Method and device suitable for measuring fluffing and pilling amount and abrasion amount of textile

A technology of pilling and measuring devices, which is applied in the directions of measuring devices, adopting mechanical devices, testing wear resistance, etc., can solve the problems of high price, affecting test accuracy, test reproducibility, and poor representativeness of samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

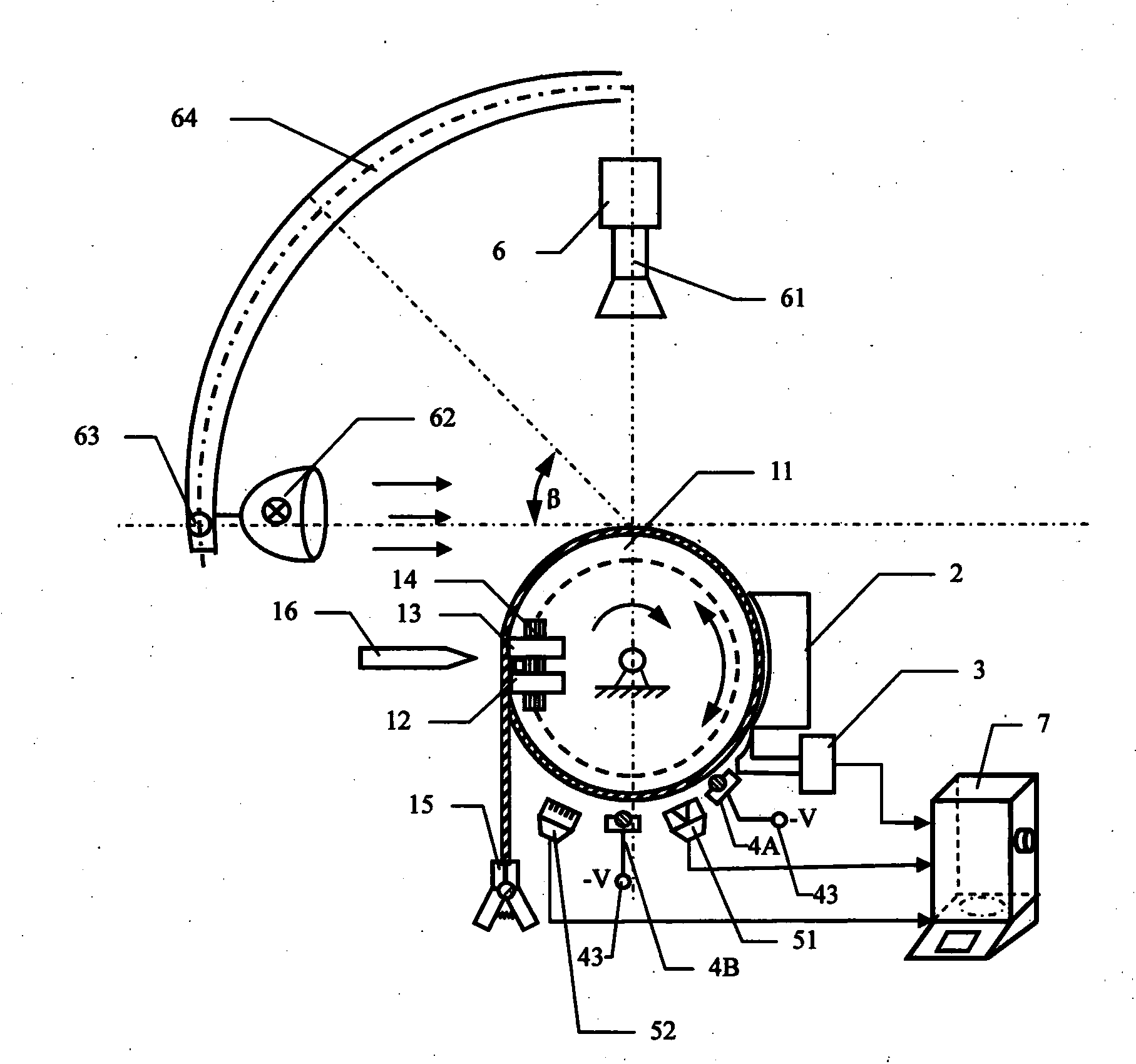

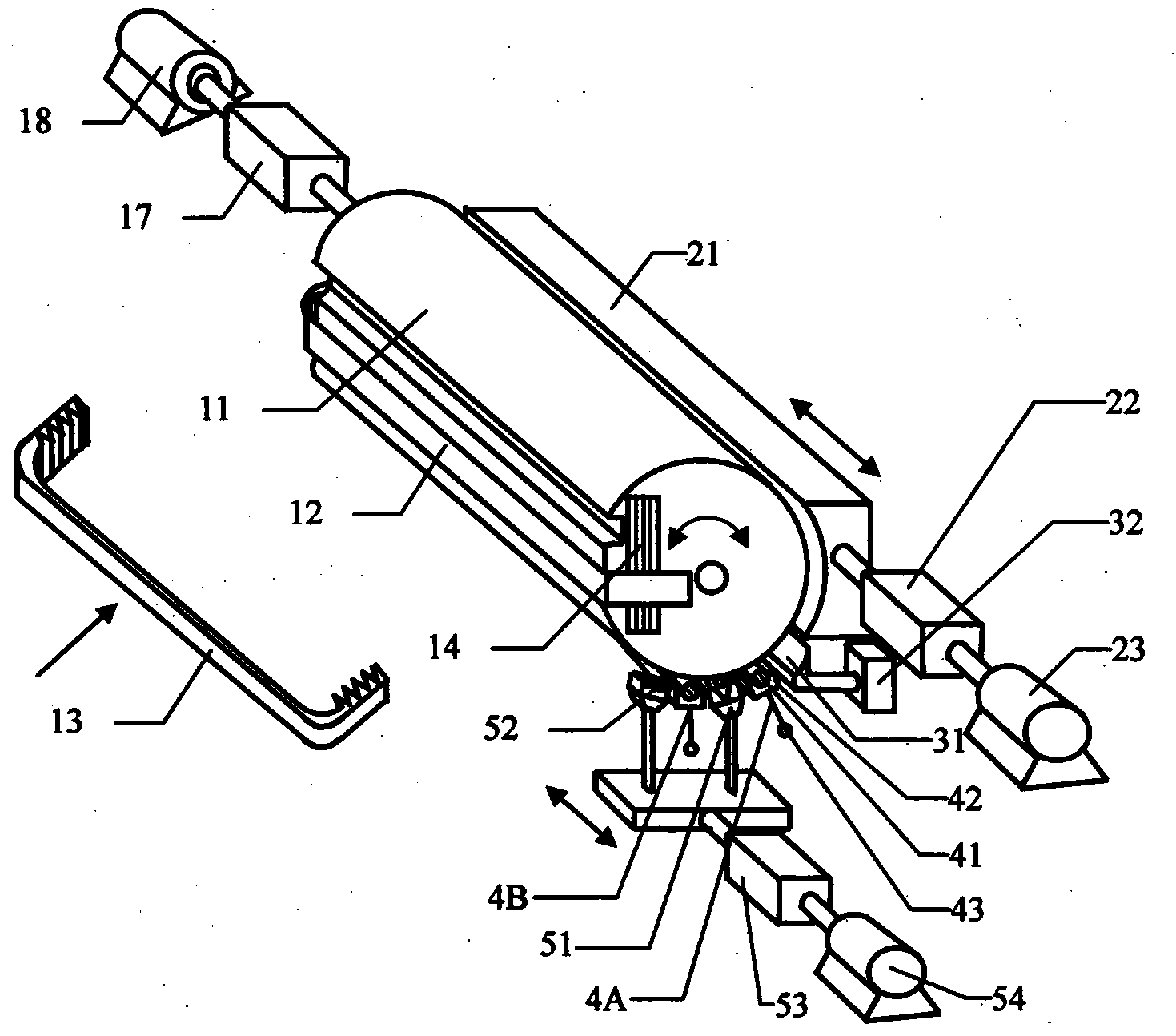

[0096] Using the device of the present invention, such as Figure 1~3 As shown, the measurement of the process friction sample in the first step to the third step is done for the pilling of the all-wool woven fabric whose yarn count is Nm48 / 2, and its measurement condition parameters and actual measurement results are shown in the following table embodiment 1 One column and the process measurement curve of the third step are shown in Figure 4 . The asymmetric back and forth rotation of the cloth sample cylinder 1 is adopted, that is, the advancing angle is 60°, and the retreating angle is 55°; the supporting reciprocating movement distance is 6cm, so that the friction block 21 can gradually move the fabric on the cloth sample cylinder 1. Ru curve friction. From the actual measurement results, it can be seen that the final state of the all-wool woven fabric after wear is more fuzzy, the average hairiness length is 5.6mm, the density is 0.175, and the hairiness significance i...

Embodiment 2

[0098] Using the same method and device as in Example 1, the cashmere knitted fabric with a yarn count of Nm28 / 2 is pilling according to the full set of measurement and calculation results from the first step to the fourth step, and the initial sample of the measured cloth sample is obtained. , the fuzzing and pilling of the process friction sample and the final state friction sample, one by one analysis and the comprehensive evaluation of the final results, the measurement condition parameters and the actual measured final state friction sample results are shown in the column of Example 2 in the table below. The symmetrical rotation in the reciprocating rotation of the cloth sample cylinder 1 is adopted, that is, the rotation in which the advancing angle of forward rotation is equal to the retreating angle of reverse rotation. The cashmere knitted fabric on cylinder 1 is subjected to constant Lissajous curve friction, and its friction number N2 is only 2 / 3 of that of Example 1...

Embodiment 3

[0100]Using the same method and device as in Example 1, the pilling of wool polyester sweaters with a yarn count of Nm32 / 2 is based on the fourth step of measurement under the same experimental conditions and the influence of the first step of the package sample. Combined with the calculated results, a comprehensive evaluation of the pilling performance of the tested fabric sample is obtained. Its measurement condition parameters and actual measurement results are shown in the column of Example 3 in the following table. The drum 11 is not moved and the friction block 21 is used for reciprocating translation friction sample preparation. The supporting reciprocating movement distance is 2.5cm. Every time 50 times of reciprocating grinding are completed, it is rotated 90° until 20 cycles of 1000 times of friction. Example 1 has the same number of frictions, but different trajectories. It can be seen from the actual measurement results that the final friction-like fluffing of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com