Patents

Literature

116results about How to "Improve the pull-out capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

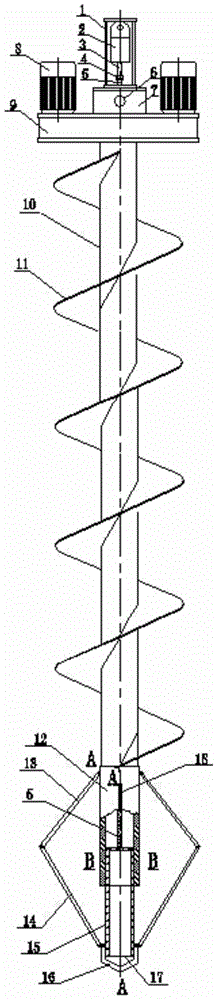

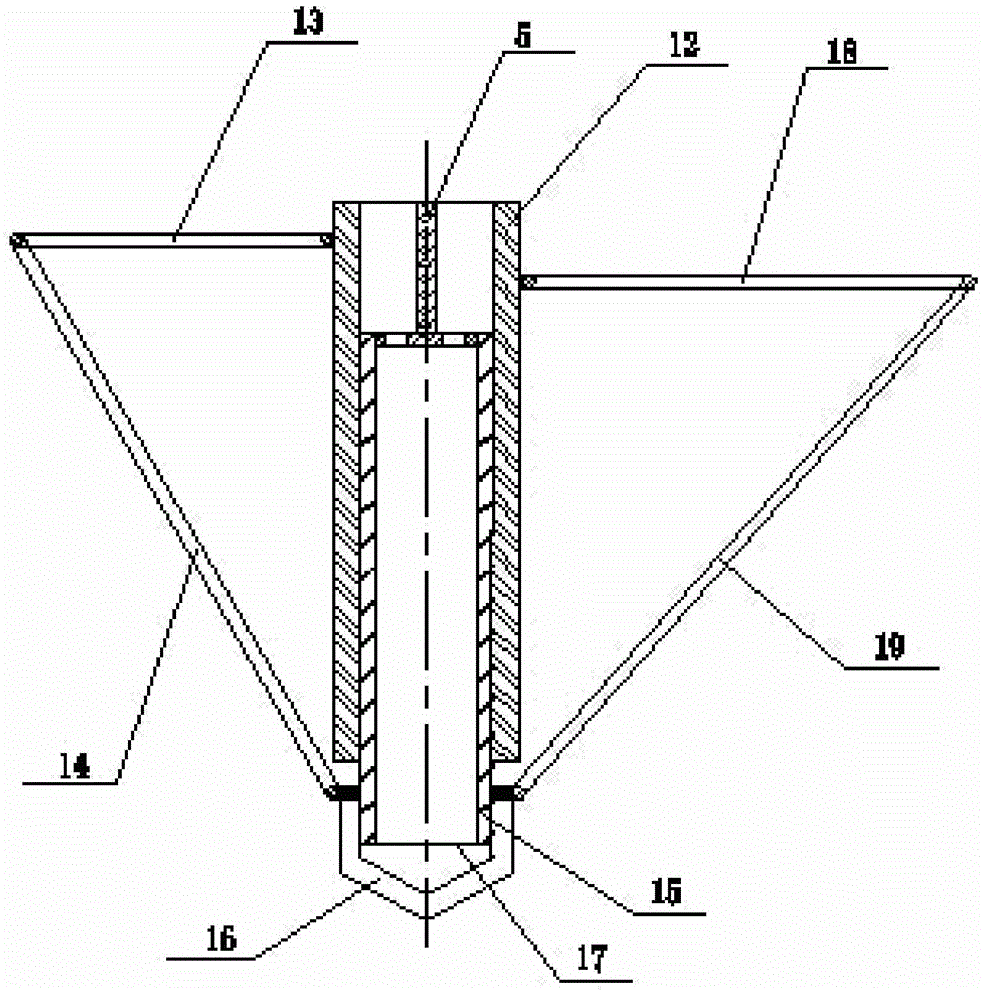

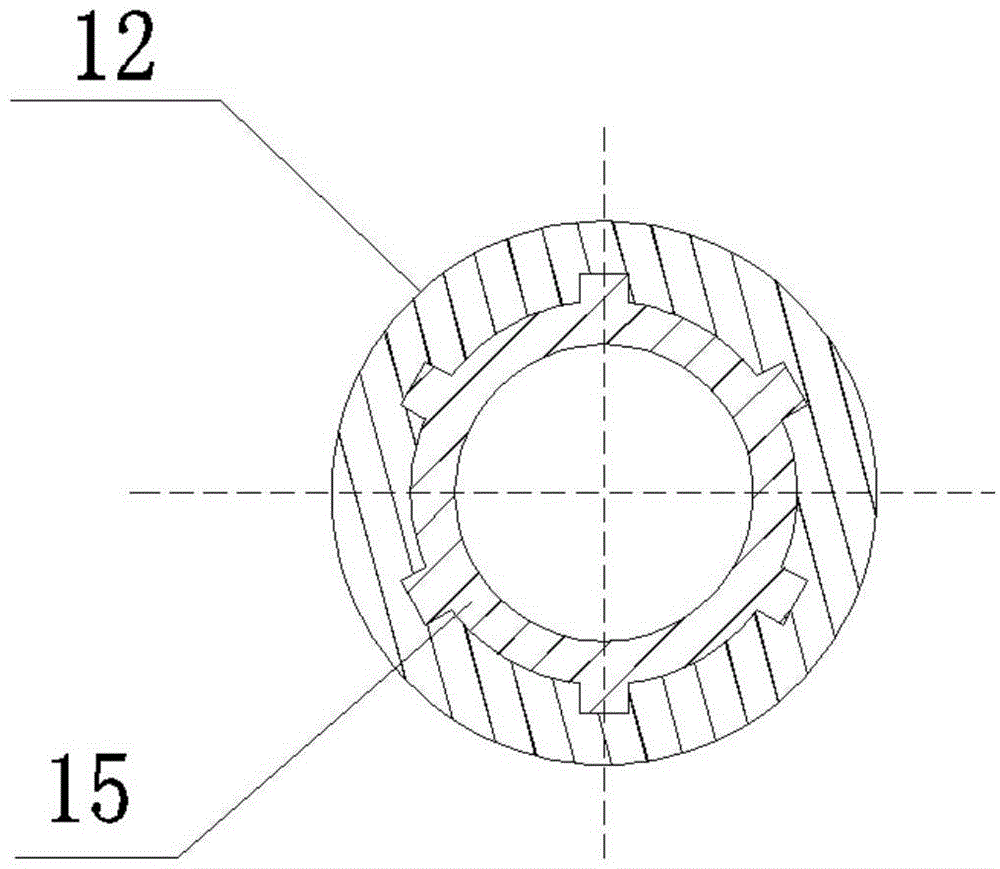

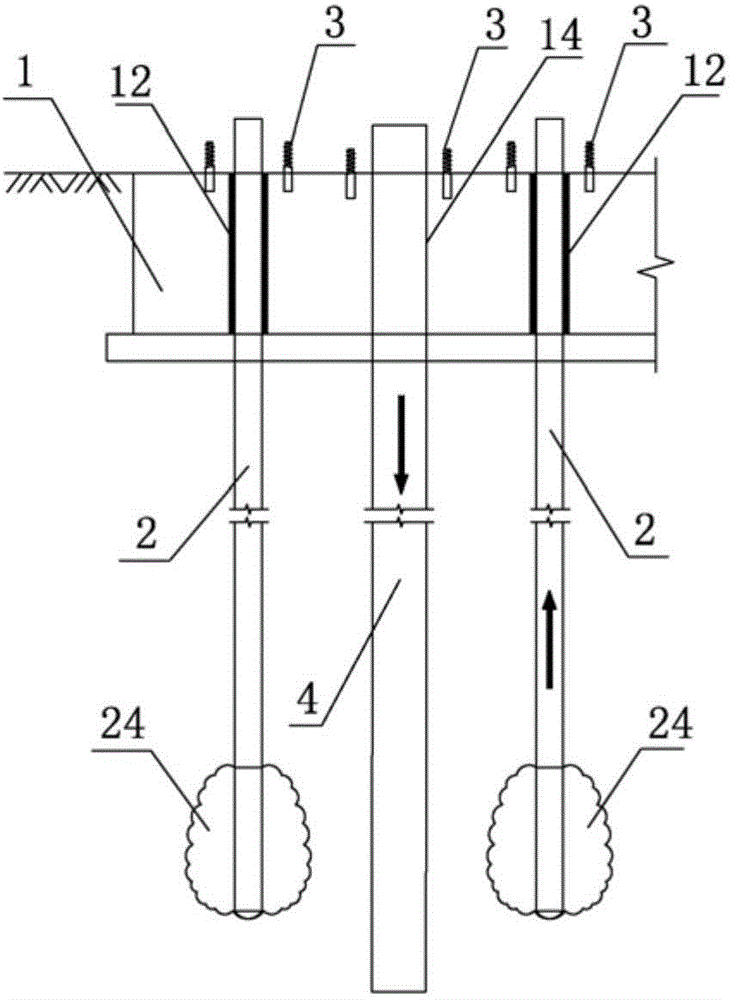

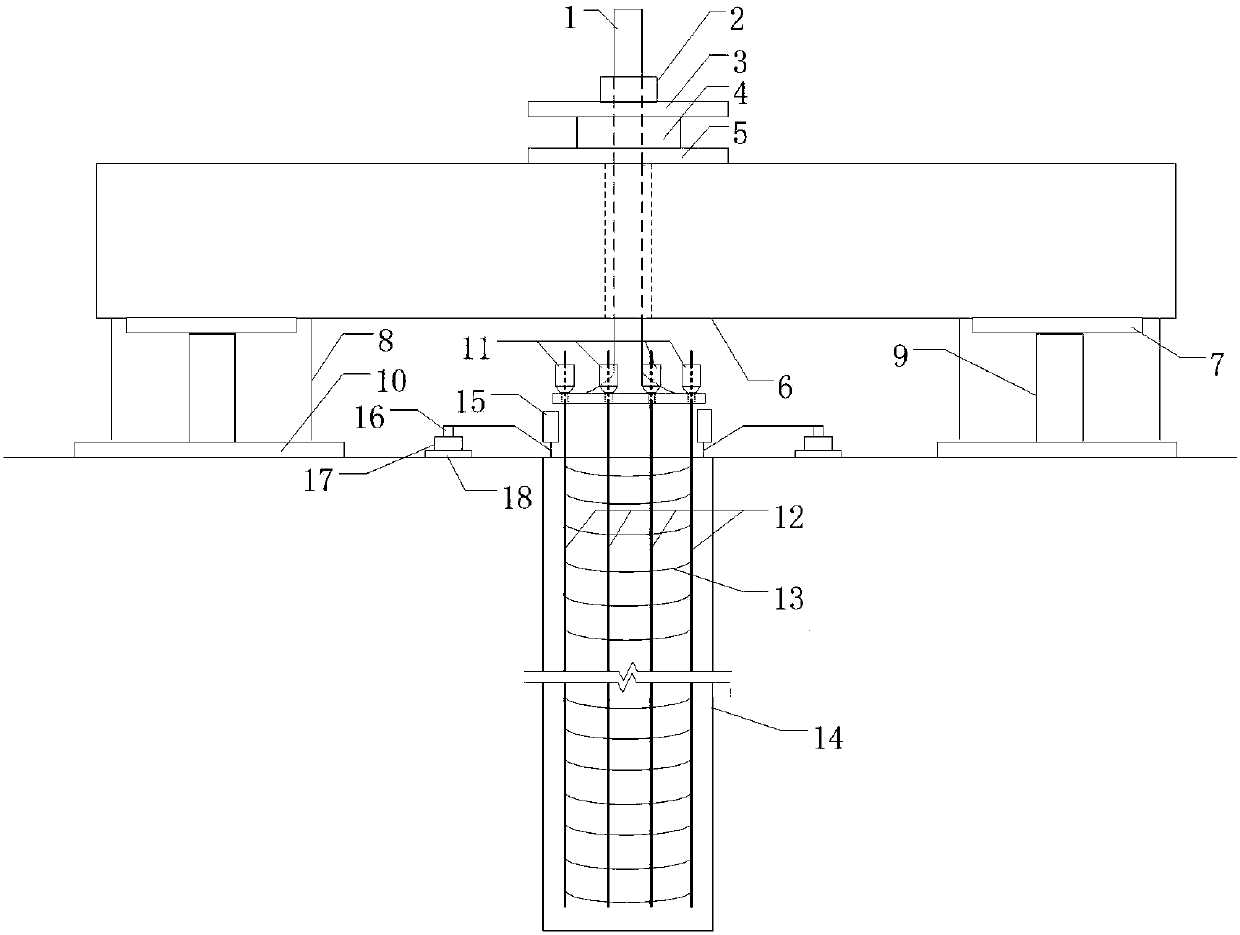

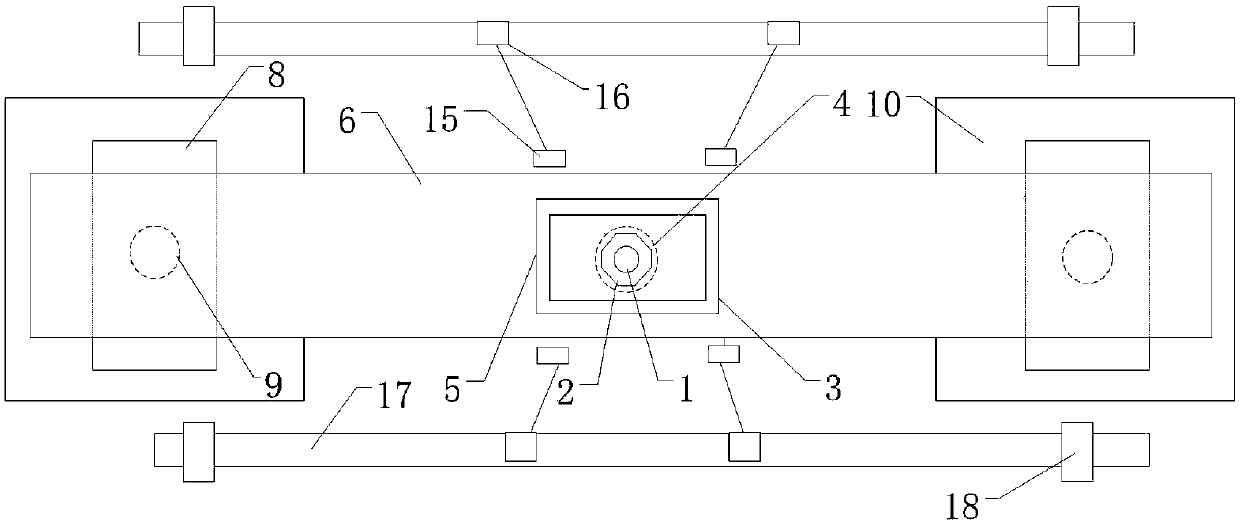

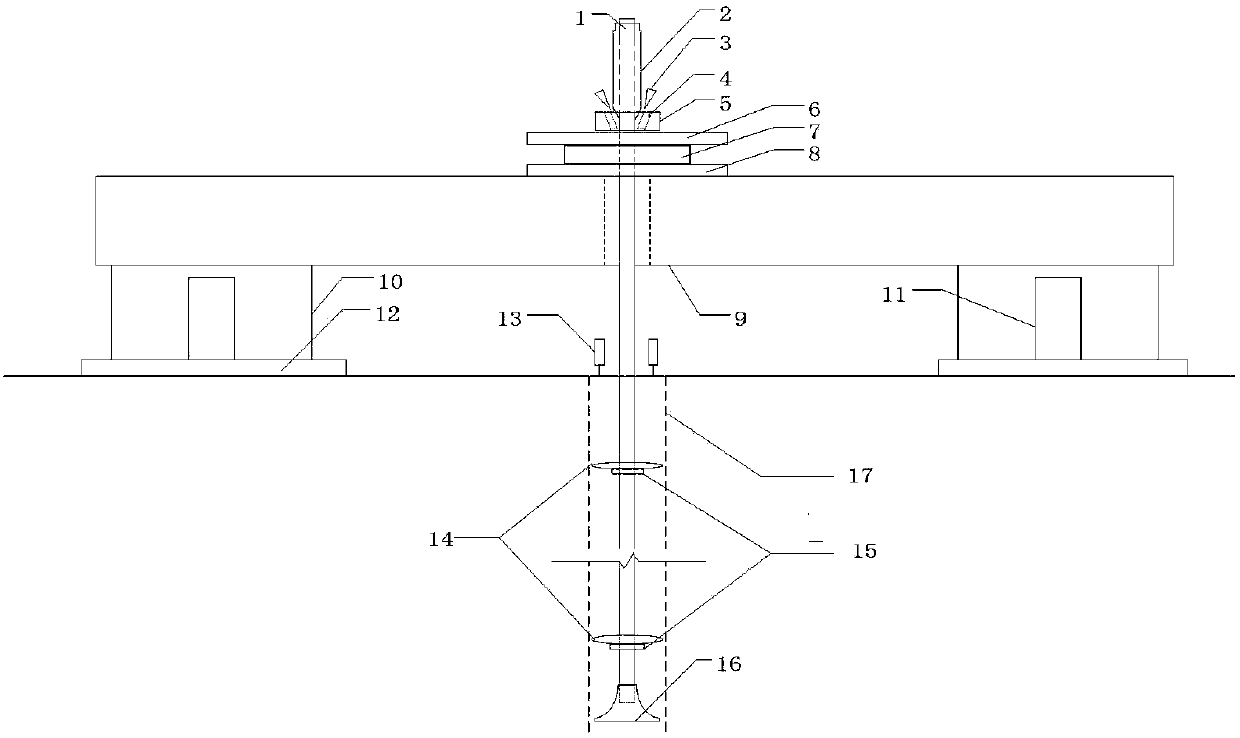

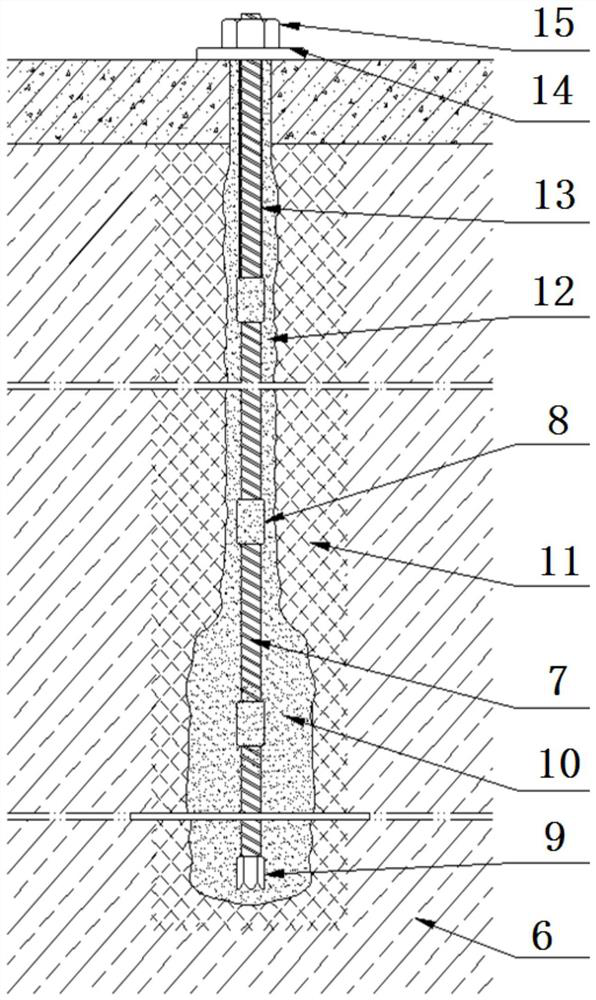

Long auger drilling and bottom expanding device and expanded anchor rod construction method

ActiveCN104453717AImprove the pull-out capacityImprove bearing capacityDrill bitsBulkheads/pilesSlurryUltimate tensile strength

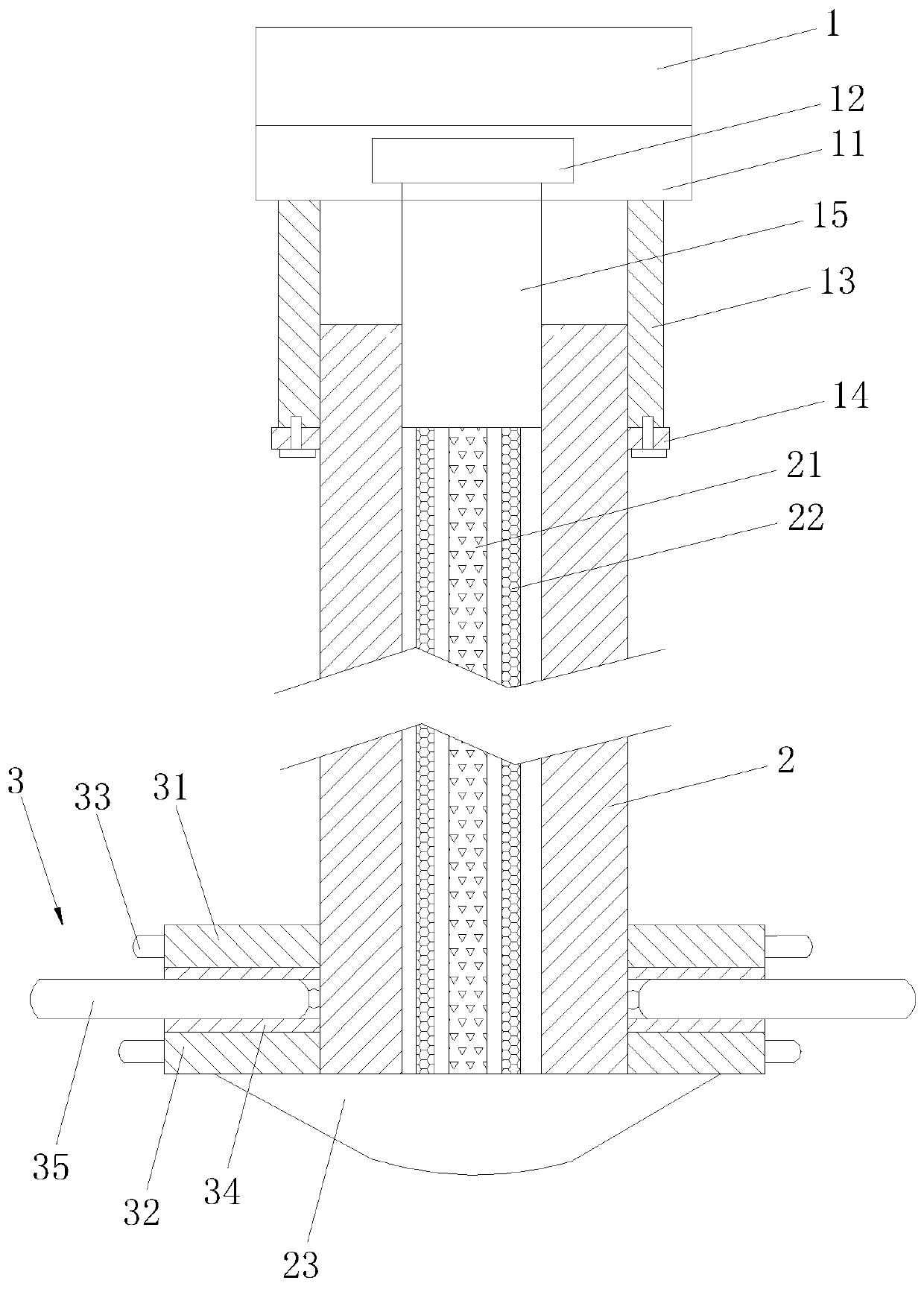

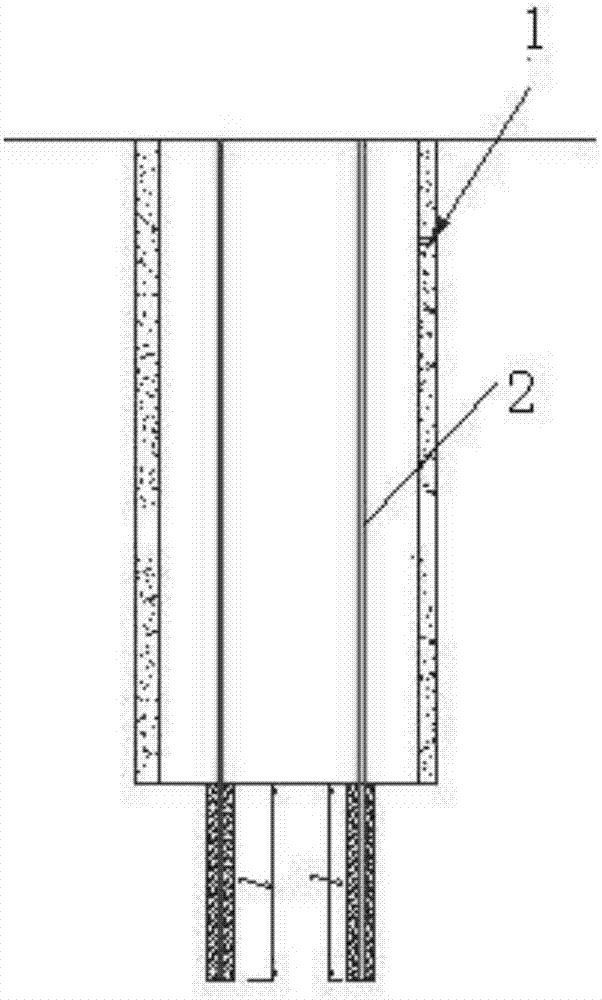

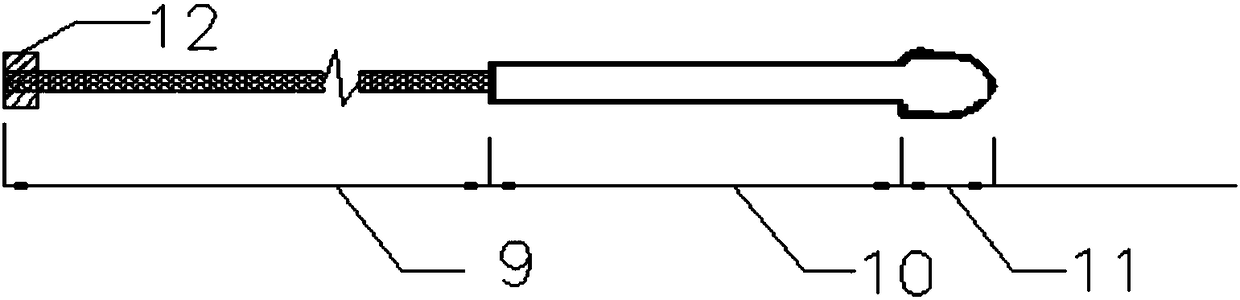

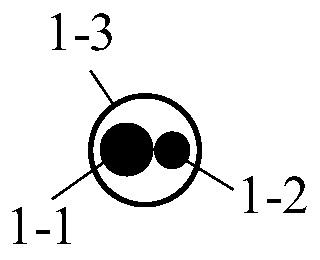

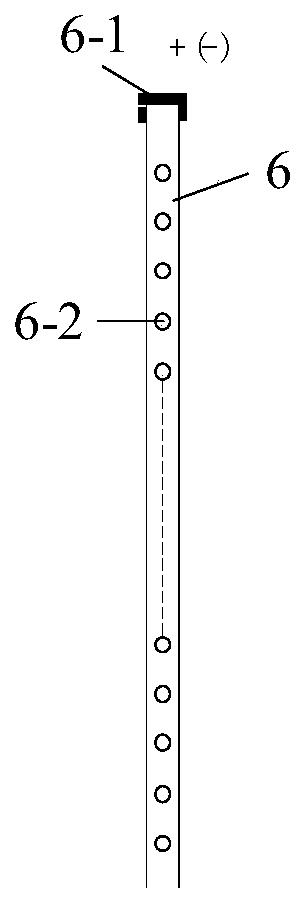

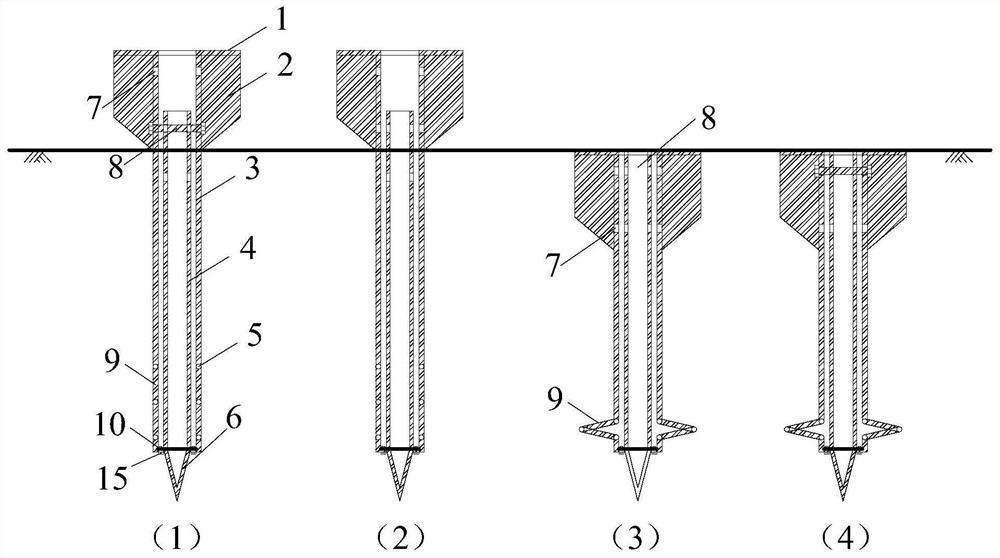

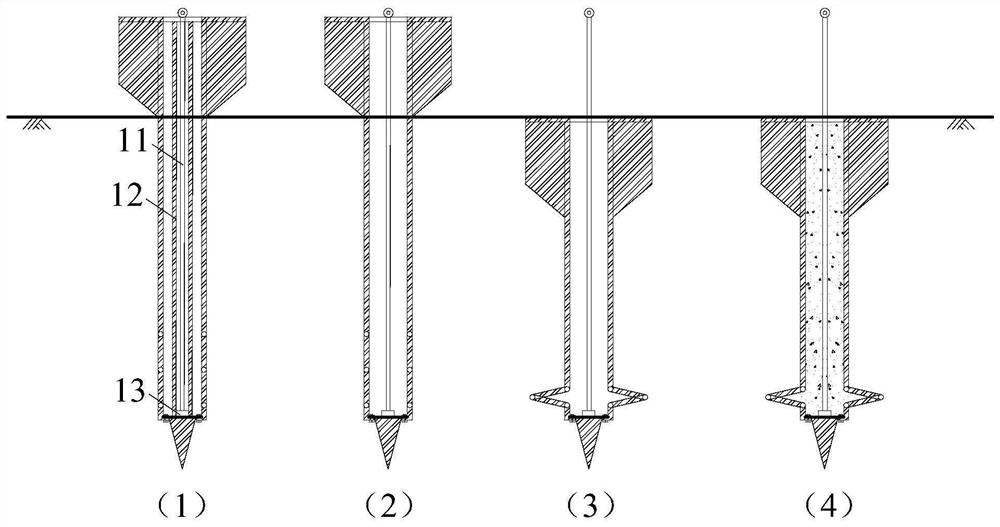

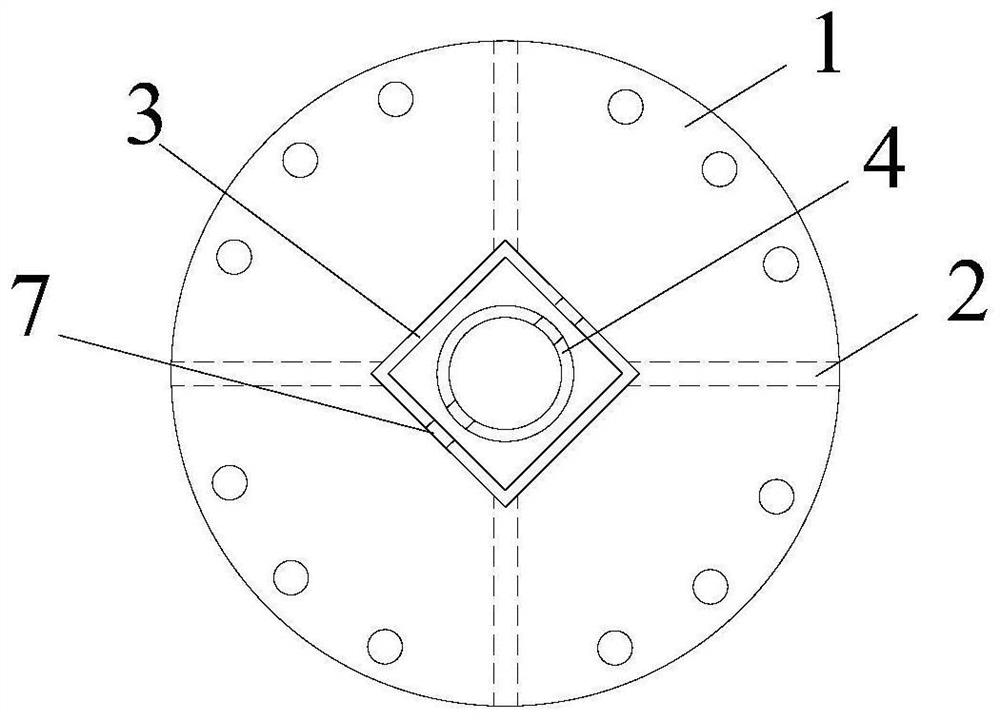

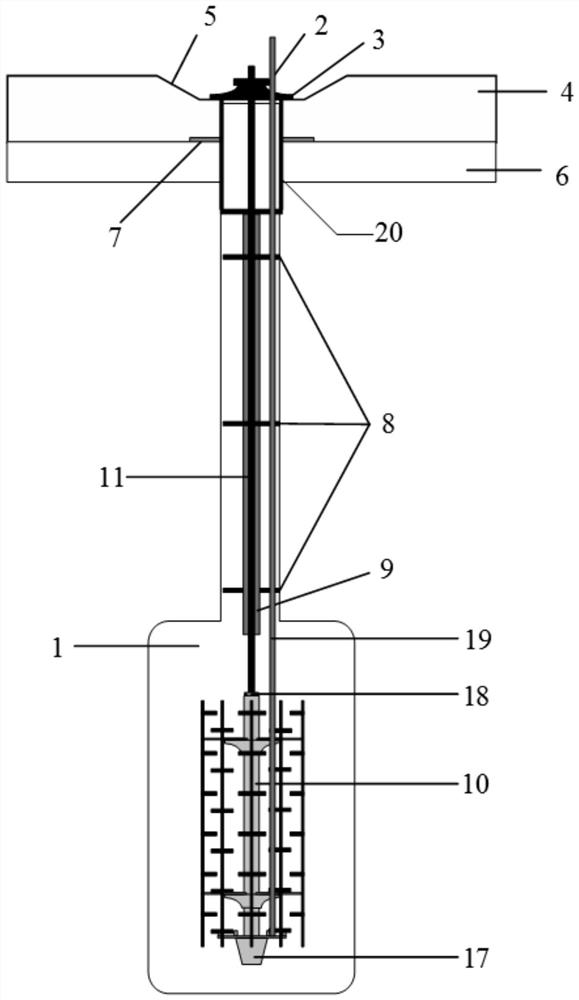

The invention relates to a long auger drilling and bottom expanding device and an expanded anchor rod construction method. The long auger drilling and bottom expanding device comprises an auger drilling rod with an auger blade and a front guide drill bit. The upper portion of the auger drilling rod is connected with a power box of a pile machine through a rotary connector, a slurry inlet is formed in the rotary connector, motors are arranged on the two sides of the upper portion of the power box, a broaching oil cylinder support and a broaching oil cylinder are arranged in the middle of the upper portion of the power box, a connecting lug is arranged in the middle of the upper portion of the oil cylinder support, the broaching oil cylinder is hinged to the broaching oil cylinder support through the connecting lug, the lower end of a piston rod of the broaching oil cylinder is connected with the top of a broaching connecting rod through a transfer connector, the lower portion of the broaching connecting rod is arranged in an axial central through hole of the auger drilling rod, a rotary broaching device is arranged between the front guide drill bit and the auger drilling rod, the lower end of the broaching connecting rod is connected with the rotary broaching device, and the lower portion of the rotary broaching device is connected with the front guide drill bit. According to the long auger drilling and bottom expanding device and the expanded anchor rod construction method, noise, vibration and slurry are avoided in the construction process, an anchoring body is high in strength, good in quality, low in cost, high in working efficiency and good in environmental friendliness, and the uplift bearing capability of an anchor rod is high.

Owner:SHANDONG ZHENGYUAN CONSTR ENG

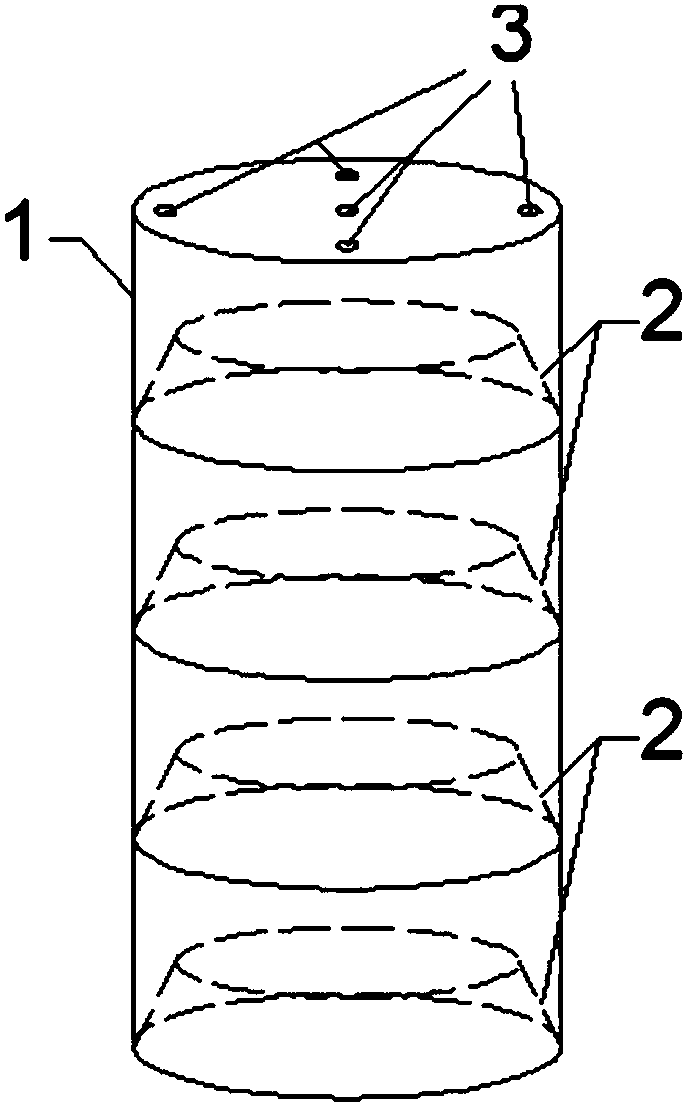

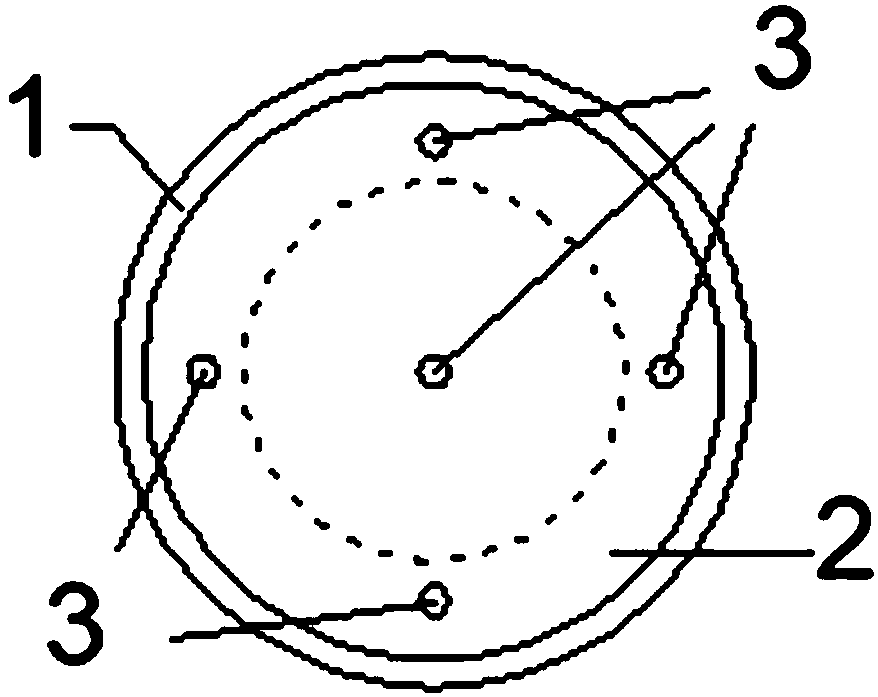

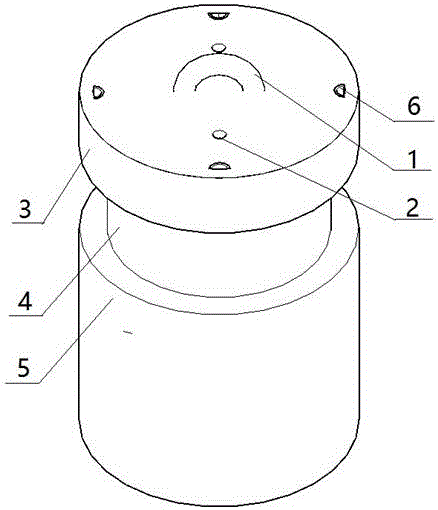

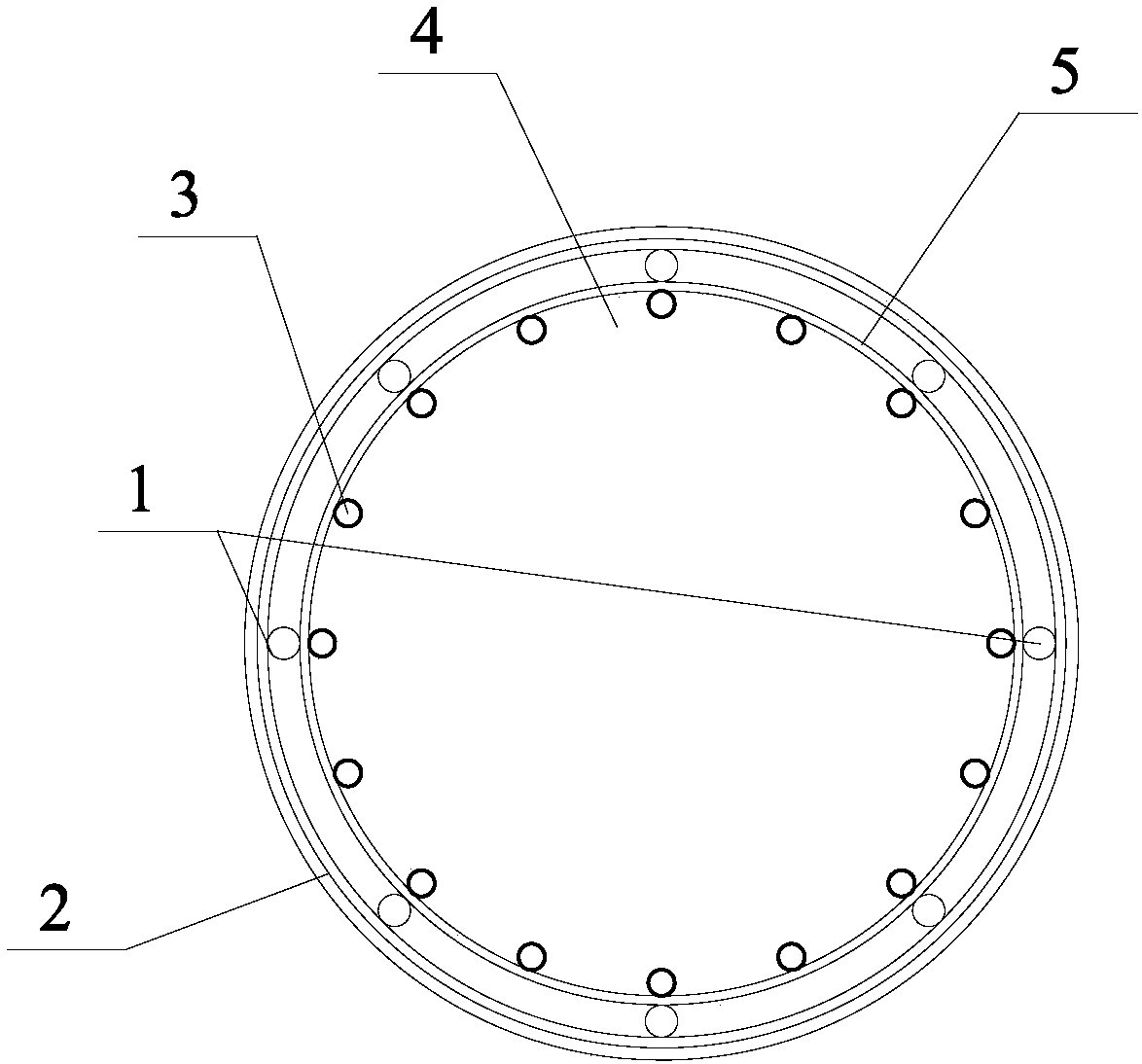

Inner ring type seabed suction anchor for deep sea and installation method thereof

ActiveCN108425379AReduce resistanceReduce construction costsFoundation engineeringSuction stressSea waves

The invention discloses an inner ring type seabed suction anchor for deep sea and an installation method thereof. The suction anchor comprises a suction main barrel, the suction main barrel is of a barrel type structure of which the bottom is opened and the top end is closed, the inner wall of the suction main barrel is provided with a plurality of hollow annular bulges at equal intervals along anaxial direction, the inner wall of the suction main barrel and the side walls of the hollow annular bulges form a barb-shaped structure, and the center and the edges of the top of the suction main barrel are provided with drainage holes. The suction anchor can more smoothly sink and penetrate into the soil, can sink to the preset design depth, reduces the disturbance to the soil outside the barrel to the maximum extent under the effect of increasing side friction resistance, and reduces the erosion of sea waves on existing foundations; the vertical bearing capacity and the ultimate pull-out resistance bearing capacity of the suction anchor can be greatly improved under various working conditions; and under the condition of realizing the functions, the convenience of recycling the suctionanchor can also be ensured.

Owner:ZHEJIANG UNIV

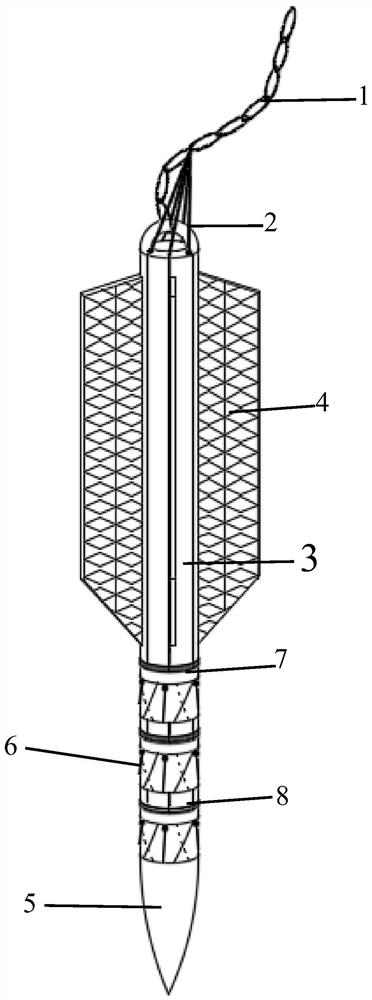

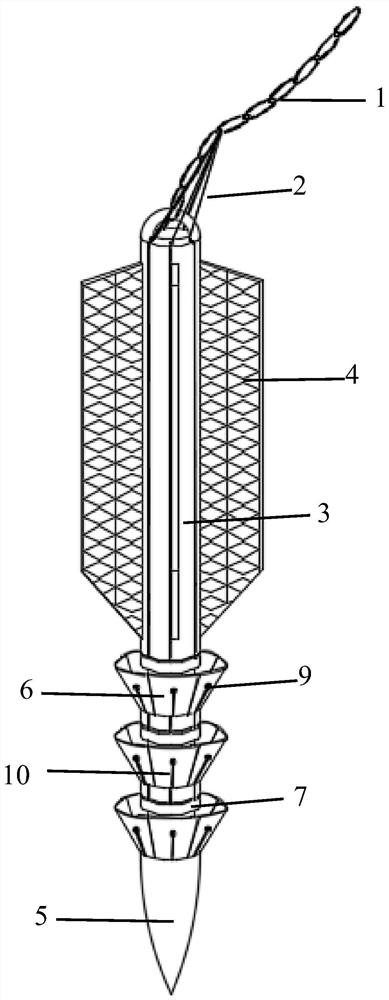

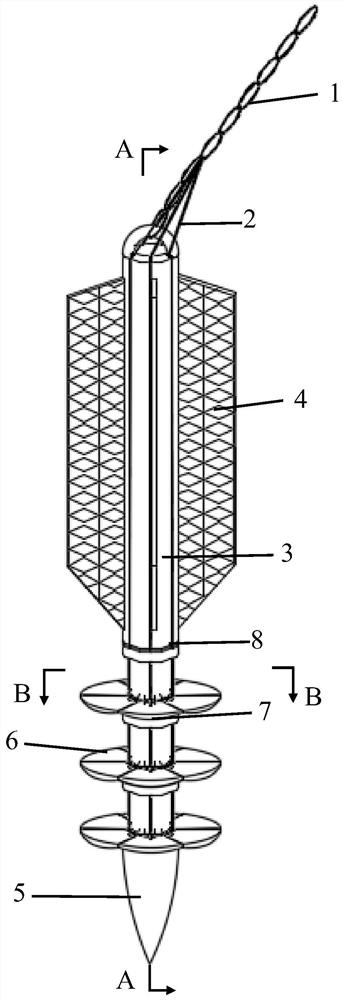

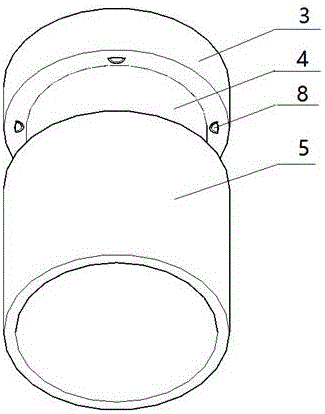

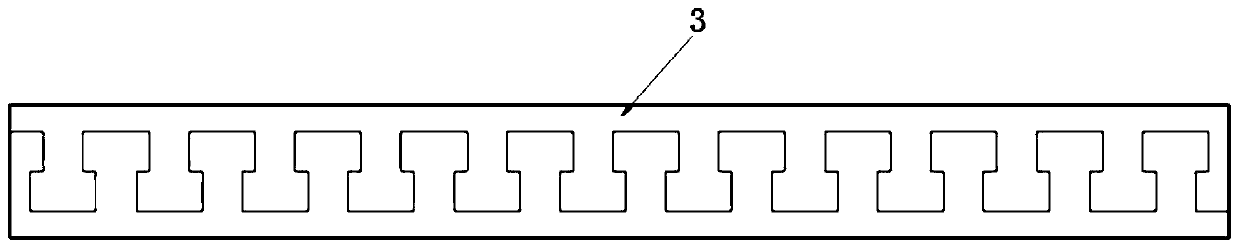

Composite torpedo anchor based on bionics and installation method thereof

ActiveCN112092979AImprove the pull-out capacityImprove stabilityAnchorsClassical mechanicsEngineering

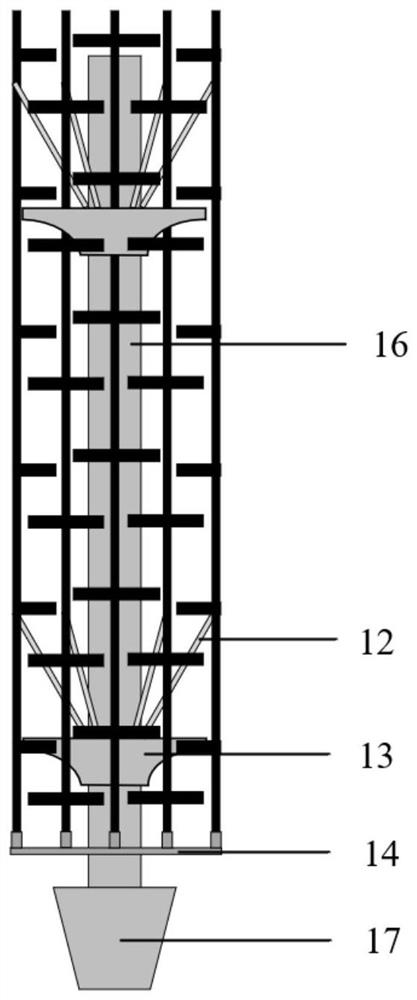

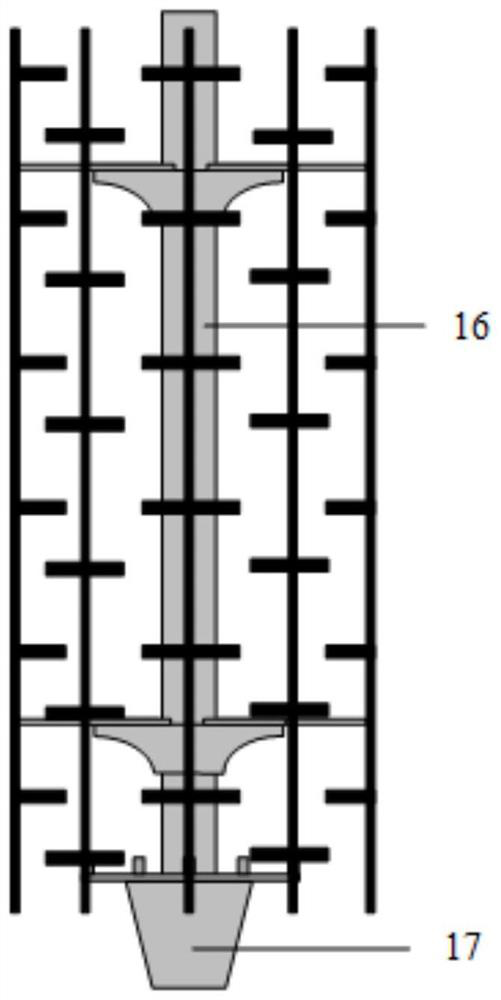

The invention discloses a composite torpedo anchor based on bionics and an installation method thereof. The composite torpedo anchor comprises an anchor tip, an anchor rod, an anchor wing, transverseanchor discs, a safety spring, a limiting lantern ring, a main steel strand, a working anchor chain and a branch steel strand. According to the composite torpedo anchor based on bionics and the installation method thereof, the shape of the anchor tip is designed through bionics, and resistance in the installation and penetration process is reduced; the bearing capacity of the anchor wing is improved by utilizing the characteristics of compression shrinkage and tension expansion of a negative poisson ratio material; the soil body between anchor disc layers and an anchor body form a whole by opening the transverse anchor discs, and the uplift bearing capacity of the anchor body is improved; and a multi-layer transverse anchor disc opening device is easy to manufacture, no extra power sourceexists in the tensioning process, operation is easy, and the installation penetration depth, the uplift bearing capacity and the stability of the torpedo anchor are improved.

Owner:DALIAN UNIV OF TECH

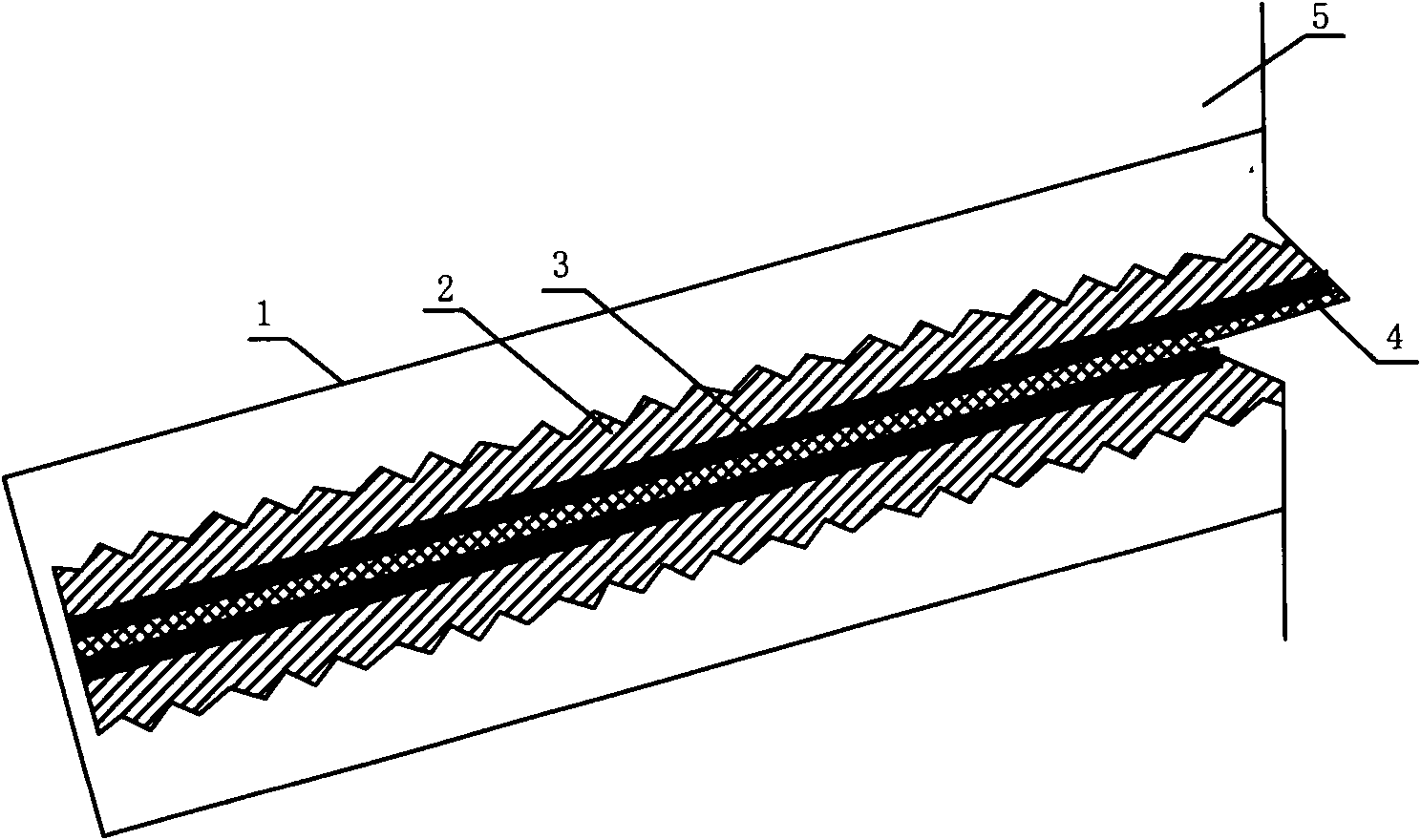

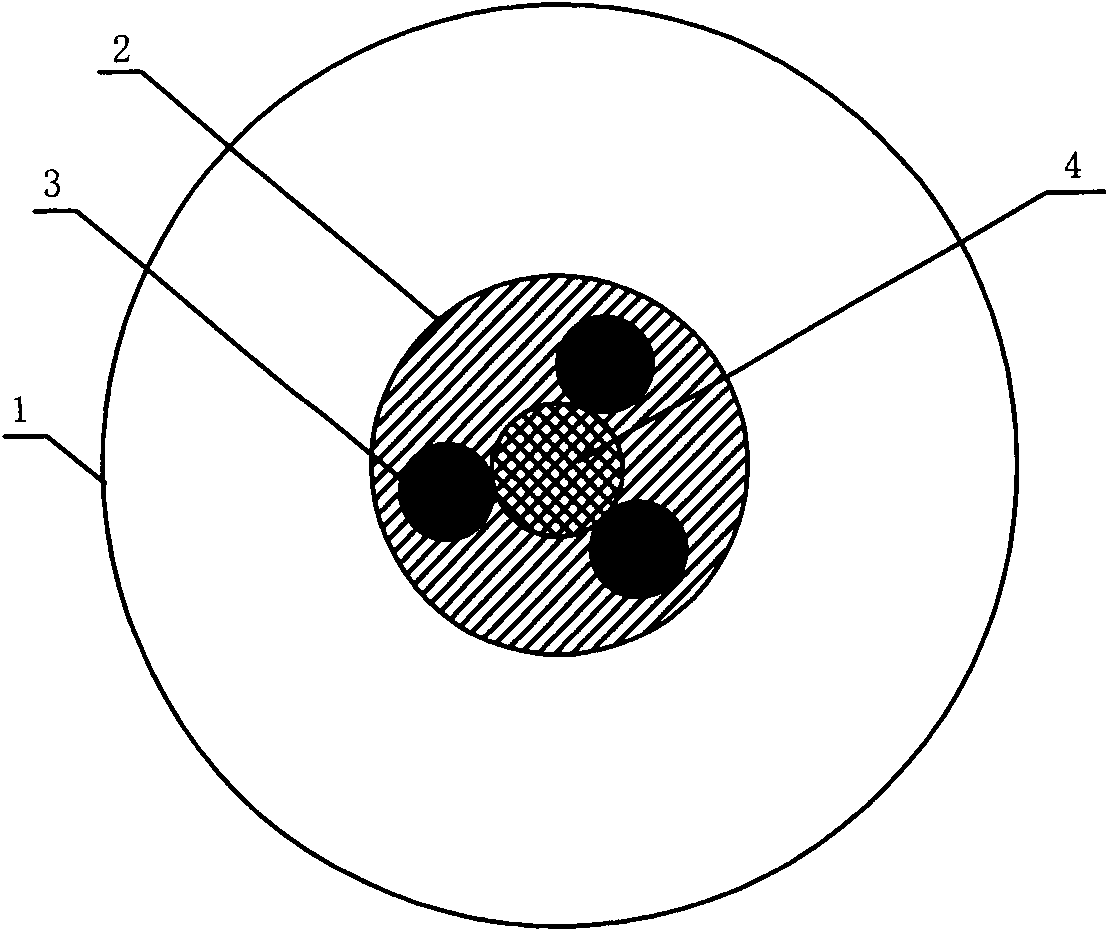

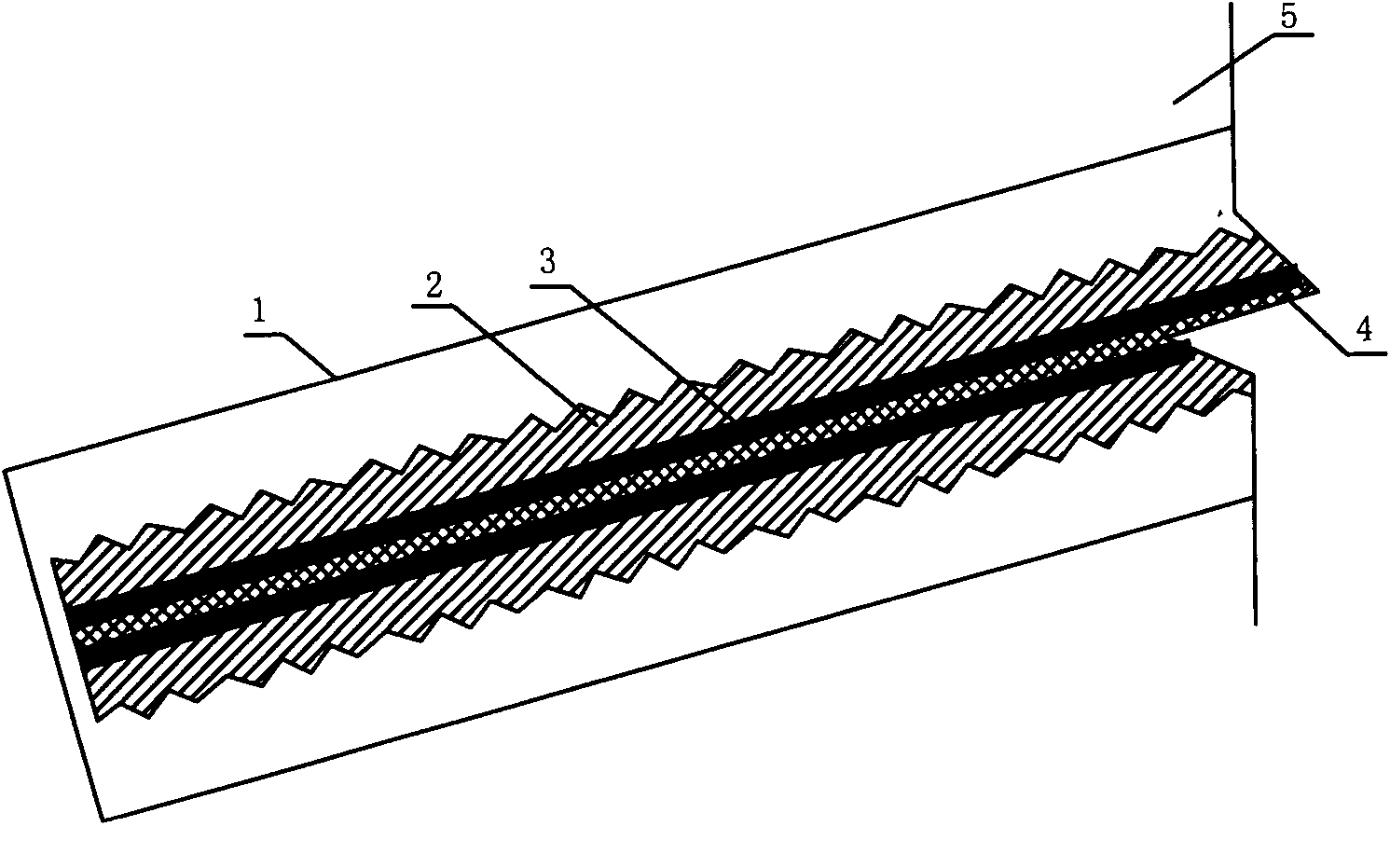

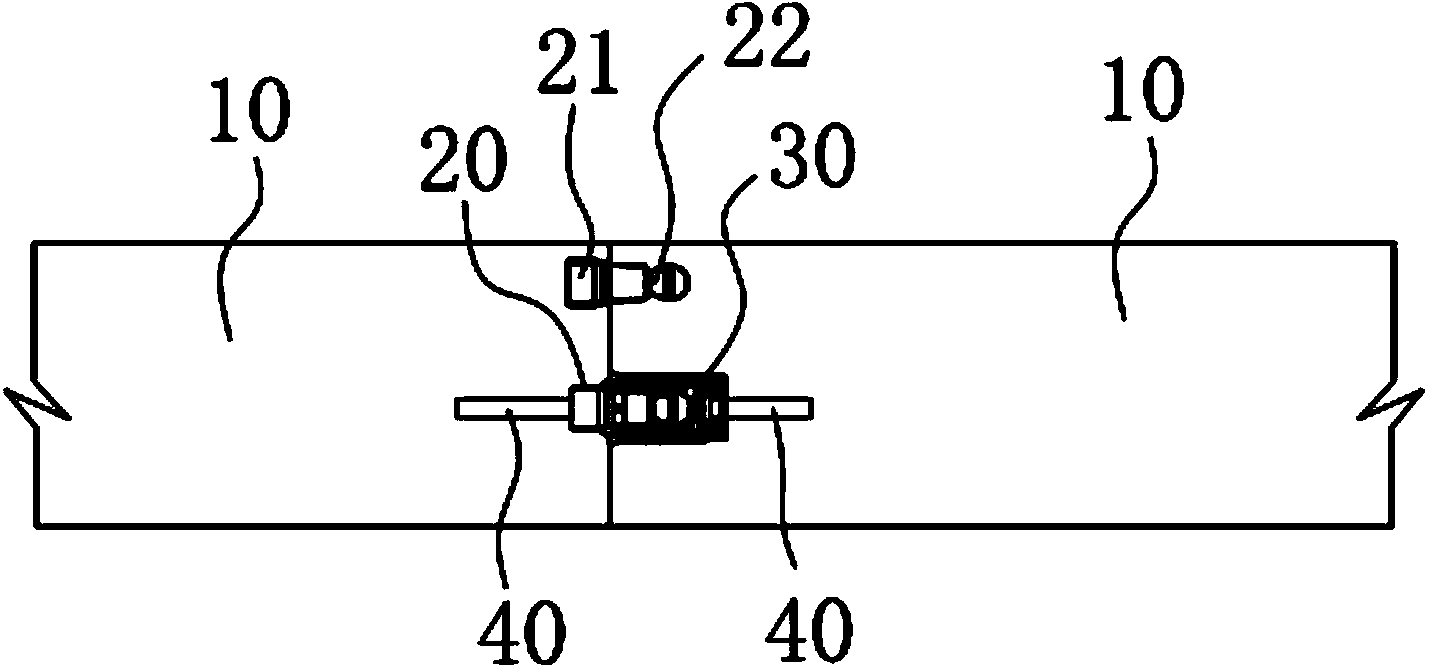

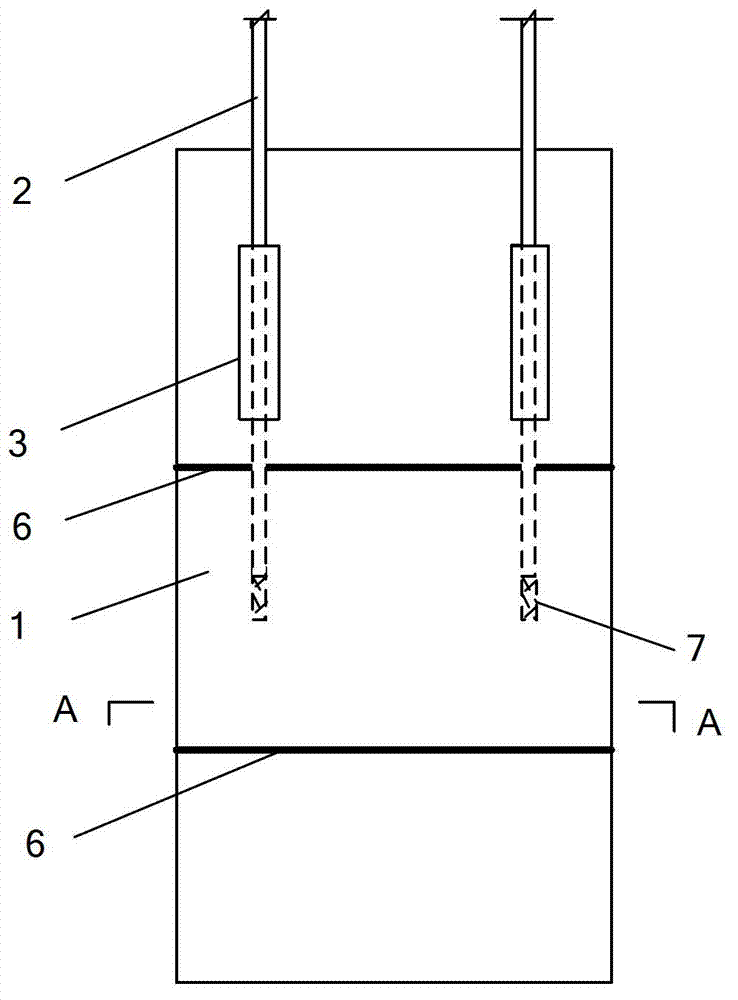

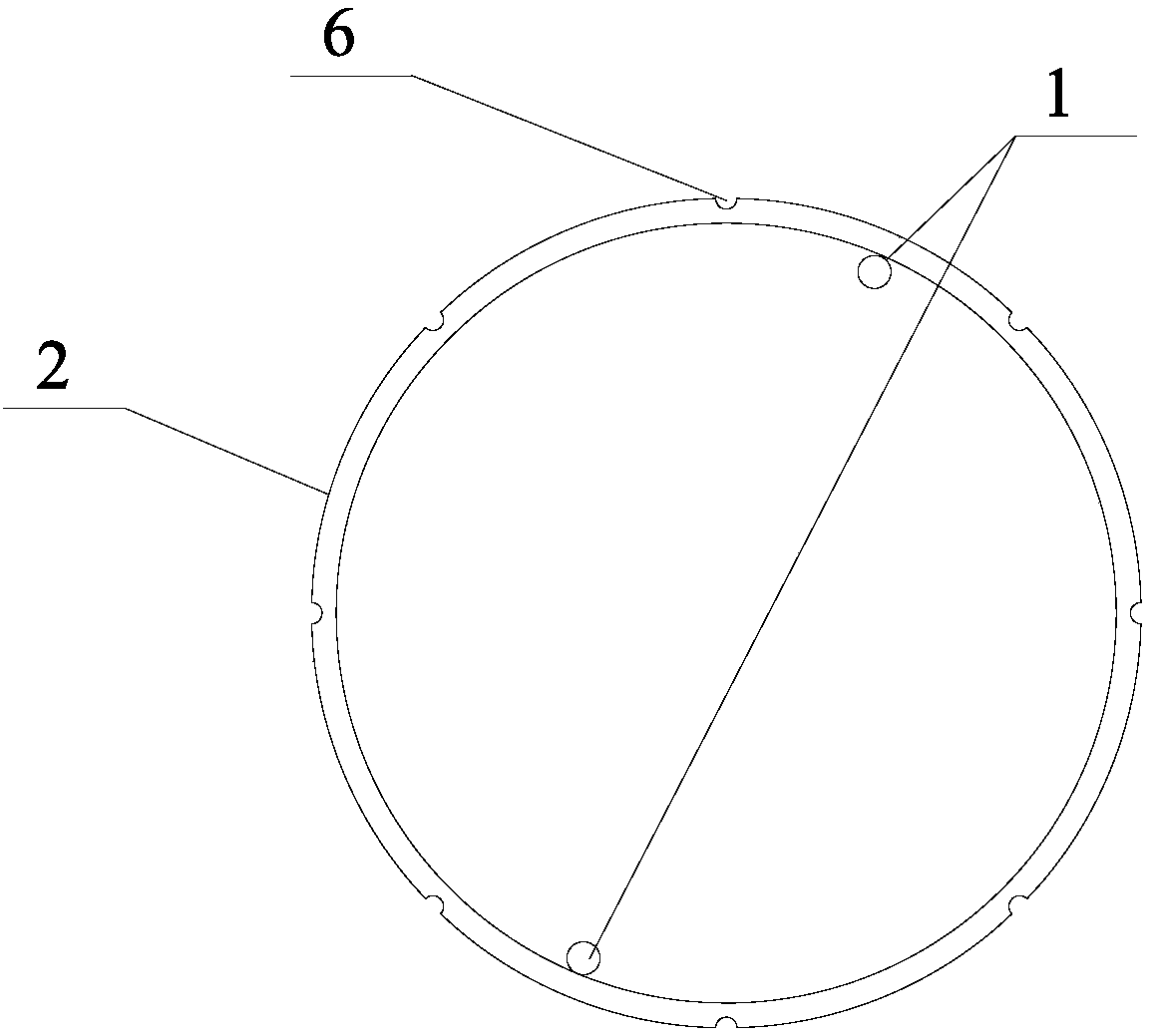

Recoverable composite anchor rod and construction method thereof

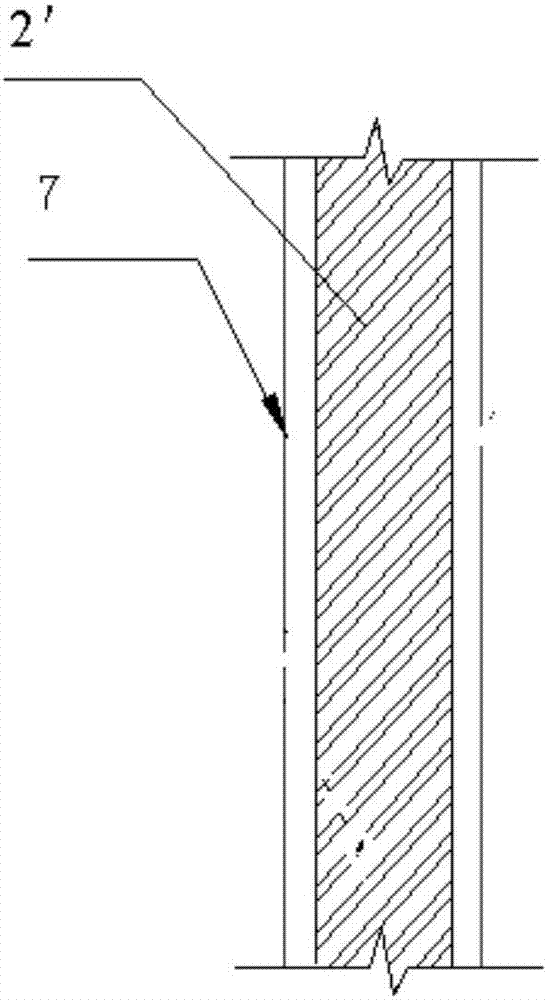

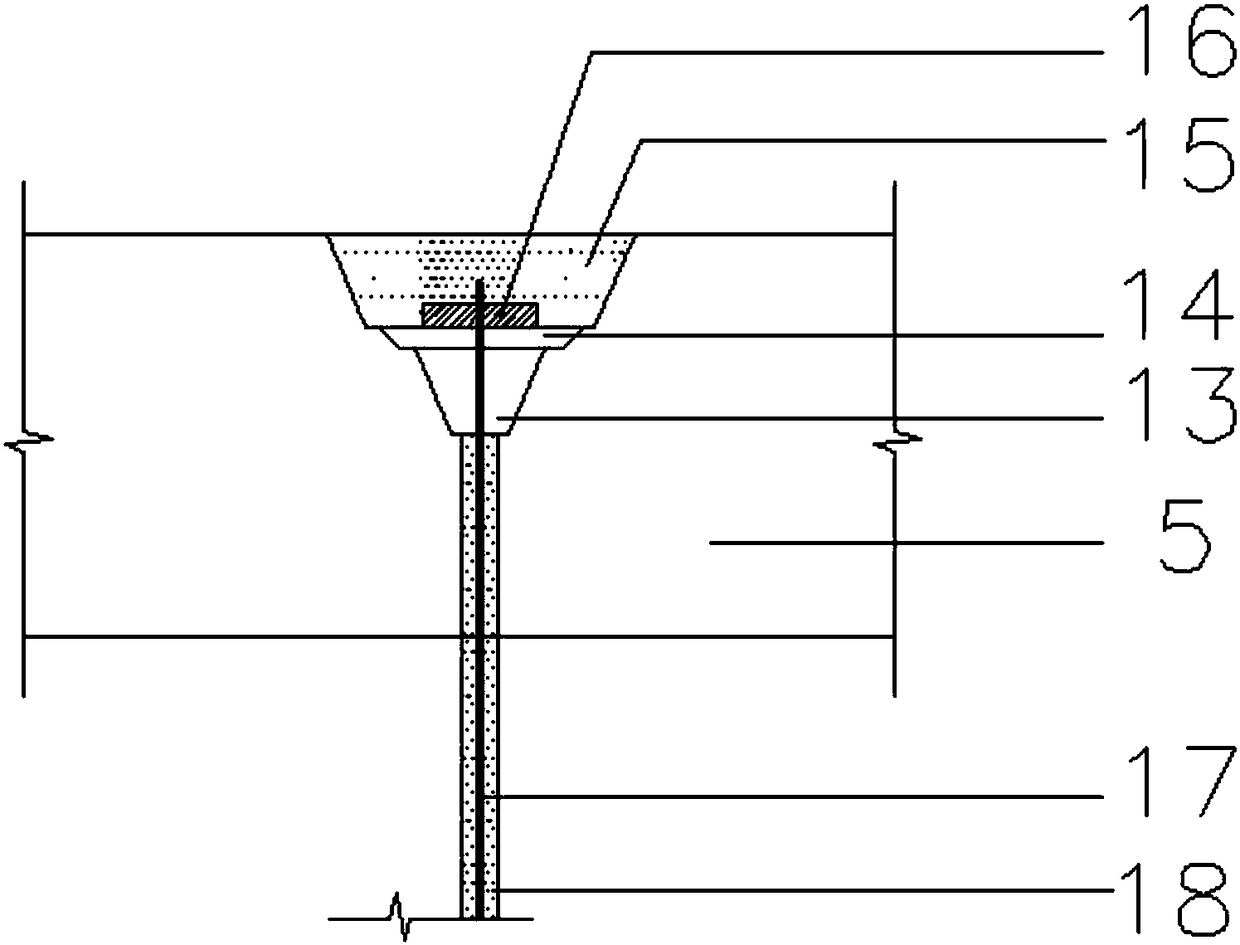

The invention relates to a recoverable composite anchor rod and a construction method thereof in the field of geotechnical engineering anchoring. The recoverable composite anchor rod comprises a hot melt force transfer strip (2), a steel bar or a steel stranded wire (3), a heater (4) and a cement-soil anchor body (1), wherein the cement-soil anchor body (1) is connected with a rock-soil body (5) and provides anti-pulling bearing force; and the anti-pulling bearing force of the anchor rod is transferred through the gripping action of the hot melt force transfer strip (2), and the anchor rod is recovered by melting the hot melt force transfer strip (2). The anti-pulling bearing force of the anchor rod is improved, and the main stressed members of the anchor rod are convenient to recover simultaneously; and the anchor rod has a high recovery rate, is convenient to recover and construct, has low manufacturing cost and prominent environmental-friendly benefits, successfully solves the problem that the anchor rod exceeds a property line underground in cities during construction, can be widely applied to the fields of foundation pit enclosure engineering and the like, and can be popularized in soft soil areas.

Owner:张继红

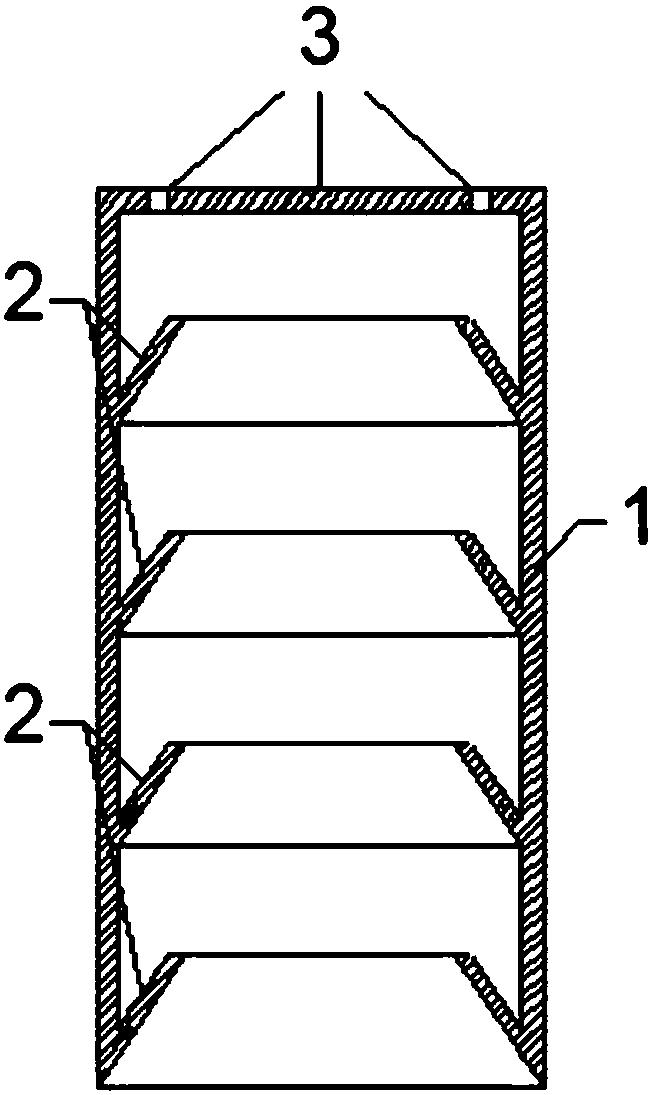

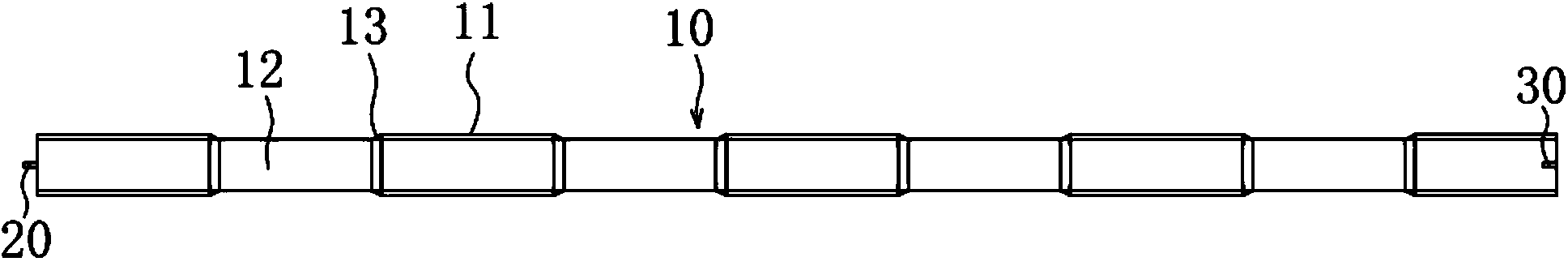

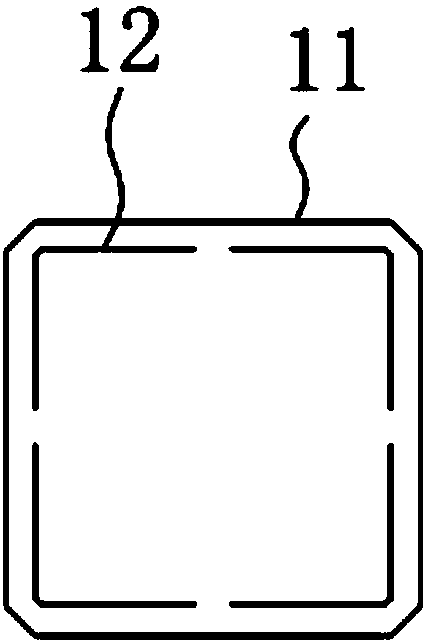

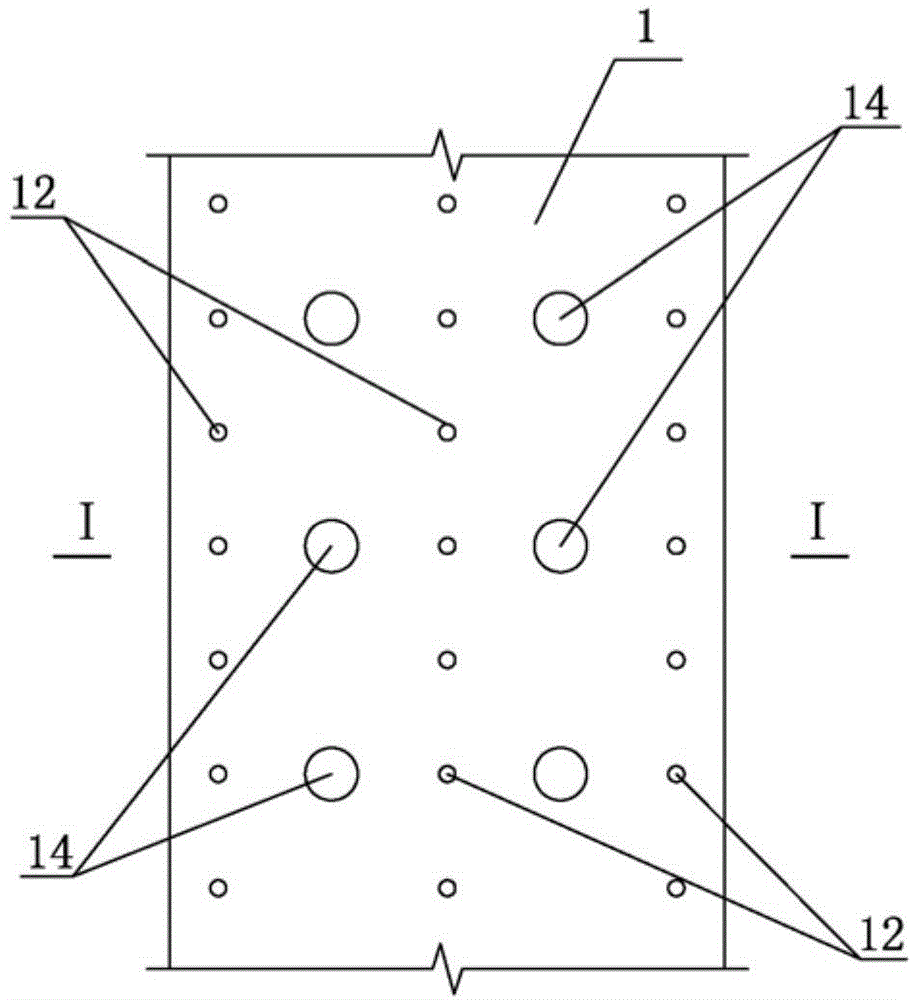

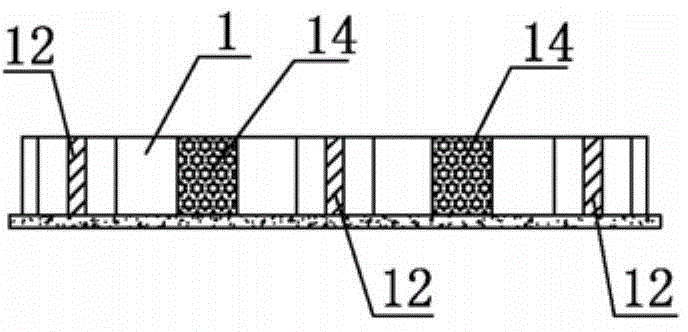

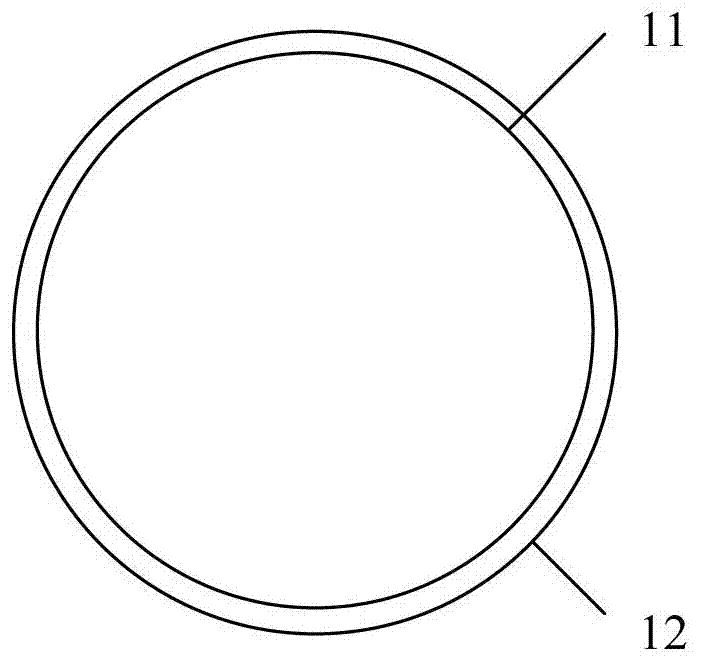

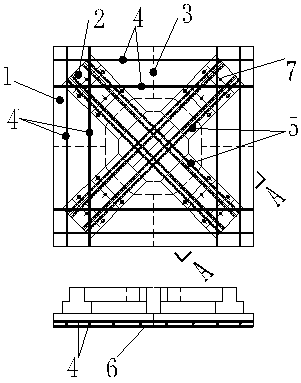

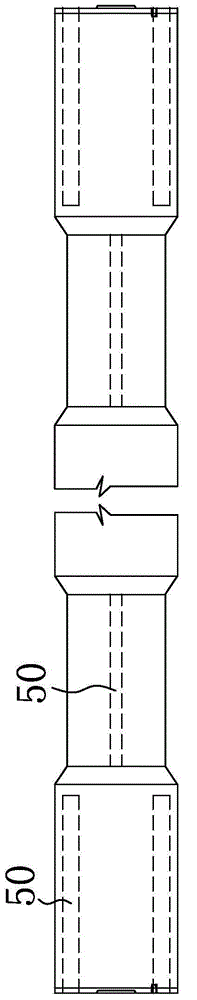

Variable-section concave-convex pile

ActiveCN104358253AIncrease frictionImprove the pull-out capacityBulkheads/pilesConvex sideEngineering

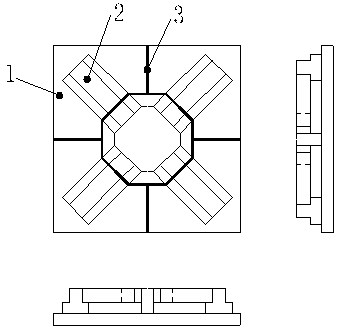

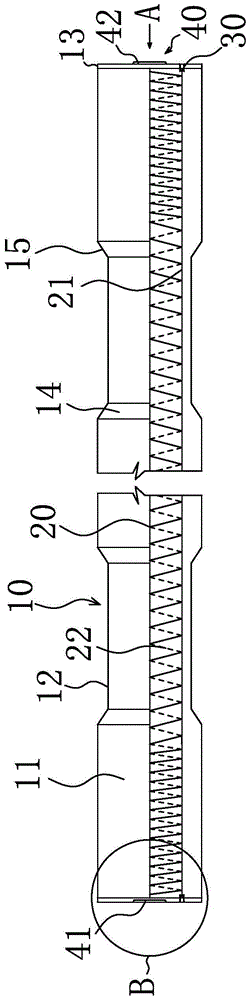

The invention discloses a variable-section concave-convex pile. The variable-section concave-convex pile comprises strip-shaped pile bodies, wherein each pile body is of a concave-convex shape and has different section areas; at least one connecting piece capable of connecting every two pile bodies is arranged at each of two ends of each pile body; each connecting piece comprises a plug assembly and a socket assembly; each plug assembly protrudes out of one end of the corresponding pile body, and each socket assembly is recessed in one end of the corresponding pile body; each plug assembly and the corresponding socket assembly are positioned at the two ends of the corresponding pile body respectively; when the plug assembly of one pile body is inserted into the socket assembly of another pile body, the plug assembly and the socket assembly are hermetically connected. The variable-section concave-convex pile has the advantages of high uplift bearing capacity, high convenience in connection, high corrosion resistance, long service life and the like.

Owner:周兆弟

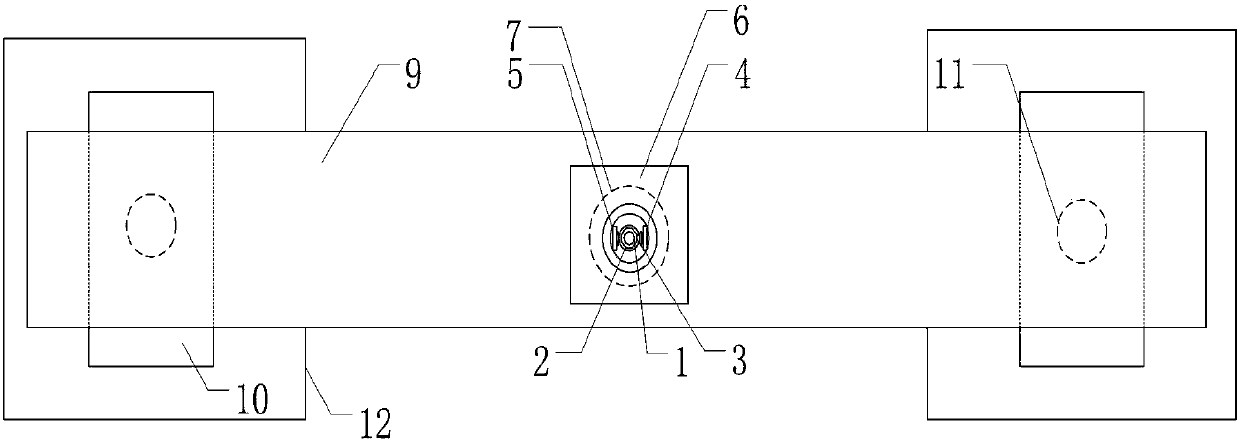

Anchor-arm static-pressure pile device with self-sufficient pile pressing counter-force and constructing method of anchor-arm static-pressure pile device

The invention relates to an anchor-arm static-pressure pile device with self-sufficient pile pressing counter-force and a constructing method of the anchor-arm static-pressure pile device, and aims to provide the anchor-arm static-pressure pile device with the self-sufficient pile pressing counter-force. When an indoor construction pile foundation cannot provide a pile pressing counter-force, construction requirements can be realized by self-sufficient pile pressing counter-force, so that the efficiency is high, the cost is relatively lower, and pollution to the environment is avoided. The anchor-arm static-pressure pile device adopting steel pipe piles of which the pile tips are filled with slurry to provide counter-force comprises a pressure pile baseplate, the steel pipe piles and anchors, wherein anchor-arm static-pressure pile pressing holes and steel pipe pile pressing holes are formed in the pressure pile baseplate; the steel pipe piles are inserted through the steel pipe pile pressing holes and pressed to a certain depth; the slurry is arranged in the pile tips of the steel pipe piles; the tops of the steel pipe piles are connected with the press pile baseplate through grouting material tamping; the anchors are arranged outside the steel pipe pile pressing holes and the anchor-arm static-pressure pile pressing holes respectively, connected with a press pile counter-force rack and used for pressing the steel pipe piles or anchor-arm static-pressure piles to certain depths.

Owner:SHANGHAI CHANGKAI GEOTECHN ENG +1

Uplift bearing capacity testing device for miniature fiber bar uplift pile

The invention relates to the technical field of foundation bases, and relates to an uplift bearing capacity testing device for a miniature fiber bar uplift pile. According to the testing device, the upper portion of a first steel base plate is connected with a high-strength nut, the lower end of the first steel base plate is connected with a load sensor, the lower portion of the load sensor is connected with a second steel base plate, and the bottom of the second steel base plate is connected with a counter-force beam; jack base plates are placed on the two sides of a pile hole, the bottoms ofjacks are installed in the centers of the jack base plates, the tops of the jacks are tightly attached to third steel base plates, beam stools are placed on the jack base plates, and hooping bars andfiber bars in the pile hole are connected to form an uplift pile fiber bar cage; fiber bar lock heads and the fiber bars are anchored on an head-expanded high-strength drawing screw rod, displacementsensors are symmetrically arranged on the two sides of the pile top of the miniature fiber bar uplift pile, and the displacement sensors are fixedly arranged on a reference beam; and the two ends ofthe reference beam are correspondingly supported on buttresses. The testing device is simple to mount and high in operability, the safety and reliability are high, the device is not prone to be damaged, the device can be repeatedly used, the cost is low, and larger uplift bearing capacity can be obtained.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

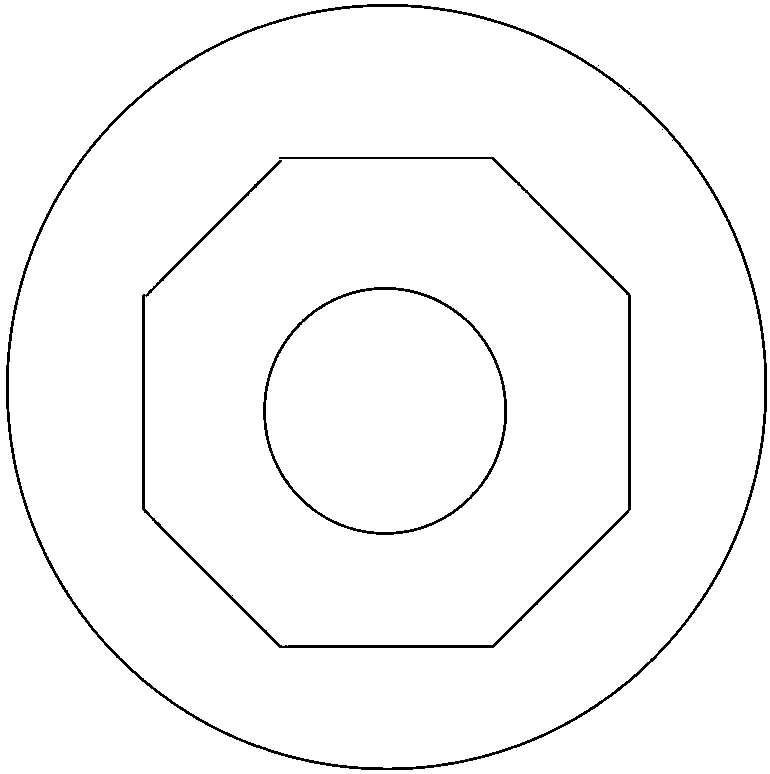

Grouting molding pedestal pile and construction method thereof and pedestal expanding device

ActiveCN103114578ANot affected by unfavorable factors such as hole collapseSimple construction processBulkheads/pilesDevice formSlurry

The invention discloses a pedestal expanding device which comprises a geotechnical cloth bag and a grouting pipe, wherein the geotechnical cloth bag is sleeved on the outer side of the bottom of a steel reinforcement cage. The upper end and the lower end of the geotechnical cloth bag are fixed with the bottom of the steel reinforcement cage. The middle portion of the geotechnical cloth bag is tightened by a plurality of elastic bands, and one end of the grouting pipe is inserted into the geotechnical cloth bag. The invention further discloses a grouting molding pedestal pile and a construction method thereof. The method includes the steps of setting the pedestal expanding device on the outer side of the bottom of the steel reinforcement cage, and placing downward the steel reinforcement cage provided with the pedestal expanding device at the bottom in place, and pouring concrete into the steel reinforcement cage, and beginning to grout after the maintenance of the concrete. The geotechnical cloth bag of the pedestal expanding device forms a plump cylindrical grouting bag structural body under the filling of cement paste, the diameter of the geotechnical cloth bag swells continuously along with the injection of the cement paste liquid and is expanded, then the geotechnical cloth bag can squeeze the concrete around and enables the soil body around to be dense, and finally a pile end expanding head is formed, so occlusion capacity of pile soil and bearing capacity of the pile can be greatly improved.

Owner:上海同人里岩土工程技术有限公司

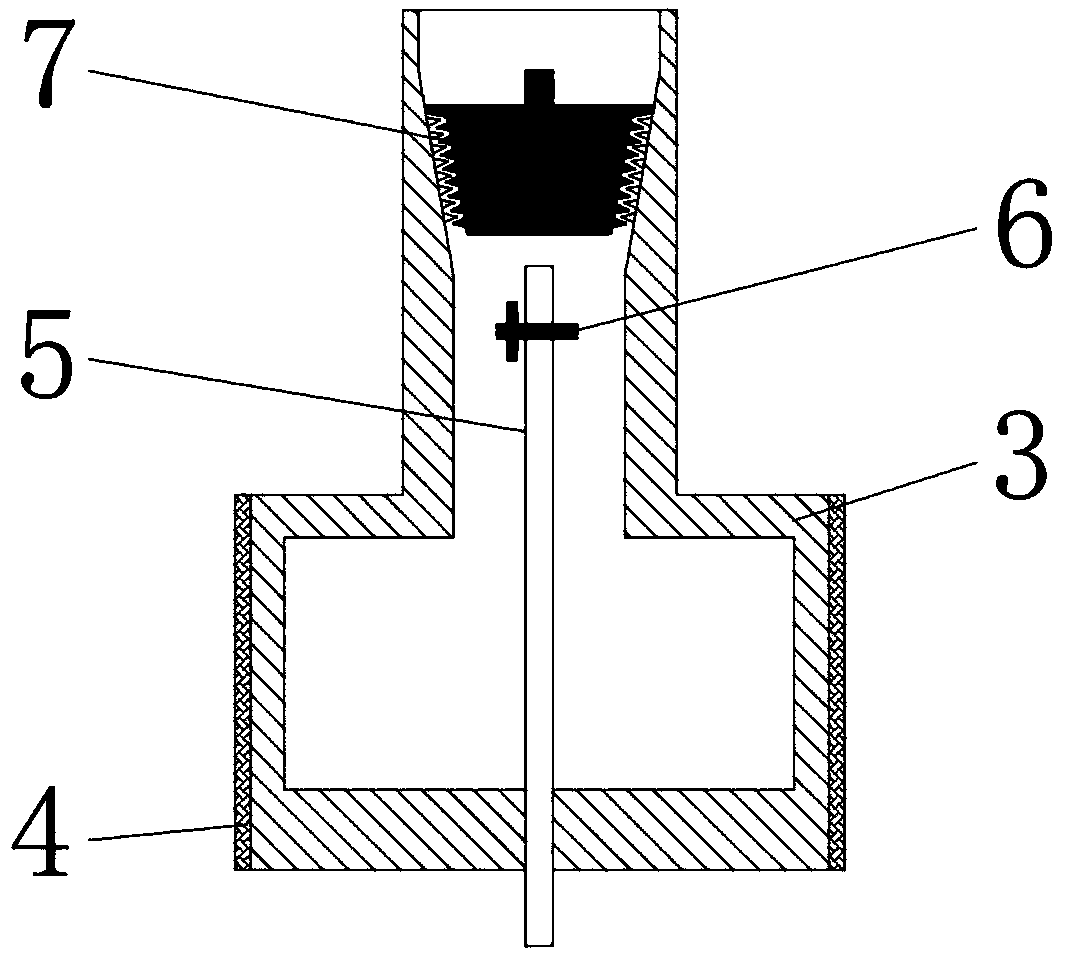

Mechanical expanding type anti-floating anchor and construction method thereof

PendingCN110714463AImprove efficiencyReduce replacement stepsProtective foundationBulkheads/pilesRock boltDrilling machines

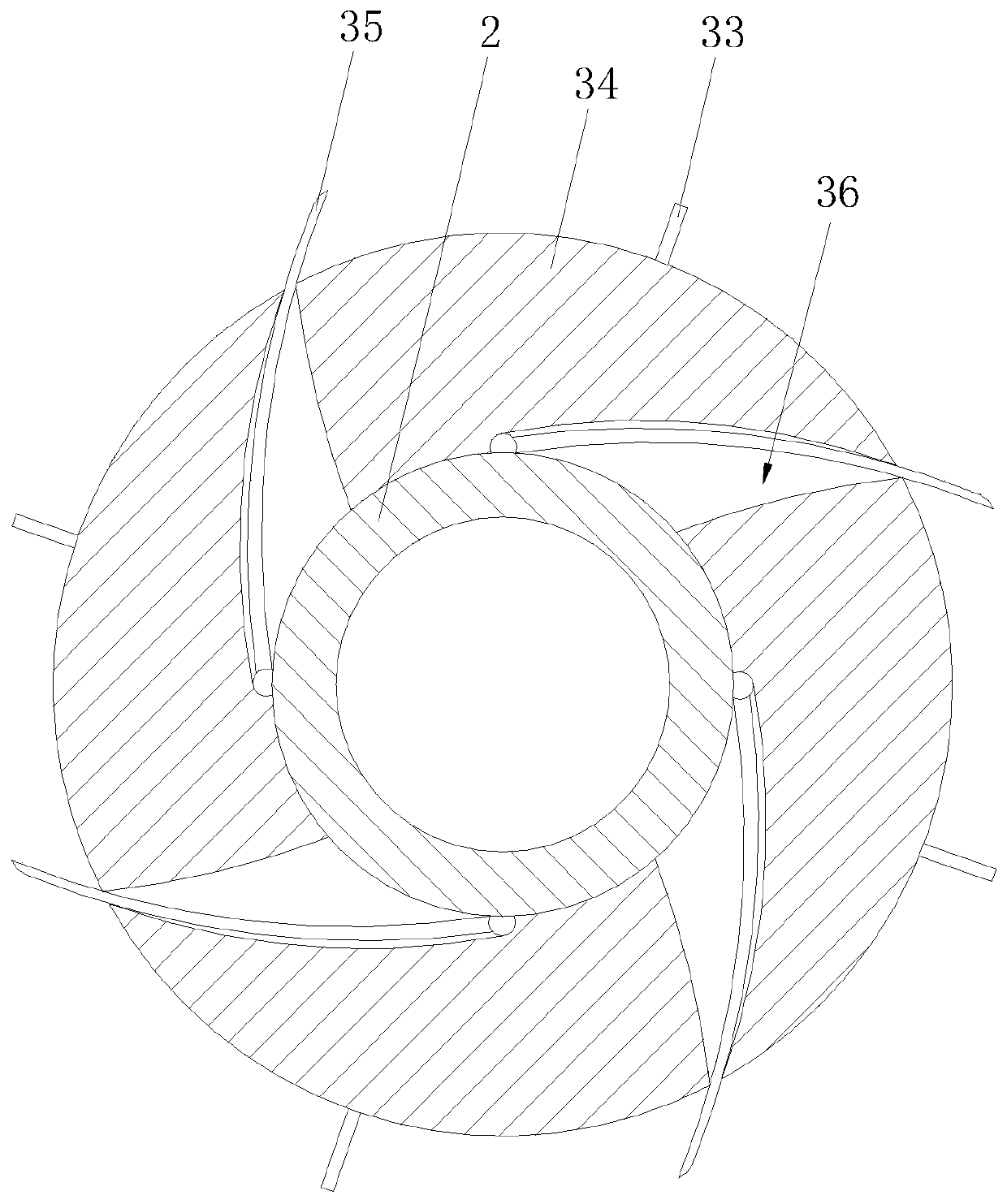

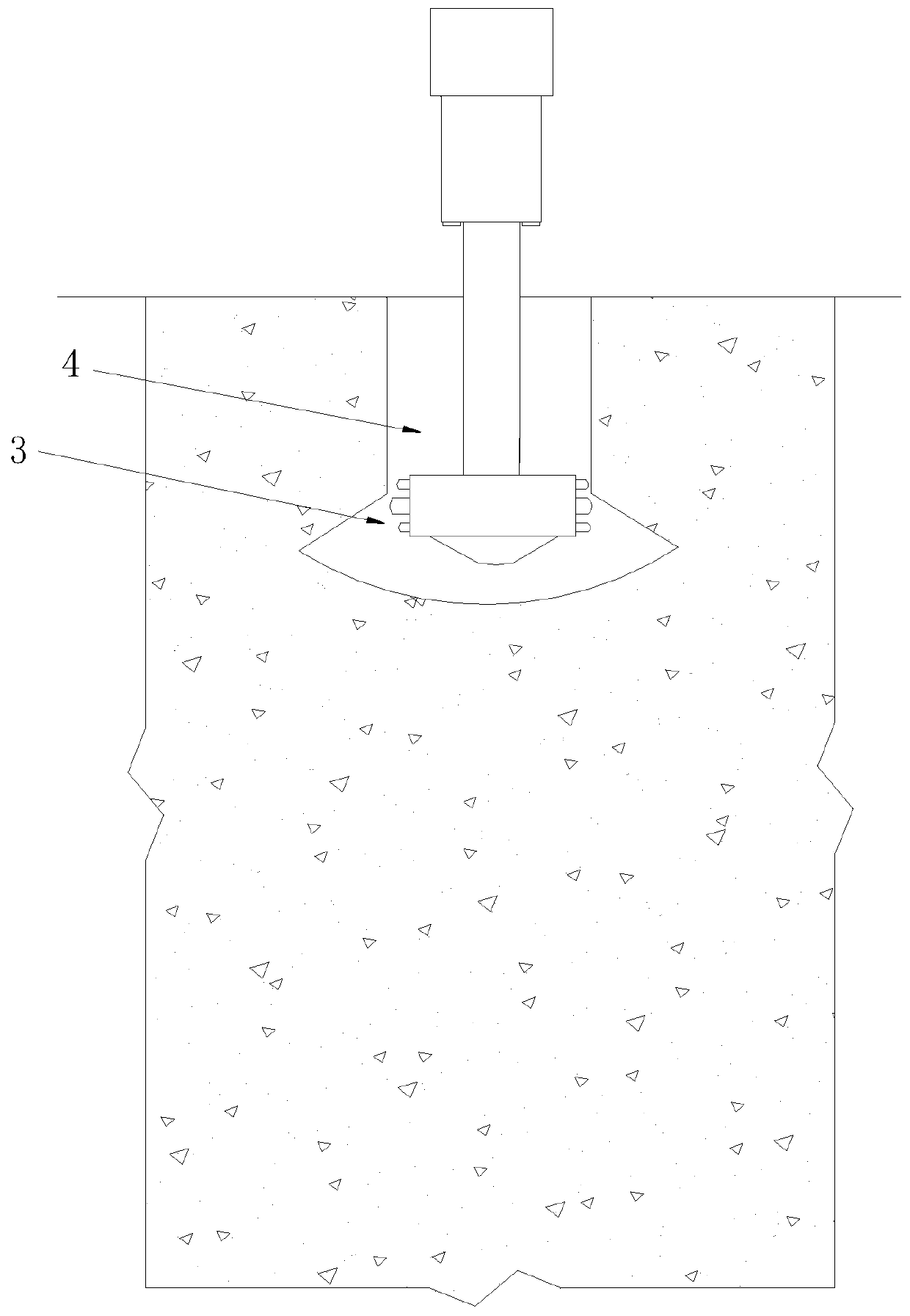

The invention discloses a mechanical expanding type anti-floating anchor and a construction method thereof and relates to the technical field of anti-floating anchors. The problems that potential quality and safety hazards are likely to be formed by an equal-diameter anti-floating anchor, and construction operation is complex are solved. According to the technical scheme, the mechanical expandingtype anti-floating anchor is characterized by comprising a hollow drill rod, an expanding drill bit and a drilling machine device; an anchor bar material and a grouting pipe can be arranged in the hollow drill rod, and the bottom end of the anchor bar material and the bottom end of the grouting pipe are fixedly connected with an anti-blocking plate; a rotating device fixedly connected with the hollow drill rod is arranged in the drilling machine device, and a telescopic device fixedly connected with the anchor bar material and the grouting pipe is arranged in the rotating device; and the expanding drill bit comprises a ring-shaped body connected with the hollow drill rod in a sleeving manner and expanding edge parts, multiple movable cavities are formed in the ring-shaped body in a circular manner, the expanding edge parts penetrate the movable cavities, then one ends of the expanding edge parts are hinged to the hollow drill rod, and the other ends of the expanding edge parts stretchout of the outer wall of the ring-shaped body. The mechanical expanding type anti-floating anchor and the construction method thereof have the effects that the input cost of anti-floating anchor construction is reduced, the uplift bearing capacity is improved, the construction quality is improved, and construction operation is convenient.

Owner:SOUTHWESTERN ARCHITECTURAL DESIGN INST

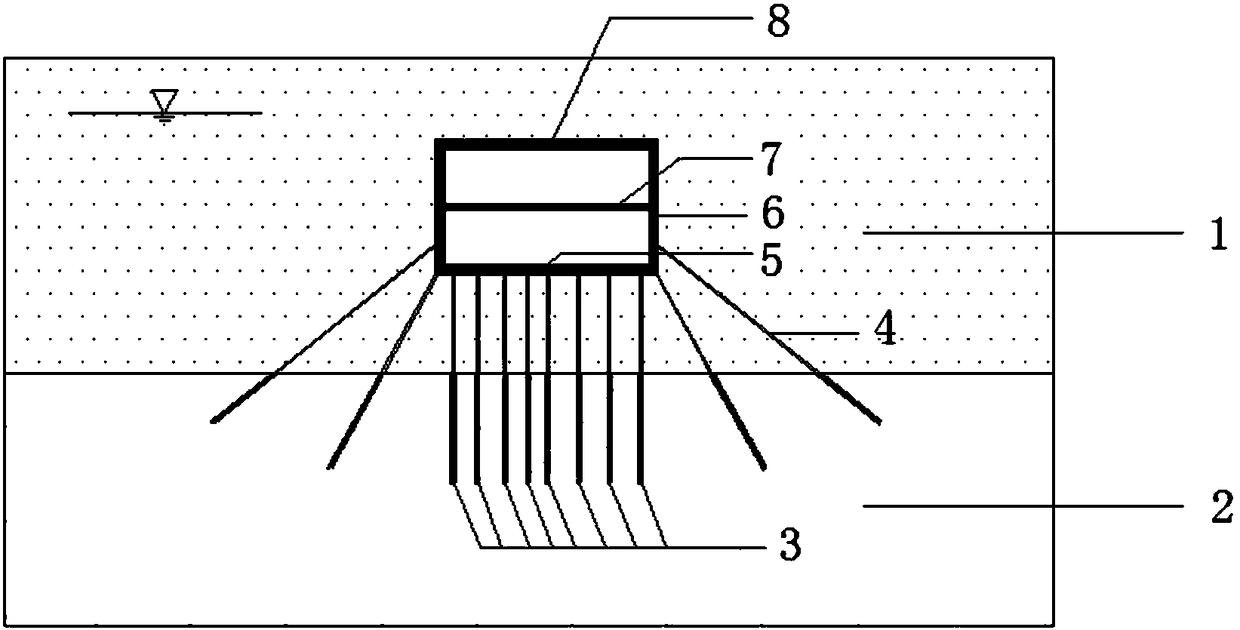

Grouting suction anchor and installation method thereof

InactiveCN106240749APrevent pull upImprove ultimate pull-out capacityAnchorsBulkheads/pilesEngineeringCement mortar

The invention discloses a grouting suction anchor comprising a cylinder body; the cylinder body has an integral structure comprising an upper part, an intermediate part and a lower part; the diameter of the upper cylinder body is identical to that of the lower cylinder body; the diameter of the intermediate cylinder body is less than those of the upper cylinder body and the lower cylinder body; the upper, the intermediate and the lower cylinder body share a same center line; a top part of the upper cylinder body is provided with multiple grouting inlets and scuppers; the grouting inlets are communicated with a grouting channel inside a side wall of the upper cylinder body; the grouting channel extends downwards to a lower end surface of the upper cylinder body; an outlet of a lower end of the grouting channel is positioned between the outer lateral surface of the upper cylinder body and the outer lateral surface of the intermediate cylinder body; the grouting channel and the cylinder body inner chamber are separated from each other. The invention also discloses an installation method of the suction anchor. After downward penetration of the suction anchor is completed, the intermediate cylinder body and soil body interspace are filled with cement mortar which can improve the lateral bearing capacity of the suction anchor. After the cement mortar is solidified, the friction coefficient between surrounding soil body and anchor cylinder contact surface is increased and the limit bearing capacity of the suction anchor is increased.

Owner:OCEAN UNIV OF CHINA

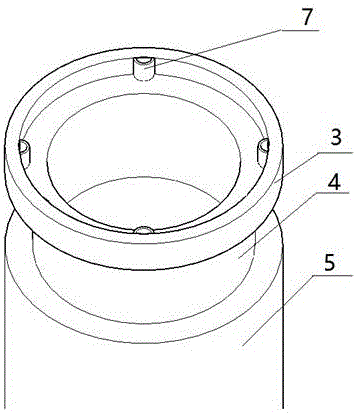

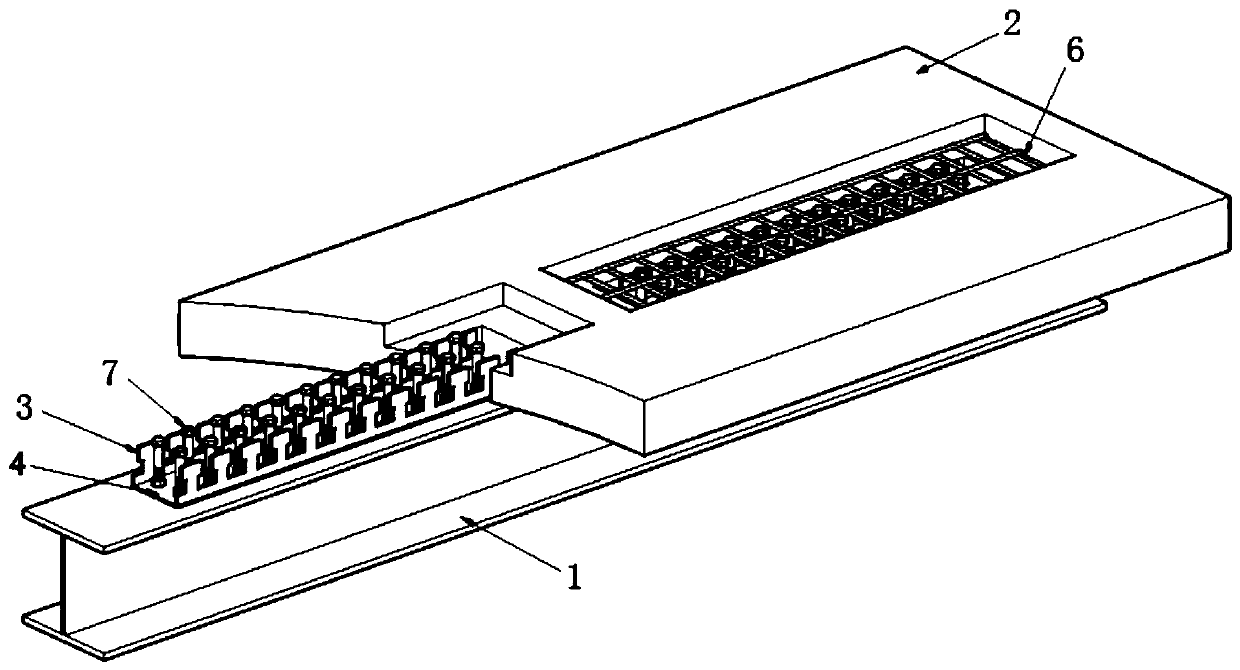

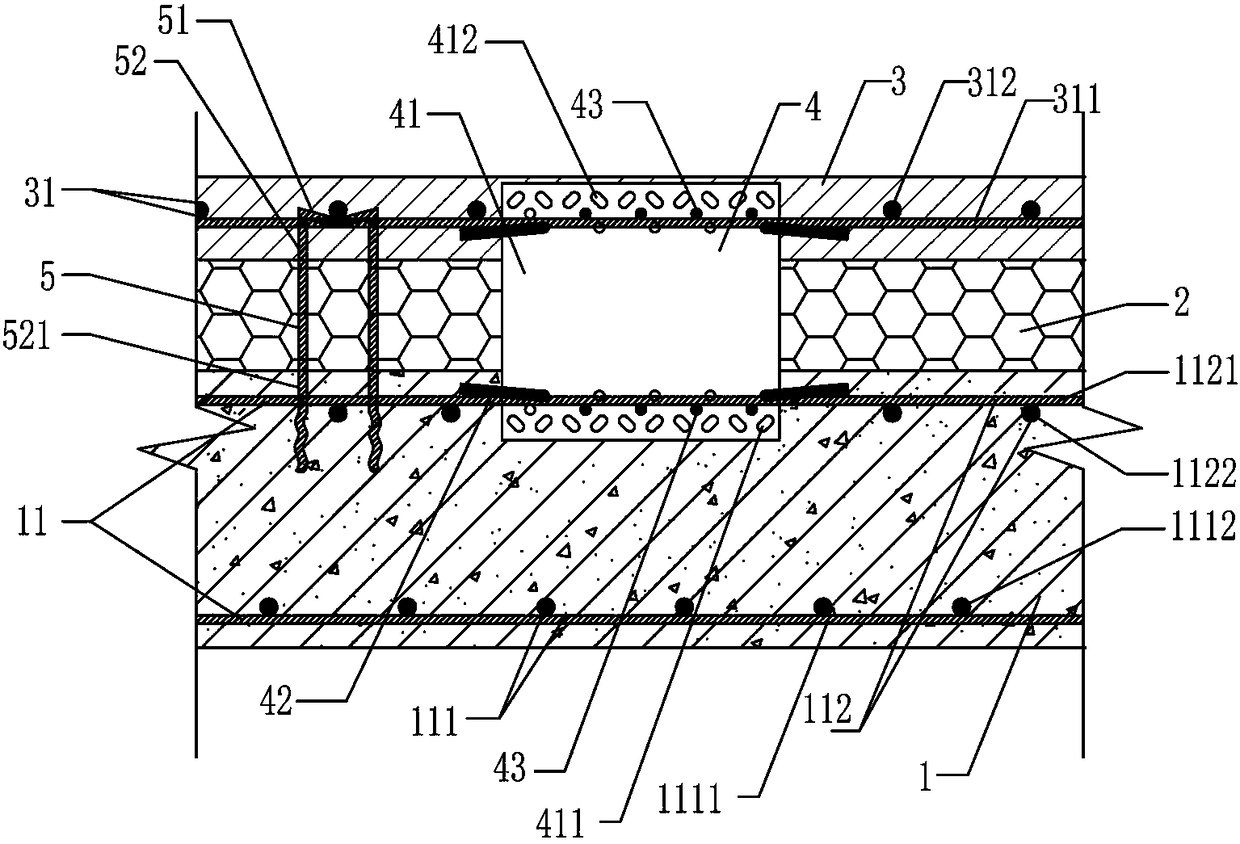

Detachable prefabricated assembly type steel-concrete composite beam and construction method thereof

PendingCN110080462AImprove shear resistanceHigh ductility and energy dissipation performanceLoad-supporting elementsRebarSheet steel

The invention provides a detachable prefabricated assembly type steel-concrete composite beam. The composite beam comprises a steel beam, a concrete slab, concave-convex steel board connecting piecesand a splicing steel board, the steel beam is of an I-shaped steel or rectangular steel structure, and the splicing steel board is arranged on the upper surface of the steel beam. The two concave-convex steel board connecting pieces are arranged on the two sides of the splicing steel board, and the two concave-convex steel board connecting pieces and the splicing steel board form a U-shaped structure. A T-shaped shear notch is formed in the middle of the concrete slab, the concrete slab is arranged above the steel beam, and the U-shaped structure formed by the two concave-convex steel board connecting pieces and the splicing steel board is located in the T-shaped shear notch of the concrete slab, and a shear groove post-pouring concrete layer is poured in the T-shaped shear groove openingof the concrete slab. The detachable prefabricated assembly type steel-concrete composite beam is convenient to construct, high in bearing capacity, high in shear capacity of connection between the steel beam and the prefabricated reinforced concrete slab, high in uplift bearing capacity, good in energy consumption performance and convenient to disassemble.

Owner:XIANGTAN UNIV

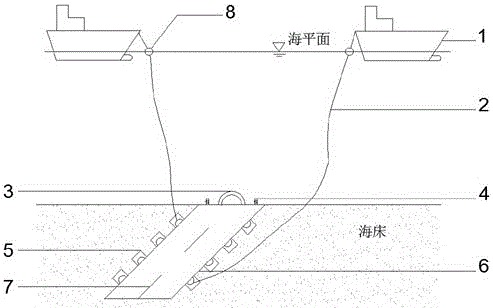

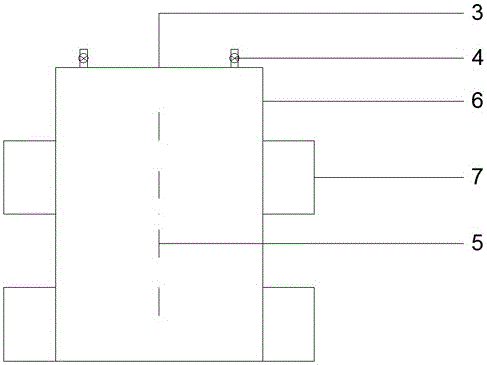

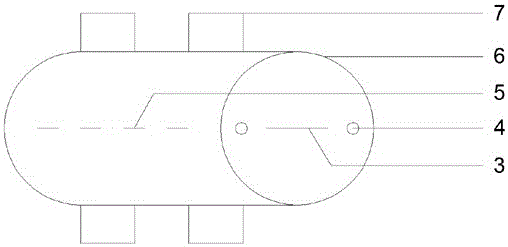

Inclined type barrel-shaped foundation mooring system and construction method thereof

InactiveCN105019471AIncrease the bearing areaIncreased torque capacityCaissonsFloating buildingsSuction forceMooring system

The invention discloses an inclined type barrel-shaped foundation mooring system and a construction method thereof. The inclined type barrel-shaped foundation mooring system comprises structures floating on the sea, buoys, anchor chains, a foundation ring, an inclined type barrel-shaped foundation, water drainage pipes, anchor bolts and steel wing plates. The inclined type barrel-shaped foundation is embedded in a seabed in a suction force sinking and penetrating manner. The steel wing plates and the anchor bolts are symmetrically welded to the side walls of the inclined type barrel-shaped foundation. The foundation ring used for hoisting the foundation is welded in the middle of a top cover of the inclined type barrel-shaped foundation. The two water drainage pipes with switches are arranged on the two sides of the foundation ring. The lower portions of the anchor chains are connected with the anchor bolts. The buoys are arranged on the upper portions of the anchor chains and connected with the structures floating on the sea. When upwards-pulled loads are borne by the inclined type barrel-shaped foundation, the uplift bearing capacity can be improved by fully utilizing the dead weight of the side walls of the inclined type barrel-shaped foundation, the dead weight of soil bodies on the upper portions of the steel wing plates and the friction force of the foundation and the soil bodies. One or more structures floating on the sea can be fixed; and when the upwards-pulled loads are borne by the anchor bolts on the upper portion and the lower portion of the inclined type barrel-shaped foundation, the dead weight of the steel wing plates and the soil bodies on the upper portion of the foundation can effectively resist the rotation torque generated by the inclined type barrel-shaped foundation at the moment.

Owner:SHANDONG UNIV OF SCI & TECH

Pre-stressed anchor cable manual hole digging uplift pile and construction method thereof

PendingCN106968245AIncreased durabilityImprove the pull-out capacityBulkheads/pilesPre stressGeotechnical engineering

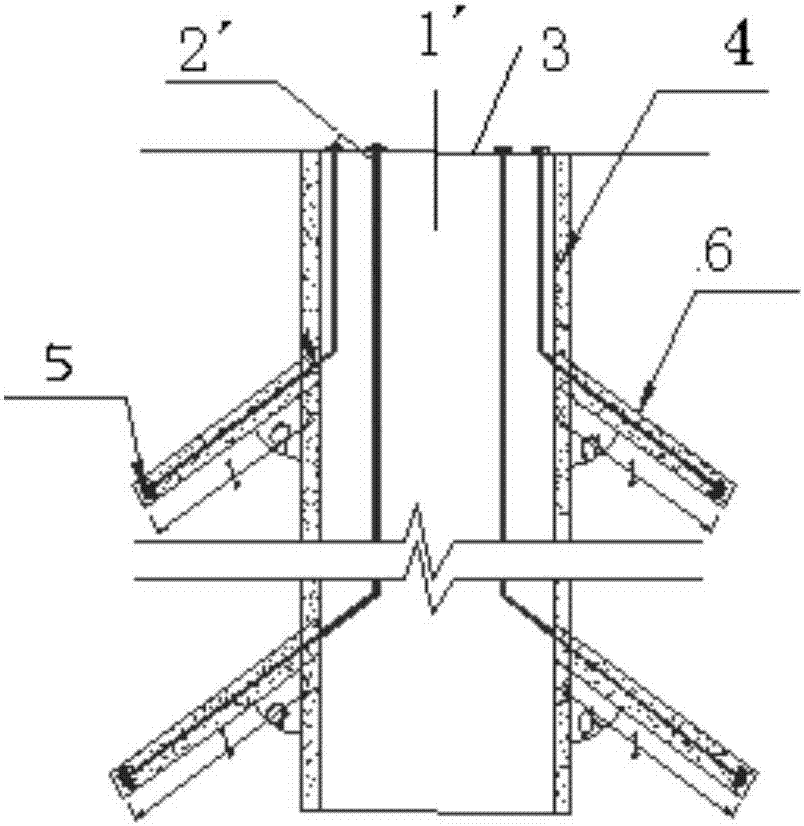

The invention discloses a manual hole digging uplift pile structure. The manual hole digging uplift pile structure comprises a pile body and one or more pre-stressed anchor cables used for increasing axial uplift resistance of the pile body. The axial pre-stressed anchor cables are arranged in the pile body, the upper ends of the axial pre-stressed anchor cables are anchored to the pile head of the pile body, and the lower ends of the pre-stressed anchor cables radially penetrate through the side wall of the pile body and are anchored to the formation around the pile body. Concrete is poured to the pile body of a manual hole digging pile, after the strength reaches the design strength, the uplift resistance of the manual hole digging pile is increased by stretching the pre-stressed anchor cables, and the pile body durability and the uplift bearing capacity can be greatly improved. The structure is easy to construct, construction is conducted in a sectioned mode, and the quality is controllable; when the manual hole digging pile bears upward uplift resistance, especially the manual hole digging pile of a montanic socketed pile with low side friction, through the structure and a construction method thereof, the uplift resistance of the manual hole digging pile can be effectively improved, and the durability of the manual hole digging pile body is greatly improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

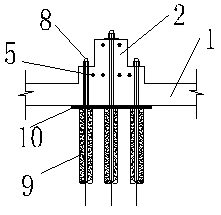

Assembled concrete pile cap and miniature pile combined foundation and construction method

PendingCN108265737AReduce settlementShort construction periodFoundation engineeringPile capPre stress

The invention discloses an assembled concrete pile cap and miniature pile combined foundation and a construction method thereof. The assembled concrete pile cap and miniature pile combined foundationis divided into two parts, the lower part is micro grouting steel pipe piles, the upper part is the assembled concrete pile cap, and the pile cap and the micro grouting steel pipe piles are connectedby the adoption of a grouting technology after reinforcing steel bars in pile bodies are anchored into anchor bolt reserved holes. Double-layer bi-directional arrangement of pre-stressed tensioning isadopted in the site, and pre-stressed tension is carried out in two times, so that the assembled concrete pile cap has the beneficial effects of being high in integrity and uniform in stress. The combined foundation is the combination of the upper assembled concrete pile cap and the lower miniature steel pipe pile group and has the beneficial effects that the settlement of the foundation is reduced, the application range is wide, and the construction period is short.

Owner:HUAIHAI INST OF TECH

Inverted wedge type recoverable anchor rod

InactiveCN104631454AImprove the pull-out capacityReasonable forceBulkheads/pilesArchitectural engineeringScrew thread

The invention discloses an inverted wedge type recoverable anchor rod which comprises a threaded rod body with threads on the outer side. One end of the threaded rod body serves as an anchorage section and is provided with a first nut for fastening, and the other end of the threaded rod body serves as an anchor head and is provided with a tray and a second nut; the outer side of the threaded rod body located between the tray and the first nut is connected with a threaded casing pipe system through surface threads, the threaded casing pipe system is composed of multiple threaded casing pipe subsystems, and the threaded casing pipe subsystems are fixedly connected; each threaded casing pipe subsystem comprises a threaded steel pipe and a wedge, the threaded steel pipes are fixedly connected with the wedges, threaded casing pipes and wedges of every two adjacent threaded casing pipe subsystems are connected. After mounting of the anchor rod is completed, a broken rock-soil body is firmly hung on a stable rock-soil body, therefore, the overall strength of rock is increased, the uplift bearing capacity of the anchor rod is improved, and meanwhile the force of the anchor rod is more reasonable. A support effect can be played as soon as possible after mounting, the rod body can be taken out for temporary support, and materials are saved.

Owner:SHANDONG UNIV

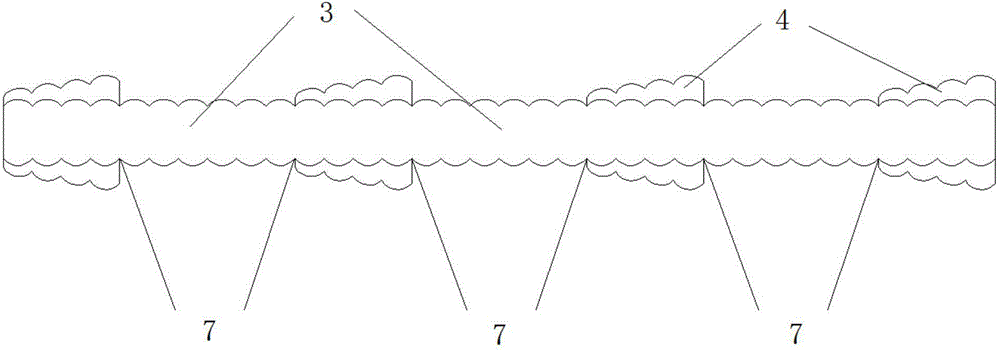

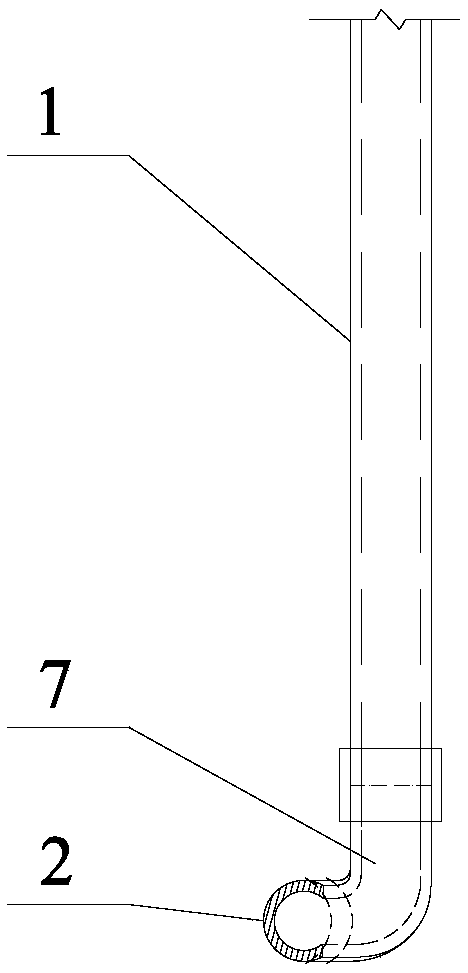

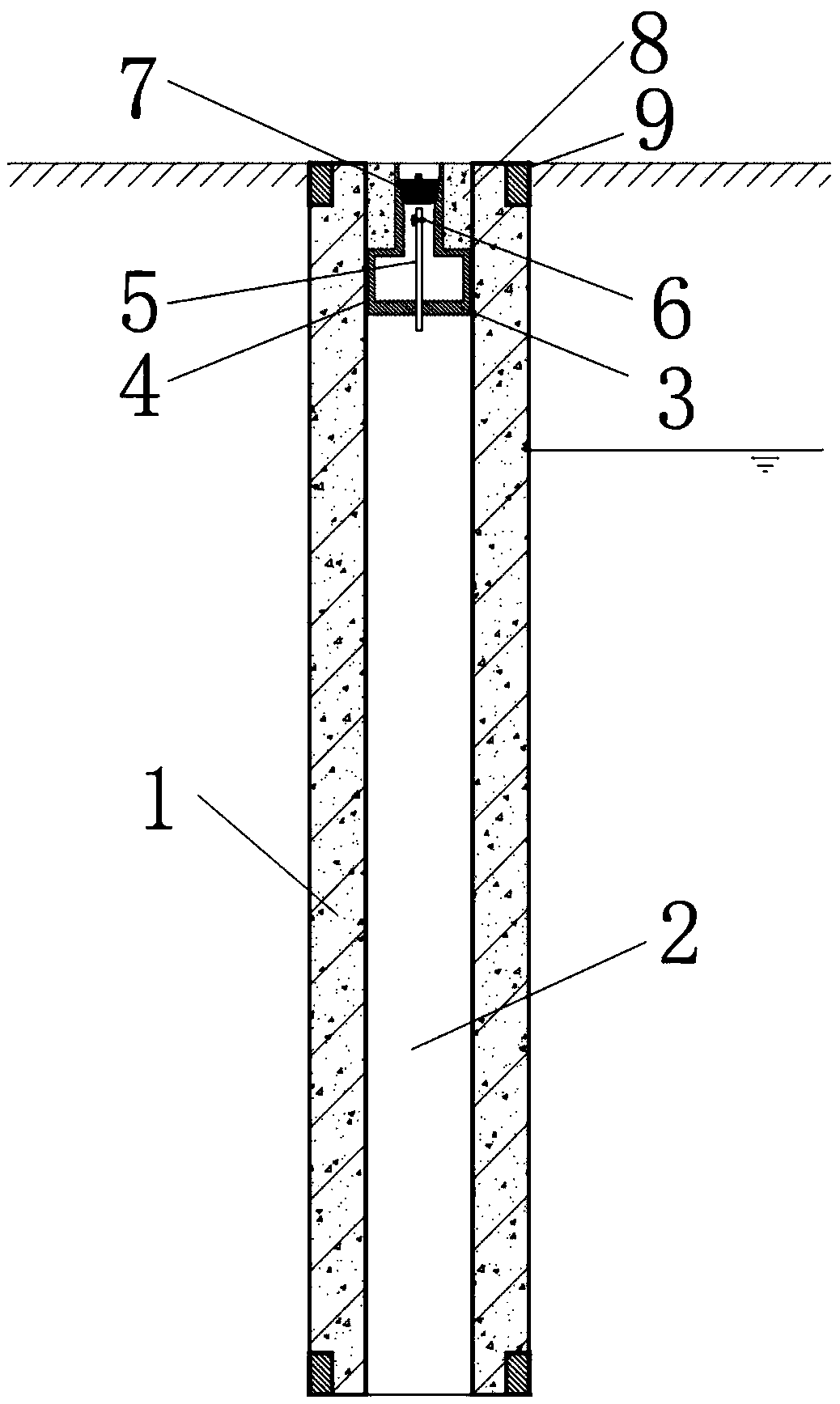

Uplift pile side post grouting device and construction method

The invention discloses an uplift pile side post grouting device. The uplift pile side post grouting device comprises a plurality of grouting vertical tubes and a plurality of grouting ring tubes withdifferent elevations, wherein the grouting vertical tubes are fixed on the periphery of an uplift pile reinforcement cage; the grouting ring tubes are connected with the grouting vertical tubes and are fixed on the outer sides of the grouting vertical tubes; the bottom ends of each two grouting vertical tubes communicate with one corresponding grouting ring tube; a plurality of slurry outlet nozzles are arranged on each grouting ring tube along the periphery; and each slurry outlet nozzle can be temporarily closed by a closing device which can be flushed away by water pumped in by a water pump. A construction method of the uplift pile side post grouting device comprises the following steps: fixing the prefabricated grouting vertical tubes and the prefabricated grouting ring tubes on a pile body reinforcement cage; temporarily closing the slurry outlet nozzles on the grouting ring tubes by wrapping adhesive tapes or one-way valves, wherein each one-way valve is connected with water-permeable and slurry-tight slurry bags at intervals in a sealed manner; and unplugging the grouting vertical tubes and the grouting ring tubes by high-pressure water and completing pile side post grouting in twice or at a time. By the device and method, post grouting on the side surfaces of the peripheries of uplift piles can be uniformly distributed along the peripheries, grouting is smooth, and theconstruction efficiency is high.

Owner:NINGBO HONGCHEN CONSTR

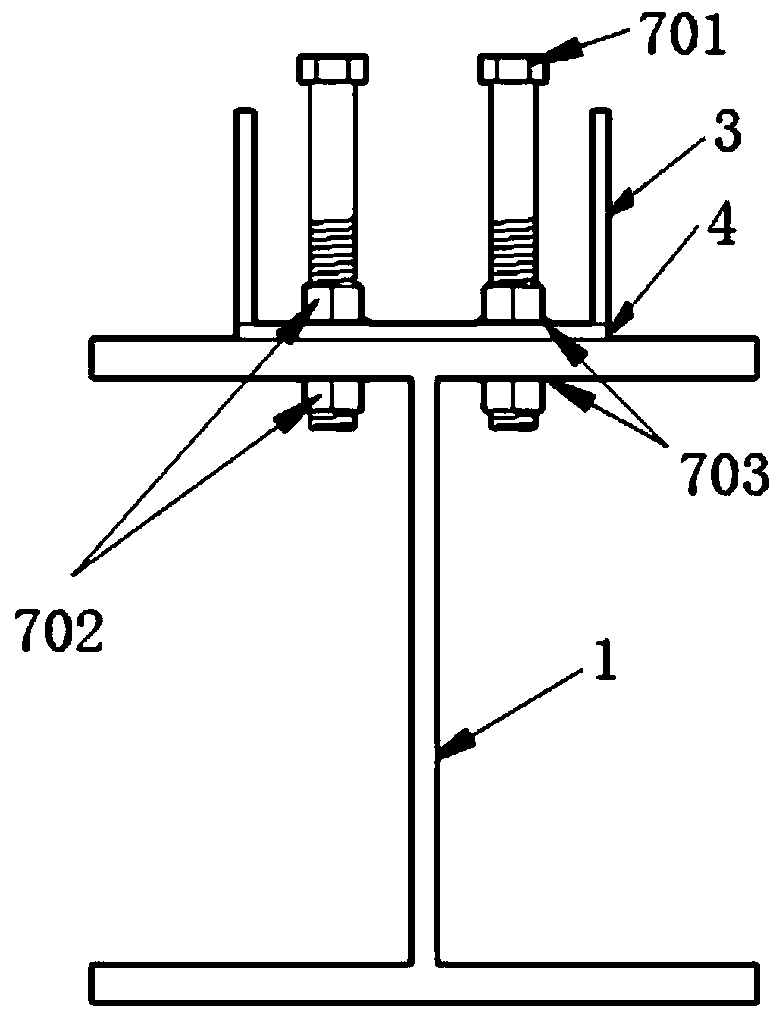

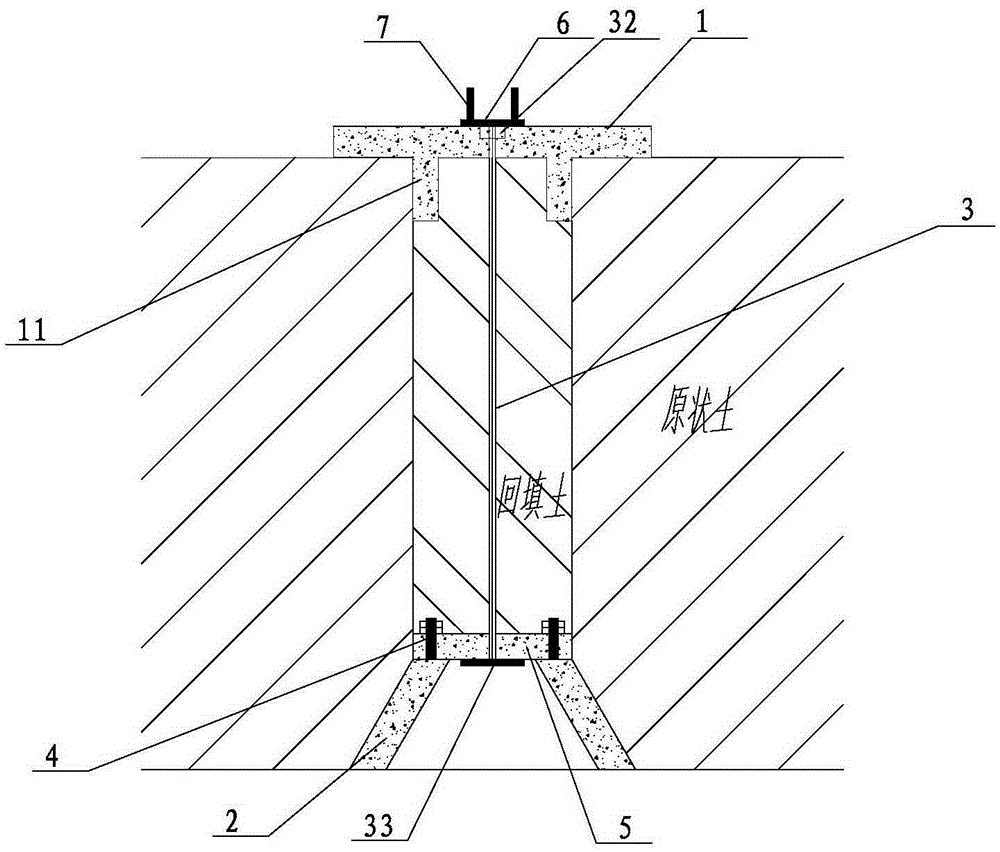

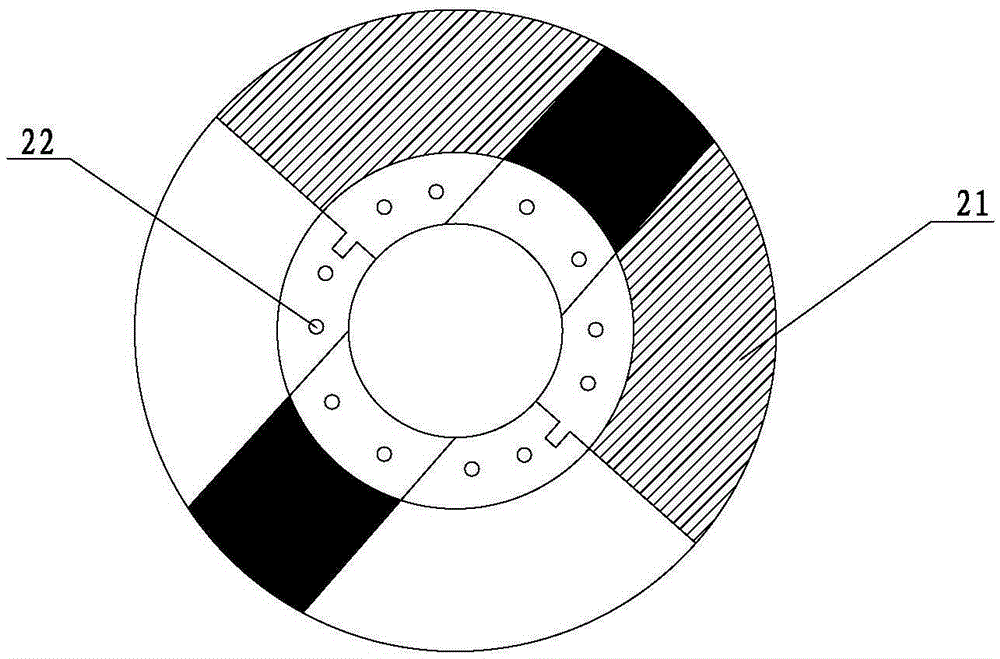

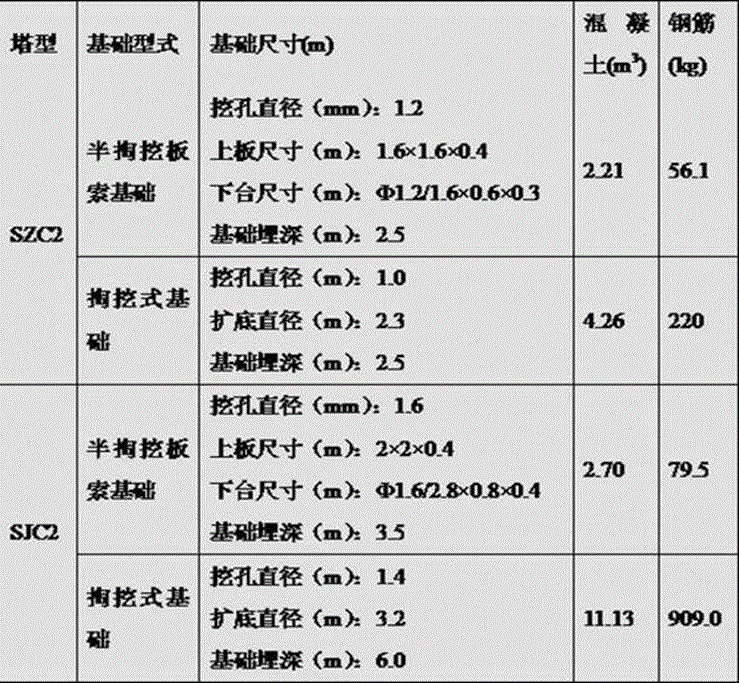

Assembled type flexible half-excavation foundation for electric transmission lines in mountainous areas

InactiveCN105297763AImprove the pull-out capacityIncreased resistance to horizontal loadsFoundation engineeringLoad resistanceAcoustic transmission line

The invention discloses an assembled type flexible half-excavation foundation for electric transmission lines in mountainous areas. The assembled type flexible half-excavation foundation comprises an upper slab, a base and an anchor cable used for connecting the upper slab and the base. The base is formed by splicing a plurality of prefabricated slabs and is in a circular truncated cone shape. The upper top face of the base is fixedly connected with a lower anchor slab through bolts. A steel cushion plate is arranged at the top of the upper slab. The center of the lower anchor slab and the center of the upper slab are each provided with a through hole used for allowing the anchor cable to penetrate through. The bottom end of the anchor cable is connected with the base through the lower anchor slab. The top end of the anchor cable is fixed to the upper slab through the steel cushion plate. An annular baffle is arranged on the lower surface of the upper slab. The circle center of the annular baffle is identical to the center of the upper slab. According to the assembled type flexible half-excavation foundation of the structure, the lower spliced type circular-truncated-cone-shaped base is embedded under undisturbed soil, by means of the structure, the uplift performance of the undisturbed soil can be brought into full play, and the uplift bearing capacity of the foundation is substantially improved; meanwhile, through the arrangement of the annular baffle on the lower surface of the upper slab, the horizontal load resistance of the foundation is improved.

Owner:SHAOXING UNIV YUANPEI COLLEGE +1

Earthquake liquefaction and suspension resisting structure and method for metro station

PendingCN108532647ALimit floating displacementEffective drainageProtective foundationBulkheads/pilesMetro stationPull force

The invention discloses an earthquake liquefaction and suspension resisting structure and an earthquake liquefaction and suspension resisting method for a metro station, solves the problem that in theprior art the metro station easily loses anti-pull force after a soil layer is liquefied, and achieves the beneficial effect of enhancing the anti-pull force of a bed rock section. The earthquake liquefaction and suspension resisting structure comprises a plurality of anti-suspension anchor rods; one end of each anti-suspension anchor rod is connected with the sidewall of the metro station or a base plate of the metro station; the other end of each anti-suspension anchor rod is arranged at a bed rock ground layer, wherein each anti-suspension anchor rod adopts a segmented type anchor rod; thecircumferential side of the second section, inserted into the bed rock ground layer, of each anti-suspension anchor rod is provided with high-strength mortar; and the circumferential side of the first section, inserted into a liquefiable ground layer, of each anti-suspension anchor rod is provided with common mortar.

Owner:JINAN RAILWAY TRANSPORT GRP CO LTD

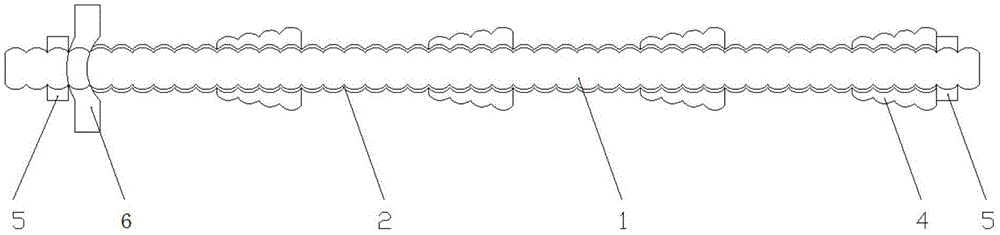

Precast pile with concave clamping platform and convex clamping platform

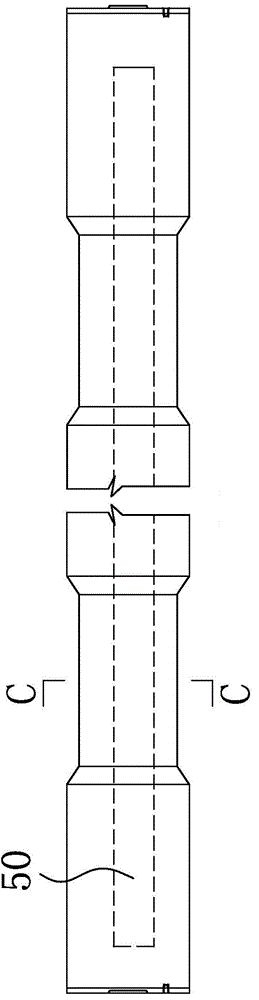

The invention belongs to the technical field of preformed units in the building industry and relates to a precast pile with a concave clamping platform and a convex clamping platform. The precast pile solves the technical problems that in the prior art, connection is not convenient and not firm. The precast pile comprises a pile body. The pile body is internally provided with a reinforcement cage. The reinforcement cage comprises a plurality of longitudinal reinforcement bars and spiral reinforcement bars fixedly connected with the longitudinal reinforcement bars. The two ends of the pile body are provided with a concave-convex clamping platform mechanism. When two adjacent pile bodies get close to each other, the concave-convex clamping platform mechanism can enable the two pile bodies to be matched in a clamped and connected manner so that the two pile bodies can be connected. According to the precast pile, the pile bodies can be quickly and firmly connected.

Owner:周兆弟

Construction method for expanded reinforced cast-in-situ bored pile with hydraulic extruding and expanding combined bag grouting pile body

The invention relates to a construction method for an expanded reinforced cast-in-situ bored pile with a hydraulic extruding and expanding combined bag grouting pile body. The construction method is characterized by comprising the steps that after drilling is finished, a manufactured reinforcement cage and hydraulic equipment are placed in a drilled hole, a bag grouting extruding and expanding body is wrapped with a bag, then the reinforcement cage is placed in the hole to be subjected to hydraulic extruding and expanding, and finally bag grouting and concrete pouring are carried out. The construction method comprises the steps of drilling and forming the hole, manufacturing the reinforcement cage, installing a steel sleeve, an expansion plate, the bag and the like, installing the hydraulic equipment, lowering the reinforcement cage, hydraulic extruding and expanding construction, grouting the bag, pouring the concrete, and cleaning and maintenance of the hydraulic equipment. The extruding and expanding body can be unfolded in a corresponding soil layer, and reinforcing ribs are arranged in the extruding and expanding body, so that the strength of the extruding and expanding body and the interface strength between the extruding and expanding body and a pile body are improved, the contact area between the extruding and expanding body and the soil body is increased, the uplift bearing capacity is improved, the length and the distance of the cast-in-place pile are reduced, the cost is reduced, and resources are saved.

Owner:中煤长江基础建设有限公司

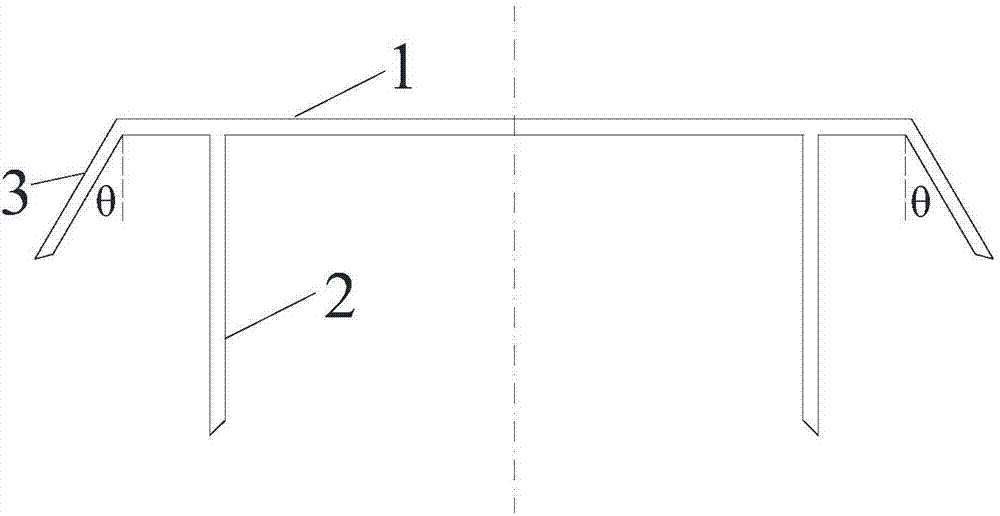

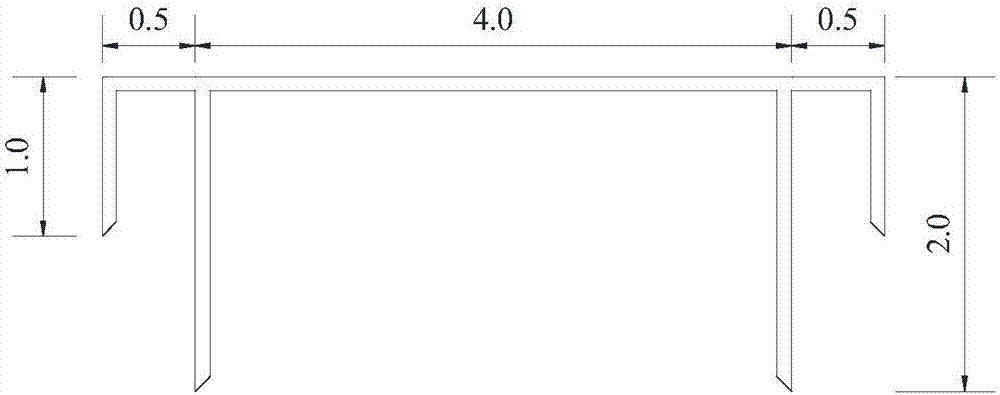

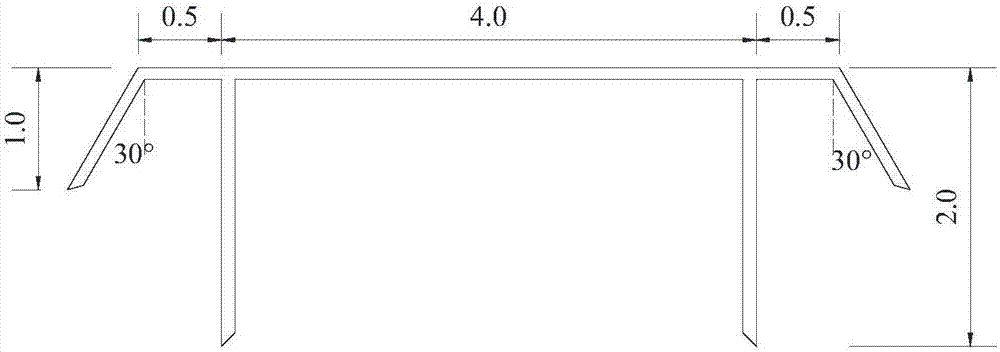

Oblique skirt type suction foundation suitable for soft soil foundation

InactiveCN107119709AImprove vertical bearing capacityImprove the pull-out capacityArtificial islandsFoundation engineeringSuction stressHorizontal and vertical

The invention discloses an oblique skirt type suction foundation suitable for a soft soil foundation. The oblique skirt type suction foundation comprises a main bucket, a foundation top plate fixedly connected to the main bucket, and a skirt structure annularly fixed to the outer edge of the foundation top plate. The skirt structure is an oblique skirt structure, and the oblique skirt structure is in a horn shape. The horn-shaped oblique skirt structure is adopted, and when a structure object on the foundation is subjected to horizontal and vertical loads, the foundation area is increased in the vertical direction through a horn-shaped body of the oblique skirt structure, and therefore the vertical bearing force of the foundation is increased. Meanwhile, due to existence of the horn-shaped body of the oblique skirt structure, the uplift bearing force of the foundation is increased. The horn-shaped body of the oblique skirt structure generates the vertical pressure component under the action of the horizontal loads, accordingly, the horizontal bearing force of the foundation is increased, and therefore the vertical bearing force, the uplift bearing force and the horizontal bearing force of the suction foundation can be improved, and the safety coefficient of the suction foundation is improved; and meanwhile, construction is convenient, and the project cost can be reduced.

Owner:TIANJIN RES INST FOR WATER TRANSPORT ENG M O T

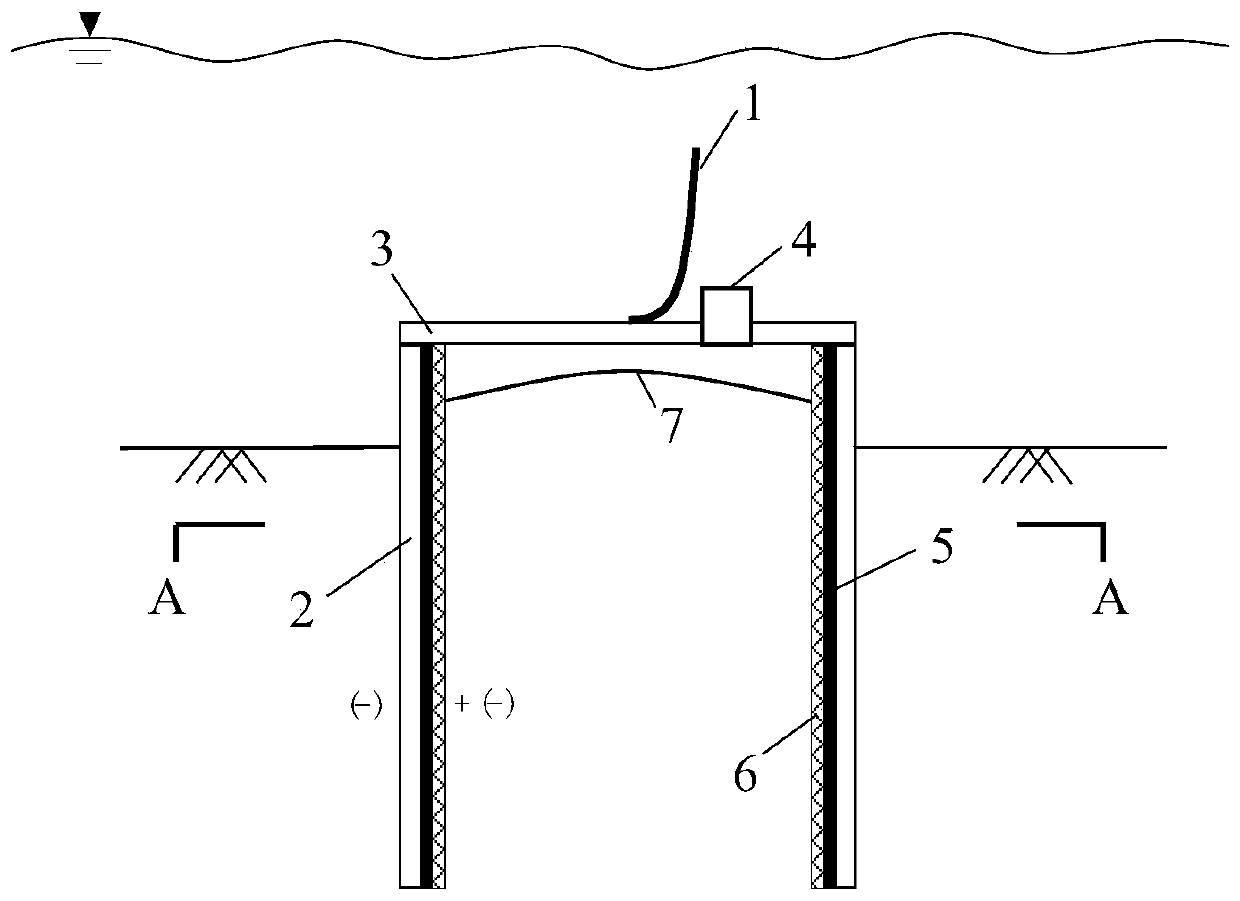

Suction cylindrical foundation sink tube deviation correction and reinforcing device and manufacture method thereof

ActiveCN109695264AWeaken frictionImprove penetration efficiencyProtective foundationFoundation repairUltimate tensile strengthSteel tube

The invention belongs to the technical field of marine structure foundations, and discloses a suction cylindrical foundation sink tube deviation correction and reinforcing device. The device has the advantages that a suction cylindrical foundation sink tube serves as a cathode, an attached copper tube or steel tube serves as an anode, electroosmosis is formed on the periphery of the wall of the sink tube, the friction resistance of a contact surface between the wall of the sink tube and deep sea soil is weakened during the penetration of the sink tube, and the penetration efficiency is improved; when a suction cylindrical foundation is inclined, the effect of deviation correction is achieved through electroosmosis in a corresponding position; finally, the strength of soil of the interior of the sink tube and the wall of the sink tube are improved through a chemical electrodialytic method, and the overall uplift bearing capacity of the suction cylindrical foundation is improved. The technical scheme is convenient for construction and good in economical efficiency.

Owner:DALIAN UNIV OF TECH

Static pressure type rear support spiral pile based on bionics and construction method thereof

The invention discloses a static pressure type rear support screw pile based on bionics, which comprises a pile tip, an outer sleeve, a flange and an empennage, the empennage is arranged at the upperend of the outer sleeve, the flange is arranged at the top ends of the empennage and the outer sleeve, an outer support blade is arranged at the lower part of the outer sleeve, and when the outer support blade is pressed at the top of the outer sleeve, the outer supporting blades are unfolded outwards. A built-in steel pipe or a flexible anchor rod is arranged in the outer sleeve, and the pile tipis fixedly connected with the built-in steel pipe or the flexible anchor rod. By optimally designing the pile body, the side resistance is small during static pressure pile sinking penetration, the outer supporting blades are unfolded through secondary sinking of the outer sleeve, the vertical uplift and compression resistance bearing capacity of the outer supporting blades is improved, the horizontal bearing capacity of the outer supporting blades is improved through the arrangement of the empennage, and the uplift bearing capacity of the pile side and the blades is improved by utilizing thecharacteristics of compression shrinkage and tension expansion of negative poisson ratio materials. The method has the advantages of small soil disturbance, low construction noise and environmental friendliness.

Owner:HOHAI UNIV +3

Prestressed expanded-head anti-floating anchor rod and construction method

The invention belongs to the technical field of rock-soil anchoring, and relates to a prestressed expanded-head anti-floating anchor rod and a construction method.The variable-diameter reinforcement cage is installed on the anchoring section of an anchor rod body, the outer side of the free section of the anchor rod body is sleeved with an anti-corrosion lantern ring, an anchor rod centering device is arranged on the free section of the anchor rod body, and the upper portion of the anchor rod body is sleeved with a second steel sleeve; the bottom of the second steel sleeve is connected with the top of the anti-corrosion lantern ring, and the top of the second steel sleeve is aligned with the bottom face of the anchor pit in parallel and connected with a stress diffusion anchor disc which is fixed through a fastening nut. The anchor rod impermeable layer is arranged between the building foundation bottom plate and the foundation waterproof layer, and the grouting pipe is arranged on one side of the anchor rod body; when the variable-diameter reinforcement cage is unfolded, the contact area of the anchor rod body and an anchoring body can be increased, bonding of the anchor rod body and the anchoring body is enhanced, the uplift bearing capacity of the anchor rod is improved, cracking of anchoring section concrete is effectively controlled, and the integrity of the anchor rod is enhanced. The variable-diameter reinforcement cage is opened by means of grouting pressure and the gravity of the device, and construction is simple and fast.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Enlarged head non-metal anti-floating anchor rod rapid pull-out test device

ActiveCN107621412AImprove the pull-out capacityIncreased durabilityMaterial strength using tensile/compressive forcesOperabilityFoundation engineering

The invention belongs to the technical field of ground foundation engineering equipment and relates to an enlarged head non-metal anti-floating anchor rod rapid pull-out test device. Multi-positioninganti-pull enlarged heads are arranged at the rod end and on the rod body of a non-metal anchor rod; after the rod body is put into a drill hole and grouted to form the anchor rod, the rapid pull-outtest device is used for performing anti-floating anchor rod anti-pull bearing capacity and deformation tests; the enlarged head non-metal anti-floating anchor rod rapid pull-out test device is convenient and rapid in construction, simple to mount, safe, reliable, high in operability, high in testing precision, not liable to damage, reusable, low in cost, high in anti-pull bearing capacity of the anchor rod and high in durability, and can effectively improve the anti-floating capability of the anchor rod.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Suction matching device capable of improving uplift bearing capacity of tubular pile

InactiveCN108643168AImprove structural strengthReasonable and reliable structureBulkheads/pilesEngineeringSilica gel

The invention discloses a suction matching device capable of improving the uplift bearing capacity of a tubular pile. The suction matching device comprises a tubular pile body, a hollow cavity and a suction box, wherein the upper end of the tubular pile body and the lower end of the tubular pile body are each provided with a pile hoop; the hollow cavity is located in the center of the tubular pile, and the top of the hollow cavity is sealed by plain concrete; the suction box is arranged at the top of the hollow cavity in a matched mode and comprises a box body, an air suction pipe, an air valve and a piston; the box body is arranged at the top of the hollow cavity and is connected with the inner wall of the tubular pile body through a silica gel layer; the air suction pipe penetrates through the bottom of the box body, and the air on the upper side of the box body communicates with the air on the lower side of the box body through the air suction pipe; the air valve is located at the top of the air suction pipe; and the piston is located at the top of the box body. The suction matching device capable of improving the uplift bearing capacity of the tubular pile is suitable for a prefabricated embedded type tubular pile foundation, the suction capacity of the tubular pile to a soil body is improved by utilizing the principle of the negative pore pressure of the soil body, and theuplift bearing capacity of the tubular pile is improved.

Owner:TONGJI UNIV

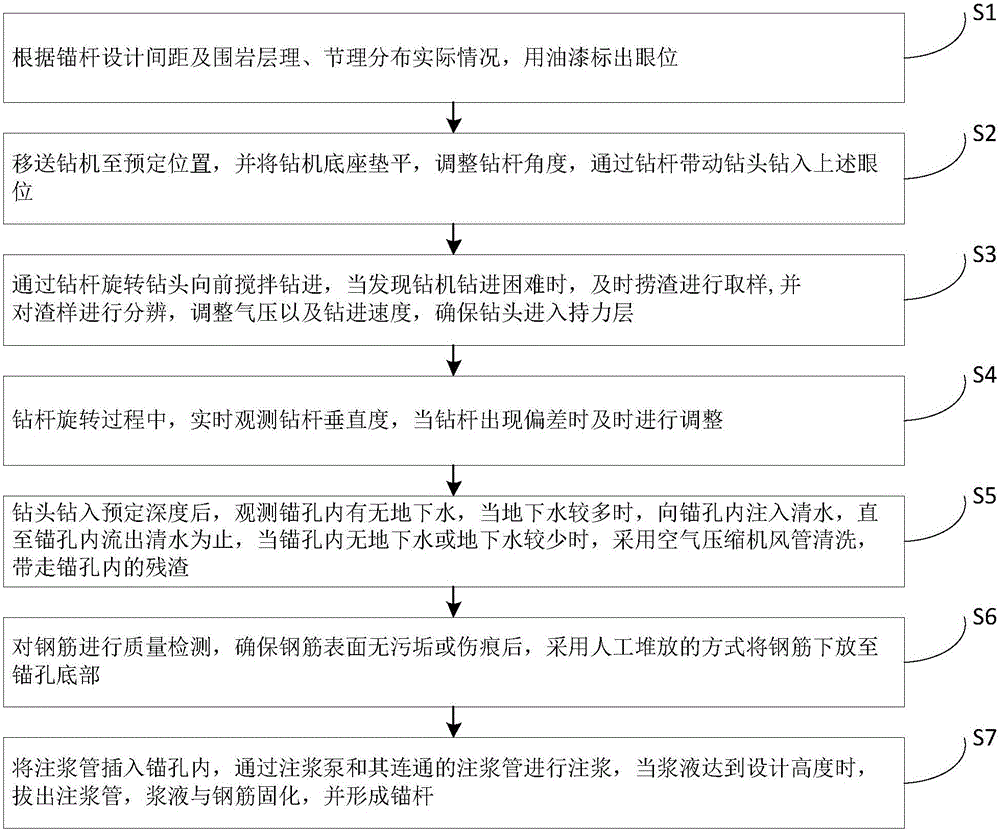

Construction method for anchor rod for civil engineering

The invention provides a construction method for an anchor rod for civil engineering. The construction efficiency is high, mud and vibration are avoided, the stability performance of anchor holes is high, the strength of the anchor rod is high, and the anti-puling bearing capability of the anchor rod is high. The construction method comprises the following steps that an eye position is marked through paint; a drilling machine is moved to the preset position, and a drill bit is driven by a drill rod to drill into the eye position; when it is found that drilling is difficult for the drilling machine, the air pressure and the drilling speed are adjusted in time; in the rotating process of the drill rod, the perpendicularity of the drill rod is observed in real time; after the drill bit drills into the position by the preset depth, whether underground water exists in an anchor hole or not is observed, and when a large amount of underground water exists, clean water is injected in the anchor hole, and when no underground water or a small amount of underground water exists in the anchor hole, cleaning is carried out through an air compressor air pipe; quality detection is carried out on a steel bar, and the steel bar is placed into the bottom of the anchor hole in a manual stacking manner; and a grouting pipe is inserted into the anchor hole, grouting is carried out through a grouting pump and the grouting pipe communicated with the grouting pump, and when the grout reaches the designed height, the grouting pipe is pulled out, and the grout and the steel bar are solidified and form the anchor rod.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

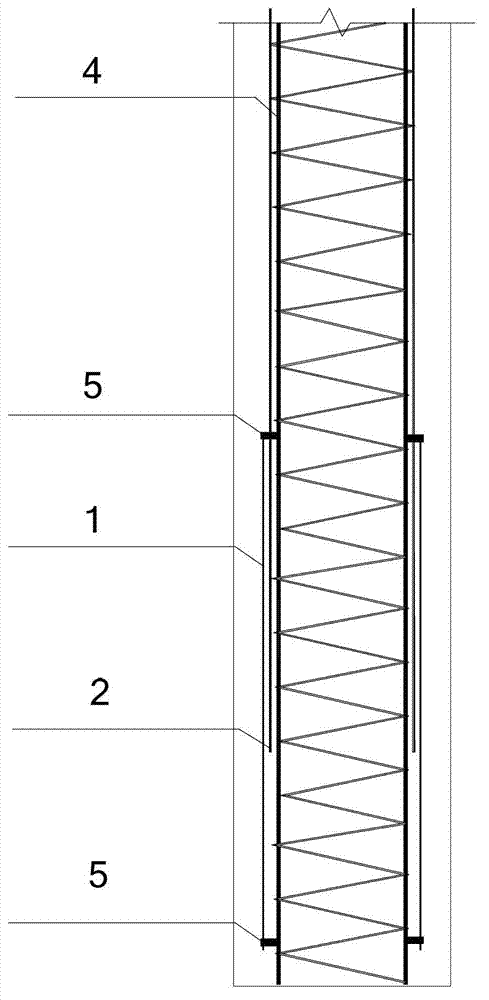

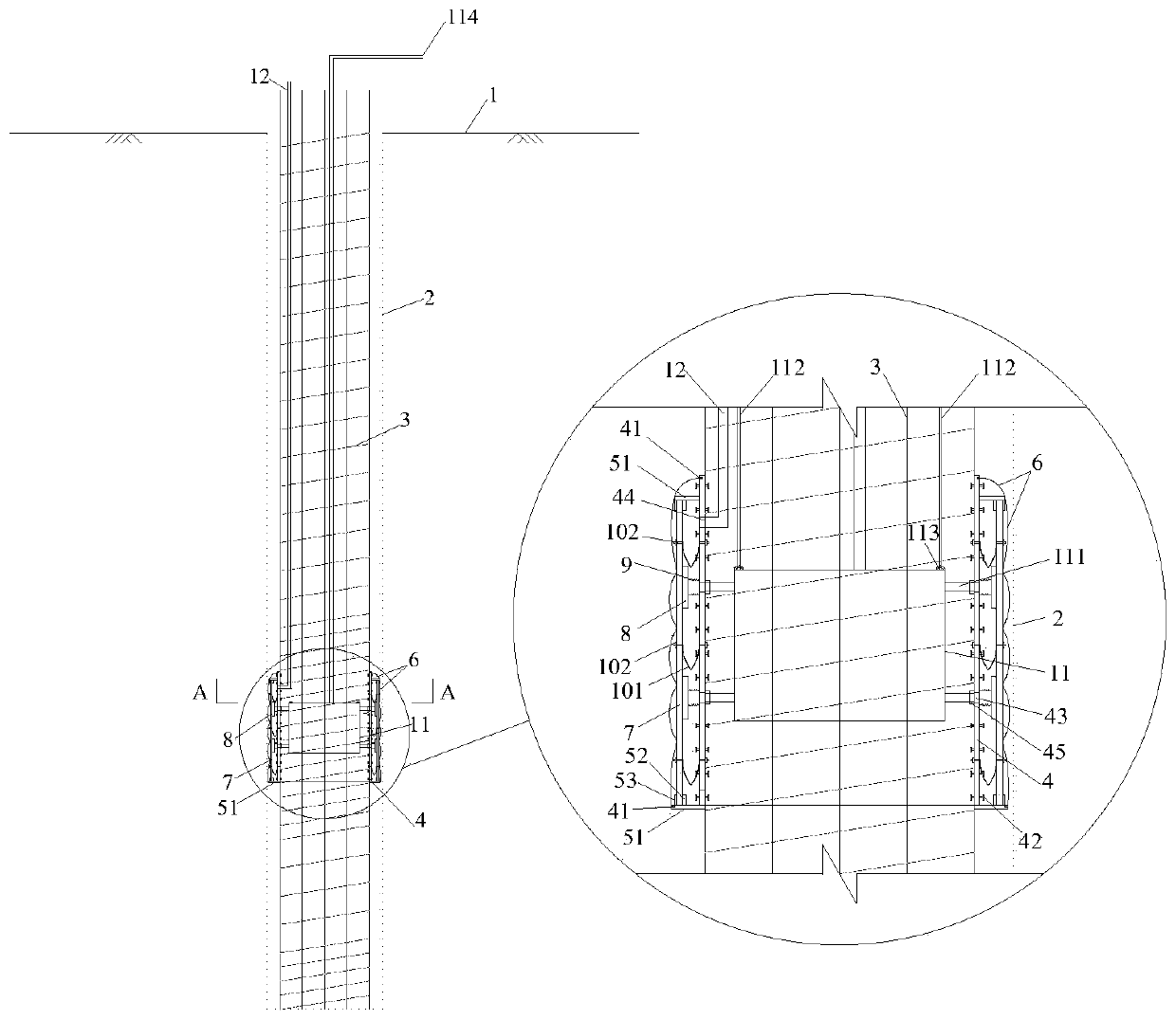

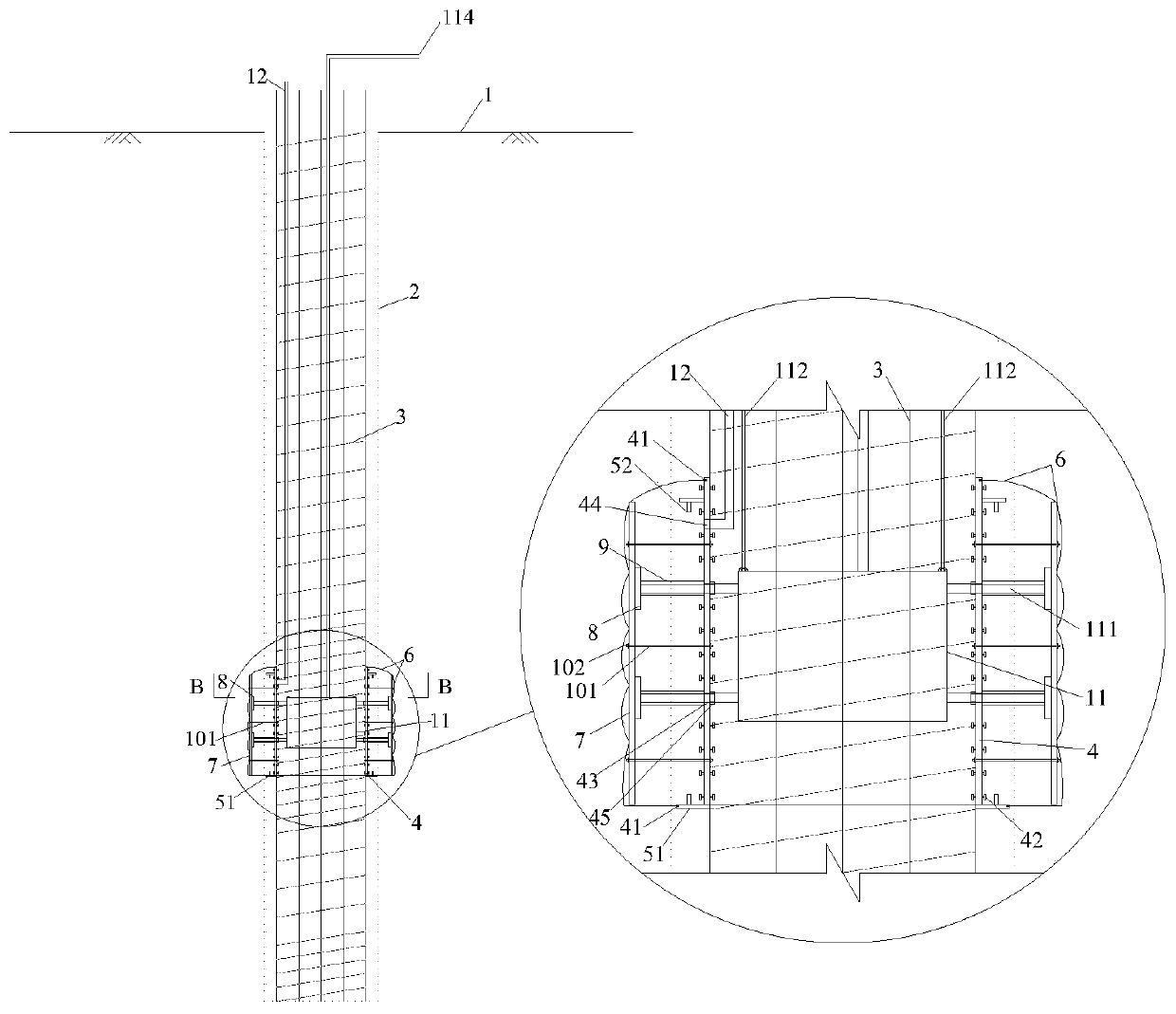

Novel prefabricated stainless steel heat preservation connector outer wall and production method

PendingCN108149838AImprove mechanical propertiesGood heat insulationCeramic shaping apparatusBuilding reinforcementsRelative displacementEngineering

The invention relates to a novel prefabricated stainless steel heat preservation connector outer wall. A heat preservation layer is arranged on the outer side of an inner leaf wall board, and an outerleaf wall board is arranged on the outer side of the heat preservation layer; one end of a heat preservation connector is fixed in the inner leaf wall board, and the other end of the heat preservation connector penetrates the heat preservation layer to be fixed in the outer leaf wall board; one end of a limit pull member is fixed in the inner leaf wall board, and the other end of the limit pull member penetrates the heat preservation layer to be fixed in the outer leaf wall board; and the invention also relates to a production method for the novel prefabricated stainless steel heat preservation connector outer wall. The novel prefabricated stainless steel heat preservation connector outer wall has the beneficial effects that the thermal expansion coefficient of the connector needs to be close to wall bodies on both sides to ensure that during the use of the wall boards, the relative displacement between the inner and outer leaf wall boards is prevented; the novel stainless steel connector is easy to operate and simple in process in the production of the outer wall, and the stainless steel connector has better corrosion resistance and mechanical strength than a conventional connector; and the overall shear resistant strength of the prefabricated wall is increased, and the pulling-resistant bearing capacity is high.

Owner:山东海龙建筑科技有限公司

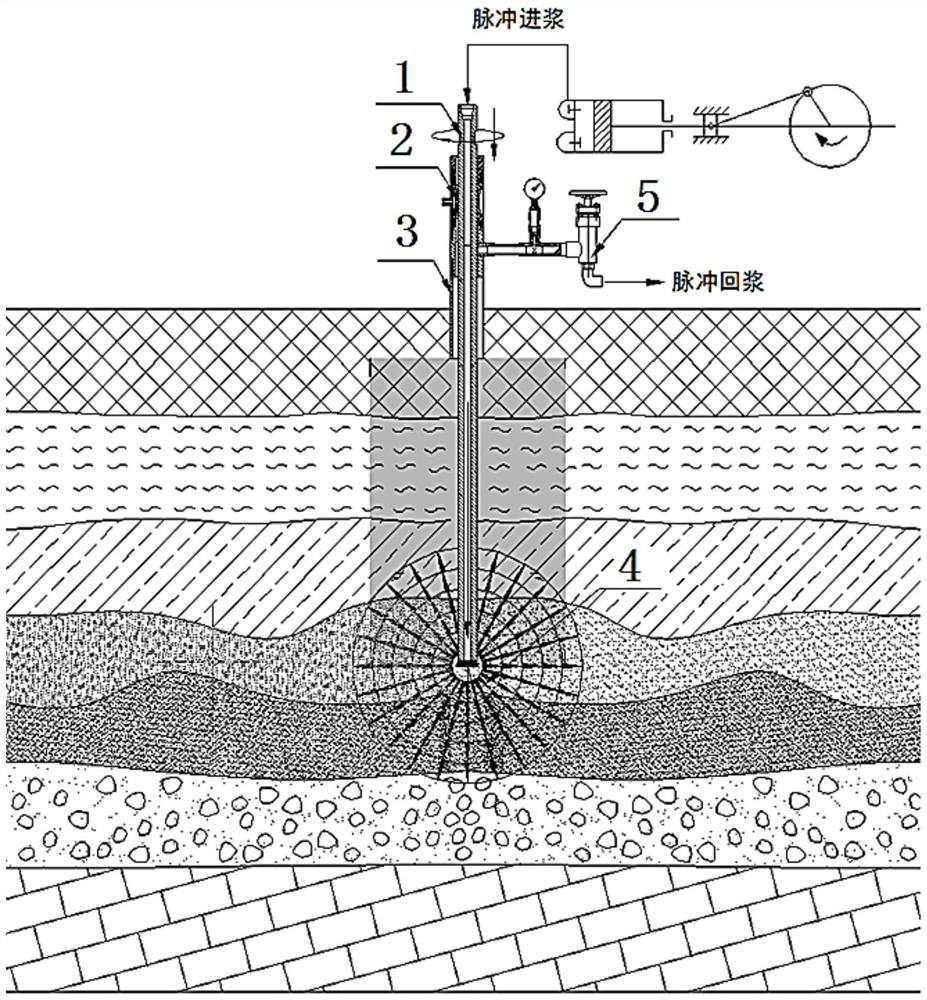

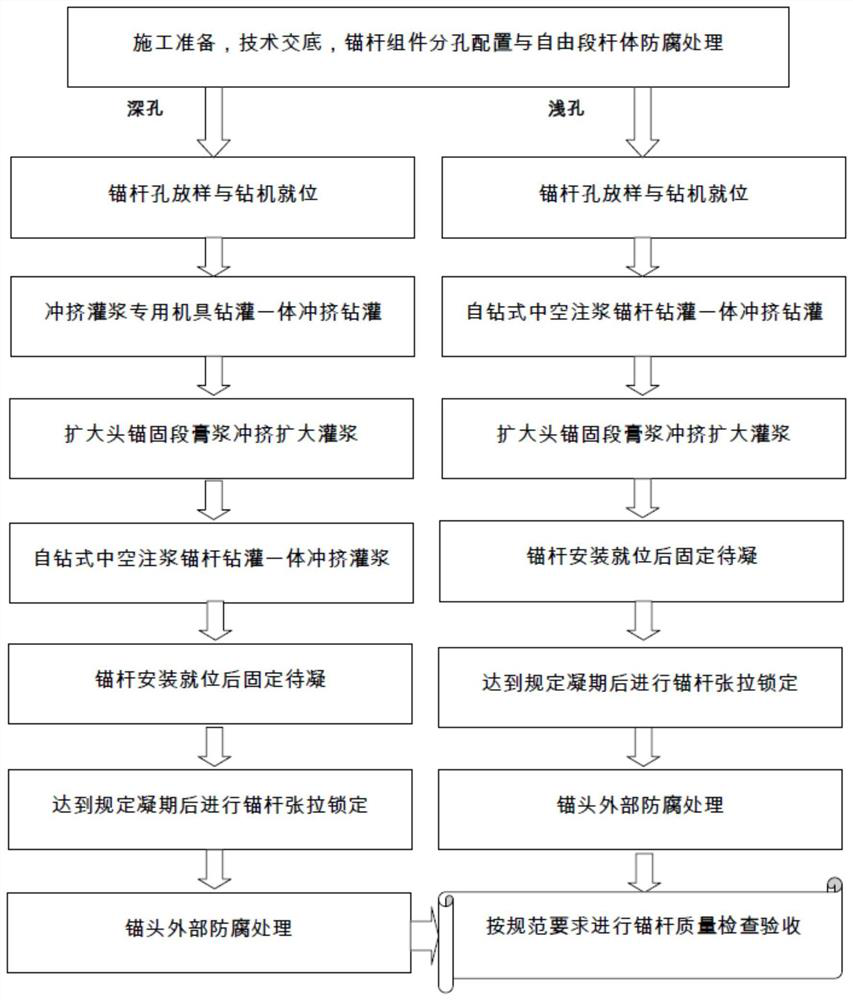

Paste slurry drilling, grouting and impact extrusion expanded-head anchor rod structure system and construction method thereof

PendingCN111910615AImprove the pull-out capacitySmall amount of creepBulkheads/pilesSoil preservationSlurryRock bolt

The invention discloses a paste slurry drilling, grouting and impact extrusion expanded-head anchor rod structure system and a construction method thereof. According to the construction method, a self-drilling type hollow grouting anchor rod meeting the design requirement is directly used, and a drilling and grouting integrated in-situ impact extrusion grouting method is adopted, and middle-high pressure paste slurry impact extrusion drilling and grouting are conducted on full-hole section surrounding soil from top to bottom; and then a paste slurry pulse high-pressure pile squeezing and splitting method is adopted for conducting segmented reciprocating high-pressure paste slurry impact extrusion expanding grouting on an expanded-head anchoring hole section from bottom to top, after the expanded-head anchoring section meeting the design requirement is formed, middle-high pressure paste slurry impact extrusion drilling and grouting are conducted from top to bottom, and the self-drillingtype hollow grouting anchor rod is installed in place, so that the composite anchor rod structure system is formed, wherein the composite anchor rod structure system is combined with the self-drilling type hollow grouting anchor rod, and the composite anchor rod structure system is composed of upper non-anchored section middle-high pressure paste slurry impact extrusion grouting composite surrounding soil, a lower anchored section high-pressure paste slurry impact-extrusion expanded head pile body, a pile periphery slurry extrusion and splitting vein and a compacted soil body. The paste slurry drilling, grouting and impact extrusion expanded-head anchor rod structure system is convenient to construct, small in waste slurry amount, safe, environment-friendly and controllable in quality.

Owner:POWERCHINA ZHONGNAN ENG +1

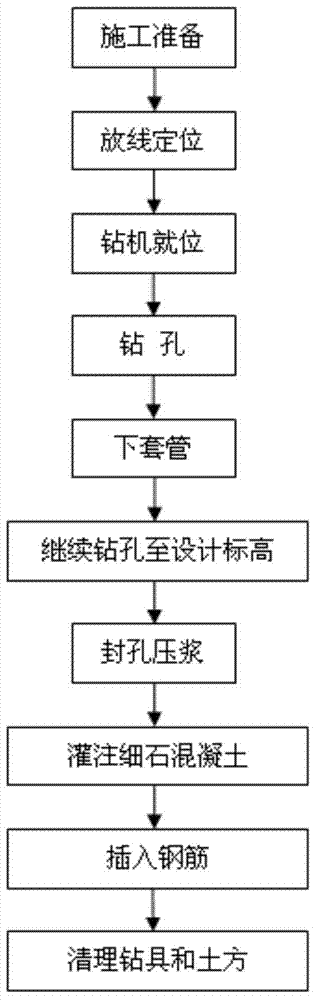

Drilling and high-pressure grouting construction method for uplift pile

ActiveCN104727305AReduce consumptionImprove pullout resistanceBulkheads/pilesSocial benefitsHigh pressure

The invention discloses a drilling and high-pressure grouting construction method for an uplift pile. The drilling and high-pressure grouting construction method includes the steps that step1, construction preparation is performed; step2, paying-off positioning is performed; step3, a drilling machine is in place; step4, drilling is performed; step5, casing running is performed; step6, drilling is continued to a designed elevation; step7, hole sealing grouting is performed; step8, concrete pouring is performed; step9, steel bars are inserted; step10, drilling tool and earthwork clearing is performed. The drilling and high-pressure grouting construction method has the advantages that in the drilling process, noise is low, vibration is small, the construction period is short, influences on surrounding traffic and social activities are small, and the construction method is a green construction method; while the uplift bearing capacity of a foundation is improved, the construction method saves a lot of resources and energy, and has remarkable social benefits.

Owner:ANHUI TONGJI CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com