Power anchor increasing penetration depth and improving anti-pullout performance

A technology of penetration depth and dynamic anchor, which is applied in the direction of anchor point, anchor arrangement, transportation and packaging, etc. It can solve the problems affecting the pull-out bearing performance and the bearing capacity of dynamic anchor, so as to improve the falling kinetic energy and increase the penetration depth , the effect of increasing the force surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further illustrated below in conjunction with the accompanying drawings and specific examples, and these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

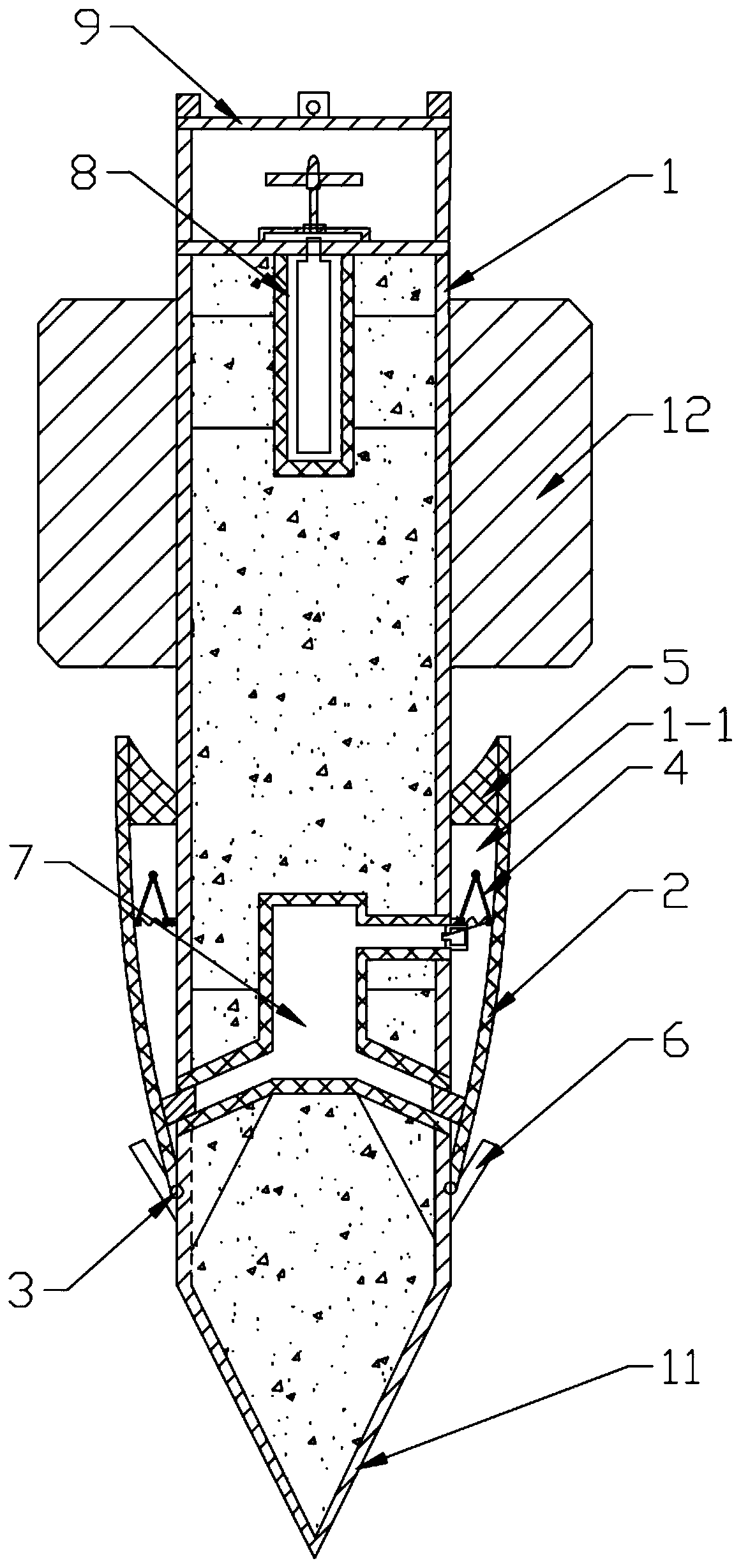

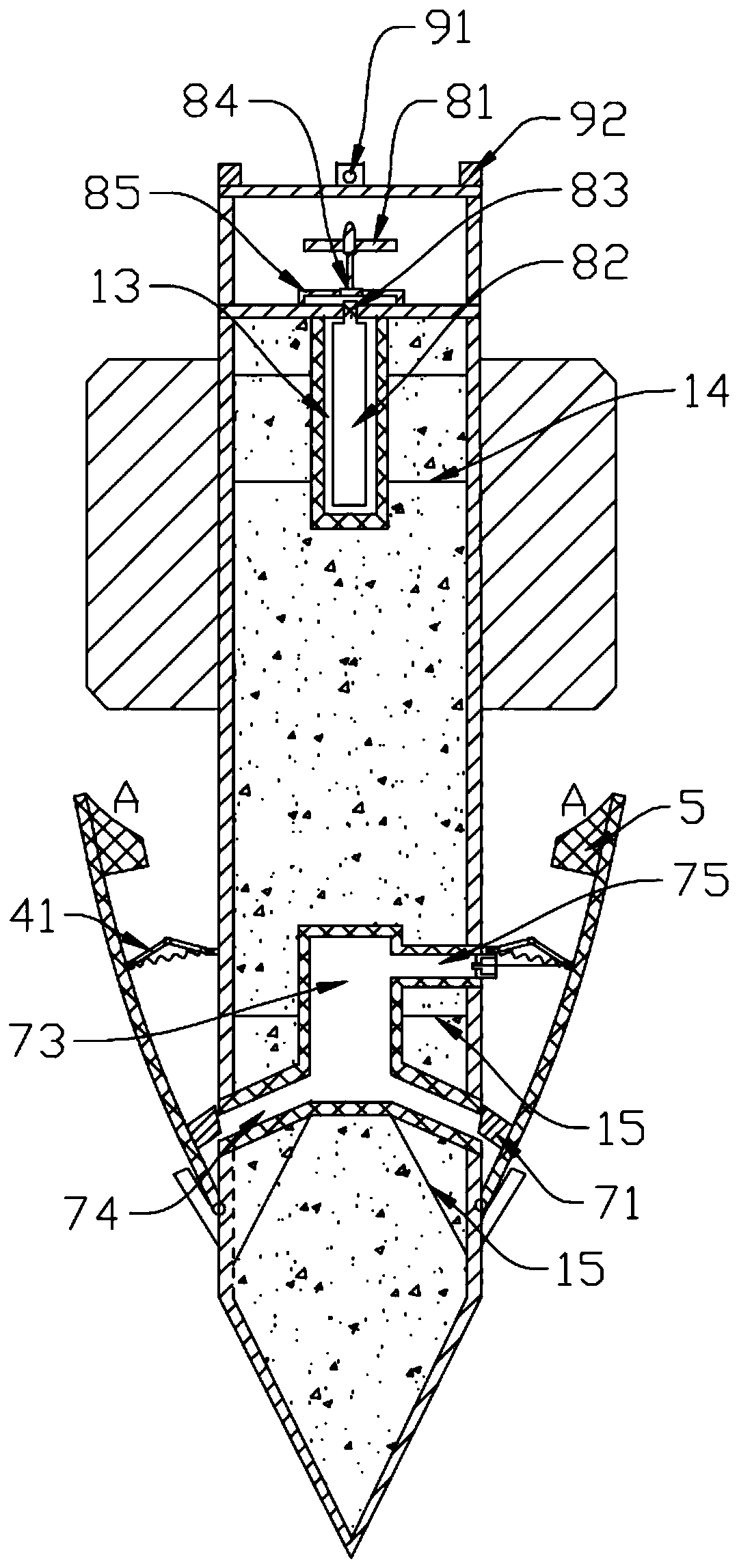

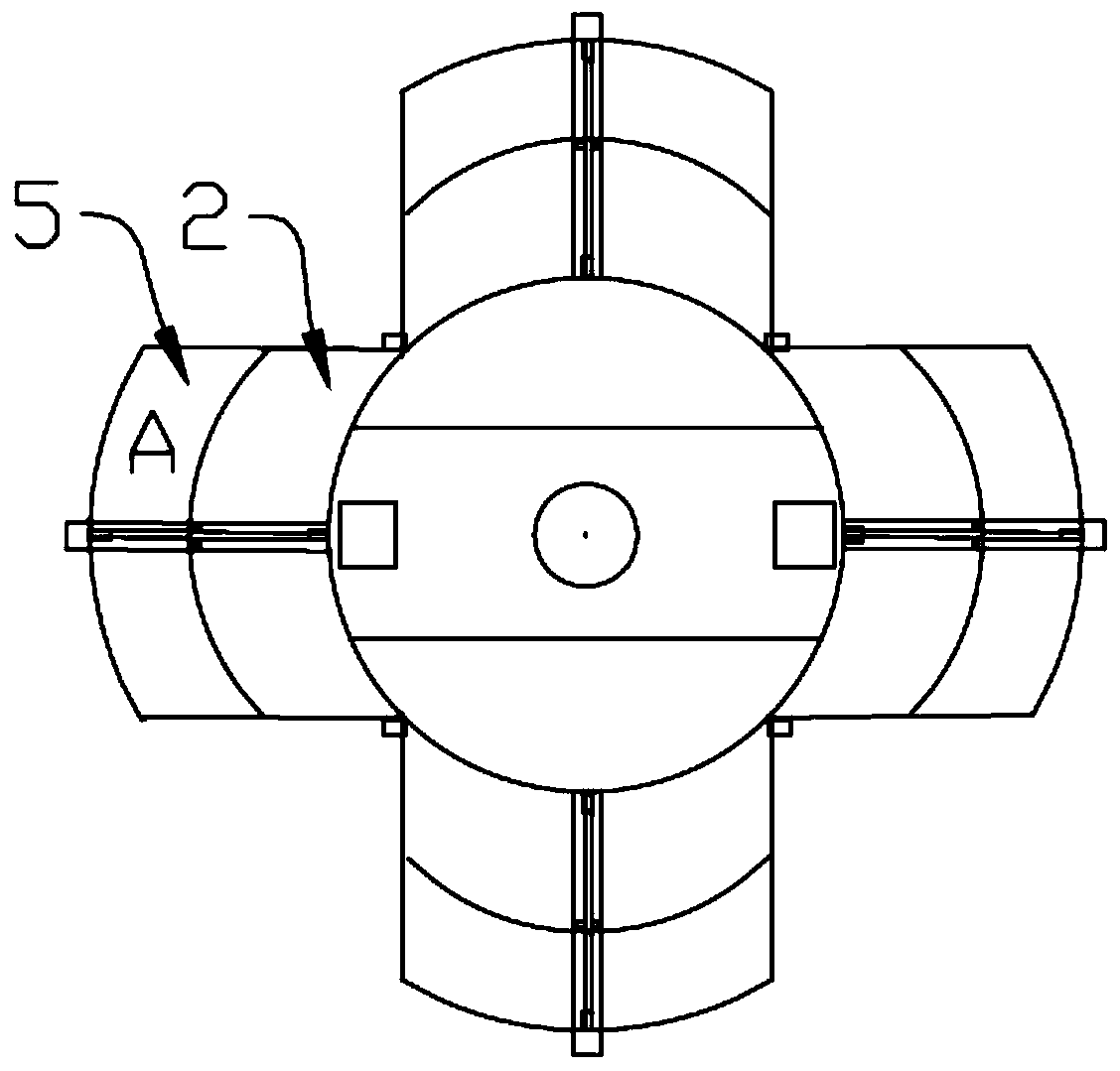

[0024] A dynamic anchor with increased penetration depth and pullout resistance, as attached figure 1 , 2 As shown, it includes an anchor body 1, a pull-out wing 2, a hinge mechanism 3, a relaxation mechanism 4, a force receiving body 5, a limit plate 6, a grouting mechanism 7, a propulsion mechanism 8, and an anchor tail protection cover 9.

[0025] The anchor body 1 has a tapered anchor head 11 at the front end and a balance wing 12 at the tail. In this embodiment, the anchor body 1 adopts a hollow cylindrical structure, and concrete is poured inside to increase its own weight; the balance wing plate 12 adopts a similar rectangular structure, which is four vertically arranged, and is evenly welded on the anchor bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com