Railway bridge double spherical surface shock absorption and separation mount

A double-spherical, shock-absorbing and isolation technology, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problems that the shock-absorbing and isolating bearings cannot be applied, the seismic force and energy are large, and the shear stiffness is small, and the working principle is simple. Clear, good earthquake period, and reduce the effect of vertical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

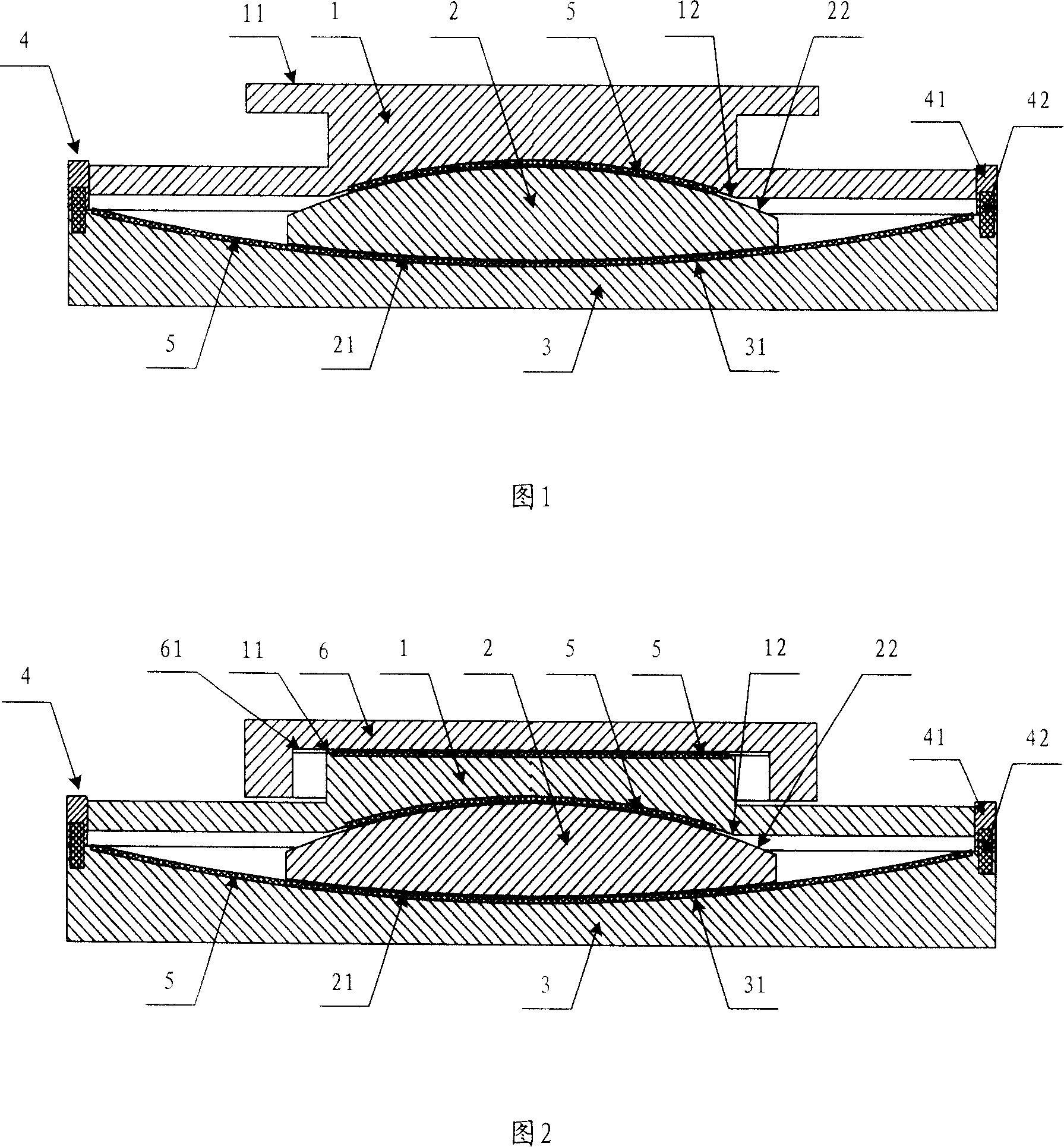

[0018] Fig. 1 is a schematic structural diagram of the first embodiment of the present invention. As shown in Figure 1, the double-spherical seismic isolation bearing of the railway bridge in this embodiment includes an upper bearing plate 1, a middle bearing plate 2 and a lower bearing plate 3, and the upper surface of the lower bearing plate 3 is set as a concave spherical surface 31 , the lower surface of the middle support plate 2 is set as a convex spherical surface 21, and the concave spherical surface 31 and the convex spherical surface 21 have the same large radius of curvature, and a polytetrafluoroethylene sliding plate 5 is arranged between them to form a spherical sliding friction surface, which is used in earthquakes. Provide the displacement that consumes the seismic energy, and provide the required self-resetting ability through the self-weight of the structure, so that the upper structure returns to its original position. The lower surface of the upper support ...

no. 2 example

[0025] Fig. 2 is a schematic structural diagram of the second embodiment of the present invention. This embodiment is a movable support formed by adding a translational friction surface on the basis of the technical solution of the fixed support of the first embodiment shown in Fig. 1 . As shown in Figure 2, the double-spherical shock-absorbing and isolation bearing of the railway bridge in this embodiment includes an upper bearing plate 1, a middle bearing plate 2, a lower bearing plate 3, a top basin 6 and a polytetrafluoroethylene slide plate 5 arranged therebetween , the lower support plate 3 is fixedly connected with a shear component 4, the concave spherical surface 31 on the upper surface of the lower support plate 3 and the convex spherical surface 21 on the lower surface of the middle support plate 2 form a spherical sliding friction surface, and the lower surface of the upper support plate 1 The concave spherical surface 12 and the convex spherical surface 22 on the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com