Laser displacement sensor installion and fine adjustment device

A laser displacement and fine-tuning device technology, which is applied to metal processing machinery parts, measuring/indicating equipment, metal processing equipment, etc., can solve the problem that the installation bracket does not meet the use requirements, etc., achieve simple structure, easy installation and disassembly, and prevent pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

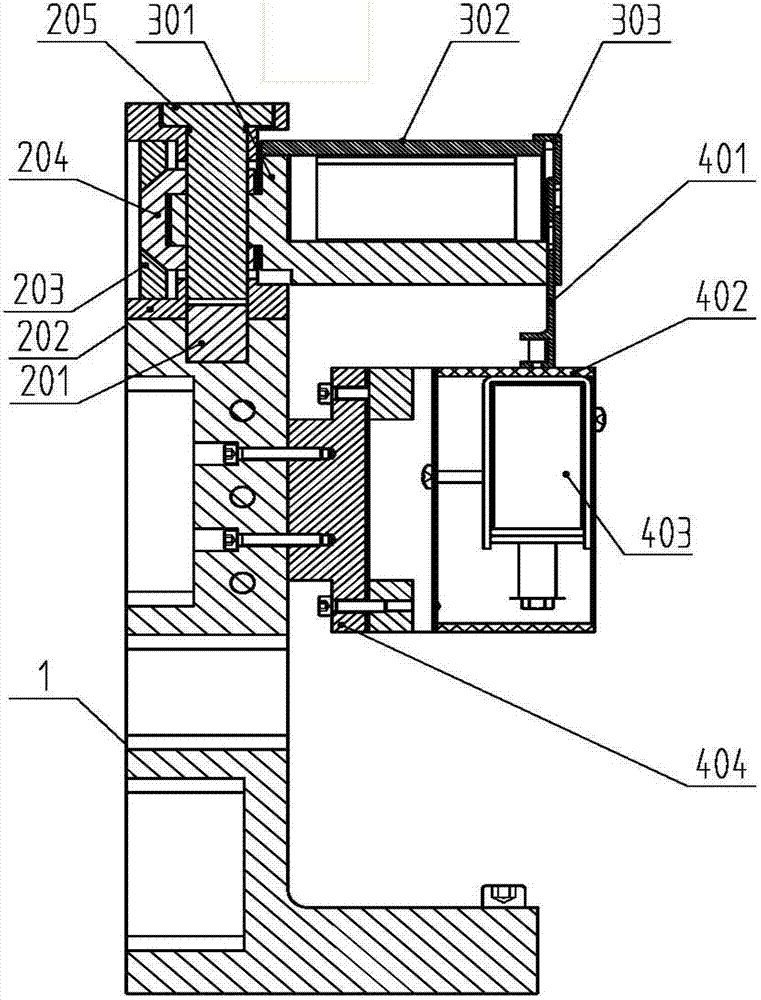

[0021] like figure 1 As shown, the laser displacement sensor installation and fine-tuning device of the present invention includes a column bracket 1 , a fine-tuning component 2 and a mounting box component 3 . The fine adjustment assembly 2 is fixedly connected above the column support 1, the installation box assembly 3 is located on one side of the column support 1, and the installation box assembly 3 is connected with the fine adjustment assembly. Wherein the column bracket 1 provides support for the installation of the fine-tuning assembly 2 and the installation box assembly 3, in order to reduce the weight of the device of the present invention, a lightening hole is provided on the column bracket 1. The fine-tuning bracket 2 is a component for realizing the fine-tuning of the present invention, and the installation box assembly 3 is a component for placing the laser d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com