Fine dried noodle bending and breaking rate measuring method and determinator based on axial compression amount

A technology of axial compression and measurement method, which is applied in the direction of using stable bending force to test the strength of materials, test food, material inspection products, etc. The effect of high, measurement science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

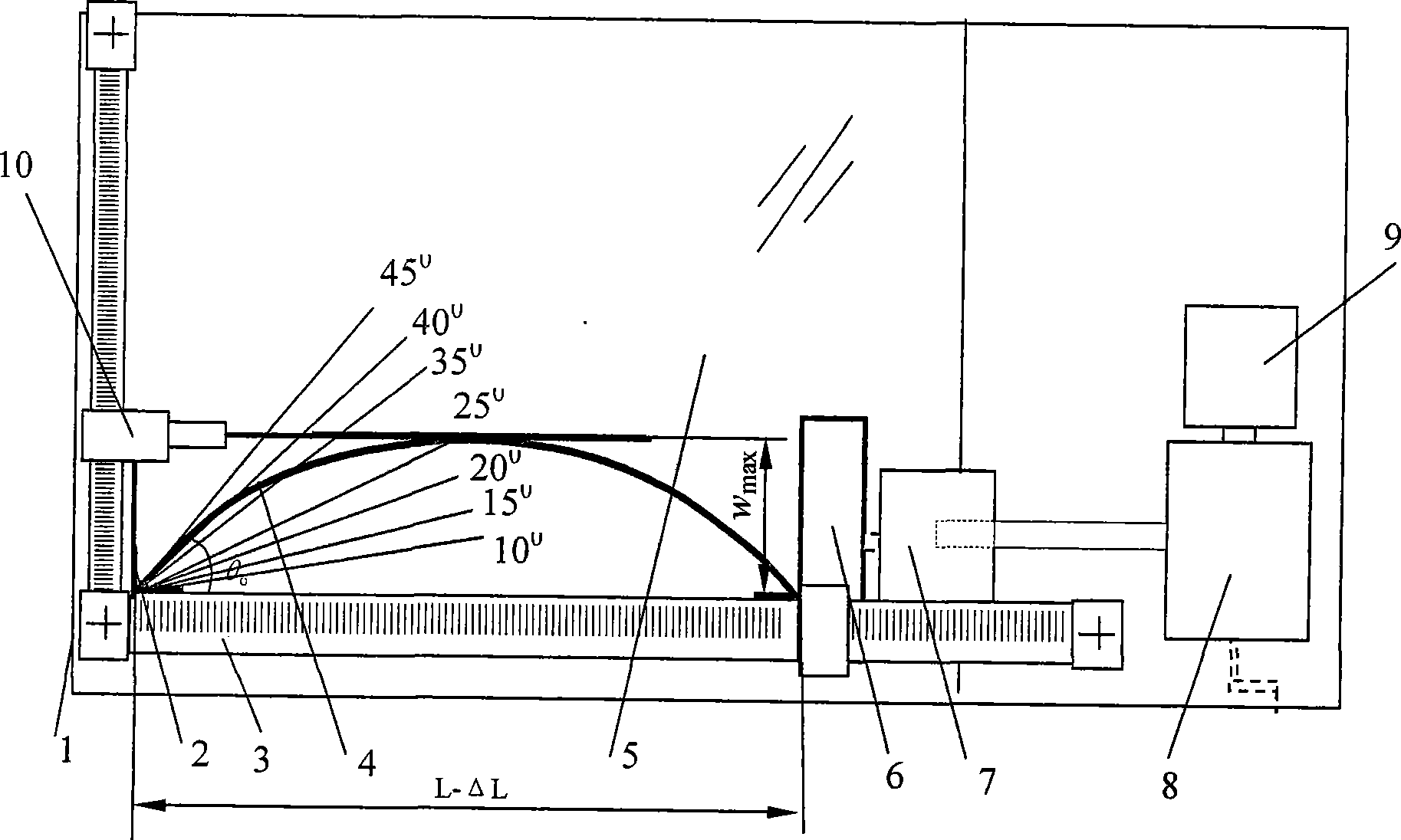

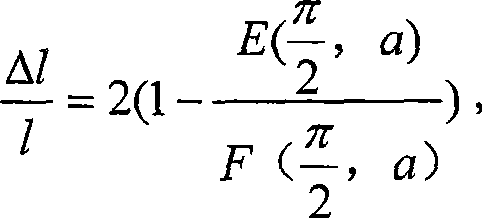

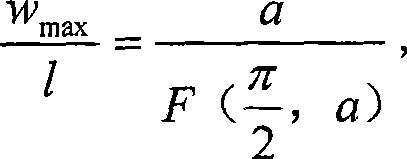

Embodiment 1

[0026] Measuring method of bending strip breaking rate of noodles 4 with a length of 180mm, randomly select 20 noodles, cut them into 180mm, and place them between the static support baffle 2 and the dynamic support baffle 6 of the measuring instrument, and make the static support baffle 2 The distance between the measuring groove on the movable support baffle 6 is equal to the length of the noodle 4 (180mm), and the movable support baffle 6 is pushed by the motor 9, the continuously variable transmission device 8 and the nut screw 7 to cause the noodle 4 to produce axial compression and instability bending When the axial compression (displacement) of the dynamic support baffle 6 does not reach the specified value, the axial compression is broken, that is, the bending fracture strip. When the thickness of the noodle 4 is greater than 0.9mm, the specified axial compression is greater than or equal to 8.50mm (equivalent to the current standard bending angle greater than or equal to ...

Embodiment 2

[0028]The measuring method of the bending strip rate of the noodle 4 with a length of 210mm. 20 noodles are randomly selected and cut into 210mm. They are placed between the static support baffle 2 and the dynamic support baffle 6 of the measuring instrument, and the static support baffle 2 The distance between the measuring groove on the movable support baffle 6 is equal to the length of the noodle (210mm). The motor 9, the continuously variable transmission device 8 and the nut screw 7 push the movable support baffle 6 to cause the noodle 4 to produce axial compression and instability bending. When the axial compression amount (displacement) of the dynamic support baffle 6 does not reach the specified value, the axial compression amount breaks, that is, the bending fracture strip. When the thickness of the noodle 4 is greater than 0.9mm, the specified axial compression is greater than or equal to 13.27mm (equivalent to the bending angle greater than or equal to 29°); when the th...

Embodiment 3

[0030] The method for measuring the bending strip rate of the noodle 4 with a length of 150mm, randomly select 20 noodles, cut them into 150mm, and place them between the static support baffle 2 and the dynamic support baffle 6 of the measuring instrument, and make the static support baffle 2 The distance between the measuring groove on the movable support baffle 6 is equal to the length of the noodle 4 (150mm), and the movable support baffle 6 is pushed by the motor 9, the continuously variable transmission device 8 and the nut screw 7 to cause the noodle 4 to produce axial compression and unstable bending , When the axial compression (displacement) of the dynamic support baffle 6 does not reach the specified value and the axial compression is broken, it is a bending break. When the thickness of the noodle 4 is greater than 0.9mm, the specified axial compression is greater than or equal to 5.01mm (equivalent to the bending angle greater than or equal to 21°); when the thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com