Preparation method for prestressed high-strength concrete pile

A high-strength concrete and prestressed technology, which is used in reinforcement molding, manufacturing tools, ceramic molding machines, etc., can solve the problems of pile quality that cannot meet the design requirements, low friction between the pile body and the soil layer, and inflexible reinforcement methods. , to reduce the damage of the pile body, improve the bearing capacity of the pile body, and improve the horizontal bending and shearing performance and seismic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

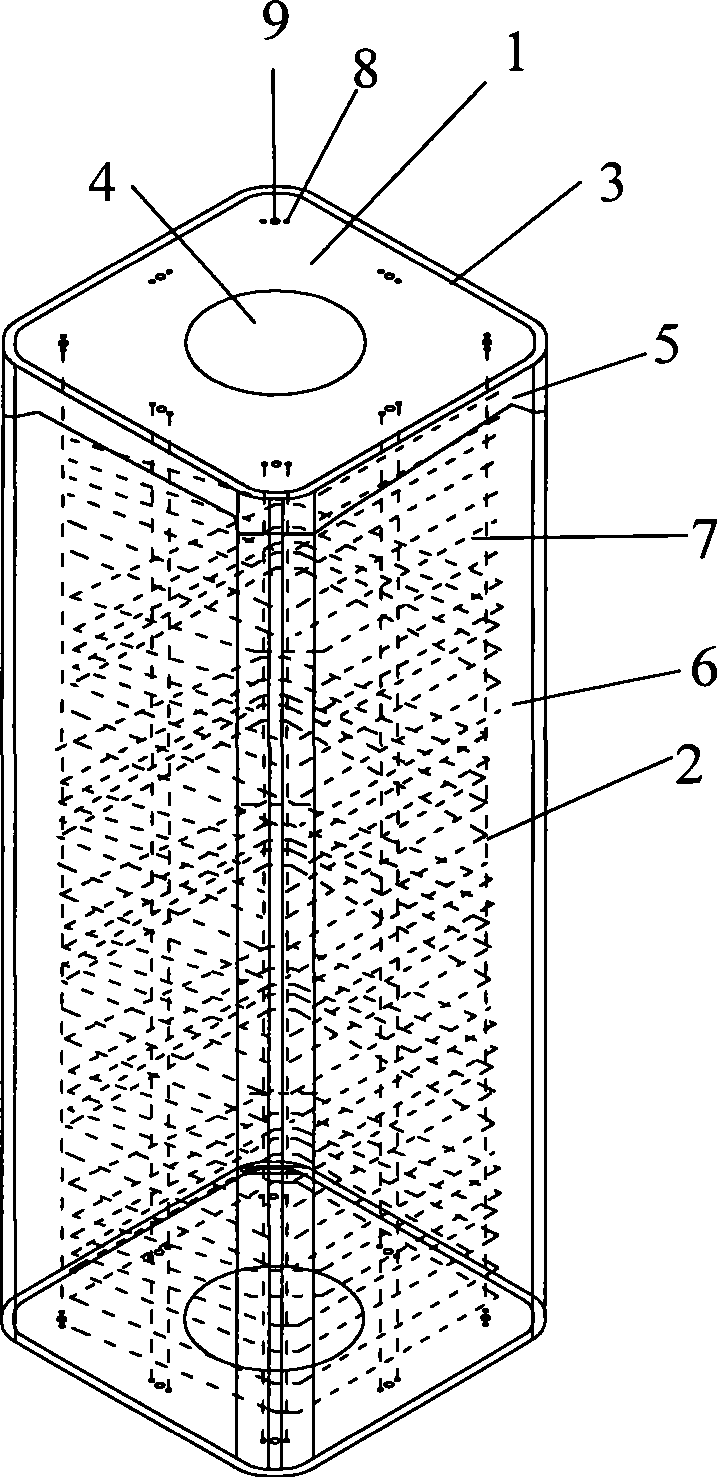

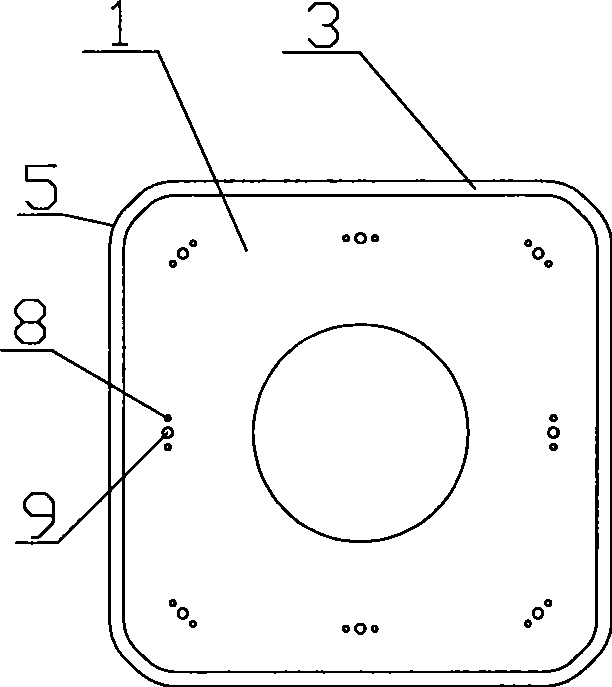

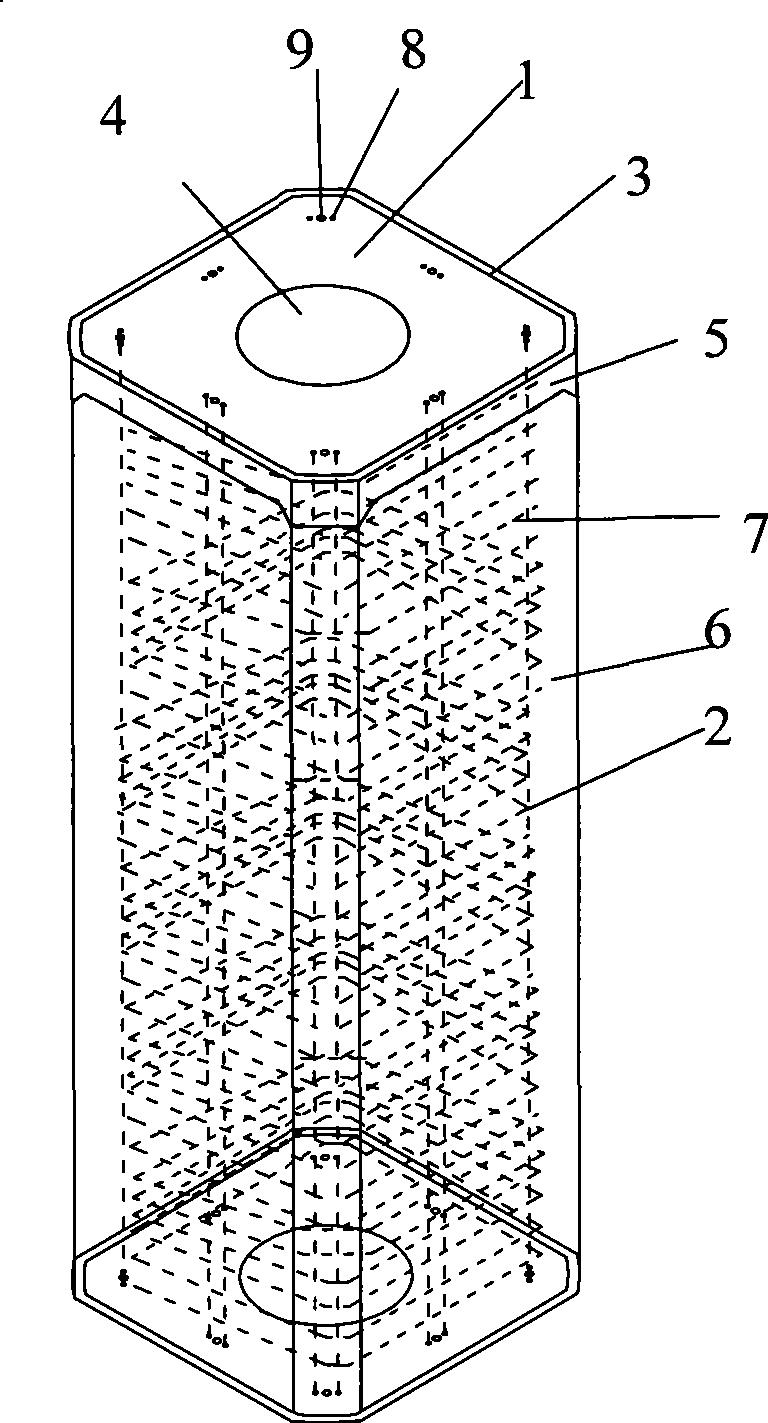

[0041] Such as figure 1 , 2 The preparation method of the shown prestressed high-strength concrete pile comprises: concrete, steel cage, end plate 1, described end plate 1 shape is a rounded square, and the diameter of the arc section at each rounded corner is equal and is 1.1 of the side length of the square. times, the central angle of each arc segment is 13°, and the length of the straight line segment is 0.3 times the side length of the square;

[0042] The concrete strength grade is C50;

[0043] The main bars 2 of the reinforcement cage are arranged on a square with the centroid of the end plate as the centroid.

[0044] The preparation method of the prestressed high-strength concrete pile is:

[0045] a, prepare the steel cage skeleton;

[0046] b. Prepare high-performance concrete and matching molds, and apply isolation lubricant on the molds;

[0047] c. Install the reinforcement cage on the mold and tighten the tension device;

[0048] d. Feed the prepared high...

Embodiment 2

[0062] The preparation method of the prestressed high-strength concrete pile comprises: concrete, steel bar cage, end plate 1, described end plate 1 shape is a rounded corner square, and the diameter of each rounded corner arc section is equal and is 1.2 times of the side length of the square, The central angle of each arc segment is 15°, and the length of the straight line segment is 0.4 times the side length of the square.

Embodiment 3

[0064] The preparation method of the prestressed high-strength concrete pile comprises: concrete, steel cage, end plate 1, described end plate 1 shape is a rounded corner square, and the diameter of each rounded corner arc section is equal and is 1.3 times of the side length of the square, The central angle of each arc segment is 17°, and the length of the straight line segment is 0.5 times the side length of the square.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com