Patents

Literature

54results about How to "Measurement science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

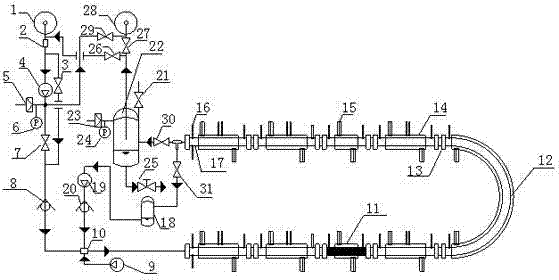

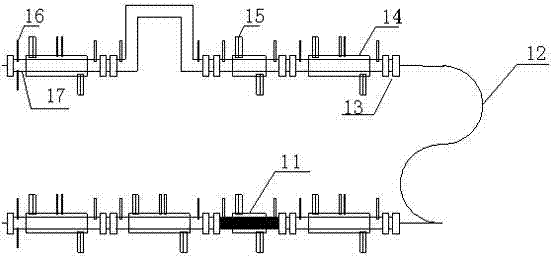

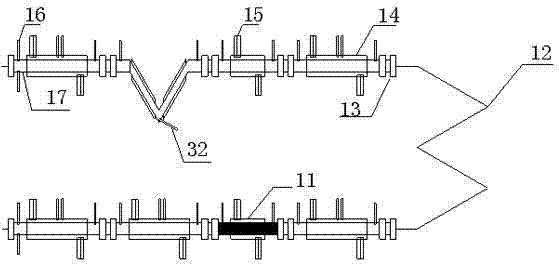

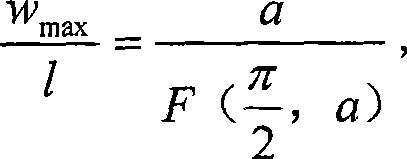

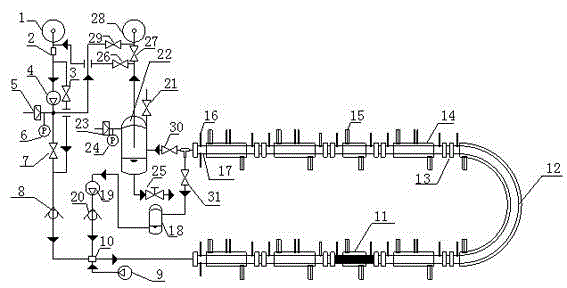

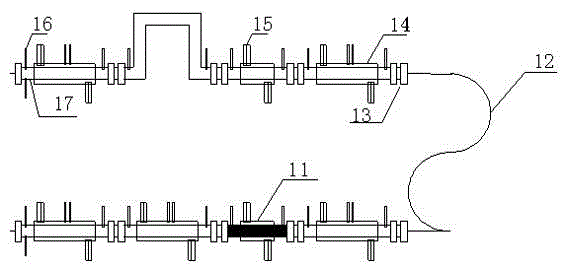

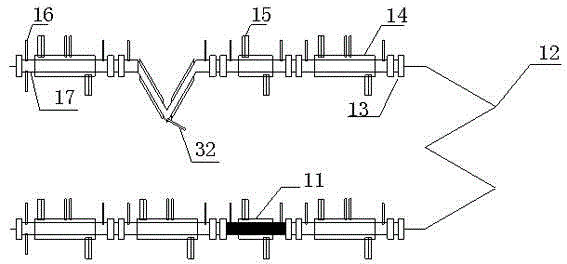

Simulating device for fluid flow safety evaluation of oil-gas pipelines

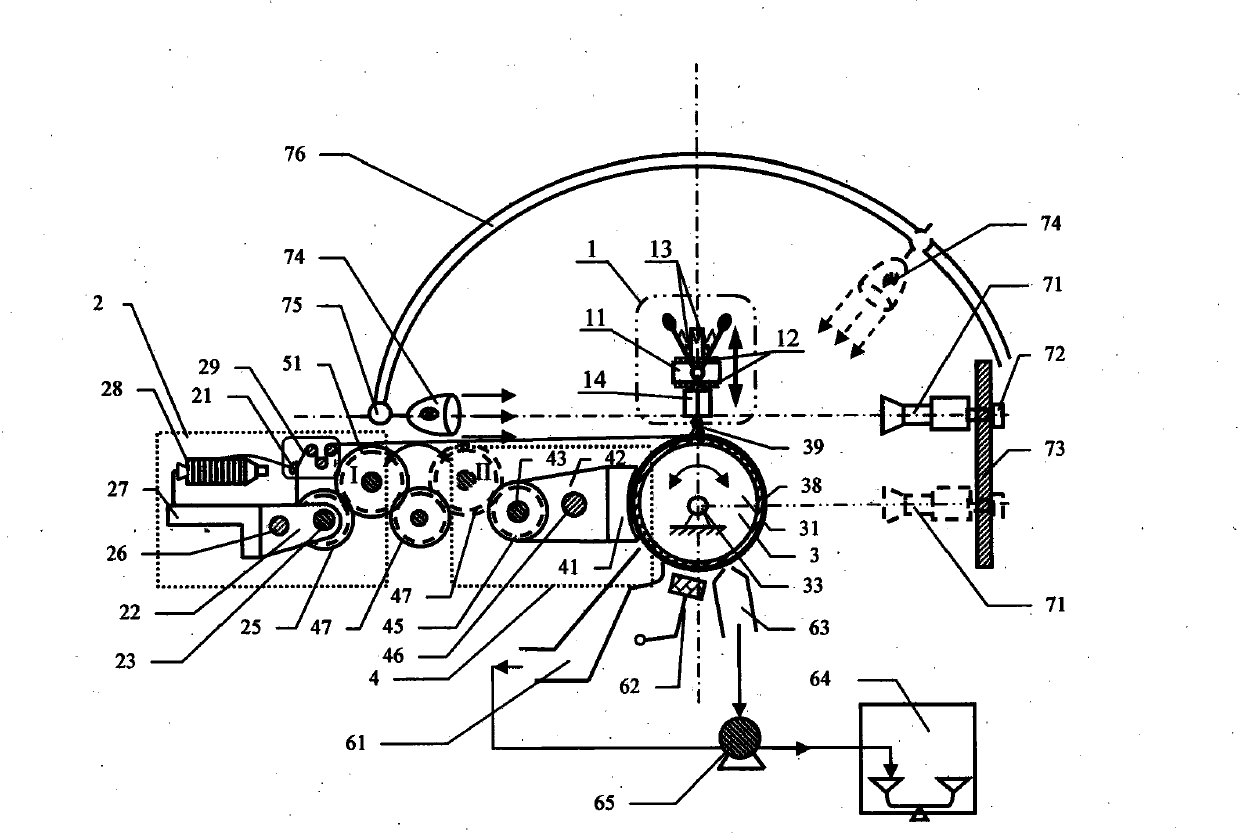

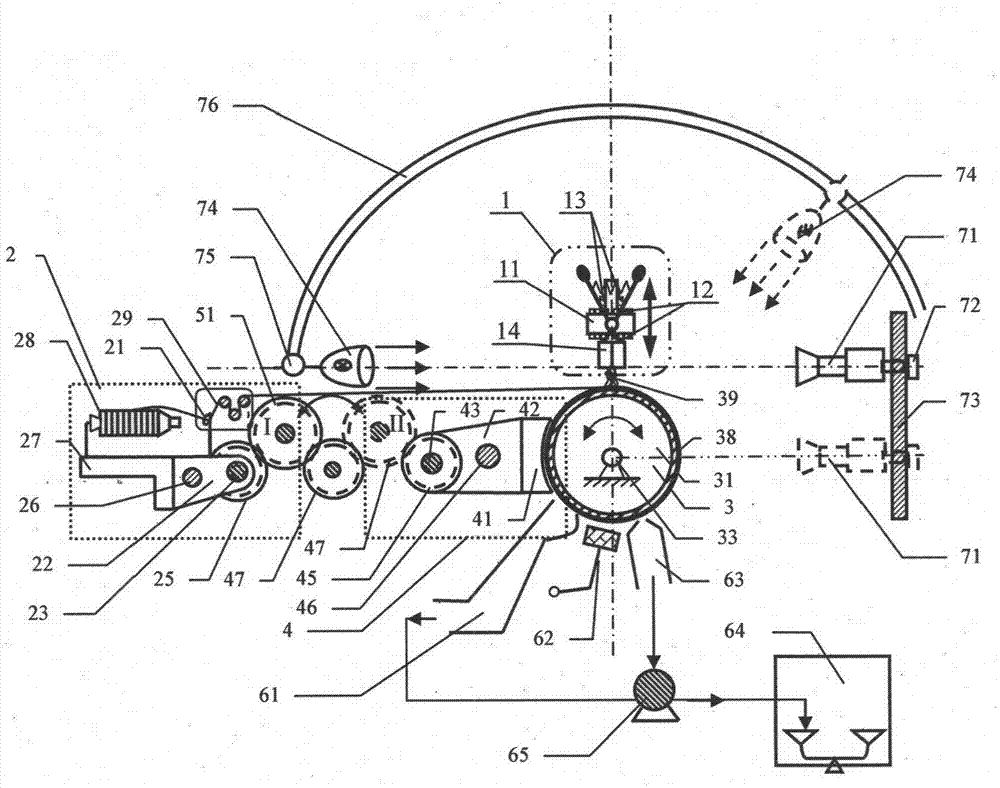

The invention discloses a simulating device for fluid flow safety evaluation of oil-gas pipelines. The device comprises a multiphase flow circulating system, a separating system, a fluid injecting system and a waste gas recovery system. The device disclosed by the invention emerges on the basis of fully considering the current fluid flow safety hotspot problem and is capable of simulating a low-temperature high-pressure environment to carry out the fluid flow safety evaluation of the oil-gas pipelines, wherein the evaluation content comprises oil-gas pipeline blockage caused by problems such as hydrate and wax deposit and the oil-gas transmission safety problem caused by pipeline corrosion. The device disclosed by the invention is not limited to the evaluation content and can also be used for exploring the research on the evaluation of multi-phase fluid flow regularity, hydrate inhibitor performance and the like. The device disclosed by the invention has the characteristics of reasonable structure, ingenious design, operational flexibility, accuracy in measurement and the like.

Owner:SOUTH CHINA UNIV OF TECH

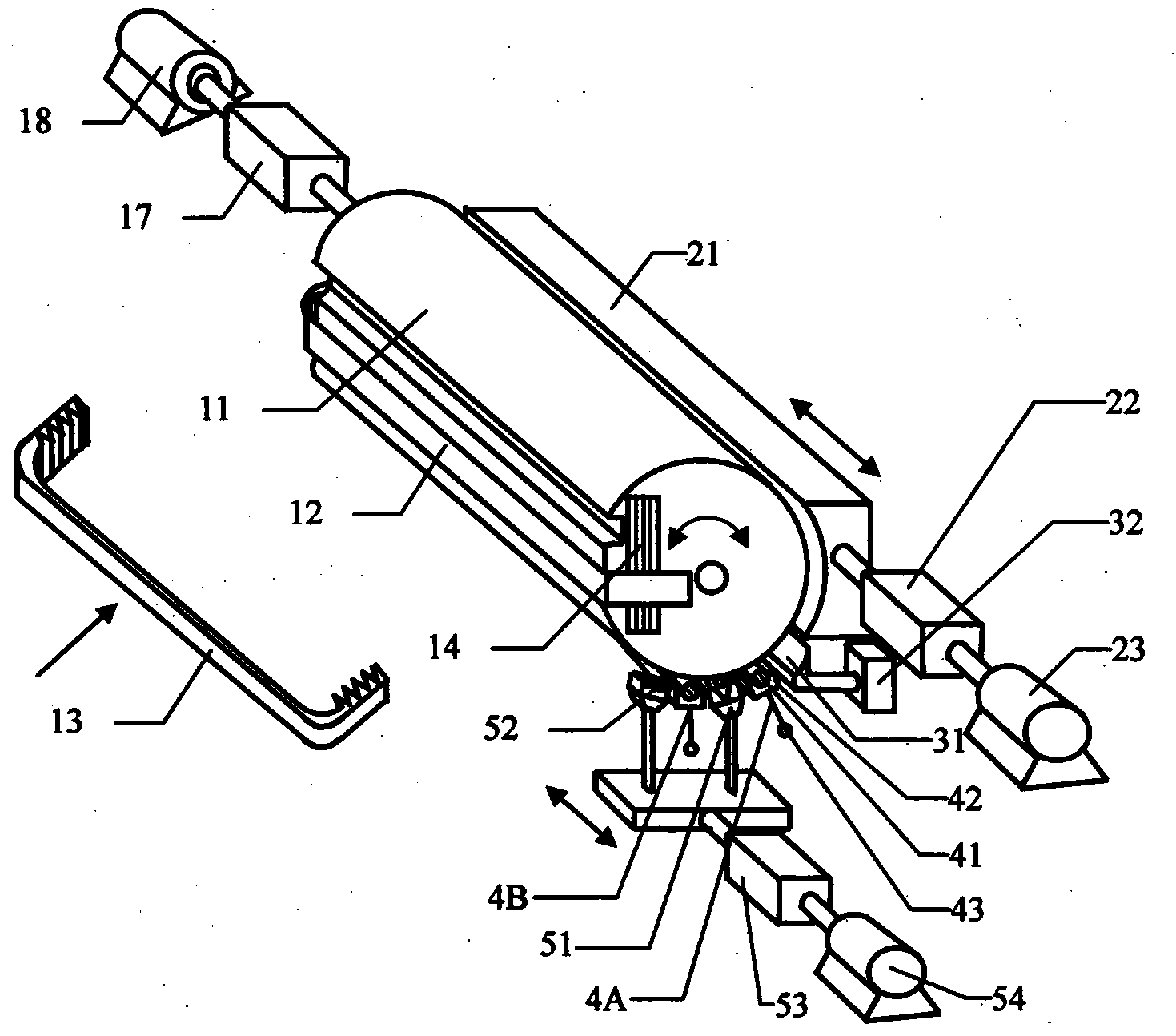

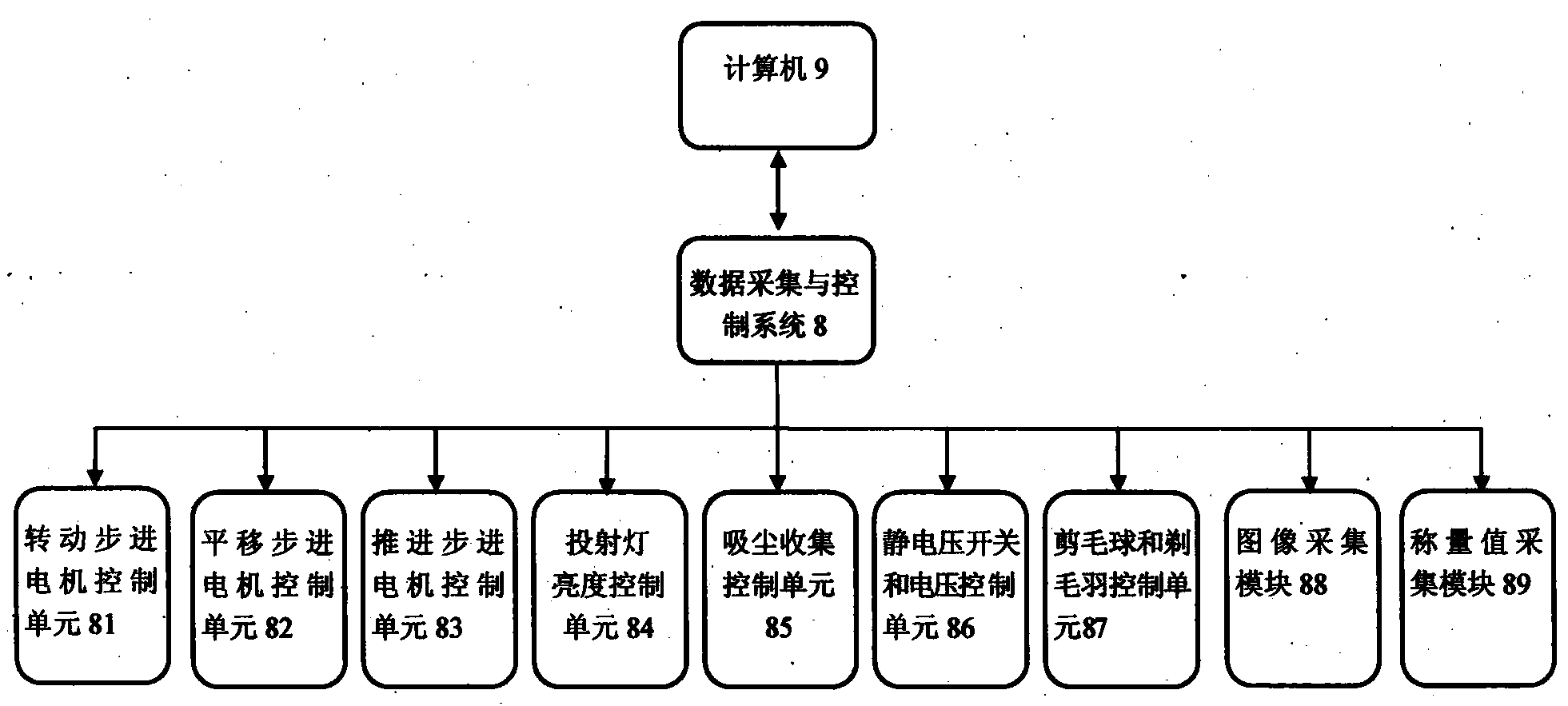

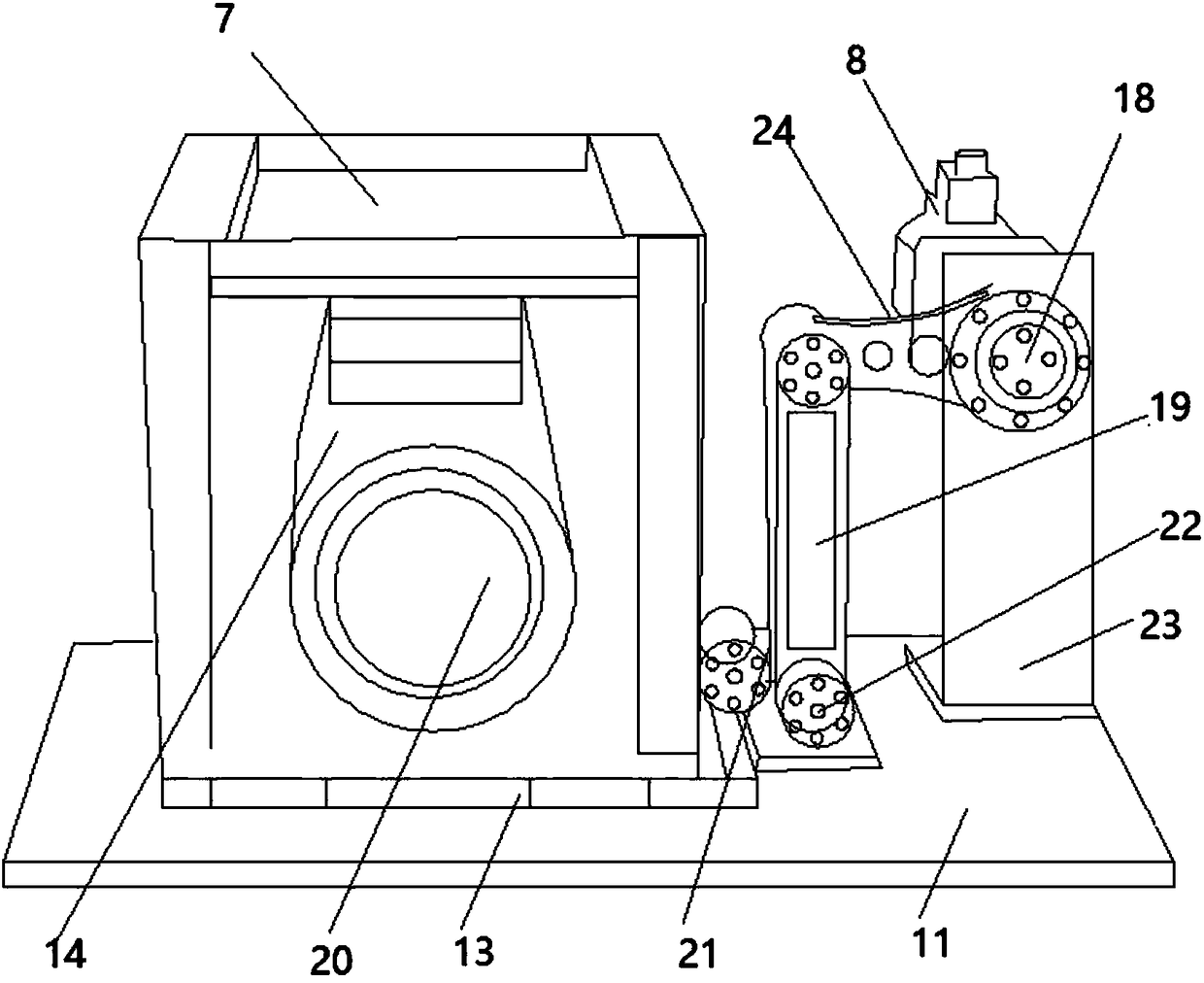

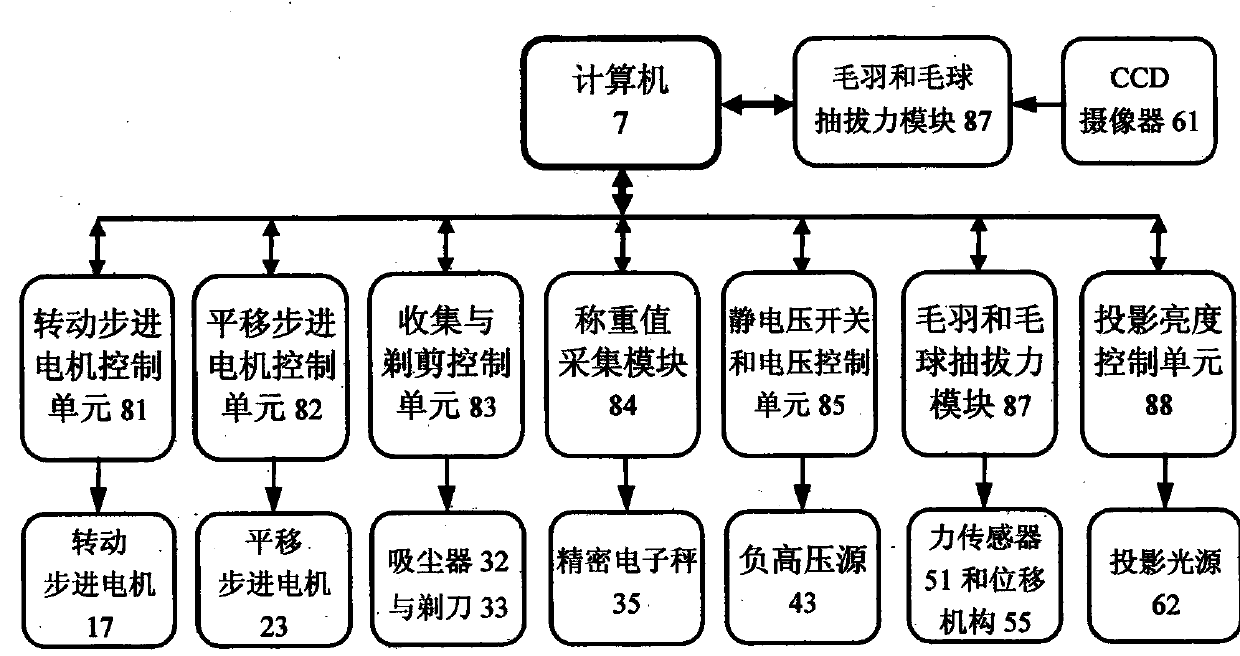

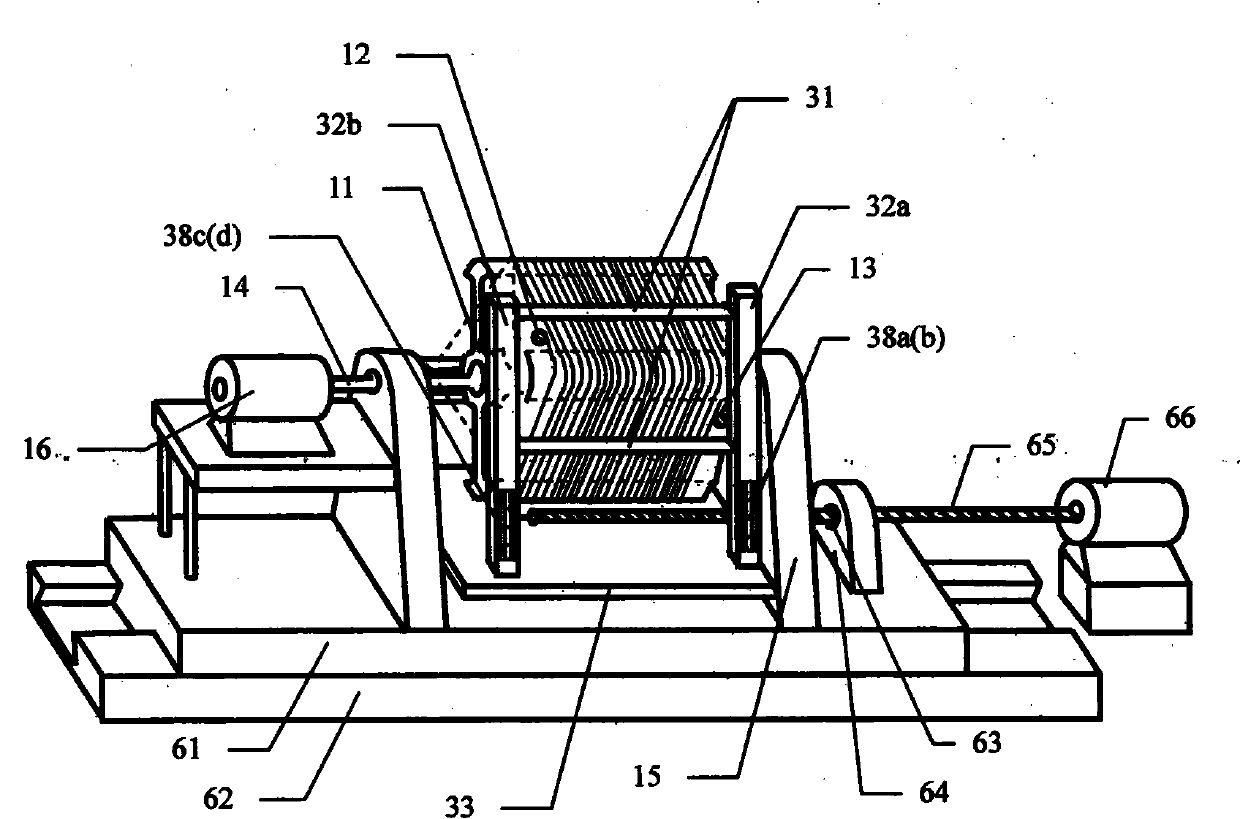

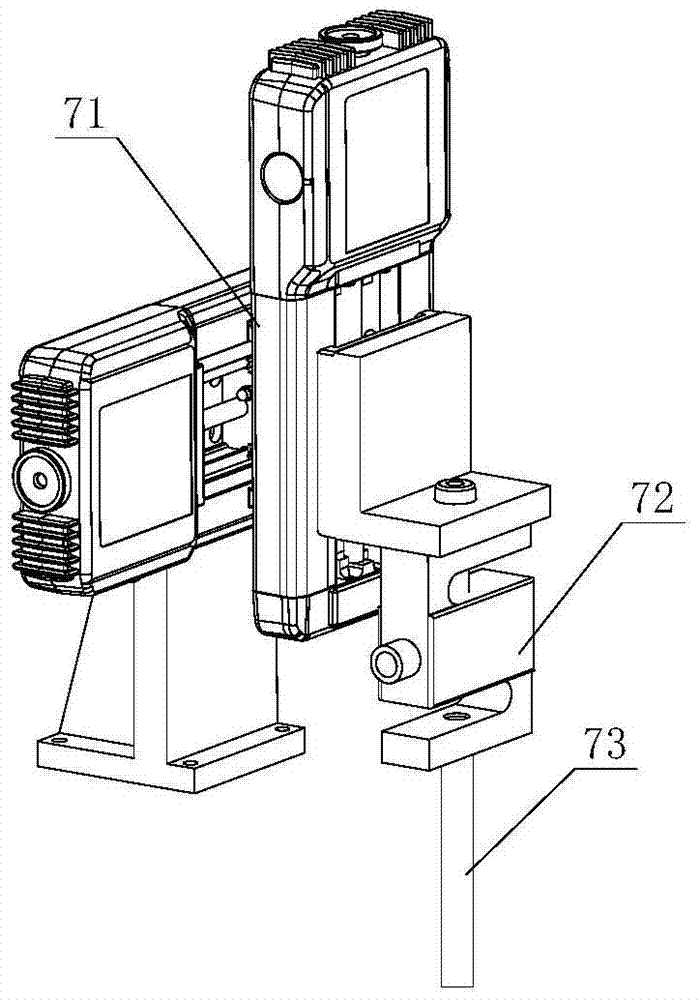

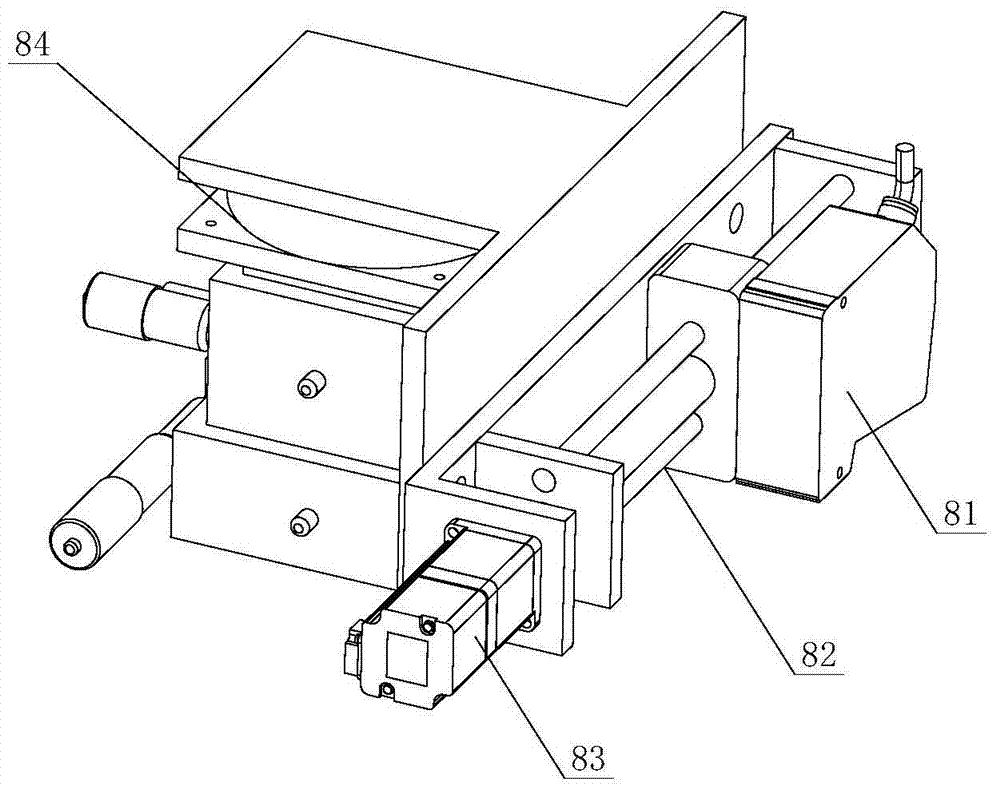

Method and device suitable for measuring fluffing and pilling amount and abrasion amount of textile

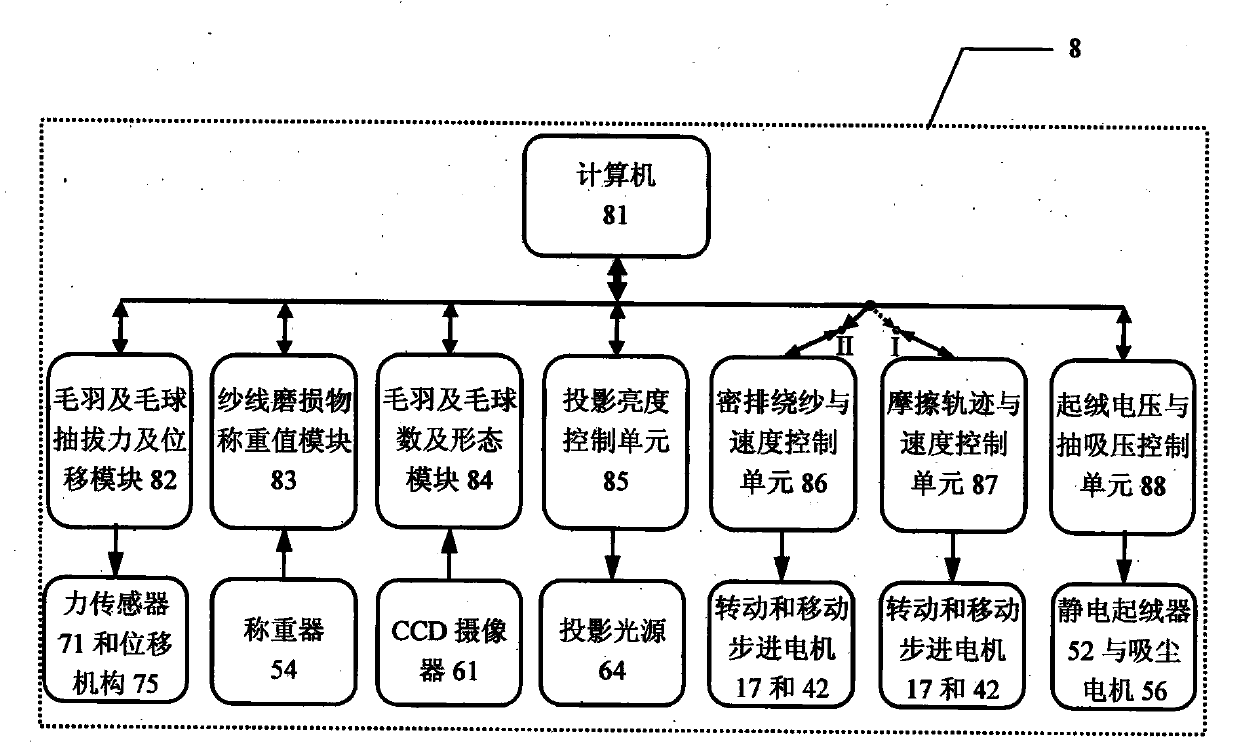

ActiveCN103454213AAccurate collectionFree from lossUsing mechanical meansInvestigating abrasion/wear resistanceFiberControl system

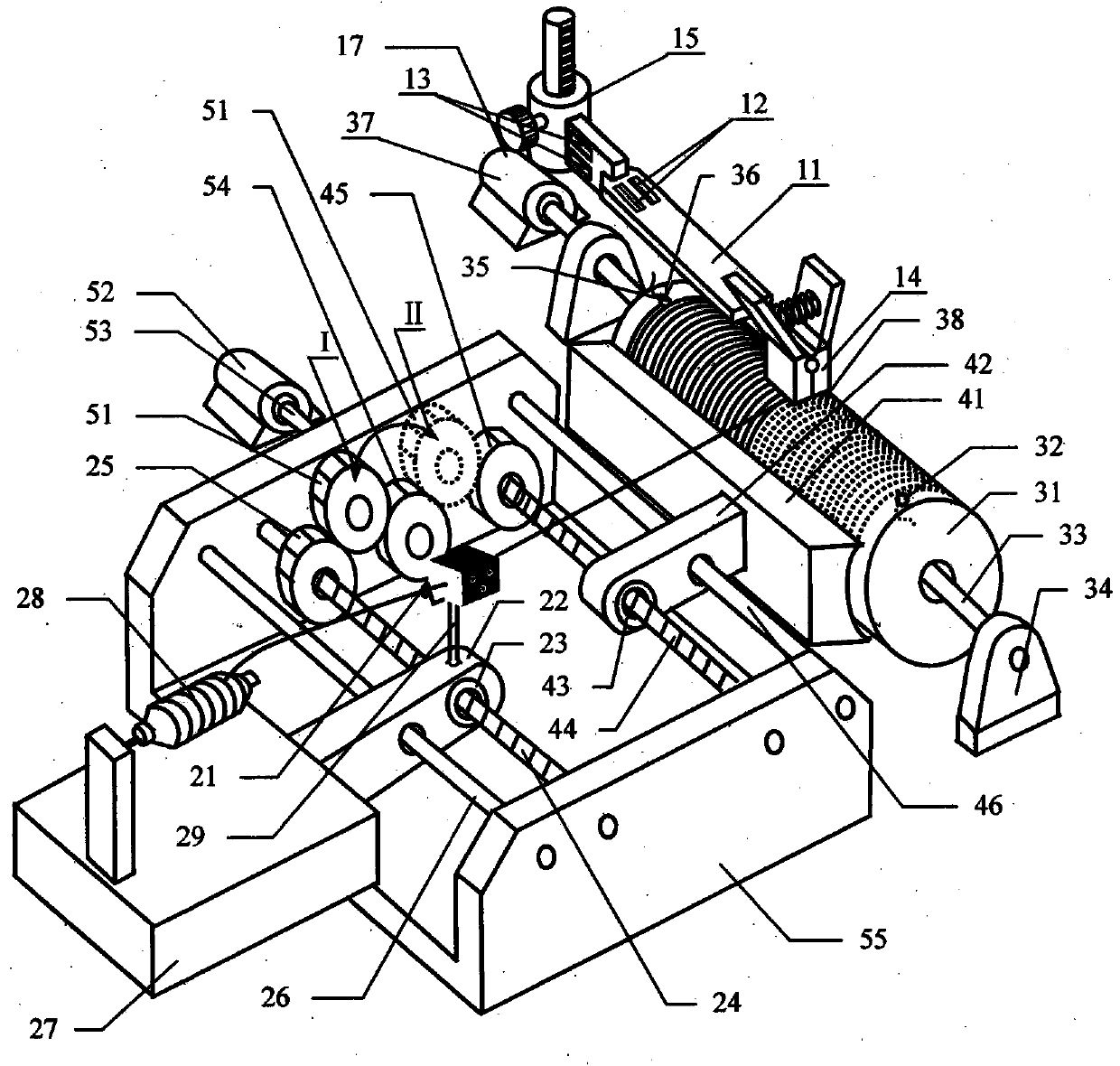

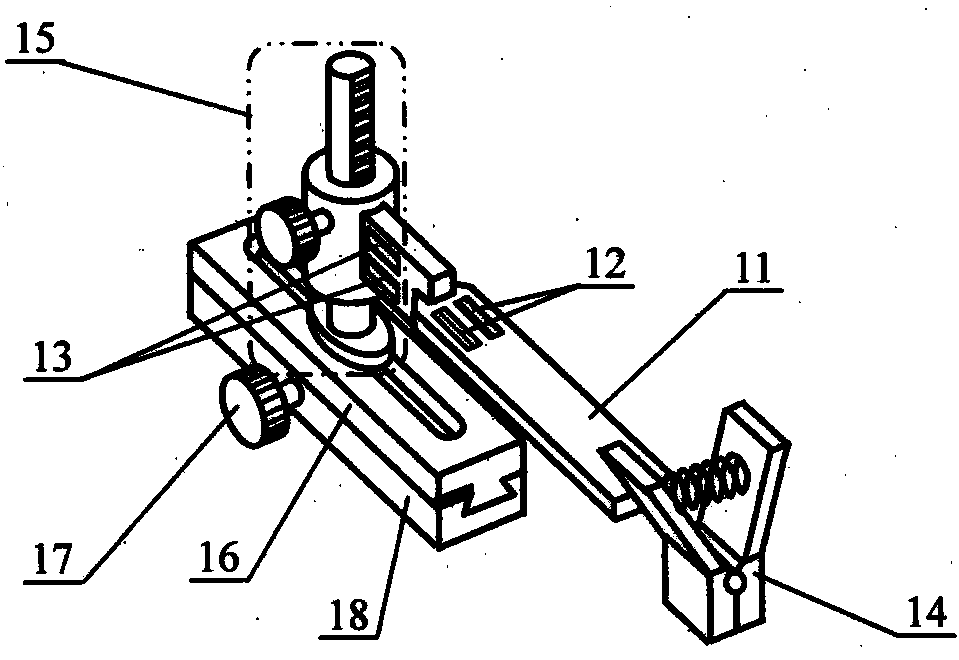

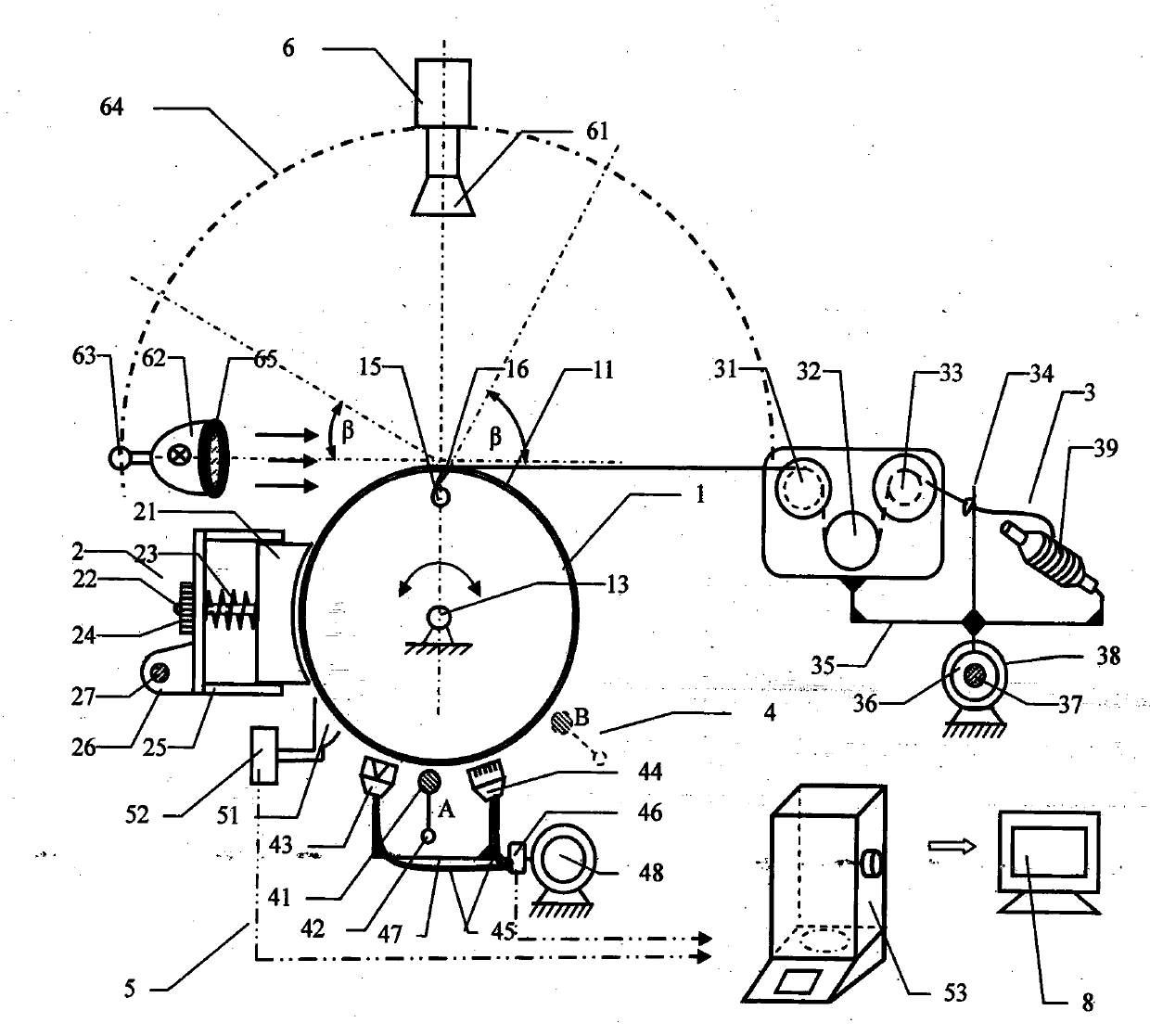

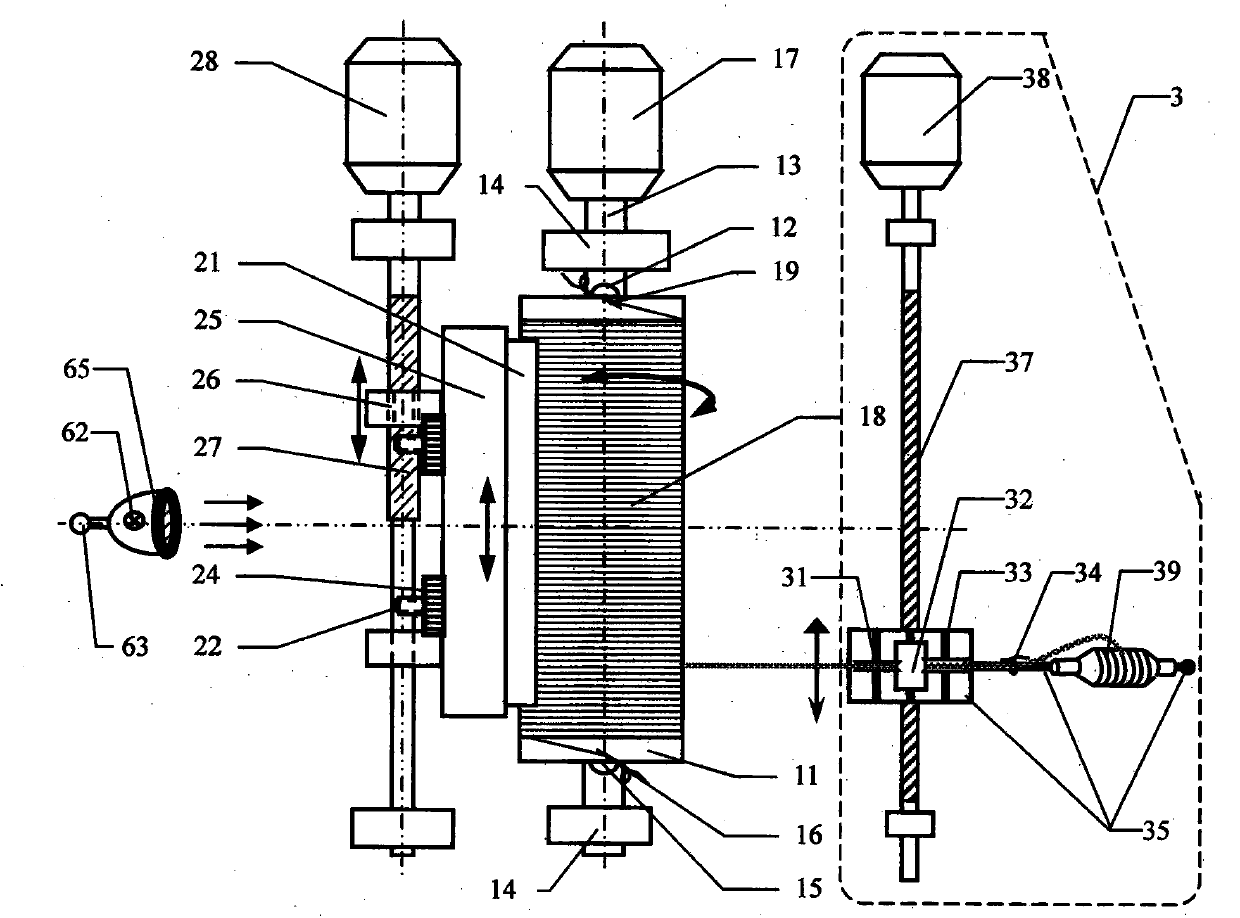

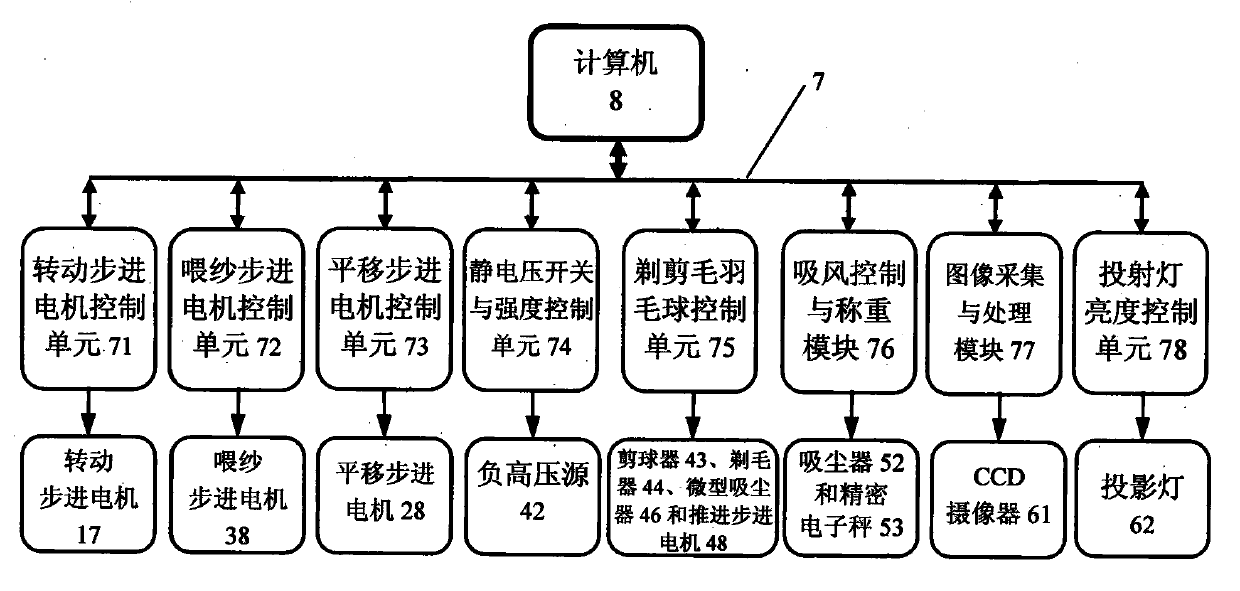

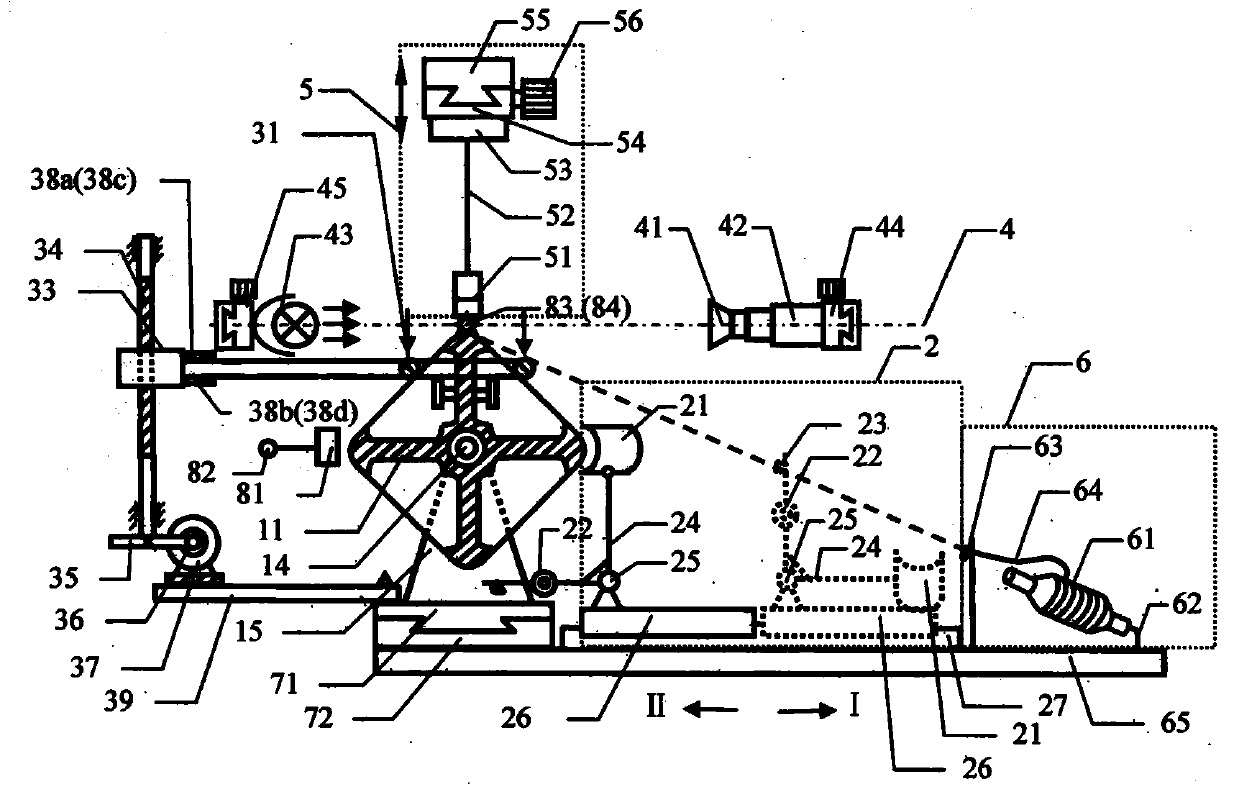

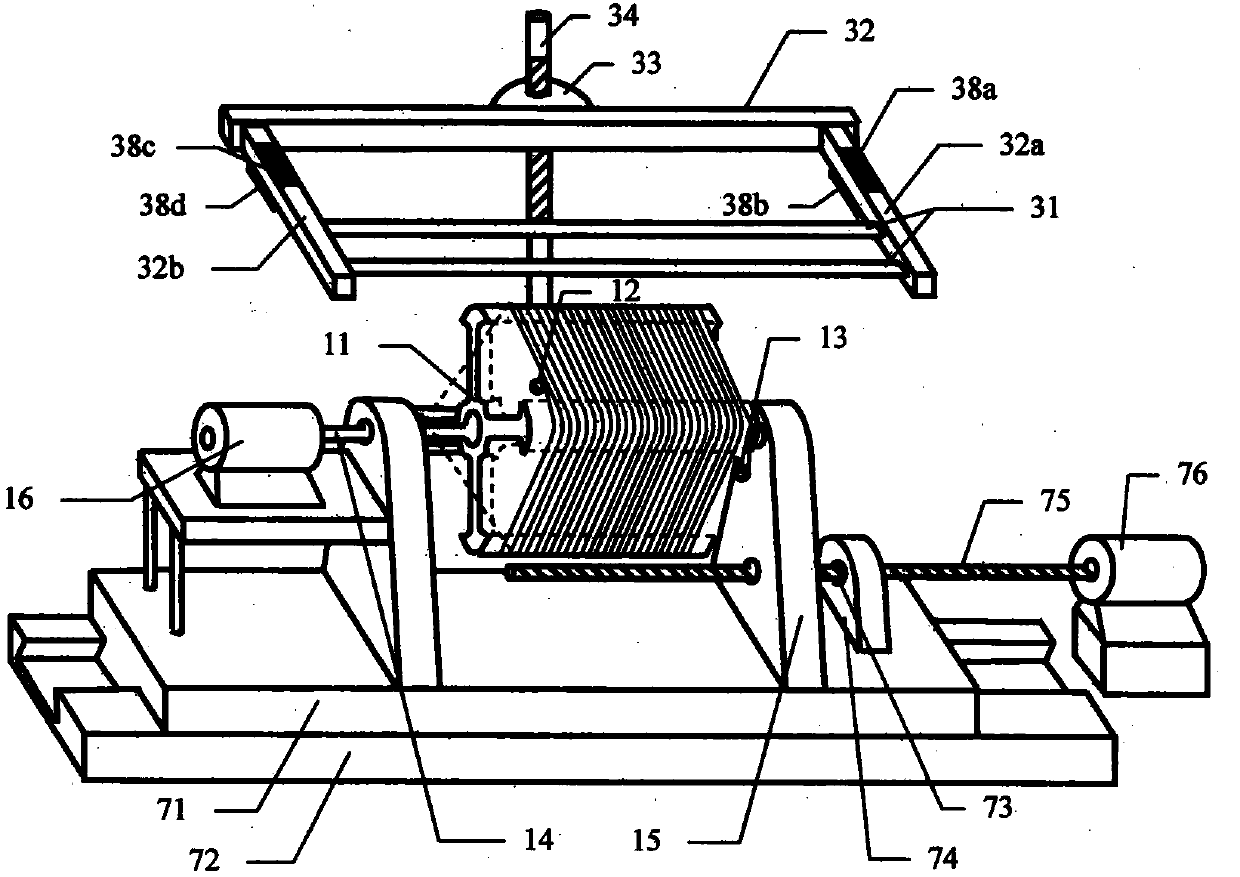

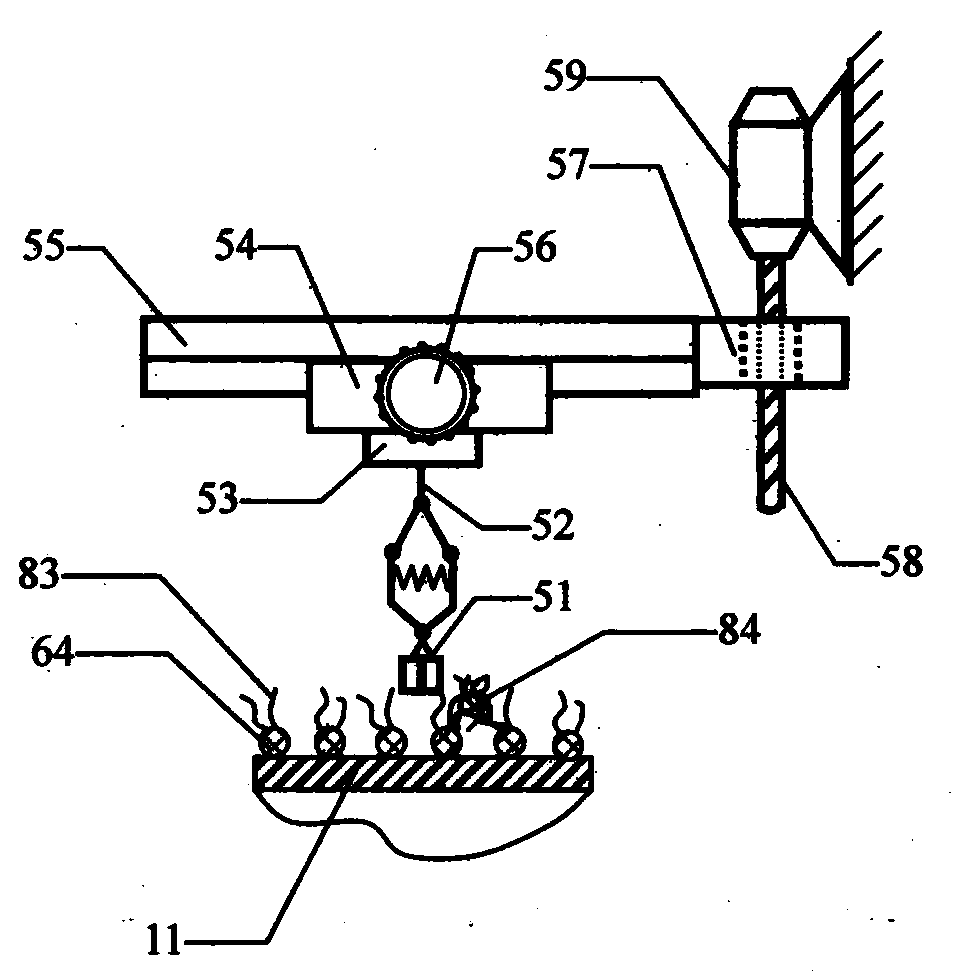

The invention relates to a method and a device suitable for measuring the fluffing and pilling amount and abrasion amount of a textile. The device is composed of a cloth sample barrel for coiling and clamping the textile, a rubbing mechanism for fluffing and pilling a cloth sample, a mini-type dust collector for collecting fallen fibers and fuzzy balls, an electrostatic electrode for assisting filoplume to be vertical, a collector for shearing and collecting the fuzzy balls and the filoplume, an optical measurement system for observing the fuzzy balls of the cloth sample, an electronic scale for weighing the weight of the filoplume fuzzy balls, a data acquisition and control system and a computer. The measurement method comprises the following steps: after coiling the cloth sample by equal tension, immediately measuring the filoplume significance as well as the quantity, form, size and distribution of the fuzzy balls; rubbing, fluffing and pilling to prepare a sample and synchronously measuring the process and measuring the filoplume significance of a final rubbing sample, the fuzzy ball quantity, the abrasion to the filoplume fuzzy balls and the remaining amount. The device and the method are ingenious, practical, accurate and quantitative; in-situ measurement for one machine with a plurality of purposes and one measurement process with a plurality of indexes is realized; the device and the method can be used for preparing the sample by fluffing and pilling the textile, measuring the fluffing and pilling amount and abrasion amount of the textile, and carrying out comprehensive analysis and evaluation.

Owner:DONGHUA UNIV

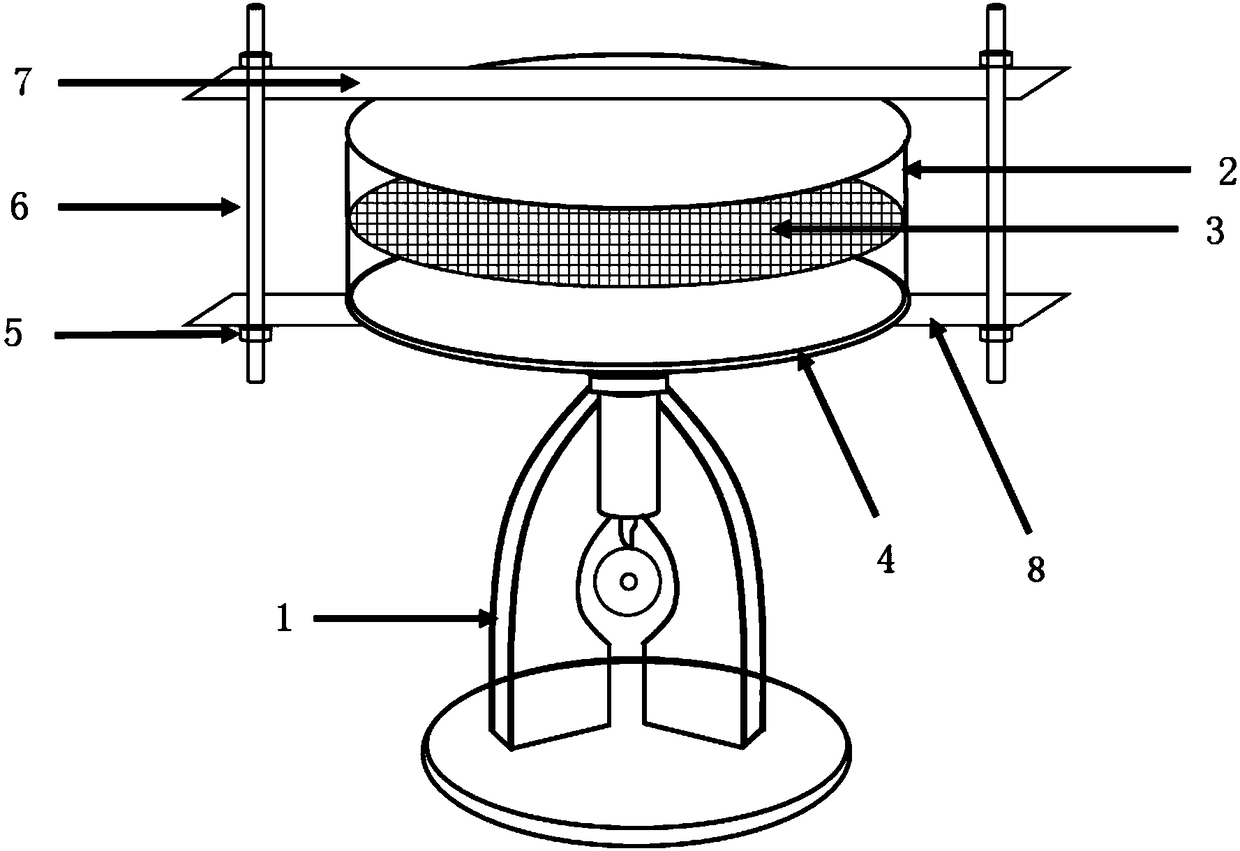

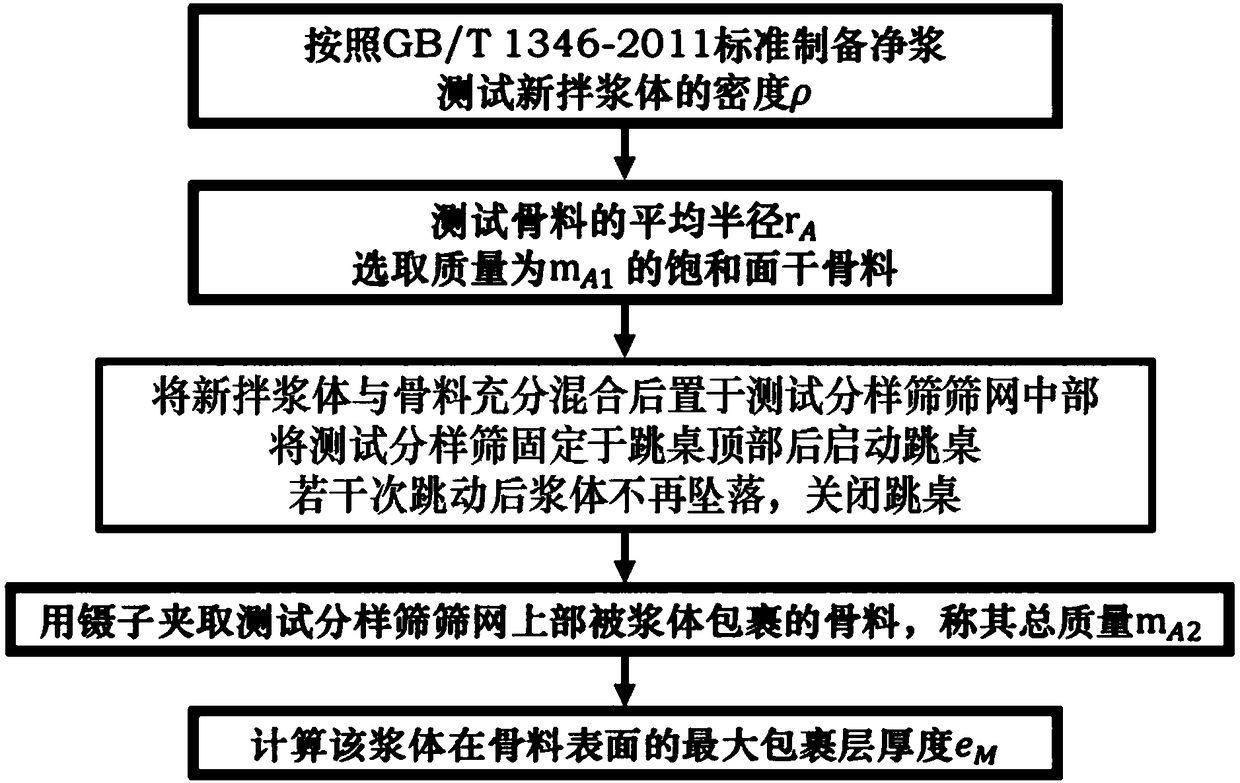

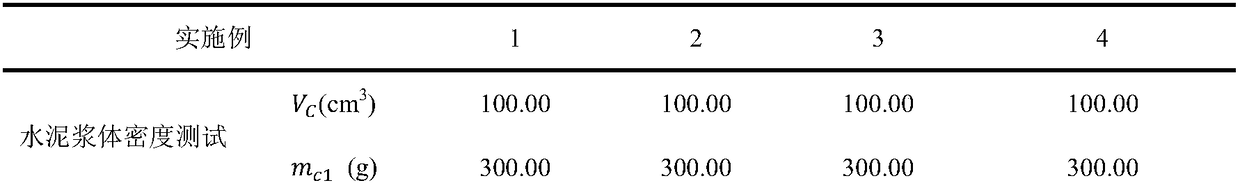

Method for testing maximum wrapping layer thickness of slurry at aggregate surface in permeable concrete

ActiveCN108303056AReasonable dosageMeasurement scienceSpecific gravity measurementSlurryLayer thickness

The invention relates to a method for testing the maximum wrapping layer thickness of slurry at the aggregate surface in permeable concrete, which comprises the steps of first, preparing slurry, and then testing the density [rho] of the slurry; second, testing the total surface area S of aggregate; third, testing the maximum wrapping mass mP of the slurry at the aggregate surface; and fourth, calculating the maximum wrapping layer thickness eM of the slurry at the aggregate surface, wherein eM=mP / [rho]S. The testing method comprises slurry density testing, aggregate surface area testing and aggregate surface slurry maximum wrapping mass testing, and thus the actual maximum wrapping layer thickness of the slurry at the aggregate surface is calculated. The testing device and method providedby the invention can scientifically determine the maximum wrapping layer thickness of the slurry, thereby providing theoretical guidance for mix proportion design of the permeable concrete, and havingimportance practical significance.

Owner:SOUTH CHINA UNIV OF TECH

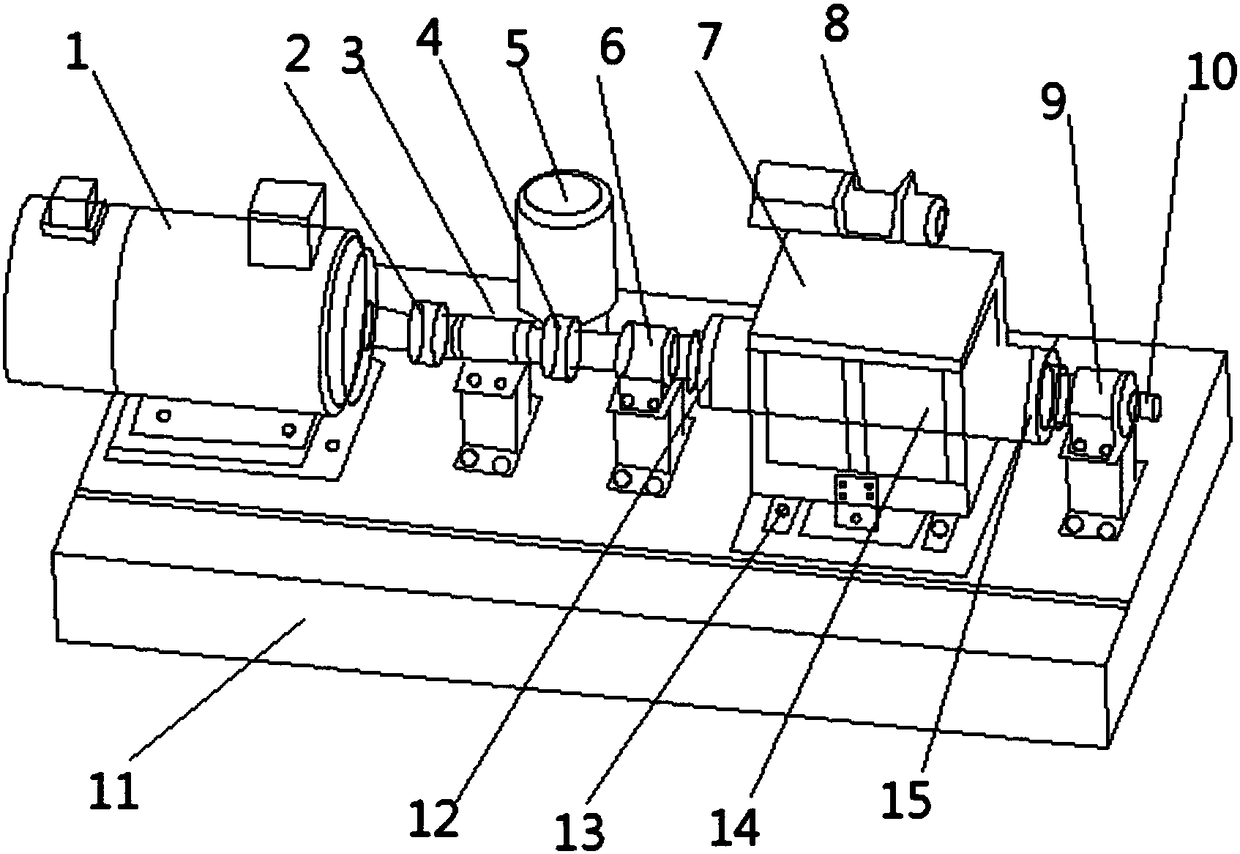

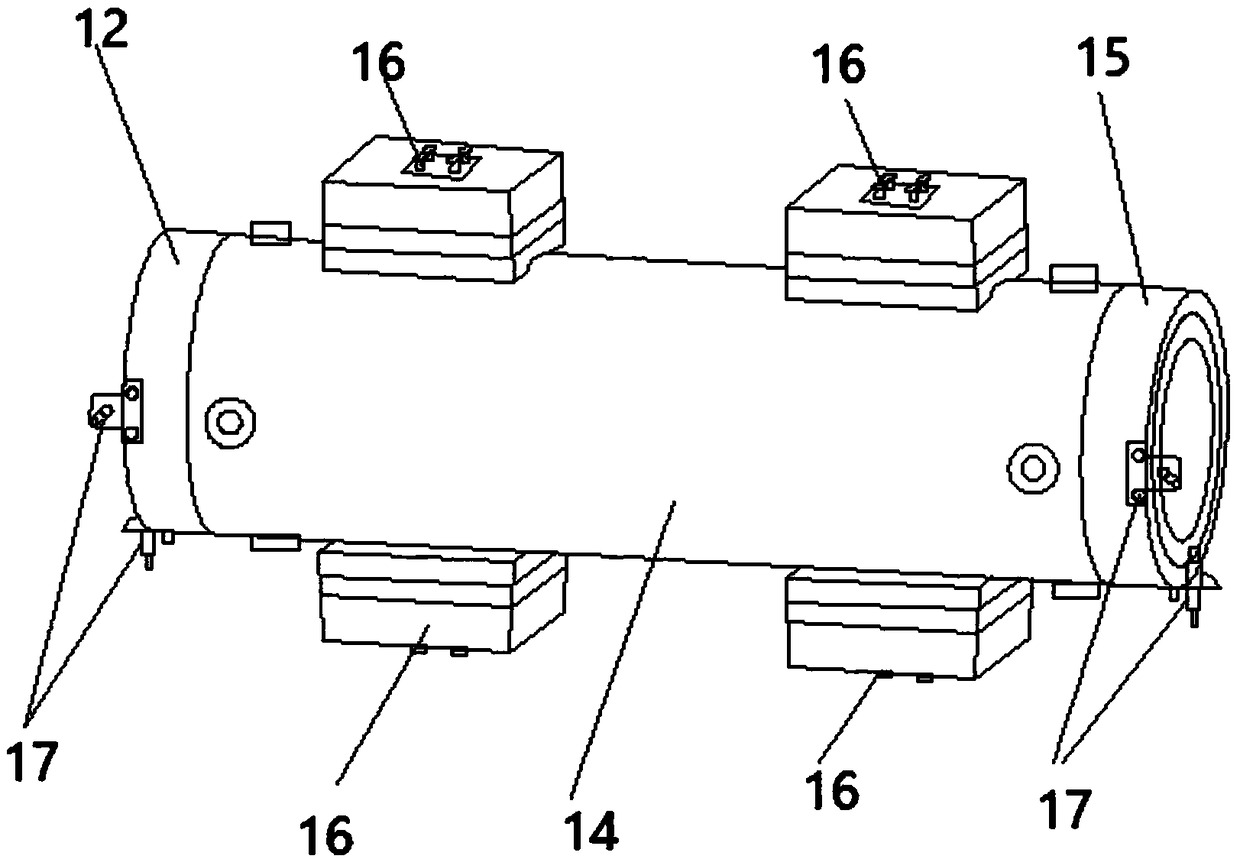

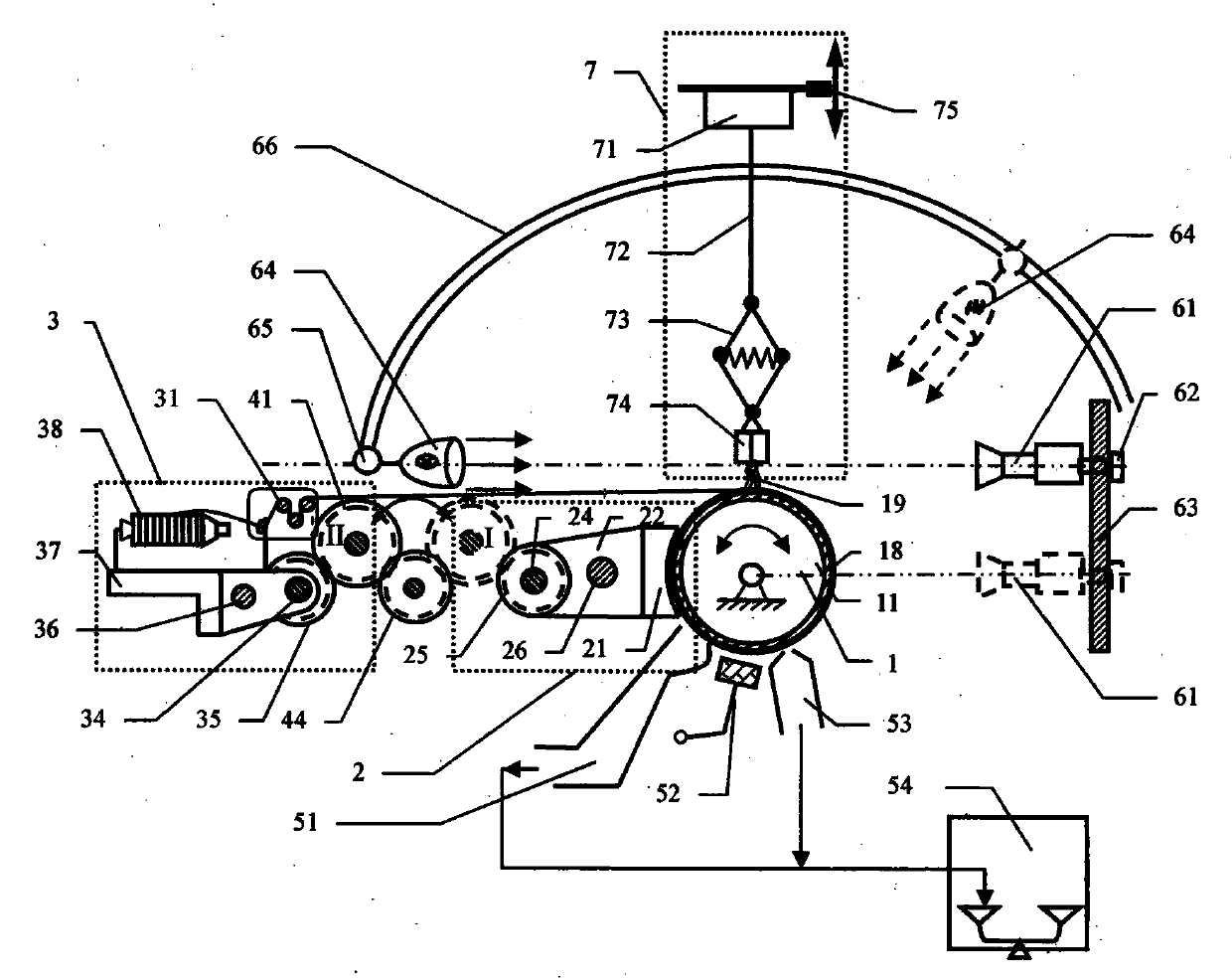

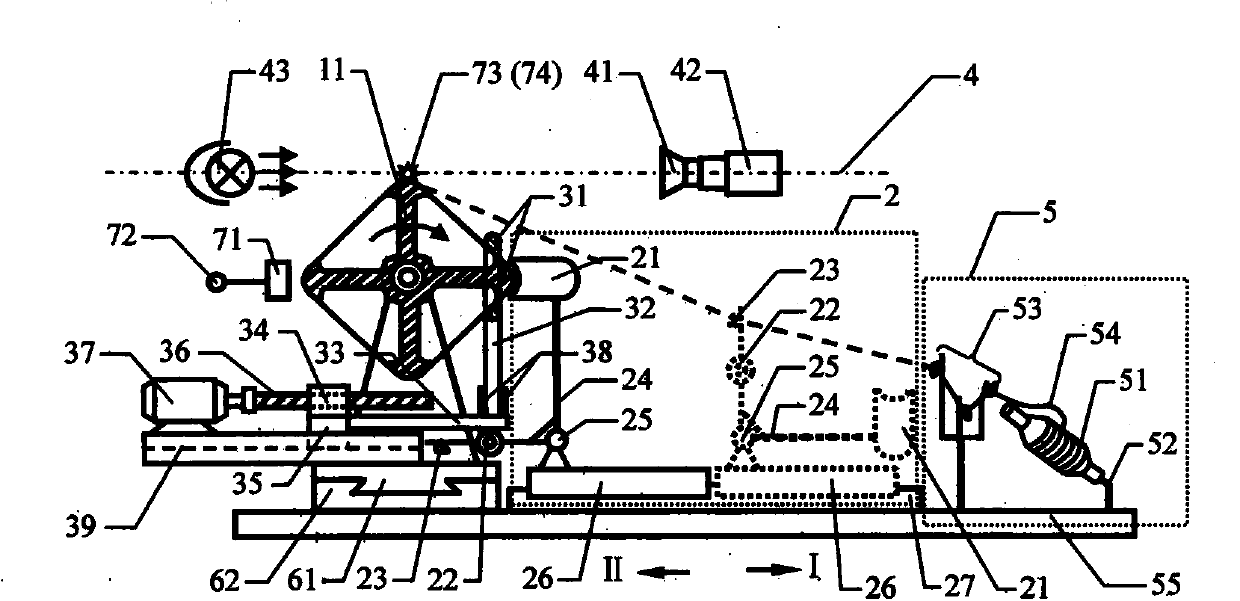

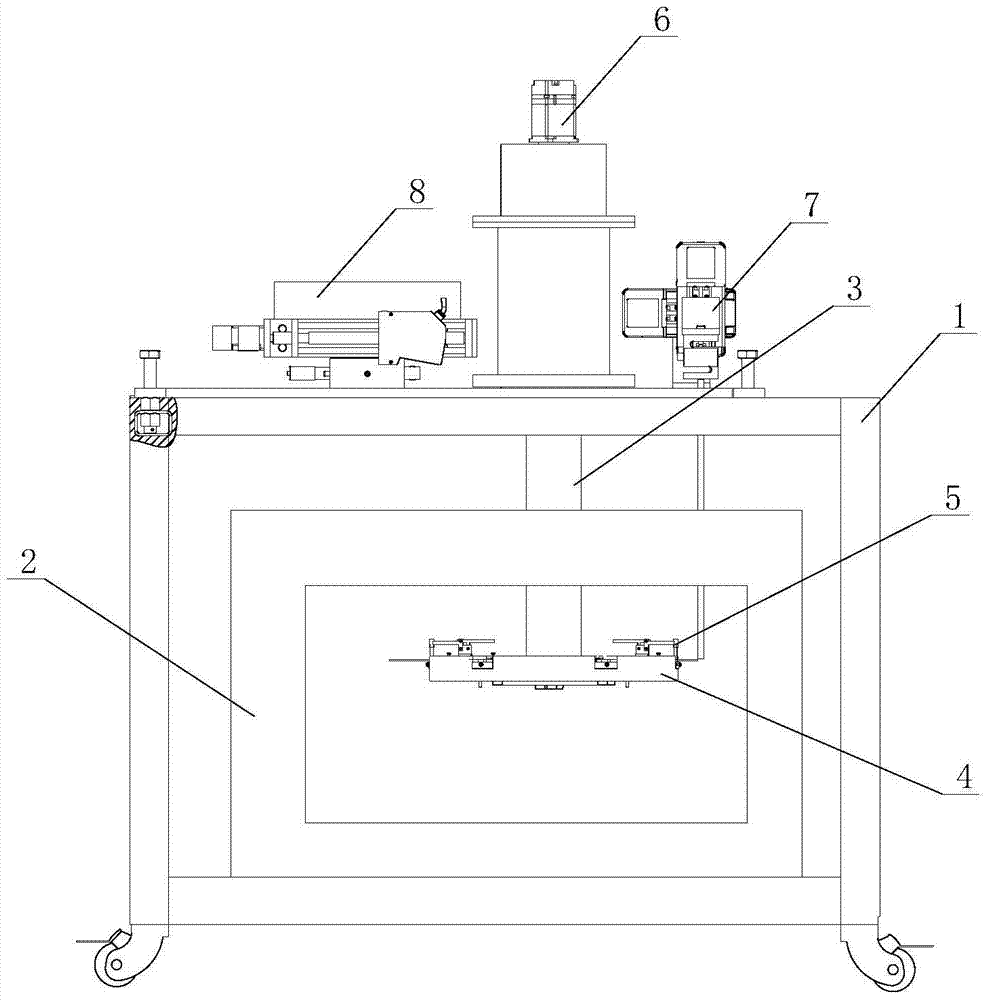

Water lubrication rubber bearing performance test stand and test method thereof

PendingCN108106847ATest operating characteristicsImplement dynamic loadingMachine gearing/transmission testingMachine bearings testingInterference resistanceDrive shaft

The invention discloses a water lubrication rubber bearing performance test stand and a test method thereof. The test stand consists of five portions. A driving portion comprises a variable-frequencymotor, a coupler, a driving shaft, a front supporting bearing and a rear supporting bearing which are successively connected with one another; a water lubrication rubber bearing portion comprises a water lubrication rubber bearing and an outer bearing sleeve, and the bearing sleeve is connected with an outer supporting framework by virtue of a three-shaft force sensor; a loading portion comprisesa supporting framework arranged on a guide rail, as well as a rocker bar mechanism and a shock excitation motor with an eccentric wheel which are connected with the supporting framework in sequence; acontrol test portion comprises a control cabinet, a sensor, a current collection ring, a data acquisition system and the like; and an auxiliary portion comprises a circulating water system, a sealingapparatus, a supporting seat and the like. The driving shaft rotates in the water lubrication rubber bearing, and the static or dynamic loading for the water lubrication rubber bearing can be realized by virtue of the loading system. The water lubrication rubber bearing performance test stand can be used for testing the performance of the water lubrication rubber bearing and is high in interference resistance.

Owner:XIAN UNIV OF SCI & TECH

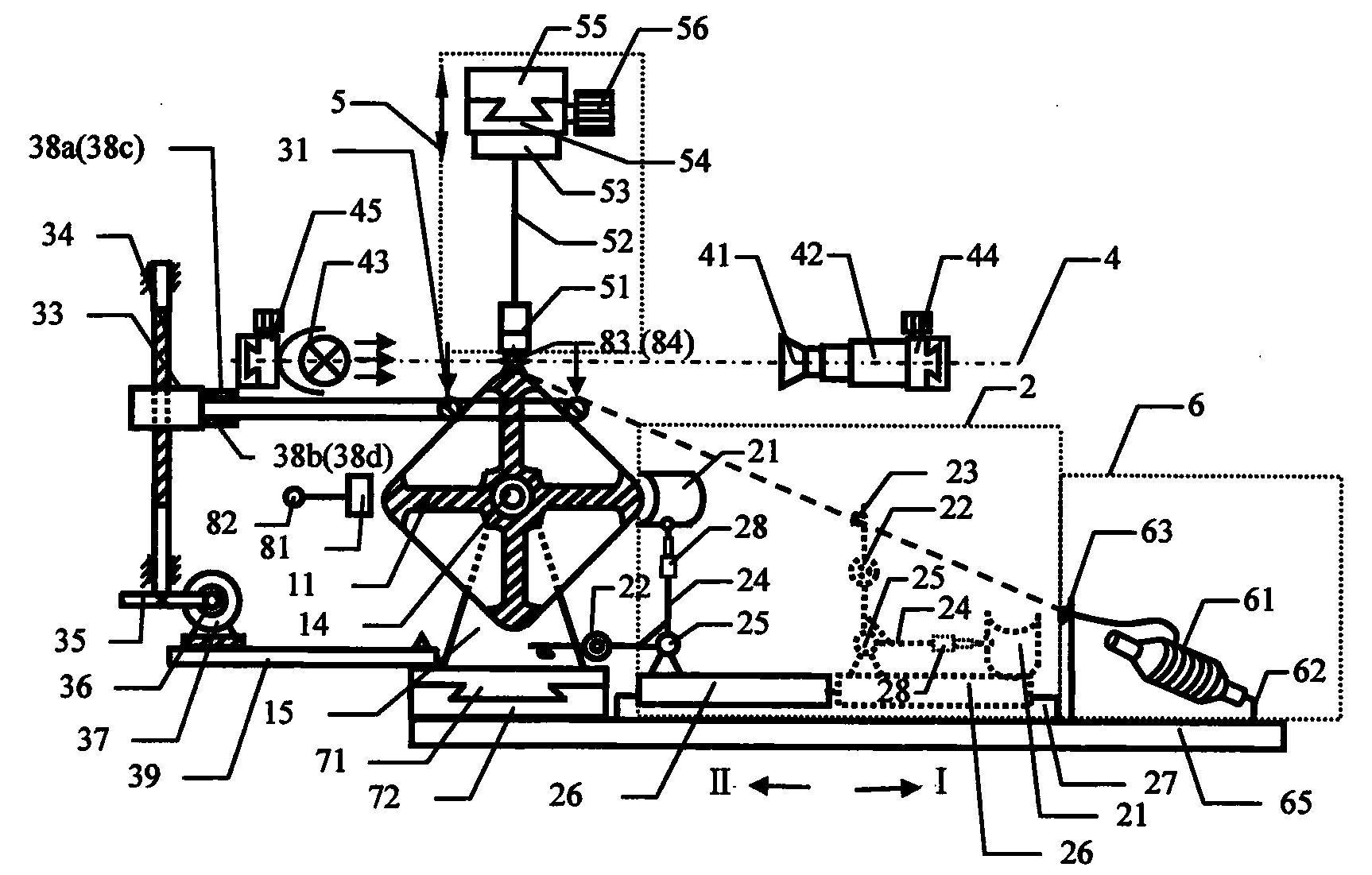

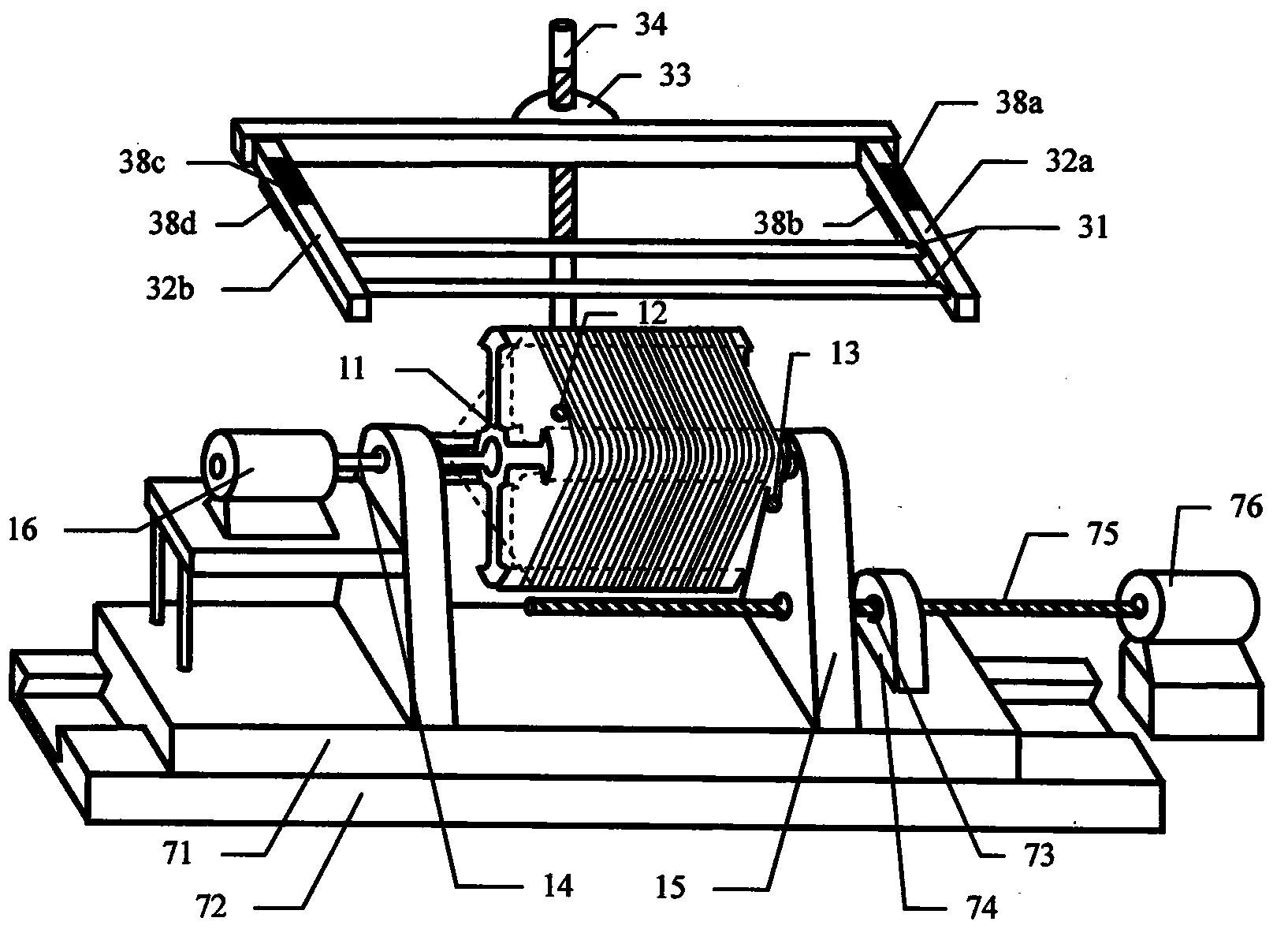

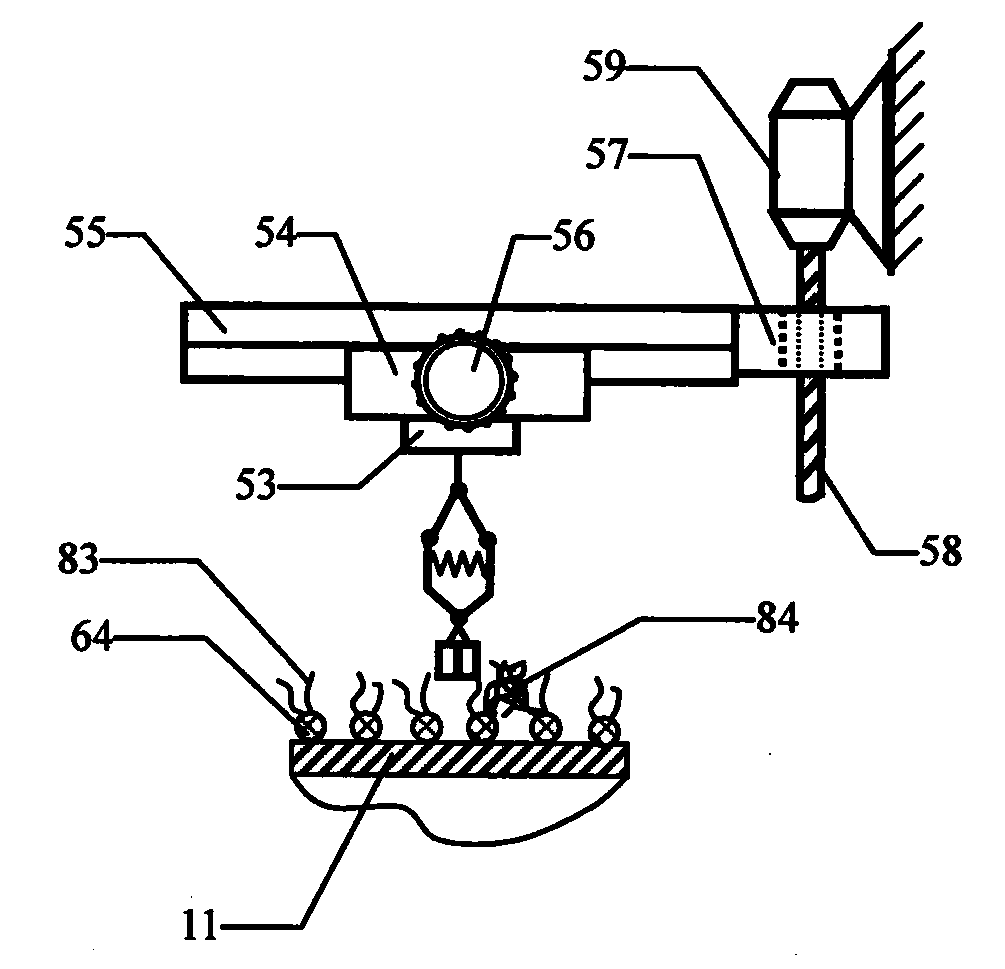

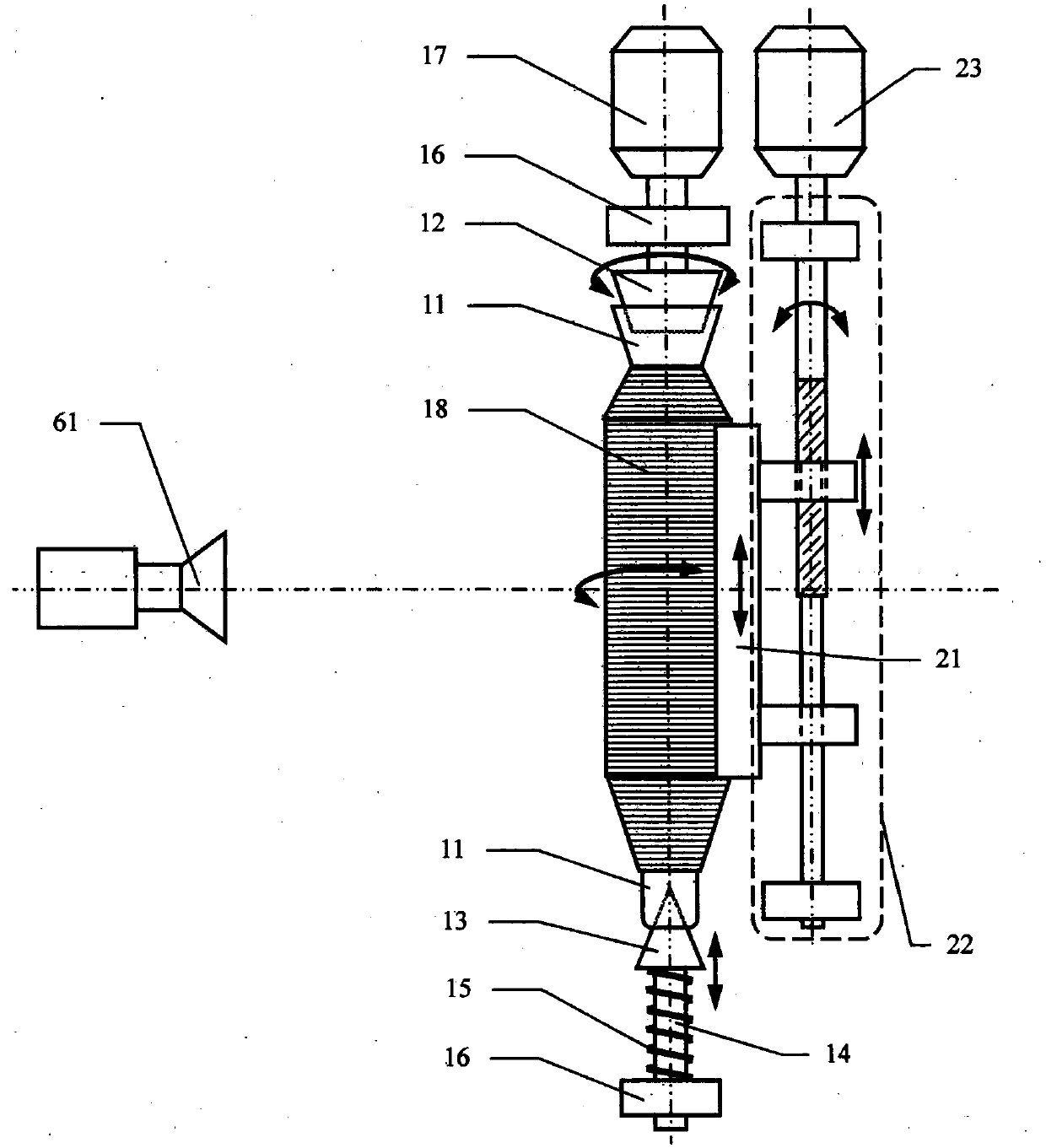

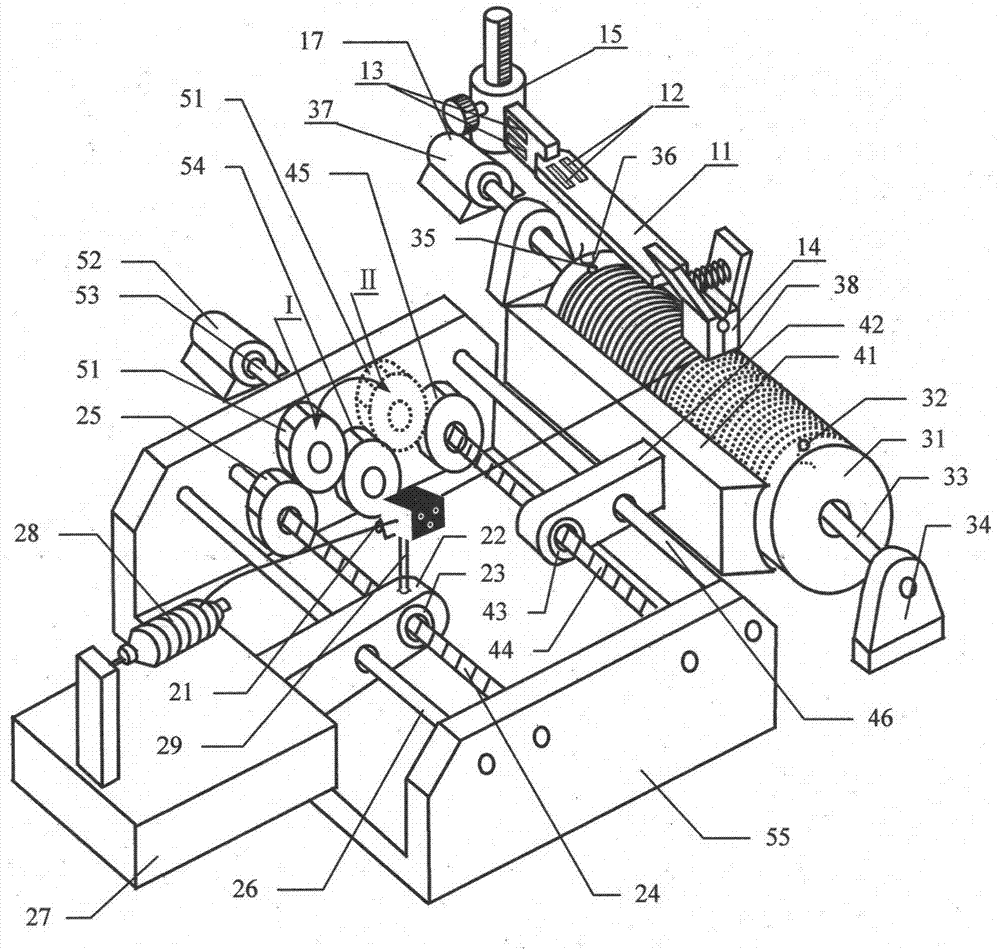

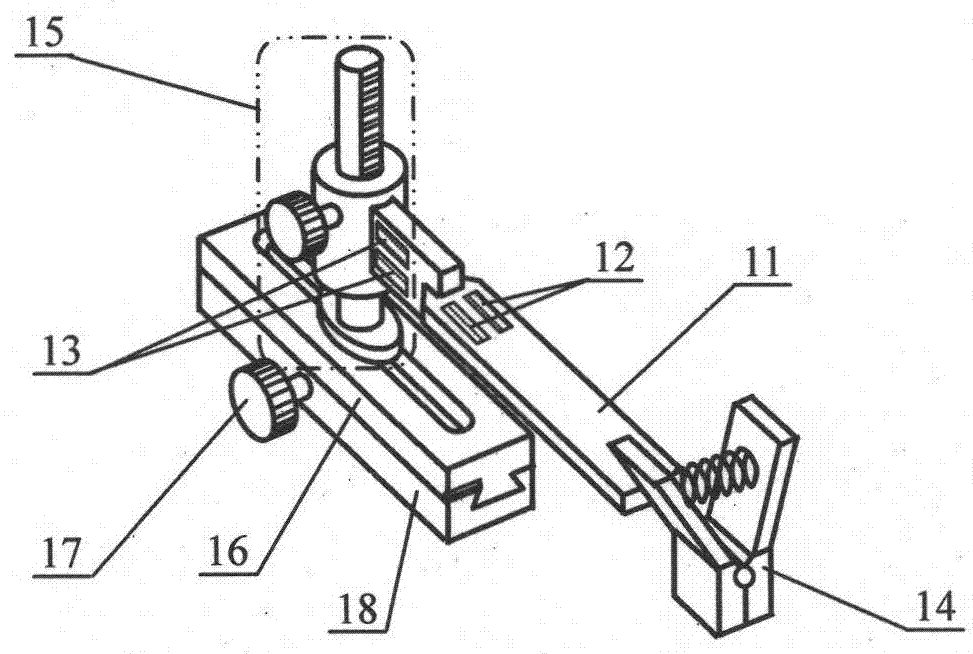

Measuring device and method for fluffing and balling shape as well as hair bulb stripping of yarn

ActiveCN103472210AEasy to measureAccurate collectionTextile testingInvestigating abrasion/wear resistanceYarnEngineering

The invention relates to a device and a method for measuring fluffing and balling shape as well as hair bulb stripping of a yarn. The device comprises a mechanism clamping hair bulbs to implement stripping, a yarn delivery mechanism performing equal-tension close packing, a yarn winding mechanism winding the yarn at a constant speed, a yarn grinding mechanism performing friction on the close packed and wound yarn, a translation driving mechanism driving the yarn delivery mechanism and the yarn winding mechanism in a switching manner, an abrasion object collector, a microimaging system and a control and data analysis system. The measuring method comprises the steps that a gap bridge wheel of the translation driving mechanism transposes the yarn delivery mechanism and the yarn grinding mechanism, and is matched with the yarn winding mechanism, so that close packing yarn winding and yarn grinding sampling are achieved; a yarn grinding sample in a yarn grinding process is measured in situ; and comprehensive measuring and evaluation are performed on the yarn grinding sample in a final state. The device is ingenious in structure, practical, precise in measuring, quantitative, and multipurpose, is an in-situ measuring device for measuring multiple indexes, and can be used for measuring of the hair feather and hair bulb quantity, the shape, the abrasion loss and the back-and-forth drag stripping property of the yarn, and for comprehensive evaluation of the fluffing resistance and the balling resistance.

Owner:DONGHUA UNIV

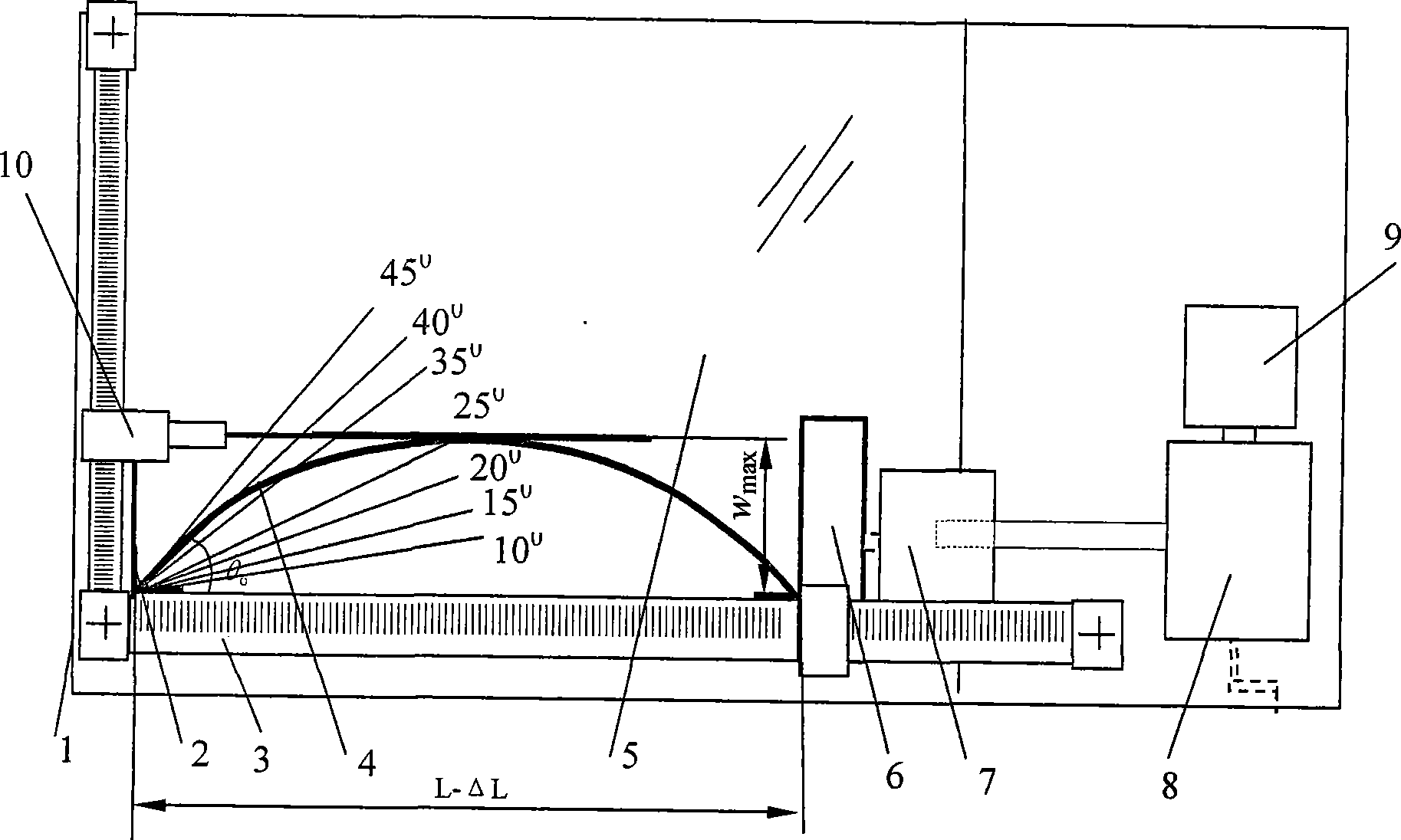

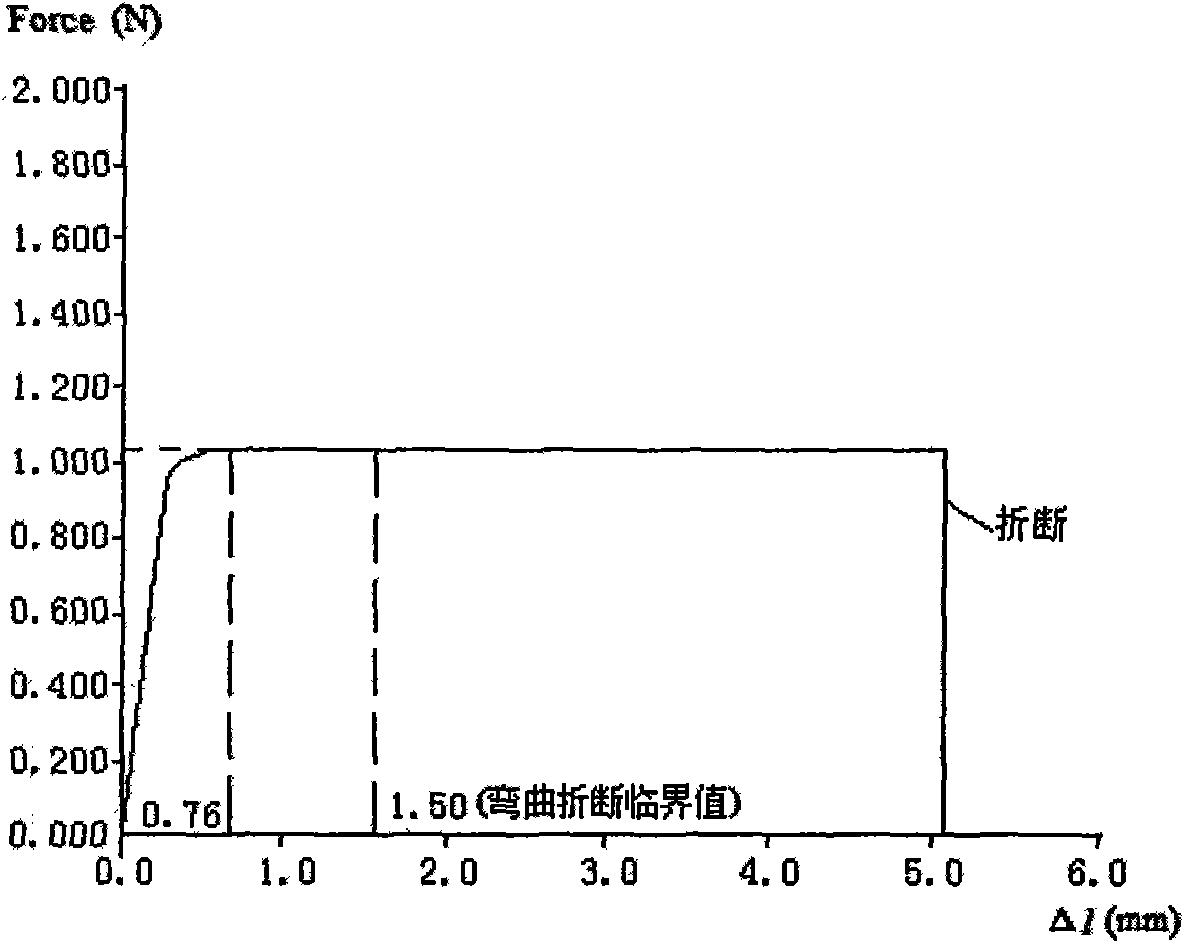

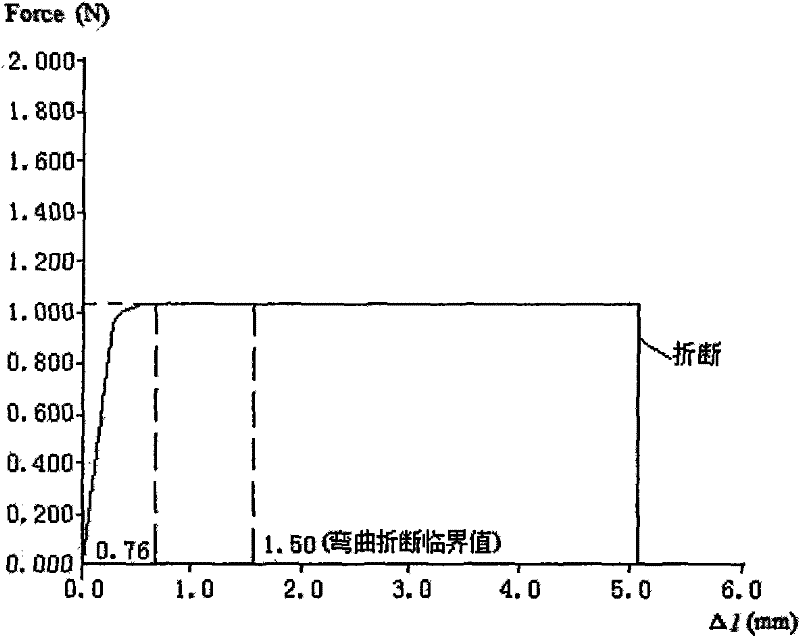

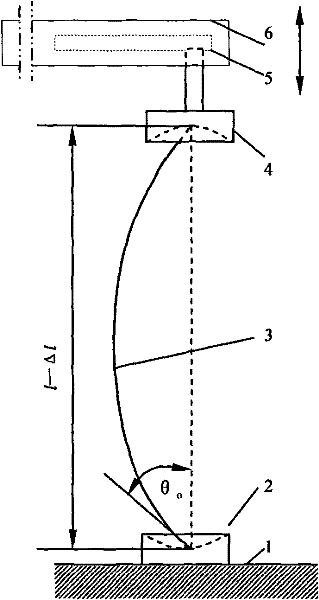

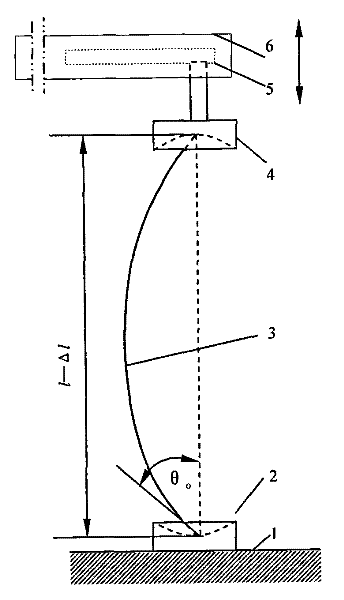

Fine dried noodle bending and breaking rate measuring method and determinator based on axial compression amount

InactiveCN101451934ASimultaneous testingImplement testMaterial strength using steady bending forcesTesting foodAxial compressorAxial compression

The invention discloses a dried noodle bending fracture rate measuring method based on axial amount of compression and a goniophotometer. First dried noodles in certain number are extracted, cut into given length, separatively fixed between a static supporting baffle and a movable supporting baffle. Then a motor is started, for driving a stepless speed change device and a nut screw, the movable supporting baffle is pushed to cause the dried noodles to generate axial compression unstable bending; the size of axial amount of compression is read by a horizontal type electronic digital staff gauge. The dried noodle are broken when the axial amount of compression of the movable supporting baffle does not reach the given axial amount of compression, namely a bent fracture strip; percent of the number of bent fracture strip to the number of extracted ones is the dried noodle bending fracture rate. According to the invention, objective measurement is realized through mechanics of materials pressure lever stability principle and large-deflection theory and stress equivalence principle, the bending fracture rate is correctly measured, measurement is more scientific and precise.

Owner:JIANGSU UNIV

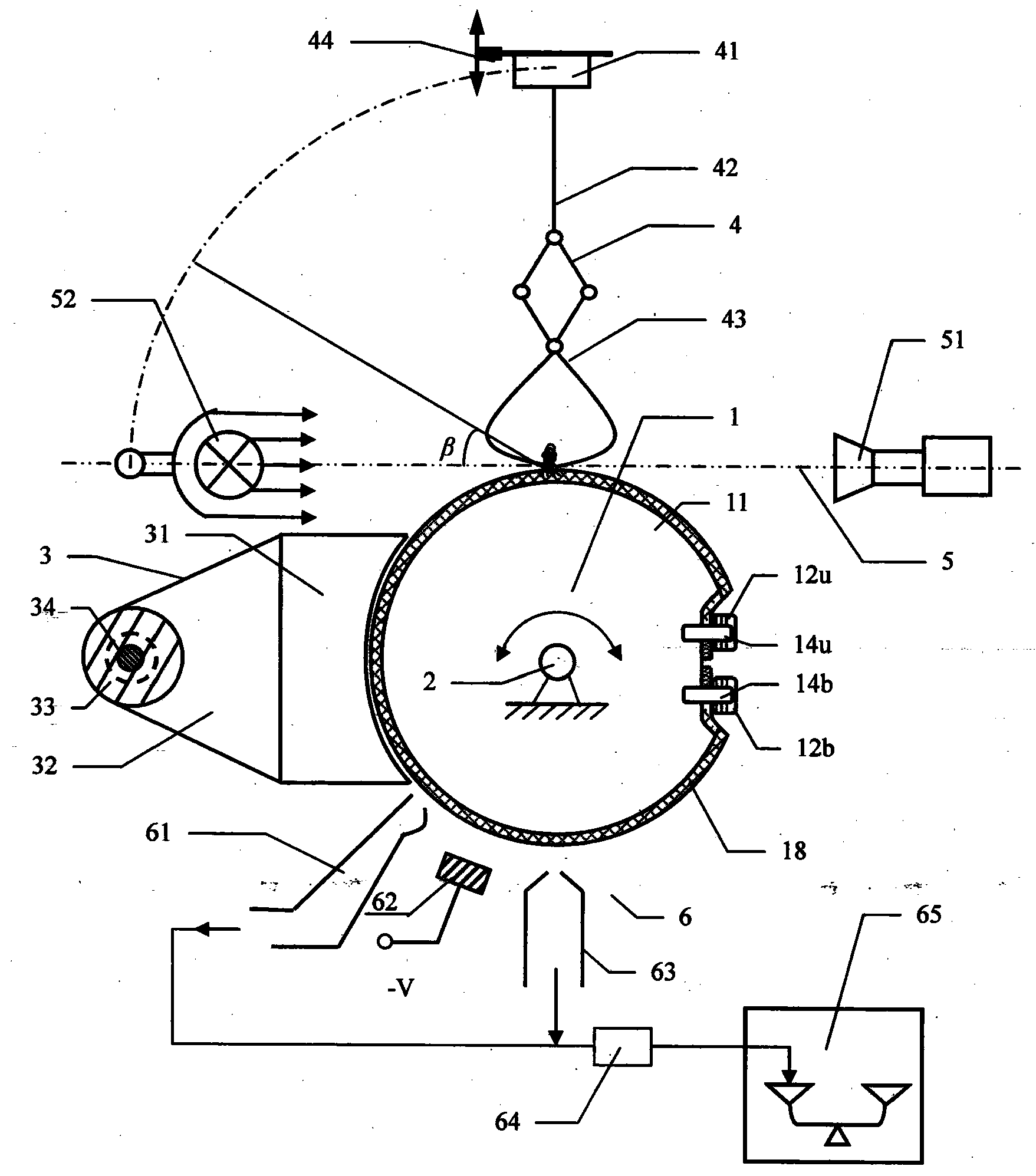

Device and method used for measuring pilling form and pulling force of yarns

ActiveCN103471651AGet the right measurementsAchieve estimatesMaterial analysis by optical meansYarnPull force

The invention relates to a device and method used for measuring the pilling form and pulling force of densely arranged yarns. The device consists of a yarn winding mechanism, a yarn grinding mechanism, a yarn feeding mechanism, a translational driving mechanism, a wearer collector, a microscopic camera system, a clamping and pulling mechanism, and a control and data analysis system. The method comprises the steps of bridging and rotating the yarn feeding mechanism and the yarn grinding mechanism through the translational driving mechanism, kinetically matching with the yarn winding mechanism to achieve the winding of the densely arranged yarns and yarn grinding sample preparation, and carrying out on-line measurement on yarn samples in the process of yarn grinding as well as comprehensive measurement, calculation and evaluation on yarn grinding samples in a final state. The device is ingenious in structure, practical, and precise and quantitative in measurement, and the device and the method are an in-situ measuring device and an in-situ measuring method which are multi-purpose and multi-index in one measurement. The device and the method can be used for the measurement of the pilling quantity, form and wear quantity of the yarns and pulling forces of hairiness and hair bulbs as well as the comprehensive evaluation of the pilling resistance.

Owner:DONGHUA UNIV

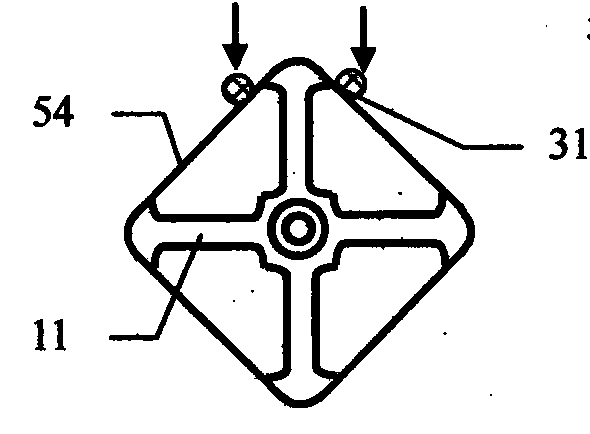

Polygonal-barrel tension-controllable fuzzing and pilling form and pulling measurement device and method

ActiveCN103898730APredicting Pilling ResistanceSample preparation results are stableInspecting textilesMeasurement deviceYarn

The invention relates to a polygonal-barrel tension-controllable fuzzing and pilling form and pulling measurement device and method. The device comprises a polygonal barrel, a friction mechanism, a tension mechanism, a microscopy photographing mechanism, a pulling mechanism, a creel, a static raising device and a control and data collection analysis system. The method includes the steps that after yarns are arranged and wound, by means of the polygonal barrel rotating angle by angle clockwise, raising, form observation and fuzzing and pilling sample preparation are carried out synchronously angle by angle on original yarn, ground yarn is obtained, raising and form observation are carried out synchronously angle by angle on the ground yarn until friction sample preparation and form measurement of all angles are finished, and then a microscopy form value and a pull force curve of yarn hairness and hair balls pulled from the ultimate ground yarn which pre-tension is exerted on are measured angle by angle. The measurement device and method are quick, easy and convenient to use, practical and accurate, can be used for fuzzing and pilling sample preparation of the yarn, measurement of fuzzing and pilling yarn hairness, hair ball quantity and form and the pulling curve and comprehensive evaluation of anti-pilling performance of the yarn.

Owner:DONGHUA UNIV

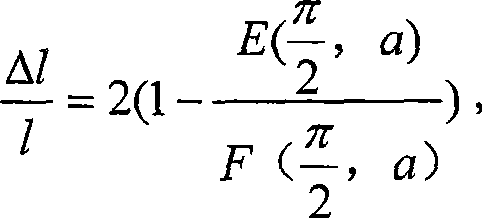

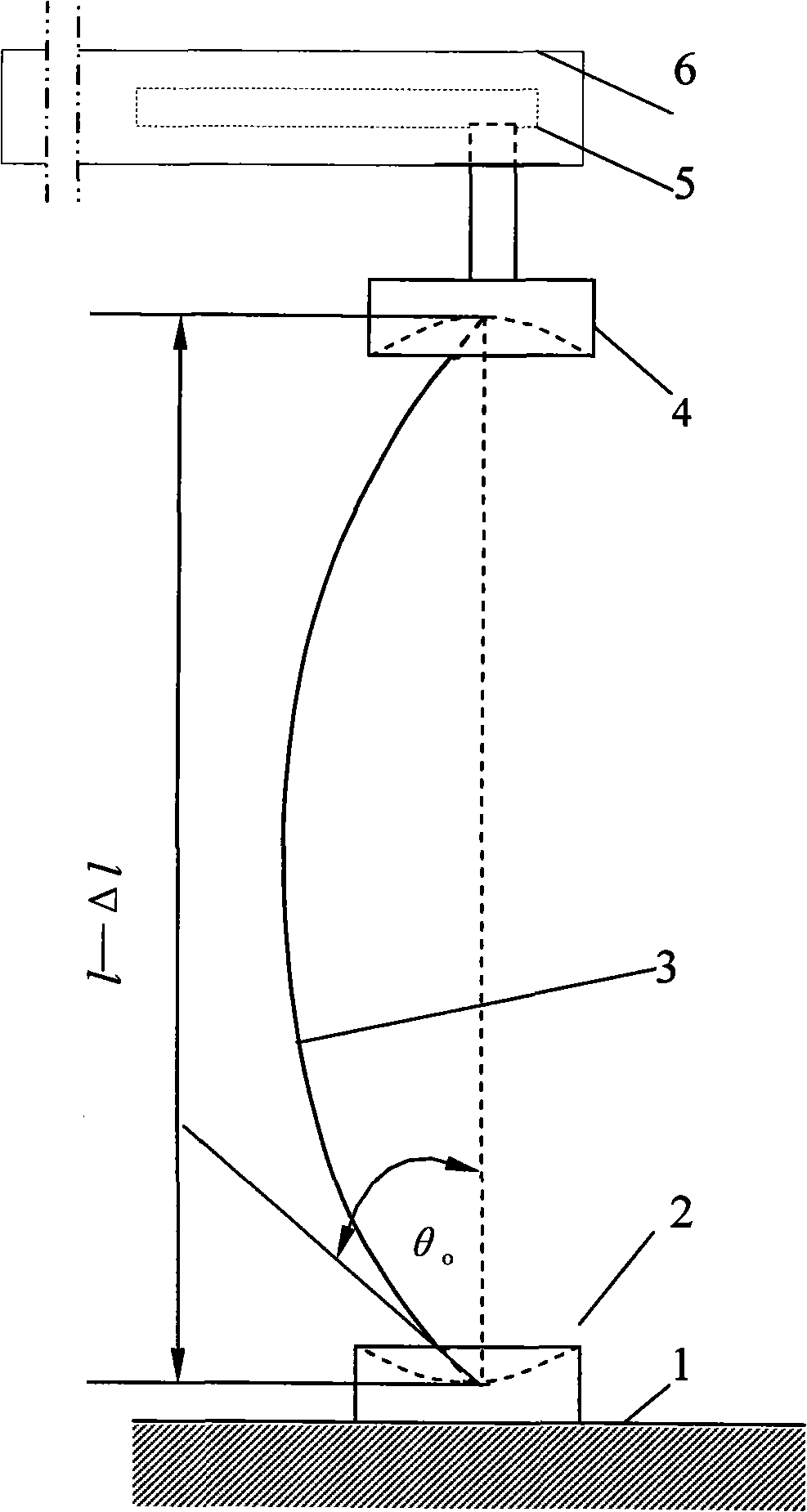

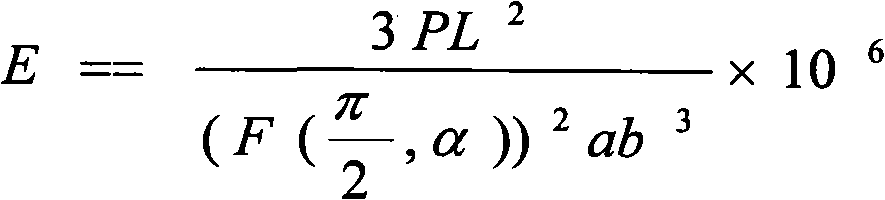

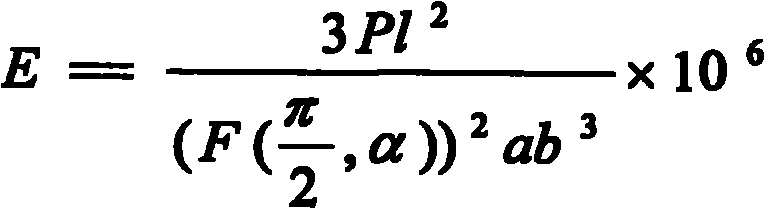

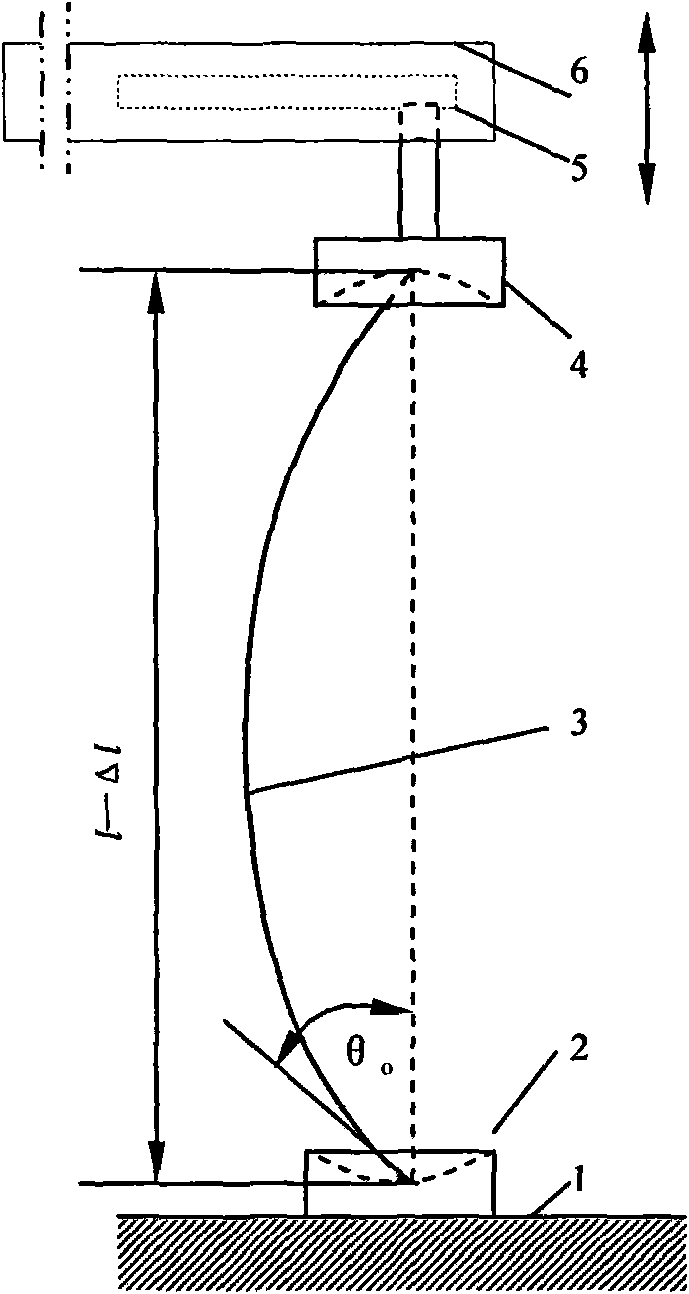

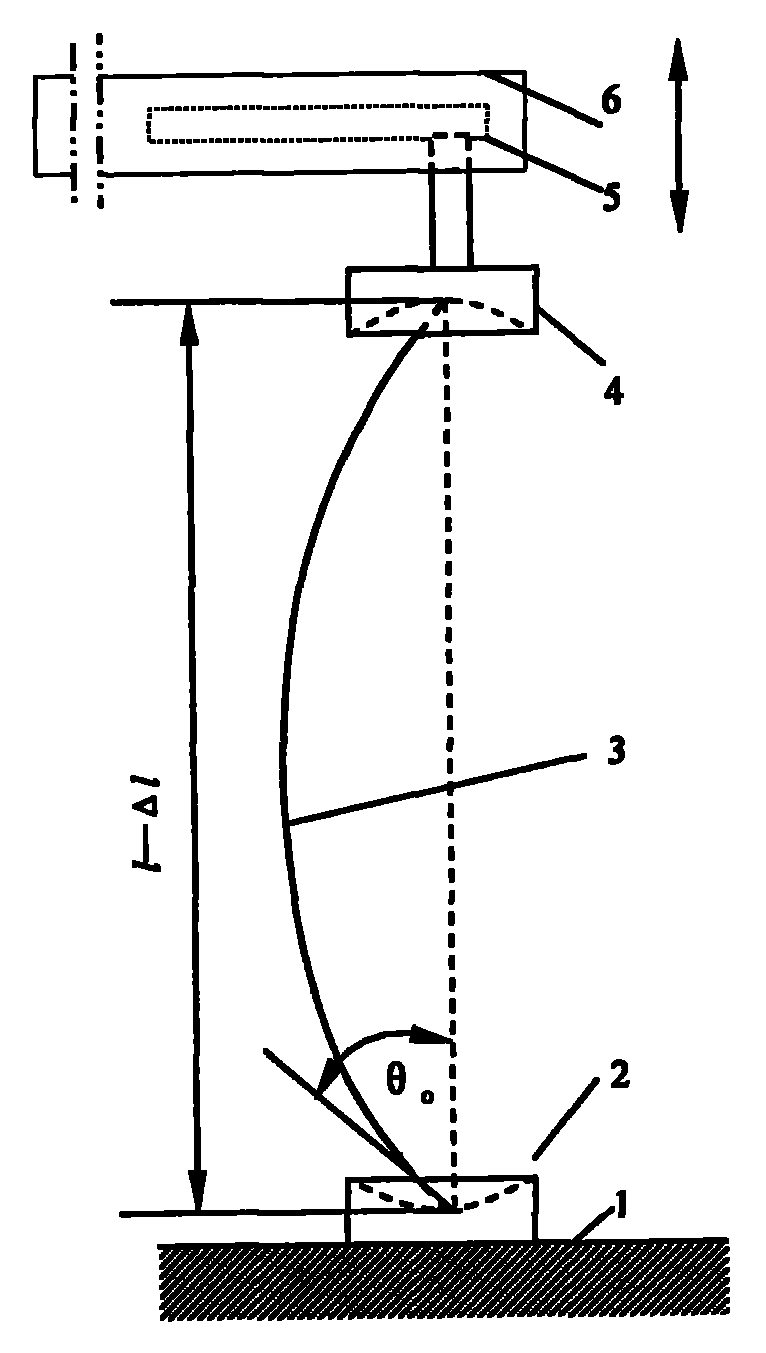

Fine dried noodles elasticity modulus measuring method based on pressure lever post-buckling

InactiveCN101526456AEasy to measureNoodle length is not limitedInvestigating material hardnessMeasurement deviceAxial compression

The invention discloses a fine dried noodle elasticity modulus measuring method based on pressure lever post-buckling. A load measuring device is installed firstly, a static pressure head of the load measuring device is fixed on a base, a force sensor is arranged on a movable arm of the load measuring device, and then a dynamic pressure head is fixedly connected with the force sensor; a certain number of fine dried noodles cut to have corresponding length are respectively arranged between the static pressure head and the dynamic pressure head; and the amount of movement of the dynamic pressure head is determined according to the length of the fine dried noodle and an set intersection angle of the end part of a twisted curve, then the load measuring device is started again, the dynamic pressure head is driven by the load measuring device to load the fine dried noodles in a speed of 0.01mm / s, load corresponding to the amount of movement of the dynamic pressure head is measured by the load measuring device, and at last the fine dried noodle elasticity modulus is counted by a formula relationship. The invention uses pressure lever stability principle and large deflection theory of mechanics of materials to establish the relationship of axial compression, the end part intersection angle and pressure, establishes a counting method of the fine dried noodle elasticity modulus, has simple and convenient measuring method and high precision, and can control the length of the fine dried noodle elasticity modulus to be between 60 mm and 220mm.

Owner:JIANGSU UNIV

Measuring device and method for apparent fluffing and balling as well as abrasion loss of yarn

The invention relates to a measuring method and a device for apparent fluffing and balling as well as abrasion loss of a yarn. The device comprises a yarn winding mechanism with a yarn grinding function, a yarn grinding mechanism with controllable friction pressure, a yarn feed mechanism with adjustable tension, a static and clipping mechanism, a hair bulb and hair feather collection mechanism, an optical measuring system for instant observation of yarn sample fluffing and balling shape and quantity, a data acquisition and control system and a computer. The method comprises the steps that the hair feather significance, the hair bulb shape and the hair bulb quantity of the yarn are immediately measured after a yarn sample is formed by winding the yarn through equal-tension close packing; friction fluffing and balling sampling is performed; and the hair feather significance, the hair bulb quantity, the hair feather and hair bulb abrasion, and the hair feather and hair bulb maintenance quantity of a yarn grinding sample in a process and in a final state are measured synchronously. The device is ingenious and practical in structure, and takes measurements precisely and quantitatively, the in-situ measuring device and the method are multipurpose, can measure multiple indexes, can be used for comprehensive evaluation of the yarn fluffing significance, the balling quantity and shape, the abrasion fiber quantity, the fluffing resistance, and the balling resistance, and can also be used for estimating fluffing and balling grades of fabric.

Owner:DONGHUA UNIV

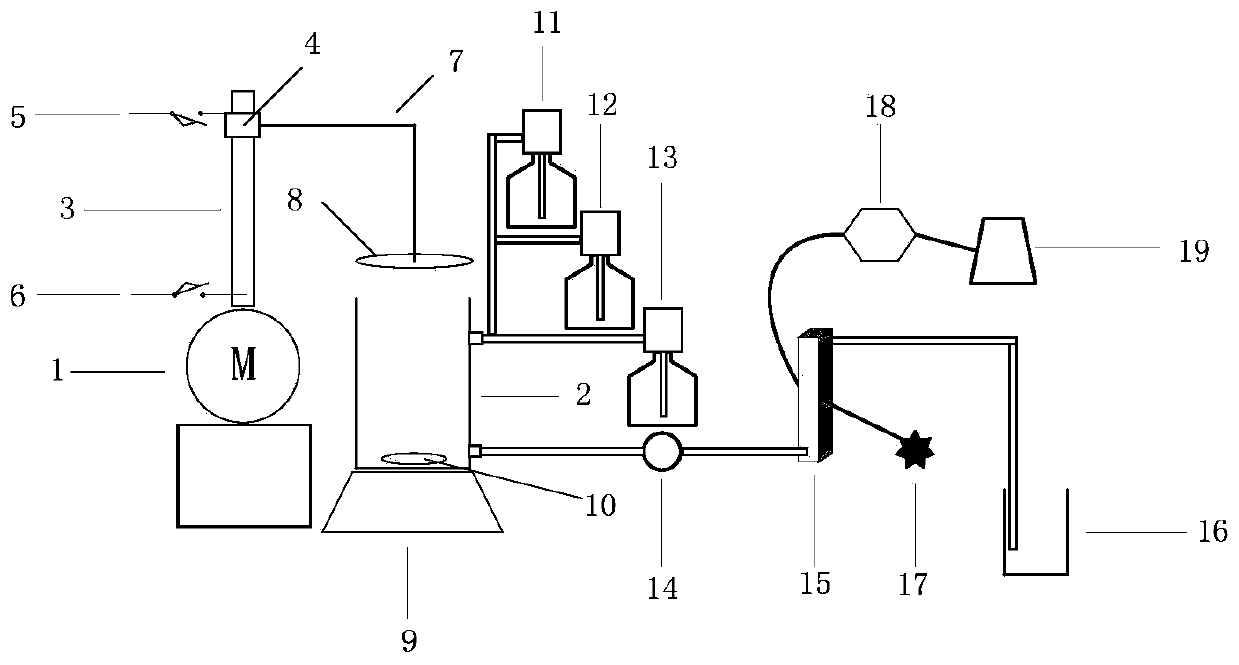

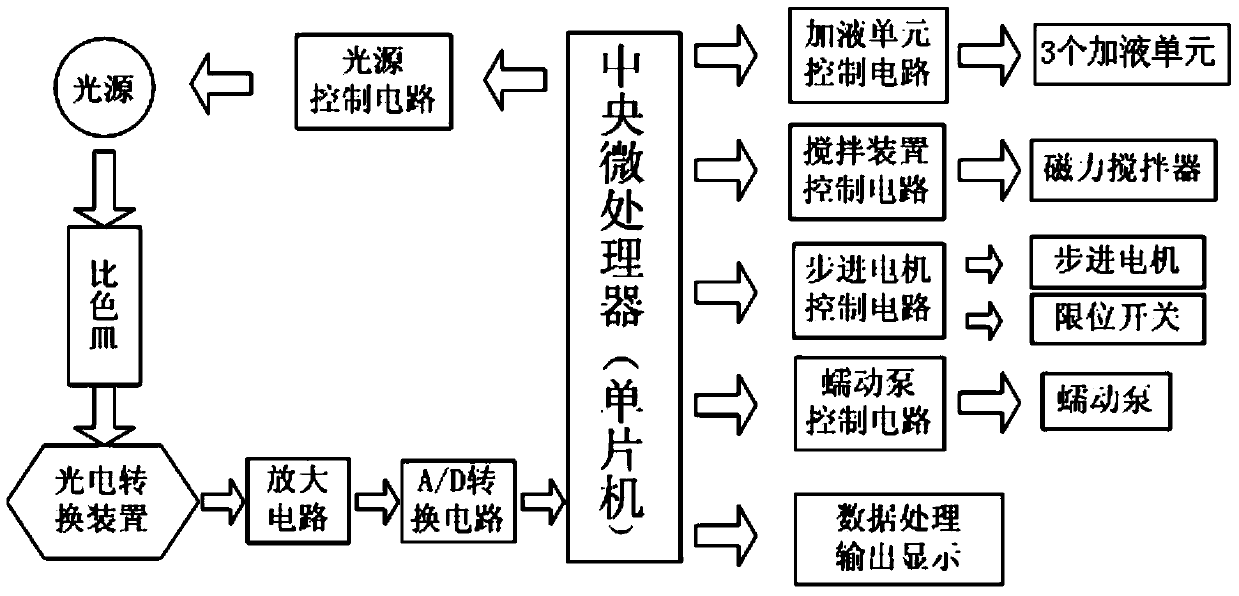

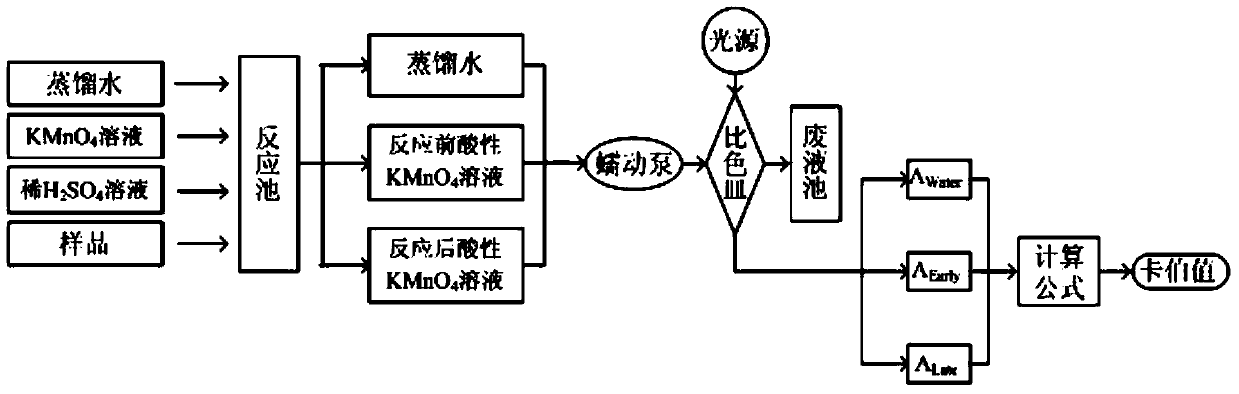

Rapid tester for paper pulp kappa number and control method of rapid tester

InactiveCN103630501AIncrease acidityHigh degree of intelligenceProgramme controlComputer controlData displayMicrocontroller

The invention discloses a rapid tester for a paper pulp kappa number and a control method of the rapid tester. The rapid tester comprises a reaction tank, three liquid adding units, a magnetic stirrer, a stepping motor, a sliding rail connected with the stepping motor, a slide block arranged on the sliding rail, an upper limiting switch, a lower limiting switch, a bracket fixedly connected with the slide block, a cuvette, a waste liquid tank, a peristaltic pump, a light source, a photovoltaic conversion device and a data displaying device, wherein the three liquid adding units are communicated with the reaction tank and are the same in structure; the magnetic stirrer is used for bearing the reaction tank; the peristaltic pump can be used for pumping liquid from the reaction tank to the waste liquid tank through the cuvette; light emitted by the light source passes through the cuvette and is received by the photovoltaic conversion device, and then the light is converted and conveyed into a single chip microcomputer; after the tester is electrified, self detection is carried out to ensure that the tester is at a normal initial state and simultaneously a power supply is driven to emit the light to pre-heat; before a sample to be detected is detected officially, blank deduction, base solution detection and standard sample detection operations need to be carried out firstly; after an experiment is finished, the device is washed.

Owner:SOUTH CHINA UNIV OF TECH

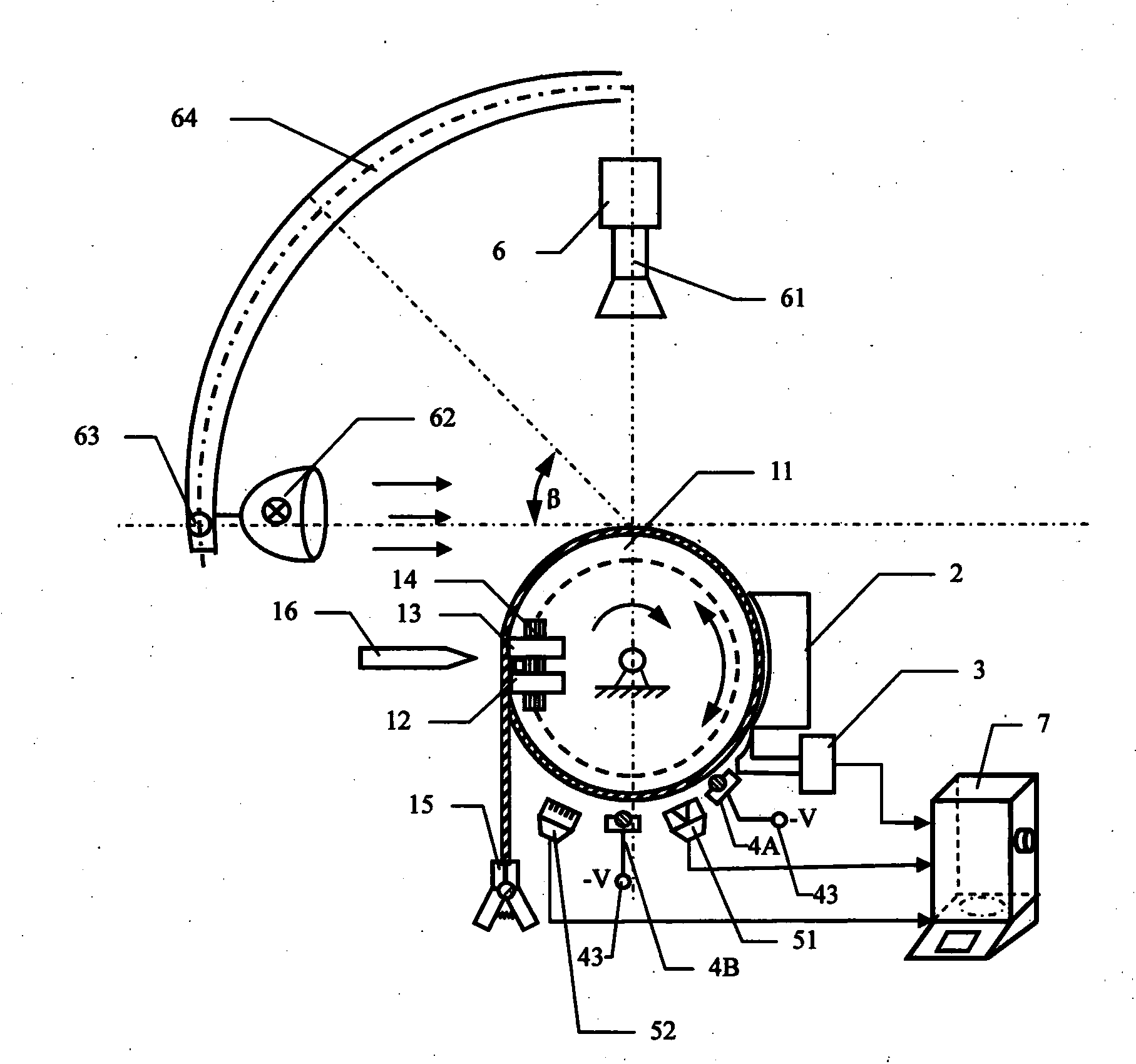

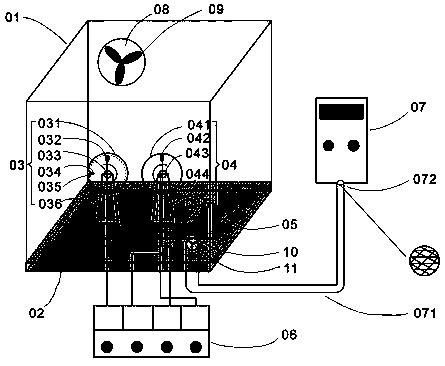

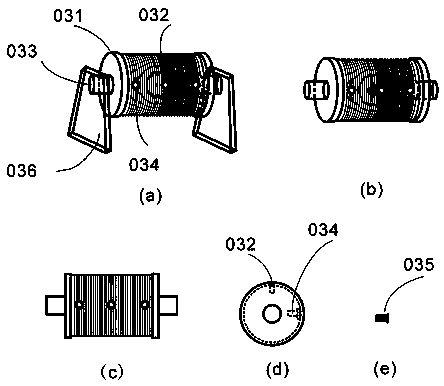

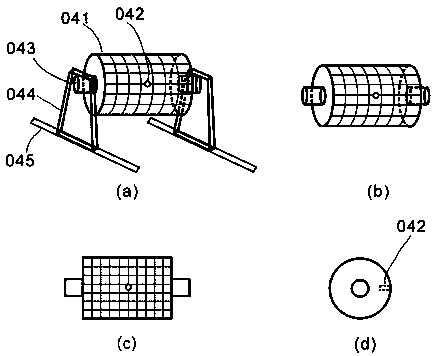

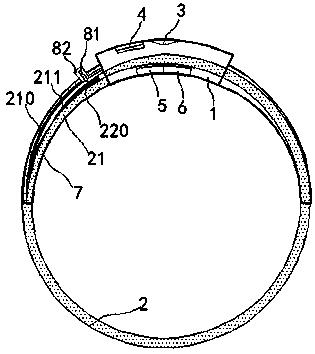

Negative ion performance measuring device and method for negative ion textile

ActiveCN109696397AMake up for the gap in the field of negative ion performance measurement technologyMeasurement scienceUsing mechanical meansMaterial analysisElectrical resistance and conductanceFiber

The invention relates to a negative ion performance measuring device and method for negative ion textile. The negative ion performance measuring device for negative ion textile comprises a cover-shaped glass box body (01) and a box body base (02) arranged below the glass box body (01), a winding press roller (03), a transmission press roller (04) and a heating resistor (05) installed in the glassbox body (01) and located on a box body base, and a temperature sensor (032) and a pressure sensor (042) installed in a winding roller (031) of the winding press roller (03) and a transmission roller(041) of the transmission press roller (04) respectively. The device also comprises an external test controller (06), a negative ion tester (07), an air inlet fan (09) installed on an air inlet of theglass box body, an exhaust fan (11) installed on an exhaust port of the glass box body, and a hollow pipe (071) connecting the negative ion tester and the exhaust port of the glass box body. The testcontroller (06) is electrically connected with the heating resistor (05), motors used for driving the winding press roller (03) and the transmission press roller (04) to rotate, and the temperature sensor (032) and the pressure sensor (042). The negative ion performance of negative ion fiber and negative ion fabric can be accurately measured.

Owner:MINJIANG UNIV

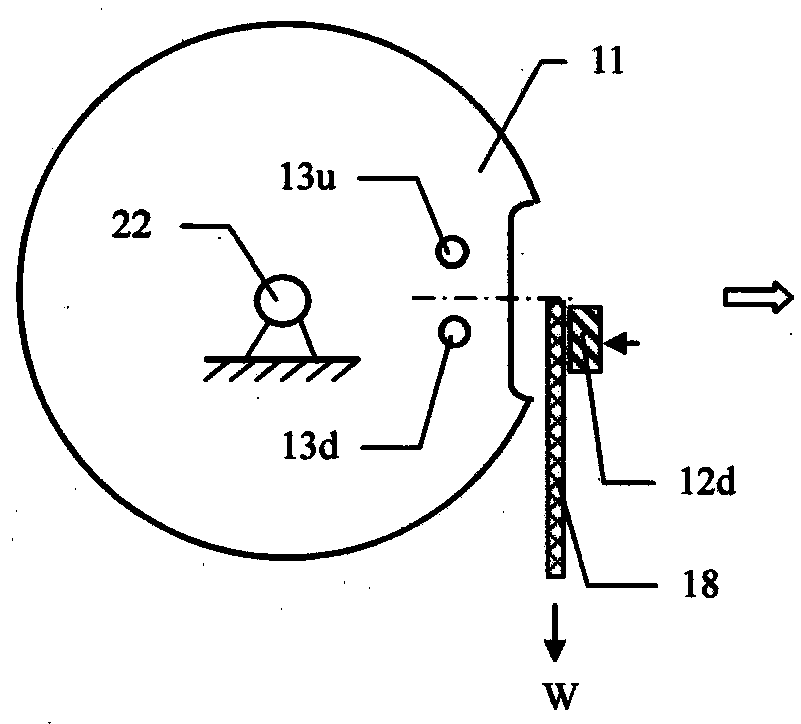

Polygonal cylinder type yarn grinding hairness and hair bulb tension holding pull measuring device and method

ActiveCN103469533APredicting Pilling ResistanceThe results of the extraction measurement are accurateInspecting textilesUsing mechanical meansYarnPull force

The invention relates to a polygonal cylinder type yarn grinding hairness and hair bulb tension holding pull measuring device and method. The device comprises a polygonal cylinder with 3-6 angles, a friction mechanism, a yarn layer tension mechanism, a microscopy camera mechanism, a pull mechanism, a yarn frame, a static raising device and a control and data collection analyzing system. The method includes: when dense yarn winding is completed, performing Lissajous curve friction on yarn on the polygonal cylinder angle by angle to obtain yarn grinding samples, pressurizing the yarn grinding samples turning to the top angle by angle, holding yarn layers, clamping ground hairness or hair bulbs for pull force measurement and hairness or hair bulb formation observation until pull measurement of each angle is completed so as to obtain hairness and hair bulb microscopy formation values and pull force curves under tension holding. The device and the method are fast, simple, practical, accurate, applicable to hairness and hair bulb sampling of yarn. measurement of hairness and hair bulb pull curves and formation, and comprehensive evaluation of anti-hairness and anti-hair-bulb performance of yarn.

Owner:DONGHUA UNIV

Device and method for measuring friction fuzzing and pilling forms and pulling-out force of bobbin yarns

ActiveCN103471650AEliminate the winding processSimple sample preparationMaterial analysis by optical meansYarnEngineering

The invention relates to a device and method for measuring friction fuzzing and pilling forms and a pulling-out force of bobbin yarns. The device comprises a cop creel for clamping cops to rotate, a friction mechanism for fuzzing and pilling bobbin yarns, a collecting mechanism for collecting shaving and shearing filoplumes and fuzzy balls, a static raising device for helping filoplumes to stand, a pulling-out mechanism used for measuring the pulling-out force of the filoplumes and fuzzy balls, an imaging system for observing the filoplumes and fuzzy balls of the bobbin yarns, a computer and a data acquiring and controlling system. The method comprises the steps of: measuring the prominence of the filoplumes and the number, the form size and distribution of the fuzzy balls after coaxially jacking and clamping the cops, carrying out friction for fuzzing and pilling and synchronously measuring the prominence of the filoplumes, the number of the fuzzy balls, the abrasion loss and retention of the filoplumes and fuzzy balls, and the pulling-out force of the filoplumes and fuzzy balls of the process and a final friction sample. The device and method are exquisite, practical, accurate and quantitative, and can be used for measuring the fuzzing and pilling forms of the bobbin yarns and comprehensively evaluating the fuzzing and pilling resistance. In situ measurement of multiple functions in one machine and multiple indexes in one-time measurement is adopted in the device and method.

Owner:DONGHUA UNIV

Device and method for measuring hairiness and hair ball state and pulling-off force of fabric

The invention relates to a device and method for measuring the hairiness and hair ball state and pulling-off force of fabric. The device is composed of a cloth sample barrel of rolled fabric, a rotating mechanism driving the cloth sample barrel, a friction mechanism enabling a cloth sample to be in a pilling state, a pulling-off mechanism clamping and pulling hairiness and hair balls off, an optical measuring system used for observing the hairiness and ball top state of the cloth sample, a collecting and weighing mechanism used for collecting and weighing falling fiber and ball tops, a data collection and control system and a computer. The method comprises the steps of measuring the height and the amount of the hairiness and the size and the number of the ball tops after the cloth sample is packaged in a rolling mode with the same tension, sampling through rubbing to enabling the cloth sample to be in the pilling state, and measuring the amount of the hairiness of a friction sample which is in process and is finished , the number of the ball tops of the friction sample which is in process and is finished, the pulling-off force of the friction sample which is in process and is finished and the abrasion amount of the hairiness and the ball tops of the friction sample which is in process and is finished at the same time. The device and method are exquisite, practical, accurate and quantitative. The purposes that one machine is used for multiple purposes, and multiple indexes are measured at one time are achieved. The device and method can be used for sampling pilling fabric, measuring the amount of the hairiness, the number of the ball tops, the pulling-off force and the abrasion amount of the hairiness and the ball tops and comprehensively analyzing and assessing.

Method for measuring mechanical texture characteristic of dried rice noodle

InactiveCN101929933AEasy to testUnlimited lengthMaterial strength using steady bending forcesAxial displacementEngineering

The invention provides a method for measuring the mechanical texture characteristic of dried rice noodle, belonging to the measurement field of the physical mechanics of foods and materials. The method comprises the following steps of: respectively arranging dried rice noodles samples with a certain standards between a fixed press head and a movable press head; starting up a loading measurer; axially bending and loading the dried rice noodles sample through the movable press head under the drive of a movable arm of the loading measurer to axially bend and deform the rice noodle; automatically recording and storing the axial displacement quantity and the loaded load of the samples when loading the press head by the loading measurer; giving the relationship test curve between the axial displacement quantity delta 1 and the load p by the loading measurer after measuring the sample; and extracting the axial displacement quantity delta 1 and the corresponding load p at the end of the stated dried rice noodle from the test curve, and computing and appraising to obtain the elastic modulus and the bending break off rate of the rice noodle. Based on the large-deflection theory of the post buckling of a press rod, the method builds a method for measuring the elastic modulus and the bending break off rate of the rice noodle.

Owner:JIANGSU UNIV

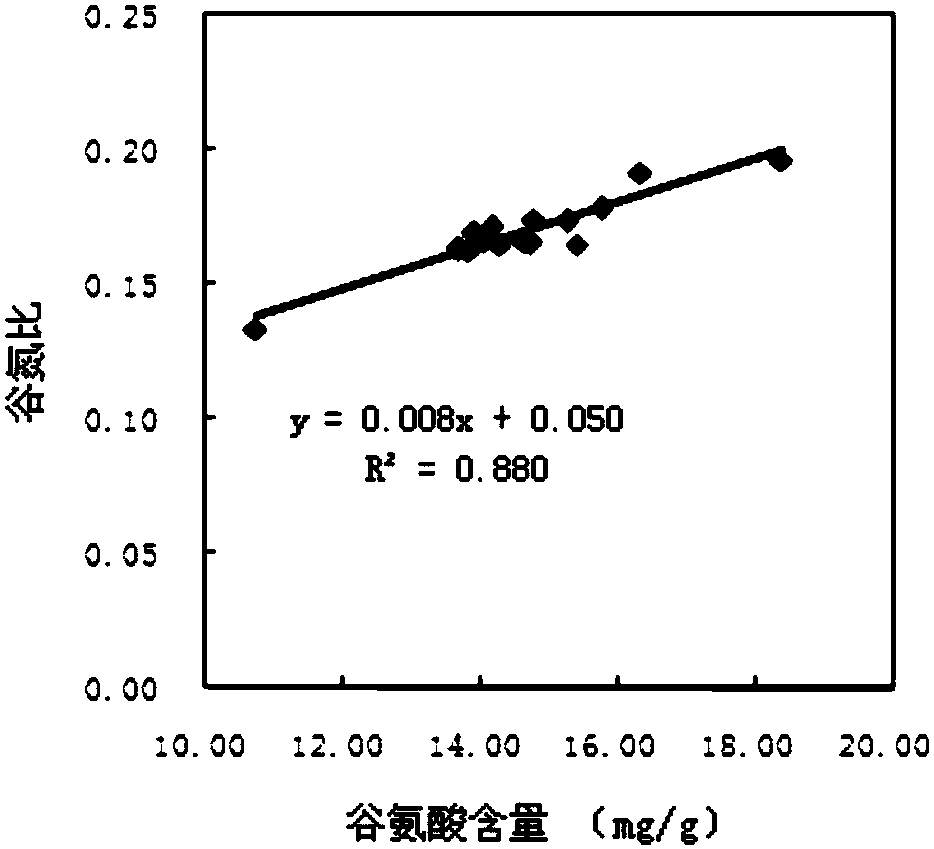

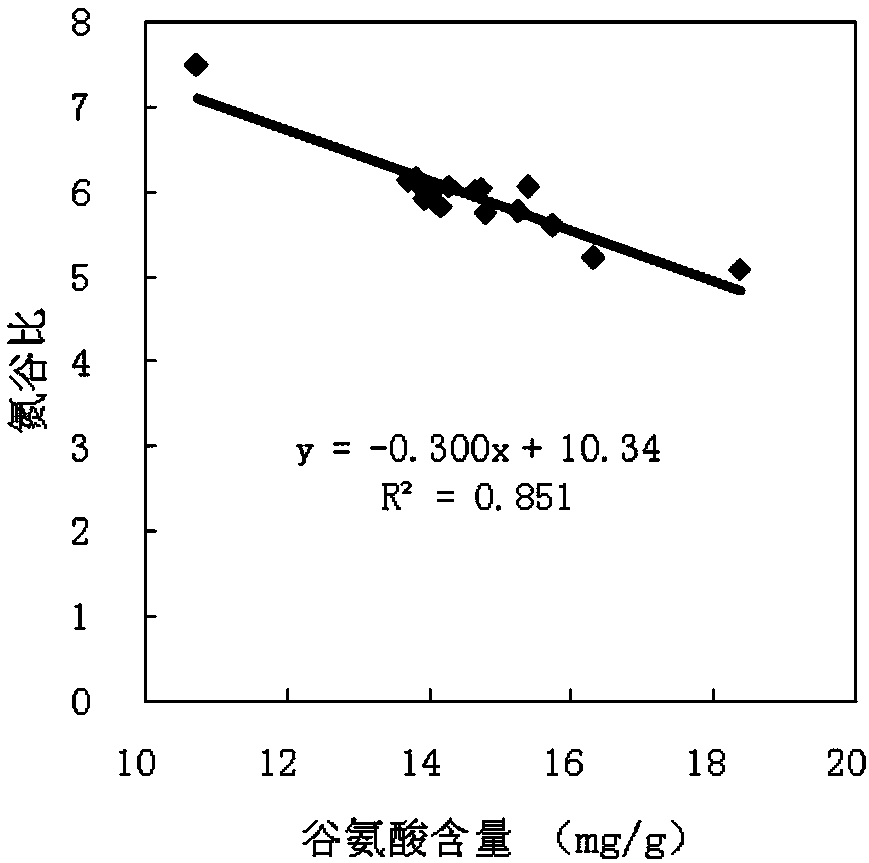

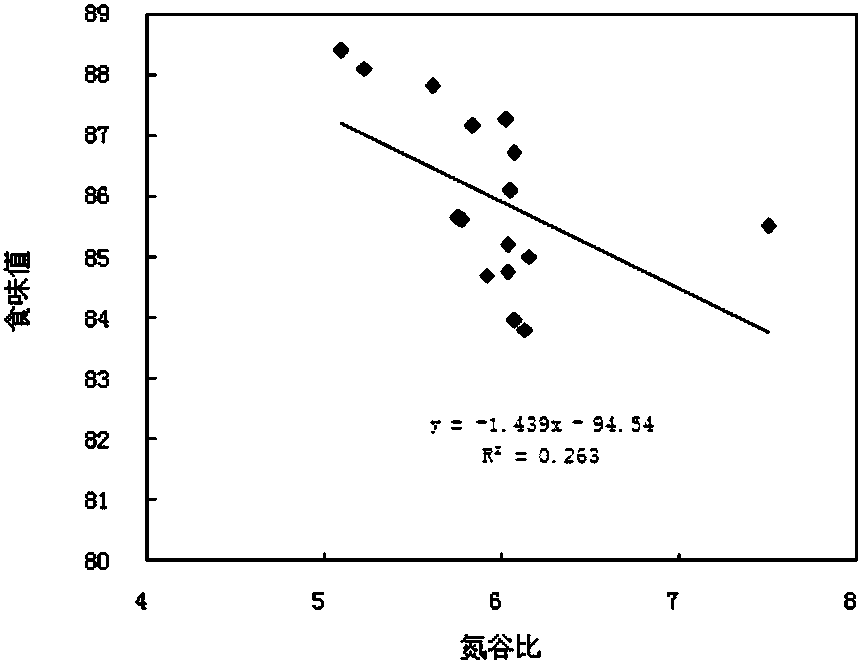

Method for screening japonica rice with high taste value and high protein content by ratio of brown rice protein content to glutamic acid content

InactiveCN107624569AMeasurement scienceAvoid negative effectsRice cultivationJaponica riceHorticulture

The invention relates to the field of rice breeding, in particular to a method for screening japonica rice with high taste value and high protein content by ratio of brown rice protein content to glutamic acid content or ratio of the glutamic acid content to the brown rice protein content. The method has the advantages that materials with high taste value and high protein content can be selected out, materials which high taste value but medium or relatively low protein content can be identified and selected out, materials with relatively low taste value can be identified and eliminated, and the like.

Owner:SHENYANG YUGENG SEED IND +1

Device and method for measuring fuzzing amount, balling amount and morphology during pressurized yarn grinding of polygonal barrels

The invention relates to a device and a method for measuring fuzzing amount, balling amount and morphology during pressurized yarn grinding of polygonal barrels. The device comprises four multiples of polygonal barrels, a friction mechanism, a tension mechanism, a projection and pickup mechanism, a creel, an electrostatic raising device and a control and data acquisition analysis system. The method comprises the steps of accomplishing close packing and yarn winding to form a yarn winding sample, rotating clockwise directly through the polygonal barrels angle by angle, observing raising of the yarn winding sample angle by angle, and the morphology after delay of 1-3 angles, then delaying by 1-3 angles for synchronous pressurization and stabilization, sampling fuzzing and balling to form a yarn grinding sample, and after rotating the yarn grinding sample by 180 degrees angle by angle (namely, rotating the polygonal barrels by a cycle), performing synchronous raising and morphology observation angle by angle till friction sampling and morphology measurement of each angle are finished. The measuring device and the method are quick, practical, in-situ, dynamic and precise, and use the same sample, can be used for sampling of the fuzzing and the balling, measurement of the fuzzing amount, the balling amount and the morphology of a yarn, and comprehensive evaluation of fuzzing and balling resistance of the yarn.

Owner:DONGHUA UNIV

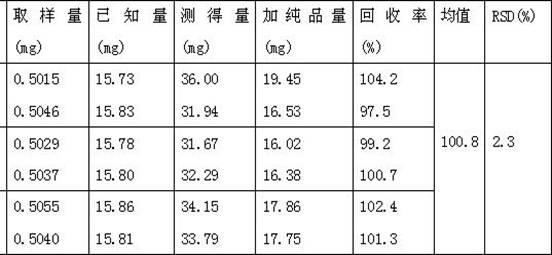

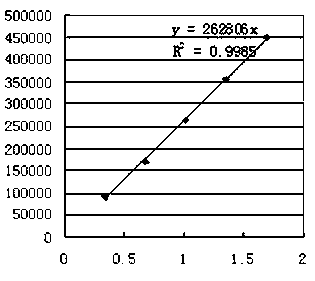

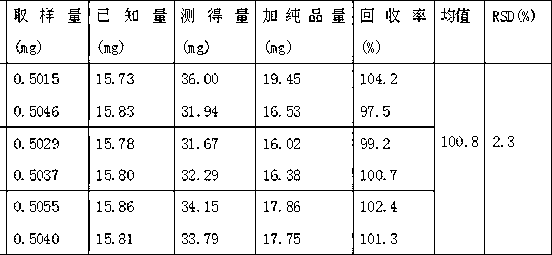

Method for detecting mannitol content of cordyceps hawkesii

ActiveCN102183593AAccurate measurementMeasurement scienceComponent separationFlame ionization detectorChemistry

The invention discloses a method for detecting mannitol content of cordyceps hawkesii, and belongs to the technical field of Chinese medicinal component content measurement. The mannitol content of the cordyceps hawkesii is measured by using gas chromatography, and the efficient and accurate measurement of the mannitol content of the special cordyceps hawkesii in Shanxi is realized. The method comprises the following steps of: preparing reference solution; preparing sample solution; and performing measurement by adopting a gas chromatograph, wherein the chromatography conditions comprise that: the initial temperature of column temperature is 220 DEG C and kept for 1 minute, the temperature is raised to between 220 and 230 DEG C at the rate of 10 DEG C per minute, the raised temperature iskept for 26 minutes, the temperature of a vaporizing chamber and the temperature a hydrogen flame ionization detector are 300 DEG C, the flow rate of H2 is 34 to 40ml / min, the flow rate of air is 350to 400ml / min, the flow rate of N2 is 30 to 35 / min, and the split ratio is 50:1. The method is simple, convenient, quick and accurate, has good repeatability, can measure the mannitol content of the special cordyceps hawkesii in Shanxi more scientifically and accurately, and effectively improves the quality of a product.

Owner:山西省药品检验所

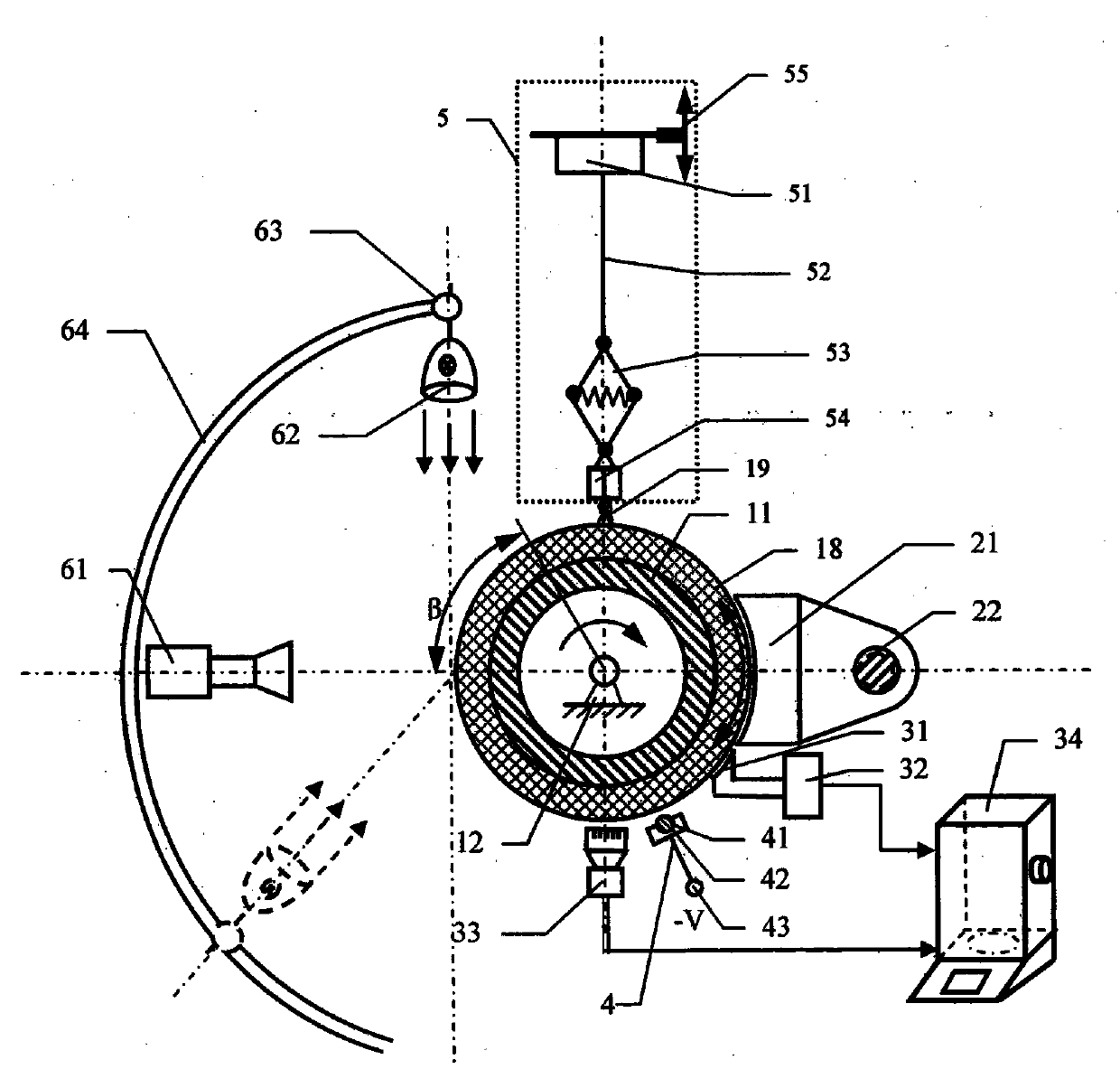

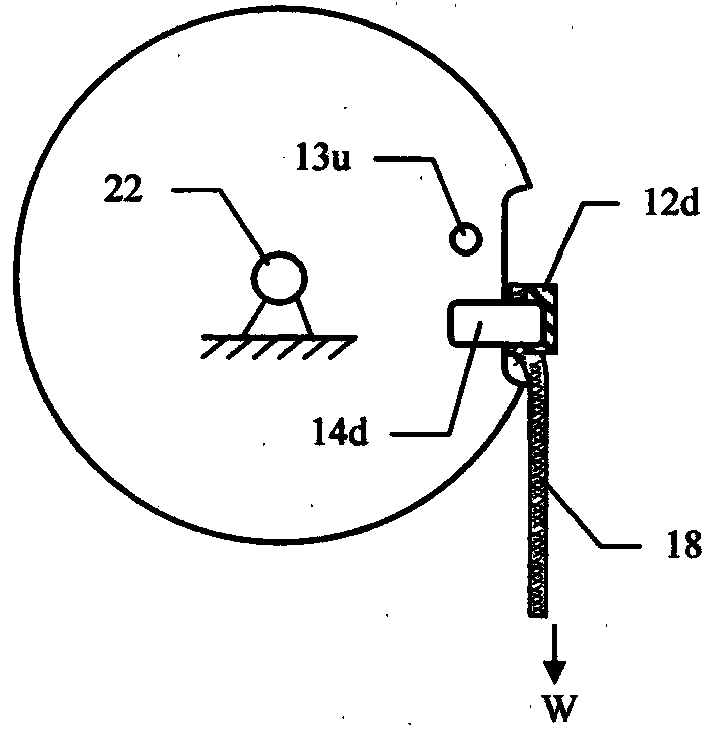

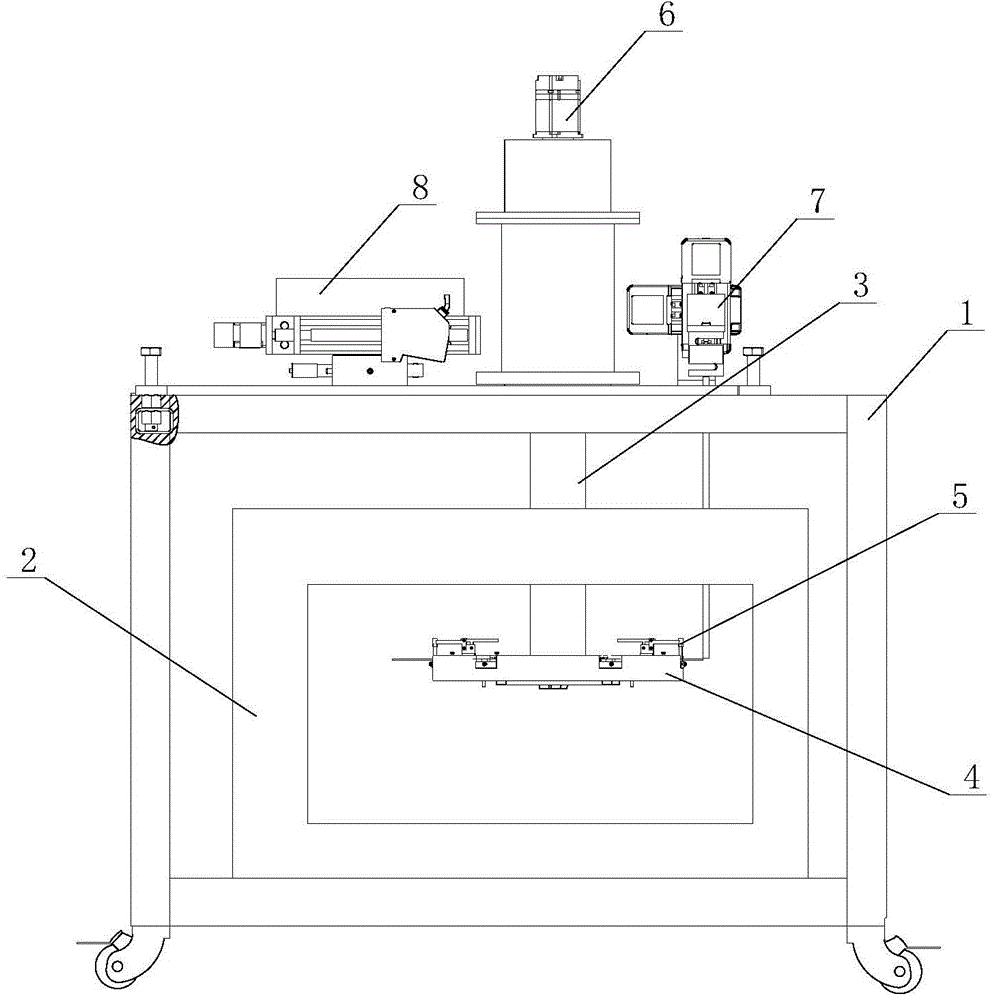

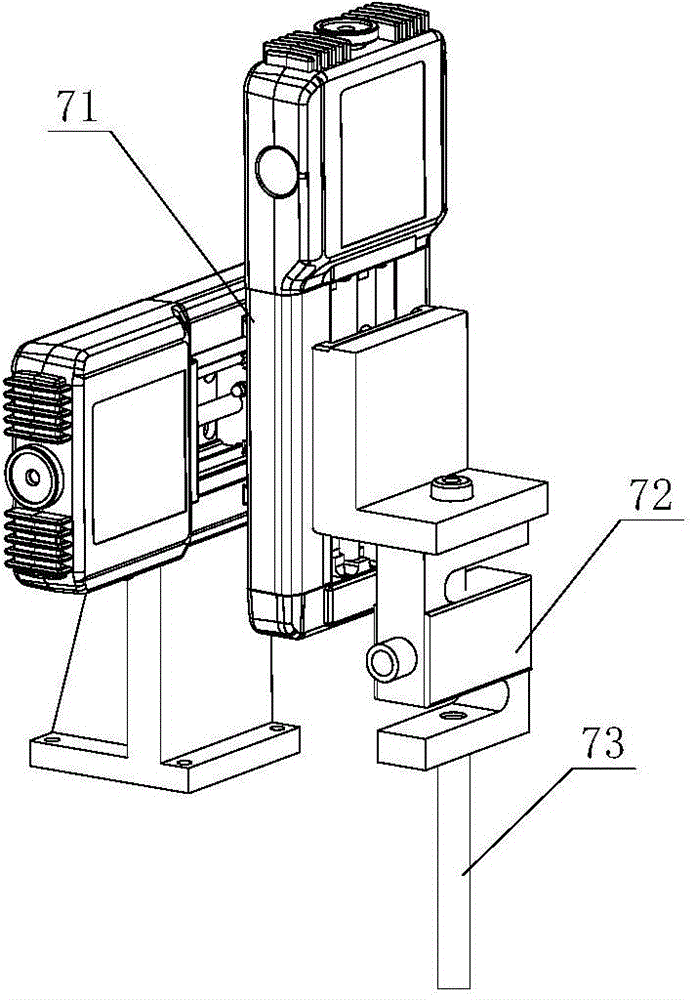

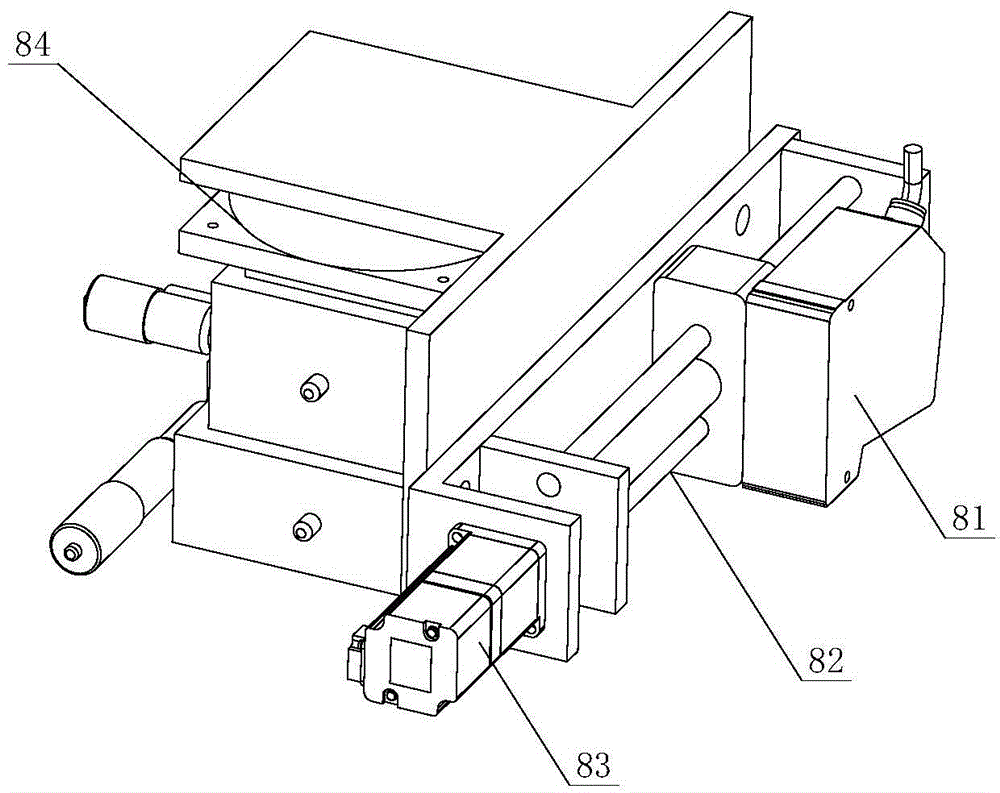

Apparatus for measuring consistency of thermal deformation and deformation force of thermal bimetallic strip

ActiveCN104897713AMeasurement scienceGuaranteed measurement positionMaterial thermal analysisTest efficiencyThermal deformation

The invention relates to an apparatus for measuring consistency of thermal deformation and deformation force of a thermal bimetallic strip, which belongs to the field of precise instruments. The apparatus for measuring consistency of thermal deformation and deformation force of the thermal bimetallic strip comprises: a horizontal mounting table with a horizontal adjusting function; a high temperature thermotank located below the horizontal mounting table; a rotary table arranged below the horizontal mounting table in a suspended way through a main shaft and extending into the high temperature thermotank, wherein a plurality of centrosymmetric positioning clamps used for clamping the thermal bimetallic strip are arranged along the circumference of the rotary table and a rotary motor connected with the main shaft is arranged on the horizontal mounting table; a thermal deformation force measuring mechanism and a flexibility measuring mechanism arranged on the horizontal mounting table and respectively located at two sides of the main shaft; and U-shaped grooves arranged on the upper surfaces of the horizontal mounting table and the high temperature thermotank at positions corresponding to the thermal deformation force measuring mechanism and the flexibility measuring mechanism. The apparatus provided by the invention has the advantages of scientific measurement, small errors of testing results and high testing efficiency.

Owner:SHANGHAI UNIV OF ENG SCI

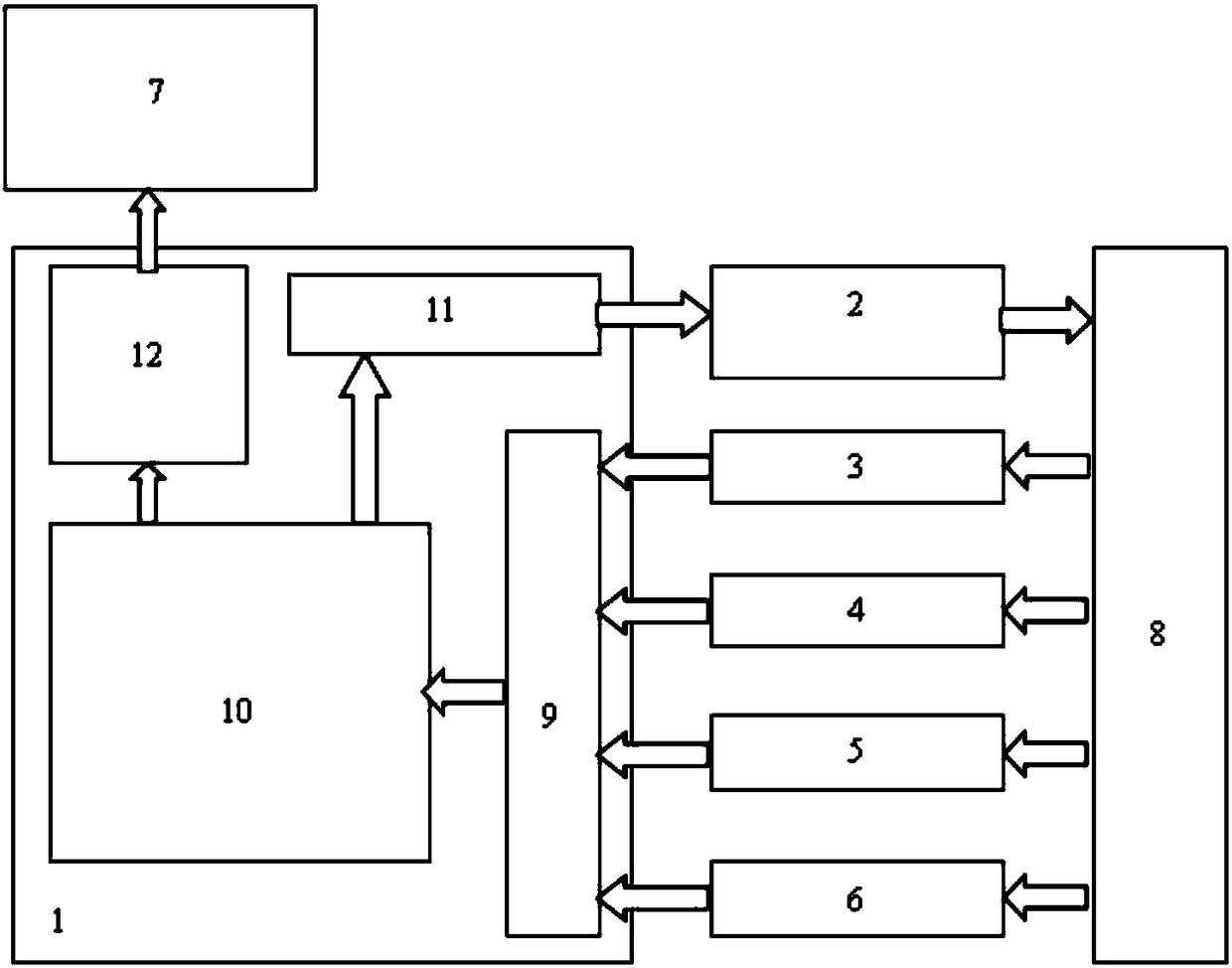

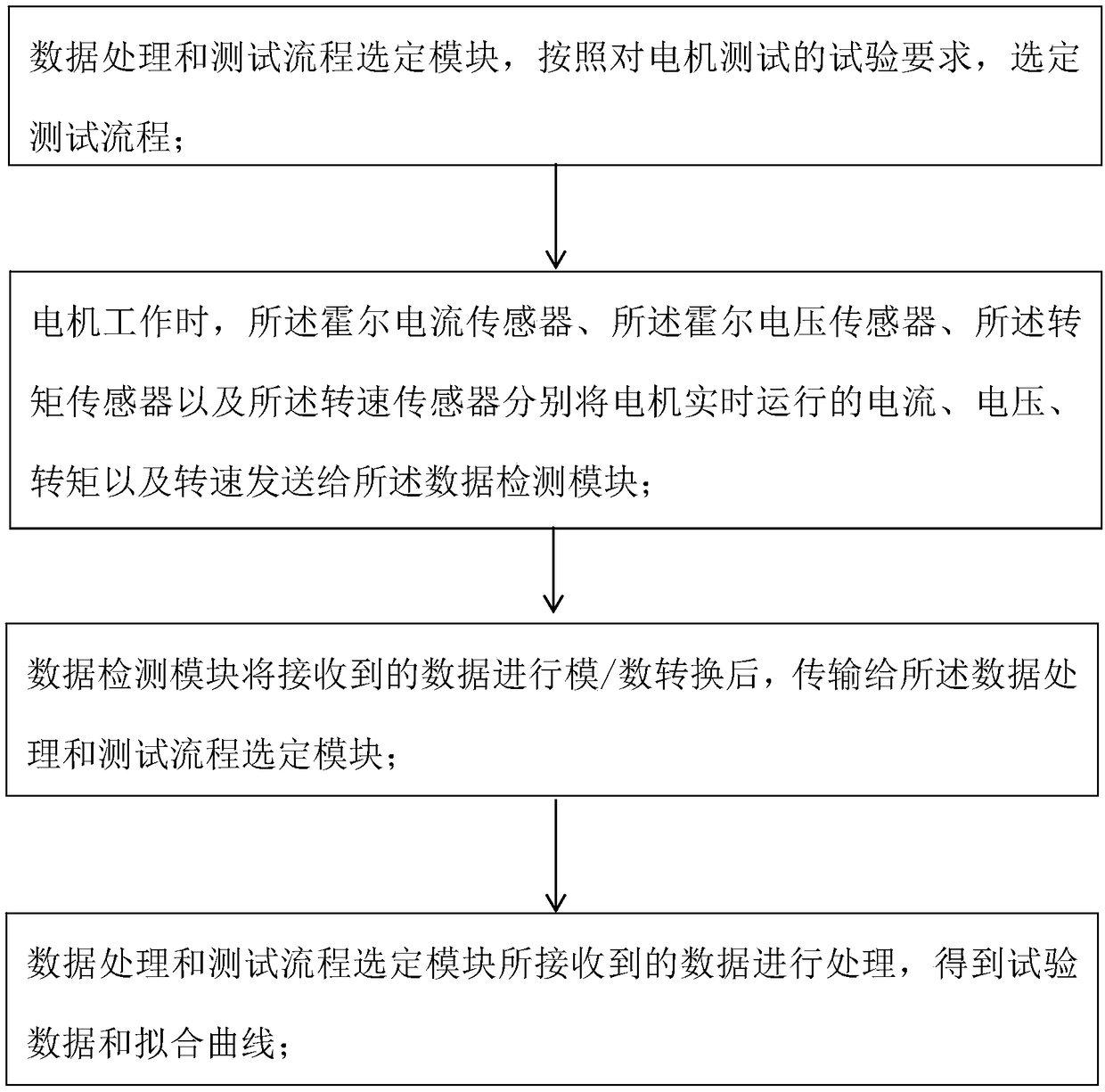

DC motor detection system and method

InactiveCN108120926AQuality objectiveMeasurement scienceDynamo-electric machine testingDC motorTorque sensor

The invention relates to the technical field of motor detection and specifically provides a DC motor detection system including a programmable logic controller, a motor driving circuit, a Hall currentsensor, a Hall voltage sensor, a torque sensor and a rotation speed sensor. The programmable logic controller also includes a data detection module, a data processing and test flow selection module and a state machine control module. When a motor is working, the Hall current sensor, the Hall voltage sensor, the torque sensor and the speed sensor send current, voltage, torque and a rotation speedof the real-time operation of the motor to the data detection module. The data detection module carries out analog / digital conversion on the received data and transmits the data to the data processingand test flow selection module. The data processing and test flow selection module processes the received data to obtain test data and a fitted curve. The DC motor detection system of the present invention has the advantages of high reliability, high precision and long-term monitoring.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

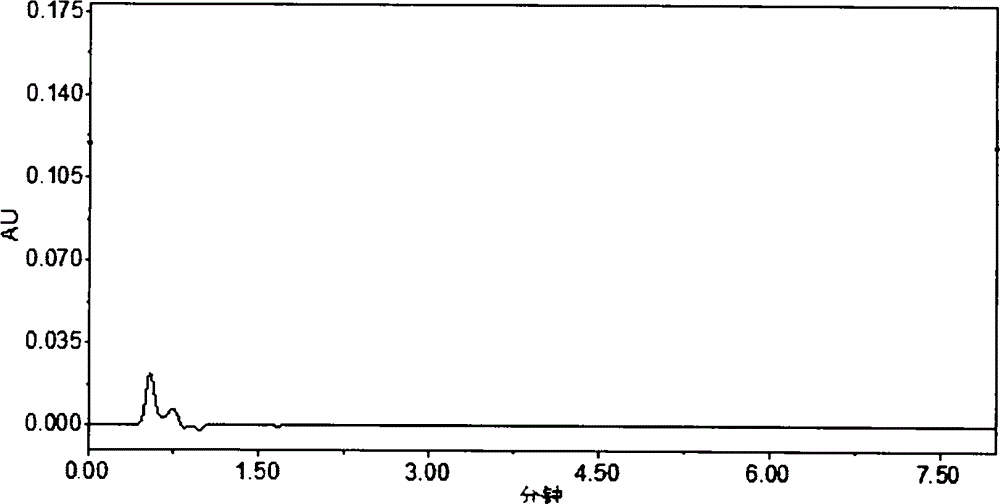

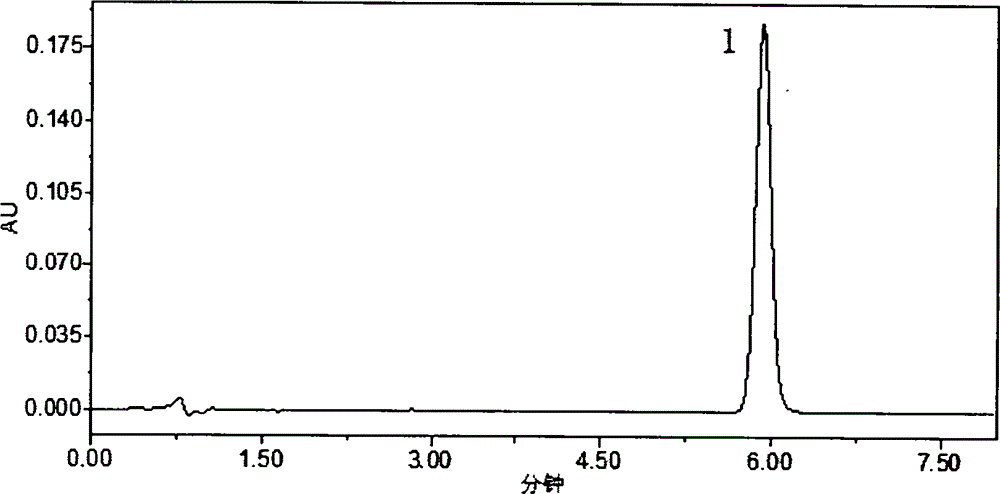

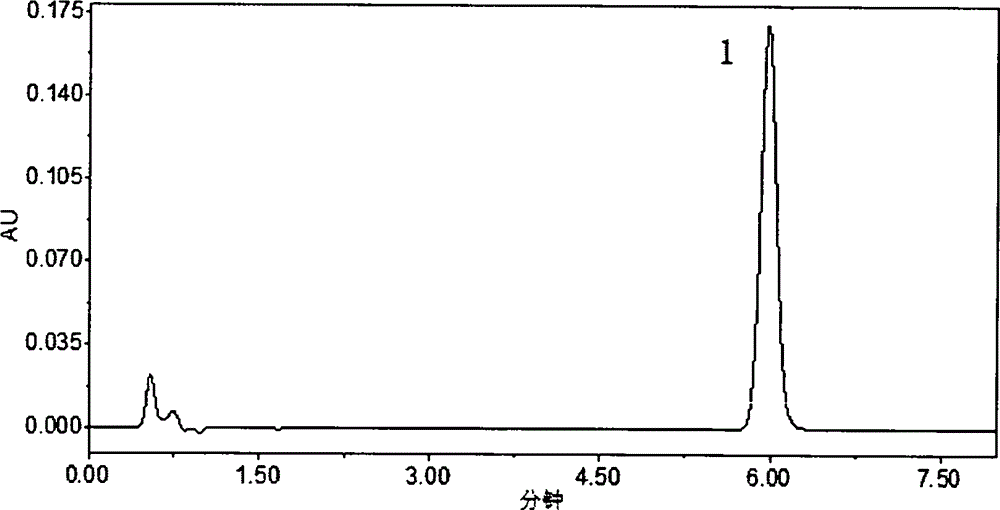

HPLC (High Performance Liquid Chromatography) method for determining dissolution rate of Lercanidipine hydrochloride tablet

InactiveCN104807898AQuality improvementOvercoming the flaws of interferenceComponent separationHplc methodColumn temperature

The invention relates to an HPLC (High Performance Liquid Chromatography) method for determining the dissolution rate of a Lercanidipine hydrochloride tablet. The method comprises the following steps: (1) test of the dissolution rate of the Lercanidipine hydrochloride tablet and preparation of a sample solution; (2) preparation of a reference solution of Lercanidipine hydrochloride; (3) HPLC determination, to be specific, performing determination analysis on the reference solution and the sample solution under the following chromatographic conditions: a chromatographic column is Waters SunFire C18 (4.6 mm*150 mm, 5 [mu]m), a flowing phase is formed by a 0.15 mol.L<-1> sodium perchlorate solution (of which the pH is adjusted by a 70% perchloric acid to be 3.0-4.0) and acetonitrile, the ratio of the sodium perchlorate solution to the acetonitrile is 40:60, the column temperature is 25-30 DEG C, the detection wavelength is 240 nm, the flow speed is 1.0 ml.min<-1>, and the sample injection amount is 40 [mu]L. A methodological test shows that the method is high in specificity, accurate in result, good in stability, simple and convenient to operate, and suitable for the determination of the dissolution rate of the Lercanidipine hydrochloride tablet, and can control the quality of the Lercanidipine hydrochloride tablet more scientifically and effectively.

Owner:CHONGQING MEDICAL UNIVERSITY

Method for measuring mechanical texture characteristic of dried rice noodle

InactiveCN101929933BSuperiorEasy to testMaterial strength using steady bending forcesClassical mechanicsEngineering

Owner:JIANGSU UNIV

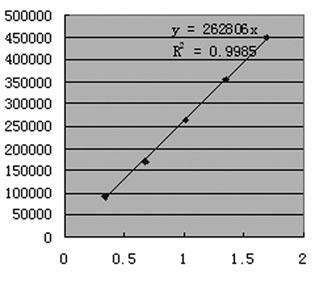

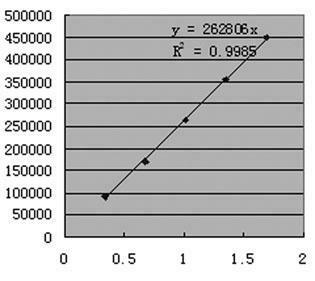

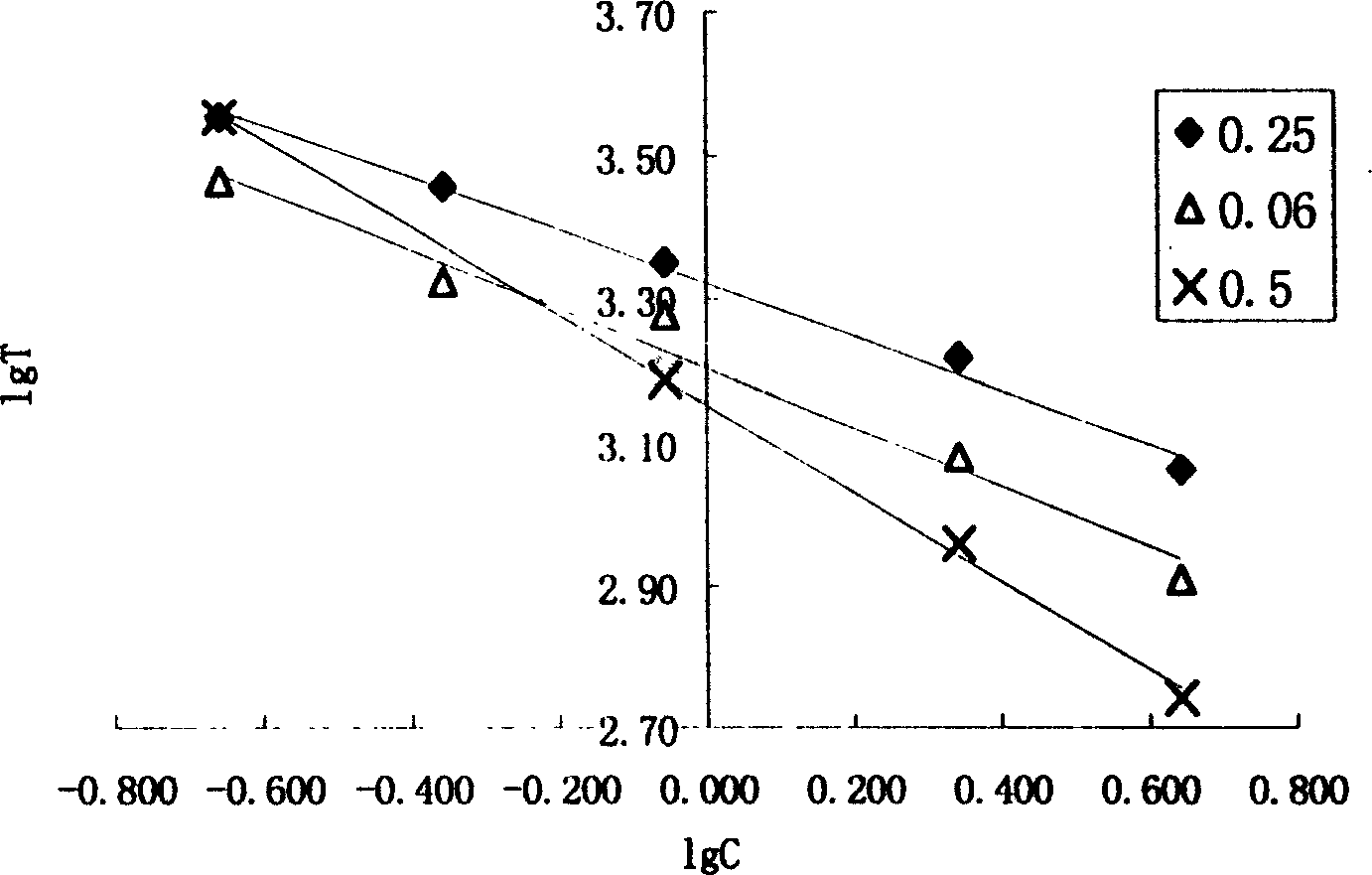

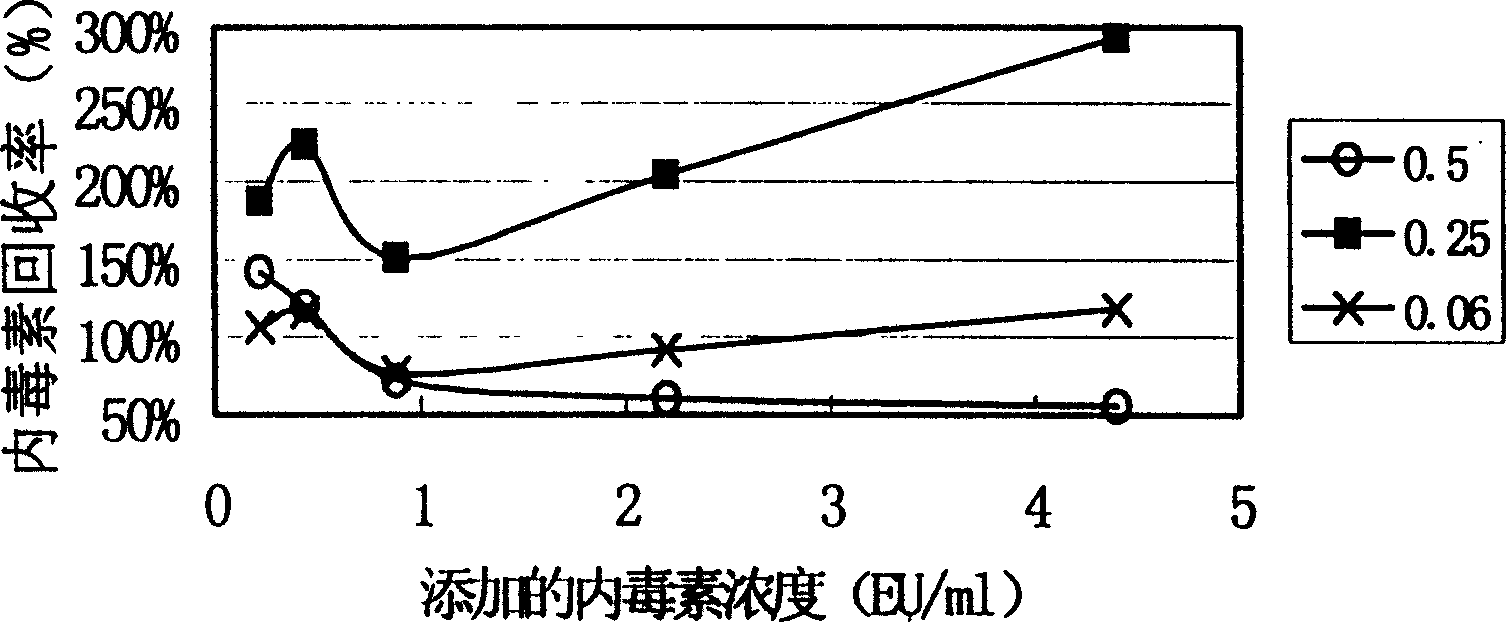

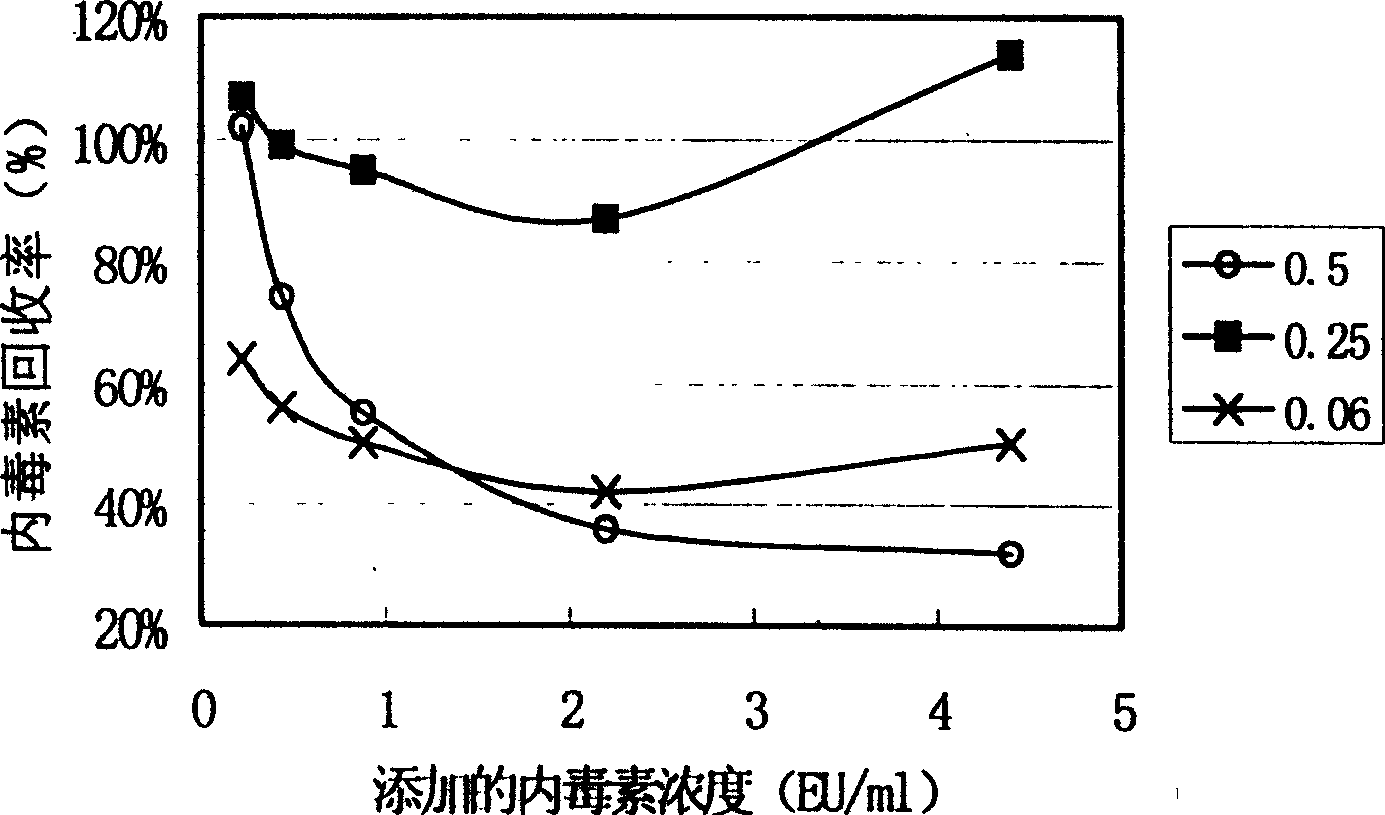

Method for determing sensitivity of limulus reagent

InactiveCN1536363AShort reaction timeShort test preparation timeBiological testingLinear regressionAbsorbance

The invention relates to the detection for bacterial endotoxin, concretely a limuloid reagent sensitivity determining method, its character: 1) adopt standard endotoxins at 3-6 concentrations to test standard limuloid reagents at different sensitivities on the endotoxin determiner, make linear regression on the logarithms of reacting time and endotoxin concentration, to obtain the corresponding standard curves at different sensitivities as the justification basis; 2) make the limuloid reagent to be measured react with standard endotoxins at 1-6 concentrations, on the corresponding condition of reacting time or solution absorbency, use the standard curves to calculate endotoxin concentration and recovery, according to the sensitivity corresponding to the standard curve at the recovery 75-120%, determine it as the sensitivity of the limuloid reagent to be measured.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Fine dried noodles elasticity modulus measuring method based on pressure lever post-buckling

InactiveCN101526456BEasy to measureNoodle length is not limitedInvestigating material hardnessMeasurement deviceAxial compression

The invention discloses a fine dried noodle elasticity modulus measuring method based on pressure lever post-buckling. A load measuring device is installed firstly, a static pressure head of the load measuring device is fixed on a base, a force sensor is arranged on a movable arm of the load measuring device, and then a dynamic pressure head is fixedly connected with the force sensor; a certain number of fine dried noodles cut to have corresponding length are respectively arranged between the static pressure head and the dynamic pressure head; and the amount of movement of the dynamic pressure head is determined according to the length of the fine dried noodle and an set intersection angle of the end part of a twisted curve, then the load measuring device is started again, the dynamic pressure head is driven by the load measuring device to load the fine dried noodles in a speed of 0.01mm / s, load corresponding to the amount of movement of the dynamic pressure head is measured by the load measuring device, and at last the fine dried noodle elasticity modulus is counted by a formula relationship. The invention uses pressure lever stability principle and large deflection theory of mechanics of materials to establish the relationship of axial compression, the end part intersection angle and pressure, establishes a counting method of the fine dried noodle elasticity modulus, has simple and convenient measuring method and high precision, and can control the length of the fine dried noodle elasticity modulus to be between 60 mm and 220mm.

Owner:JIANGSU UNIV

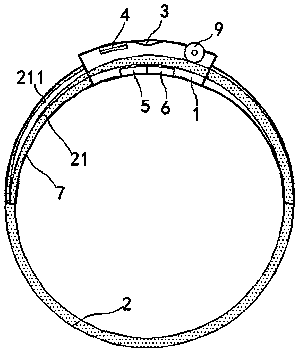

ring wear sizer

The invention relates to a ring wearing size measurer which comprises a measuring base and a measuring belt. The measuring belt is engraved with scales. The upper portion of the measuring base is provided with an observation window and an analyzer. An LED green light emitting piece and a light sensing piece are installed at the bottom of the measuring base. The light sensing piece is electrically connected with the analyzer. The tail end of the measuring belt is fixed to the left side wall of the measuring base. The tail end of the measuring belt comprises a wedge-shaped protecting cavity. The tip end of the measuring belt penetrates through the right side wall of the measuring base and extends into the protecting cavity. An adjusting device for controlling the measuring belt to move is arranged on the measuring base. Through scientific detection, the most suitable wearing size is measured, and the purchase accuracy and comfort are effectively improved; the measurer is convenient and rapid to use, attractive in appearance and convenient to store.

Owner:怀远县翰邦科技咨询有限公司

A safety evaluation device for simulating fluid flow in oil and gas pipelines

ActiveCN103675213BExpand the scope of researchConvenient and detachableMaterial analysisWaxEngineering

Owner:SOUTH CHINA UNIV OF TECH

Device and method for measuring yarn pilling shape and pilling peeling

ActiveCN103472210BEasy to measureAccurate collectionTextile testingInvestigating abrasion/wear resistanceYarnEngineering

The invention relates to a device and a method for measuring fluffing and balling shape as well as hair bulb stripping of a yarn. The device comprises a mechanism clamping hair bulbs to implement stripping, a yarn delivery mechanism performing equal-tension close packing, a yarn winding mechanism winding the yarn at a constant speed, a yarn grinding mechanism performing friction on the close packed and wound yarn, a translation driving mechanism driving the yarn delivery mechanism and the yarn winding mechanism in a switching manner, an abrasion object collector, a microimaging system and a control and data analysis system. The measuring method comprises the steps that a gap bridge wheel of the translation driving mechanism transposes the yarn delivery mechanism and the yarn grinding mechanism, and is matched with the yarn winding mechanism, so that close packing yarn winding and yarn grinding sampling are achieved; a yarn grinding sample in a yarn grinding process is measured in situ; and comprehensive measuring and evaluation are performed on the yarn grinding sample in a final state. The device is ingenious in structure, practical, precise in measuring, quantitative, and multipurpose, is an in-situ measuring device for measuring multiple indexes, and can be used for measuring of the hair feather and hair bulb quantity, the shape, the abrasion loss and the back-and-forth drag stripping property of the yarn, and for comprehensive evaluation of the fluffing resistance and the balling resistance.

Owner:DONGHUA UNIV

A device for measuring thermal deformation and deformation force consistency of thermal bimetal

ActiveCN104897713BMeasurement scienceGuaranteed measurement positionMaterial thermal analysisTest efficiencyElectric machine

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com