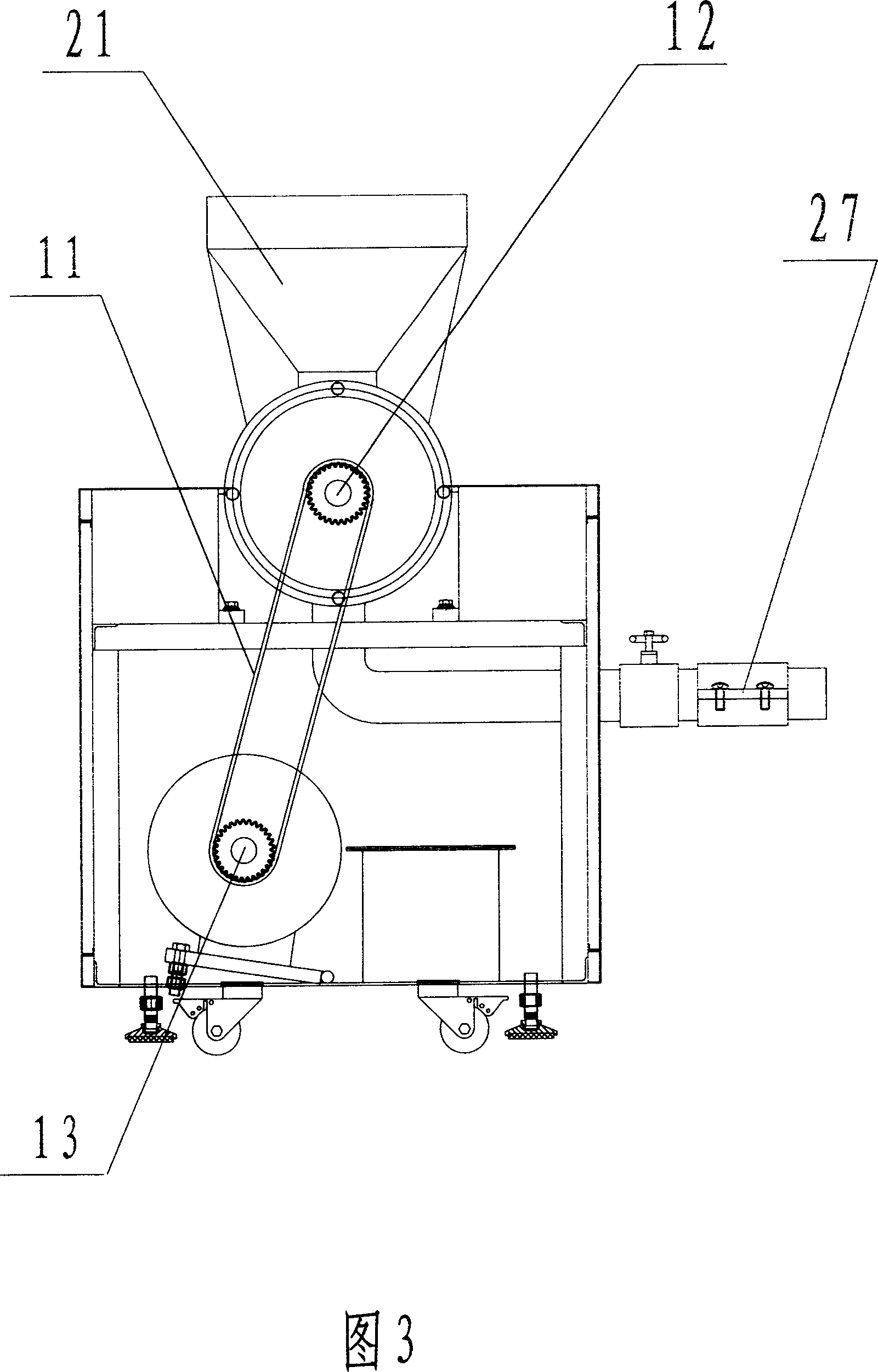

Microwave counter current continuous extraction apparatus

InactiveCN1935308ADischarge in timeIncrease concentrationEnergy based chemical/physical/physico-chemical processesSolid solvent extractionChemical industryMicrowave

The present invention mainly is relates to an extraction equipment used in the fields of food industry, pharmaceuticals industry and chemical industry. In particular, it relates to a microwave countercurrent continuous extraction equipment. It includes the following several portions: extraction drum, its oned end is equipped with feed funnel and extract outled, its another end is equipped with residuum outlet and extract inlet; on the extraction drum a microwave system is set, in the inner cavity of extraction drum a screw-type propeller is mounted, said screw-type propeller is driven by drive device. Besides, said invention also provides its working principle and concrete operation method.

Owner:TIANSHUI HUAYUAN PHARMA EQUIP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com