Construction method for expanded reinforced cast-in-situ bored pile with hydraulic extruding and expanding combined bag grouting pile body

A technology of bored cast-in-place piles and construction methods, which are applied in sheet pile walls, foundation structure engineering, construction, etc., to achieve the effects of reducing length, easy quality assurance, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

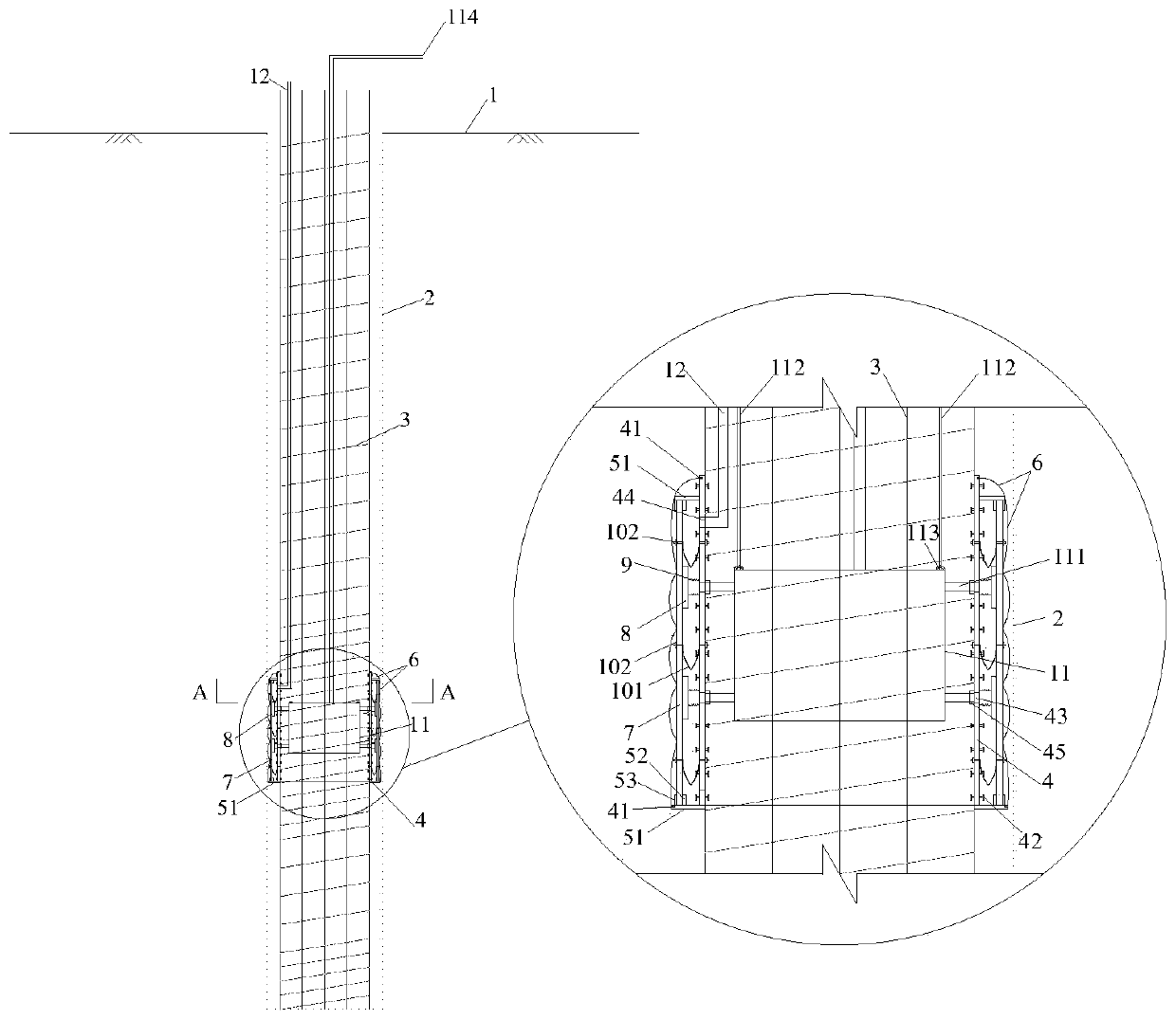

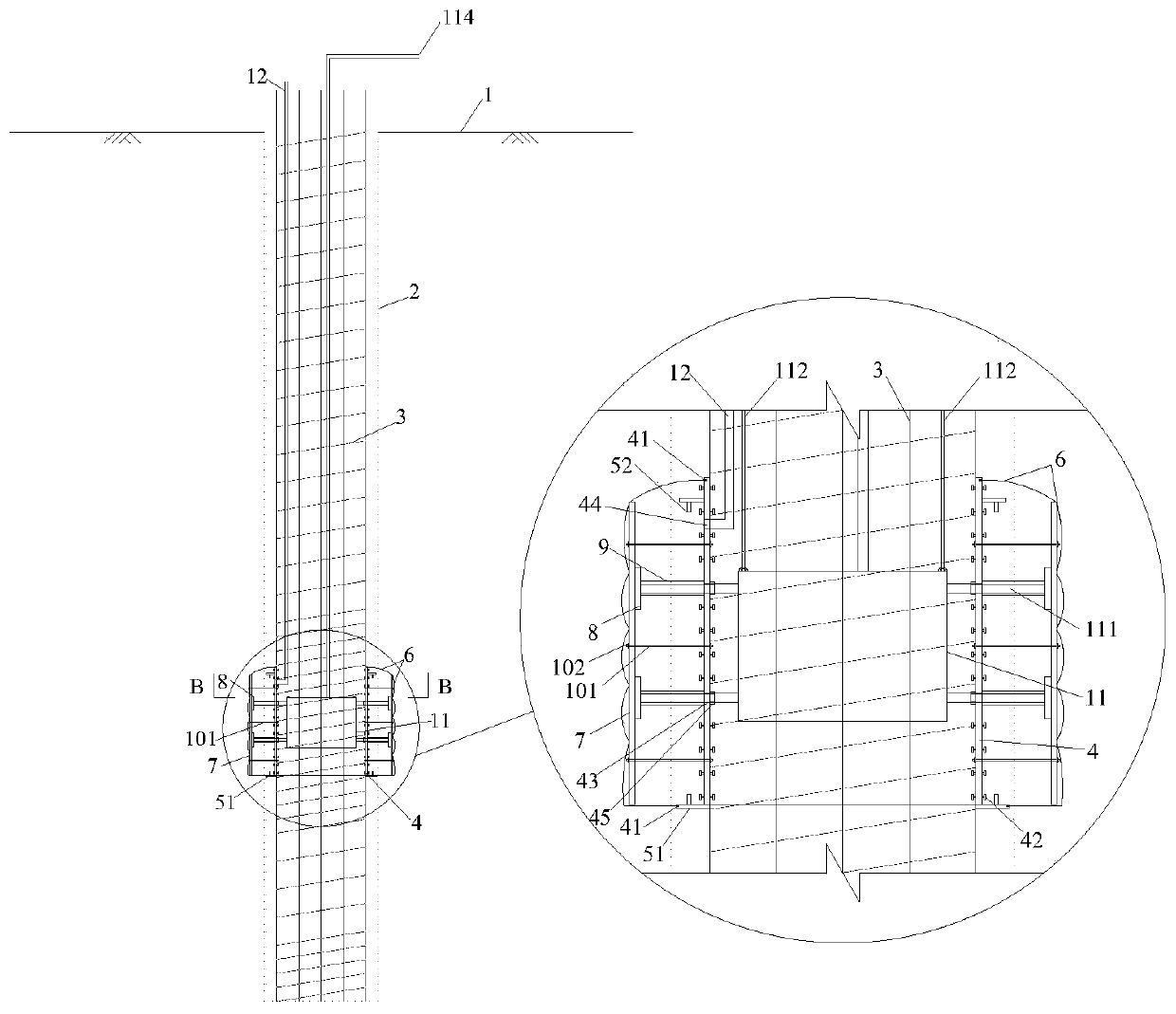

[0047] In order to deepen the understanding of the present invention, reference will be made to Figure 1 to Figure 13 , the embodiments of the present invention are described in detail, the following embodiments are implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

[0048] combined with Figure 5 with 9 As shown, a kind of hydraulic squeeze expansion joint bladder grouting pile body that the present invention relates to expands the reinforced bored cast-in-place pile, comprises cast-in-place pile pile body, and cast-in-situ pile pile body comprises reinforcement cage 3 and concrete 14, and cast-in-situ pile pile length is The diameter of cast-in-situ pile is 22m, the diameter of cast-in-situ pile is 1m, the longitudinal bar of steel cage is hot-rolled ribbed HRB400Φ16, the stirrup is spiral hoop HPB235Φ8@100, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com