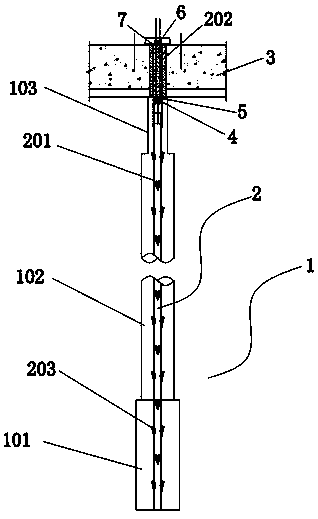

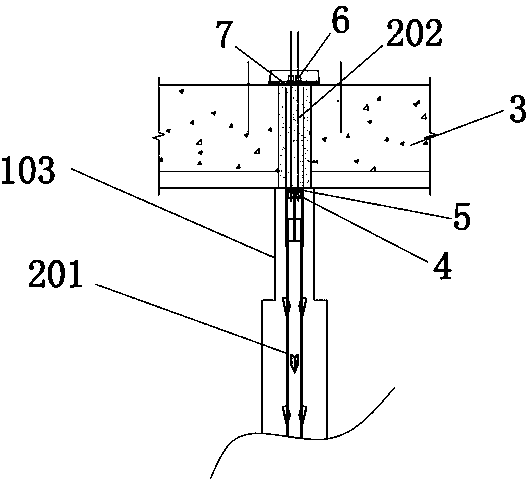

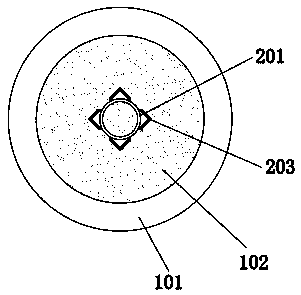

High-pressure jet grouting combined uplift pile for existing building and construction method

A high-pressure rotary grouting pile and high-pressure rotary grouting technology are applied in construction, sheet pile walls, foundation structure engineering, etc. It can solve problems such as bottom plate or beam-column joint cracking, small buoyancy resistance, and overall floating, so as to avoid structural cracking, High pull-out bearing capacity, effect of reducing vertical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] The underground passage connecting the north and south districts in a residential area is 47m long, 12m wide, and 3.8m clear. The overlying soil on the passage is about 3.8m. The pull-out bearing capacity is 300KN, the thickness of the bottom plate is 800mm, the thickness of the outer wall is 500mm, the concrete strength grade of the channel is C35, and the impermeability grade is P6. Due to the local failure of the water-stop curtain of the original foundation pit, the seepage of groundwater outside the pit caused a large buoyancy force, and the actual uplift resistance of the uplift piles could not meet the design requirements (the anchorage length of some piles was not enough), causing the channel to float up. The project uses prestressed reinforced high-pressure rotary grouting combined uplift piles to strengthen the foundation. The reinforced body is made of straight seam steel pipes with a diameter of 168x12. The high-pressure rotary grouting piles have a diameter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com