Reinforcement method of electric spark on surface of copper or copper alloy

An electric spark, copper alloy technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of high specific gravity, processing and forming, dimensional accuracy and organization uniformity are not easy to ensure, to improve the use of performance, increased penetration depth, improved surface quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The base material used in the experiment is the red copper material (the mass percentage of copper reaches 99.9%) made of the armor-piercing drug type cover, the size is 16mm × 16mm × 3mm, and the electrode uses a tungsten electrode rod (model: WCe20, dopant CeO 2 , content 1.8% to 2.2%, the rest is W), and the diameter is φ3mm.

[0047] The experimental equipment used the metal surface strengthening and repairing machine (3H-ES-X800, 3H-ES-1500, 3H-ES-3000) produced by the Institute of Metal Research, Chinese Academy of Sciences (for details, see the Chinese utility model patent, the patent number is 03214166.1). During the deposition process, the argon gas protection is introduced, the electrode material adopts self-rotation mode (axial rotation), the electrode rotation speed is 3000r / min, and the clamping mode of the electrode is mechanical mode. The parameters of EDM deposition are: output power: 420W; discharge frequency: 200Hz; output voltage: 60V; specific depo...

Embodiment 2

[0050] The difference from Example 1 is:

[0051] The electrode uses a Cu-W electrode (Cu-W75, mass percentage: Cu 25%, impurity 0.3%, and the rest is W) manufactured by powder metallurgy, with a diameter of φ3.6mm.

[0052] The experimental equipment still uses the metal surface strengthening and repairing machine (model 3H-ES-X800, 3H-ES-1500, 3H-ES-3000) produced by the Institute of Metal Research, Chinese Academy of Sciences. Argon protection is introduced during the deposition process, and the electrode material is made of Self-rotation mode (axial rotation), the electrode rotation speed is 3000r / min, and the electrode clamping method is mechanical. The parameters of EDM deposition are: output power: 420W; discharge frequency: 100Hz; output voltage: 60V; specific deposition time: 5min; protective gas flow rate: 30L / min. During the experiment, the copper substrate and electrode material were first polished with 800# water sandpaper to remove impurities such as copper rust...

Embodiment 3

[0057] The difference from Example 1 is:

[0058] The electrode uses cemented carbide YG8, its main component is WC (tungsten carbide is the main component of YG series alloys), and its diameter is φ4mm. The deposition parameters are: output power: 420W; discharge frequency: 100Hz; output voltage: 60V; specific deposition time 5min; protective gas flow rate: 30L / min.

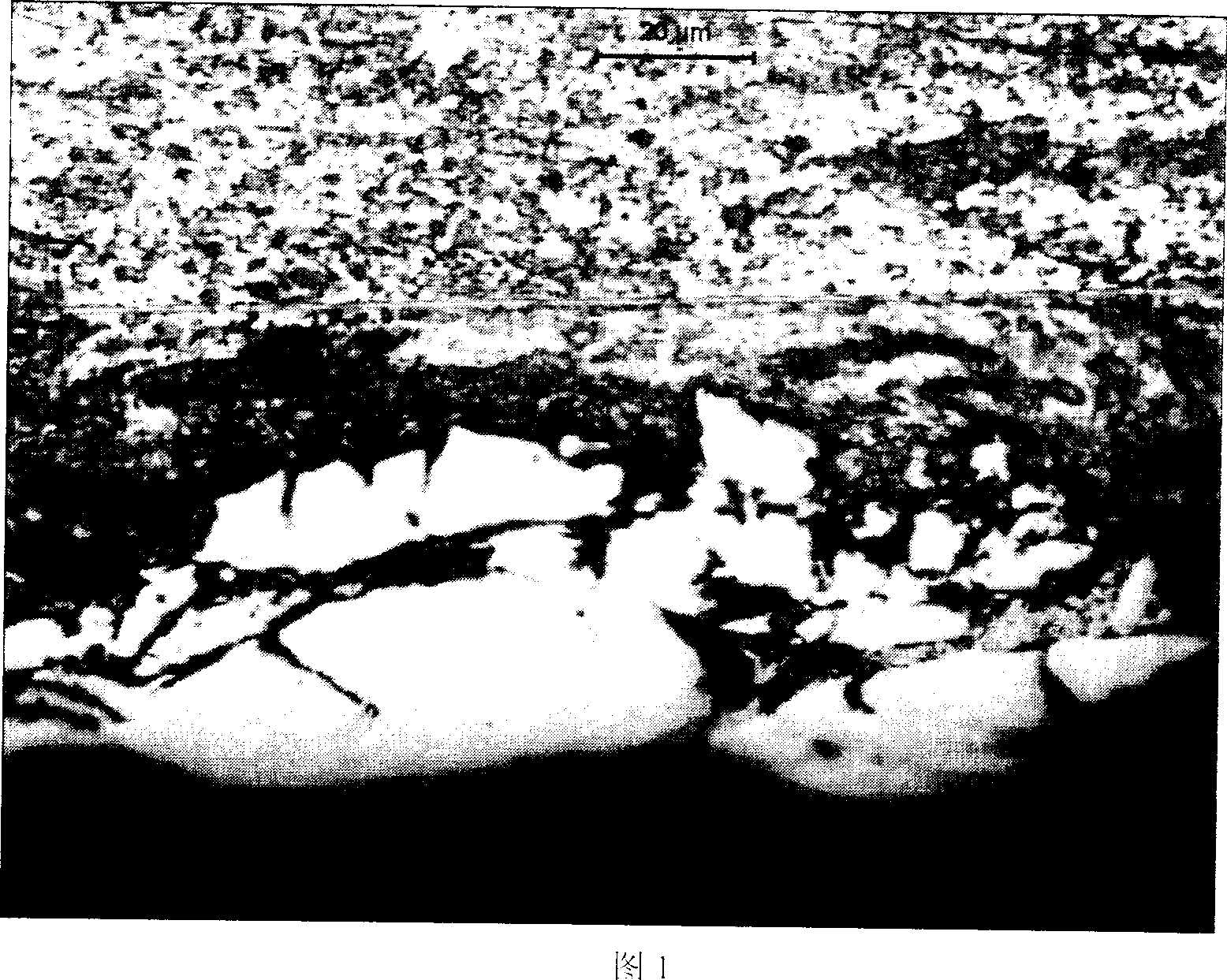

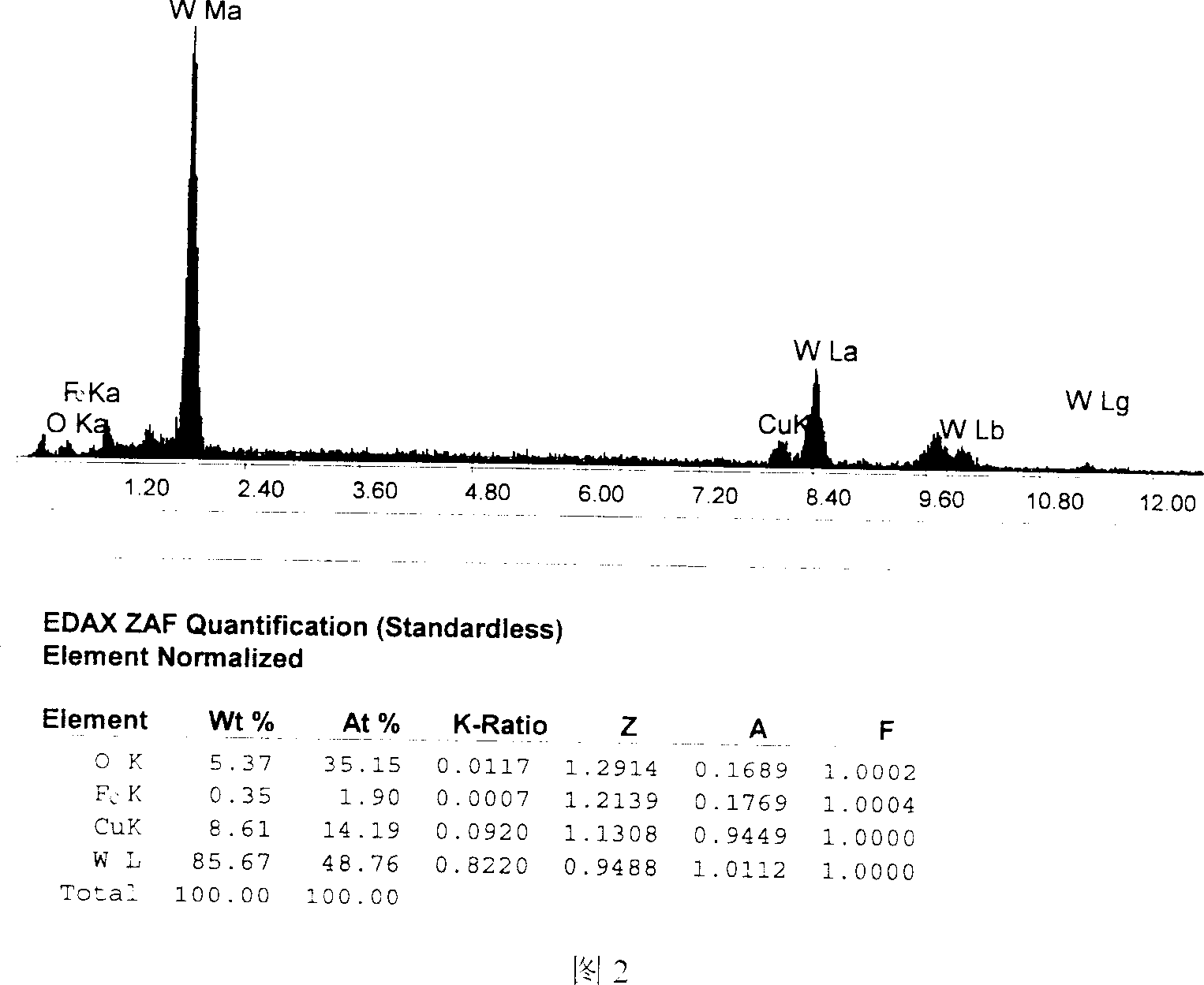

[0059] As shown in Figure 5, the surface morphology of EDM deposited WC (YG8) on Cu surface; as shown in Figure 6, the cross-sectional structure of EDM deposited WC on Cu surface (800×). The deposition points are not very continuous, and the deposition layer is relatively thin, but the transition layer is relatively thick. Compared with the deposition with W electrode, the deposition layer is relatively similar, but the white spots are much less, and there are more black substances, and the transition layer between the deposition surface layer and the substrate is more obvious. We already know that the white s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com