Patents

Literature

265results about How to "Meet the measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

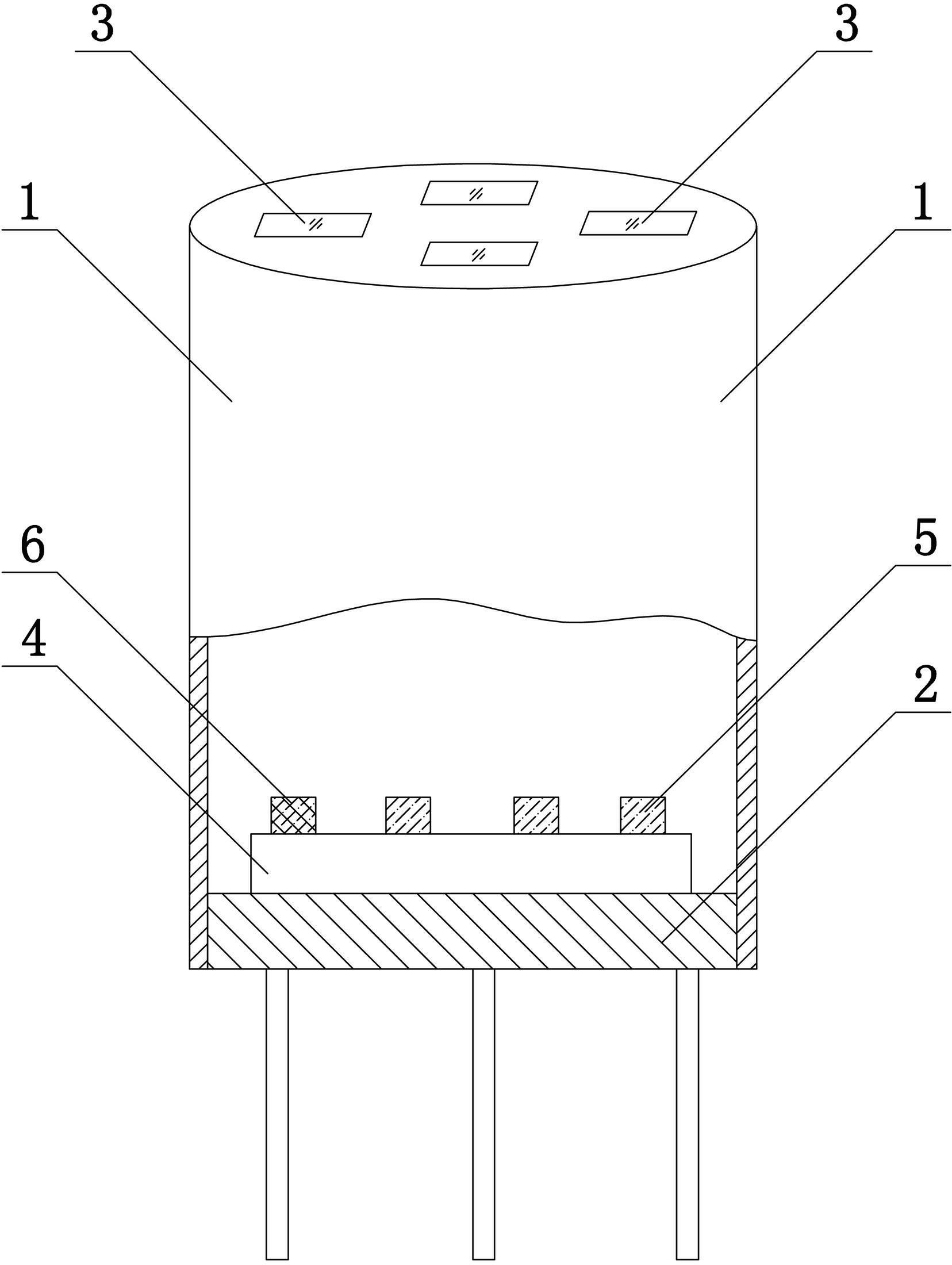

Nonideal explosive work capacity measuring device

InactiveCN103412107AExplosive capability measurement meetsMeet the measurementFuel testingShock waveMeasurement device

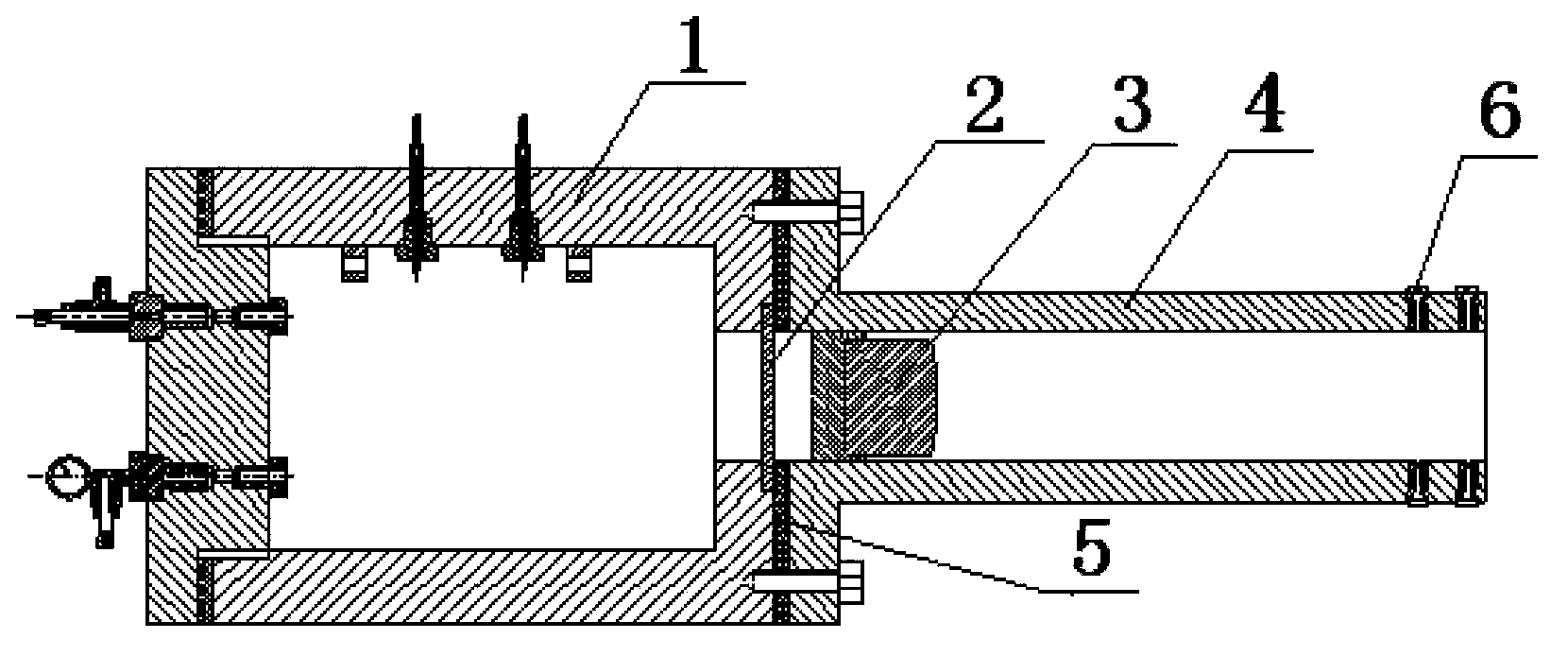

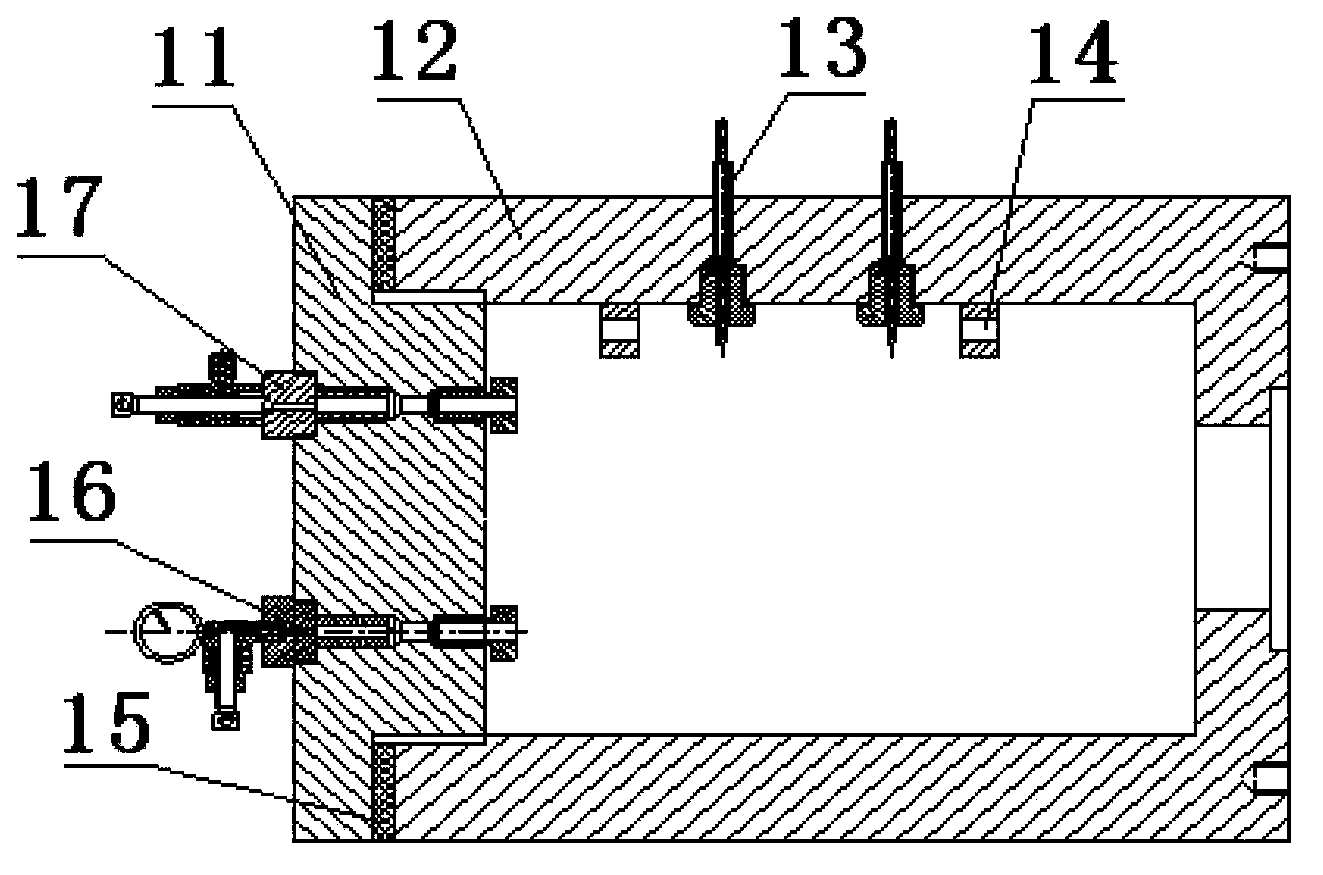

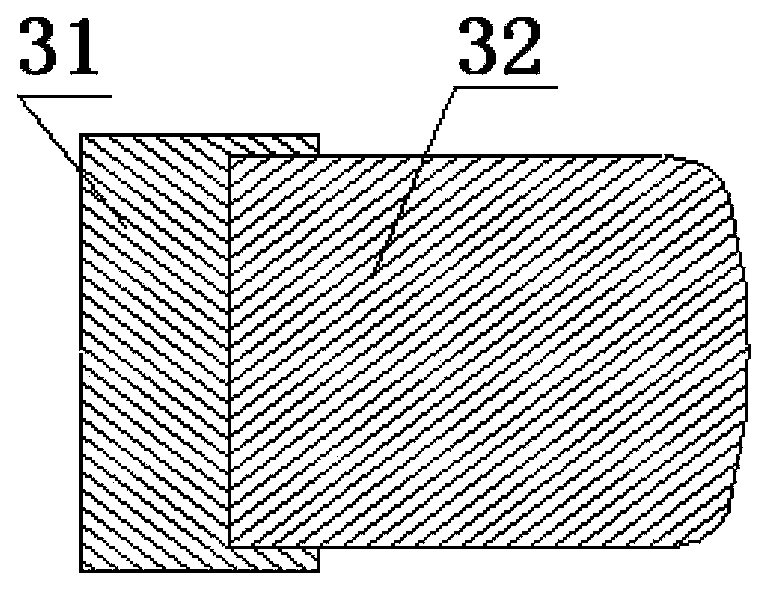

The invention discloses a nonideal explosive work capacity measuring device. The device comprises a priming electrode, an explosion cavity, a bullet sliding cylinder, bullets and a velometer, wherein the inner top of the explosion cavity is provided with an explosive suspension loop; the priming electrode is internally communicated with the explosion cavity; the explosion cavity is connected with the bullet sliding cylinder and the explosion cavity and the bullet sliding cylinder are communicated; the bullets are arranged in the bullet sliding cylinder; and the velometer is arranged in the bullet sliding cylinder. According to the measuring device, the bullets and the bullet sliding cylinder are designed, and the bullet sliding cylinder is communicated with the explosion cavity, so that explosion impact shock wave energy, product expansion energy and energy released by sustained reaction are converted into kinetic energy for accelerated motion of the bullets in the bullet sliding cylinder, the velocity of the bullets flying out of an opening of the bullet sliding cylinder is measured by utilizing the velometer arranged at the tail end of the bullet sliding cylinder, and the flight kinetic energy of the ruler bullets can be calculated; according to the principle of energy transformation and conservation, the kinetic energy of the bullets is the work load of an explosive, namely the explosive work capacity.

Owner:XIAN MODERN CHEM RES INST

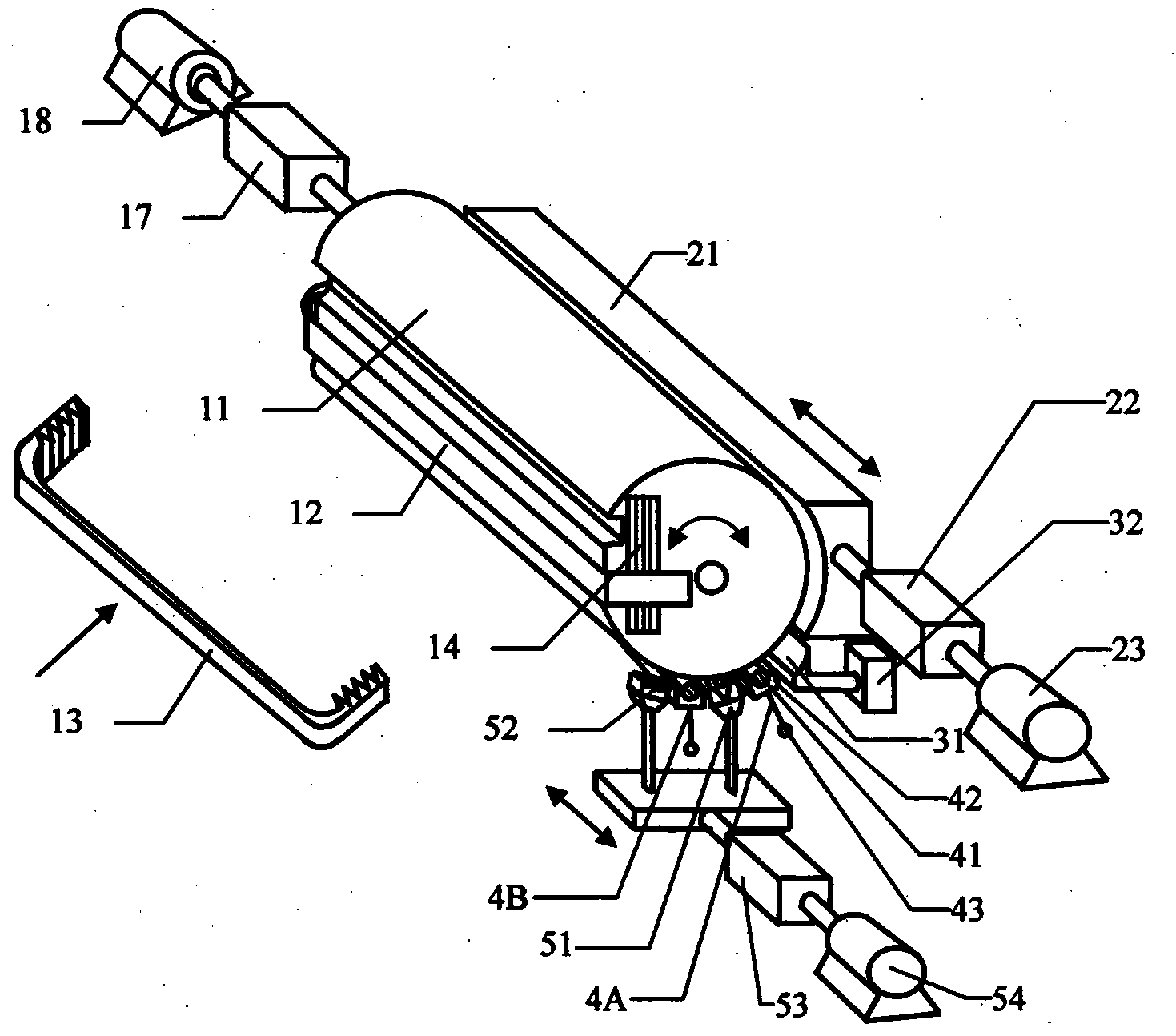

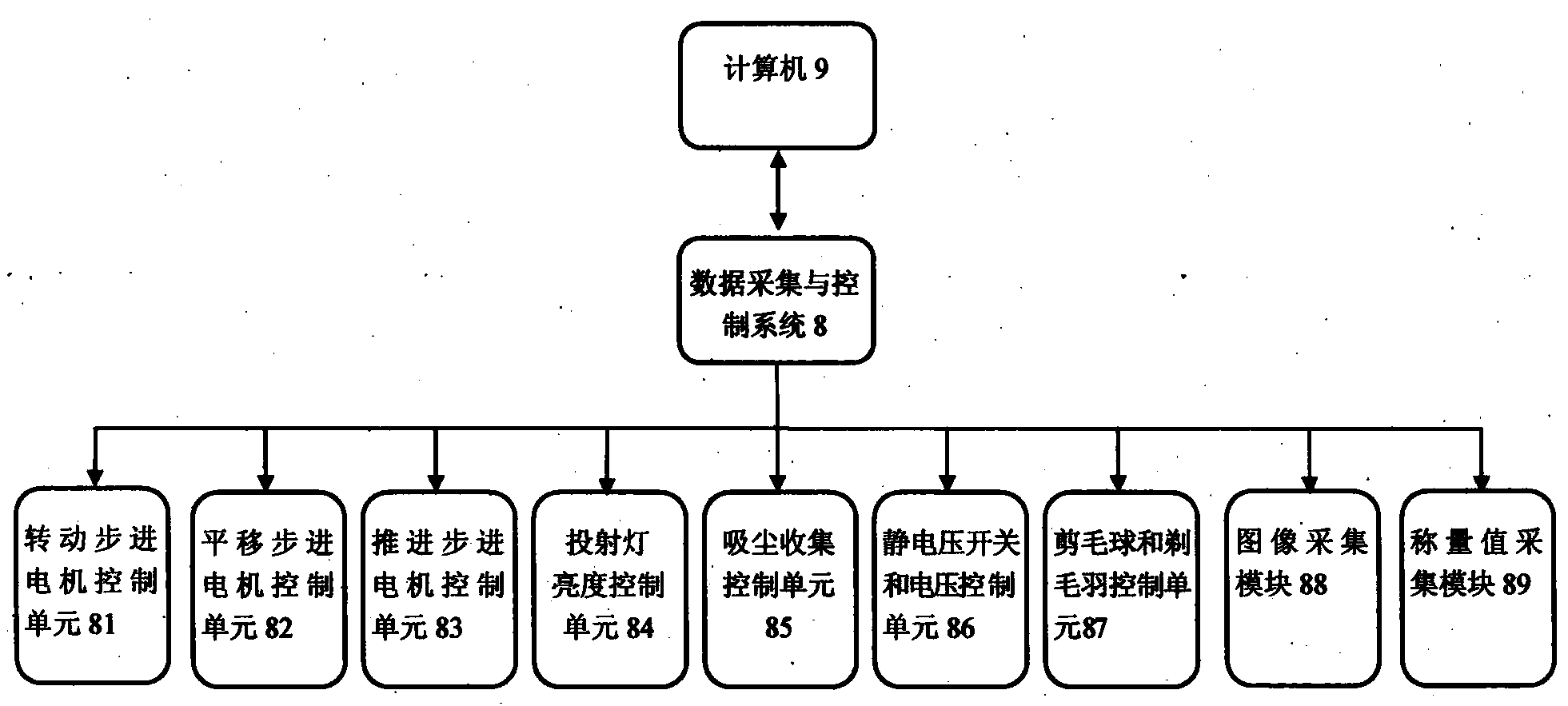

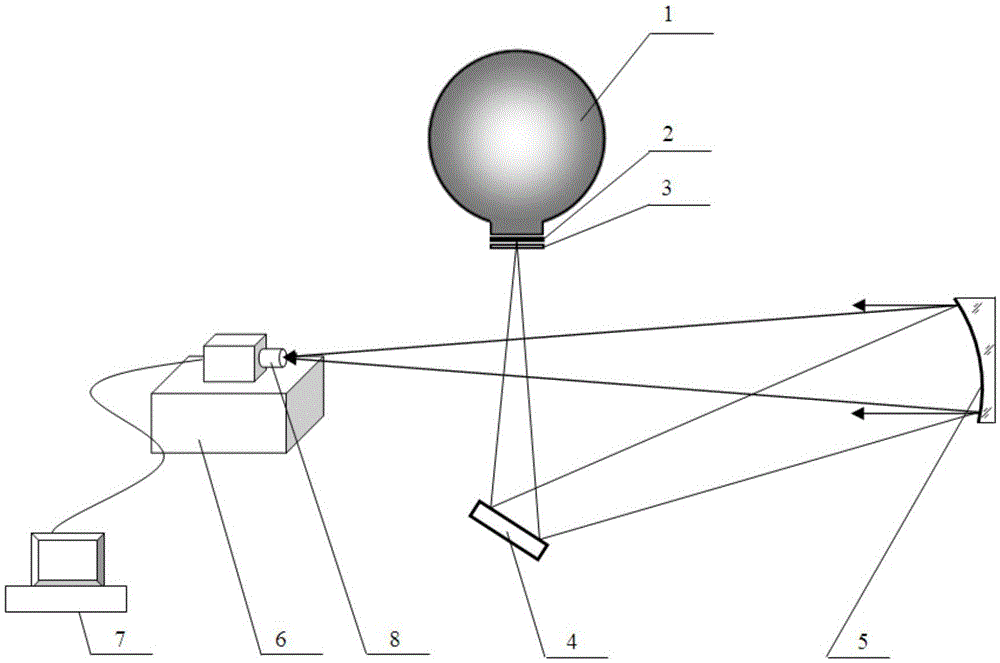

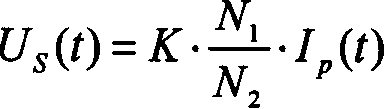

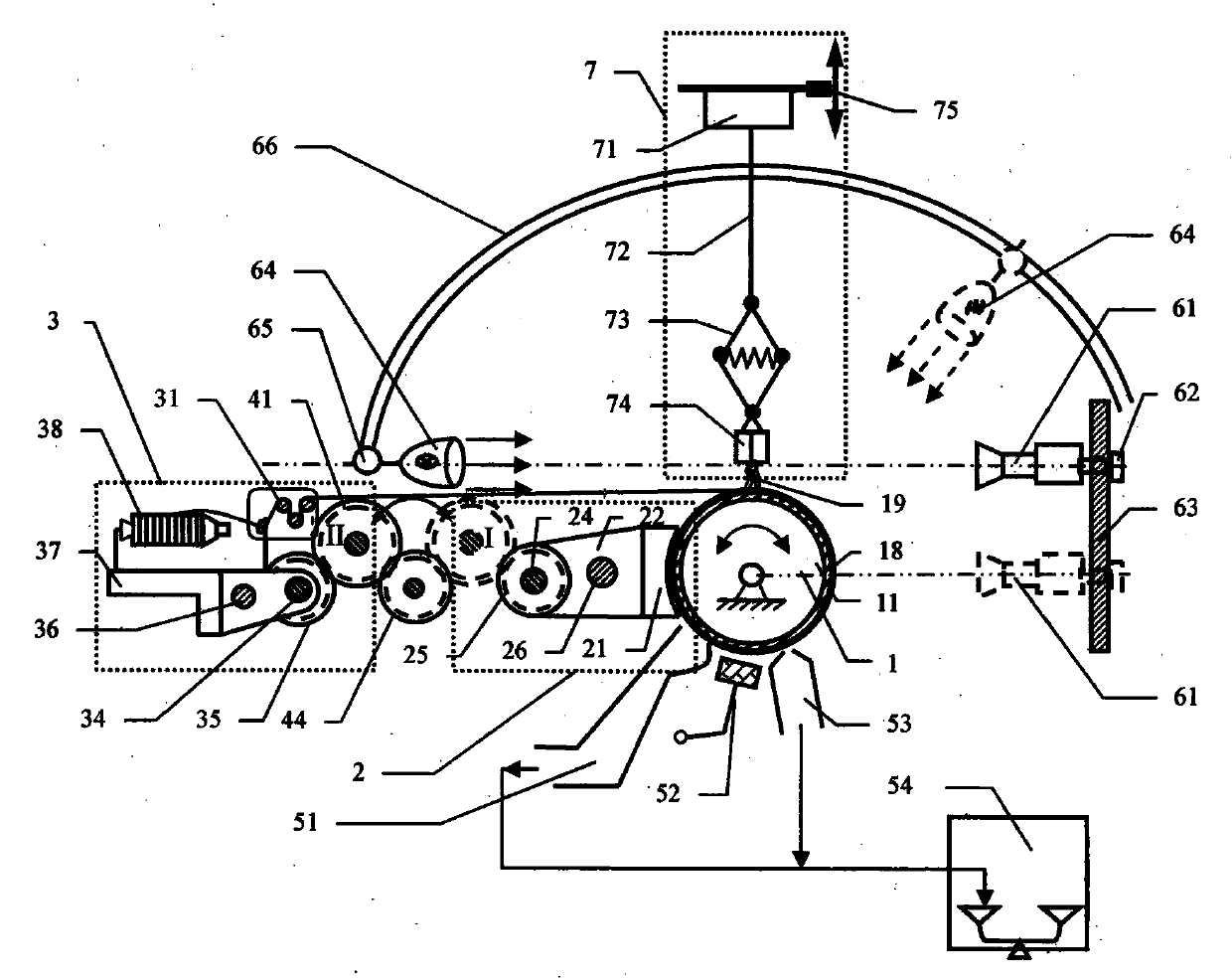

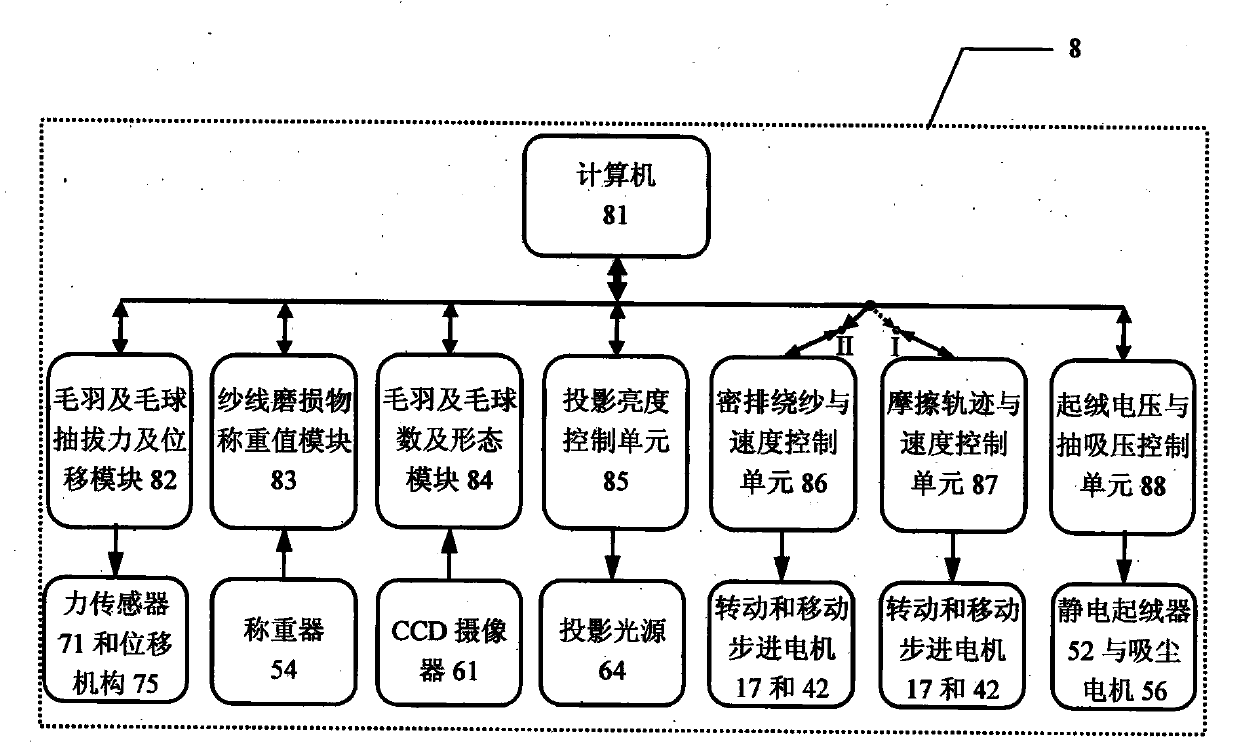

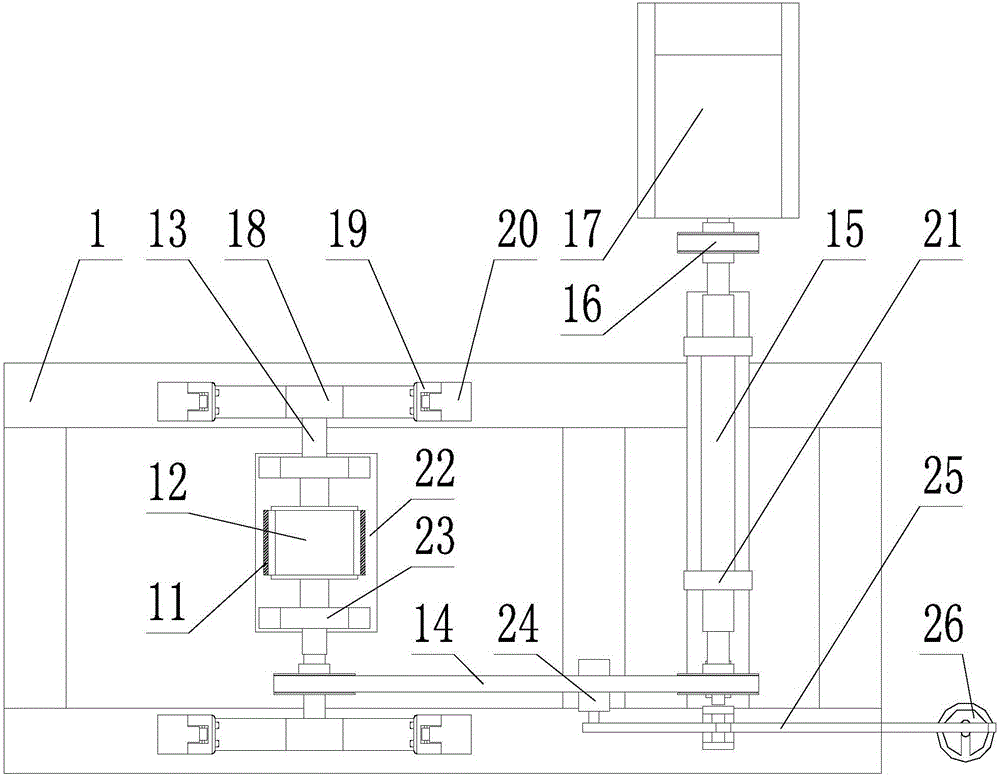

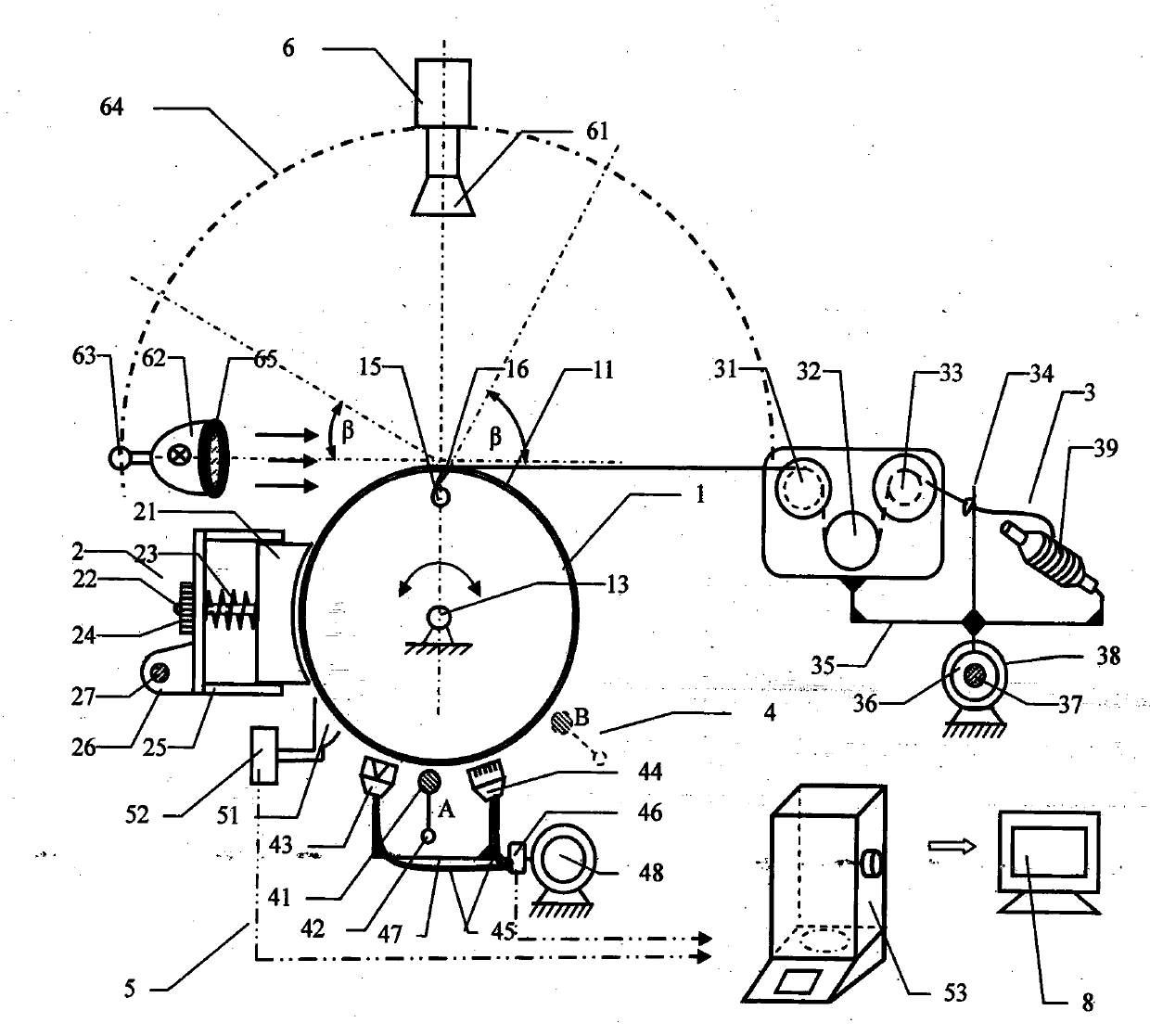

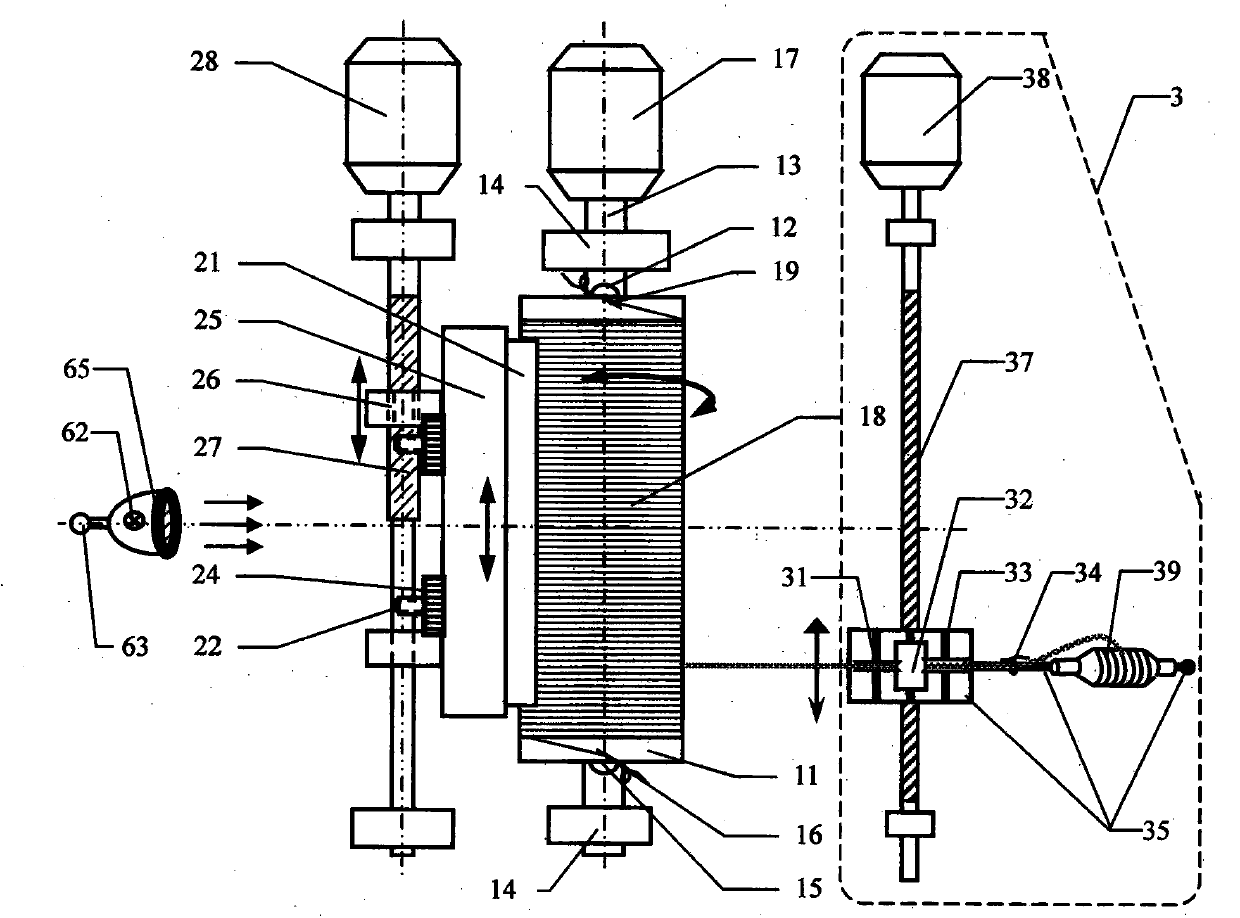

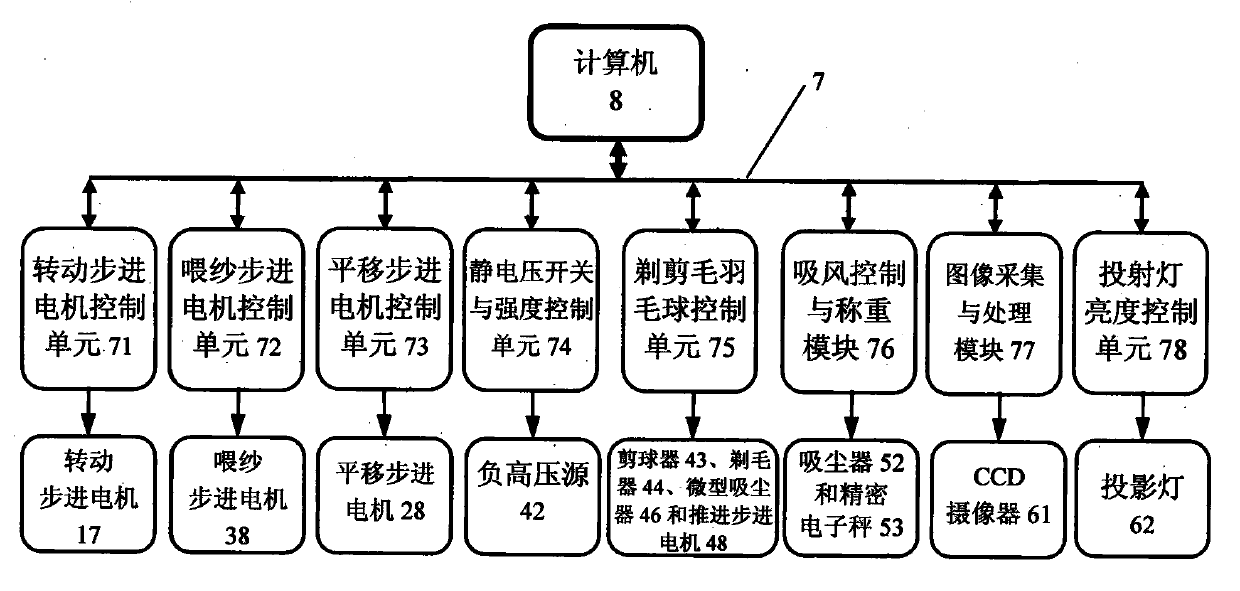

Method and device suitable for measuring fluffing and pilling amount and abrasion amount of textile

ActiveCN103454213AAccurate collectionFree from lossUsing mechanical meansInvestigating abrasion/wear resistanceFiberControl system

The invention relates to a method and a device suitable for measuring the fluffing and pilling amount and abrasion amount of a textile. The device is composed of a cloth sample barrel for coiling and clamping the textile, a rubbing mechanism for fluffing and pilling a cloth sample, a mini-type dust collector for collecting fallen fibers and fuzzy balls, an electrostatic electrode for assisting filoplume to be vertical, a collector for shearing and collecting the fuzzy balls and the filoplume, an optical measurement system for observing the fuzzy balls of the cloth sample, an electronic scale for weighing the weight of the filoplume fuzzy balls, a data acquisition and control system and a computer. The measurement method comprises the following steps: after coiling the cloth sample by equal tension, immediately measuring the filoplume significance as well as the quantity, form, size and distribution of the fuzzy balls; rubbing, fluffing and pilling to prepare a sample and synchronously measuring the process and measuring the filoplume significance of a final rubbing sample, the fuzzy ball quantity, the abrasion to the filoplume fuzzy balls and the remaining amount. The device and the method are ingenious, practical, accurate and quantitative; in-situ measurement for one machine with a plurality of purposes and one measurement process with a plurality of indexes is realized; the device and the method can be used for preparing the sample by fluffing and pilling the textile, measuring the fluffing and pilling amount and abrasion amount of the textile, and carrying out comprehensive analysis and evaluation.

Owner:DONGHUA UNIV

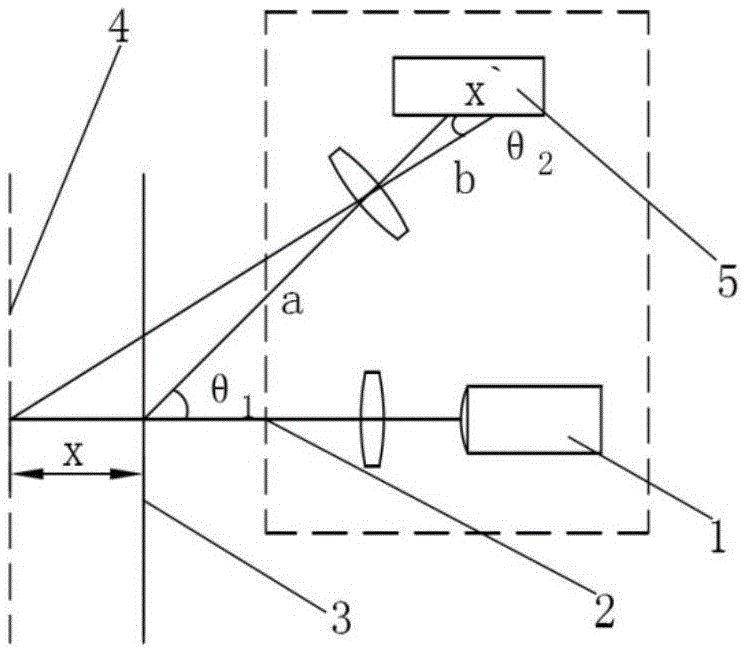

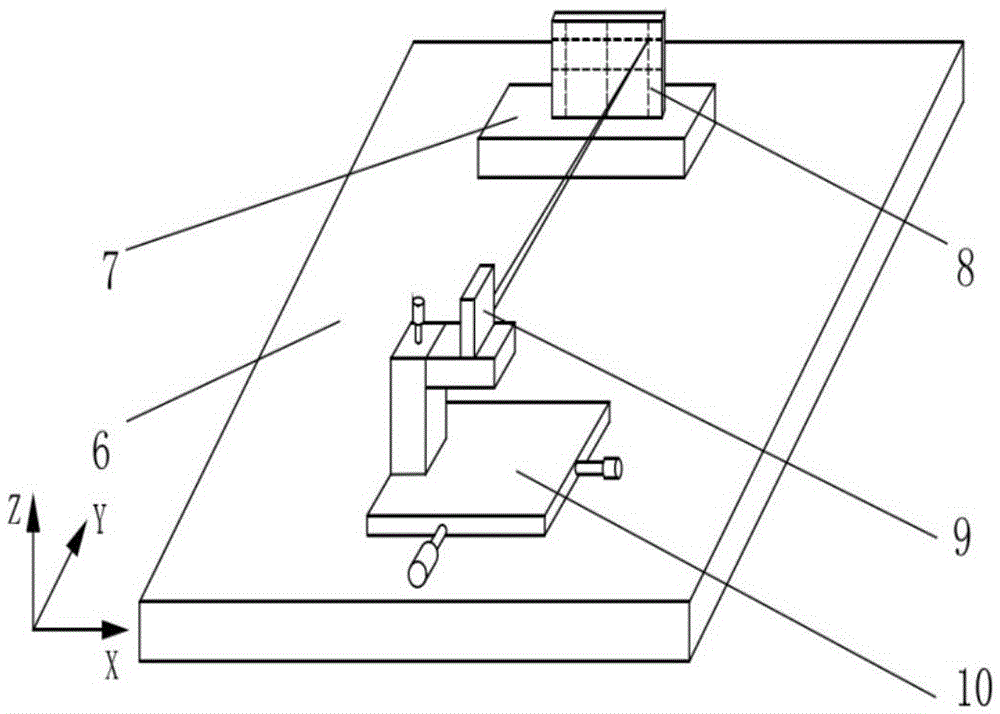

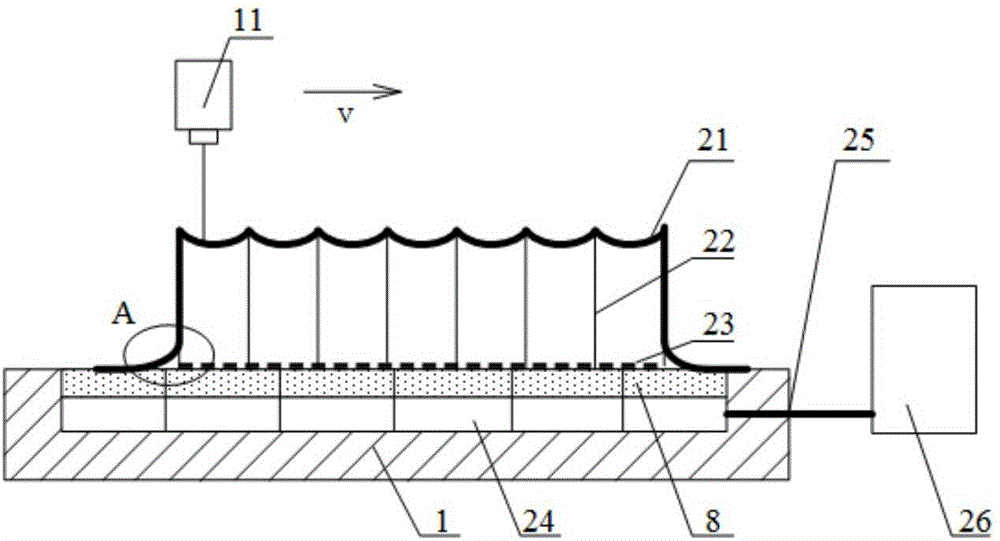

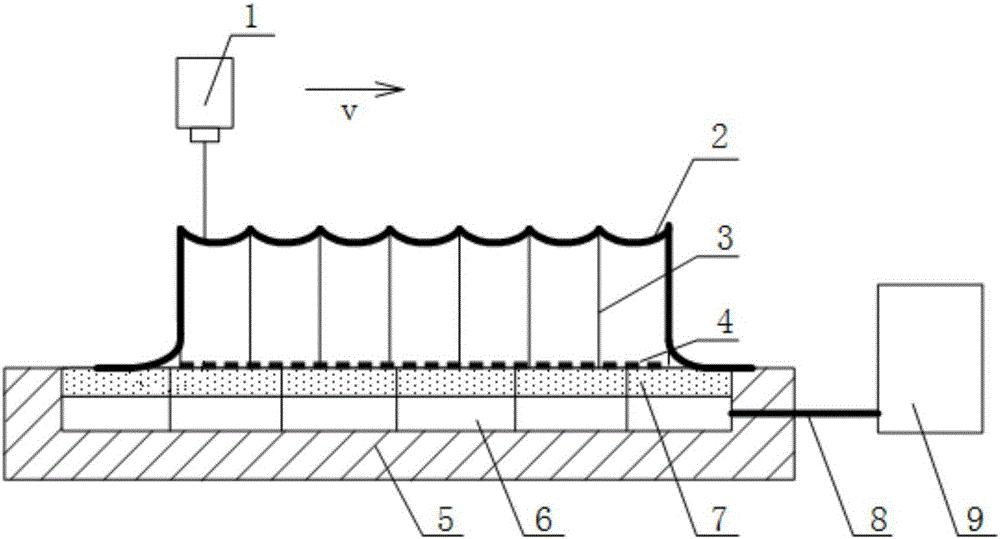

Real-time measurement method and device for deformation of formed part in additive manufacturing process

ActiveCN105571505ALarge rangeMorphing Behavior MonitoringUsing optical meansPhysicsMeasurement device

The invention relates to a real-time measurement method and device for deformation of a formed part in an additive manufacturing process. The method comprises the steps of: 1, initializing the measurement device; 2, determining the position of a measurement point; 3, starting forming a component on a substrate, starting distance measurement when forming is beyond the position of measurement point and a laser distance measurement instrument is capable of receiving a self-measured light beam signal, and stopping the measurement when part forming is accomplished and the temperature falls below an indoor temperature; 4, obtaining a real-time displacement at the position of the measurement point on the part in the forming process according to distance measurement data of adjacent moments, obtaining a real-time deformation curve at the position of the measurement point in the part additive manufacturing process according to the relationship between the displacement and time; and 5, adopting a plurality of laser distance measurement instruments, carrying out steps from 1 to 4 simultaneously on each laser distance measurement instrument, and performing deformation measurement on a plurality of points on the formed part, thereby obtaining the real-time deformation curve at a position corresponding to each laser distance measurement instrument of the formed part in additive manufacturing process.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

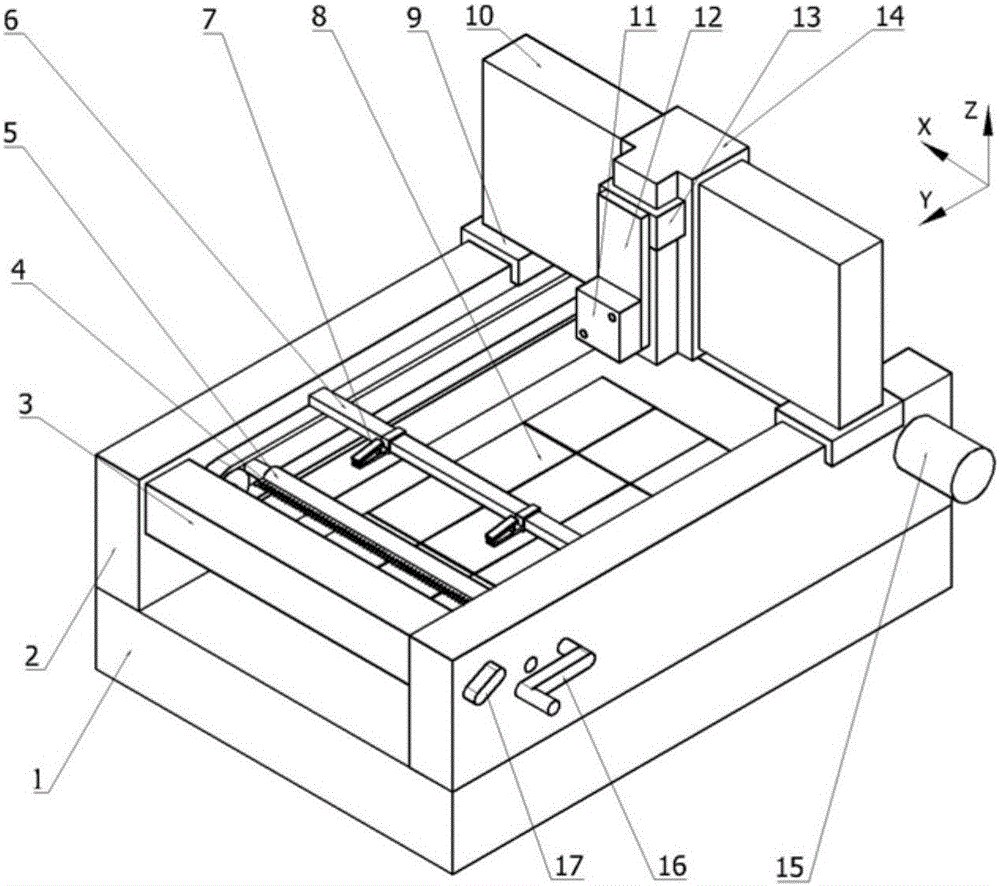

Honeycomb core surface shape measuring device

ActiveCN106017353AHigh measurement accuracyHigh precisionUsing optical meansData processing systemControl system

The invention discloses a honeycomb core surface shape measuring device, which comprises a laser measuring sensor, a measurement motion system, a reflecting film vacuum absorbing system, a reflecting film laying system, a motion control system for controlling the measurement motion system, and a data processing system for processing data of the laser measuring sensor, wherein the reflecting film laying system coats a reflecting film on a surface to be measured of a honeycomb core, the reflecting film vacuum absorbing system performs vacuum adsorption on the reflecting film so that the reflecting film is closely adhered to the surface to be measured of the honeycomb core, and the reflecting film at honeycomb hole lattices is recessed downwards; and the laser measuring sensor installed in the measurement motion system is controlled by the motion control system for scanning the honeycomb core three-dimensionally so as to obtain honeycomb wall heights of the honeycomb core at different spatial positions, and acquiring a surface shape of the honeycomb core by means of the data processing system. By adopting the method of coating the reflecting film on the surface of the honeycomb core, the honeycomb core surface shape measuring device solves the problem that the surface shape is difficult to measure due to discontinuous characteristic of porous thin walls of the honeycomb core.

Owner:DALIAN UNIV OF TECH

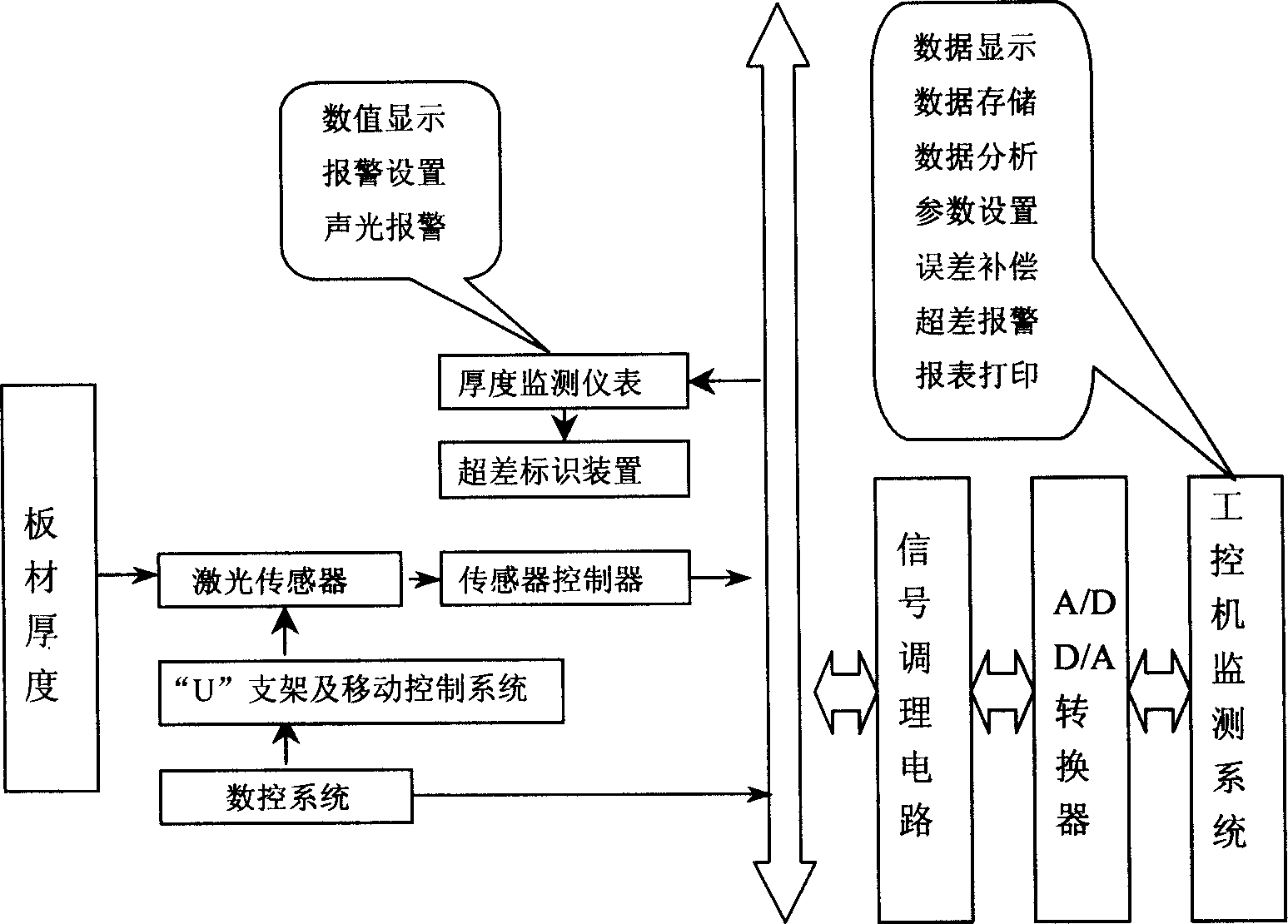

Online monitoring system for measuring thickness of clean-surface panel

InactiveCN1670472ADoes not affect measurement accuracyRealize measurementUsing optical meansSignal conditioning circuitsMonitoring system

This invention relates to smooth surface board materials thickness on-line measurement and especially to the ones influenced by temperature, which comprises the following steps: eliminating the impact on the structure deformation from temperature through extra set mark block in each journey. The measured board thickness signals from laser sensor, temperature compensation thickness signals and rack journey position signals are sent to the working control machine to accomplish the signal process to realize the monitoring.

Owner:JIAXING UNIV

Honeycomb core surface shape measuring method

ActiveCN106017352AHigh measurement accuracyHigh precisionUsing optical meansHoneycombOptoelectronics

The invention discloses a honeycomb core surface shape measuring method, which is characterized by comprising the steps of: coating a reflective film on a surface to be measured of a honeycomb core, and adopting a vacuum adsorption method so that reflecting film is closely adhered to the surface to be measured of the honeycomb core and the reflecting film at honeycomb hole lattices is recessed downwards; and carrying out scanning measurement on the reflecting film on the surface to be measured of the honeycomb core to obtain honeycomb wall heights of the honeycomb core at different spatial positions. The honeycomb core surface shape measuring method has the advantages of being high in measurement precision, low in usage cost, high in measurement efficiency, good in applicability, rich in acquired information and capable of realizing in-suit measurement.

Owner:DALIAN UNIV OF TECH

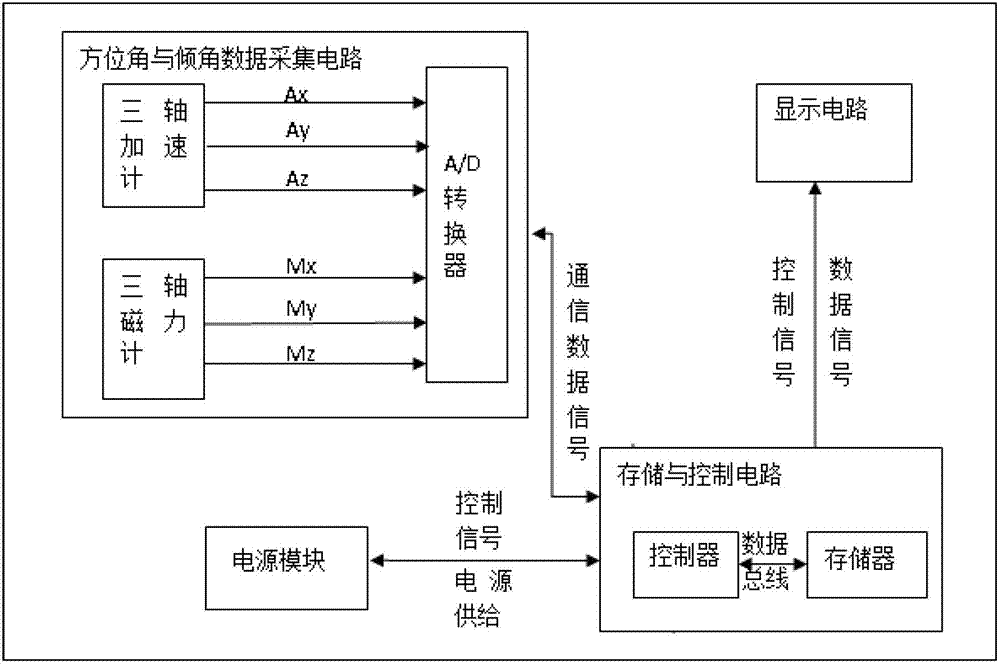

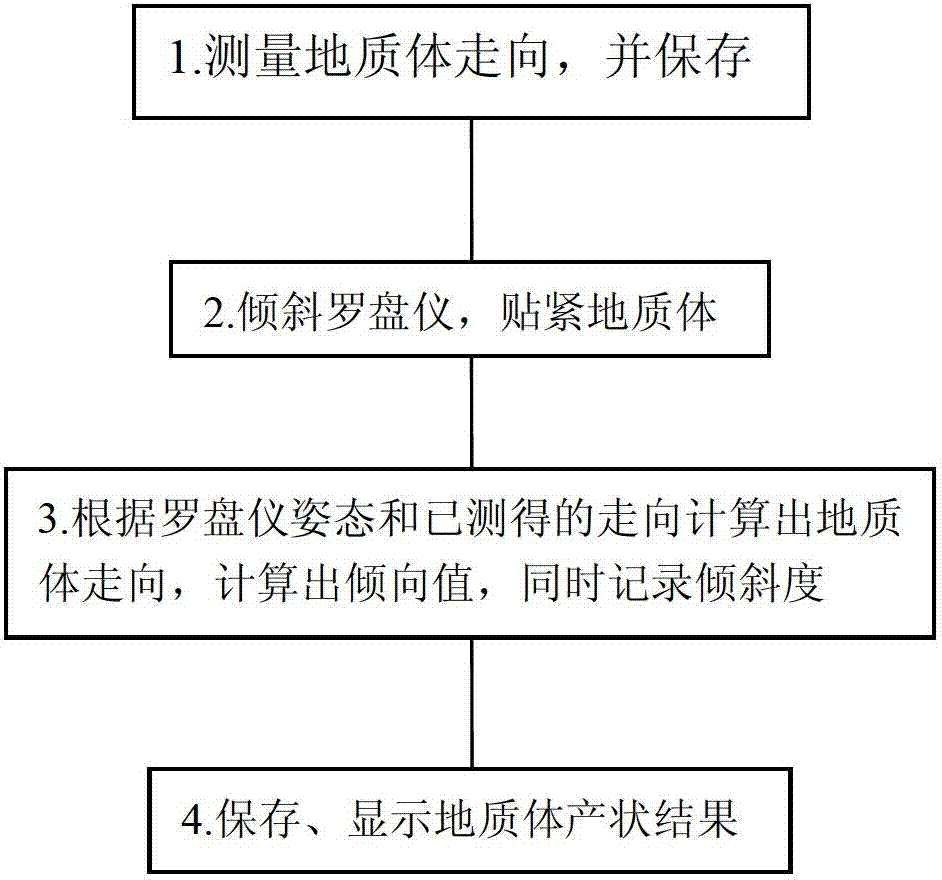

Digital geological compass and method for measuring geological occurrence

The invention provides a digital geological compass and a method for measuring geological occurrence, an azimuth angle and inclination angle data acquisition module, a laser module, a power supply circuit and a display module respectively connected to a storage and control module are provided in a casing; the azimuth angle and inclination angle data acquisition module comprises a magnetic sensor, an acceleration sensor and an A / D converter; the storage and control module reads the azimuth angle and inclination angle data measured by the azimuth angle and inclination angle data acquisition module, a pitching angle and a roll angle are obtained, the azimuth angle, the pitching angle and the roll angle data are sent to the display module for displaying and storing when necessary. The digital geological compass and the method for measuring geological occurrence have the advantages of high precision, convenient operation and high efficiency, and have angle compensation function by using a three-dimensional (shaft) technology when the azimuth angle is read, the real-time reading under compass horizontal are not necessary, so that the operation time can be greatly reduced.

Owner:XIAN UNIV OF SCI & TECH

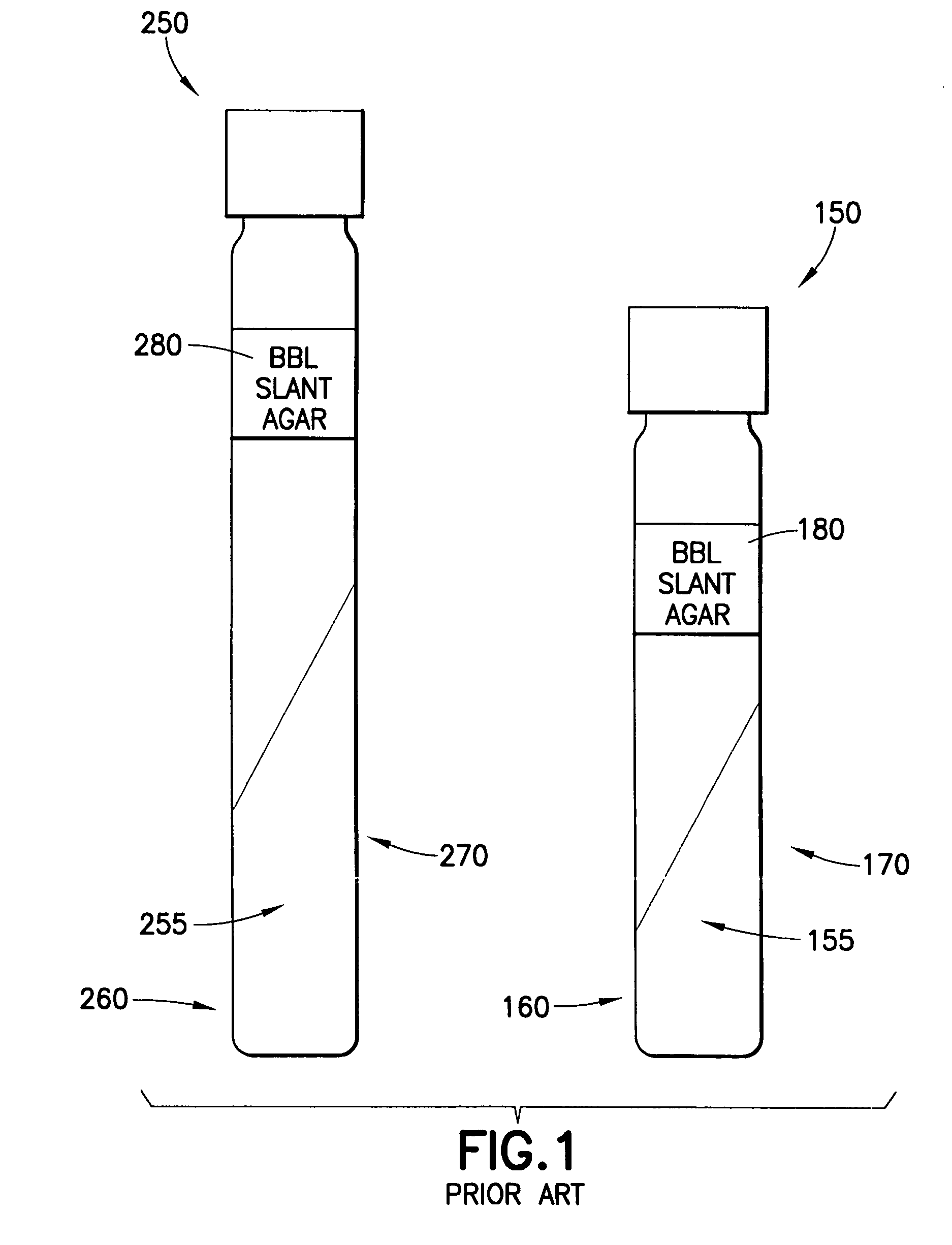

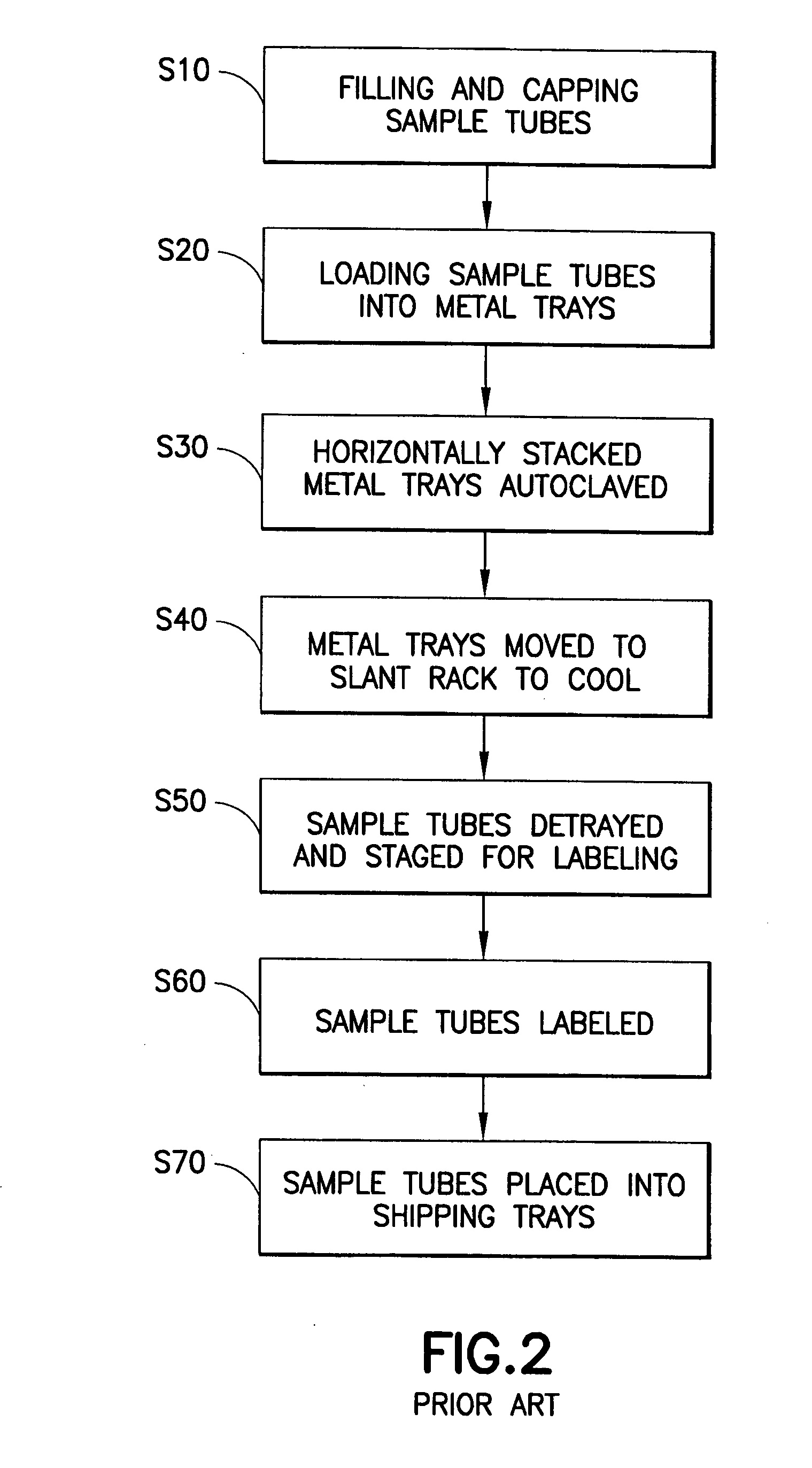

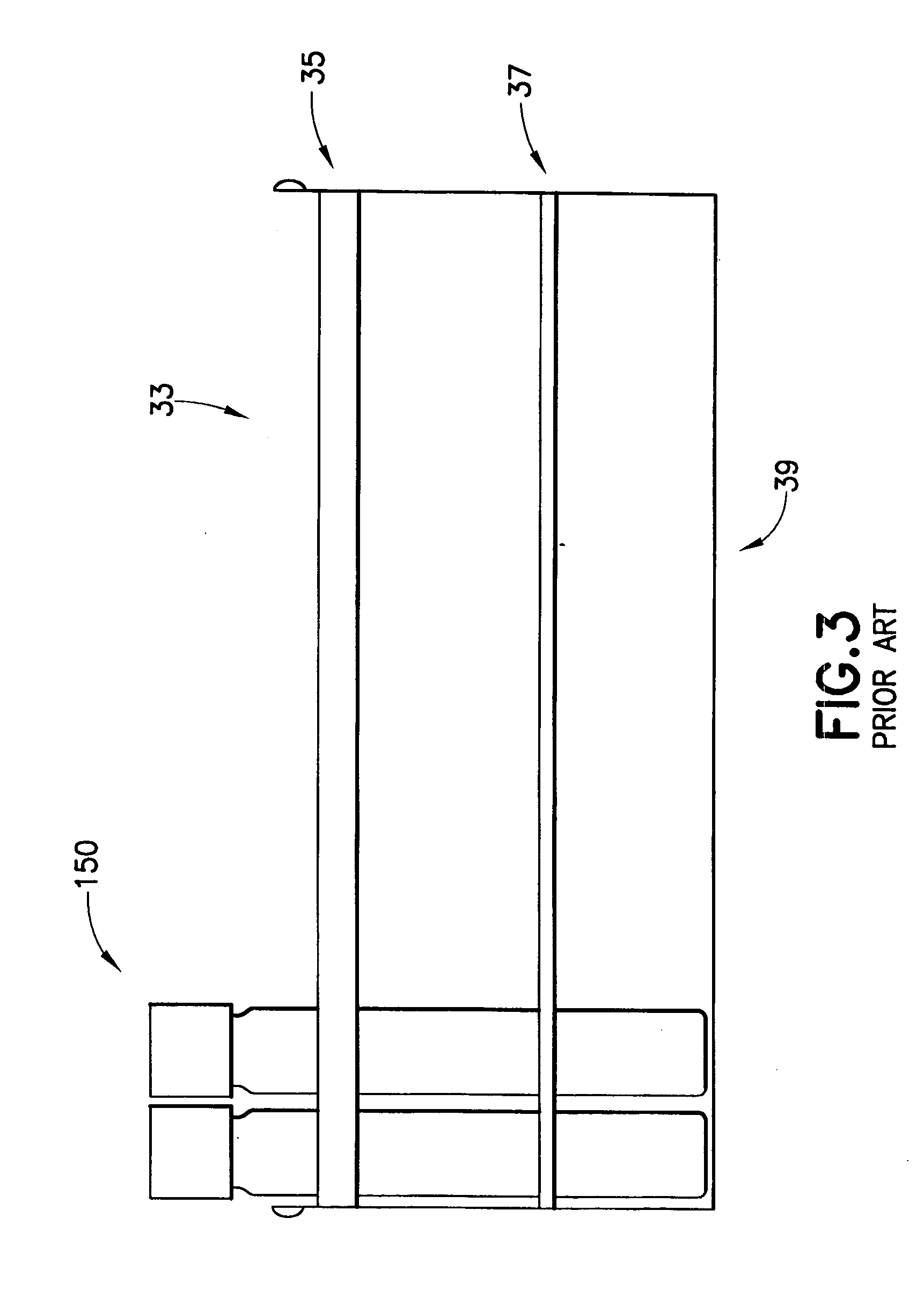

Method of making microorganism sampling tube containing slanted culture medium and sample tube tray therefor

ActiveUS20050214924A1Meet the measurementEasy to operateFungiLiving organism packagingMicroorganismSlant angle

A method of making sampling tubes containing culture growth media by loading the sample tubes containing culture media into a tray that holds the sample tubes, placing the sample tube trays into a rack with shelving to hold the trays and tubes at a predetermined angle, and sterilizing and cooling the sample tubes in an autoclave or inspissator. The culture growth media solidifies at the predetermined slant angle and the sample tube trays are loaded into the packaging box used for shipment. The trays are subsequently used by the end user for processing microbial growth, including storing and collecting data about microbial samples.

Owner:BECTON DICKINSON & CO

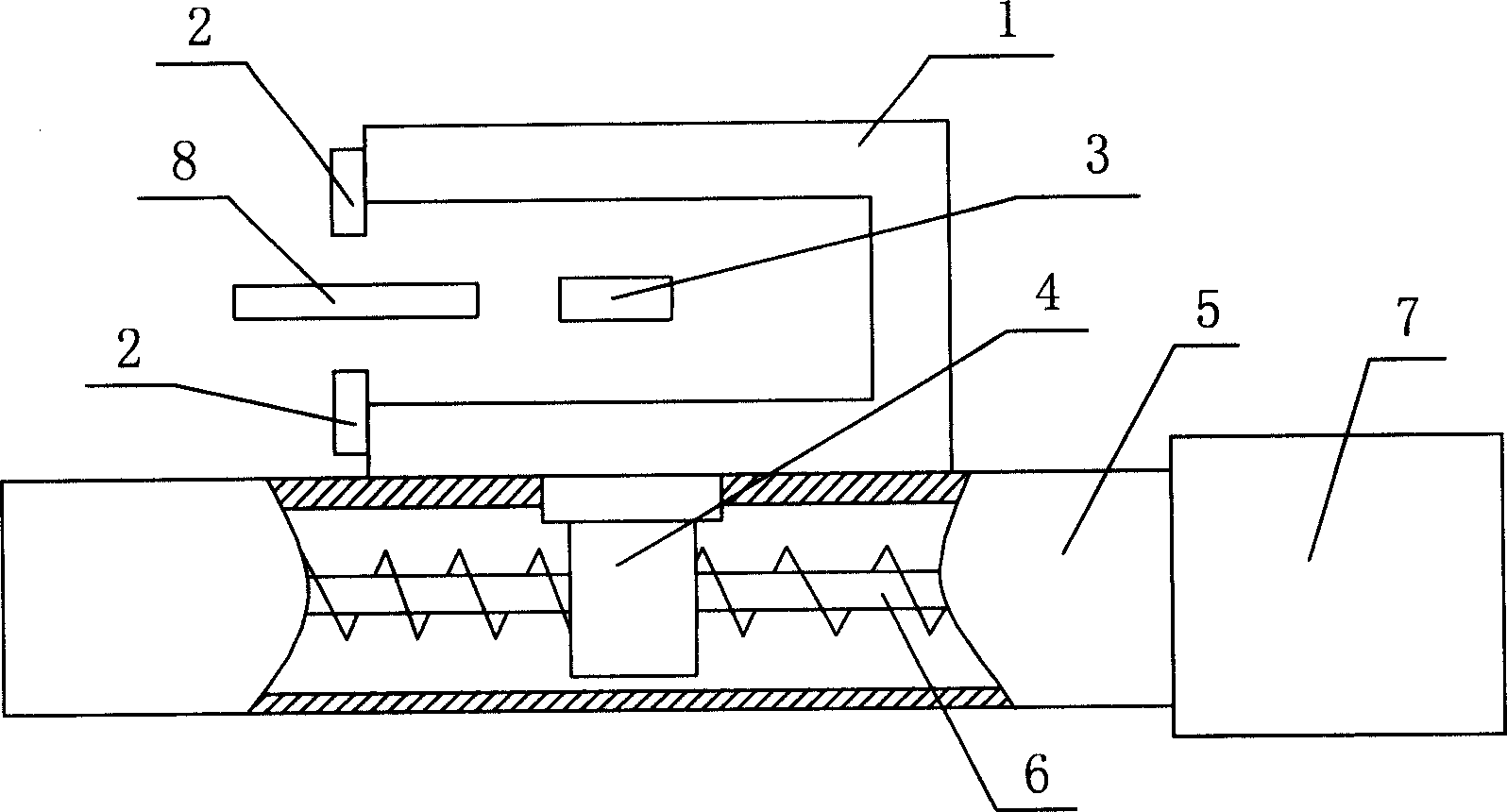

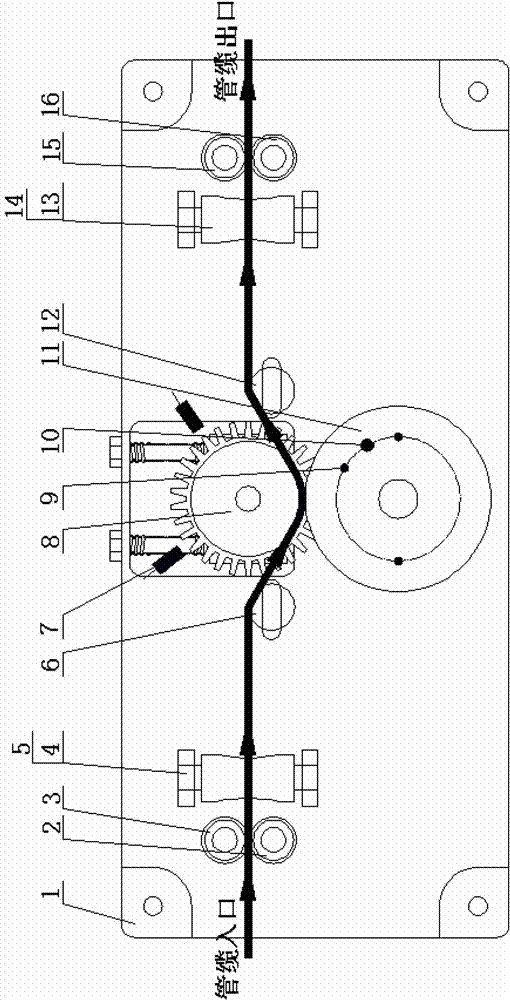

Reversibly accurate and automatic large-stroke detection method and device of pipe cable

InactiveCN102927948AIncrease contact areaIncrease frictionMeasurement devicesAviationProgrammable logic controller

The invention discloses reversibly accurate and automatic large-stroke detection method and device of a pipe cable. The device comprises an engine base, eight limiting wheels, two tensioning wheels, a counter wheel, a pressing and limiting wheel, a gear counting sensor, an approach switch and a sensing element. The device is characterized in that judgment of a measurement and movement direction of the pipe cable can be achieved by use of the approach switch and the sensing element; reversible measurement is achieved; reversible measurement is achieved; the positions of one counter wheel and a tensing wheel in each pair of limiting wheels can be automatically adjusted; measurement of pipe cables in different diameters can be met; the pressing force of the pipe cable is adjusted; the pipe cable is prevented from slipping; the reliability and the accuracy of pipe cable measurement can be improved by use of two counting sensors, and the reliability of the pipe cable detection is increased by using a PLC (programmable logic controller). The method and the device are advanced, scientific, strong in practicability, simple in structure, and suitable for special environments such as aviation, and reversibly accurate and automatic large-stroke detection of the pipe cable can be met.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

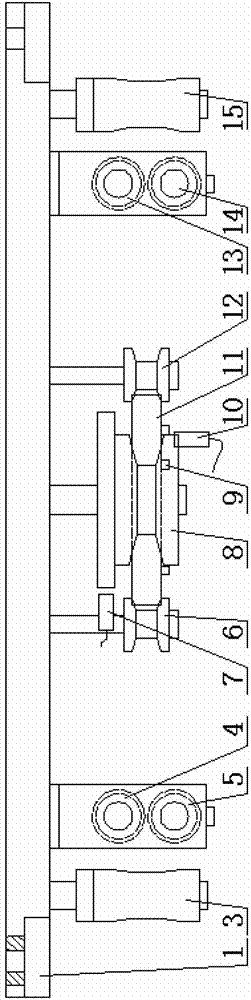

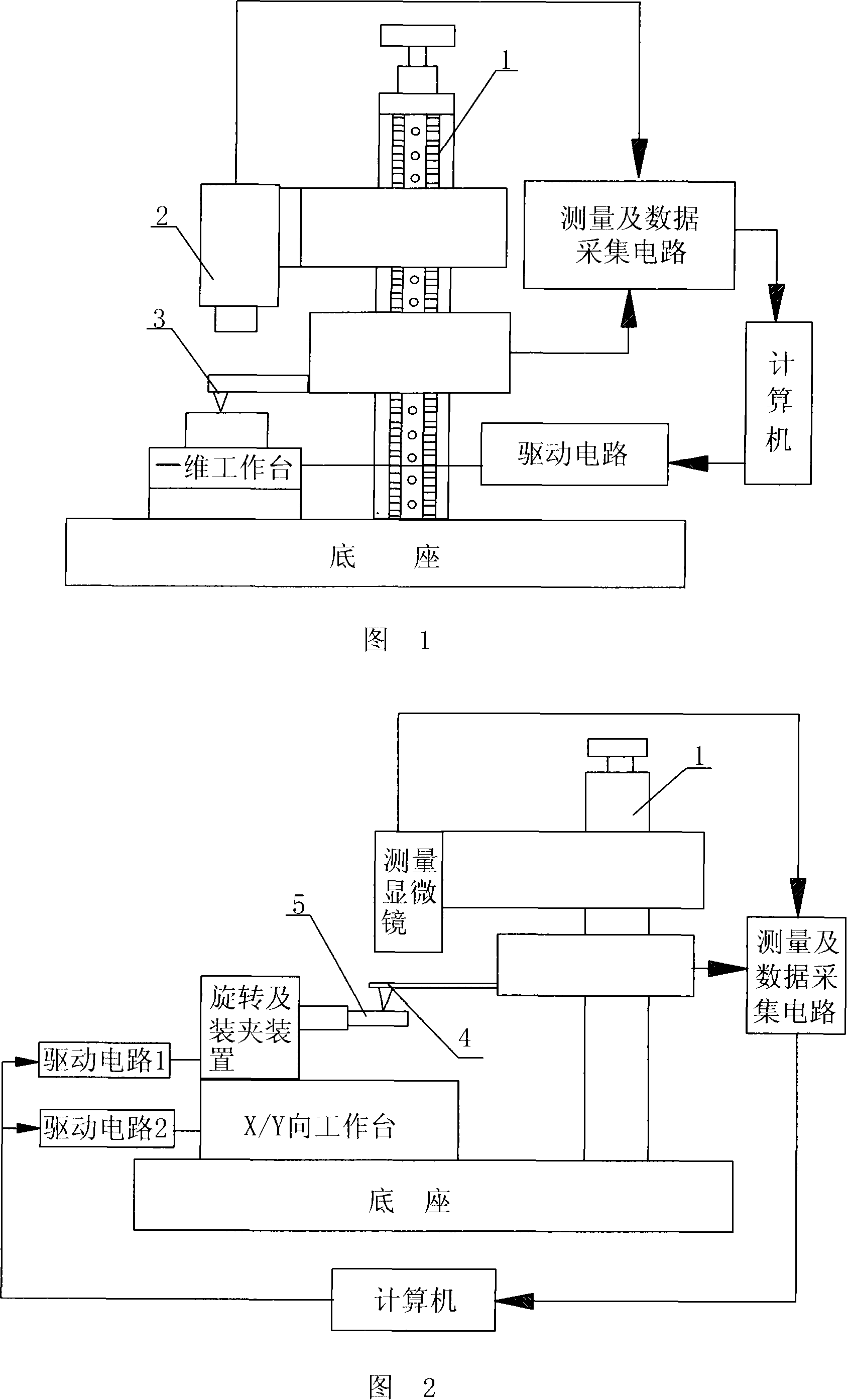

Contact and non-contact type dual-purpose surface roughness measuring systems

InactiveCN101140163AEasy to correctLow costElectric/magnetic contours/curvatures measurementsElectric/magnetic roughness/irregularity measurementsMeasuring instrumentData acquisition

The invention relates to a contact and non-contact type dual-purpose surface roughness measuring system which comprises a measuring sensor a computer and is characterized in that the computer is connected and provided with two groups of measuring sensors through measurement and data acquisition circuit, and the two groups of measuring sensors are respectively a non-contact type measuring head and a contact type measuring head. The contact and non-contact type dual-purpose surface roughness measuring system can realize the contact and non-contact type engineering surface roughness measuring method through a measuring instrument, centralize the advantages of contact type and non-contact type, enlarge the range of measuring objects, reduce the cost, provide the precise and reasonable measuring data, implement the real-time contrast and deviation correction for the two measuring results, and be applied to the two-dimensional or three-dimensional mark measurement of engineering roughness of various complex workpiece surfaces to be measured.

Owner:北京恒安通达科技有限公司

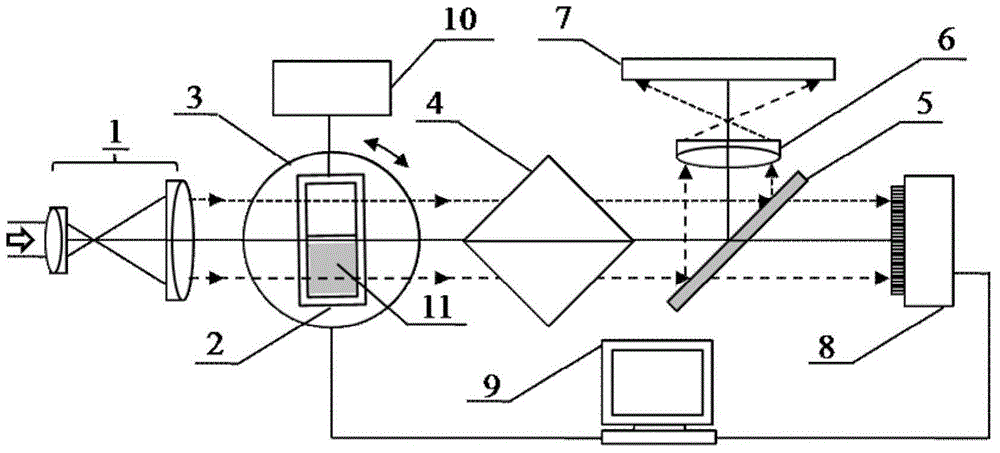

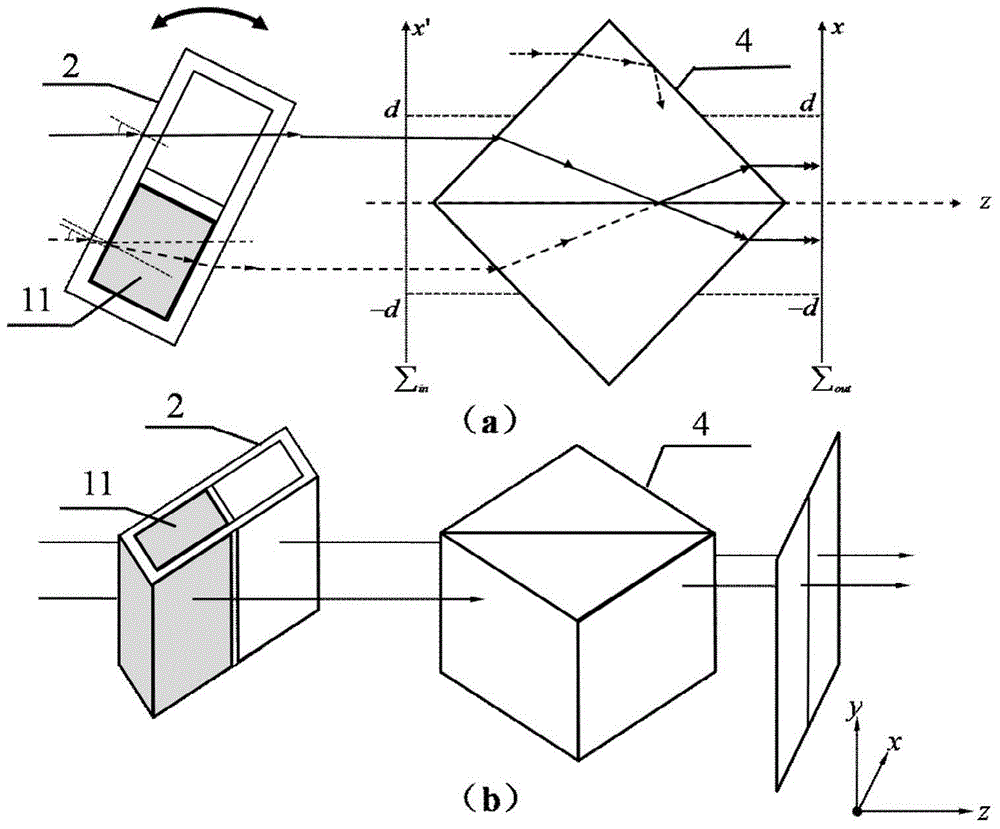

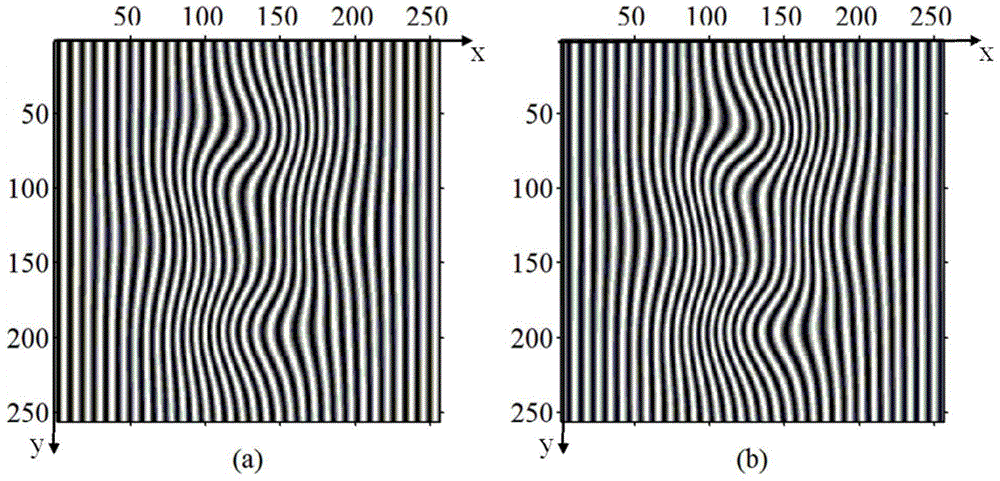

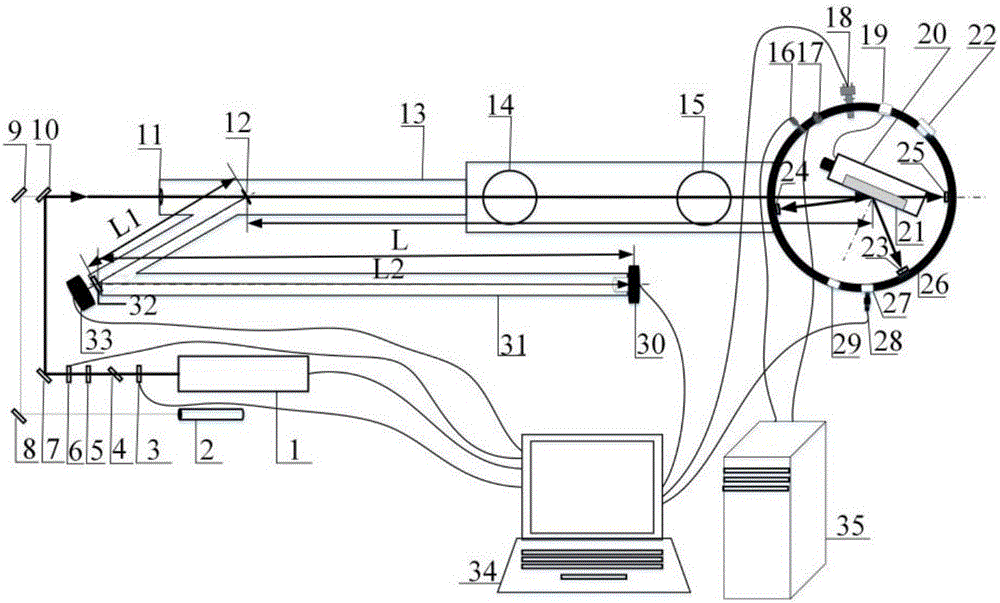

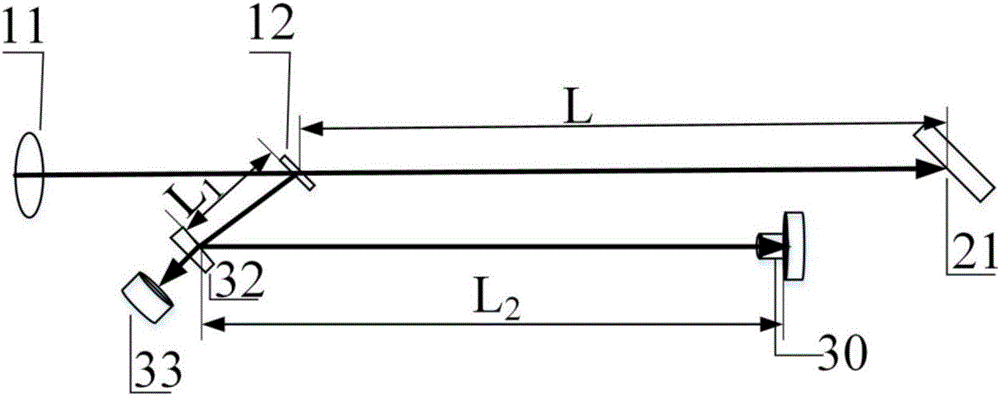

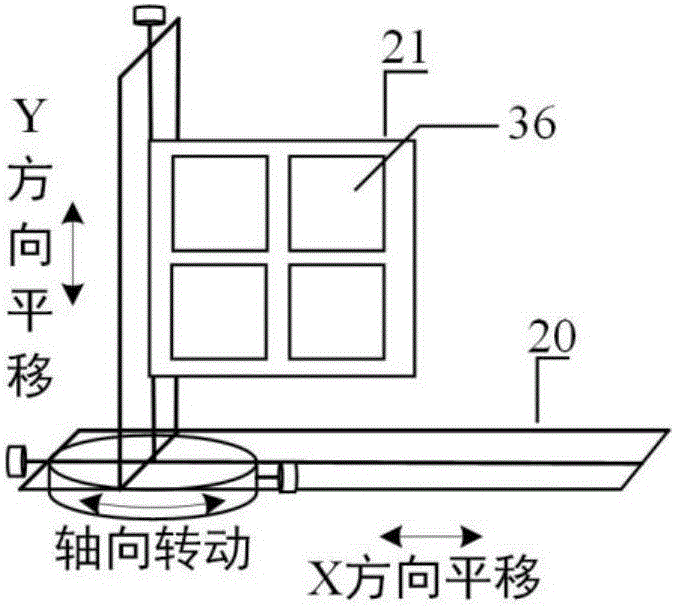

Method for measuring refractive index distribution of transparent medium on basis of interference fringe image processing

ActiveCN104596989AEasy to handleReduce the number of measurementsPhase-affecting property measurementsBeam splittingThree dimensional beam

The invention relates to a method for measuring the refractive index distribution of a transparent medium on the basis of interference fringe image processing, and belongs to the technical field of substance refractive index measurements. The method comprises the following steps: generating an interference fringe image by virtue of the beam splitting surface of a three-dimensional beam splitting prism, and then measuring the refractive index distribution of the transparent medium to be measured by calculating the interference fringe movement number generated by changing the difference between an optical path of an input light transmitting the sample to be measured and an optical path of the input light transmitting a reference medium. The invention also provides a measurement device for realizing the measurement method. The measurement method disclosed by the invention is capable of measuring the refractive index of a uniform transparent medium with higher accuracy, and measuring the refractive index distribution of a non-uniform transparent medium. The measurement method and the measurement device thereof disclosed by the invention further have the advantages of reducing measurement times, shortening measurement time and simplifying data processing on the premise of ensuring measurement accuracy and stability.

Owner:SICHUAN UNIV

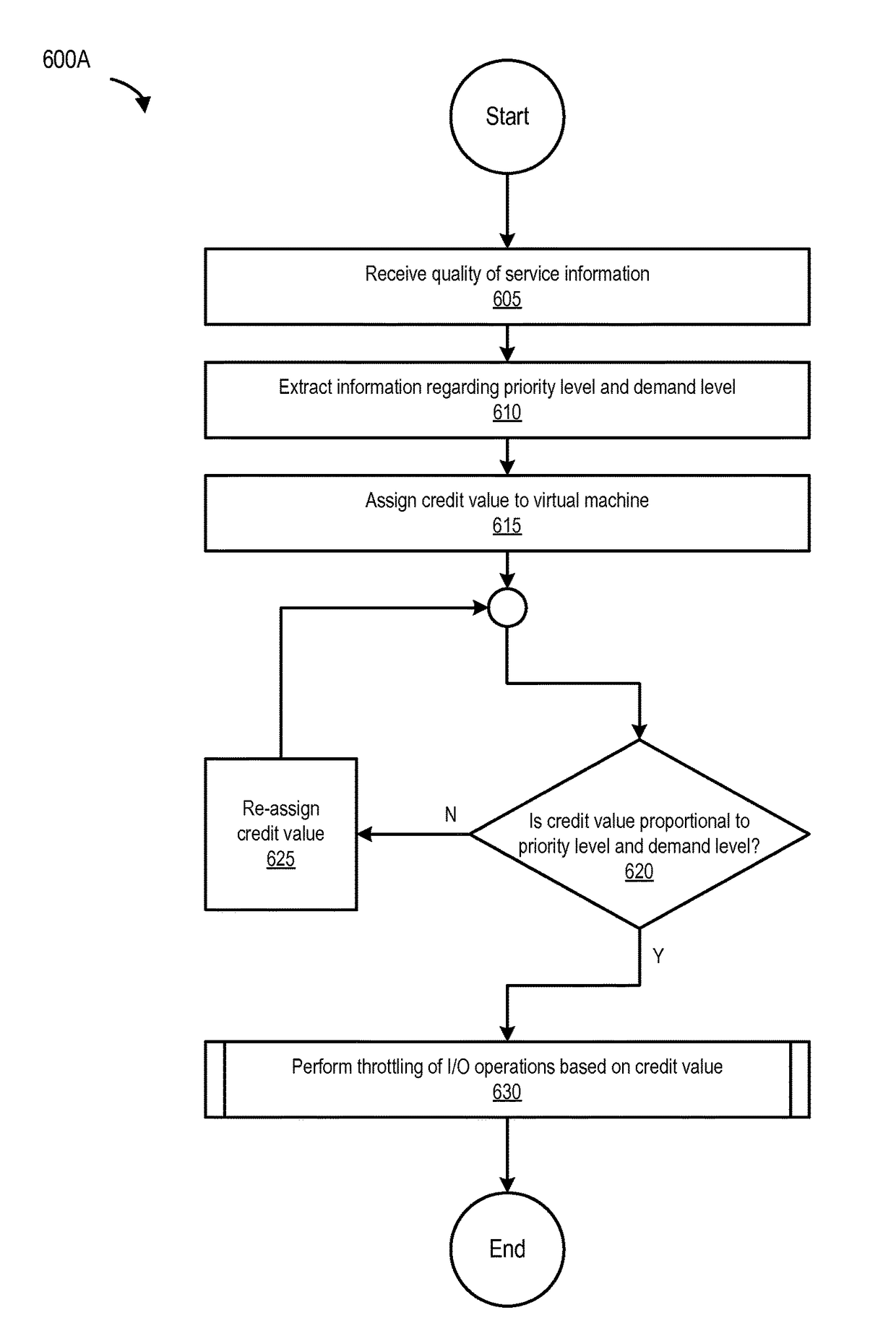

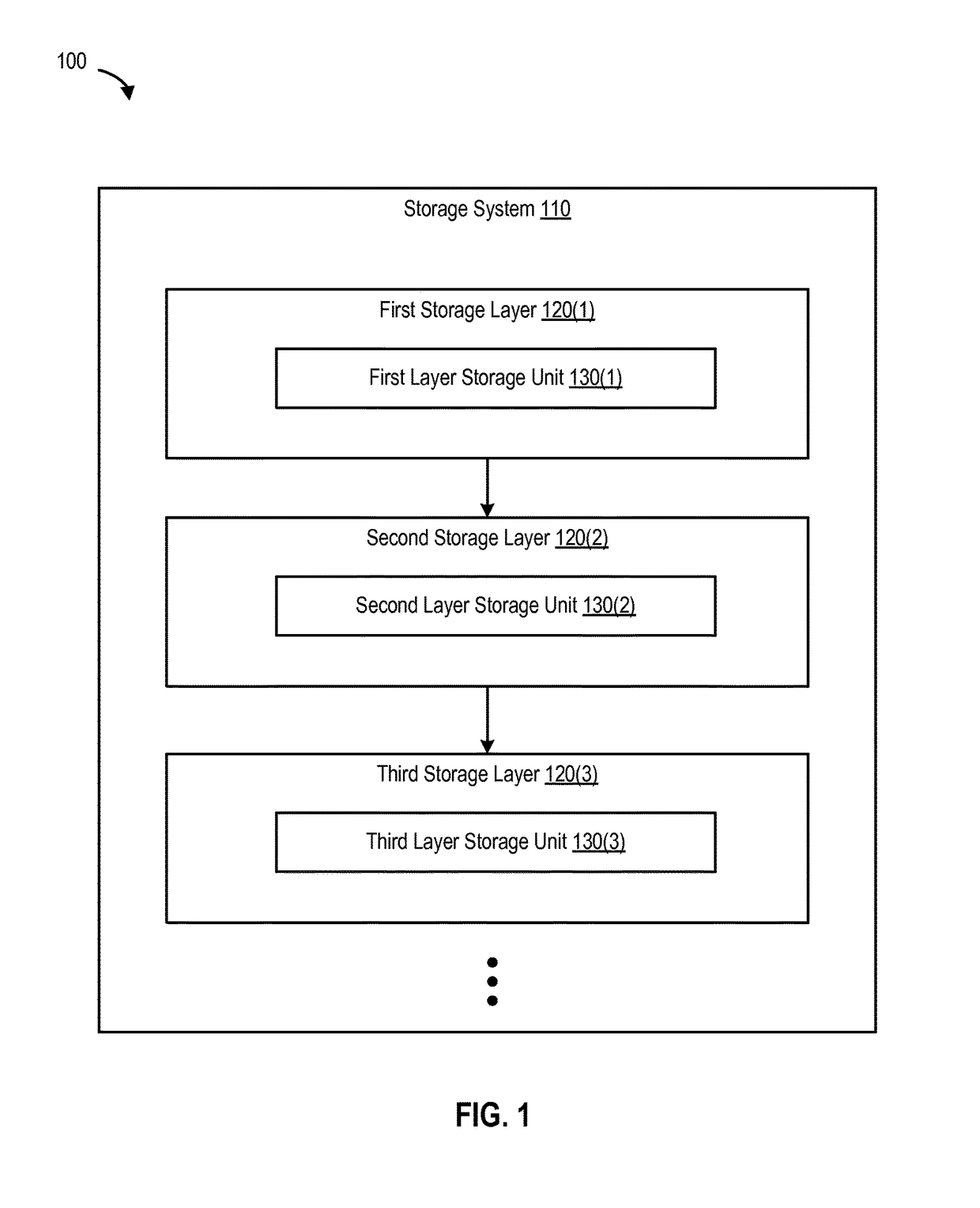

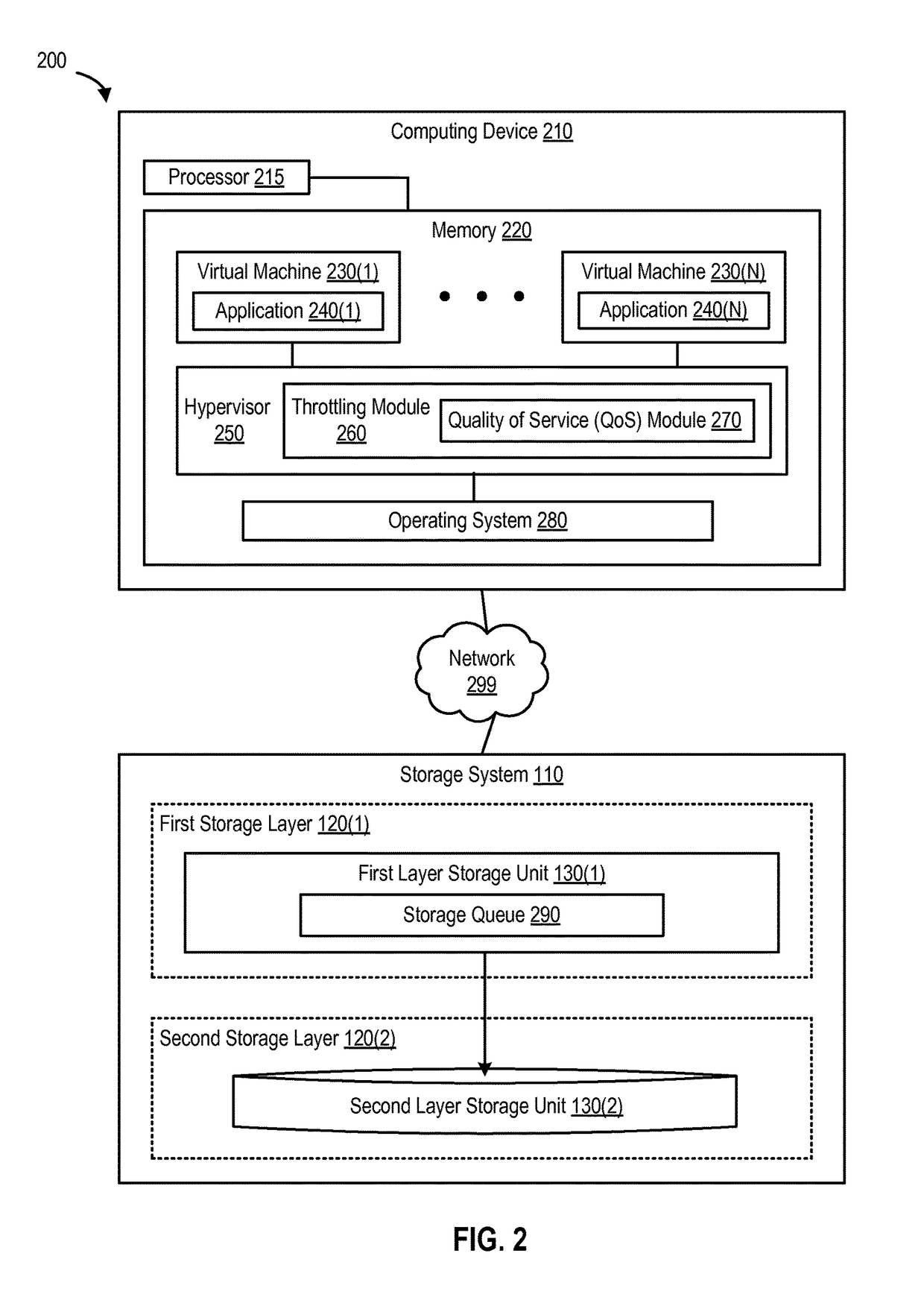

Adaptive throttling in hybrid storage environments

ActiveUS9760392B1Meet the measurementSoftware simulation/interpretation/emulationQuality of serviceApplication software

Various systems, methods, and processes to perform adaptive throttling of write operations in hybrid storage environments are disclosed. A credit value is assigned to a virtual machine. Input / output (I / O) operations generated by an application executing on the virtual machine are throttled based on the credit value assigned to the virtual machine. The credit value is assigned to the virtual machine in proportion to static measures and dynamic conditions. The static measures and the dynamic conditions are used to calculate a quality of service provided to the virtual machine by a storage system.

Owner:VERITAS TECH

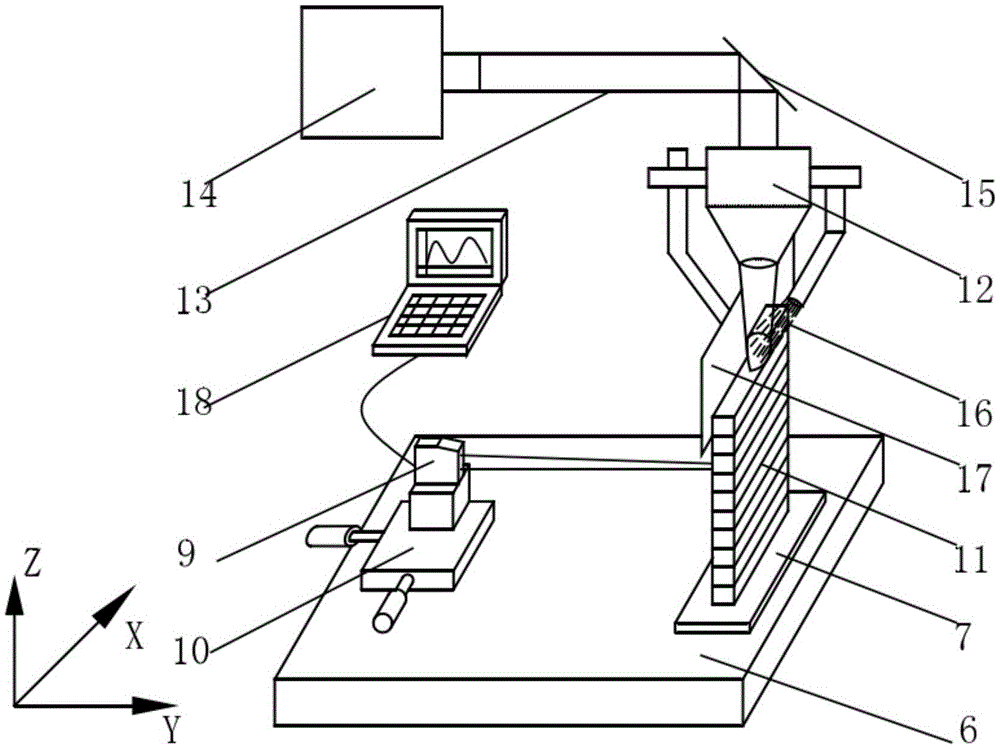

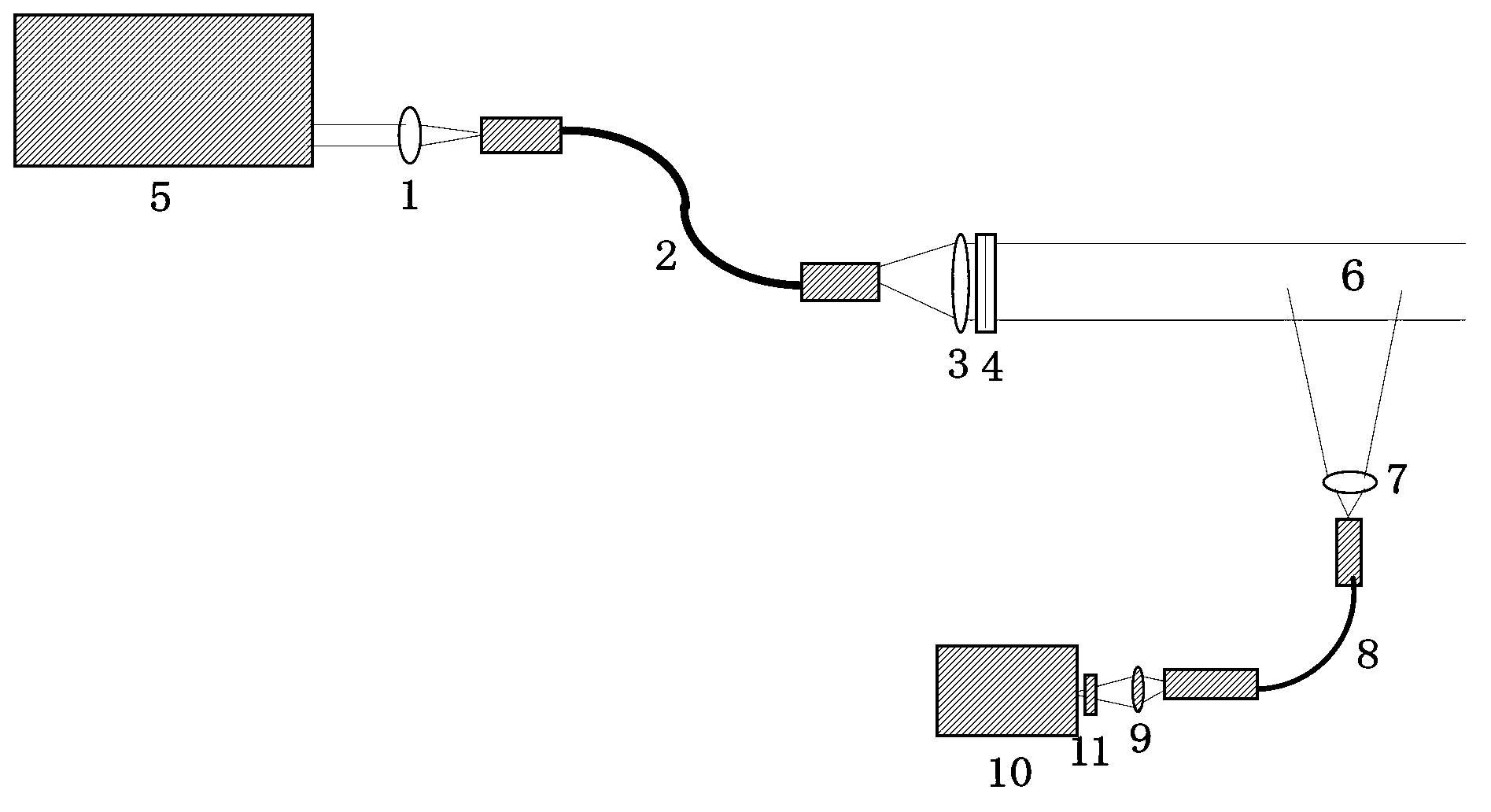

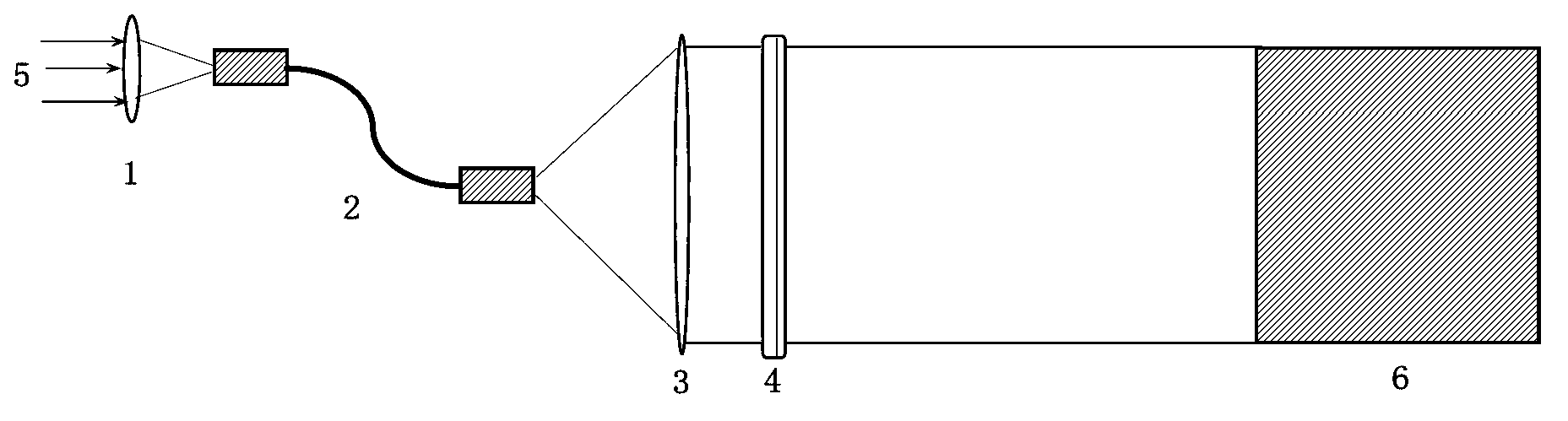

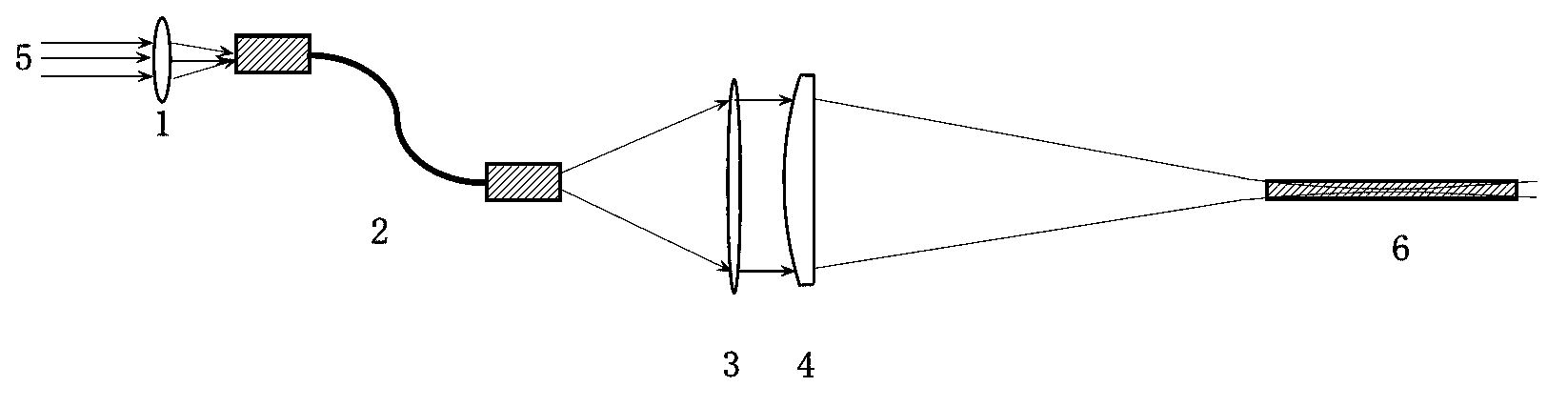

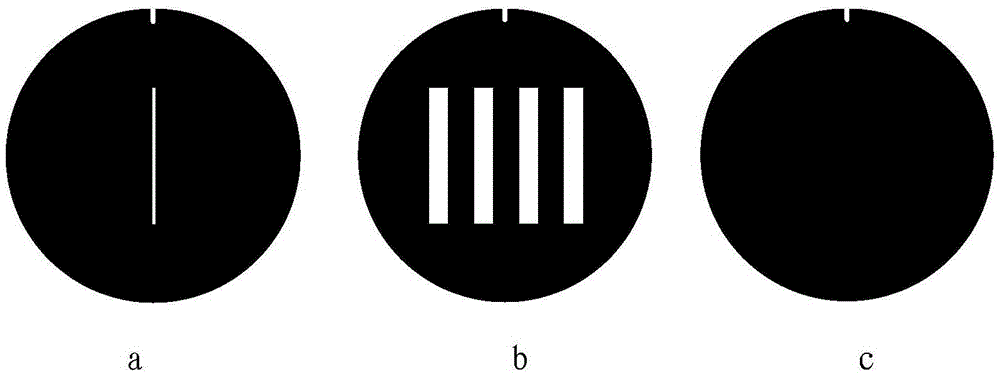

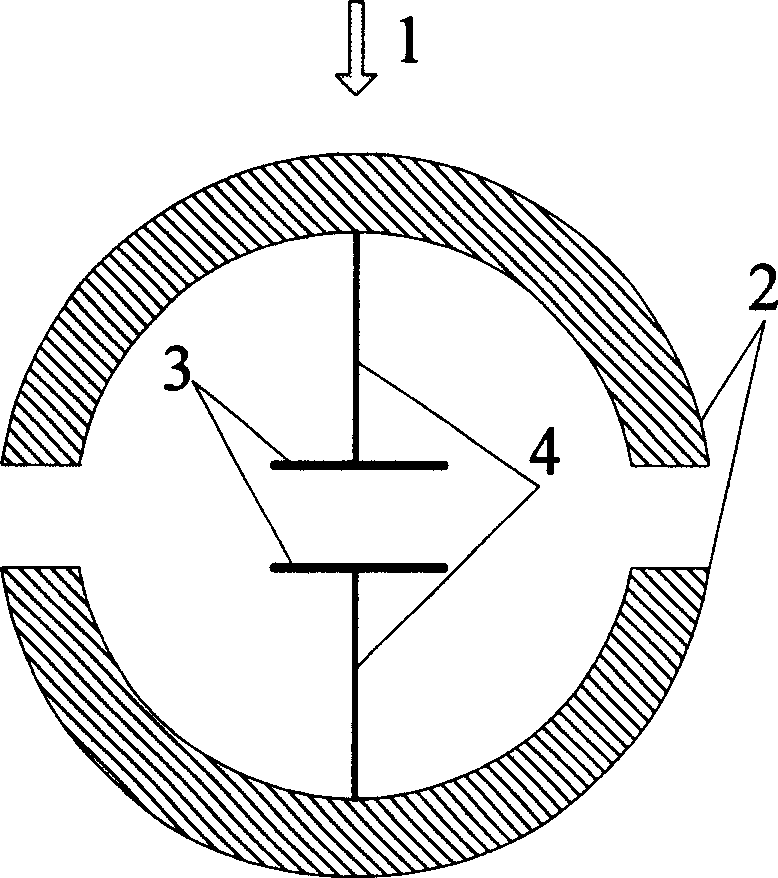

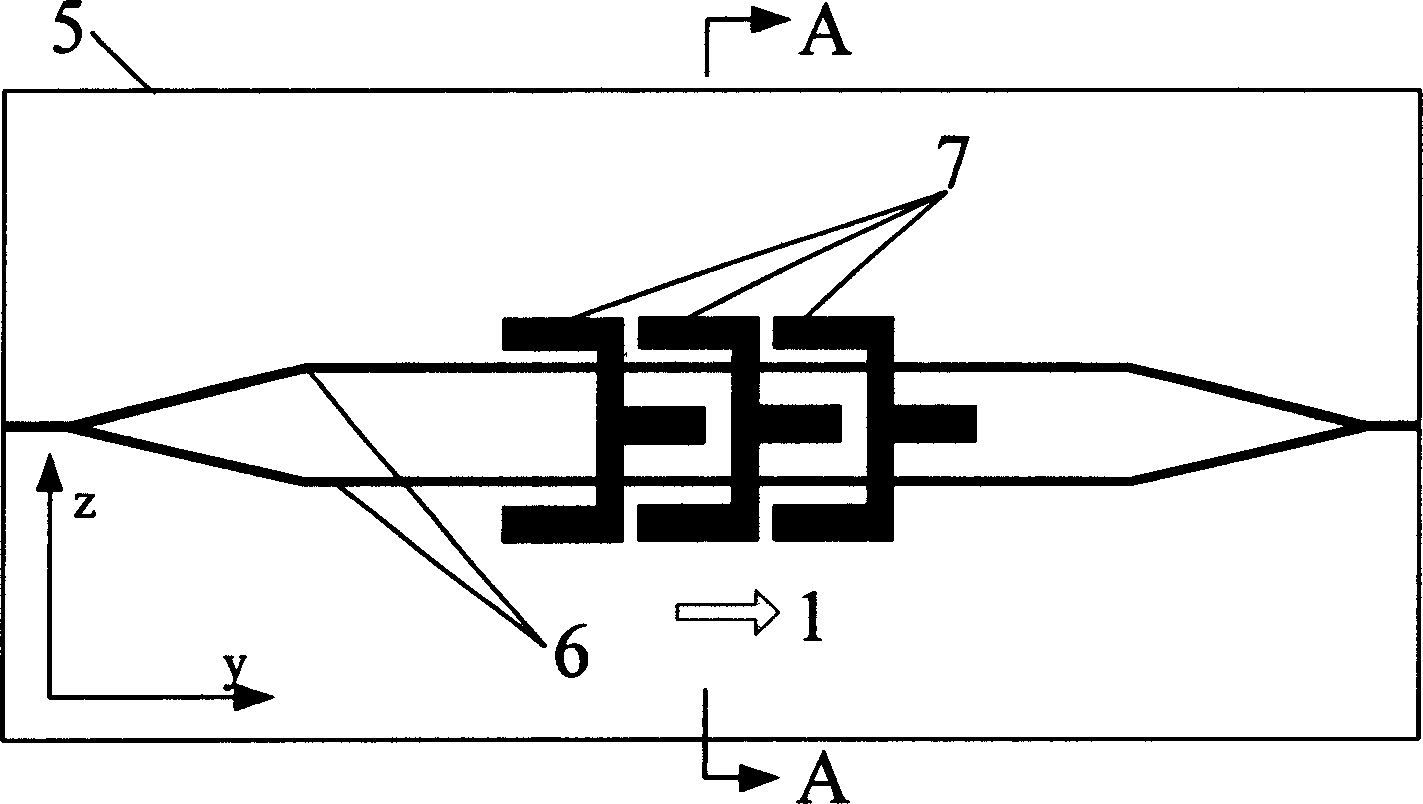

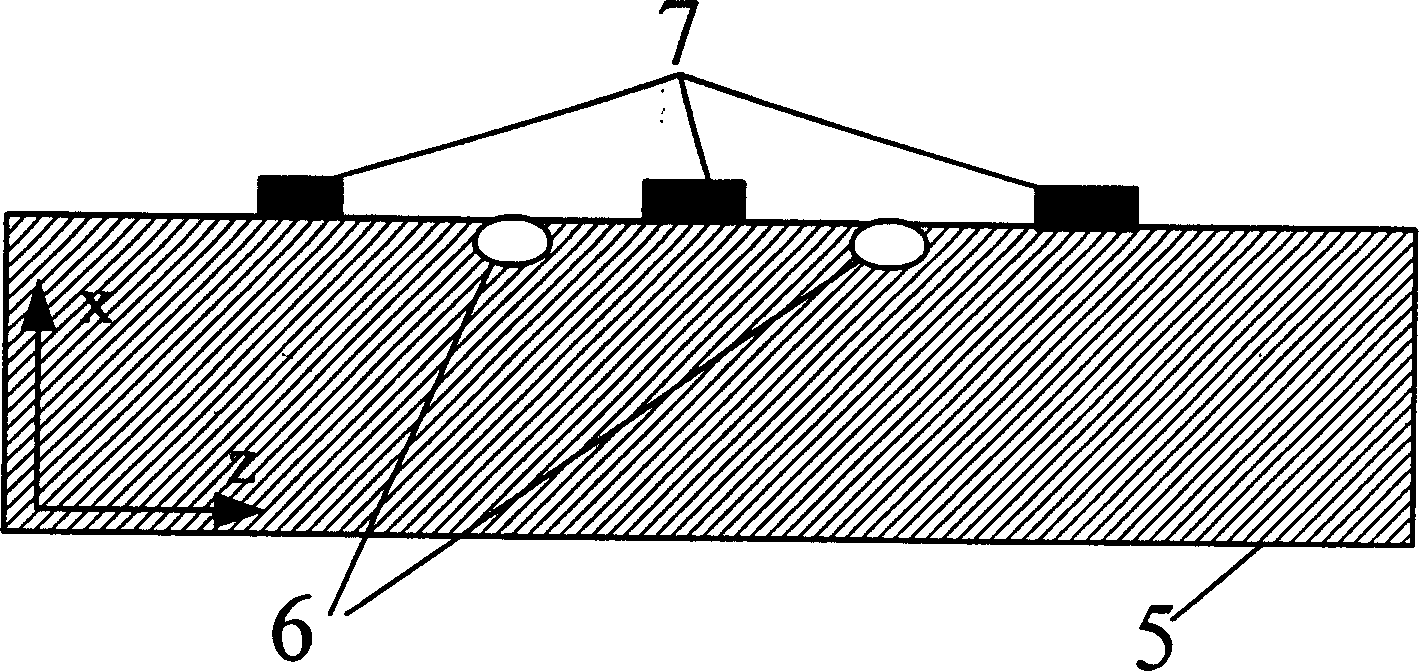

Laser-induced fluorescence combustion field parameter measuring device

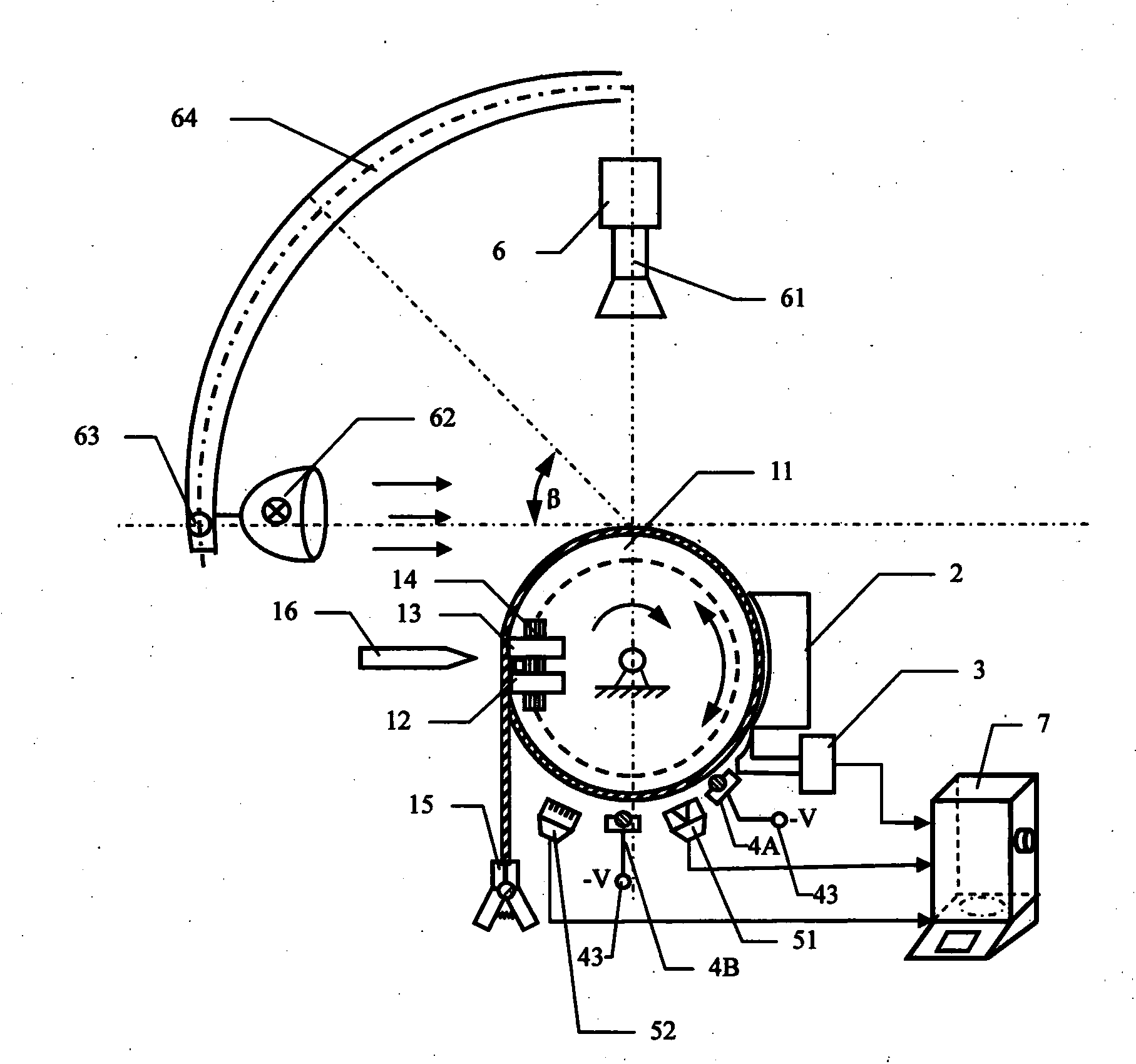

InactiveCN103063640AMeet the measurementEasy to layoutFluorescence/phosphorescenceCombustionLight beam

The invention discloses a laser-induced fluorescence combustion field parameter measuring device which comprises a light source system and a detection system, wherein the light source system comprises a laser (5), an optical fiber coupling lens (1), a plastic optical fiber bundle (2), a spherical lens (3) and a cylindrical lens (4), wherein the optical fiber coupling lens (1), the plastic optical fiber bundle (2), the spherical lens (3) and the cylindrical lens (4) are arranged in the laser transmission direction in sequence; an optical fiber configuration section on the incident end surface of the plastic optical fiber bundle (2) is matched with a light beam section of the laser (5), and the emergent end surface of the plastic optical fiber bundle (2) is configured into a linear shape; and a cylindrical center line of the cylindrical lens (4) is parallel to an optical fiber configuration line on the emergent end surface of the plastic optical fiber bundle (2). The laser-induced fluorescence combustion field parameter measuring device has the benefits that a lamellar light beam with uniform light intensity in an area on the light beam transmission direction is realized, the demands that the combustion flow field two-dimensional parameter measurement is realized by adopting a planar laser-induced technology are satisfied, the combustion flow field parameter measurement under the strong-vibration and strong-noise impact environment are simultaneously satisfied, and the environmental adaptability of the system is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

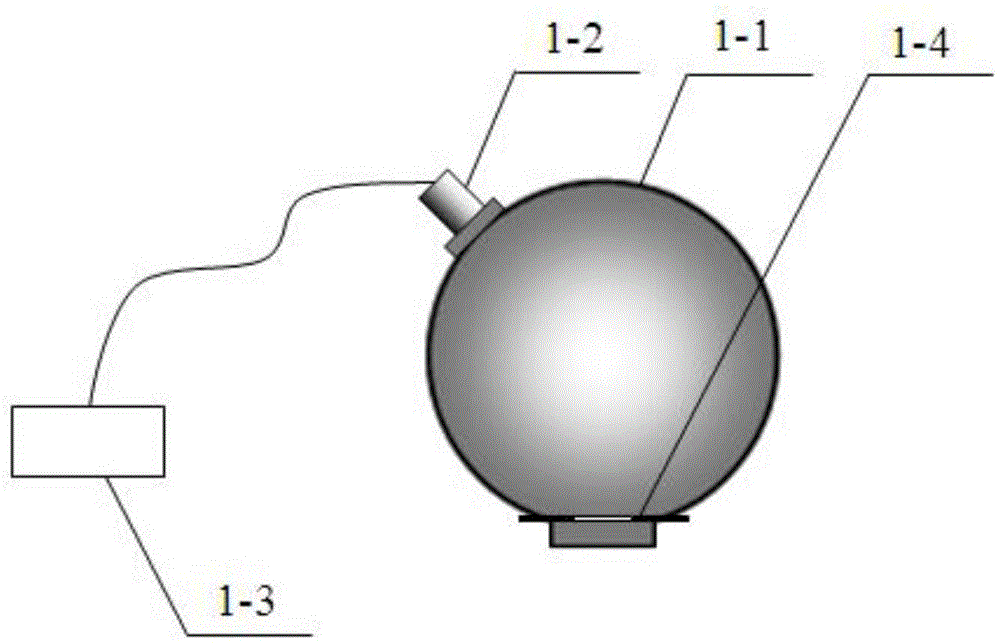

Television imaging system modulation transfer function test device and method

ActiveCN105486489AAccurate measurementImprove measurement accuracyTesting optical propertiesLine Spread FunctionLight source

The invention provides a television imaging system modulation transfer function test device and method and belongs to the technical field of optical measurement. The television imaging system modulation transfer function test device and method are characterized in that a television imaging system to be tested is placed in an optical collimation system illuminated by an integrating sphere light source, of which the light intensity is adjustable and which is high in space uniformity, and slit targets are arranged in the focal plane of the optical collimation system; the slit targets, after passing through the optical collimation system and the television imaging system to be tested, are imaged to a target surface of the television imaging system; and after an image recording and processing system carries out a series of calculation and processing on the slit images, line spread function distribution of the slit targets and the MTF value are obtained, and thus MTF measurement of the television imaging system is finished.

Owner:西安应用光学研究所

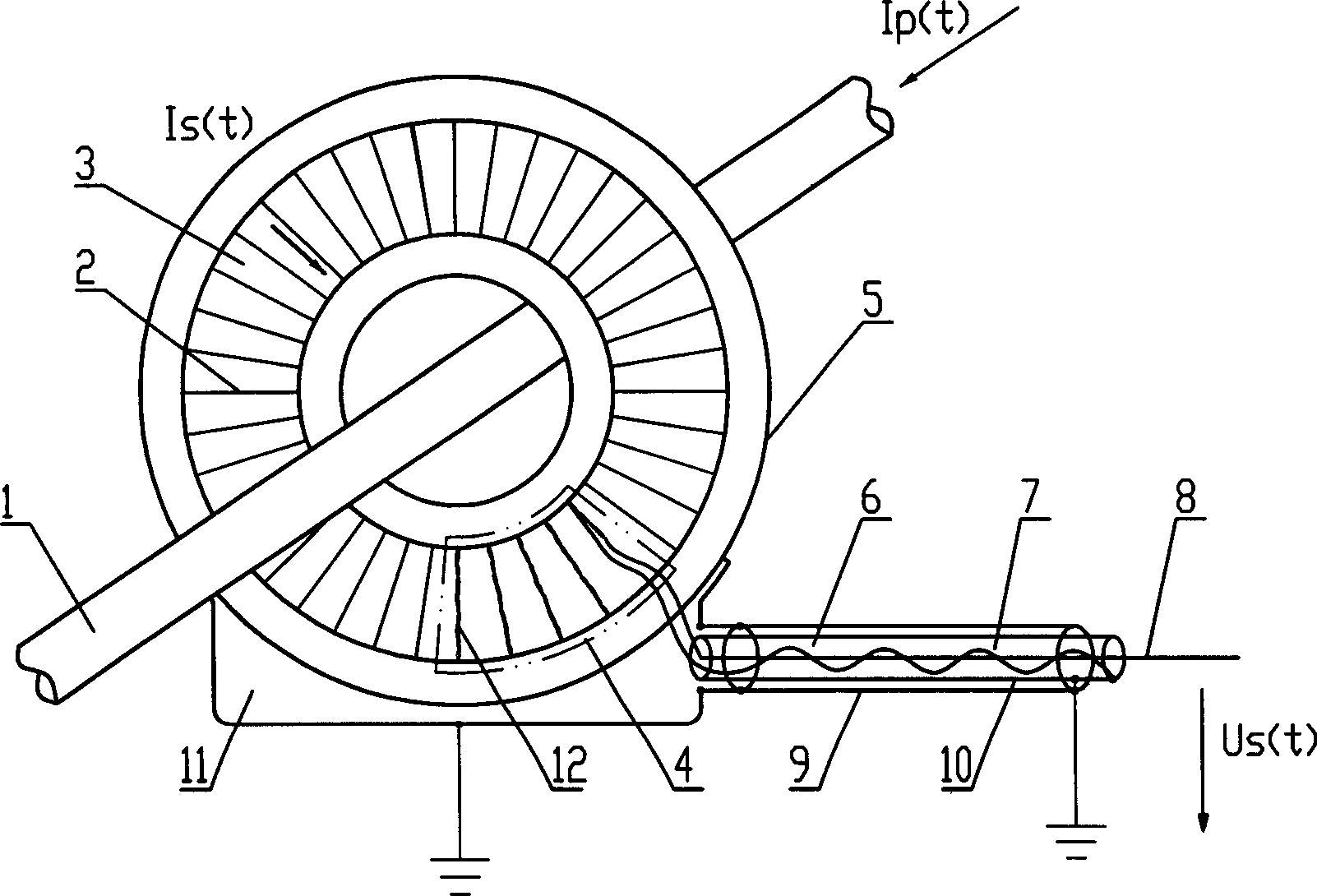

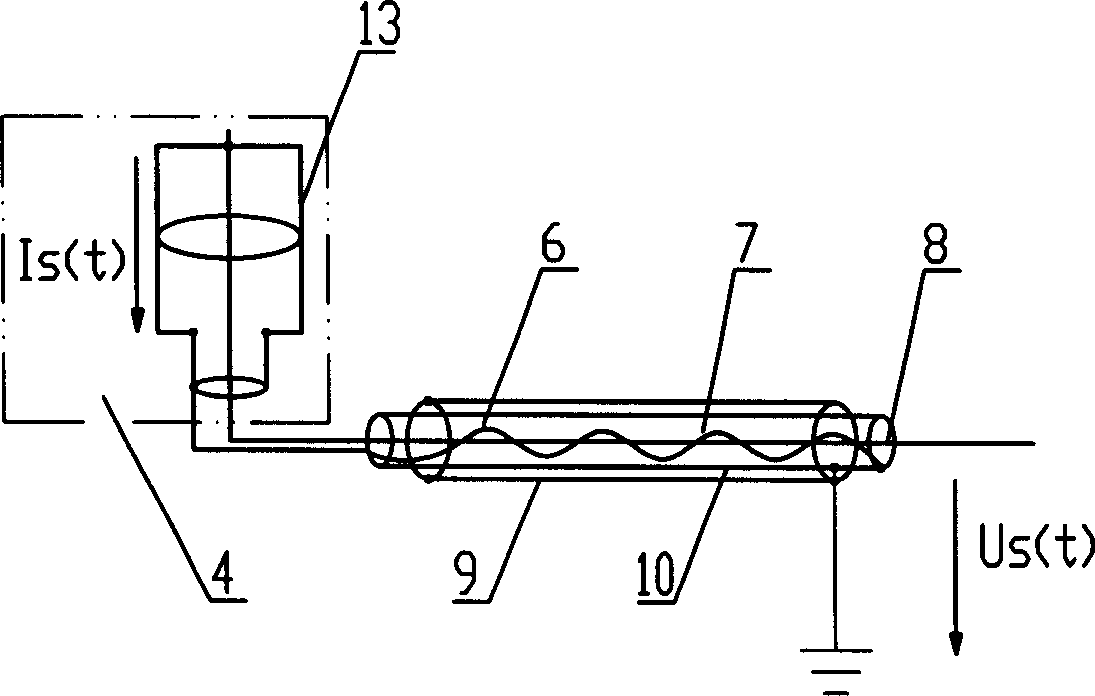

Low-power electronic current mutual inductor

ActiveCN1658344AGuaranteed measurement accuracyAccurate outputTransformersElectrical measurementsEngineeringLinearity

This invention relates to a low-power electronic current transformer, and is the equipment without power source. It includes primary winding, secondary winding, magnet core, secondary shunt resistance, screen cover, double-screen multiple twin and base frame. The primary winding passes through the center of the magnet core, the secondary brown lead circles around the magnet core evenly, the screen cover and the base frame integrate together, a secondary shunt resistance connects with the end of the secondary brown lead, and the secondary shunt resistance also circles evenly around the secondary winding composed of magnet core and the secondary brown lead, the whole secondary winding is put in the screen cover, the secondary low-power voltage is output by the double-screen multiple twin. The secondary output of this invention is the low-power voltage signal that has linearity proportion relation with the primary current; a transformer winding can meet all kinds of demands of measurement and protection at the same time; the measuring distance is far, the precision is high; it does not have the secondary loop problem, it is open-circuit and short-circuit, and the weight is light, the cost of materials is low and the magnetic compatibility is strong.

Owner:传奇电气(沈阳)有限公司

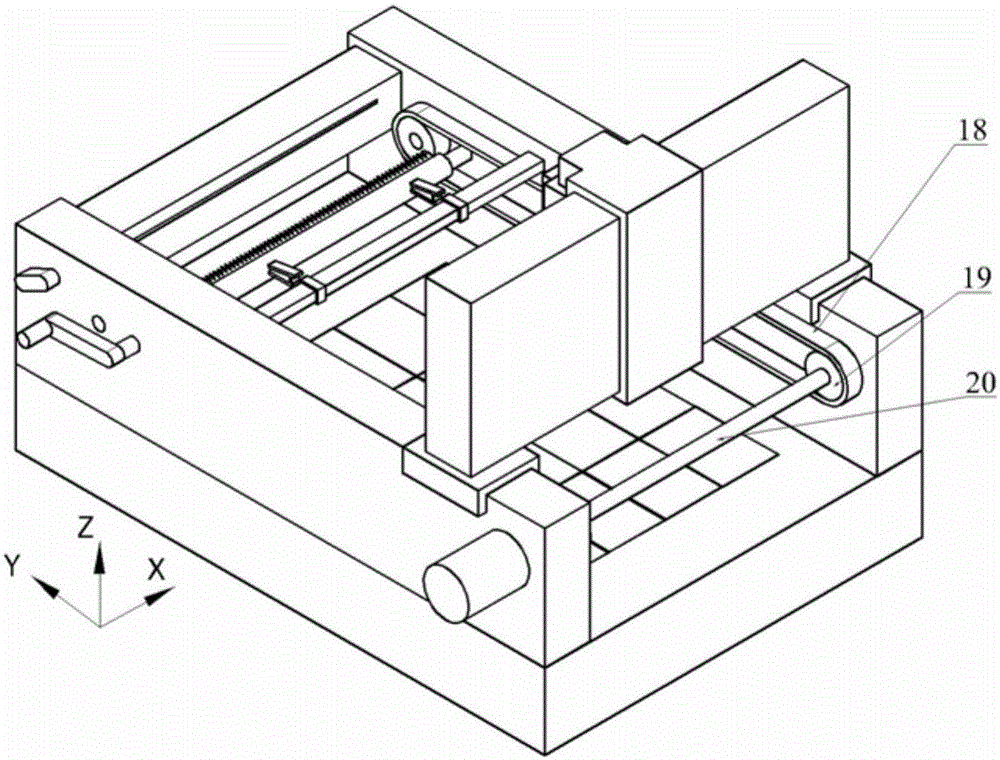

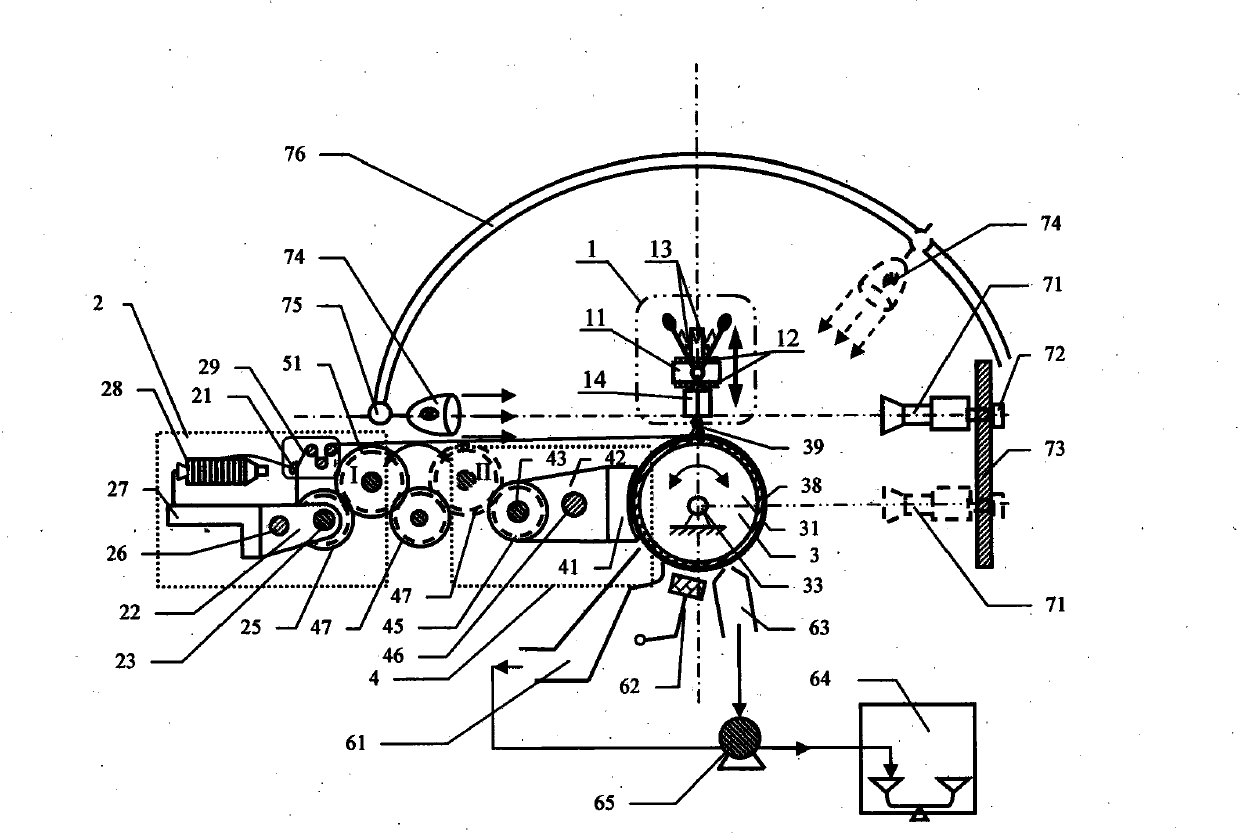

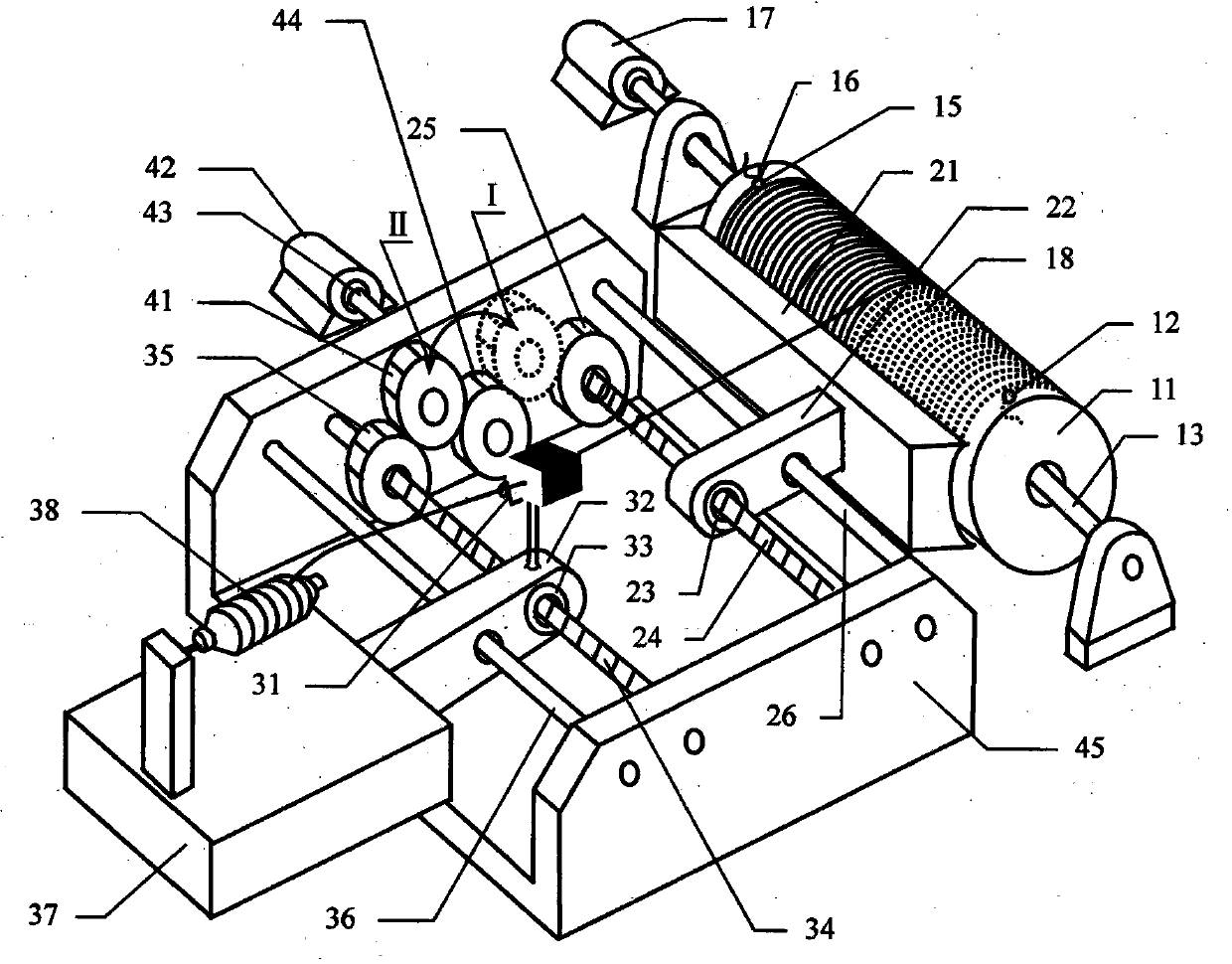

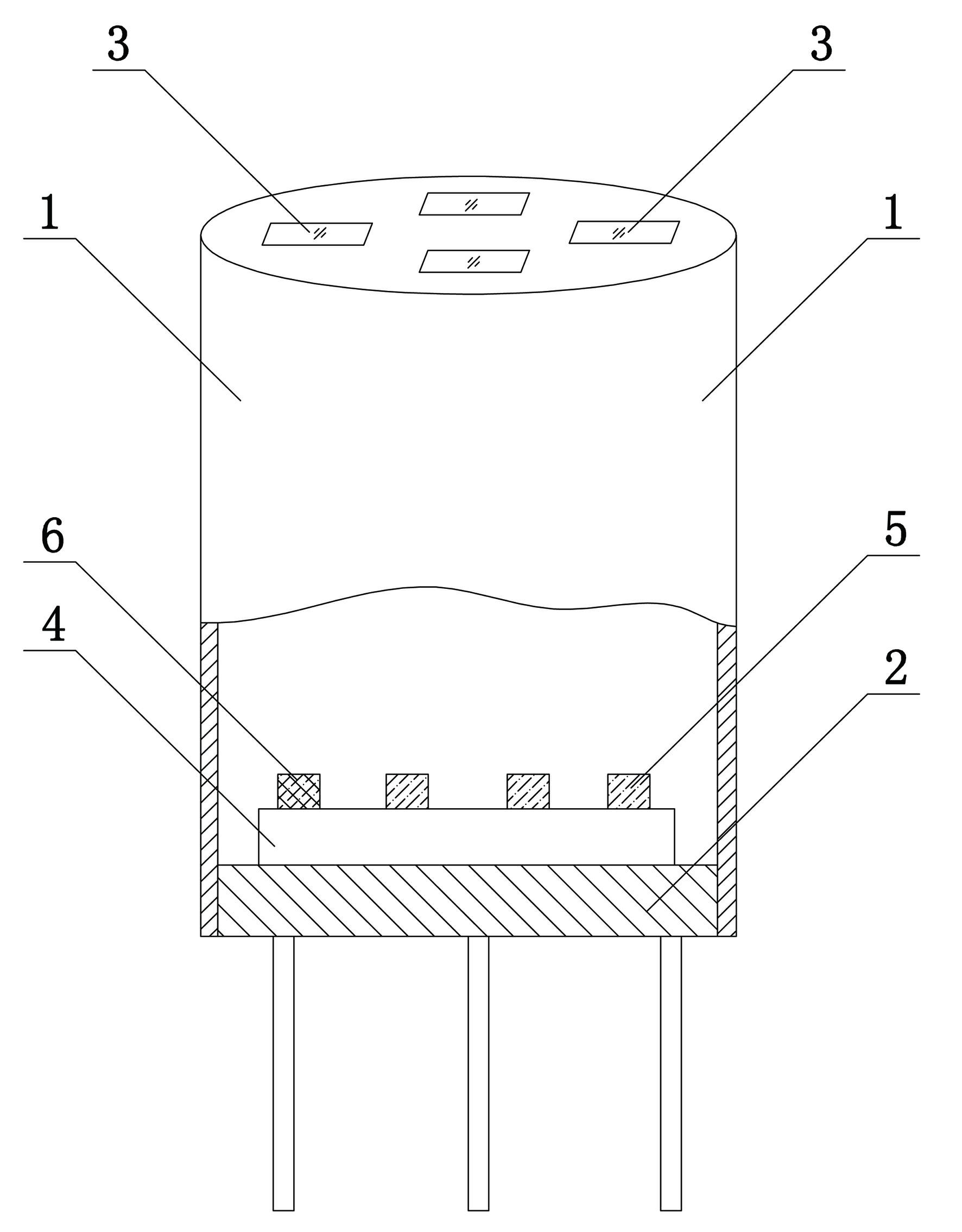

Measuring device and method for fluffing and balling shape as well as hair bulb stripping of yarn

ActiveCN103472210AEasy to measureAccurate collectionTextile testingInvestigating abrasion/wear resistanceYarnEngineering

The invention relates to a device and a method for measuring fluffing and balling shape as well as hair bulb stripping of a yarn. The device comprises a mechanism clamping hair bulbs to implement stripping, a yarn delivery mechanism performing equal-tension close packing, a yarn winding mechanism winding the yarn at a constant speed, a yarn grinding mechanism performing friction on the close packed and wound yarn, a translation driving mechanism driving the yarn delivery mechanism and the yarn winding mechanism in a switching manner, an abrasion object collector, a microimaging system and a control and data analysis system. The measuring method comprises the steps that a gap bridge wheel of the translation driving mechanism transposes the yarn delivery mechanism and the yarn grinding mechanism, and is matched with the yarn winding mechanism, so that close packing yarn winding and yarn grinding sampling are achieved; a yarn grinding sample in a yarn grinding process is measured in situ; and comprehensive measuring and evaluation are performed on the yarn grinding sample in a final state. The device is ingenious in structure, practical, precise in measuring, quantitative, and multipurpose, is an in-situ measuring device for measuring multiple indexes, and can be used for measuring of the hair feather and hair bulb quantity, the shape, the abrasion loss and the back-and-forth drag stripping property of the yarn, and for comprehensive evaluation of the fluffing resistance and the balling resistance.

Owner:DONGHUA UNIV

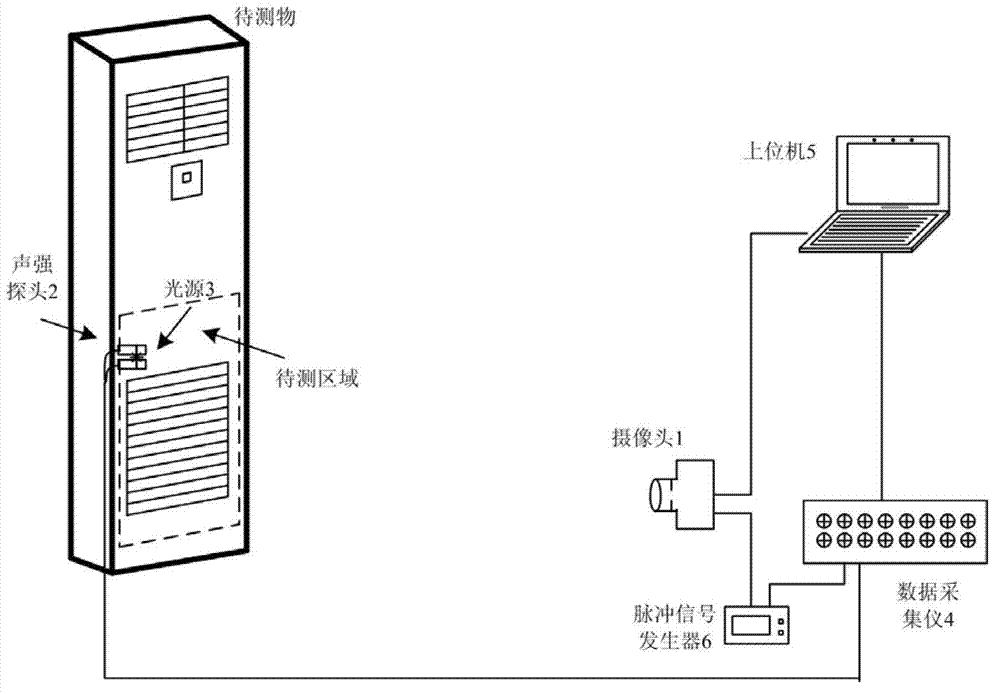

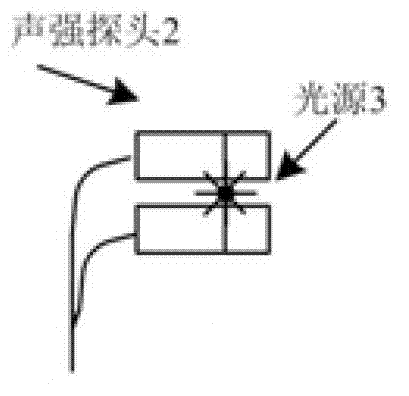

System and method for quickly positioning noise source through image identification and sound intensity scanning

InactiveCN102879763ARapid positioningAvoid interferencePhotogrammetry/videogrammetryPosition fixationNoiseData acquisition

The invention discloses a system and a method for positioning a noise source. The method comprises the following steps of: adjusting the position and focal length of a camera until a taken image comprises a region to be detected, and storing an image which is taken as a background image into an upper computer; fixing a light source on a sound intensity probe which is connected with a data acquirer; endowing the image which is taken by the camera with the color of a light source by filtering; moving the sound intensity probe, and scanning on the surface of the region to be detected at constant speed; outputting a trigger signal by a pulse signal generator, continuously taking images by the camera, recording a motion image of the light source, recording the trigger signal and an acoustic signal by the data acquirer, and synchronizing the acoustic signal and image taking time; after detection is finished, processing the image, and thus obtaining the position of the light source in a picture; extracting the acoustic signal, and thus obtaining acoustic physical quantity information at a corresponding moment; dividing the region to be detected into triangular units, wherein nodes are the positions of the light source, which are acquired at all moments, and the acquired acoustic physical quantity serves as a cloud picture measuring value; and acquiring a sound field cloud picture, and displaying the sound field cloud picture. The invention has the advantages of quick positioning, accurate measurement and high accuracy.

Owner:SHANGHAI JIAO TONG UNIV

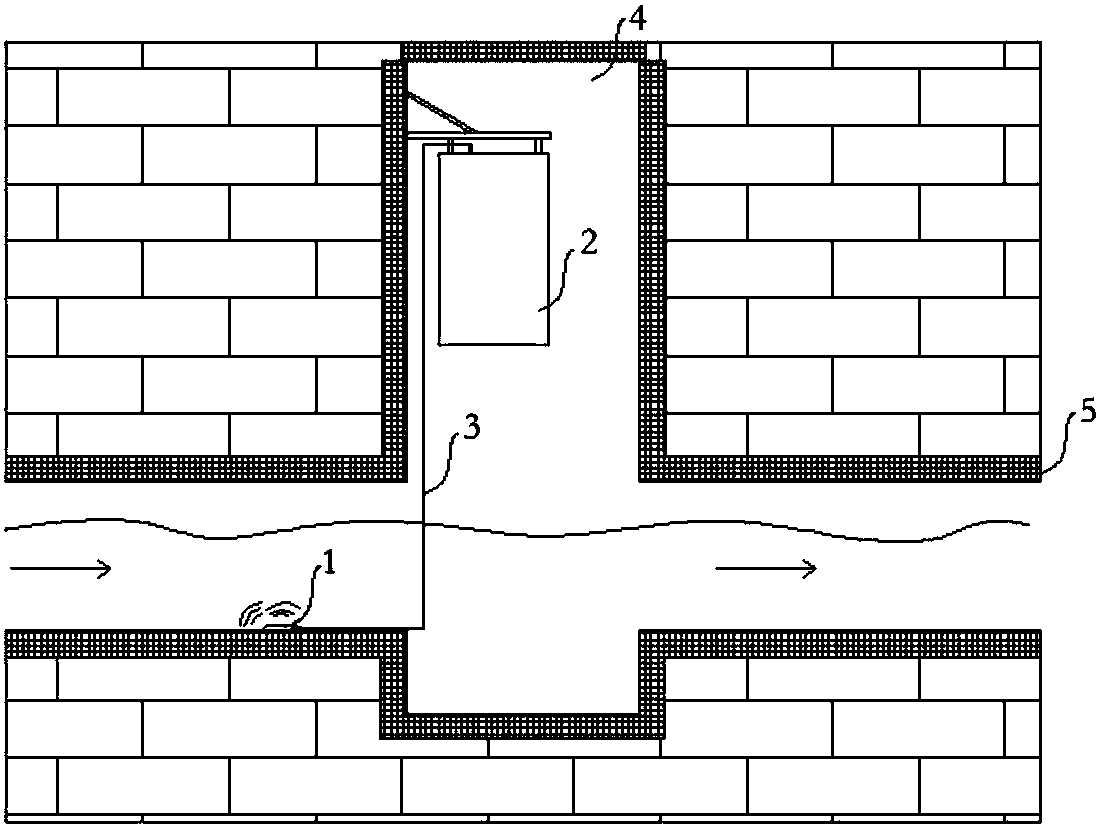

Flow measuring device for partially filled pipe drainage pipeline

ActiveCN108318092ASimplify installation and maintenance problemsHigh utility valueVolume/mass flow measurementUltrasonic dopplerComputer module

The invention discloses a flow measuring device for a partially filled pipe drainage pipeline. The measuring device is a separated type structure, the device comprises a streamline probe and a flowmeter host, and the streamline probe is connected with the flowmwter host through a waterproof cable; the streamline probe is a totally-enclosed waterproof structure, wherein the front end of the streamline probe is provided with a first underwater acoustic transducer and a second underwater acoustic transducer in parallel, the top end is provided with a third underwater acoustic transducer, the bottom of the probe is provided with a pressure transmitter, and the back end is provided with a temperature sensor; the flowmeter host comprises an ultrasonic Doppler flow rate measuring module, ultrasonic liquid level measuring module, a pressure transmitter measuring module, a temperature measuring module, an FPGA operational module, an MCU main control module, a battery and voltage-stabilized source module, a GPRS communication module and a debugging interface circuit. According to the device, through the separated type structure of integrating the streamline probe with five sensors and the host, the problems are simplified that the flowmeter installation and maintenance are difficult.

Owner:TAIHUA WISDOM IND GRP CO LTD

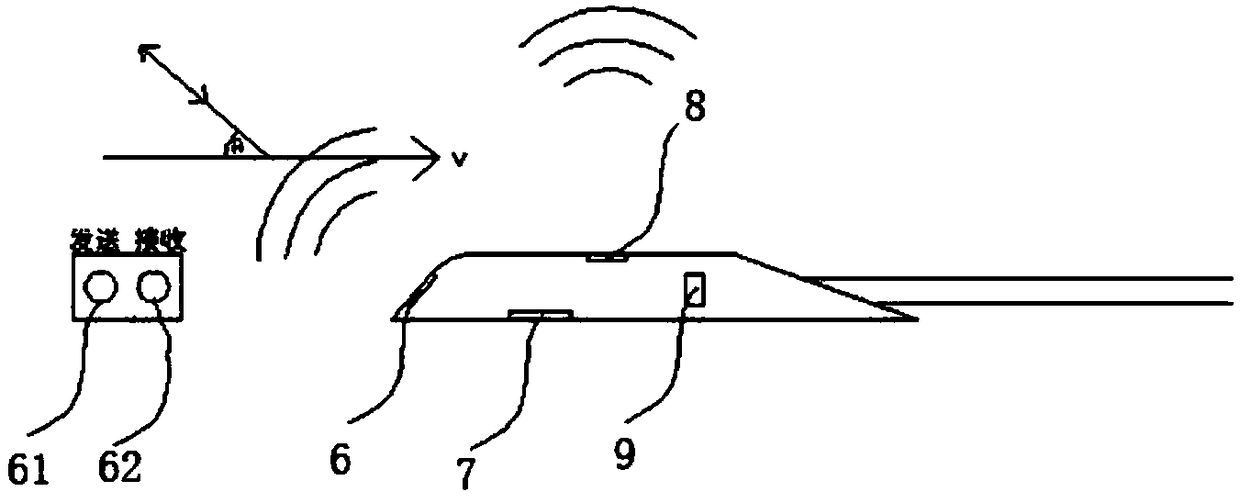

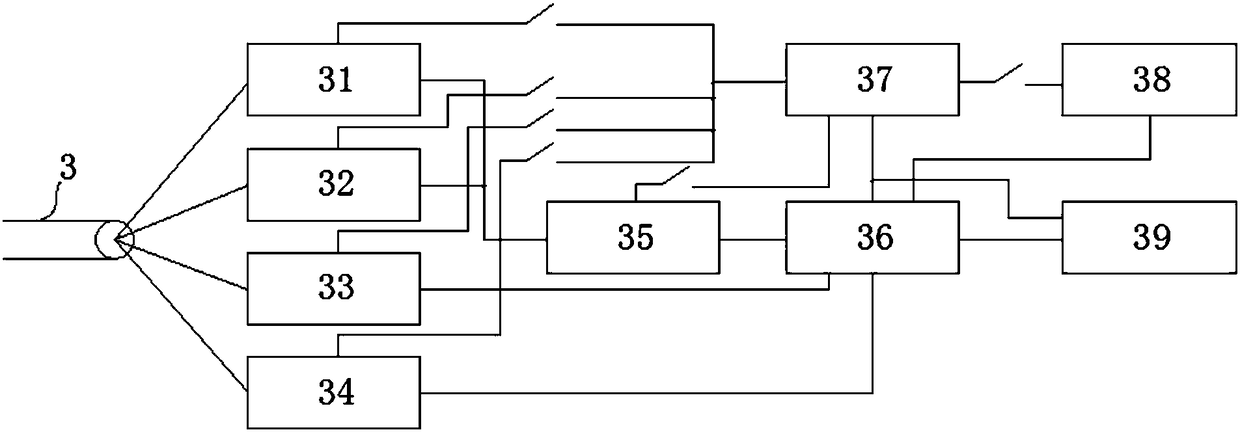

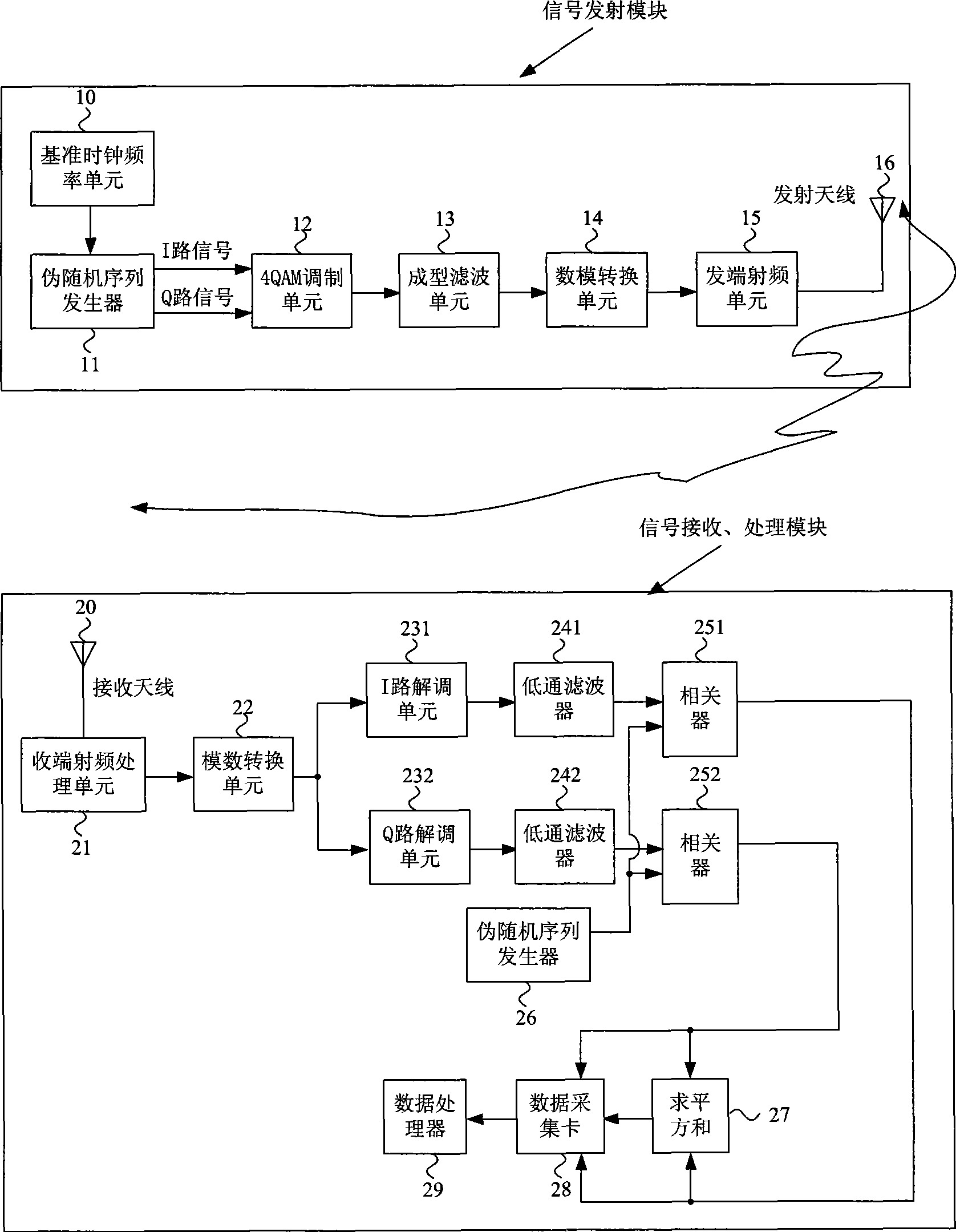

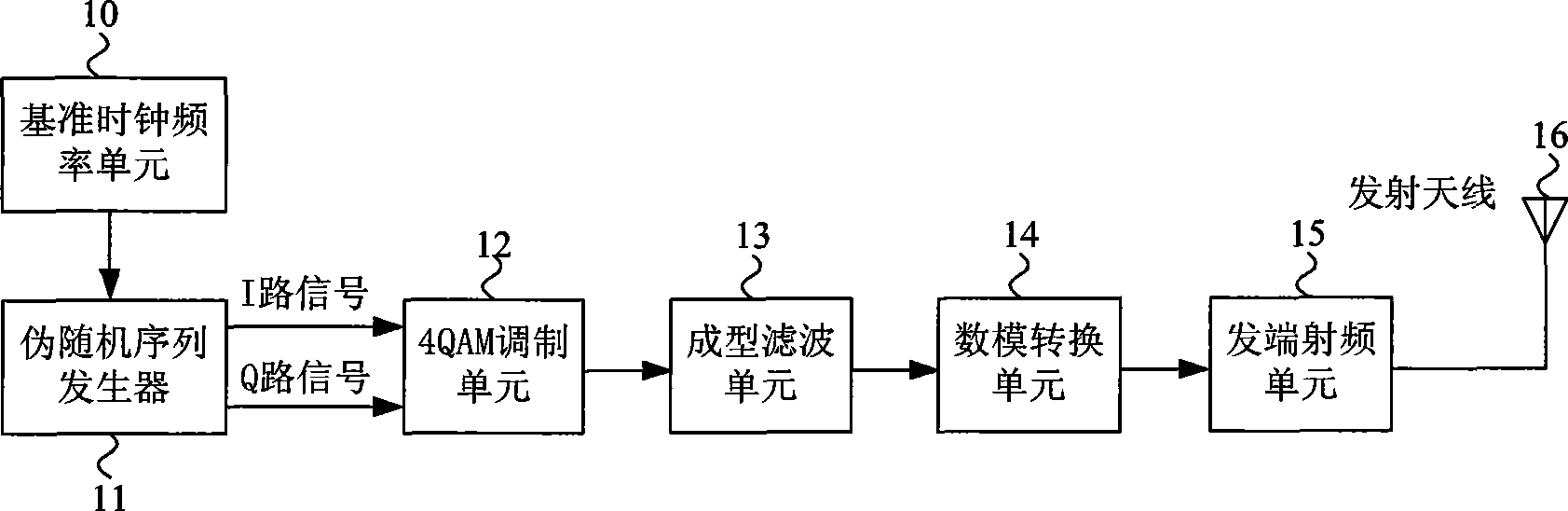

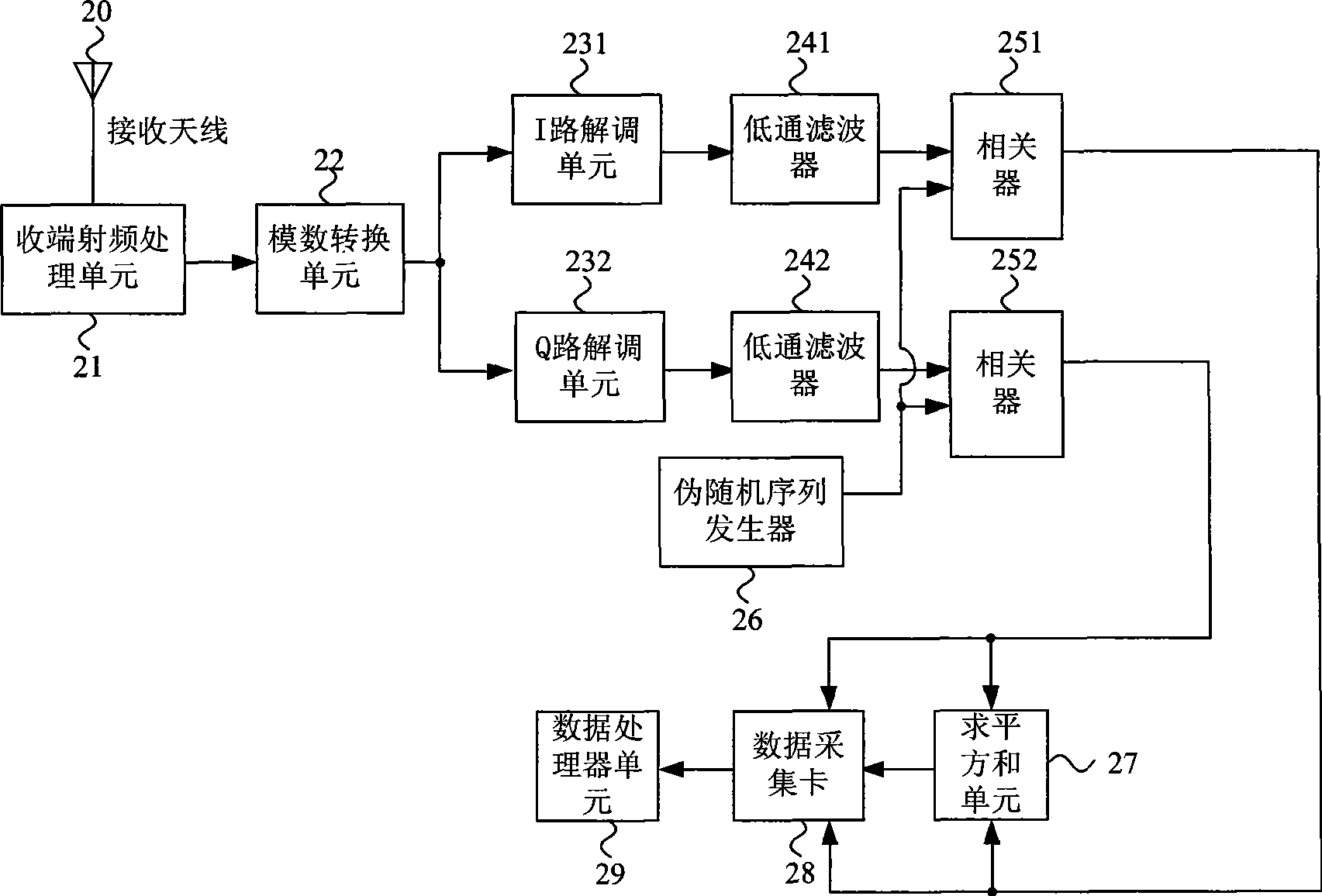

Wireless channel parameter measurement device and method thereof

InactiveCN101534160AFulfil requirementsFulfillment requirementsTransmission monitoringMultiple carrier systemsMeasurement deviceChannel parameter

The invention relates to a wireless channel parameter measurement device and a method thereof in the technical field of wireless communication. The device comprises a signal transmission module and a signal receiving and processing module. The method comprises the following steps that: two paths of pseudo-random sequences are generated, and are subjected to 4QAM modulation; a modulated baseband digital signal is subjected to molding and filtering; the baseband digital signal is converted into an analog signal to be transmitted through a transmission antenna; a received radio frequency signal is subjected to radio frequency processing and analog-to-digital conversion to be changed into a digital signal; and the digital signal is subjected to I path demodulation and Q path demodulation, and is subjected to low-pass filtering to be converted into a baseband digital signal; the baseband digital signal is related to the local pseudo-random sequence, and outputs related signals and a result of the quadratic sum of related signals to acquire a required channel parameter through calculating. The device and the method can provide more accurate and overall testing results, and lead the whole collecting process to be more complete and convenient as a data acquisition and processing unit is added.

Owner:SHANGHAI JIAO TONG UNIV

Electrode antenna integrated photoelectric integrated sensor for testing strong electric field

InactiveCN1862264AMeet the measurementSmall sizeCurrent/voltage measurementElectrostatic field measurementsDiffusionTitanium metal

The present invention relates to an electrode antenna unified photoelectric integrated sensor used for making strong electric field measurement, belonging to the field of high-voltage measurement technology. It is characterized by that it adopts a wafer with electro-optic effect, on the wafer surface said invention adopts titanium metal diffusion process or proton exchange process to form optical waveguides whose two ends are made into the form of Y-shaped bifurcation and middles are mutually parallel, on two mutually-parallel optical waveguides three inverted U-shaped electrode antennas whose tops are respectively equipped with a projection are set, said three mutually-parallel inverted U-shaped electrode antennas are crossed over two mutually-parallel optical waveguides. The invented photoelectric integrated sensor can be used for measuring the information of amplitude, frequency and phase of strong electric field signal.

Owner:TSINGHUA UNIV

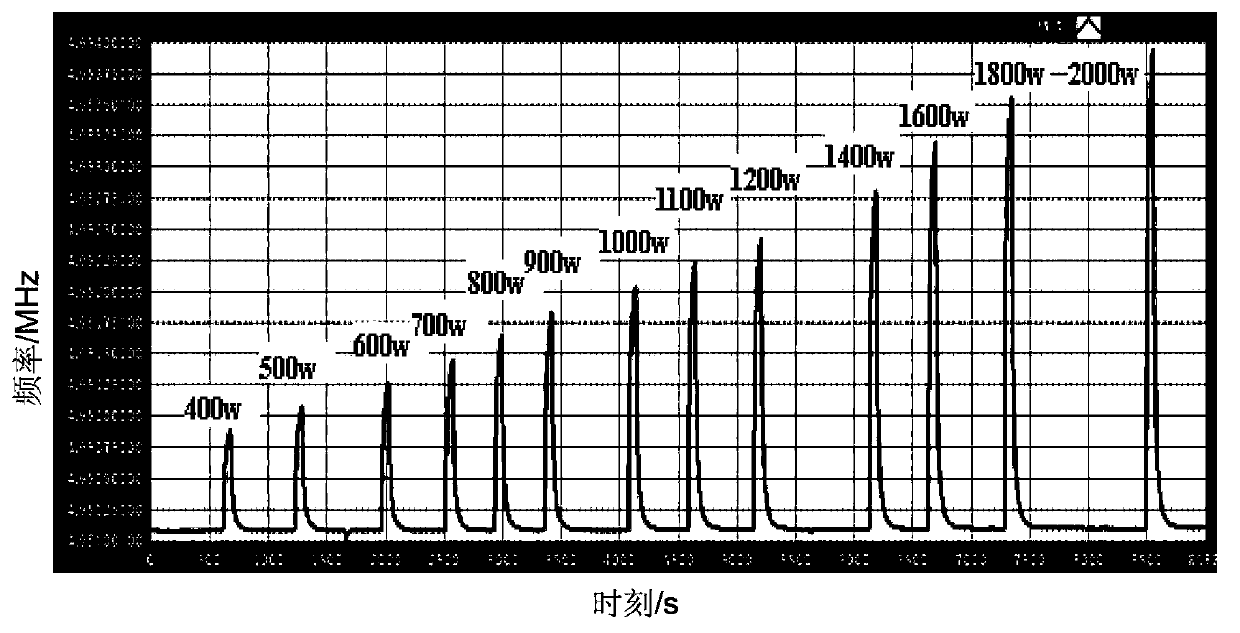

Method and device for measuring optical power parameters on basis of crystal resonator

InactiveCN104215326AReduced requirements for the ability to withstand laser radiationRealize online monitoringPhotometry using electric radiation detectorsLaser lightHigh energy laser

The invention discloses a method and a device for measuring optical power parameters on the basis of a crystal resonator. The device comprises the crystal resonator, an oscillation starting circuit and a frequency measuring unit. An input end of the oscillation starting circuit is connected with an electrode of the crystal resonator, an output end of the oscillation starting circuit is electrically connected with the frequency measuring unit, and to-be-measured light beams are incident on a working surface of the crystal resonator. The method and the device for measuring the optical power parameters have the advantages that incident laser light is effectively reflected during application of the method and the device, the requirement on the laser irradiation bearing ability of a measuring system can be lowered, the method and the device can be used for measuring the high-energy laser parameters under long-time emergent conditions, power of the laser light can be converted into frequencies to be measured during implementation, the method and the device are high in measurement precision and resolution by the aid of a modern frequency measuring technology, requirements on measuring parameters of laser light under different power conditions can be met, the method and the device are high in applicability, wide in dynamic range and simple in engineering, the device is compact in structure, and the like.

Owner:NORTHWEST INST OF NUCLEAR TECH +1

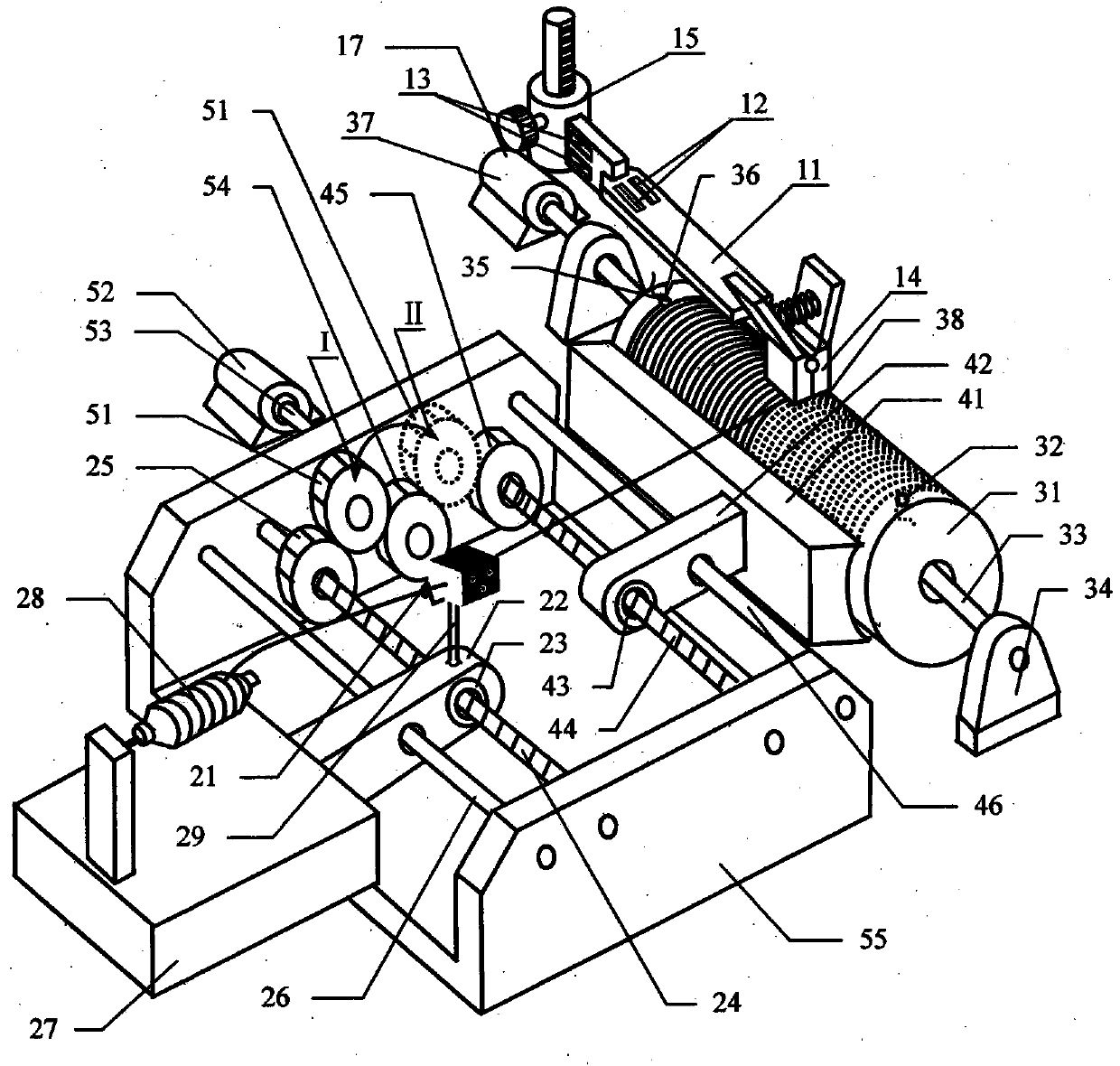

Device and method used for measuring pilling form and pulling force of yarns

ActiveCN103471651AGet the right measurementsAchieve estimatesMaterial analysis by optical meansYarnPull force

The invention relates to a device and method used for measuring the pilling form and pulling force of densely arranged yarns. The device consists of a yarn winding mechanism, a yarn grinding mechanism, a yarn feeding mechanism, a translational driving mechanism, a wearer collector, a microscopic camera system, a clamping and pulling mechanism, and a control and data analysis system. The method comprises the steps of bridging and rotating the yarn feeding mechanism and the yarn grinding mechanism through the translational driving mechanism, kinetically matching with the yarn winding mechanism to achieve the winding of the densely arranged yarns and yarn grinding sample preparation, and carrying out on-line measurement on yarn samples in the process of yarn grinding as well as comprehensive measurement, calculation and evaluation on yarn grinding samples in a final state. The device is ingenious in structure, practical, and precise and quantitative in measurement, and the device and the method are an in-situ measuring device and an in-situ measuring method which are multi-purpose and multi-index in one measurement. The device and the method can be used for the measurement of the pilling quantity, form and wear quantity of the yarns and pulling forces of hairiness and hair bulbs as well as the comprehensive evaluation of the pilling resistance.

Owner:DONGHUA UNIV

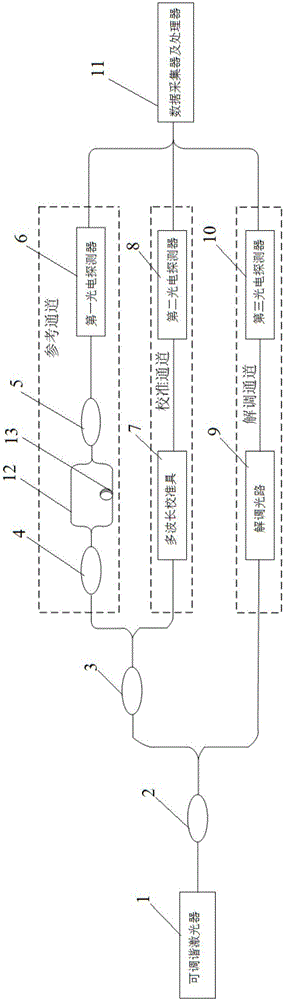

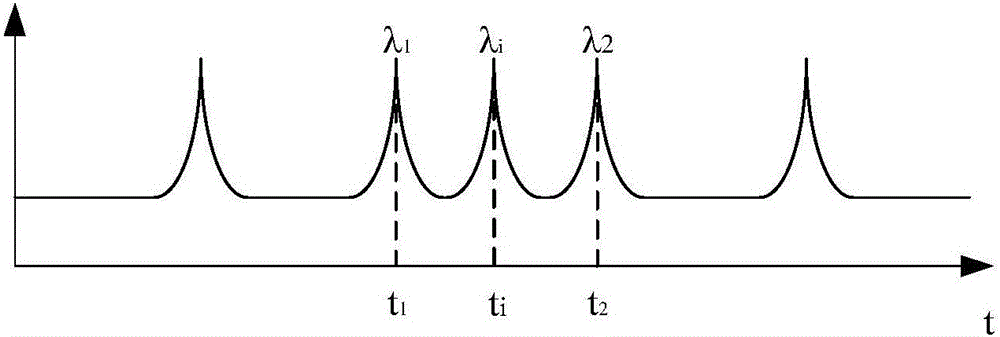

High-wavelength-resolution fiber grating demodulation system and method

ActiveCN106248118AHigh-resolutionRealize demodulationConverting sensor output opticallyGratingTime delays

The invention provides a high-wavelength-resolution fiber grating demodulation system. In the system, the output end of a tunable laser is connected with a first light demultiplexer, the first output end of the first light demultiplexer is connected with a second light demultiplexer, the first output end of the second light demultiplexer is connected with a first optical coupler, the first sweep-frequency light output end of the first optical coupler is connected with a second optical coupler, the second sweep-frequency light output end of the first optical coupler is connected with the second optical coupler via a time delay fiber, the output end of the second light coupler is connected with a first photoelectric detector, the second output end of the second light demultiplexer is connected with a multi-wavelength calibration tool, the output end of the multi-wavelength calibration tool is connected with a second photoelectric detector, the second output end of the first light demultiplexer is connected with a demodulation optical path, the output end of the demodulation optical path is connected with a third photoelectric detector, and the output ends of the first, second and third photoelectric detectors are connected to a data collector and processor. According to the invention, the nonlinear tuning defect of the tunable laser can be overcome effectively, and the wavelength resolution is high.

Owner:WUHAN UNIV OF TECH

Head mounted eye tracker detection method

InactiveCN103996020AAccurate measurementMeet the measurementCharacter and pattern recognitionEye movementPupil

The invention discloses a head mounted eye tracker detection method, which comprises the steps of extracting the cornea emitting facula center; extracting the feature points of the pupil outline and fitting the pupil outline. The head mounted eye tracker detection method has the advantages that the position of the eye fixation point is worked out according to the anti-interference performance of an infrared light source, then, the positions of eyes during eye closing and eye twinkling are fit according to a tracking algorithm, the eye movement fixation orientation can be precisely measured, the precision of an identification algorithm is high, and the measurement on the eye movement fixation orientation at a high-precision requirement can be met.

Owner:AVIC HUADONG OPTOELECTRONICS (SHANGHAI) CO LTD

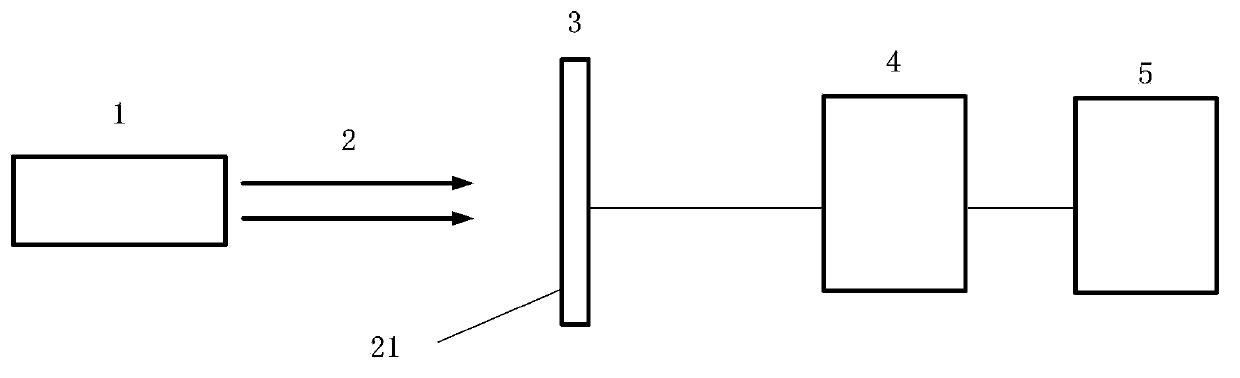

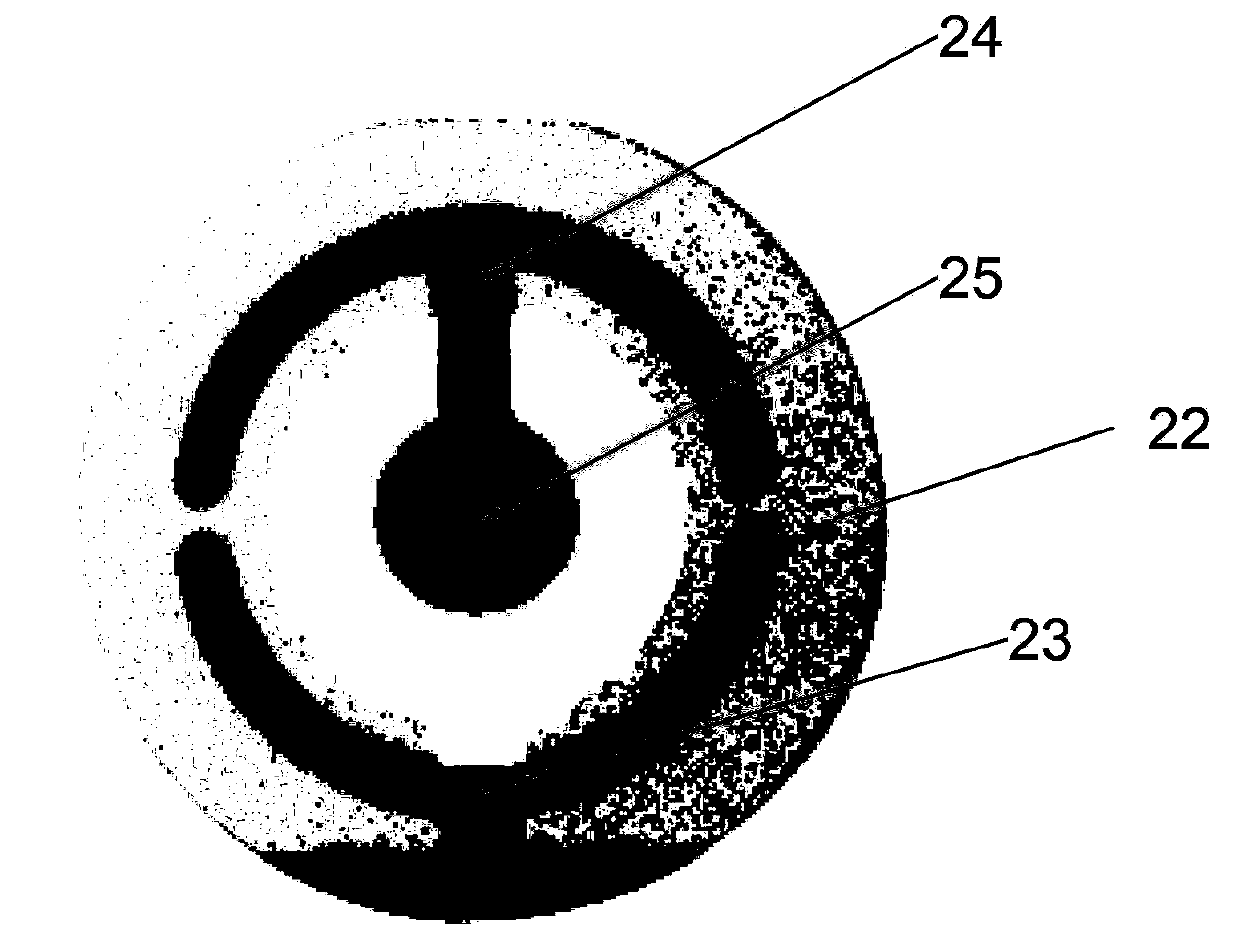

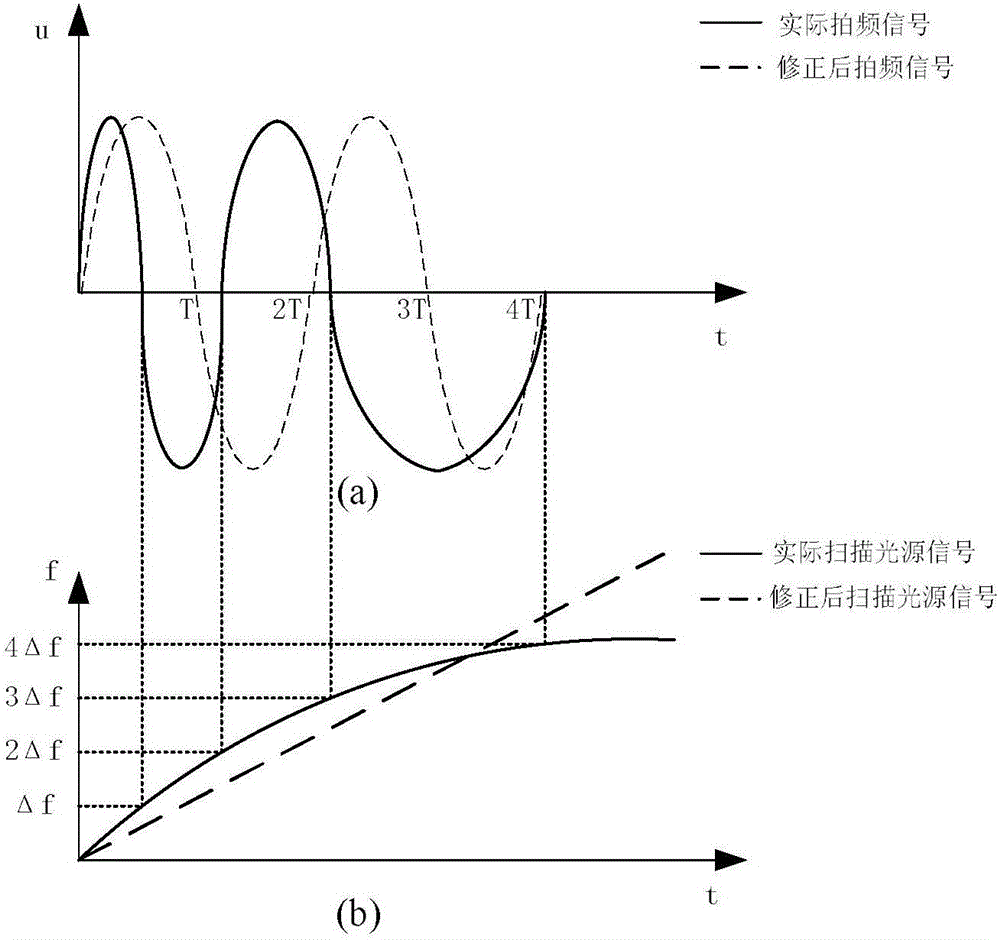

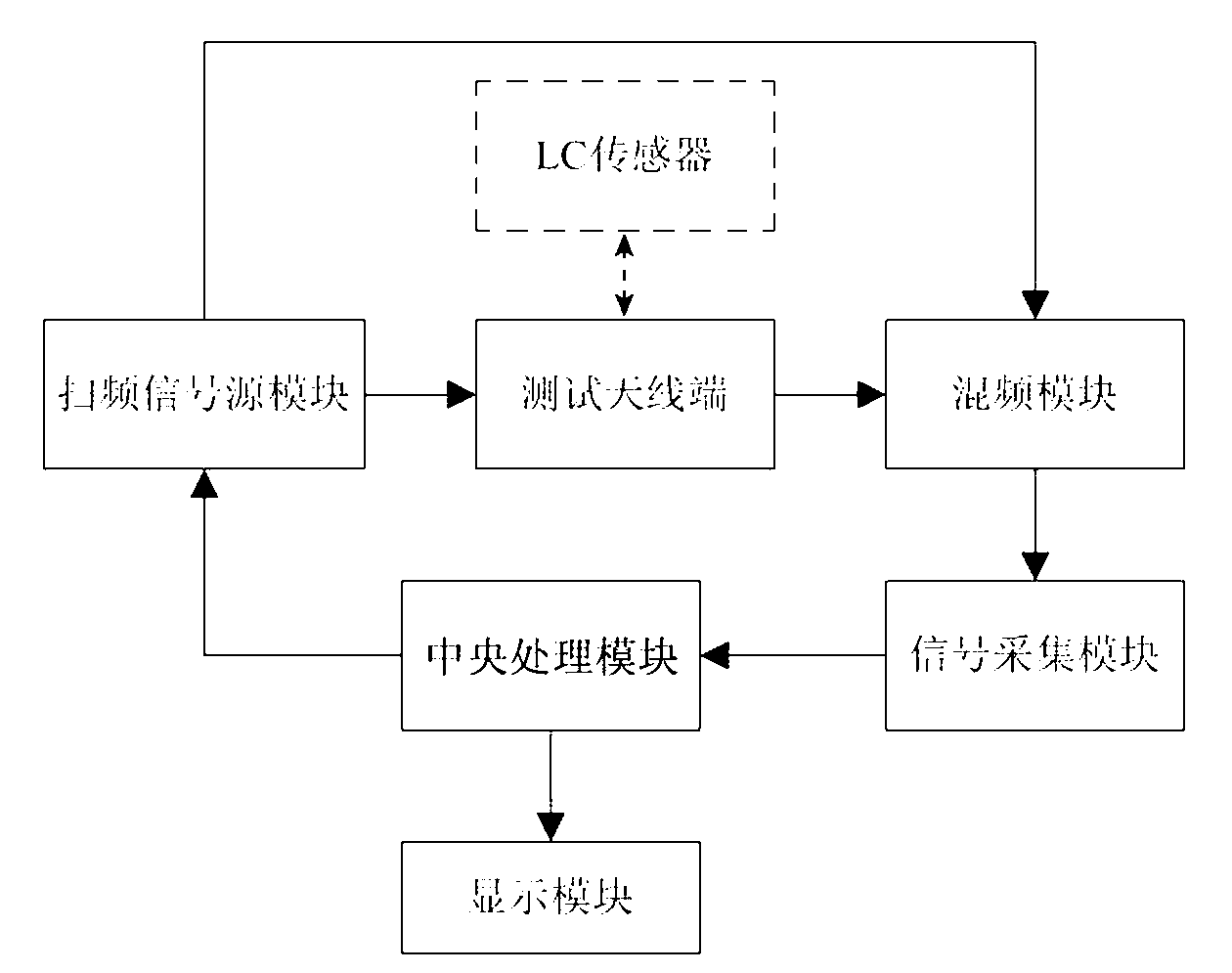

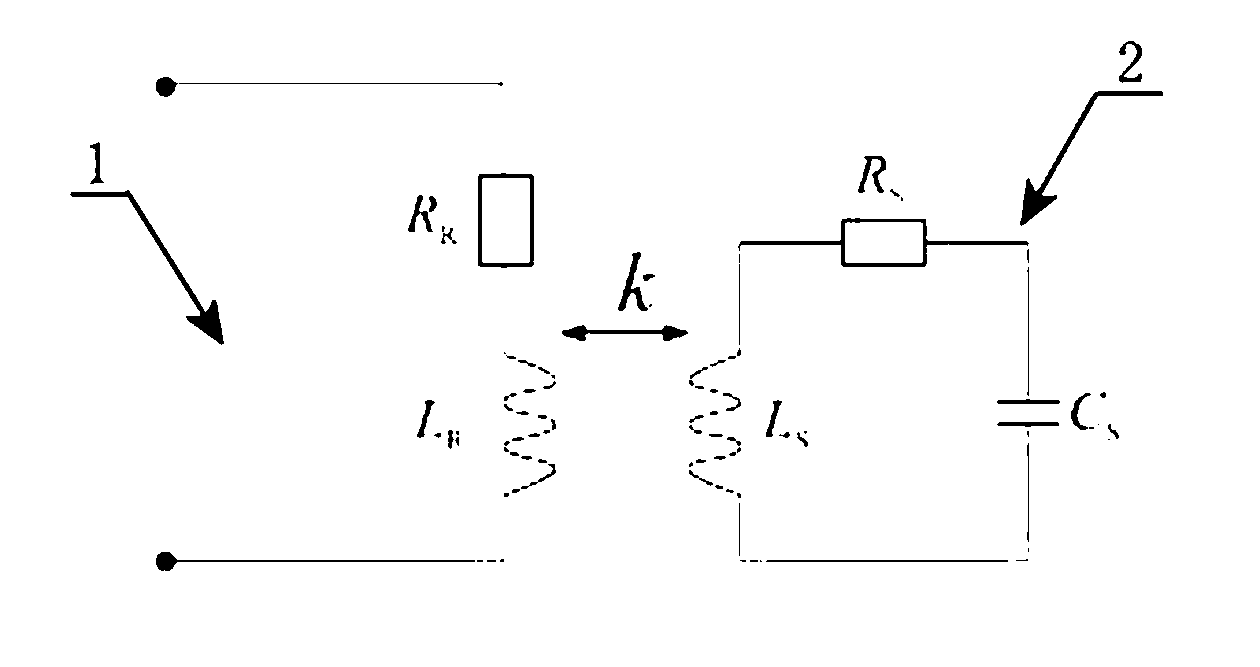

Measuring system and method of LC (inductive capacitive) sensor in sweep frequency mode

The invention provides a measuring system and method of an LC (inductive capacitive) sensor in sweep frequency mode and solves the problem that existing measuring methods are incomplete and low in accuracy and are useless in severe environment and the like. The measuring system comprises a sweep frequency signal source module, a testing antenna end, a mixing frequency module, a signal acquiring module, a central processing module and a display module. An output end of the sweep frequency signal source module is connected with an input end of the testing antenna end and an input end of the mixing frequency module, an output end of the testing antenna end is connected with an input end of the mixing frequency module, an output end of the mixing frequency module is connected with an input end of the signal acquiring module, an output end of the signal acquiring module is connected with an input end of the central processing module, and an output end of the central processing module is connected with an input end of the sweep frequency signal source module and an input end of the display module. The measuring system is simple in structure, convenient to move, easy to implement, convenient to operate, accurate to measure, non-contactable in measuring and applicable to severe environment.

Owner:ZHONGBEI UNIV

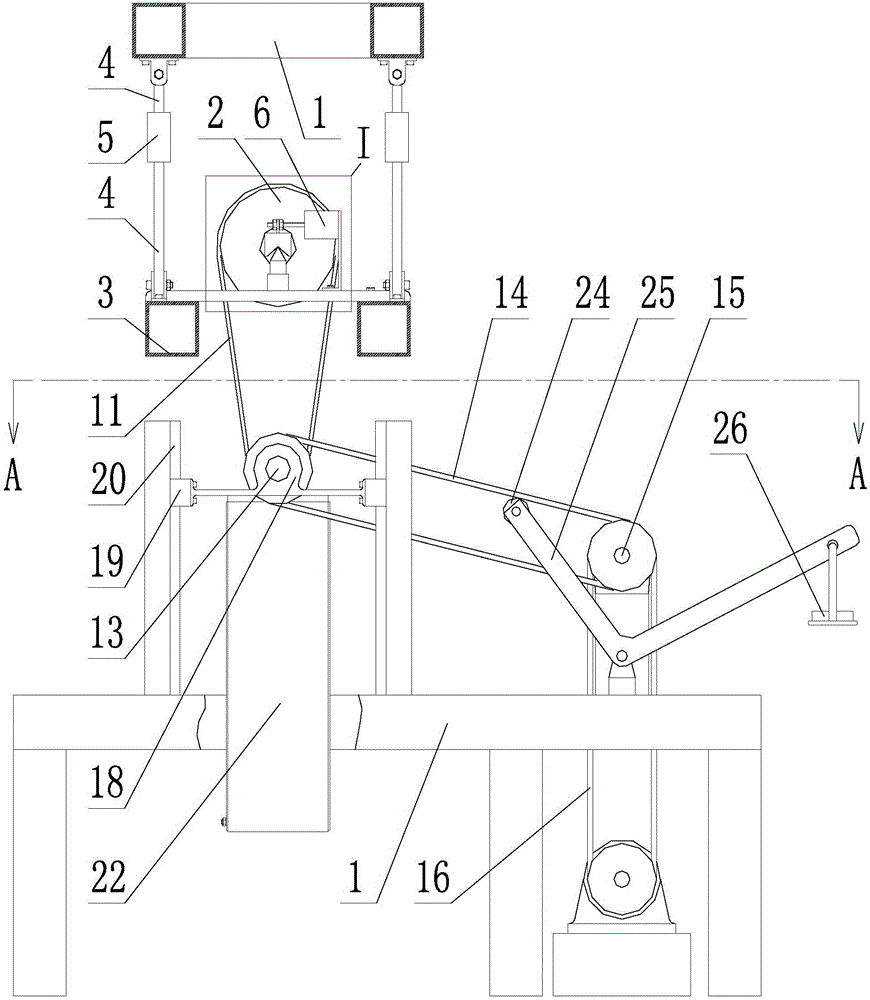

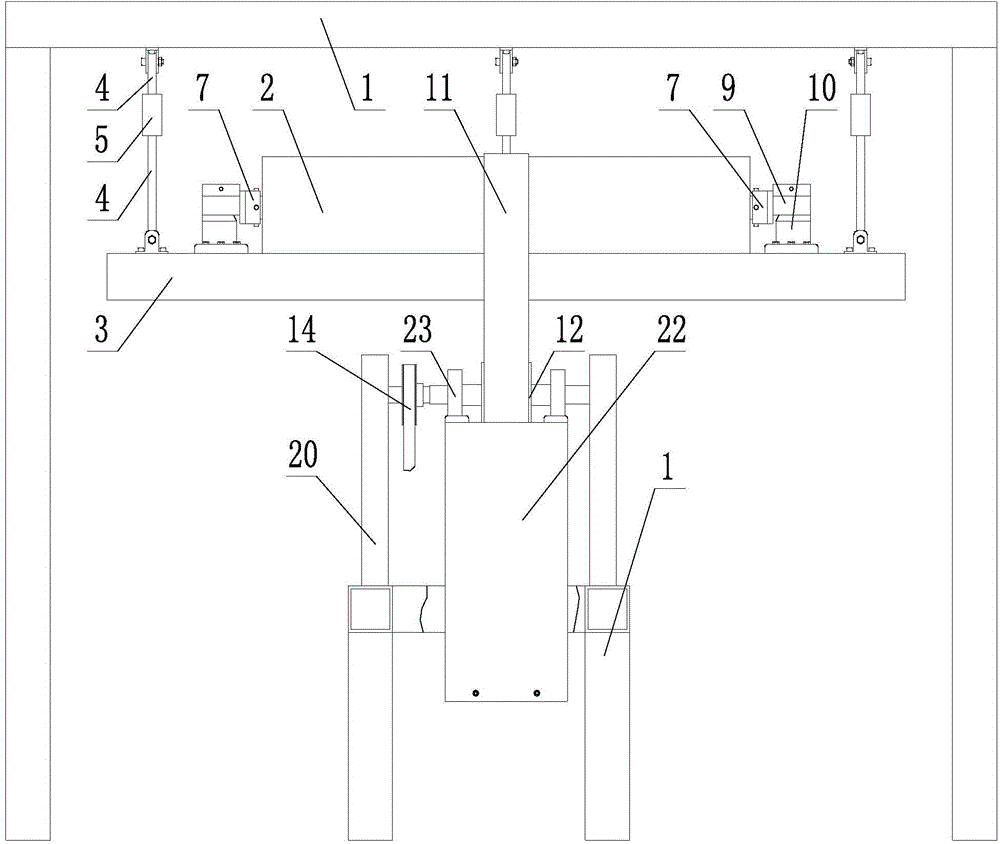

Carrier roller rotation resistance measuring device

ActiveCN104697693AAccurately measure instantaneous speedAvoid influenceApparatus for force/torque/work measurementEngineeringSelf adaptive

The invention discloses a carrier roller rotation resistance measuring device and belongs to the technical field of carrier roller mechanics performance testing. The carrier roller rotation resistance measuring device comprises a machine frame, a suspension type carrier roller measurement module, a carrier roller driving module, a synchronous speed measuring module and a belt self-tensioning module, wherein a carrier roller is installed in a suspended mode, the influence on a measurement result of outside vibration can be avoided, a column type tension sensor is located between an upper suspension point and a lower suspension point, hinge pins of the upper suspension point and the lower suspension point are mutually perpendicular, and the stability of the measuring process is ensured. The synchronous speed measuring module is located on a carrier roller installing rack under the carrier roller and used for accurately measuring the instantaneous speed of the carrier roller and can adapt to carrier rollers of different roller diameters by itself. Under the joint effects of a weight box, a slide block and a slide rail, the self-adapting tensioning of a main drive belt and the vertical relation between the main drive belt and the carrier roller can be always ensured. Under the joint effect of a balancing weight of the belt self-tensioning module and an L-shaped lever, a toothed belt of a primary belt wheel mechanism can be always tensioned through a tensioning wheel, and rotation resistance measurement of the carrier rollers of different roller diameters can be achieved.

Owner:NORTHEASTERN UNIV

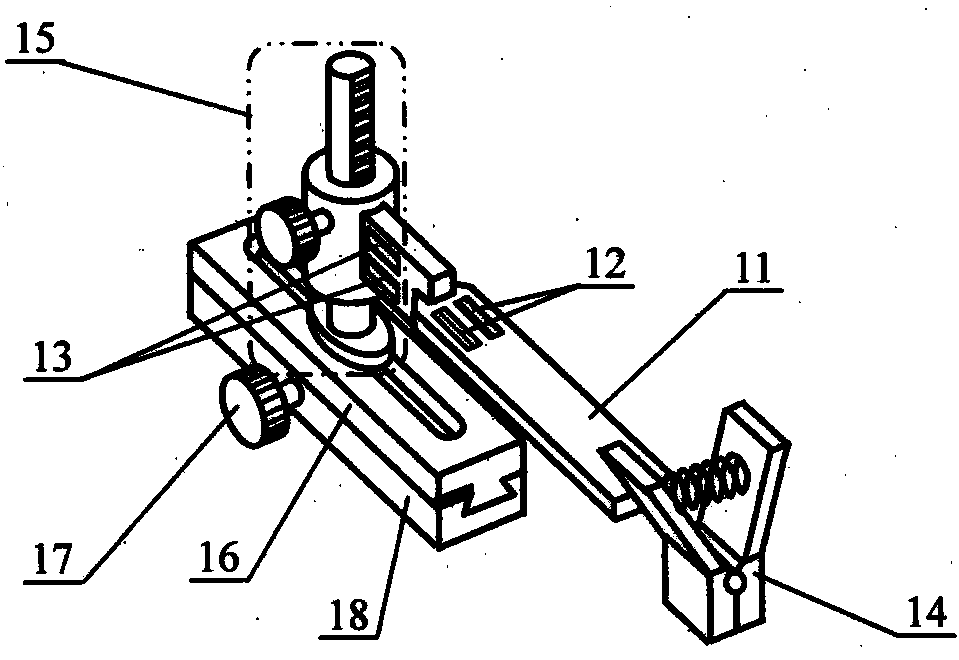

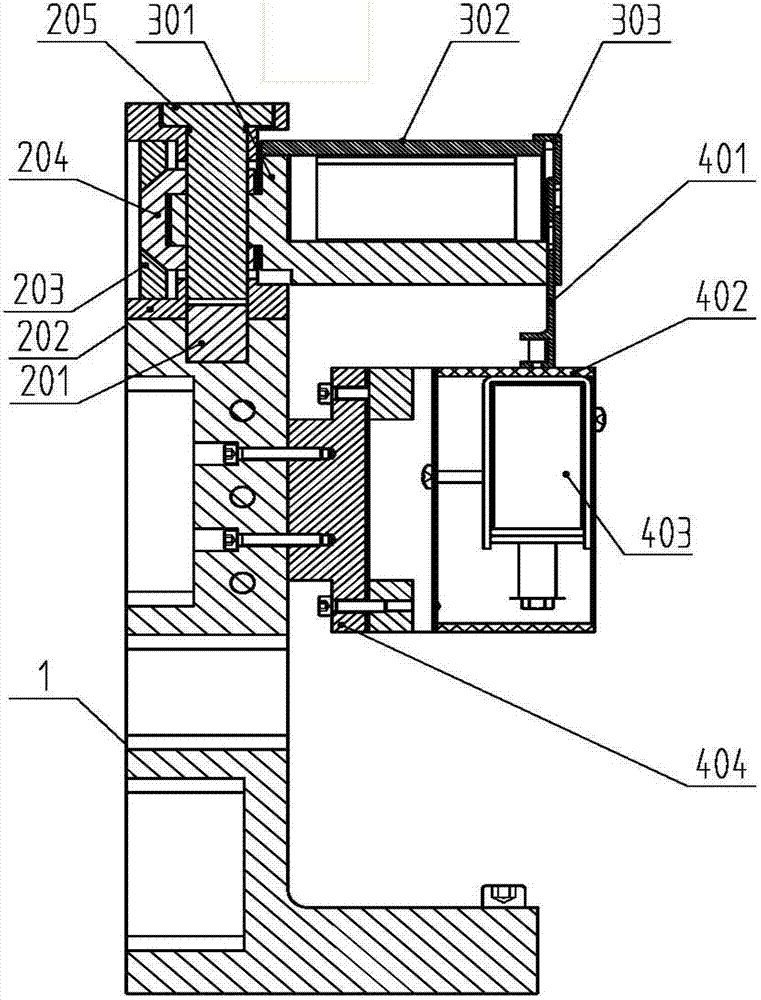

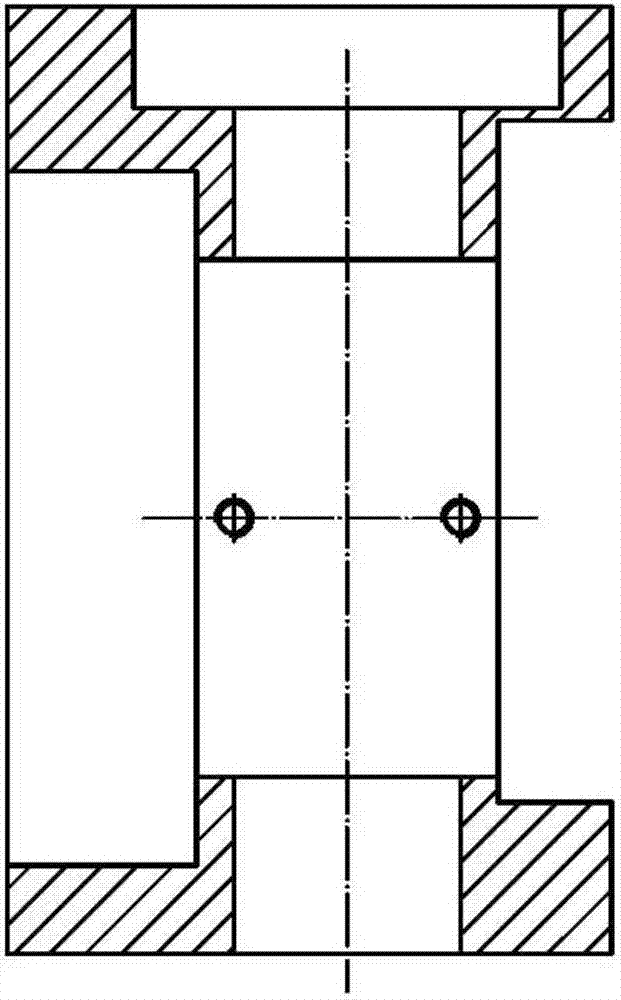

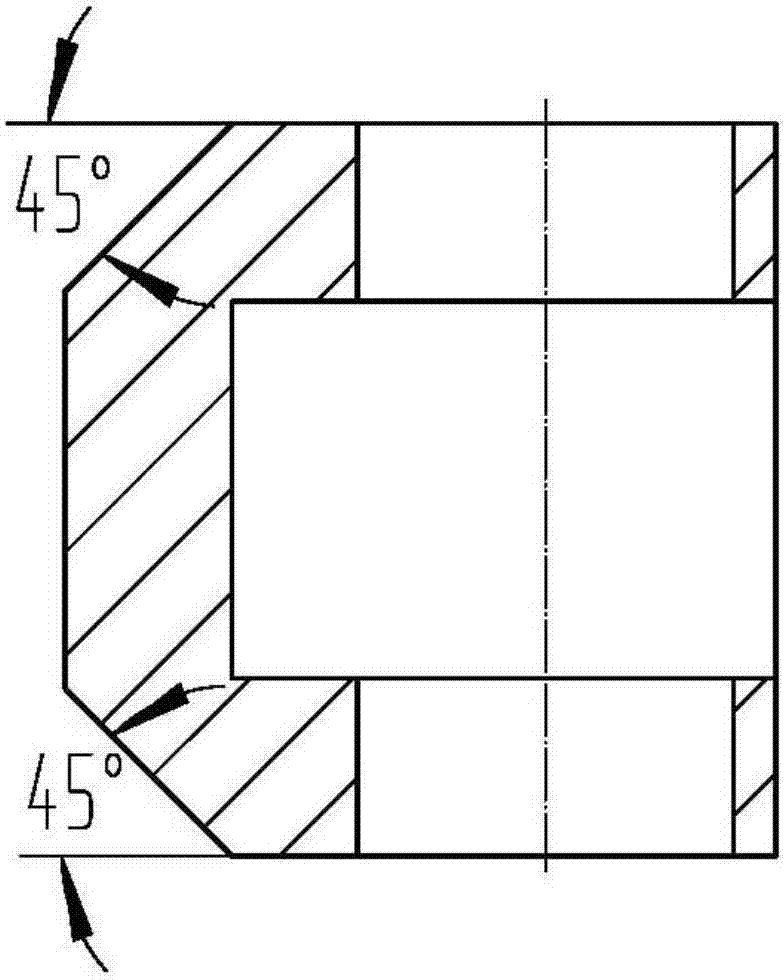

Laser displacement sensor installion and fine adjustment device

ActiveCN103111914AAchieve fine-tuningMeet the measurementMeasurement/indication equipmentsEngineeringMechanical engineering

The invention provides a laser displacement sensor installion and fine adjustment device. The device can be achieved a fine adjustment to height location of a laser head and an emission line angle in a level plane. The laser displacement sensor installion and fine adjustment device comprises an upright pillar support, a fine adjustment assembly and an installion box assembly. The fine adjustment assembly is fixedly connected with an upper portion of the upright pillar support. The installing box assembly is located on one side of the upright pillar support. The installing box assembly is connected with the fine adjustment assembly. The fine adjustment assembly mainly consists of a fine adjustment support, two adjustment wedge blocks, a guiding sleeve and a guiding pillar. Two adjustment wedge blocks are located between the guiding sleeve and the upright pillar support. The installing box assembly is used for arranging the laser displacement sensor. According to the laser displacement sensor installion and fine adjustment device, locations of the two adjustment wedge blocks can be adjusted to achieve the fine adjustment of the fine adjustment assembly along the vertical direction. The fine adjustment assembly can be further used for driving the box installing assembly so as to achieve the fine adjustment of the height location of the laser displacement sensor. Therefore, measurements of torsion shafts can be met, wherein the torsion shafts are in different types and different batches.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Measuring device and method for apparent fluffing and balling as well as abrasion loss of yarn

The invention relates to a measuring method and a device for apparent fluffing and balling as well as abrasion loss of a yarn. The device comprises a yarn winding mechanism with a yarn grinding function, a yarn grinding mechanism with controllable friction pressure, a yarn feed mechanism with adjustable tension, a static and clipping mechanism, a hair bulb and hair feather collection mechanism, an optical measuring system for instant observation of yarn sample fluffing and balling shape and quantity, a data acquisition and control system and a computer. The method comprises the steps that the hair feather significance, the hair bulb shape and the hair bulb quantity of the yarn are immediately measured after a yarn sample is formed by winding the yarn through equal-tension close packing; friction fluffing and balling sampling is performed; and the hair feather significance, the hair bulb quantity, the hair feather and hair bulb abrasion, and the hair feather and hair bulb maintenance quantity of a yarn grinding sample in a process and in a final state are measured synchronously. The device is ingenious and practical in structure, and takes measurements precisely and quantitatively, the in-situ measuring device and the method are multipurpose, can measure multiple indexes, can be used for comprehensive evaluation of the yarn fluffing significance, the balling quantity and shape, the abrasion fiber quantity, the fluffing resistance, and the balling resistance, and can also be used for estimating fluffing and balling grades of fabric.

Owner:DONGHUA UNIV

Full-scale range infrared gas detector and measuring method thereof

ActiveCN102435578AExpand application spaceRealize measurementColor/spectral properties measurementsPhase detectorGas detector

The invention provides a full-scale range infrared gas detector and a measuring method thereof. The gas detector comprises a metal shell which is provided with optical filters and a pedestal which is provided with a detector; the metal shell and the pedestal are encapsulated together; the metal shell is provided with four optical filters of different wavelength; the detector comprises a reference thermopile chip and three identical measurement thermopile chips; a first optical filter and the reference thermopile chip form a reference channel, and the rest three optical filters and the three measurement thermopile chips form three measurement channels. The measuring method is as follows: full-scale range of gas to be detected is divided into three ranges to be detected, and the three measurement channels respectively correspond to one of the ranges to be detected; finally, measuring-signal values obtained in the measurement channels and basic values obtained in the reference channel are output. The gas detector has the advantages of convenient usage, strong practicality and high precision; the measuring method is simple and practical and widens application space of the detector.

Owner:HENAN HANWEI ELECTRONICS

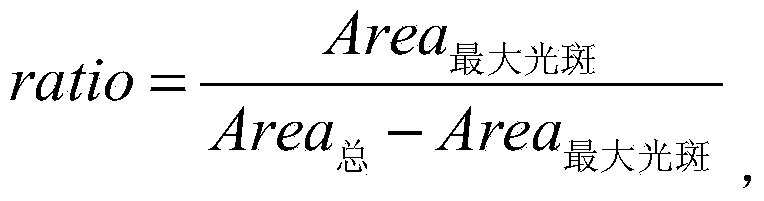

Measuring device and method for optical element damage threshold under vacuum environment

ActiveCN106840610ARealize measurementImprove efficiencyTesting optical propertiesTest efficiencyMeasurement device

The invention discloses a measuring device and method for an optical element damage threshold under the vacuum environment. By adopting an equivalent light path, accurate measurement of a facula area and the facula quality in the measuring process under the vacuum environment are monitored in real time, and accurate measurement of the optical element damage threshold is ensured. The device can perform damage threshold measurement on four transmission and reflection elements and diffraction element samples under the vacuum environment at a time in 1-on-1, S-on-1, R-on-1 and raster scanning modes, and residual gas in the testing environment can be analyzed. The equipment can automatically control the measuring process and achieve automatic data collection, and the damage testing efficiency of the optical element under the vacuum environment is greatly improved.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com