Patents

Literature

760results about How to "Simple working principle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

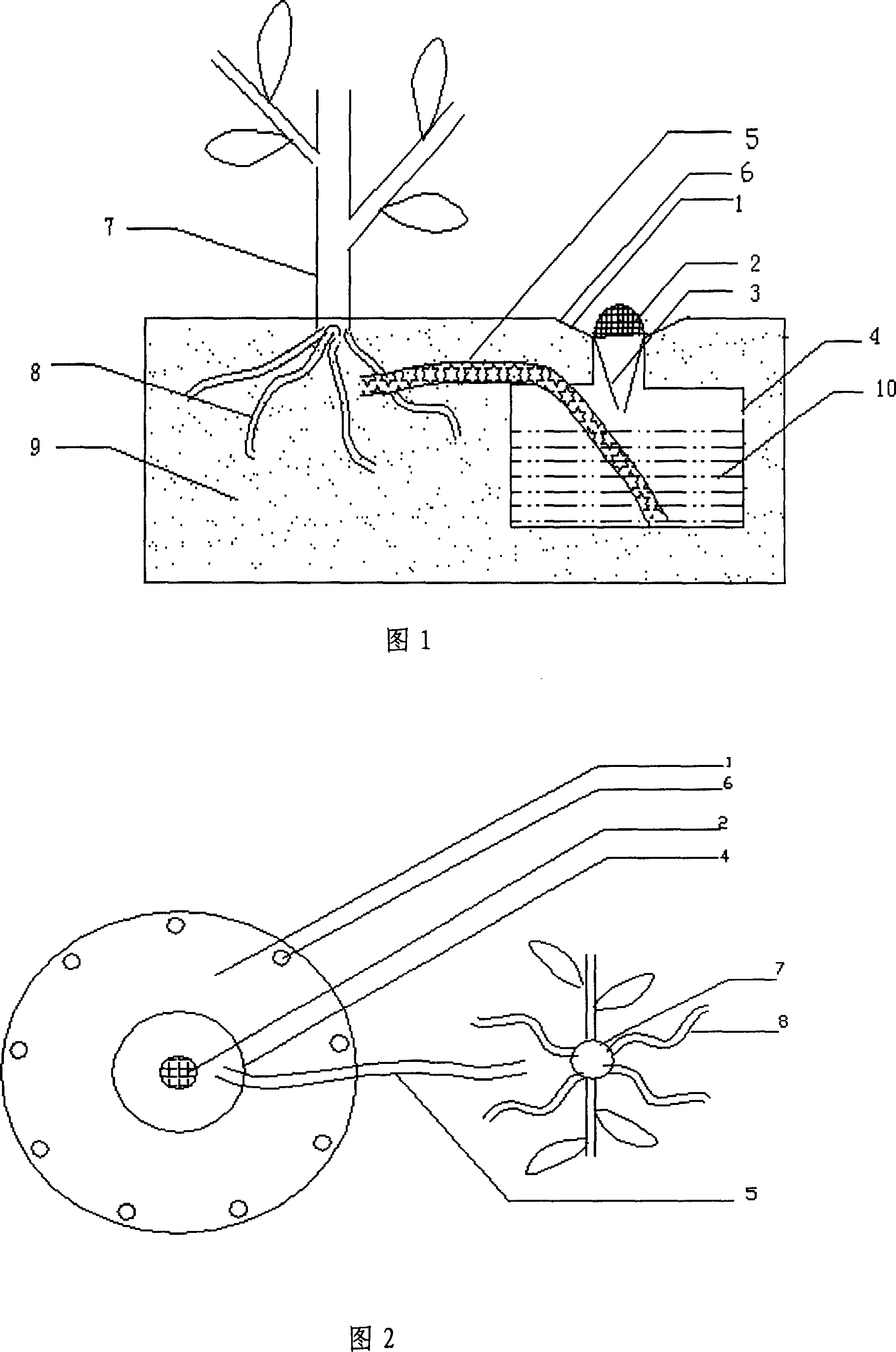

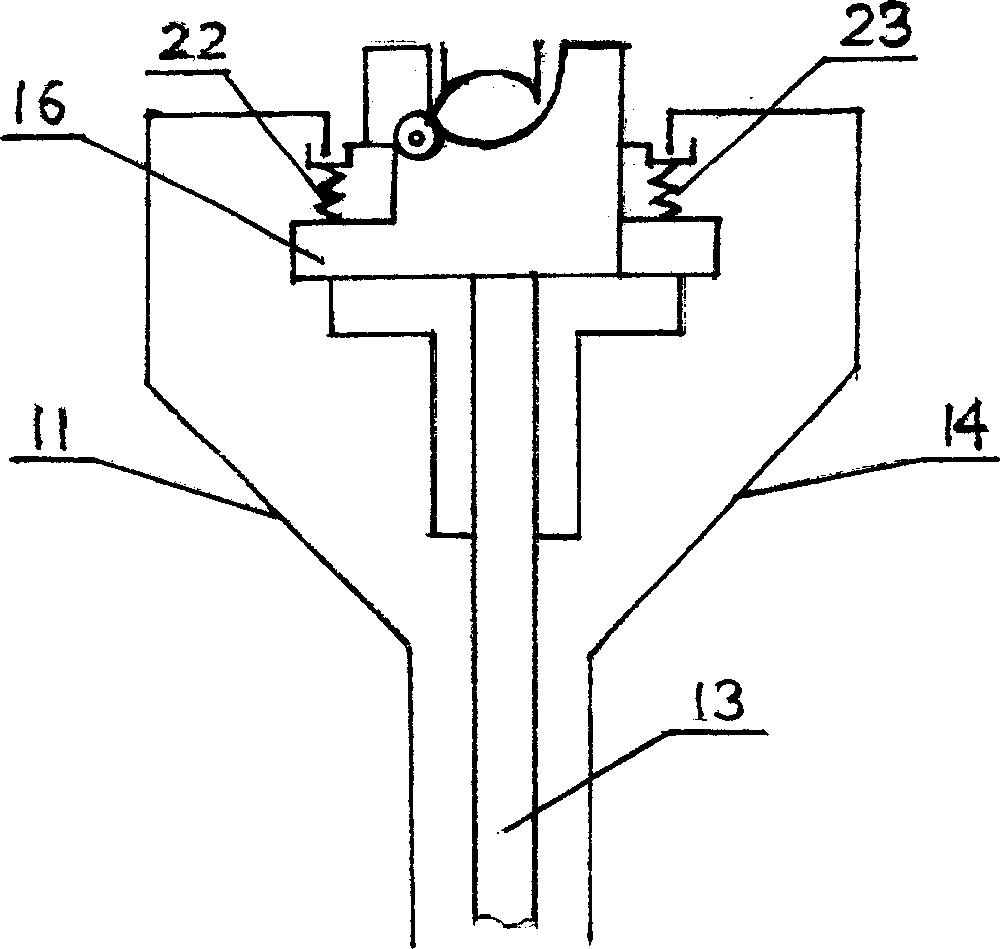

'Wick' type garden rain water collector

InactiveCN101019500ADrought resistanceConducive to growth and developmentGeneral water supply conservationSelf-acting watering devicesFilter funnelStormwater

The wick-type garden rain water collector consists of five parts including rain water collecting funnel to collecting surface water, filtering net to filter out impurity, movable inlet tongue to avoid evaporation loss of water, water collecting bottle to store water rain and wick type watering pipe to irrigate trees through permeation. The wick-type garden rain water collector may be used widely to irrigate trees durably and fight drought effectively.

Owner:张正梁

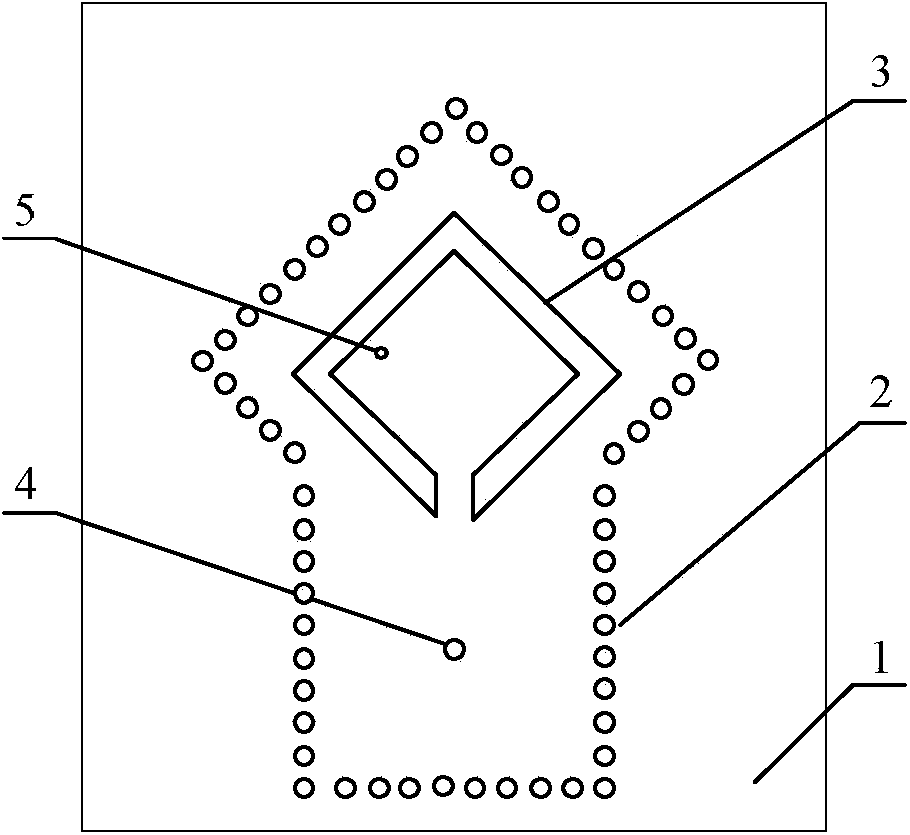

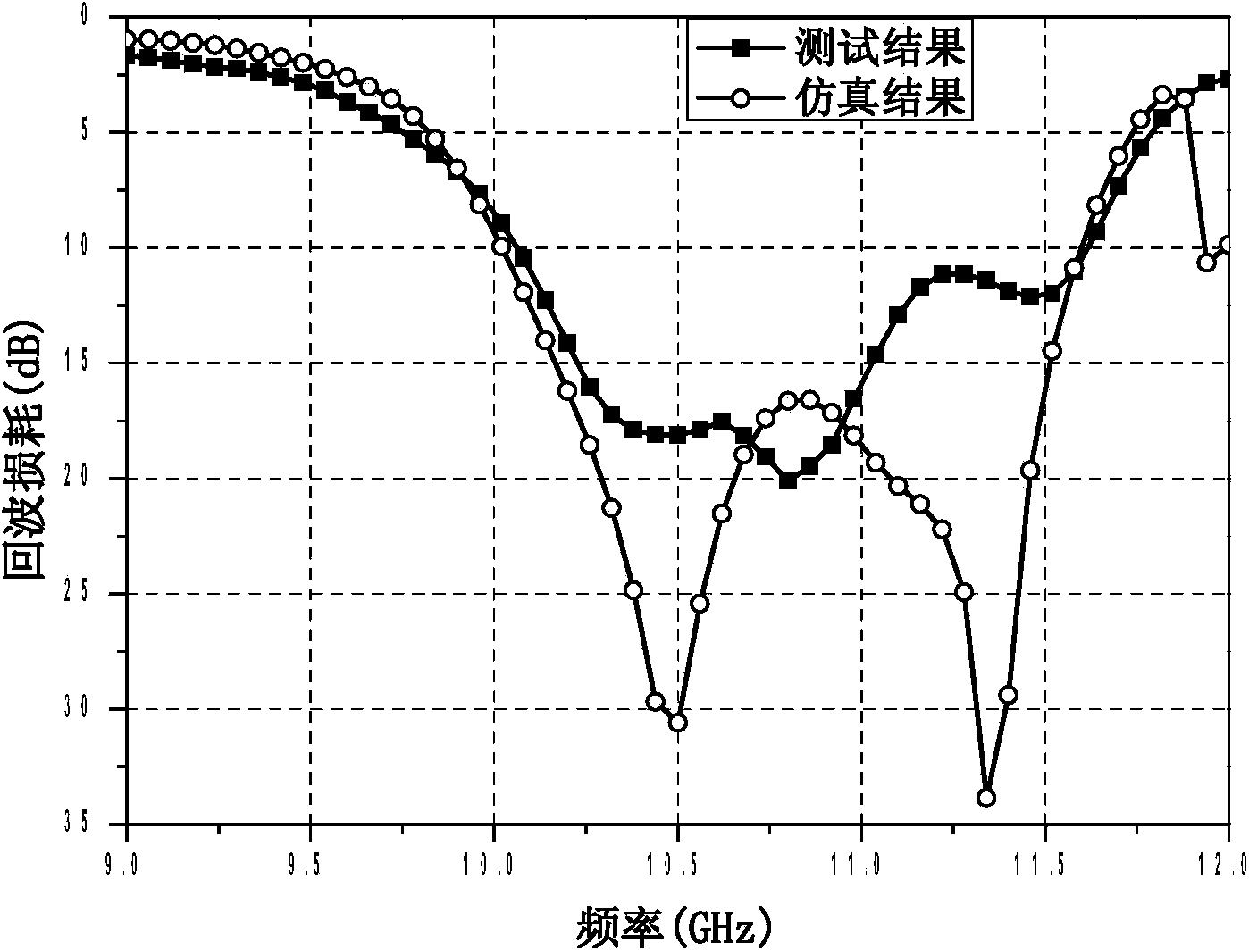

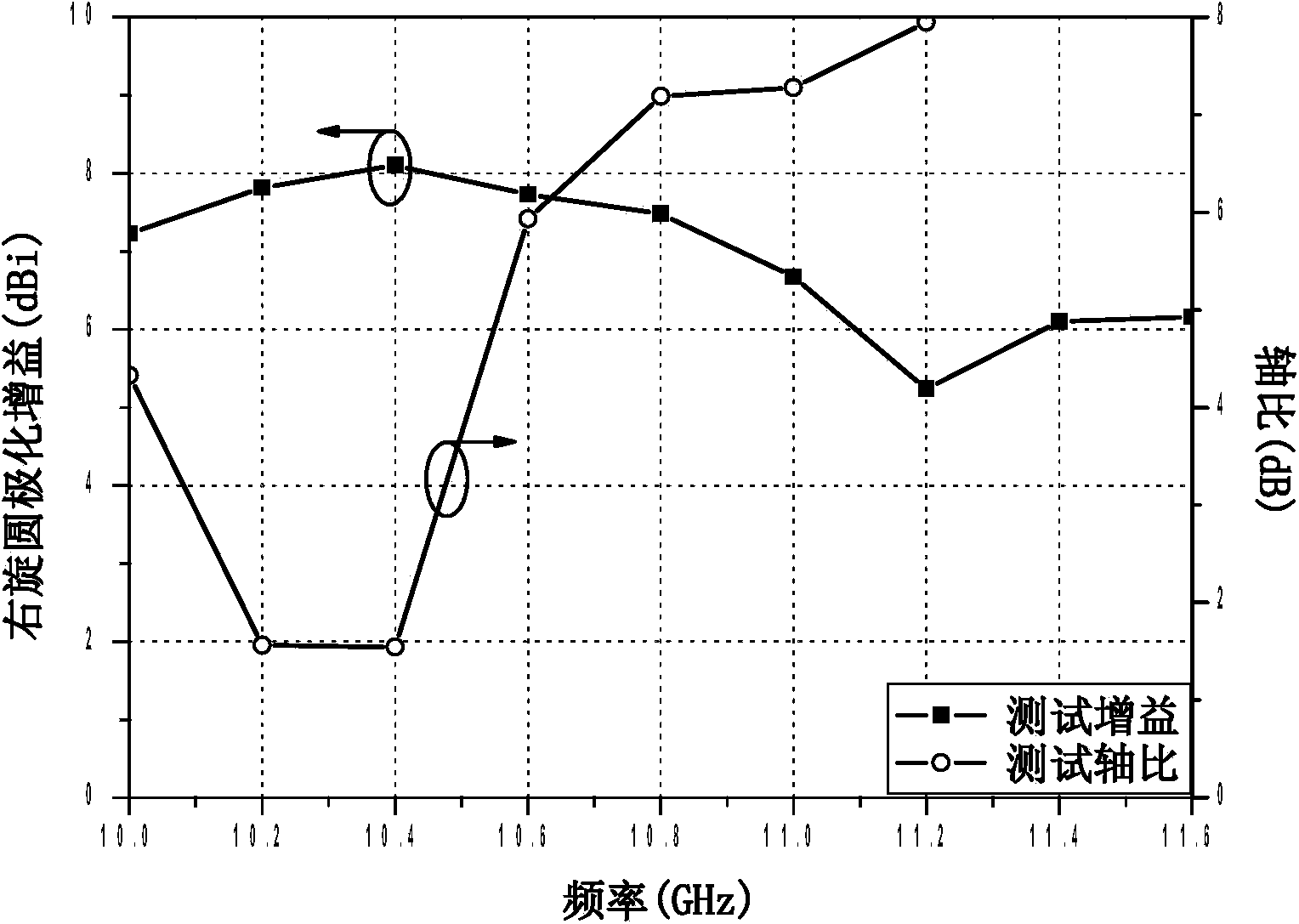

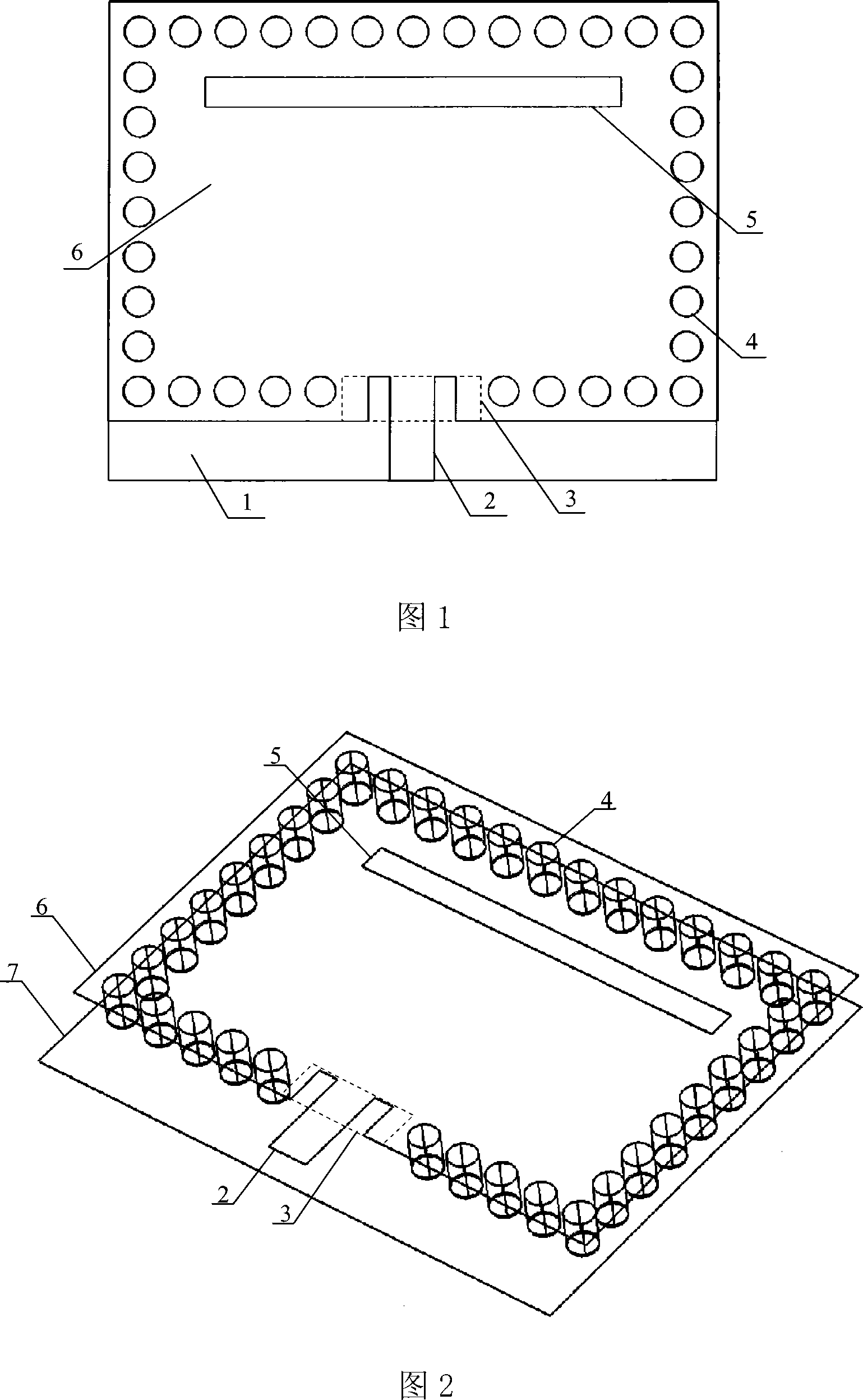

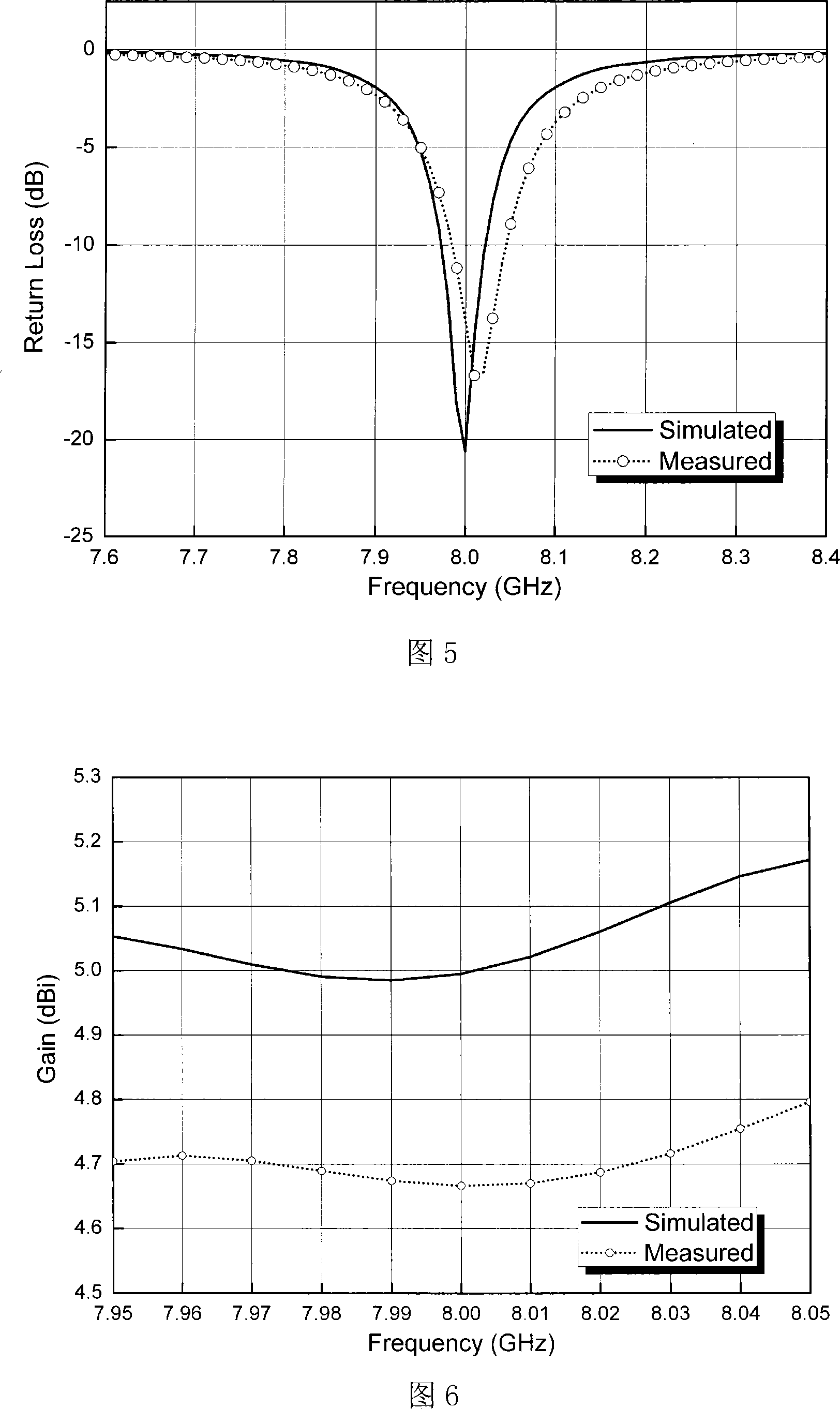

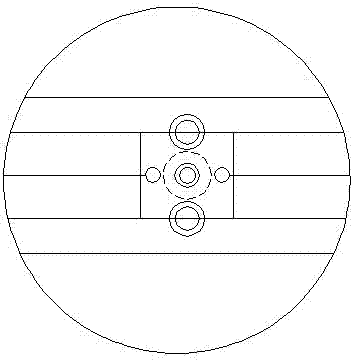

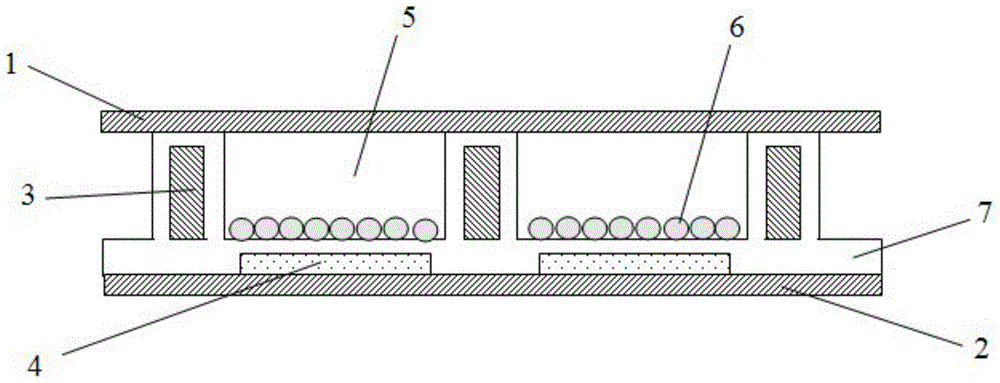

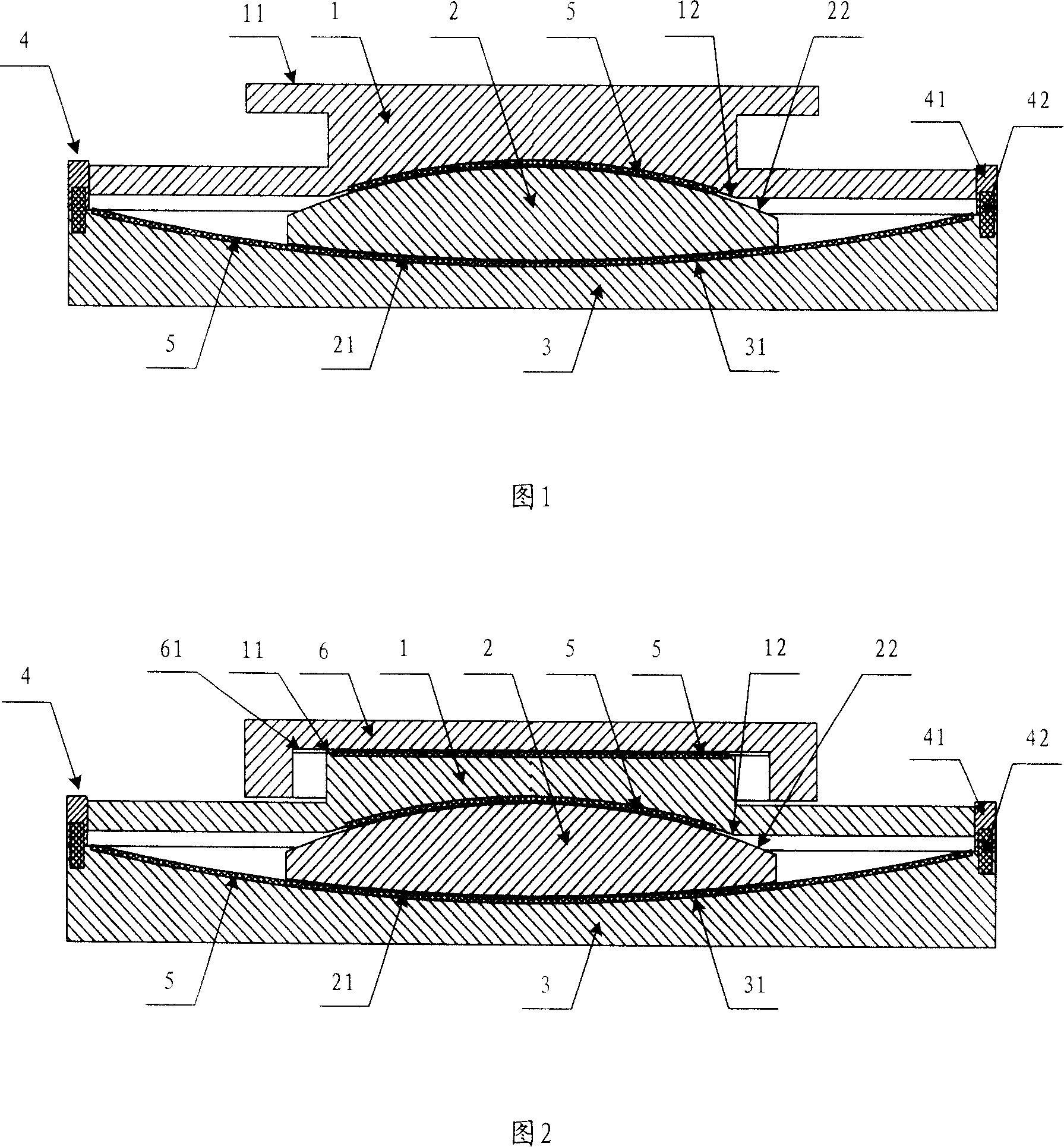

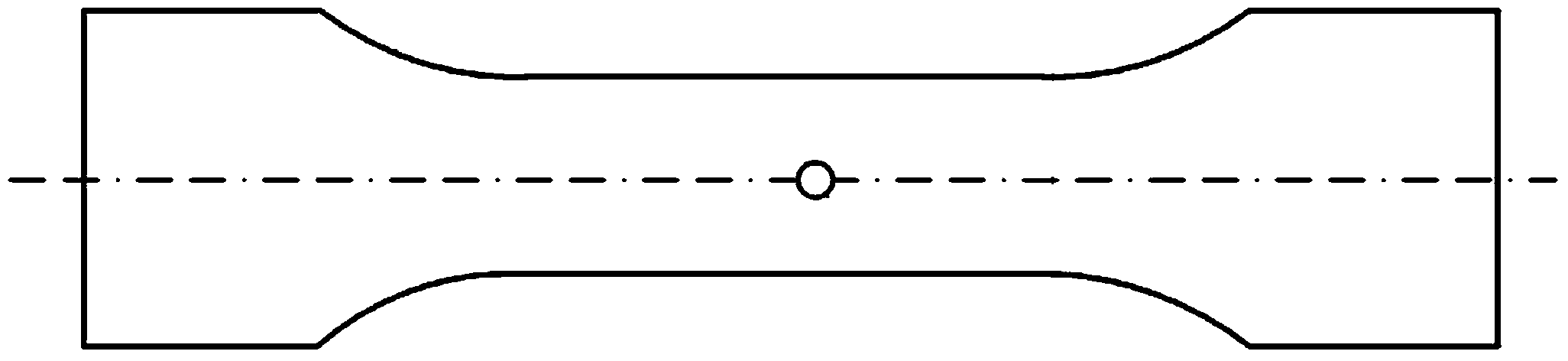

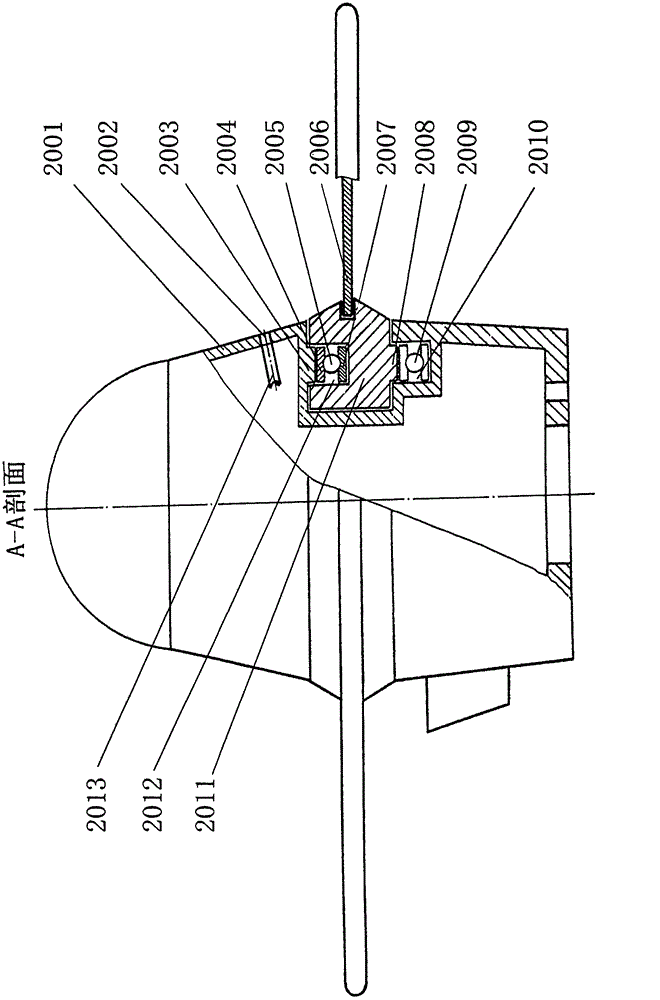

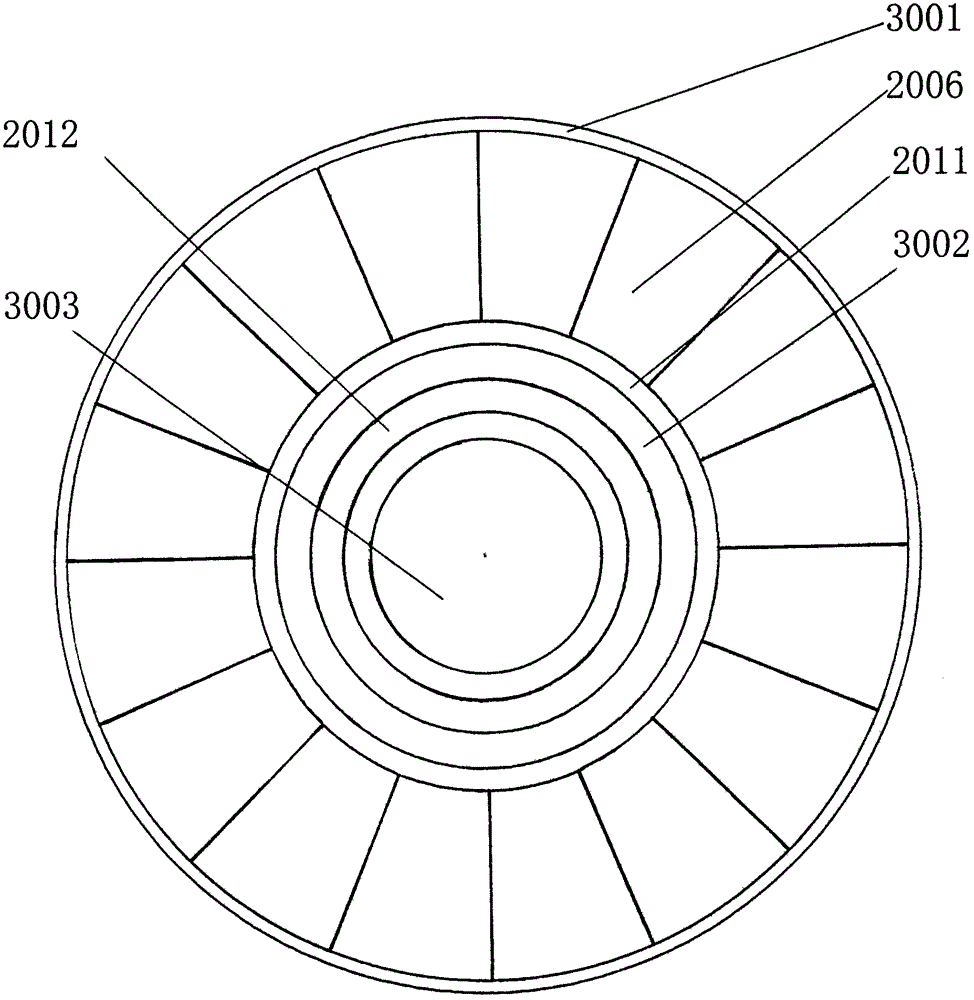

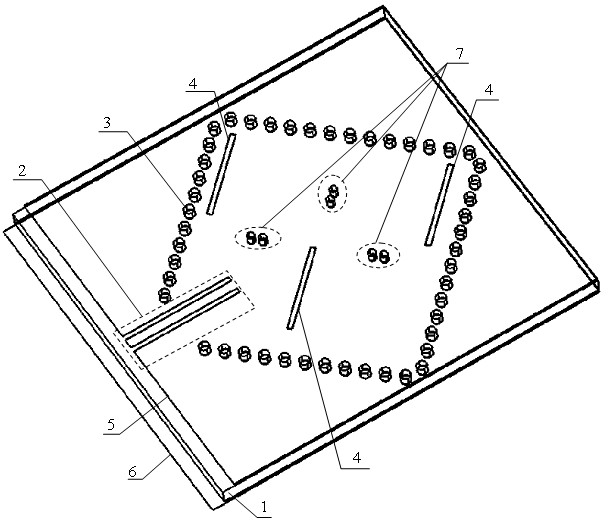

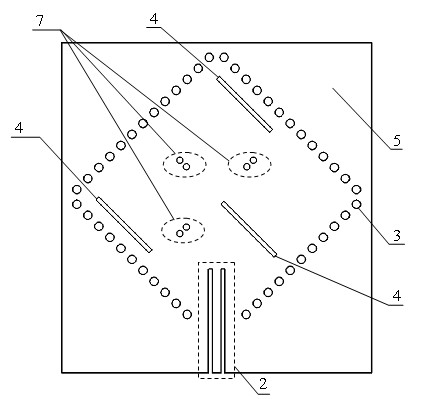

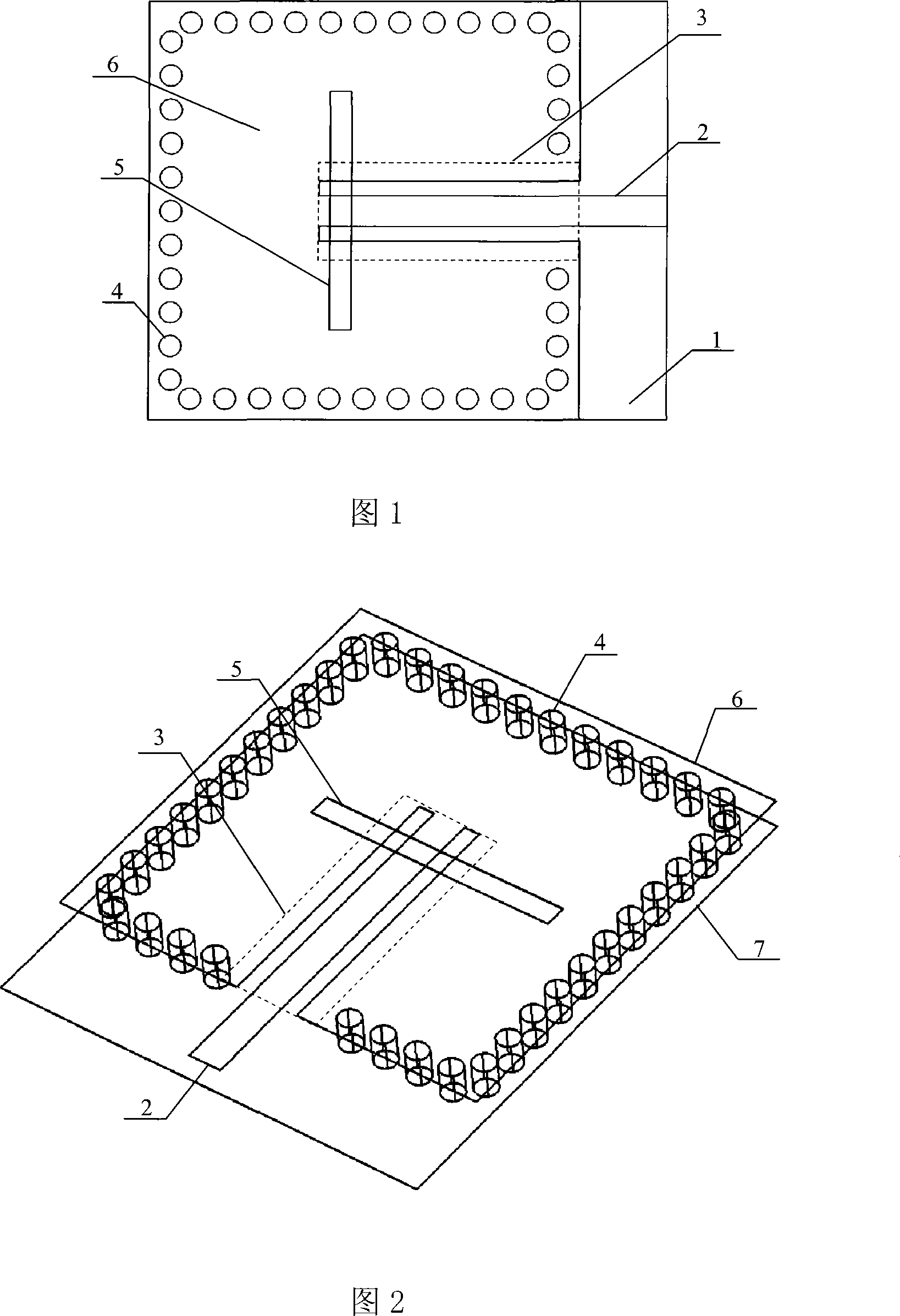

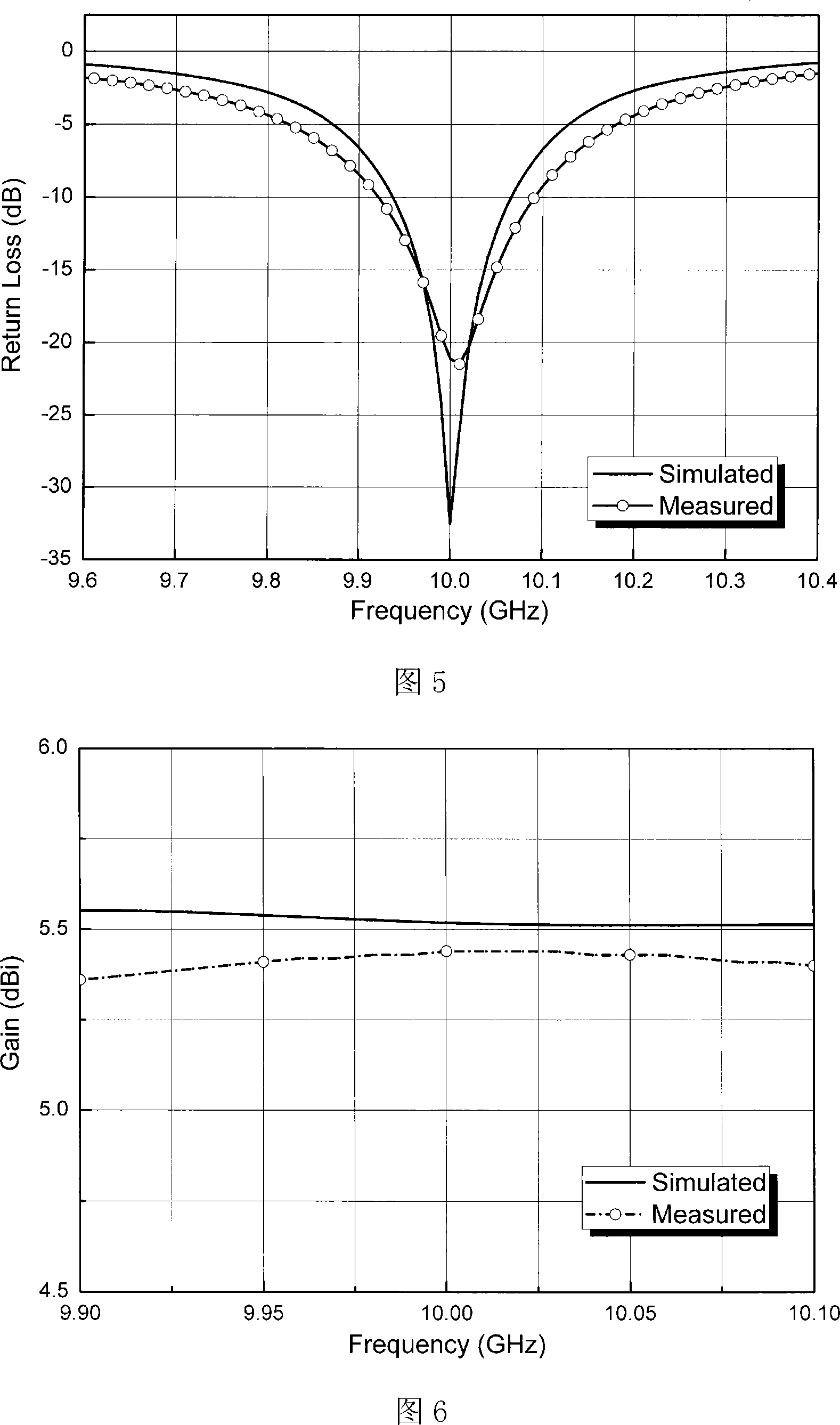

Broadband substrate integrated waveguide circularly polarized antenna array and manufacturing method thereof

InactiveCN103531918ASimple structureSimple working principleAntenna arraysRadiating elements structural formsCircularly polarized antennaBroadband

The invention discloses a substrate integrated waveguide technology-based high-gain circularly polarized antenna array and a manufacturing method of the antenna array. The broadband substrate integrated waveguide circularly polarized antenna array comprises an upper-layer radiation substrate and a lower-layer feed substrate, wherein the radiation substrate comprises a first antenna unit, a second antenna unit, a third antenna unit and a fourth antenna unit, and the first antenna unit, the second antenna unit, the third antenna unit and the fourth antenna unit are symmetrically arranged by taking the center of a circle as an axis; a radial substrate integrated waveguide power distributor which is divided into four parts is distributed on the feed substrate and is used for feeding the four antenna units. The high-gain circularly polarized antenna array disclosed by the invention has the advantages that the gain is high, the broadband is wide, the radiation characteristic is good, the design is simple, the machining is easy and the cost is low; compared with the current substrate integrated waveguide circularly polarized antenna, the antenna provided by the invention has the advantages that the gain is remarkably improved and the circularly polarized bandwidth is remarkably increased.

Owner:XIDIAN UNIV

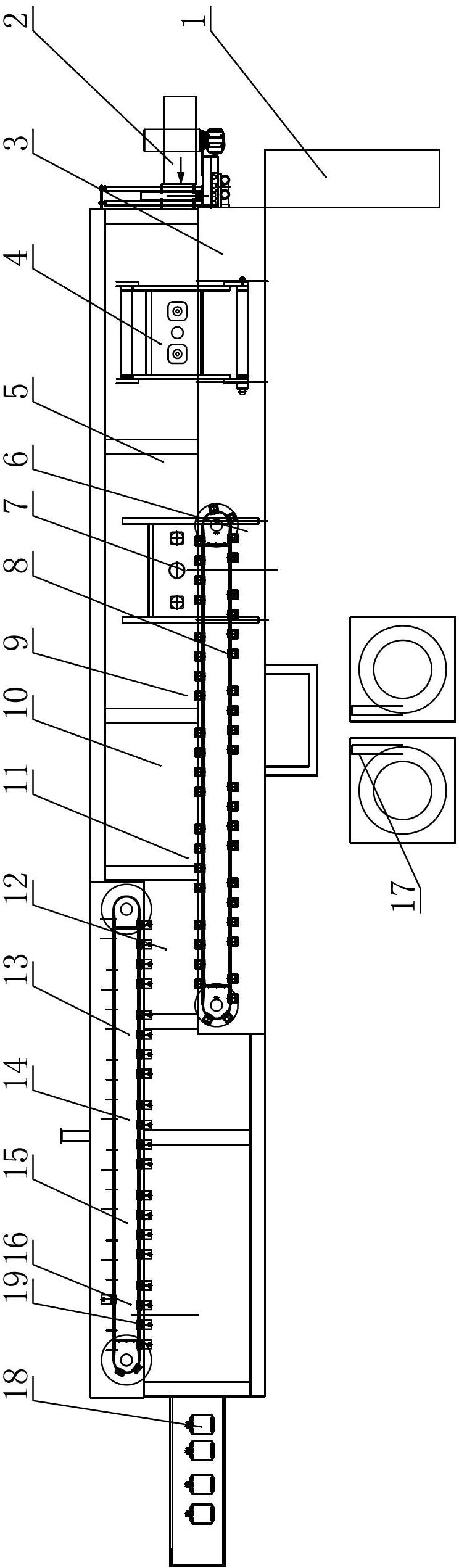

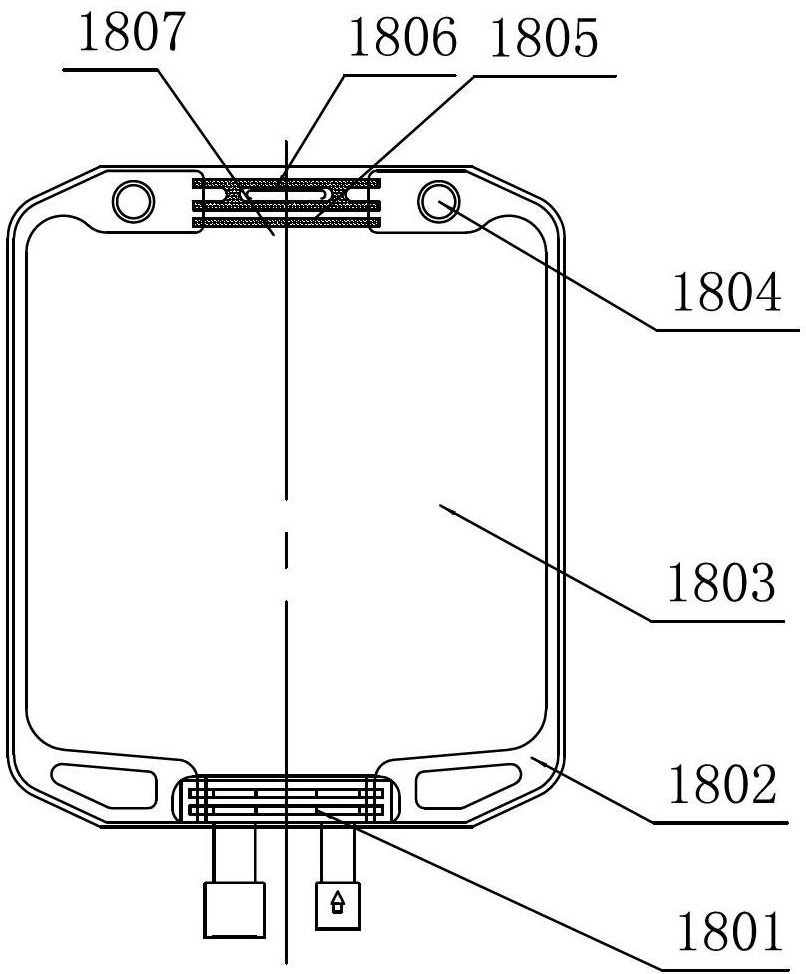

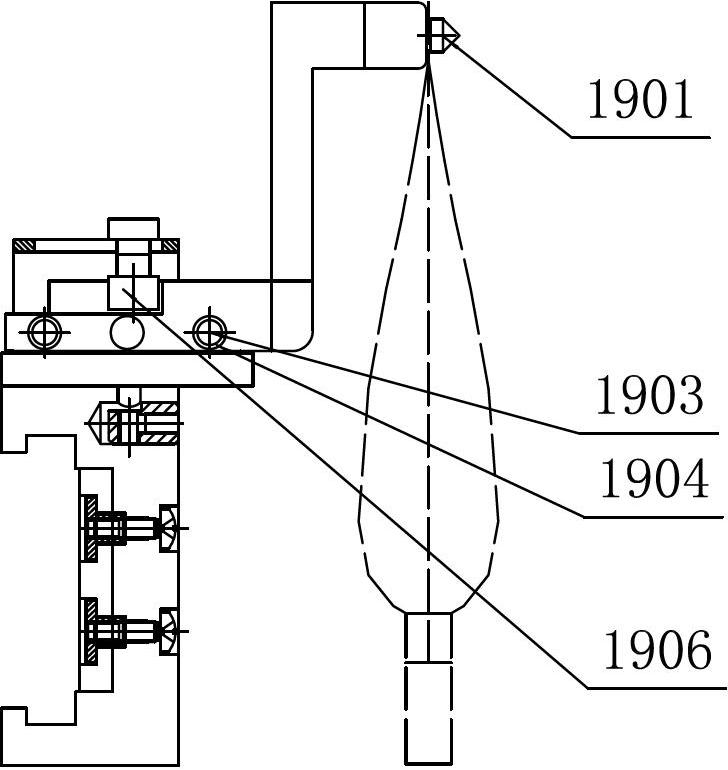

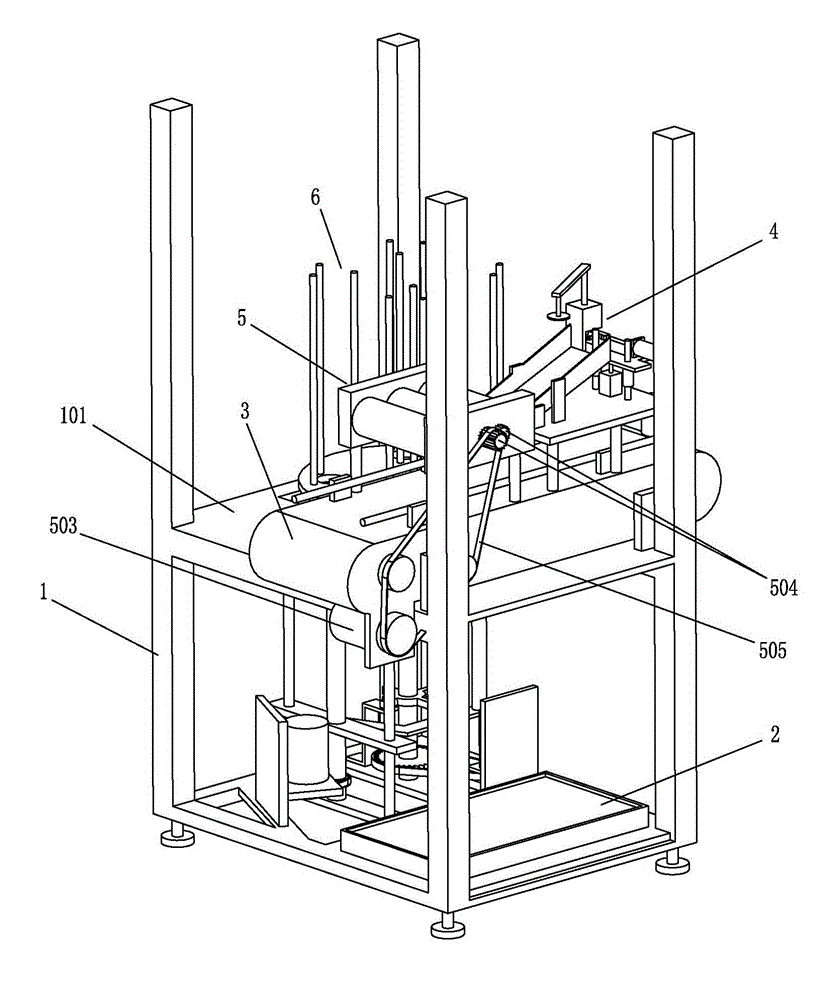

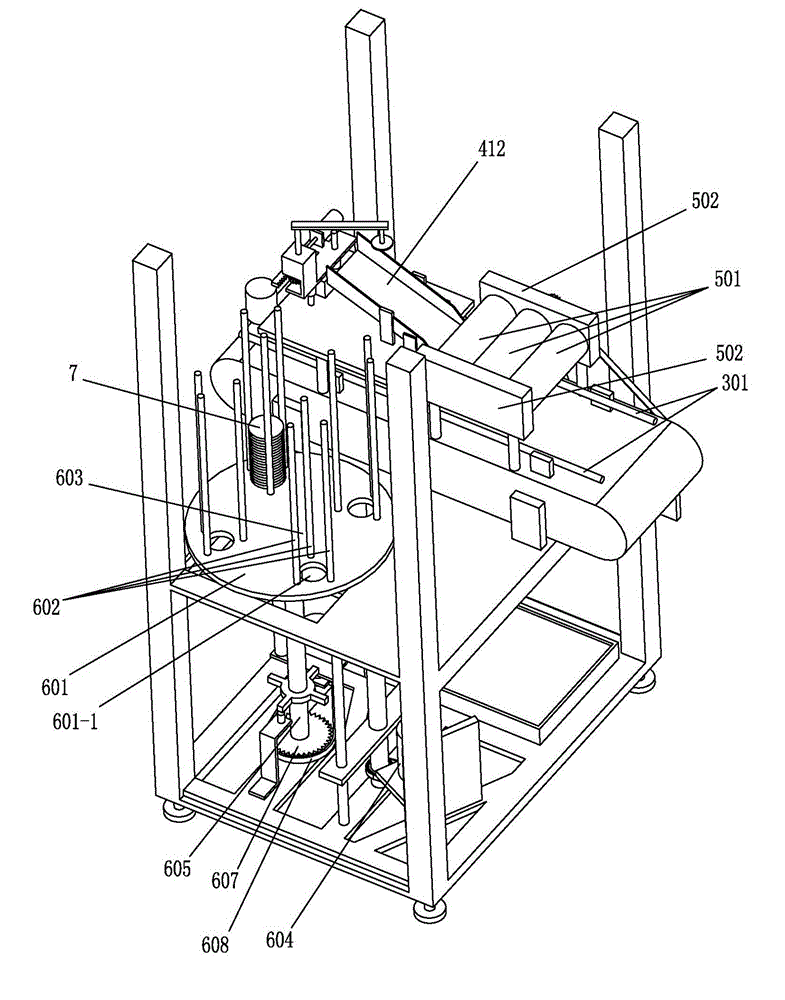

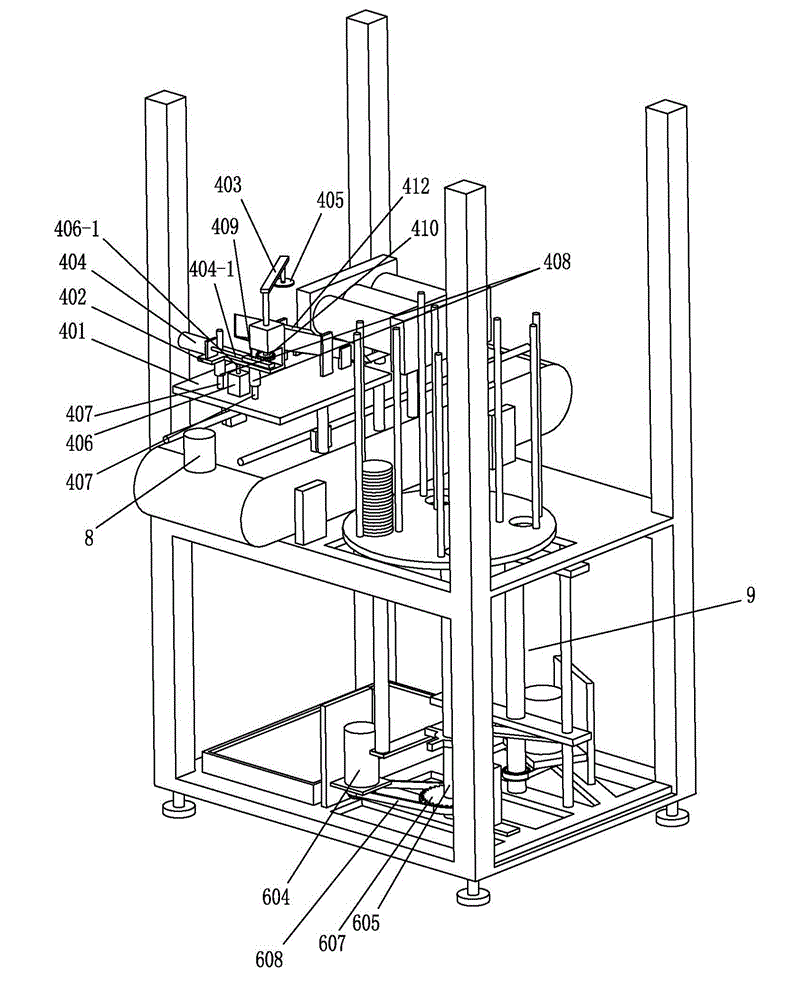

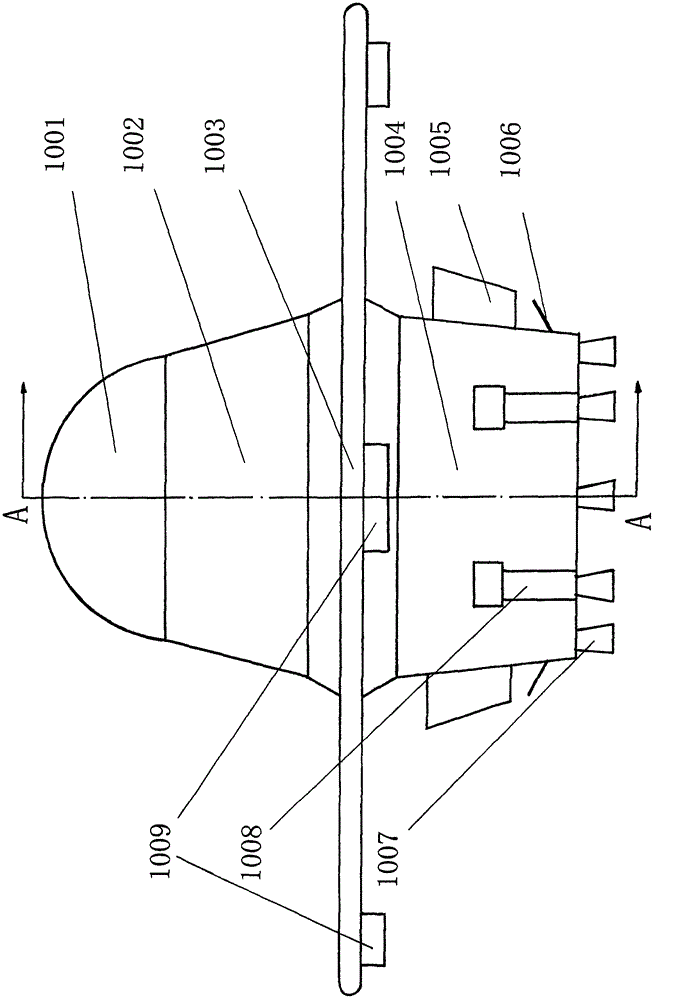

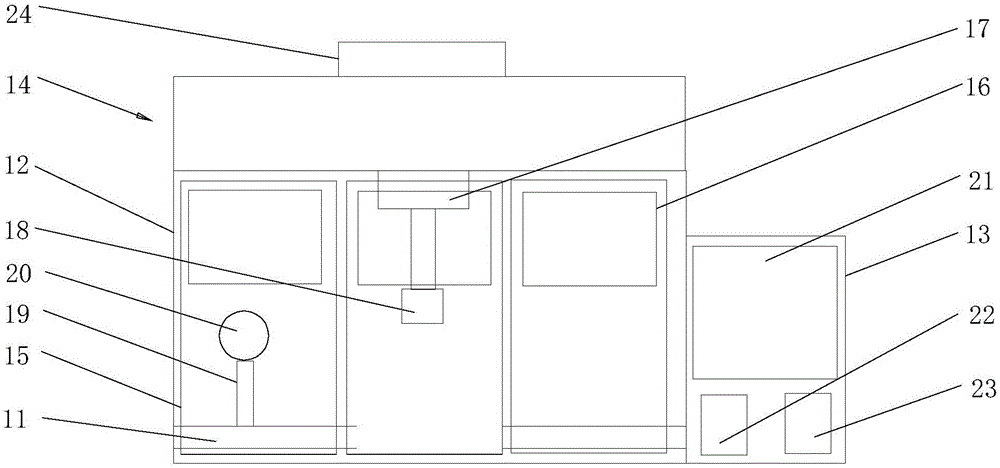

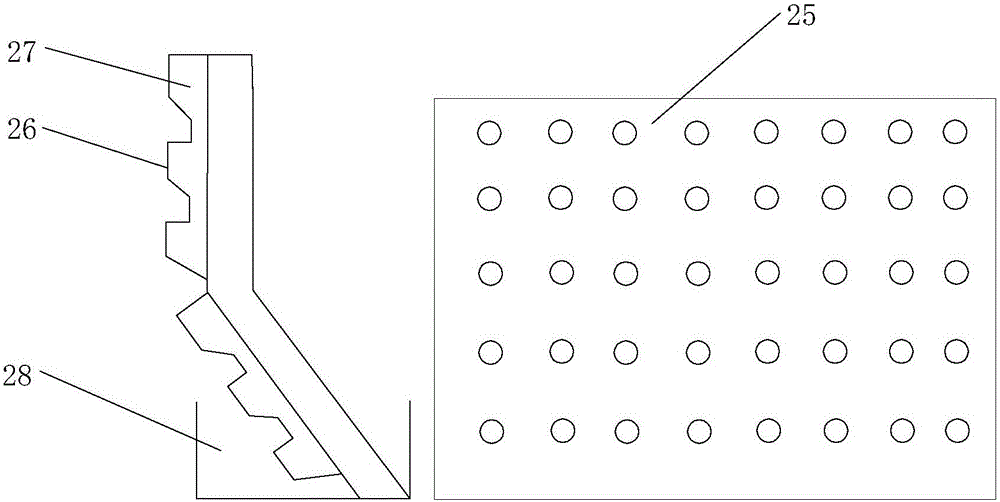

Full-automatic bag making and filling and sealing machine of bag tail filling non-PVC membrane transfusion soft bag

ActiveCN102642630ARealize automated productionSimple working principleWrapper twisting/gatheringLiquid materialFailure ratePolyvinyl chloride

The invention relates to a full-automatic bag making and filling and sealing machine of a bag tail filling non-PVC (polyvinyl chloride) membrane transfusion soft bag, which belongs to the technical field of pharmacy packing machine. The full-automatic bag making and filling and sealing machine comprises a machine body which consists of a frame component (3), wherein a distribution box (1) is arranged at one side of the machine body, and a bag making machine and a filling and sealing machine are arranged on the upper part of the machine body. The machine is characterized in that a bag body transfer mechanism (12) is arranged between the bag making machine and the filling and sealing machine, a connector supply mechanism (17) and a preheating mechanism (6) are arranged at one side of the bag making machine, the bag making machine is provided with a made bag annular conveying component (8), the made bag annular conveying component is provided with a connector fixture, the filling and sealing machine is provided with an annular conveying belt, and the annular conveying belt is provided with a bag fixture (19). According to the invention, full-automatic production of the tail filling non-PVC membrane transfusion soft bag is realized through improving the bag, the working principle is simple, the structure is reliable, the operation is stable, the failure rate is low, the occupied space is small, and according to the characteristics of the soft bag, the production cost can be obviously reduced. The action of the machine is fast, and the production efficiency is high.

Owner:SHINVA MEDICAL INSTR CO LTD

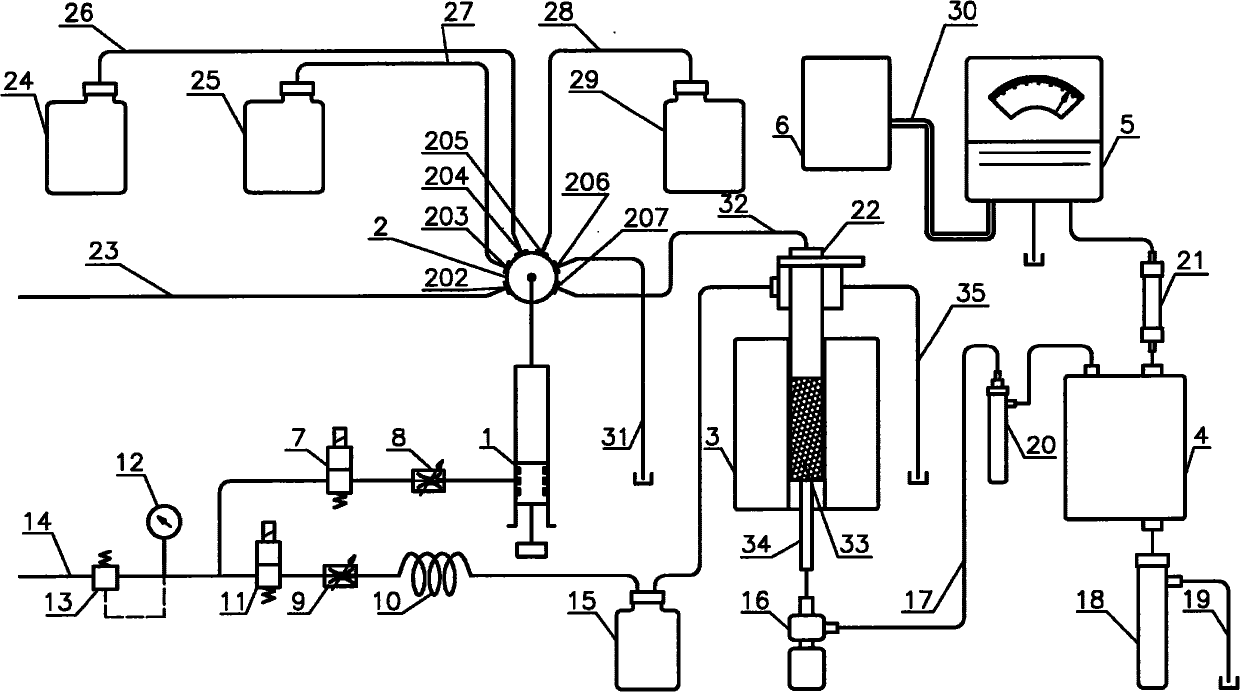

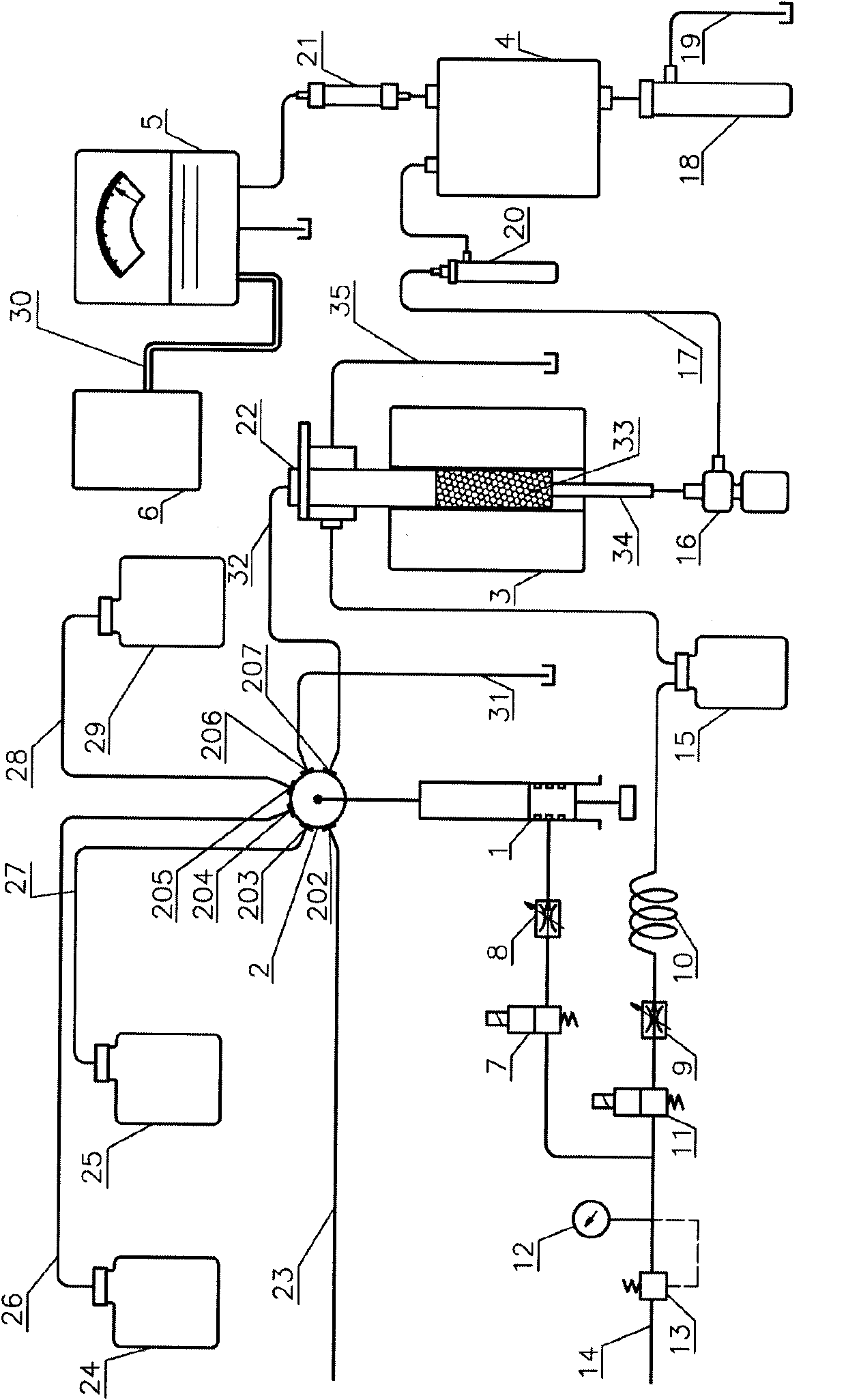

Total organic carbon online analyzer and method for analyzing total organic carbon

InactiveCN101907558AReduce consumptionSimple working principleColor/spectral properties measurementsPtru catalystWater quality

The invention discloses a total organic carbon online analyzer for water, which mainly comprises an injection pump, a multi-ported valve, an oxygen diffusion pipe, a combustion furnace, a platinum catalyst, a condenser and a carbon dioxide gas detector (NDIR). The invention also relates to a method for analyzing the total organic carbon in the water by using the total organic carbon online analyzer for water. The total organic carbon online analyzer and the method can detect 0-2,000ppm water samples, and have the advantages of simple working principle, stability, reliability, low reagent consumption, no secondary pollution, simple and easy use, and wide application prospect in the water quality environment monitoring industry.

Owner:浙江环茂自控科技有限公司

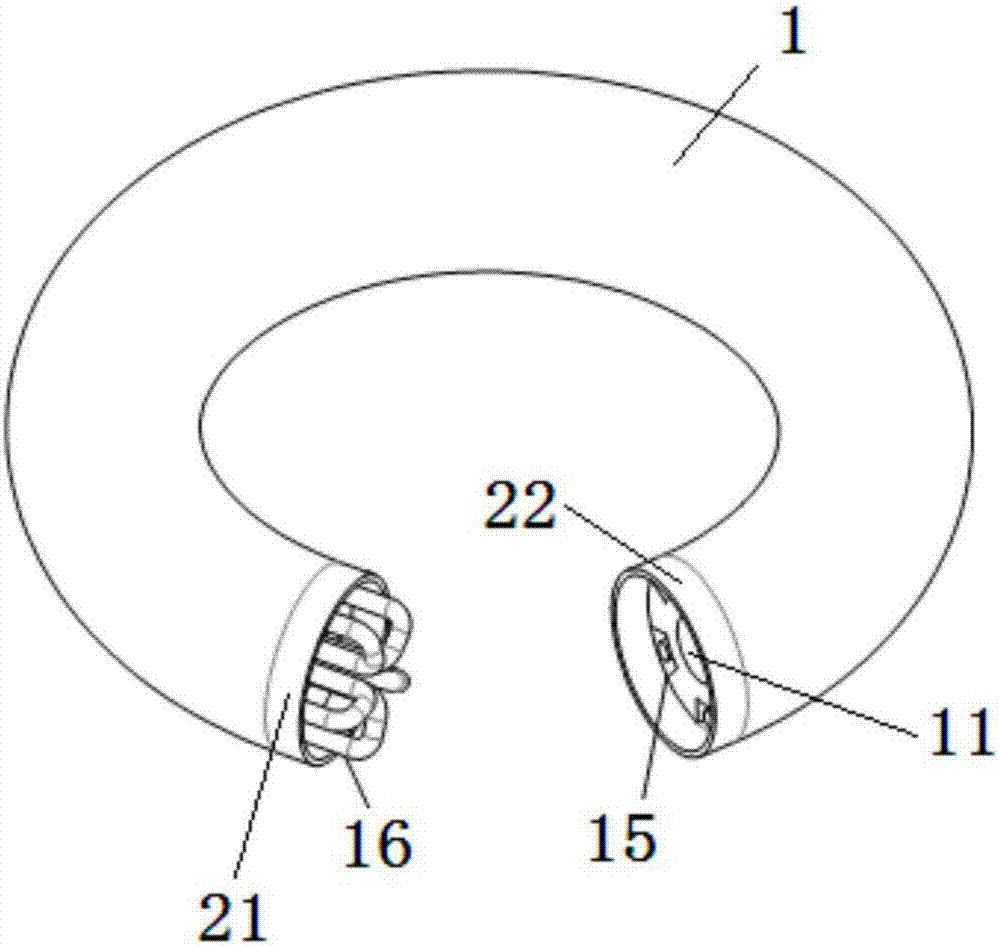

Pneumatic soft pole-climbing robot

ActiveCN106965868AOvercome the disadvantage of being big and bulkyOvercome the limitations of lack of flexibilityVehiclesControl systemRemote control

The invention discloses a pneumatic soft pole-climbing robot. The pneumatic soft pole-climbing robot comprises a soft robot body, an electromagnetic clamping device, a driving control system and remote control equipment. The soft robot body is in an annular shape with an opening; and the section of the soft robot body is circular. A central accommodating cavity and a plurality of sealed air cavities are formed in the soft robot body. Three material layers with gradually increased rigidity are arranged on the soft robot body; and the three material layers are a deformation layer, a middle layer and a restriction layer. The electromagnetic clamping device comprises an electromagnet A and an electromagnet B which are arranged on two open end surfaces. The driving control system is arranged in the central accommodating cavity; and the driving control system comprises an inflation control valve, an air pump, a micro controller and a portable power supply. The portable power supply is used for supplying power to the electromagnet A and the electromagnet B; and the remote control equipment is in wireless connection with the micro controller. As the pneumatic soft pole-climbing robot is built by using a soft material, the pneumatic soft pole-climbing robot has very high adaptive capacity of the robot to environment, can be applied to climbing within or outside pole-shaped tubes, and can climb pipes which are bent to a certain extent.

Owner:NANJING UNIV OF POSTS & TELECOMM

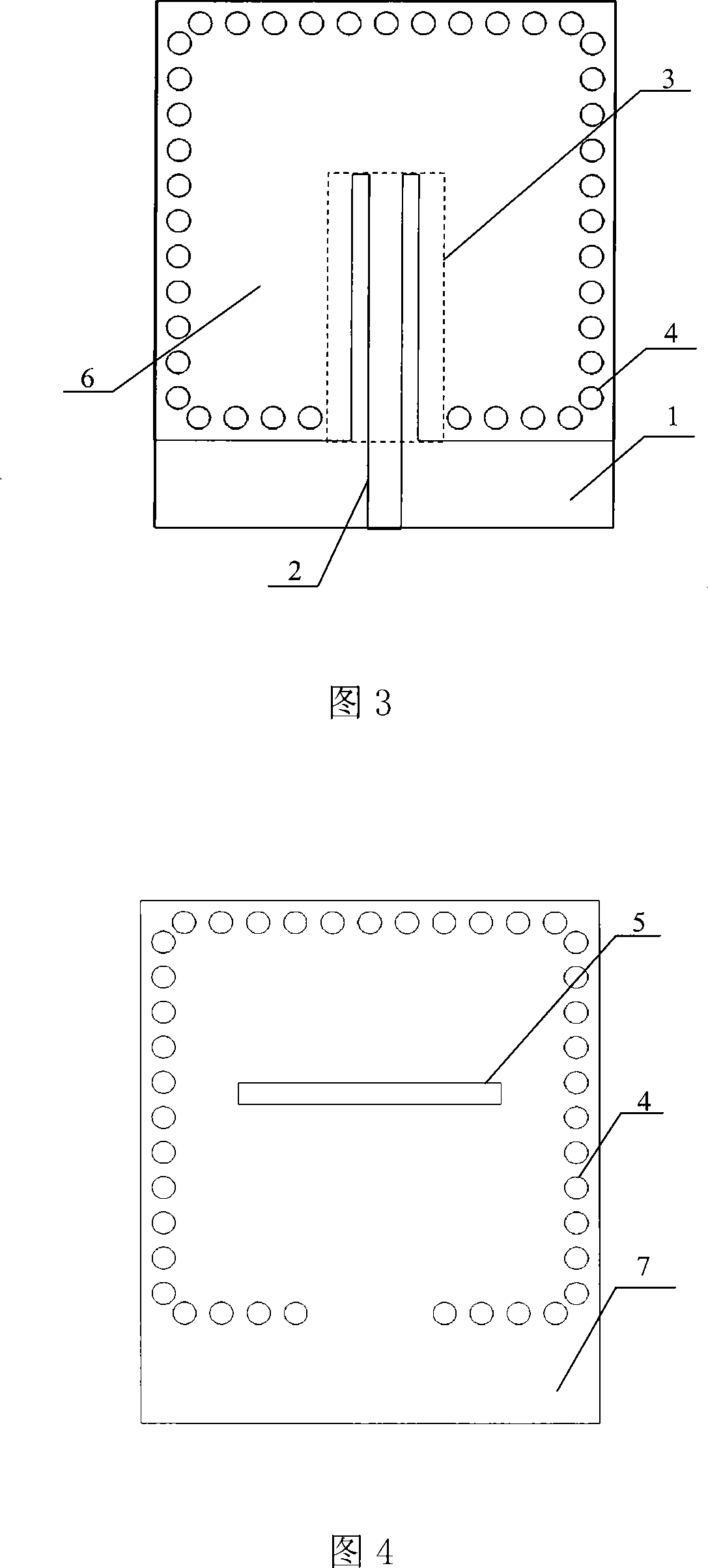

Dimension reduction low profile rear cavity line polarization antenna

InactiveCN101170214AReduce volumeLow production costWaveguide mouthsRadiating elements structural formsPhysicsDielectric substrate

The present invention relates to a reduced size low profile cavity backed linearly polarized antenna. The performance of a single radiating element of a traditional linearly polarized antenna is low and the volume is large. In the present invention, a metal layer is plated on both sides of the dielectric substrate, and the upper metal layer is etched with a microstrip line for power feeding and a common ground coplanar waveguide transmission line, and the middle metal strip of the coplanar waveguide transmission line extends outwards as a microstrip line . Through the upper metal layer, the dielectric substrate and the lower metal layer, a plurality of metallized through holes arranged in a rectangle form a cavity, and the coplanar waveguide transmission line extends into the cavity. The lower metal layer is etched with a strip-shaped radiation slit with a wide side parallel to the wide side of the cavity and close to the wide side of the non-feeding end of the cavity in the region corresponding to the cavity. The invention adopts common PCB technology to produce, the production cost is significantly reduced, and the seamless integration with the microstrip circuit can be realized, and the integration degree of the system is improved. Compared with traditional cavity-backed antennas that require precise machining, the manufacturing speed is fast and the cost is low.

Owner:舟山乐讯智能科技有限公司

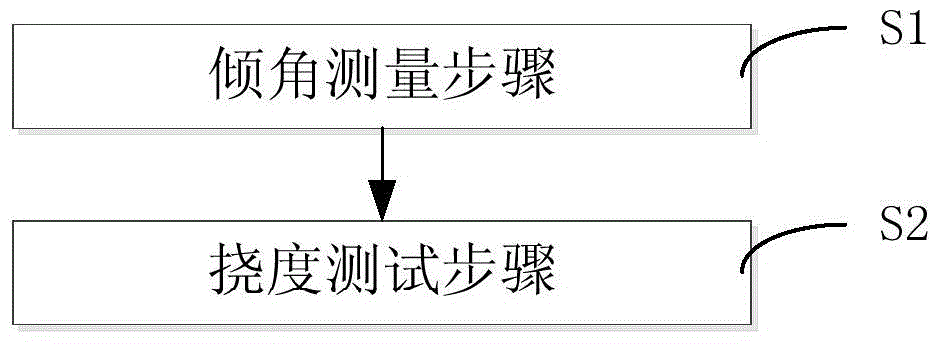

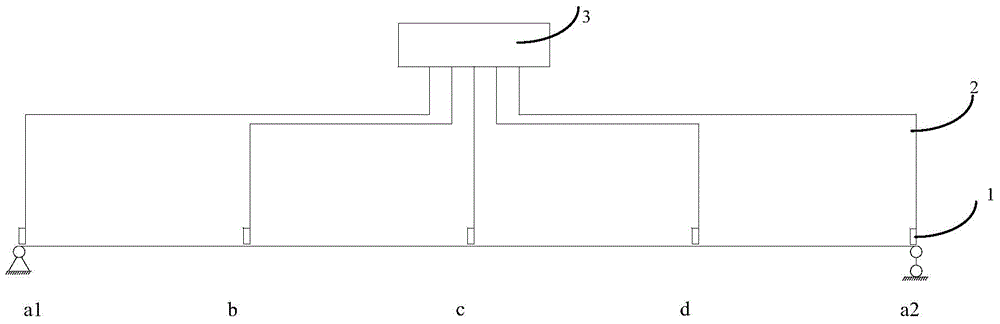

Bridge deflection test method based on inclinometers and system thereof

ActiveCN105320596ASimple working principleReliable theoretical basisSoftware testing/debuggingEngineeringInclinometer

The invention discloses a bridge deflection test method based on inclinometers. The bridge deflection test method comprises the following steps: an inclination measurement step for measuring the cross section corners of a bridge by setting the inclinometers at a plurality of cross section positions of the bridge so as to obtain the corner values of the inclinometers; a deflection test step for obtaining the combination coefficient of an n-order vibration type based on the difference of corner values collected by each inclinometer at the same moment and the initial corner value of each inclinometer and calculating to obtain bridge deflection based on the combination coefficient. The invention also discloses a bridge deflection test system based on the inclinometers.

Owner:铁科检测有限公司 +1

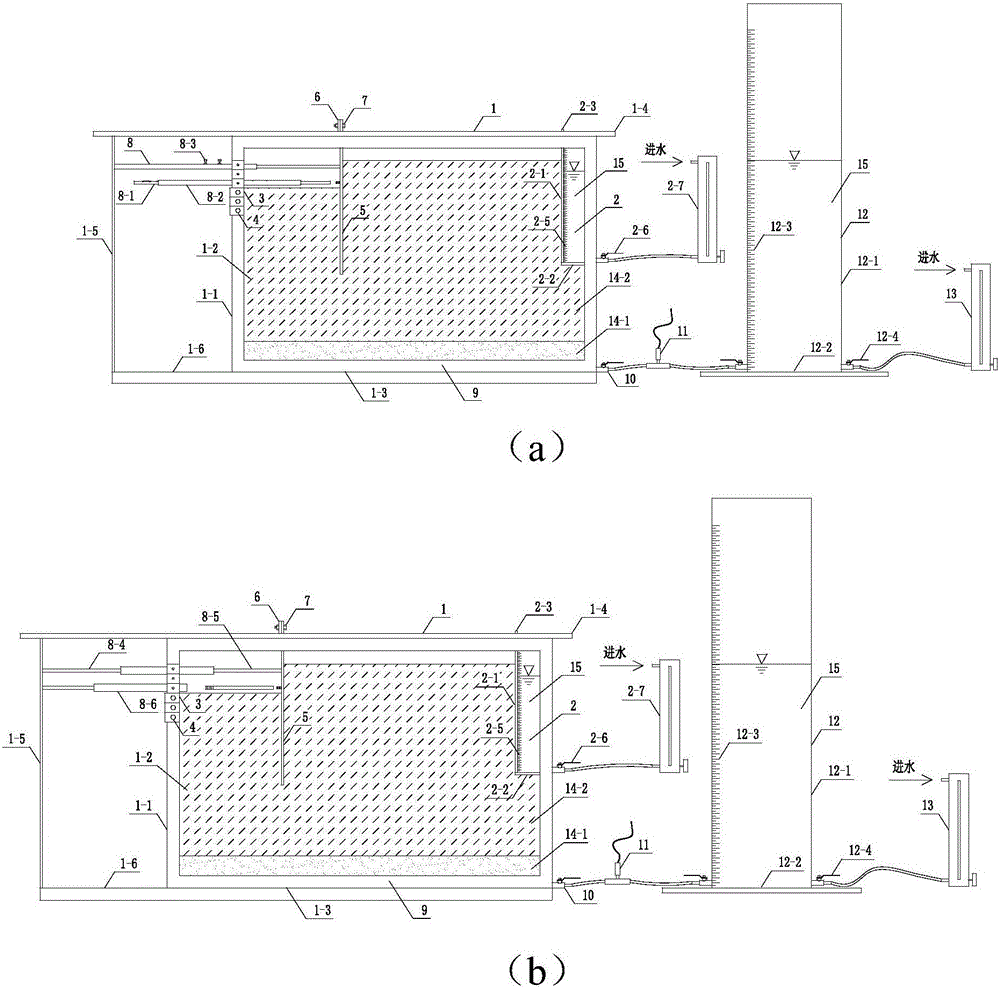

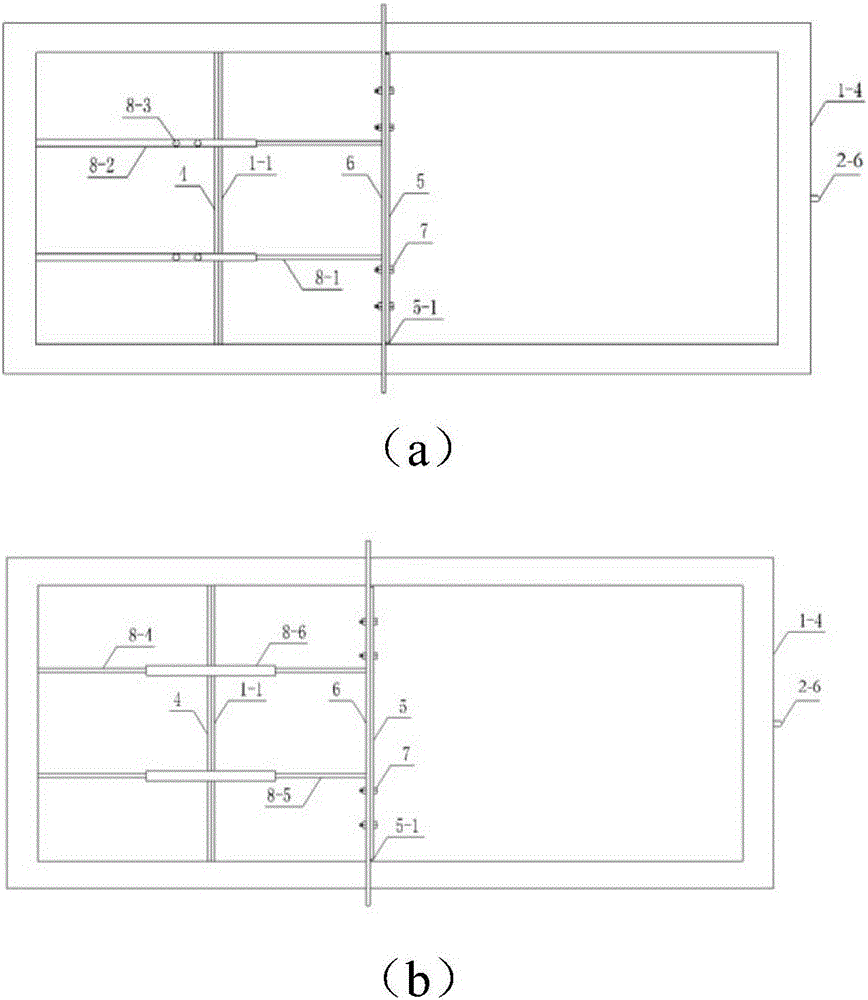

Foundation pit excavation model test device used in complicated groundwater environment

ActiveCN105716960AAvoid starvationAvoid problemsMaterial strength using tensile/compressive forcesConfined waterPore water pressure

The invention discloses a foundation pit excavation model test device used in the complicated groundwater environment. The foundation pit excavation model test device comprises a model box, a water tank, symmetry-plane soil retaining units, a foundation pit supporting structure, a pressure-bearing empty space, a confined water pressure adjusting system and a measuring system, wherein the water tank is arranged at the upper right part inside the model box; the symmetry-plane soil retaining units are fixed on the model box; the pressure-bearing empty space is arranged at the bottom of the model box; the confined water pressure adjusting system comprises a miniature water pressure transmitter, an organic glass cylinder device and a flowmeter. According to the foundation pit excavation model test device, dynamic change of water table level and confined water pressure in a foundation pit excavation process can be simulated; water-soil pressure and deformation of a foundation pit under the action of dynamically changed water table level and confined water pressure are measured, related test data are disposed, the issues about foundation pit stress, deformation development rules and the like are determined, effective test data support is provided for research of foundation pit problems caused by complicated groundwater environment such as the dynamic change of the water table level and the confined water pressure and the like, and the basis is provided for a later theoretical analysis model.

Owner:ZHEJIANG UNIV

Detecting device and detecting method for surface evenness of gate

ActiveCN104776823ASimple working principleImprove adaptabilityMeasurement devicesPressure sensitiveData processing

The invention relates to a detecting device and a detecting method for surface evenness of a gate. The detecting device comprises two longitudinal slideways symmetrically arranged on two sides of the upstream surface of the gate, the two longitudinal slideways are both internally provided with movable plates, a horizontal rail is arranged between the movable plates, the horizontal rail is provided with an elastic pressure-sensitive box, the elastic pressure-sensitive box is internally provided with a steel ball which abuts against the gate, a spring is squeezed by the steel ball, the spring is connected with a pressure sensor., and the pressure sensor is connected with a data meter through a data line. The detecting method for the surface evenness of the gate comprises the following steps that 1 the detecting device for the surface evenness of the gate is installed; 2 a coordinate system is established; 3 the surface of the gate is detected; 4 data processing is conducted. The adaptability for environment is high, the mechanical automation degree is high, locating is accurate, the cost is low, and the device and method are easy to achieve.

Owner:HOHAI UNIV

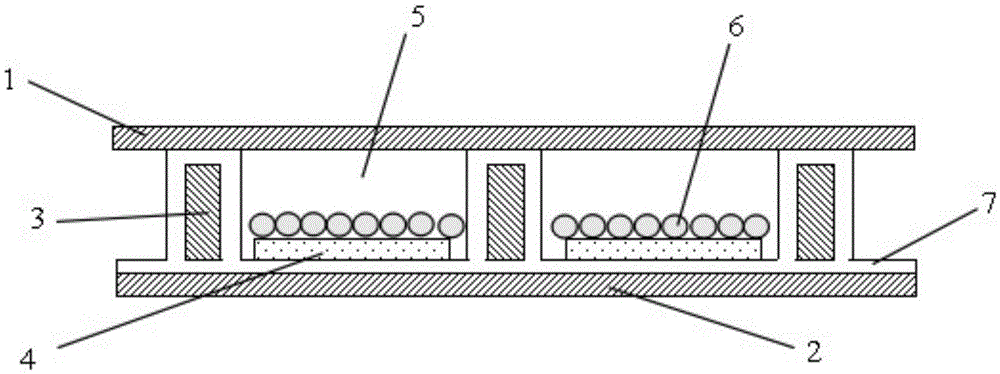

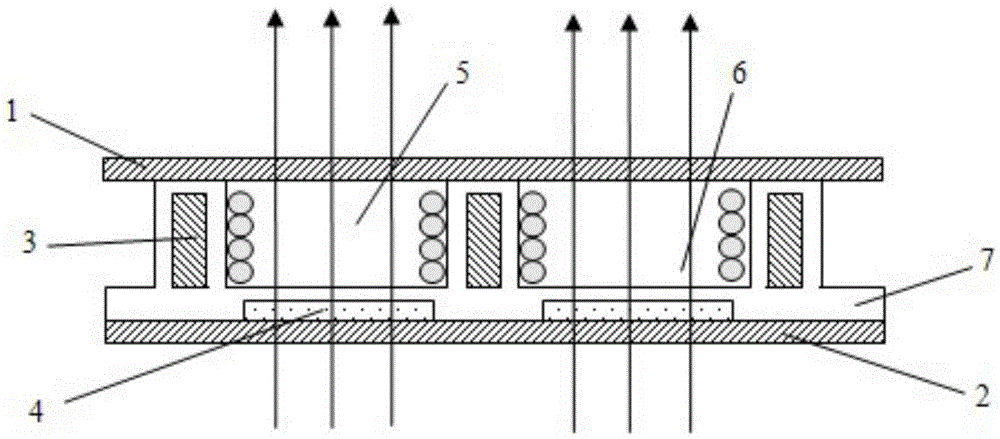

Light valve element and control method thereof and display device

InactiveCN105589252AAchieve throughImplement reflectionStatic indicating devicesNon-linear opticsDisplay deviceEngineering

The invention provides a light valve element and a control method thereof and a display device, and belongs to the technical field of display. The problems that an existing light valve element is complex in structure, difficult to prepare, large in power consumption and high in cost can be solved. The light valve element comprises a first substrate and a second substrate which are oppositely arranged in parallel, the space between the first substrate and the second substrate are divided into multiple chambers, and first electrodes and second electrodes are arranged in each chamber, are insulated from each other and are perpendicular to each other; each chamber is filled with an electrophoretic buffer solution containing charged reflection particles, and the reflection particles can be adsorbed to the surfaces of the first electrodes or the surfaces of the second electrodes. The light valve element is simple in working principle, easy to prepare, little in power consumption, low in cost and convenient and efficient to control.

Owner:BOE TECH GRP CO LTD +1

Cleaning device for adhesions on inner wall of pipeline

InactiveCN105642621AAvoid harmObserve the situation in real timeLighting elementsHollow article cleaningEngineeringMechanical engineering

The invention discloses a cleaning device for adhesions on the inner wall of a pipeline. The cleaning device comprises a small-sized servo motor, a shift ring, at least two long handles and short handles, wherein an extending shaft of the small-sized servo motor is provided with threads; the shift ring is provided with balls; the balls slide in a threaded groove of the extending shaft of the small-sized servo motor; one end of each long handle is connected onto the shift ring, and the other end of each long handle extends; a scraper is arranged at the extending end; a polyester fabric covers the outer sides of the long handles; the number of the short handles is identical with that of the long handles; the short handles are used for supporting the corresponding long handles; and an illuminating lamp, a camera, a control device and a push-pull tube are arranged on the small-sized servo motor. According to the cleaning device disclosed by the invention, the device is mounted into the pipeline by the push-pull tube; the adhesions are found by pushing and pulling the push-pull tube; the small-sized servo motor is started, the long handles drive the polyester fabric to be opened, and the adhesions on the inner wall of the pipeline are scratched by outer ends of the long handles; and the scratched adhesions are collected in the hopper-like polyester fabric, and the push-pull tube is drawn to withdraw from the pipeline. According to the cleaning device disclosed by the invention, the adhesions on the inner wall of the pipeline are removed by adopting a physical method, so greenness and environmental protection are realized; and working efficiency and economic benefits of pipeline maintenance departments or enterprises are improved.

Owner:XIAMEN KINGTOP INFORMATION TECH

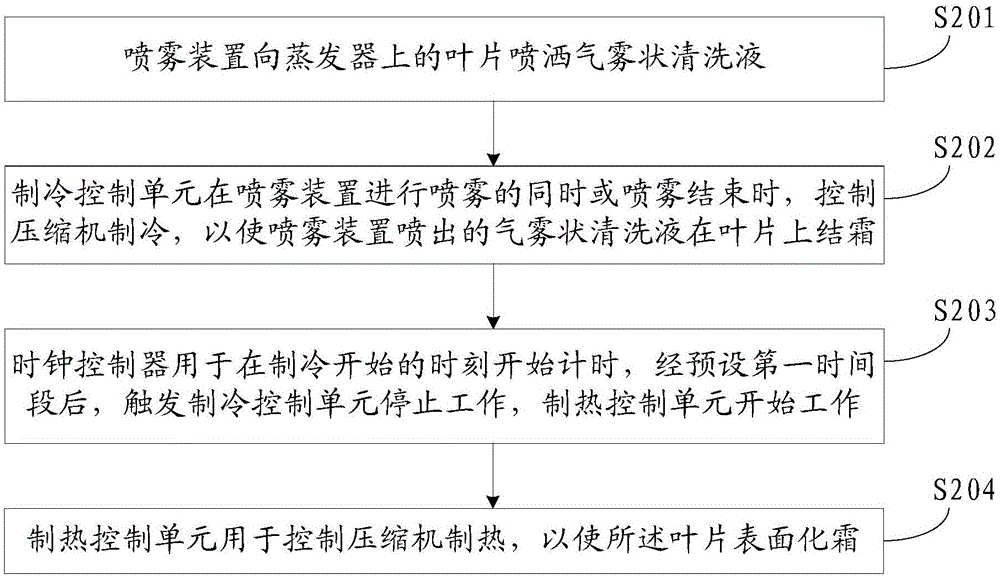

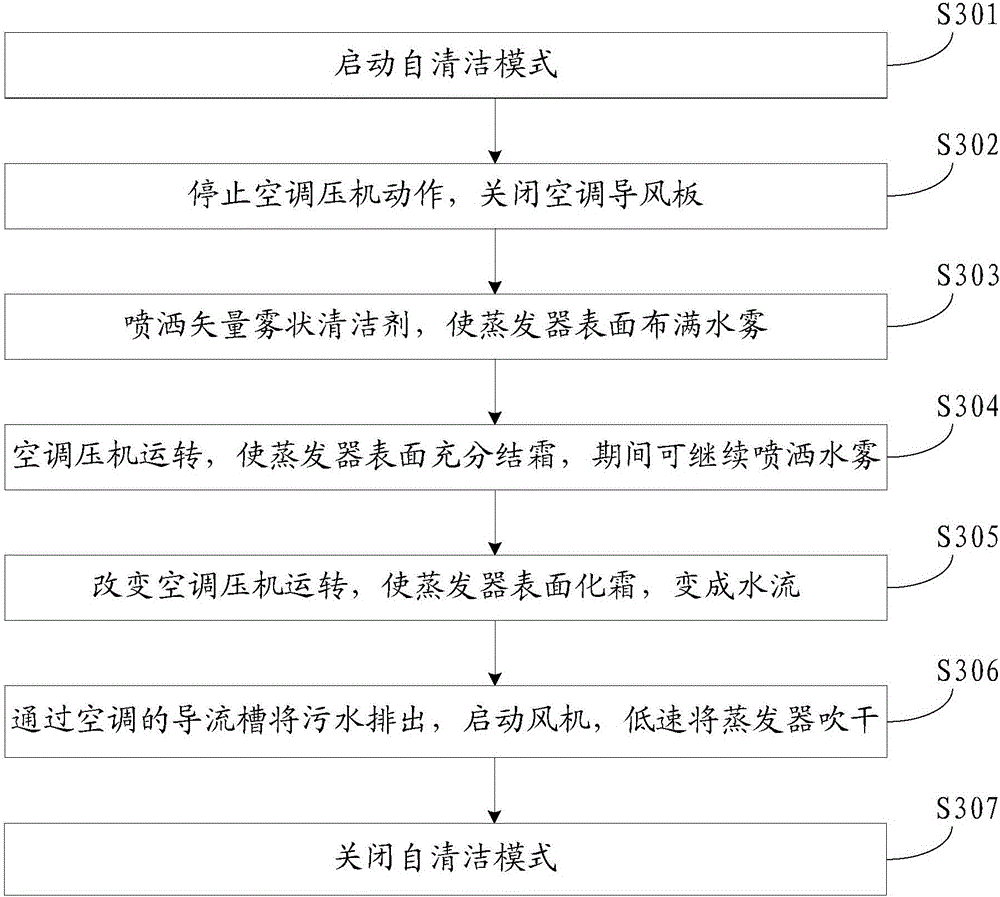

Air conditioner and air conditioning self-cleaning method

InactiveCN106247695ARealize self-cleaningDifficult to cleanEvaporators/condensersCorrosion preventionEngineeringCleaning methods

The invention discloses an air conditioner and an air conditioning self-cleaning system. According to the invention, spraying devices are adopted to spray cleaning solution on blades of an air conditioning evaporator, and then the operating mode of a press is converted to enable the cleaning solution to refrigerate and frost on the blades of the air conditioning evaporator and finally heat and defrost after frosting is carried out to a certain degree, so that the air conditioner can take away more floating dust and dirt on the blades of the air conditioning evaporator. That is, the air conditioner is simple in working principle; and compared with the traditional air conditioner, the air conditioner, disclosed by the invention, can better realize self cleaning with the spraying devices additionally provided to effectively solve the problem in the prior art that the air conditioning evaporator is difficult to clean.

Owner:HAIER YOUJIA INTELLIGENT TECH (BEIJING) CO LTD

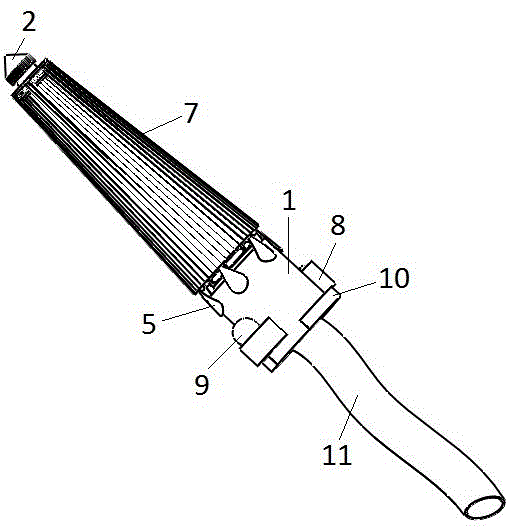

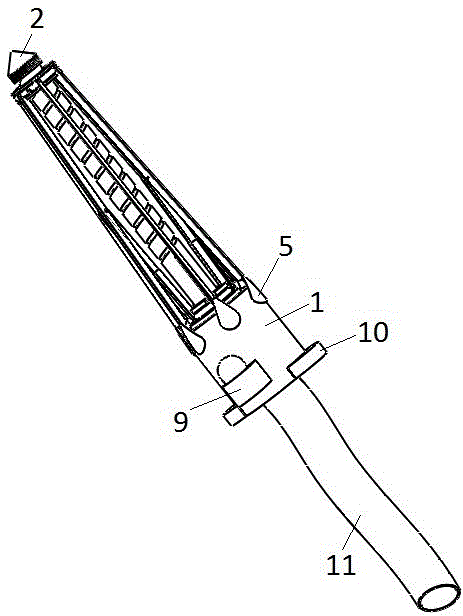

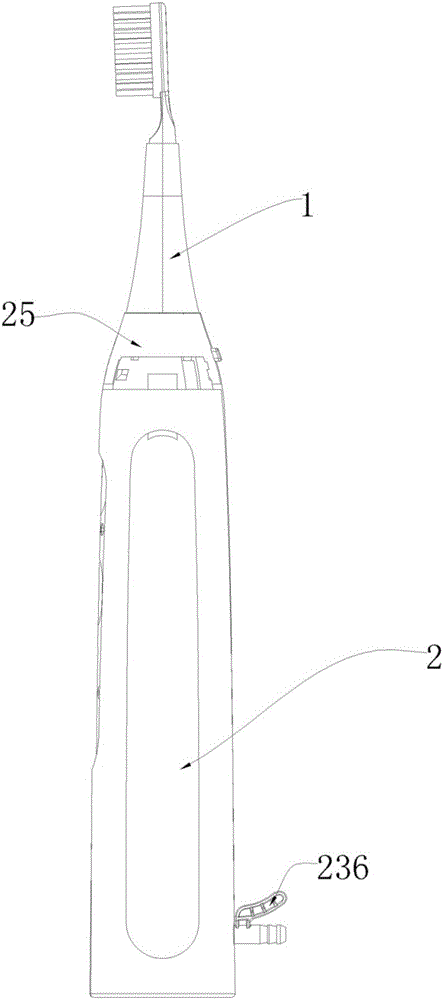

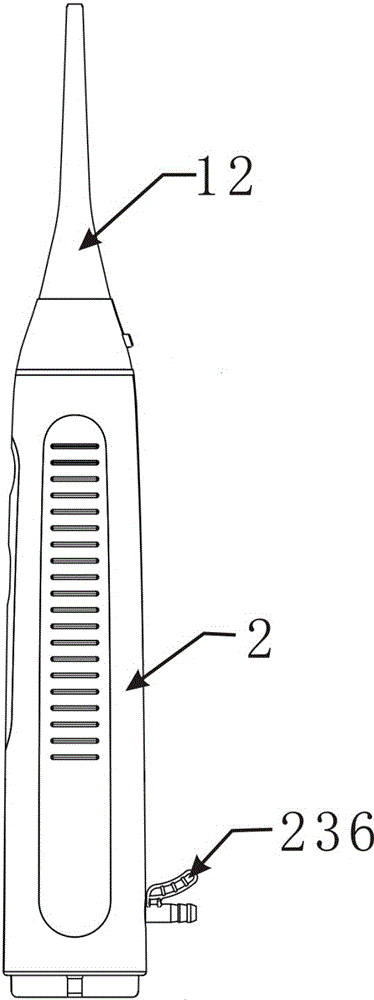

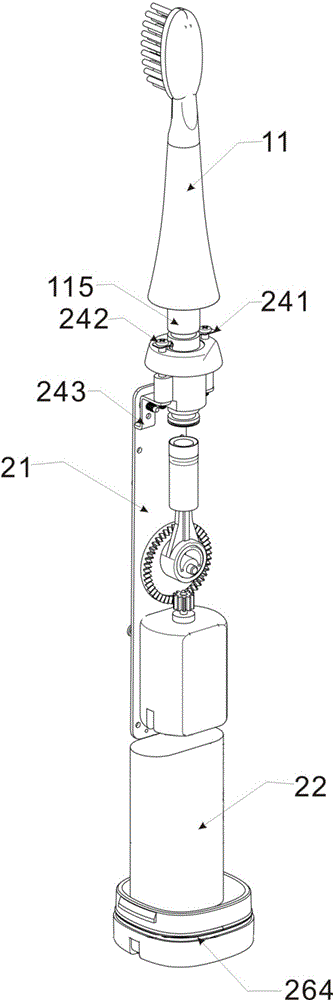

Multifunctional electric toothbrush and tooth cleaning method

ActiveCN106420095AImprove experienceSolve the shortcomings of single functionTooth cleaningElectricityElectrical battery

The invention discloses a multifunctional electric toothbrush and a tooth cleaning method. The multifunctional electric toothbrush comprises a cleaning part and a handle, wherein the cleaning part is a toothbrush head or water spray pipe mounted on the handle in a replaceable manner; a main control circuit board, a battery, a water spray component and a terminal are arranged in the handle; the main control circuit board is electrically connected with the terminal, the water spray component and the battery respectively; the water spray component is positioned at the lower end of the terminal; the end part of a water spray pipe is directly connected with the water spray component; a vibration motor and a transfer circuit board are arranged on the toothbrush head; the transfer circuit board controls the vibration motor to vibrate, so as to drive the toothbrush head to vibrate; and the terminal is arranged at the joint between the handle and the cleaning part and is electrically connected with the transfer circuit board. According to the invention, an aim of deeply cleaning teeth is achieved by use of multiple types of cleaning parts; the application method and working principle are simple; and multiple cleaning parts are used together without mutual influence, thereby improving the customer experience and being more economical.

Owner:SHENZHEN AIBOER ELECTRONICS TECH CO LTD

Railway bridge double spherical surface shock absorption and separation mount

ActiveCN101148858ASmall vertical displacementAdaptive force transmissionBridge structural detailsEngineeringStructural safety

The double spherical shock absorbing and insulating bearer for railroad bridge includes an upper bearing plate, a middle bearing plate and a lower bearing plate superposed successively and sliding teflon plates set between bearing plates. The lower bearing plate has fixed shearing force member. The middle bearing plate has an upper spherical surface in small curvature radium for connection to the upper bearing plate through spherical spin friction, and a lower spherical surface in great curvature radium for connection to the lower bearing plate through spherical sliding friction. In addition, there are also a top basin on the upper bearing plate and a sliding teflon plate in between. the present invention has obvious shock absorbing and insulating effect, easy control and regulation, capacity of ensuring structural safety and lowering engineering cost, and other features.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

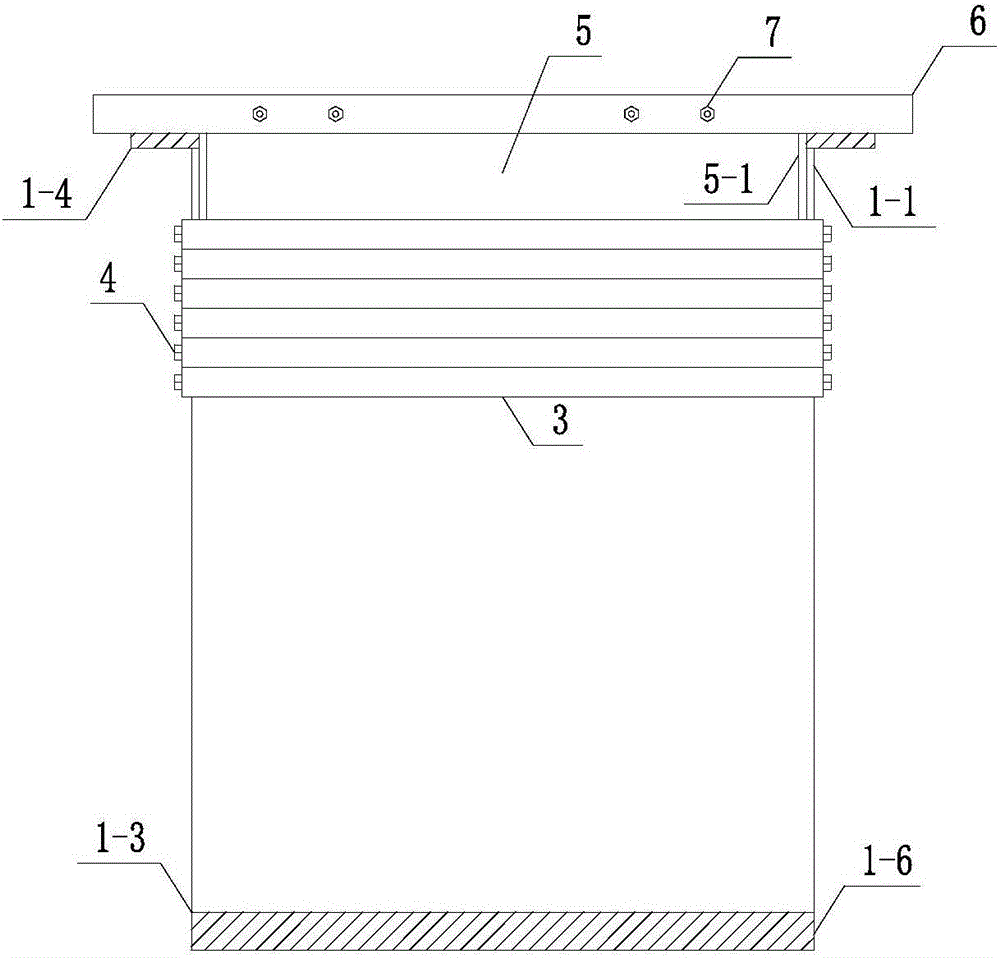

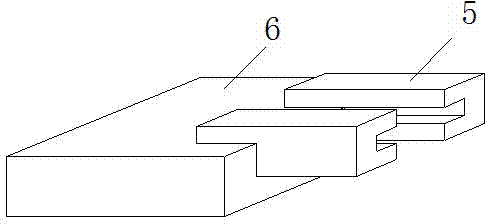

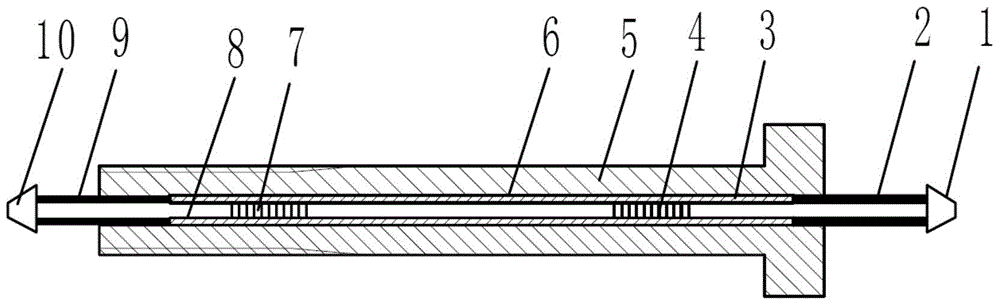

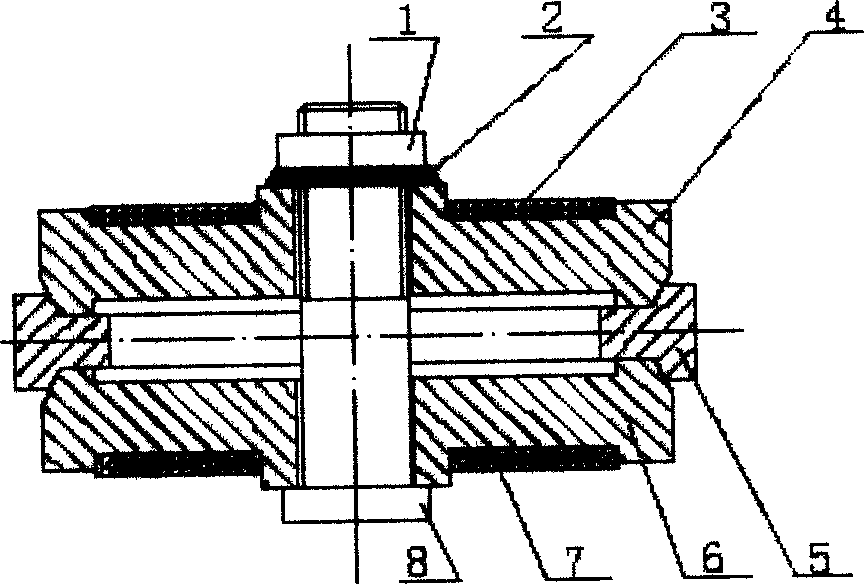

Optical fiber Bragg grating sensing principle-based temperature-self-compensating intelligent bolt

InactiveCN104567998AEnables strain monitoringInhibit sheddingConverting sensor output opticallyGratingAdhesive

The invention relates to an optical fiber Bragg grating sensing principle-based temperature-self-compensating intelligent bolt, and belongs to the field of optical fiber sensing and structure health monitoring. The optical fiber Bragg grating sensing principle-based temperature-self-compensating intelligent bolt comprises a bolt body 5, an optical fiber 8, a first optical fiber Bragg grating sensor 4 and a second optical Bragg grating sensor 7, wherein the first optical fiber Bragg grating sensor 4 and the second optical Bragg grating sensor 7 are formed in the same optical fiber 8 by carving; the first optical fiber Bragg grating sensor 4 senses temperature and strain; the second optical Bragg grating sensor 7 senses the temperature; an axial sensor implanting hole 6 which penetrates through the bolt body 5 is formed in the bolt body; the optical fiber 8 penetrates through the sensor implanting hole 6; the first optical fiber Bragg grating sensor 4 and the second optical Bragg grating sensor 7 are positioned in the sensor implanting hole 6; a packaging adhesive is injected into the sensor implanting hole 6 to package the first optical fiber Bragg grating sensor 4 in the sensor implanting hole 6; heat-conducting silicone grease is injected into the sensor implanting hole 6 to package the second optical Bragg grating sensor 7. According to the temperature-compensating intelligent bolt, the strain of the bolt in a working state can be monitored online in real time.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Oriented steel fiber arrangement device and steel fiber concrete manufacturing method

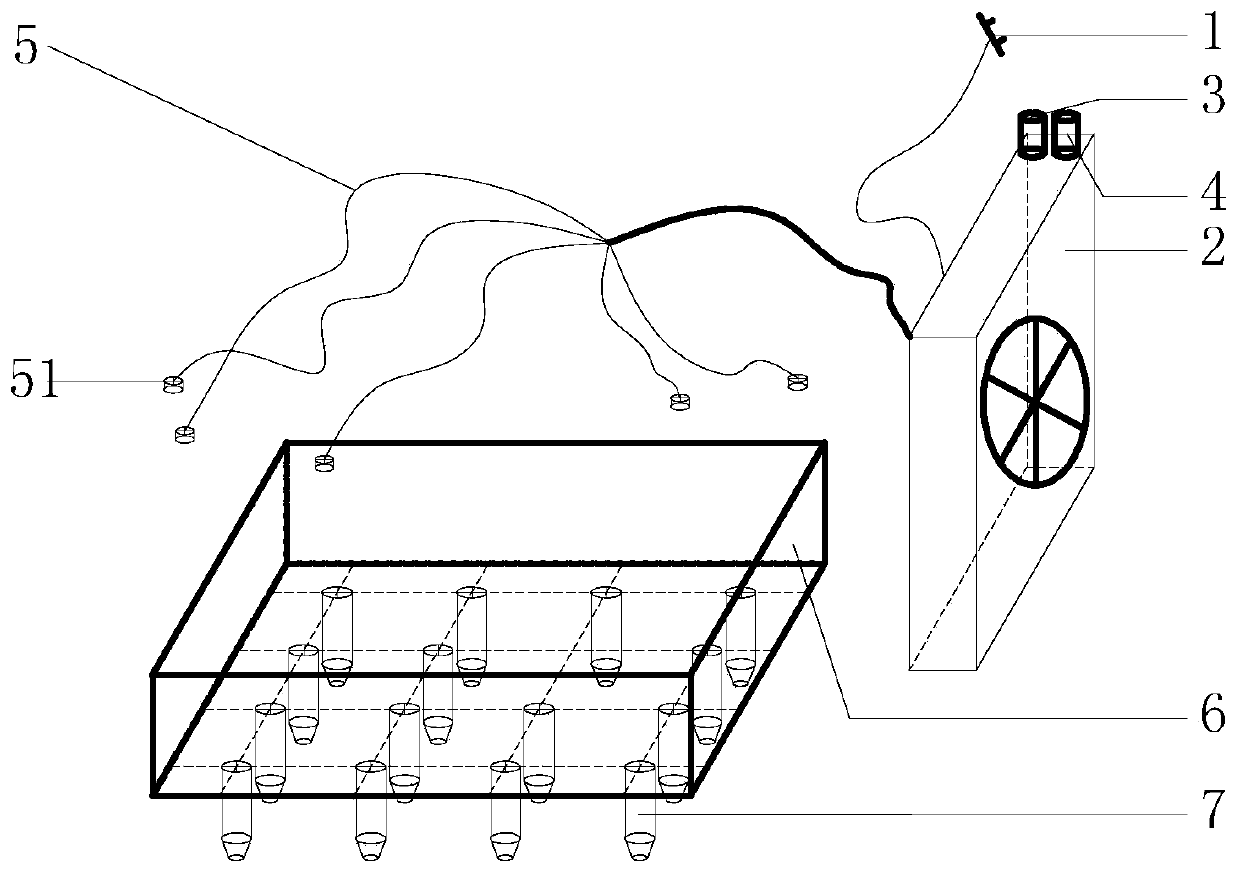

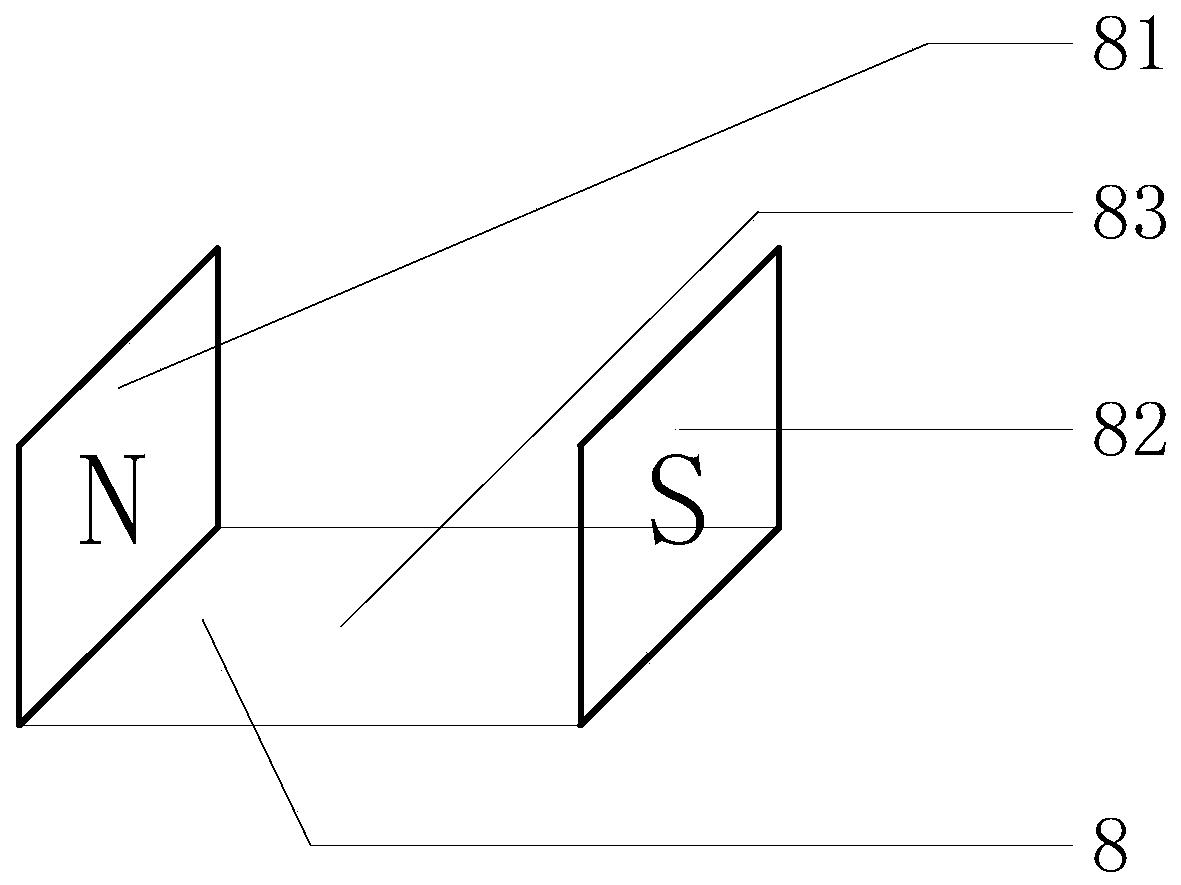

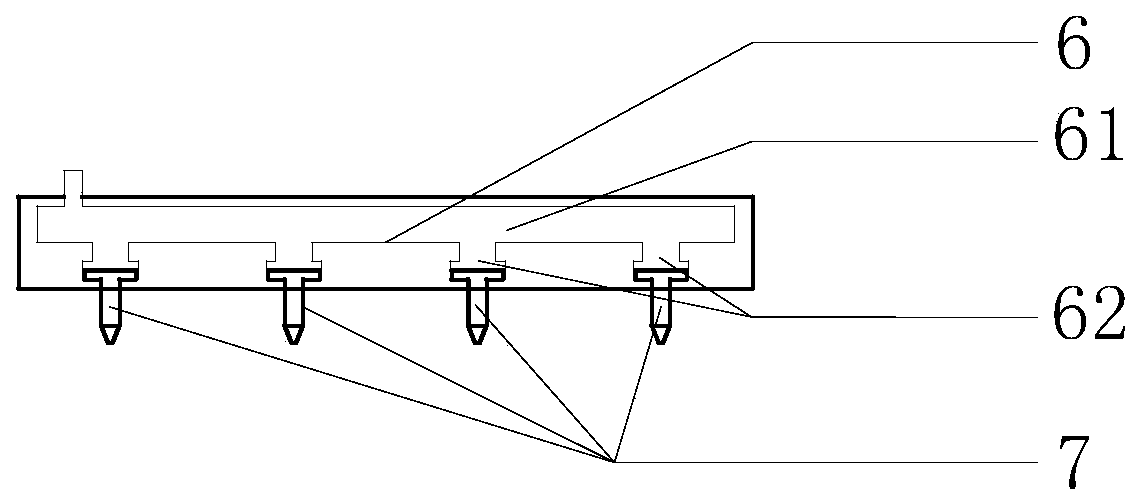

ActiveCN110216776AUniform orientationImprove tensile propertiesCeramic shaping apparatusSurface layerSuction stress

The invention discloses an oriented steel fiber arrangement device and a steel fiber concrete manufacturing method. An air blower, an adsorption switch, a tight adsorbing switch, an air pipe, a steelfiber adsorption disc, adsorption needles and an oriented magnetic field belt are included. The air blower is utilized for driving gas to generate attraction force, the gas pipe is used for transmitting the attraction force to the adsorption needles of the steel fiber adsorption disc, after the adsorption needles tightly absorb fiber, the fiber tends to be arranged in the same direction under theaction of magnetic force of the oriented magnetic field belt, the tight adsorbing switch is turned on, it is guaranteed that the steel fiber and the adsorption needles are fixed, then, the steel fiberarranged in the oriented manner is placed in a layer-by-layer poured concrete surface layer, and steel fiber concrete in which the steel fiber is arranged in the oriented manner is formed. The oriented steel fiber arrangement device and the steel fiber concrete manufacturing method have a series of preparing advantages that operation is simple, and steel fiber arrangement is uniform, and the oriented steel fiber arrangement device and the steel fiber concrete manufacturing method are suitable for manufacturing of the steel fiber concrete in which the steel fiber is arranged in the oriented manner.

Owner:HOHAI UNIV

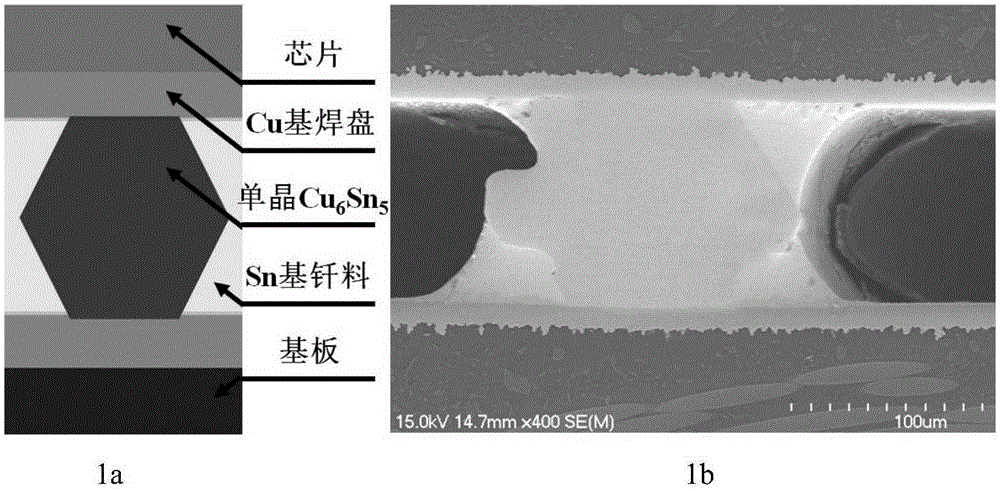

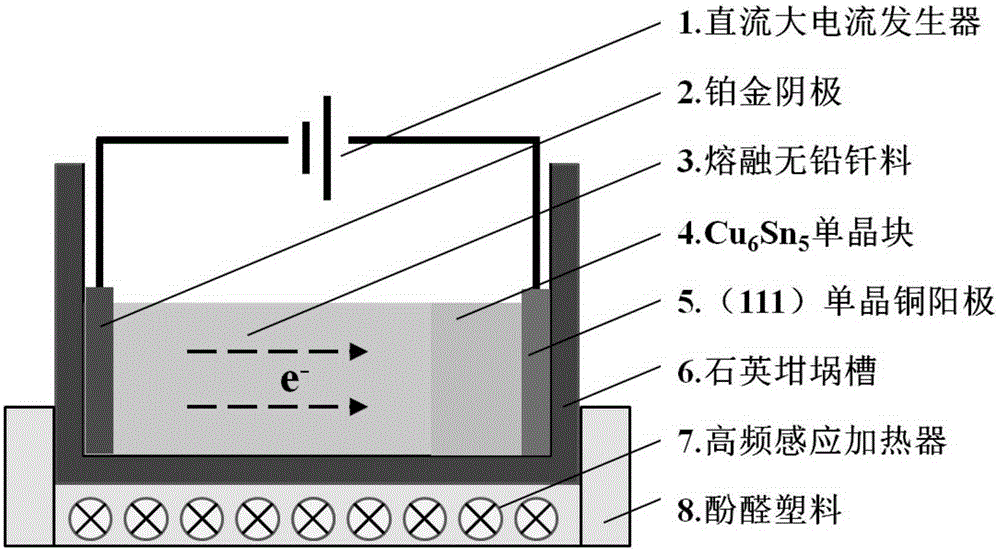

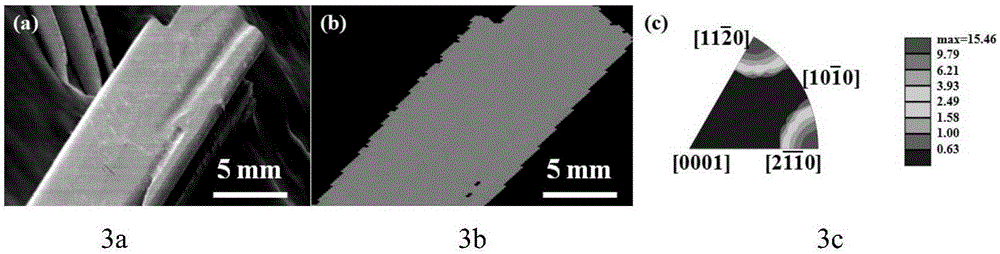

Directional interconnection method for Cu6Sn5-base single-crystal lead-free solder joints for high-temperature packaging

InactiveCN105171168ALow costStrong creep resistanceSolid-state devicesSemiconductor/solid-state device manufacturingInterconnectionFiller metal

The invention belongs to the technical field of materials, and provides a directional interconnection method for Cu6Sn5-base single-crystal lead-free solder joints for high-temperature packaging. The method comprises the steps of firstly, preparation of a Cu6Sn5-base single-crystal block body, secondly, cutting of the Cu6Sn5-base single-crystal block body, thirdly, surface pretreatment of a Cu-base welding disc, and fourthly, interconnection of Cu6Sn5-base single-crystal welding blocks. The elasticity modulus of the Cu6Sn5-base single-crystal lead-free interconnected solder joints prepared with the method is 235% of that of common Sn-base brazing filler metal, the conductivity of the Cu6Sn5-base single-crystal lead-free interconnected solder joints is 52.4% that of the Sn-base brazing filler metal, and the heat conductivity of the Cu6Sn5-base single-crystal lead-free interconnected solder joints is 57.8% that of the Sn-base brazing filler metal. The method has the beneficial effects of being low in cost, resistant to high temperature, high in reliability of interconnection of the solder joints and a Cu-base welding disc, high in creep-resistance, and capable of being used for a long time under the severe condition. The method has the beneficial effects of being simple in working principle, low in cost, rapid in single-crystal preparation and high in quality.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

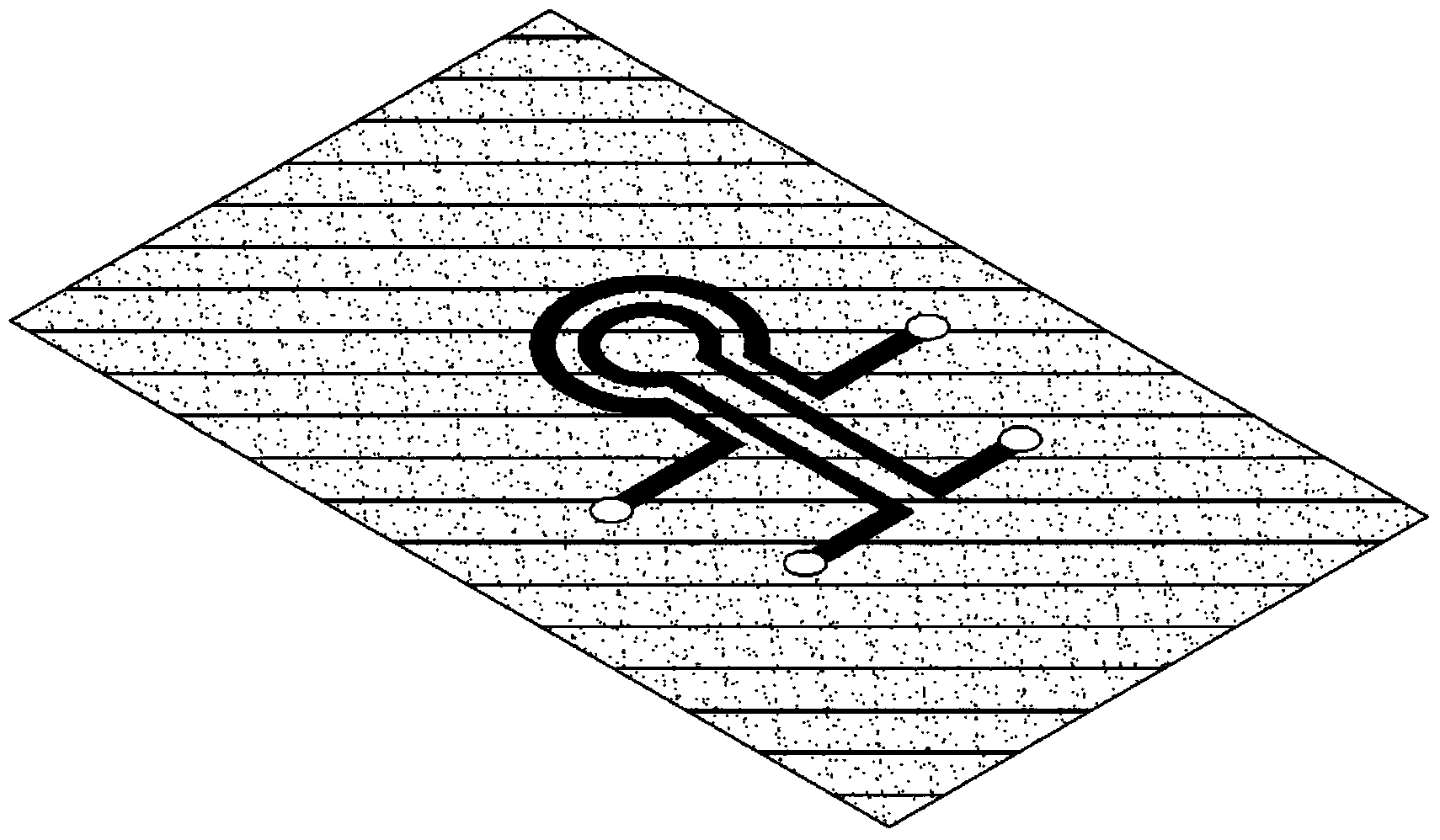

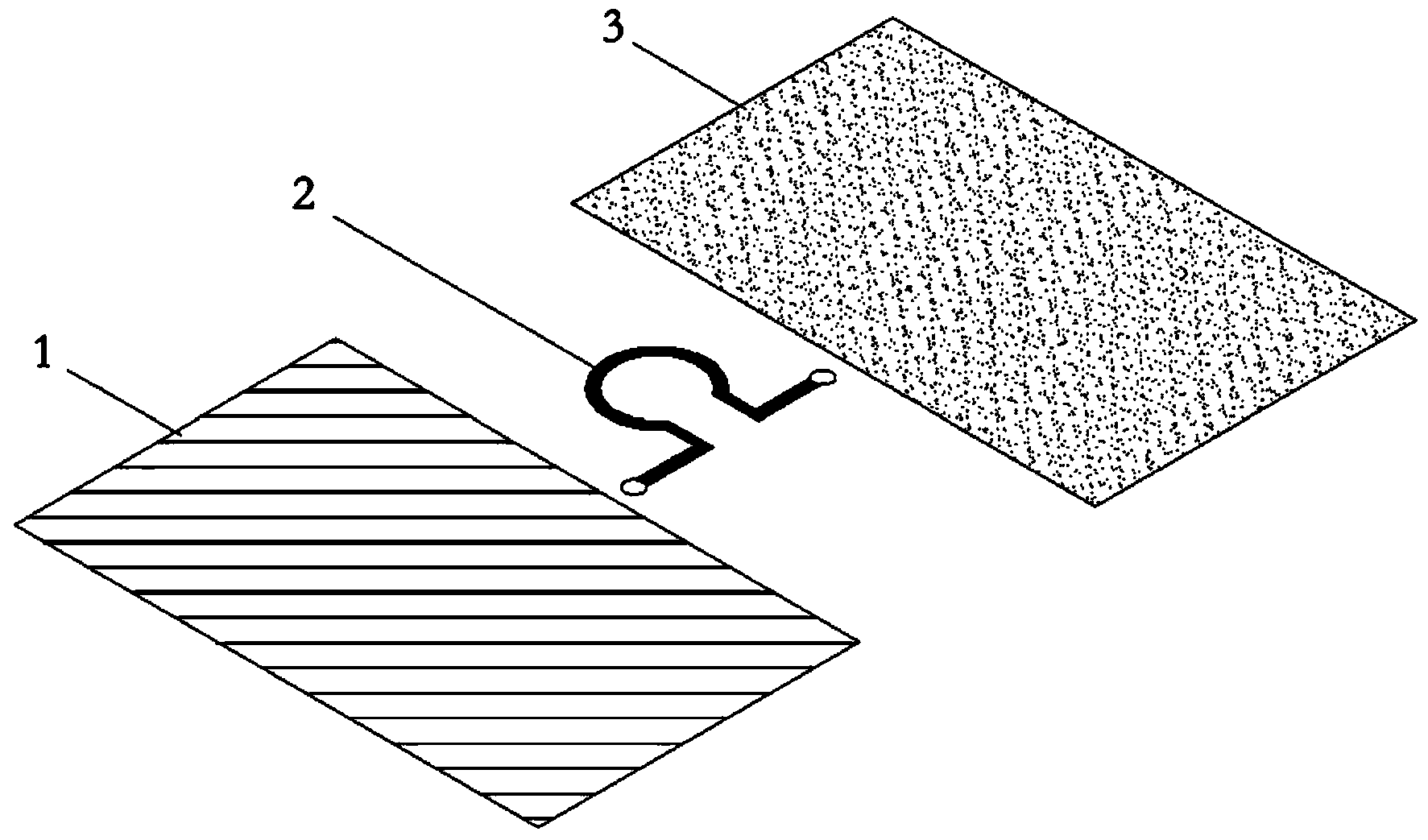

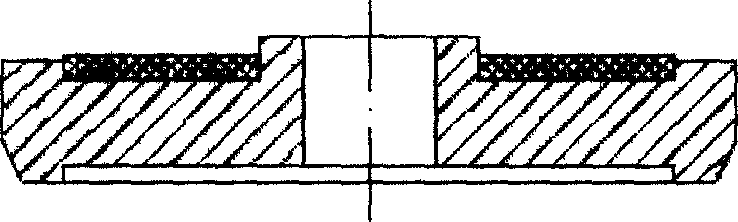

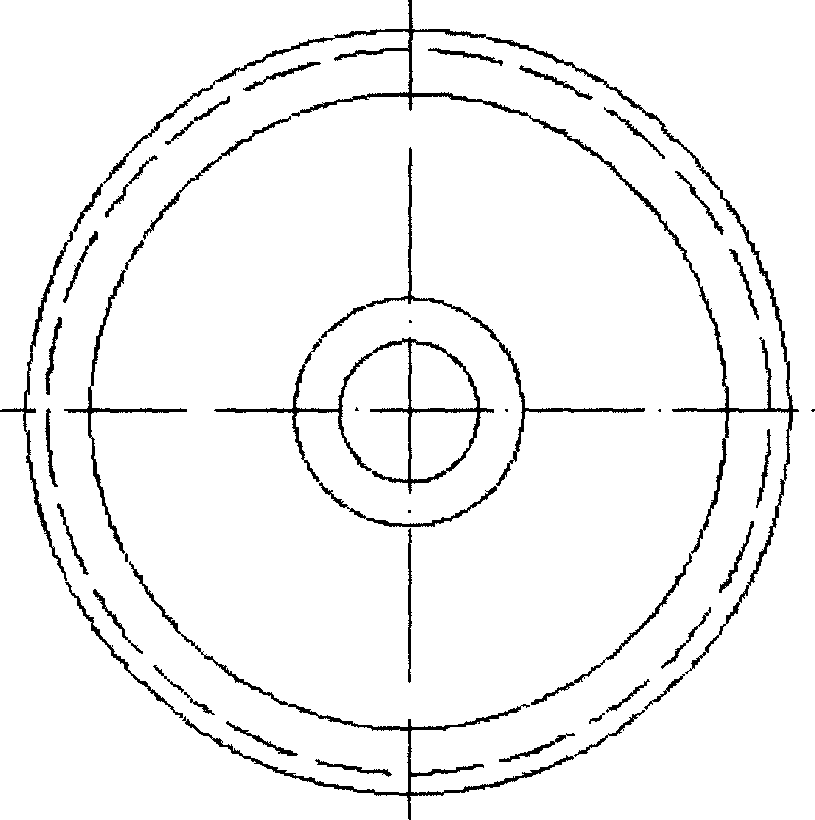

Thin film sensor array and preparation method thereof

ActiveCN104165920AAccurate Potential MonitoringExcellent Damage ConsistencyMaterial analysis by electric/magnetic meansThin film sensorSensor array

The invention discloses a thin film sensor array, which is characterized by comprising a plurality of concentric annular thin film sensors, wherein an entire monitoring area is covered by the formed thin film sensor array; each annular thin film sensor mainly comprises three layers of structures which are micron thick, i.e., an insulating supporting layer, a conductive sensing layer and an encapsulated protective layer from bottom to top, wherein the insulating supporting layer is formed on the surface of a substrate and is integrated with the substrate; the conductive sensing layer is of an annular structure. The thin film sensor array disclosed by the invention has the beneficial effects that potential monitoring is carried out on the thin film sensor array which is integrated with a metal structure accurately in crack initiation and expansion stages, thus realizing quantitative and real-time monitoring on a full process of structure fatigue crack expansion; the thin film sensor array easily realizes integrated design and integration with the metal structure and is widely applicable to real-time monitoring of typical metal structure. The thin film sensor array is high in sensitivity, adjustable in monitoring precision, wide in monitoring range, low in power consumption, free from signal conversion and high in comprehensive cost effectiveness.

Owner:AIR FORCE UNIV PLA

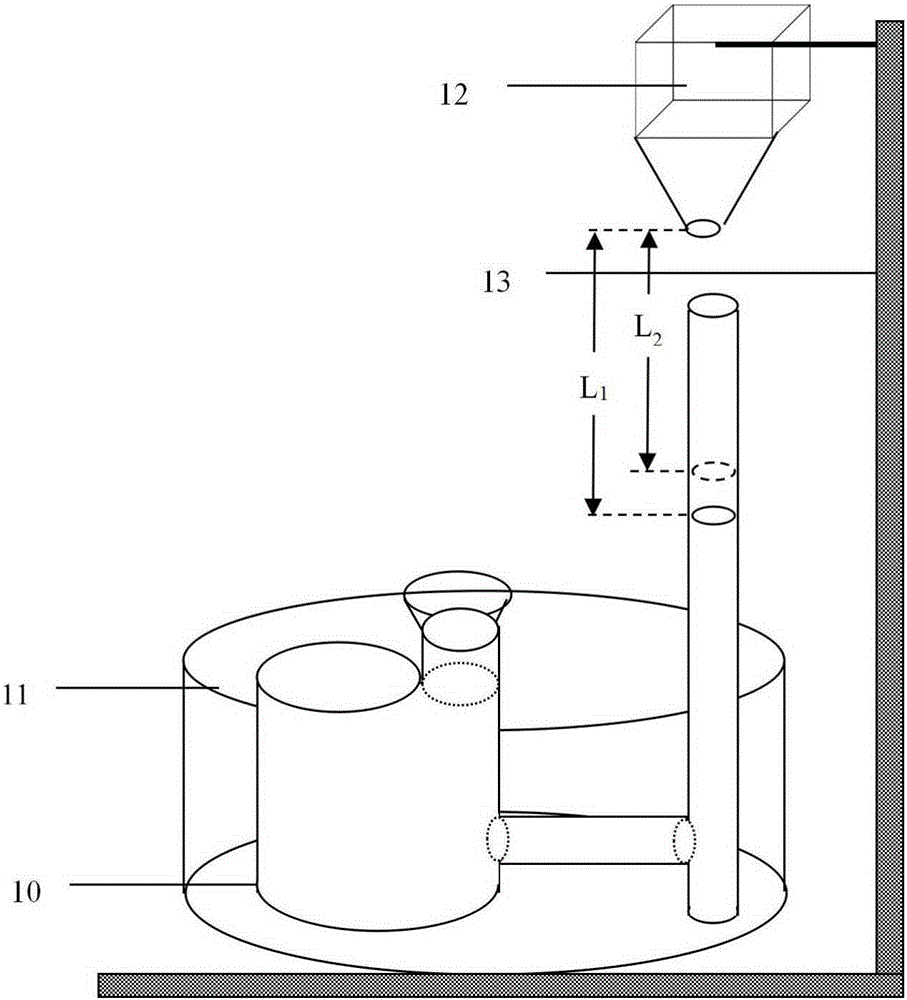

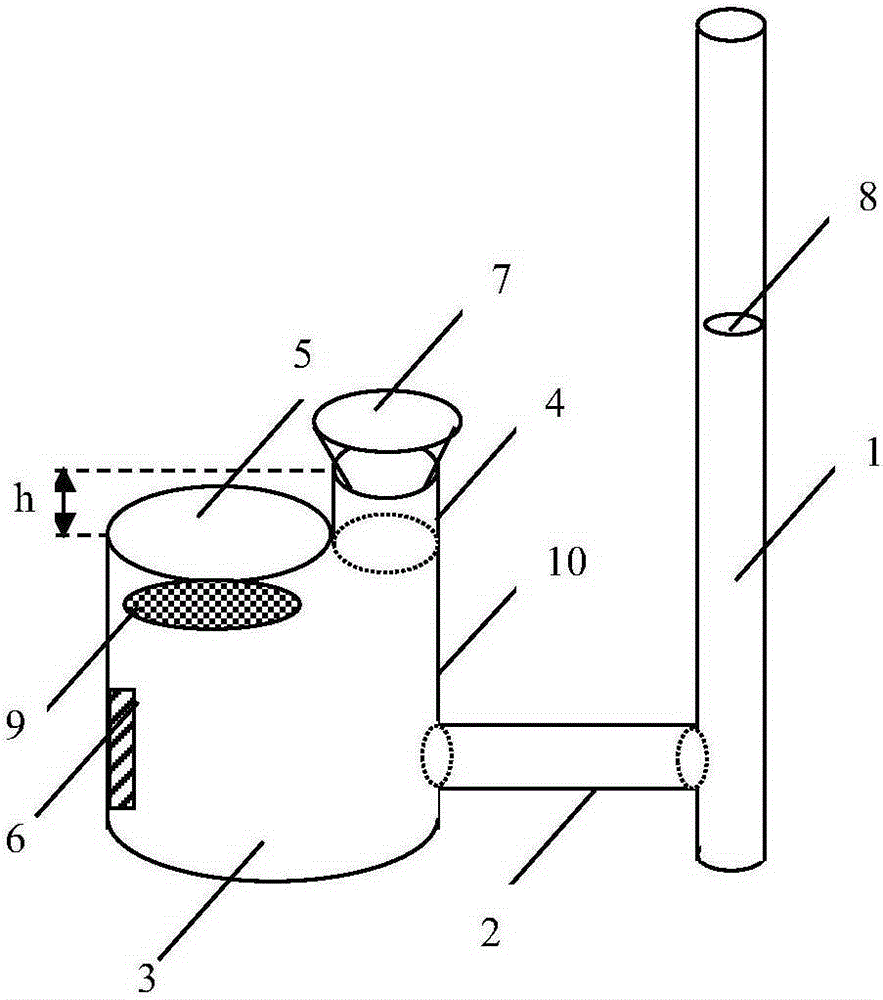

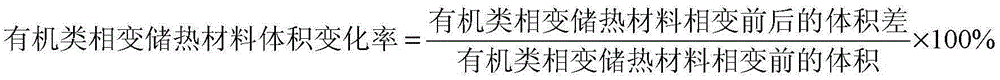

Device and method for testing volume deformation of organic phase-change heat storage material

ActiveCN105352990ASimple working principleImprove test accuracyMaterial thermal coefficient of expansionWater bathsHeat storage material

The invention relates to a device and a method for testing volume deformation of an organic phase-change heat storage material and aims to solve problems of low testing precision and poor repeatability of existing devices and methods. The device comprises a communicating container, a water bath heating device, a fixing support and a laser displacement sensor. The method comprises steps as follows: I, weighing is performed; II, water is injected; III, the whole communicating container is placed in the water bath heating device, the initial temperature T1 of a liquid in the communicating container is recorded by the laser displacement sensor, the laser displacement sensor is fixed right above a thin tube of the communicating container through the fixing support, and the initial distance L1 of a plastic sheet is recorded by the laser displacement sensor; IV, the temperature T2 of the liquid in the communicating container is recorded by a temperature sensor, and the distance L2 of the plastic sheet is tested by the laser displacement sensor; V, the volume change rate of the organic phase-change heat storage material is calculated. The device and the method are applied to the field of organic phase-change heat storage materials.

Owner:HARBIN INST OF TECH

Automatic capping packaging machine

ActiveCN102718175ASimple working principleSimple mechanical structureCapsClosure using capsEngineeringBottle

The invention relates to an automatic capping packaging machine which comprises a stand and an electronic control device, wherein a working platform is arranged on the stand; a conveying track is fixedly arranged on the working platform; a cover taking device and a capping device are respectively arranged above the conveying track along the direction of forward motion of the conveying track; and a cover storage device is arranged at one side (close to the cover taking device) of the conveying track. The automatic capping packaging machine is simple in working principle, simple and reasonable in mechanical structure and short in capping time, thus effectively improving the capping efficiency of bottle cans and reducing the production cost.

Owner:广州市利悦食品包装技术有限公司

Large-size high-speed invisible flying saucer

InactiveCN105314111AIncrease the moment of inertiaReduce oil supplyAircraft navigation controlJet type power plantsCircular discNacelle

The invention discloses a flying saucer and two smoke- and fire-free engines. The flying saucer is composed of a cabin and a disk which rotates round the cabin. The disk includes a disk-shaped wing and a rotary engine. The cabin includes a driving cabin, a passenger cabin and a device cabin. The rotary engine sucks air which is mixed with water, and then the mixture is jetted out horizontally through jet tubes installed on the edge of the disk according to the sprayer principle, so that a generated reactive force enables the disk to rotate at a high speed, thereby generating an upward raising force on the disk. Four fixing wings are installed outside the device cabin to eliminate reverse rotation of the cabin. A vector engine and a diesel power generating set are installed in the device cabin under the disk. The vector engine sucks large amount of air through an air inlet duct in the passenger cabin to form vacuum above the passenger cabin, which enables air pressure difference between an upper surface and a lower surface of the disk to be increased, thereby generating a huge raising force. The sucked air is compressed to form high-pressure gas which is discharged into vector jet tubes and is jetted out, wherein the directions and the angles of the vector jet tubes are adjustable to generate pushing forces in different directions, thereby achieving maneuvering flight of the flying saucer.

Owner:周彦辉

Rotary type ultraphonic motor

InactiveCN1909355AConsistent performanceRealize forward and reverse continuous motionPiezoelectric/electrostriction/magnetostriction machinesElastomerEngineering

The invention relates to a rotation ultra-sonic motor, which comprises: vibrator and rotor, wherein said vibrator is formed by adhered piezoelectric ceramic and metal elastic element; said rotor is annular and sheathes the vibrator; the tension force between vibrator and rotor via adjustable tension device can be adjusted; the contact part between the metal elastic element and the rotor is round; the inner annular surface of rotor at least has one area to match the contact part of metal elastic element. In said invention, the rounds of vibrator and the rotor are contacted, to transform the traveling vibration of metal elastic element into the vibration of vibrator; and it has small axial volume, to obtain higher torque and self-lock force, with simple structure and reliable operation.

Owner:SOUTH CHINA AGRI UNIV

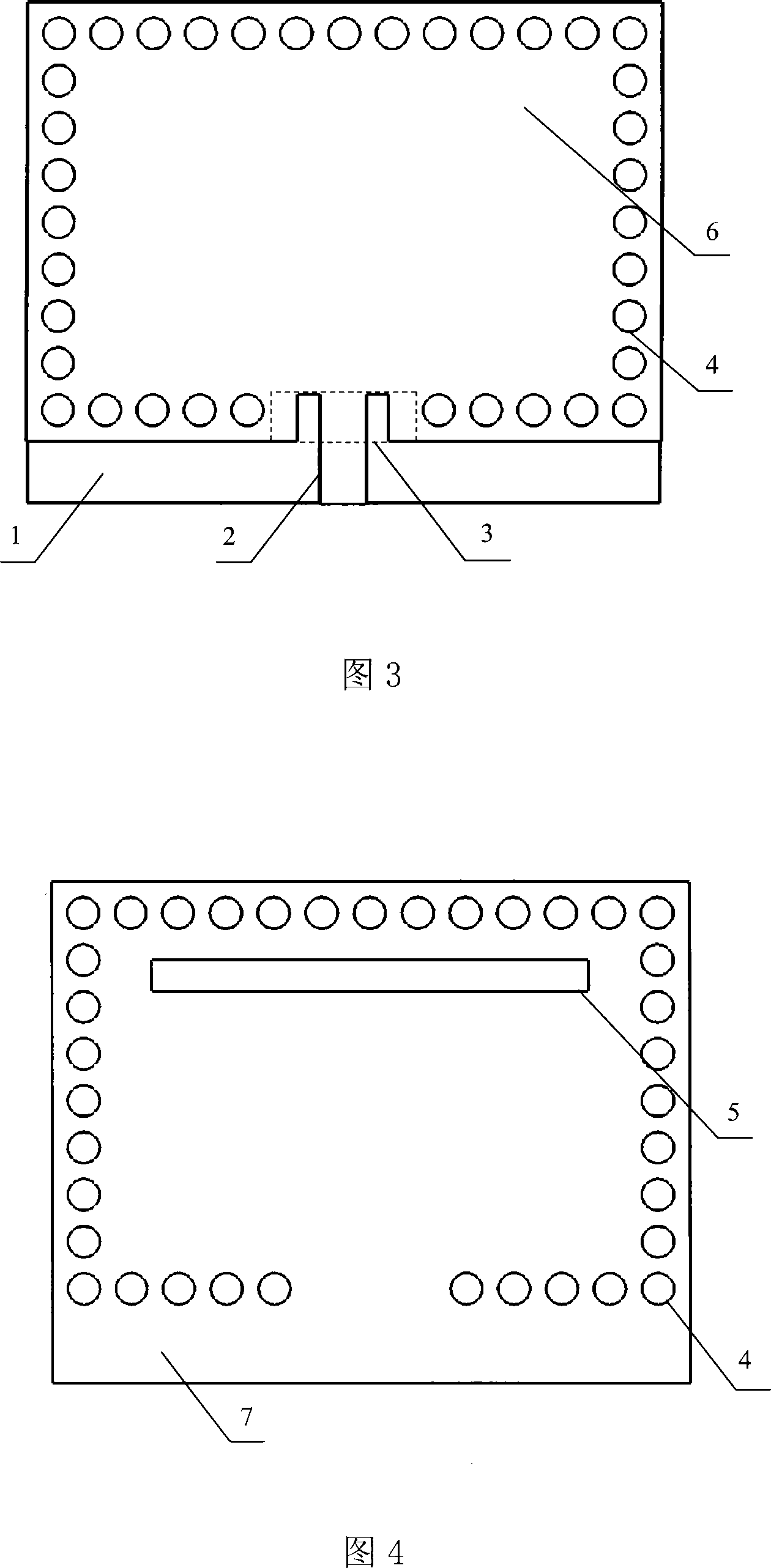

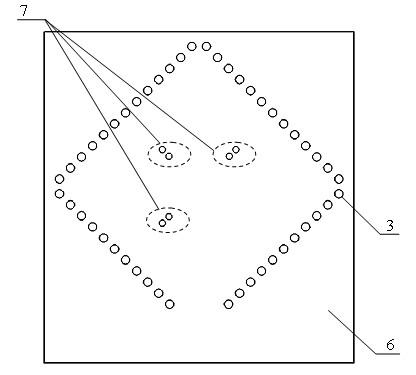

High gain integrated antenna based on high order cavity resonant mode

InactiveCN102142617AHigh gainReduce volumeRadiating elements structural formsSlot antennasElectricityDielectric substrate

The invention relates to a high gain integrated antenna based on a high order cavity resonant mode. A backed cavity of the traditional antenna consists of a smooth metal cavity, and has a large volume and high processing cost. The high gain integrated antenna based on the high order cavity resonant mode comprises a dielectric substrate, an upper metal layer which is coated on the upper surface of the dielectric substrate, and a lower metal layer which is coated on the lower surface of the dielectric substrate. A plurality of electric interconnection units which pass through the upper metal layer, the dielectric substrate and the lower metal layer are arranged in sequence to form an electric interconnection array; an area which is surrounded by the upper metal layer, the lower metal layer and the electric interconnection array forms a cavity body, and a feed unit stretches into the cavity body; the plurality of electric interconnection units which pass through the upper metal layer, the dielectric substrate and the lower metal layer inside the cavity body form a plurality of tuning electric interconnection groups; and a plurality of parallel radiating gaps are formed on the upper metal layer inside the cavity body. The volume of the cavity backed antenna is greatly reduced; manufacturing cost is reduced remarkably; and seamless integration between the high gain integrated antenna based on the high order cavity resonant mode and a planar circuit can be realized.

Owner:HANGZHOU DIANZI UNIV

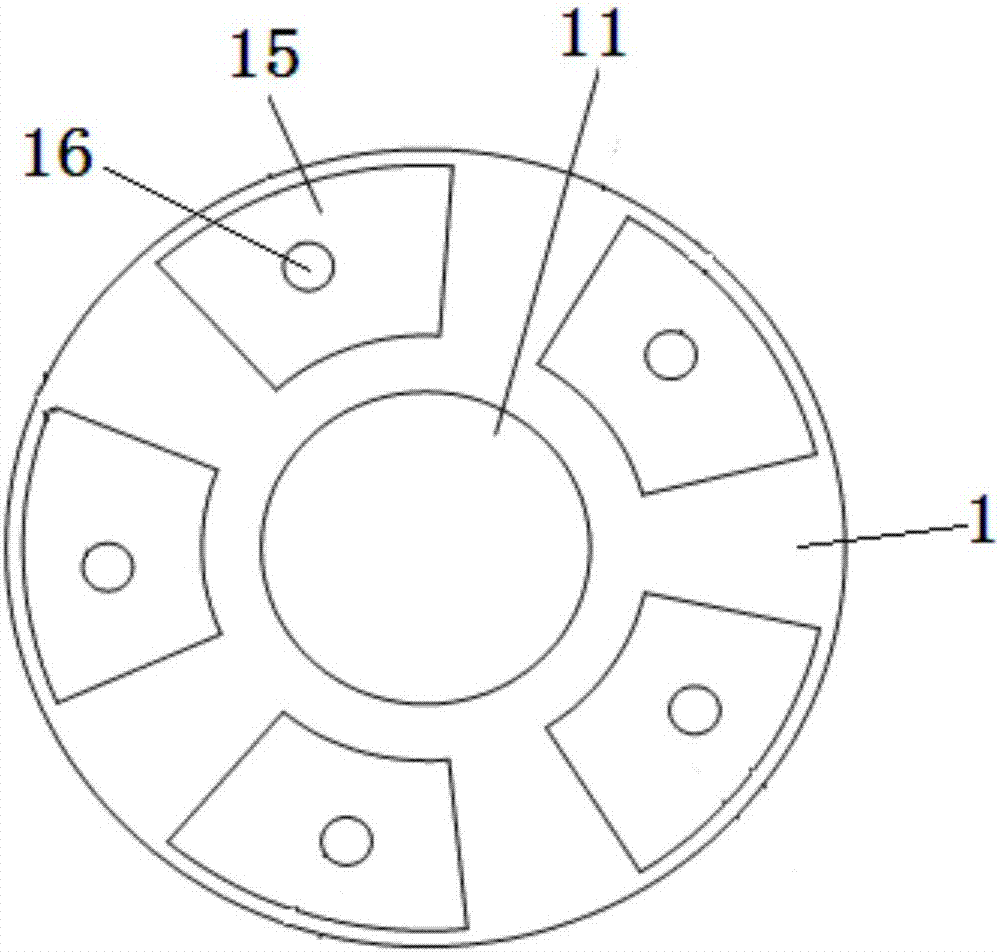

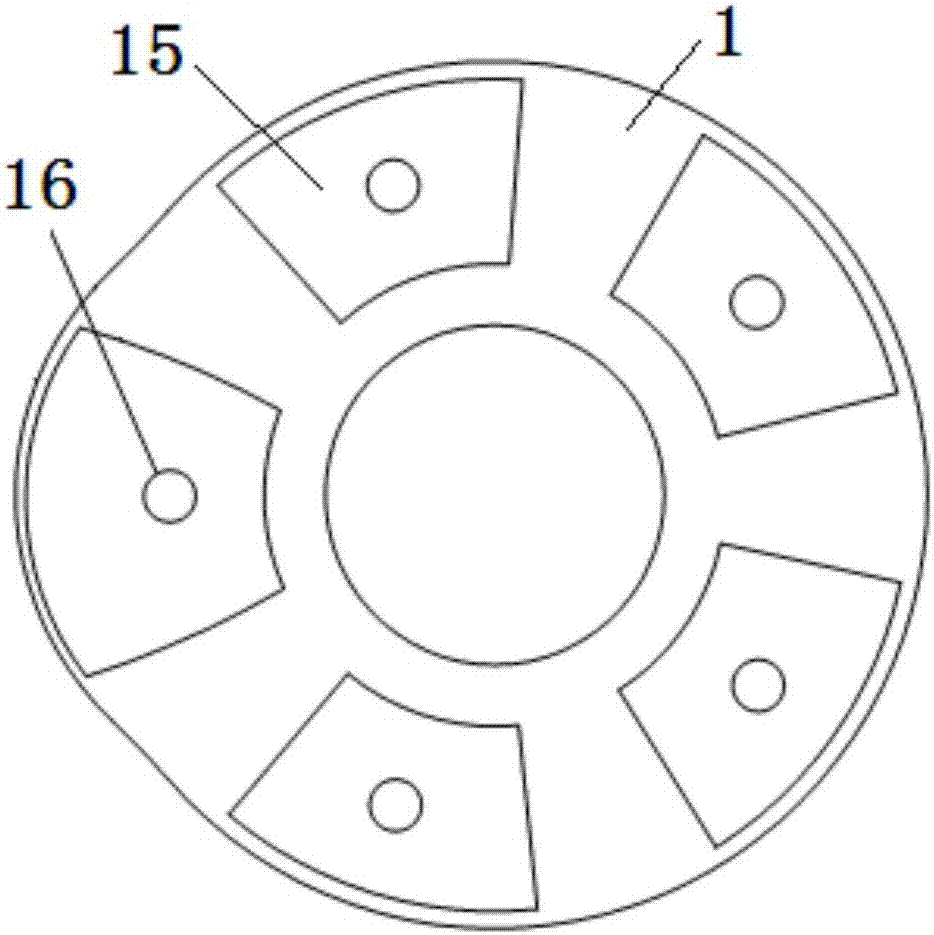

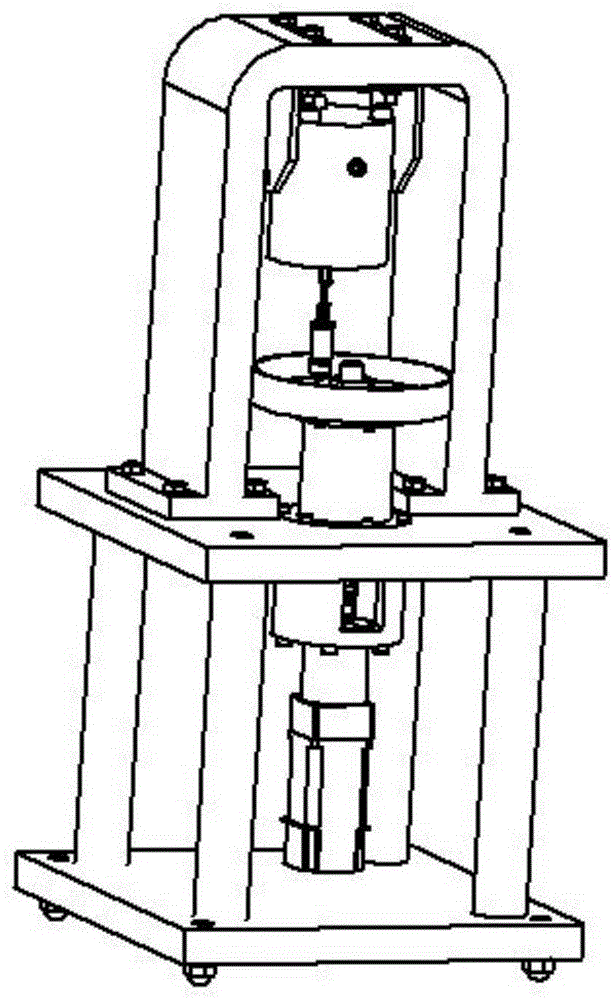

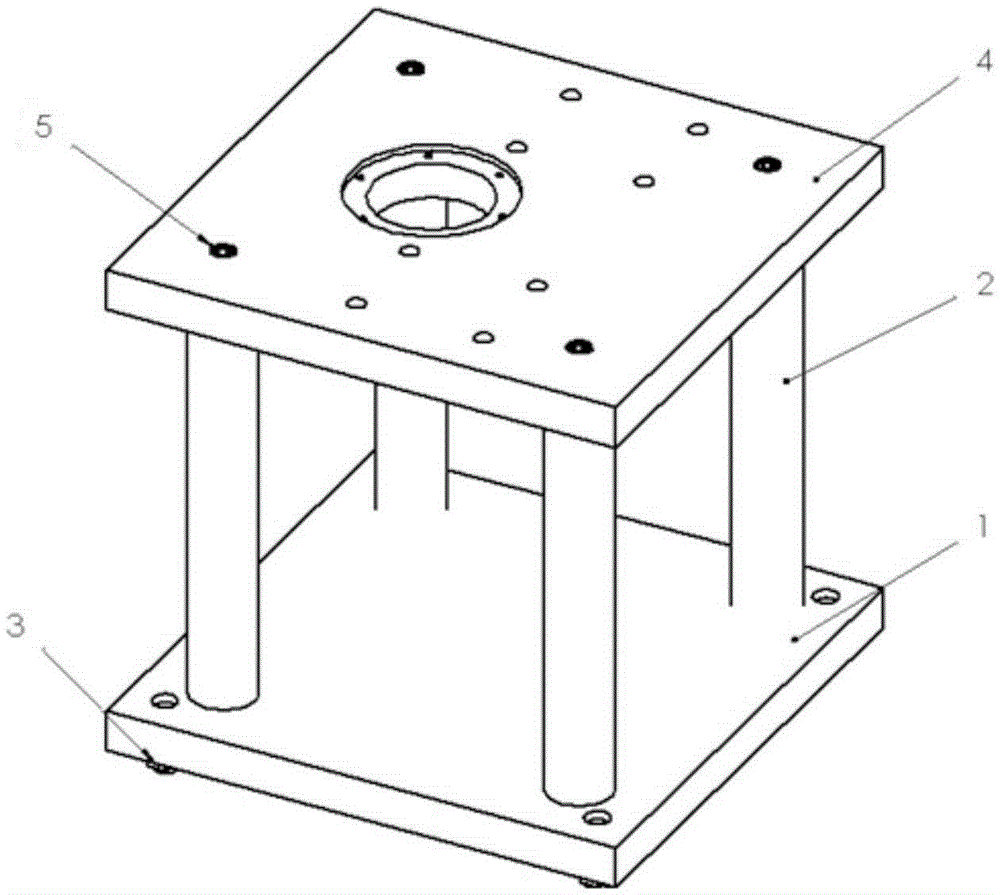

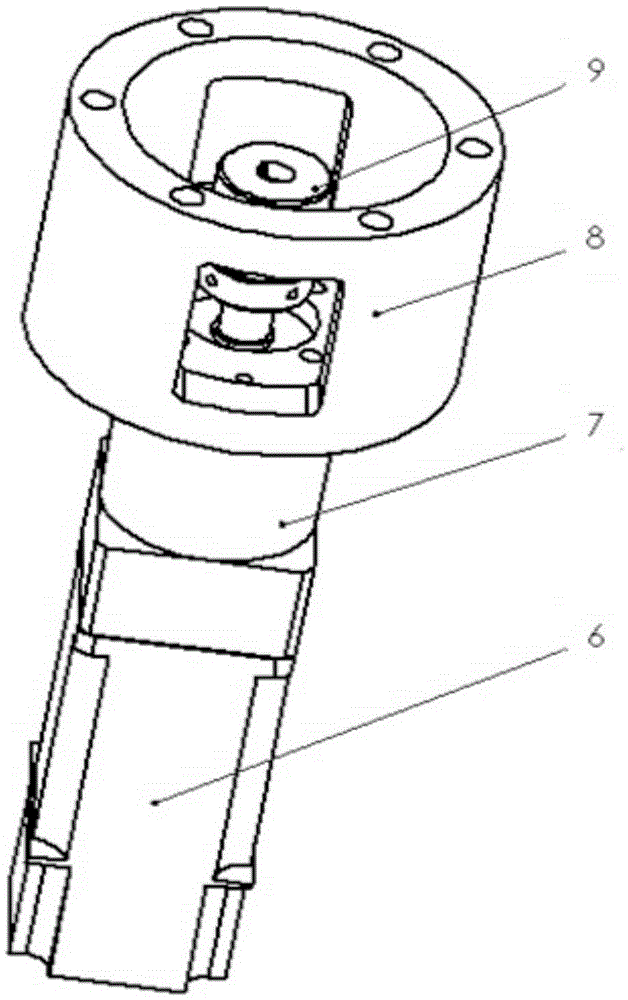

Small-load impact abrasion testing machine with tangential velocity

InactiveCN105300823AGood reproducibilityHigh degree of automationInvestigating abrasion/wear resistanceCouplingSoftware engineering

The invention provides a small-load impact abrasion testing machine with a tangential velocity. The small-load impact abrasion testing machine comprises a substrate, a motion system, a test piece installation system and an impacting device, wherein the substrate is provided with an upper table top 4 and a lower bottom plate 1; the upper table top 4 is provided with an installation hole; the motion system is arranged between the upper table top 4 and the lower bottom plate 1 and is fixedly connected with the upper table top 4 through a fixing device; the motion system is provided with a coupler 9 and is connected with the test piece installation system 6 through the coupler 9; the test piece installation system comprises a main shaft 16 and a disk test piece 11 installed above the main shaft 16. The testing machine is suitable for a small-load impact abrasion test, the abrasion experiment of an impact working condition of the tangential velocity can be realized through the arrangement of the impact device, the motion system and the test piece installation system, and the small-load impact abrasion testing machine has the advantages of high automation degree, stable working load, good lasting work capability, high precision and good test data reproducibility.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

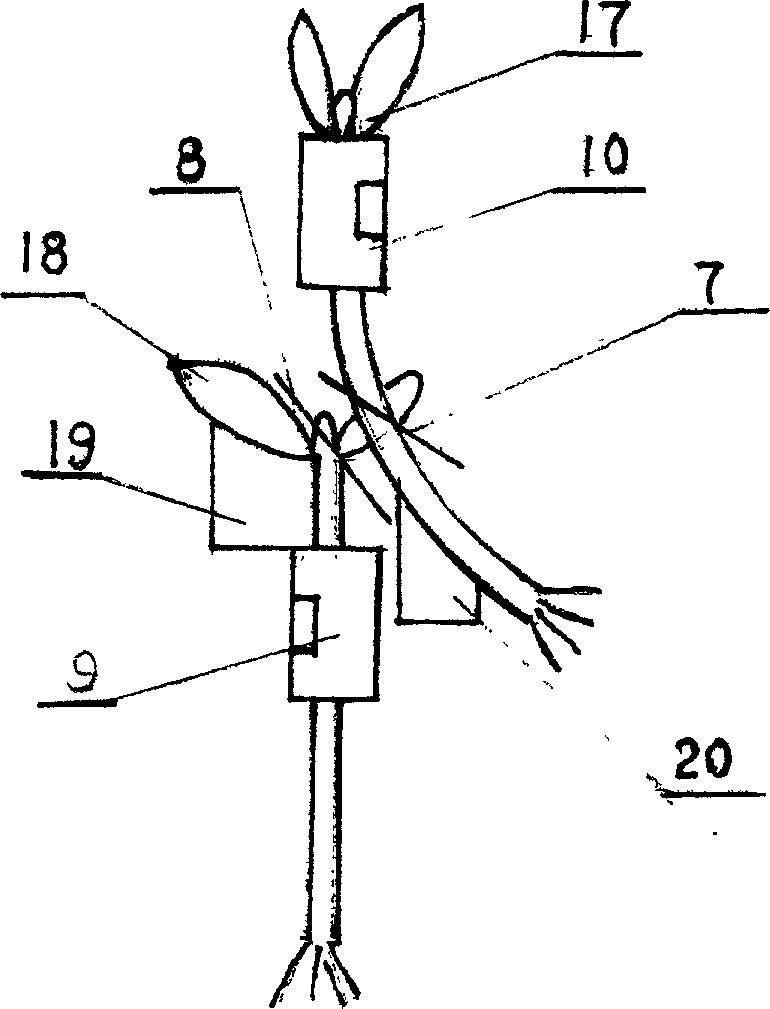

Automatic grafting machine for vegetable

There is disclosed an automatic vegetable grafting machine for vegetable grafting. Its stake clamp, which is on the operating platform, is aligned with the center of the graft clamp. The graft clamp's two explorators positions can be adjusted according to the sprout size; one leaf of stake sprout is relied to the exploratory, and scion stalk is relied to the exploratory and is a little bent. The stake and the graft incision fold automatically because of the two knives relative positions on knife-carrier slide and the graft scion bending. Wherein, compression lever and support swing link are separately joined with frame by means of gemels; the stake clamp swing link and the graft clamp swing link are contacted with cam and are joined with the support by means of gemels, and control opening or shutting of the stake and the graft incision and up-or-down movement of the lifter and the knife carrier. After cutting, the stake and the graft incision ascend along the stake and the scion until the graft stalk is unbend and automatically fold with the stake sprout incision, then the stake clamp and the graft clamp open and graft is completed. The machine has simple structure and high work efficiency of 600 trees per hour.

Owner:HUNAN AGRICULTURAL UNIV

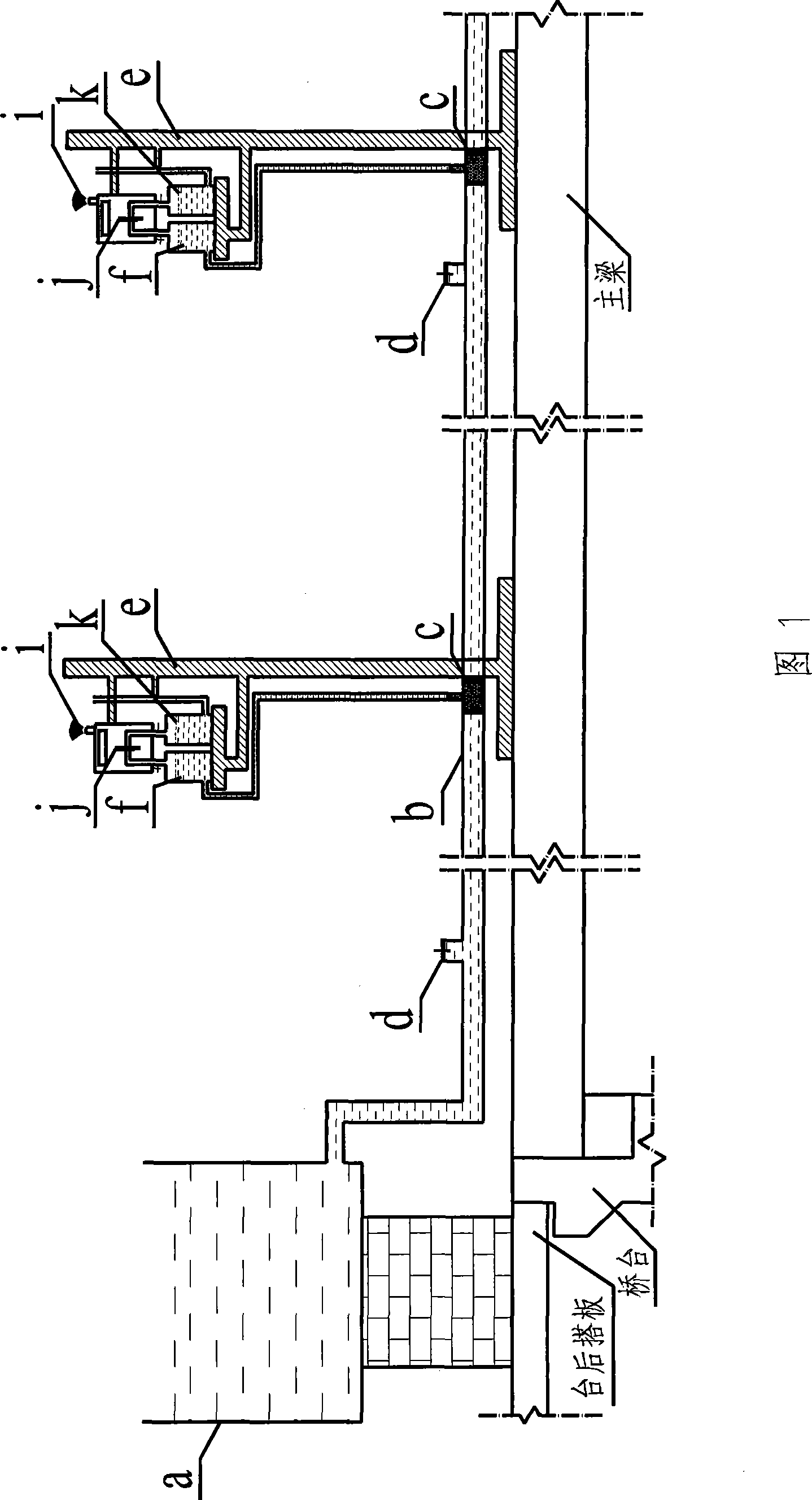

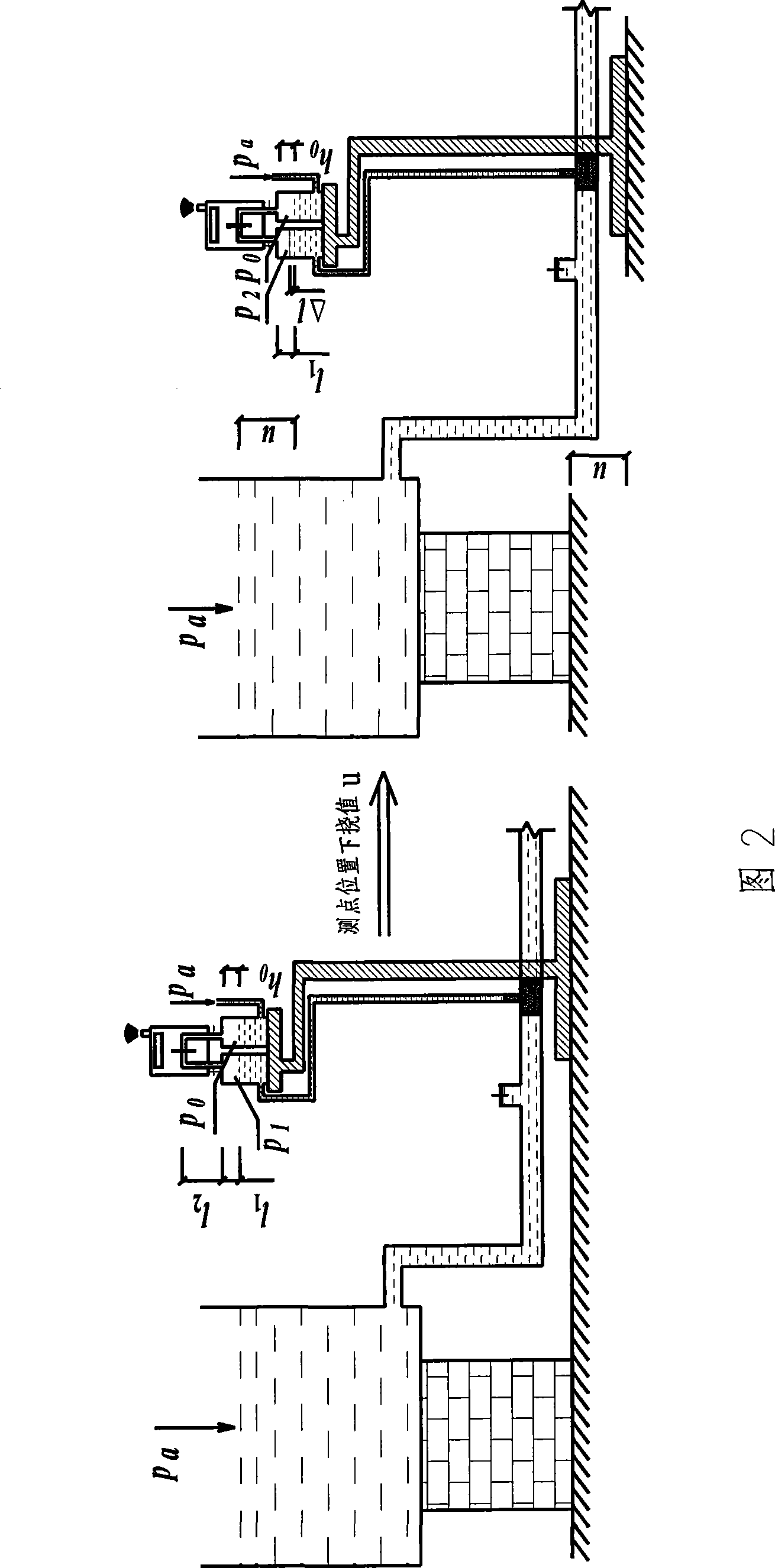

Liquid-gas coupling differential pressure type bridge deflection test method

ActiveCN101451902ASimple working principleReliable theoretical basisUsing fluid meansPressure difference measurement between multiple valvesViscous dampingDifferential pressure

The invention provides a liquid-gas coupling pressure difference type bridge deflection test method, which overcomes the defect of the prior open communicating pipe deflection test method, and converts change of liquid-gas coupling pressure difference in the whole test into change of bridge deflection, namely, gas with smaller volume is sealed at each test point end, meanwhile, because assistant actions of each gas column adjuster and a liquid adjusting box, liquid in a communicating pipe is in a quasi stationary state during whole test. The method effectively overcomes viscous damping force and capillary effect generated due to relative flow between a pipe wall and the liquid, in addition, the method transmits pressure reading of an air pressure difference sensor to a signal acquisition system conveniently in time through a signal transmitting device, so as to calculate a deflection value of each test point. Therefore, the method not only has high measuring accuracy, but also has high measuring efficiency and higher utility value.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

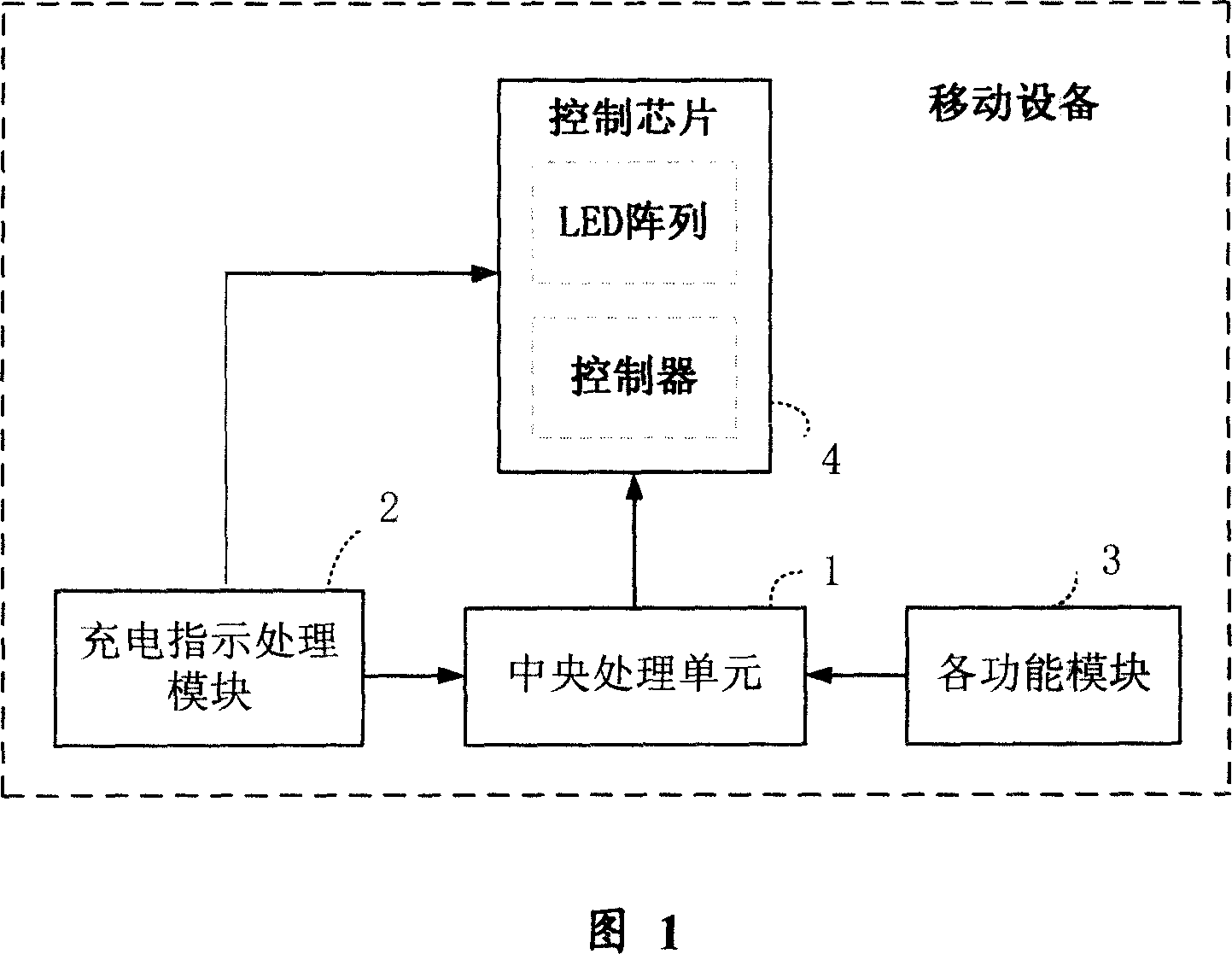

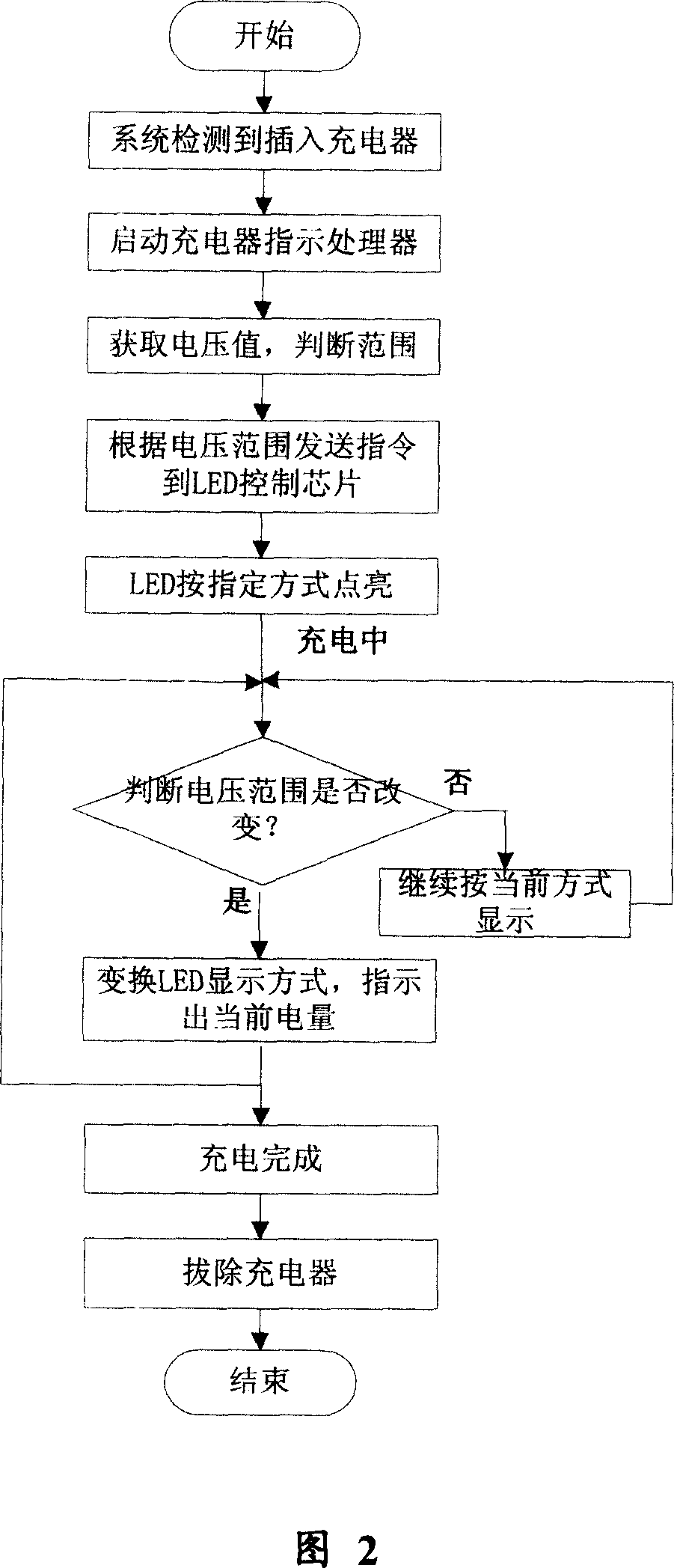

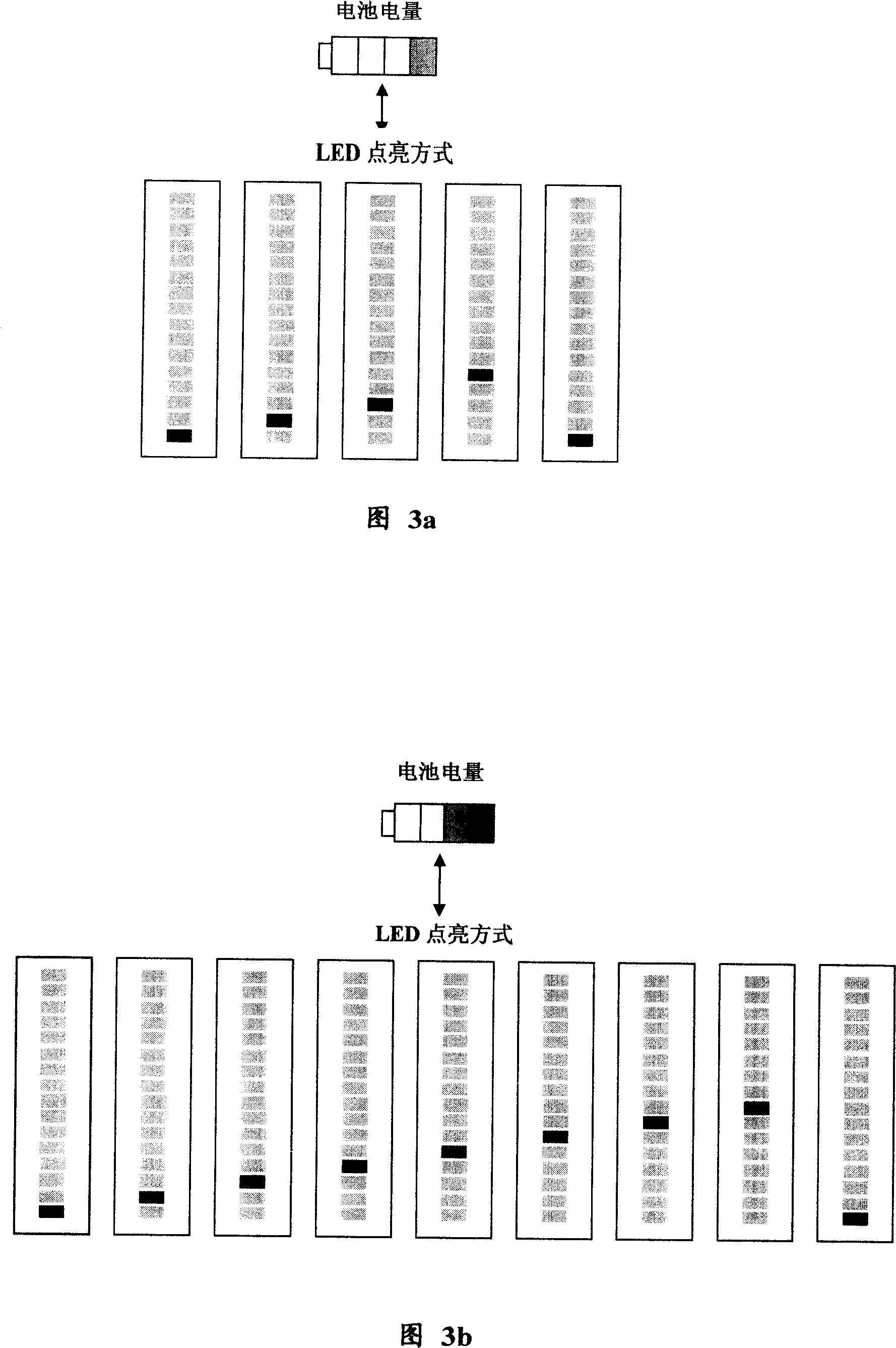

Charging guage device and indicating method for mobile equipment

InactiveCN101119032AImprove visual effectsSimple working principleBatteries circuit arrangementsElectrical testingElectrical batteryVoltage

The present invention relates to a charging progress indicating device and operational method of mobile device. The device includes a CPU, each functional modules, a charging inducting processing module, a LED controlling module and a LED array; the charging inducting processing module is connected with the CPU, and is connected with the LED array by the LED controlling module. The method includes the steps as follows: starting to charge, starting the charging inducting processing module, acquiring voltage value of the charging battery to make the area judgment, sending the section display controlling instruction to the LED controlling module according to the judgment result, starting up the LED array to lighten and display, then charging process is finished. The charging progress indicating device and method at the mobile device can easily get the detailed information of the current charging progress and the charging quantity, to form the best vision effect, so the present invention is beautiful and practicable; the operation principle is simple, and the using is convenient and quick, the operation progress is stable and accurate, so the present invention is suitable for a wider using range, to bring the greater convenience for using the mobile device.

Owner:YINGHUADA (SHANGHAI) ELECTRONIC CO LTD

Full-automatic paint spraying production line

ActiveCN105834034ASimple working principleHigh degree of automationSpraying apparatusPretreated surfacesLacquerEngineering

The invention discloses a full-automatic paint spraying production line. The full-automatic paint spraying production line comprises a feeding region, a drying region, an automatic primer / colored paint spraying region, a primer leveling and drying region, a pre-spraying region, an automatic UV paint spraying region, a UV leveling and curing region, a discharging region, a master control machine and a slave control machine. The drying region comprises a heating and dehumidifying device. The automatic primer / colored paint spraying region and the automatic UV paint spraying region are completely the same in structure. The full-automatic paint spraying production line comprises automatic paint spraying equipment. The primer leveling and drying region comprises a leveling and drying machine. The UV leveling and curing region comprises a leveling and curing machine. After being fed from the feeding region and dried in the drying region by means of the conveying chain, helmets to be sprayed with paint are subjected to primer / colored paint spraying, leveling and drying, UV paint spraying and leveling and curing and are finally discharged from the discharging region by means of the conveying chain. The full-automatic paint spraying production line is simple in principle and high in automation degree, production cost is saved, labor intensity is reduced, production efficiency is improved, and the enterprise market competitiveness is improved.

Owner:ZHEJIANG HUAAN SECURITY EQUIP

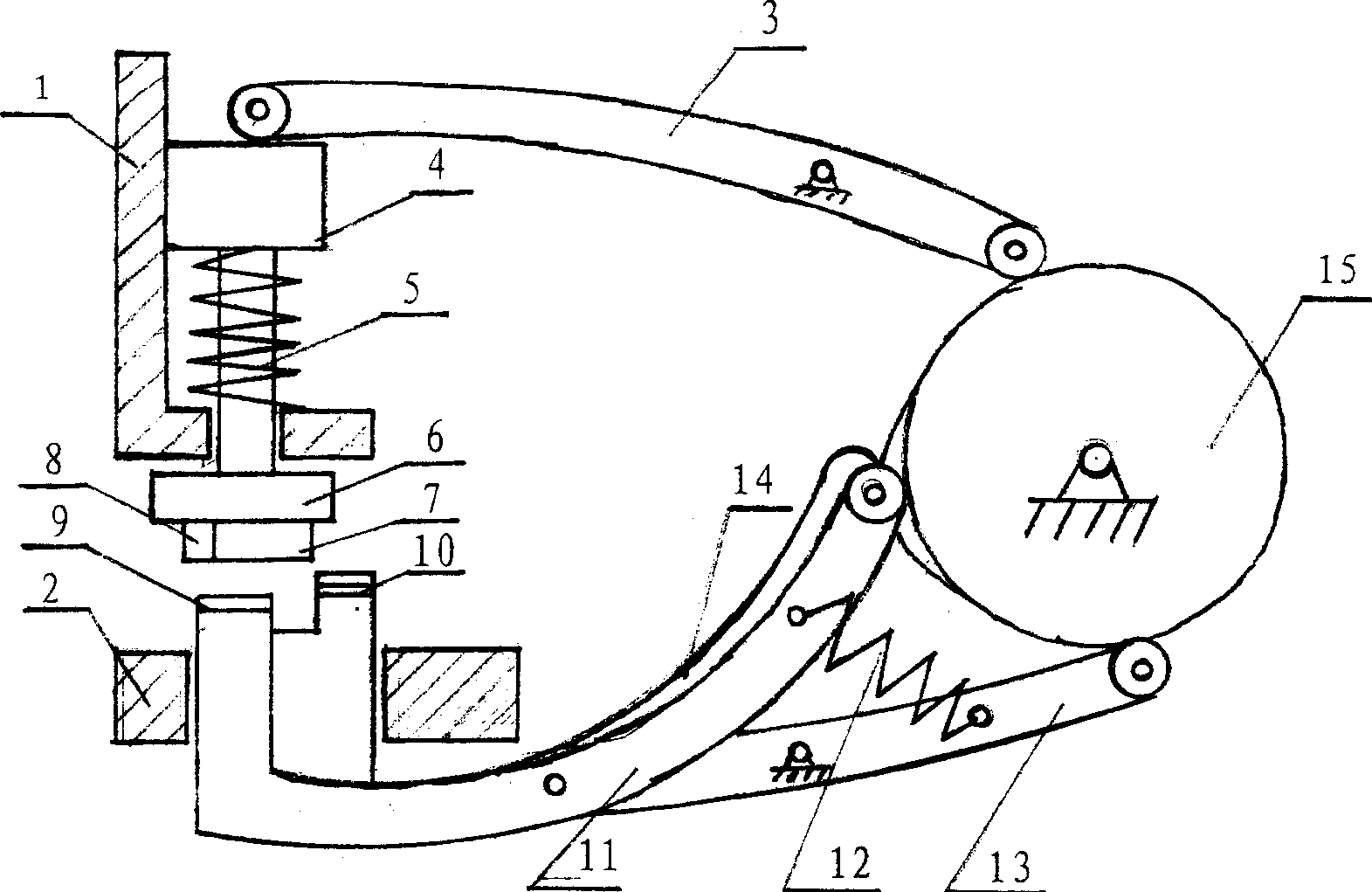

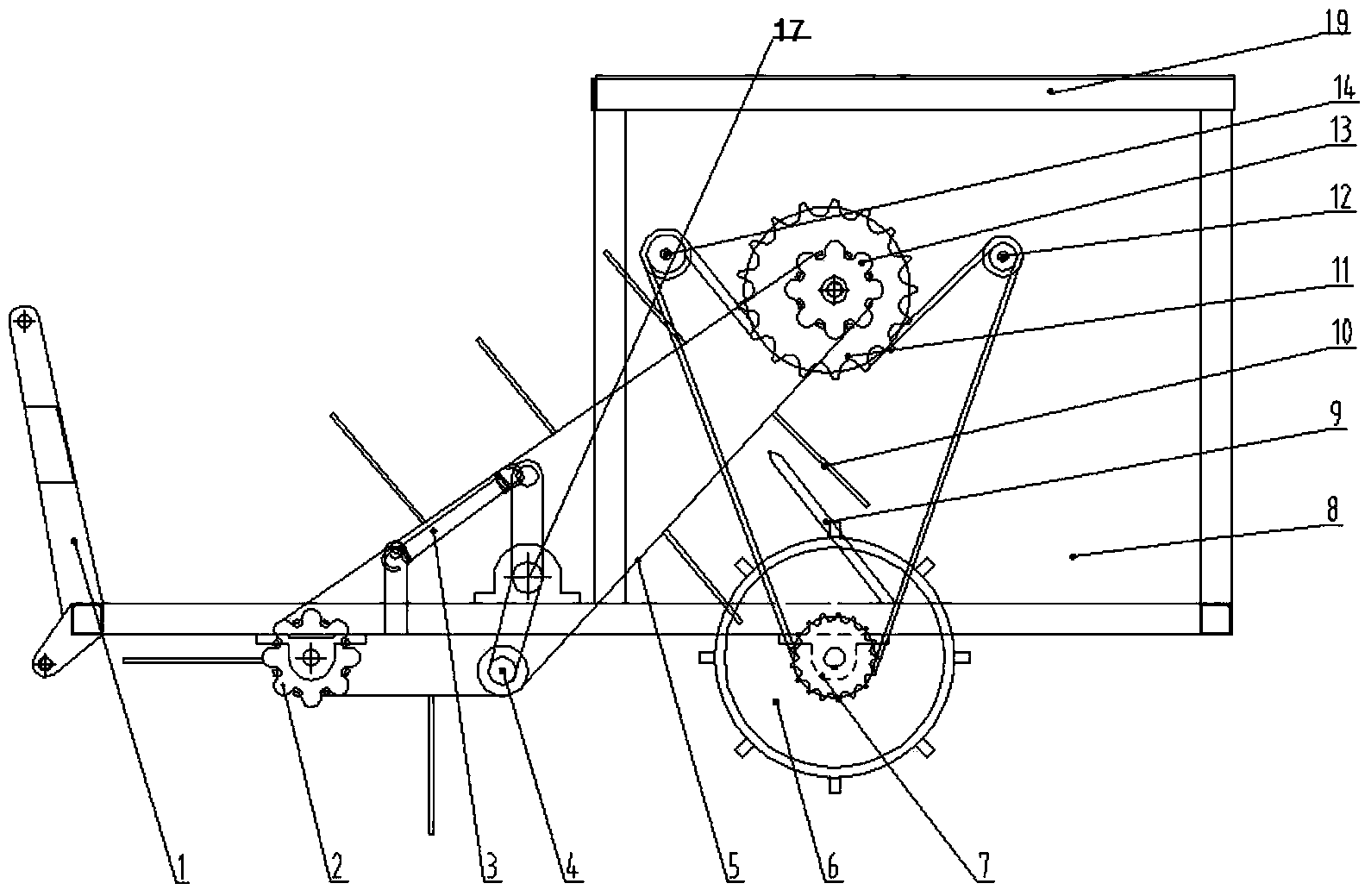

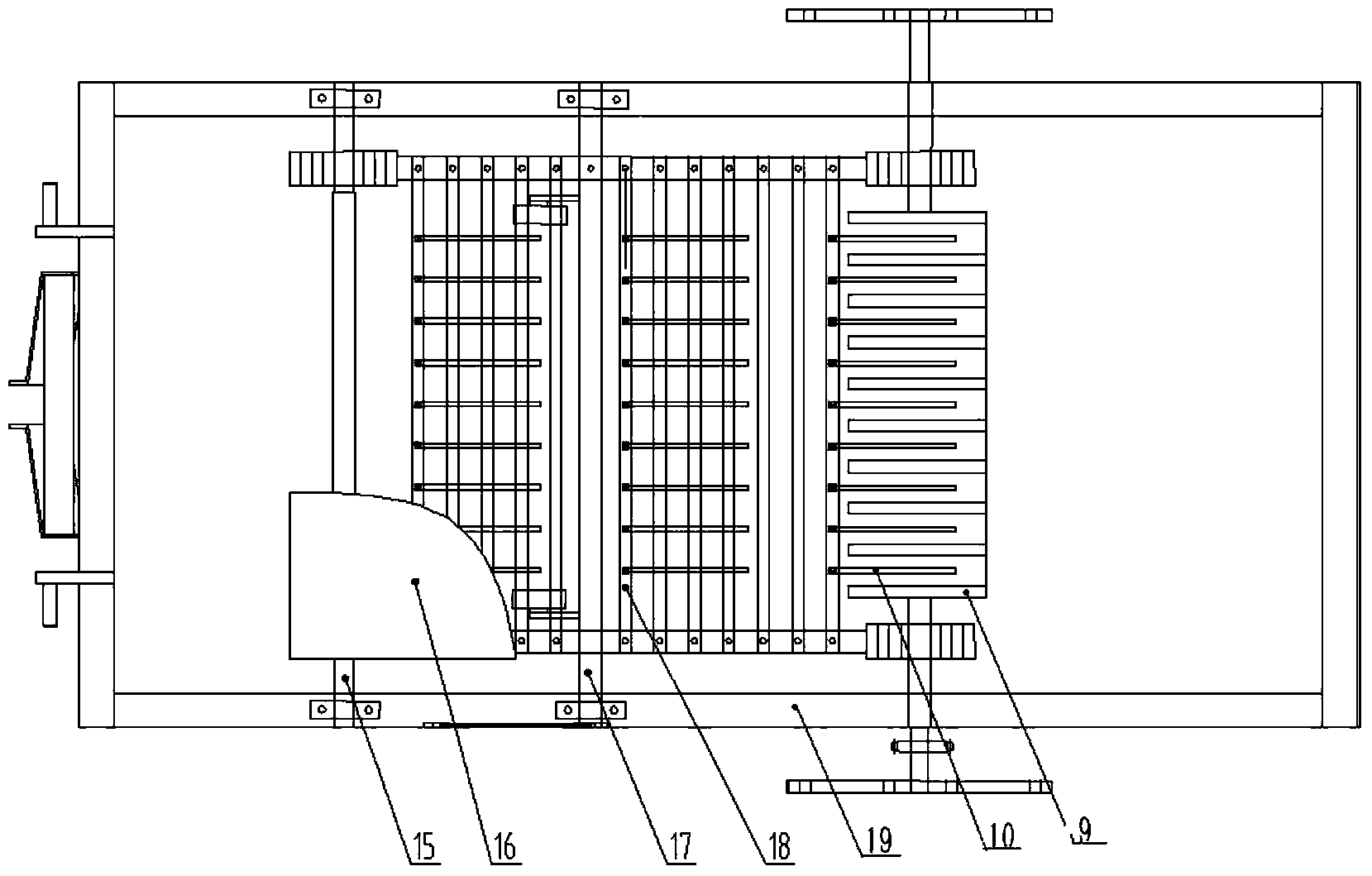

Elastic toothed chain wheel plastic film residue recycling machine

InactiveCN104303628ASimple working principleEasy maintenanceGatherer machinesEngineeringPlastic film

The invention belongs to the field of agricultural machinery and particularly relates to an elastic toothed chain wheel plastic film residue recycling machine which is applicable to crops with regular film mulching and small stubbles. The elastic toothed chain wheel plastic film residue recycling machine is reliable during working, simple in structure and easy to implement. The elastic toothed chain wheel plastic film residue recycling machine is simple in working principle, the motive power is provided by land wheels without an extra power system, the film recycling is reliable, the maintaining is convenient, elastic teeth with a certain elasticity are used as lifting teeth, the lifting teeth can be prevented from being bent or broken when meeting hard objects in a field, and light and leak-proof films are applied to a crawler belt so that a mulching film can be prevented from being stuck to the crawler belt during picking up.

Owner:CHINA AGRI UNIV

Rectangle substrate integrated waveguide back cavity linear polarization antenna

InactiveCN101183742AReduce volumeReduce manufacturing costWaveguide mouthsRadiating elements structural formsDielectric substrateCoplanar waveguide

The invention relates to a polarized antenna with wave guiding cavity-backed lines integrated on a rectangular substrate. The traditional polarized antenna has the disadvantages of low performance of single radiation unit, large bulk, complex structure and high manufacturing cost. The dielectric substrate of the invention is plated with metallic layers on two sides; the upper metallic layer is etched with a microstrip line for feeding and a plurality of coplanar wave guiding transmission lines; the coplanar wave guiding transmission lines are grounded coplanar wave guiding structure, wherein, the metallic strip in the middle is extended outwards to form the microstrip line. A plurality of metallized through holes, which are arrayed as a square, are penetrated through the upper metallic layer, the medium substrate and the lower metallic layer to form the cavity; the coplanar wave guiding transmission lines are extended into the cavity. An elongated radiation slit is etched on the lower metallic layer corresponding to the cavity. The invention has the advantages that: by adopting the general PCB technology, the production cost is notablely decreased and the invention can be integrated with the microstrip circuit without seam, the integrity of the system is improved; compared with the exact machining of the traditional cavity-backed antennas, the manufacture speed is high and the cost is low.

Owner:舟山亿佳电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com