Real-time measurement method and device for deformation of formed part in additive manufacturing process

An additive manufacturing and real-time measurement technology, applied in the field of additive manufacturing, can solve the problems of large error, low measurement accuracy, lack of experimental verification of deformation of formed parts, etc., and achieve the effect of large scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

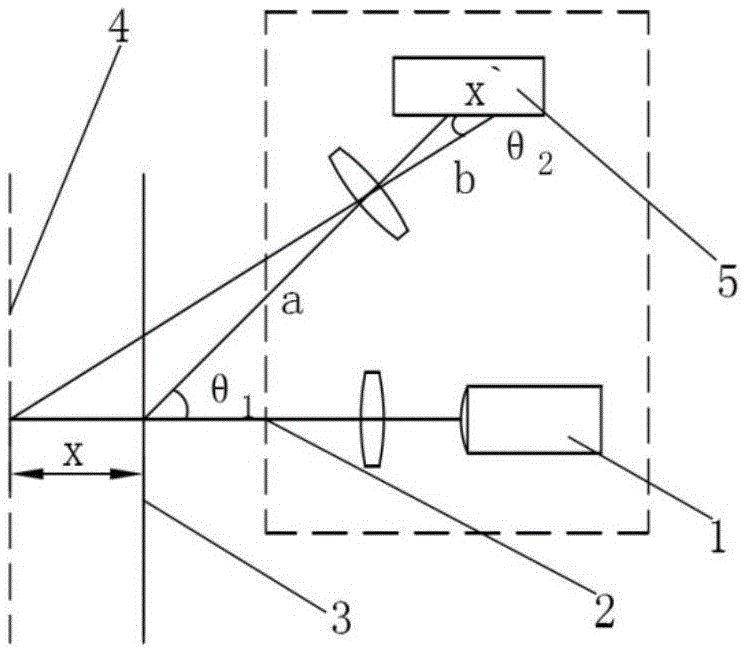

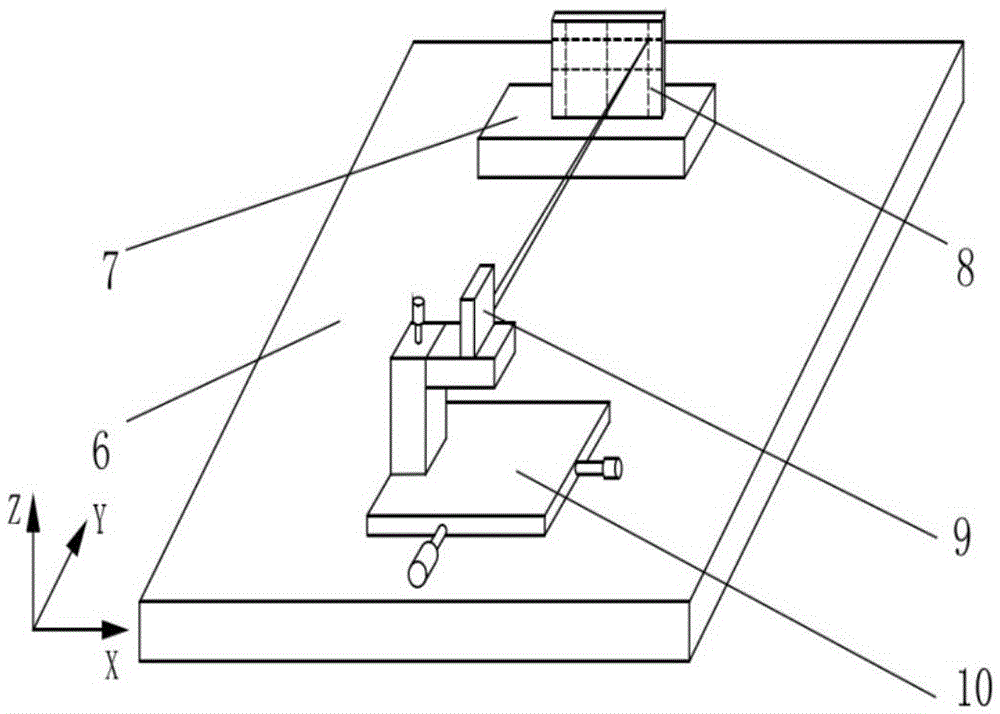

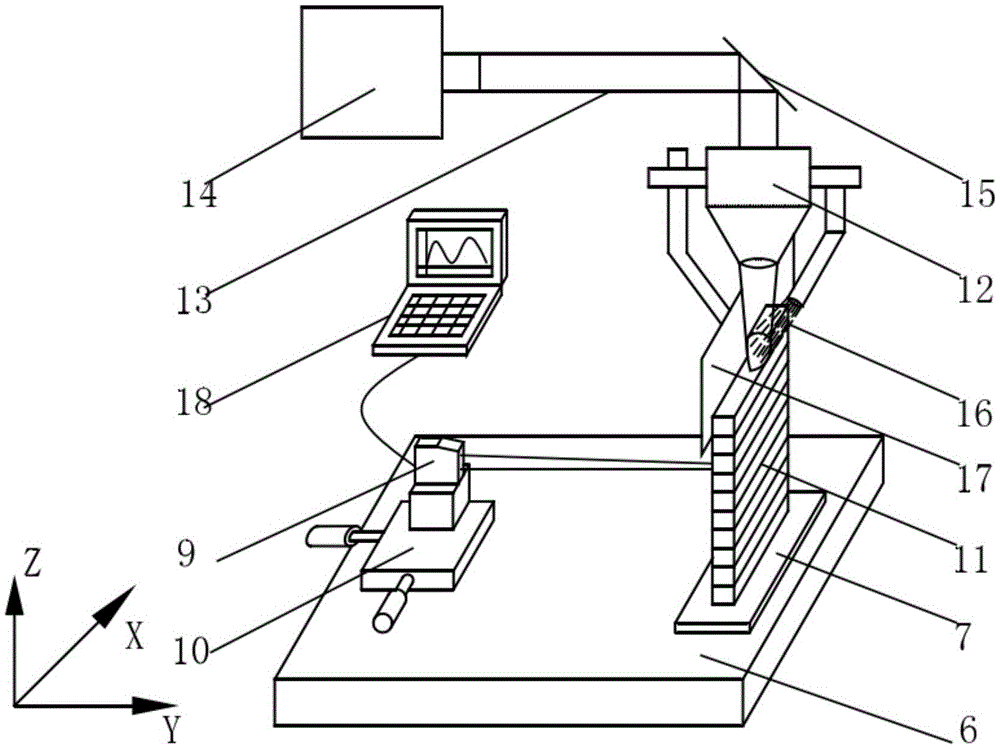

[0032] The purpose of the invention is to solve the problem of real-time measurement of the deformation of formed parts in the process of high-energy beam additive manufacturing. With the development of high-energy beam additive manufacturing, the deformation problem of parts during the forming process has not been effectively solved for a long time, which seriously affects the progress of the forming process and the final forming quality of the formed parts. If some means can be used Real-time monitoring of the deformation behavior of the formed part, through the understanding of the deformation behavior of the formed part under different conditions, including the size of the formed part, the simplicity of the shape of the formed part, the wall thickness of the formed part, the forming method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com