Reversibly accurate and automatic large-stroke detection method and device of pipe cable

An automatic detection and large stroke technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of no judging function of the moving direction of the umbilical cable, inability to adapt to the measurement of umbilical cables of different diameters, and inability to realize the reversible detection of the umbilical cable, etc., to achieve accurate length, The effect of preventing slippage and measuring length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

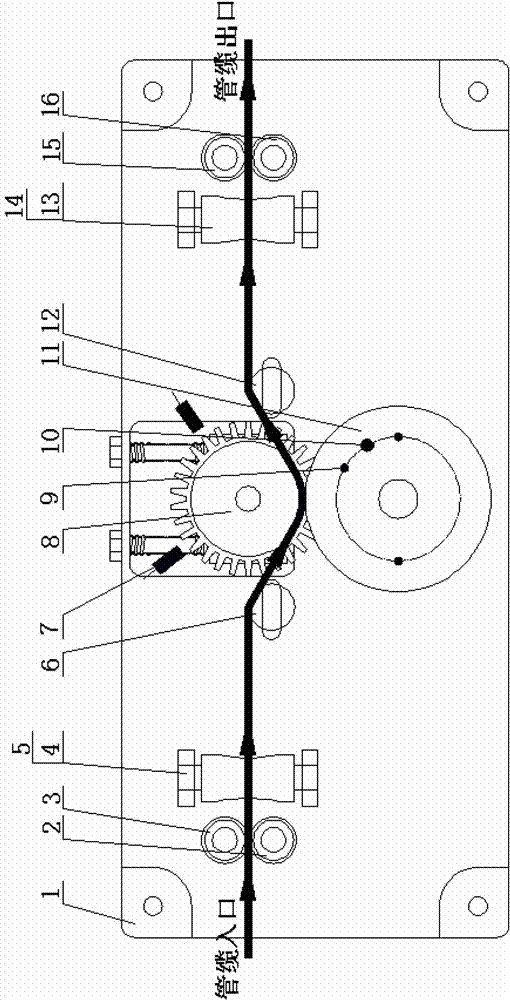

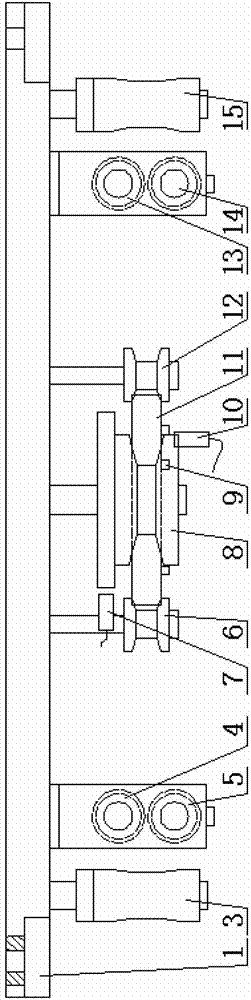

[0023] Such as figure 1 , in this embodiment, it is a large-stroke reversible and accurate automatic detection device for aircraft airspeed calibration towing cone umbilical cable retraction process, including a meter counting mechanism and two sets of limit mechanisms symmetrically placed on both sides of the meter counting mechanism; Both the meter counting mechanism and the two sets of limit mechanisms are located on the machine base 1;

[0024] Among the limiting mechanisms, the left limiting mechanism is composed of limiting wheel I2, limiting wheel II3, limiting wheel III4, and limiting wheel IV5; the vertically installed limiting wheel I2 and the limiting wheel II3 are the same as the horizontally installed A cross hole is formed between the limiting wheel III4 and the limiting wheel IV5 for the passage of the umbilical cable to be tested;

[0025] The limit mechanism on the right is composed of limit wheel V13, limit wheel VI14, limit wheel VII15 and limit wheel VIII1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com