High-flux micro four-point bending stress corrosion initiation test device and method

A technology of stress corrosion and four-point bending, which is applied in measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve problems such as difficulty in accurately obtaining crack initiation stress and low test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

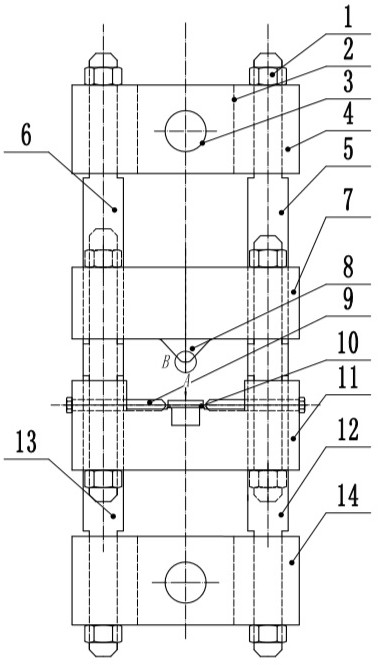

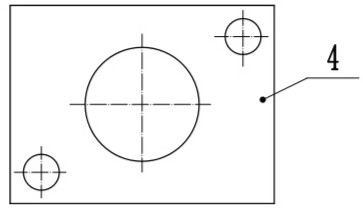

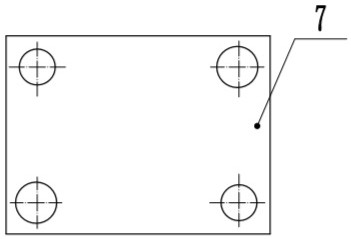

[0038] The design of the test device in this embodiment: the device includes a test fixture and a connecting device. In this embodiment, the size of the sample is selected as 8×4×1mm, and the sample is a welded joint of nickel-based 625 surfacing on X80 steel, and the fusion line is located in the middle of the sample, so the material of the device is selected as nickel-based 625 alloy. The test fixture consists of a loading fixture, a concave fixture, bolts, and positioning pins. The overall size of the loading fixture is 25×20×8mm, and the size of the indenter is 7×6×2.5mm. The overall size of the concave fixture is 25×20×10mm; it is in the shape of a two-step stepped groove, the bolt specification is M3.5, and the length is 15mm. Each concave fixture needs two bolts; four positioning pins are wedged into the concave fixture The corresponding positions are 4mm apart in the width direction. There are guide holes in the four corners of the loading fixture, and the diagonals ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com