Patents

Literature

53results about How to "Simultaneous testing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

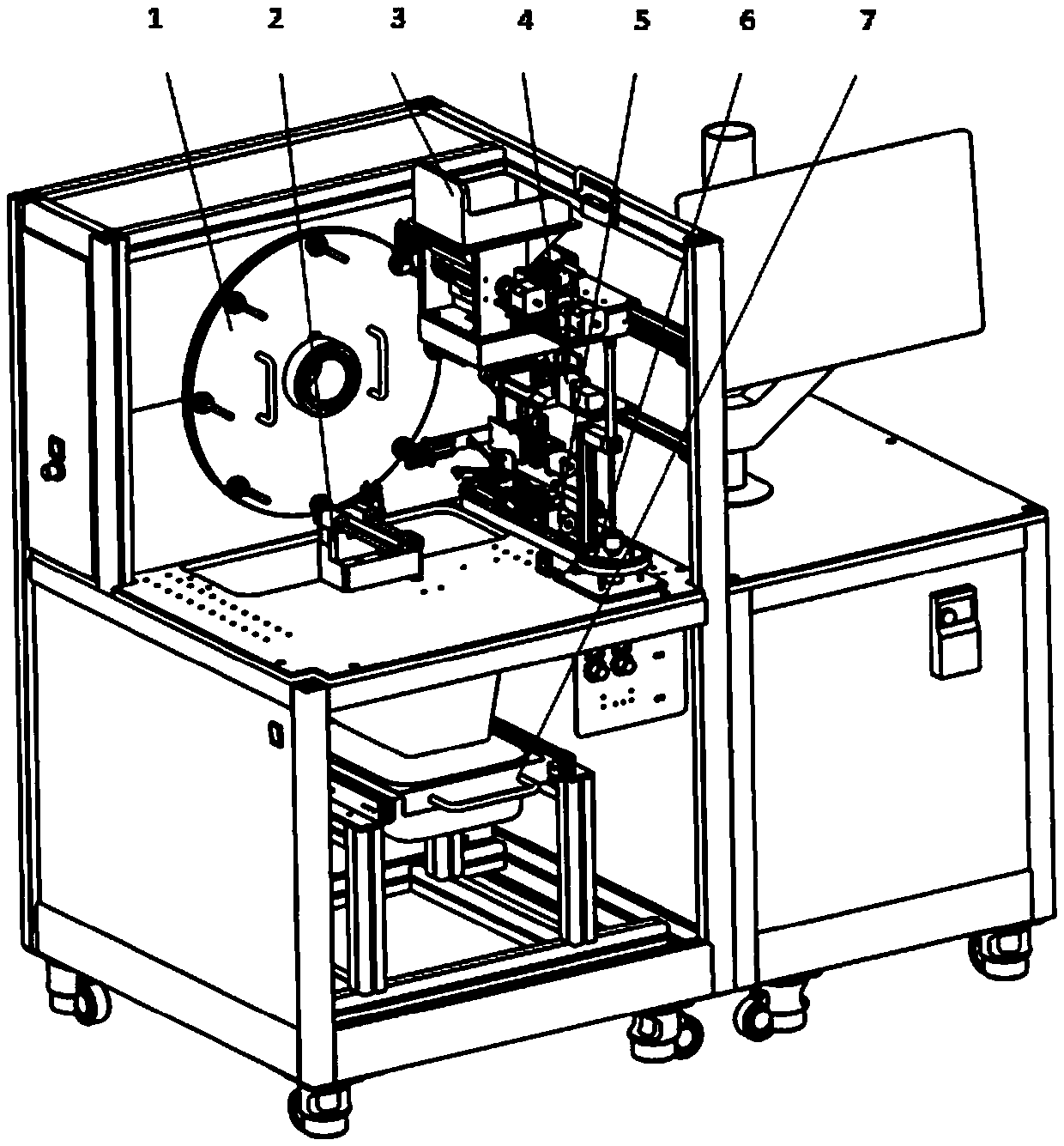

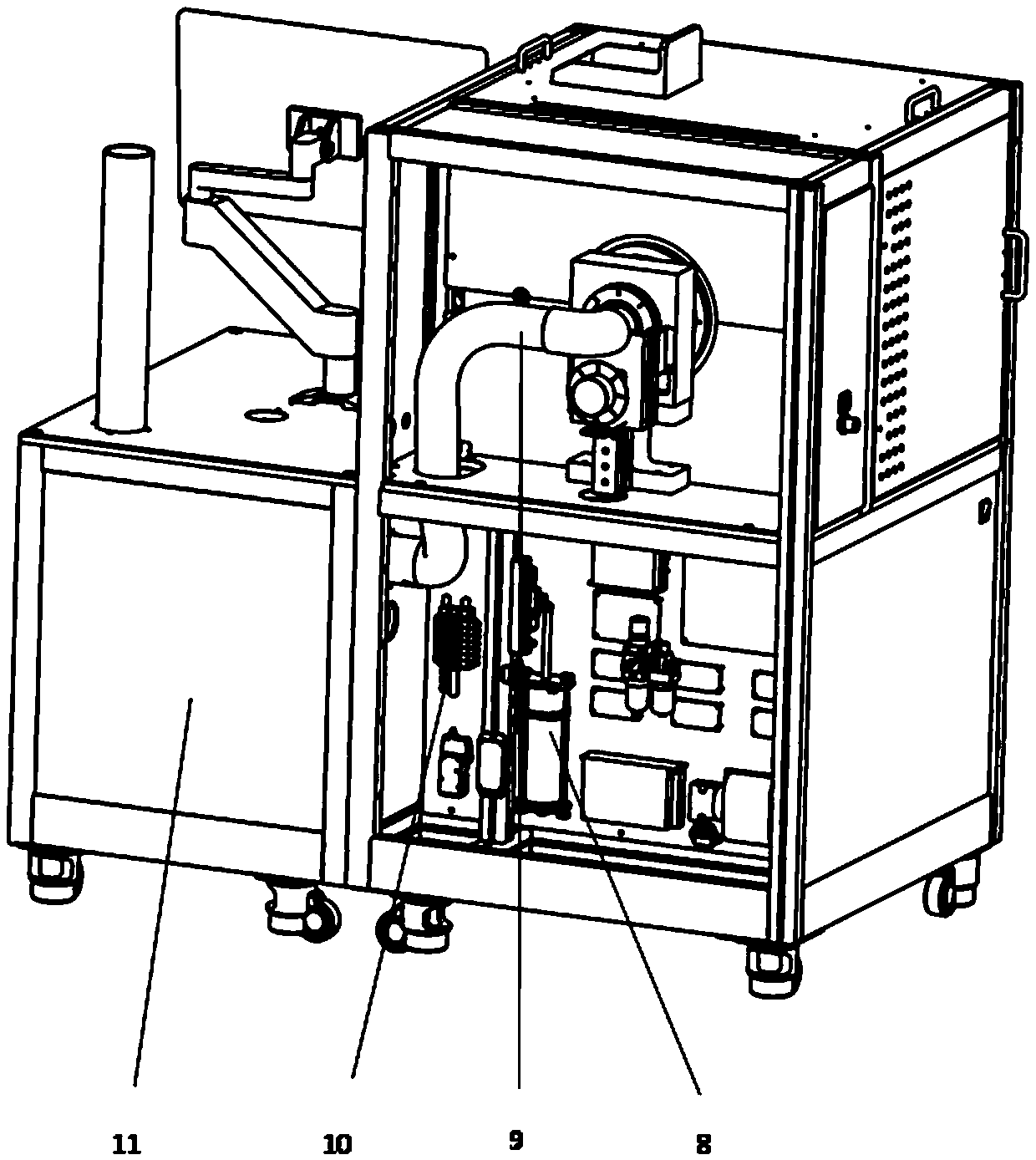

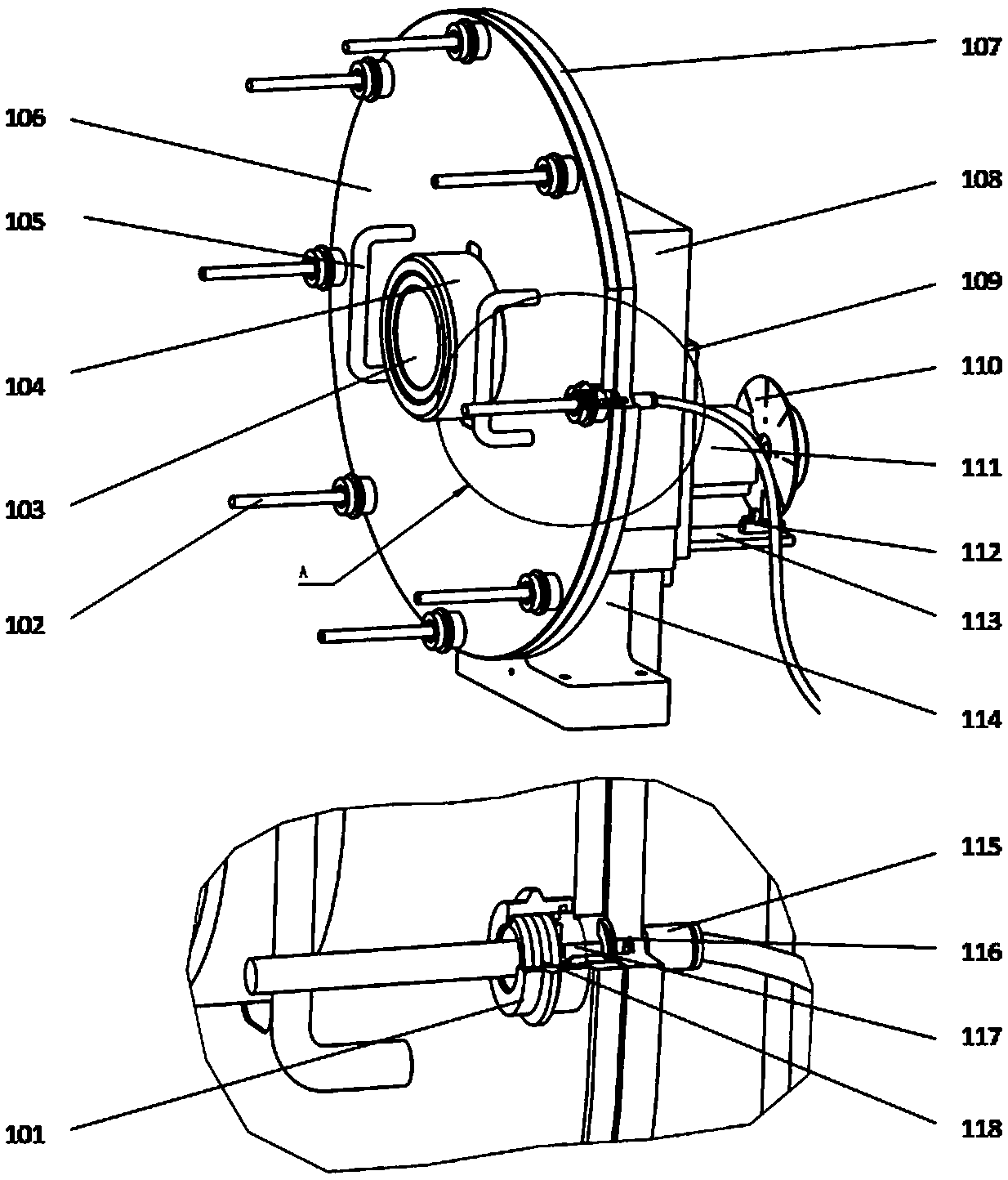

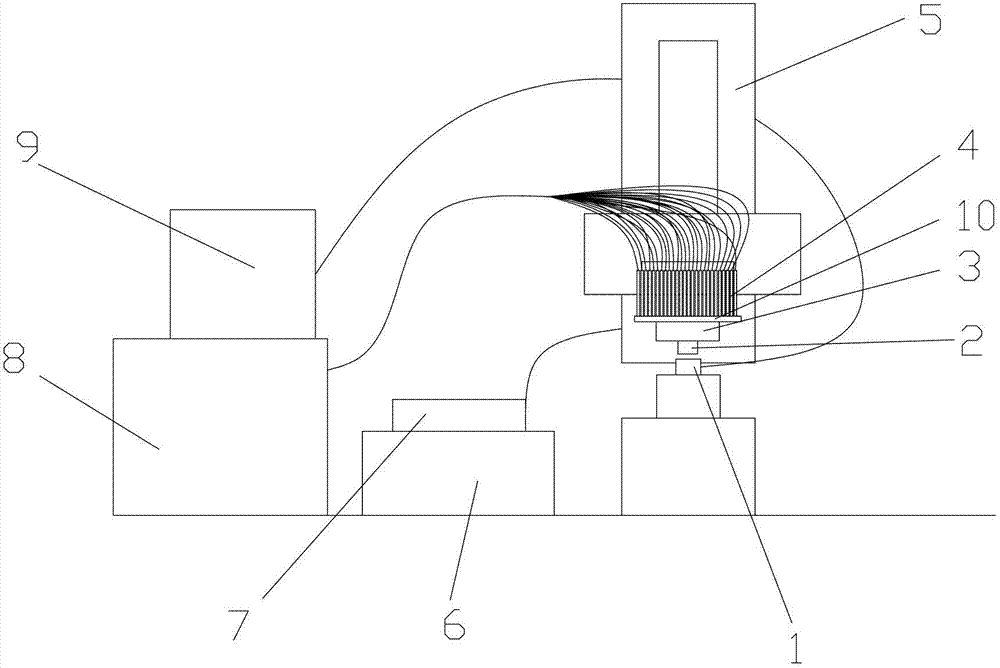

Full-automatic multi-channel cigarette drop tendency detection device and detection method

ActiveCN108037300ASimultaneous testingImprove test repeatabilitySamplingCigarette manufactureCombustionEngineering

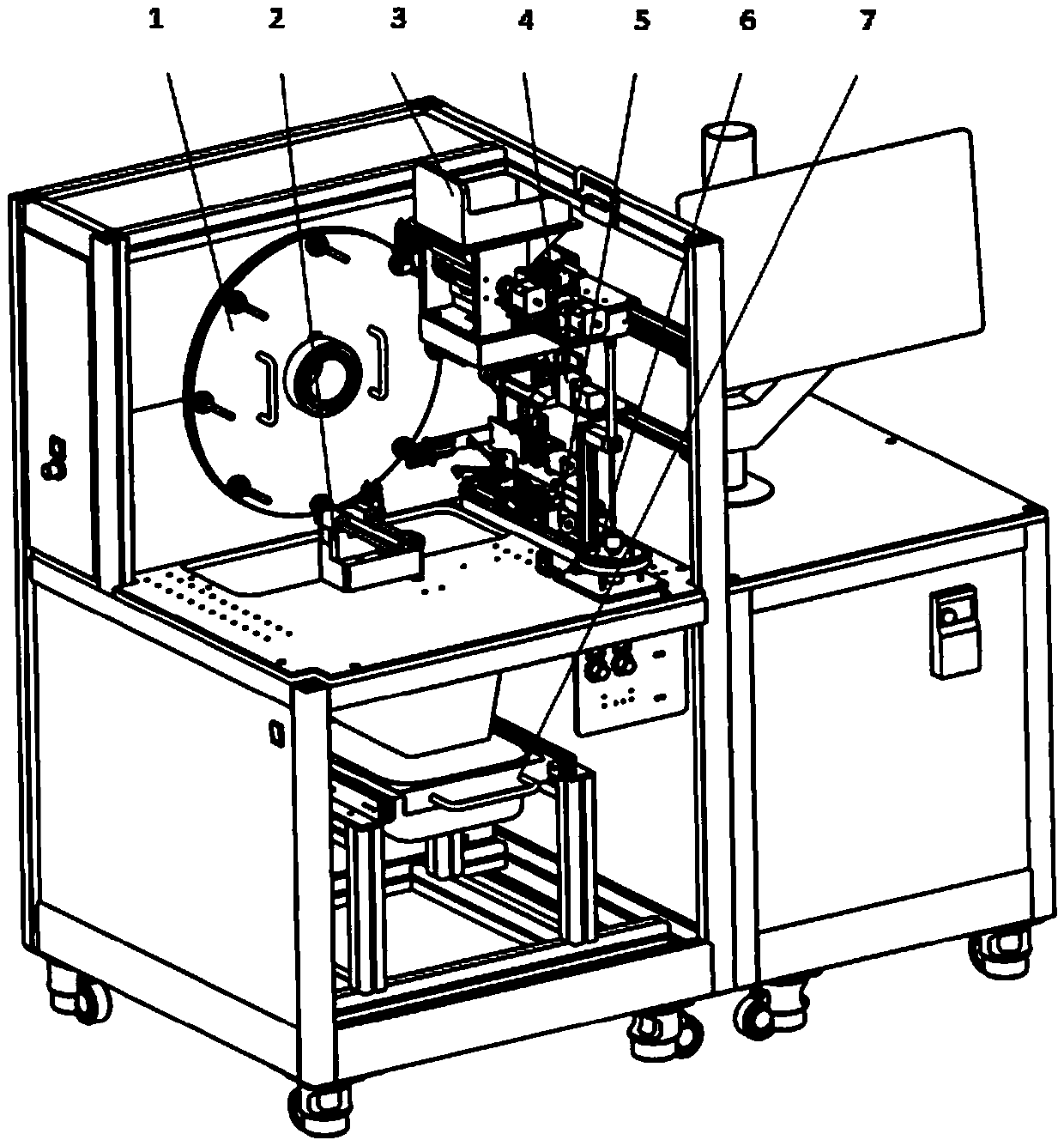

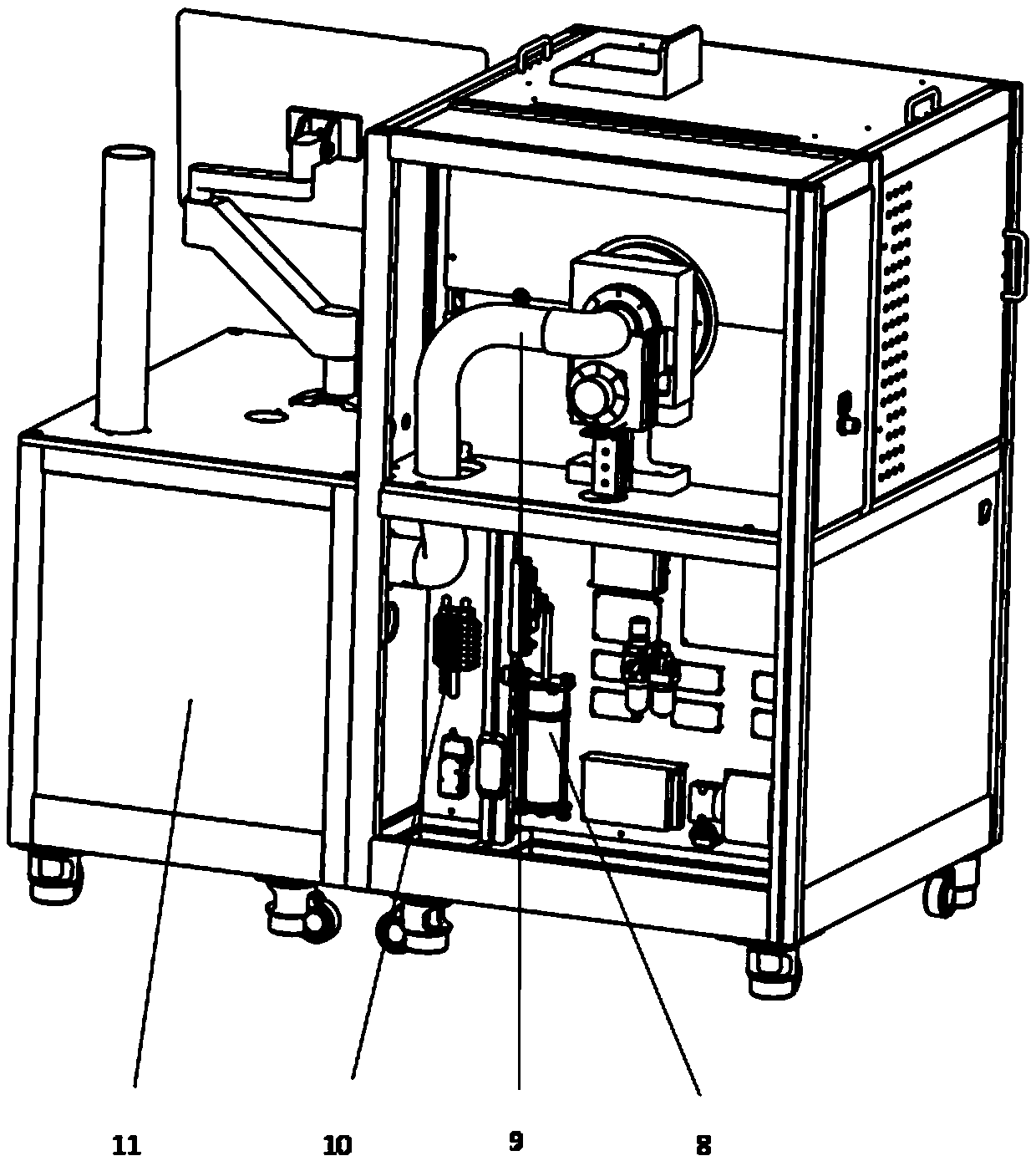

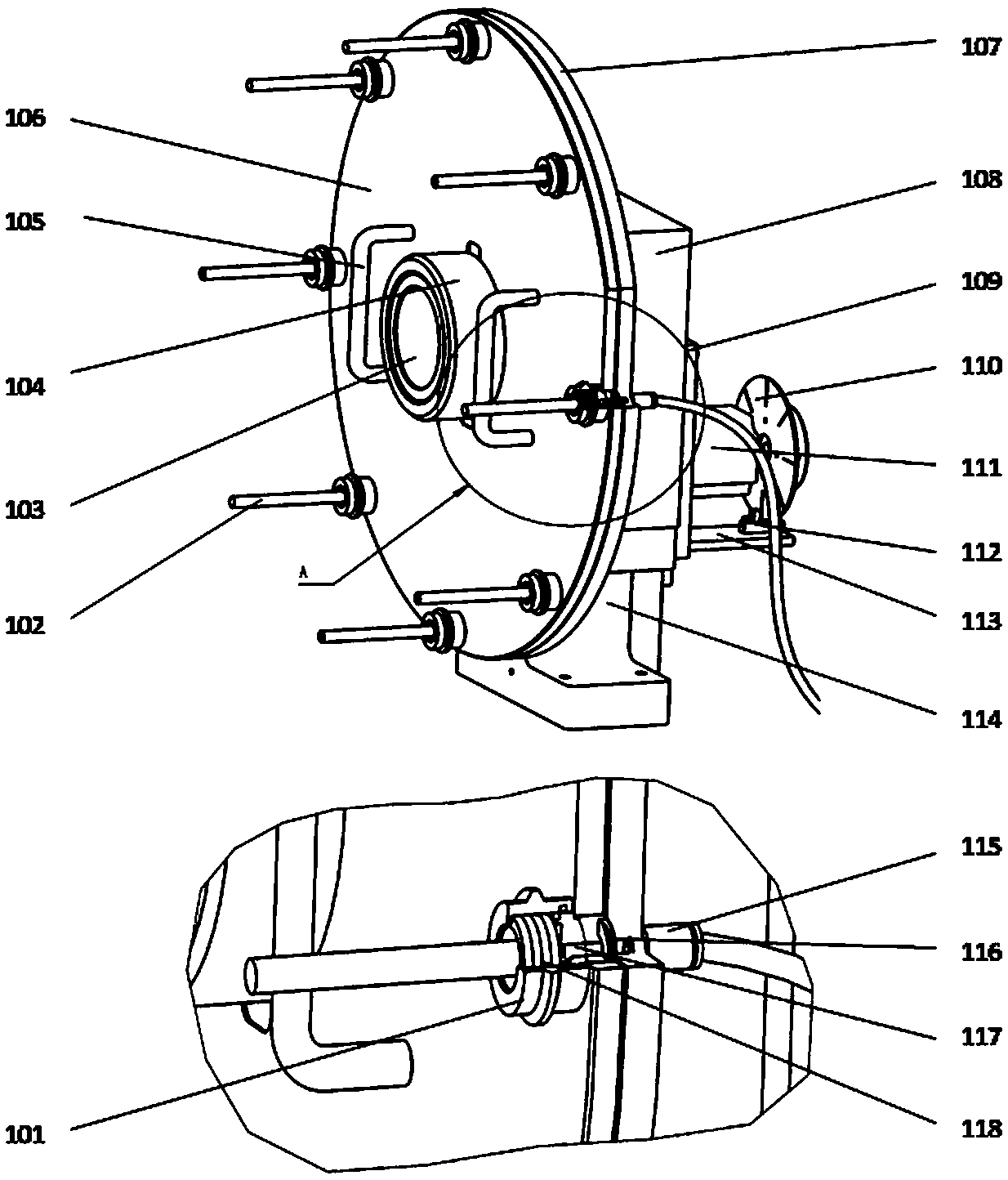

The invention discloses a full-automatic multi-channel cigarette drop tendency detection device and a detection method. The detection device is characterized by comprising a multi-channel rotating disc structure unit, an automatic cigarette sample feeding unit, an automatic cigarette sample ignition and combustion line detection unit, a tested cigarette clamping and stressing unit, an automatic drop detection and taking unit, a smoking fume capturing unit during smoking, a smoking unit and a fume exhaust unit which are arranged in a main body frame, and a circuit and gas path control unit forcontrolling action and process of the units. By adopting the detection device, according to certain steps, cigarette samples sequentially inserted into a rotating disc are automatically ignited, combustion lines are detected, controllable external force is applied to the combusting cigarette samples, and cigarette drop tendency of the cigarette products is detected according to the phenomena of drops of multiple cigarette samples. By adopting the detection device, the testing repeatability and the working efficiency can be improved.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

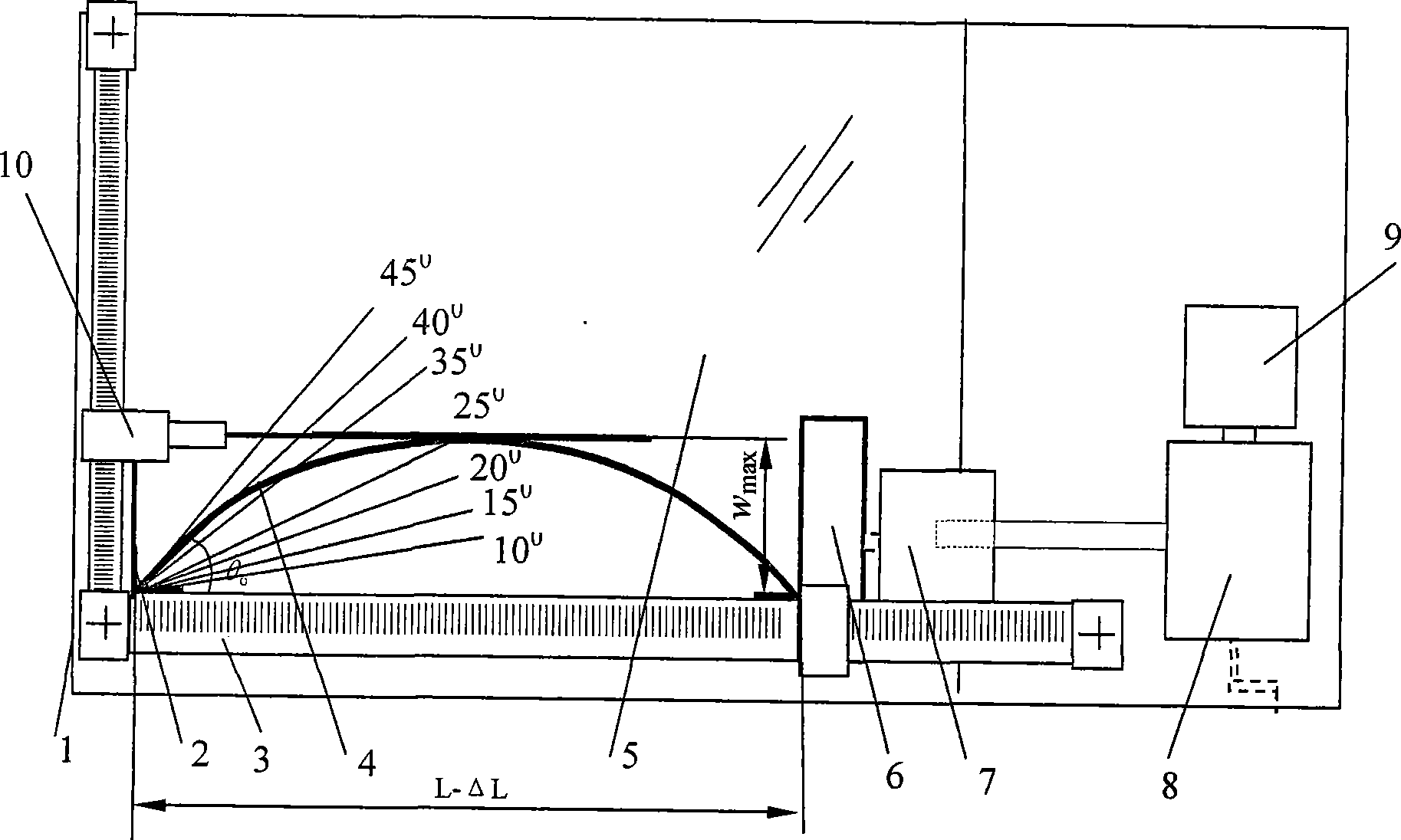

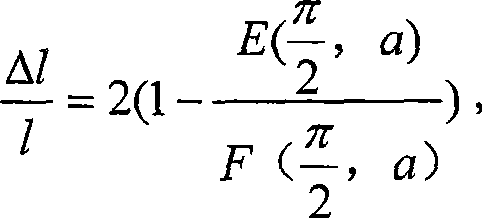

Fine dried noodle bending and breaking rate measuring method and determinator based on axial compression amount

InactiveCN101451934ASimultaneous testingImplement testMaterial strength using steady bending forcesTesting foodAxial compressorAxial compression

The invention discloses a dried noodle bending fracture rate measuring method based on axial amount of compression and a goniophotometer. First dried noodles in certain number are extracted, cut into given length, separatively fixed between a static supporting baffle and a movable supporting baffle. Then a motor is started, for driving a stepless speed change device and a nut screw, the movable supporting baffle is pushed to cause the dried noodles to generate axial compression unstable bending; the size of axial amount of compression is read by a horizontal type electronic digital staff gauge. The dried noodle are broken when the axial amount of compression of the movable supporting baffle does not reach the given axial amount of compression, namely a bent fracture strip; percent of the number of bent fracture strip to the number of extracted ones is the dried noodle bending fracture rate. According to the invention, objective measurement is realized through mechanics of materials pressure lever stability principle and large-deflection theory and stress equivalence principle, the bending fracture rate is correctly measured, measurement is more scientific and precise.

Owner:JIANGSU UNIV

System for automatically testing service life of probe

ActiveCN102768348AEnables automated assessmentPrecise positioningElectrical measurementsData processing systemTester device

The invention discloses a system for automatically testing the service life of a probe. The system comprises a touching force sensor, the probe, a probe clamp, a probe electrode outgoing line, an up-down moving device, a four-wire type tester and a data processing system, wherein the data processing system is used for automatically saving tested data and analyzing the data in real time. The system is characterized in that the probe clamp is mounted on the moving end of the up-down moving device; the probe is mounted below the probe clamp; a circuit board for leading out the electrode of the probe is mounted above the probe clamp and is connected with the input end of the four-wire type tester by the probe electrode outgoing line; the touching force sensor is fixed under the probe and is connected with the data processing system by a wire; and the output end of the four-wire type tester is connected with the data processing system. The system for automatically testing the service life of the probe is simple in structure and precise in tested data, and can implement the automatic evaluation for the service life of the probe.

Owner:CENT SOUTH UNIV

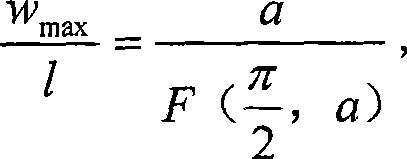

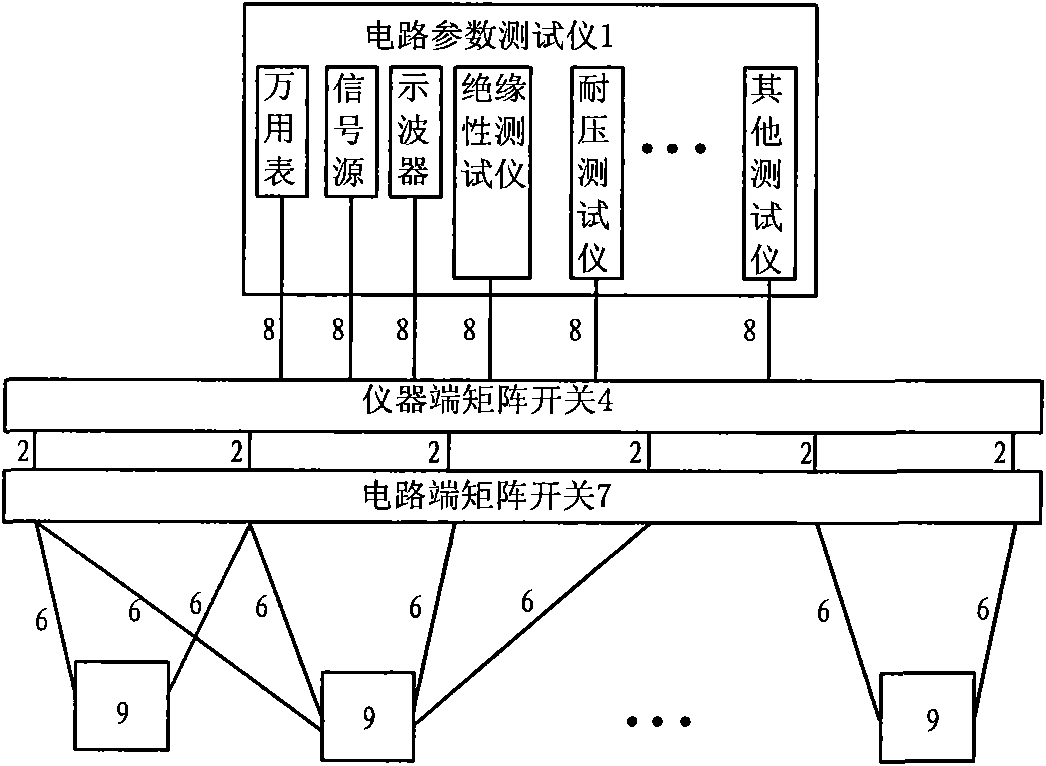

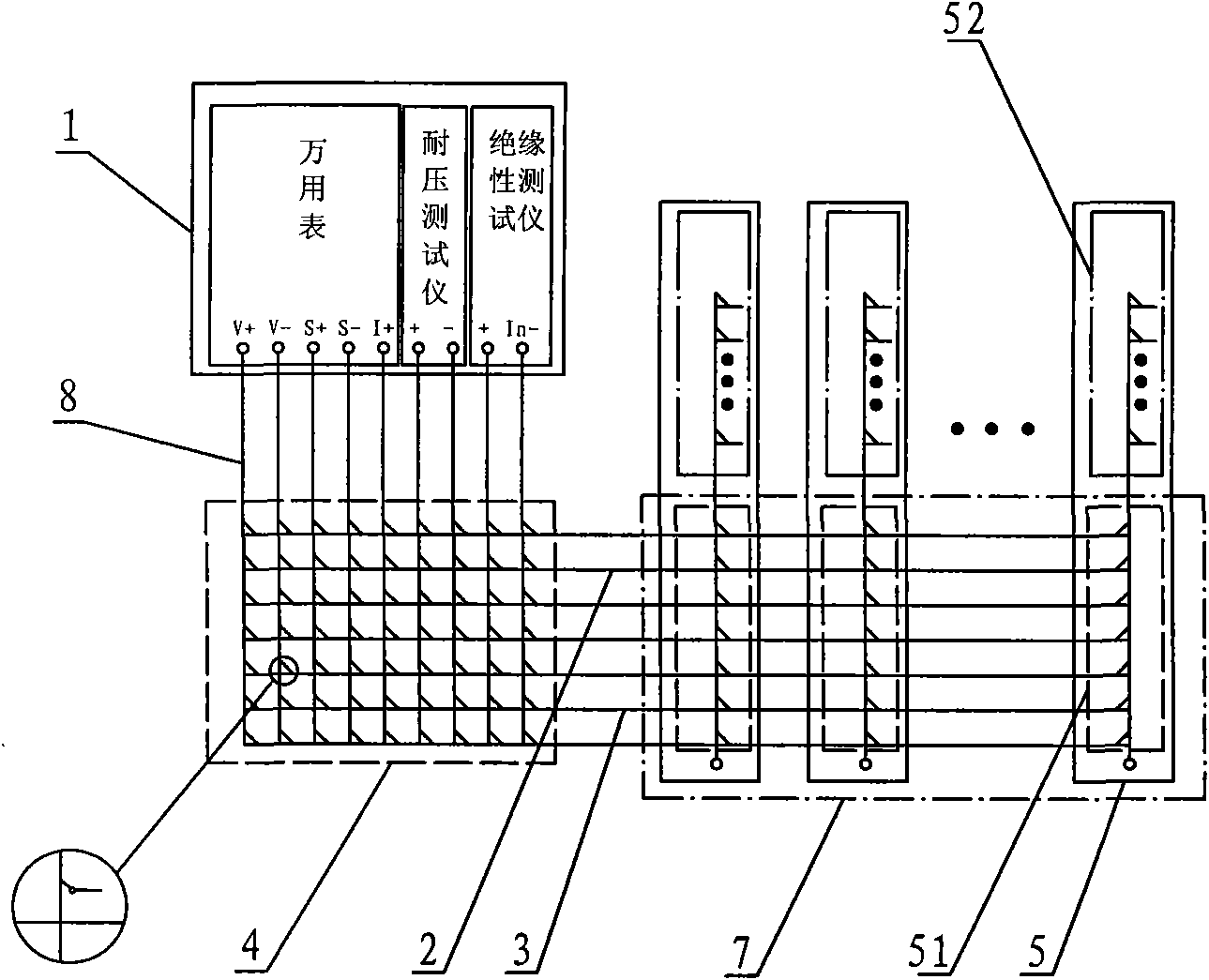

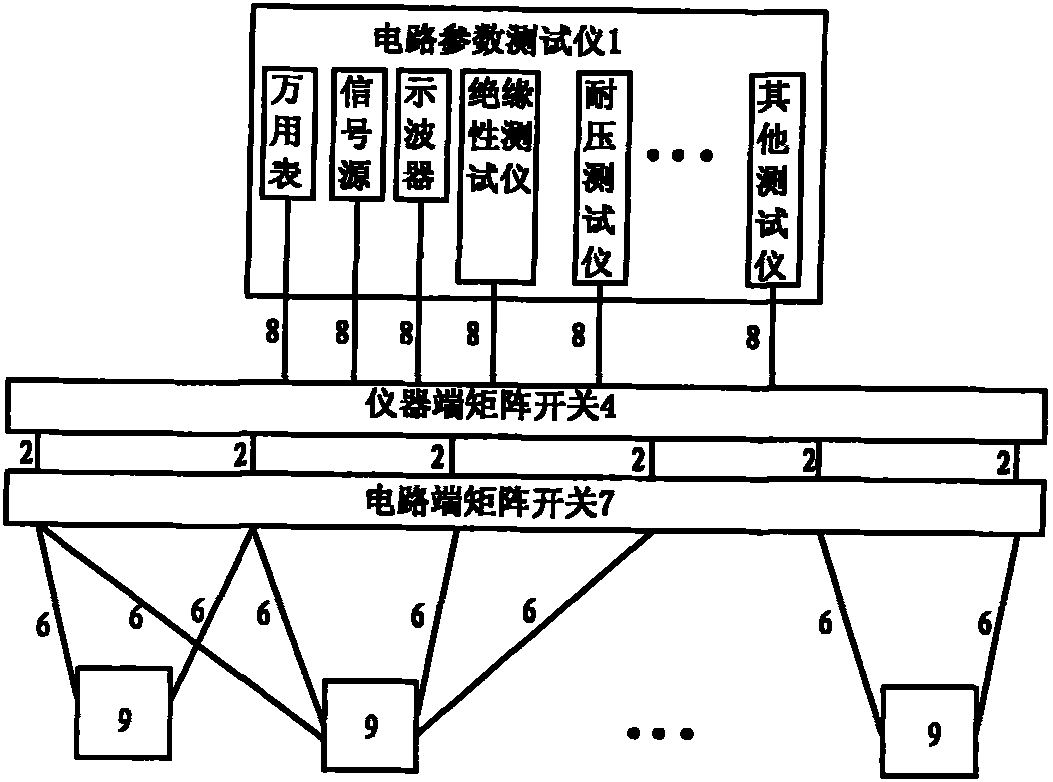

Circuit parameter multi-point tester

ActiveCN101876685AAchieve any extensionSimultaneous testingTesting dielectric strengthElectronic circuit testingMultiway switchingTester device

The invention relates to a circuit parameter multi-point tester which comprises at least one circuit parameter multi-point testing apparatus, an analogue bus, a multi-way switch group and a commutator, wherein the multi-way switch group comprises a plurality of multi-way switches; and the commutator is used for connecting the multi-way switches and circuits to be tested. The circuit parameter multi-point tester also comprises an apparatus end matrix switch which is used for gating between an apparatus test wire and the analogue bus; and each multi-way switch comprises an analogue bus connecting switch and a circuit connecting switch, and the analogue bus connecting switch of the multi-way switch group and the analogue bus form a circuit end matrix switch which is used for realizing the switching of a test loop among different circuits to be tested. The invention solves the defects of poor expansibility of the testing apparatus in the circuit parameter test, incapability of simultaneously working of a plurality of testing apparatuses, waste and inflexible test, and has the advantages of strong expansibility and flexible topological structure.

Owner:陕西海泰电子有限责任公司

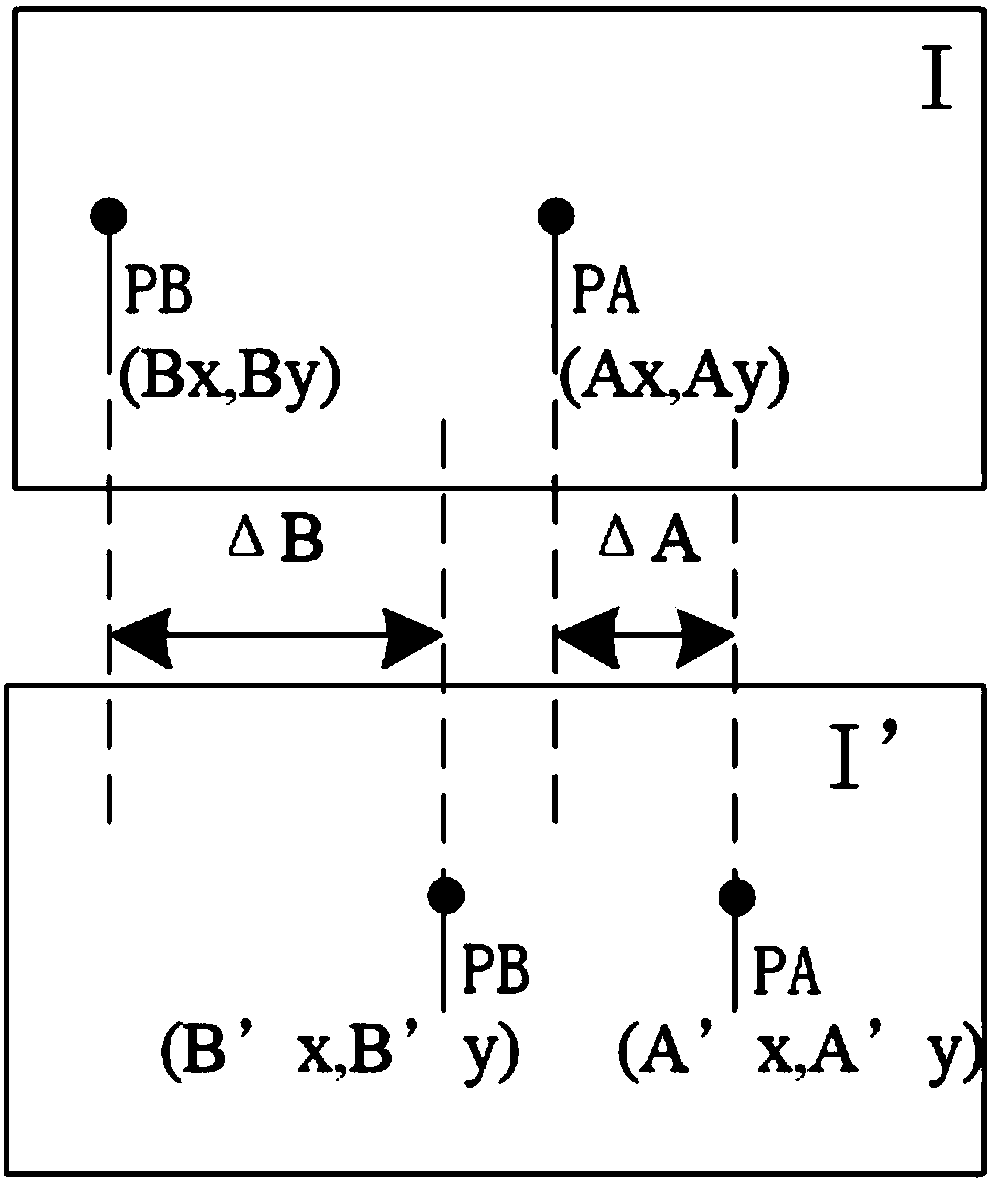

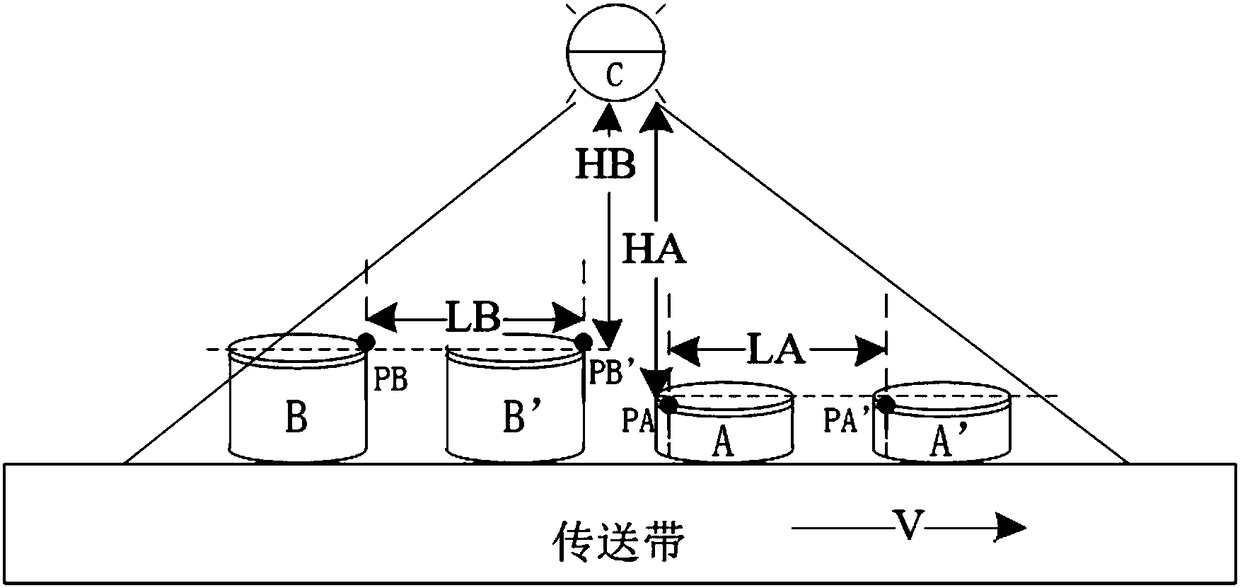

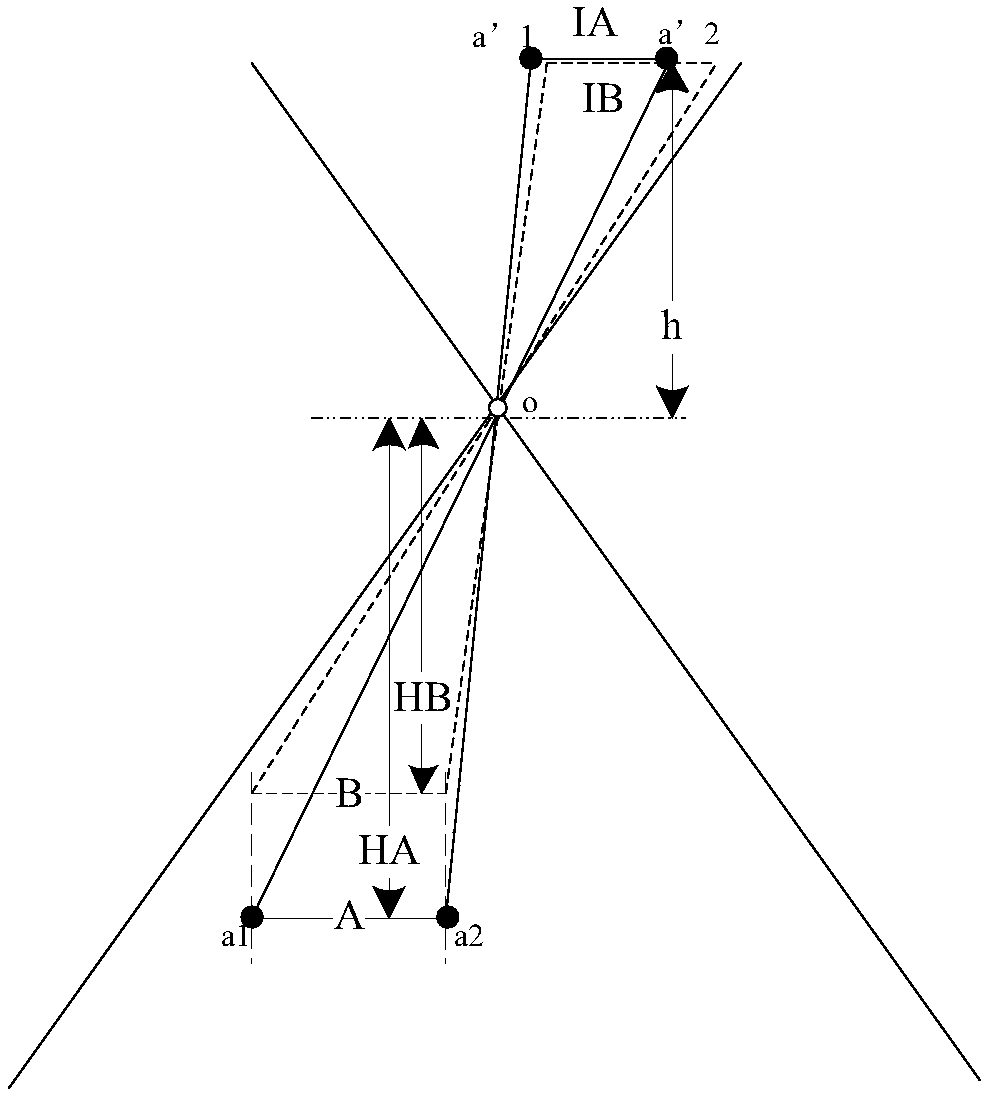

Automatic focusing method and system of scanning code device

ActiveCN108509816AQuickly adjust focusImprove efficiencySensing by electromagnetic radiationPhysicsOphthalmology

The invention belongs to the focal length adjustment technical field and relates to an automatic focusing method of a scanning code device. The method includes the following steps that: the running speed value of a conveyor belt is preset, and the focal length of the lens of the scanning code device is adjusted to be a default focal length; images are acquired according to a fixed time interval, measured objects on the conveyor belt in the images are judged, and the characteristic position of each measured object is calibrated; the deviation pixel values of the measured objects are obtained according to the deviation of the characteristic positions of the measured objects in the fixed time interval; vertical distances between the measured objects and the lens are calculated; and the focallength of the lens is automatically adjusted according to the vertical distances between the measured objects and the lens. The present invention also provides an automatic focusing system corresponding to the automatic focusing method. According to the automatic focusing method of the invention, a distance measuring device such as a distance sensor is not required to be additionally adopted, thedistances between the measured objects and the scanning lens can be quickly determined, and the focal length of the lens can be quickly adjusted.

Owner:HANGZHOU SYNOCHIP DATA SECURITY TECH CO LTD

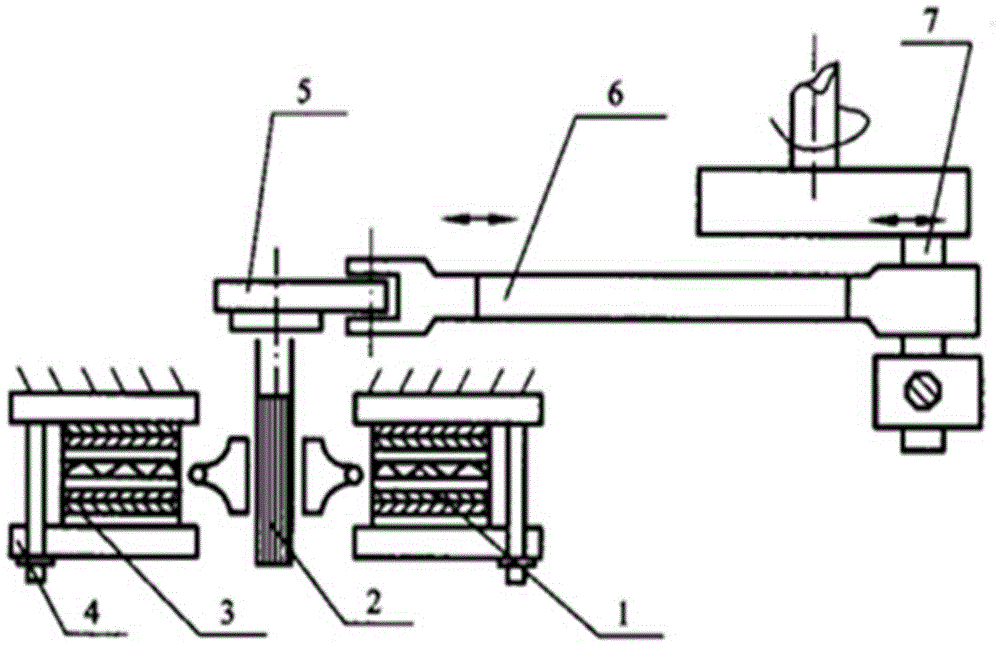

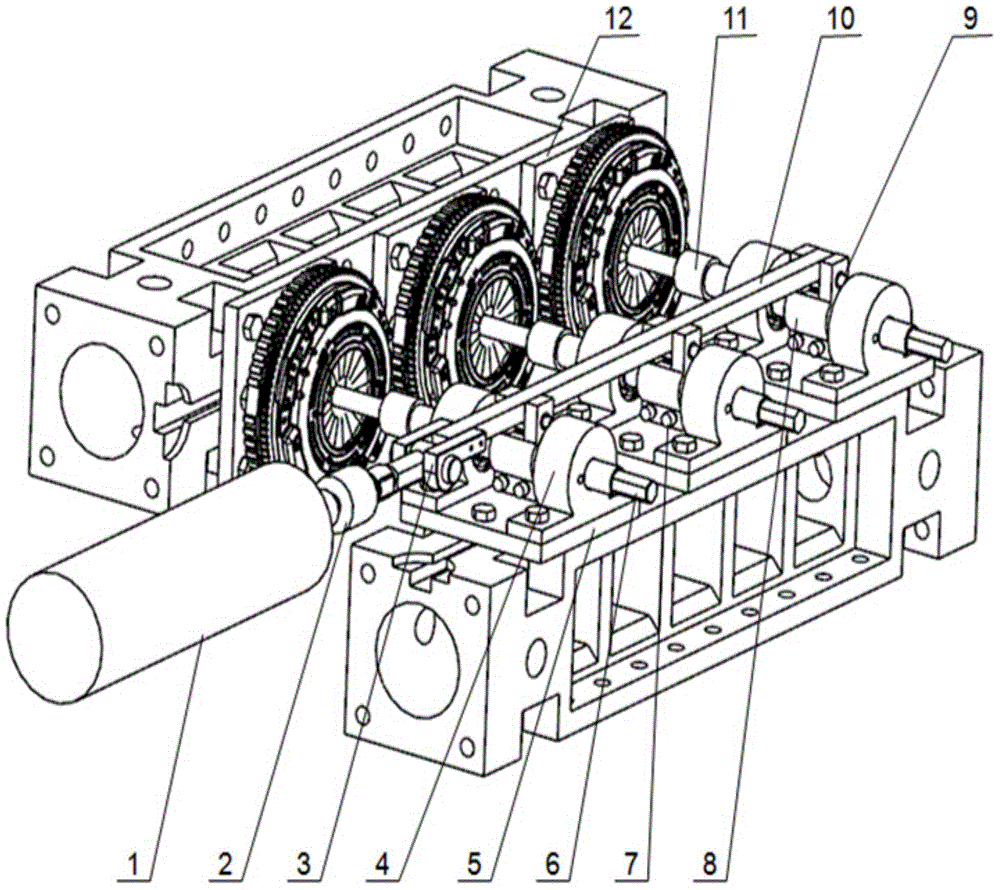

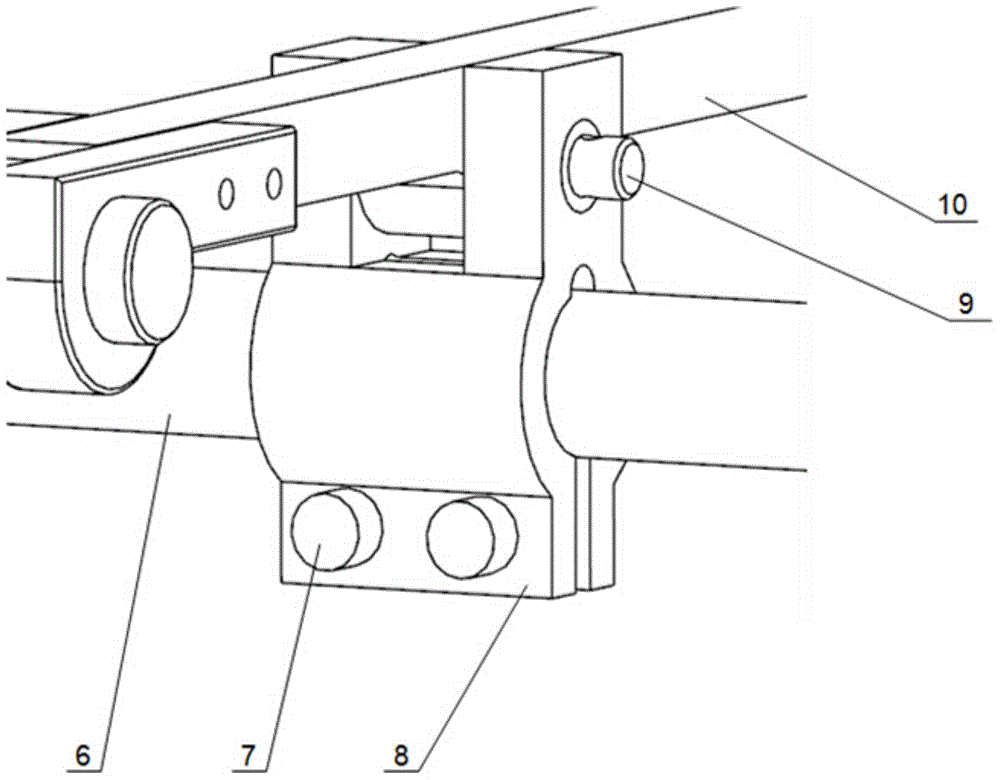

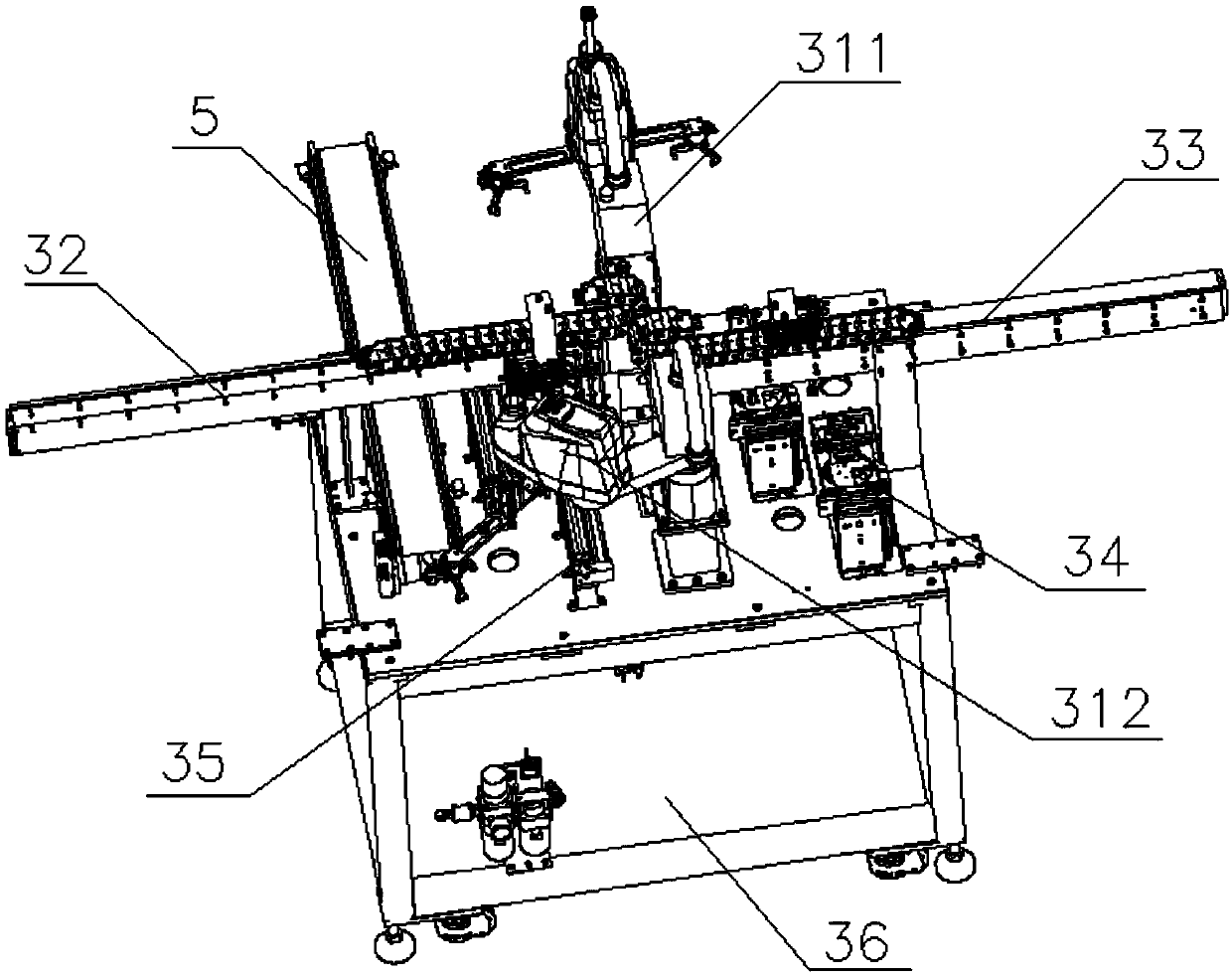

Clutch driven plate torsion durability testing device

InactiveCN104614180ASimultaneous testingReal-time monitoring of torsion angleMachine gearing/transmission testingCouplingLoad torque

The invention provides a clutch driven plate torsion durability testing device. The clutch driven plate torsion durability testing device comprises an actuator, a rocker bar and a linkage mechanism. The actuator is movably connected with the rocker bar; the linkage mechanism comprises an input shaft, a coupling sleeve and a driven plate hub, wherein the coupling sleeve is fixedly connected with the rocker bar and the input shaft; the rocker bar moves linearly to drive the coupling sleeve and the input shaft to rotate; one end of the input shaft is connected with the driven plate hub. The clutch driven plate torsion durability testing device has the advantages of being capable of adjusting torsion angle and loaded torque by controlling travel of the actuator, monitoring the torsion angle and the loaded torque in real time through an angle and torque sensor, and meanwhile, achieving simultaneous testing of multiple samples.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

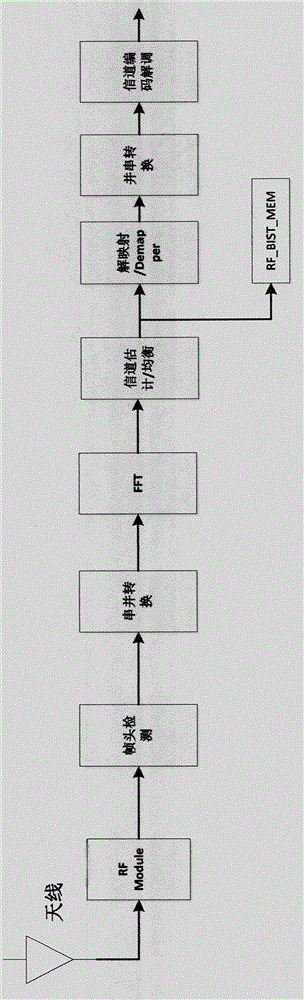

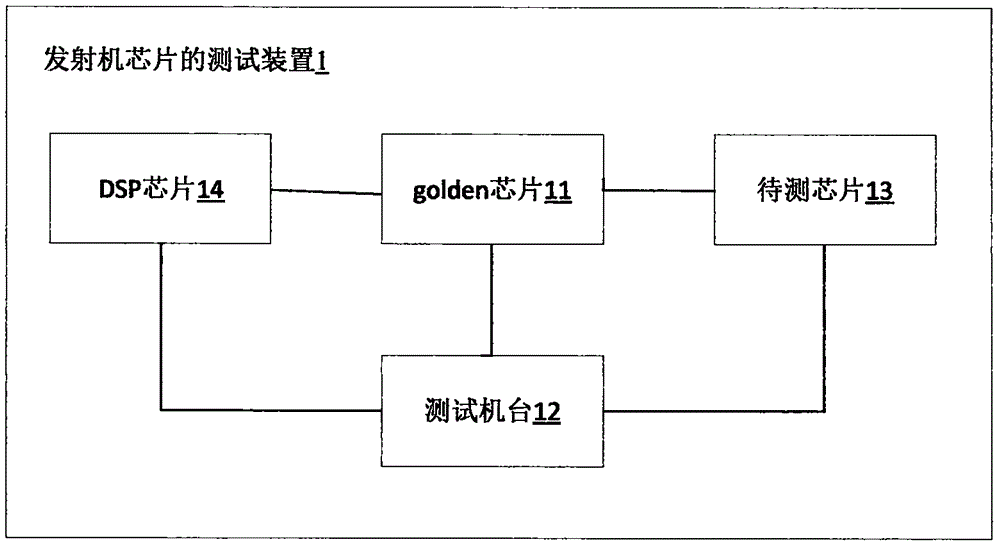

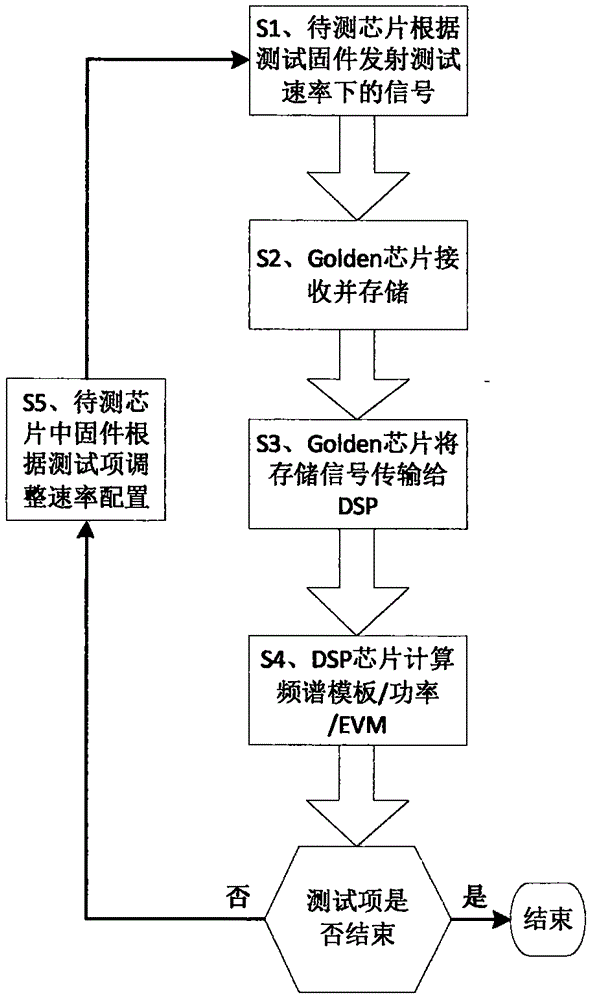

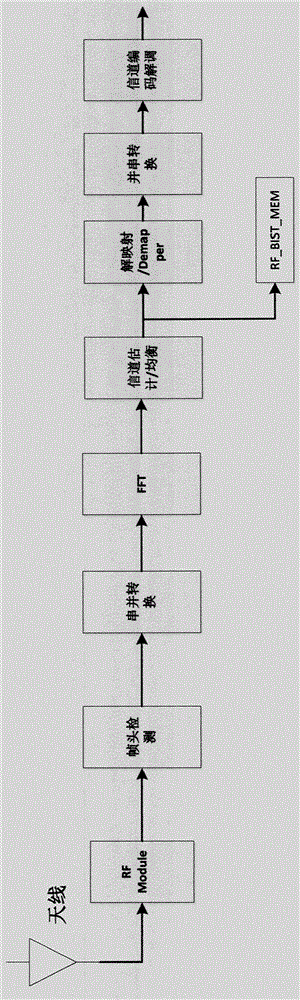

Method and apparatus for testing transmitter chip

InactiveCN105897350AFully automatedSimultaneous testingTransmitters monitoringDigital signal processingComputer science

The invention relates to a method and apparatus for testing a transmitter chip. The method comprises the steps: receiving a signal of a chip to be tested according to the transmitted test rate of a test firmware; sending the signal under the test rate to a digital signal processing chip so as to enable the digital signal processing chip to calculate and analyze the signal under the test rate to obtain the test result; and sending the test result to a testing machine. The method and apparatus for testing a transmitter chip utilize the chip to transmit and receive the signal of a chip to be tested and to analyze the signal so as to replace an instrument in a traditional calibration and testing mode, and can realize automatic calibration and testing through the firmware.

Owner:BEIJING WINNER MICROELECTRONICS

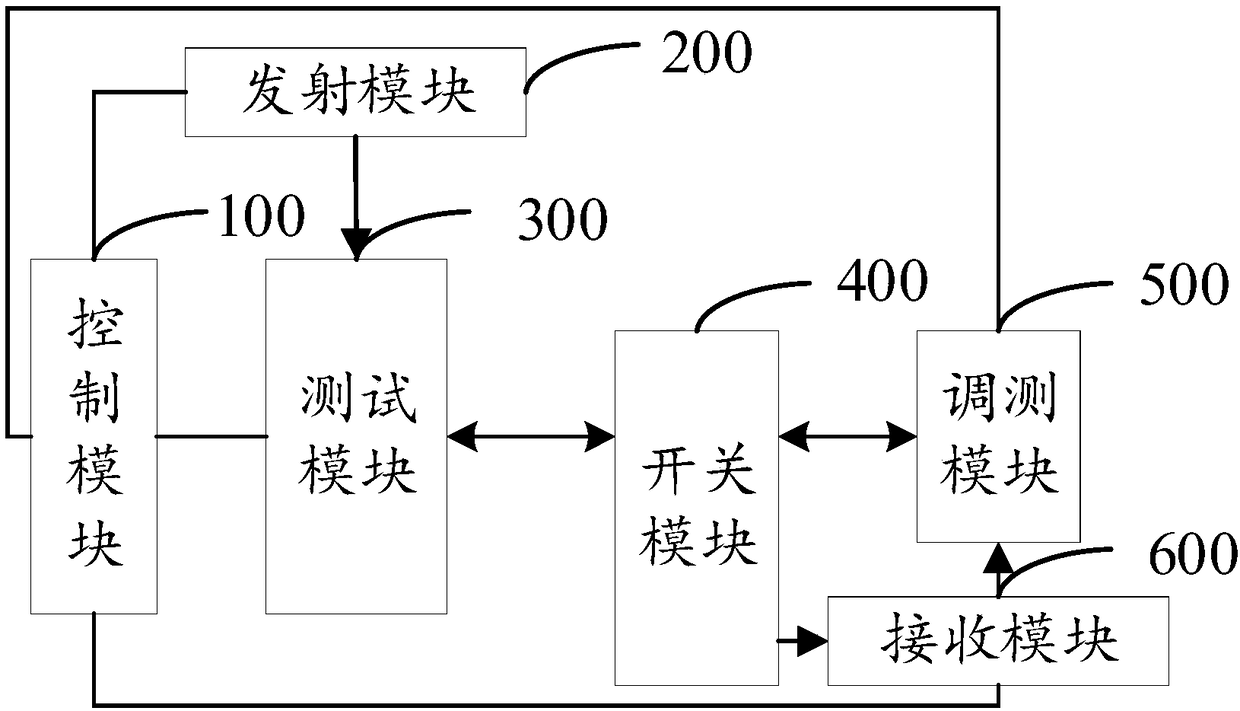

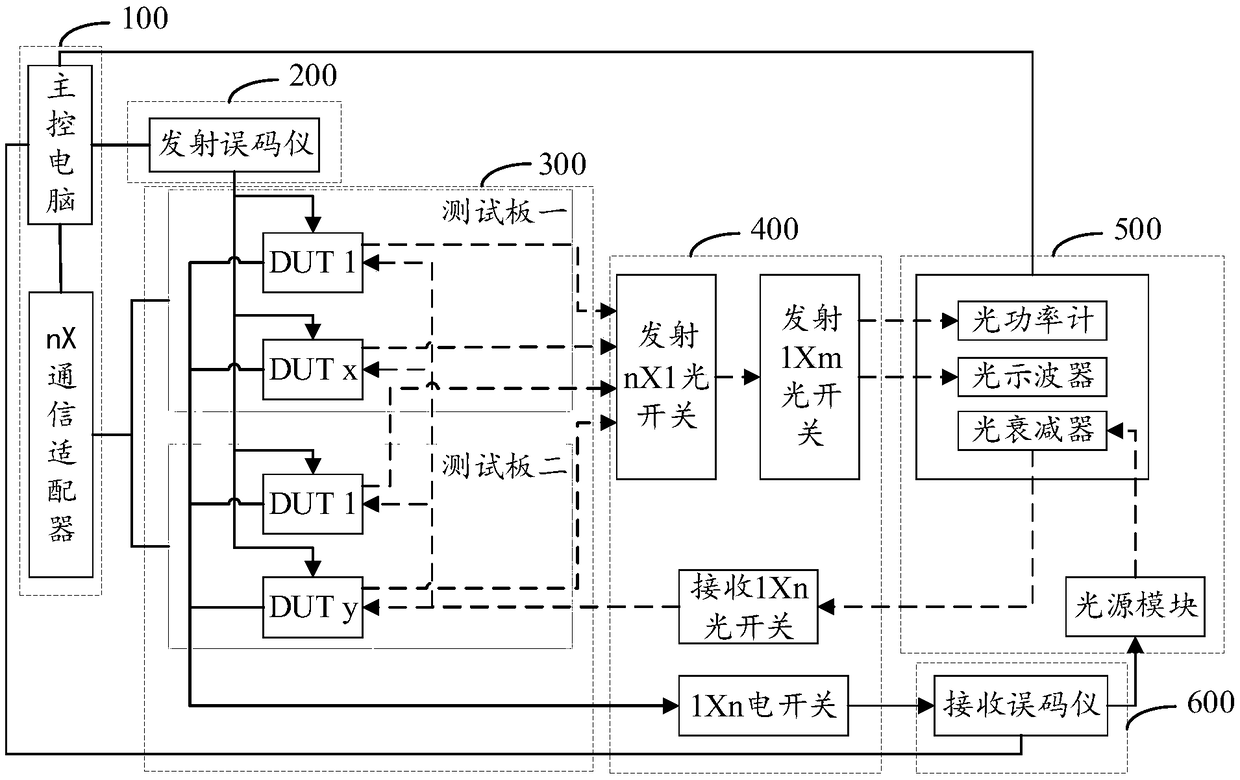

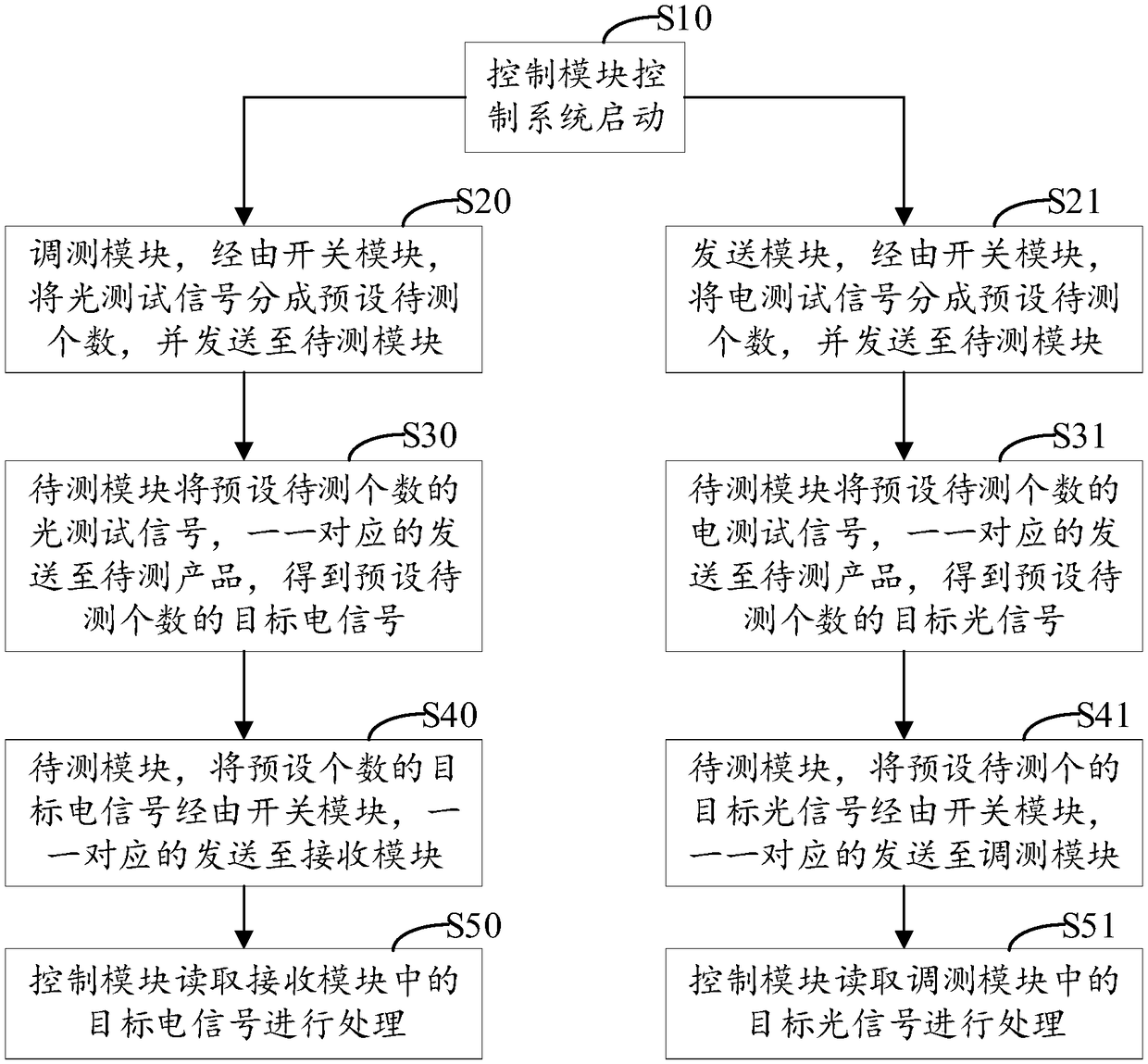

Automatic adjusting device for optical communication device, method, equipment and storage medium

PendingCN109167634ASimultaneous testingOptimize the testing processElectromagnetic transceiversOptical ModuleFunctional testing

The invention discloses an optical communication device automatic adjusting device, a method, equipment and a storage medium. Through the debugging and calibration process of the optical module, an optical module testing process and an optical device testing process are redesigned. The optical communication device products are packaged in the host computer, including debugging, calibration, testing and other functions. The optical communication device products are packaged into different functional test functions according to the different test functions. Thus, the debugging and calibration ofthe optical module and the testing of the optical device are carried out together, the utilization rate of the instrument and equipment is effectively improved, and the production efficiency is greatly improved.

Owner:APAT OPTOELECTRONICS COMPONENTS

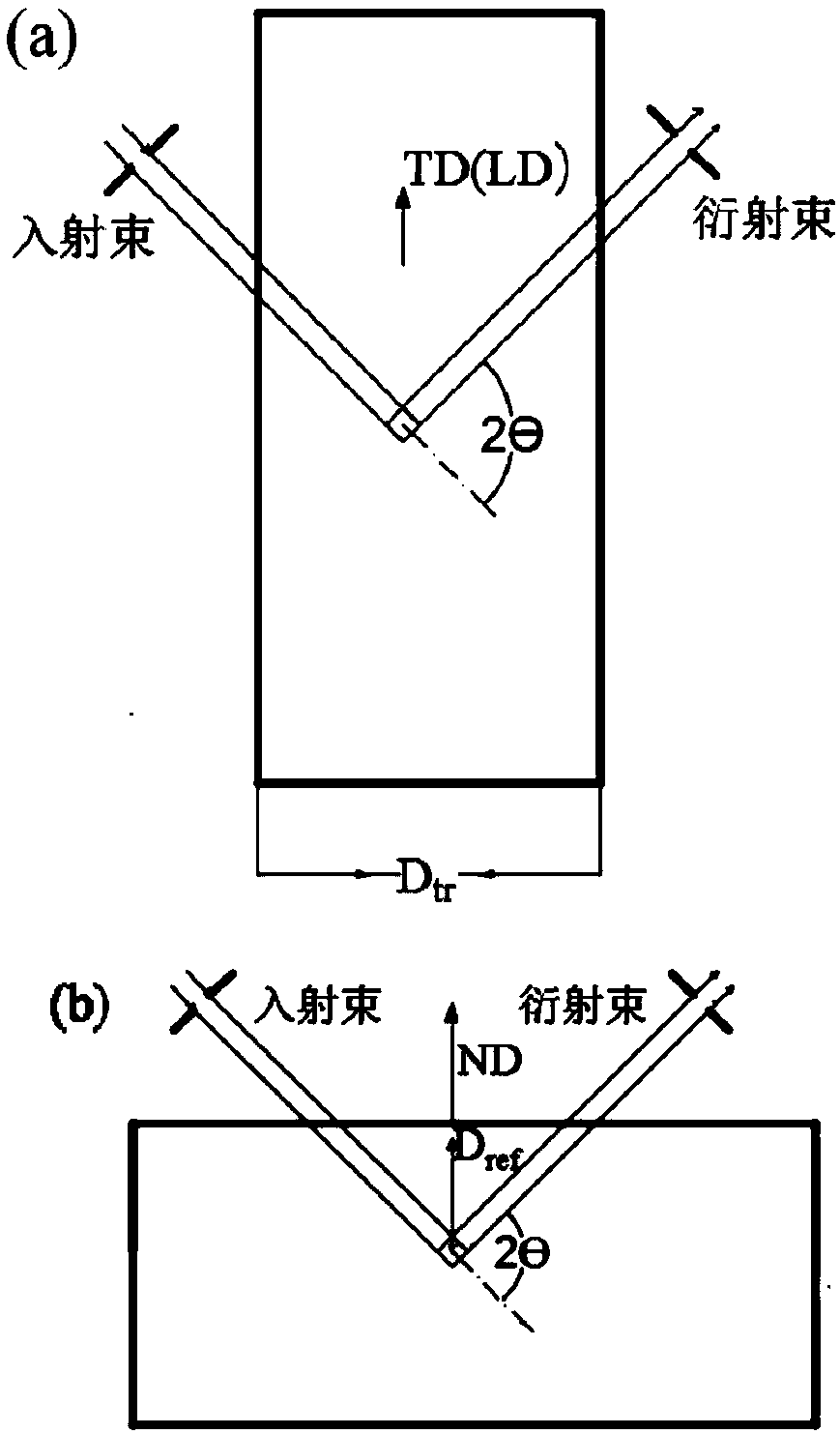

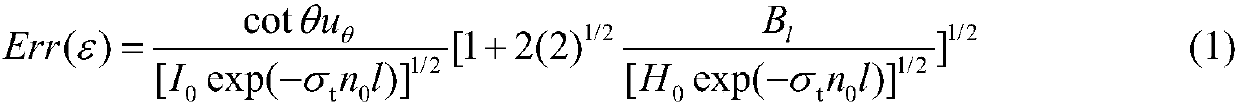

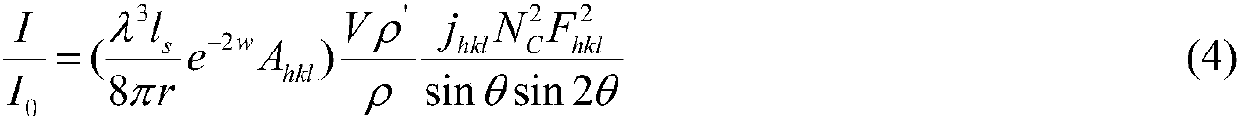

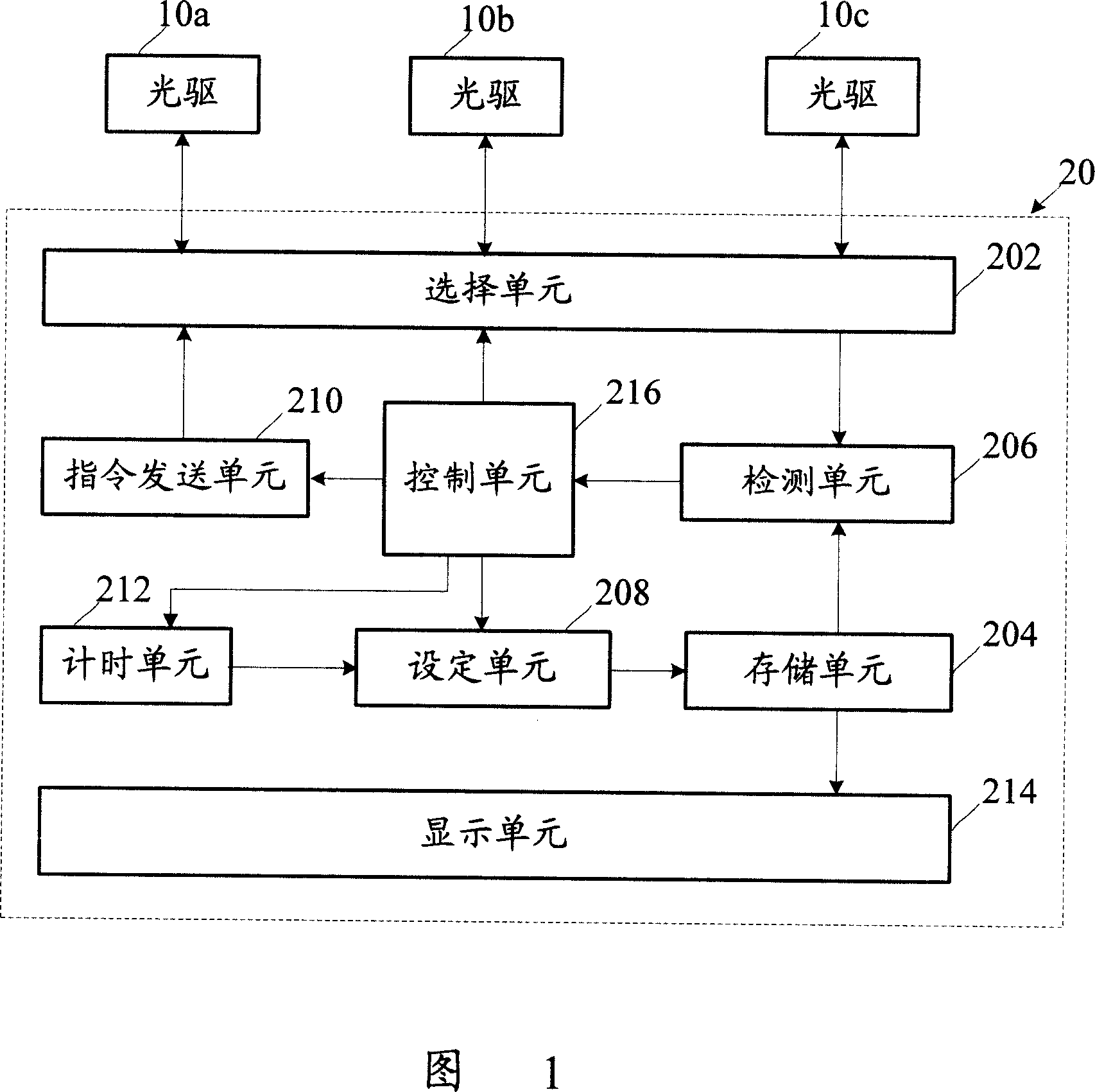

Neutron diffraction method for welding residual stress of duplex stainless steel thick plate

ActiveCN108490009AStrong penetrating powerReduce time errorMaterial analysis using wave/particle radiationApparatus for force/torque/work measurementThick plateWelding residual stress

The invention discloses a neutron diffraction method for welding residual stress of a duplex stainless steel thick plate. The method comprises the following steps: determining stress testing crystal faces in different directions and a wavelength changing manner, so that a penetration depth of the neutron in the duplex stainless steel thick plate is increased, and testing time and testing errors are reduced; accurately calculating a two-phase ratio in a standard volume of the neutron diffraction test by virtue of transformation of diffraction peak intensity; and simultaneously testing two-phasestresses under specific equipment and diffraction conditions. According to the method disclosed by the invention, the penetration depth of the neutron can be effectively improved by virtue of a variable wavelength manner; the residual stress time of the duplex stainless steel thick plate in the neutron diffraction test can be reduced; the testing error of the residual stress of the duplex stainless steel thick plate can be reduced; the two-phase ratio in the standard volume can be accurately calculated by utilizing data of the diffraction peak intensity obtained by the neutron diffraction; and the influence produced by micro stress caused by two-phase performance mismatching is clear, and macro welding residual stress distribution of the duplex stainless steel is accurately calculated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

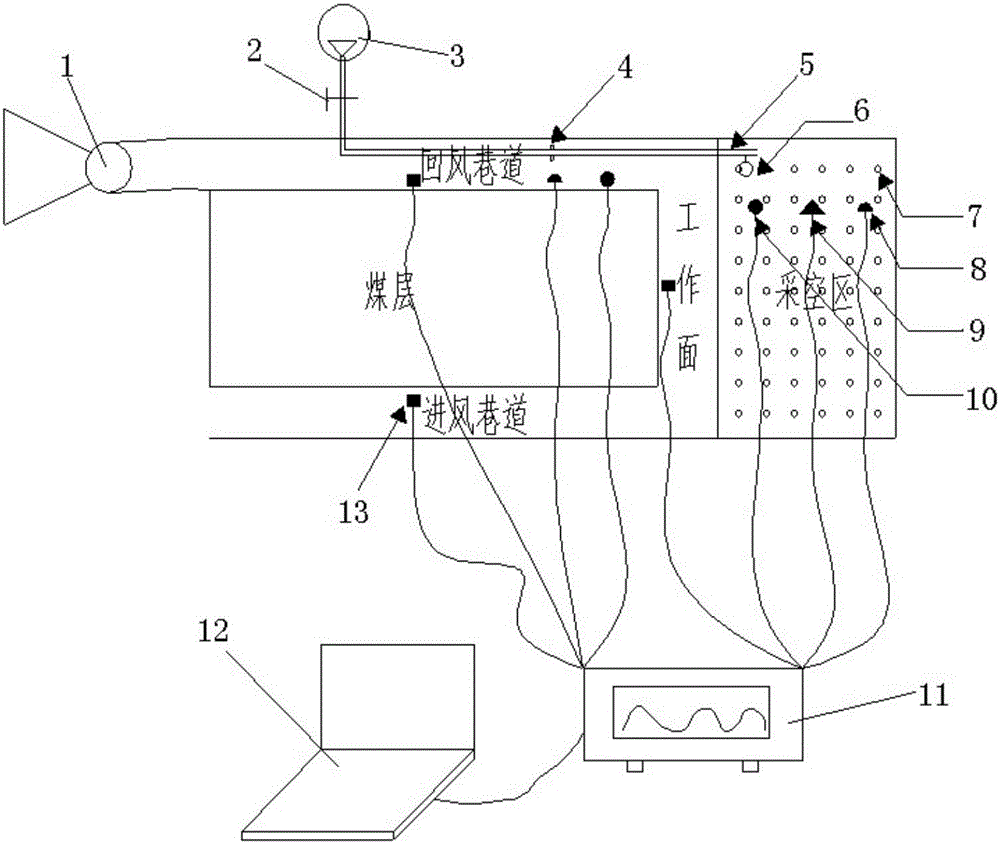

Gas Drainage and Coal Spontaneous Combustion Simulating Experimental Device in Goaf of High Gassy Coal Seam with High Spontaneous Combustion

InactiveCN103775122BPrevent spontaneous combustionSimultaneous testingTunnel/mines ventillationGas removalAir velocityCoal spontaneous combustion

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

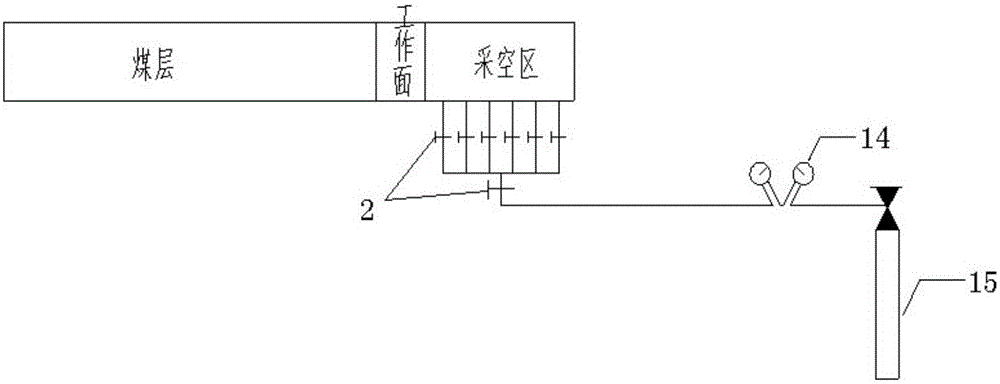

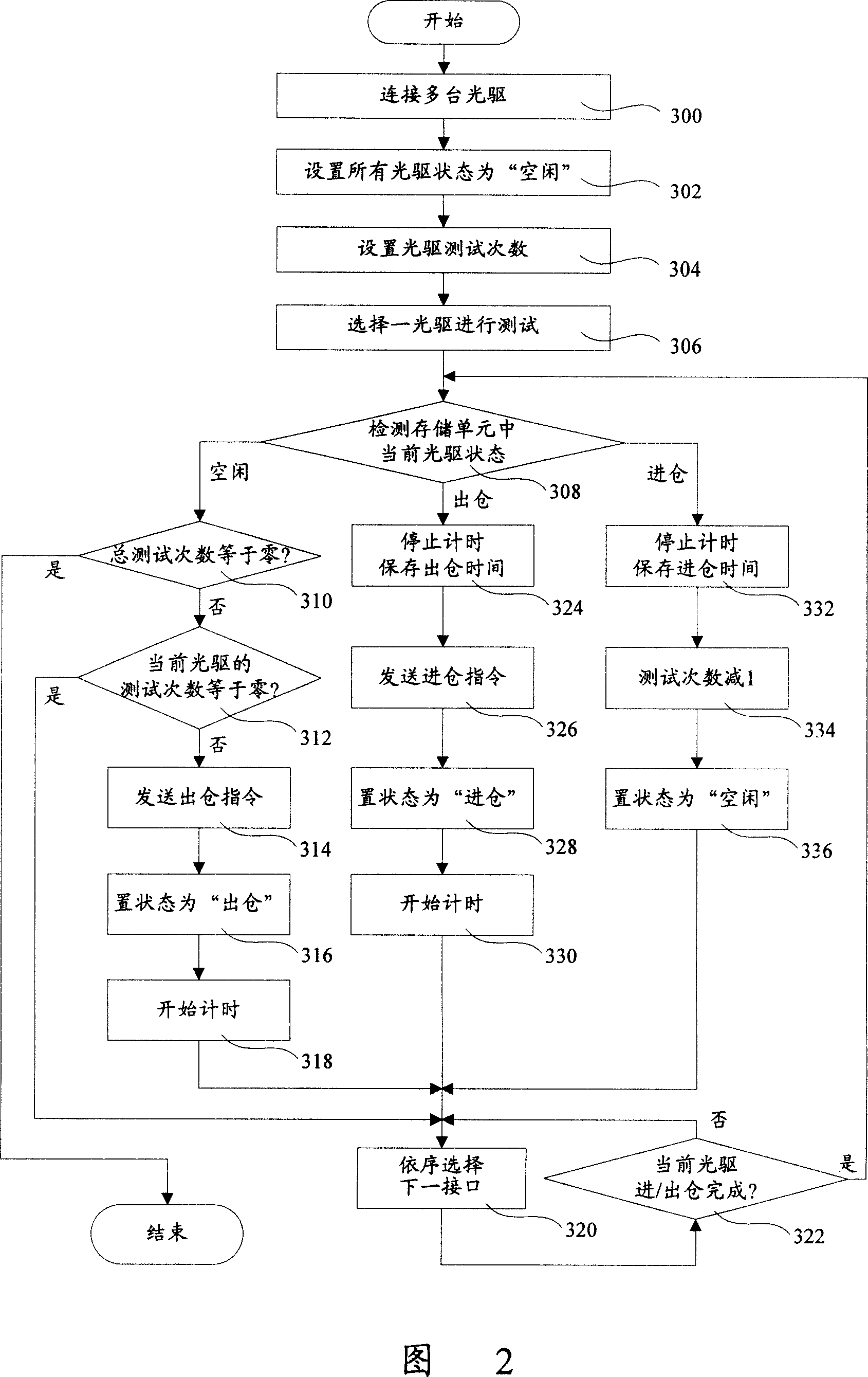

CD drive in/out tray test device and method

InactiveCN101000771AReduce average test timeImprove test efficiencyRecord information storageFunctional testing of recording headsTest fixtureElectrical and Electronics engineering

A test device of CD drive in / out tray consists of selection unit for selecting out one set of multiple optical drive to carry out test and for setting selected CD drive as current optical drive, command sending unit for sending in / out tray command to current CD drive for driving CD drive to be in / out tray, detection unit for detecting whether in / out tray of CD drive is finished or not, timing unit for recording total in / out tray time from receiving command to action finishing, control unit for controlling said selection unit to select next CD drive to be tested according to preset sequence.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

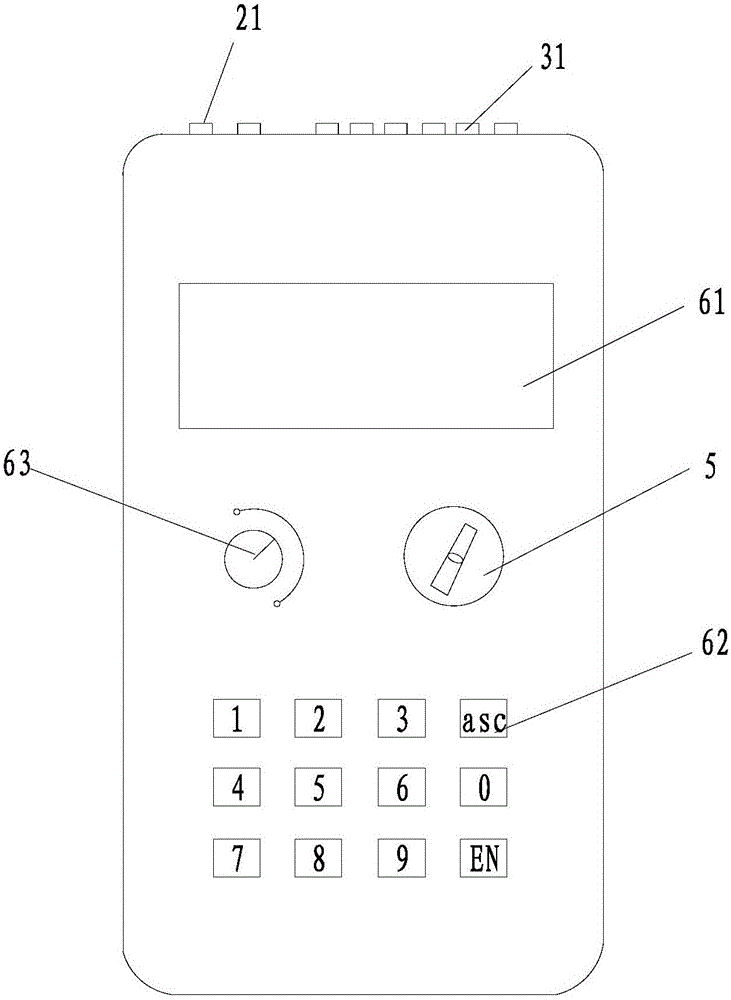

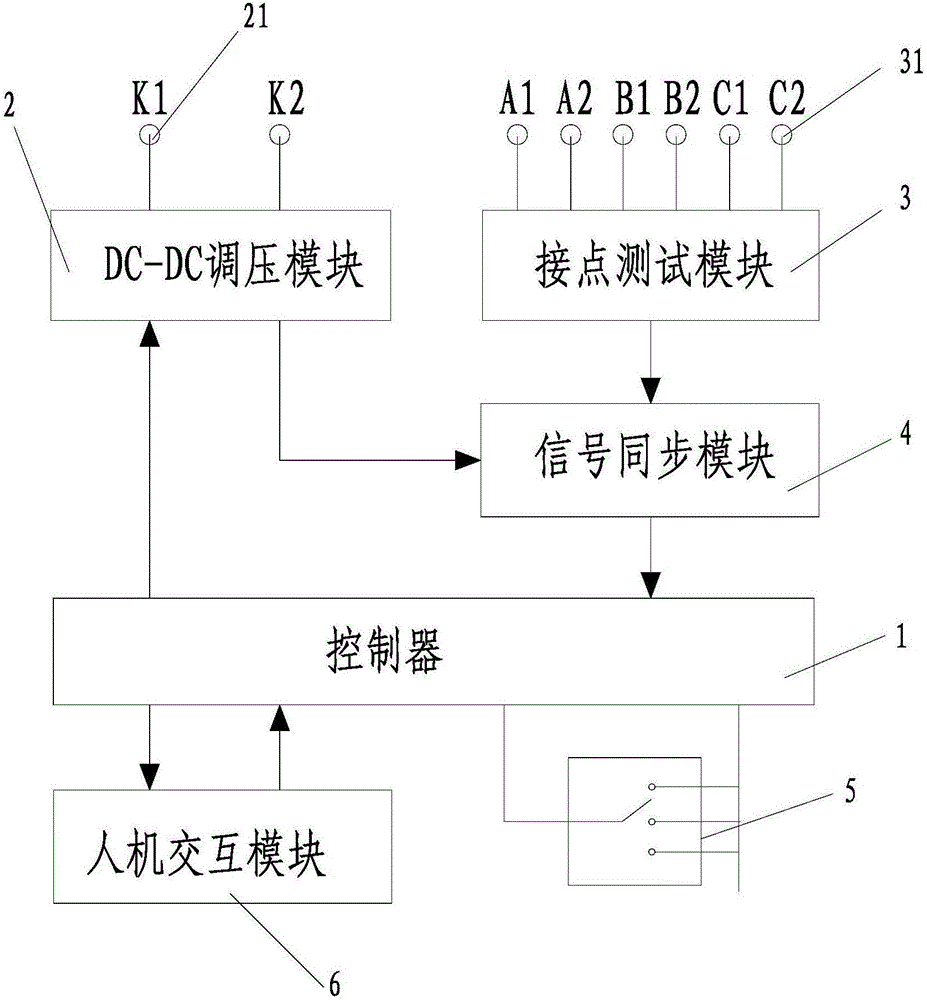

Portable multi-contact relay checking instrument and checking method thereof

InactiveCN106501713ASimultaneous testingImplement group returnCircuit interrupters testingContact testSwitching signal

The invention discloses a portable multi-contact relay checking instrument and a checking method thereof. The checking instrument is composed of a controller, a DC-DC voltage regulation module, a contact test module, a signal synchronization module, a test function switching switch and a man-machine interaction module. The man-machine interaction module is connected with the controller. The DC-DC voltage regulation module is connected with the controller and is controlled by the controller to adjust a voltage needed for output; the DC-DC voltage regulation module is provided with a positive output terminal and a negative output terminal that are used for connecting two ends of a relay coil. The contact test module has at least one pair of interfaces for connecting auxiliary contacts of the relay. The DC-DC voltage regulation module and the contact test module are connected to the controller through connection with the signal synchronization module. The signal synchronization module is used for realizing synchronous collection of the deflection voltage and time of the auxiliary contact of the contactor. The test function switching switch is connected with the controller and is used for sending a switching signal to the controller, thereby starting a corresponding testing function procedure of the controller. The portable multi-contact relay checking instrument has advantages of high portability, improved checking efficiency, and complete functions.

Owner:STATE GRID FUJIAN ELECTRIC POWER CO LTD +2

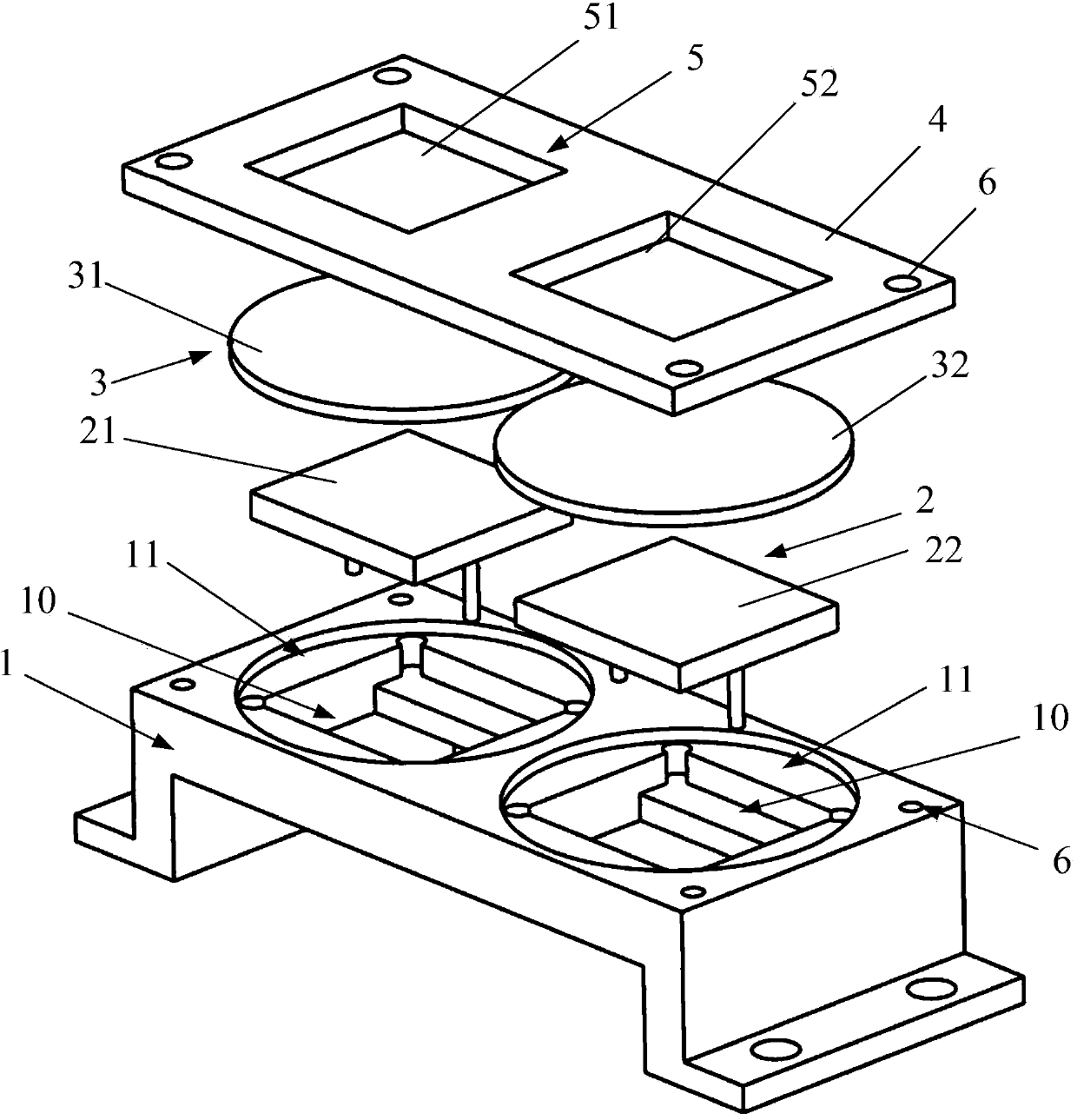

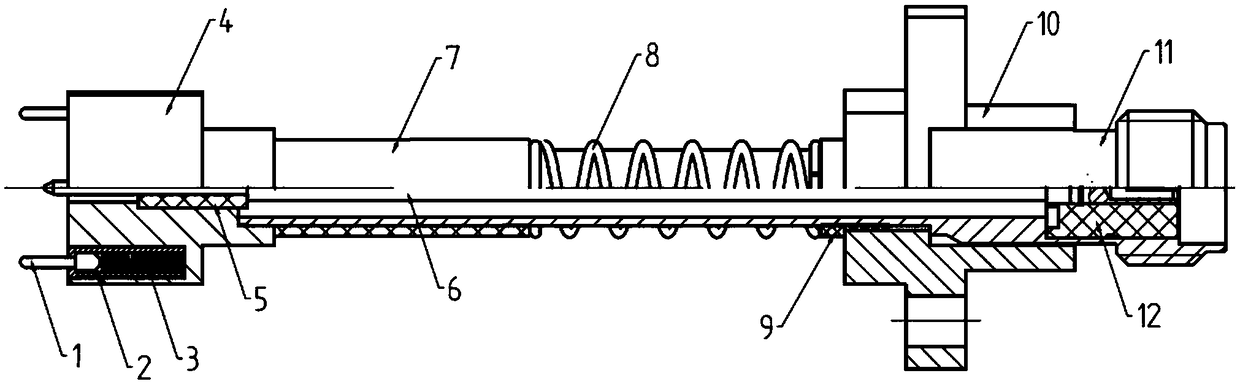

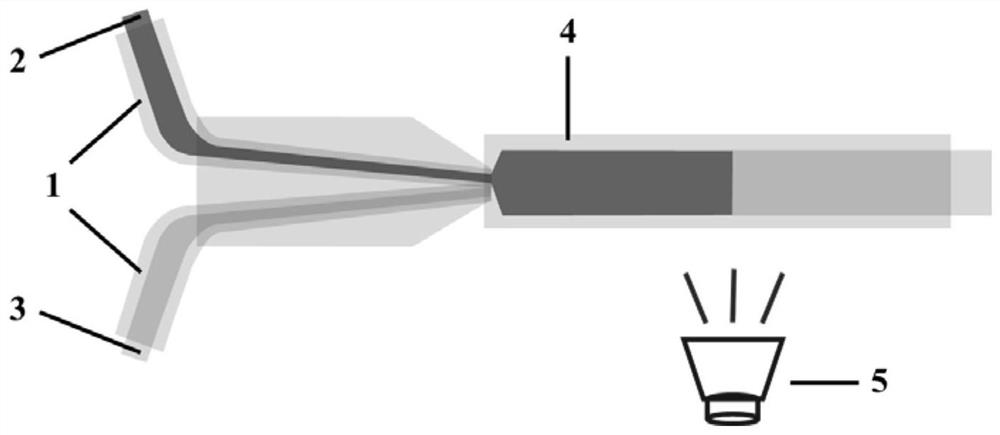

On-orbit exposure test transmittance change test probe for satellite-used material and using method of probe

ActiveCN103792178ASimple structureStable structureWeather/light/corrosion resistanceSpace environmentTest sample

The invention discloses an on-orbit exposure test transmittance change test probe for a satellite-used material and a using method of the probe. The test probe comprises a bracket, wherein more than two photoelectric sensors are arranged on the bracket, wherein a transparent optical material is correspondingly arranged above each photoelectric sensor; cover plates are arranged on the transparent optical materials; more than two through holes are formed in the cover plates; the transparent optical material is correspondingly arranged below each through hole; the cover plates are fixedly connected with the bracket. The using method comprises the following steps: overlapping the test probe to the exterior of a spacecraft, and measuring the current of each photoelectric sensor during the on-orbit operation period under the same illumination condition; and transmitting the tested current back to the ground, and comparing the current of a test sample with the current of a contrast sample, thus obtaining the comparison current change condition, namely the transmittance change condition of the transparent optical material serving as the test sample in a space environment. The test probe is simple in structure and reliable and can test the optical transmittance change of the satellite-used material during on-orbit exposure on line.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Radio frequency probe for testing PCB board impedance

PendingCN109061245ANo eccentricityImprove the problem of eccentricityResistance/reactance/impedenceElectrical measurement instrument detailsFemale structureElectrical conductor

The invention discloses a radio frequency (RF) probe for testing PCB board impedance. The RF probe comprises ground pins, a ground shell, a ground spring, a signal pin, and a flange; two ground pins and one signal pin are arranged; since the flange covers a main outer conductor shell in the testing process, three contact pins without eccentricity is guaranteed when the flange is pressed; three contact pins perfectly contact a testing point of a PCB board, the contact is good and non-eccentric; the RF probe joint type is a SMA female structure and adopts a standard structure; the RF probe is mature and stable, high in frequency and simple in processing; the probe use frequency is greater than the actual use frequency of the PCB board, the working frequency can completely adapt to the testing width required by the PCB board.

Owner:上海军友射频技术有限公司

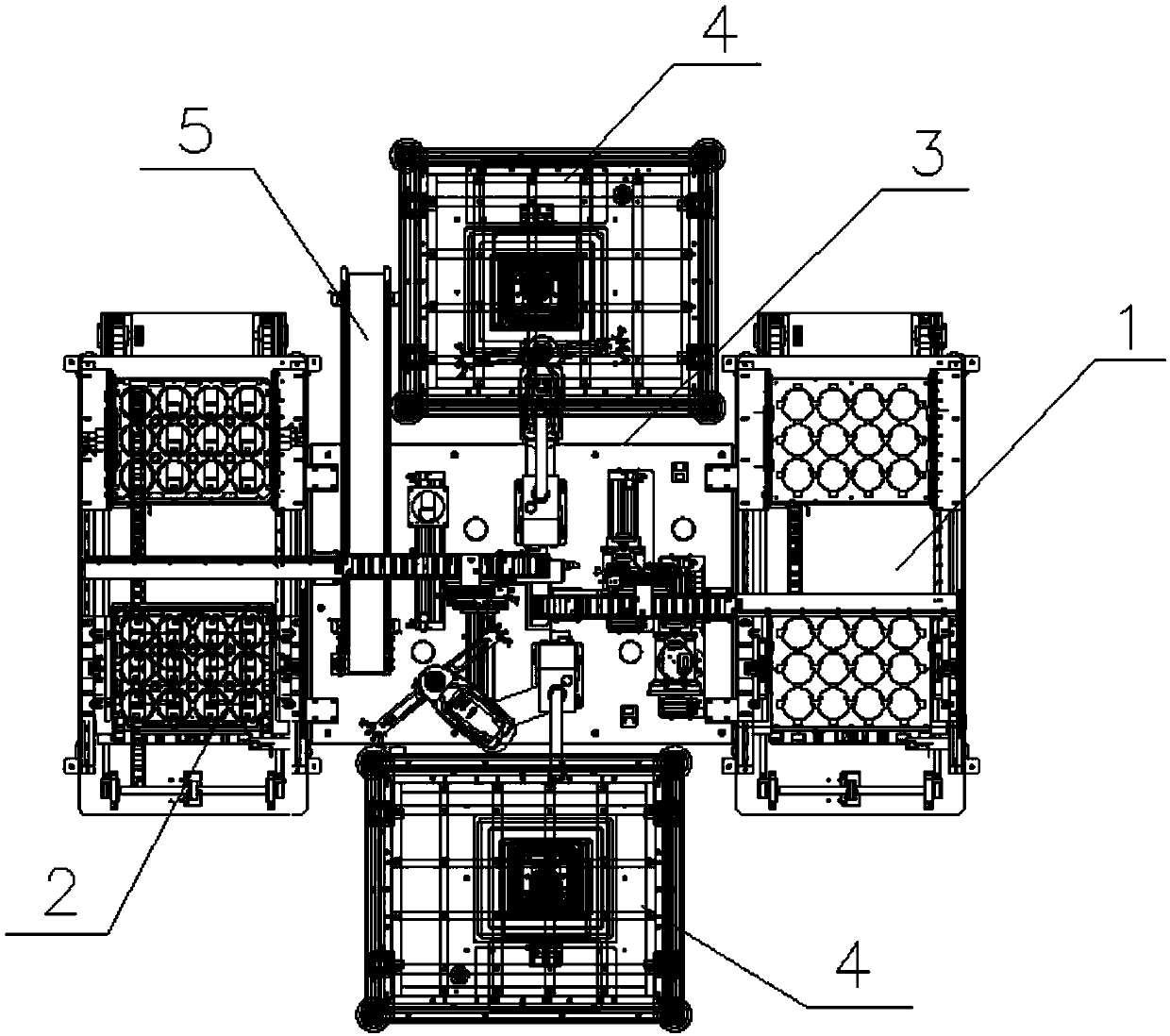

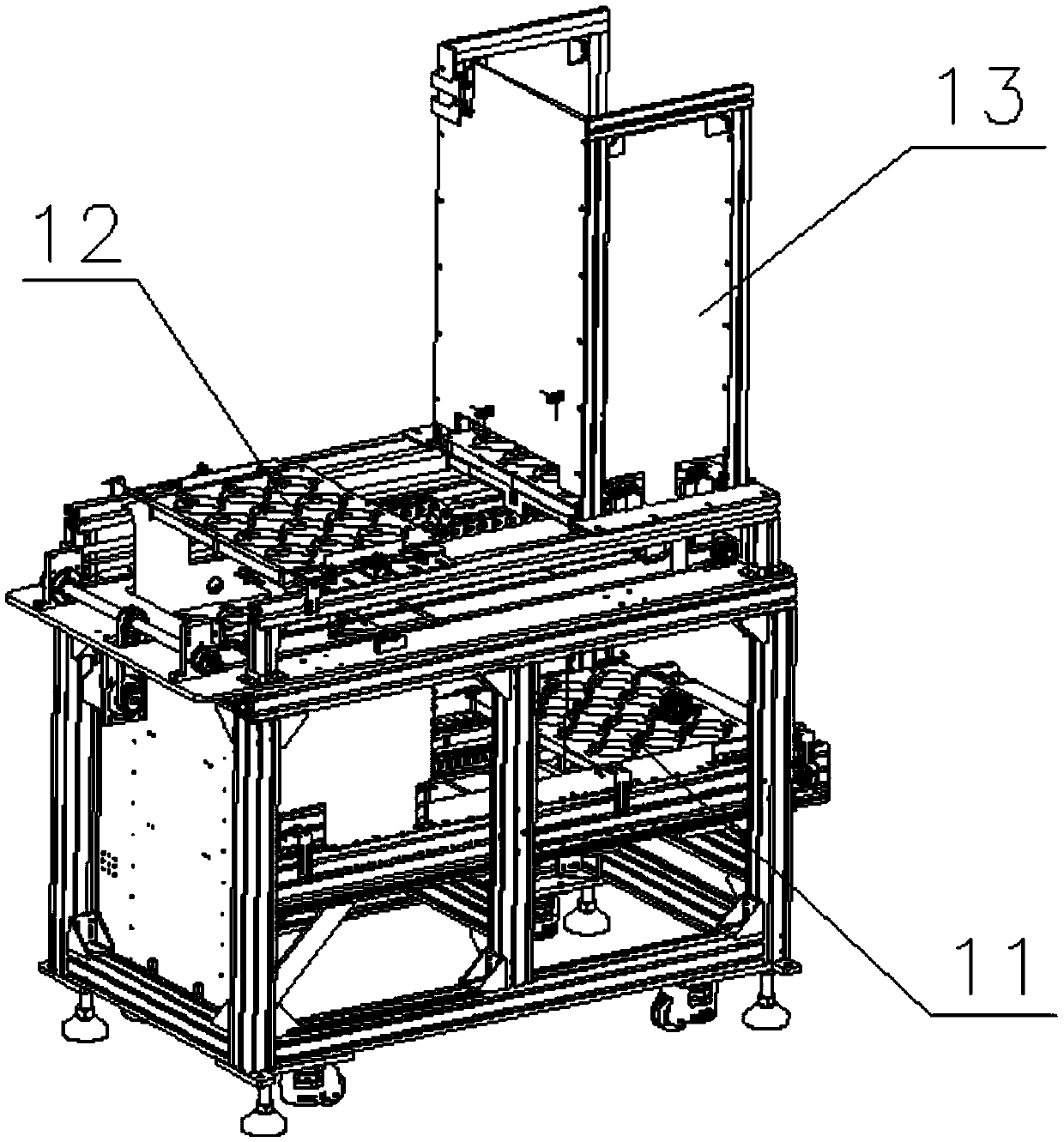

Automatic testing device and method for products

The invention provides an automatic testing device for products. The automatic testing device for the products includes a handling module, a feeding cabin, a discharging cabin, and two sets of test boxes, wherein the feeding cabin and the discharging cabin are arranged on the two opposite sides of the handing module, and the two sets of test boxes are arranged on the other two opposite sides of the handling module; the two products in the feeding cabin are respectively grabbed into two positioning and flipping assemblies by a feeding and handling assembly, and the positioning and flipping assemblies clasp the corresponding products and flip by preset angles; one of handling clamping claws grabs the products at a material taking position, and the other handing clamping claw grabs products which have been tested inside the test box on the corresponding side; the grabbed products are put in the test boxes by one handing clamping claw, and qualified products are conveyed to a conveying assembly by the other handing clamping claw; and the conveying assembly conveys the qualified products to a discharging position and a discharging handing assembly grabs the products at the discharging position into the discharging cabin. According to the automatic testing device and method for the products, the automated testing of the two products can be achieved at the same time, using is safe andreliable, and efficiency is high.

Owner:GOERTEK INC

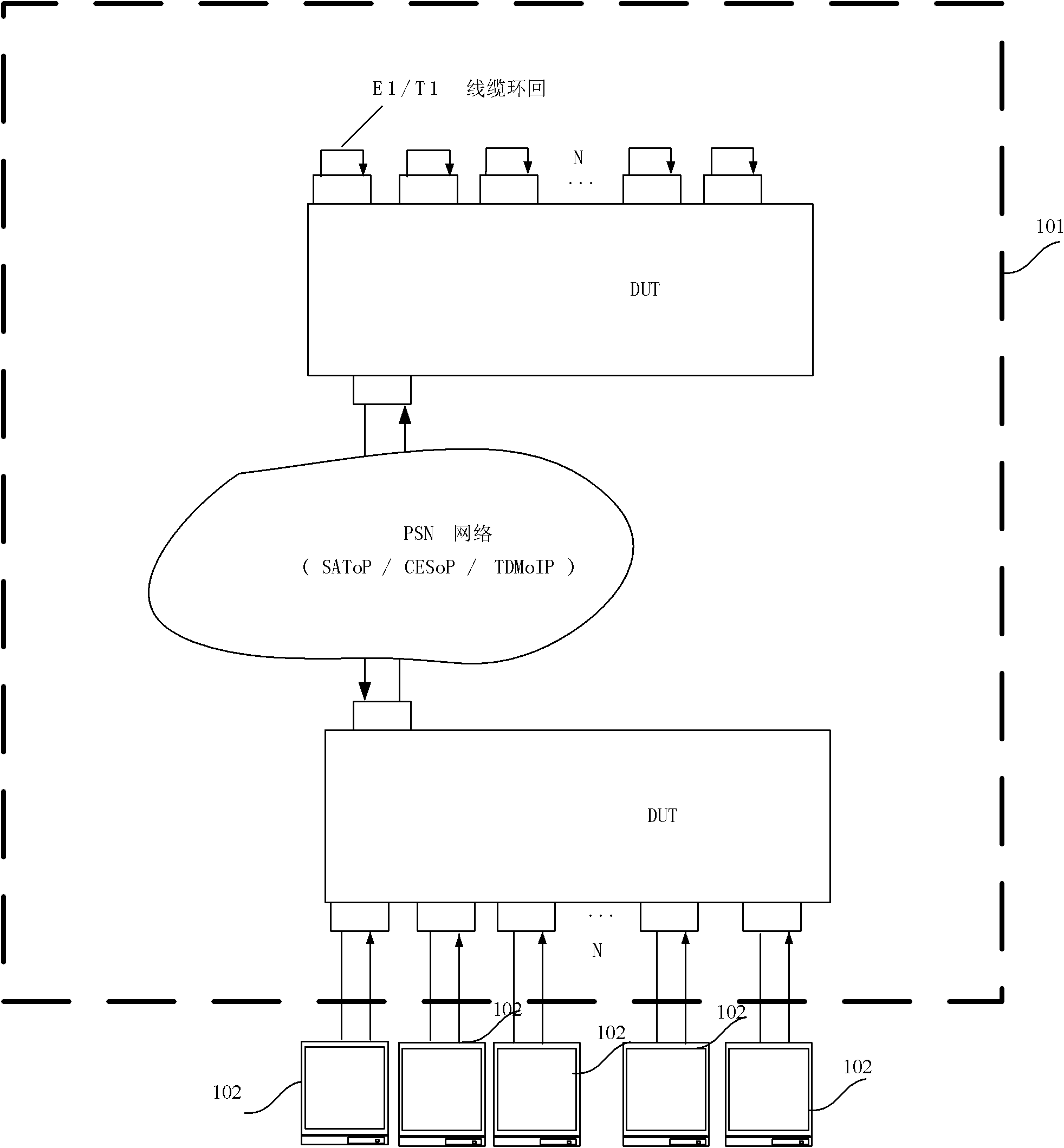

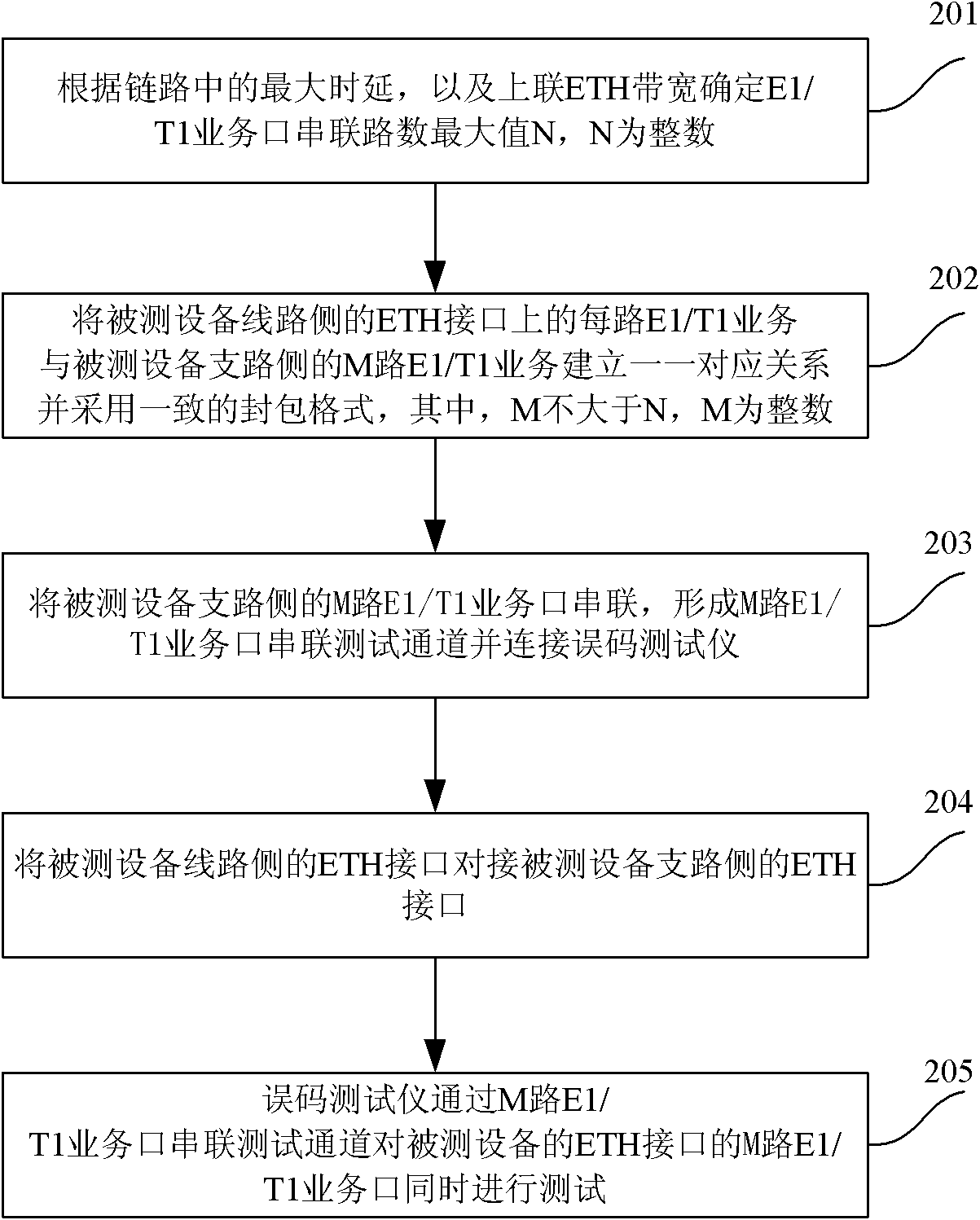

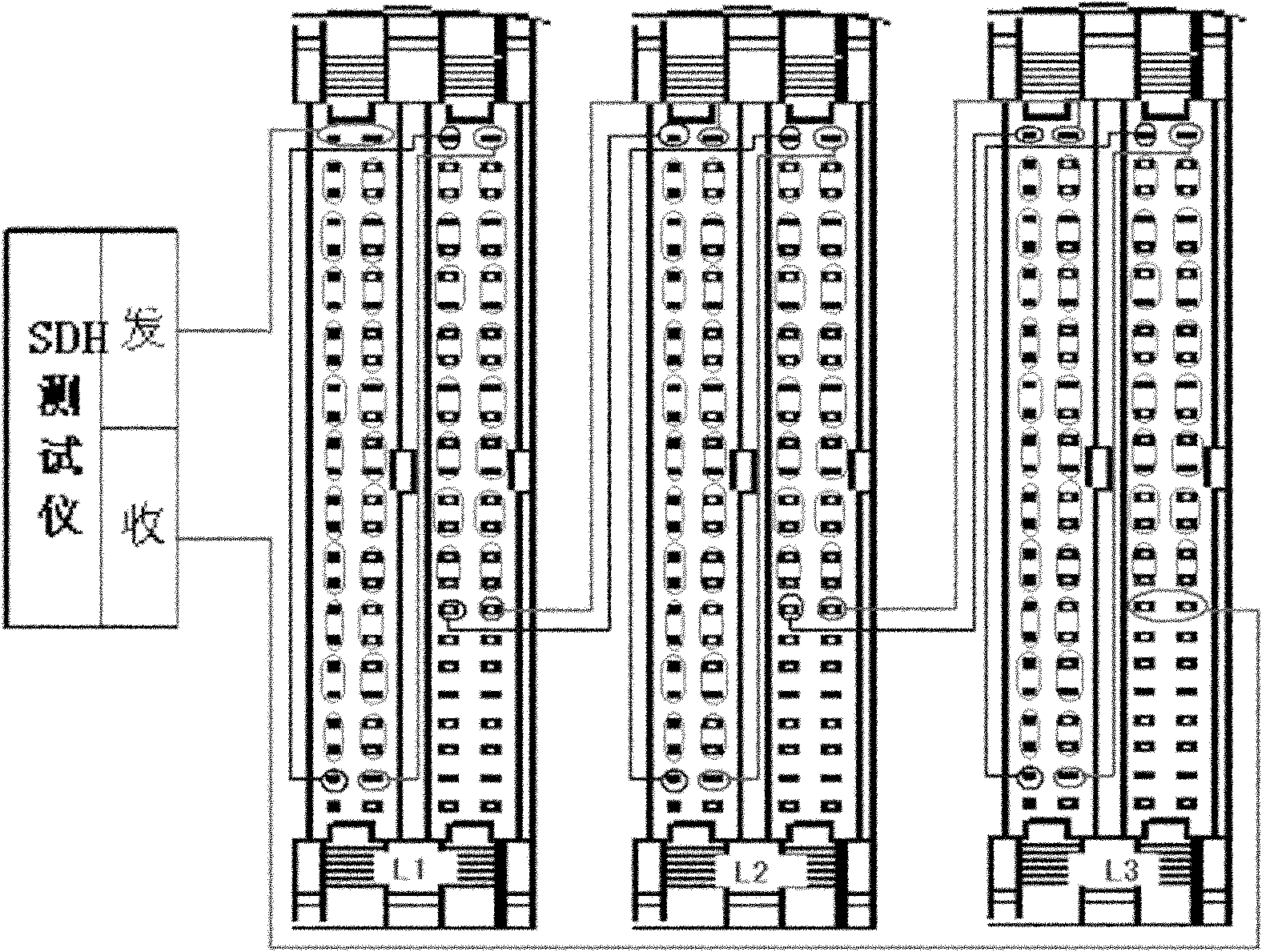

Circuit simulation service testing method and system

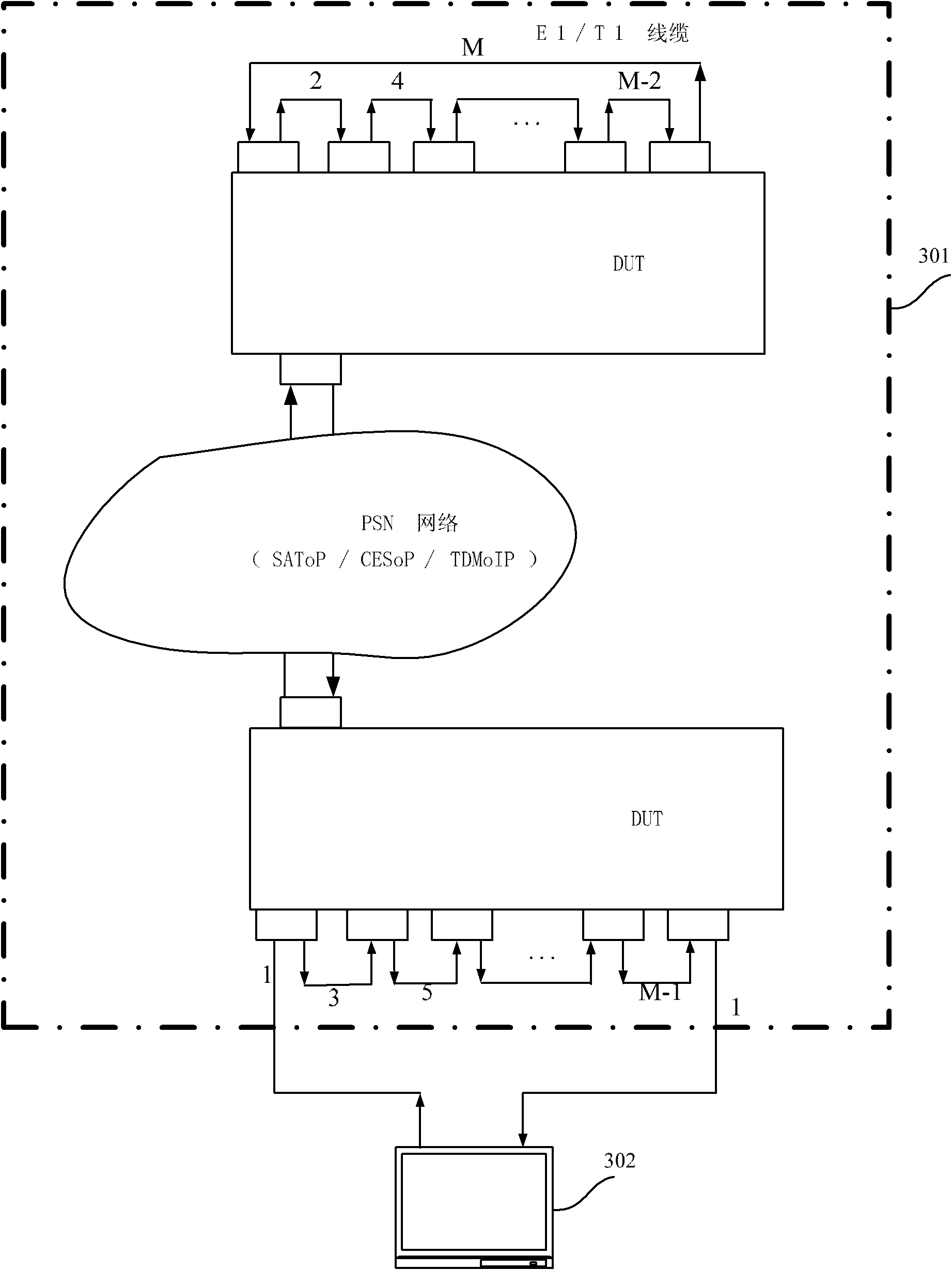

ActiveCN102413015ASimultaneous testingSave test resourcesTransmission monitoringData switching networksTest channelMulti path

The invention discloses a circuit simulation service testing method. The maximum number N of series-wound paths of an E1 / T1 service port is determined according to a maximum delay in a link and an uplink Ethernet (ETH) bandwidth. The method comprises the following steps that: one-to-one correspondence between each path of E1 / T1 service on an ETH interface on a tested equipment line side and M paths of E1 / T1 services on a tested equipment branch side is established, and a consistent encapsulation format is adopted; the M paths of the E1 / T1 service port on the tested equipment branch side are connected in series to form an M-path series-wound test channel for the E1 / T1 service port, the test channel is connected with an error code tester, and the ETH interface on the tested equipment line side is jointed with an ETH interface of the tested equipment branch side, wherein M is not greater than N, and both M and N are integers; and the error code tester simultaneously tests the M paths of the E1 / T1 service port of the ETH interface of tested equipment through the M-path series-wound test channel for the E1 / T1 service port. The invention also discloses a system based on the same inventive concept. By the method and the system, a multi-path E1 / T1 service port can be tested simultaneously, so test resources are saved.

Owner:RAISECOM TECH

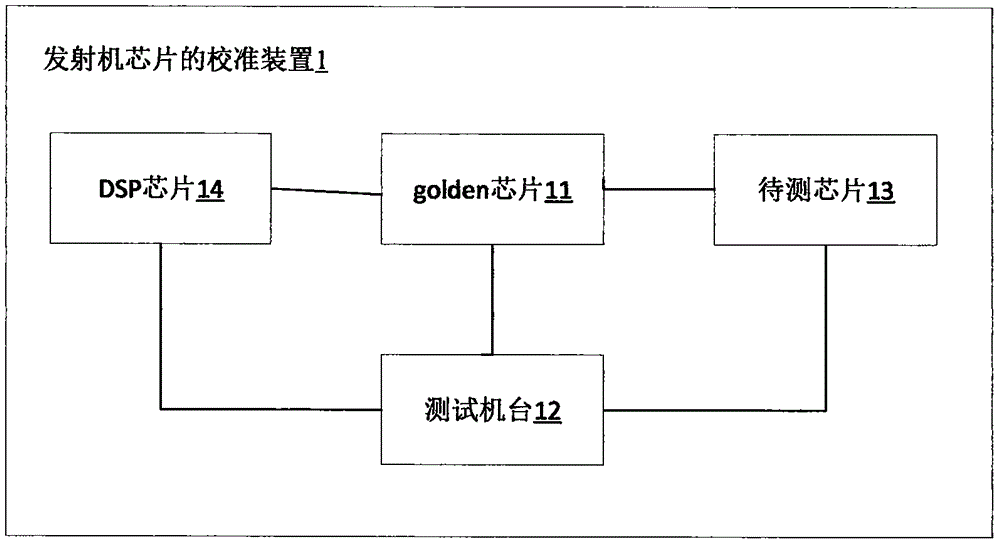

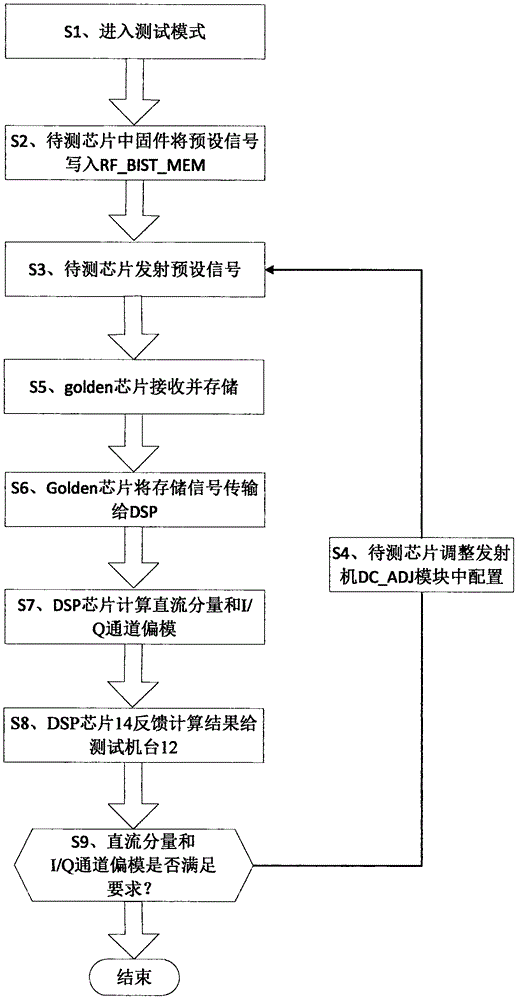

Calibration method and device for transmitter chip

InactiveCN105959067AFully automatedSimultaneous testingTransmitters monitoringDigital signal processingEngineering

The present invention relates to a calibration method and device for a transmitter chip. The method comprises the steps that a chip to be tested transmits a sinusoidal signal to a standard chip such that the standard chip can transmit the sinusoidal signal to a digital signal processing chip for analysis; the chip to be tested adjusts a DC bias parameter and an I / Q channel bias mode parameter according to the testing result sent by a testing machine platform, wherein the testing result sent by the testing machine platform is obtained by analyzing the sinusoidal signal by the digital signal processing chip. According to the calibration method and device for a transmitter chip provided by the invention, the chip can be used to transmit and receive the signal of the chip to be tested and carry out analyzing, the instrument in a conventional calibration and test mode is replaced, and the automation of calibration and test is realized through a firmware.

Owner:BEIJING WINNER MICROELECTRONICS

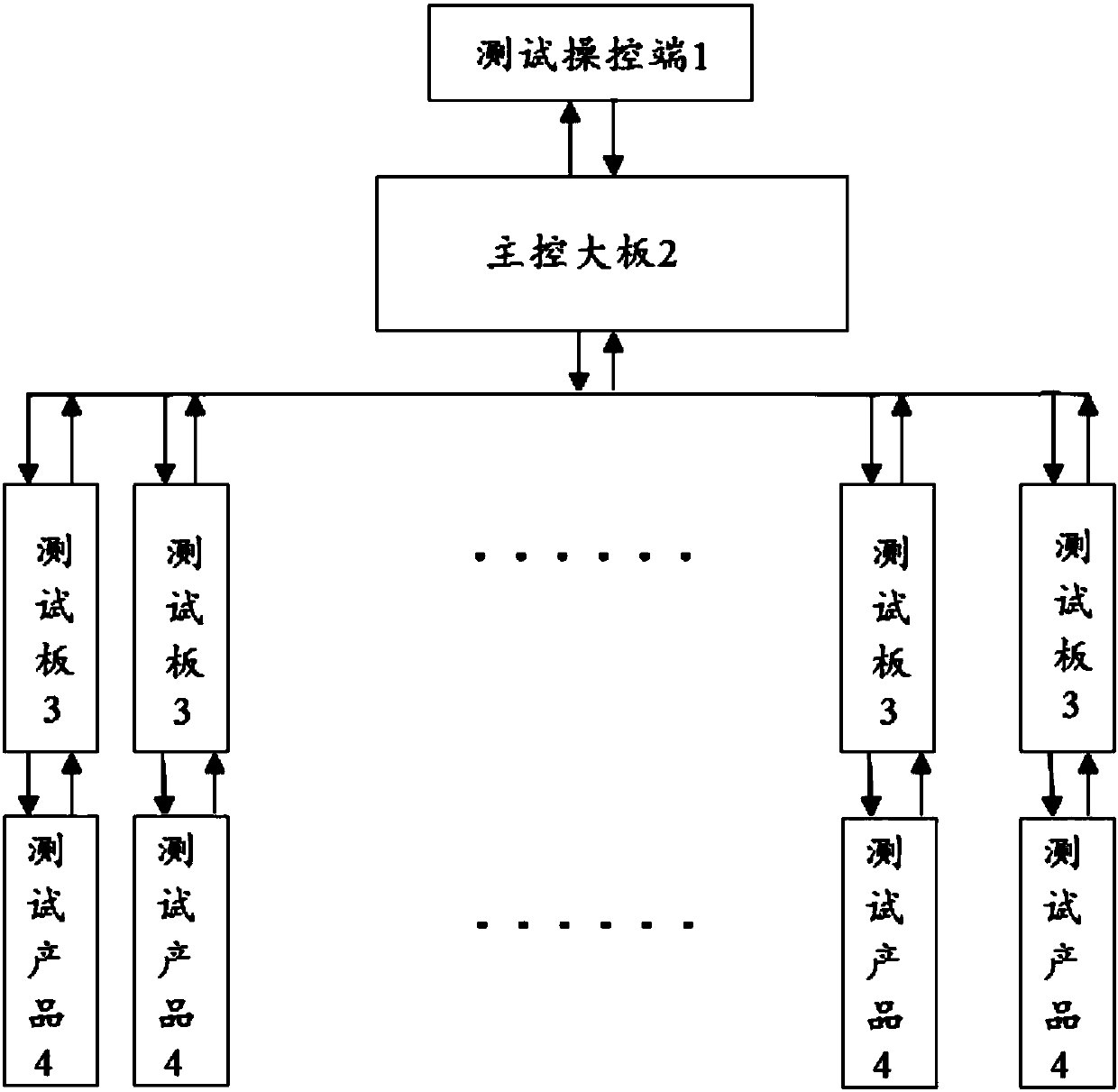

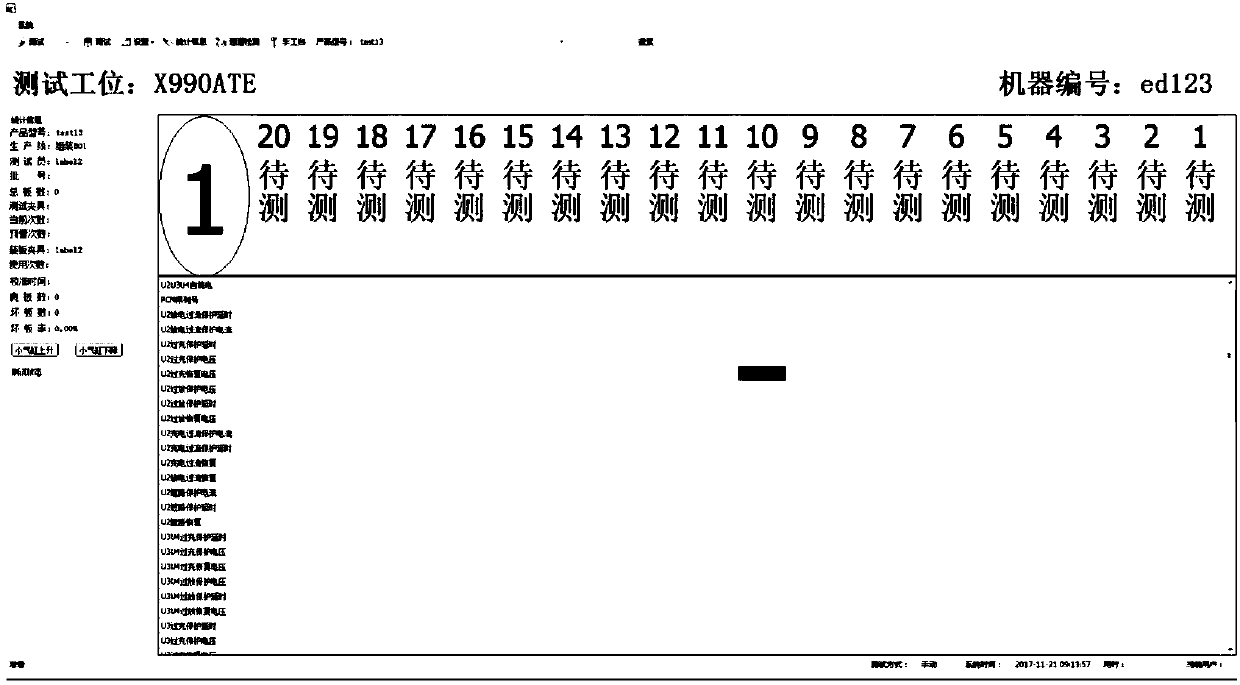

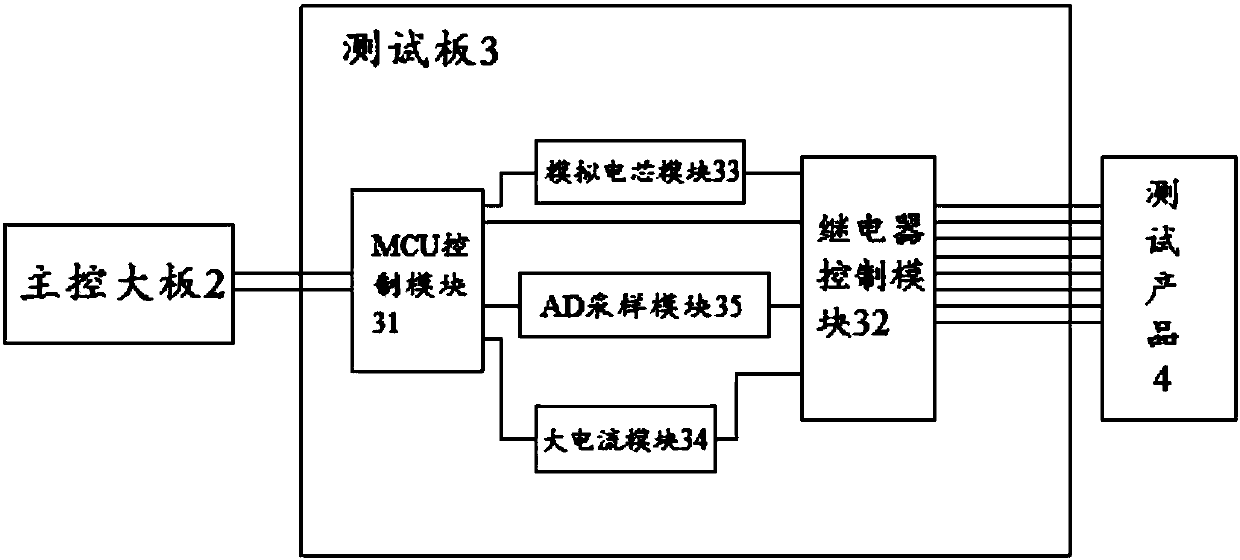

Quick test system of double-cell battery protection board and test board

ActiveCN108037461AEasy to debug and maintain laterSimultaneous testingElectrical testingElectricityTest efficiency

The invention belongs to the battery electric measurement technological field and discloses a quick test system of a double-cell battery protection board and a test board. The quick test system includes a test control end and a main control board connected with the test control end; the main control board is provided with a plurality of test channels; each test channel is connected with a test board; one test board is connected with one test product; the test board is provided with an MCU control module and a relay control module connected with the MCU control module; an analog cell module, alarge-current module, and an AD sampling module are independently connected between the MCU control module and the relay control module; and the relay control module is connected with the test product. The quick test system of the double-cell battery protection board and the test board provided by the present invention have the advantages of modularization, free channel expansion, high equipment accuracy, high test efficiency and the like.

Owner:HUIZHOU BLUEWAY ELECTRONICS

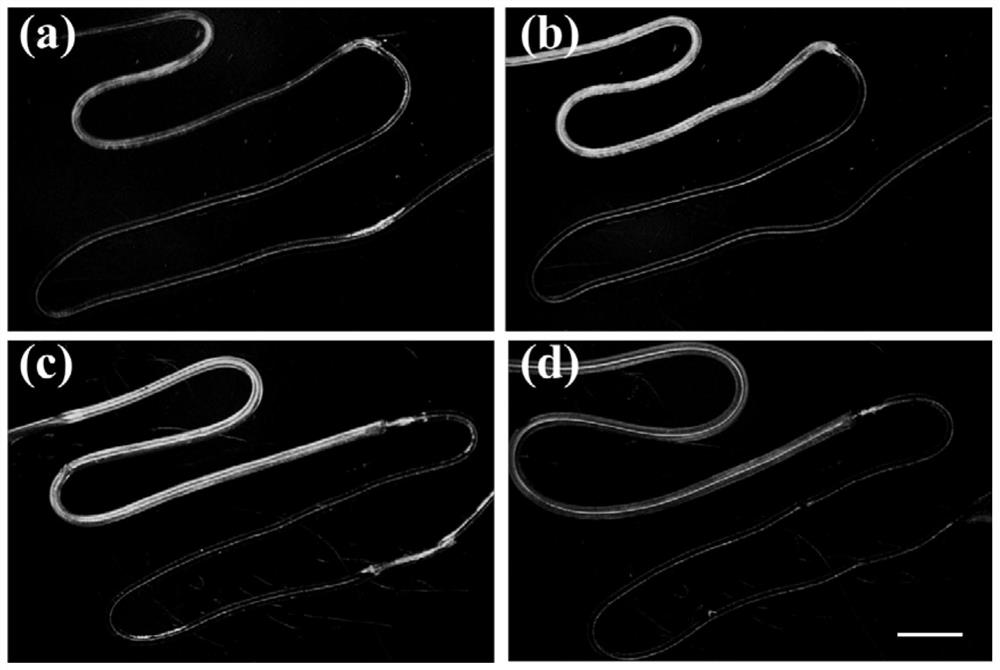

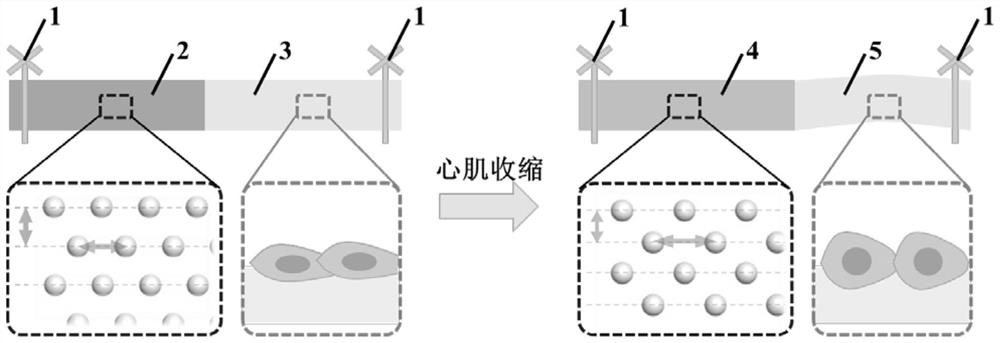

Heterostructure structural color microfiber, preparation method thereof and myocardial cell detection method

ActiveCN112485247AGuaranteed stabilityGuaranteed sensitivityMaterial analysis by observing effect on chemical indicatorLaboratory glasswaresUltraviolet lightsEngineering

The invention discloses a heterostructure structural color microfiber, a preparation method thereof and a myocardial cell detection method. The preparation method comprises the following steps that: amicro-fluidic chip is constructed for a heterostructure structural color microfiber preparation platform by adopting a capillary tube, and pre-polymerization solutions are prepared as fiber components, wherein each pre-polymerization solution comprises a biocompatible hydrogel solution and silicon dioxide non-close packing colloidal crystal pre-gel with at least one concentration, and a photoinitiator is added into each pre-polymerization solution; and the two types of pre-polymerization solutions are alternately injected into a collecting pipe in a programmed mode through the micro-fluidic chip, and the collecting pipe part is continuously irradiated through ultraviolet light to obtain the heterostructure structural color microfiber. The heterostructure structural color microfiber has the advantages of controllable preparation, low cost, capability of realizing cell physiology visual quantitative sensing and the like.

Owner:NANJING DRUM TOWER HOSPITAL

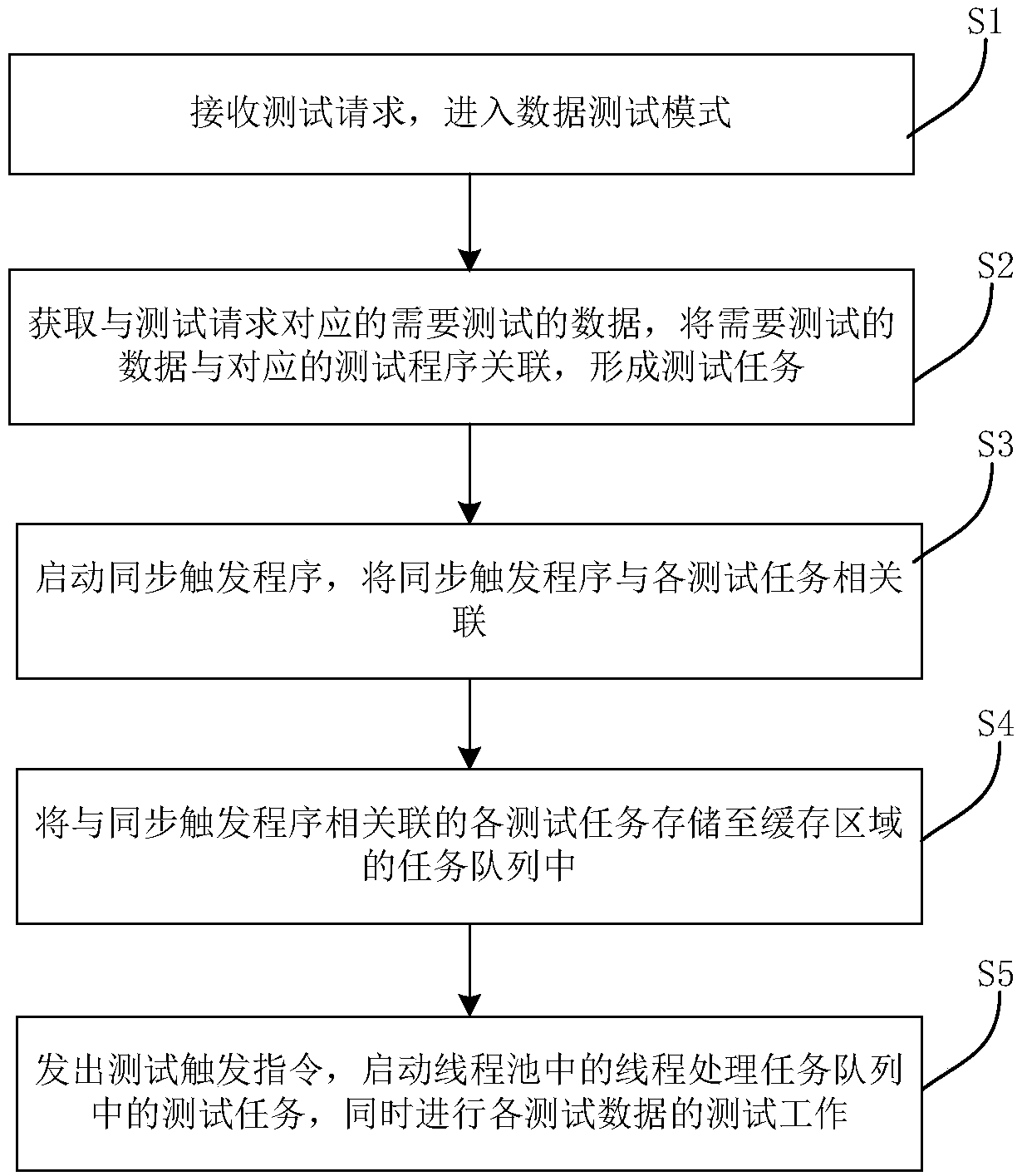

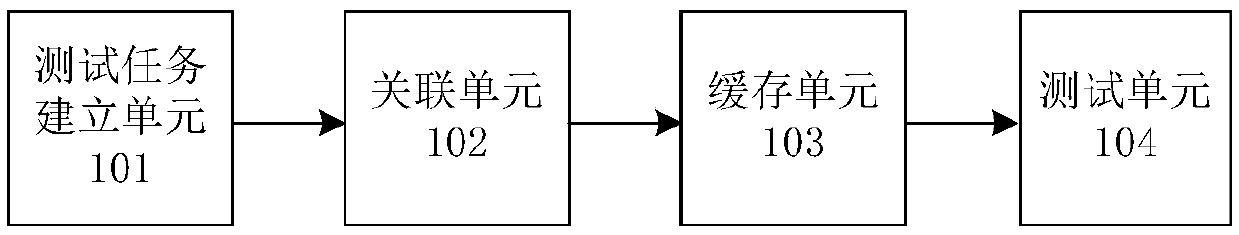

Data test method and system, electronic device and computer readable storage medium

PendingCN109634853ASimultaneous testingShorten test timeProgram initiation/switchingSoftware testing/debuggingComputer hardwareData needs

The invention relates to the field of artificial intelligence, and particularly provides a data test method and system, an electronic device and a computer readable storage medium. The test method comprises the following steps: firstly, receiving a test request, and entering a data test mode; then obtaining data needing to be tested, and associating the data with a test program to obtain a test task; starting a synchronous trigger program, and associating the synchronous trigger program with each test task; associating each test task with a synchronous trigger program associated with each testtask, and storing the test task and the synchronous trigger program in a cache region; And when a test triggering instruction is detected, testing work of each test data is carried out at the same time through a synchronous triggering program, and a test result corresponding to the data needing to be tested is obtained. According to the data testing method and system, the electronic device and the computer readable storage medium, all the testing data can be tested at the same time, all the testing processes are carried out at the same time, and compared with one-by-one testing, the testing time is shortened.

Owner:PING AN TECH (SHENZHEN) CO LTD

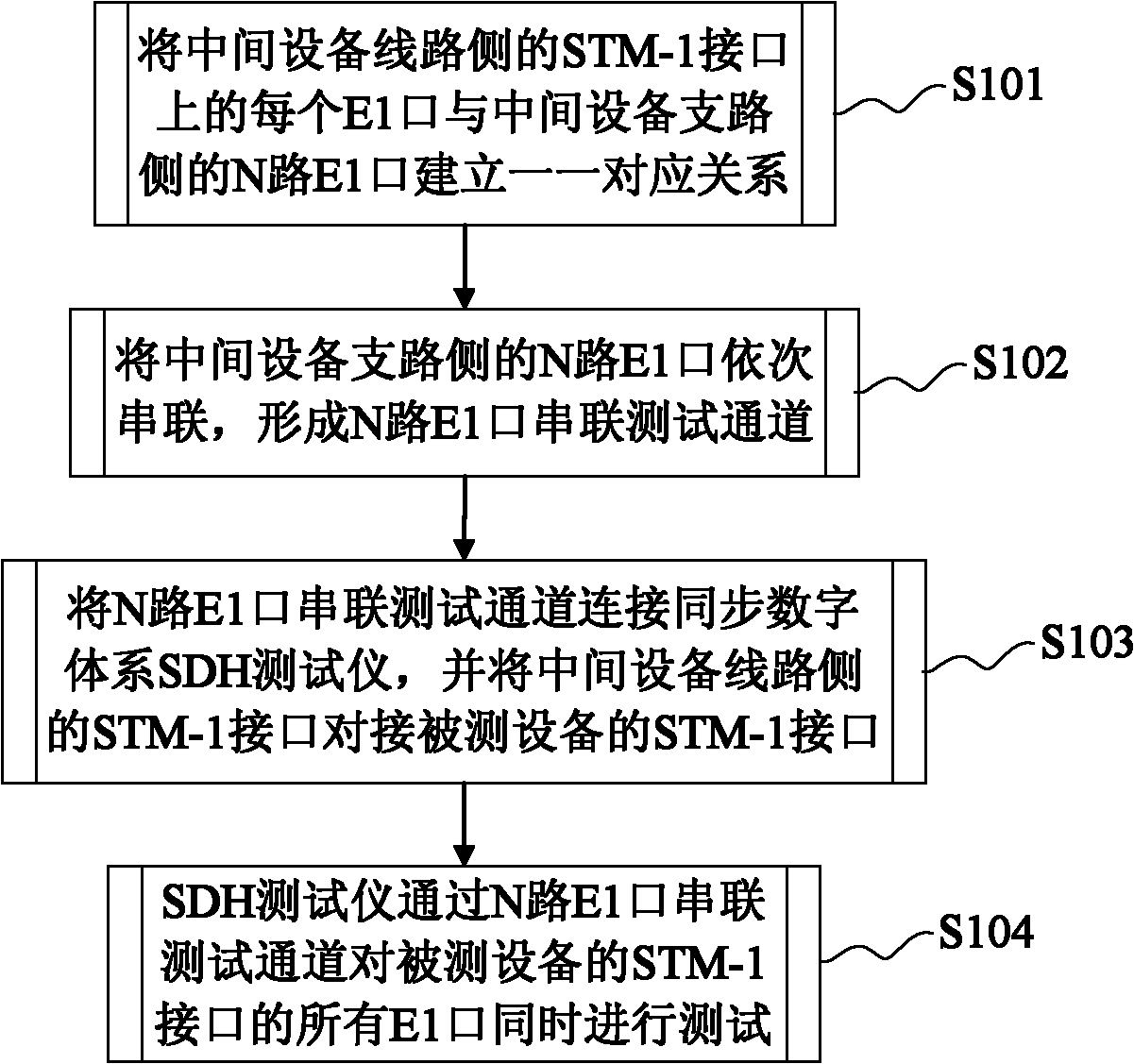

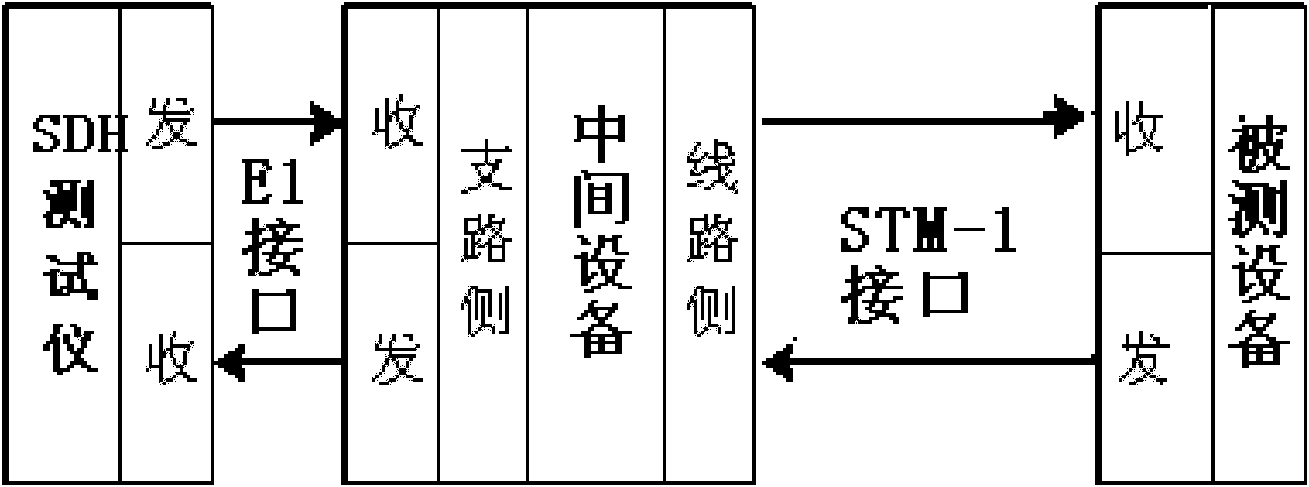

Test method and system of multiple paths of E1 ports for realizing STM-1 interface

The invention discloses a test method and system of multiple paths of E1 ports for realizing an STM-1 interface. The method comprises the following steps of: building one-to-one correspondence relationship between each E1 port on the STM-1 interface at the middle equipment circuit side and N paths of E1 ports at the middle equipment branch circuit side; sequentially connecting N paths of E1 ports at the middle equipment branch circuit side in series, forming a serial connection test passage of N paths of E1 ports, connecting an SDH (Synchronous Digital Hierarchy) test instrument, and carrying out butt joint between the STM-1 interface at the middle equipment circuit side with the STM-1 interface of the tested equipment; and simultaneously testing all the E1 ports of the STM-1 interface of the tested equipment by the SDH test instrument through the serial connection test passage of the N paths of E1 ports, wherein N is an integer greater than or equal to 2. The middle equipment is used for completing the serial connection of multiple paths of E1 ports and the mapping of the E1 ports to the STM-1 interface, the monitoring of each path of E1 port of multiple paths of E1 ports on the STM-1 interface through network management is completed, and the simultaneous test of multiple paths of E1 ports on the STM-1 interface is realized.

Owner:ZTE CORP

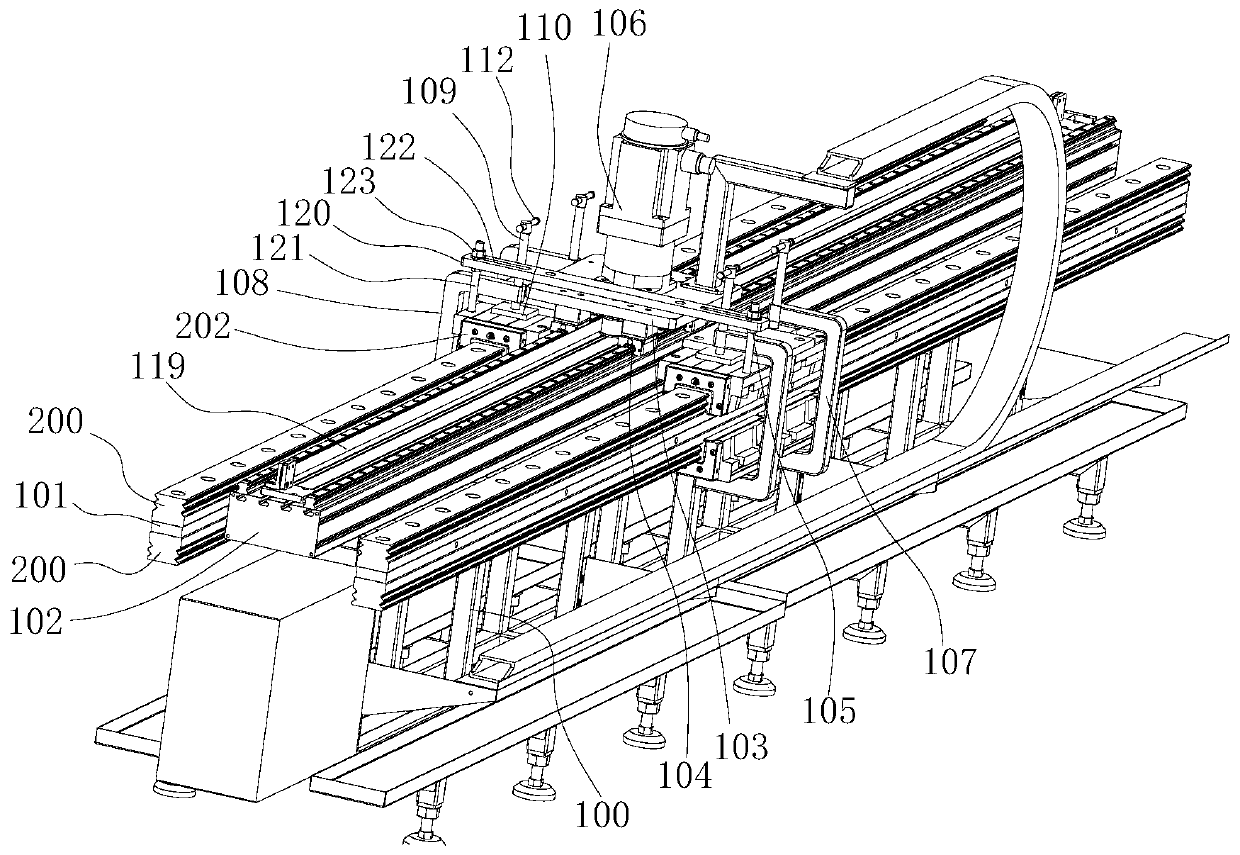

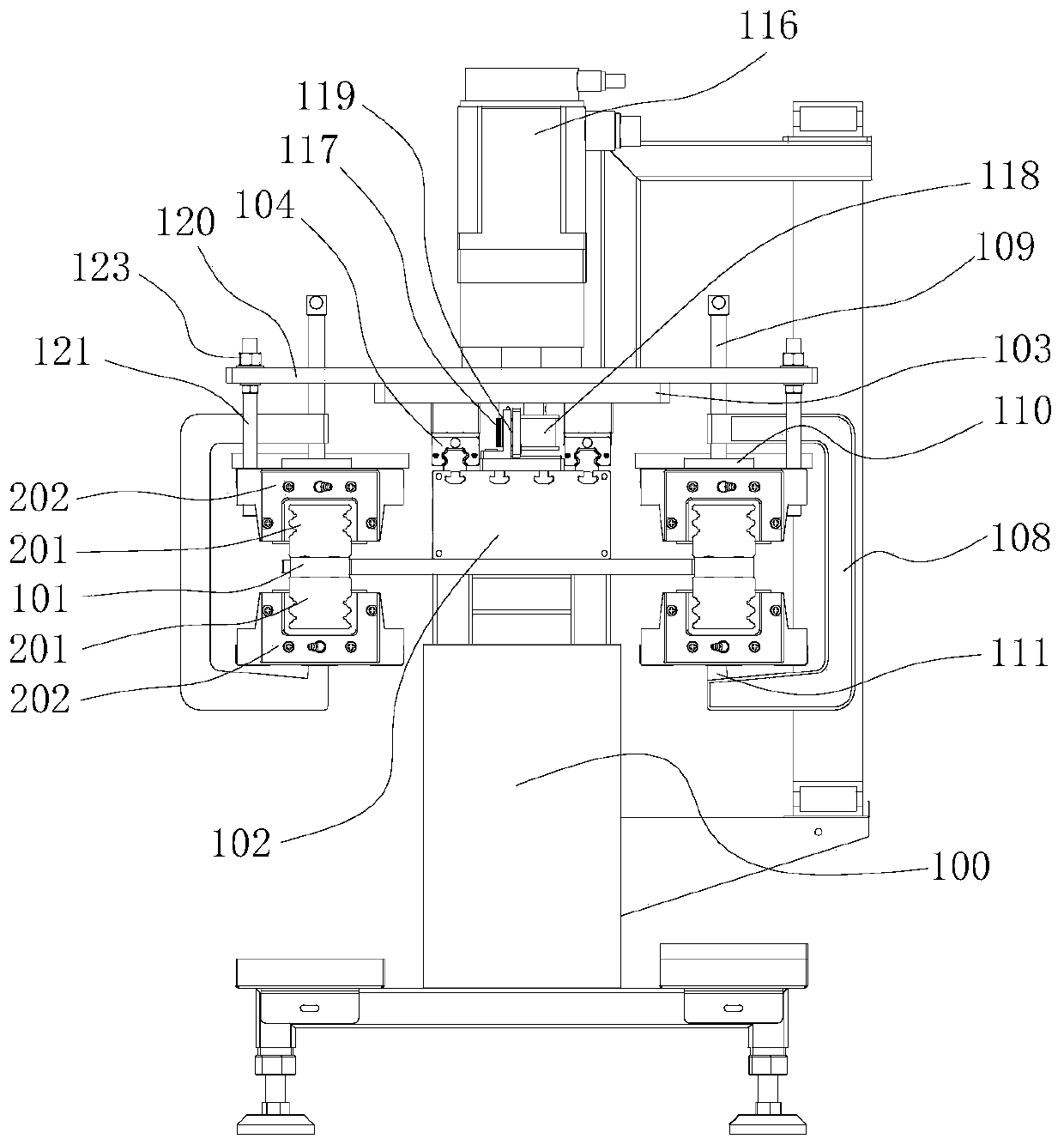

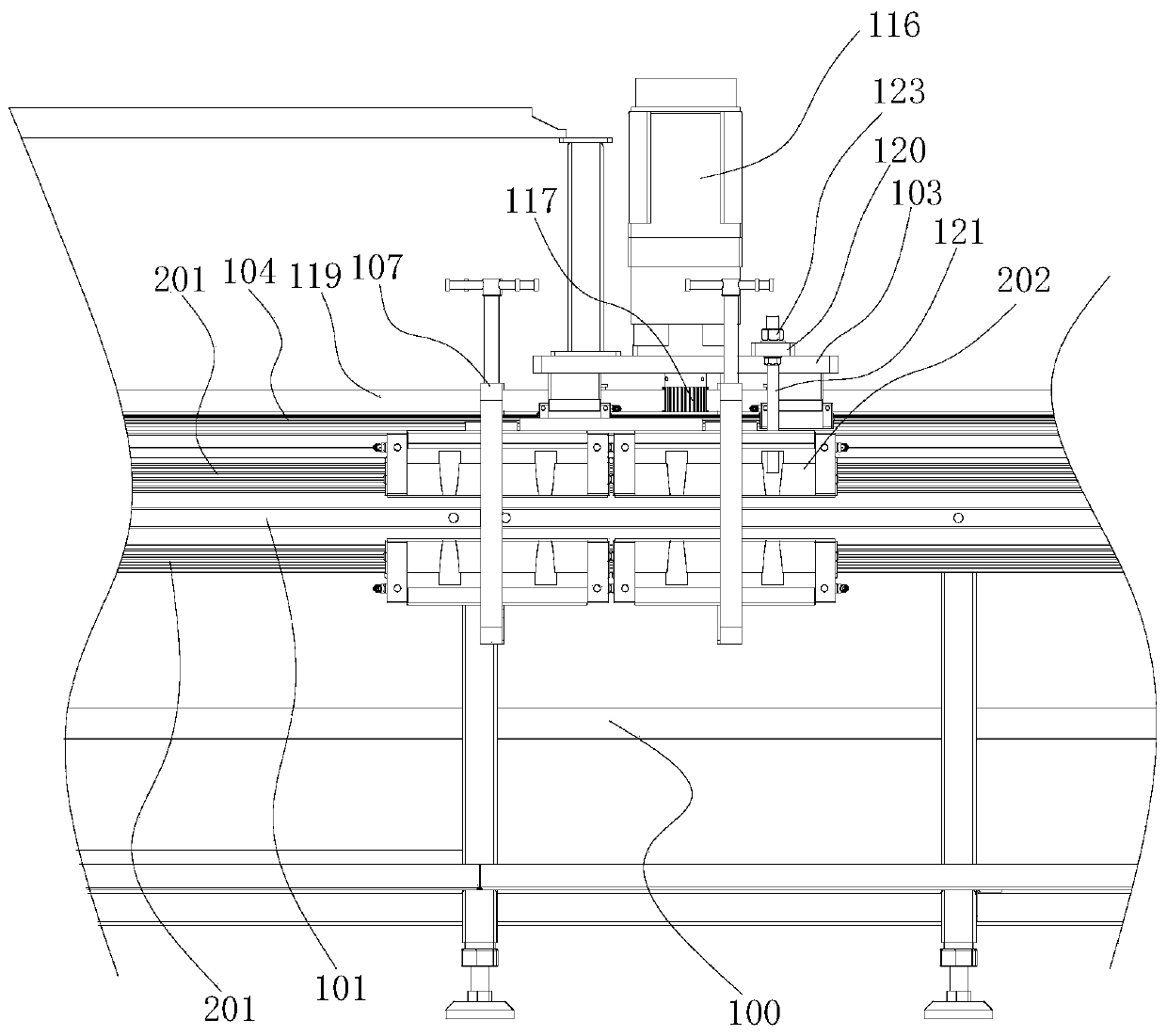

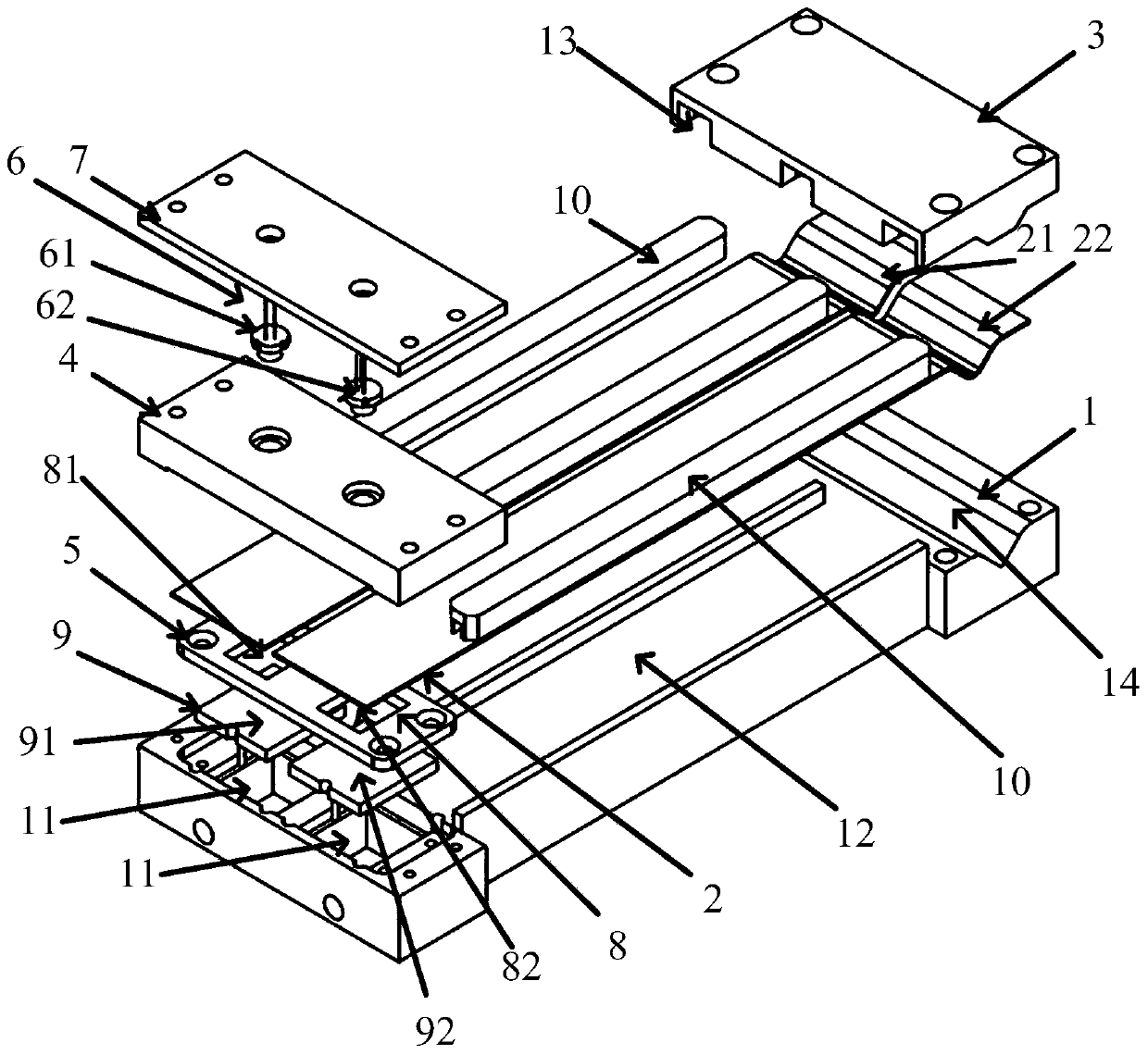

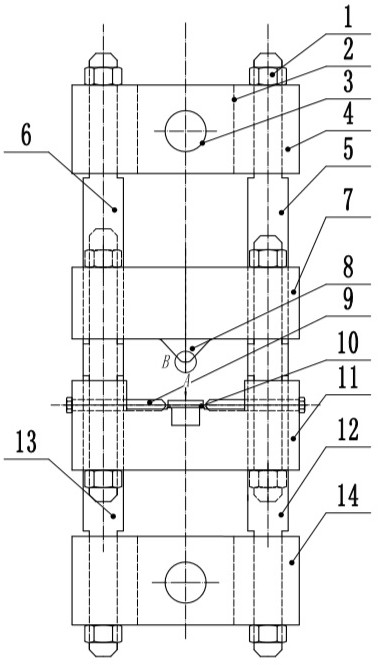

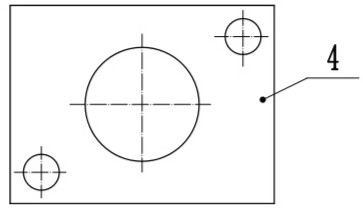

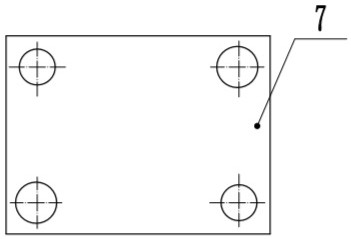

Linear guide rail pair running-in testing machine

PendingCN110954429ASimultaneous testingImprove run-in test efficiencyInvestigating abrasion/wear resistanceStructural engineeringMachine

The invention discloses a running-in testing machine for a linear guide rail pair, which comprises a machine frame, guide rail mounting plates are respectively arranged on the left and right sides ofthe top of the rack; a base and a movable support are arranged in the middle of the top of the rack. An auxiliary guide rail pair connected with the base is arranged at the bottom of the movable support; connecting assemblies for fixedly connecting the sliding blocks are arranged on the left side and the right side of the movable support respectively; a driving assembly capable of driving the movable support to move back and forth on the auxiliary guide rail pair is arranged between the movable support and the base, the linear guide rail pair running-in testing machine further comprises a loading assembly capable of applying pressure to the sliding blocks, and the loading assembly is in a jaw shape and enables the two sliding blocks installed on the upper side and the lower side of the guide rail installation plate to abut against the guide rail in a pressing mode. According to the invention, the actual frictional wear condition of the linear guide rail pair under different loads and the service life of the linear guide rail pair under various speed conditions in a speed range of 5m / s can be reliably tested with low cost, and simultaneous running-in of multiple sets of guide rail pairs to be tested can be realized.

Owner:JIANGMEN INTIN NUMERICAL CONTROL MACHINE TOOL CO LTD

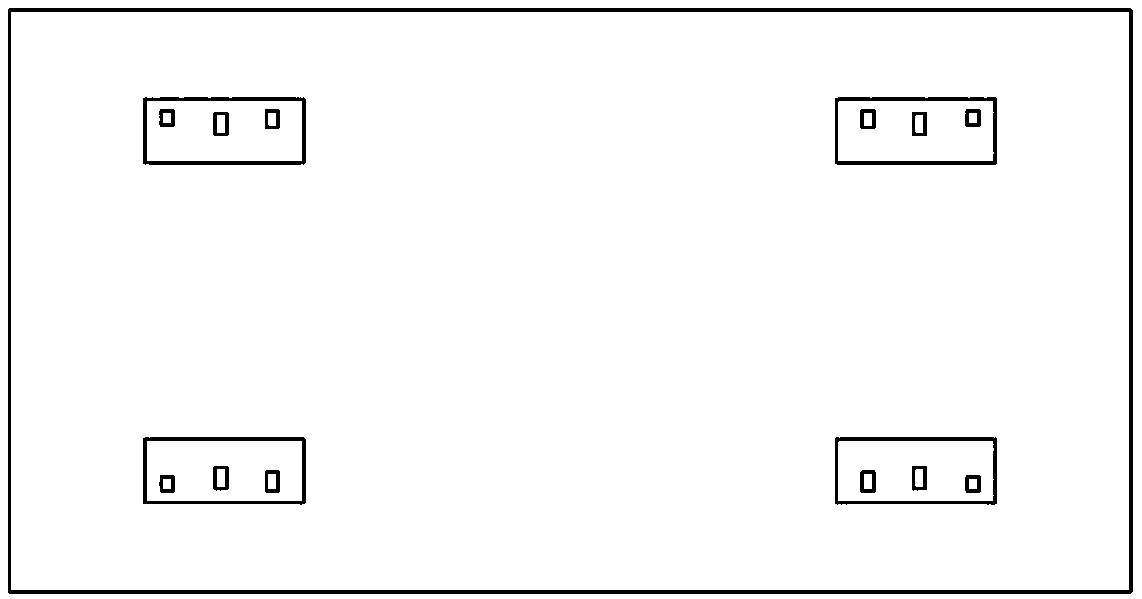

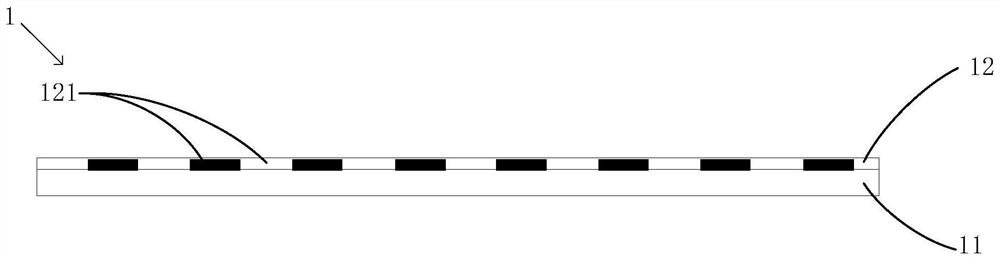

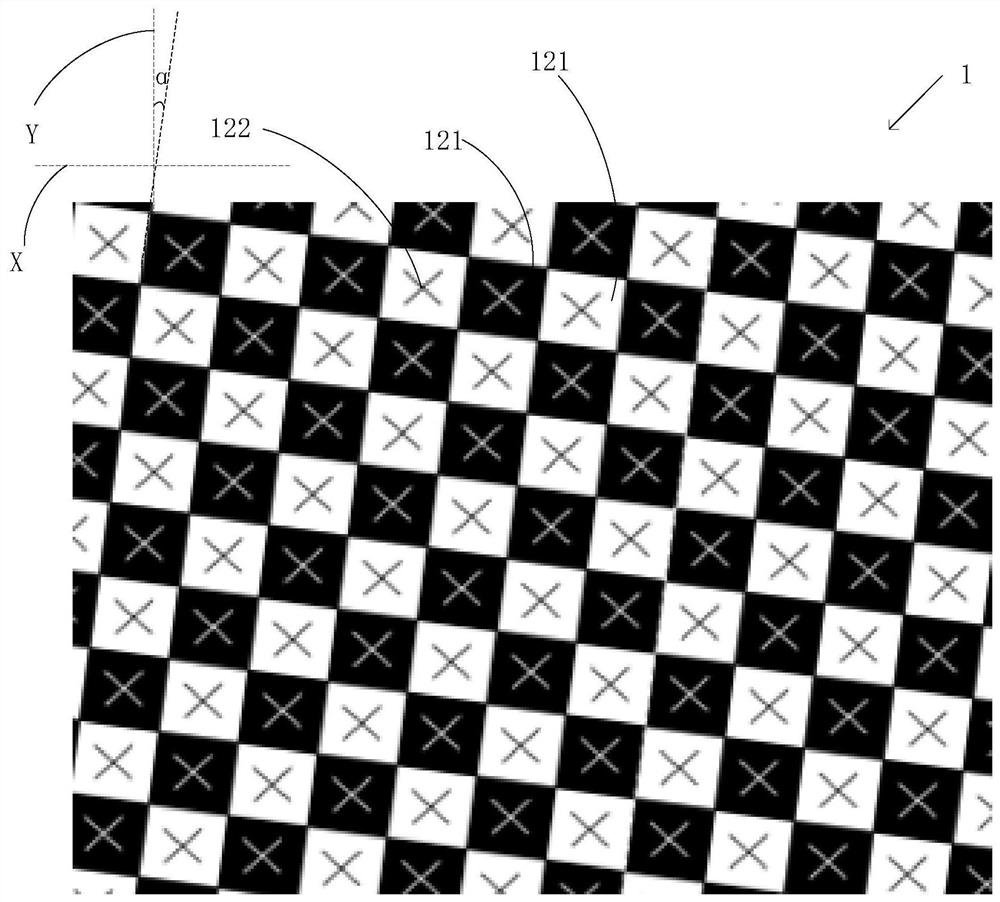

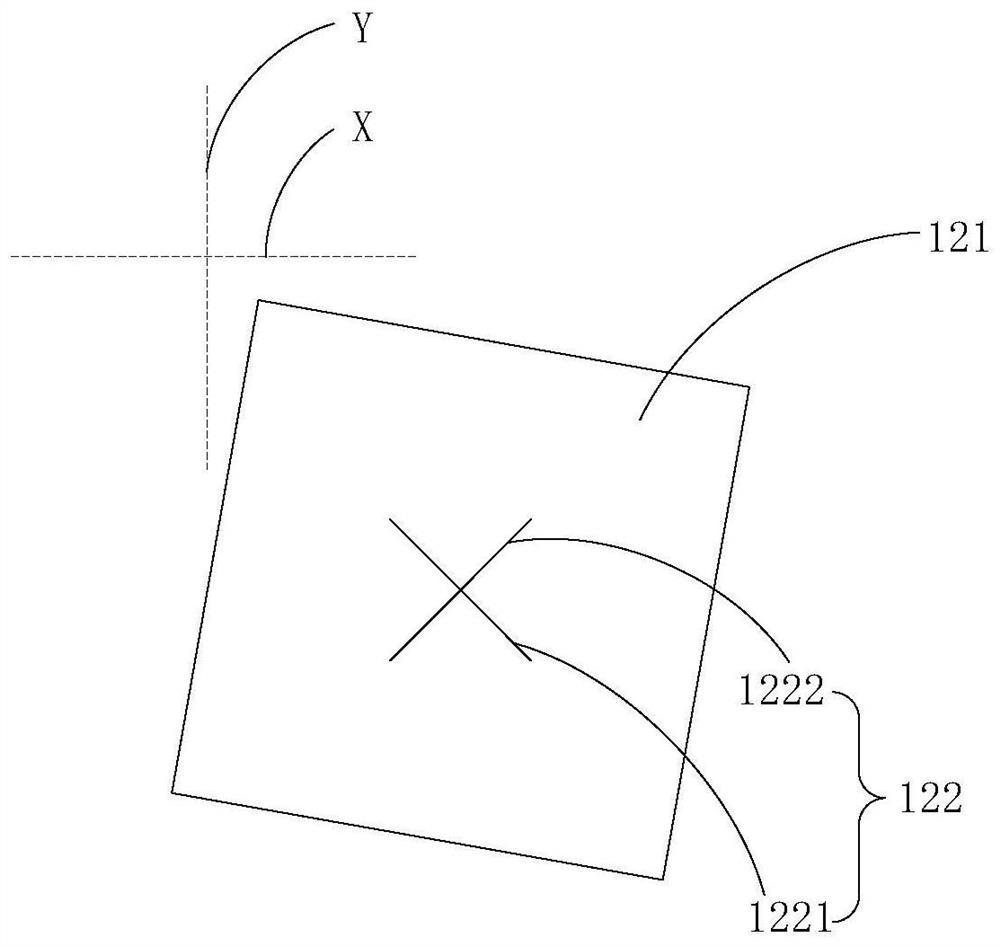

Camera performance test card and camera test system

ActiveCN112887704AImprove focusing efficiencySimultaneous testingTelevision systemsComputer graphics (images)Algorithm

The invention relates to a camera performance test card and a camera test system, and the camera performance test card is used in cooperation with a camera module and comprises a plurality of color blocks arranged in an array. The focusing mark arranged at the central position of each color block improves the focusing efficiency of the camera module; due to the fact that the color blocks with the focusing marks are arranged in an array mode, the camera performance test card can use the same algorithm for testing camera modules of different specifications, and simultaneous testing of the camera modules can be achieved. Therefore, the test effect, the compatibility and the test efficiency of the camera performance test card and the camera test system using the camera performance test card are improved.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Online on-orbit exposure test deformation test probe for film material and testing method of probe

ActiveCN103792179ASimple structureStable structureWeather/light/corrosion resistanceElectrical/magnetic solid deformation measurementPolymer thin filmsLight-emitting diode

The invention discloses an online on-orbit exposure test deformation test probe for a film material and a testing method of the probe. The probe comprises a bracket, wherein at least one test sample is arranged on the bracket; a first cover plate is arranged above one end of the test sample; a second cover plate is arranged above the other end of the test sample; a third cover plate is arranged below the test sample; a light emitting diode is arranged on the second cover plate; a fourth cover plate is arranged on the light emitting diode; a through hole is formed in the third cover plate; a photoelectric sensor is correspondingly arranged below the through hole; the photoelectric sensor is arranged at the end of the bracket; one end of the bracket is connected with the first cover plate, and the other end of the bracket is connected with the second cover plate and the fourth cover plate. The method comprises the following steps: performing calibration and on-line test, wherein the on-line test comprises the following sub-steps: recording the current generated by the photoelectric sensor which corresponds to the test sample, and comparing current data with the data, which is obtained through calibration performed on the ground, of the test sample, thus obtaining the on-orbit linear length change conditions of the test sample along with the temperature. According to the probe, the deformation of a satellite-used polymer film generated along with the temperature change can be tested on line.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

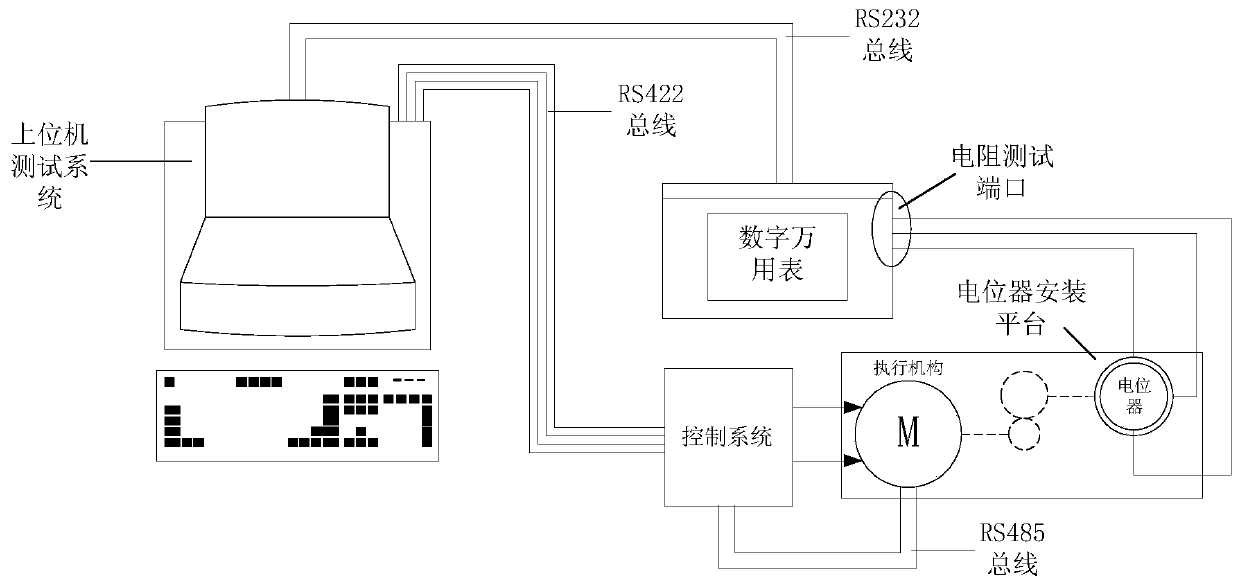

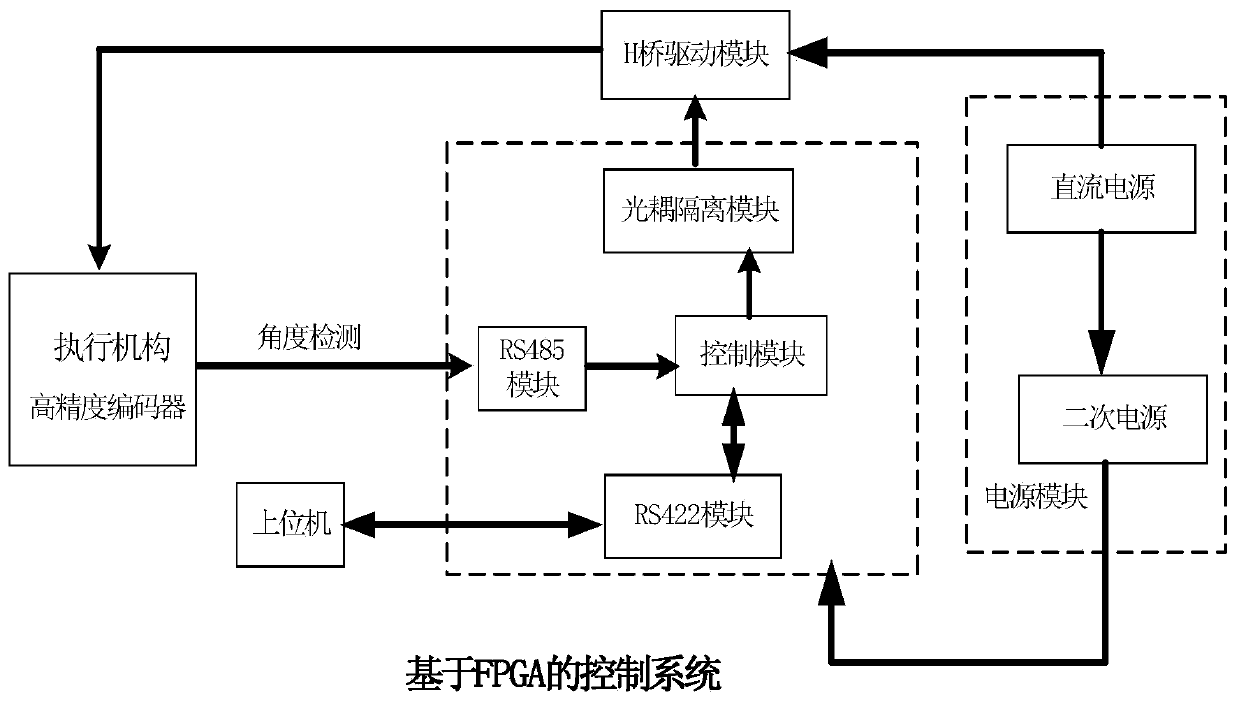

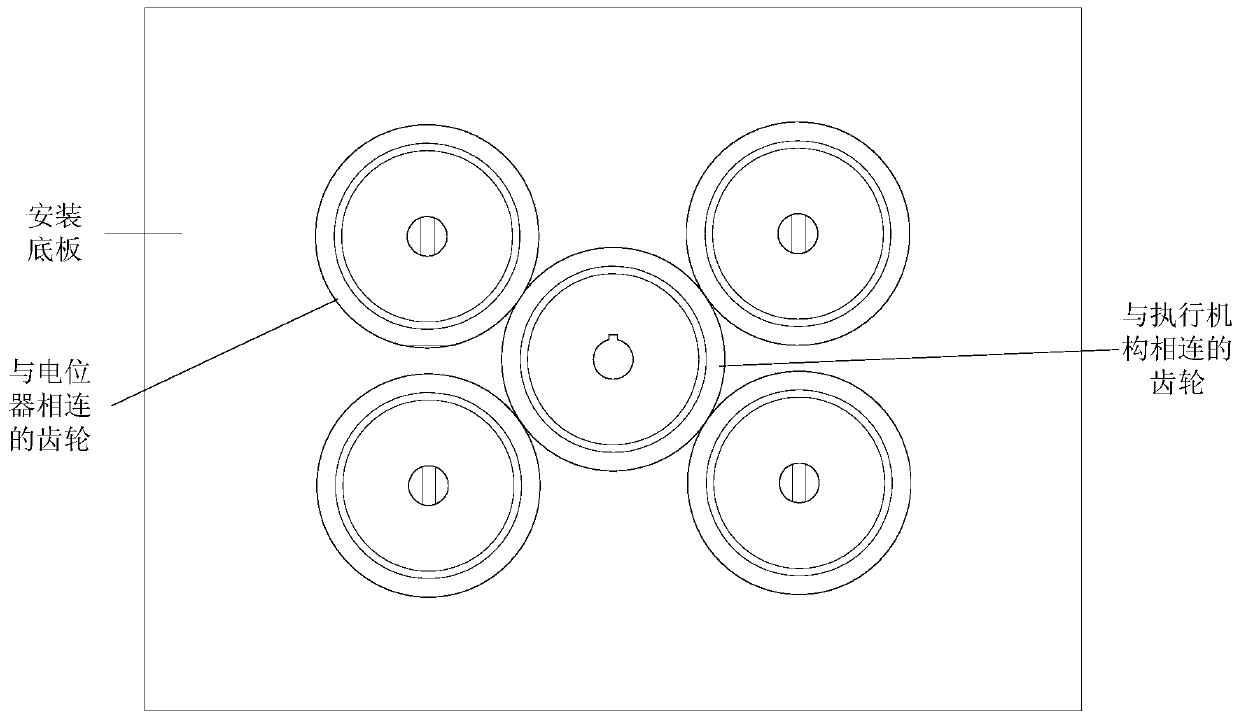

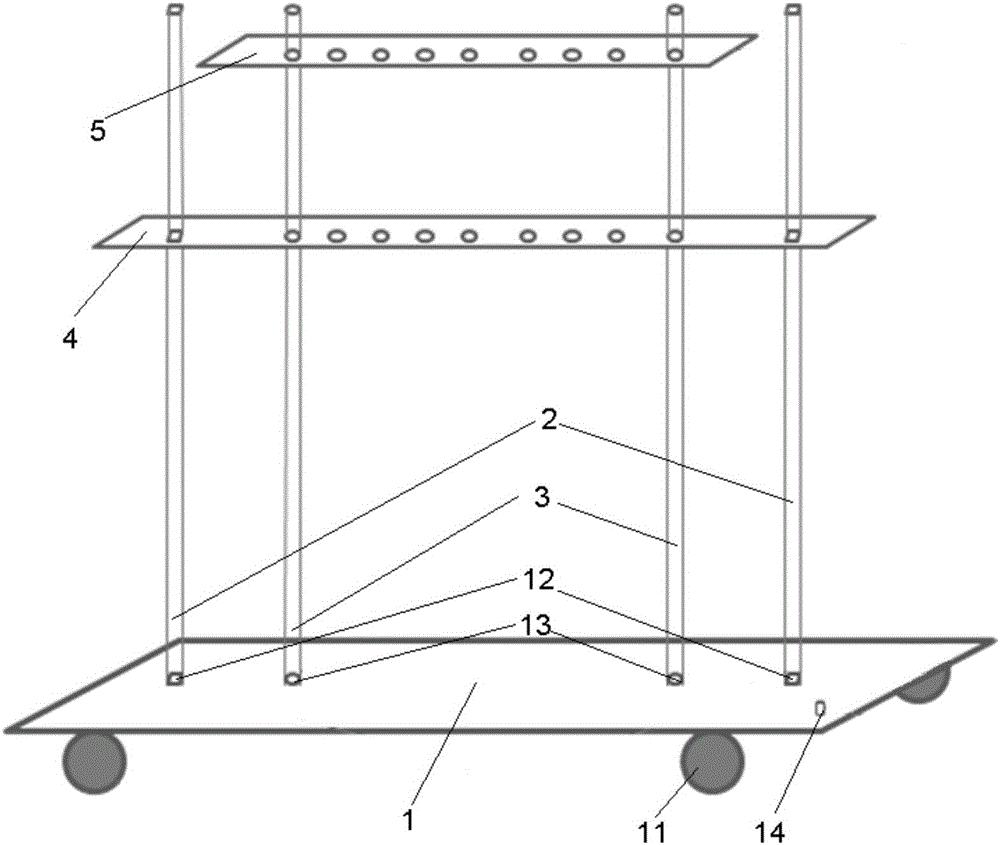

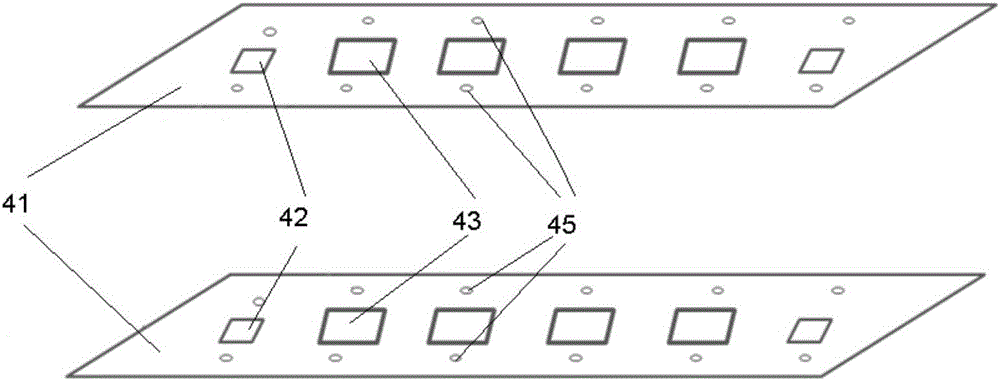

Multi-function potentiometer performance test system

InactiveCN110244159ASimple test operationAvoid errorsElectrical testingElectrical resistance and conductanceControl system

The present invention discloses a multi-function potentiometer performance test system, comprising a control system, an actuator, a digital multimeter, a host computer test system, and a potentiometer installing platform; wherein the host computer test system and the control system perform data exchange through an RS422, and the control system controls the actuator to drive a potentiometer to be tested to rotate according to an instruction of the host computer test system; the potentiometer installing platform is used to install the potentiometer to be tested; and the digital multimeter is used to test resistance data of the potentiometer and feed back the resistance data to the host computer test system through own RS232 serial port. The system has the advantages that, the system can automatically drive the potentiometer to rotate, is capable of digital display, can automatically interpret data, has high test precision, has convenient and rapid test process, and is capable of batch testing, etc., and significantly improves efficiency of the potentiometer entering a factory and of fault analysis.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

Insulation tester of insulating rods

InactiveCN106546888AAdjustable positionReduce labor intensityTesting dielectric strengthEngineeringHigh pressure

The invention discloses an insulation tester of insulating rods. The tester comprises a pedestal, metal pillars, insulated pillars, a grounding pole plate group and a pressurizing pole plate; and the metal pillars and the insulated pillars are inserted onto the pedestal, and the grounding pole plate group and a pressurizing pole plate sleeve the pillars to form an insulating rod test support which is used for insulation test of the insulating rods. The insulation tester can measure multiple insulating rods simultaneously, can measure insulating rods in different lengths effectively, is simple and convenient in operation and safe and reliable, and can reduce labor intensity of test staff, improve working efficiency, enhance analysis and determination capability of a test result in a test site, and make high-voltage test more standard and safer.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

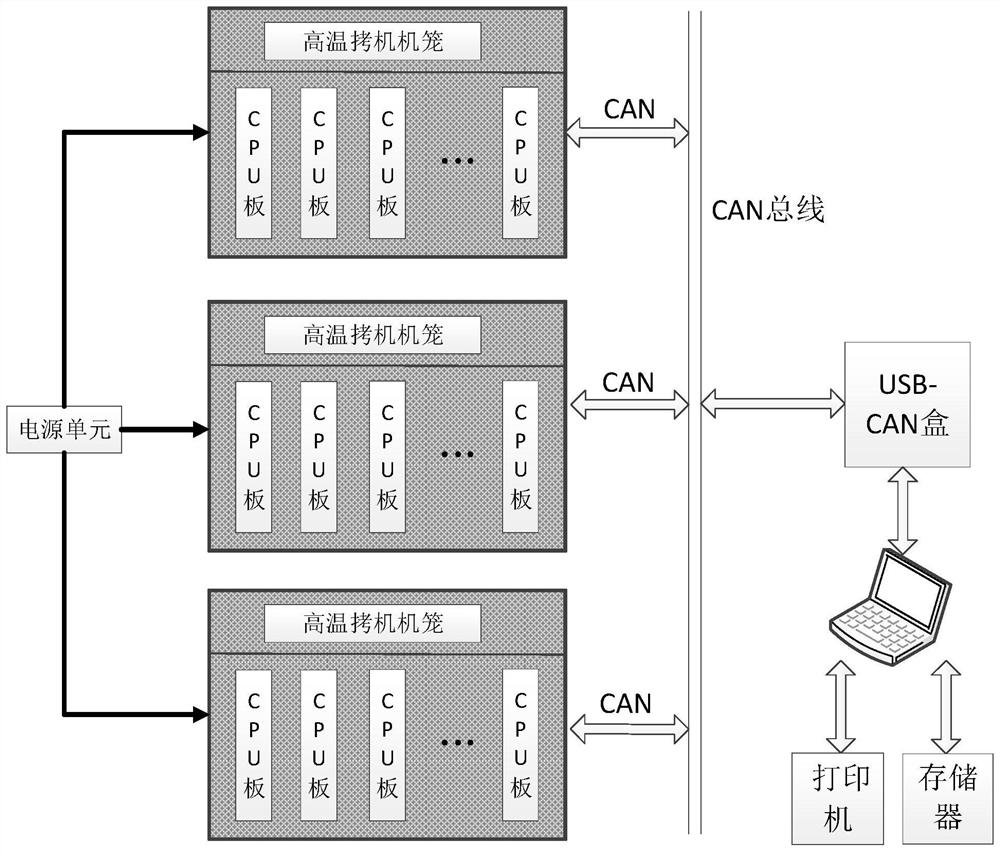

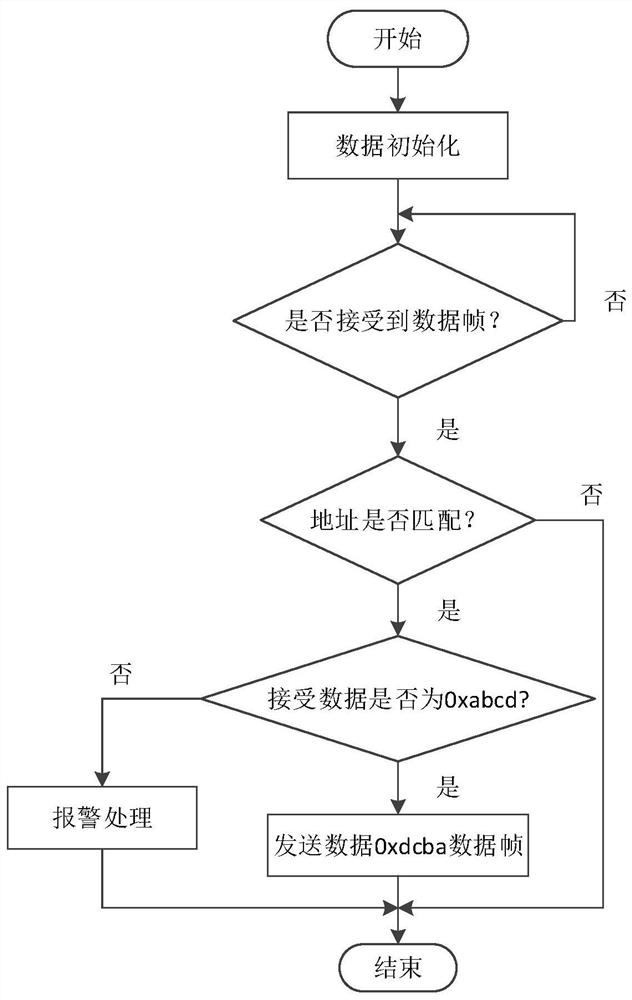

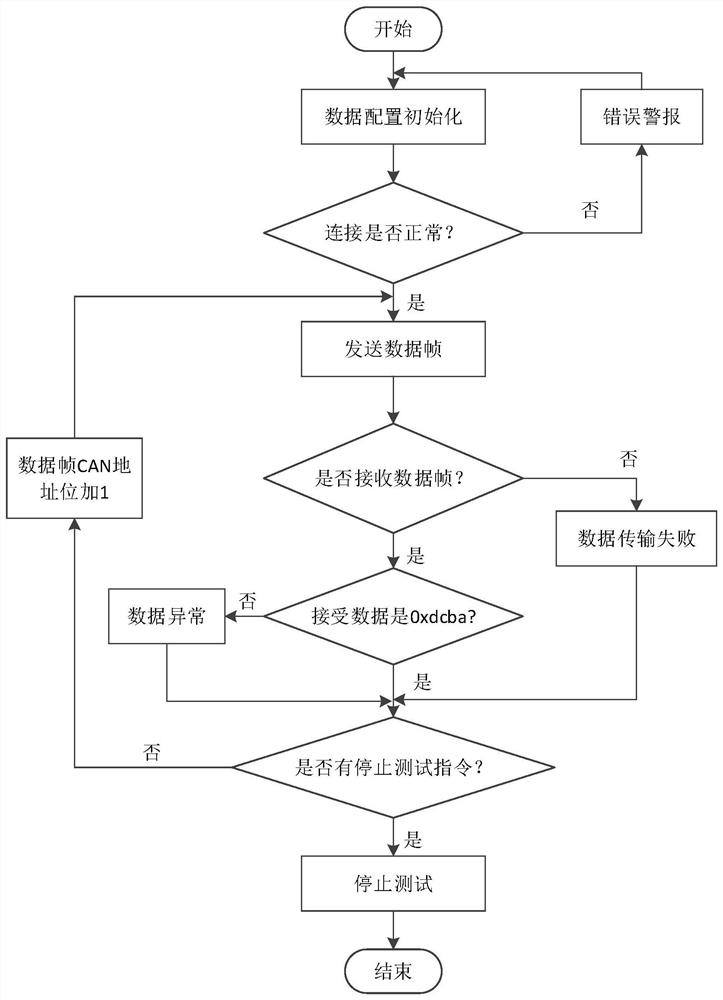

High-temperature burn-in test method, control end, tool end and system for iMS-CPU board

PendingCN112711502AAvoid normal workThe test results are complete and accurateFaulty hardware testing methodsBus networksControl engineeringCommunication control

The invention relates to a high-temperature burn-in test method, a control end, a tool end and a system for an iMS-CPU board. The test method comprises the steps that a control end sends a first type of data frame to a tool end, the CAN address in the data frame positions that the control end communicates with an iMS-CPU board matched with the CAN address, the control end carries out multiple times of cyclic polling detection, the iMS-CPU board with the corresponding CAN address responds, and a second type of data frame is returned to the control end. Compared with the prior art, the CAN communication state of the iMS-CPU board in the high-temperature environment is monitored in the whole process, the situation that the iMS-CPU board works abnormally in the high-temperature environment and cannot be monitored is avoided, and the test result is more complete and accurate.

Owner:SHANGHAI RAILWAY COMM

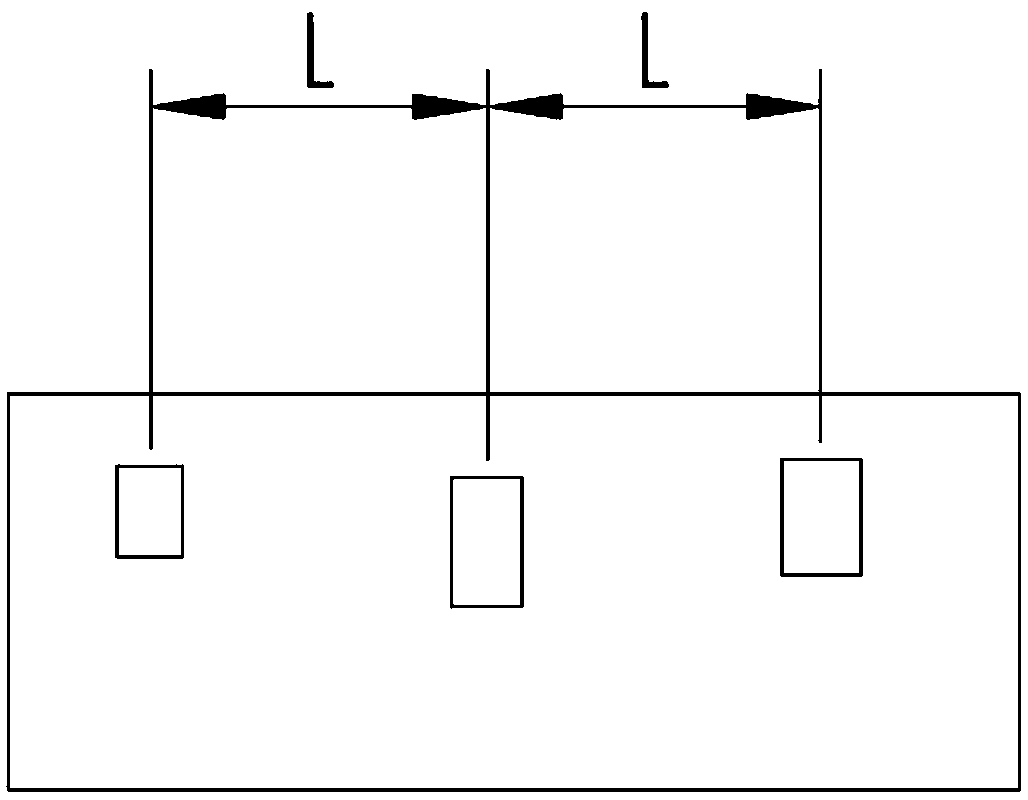

High-flux micro four-point bending stress corrosion initiation test device and method

InactiveCN113188985AEasy to controlSimultaneous testingWeather/light/corrosion resistanceSurface stressHigh flux

The invention provides a high-flux miniature four-point bending stress corrosion initiation test device and method and belongs to the technical field of corrosion science and corrosion prevention. The device comprises test clamps and a connecting device, wherein the test clamps play a role in supporting samples and applying loads, and the connecting device is used for connecting the test clamps and connecting the test clamps with a stretcher clamp and is matched with a nut to play a role in load transmission. The device is used for slowly applying a load to the micro sheet-shaped sample, and the corresponding relationship between the surface stress distribution of the sample and the external load is obtained through finite element numerical simulation, so the crack initiation stress can be accurately obtained. The test device is advantaged in the aspect of research on stress corrosion initiation of the micro-area represented by the fusion interface area of the metal welding joint, besides, a plurality of test clamps are connected in series on the guide rod, so a plurality of samples can be tested at the same time, test efficiency is greatly improved, and high-throughput evaluation of stress corrosion initiation is realized.

Owner:SOUTHWEST PETROLEUM UNIV +1

System for automatically testing service life of probe

ActiveCN102768348BEnables automated assessmentPrecise positioningElectrical measurementsData processing systemTester device

The invention discloses a system for automatically testing the service life of a probe. The system comprises a touching force sensor, the probe, a probe clamp, a probe electrode outgoing line, an up-down moving device, a four-wire type tester and a data processing system, wherein the data processing system is used for automatically saving tested data and analyzing the data in real time. The system is characterized in that the probe clamp is mounted on the moving end of the up-down moving device; the probe is mounted below the probe clamp; a circuit board for leading out the electrode of the probe is mounted above the probe clamp and is connected with the input end of the four-wire type tester by the probe electrode outgoing line; the touching force sensor is fixed under the probe and is connected with the data processing system by a wire; and the output end of the four-wire type tester is connected with the data processing system. The system for automatically testing the service life of the probe is simple in structure and precise in tested data, and can implement the automatic evaluation for the service life of the probe.

Owner:CENT SOUTH UNIV

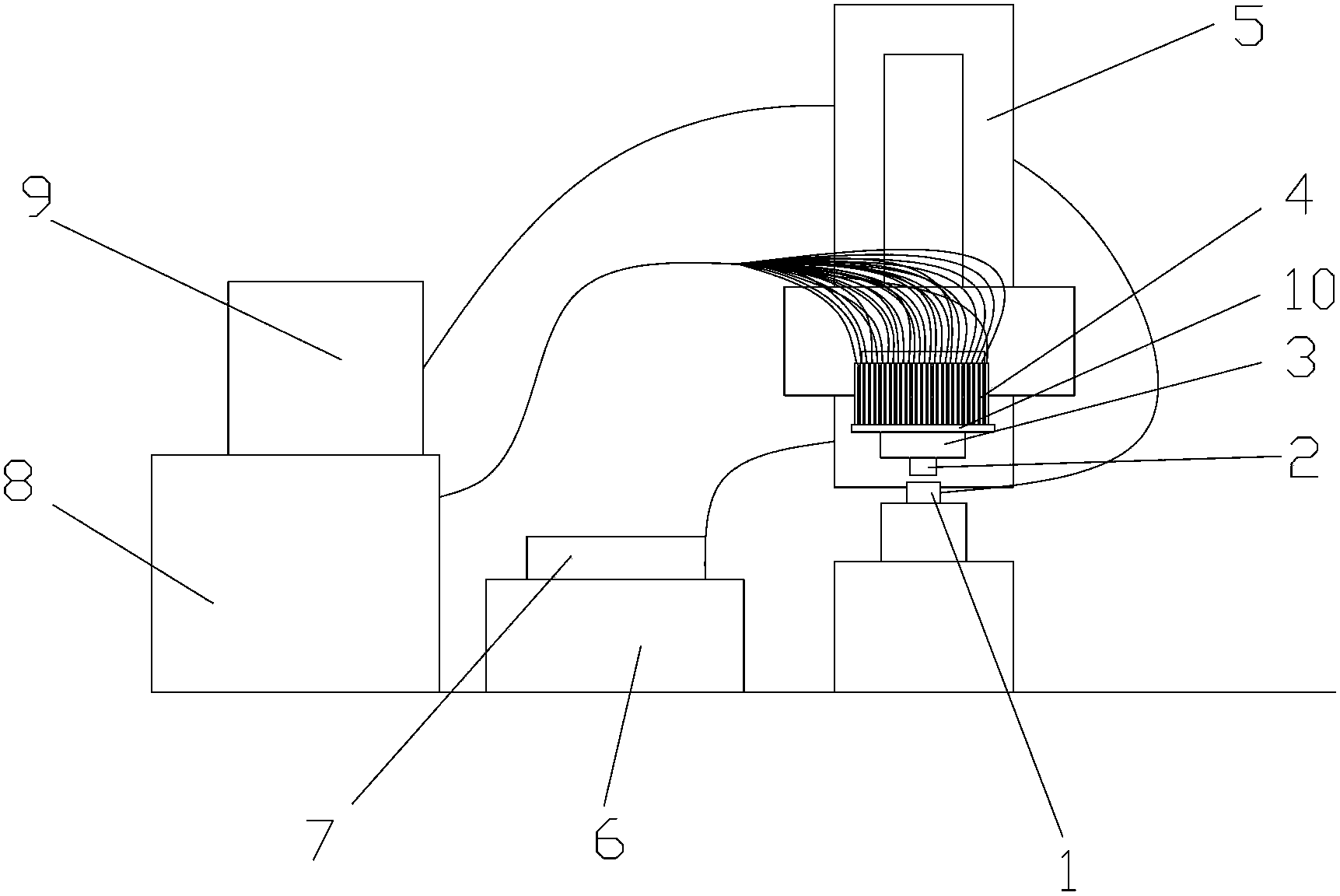

Full-automatic multi-channel cigarette head drop tendency detection device and detection method

ActiveCN108037300BSimultaneous testingImprove test repeatabilitySamplingCigarette manufactureCombustionFlue gas

A fully automatic multi-channel cigarette head drop tendency detection device and detection method, characterized in that the device includes a multi-channel turntable structural unit arranged in the main frame, a cigarette sample automatic sampling unit, cigarette sample automatic ignition and combustion line detection Unit, cigarette clamping and force application unit during test, automatic head drop detection and removal unit, smoke capture unit during smoking, suction unit, smoke removal unit, and circuits for controlling the actions and processes of the above units with air control unit. The device is used to perform automatic lighting and combustion line detection on the sample cigarettes sequentially inserted on the turntable according to certain steps, and to apply controllable external force to the cigarettes in the process of burning and smoking. The head-drop tendency performance of various cigarette products was tested. Utilizing the device can improve test repeatability and work efficiency.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com