Neutron diffraction method for welding residual stress of duplex stainless steel thick plate

A duplex stainless steel, residual stress technology, applied in force/torque/work measuring instruments, material analysis using wave/particle radiation, measuring devices, etc., can solve the problem of not being able to effectively improve the efficiency of neutron diffraction testing of thick plate residual stress And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

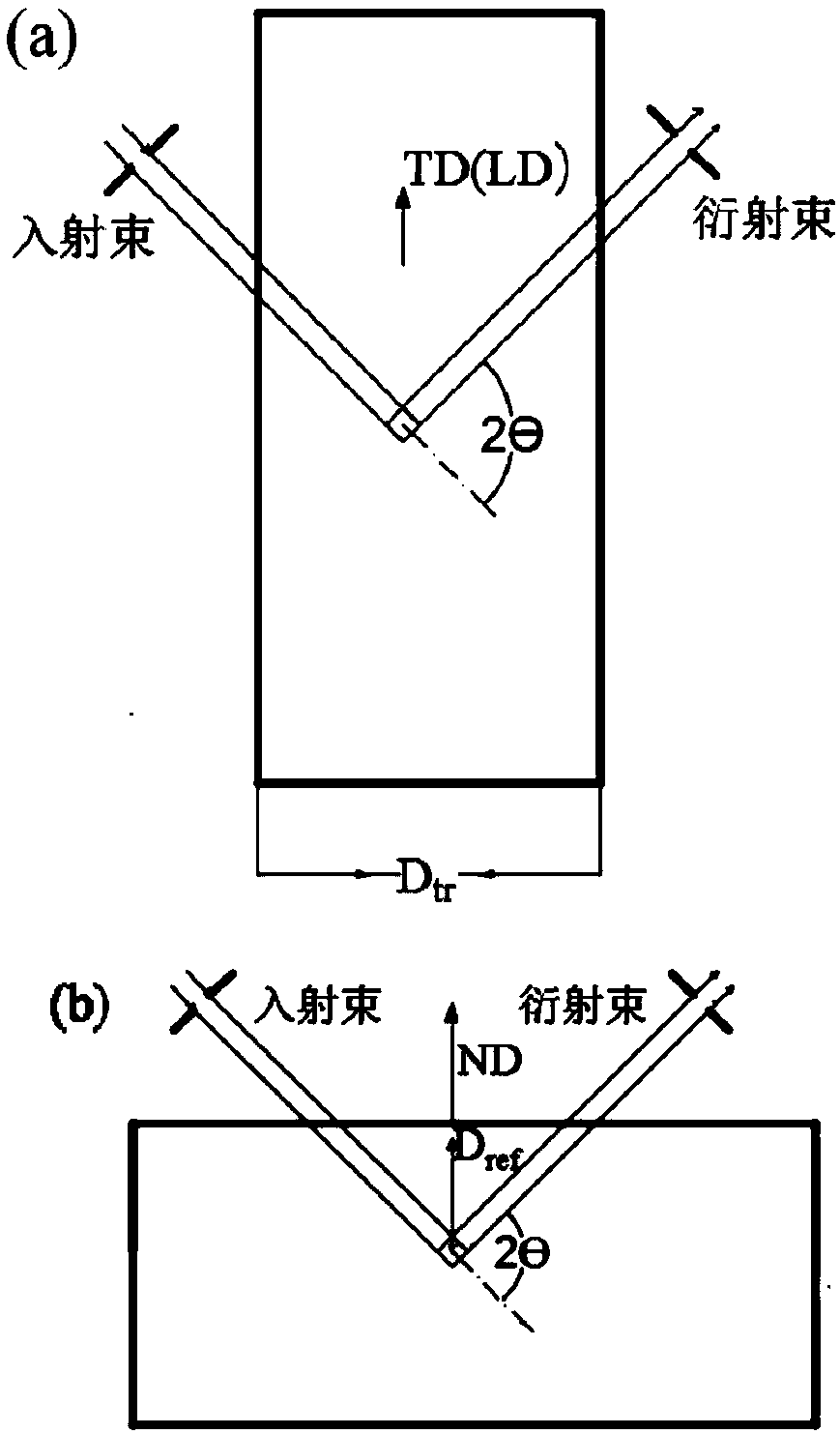

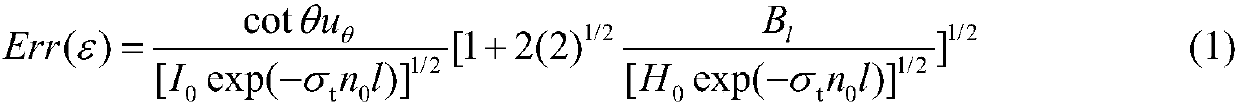

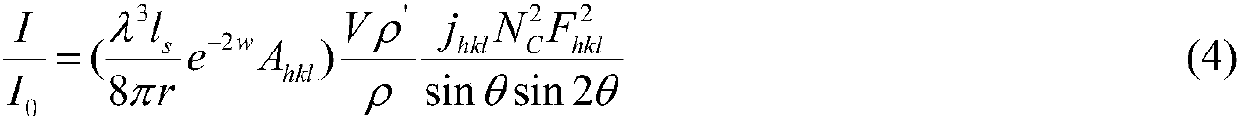

[0061] At present, the neutron diffraction test in my country only tests the macroscopic residual stress of single-phase materials, and there is no clear calculation and test method to realize the residual stress test of duplex stainless steel by neutron diffraction. Usually, the method of testing the ratio of two phases, such as EBSD and other electron microscope observation methods, can only realize the phase ratio evaluation of a certain section, and the wide-angle XRD can only realize the phase ratio test of a specific volume range, which is difficult to accurately measure by other methods The ratio of the two phases within the canonical volume in a neutron diffraction test. In general, increasing the gauge volume and test time is a common method for testing the residual stress of thick plates using neutron diffraction. However, the maximum size of the specification volume is limited by the resolution required by the test, and the test time cannot be effectively increased ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com