Nonideal explosive work capacity measuring device

A technology of working power and measuring device, which is applied in the direction of fuel oil testing and material inspection products, etc., can solve the problems such as the inability to accurately measure the explosive working power of non-ideal explosives, and the obstacles to the design and application of non-ideal explosive formulations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

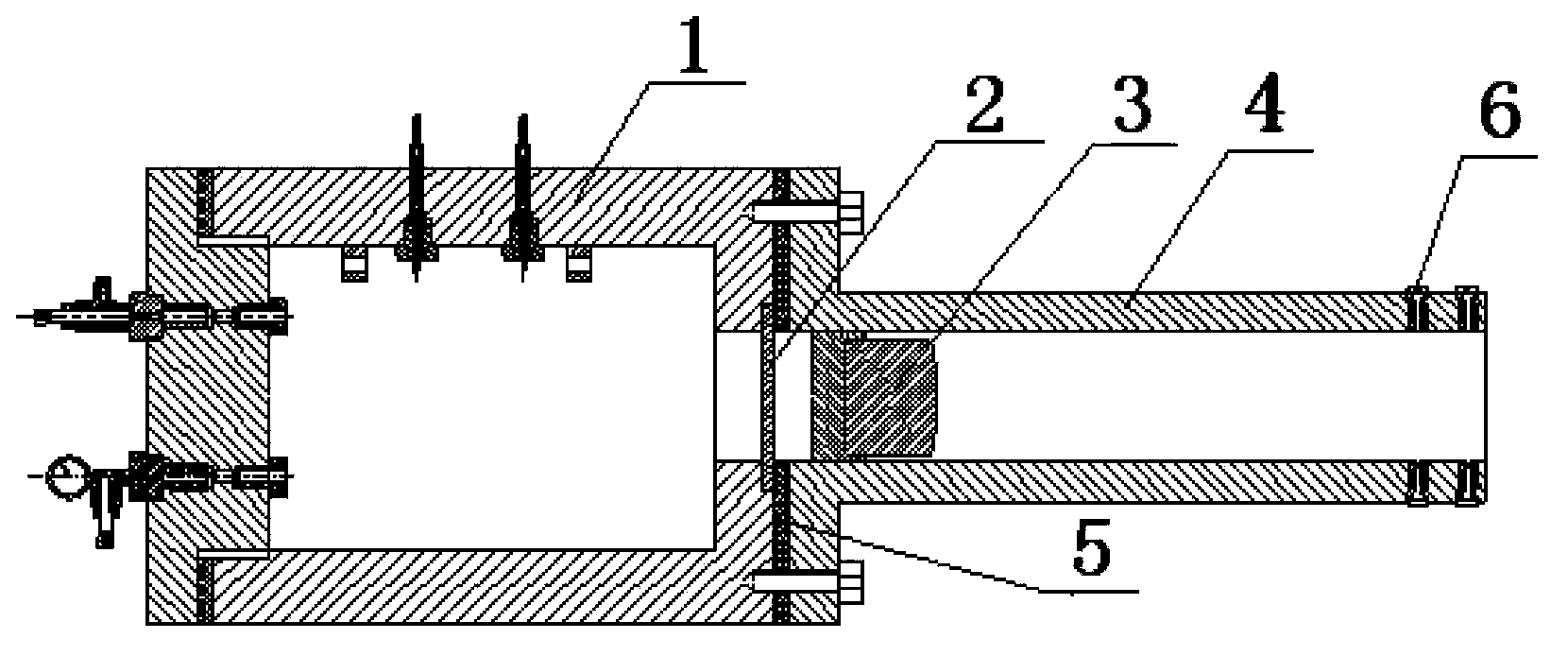

[0037] refer to Figure 1 to Figure 4 , the non-ideal explosive explosion performance measurement device in this embodiment includes an explosion chamber 1, an explosion rupture disc 2, a projectile 3, a projectile sliding cylinder 4, and a speedometer 6 (the speedometer is a standard laser speed measuring probe that can be purchased) and sealing ring 5.

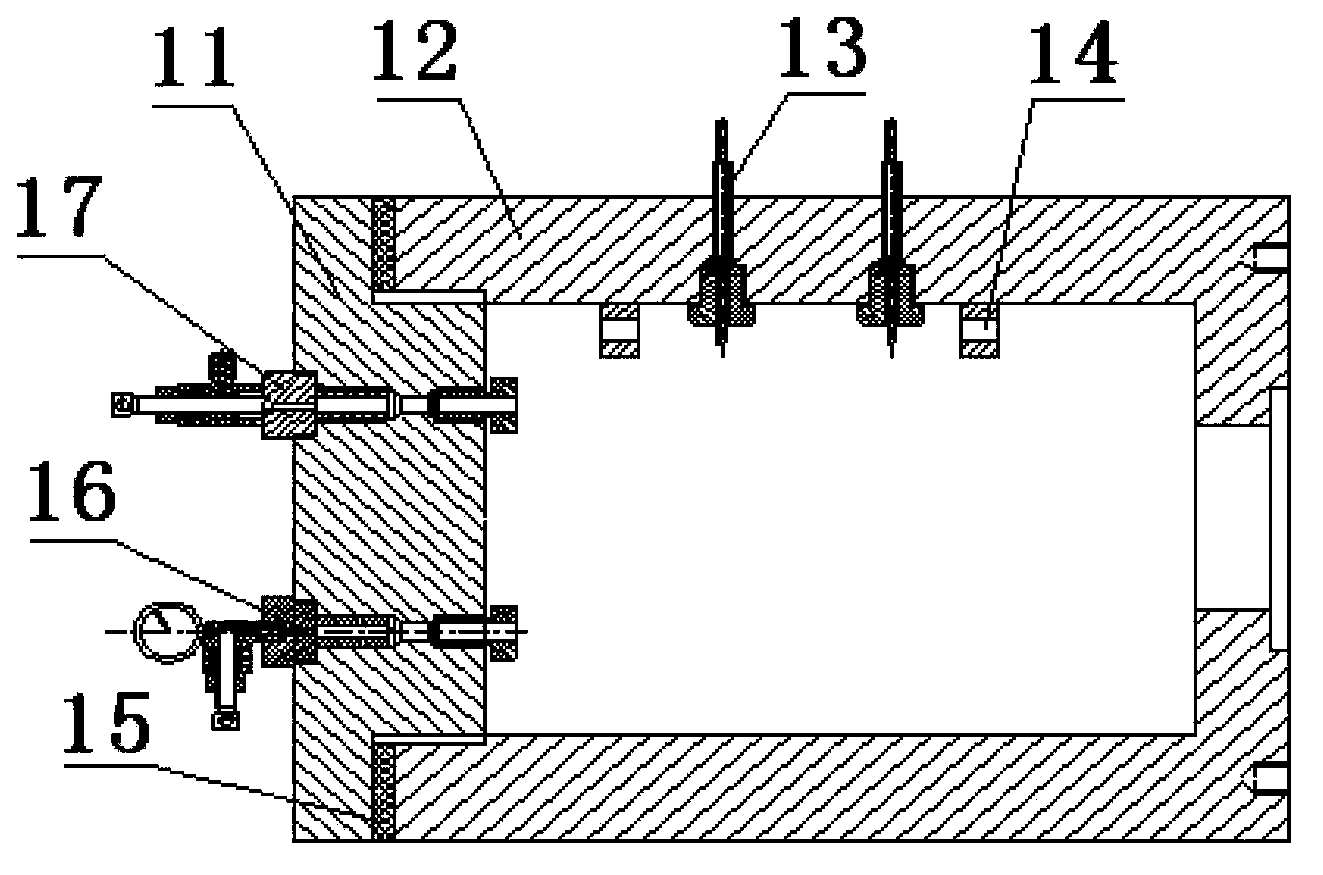

[0038] see figure 2 , The explosion chamber 1 is a horizontal cylinder, and the specific structure includes a sealing end cover 11 and an explosion chamber body 12, on which are installed an initiating electrode 13, a hanging charge ring 14, a sealing gasket 15, a pressure gauge 16 and a vent valve body 17.

[0039] The sealing end cover 11 and the explosion chamber 12 are connected by threads, and the gas sealing is carried out by a sealing gasket 15 in the middle.

[0040] The sealing end cover 11 is in the shape of a truncated cone, which is integrally processed by high-strength stainless steel. 1, along a circle with...

Embodiment 2

[0058] This embodiment gives an example of measuring the detonation performance of a non-ideal explosive containing aluminum using the device for measuring the detonation performance of a non-ideal explosive in Example 1.

[0059] The formula of the aluminum-containing non-ideal explosive used in this example is 65RDX / 30Al / 5 viscosity, and a cylindrical explosive column with a diameter of 40 mm and a height of 45 mm is prepared by a compression molding process.

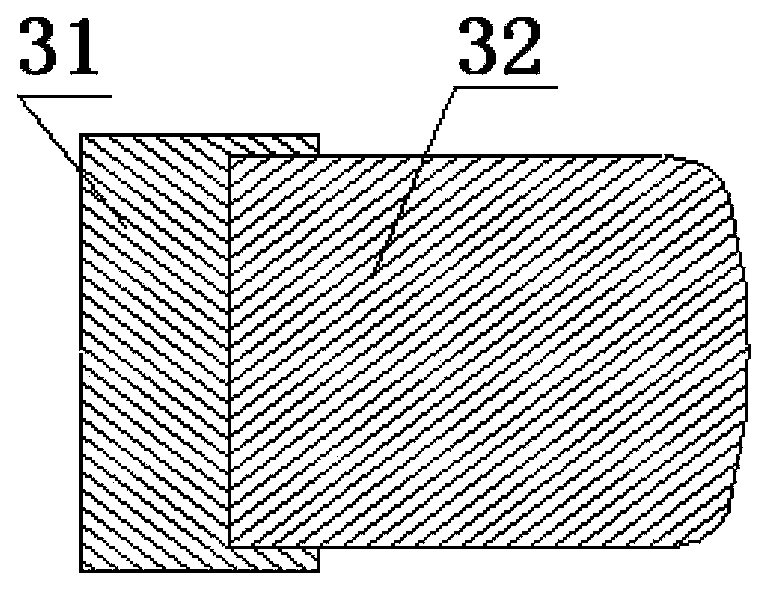

[0060] Put the explosive diaphragm 2 flatly into the circular counterbore at the right end of the explosion chamber 1; put the projectile 3 into the projectile sliding cylinder 4, and the projectile support 31 is flush with the outer end surface of the flange 41, and in the explosion chamber 1 Place the sealing ring 5 between the projectile sliding cylinder 4, pass through the through holes on the flange 41 and the sealing ring 5 successively with bolts, and screw into the threaded hole on the right end surface of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com