Patents

Literature

740results about How to "Improve pullout resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

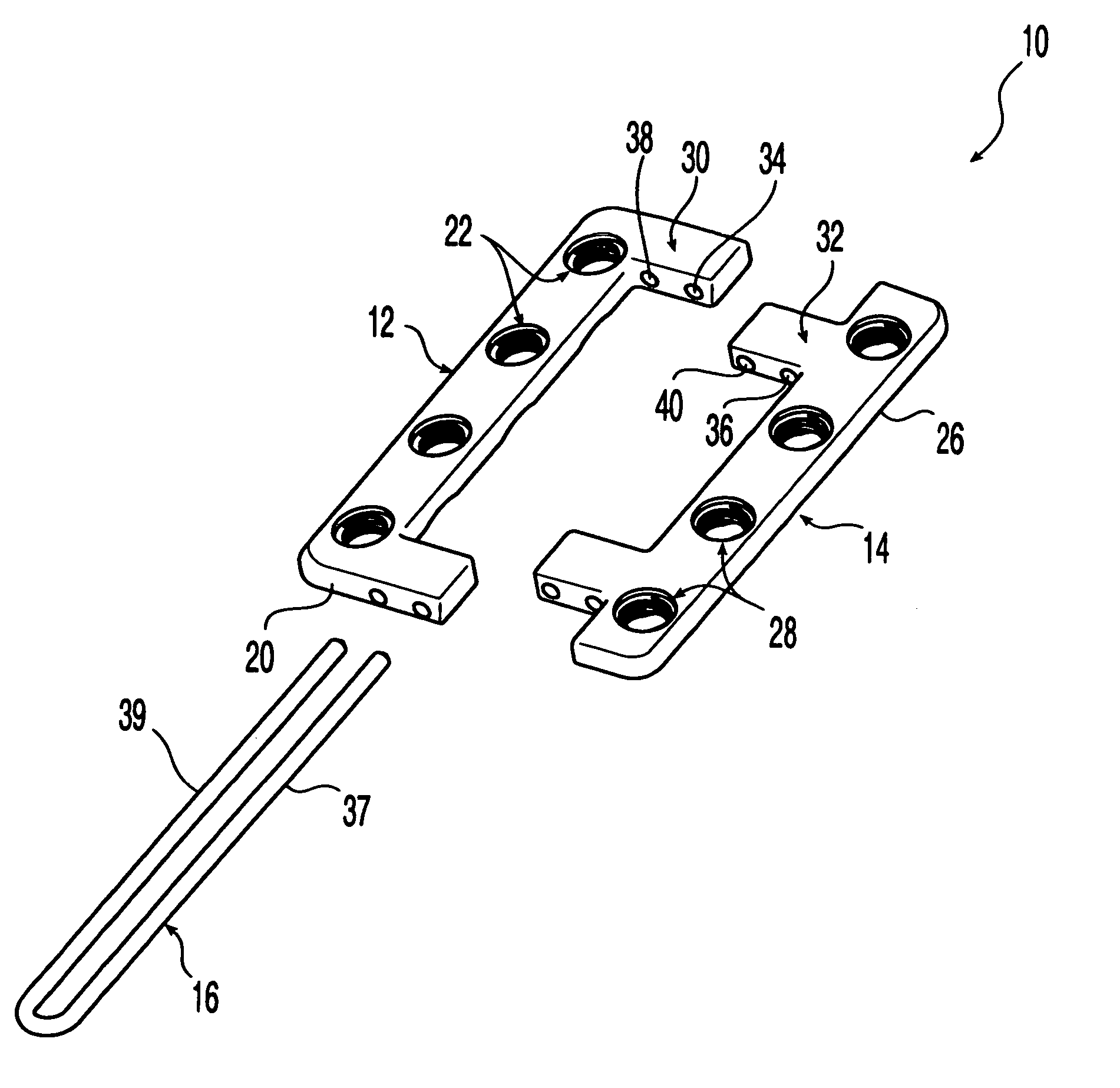

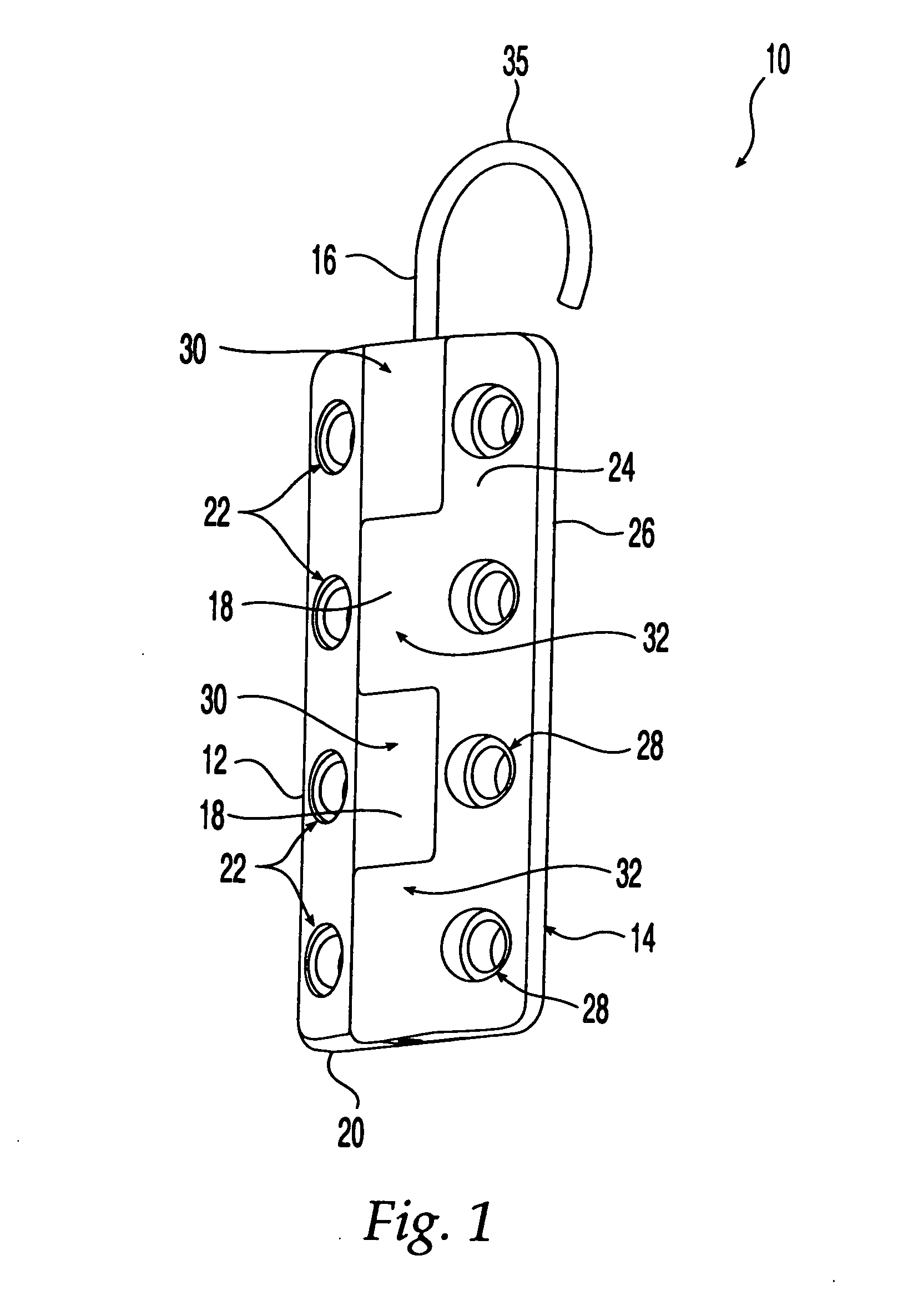

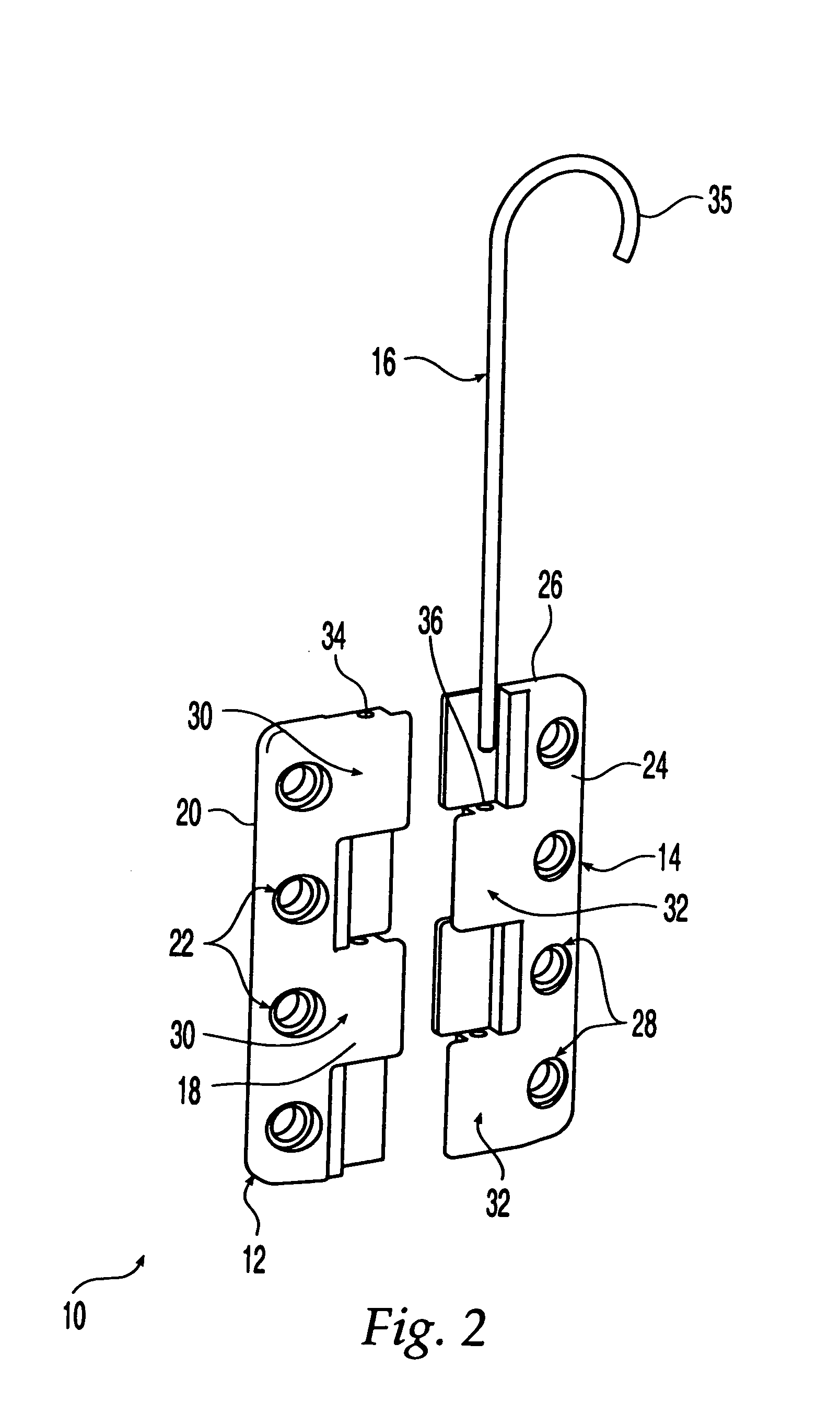

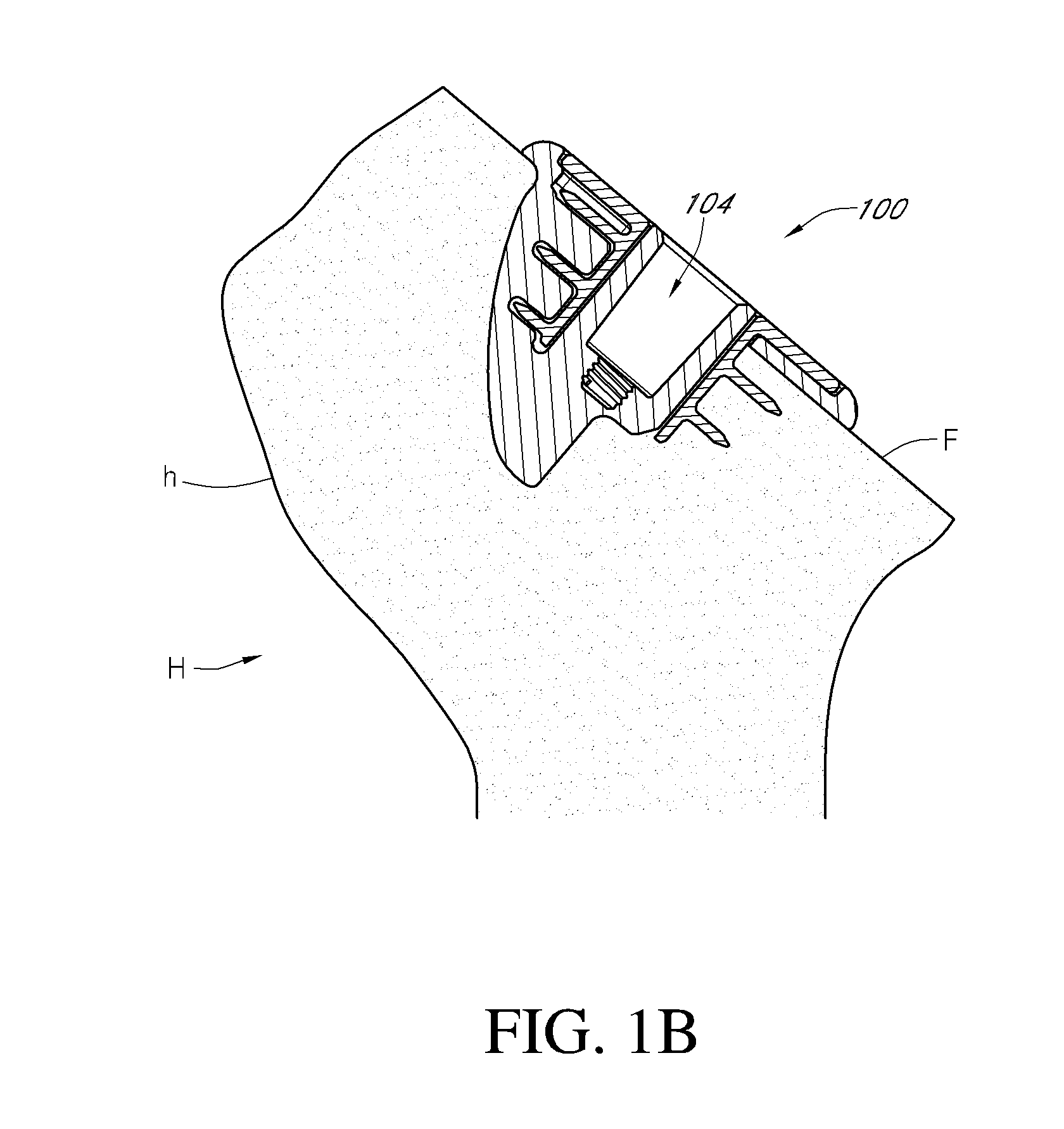

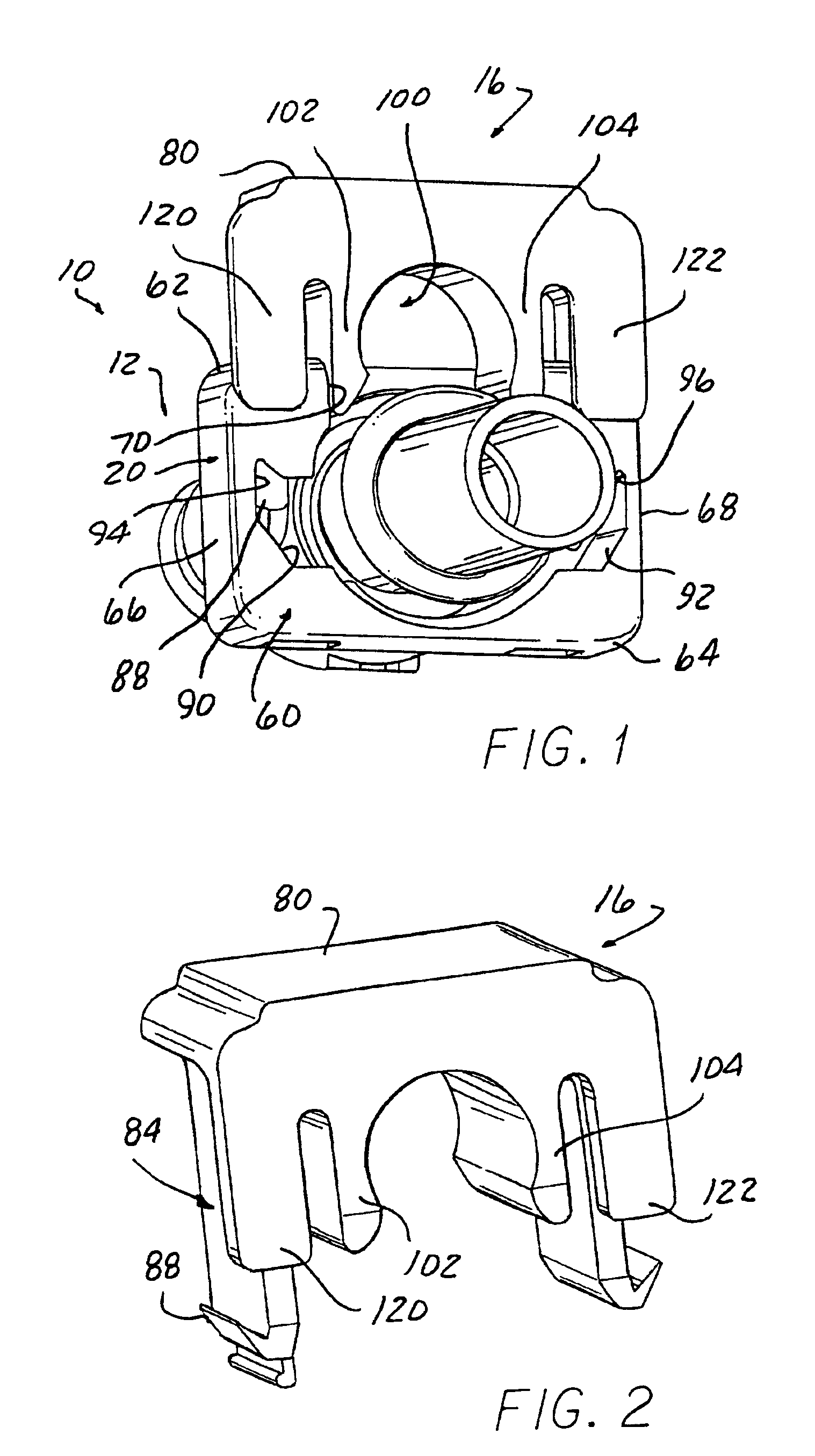

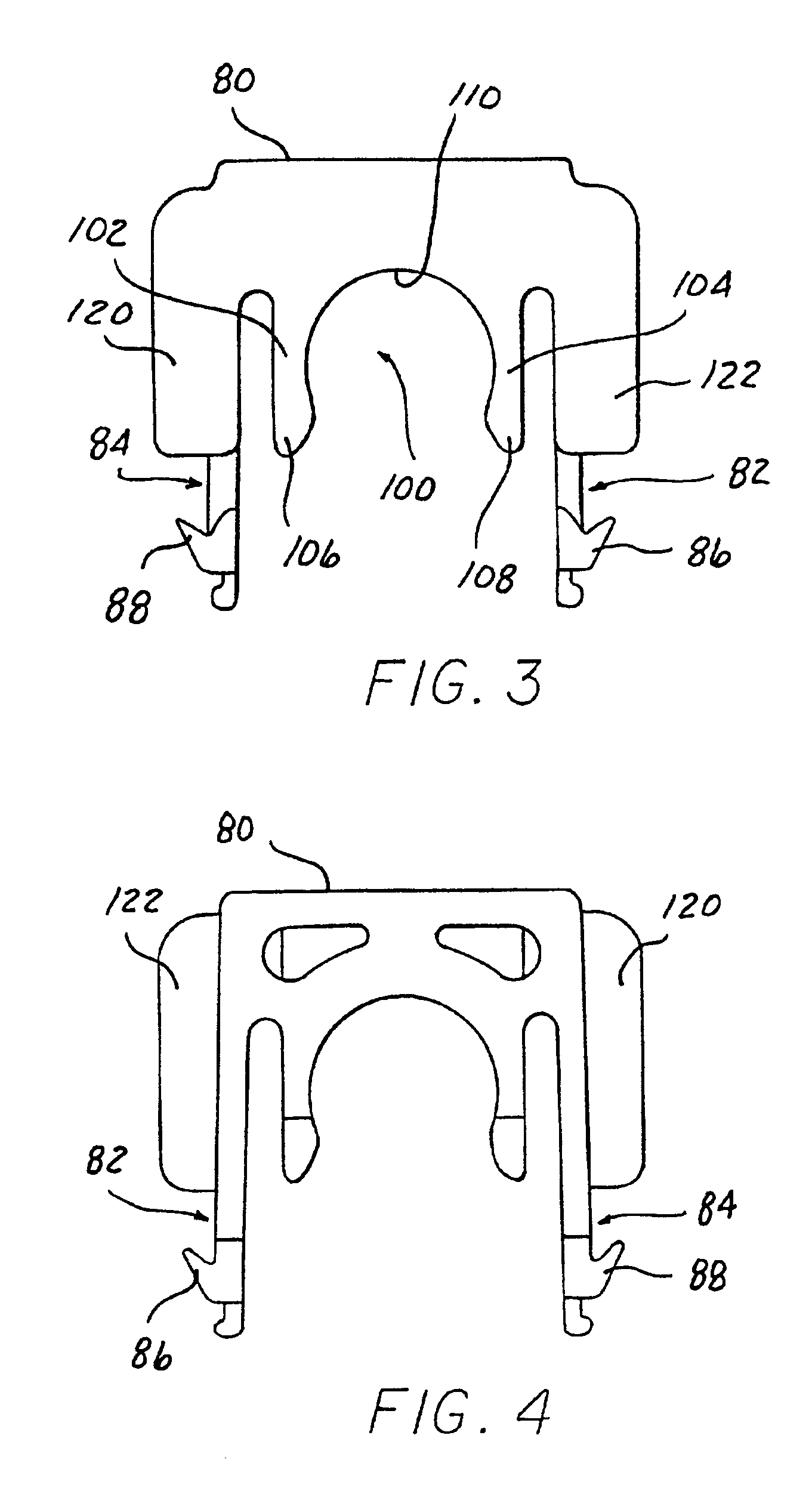

Sternum fixation device

ActiveUS20050124996A1Improve pullout resistanceInternal osteosythesisJoint implantsEngineeringBreast bone

A sternum fixation device for securing parts of a sternum includes first and second removably associated plates. The first plate has an upper surface and a sternum-contacting surface, and at least one hole passing through both of these surfaces for receiving a fastener head. The second plate has at least one attachment member for fixation to the sternum. A release member holds the first and second plates together, and is movably associated with at least one of the first and second plates such that it may be moved to allow separation of the two parts of the sternum.

Owner:SYNTHES USA

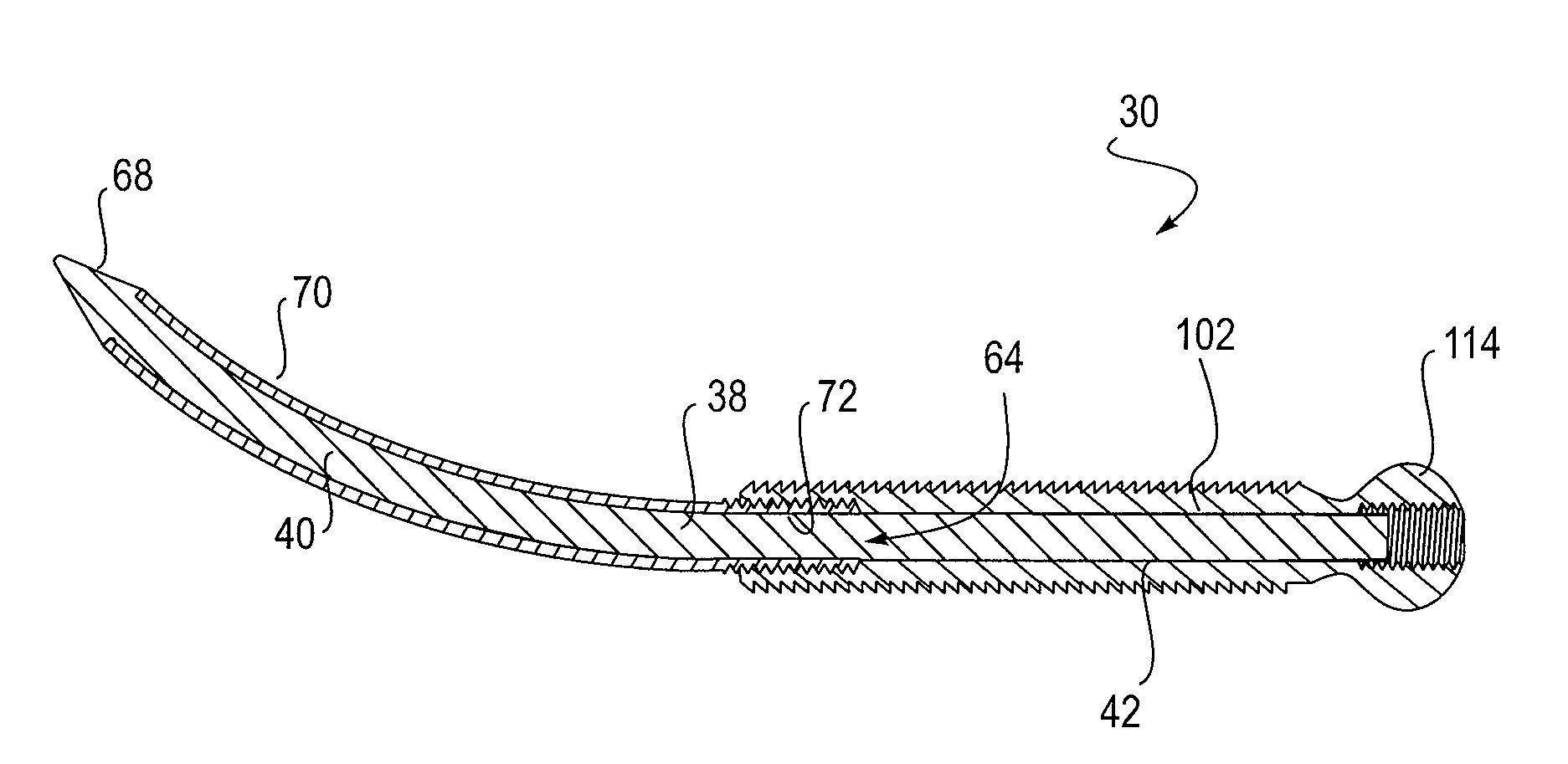

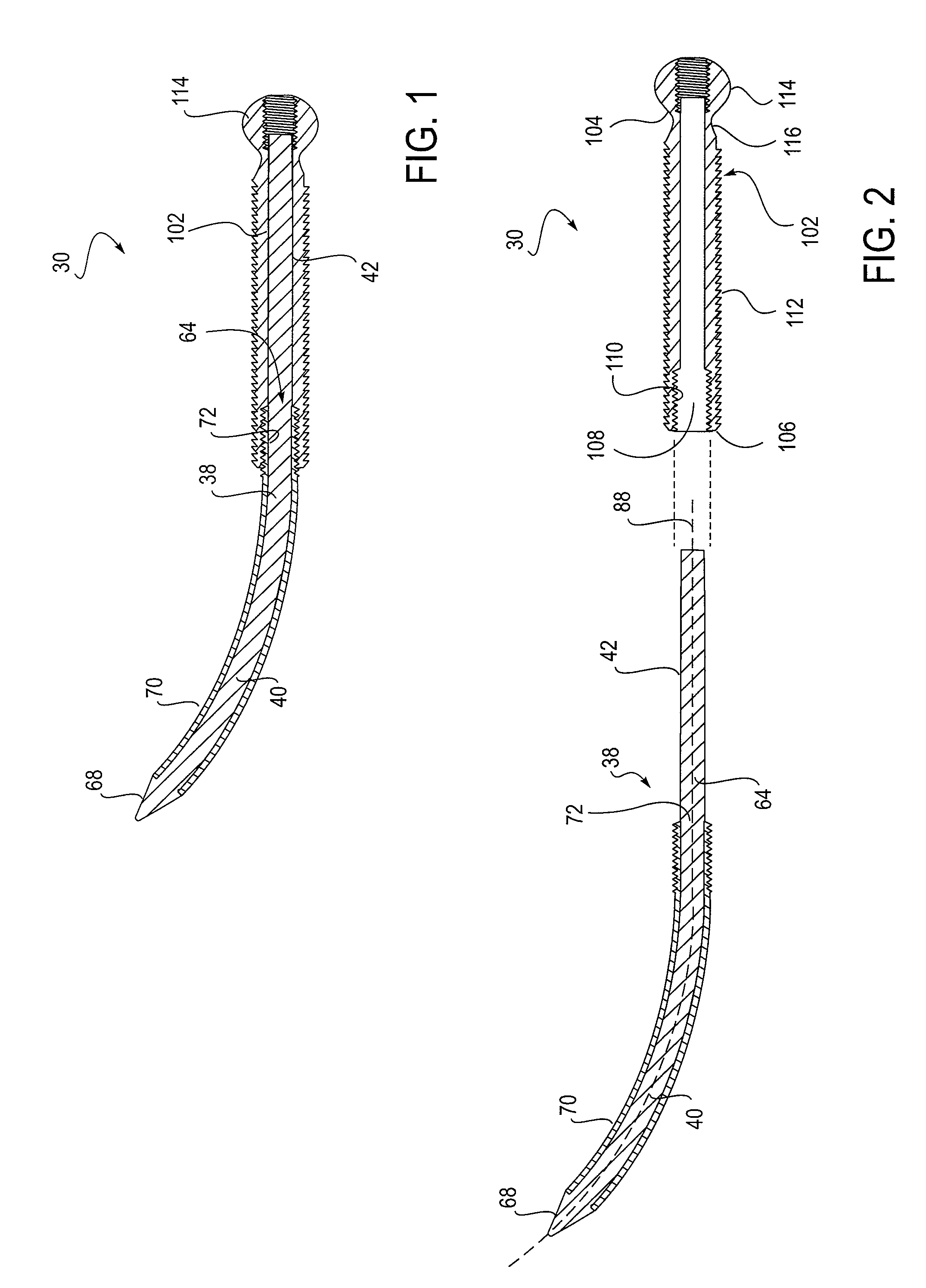

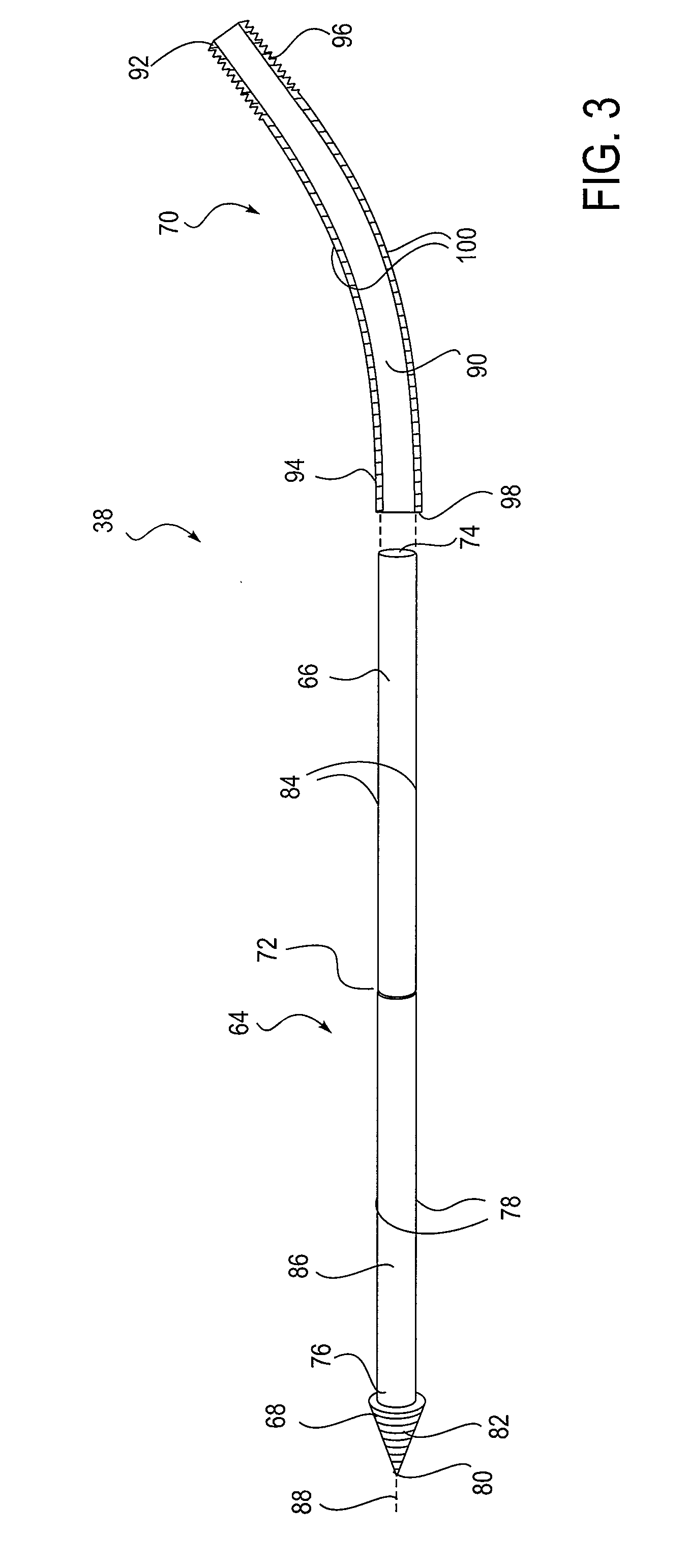

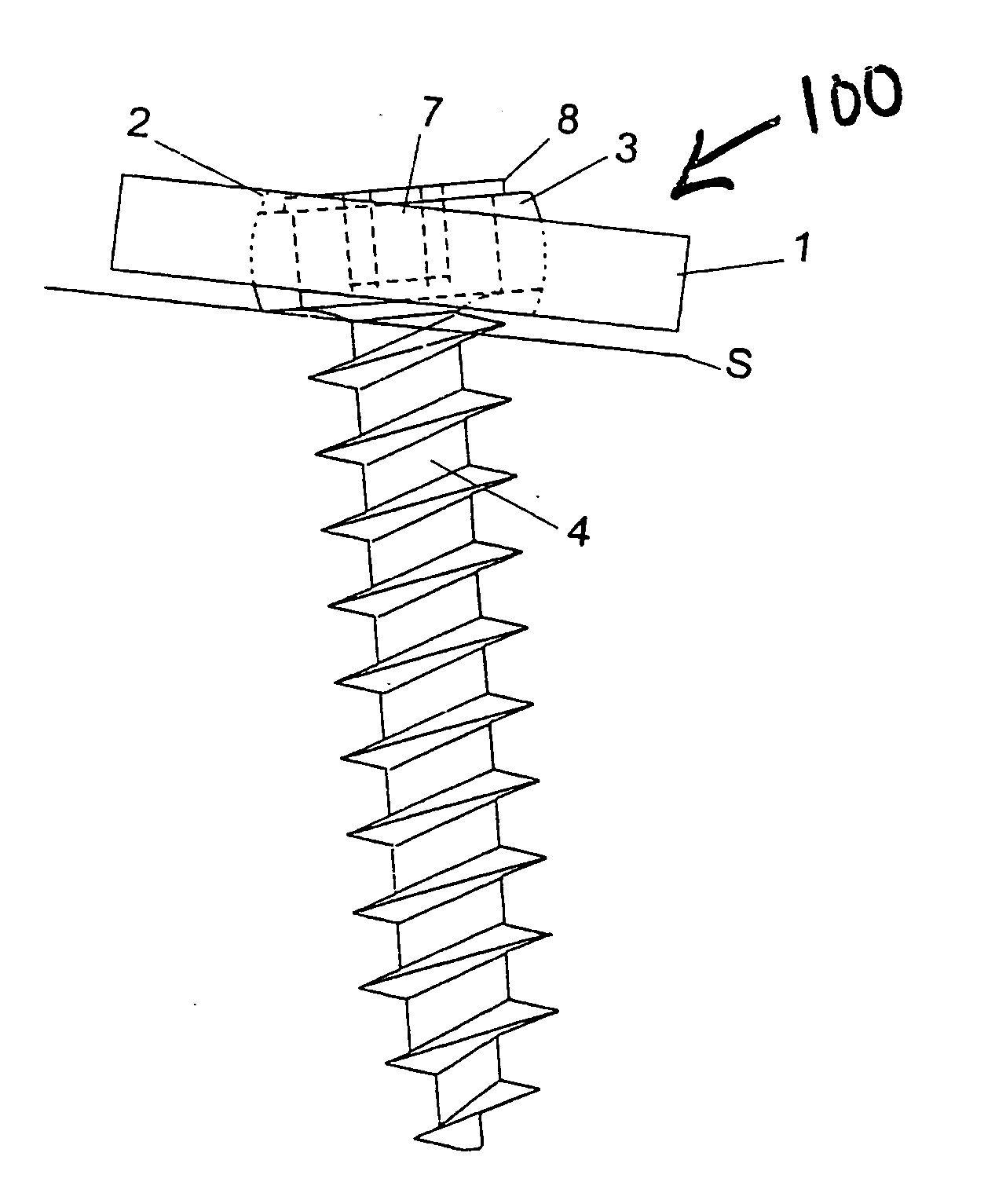

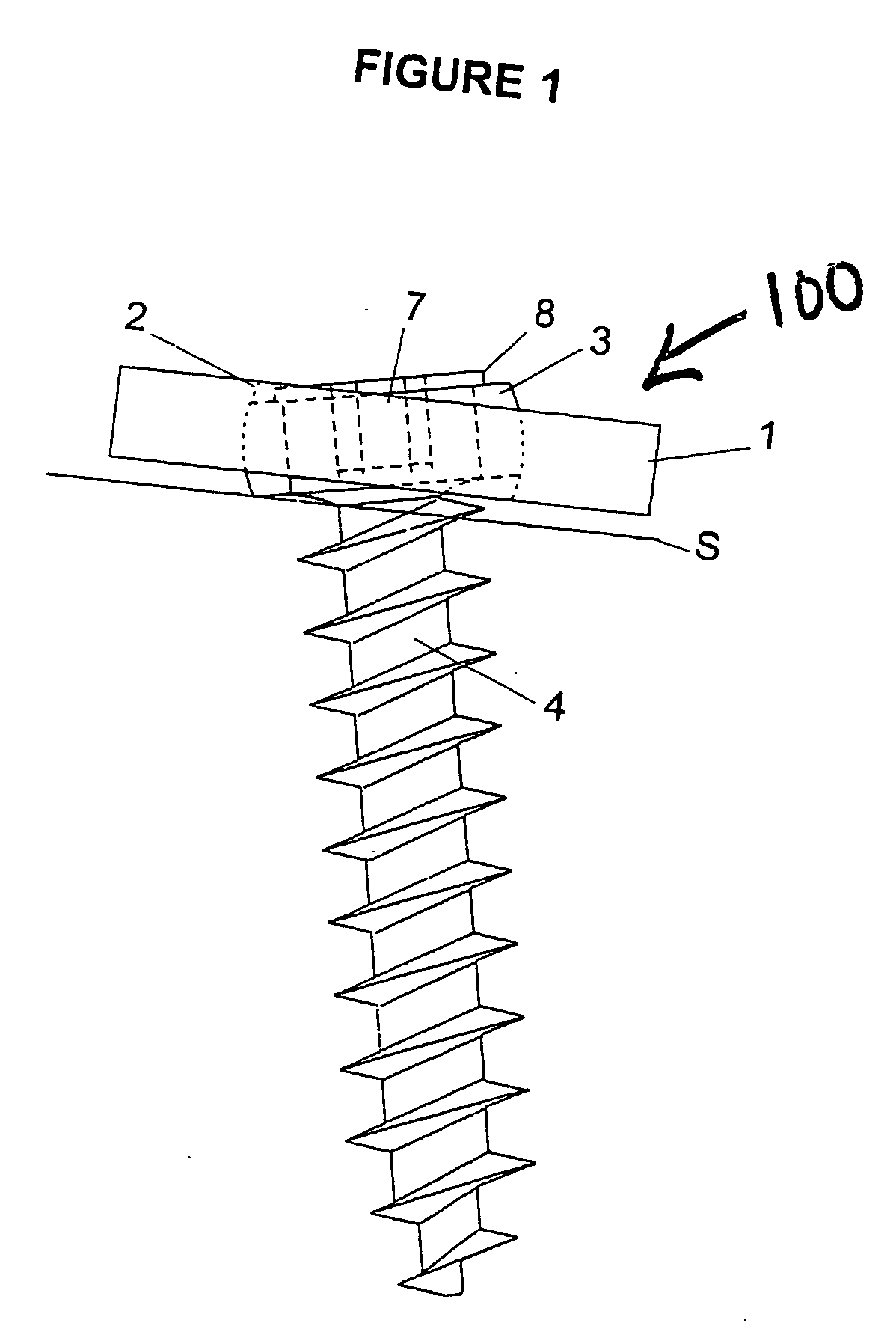

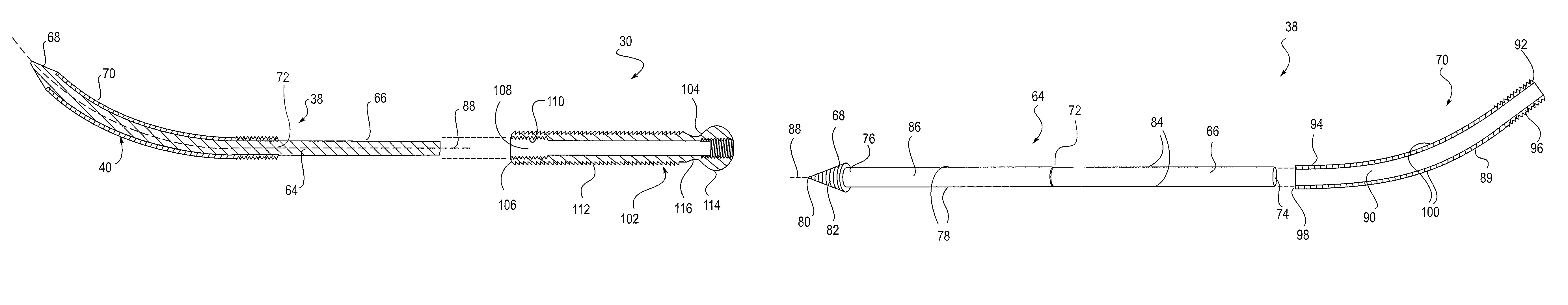

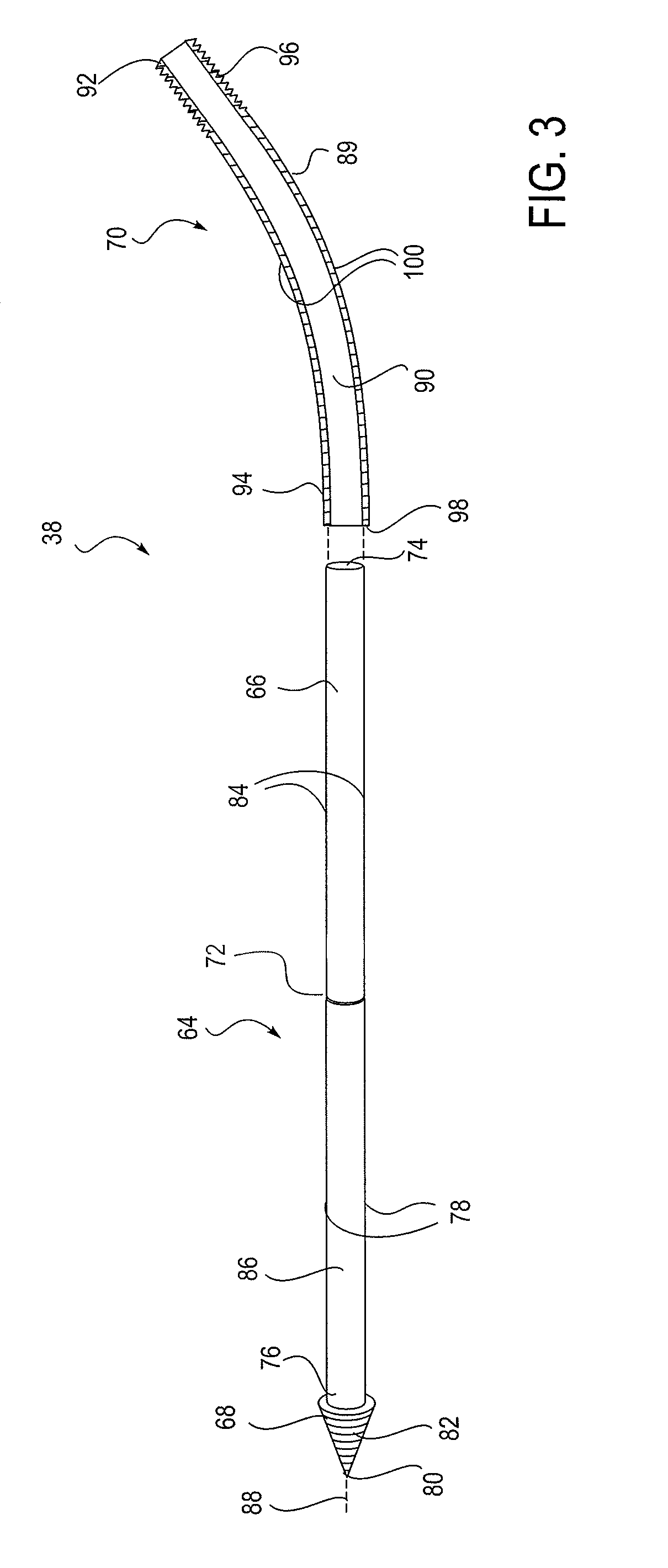

Posterior spinal fastener and method for using same

ActiveUS20100016903A1Improve stabilityImprove pullout resistanceSuture equipmentsInternal osteosythesisSpinal columnVertebra

A posterior spinal fastener is disclosed for insertion into a vertebra of a mammalian body, the vertebra having posterior elements and a vertebral body. The fastener includes an elongate member adapted for insertion into the vertebra. The elongate body has an anterior portion and a posterior portion. The anterior portion is arcuate in shape for placement in the vertebral body. The posterior portion has a length so as to be accessible at the posterior elements of the vertebra when the anterior portion is disposed in the vertebral body. A method of use of the posterior spinal fastener is also disclosed, in which the posterior spinal fastener is introduced into the vertebra at the posterior elements and arcuately extended into the vertebral body.

Owner:TOTAL CONNECT SPINE

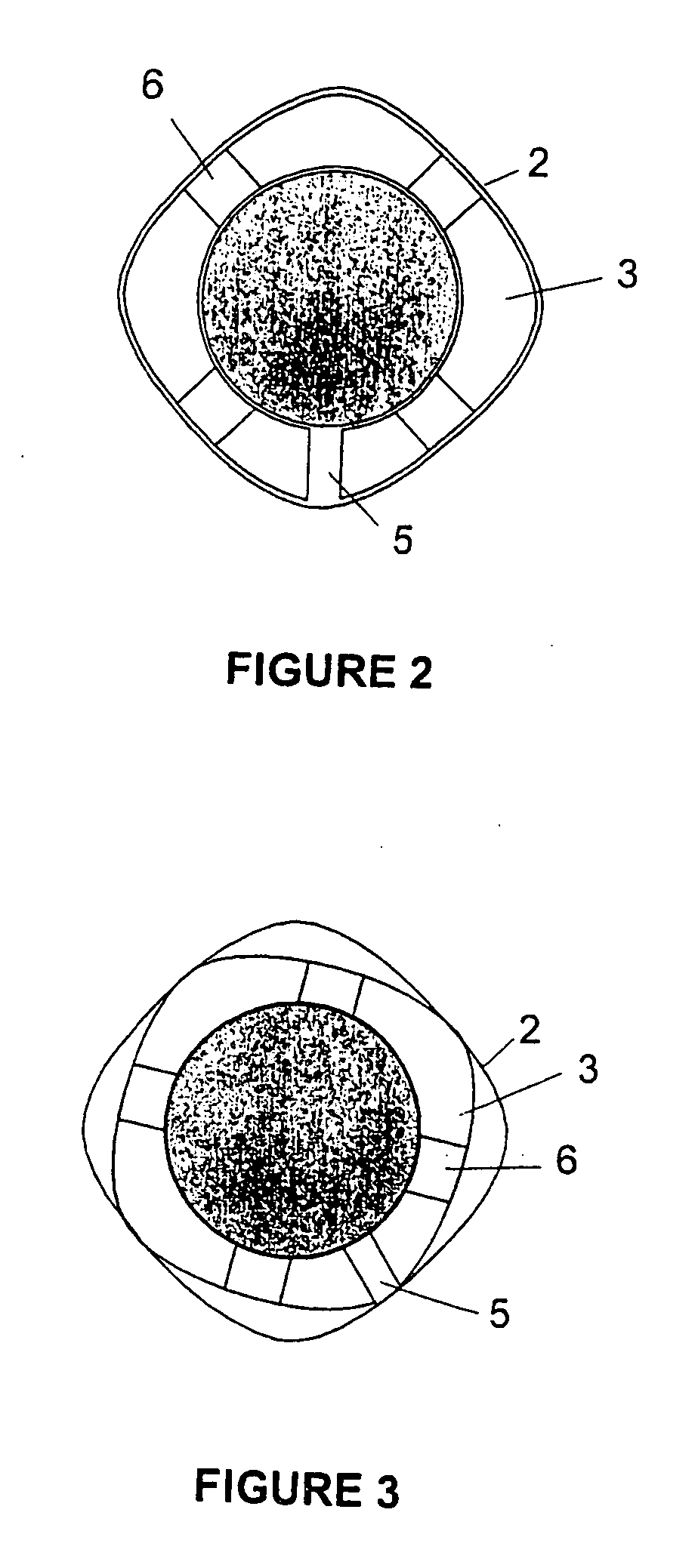

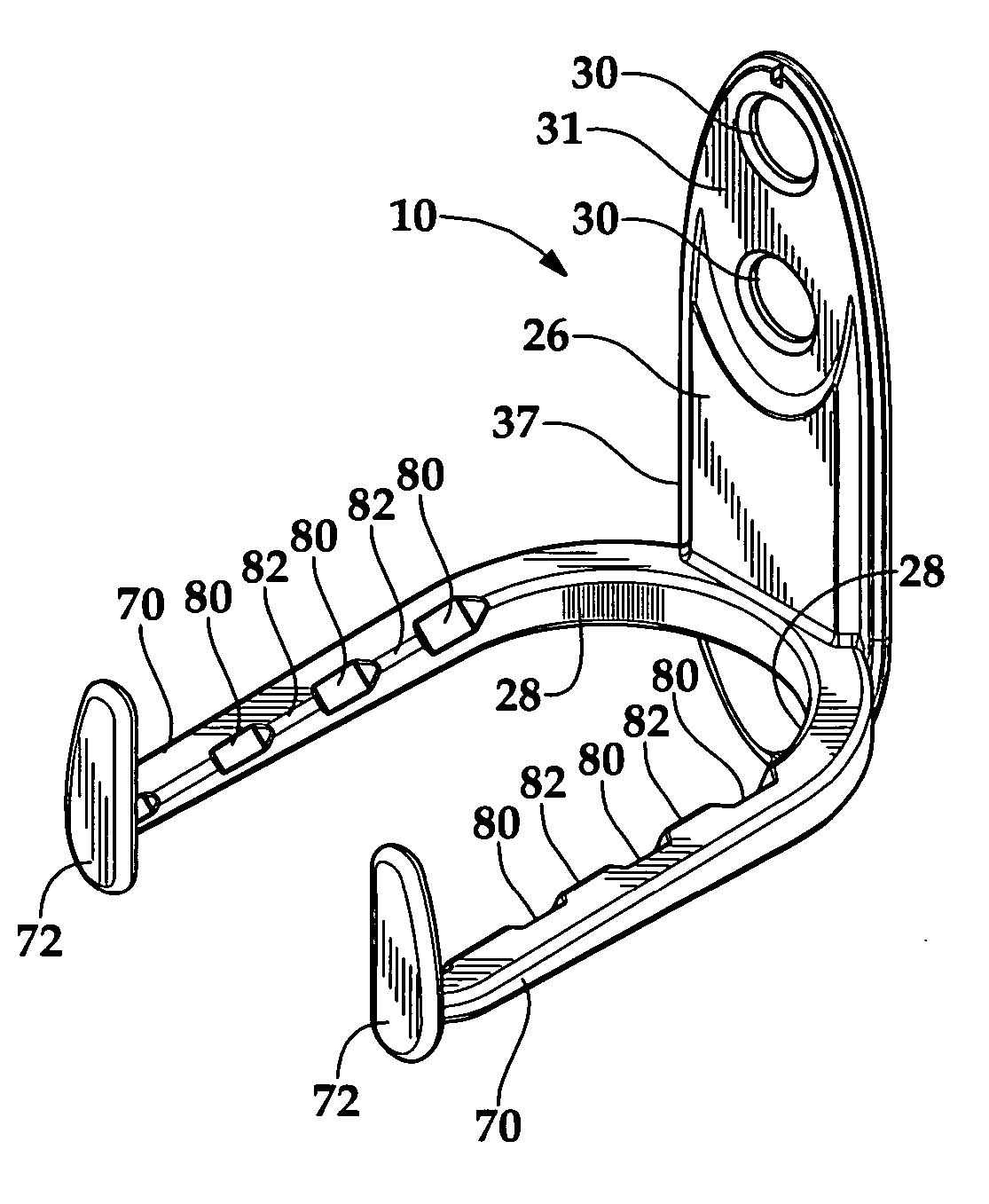

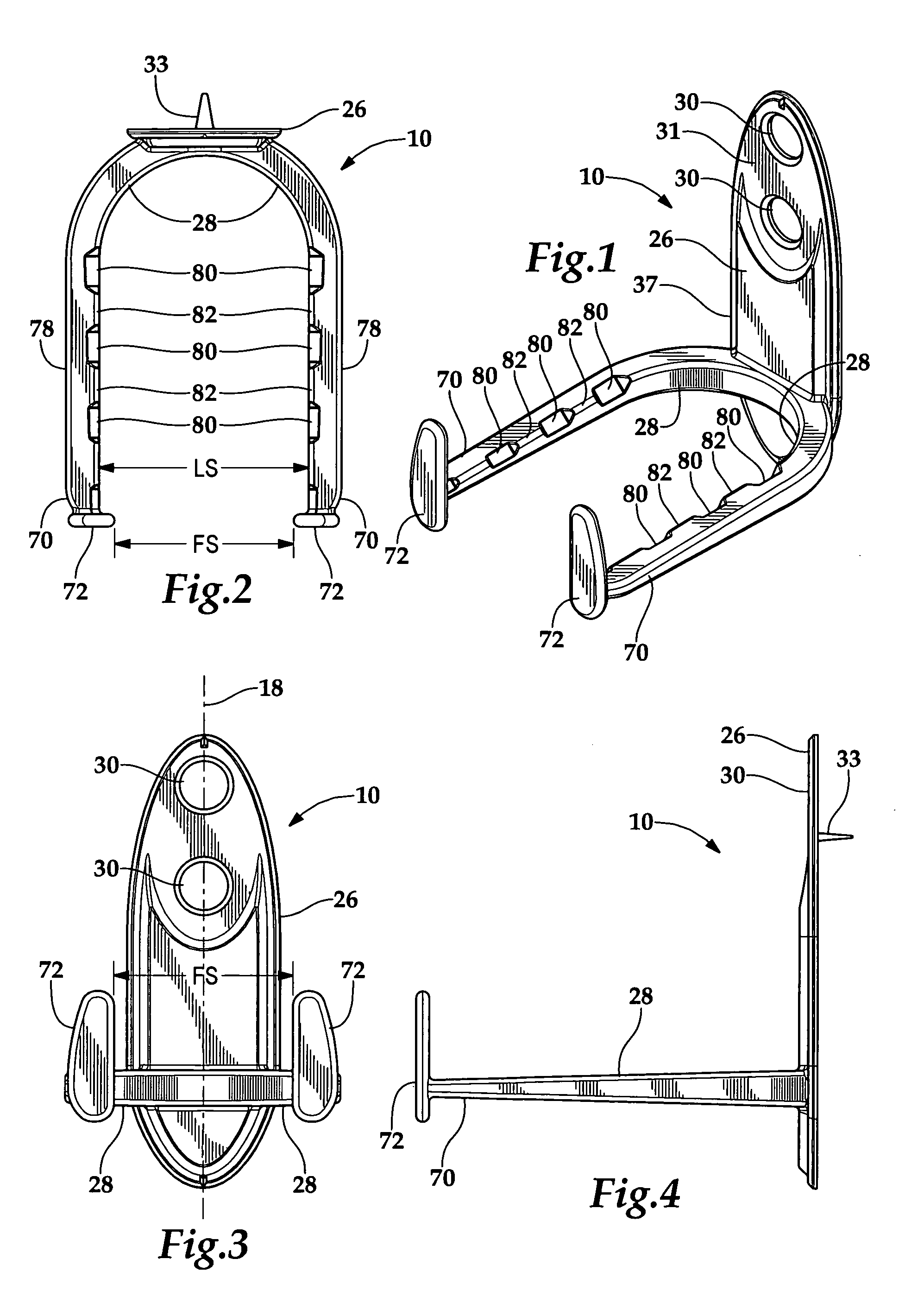

Humeral implant anchor system

ActiveUS20160324648A1Enhancing initial pull-out resistanceEnhanced initial dislodgement resistanceSurgeryJoint implantsEngineeringHumerus

A stemless humeral shoulder assembly having a base member and an anchor advanceable into the base member. The base member can include a distal end that can be embedded in bone and a proximal end that can be disposed at a bone surface. The base member can also have a plurality of spaced apart arms projecting from the proximal end to the distal end. The anchor can project circumferentially into the arms and into a space between the arms. When the anchor is advanced into the base member, the anchor can be exposed between the arms. A recess can project distally from a proximal end of the anchor to within the base member. The recess can receive a mounting member of an anatomical or reverse joint interface.

Owner:HOWMEDICA OSTEONICS CORP

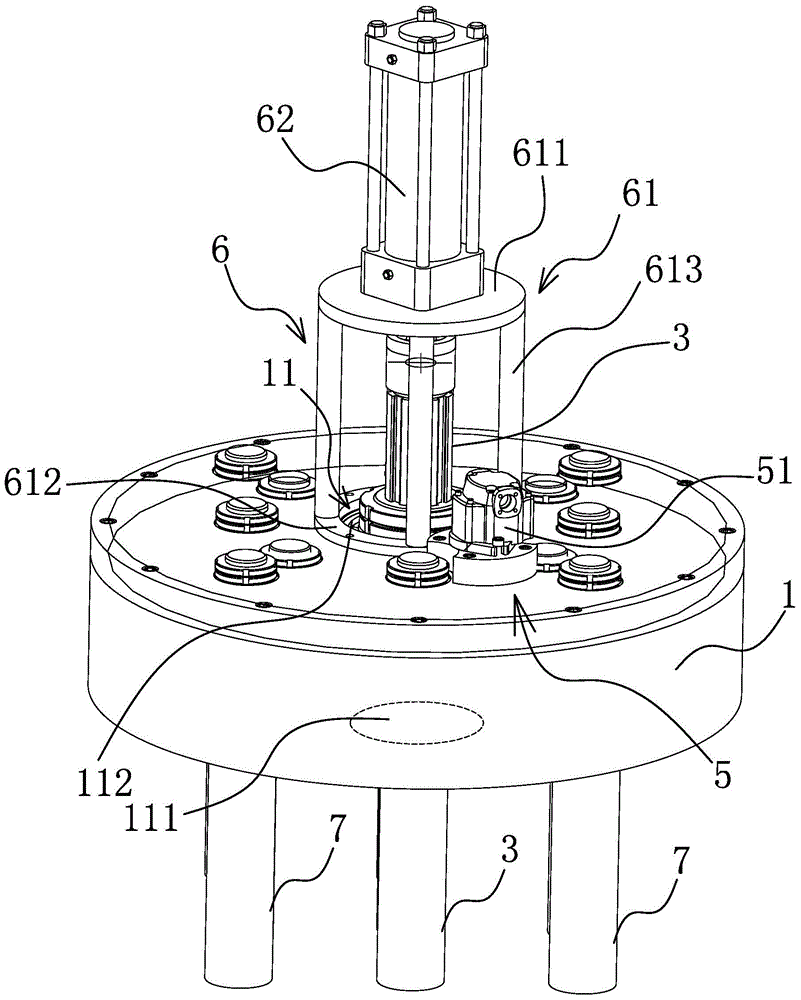

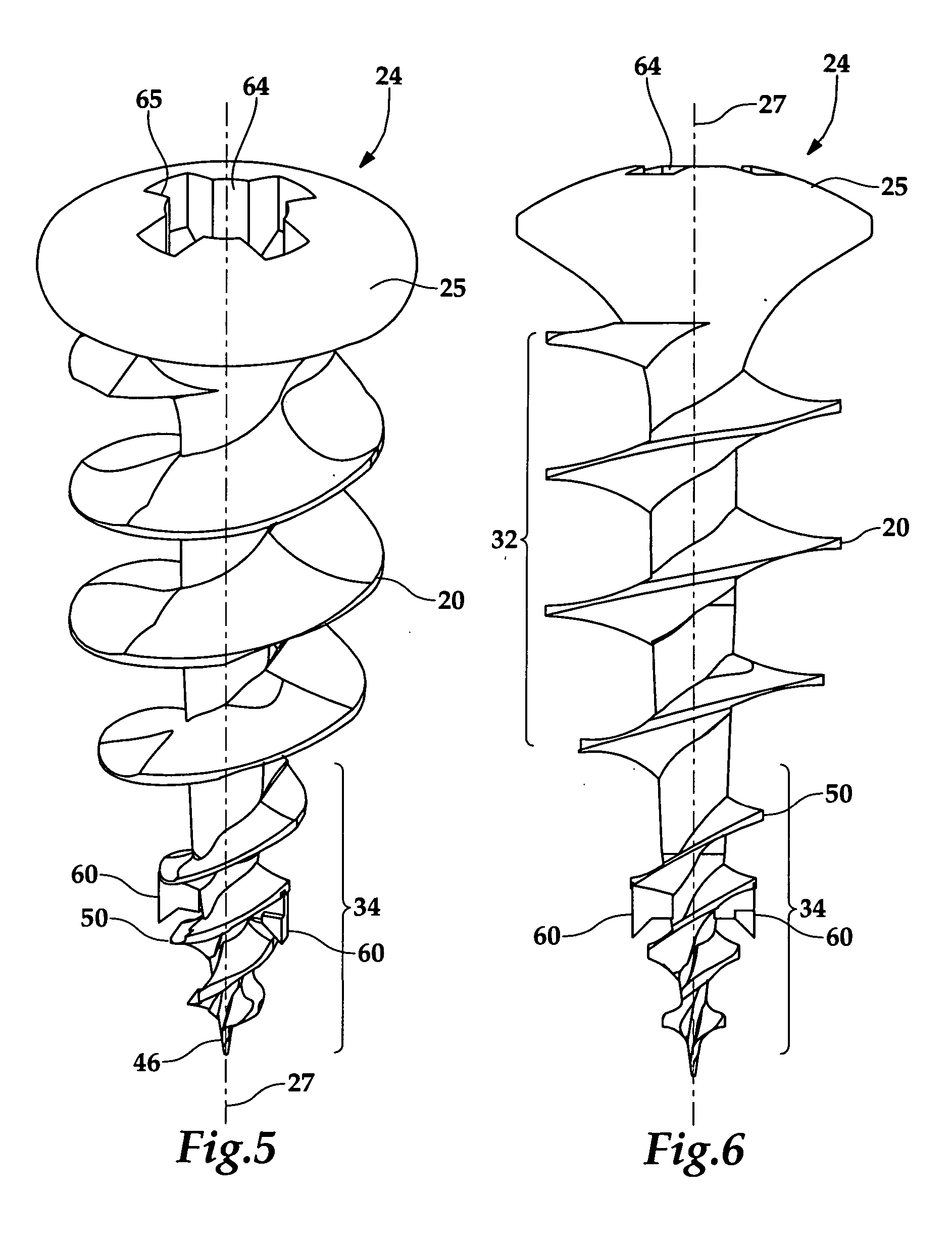

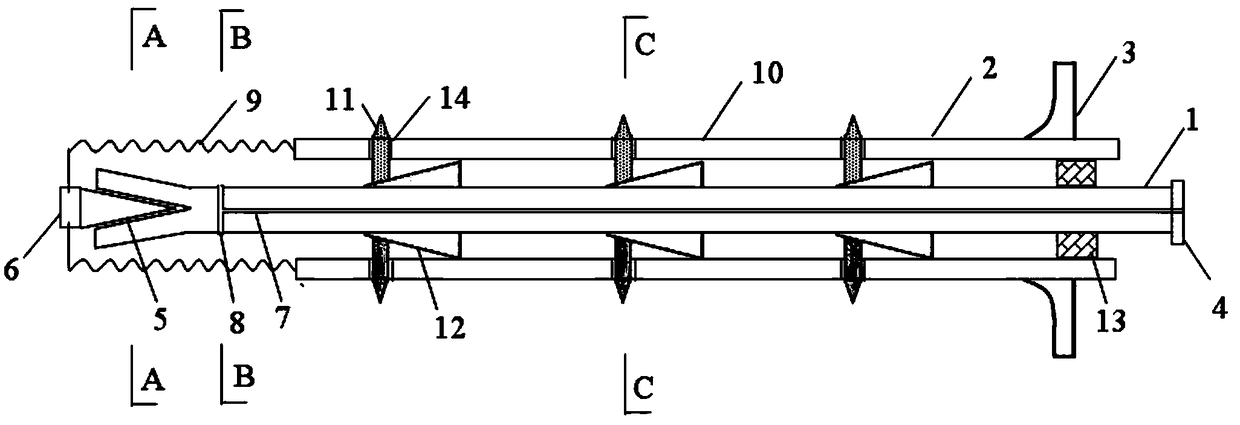

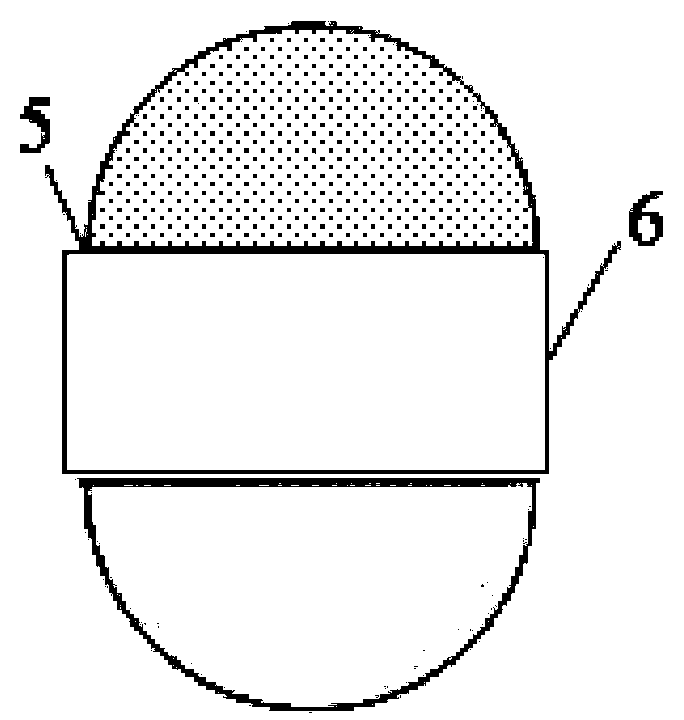

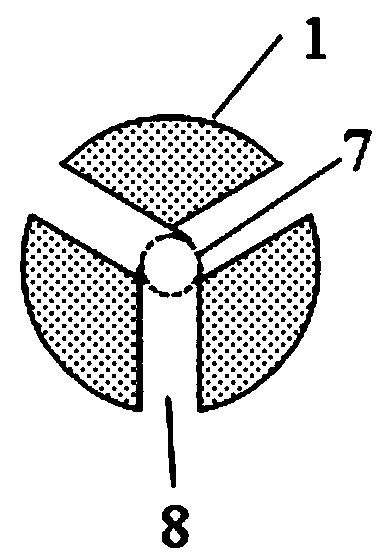

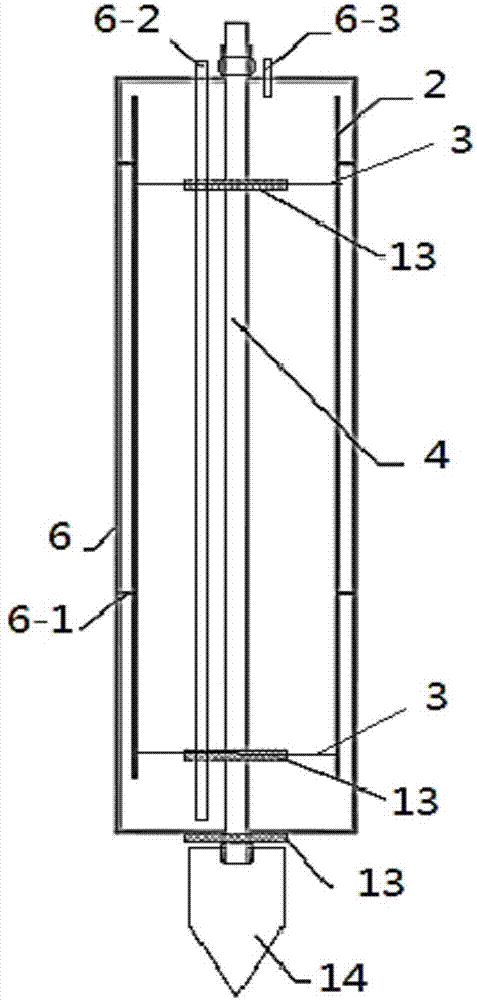

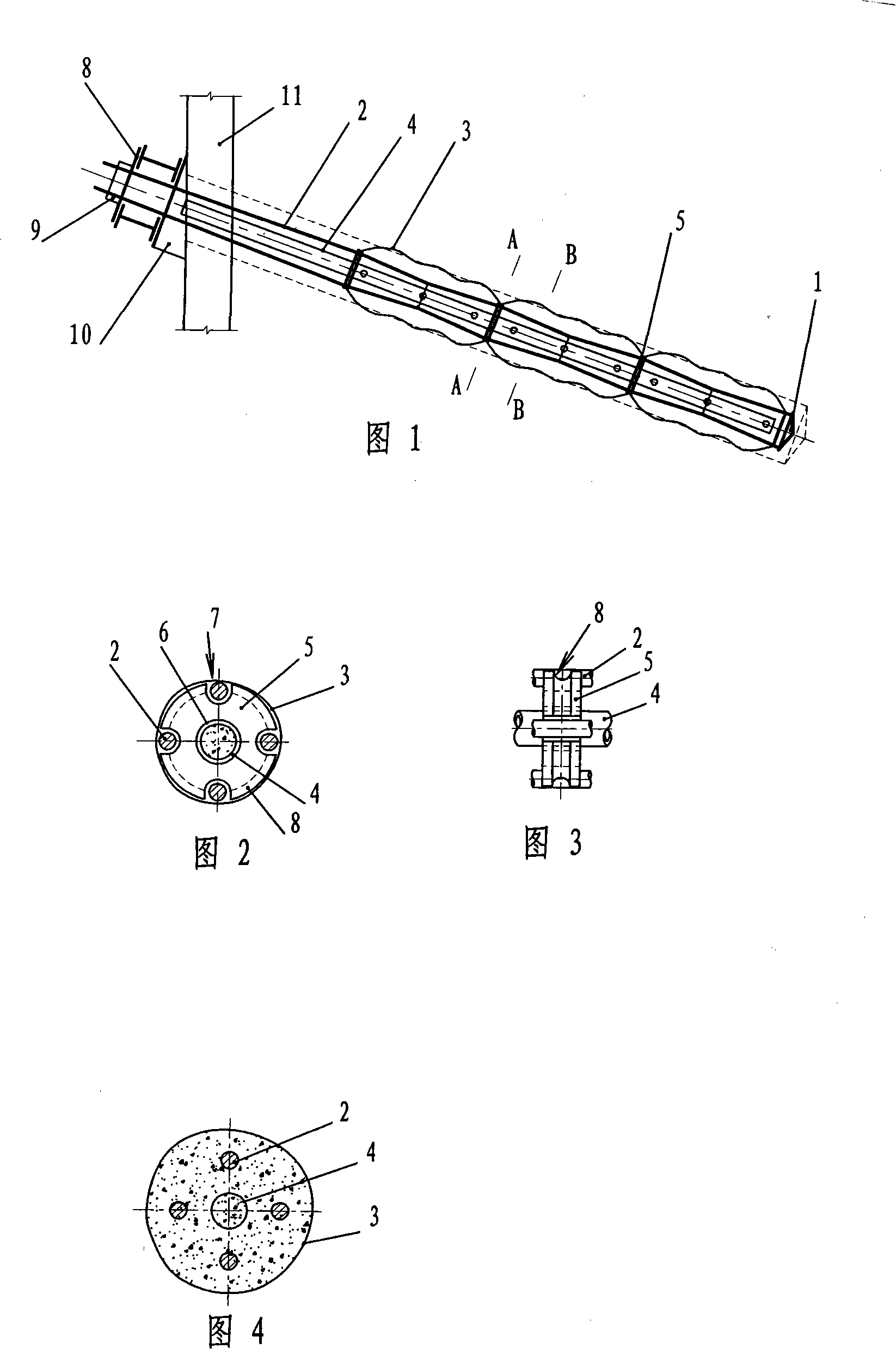

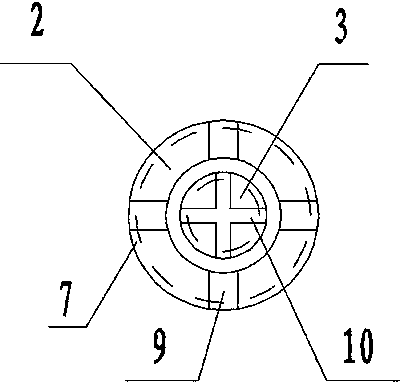

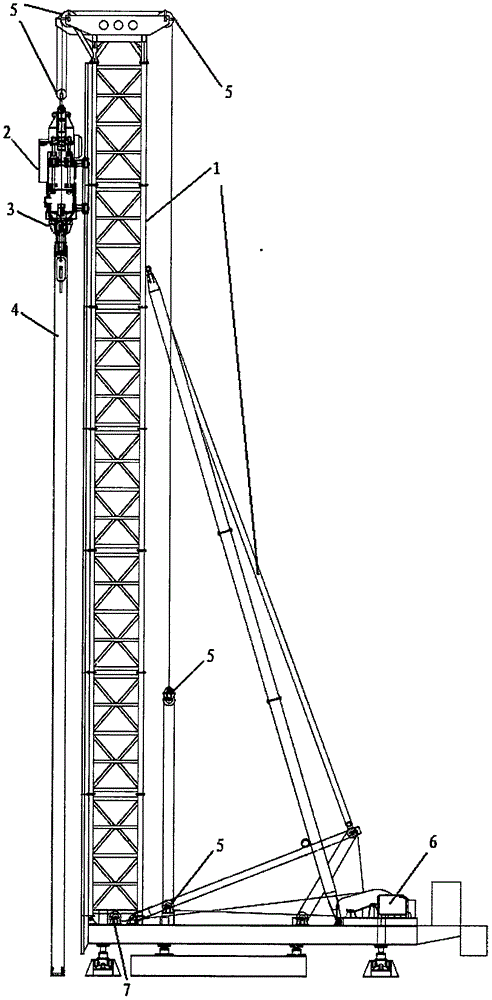

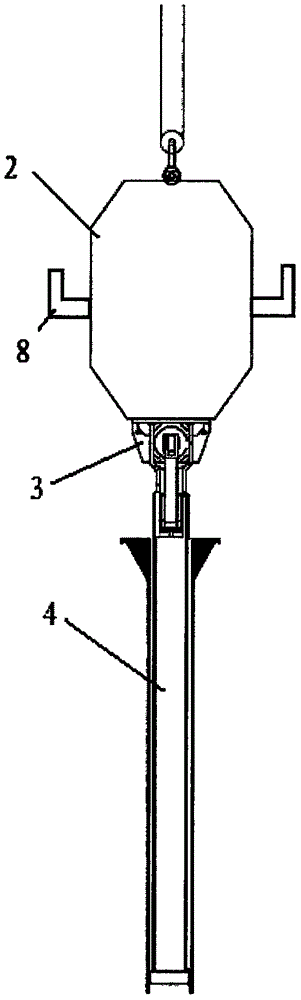

Moving drill rod of cement-soil mixing pile driver

ActiveCN105064911AImprove pullout resistanceIncrease girthRotary drillingRotary-drilling machinesDrill pipeSoil mixing

The invention belongs to the technical field of building equipment, and particularly relates to a moving drill rod of a cement-soil mixing pile driver. The moving drill rod solves the problem that existing cement-soil mixing pile drivers are prone to drill failures when drilling and the like, and comprises a driving box with an inner cavity, wherein the driving box is provided with at least one through hole which runs through the whole driving box in the axial direction; a guiding sleeve which can rotate in the circumferential direction and is cylindrical is arranged in the through hole; a drill rod which runs through the whole driving box is arranged in the guiding sleeve in a penetrating manner; an axial guiding structure is arranged between the drill rod and the guiding sleeve; the guiding sleeve is connected with a circumferential rotating mechanism which can drive the guiding sleeve to rotate in the circumferential direction; and the drill rod is connected with an axial driving mechanism which can drive the drill rod to slide back and forth in the axial direction. The moving drill rod of the cement-soil mixing pile driver has the advantages that a drill rod body can stretch in the axial direction, can rotate in the circumferential direction and slide in the axial direction at the same time, and thus is not prone to rotation failures; the perimeter of the cross section of a cement-soil mixing pile after constructing is increased; and the pull-out capacity of the cement-soil mixing pile is improved.

Owner:周兆弟

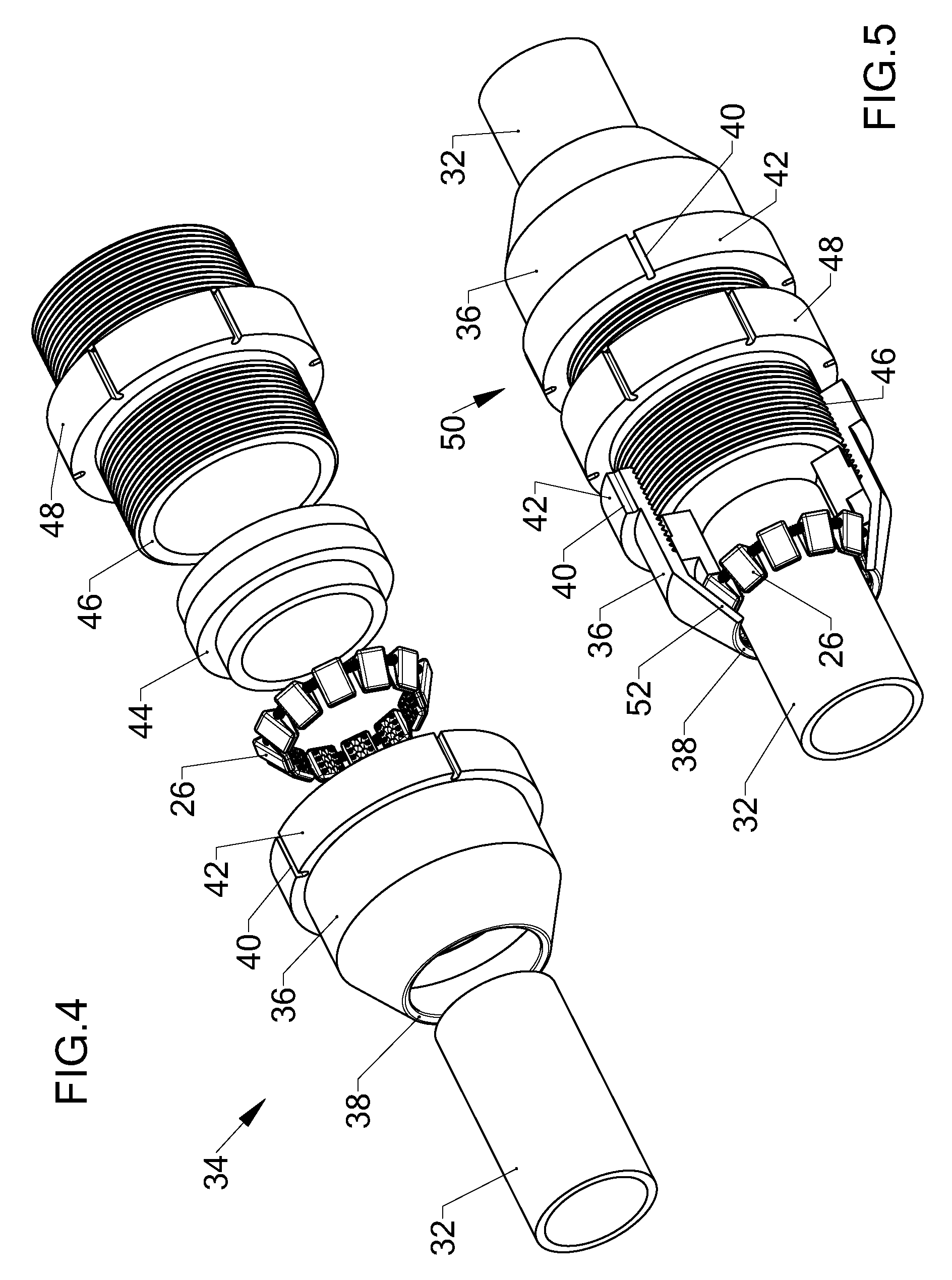

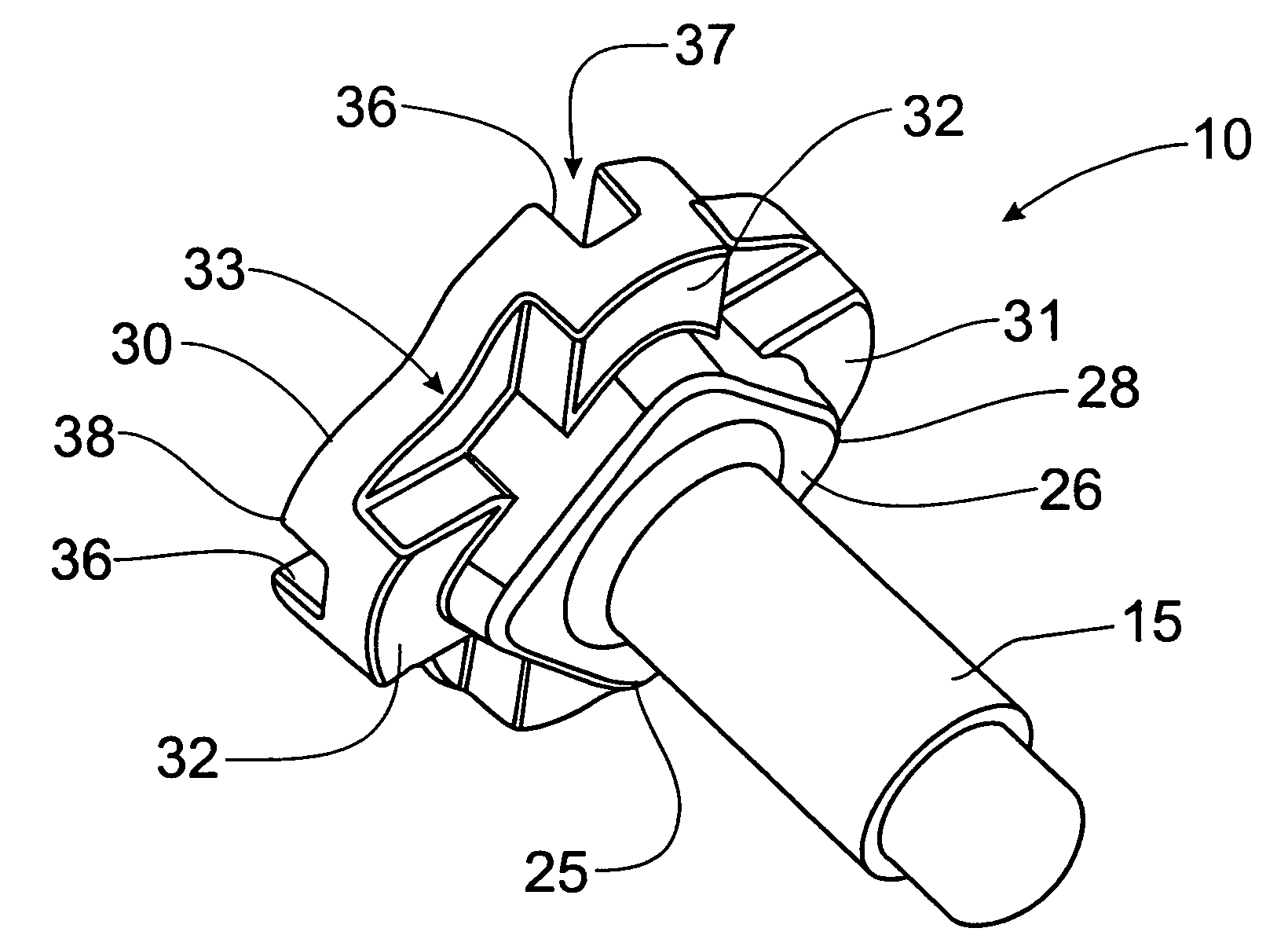

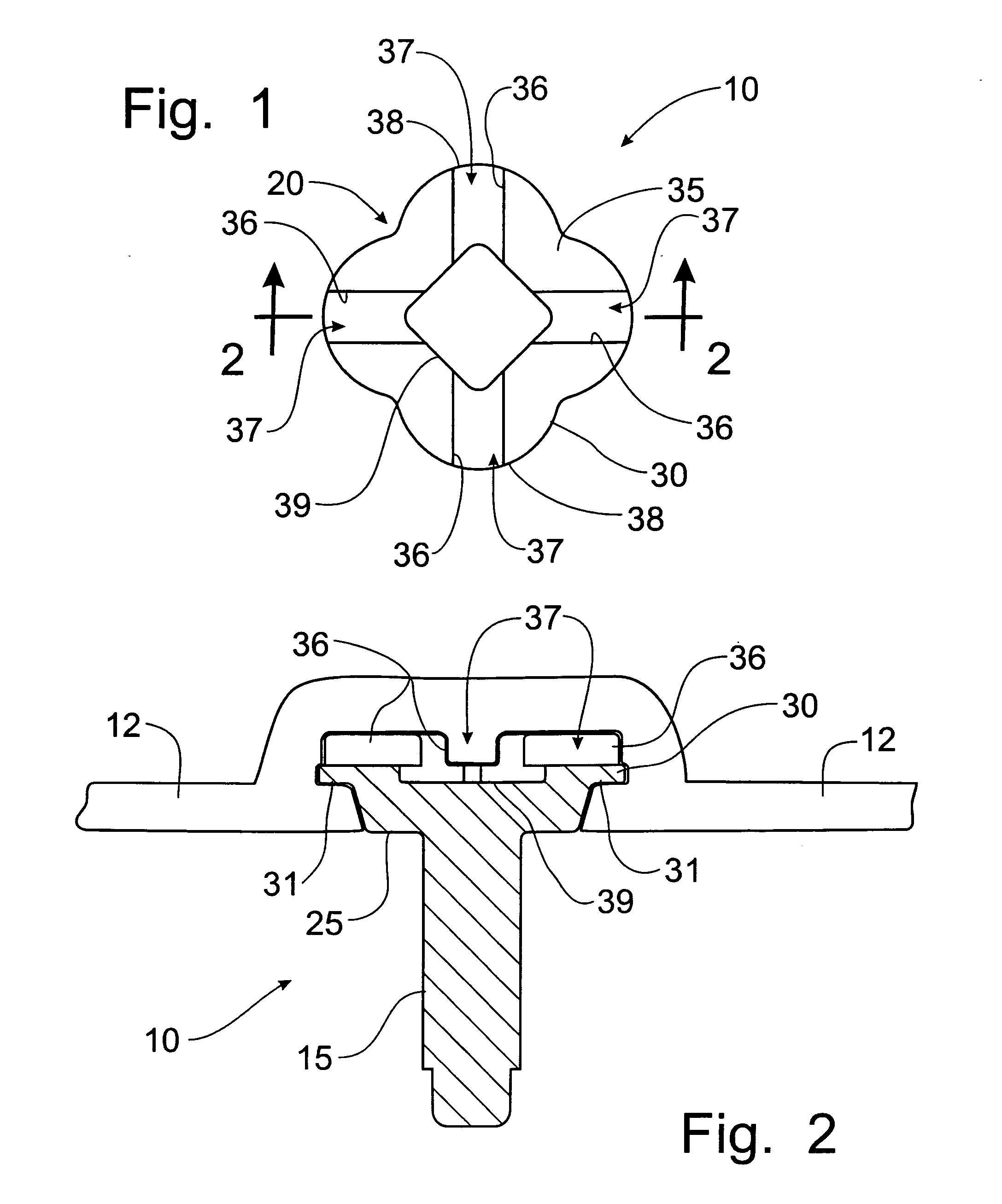

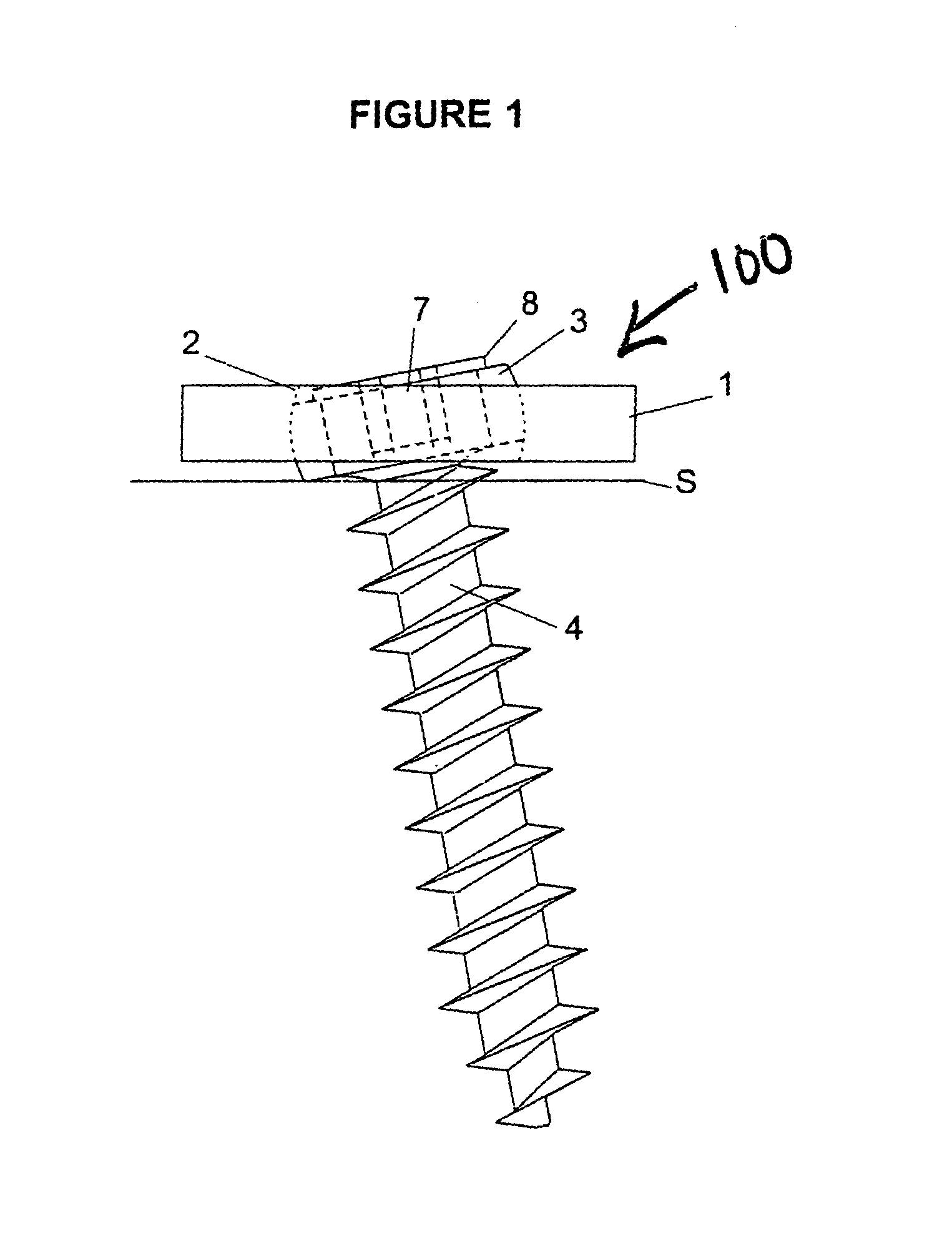

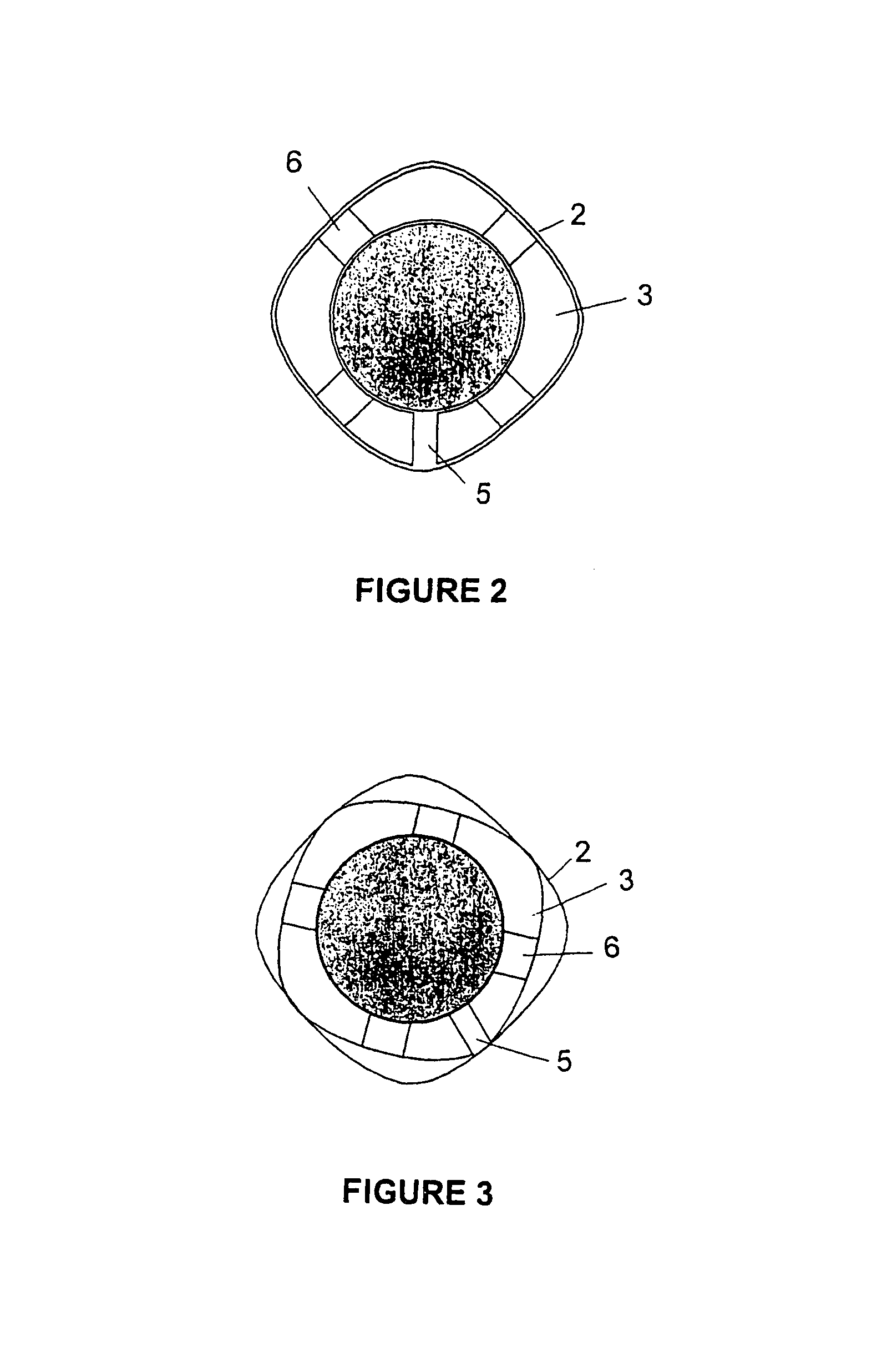

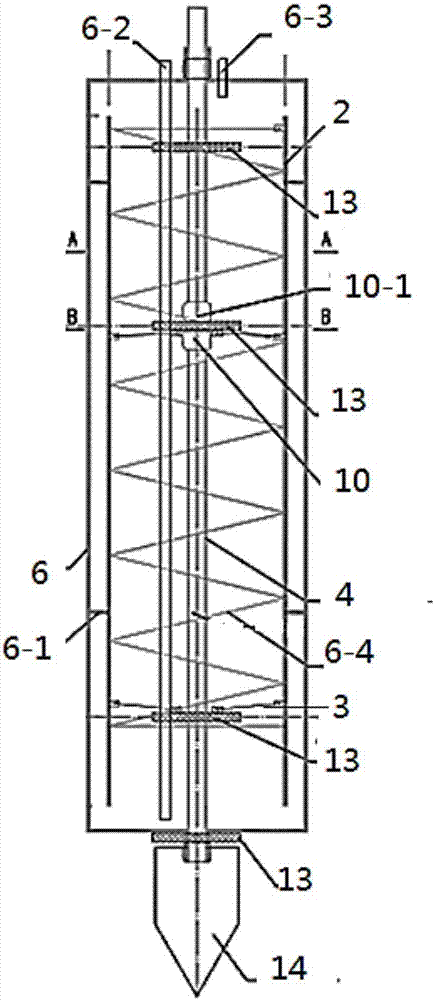

Device for connecting a screw to a support plate

ActiveUS20050143742A1Easy to installEasy to removeInternal osteosythesisJoint implantsConstriction ringEngineering

The invention relates to a device which is used for solidly connecting a part such as a plate to an underlying support using at least one fixing element such as a screw. According to the invention, said fixing element takes the form of a threaded rod a screw which passes through a hole housing a ring belonging to the part, such that it is screwed into the support material. The inventive device is characterized in that the above-mentioned ring is a constriction ring comprising a non-circular outer profile which co-operates with the non-circular inner profile of the hole, which is in the part. In this way, when the ring is rotated in the hole and wedged in place therein, it is constricted, thereby blocking the threaded rod against movement with respect to the plate.

Owner:STRYKER EURO OPERATIONS HLDG LLC

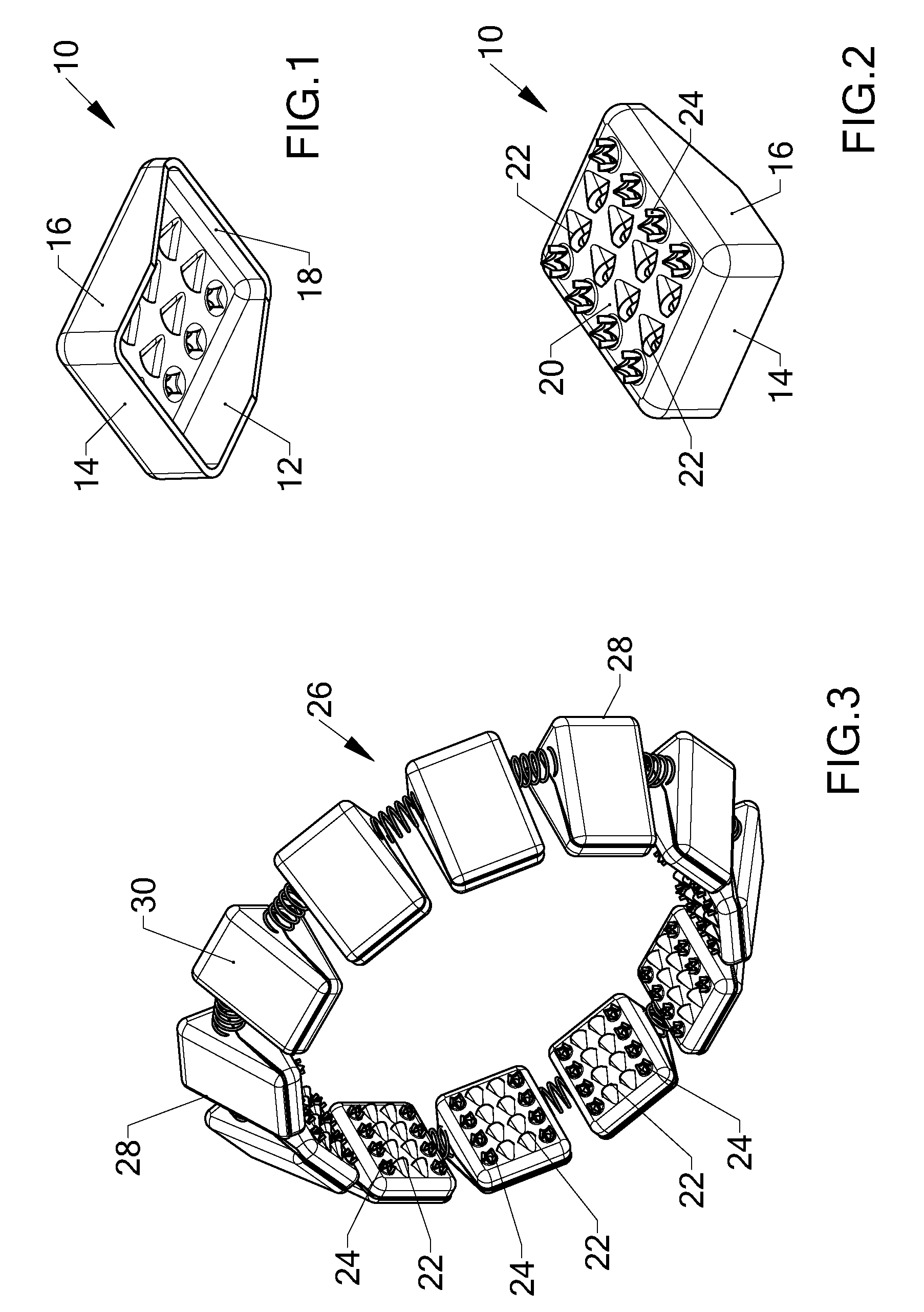

Pipe grip ring

ActiveUS7837238B2Improve pullout resistanceSleeve/socket jointsFluid pressure sealed jointsLarge toothEngineering

A grip element comprising a wedge-like structure supporting a metal plate, the exposed outer surface thereof being provided with an array of large and small gripping teeth. The large teeth project from the surface of said metal plate further than said small teeth. The invention further provides a grip element having a floor. The grip elements may be disposed around a ring for the purpose of pipe gripping. The ring is particularly useful in a pipe coupling to grip metal and plastic pipes.

Owner:KRAUSZ INDS DEVMENT

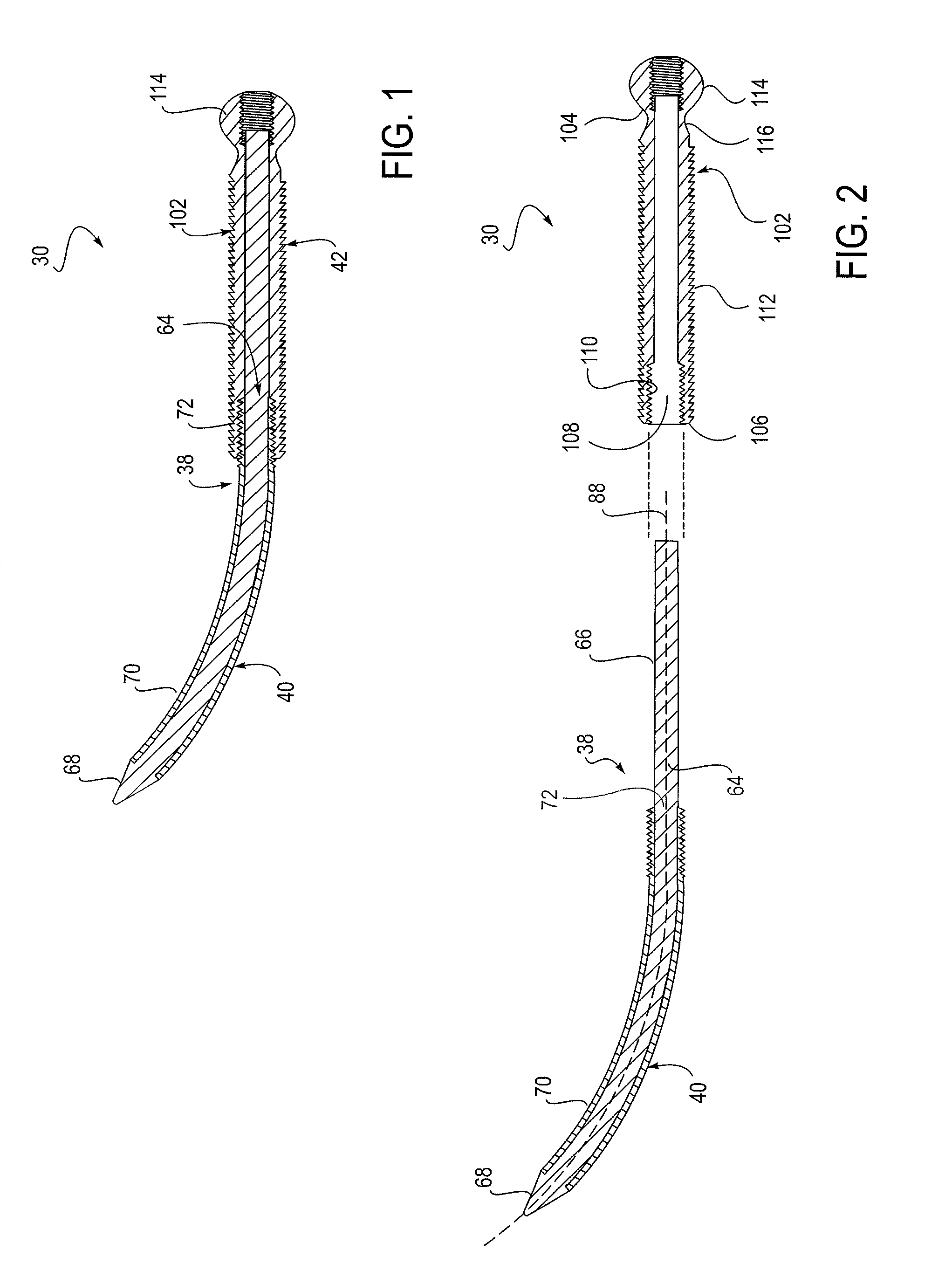

Posterior spinal fastener

ActiveUS8951295B2Improve stabilityImprove pullout resistanceSuture equipmentsInternal osteosythesisVertebraFastener

A posterior spinal fastener is disclosed for insertion into a vertebra of a mammalian body, the vertebra having posterior elements and a vertebral body. The fastener includes an elongate member adapted for insertion into the vertebra. The elongate body has an anterior portion and a posterior portion. The anterior portion is arcuate in shape for placement in the vertebral body. The posterior portion has a length so as to be accessible at the posterior elements of the vertebra when the anterior portion is disposed in the vertebral body. A method of use of the posterior spinal fastener is also disclosed, in which the posterior spinal fastener is introduced into the vertebra at the posterior elements and arcuately extended into the vertebral body.

Owner:TOTAL CONNECT SPINE

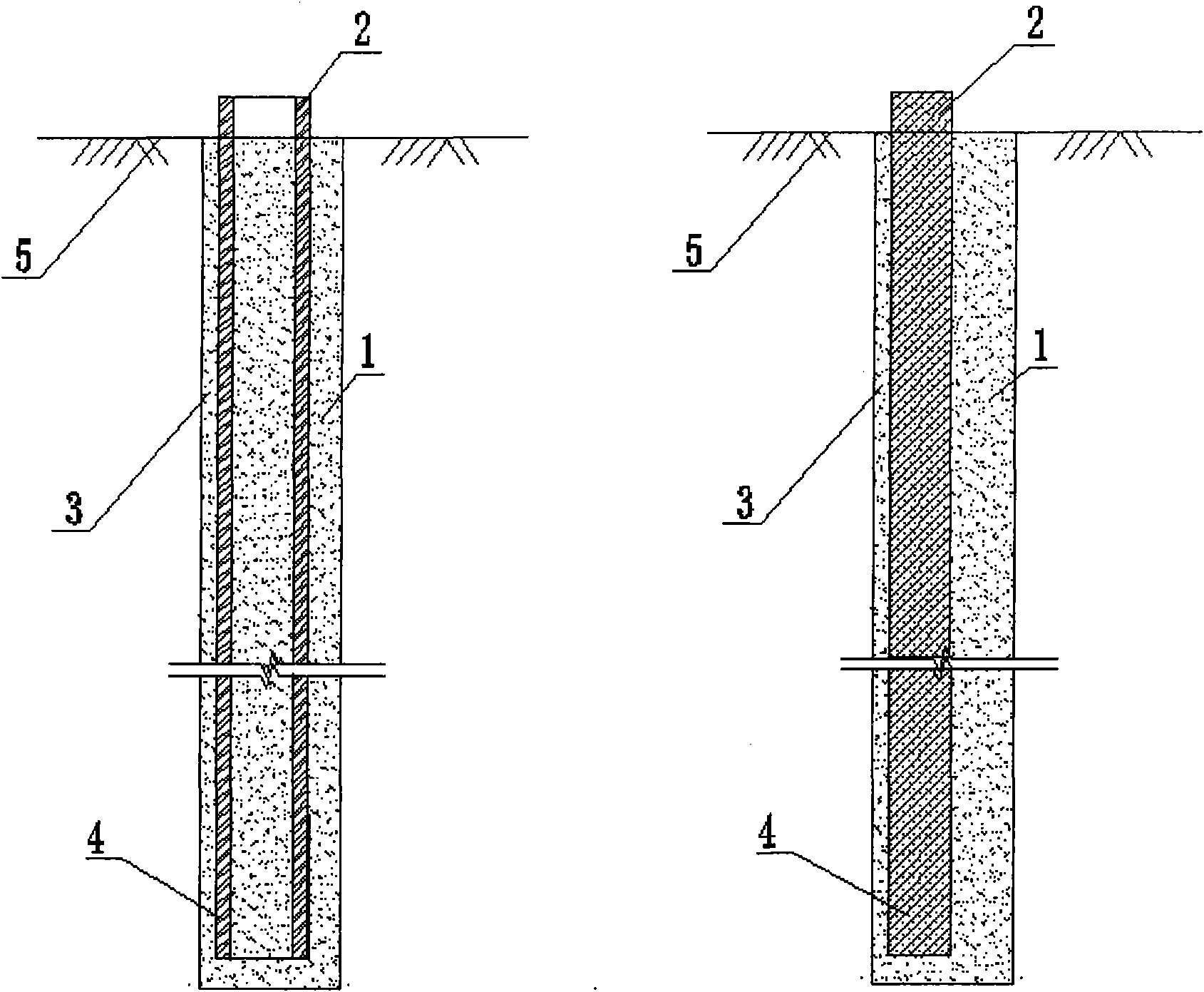

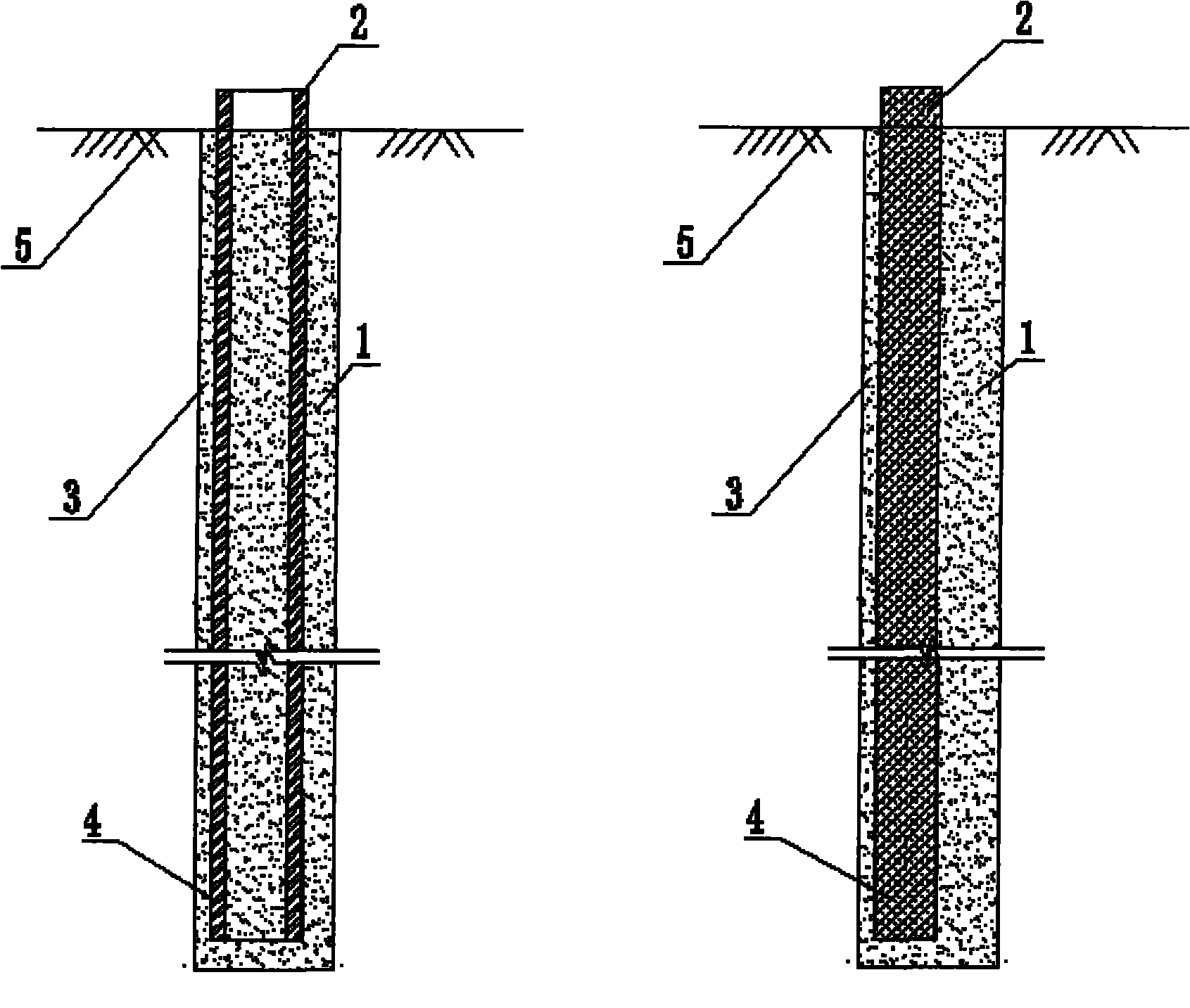

Cement-soil composite pile inserted into reinforced concrete core materials

InactiveCN101798810ATo overcome the problem that deep stirring can only stop water but not supportIncrease side frictionBulkheads/pilesReinforced concreteCement slurry

The invention relates to a cement-soil composite pile inserted into reinforced concrete core materials. The cement-soil composite pile is a novel composite pile which is formed by inserting a prestressed concrete tubular pile or a prestressed concrete square pile or a reinforced concrete member, serving as a core material, into a deeply-stirred cement-soil pile (which is formed by deeply stirring through a single-shaft, double-shaft or three-shaft stirring pile machine). The cement-soil composite pile consists of a cement-soil stirring pile and a high-strength core pile. The cement-soil composite pile is formed by the following steps of: stirring soil and cement slurry to form the cement-soil by using the single-shaft, double-shaft or three-shaft stirring pile machine; and then inserting one (or a plurality of) core material (such as the prestressed concrete tubular pile, the prestressed concrete square pile, the precast reinforced concrete member and the like) into the cement-soil by a vibration or self-weight method to obtain the composite pile body. The composite pile has higher bending strength, tensile strength and shear strength so as to meet different bearing requirements, and has the lateral bearing capacity 30 percent higher than that of the core pile and comprehensive cost 40 percent lower than that of a bored pile.

Owner:SHANGHAI STRONG FOUND ENG

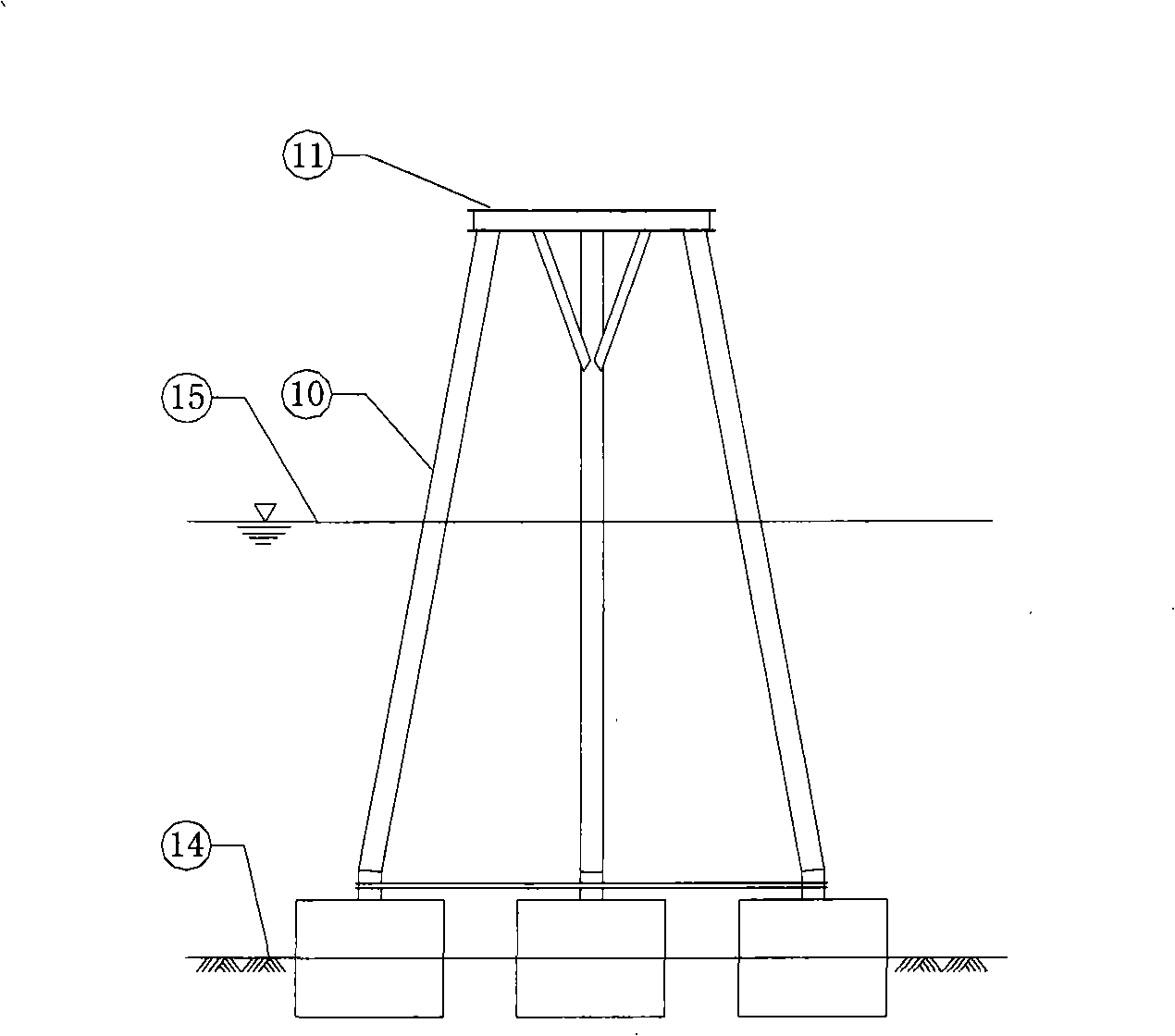

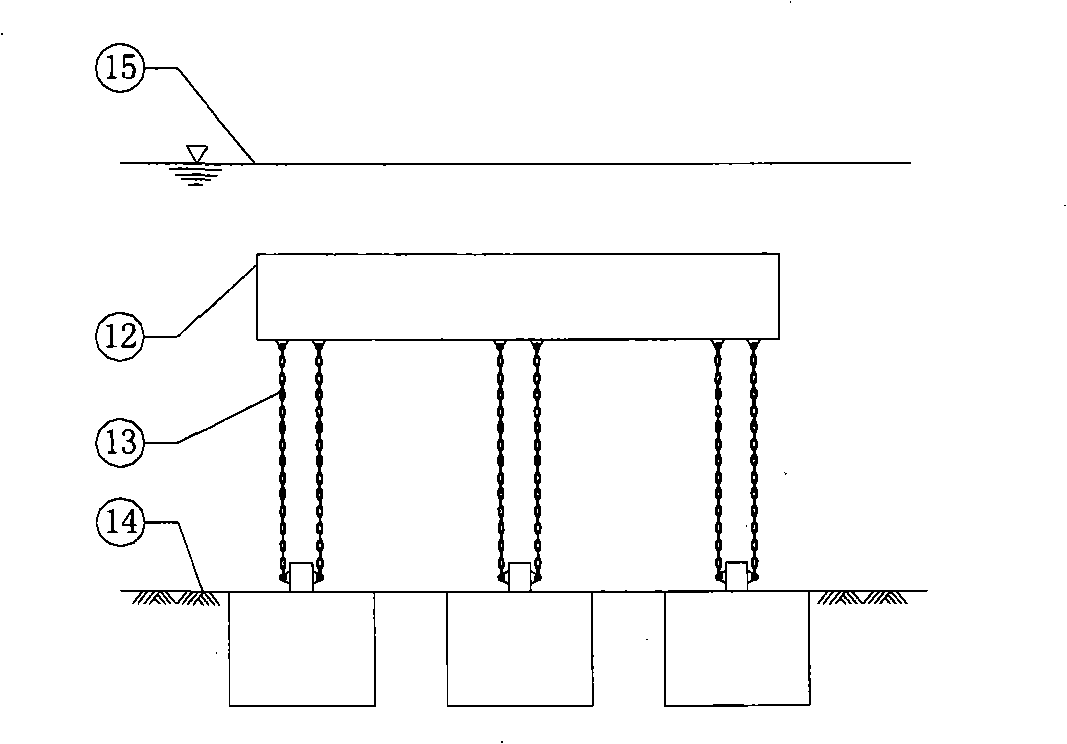

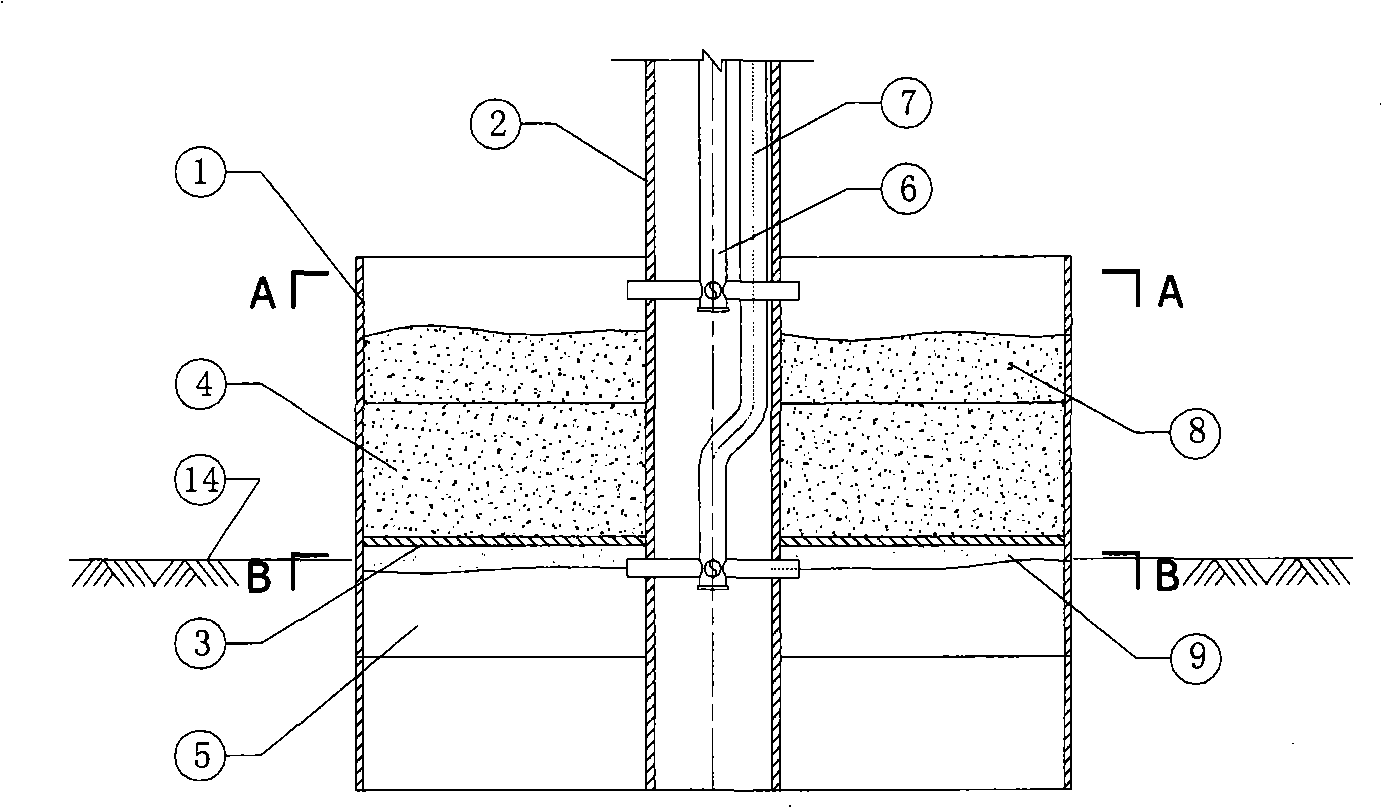

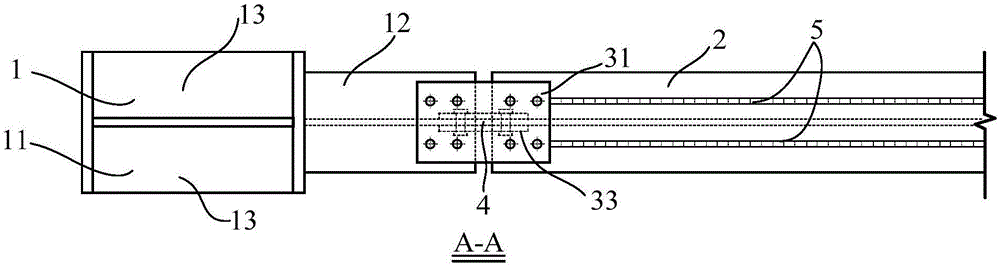

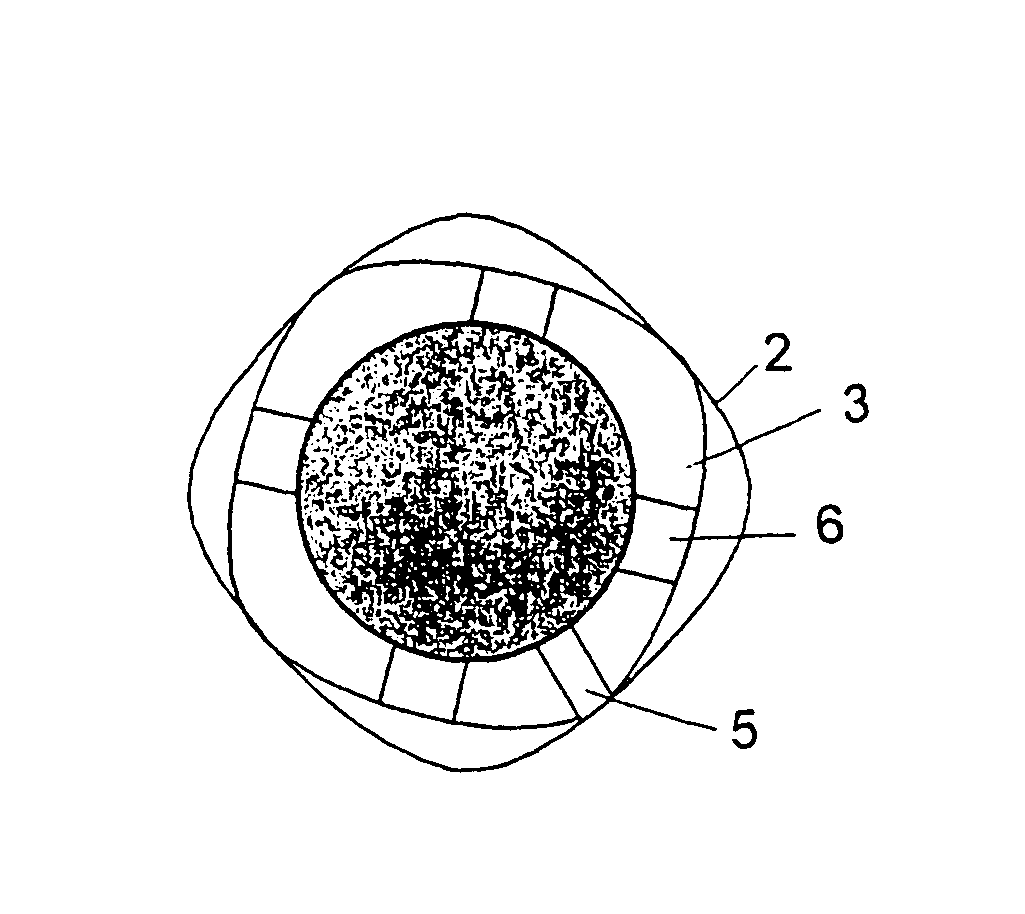

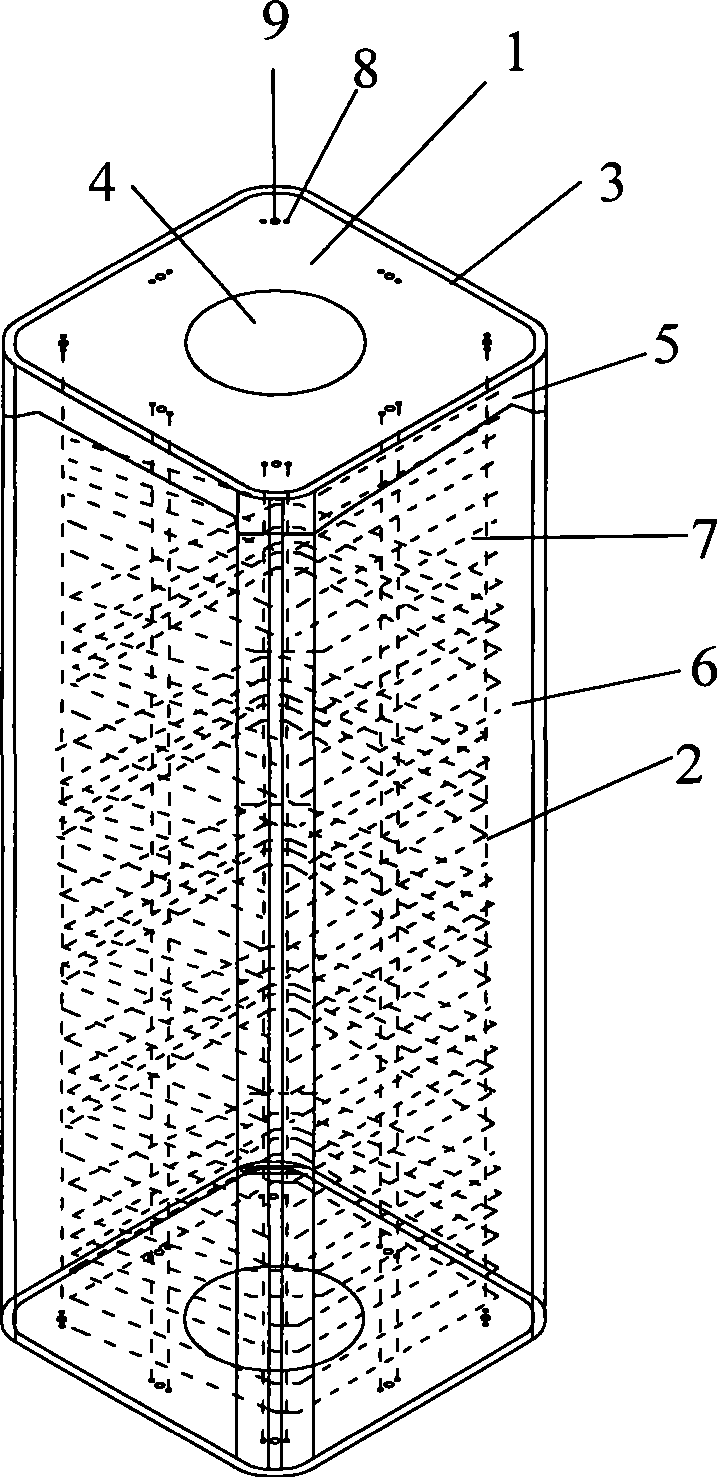

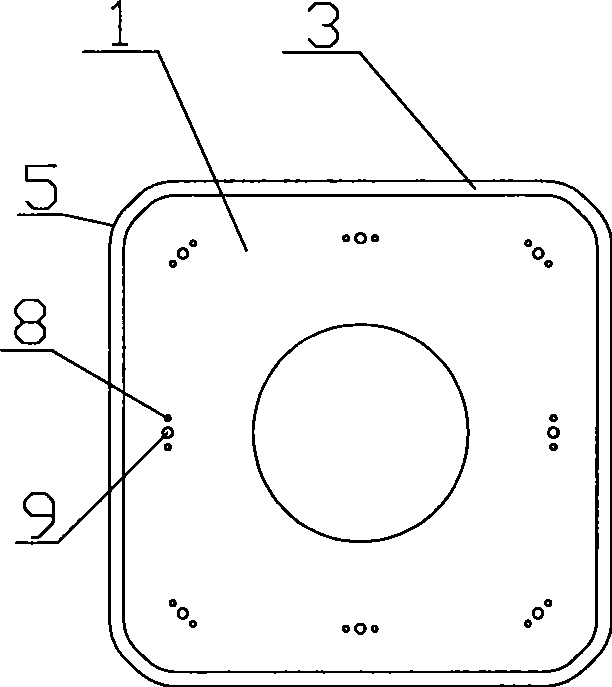

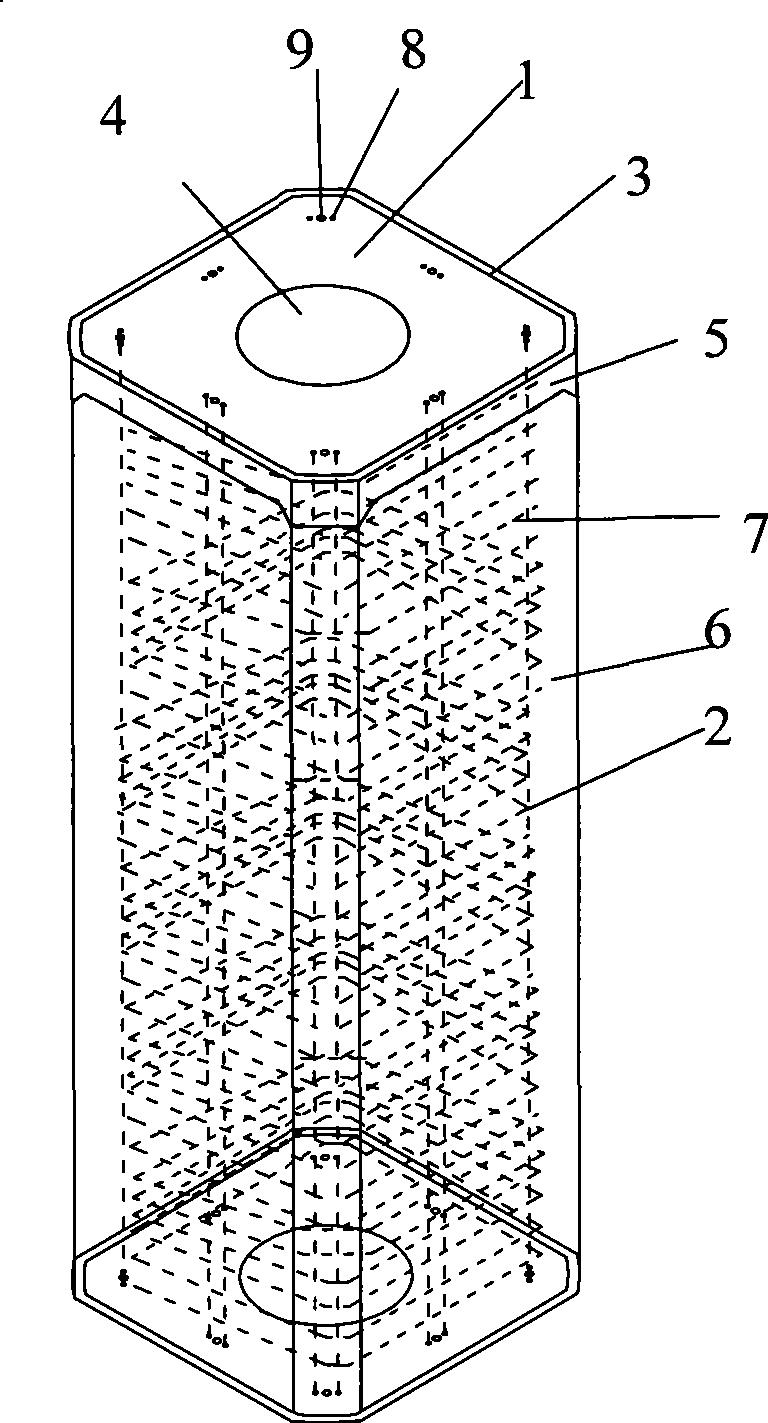

At-sea composite foundation

InactiveCN101255701AImprove pullout resistanceEasy to installArtificial islandsUnderwater structuresSpecific gravityTopsoil

A sea hybrid foundation is composed of a cylinder wall 1, a center column 2, a partition plate 3, an upper rib plate 4 and a lower rib plate 5. The invention is characterized in that the cylinder wall 1 and the center column 2 are connected to a whole steel structure through the partition plate 3, the upper rib plate 4 and the lower rib plate 5. The partition plate 3 divides the cylinder wall 1 to two cylinder cavities with one open end. The upper cylinder cavity is filled with fillers with larger specific weight, such as concrete 8. The lower cylinder barrel is homologous to a suction pile. The center column 2 and the inner part are arranged with a bottling pipeline 6 and a leveling pipeline 7. The lower end is respectively connected with the upper cylinder cavity and the lower cavity. The upper end of the bottling pipeline 6 is connected with the concrete pump on a construction supporting boat. The upper end of the leveling pipeline 7 extends to the construction supporting boat, is connected to the suction pump when the platform sinks and is connected to the mud injecting pump when the platform levels. The superiority of the invention is that a hybrid foundation form is provided for settling the problems of difficulty for sinking the cylindrical foundation and insufficient plucking resistance under the conditions of smaller water depth and higher bearing ability of topsoil. The invention also provides a settling plan for increasing the plucking resistance of the cylindrical foundation.

Owner:NEPTUNE OFFSHORE ENG DEV

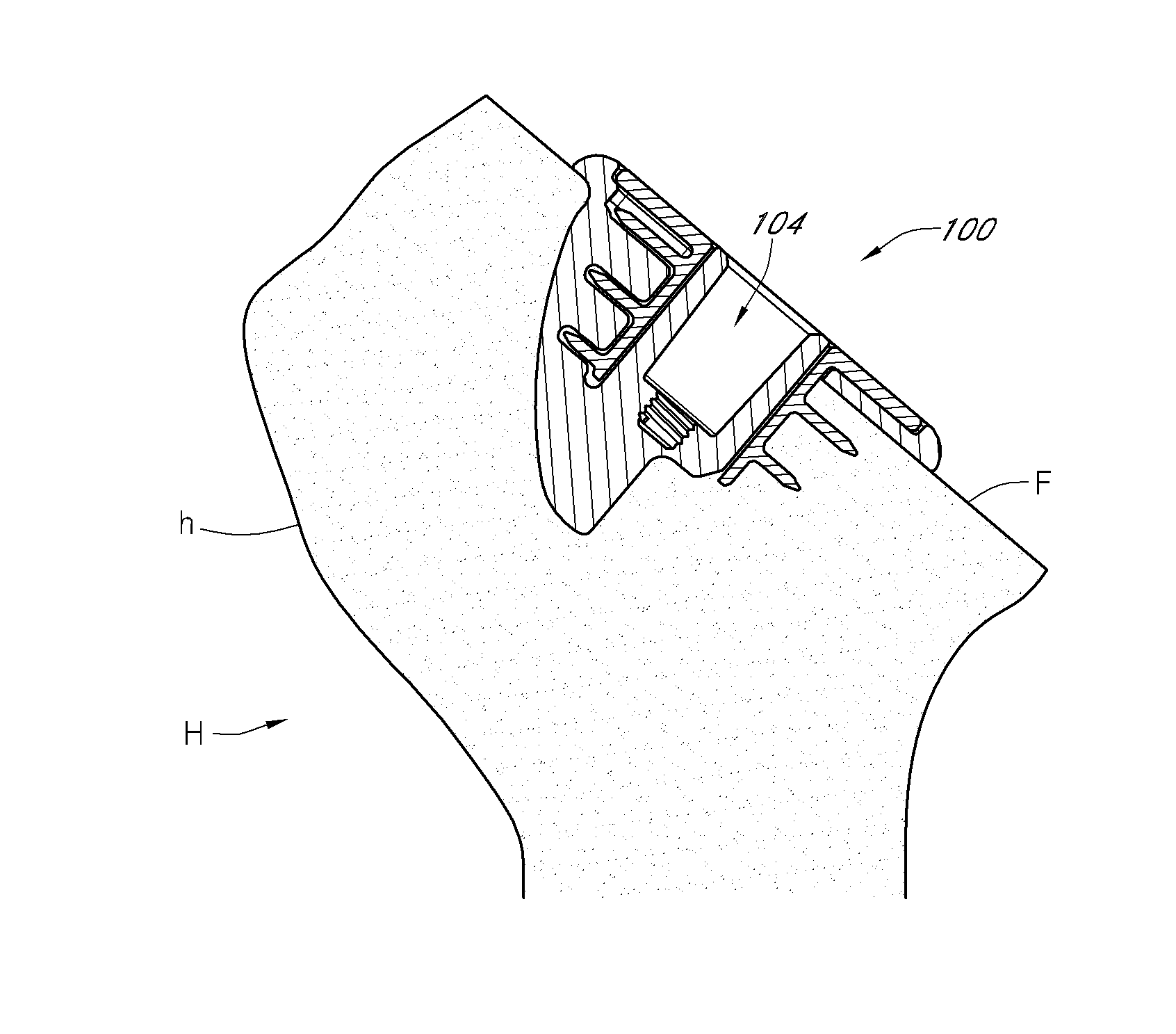

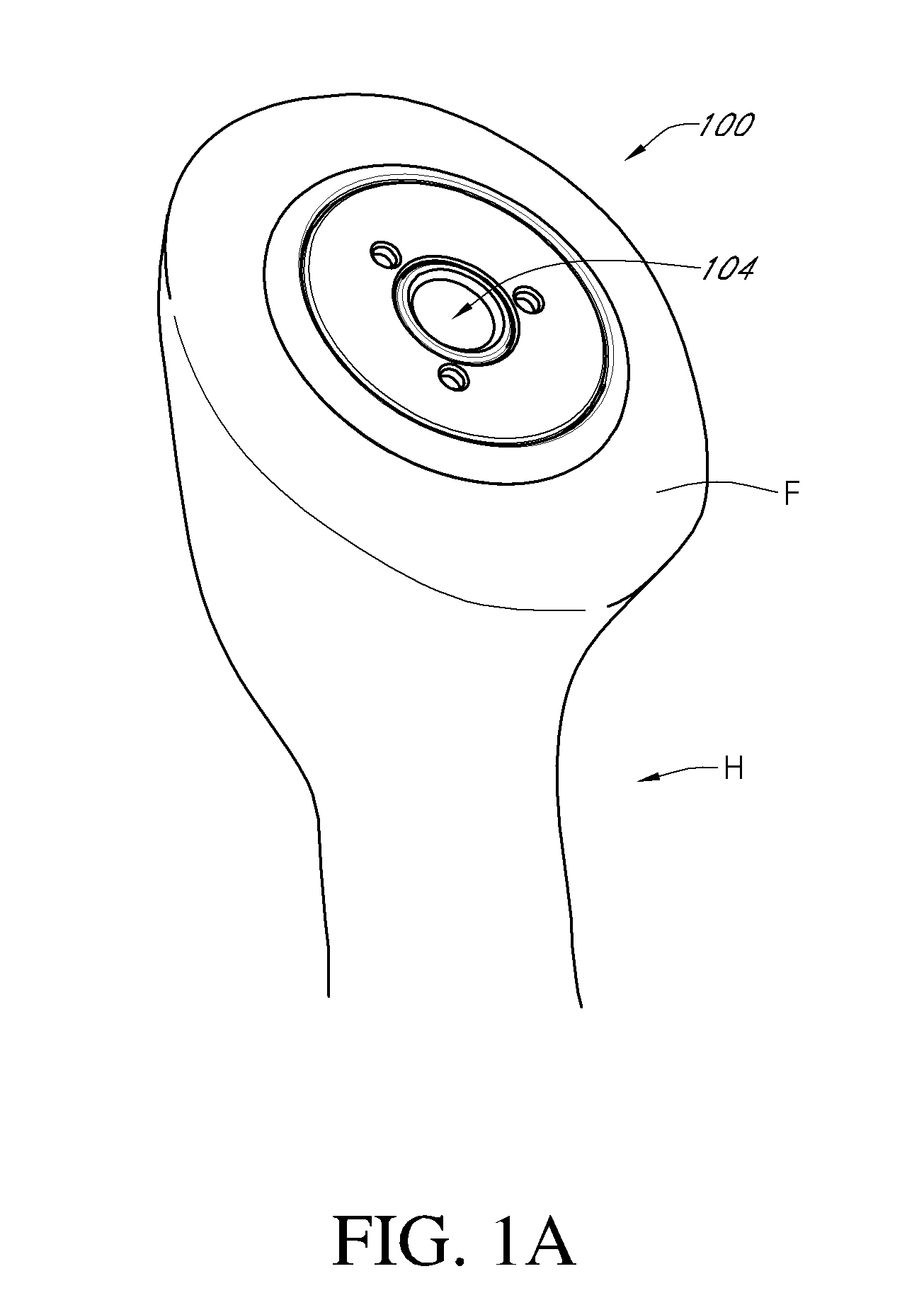

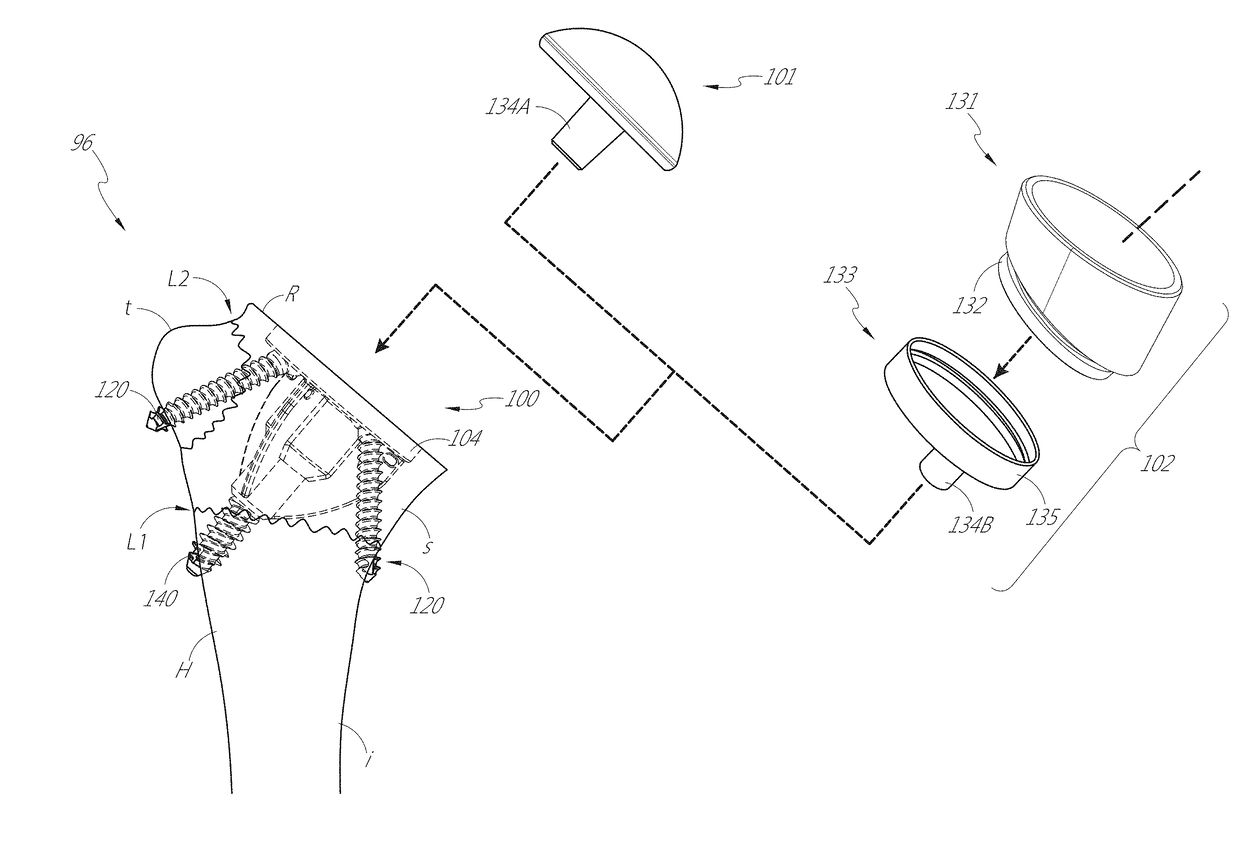

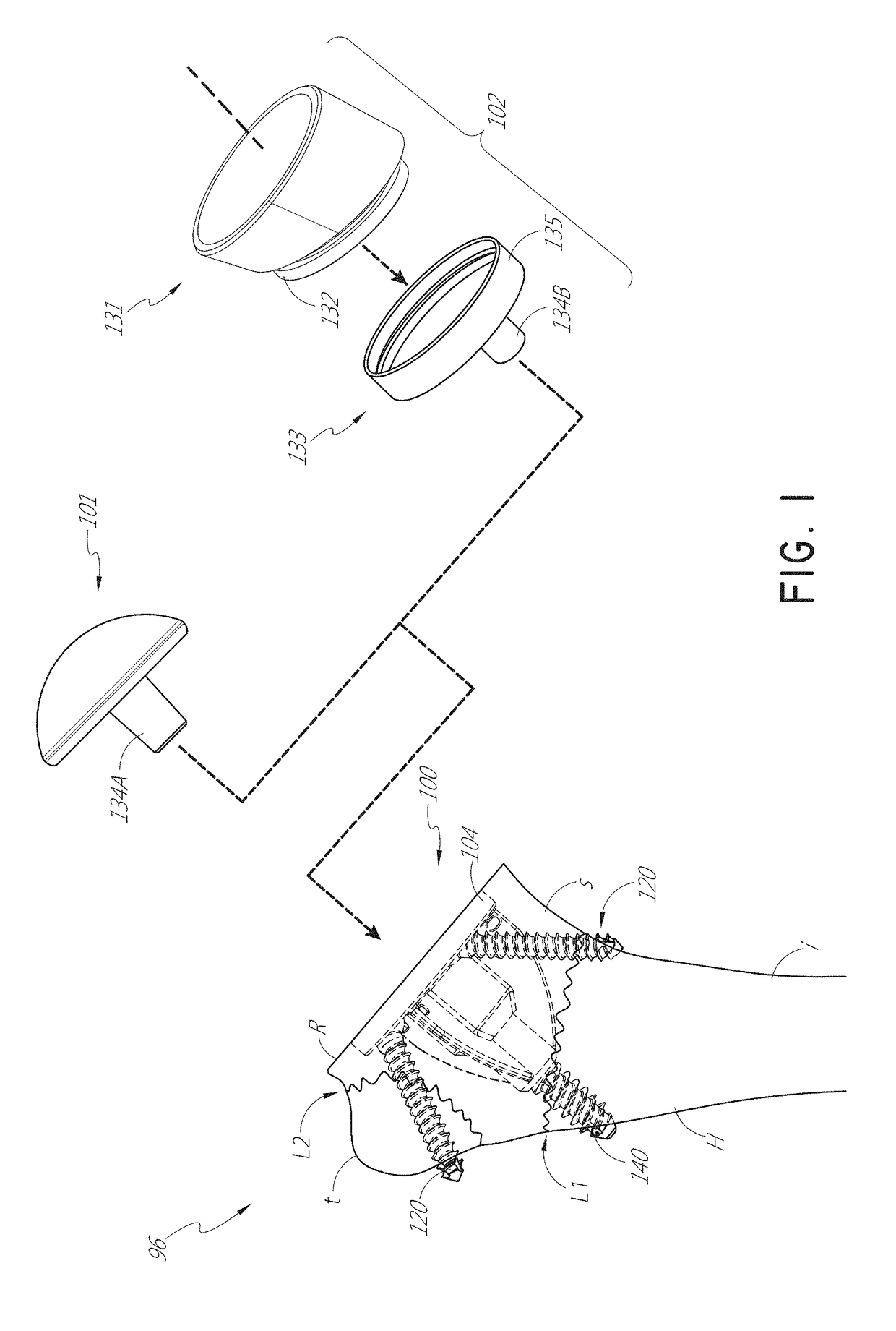

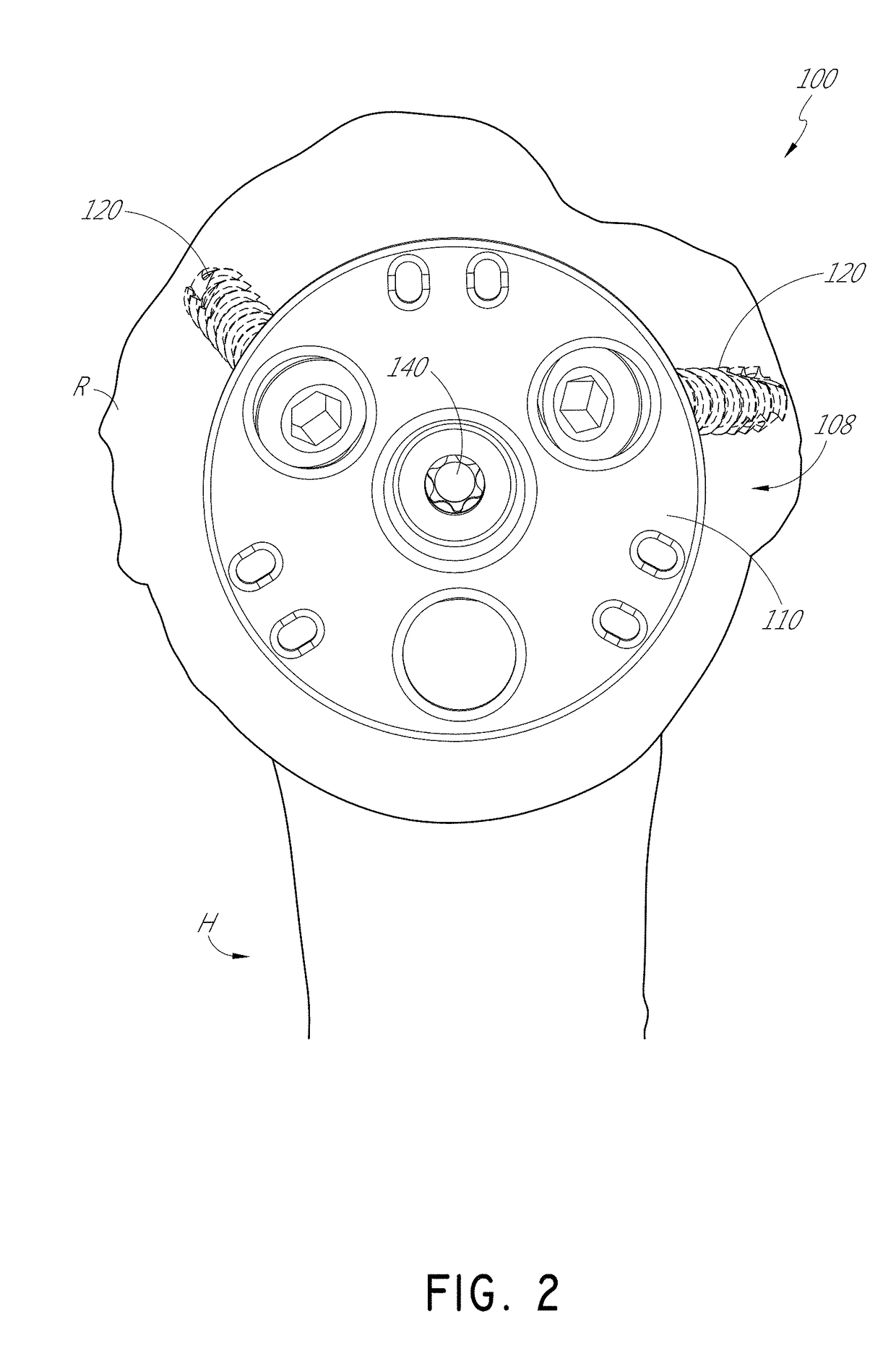

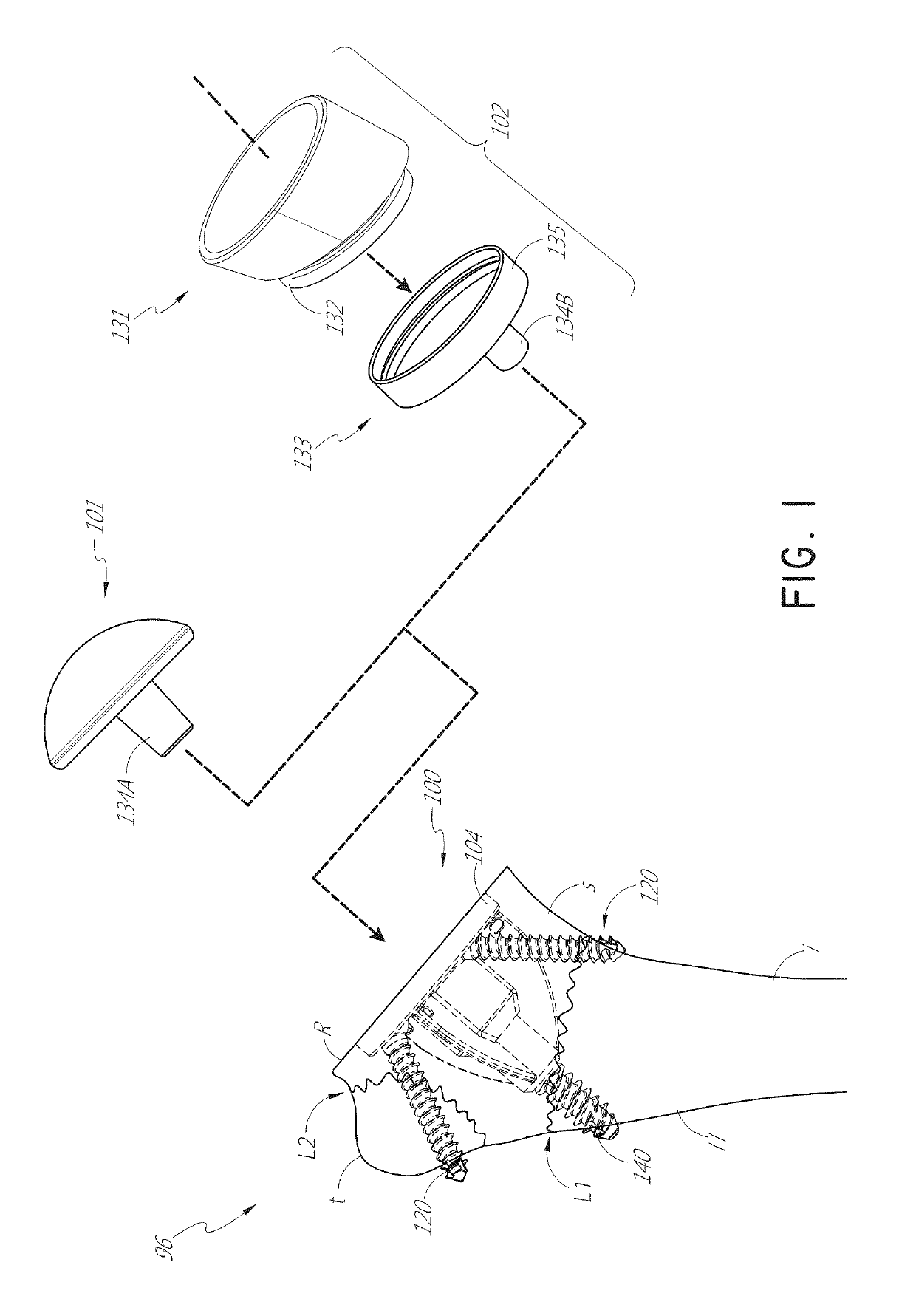

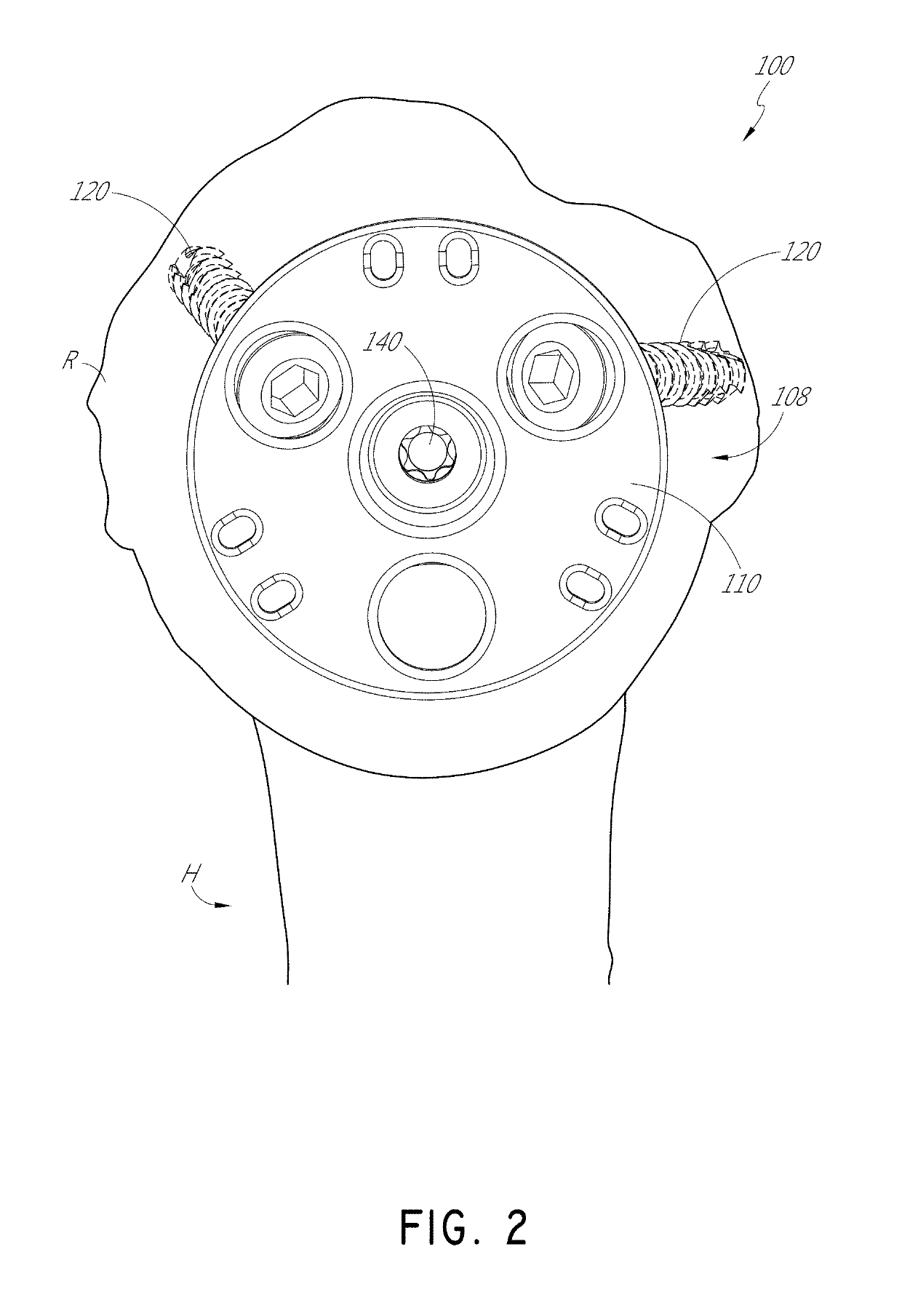

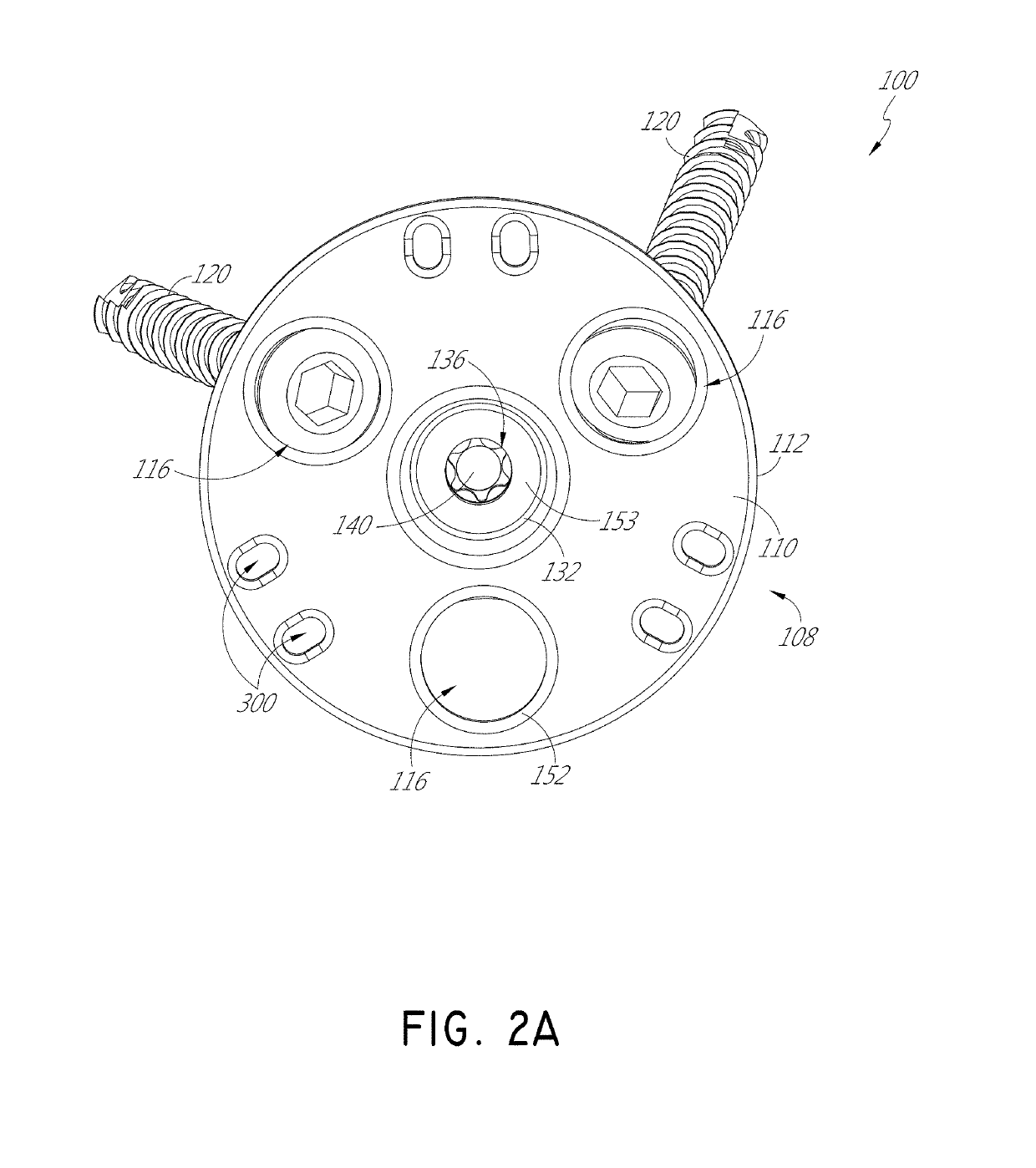

Stemless shoulder implant with fixation components

ActiveUS20170273800A1Improve securityRisk minimizationSuture equipmentsJoint implantsDistal portionBone Cortex

A humeral anchor assembly is provided that includes a humeral anchor and at least one screw. The humeral anchor is configured to form a part of or support a part of a shoulder prosthesis. The humeral anchor has a distal portion configured to be anchored in a proximal region of a humerus and a proximal portion. The proximal portion includes a proximal face configured to engage an articular component within a periphery thereof. The proximal portion also includes at least one aperture disposed adjacent to the periphery. The at least one screw is disposed through the at least one aperture. The screw has a first end portion engaged with the proximal portion of the anchor and a second end portion disposed in or through cortical bone of the humerus.

Owner:HOWMEDICA OSTEONICS CORP

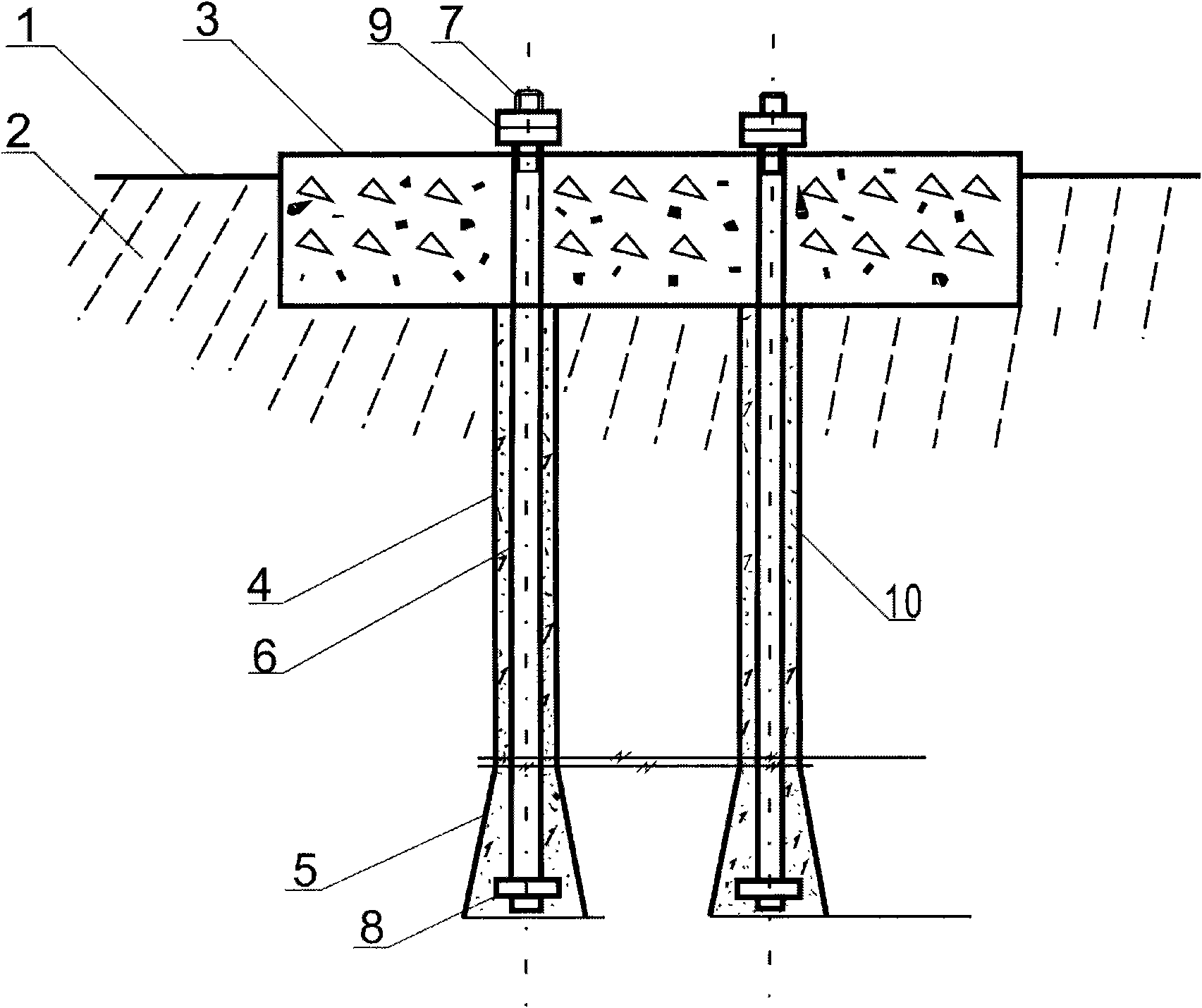

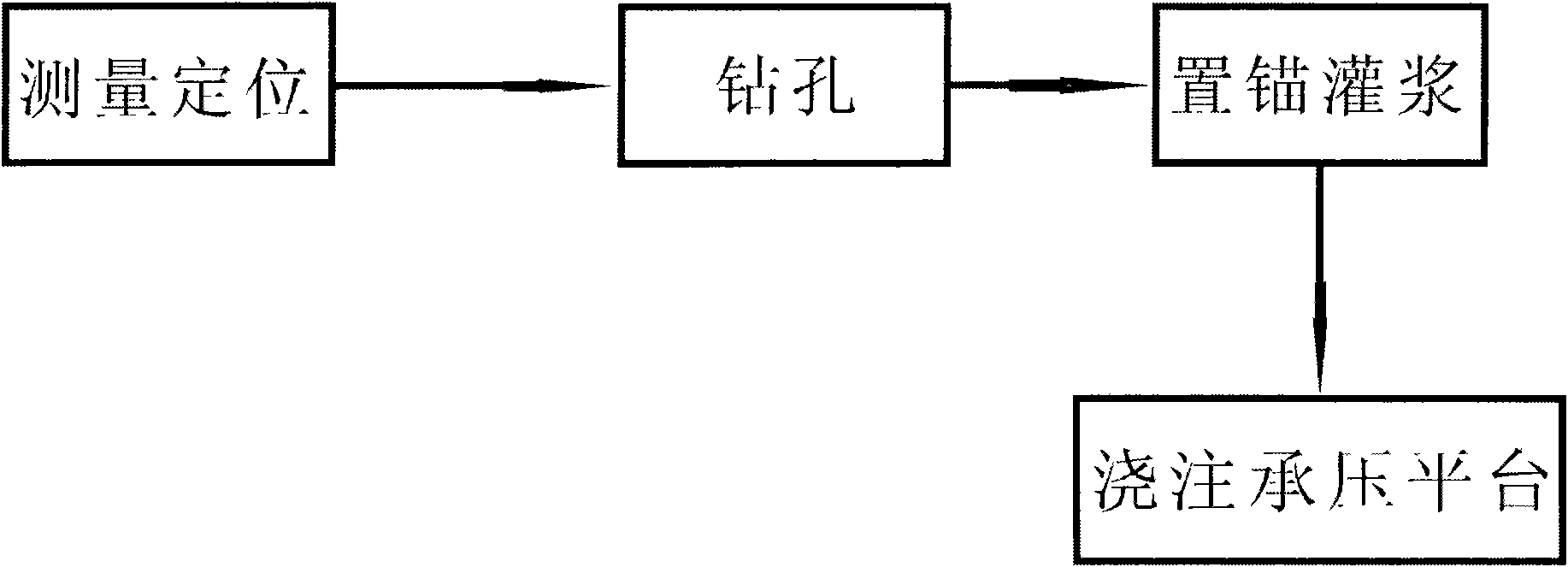

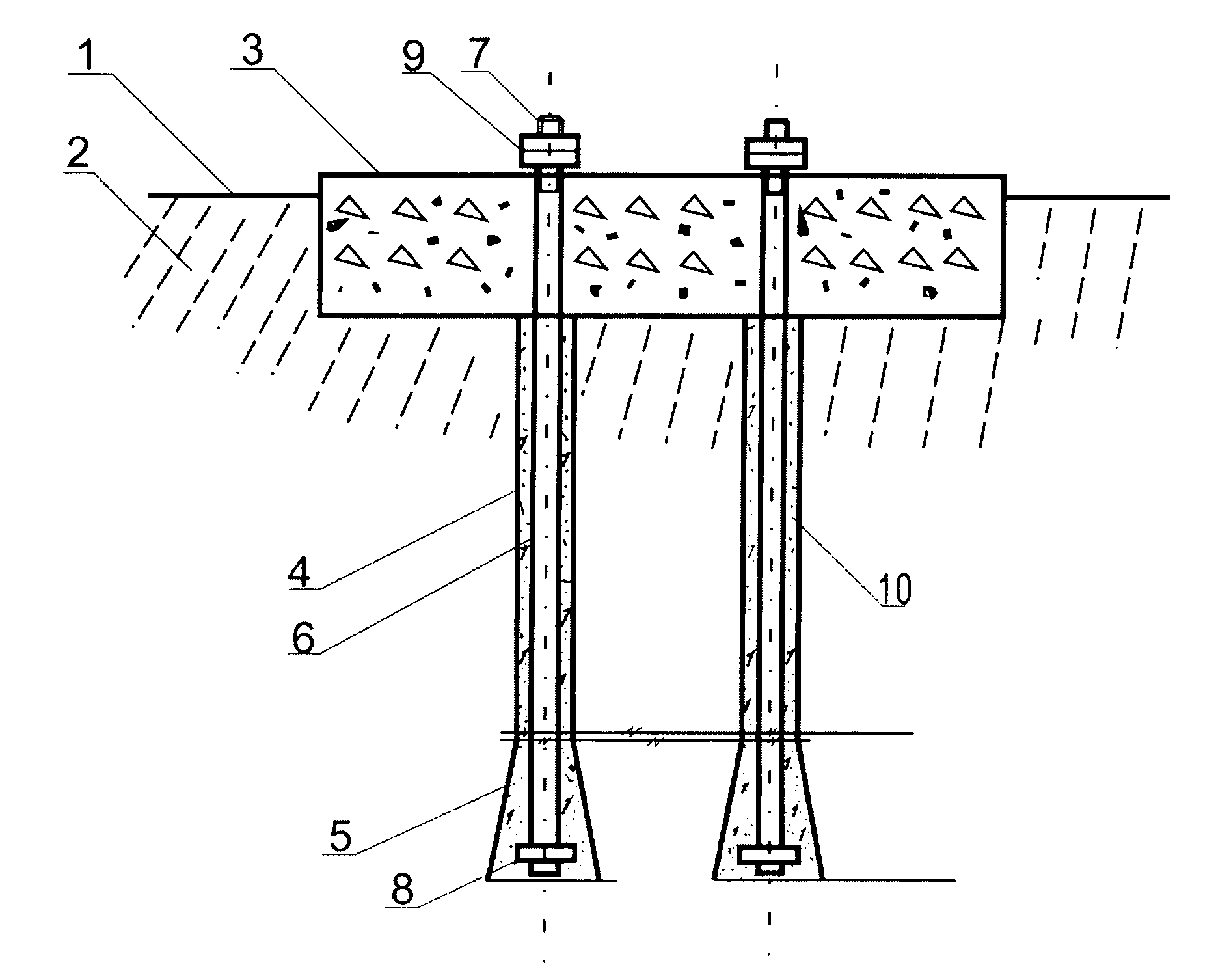

Construction process for rock enlarged toe anchor pile foundation of overhead power transmission line

The invention discloses a construction process for a rock enlarged toe anchor pile foundation of an overhead power transmission line. The construction process comprises the following steps of: (1) measuring and positioning, namely measuring a tower foot position and removing a rock surface to determine a foundation bolt base point; (2) drilling, namely drilling a straight hole at the base point by using a tubular drill until the drilling is finished, and enlarging the bottom of the straight hole by replacing a deviation bit to form a taper hole, wherein the aperture and the depth of the straight hole are determined according to the external diameter and the length of an anchor rod; the taper angle is controlled by controlling the drill bit sinking and the deviation speed; the lower bottom surface of the taper hole is coincided with the bottom of the straight hole; the taper height is determined according to the actual demand; the taper hole is coaxial with the straight hole; the upper bottom of the taper hole is the section of the straight hole; the diameter of the straight hole is 8 to 10cm more than the external diameter of the anchor rod; and the taper angle is 30 to 40 degrees; (3) placing an anchor and grouting, namely placing the anchor rod into the hole to insert a foundation nut and a part of rod body into the taper hole and grouting a CGM30 grout into the hole until the grout reaches the rim of the hole, wherein the anchor rod and the straight hole are coaxial; and (4) pouring a bearing platform, namely pouring the anchor rod which is exposed out of the straight hole into the bearing platform by using high-standard cement, wherein the foundation nut and a foundation bolt are protruded out of the surface of the bearing platform.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY

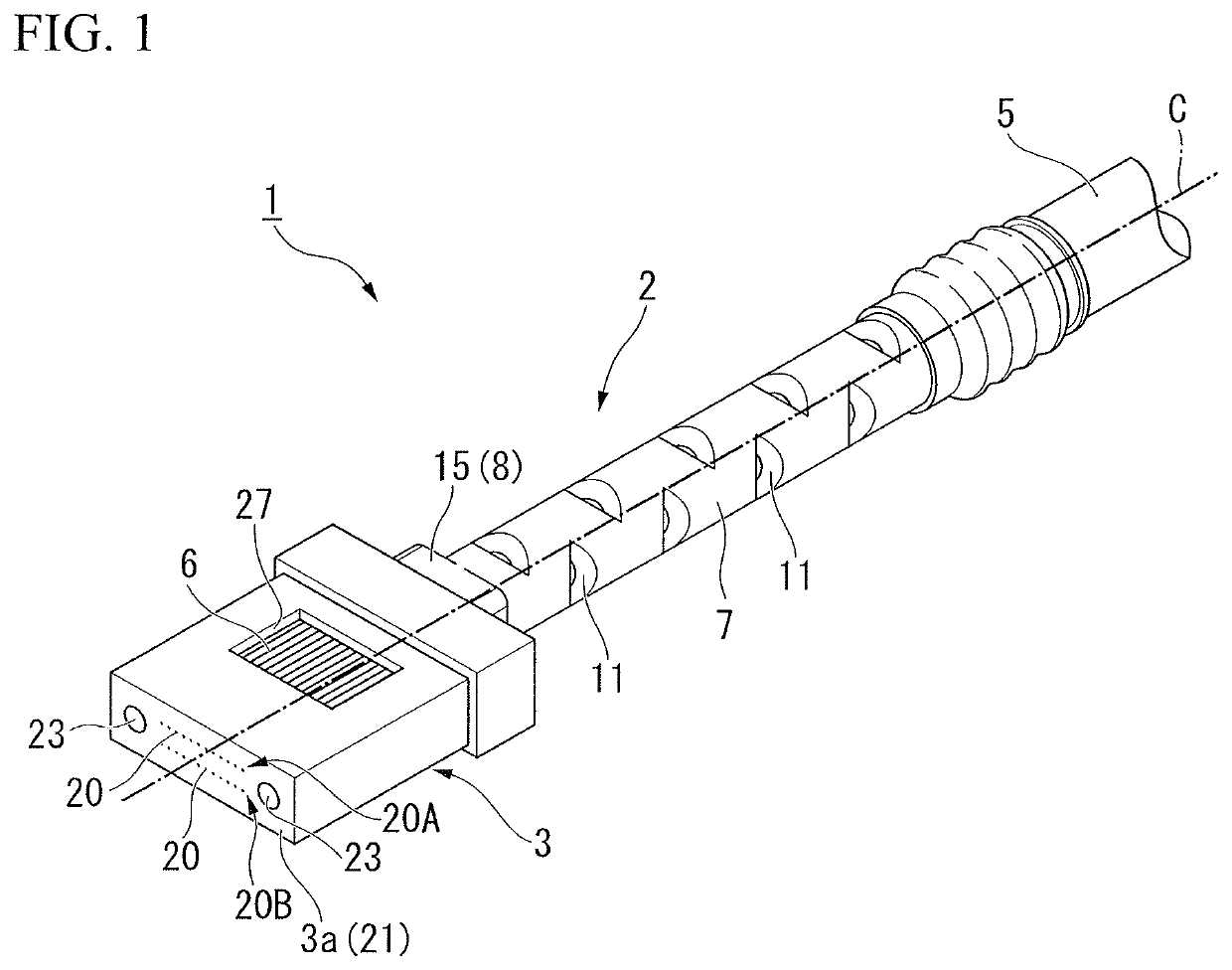

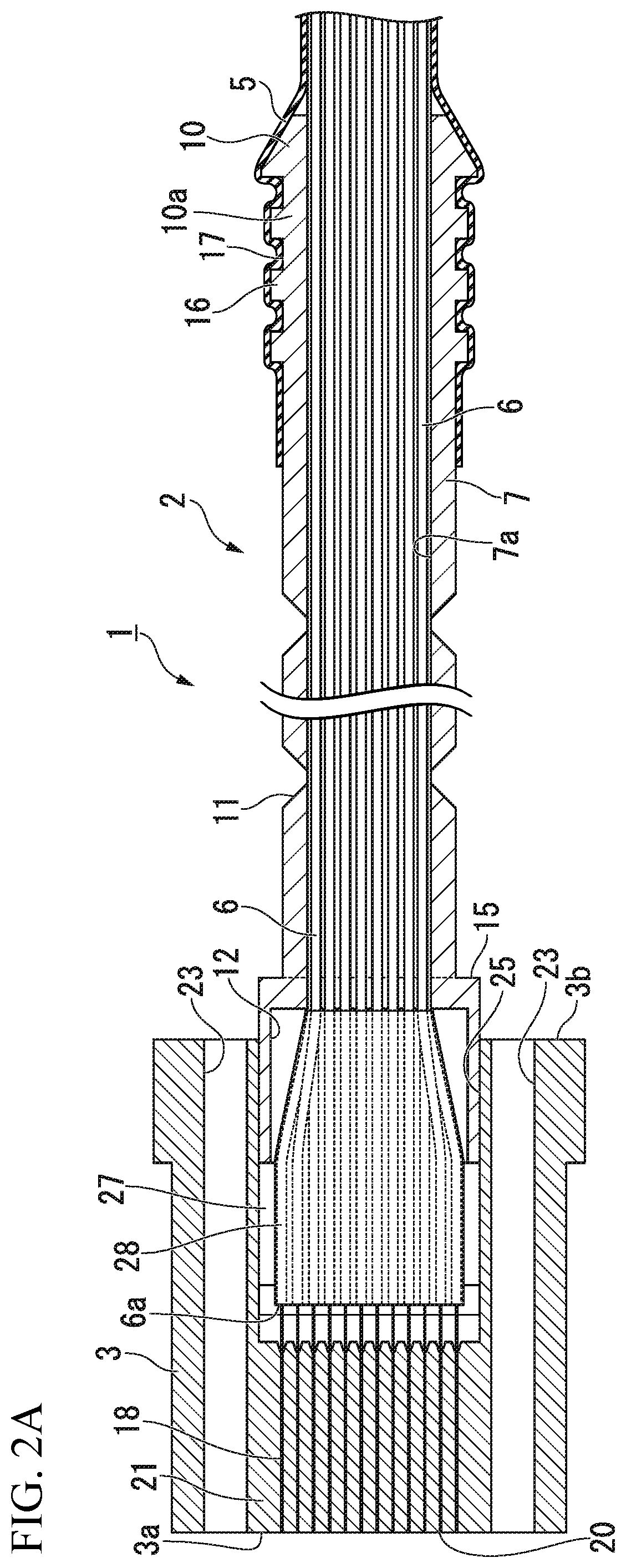

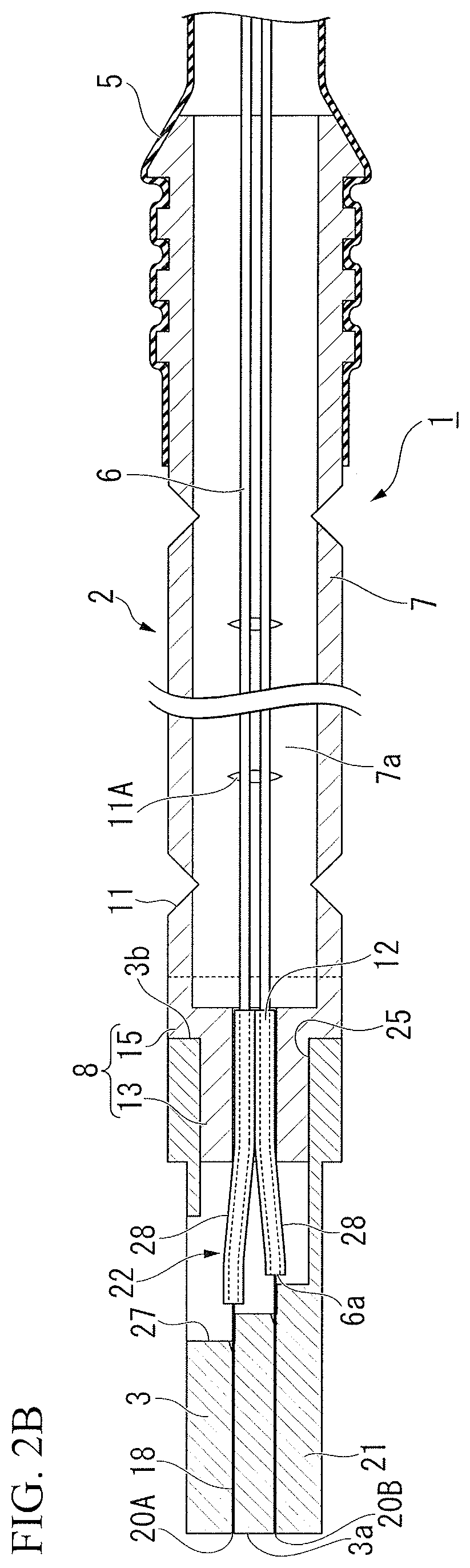

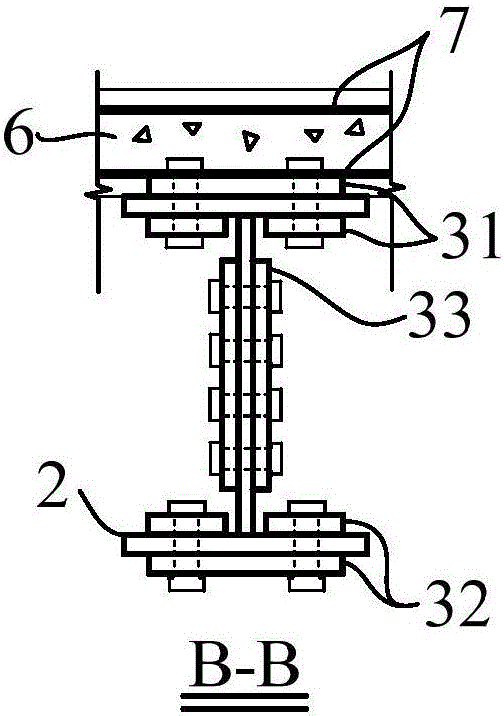

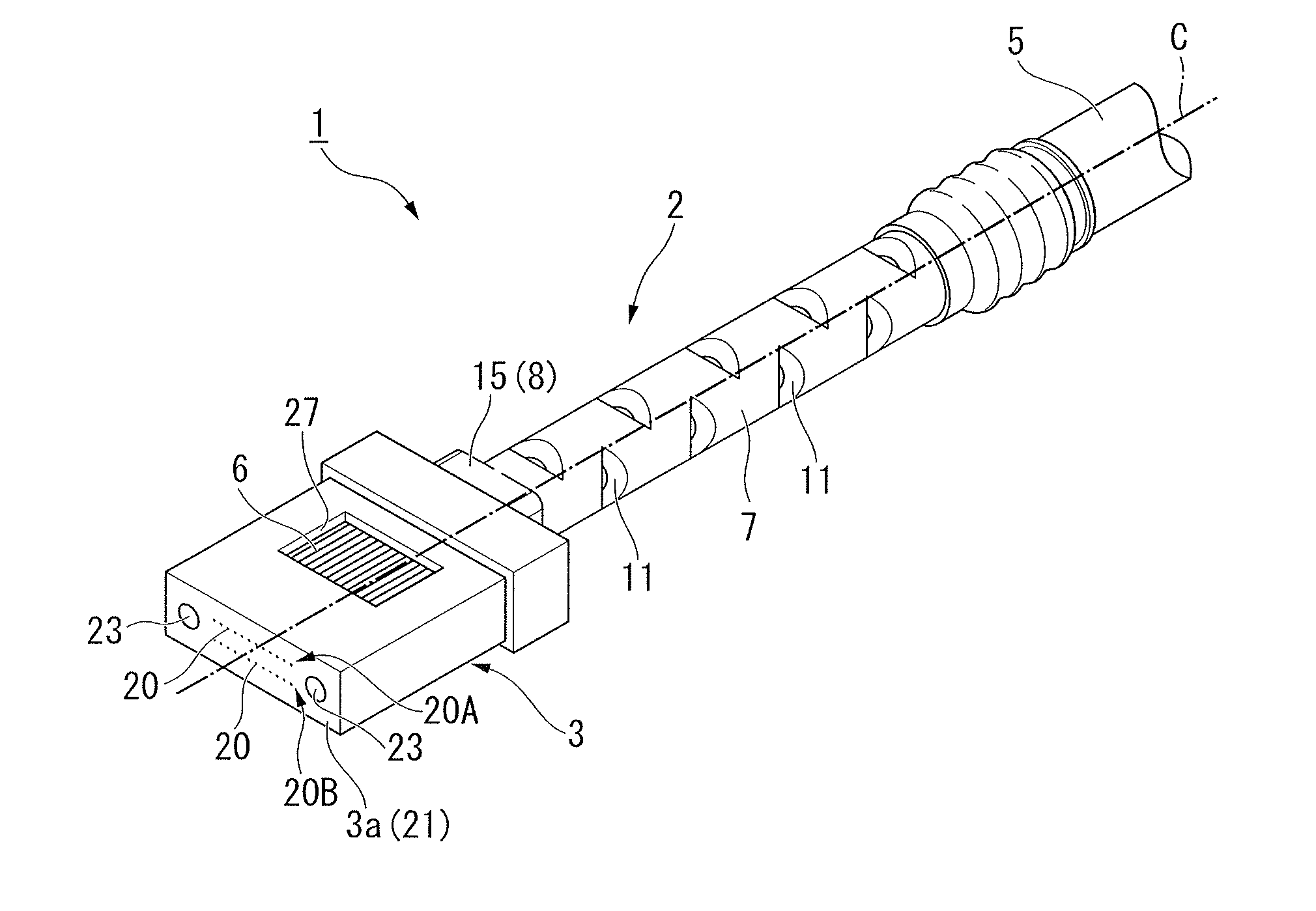

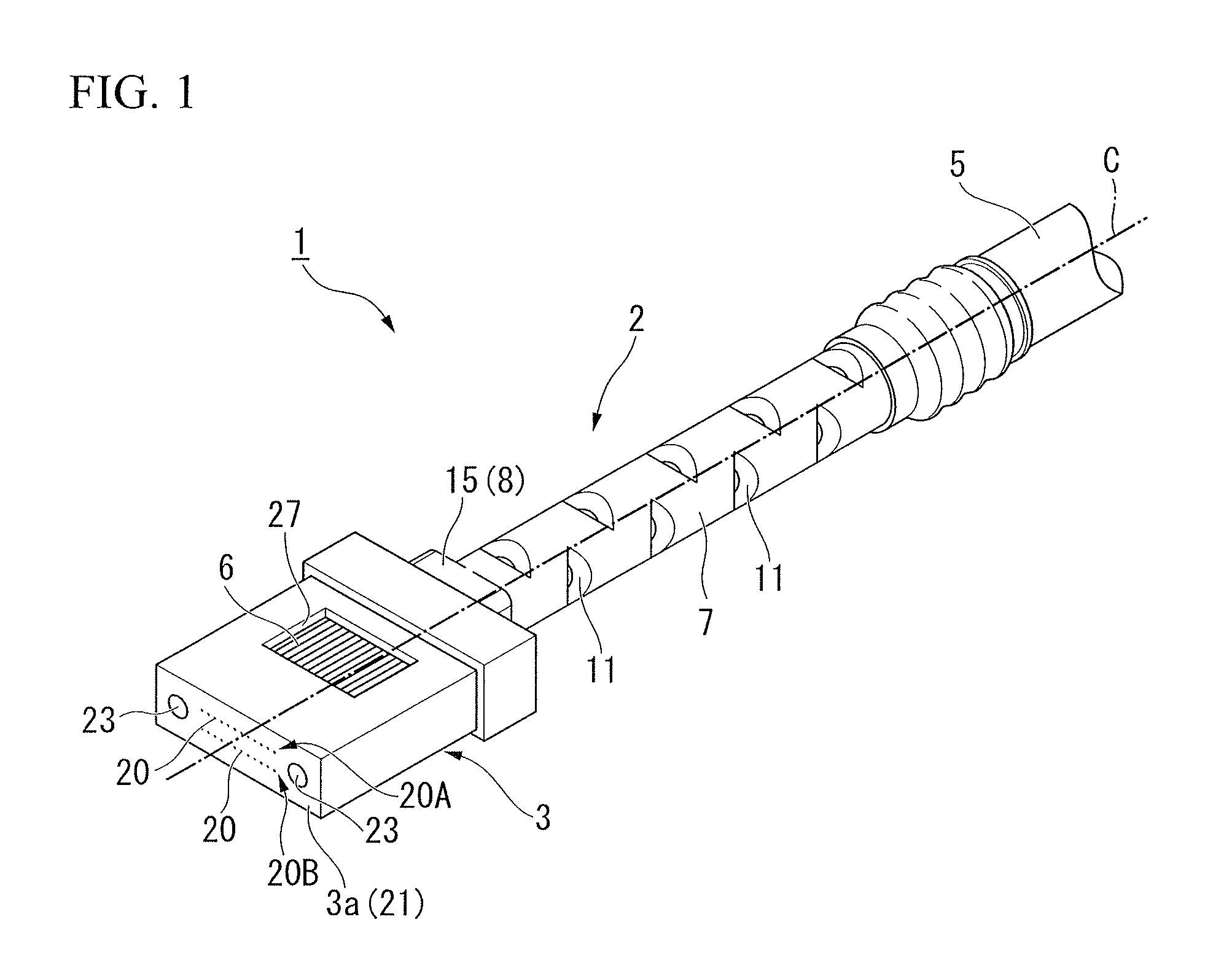

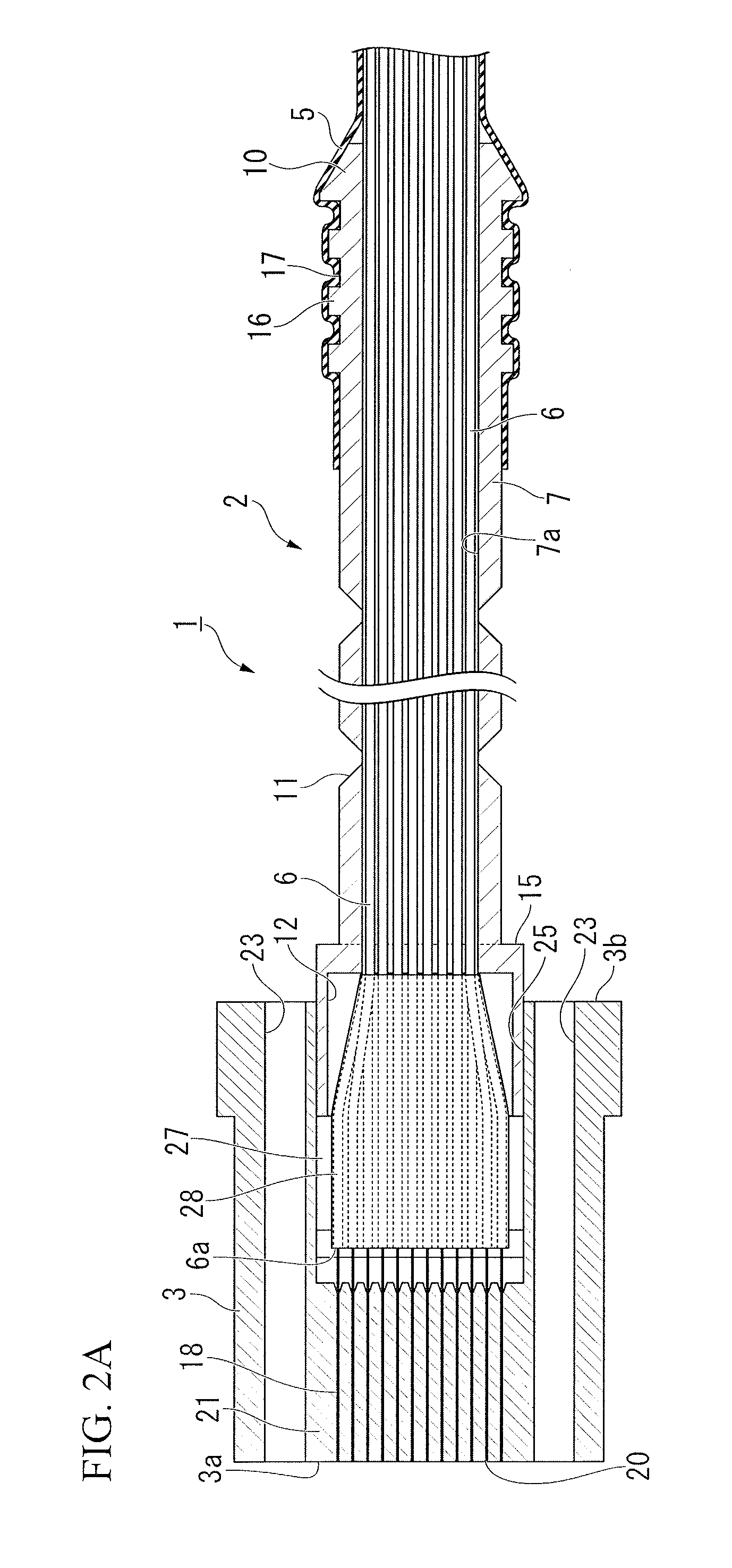

Connector attached optical fiber unit and optical connector boot with protection tube

ActiveUS10656347B2Improve pullout resistanceCoupling light guidesFibre mechanical structuresEngineeringMaterials science

A connector attached optical fiber unit includes: an MT optical connector which includes a joining end surface formed at a front end of the MT optical connector and a hollow portion opened to a rear end surface opposite to the joining end surface; a tubular boot which includes a front end insertion portion inserted and fixed into to the hollow portion and a tube attachment portion formed at a rear end portion of the tubular boot, the tubular boot extending to a rear side from the MT optical connector; a protection tube into which the tube attachment portion is inserted and to which the tube attachment portion is fixed; and a plurality of optical fibers which include tip portions inserted and fixed into the MT optical connector and are accommodated inside the boot and the protection tube.

Owner:FUJIKURA LTD

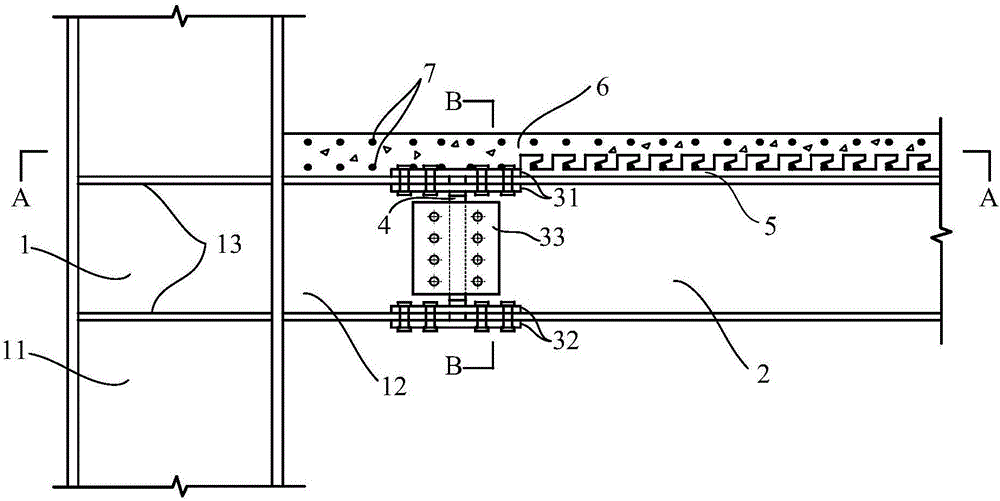

Assembly type steel frame connection node with post-seismic recoverable function

InactiveCN106638961AGuarantee the construction qualityReduce labor intensityProtective buildings/sheltersShock proofingSteel columnsFloor slab

The invention discloses an assembly type steel frame connection node with a post-seismic recoverable function. A frame steel column comprises a column body and an outward extending short beam which are vertically fixedly connected, a post-seismic replaceable energy consumption connecting plate comprises an upper flange cover plate, a lower flange cover plate and a web cover plate, an upper flange of the outward extending short beam is fixedly connected to an upper flange of a body steel beam through the upper flange cover plate, an lower flange of the outward extending short beam is fixedly connected to a lower flange of a body steel beam through the lower flange cover plate, and a web of the outward extending short beam is fixedly connected to a web of the body steel beam through the web cover plate; a gap reserved between the outward extending short beam and the body steel beam is filled with a rubber pad plate; the upper flange of the body steel beam is fixedly connected to a concrete floor slab through a lift-resistant tooth-and-slot plate connecting piece. Through the double effects of connection and energy consumption exerted by the post-seismic replaceable energy consumption connecting plate, the structural damage and failure mechanism are actively controlled, it is guaranteed that the body structure keeps elasticity, damage occurs on a specified position, as a replaceable component, the post-seismic replaceable energy consumption connecting plate facilitates post-seismic replacement and repair, and a shear force connecting piece guarantees structural integrity and full exertion of combined stressed performance.

Owner:BEIJING JIAOTONG UNIV

Connector attached optical fiber unit and optical connector boot

ActiveUS20150346435A1Improve pullout resistanceCoupling light guidesFibre mechanical structuresEngineeringMechanical engineering

A connector attached optical fiber unit includes: an MT optical connector which includes a joining end surface formed at a front end of the MT optical connector and a hollow portion opened to a rear end surface opposite to the joining end surface; a tubular boot which includes a front end insertion portion inserted and fixed into to the hollow portion and a tube attachment portion formed at a rear end portion of the tubular boot, the tubular boot extending to a rear side from the MT optical connector; a protection tube into which the tube attachment portion is inserted and to which the tube attachment portion is fixed; and a plurality of optical fibers which include tip portions inserted and fixed into the MT optical connector and are accommodated inside the boot and the protection tube.

Owner:THE FUJIKURA CABLE WORKS LTD

Three piece garage hook

In one aspect, a holder mountable to a friable substrate may include a self-drilling drywall fastener, a wall engaging base plate having an opening for receiving a fastener, and at least one leg extending from the base plate for holding an object. In another aspect, a holder may include a self-drilling drywall fastener having a drilling portion longer than a drywall thickness followed by a high-threaded portion, a wall engaging base plate, and at least one leg for holding an object. In still another aspect, a holder may include a self-drilling drywall fastener having a screw-like drilling portion longer than a drywall thickness followed by a high-threaded portion, a drywall engaging base plate having a recess for receiving a rotary driver and a pair of openings each capable of receiving a threaded drywall fastener and engaging threads thereof.

Owner:ILLINOIS TOOL WORKS INC

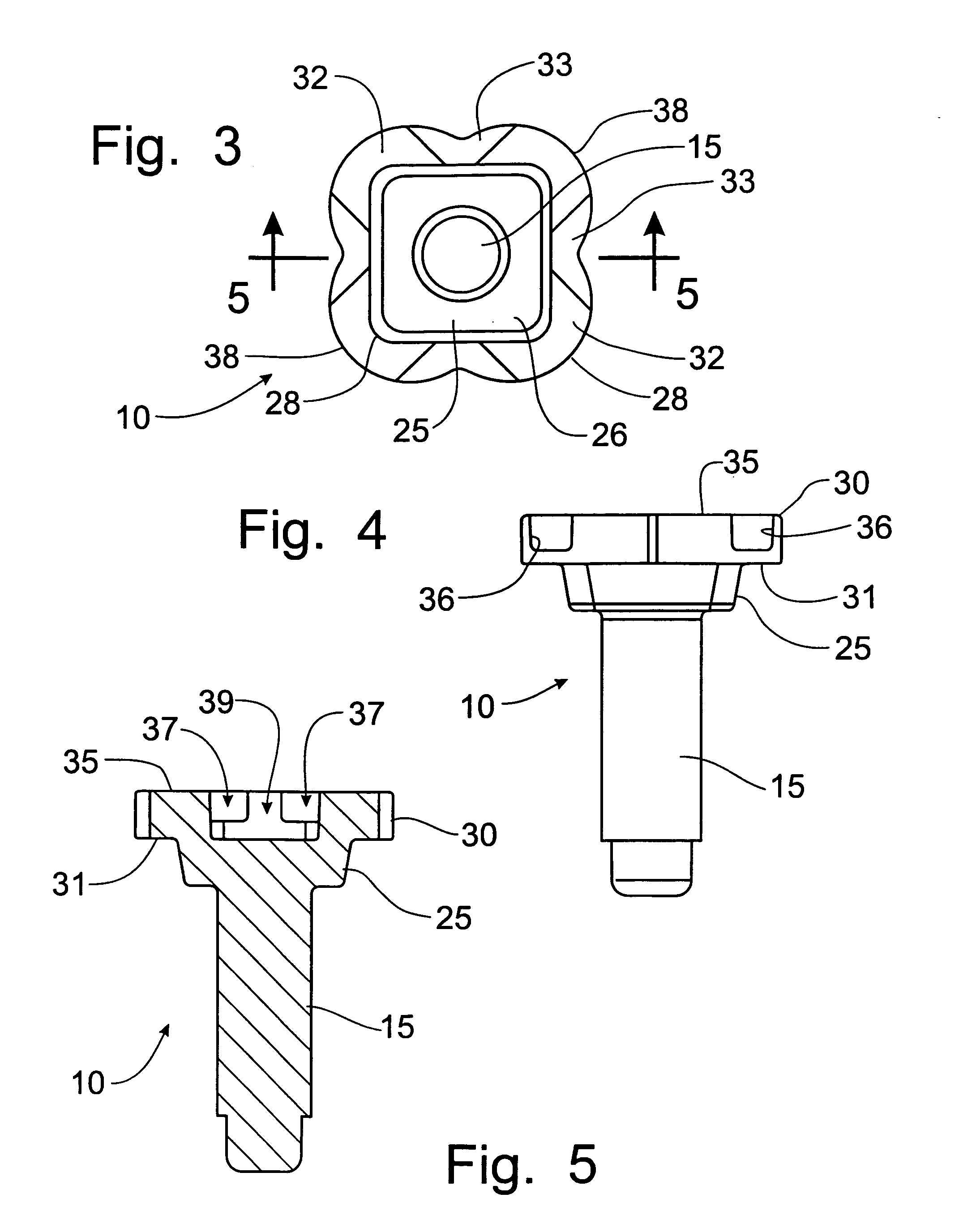

Waffle stud for insert molded plastic members

ActiveUS7156598B2Maximum spin-out torque and pull-out force valueEasy to moveTravelling carriersHoldersPlastic materialsMaterials science

A fastener is configured for use in the manufacture of molded plastic components that will be subsequently attached to other components by the fastener. The low profile head portion of the fastener has a rounded contoured and convoluted top surface to facilitate the flow of plastic material around the head portion during the molding process. The underside of the head portion is formed with a square face surrounded circumferentially by circumferential land surfaces that provides a high pull-out force resistance for the fastener. The square face on the underside and convoluted top surface of the head portion provides a high spin-out torque resistance without sacrificing the pull-out force resistance. The rounded edges of the head portion are compatible with molding processes to allow the flow of plastic material to fully encapsulate the head portion within the molded plastic component.

Owner:FORD GLOBAL TECH LLC

Device for connecting a screw to a support plate

The invention relates to a device which is used for solidly connecting a part such as a plate to an underlying support using at least one fixing element such as a screw. According to the invention, said fixing element takes the form of a threaded rod a screw which passes through a hole housing a ring belonging to the part, such that it is screwed into the support material. The inventive device is characterized in that the above-mentioned ring is a constriction ring comprising a non-circular outer profile which co-operates with the non-circular inner profile of the hole, which is in the part. In this way, when the ring is rotated in the hole and wedged in place therein, it is constricted, thereby blocking the threaded rod against movement with respect to the plate.

Owner:STRYKER EURO OPERATIONS HLDG LLC

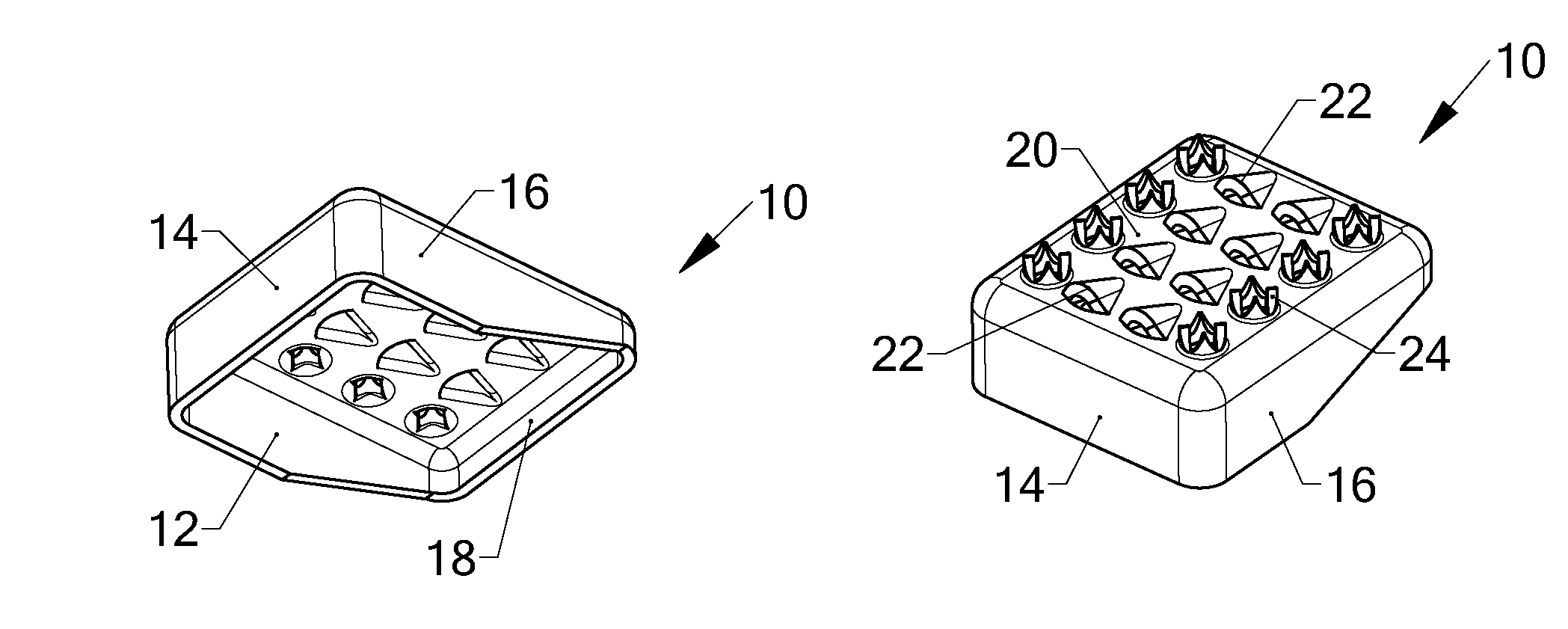

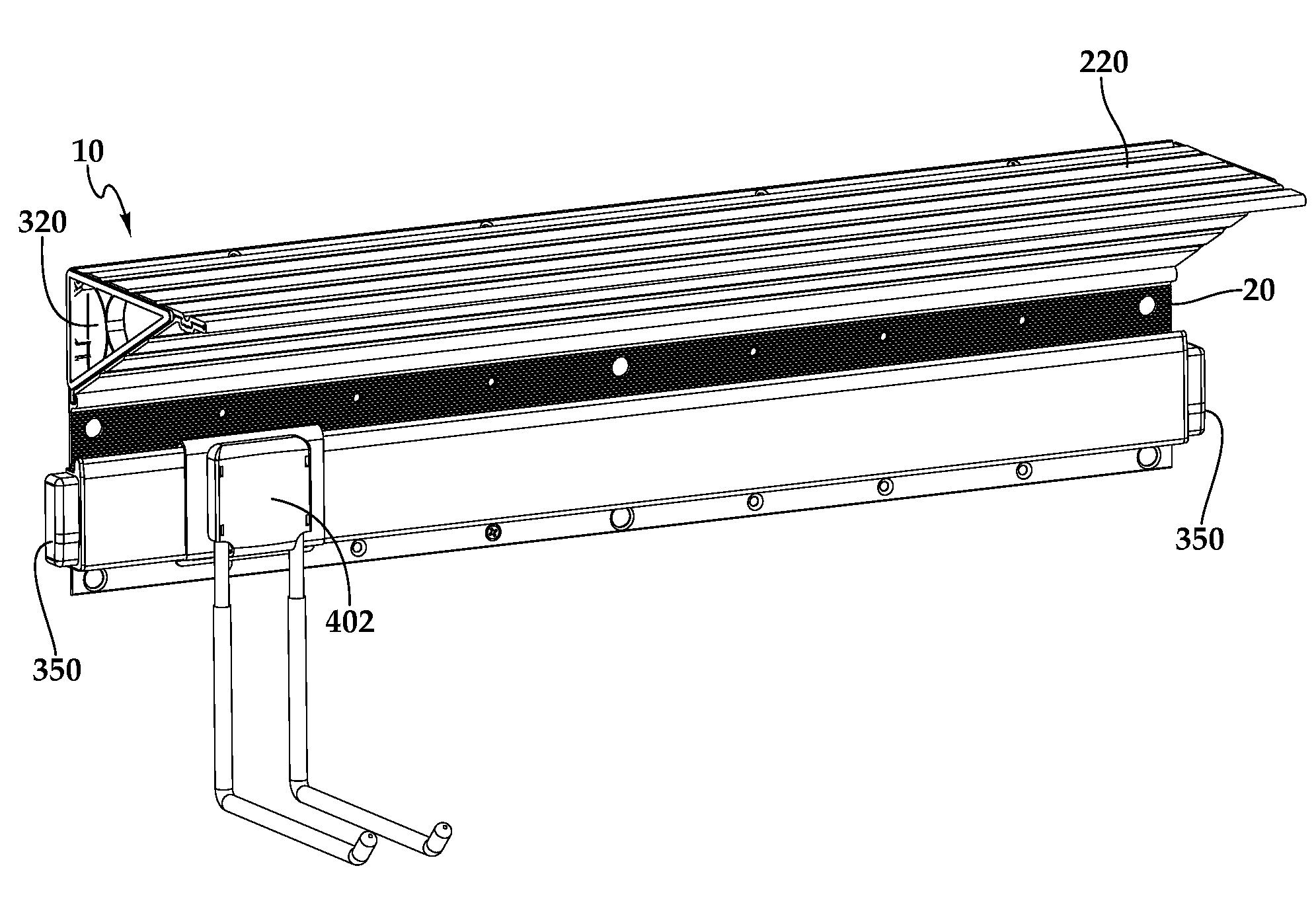

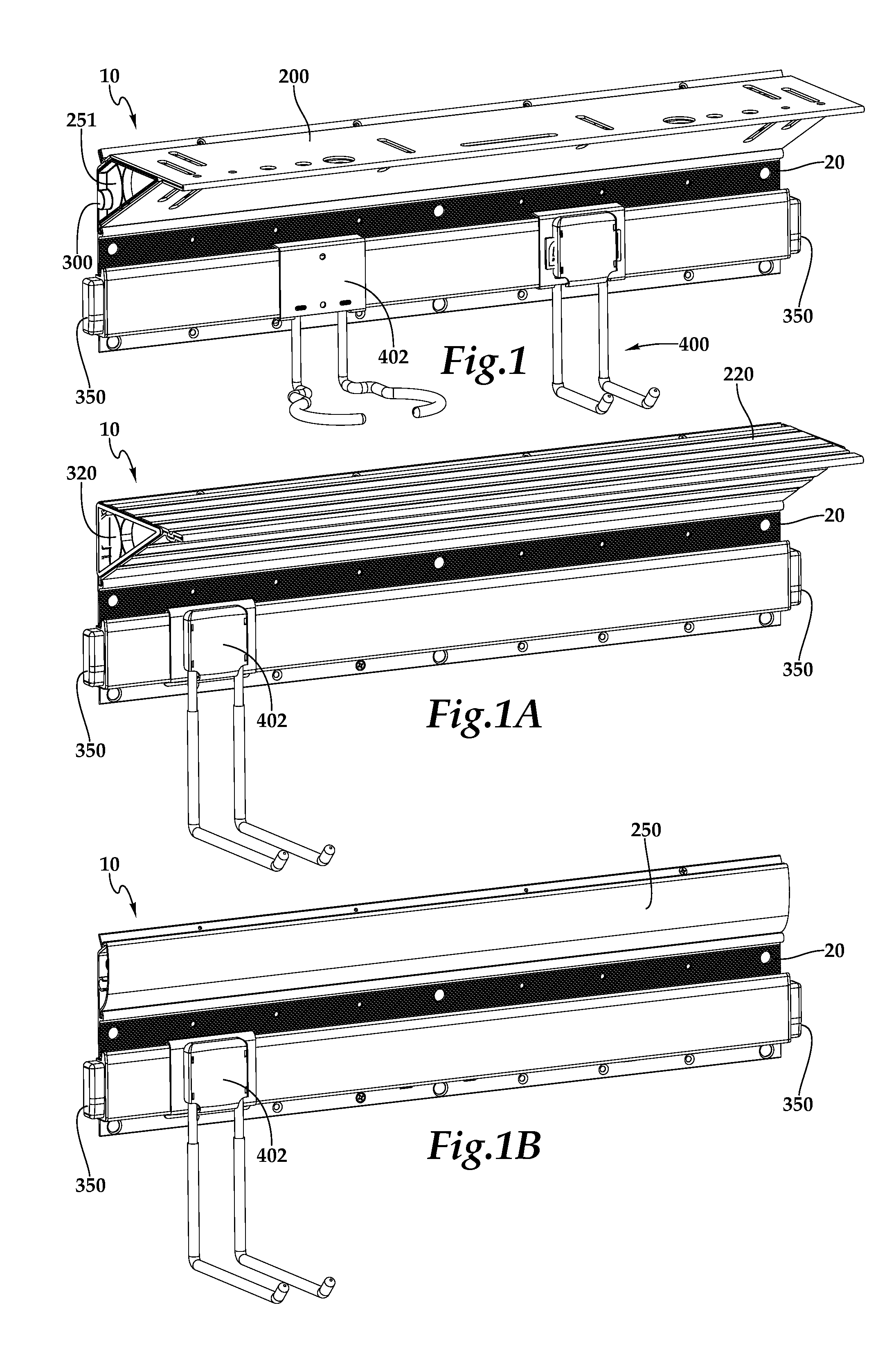

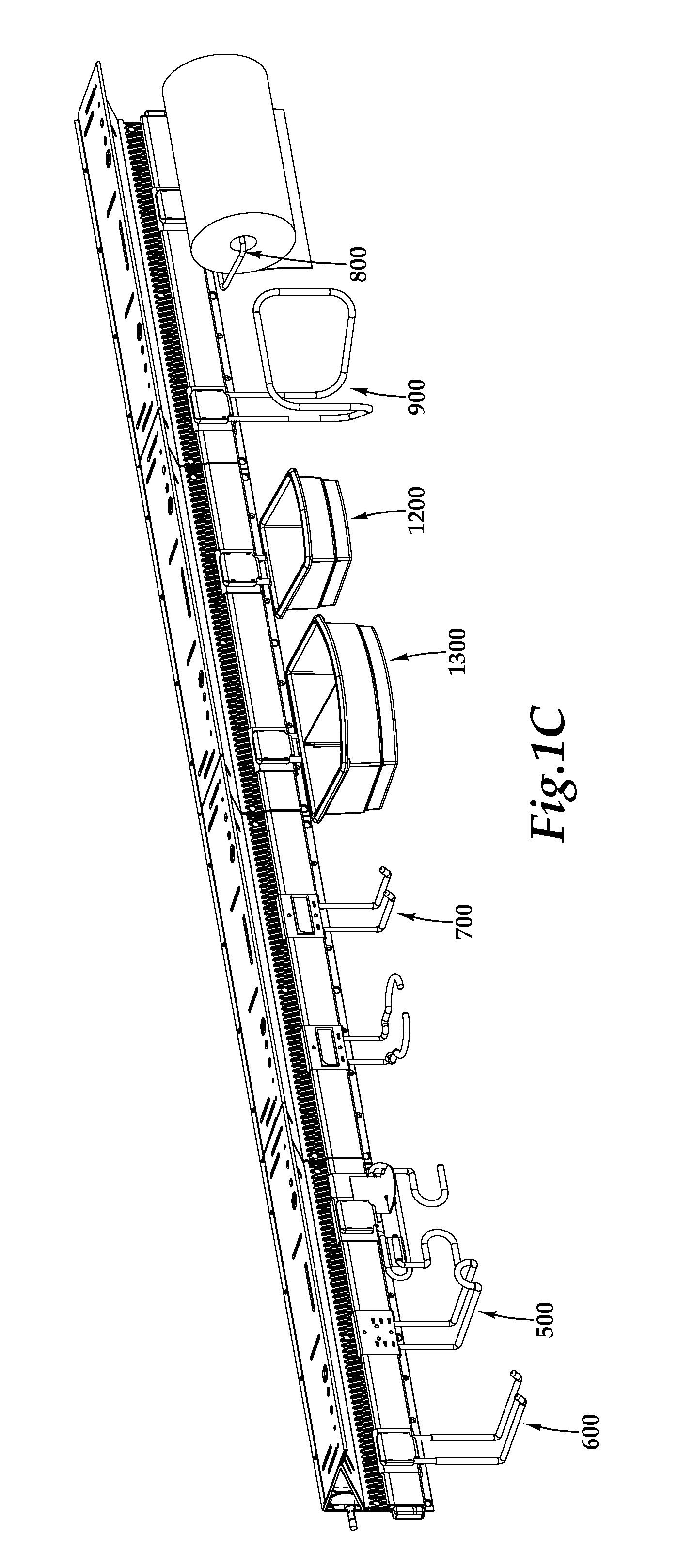

Storage System

ActiveUS20110266283A1Improve usabilityFunction increaseCandle holdersLighting support devicesEngineeringMechanical engineering

In one aspect, a storage system is disclosed. The storage system may include a base having a lower or accessory portion and an upper portion, wherein the lower portion has at least one lower projection extending outward from a front surface and wherein the upper portion has at least two upper projections extending outward from the front surface and spaced from the lower projection. The system may also include at least one accessory configured to engage the lower portion. The system further may include at least one shelf or cover configured to engage the two upper projections. In a further aspect, another storage system is disclosed, wherein the storage system may include a base having an upper ledge portion, wherein a portion of the upper ledge portion is spaced a predetermined distance from a wall. The base further may include a lower portion and an accessory portion between the upper ledge portion and the lower portion. The system further may include at least one accessory configured to engage the accessory portion. The system also may include at least one shelf or cover configured to couple to the base.

Owner:ILLINOIS TOOL WORKS INC

Preparation method for prestressed high-strength concrete pile

InactiveCN101544020AAvoid damageReduce stress concentrationShaping reinforcementsLubricant compositionHigh strength concreteStress concentration

The invention provides a prestressed high-strength concrete pile, belongs to the filed of building, and in particular relates to a driven fender pile applied to deep foundation pit engineering. The prestressed high-strength concrete pile comprises concrete, a reinforcing cage and an end plate, wherein the shape of the end plate is round-angle square; diameters of circular arc segments of round angles are equal and are 1.1 to 1.3 folds of the side length of the square, preferably 1.2 folds; central angles of the circular arc segments are 13 degrees to 17 degrees, and the length of a straight-line segment is 0.3 to 0.5 fold of the side length of the square; the grade of the concrete strength is higher than C40; and a main reinforcement of the reinforcing cage is arranged on a circle taking a centroid of the end plate as a center or on the square. The prestressed high-strength concrete pile greatly reduces the problem of stress concentration and the damage to a pile body in construction, and improves the bearing capacity of the pile body, horizontal bending resistance and shearing resistance performances, beat resistance capacity and pulling resistance performance.

Owner:SHANGHAI ZHONGJI PILE IND

Tensile expansive hollow grouting bolt structure

ActiveCN109184767AImprove pullout resistanceReduced risk of pulloutExcavationsBulkheads/pilesEngineeringRock bolt

The invention provides a tensile expansive hollow grouting bolt structure and belongs to the technical field of fractured rock reinforcement. The structure includes a hollow grouting rod body and a lateral extruding device, wherein one end of the hollow grouting rod body is provided with a rod body stopper cap, the other end is provided with an anchoring section, the axial center of the hollow grouting rod body is provided with a diversion hole, a grouting hole communicating with the diversion hole is arranged in the radial direction, the lateral extruding device includes a sleeve, multiple expanding rods and multiple tapered blocks, one end of the sleeve is provided with a drilling plug cover, the other end is connected with the anchoring section through an elastic element, the multiple expanding rods radially pass through expansion holes correspondingly set on the sleeve, the multiple tapered blocks are sleeved on the hollow grouting rod body, the sleeve is stretched, and the expansion rods are squeezed outwards along the tapered surface of the corresponding tapered blocks in a sliding mode. The structure is advantaged in that not only can compactness of the rock mass be improved, but also anti-pulling performance of an anchor itself can be improved, and an effective means is provided for reinforcement of fractured rock masses of tunnels and slopes.

Owner:SHIJIAZHUANG TIEDAO UNIV

Bag expansion diameter-variable steel reinforcement cage and anchor rod or pile foundation

The invention discloses a bag expansion diameter-variable steel reinforcement cage. The bag expansion diameter-variable steel reinforcement cage comprises an axial rod, a circular ring or an annular plate, several longitudinal ribs, several rib strips and a ring-shaped fixator, the circular ring or the annular plate is perpendicular to the axial rod, one end of each longitudinal rib is uniformly fixed to the circular ring or the annular plate, the other end or the middle of each longitudinal rib is connected to one end of a corresponding rib strip, several longitudinal ribs surround the axialrod, the other end of each rib strip is connected to the ring-shaped fixator, and the ring-shaped fixator is fixed to or slides on the axial rod or a pile foundation rod; an outer bag covers the bottoms of the several longitudinal ribs, at least the bottom of the bag is sealed, and the bag with an expanded pile bottom end covers several longitudinal ribs; at least one slurry injecting opening anda slurry outlet with a one-way valve are formed in the bag.

Owner:JIANGSU GREEN RIVER ENVIRONMENTAL TECH CO LTD

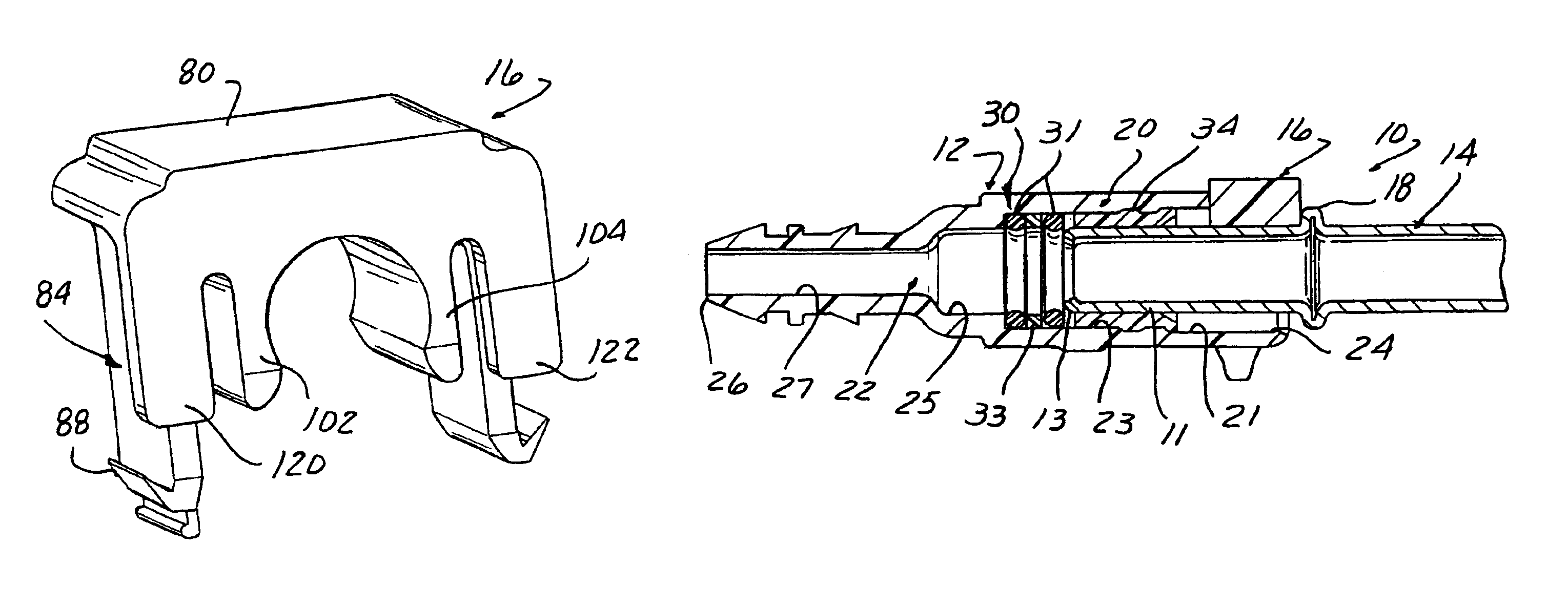

Low profile fluid quick connector

A fluid quick connector sealingly latches first and second components, one of which has a through bore and the other has a raised bead spaced from a tip end. A retainer is mountable through a transverse bore in one end of the first component and latched to the first component by projections carried on a pair of legs. A flange on the retainer is positioned to engage a surface of the first component to position the retainer on the first component. Inner disposed arms on the retainer engage a constant diameter portion of the second component and resist movement of the raised bead into or out of the bore in the housing when the retainer is in a fully latched position. The flange on the retainer is spaced from the legs of the retainer to enable the legs to be of minimal thickness for a reduced axial length for the retainer.

Owner:COOPER STANDARD AUTOMATIVE INC

Stemless shoulder implant with fixation components

ActiveUS10463499B2Risk minimizationImprove pullout resistanceSuture equipmentsJoint implantsDistal portionBone Cortex

A humeral anchor assembly is provided that includes a humeral anchor and at least one screw. The humeral anchor is configured to form a part of or support a part of a shoulder prosthesis. The humeral anchor has a distal portion configured to be anchored in a proximal region of a humerus and a proximal portion. The proximal portion includes a proximal face configured to engage an articular component within a periphery thereof. The proximal portion also includes at least one aperture disposed adjacent to the periphery. The at least one screw is disposed through the at least one aperture. The screw has a first end portion engaged with the proximal portion of the anchor and a second end portion disposed in or through cortical bone of the humerus.

Owner:HOWMEDICA OSTEONICS CORP

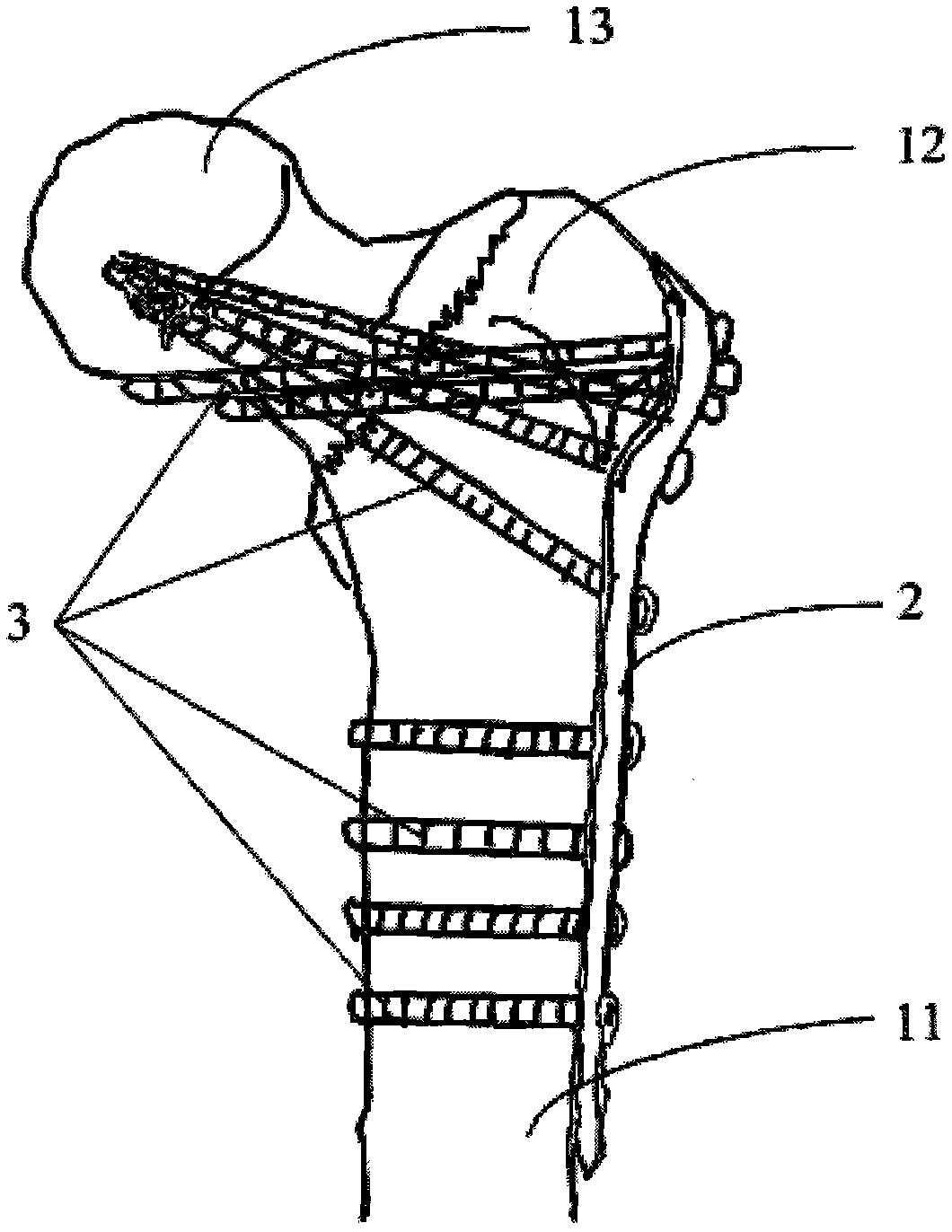

Proximal femoral anti-rotation locking device

The invention provides a proximal femoral anti-rotation locking device, which comprises a bone setting plate and a locking screw, wherein one end of the bone setting plate is a head part, the other end of the bone setting plate is a rod part, the head part is pasted with the greater trochanter, the rod part is pasted with the outer side of the thighbone, the head part is provided with five head threaded locking holes and two needle guide holes, the five head threaded locking holes respectively allow five locking screws extending into the greater trochanter, the femoral neck and the femoral calcar to be arranged on the head of the bone setting plate in a crossed way, the axial line direction of the five head threaded locking holes respectively forms an included angle with the plane and the vertical surface of the bone setting plate plane, through the axial line space, the inserted screws cannot mutually touch each other, and three lower locking screws in the five are crossed with the two upper locking screws. The proximal femoral anti-rotation locking device has the advantages that the locking screw looseness and the bone fracture setting loss can be effectively avoided, and the coxa vara malformation and the like are prevented; in addition, the application range is wide, and the proximal femoral anti-rotation locking device is applicable to instability, thrypsis, osteoporosis and intertrochanteric fracture in the old; finally, the proximal femoral anti-rotation locking device conforms to the proximal femoral anatomical structures, the pasting effect is good, the direction of the locking screws is relatively fixed, and the operation is convenient.

Owner:杨雷刚

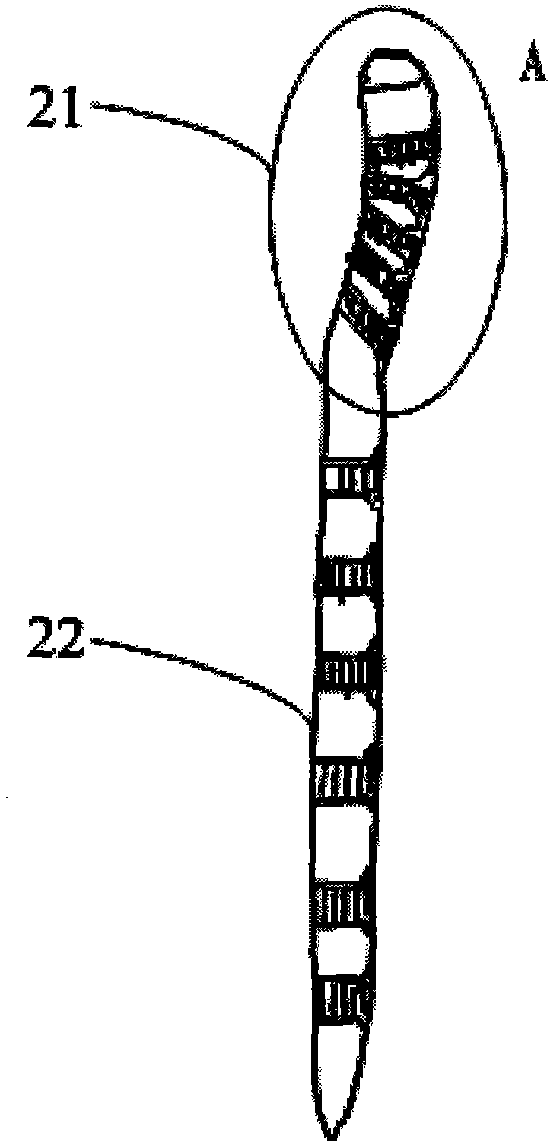

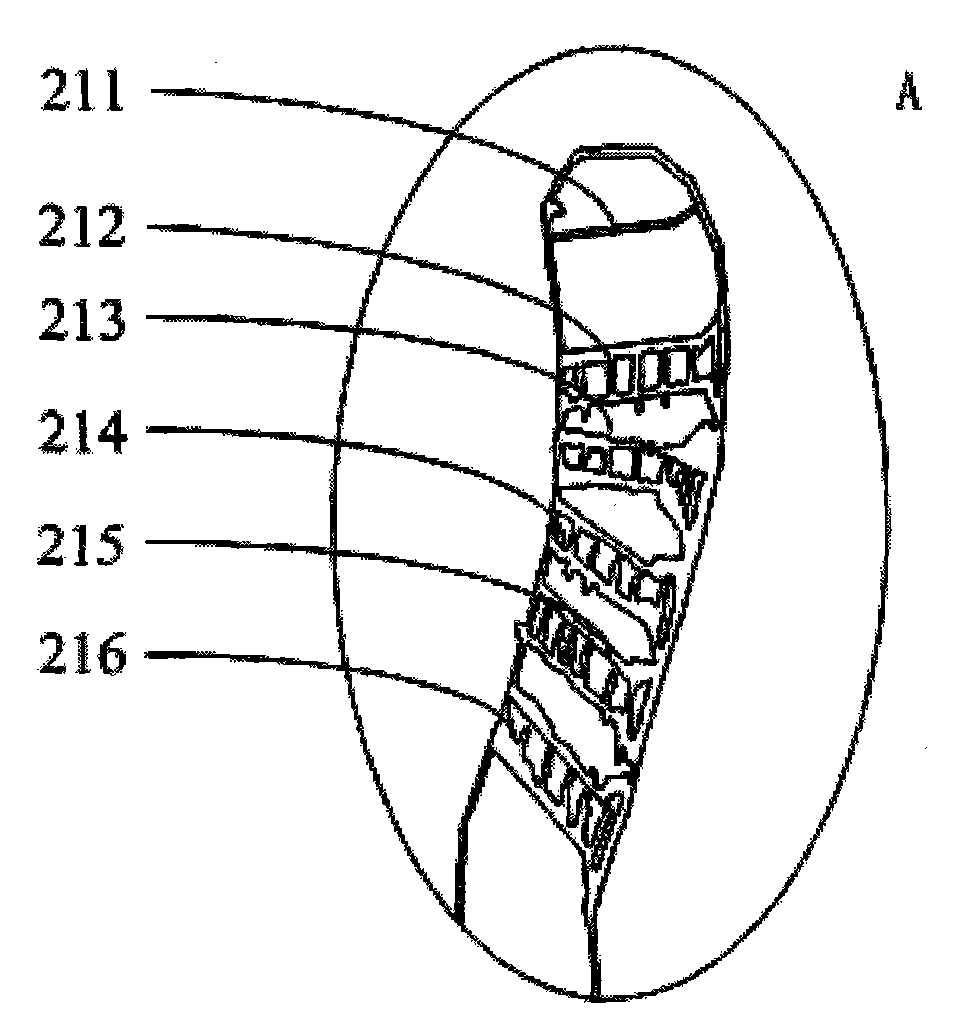

Multistage bag-type compression anchor bar

ActiveCN101148877AAvoid churnImprove pullout resistanceExcavationsBulkheads/pilesCement slurryRock bolt

The multiple section bag type extruding anchor bolt for reinforcing foundation pit, slope, tunnel and underground engineering in complicated stratum includes one bolt body connected to the guide head, and one tubular fabric bag around the anchoring section of the bolt body. The tubular fabric bag has diameter 5-10 cm greater than that of the anchor bolt hole, the guide head end tied to the bolt body and the upper end tied to the bolt body together with the inserted grouting pipe so that cement slurry or cement mortar may be deposited into the bag. The multiple section bag type extruding anchor bolt has simple structure, capacity of inhibiting flow loss of cement slurry or cement mortar, increased radial extrusion force and raised upright resistance, and is especially suitable for use in bad ground.

Owner:CHINA JINGYE ENG TECH CO LTD

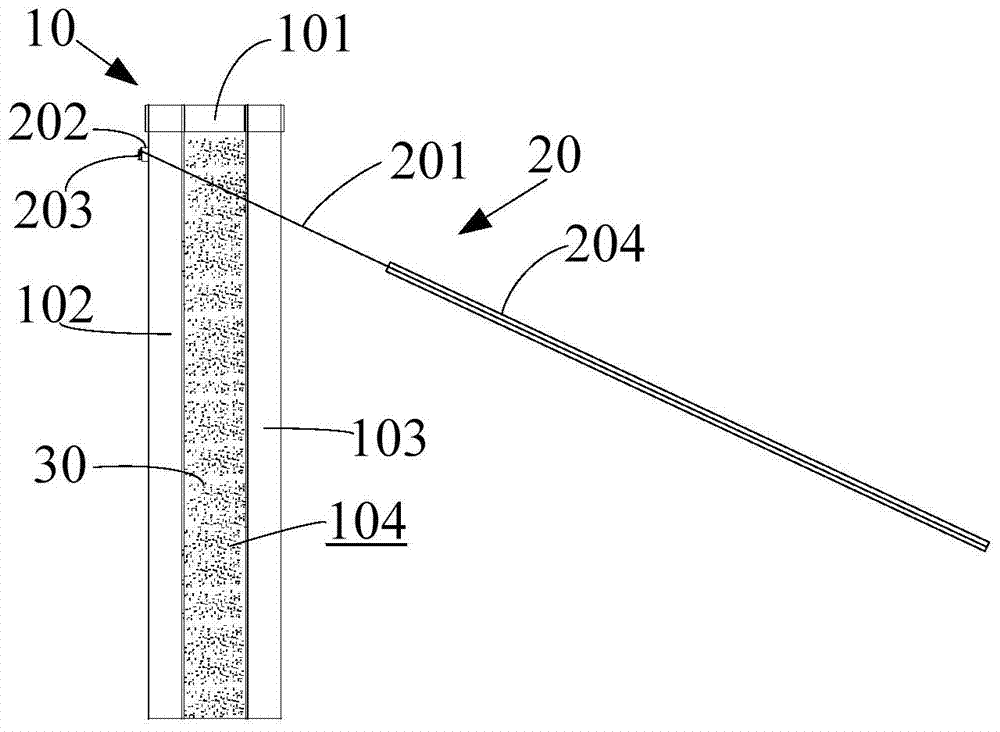

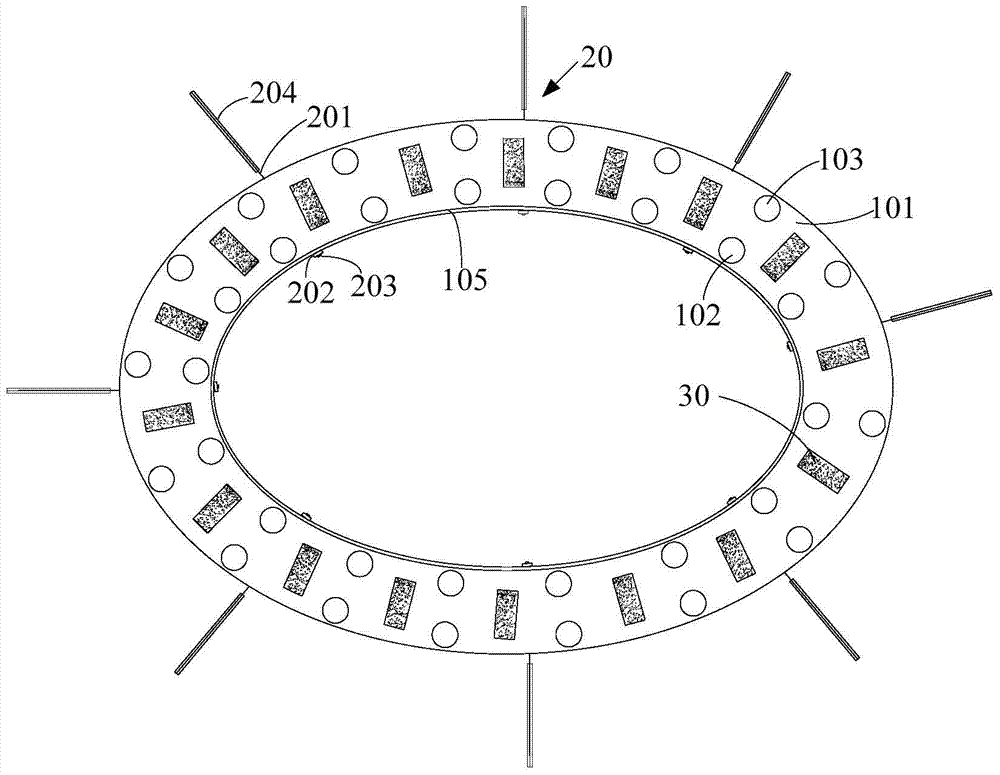

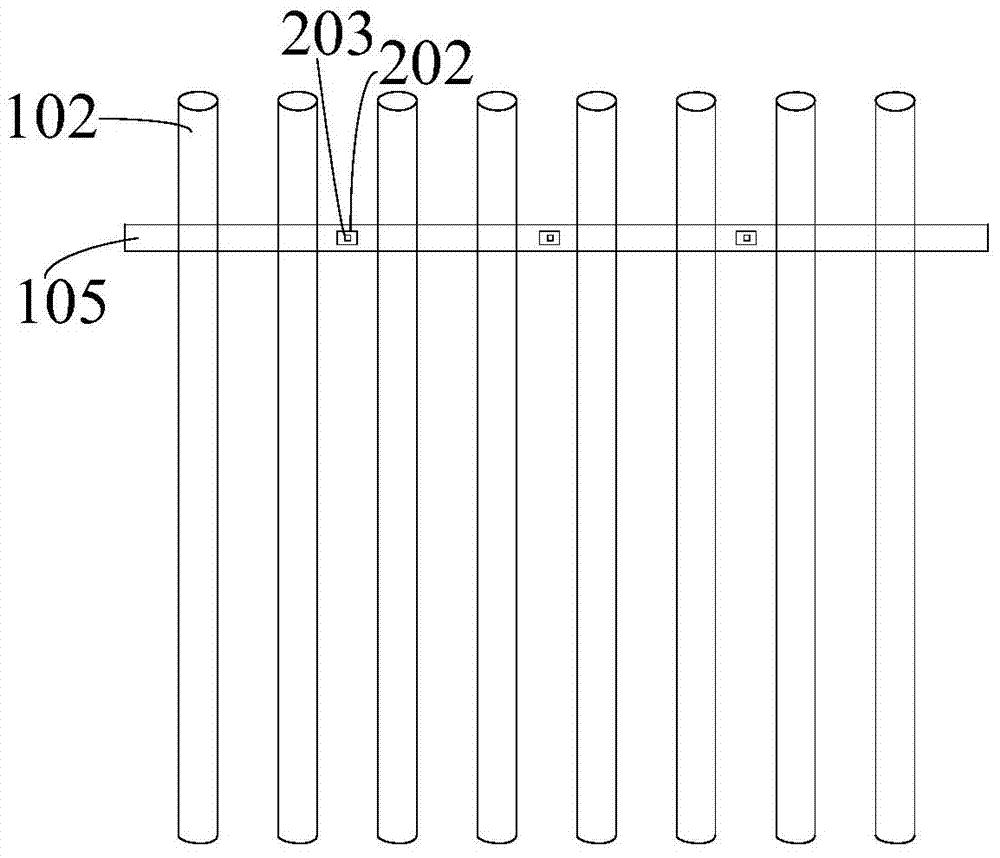

Supporting structure and supporting method for foundation pit

ActiveCN103669369AImprove support strengthHigh strengthExcavationsEngineeringUltimate tensile strength

The invention belongs to the field of construction, and particularly relates to a supporting structure and a supporting method for a foundation pit. The supporting structure for the foundation pit comprises double-row piles arranged on the periphery of the foundation pit, an anchor rod assembly and a reinforced soil body, a reinforced area is defined by the double-row piles, the double-row piles are anchored inside the ground of the foundation pit through the anchor rod assembly, and the reinforced soil body is formed in the reinforced area. The technical scheme that the reinforced soil body is arranged in the reinforced area inside the double-row piles is adopted, the integral supporting strength of the double-row piles is improved, the stability of the supporting structure for the foundation pit is guaranteed, the foundation pit is prevented from collapsing, and the problems such as potential safety hazards are solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

Locking bone screw with expansionstructure

The invention discloses a locking bone screw with an expansion structure, which belongs to the technical field of medical devices. The locking bone screw with the expansion structure is characterized by comprising an expansion screw rod and a top screw matched with the expansion screw rod, wherein internal threads are formed in a blind hole or a through hole of the expansion screw rod; external threads which are engaged with the internal threads in the blind hole or the through hole of the expansion screw rod are formed in the top screw; more than one expansion groove is formed in the head part of the expansion screw rod; a groove, a polygonal blind hole or a polygonal bump through which the top screw can be screwed into the blind hole or the through hole of the expansion screw rod is formed in the tail part of the top screw; external threads through which the expansion screw rod can be screwed into a broken bone to form a taper are formed in the tail part of the expansion screw rod; a groove through which the external threads with the taper can be screwed into the broken bone is formed in the end surface of the tail part of the expansion screw rod. According to the locking bone screw with the expansion structure, the friction force between the bone screw and a cancellous bone can be increased, and the pulling resistance of the bone is increased, so that the screw is firmly connected with a cortical bone or the cancellous bone; the bone screw is easy and convenient to operate, and is easily screwed and removed during a surgery.

Owner:ZHEJIANG CANWELL MEDICAL DEVICES CO LTD

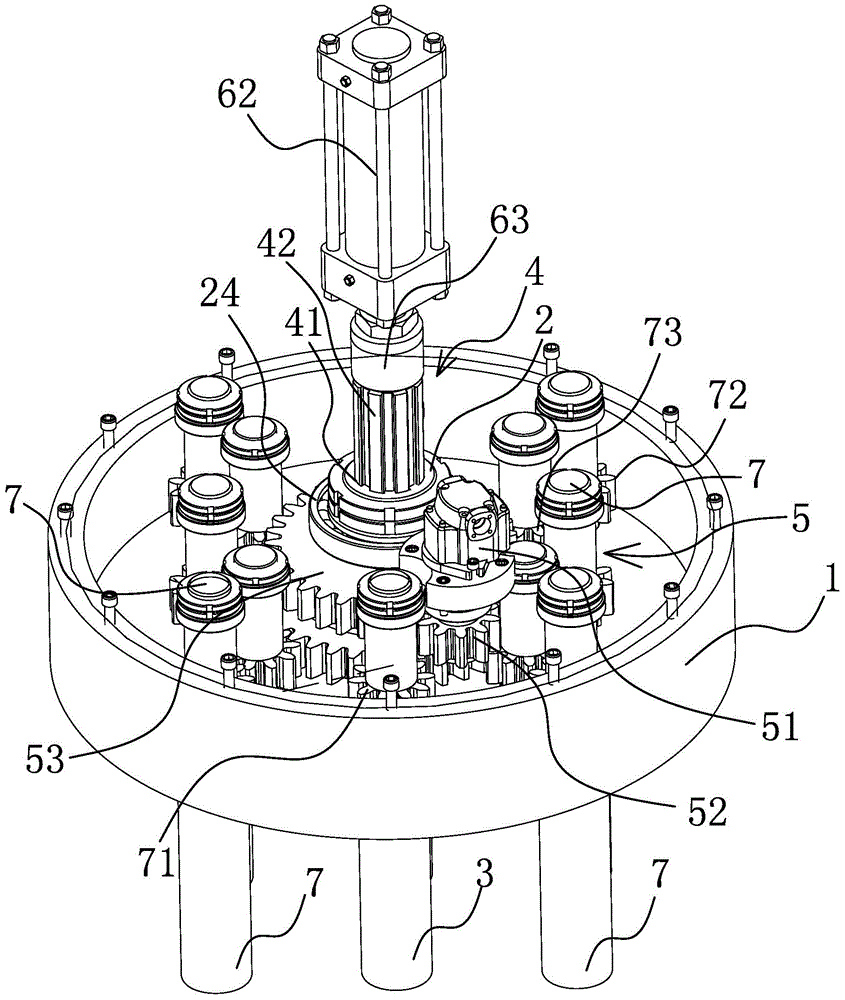

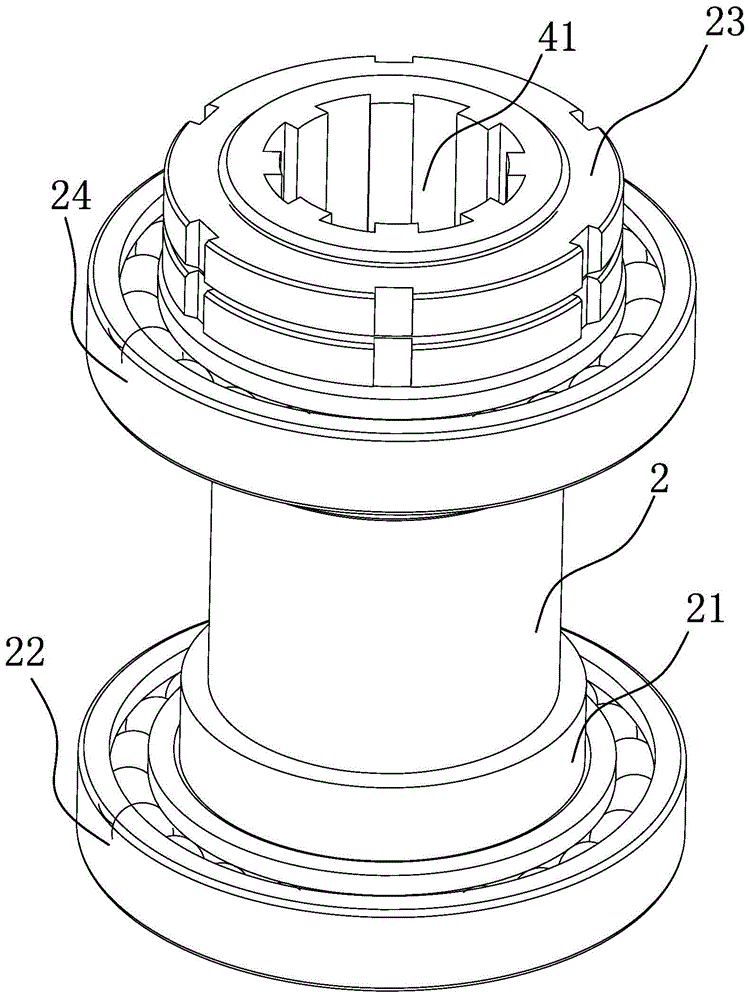

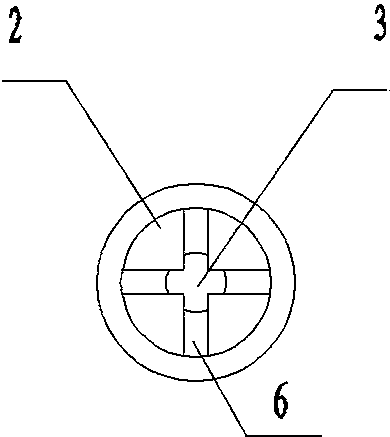

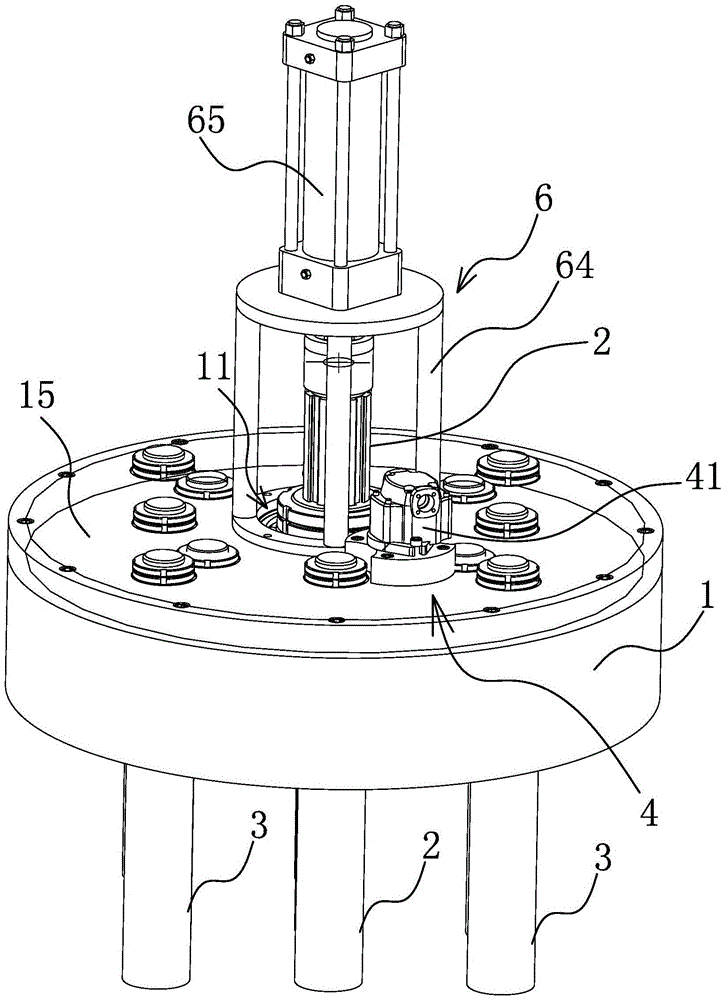

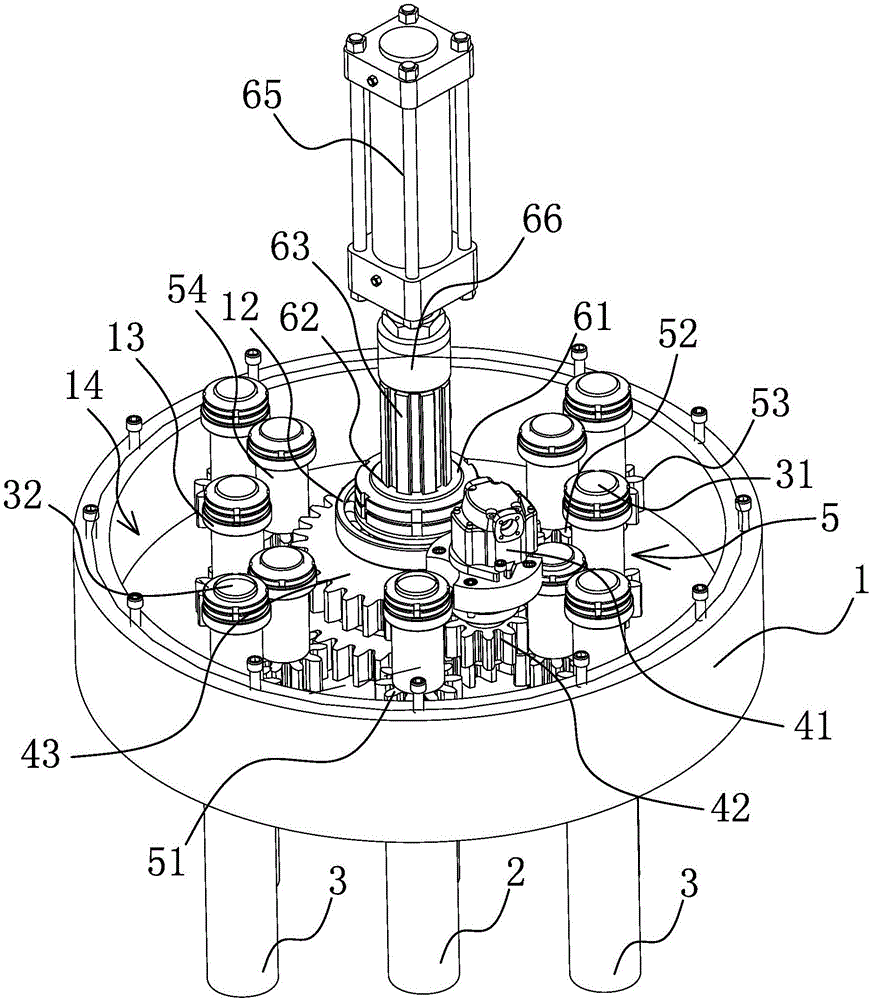

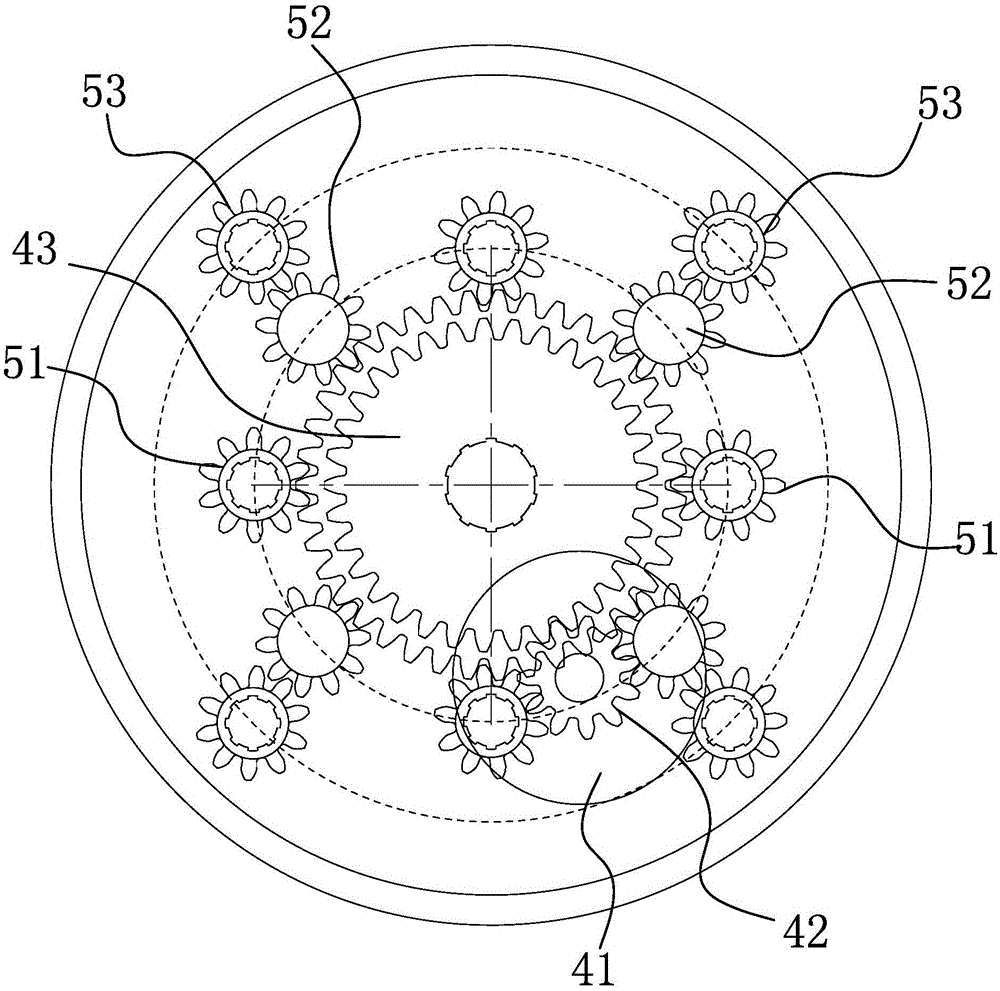

Drill rod rotation driving mechanism of cement soil mixing pile driver

ActiveCN105002898AImprove pullout resistanceIncrease girthBorehole drivesBulkheads/pilesSoil mixingPile driver

The invention belongs to the technical field of construction equipment, and particularly relates to a drill rod rotation driving mechanism of a cement soil mixing pile driver. The drill rod rotation driving mechanism of the cement soil mixing pile driver solves the problem that stirring is uneven when an existing cement soil mixing pile driver is used for drilling. The drill rod rotation driving mechanism of the cement soil mixing pile mixer comprises a drive box with an inner cavity; the drive box is provided with at least one main drill rod arranged in the vertical direction; at least two auxiliary drill rods are arranged on the outer side of the circumference of the main drill rod; the main drill rod is connected with a main drill rod driving structure capable of driving the main drill rod to rotate in the circumferential direction; an auxiliary drill rod transmission structure is arranged between the main drill rod and the auxiliary drill rods. The drill rod rotation driving mechanism of the cement soil mixing pile driver has the advantages that a single driver can achieve homodromous and reverse-direction movement of the main drill rod and the auxiliary drill rods, so that stirring uniformity is improved; drill rod bodies can axially stretch out and draw back and can axially slide while rotating circumferentially, the phenomenon of being unable to drill is not prone to happening, the perimeter of the cross section of a cement soil mixing pile after construction is increased, and the anti-pulling capacity of the cement soil mixing pile is improved.

Owner:周兆弟

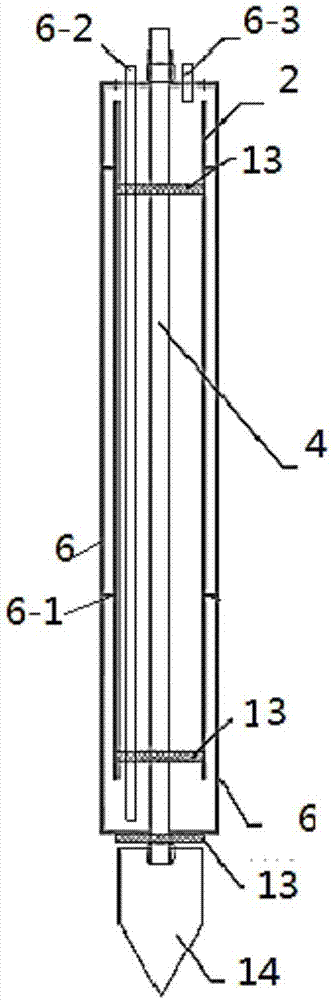

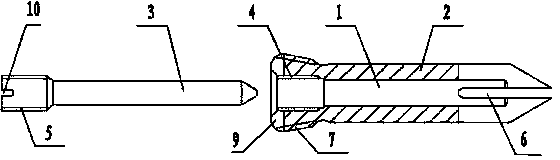

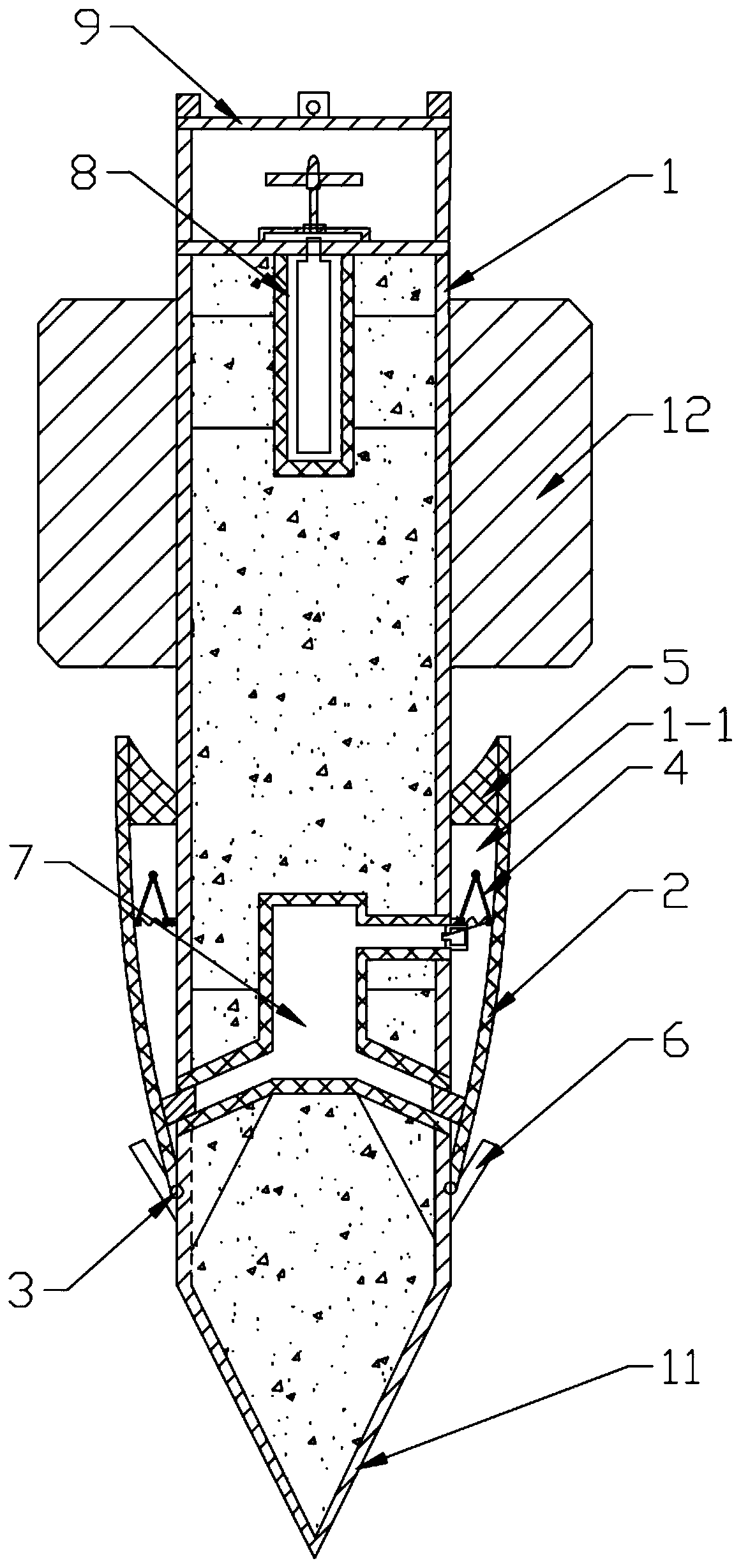

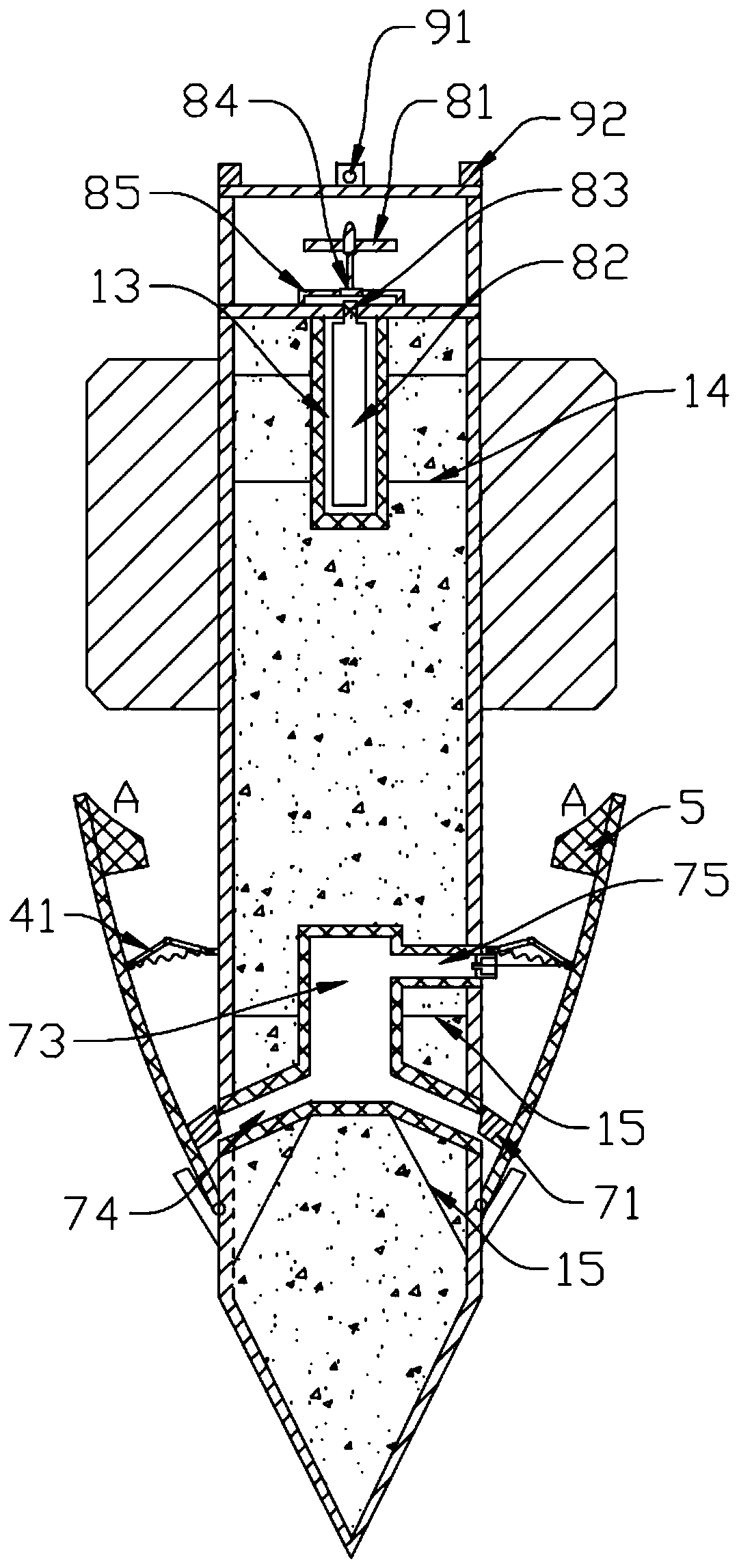

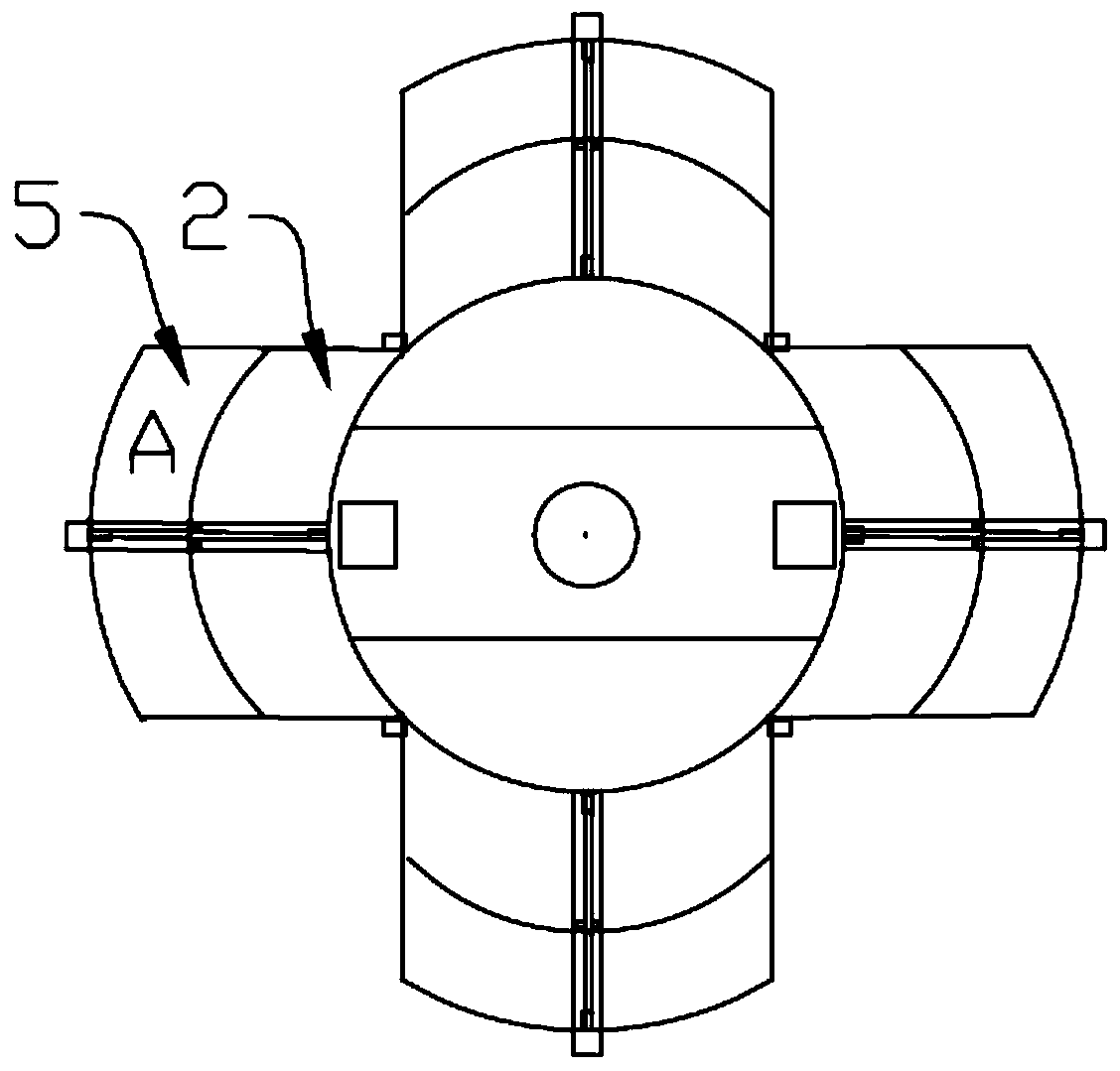

Power anchor increasing penetration depth and improving anti-pullout performance

ActiveCN109927847AIncrease the kinetic energy of fallingIncrease penetration depthAnchorsAnchoring arrangementsAerospace engineeringPenetration depth

The invention discloses a power anchor increasing the penetration depth and improving the anti-pullout performance. The power anchor comprises an anchor body, the front end of the anchor body is provided with a tapered anchor head, and the tail portion of the anchor body is provided with a balance wing plate; the power anchor further comprises an anti-pullout wing plate located between the anchorhead and the balance wing plate, the front end of the anti-pullout wing plate is hinged to the anchor body through a hinging mechanism, the inner side of the anti-pullout wing plate is fixed to the anchor body through an expansion mechanism, and a flared gap is formed between the anti-pullout wing plate and the anchor body. The power anchor has the advantages that by retracting the anti-pullout wing plate, arranging a propulsion mechanism and the like, in the penetration process, the dropping kinetic energy of the power anchor is effectively increased, and the penetration depth is increased; by opening the anti-pullout wing plate, arranging a grouting mechanism and the like, in the pulling-up process, the stress surface of the power anchor is effectively enlarged, and soil is effectively solidified, so that the anti-pullout performance is improved.

Owner:HOHAI UNIV

Vibratory hammer device and shaking press type pile body construction method adopting same

InactiveCN106168027AVibration pressure increasedFlexible adjustment of self-weightBulkheads/pilesArchitectural engineeringPulley

The invention discloses a vibratory hammer device. The device comprises a support, a vibratory hammer, a second pulley component, a winding plant and a balancing weight, wherein a first pulley component is installed on the support, the first end of the vibratory hammer is connected with the first pulley component, and the second end of the vibratory hammer is provided with a fixing structure used for fixing an inner pipe and an outer pipe; the second pulley component is installed on the support, the winding plant is installed on the support and connected with the vibratory hammer through the second pulley component and can apply a vertically downward force to the vibratory hammer, and the balancing weight is detachably connected to the vibratory hammer. In this way, construction noise is low, construction efficiency is high, and the dead weight of a hammer body can be adjusted flexibly to meet the requirement for pile forming. The invention further discloses a shaking press type pile body construction method adopting the vibratory hammer device.

Owner:刘献刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com