A compound type copper compound preservative for masson pine wood and its preservative method

A masson pine and preservative technology, applied in wood impregnation, wood treatment, wood impregnation and other directions, can solve the problems of organic solvents having no anti-corrosion ability, little 8-hydroxyquinoline copper, expensive organic solvents, etc. Enhanced broad-spectrum and bacteriostatic ability, faster water movement and evaporation, and enhanced penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

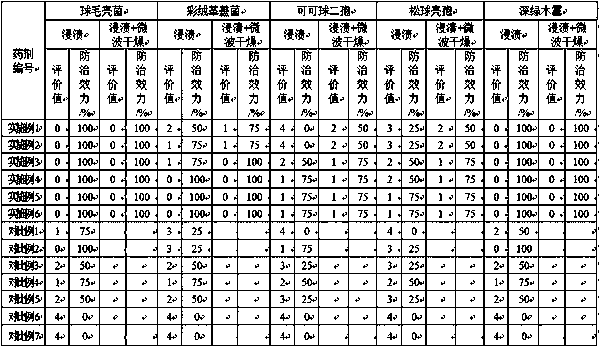

Embodiment 1

[0025] A compound type copper compound preservative for masson pine wood, which is composed of the following raw material components in mass percentage: 0.05% of 8-hydroxyquinoline copper, 0.05% of tebuconazole, 5.00% of glacial acetic acid, didecyldimethyl ammonium chloride 5.00%, and the balance is water.

[0026] Utilize a kind of anticorrosion method of the composite type copper compound preservative of masson pine wood, it may further comprise the steps:

[0027] (1) Weigh each raw material according to the amount, first mix 8-hydroxyquinoline copper and glacial acetic acid in a constant temperature water bath at 30°C to fully dissolve the 8-hydroxyquinoline copper, then add tebuconazole, didecyldimethyl Hydroxyl ammonium chloride and water, stir evenly to obtain compound type copper compound preservative;

[0028] (2) Saw the fresh masson pine, process it into a standard sample, plan it without drying;

[0029] (3) Cold soak the masson pine wood at room temperature and...

Embodiment 2

[0034] A compound type copper compound preservative for masson pine wood, which is composed of the following raw material components in mass percentage: 8-hydroxyquinoline copper 0.10%, tebuconazole 0.10%, glacial acetic acid 5.00%, didecyl dimethyl ammonium chloride 5.00%, and the balance is water.

[0035] Utilize a kind of anticorrosion method of the composite type copper compound preservative of masson pine wood, it may further comprise the steps:

[0036] (1) Weigh each raw material according to the amount, first mix 8-hydroxyquinoline copper and glacial acetic acid in a constant temperature water bath at 30°C to fully dissolve the 8-hydroxyquinoline copper, then add tebuconazole, didecyldimethyl Hydroxyl ammonium chloride and water, stir evenly to obtain compound type copper compound preservative;

[0037] (2) Saw the fresh masson pine, process it into a standard sample, plan it without drying;

[0038] (3) Cold soak the masson pine wood at room temperature and pressur...

Embodiment 3

[0043] A compound type copper compound preservative for masson pine wood, which is composed of the following raw material components in mass percentage: 0.20% of 8-hydroxyquinoline copper, 0.20% of tebuconazole, 10.00% of glacial acetic acid, didecyldimethyl ammonium chloride 10.00%, and the balance is water.

[0044] Utilize a kind of anticorrosion method of the composite type copper compound preservative of masson pine wood, it may further comprise the steps:

[0045] (1) Weigh each raw material according to the amount, first mix 8-hydroxyquinoline copper and glacial acetic acid in a constant temperature water bath at 30°C to fully dissolve the 8-hydroxyquinoline copper, then add tebuconazole, didecyldimethyl Hydroxyl ammonium chloride and water, stir evenly to obtain compound type copper compound preservative;

[0046] (2) Saw the fresh masson pine, process it into a standard sample, plan it without drying;

[0047] (3) Cold soak the masson pine wood at room temperature a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com