Pretreatment device for improving wood impregnation efficiency and wood impregnation treatment method

A pretreatment device and impregnation treatment technology, applied in wood treatment, wood impregnation, wood treatment details, etc., can solve the problems of danger, complex composition, and high requirements for blasting equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] Wet poplar wood segments with a size of 20mm (length) × 20mm (width) × 20mm (thickness) were subjected to ultrasonic pretreatment to open up the moisture channel inside the wood, so as to shorten the time of subsequent wood impregnation treatment and improve the impregnation efficiency.

[0097] In the embodiment of the present invention, except that the thickness of the wood is 2 cm as an example, other woods with a thickness of 0.1-6 cm are also suitable for the present invention, and the thickness of the wood is preferably 1.5-2 cm.

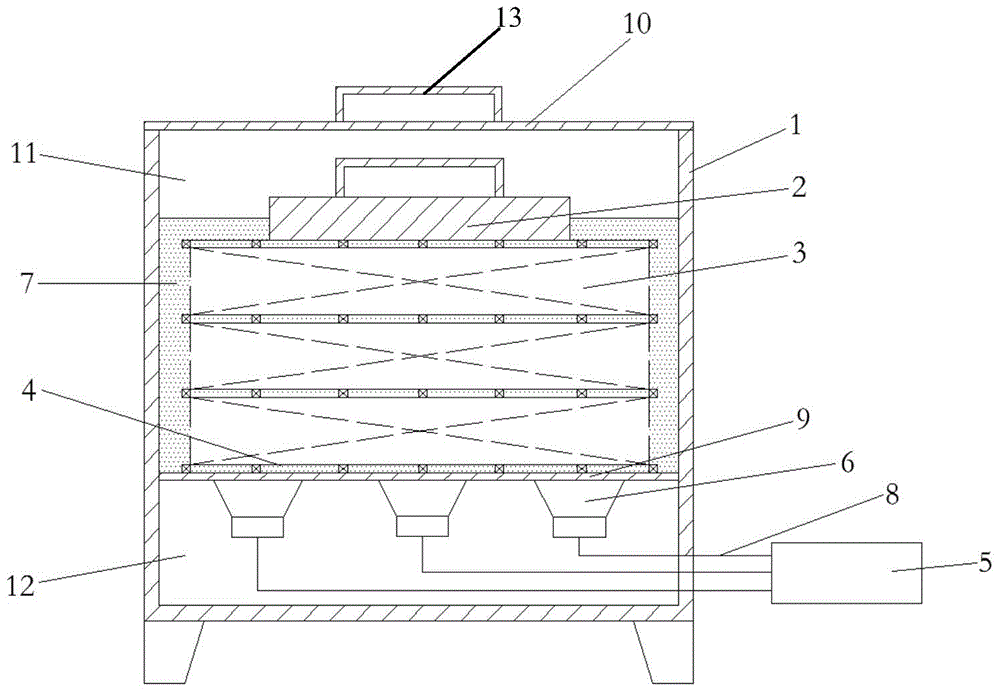

[0098] 1. Open the sealing cover 10 on the top of the wood pretreatment chamber 1, and place the poplar wet wood sample (i.e., the wood 3 to be impregnated) on the partition 9 fixed inside the upper cavity 11 of the wood pretreatment chamber 1 The top of the loading part 4, and set the pressing part 2 on the top of the poplar wet wood sample to prevent the wood from floating or exposing the surface of the pretreatment liquid, so that the...

Embodiment 2

[0111] Except that the pretreated wood is directly soaked in a phenolic resin solution (wood modifier) with a concentration of 25% by mass, no ultrasonic treatment is performed, the wood is taken out after soaking for 1 hour, and the second drying treatment is performed, the rest are the same as Example 1 is the same.

Embodiment 3

[0113] Except that the frequency of the ultrasonic wave in step 3 is 28kHz, the ultrasonic power is 5W per cubic centimeter of wood, that is, the total power of the ultrasonic transducer is adjusted to 40W; the ultrasonic treatment time in step 4 is 90min, that is, the wood In the pretreatment process, the ultrasonic power is 5W per cubic centimeter of wood, and the ultrasonic pretreatment time is 90min, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com