Simulating device for fluid flow safety evaluation of oil-gas pipelines

A technology for fluid flow and safety evaluation, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as insufficient fluid flow safety, drilling platform explosion, environmental pollution, etc., and achieve scientific experimental methods, flexible installation, and comprehensive experimental data collection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

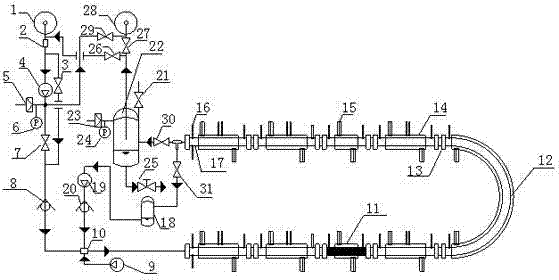

[0036] As attached figure 1 As shown, a simulated oil and gas pipeline fluid flow safety evaluation device includes a multiphase flow circulation system, a separation system, a fluid injection system, and an exhaust gas recovery system.

[0037] The multi-phase flow circulation system includes a gas-liquid mixer 10 connected in turn through auxiliary pipelines to form a circulation loop, a number of detachable pipe sections 17 connected in series by a flange 13, an eighth gate valve 31, a buffer tank 18, and a multi-phase mixed transportation. The pump 19, the second one-way valve 20, the detachable pipe section 17 is also connected with a curved pipe 12 through a flange 13,

[0038] The outer surface of a single detachable pipe section 17 is wrapped with a circulating jacket tube 14. The circulating jacket tube 14 is provided with a refrigerant circulation interface 15 for connecting refrigerant. The two ends of the single detachable pipe section 17 near the flange 13 are also prov...

Embodiment 2

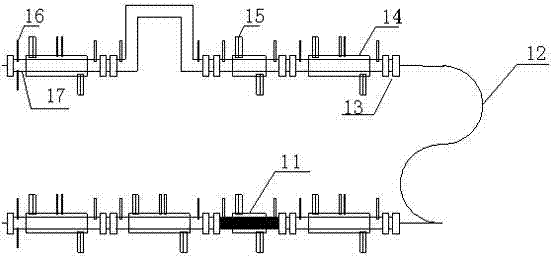

[0074] As attached figure 2 As shown, the difference between this embodiment and the first embodiment is that a part of the detachable pipe section 17 is a straight shape, and a part is a bent shape as shown in the figure, and the curved pipe 12 is an "S" shape.

Embodiment 3

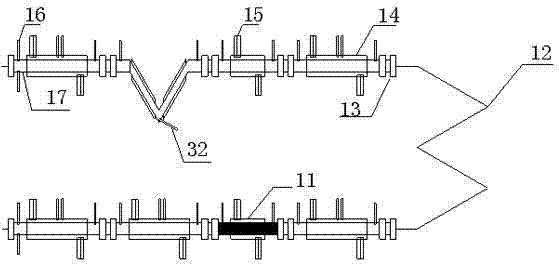

[0076] As attached image 3 As shown, the difference between this embodiment and the first embodiment is that part of the detachable tube section 17 is linear and part is "V" shape, the curved tube 12 is "M" shape, and the 32-focused beam reflects The measuring instrument is installed at the corner of the detachable pipe section 17, which can analyze and measure the flow composition change or particle change of the fluid when the fluid passes through the corner.

[0077]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com