High-temperature burn-in test method, control end, tool end and system for iMS-CPU board

A test method and technology of the control terminal, which is applied in the field of control terminal, tooling terminal and system, and high-temperature copying machine test, which can solve the problems of undetectable disconnection, bulky, complicated test process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

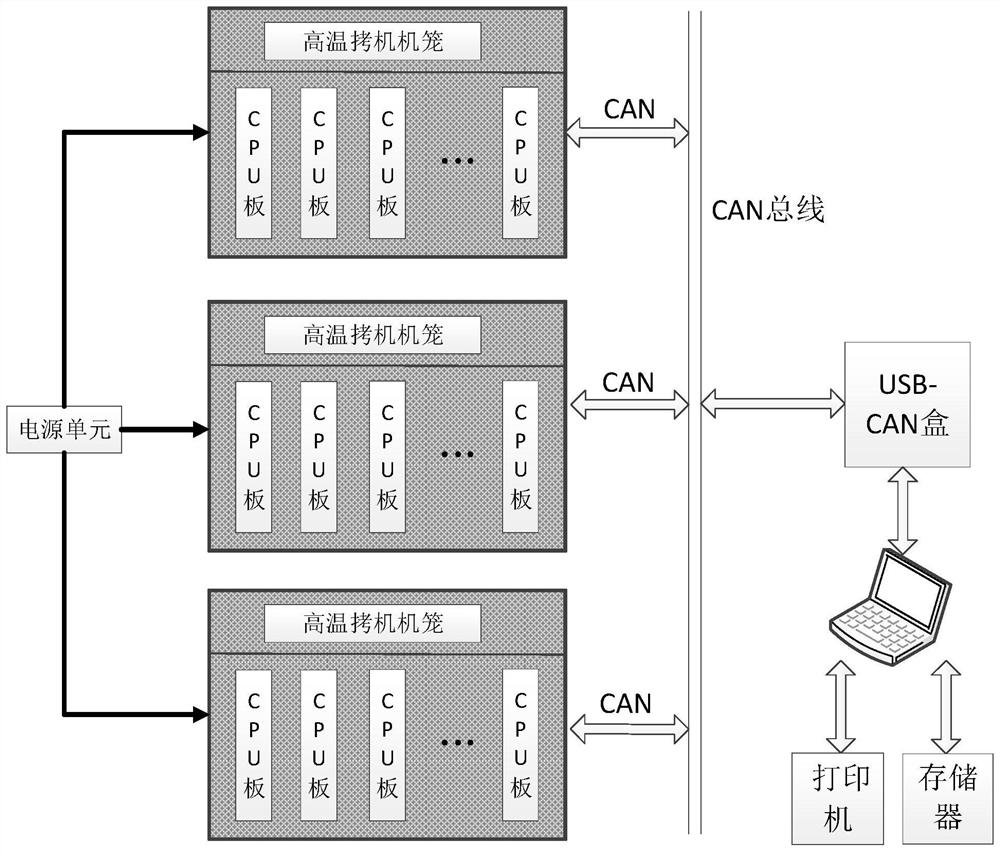

[0043] This embodiment provides a high-temperature copying test system for an iMS-CPU board, including a control terminal and a tooling terminal. The circuit structure of the test system is as follows figure 1 Shown:

[0044] The tooling side includes the power supply unit, three high-temperature copying machine cages and the iMS-CPU board to be tested. Among them, the power supply unit outputs two independent 5V voltage signals and one 24V voltage signal for each high-temperature copying machine cage, and the two independent 5V voltage signals provide power for the iMS-CPU communication and the internal chip of the iMS-CPU board card, and the 24V voltage The signal is used to power the cage. Insert 10 iMS-CPU boards into each high-temperature copying machine cage for simultaneous testing. The back panel of the cage is equipped with a power inlet, a CAN communication interface, and an analog input port. The control terminal adopts a PC with a display, and is connected to th...

Embodiment 2

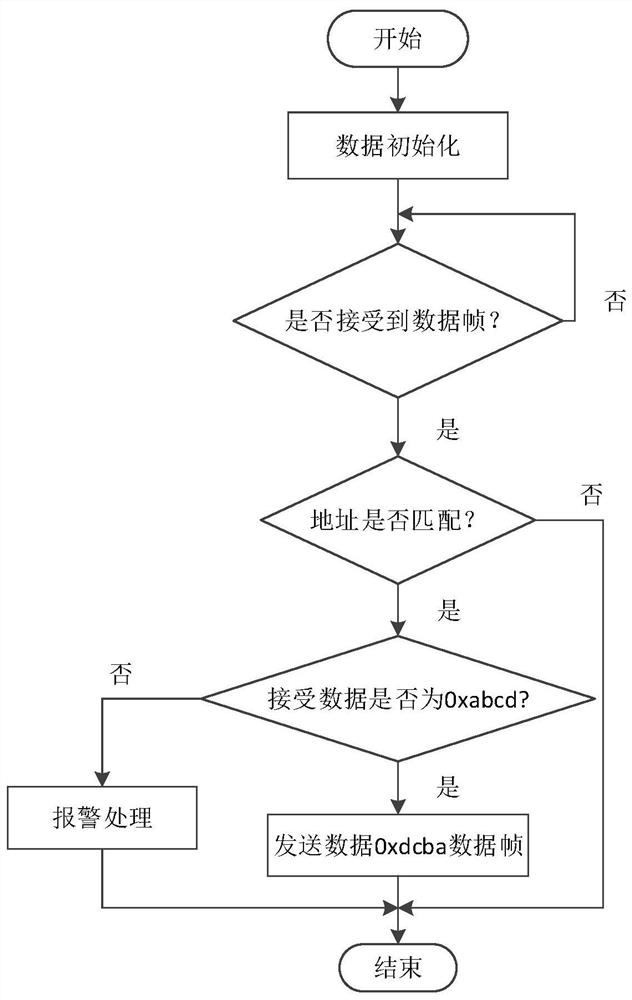

[0061] This embodiment provides a tooling end for high-temperature copying test of iMS-CPU board, including:

[0062] Tooling initialization module, used for data initialization;

[0063] The tooling receiving module is used to judge whether the first type of data frame is received;

[0064] The address matching module responds when the tooling receiving module receives the first type of data frame, and is used to judge whether the CAN address in the received first type of data frame is the same as the CAN address of the iMS-CPU board loaded on the tooling side;

[0065] The tooling processing module is used to judge whether the data information in the received first type data frame is correct;

[0066] The alarm module responds when the data information judged by the tooling processing module is wrong, and is used to send alarm information;

[0067] The tooling sending module responds when the data information judged by the tooling processing module is correct, and is used ...

Embodiment 3

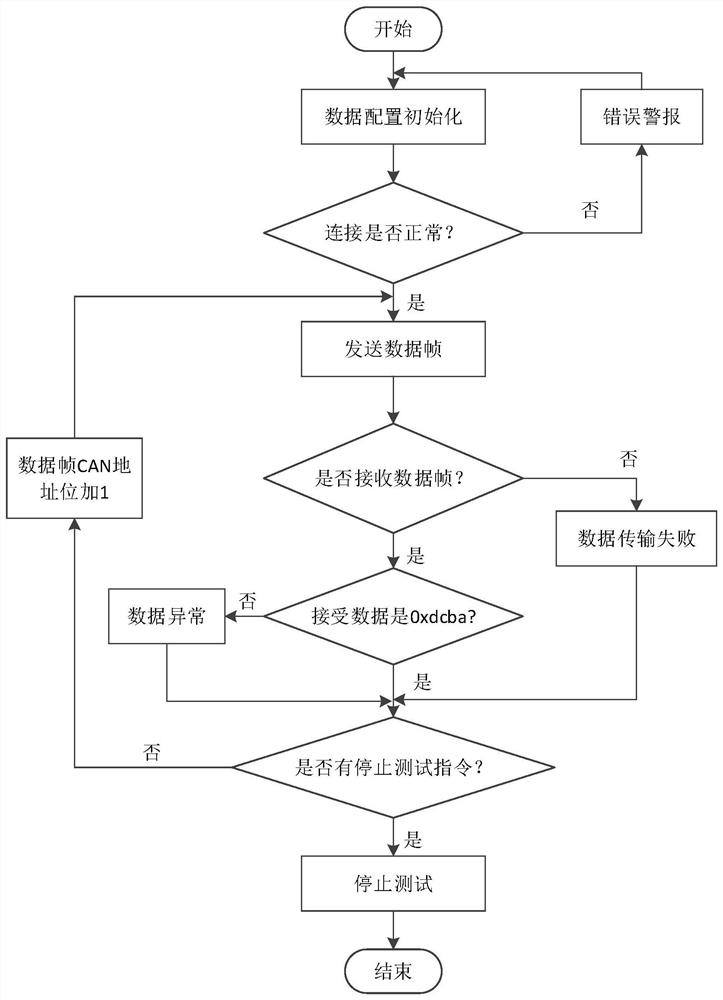

[0076] This embodiment provides a control terminal for high-temperature copying test of iMS-CPU board, including:

[0077] The control initialization module is used for data initialization;

[0078] Self-inspection module, used to detect whether the connection of the test line is correct;

[0079] Control the sending module, used to send the first type of data frame;

[0080] The control receiving module is used to judge whether the second type of data frame is received, and if the reception is successful, the control processing module is triggered; if the reception fails, the second type of data frame is skipped, and the stop judgment module is triggered;

[0081] The control processing module is used to judge whether the data information in the second type of data frame received is correct, if so, then display the correct data on the display at the control end, and trigger the stop judging module; if not, then trigger the abnormal data recording module ;

[0082] The stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com