Patents

Literature

52 results about "Blue stain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tissue products incorporating nanoporous cellulose fiber

ActiveUS8741104B2Increasing chemical accessibilityPromote productionNon-fibrous pulp additionPaper after-treatmentPorosityMedicine

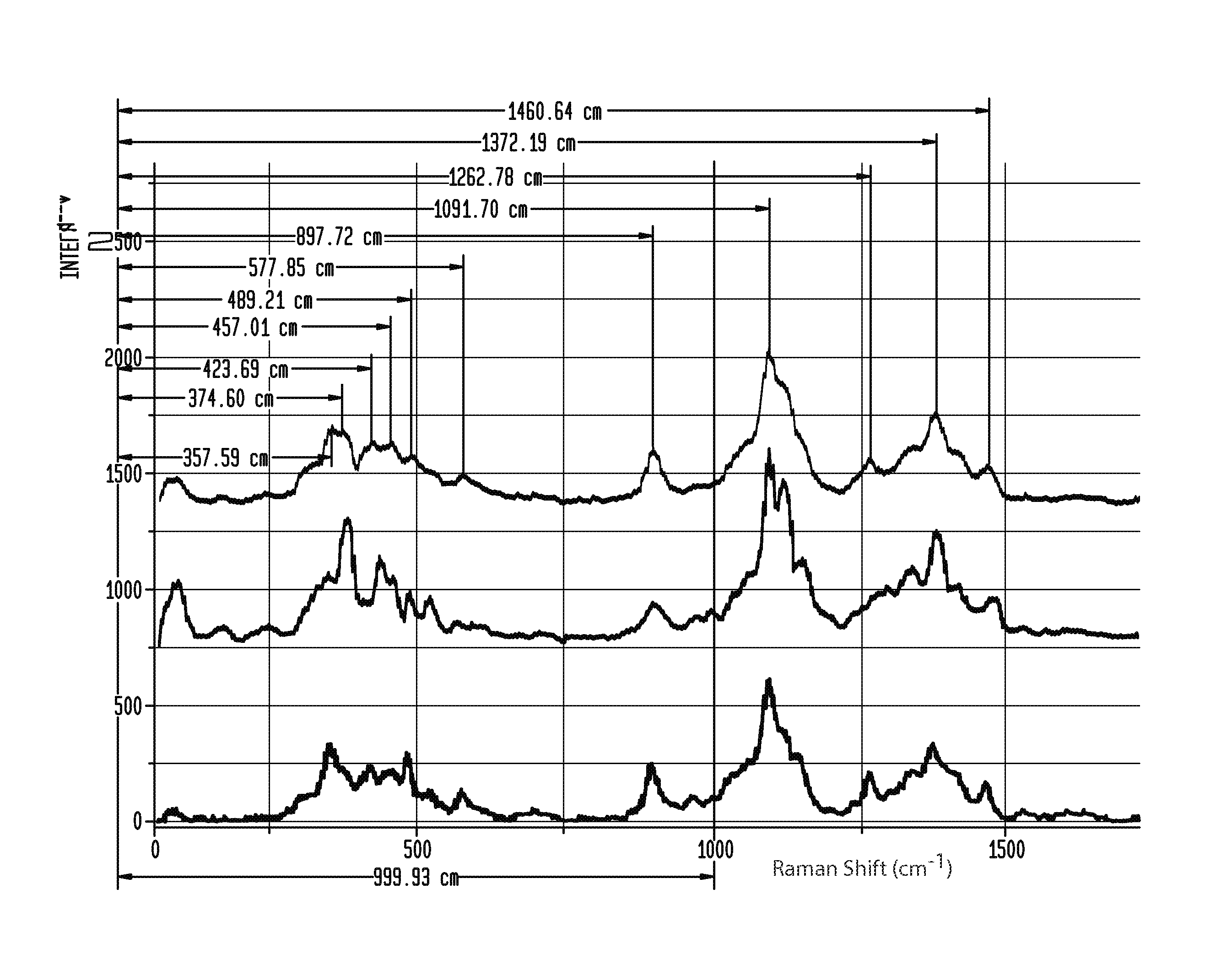

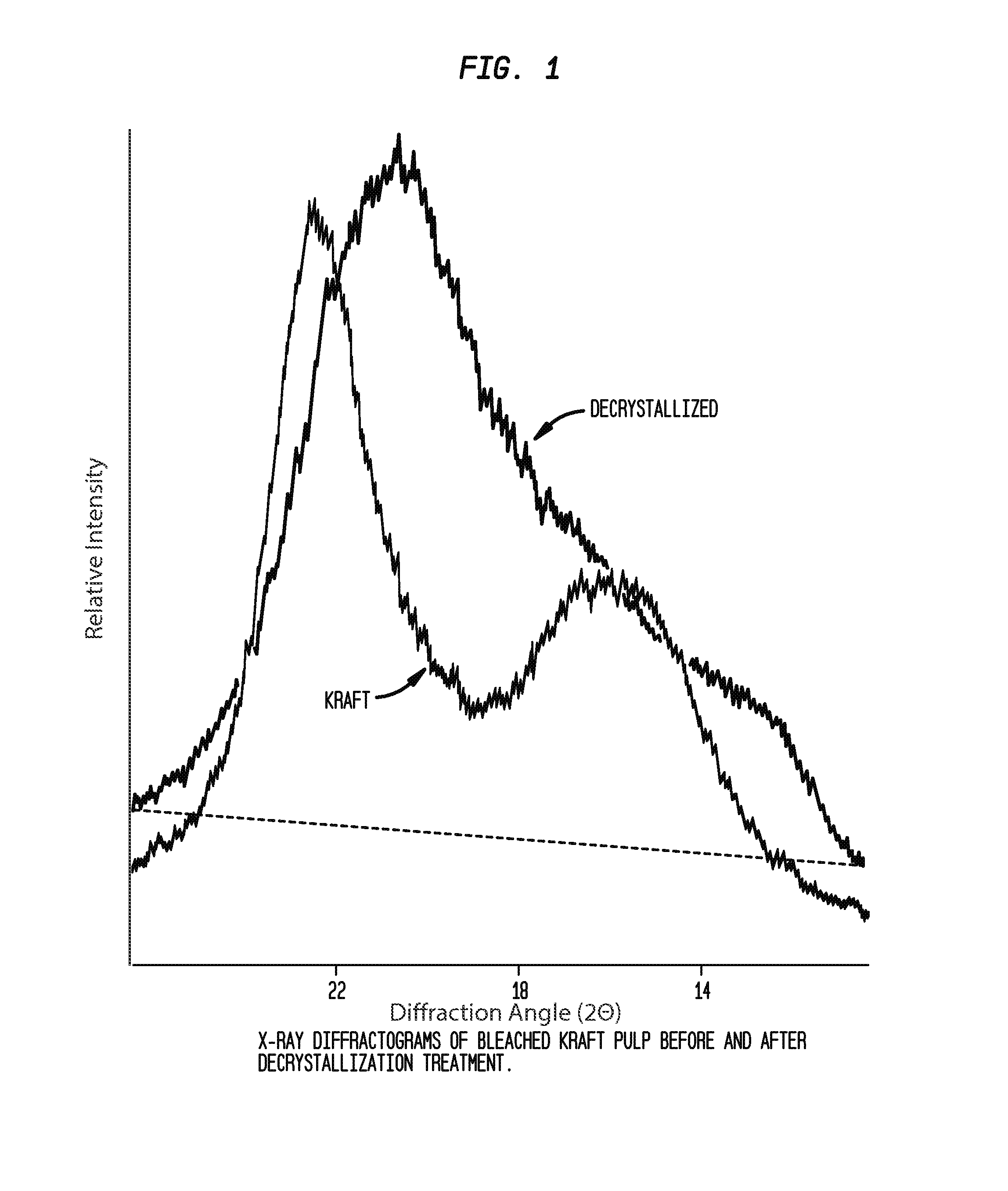

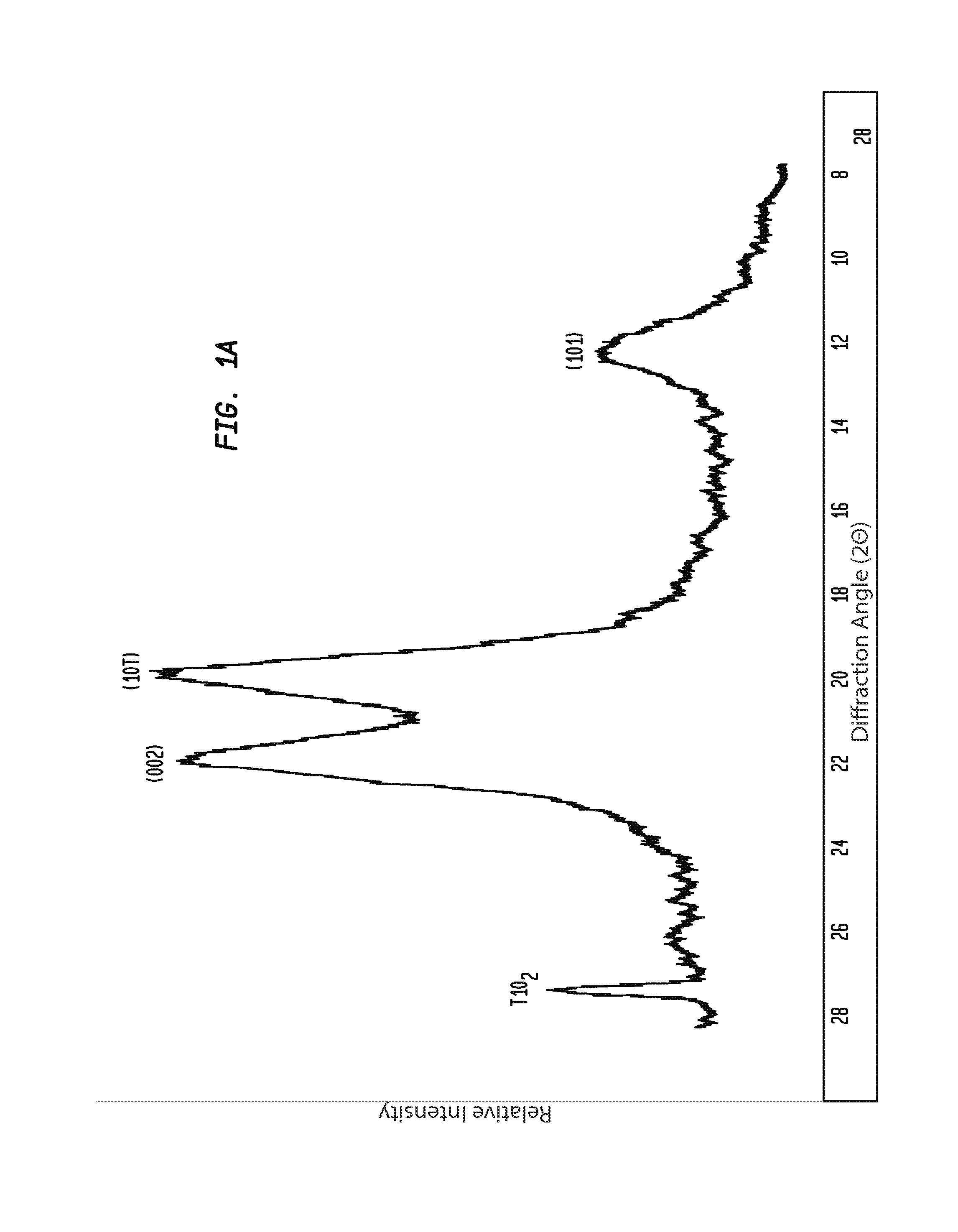

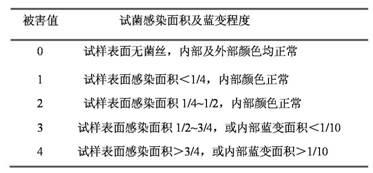

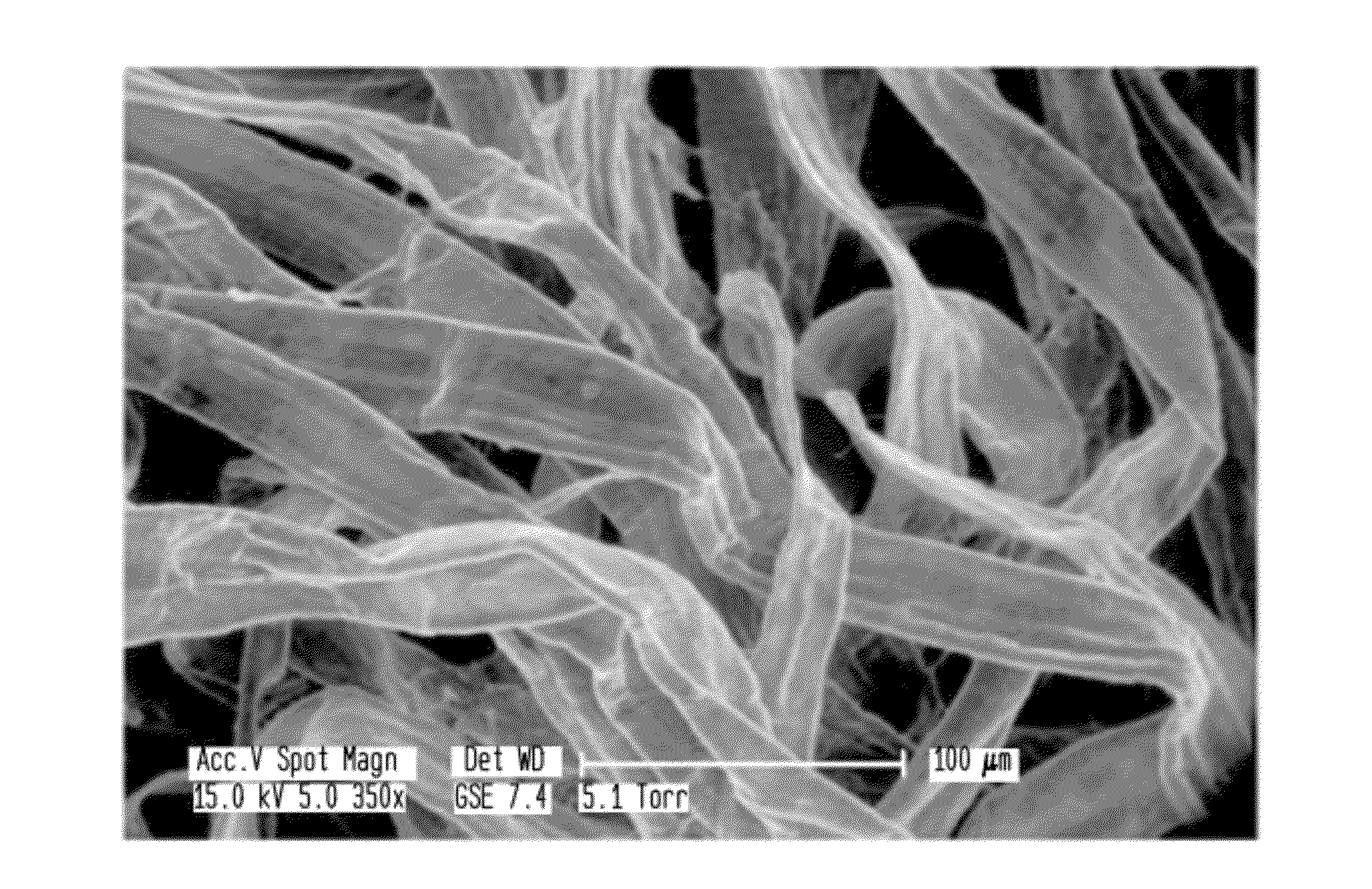

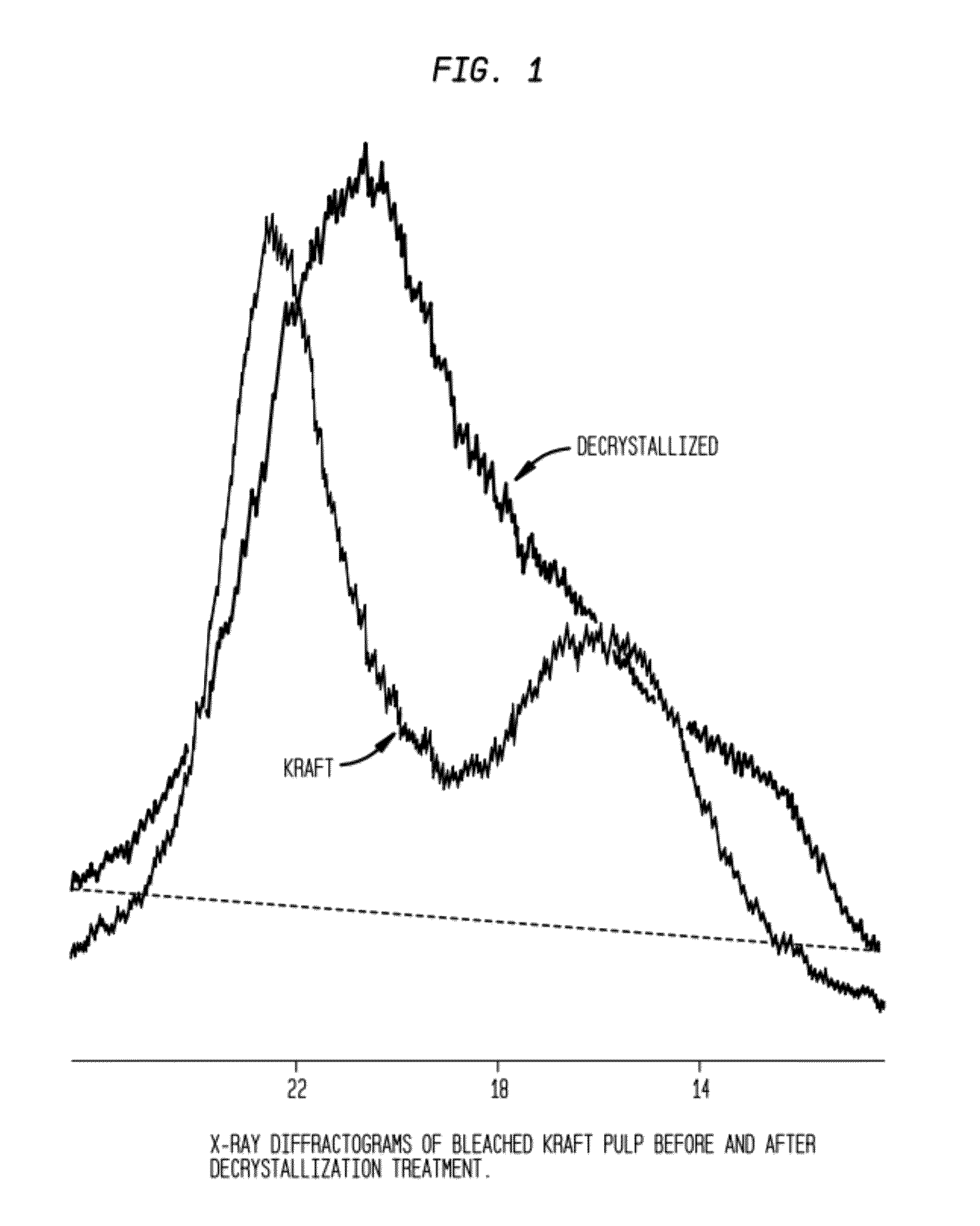

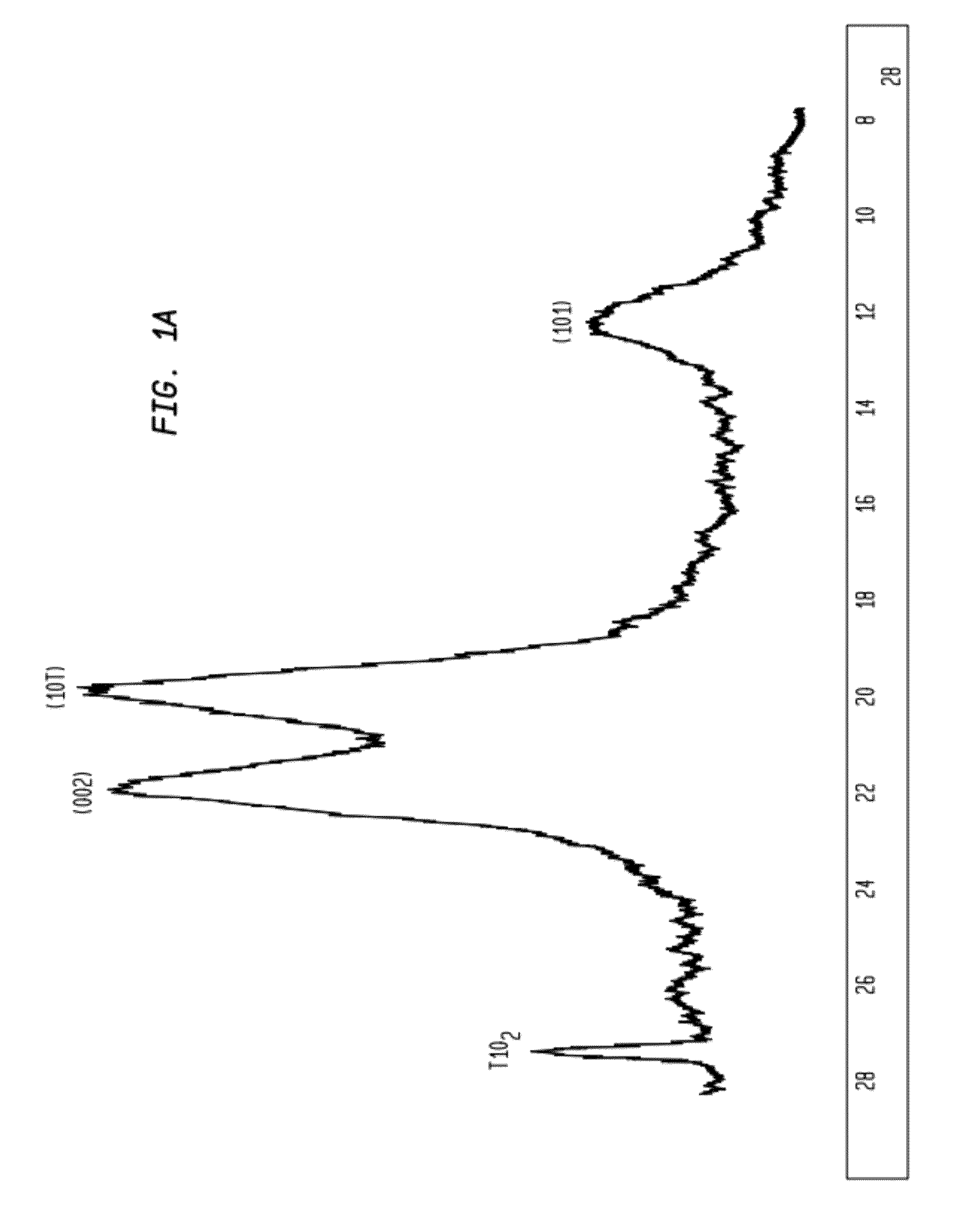

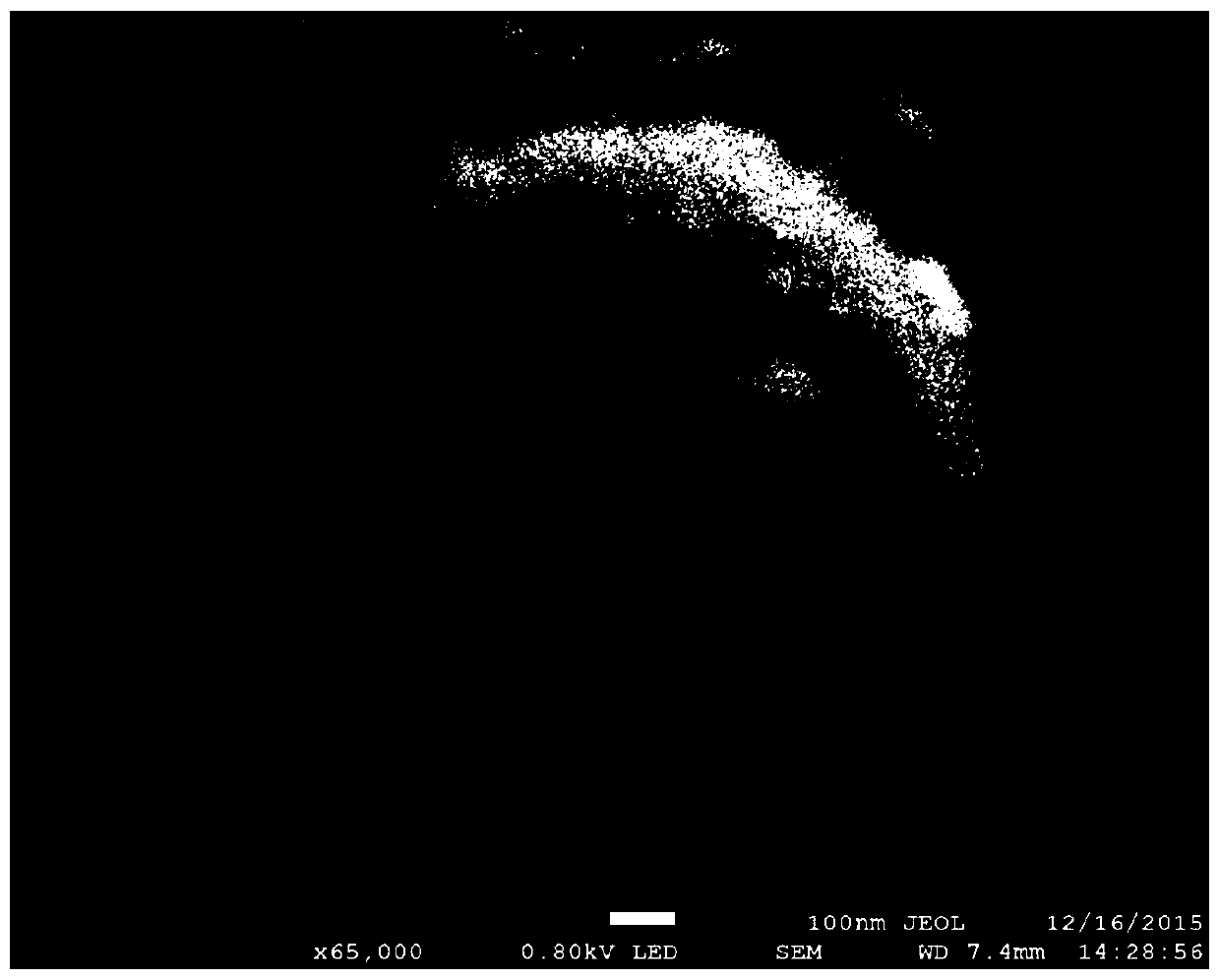

Fibrous cellulosic products incorporating both conventional cellulosic fibers and laterally expanded cellulose fibers exhibit exceptional porosity, bulk, absorbency and resiliency properties. Typical products include absorbent tissue products, absorbent fluff products and flat papers. The laterally expanded cellulose fibers exhibit: (i) a broadened X-Ray diffraction peak for the most prominent reflection having a width at half-height, (W1 / 2h)A, of at least about 3.0° 2Θ, (ii) broad overlapping maxima in their Raman spectrum between 285 and 500 cm−1, the height of the two tallest of said maxima in said spectrum between 285 and 500 cm−1 being between 35 and 50% of the height of the peak near 1098 cm−1 and (iii) a blue stain when treated with Graff C-stain, the stain exhibiting less red than the stains exhibited with bleached hardwood kraft fibers and bleached softwood kraft fibers.

Owner:CELLLOSE SCI INT

Blue stain and mildew preventing processing method for masson pine timber

InactiveCN102672772APrevent discolorationGood antibacterial effectCoating impregnationCoatingsSnow moldSolvent

The invention relates to a blue stain and mildew preventing processing method for masson pine timber. The method comprises the steps of: agitating 0.05-0.15% of thiophanate-methyl, 0.05-0.15% of carbendazim and 0.50-1.00% of double alkyl chain quaternary ammonium salt, with a solvent which is water or 75% alcohol uniformly to prepare a blue stain and mildew preventing liquid for masson pine timber; then quenching the masson pine timber naturally dried by the blue stain and mildew preventing liquid for masson pine timber for 10-20min; or processing fresh pine by way of painting or spraying, naturally drying the fresh pine and spraying for 2-3 times, and then stacking the masson pine timber processed by the blue stain and mildew preventing liquid for masson pine timber in an open type and naturally drying. The method provided by the invention can effectively inhibit propagation of various blue-stain fungi and moulds on the masson pine timber, has remarkable antibacterial effect and is simple in operational process with low processing cost, low using concentration of insecticide and low toxicity.

Owner:GUANGXI FORESTRY RES INST

Decoloring agent for decoloring bamboo or wood and method for decoloring bamboo or wood

The invention relates to a toner and a toning method of bamboo or wood, in particular to a decoloring agent for decoloring bamboo or wood and a method for decoloring bamboo or wood. The decoloring agent comprises the following components in parts by weight: 3-10 parts of oxydol of which the weight concentration is 30-50%, 0.25-1 part of water glass, 0.1-1 part of non-ionic surface active agent and 0.25-0.5 part of alkaline pH-value regulator. The invention also provides a decoloring method by using the decoloring agent. The decoloring agent and the decoloring method in the invention not only can decolor the surface of a single plate or bamboo sheet, but also can completely decolor the single plate or bamboo sheet, i.e. the surface of the single plate or bamboo sheet and blue stains, mouldy stains, insect stains, black spots and the like at the center can be decolored; the invention has the advantages of uniform decoloring, high decoloring efficiency and low cost, and is suitable for mass cyclic production; the decoloring agent and the decoloring method have low destroy degree on wood and are especially suitable for use after the reprocessing or retoning after recombined decorativematerials are processed in a single plate or bamboo sheet decoloring way.

Owner:ZHEJIANG SHENGHUA YUNFENG GREENEO

Rubber wood impregnation treatment method

InactiveCN103223685ALow costImprove working environmentPressure impregnationWood impregnation detailsBlue stainChloride sodium

The invention relates to a rubber wood impregnation treatment method, and belongs to the technical field of wood treatments, wherein a rubber wood impregnation treatment method is specifically designed. The method comprises: adopting a sodium chloride solution with a saturated concentration to carry out a soaking treatment on freshly-sawn rubber wood, and then carrying out a subsequent conventional drying treatment, wherein the surface of the rubber wood is immersed by the sodium chloride solution, and the solution maintains the saturated state during the soaking process. The treatment method has the following characteristics that: the treatment agent of the present invention is toxic and harmless, raw material cost is low, a process is simple, the existing mature traditional process can be used, production investment is low, and the treated wood has characteristics of no infesting, no mildewing, no blue stain, and no rot.

Owner:冯勇

Rubber wood protective method

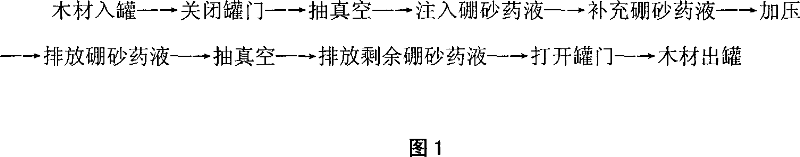

InactiveCN1328905AImprove the protective effectHigh strengthPressure impregnationVacuum pressureEnvironment effect

An environment-protecting type rubber wood protection (pest-resisting and fungi-resisting) method is characterized by using 2.5%-5.0% borax liquor to implement vacuum pressure treatment of fresh rubber wood, and when the said wood is treated, the used vacuum degree is -0.07--0.09 MPa, pressure is 1.1-1.3 MPa, the pressurizing time is dependent to the thickness of wood, and the pressurizing time of 3.0-8.5 cm thickness is 30-70 min. After the wood is treated, it can be prompty stached and dried in the air for 8-12 days, then dried in drying kiln to make its water content be reduced to 10%-8%. The wood treated by the said invention can prevent moth damage, and does not produce blue stain, so it is suitable for making furniture, and its used chemical preparation is low in toxicity, and low in cost, and its preparation is simple.

Owner:中南(海南)橡胶木材傢俱厂

Combined bleaching agent for timber

InactiveCN102642226AImprove the safety of useImprove protectionWood treatment detailsWood impregnation detailsLiriodendronBleach

The invention provides a combined bleaching agent for timber. The combined bleaching agent comprises the following main components in weight ratio per 1000 ml of solution : 15-75 g of sodium percarbonate; 5-30 g of sodium perborate; 2-8 g of sodium thiosulfate and 12-50 g of sodium sulfate. The combined bleaching agent provided by the invention has higher use security and good bleaching performance; with the adoption of the bleaching agent, dark spots, mineral lines, blue stain and the like on the timber surface and the phenomena that the timber color is uneven caused by various pollutions can be eliminated, and the color difference of heartwood can be eliminated; the overall timber color can be diluted, so that the timber surface can become white and bright and uniform in color and luster; and moreover, the original timber texture and quality can be maintained, particularly the blue-green heartwood of North American liriodendron wood can be repaired better; the bleached timber is in light yellow color, which is very attractive. The processing method further can be used for reducing the white degree reducing trend caused by phototropy, so that the light resistance performance of the timber surface can become more ideal.

Owner:GUANGDONG YIHUA TIMBER IND

Combination technique of organic blue dye for labeling the sentinel node and fluorescence imaging

InactiveCN101380226ARelieve painAvoid Radiation HazardsLuminescence/biological staining preparationDiagnostics using lightOrganic dyeLength wave

The invention relates to a combined technology for marking an organic blue dye of a sentinel lymph node and fluorescence imaging. The fluorescence given out by the organic blue dye is displayed by a fluorescence imaging device by the illumination of excitation light of the fluorescence imaging device with a wavelength not less than 570nm; wherein, the organic blue dye is one from methylene blue, Evans blue, isosulfan blue and patent blue or a compound thereof. The combined technology has the advantages of: overcoming the defect of needing to cut a larger opening on a skin for finding out a blue stain lymph node when using an organic dye to dye and position in the normal method for carrying out location of the sentinel lymph node of a tumor in clinical practice, and the sentinel lymph node can be located without an operation, thus reducing the pain of a patient. The combined technology has non-radioactivity, is convenient, fast and accurate and is a method which has excellent clinical application value.

Owner:TONGJI UNIV

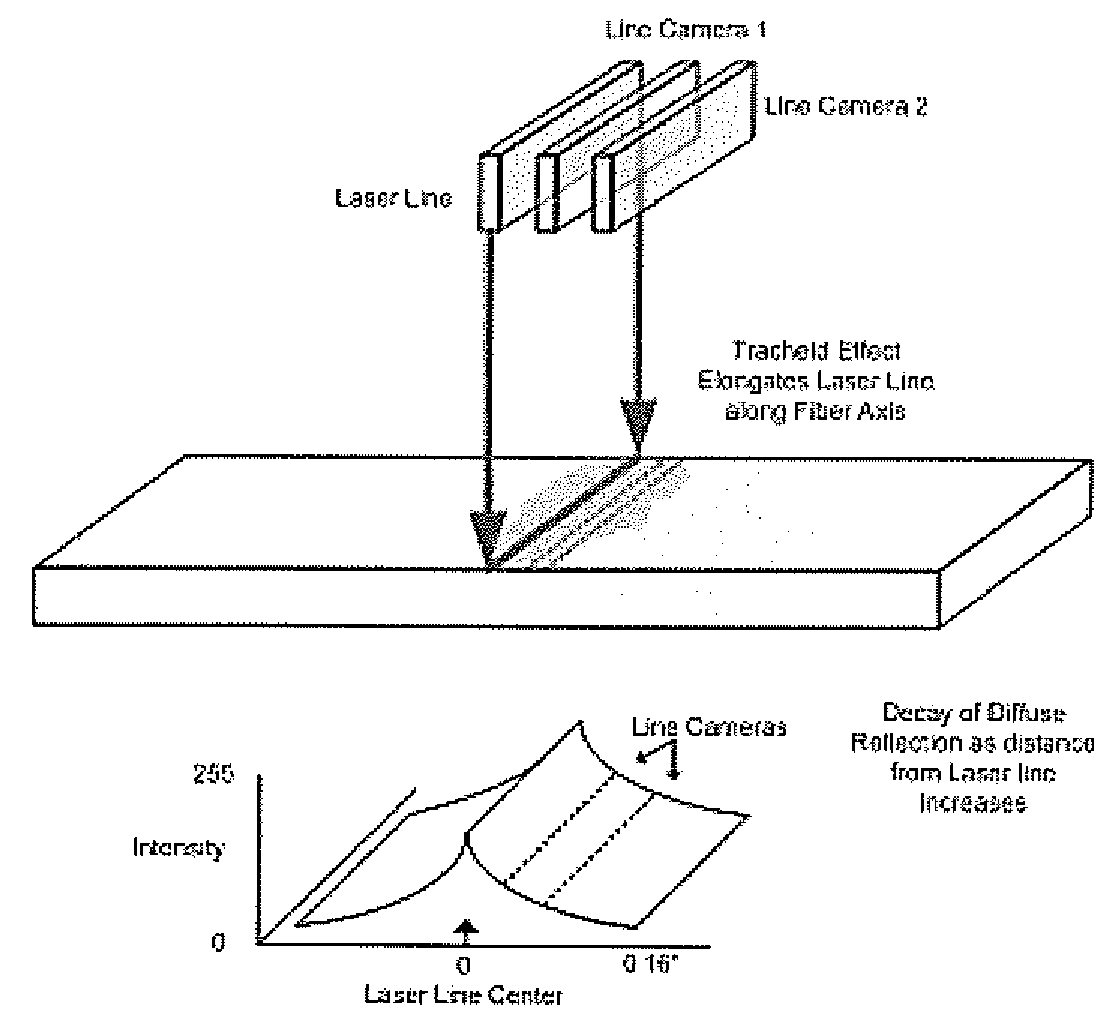

Methods for Detecting Pitch in Lumber

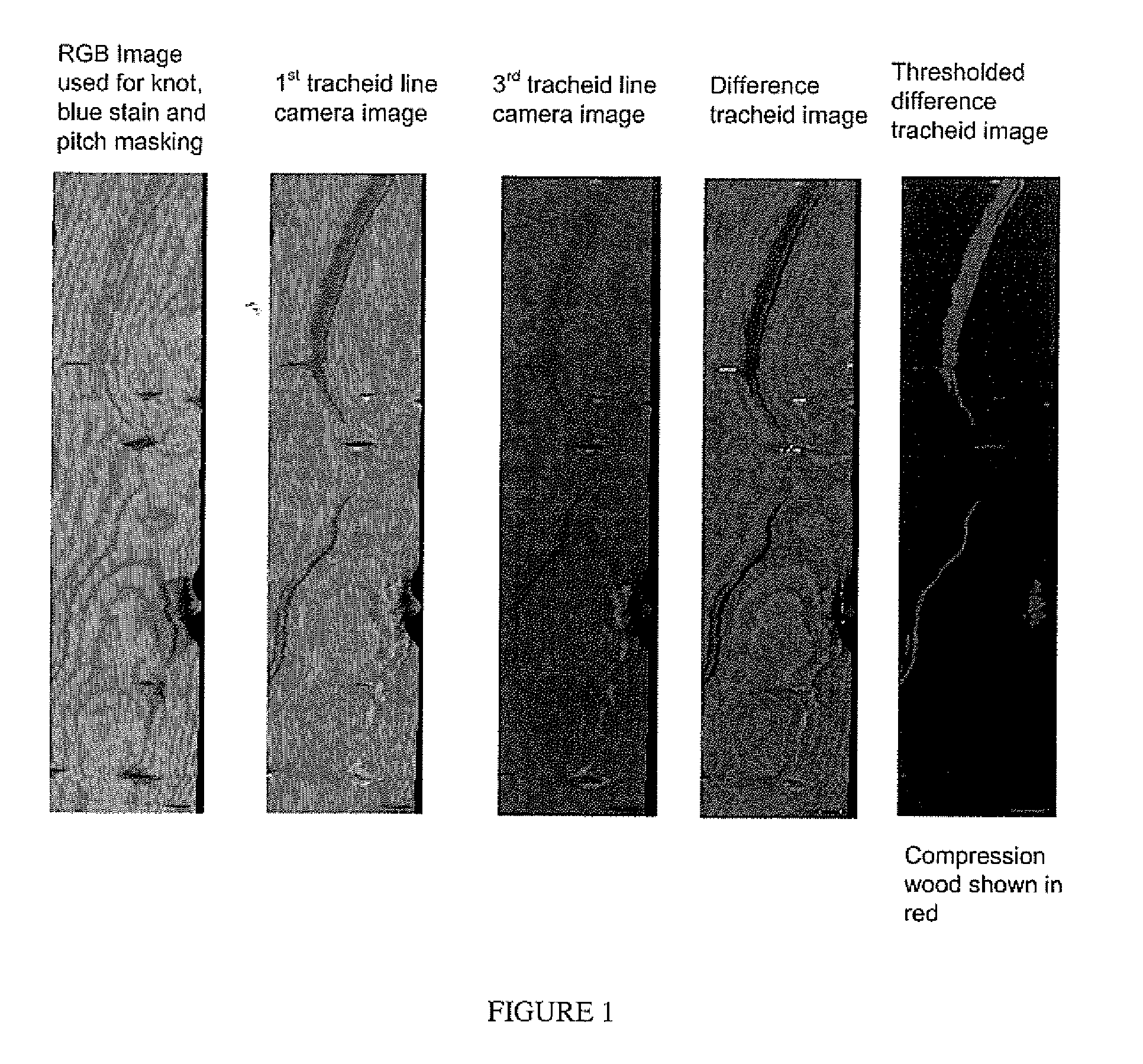

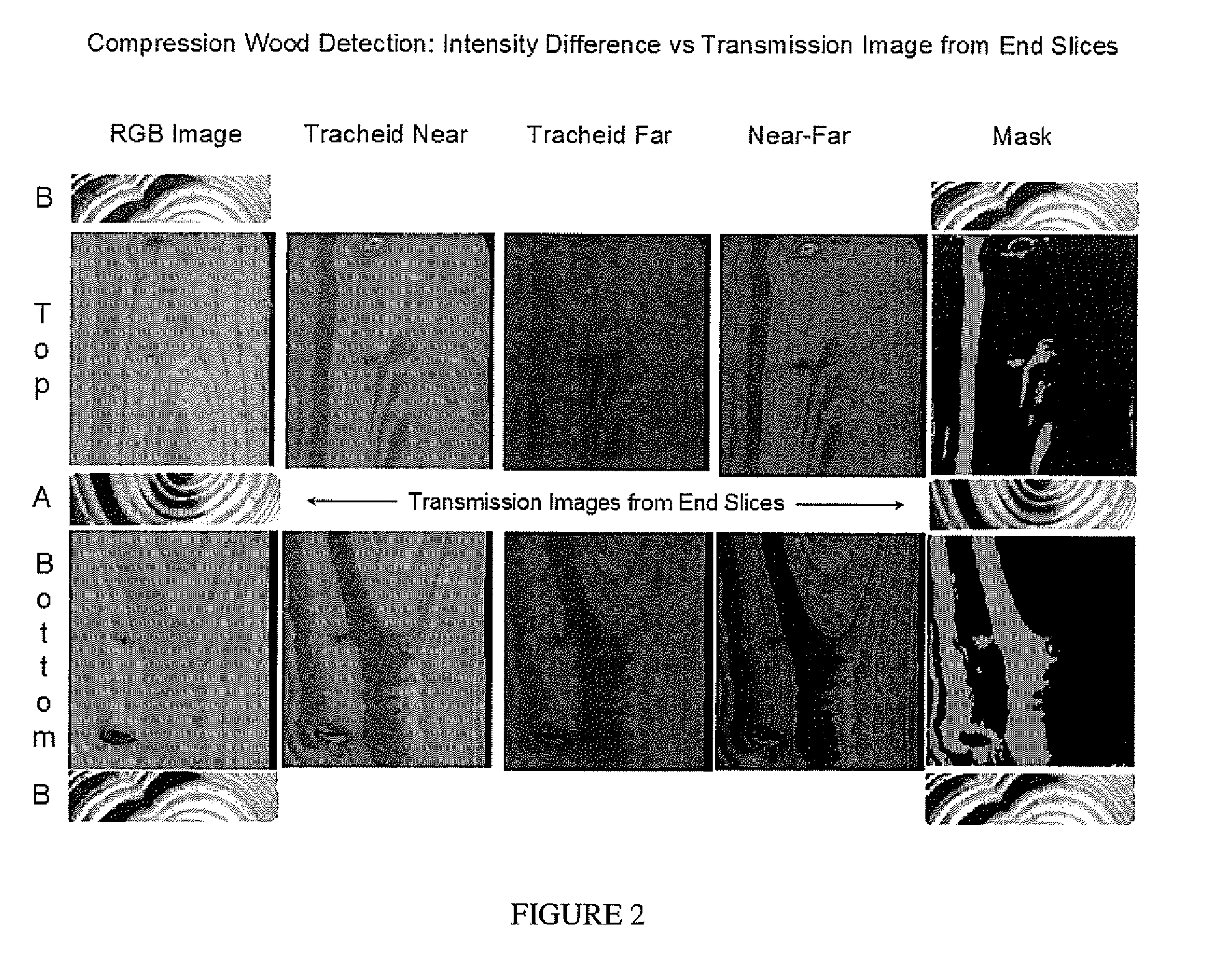

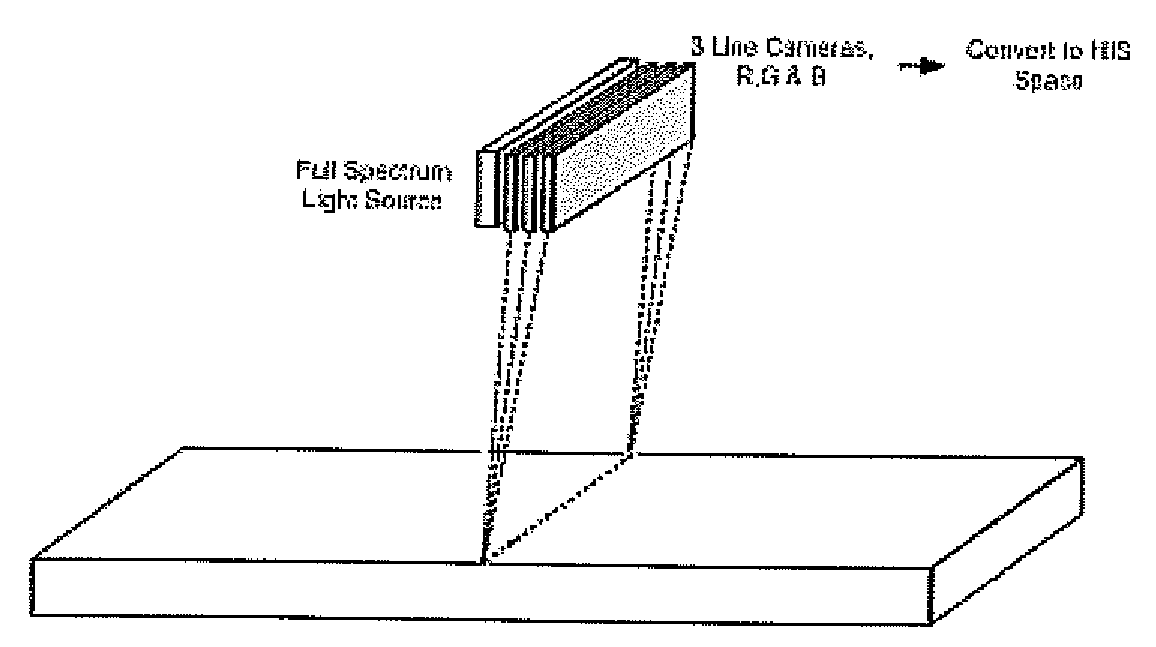

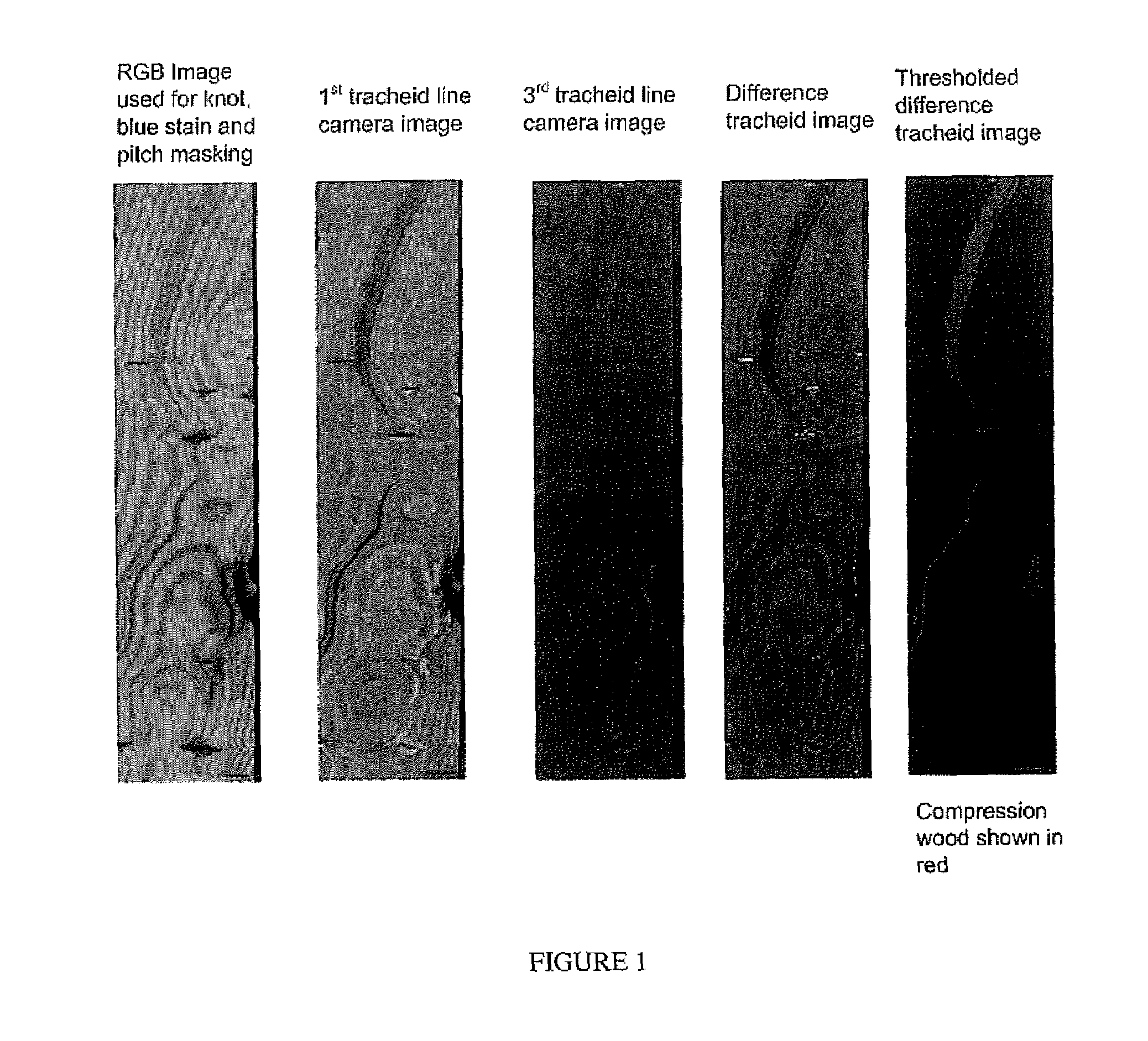

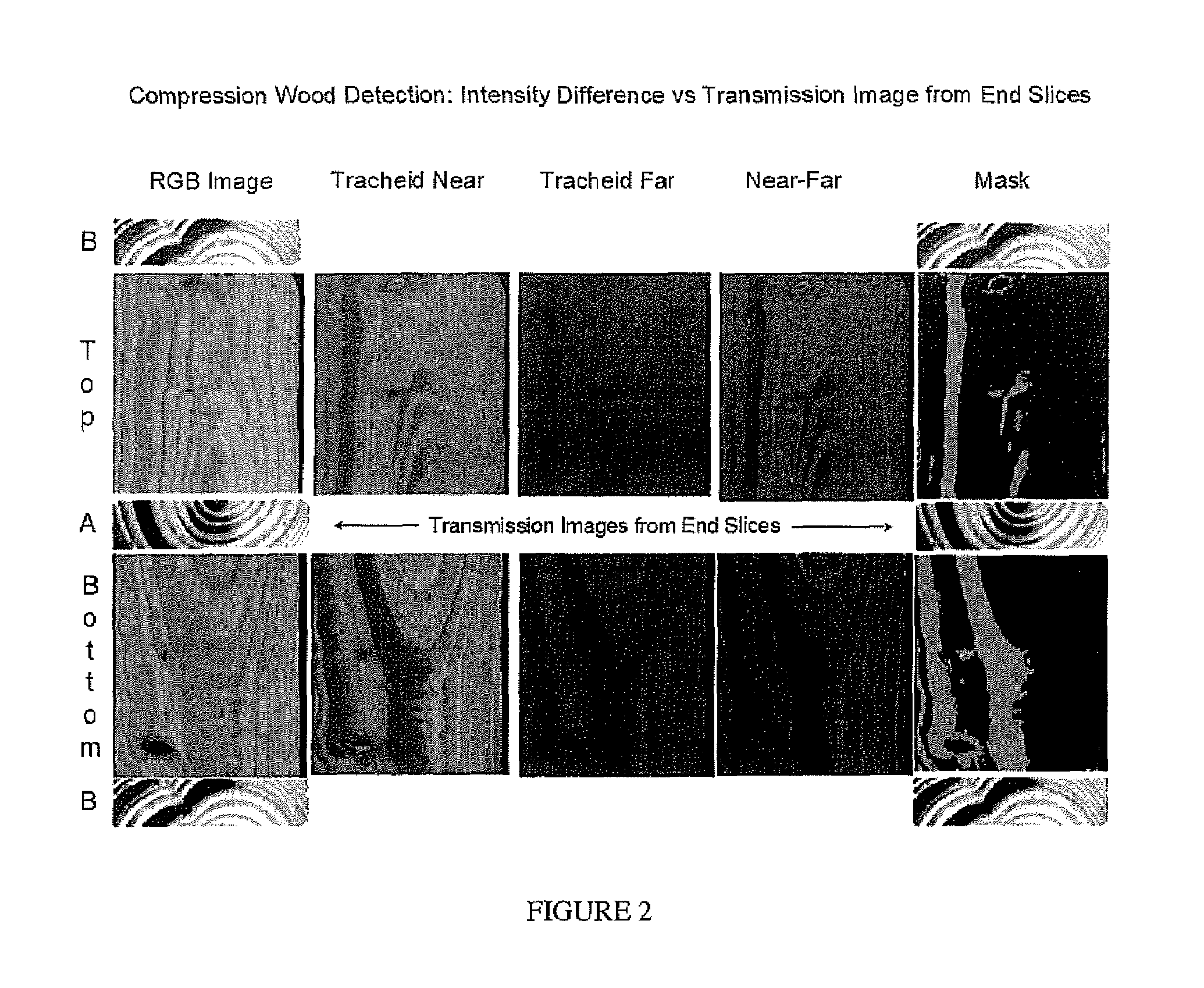

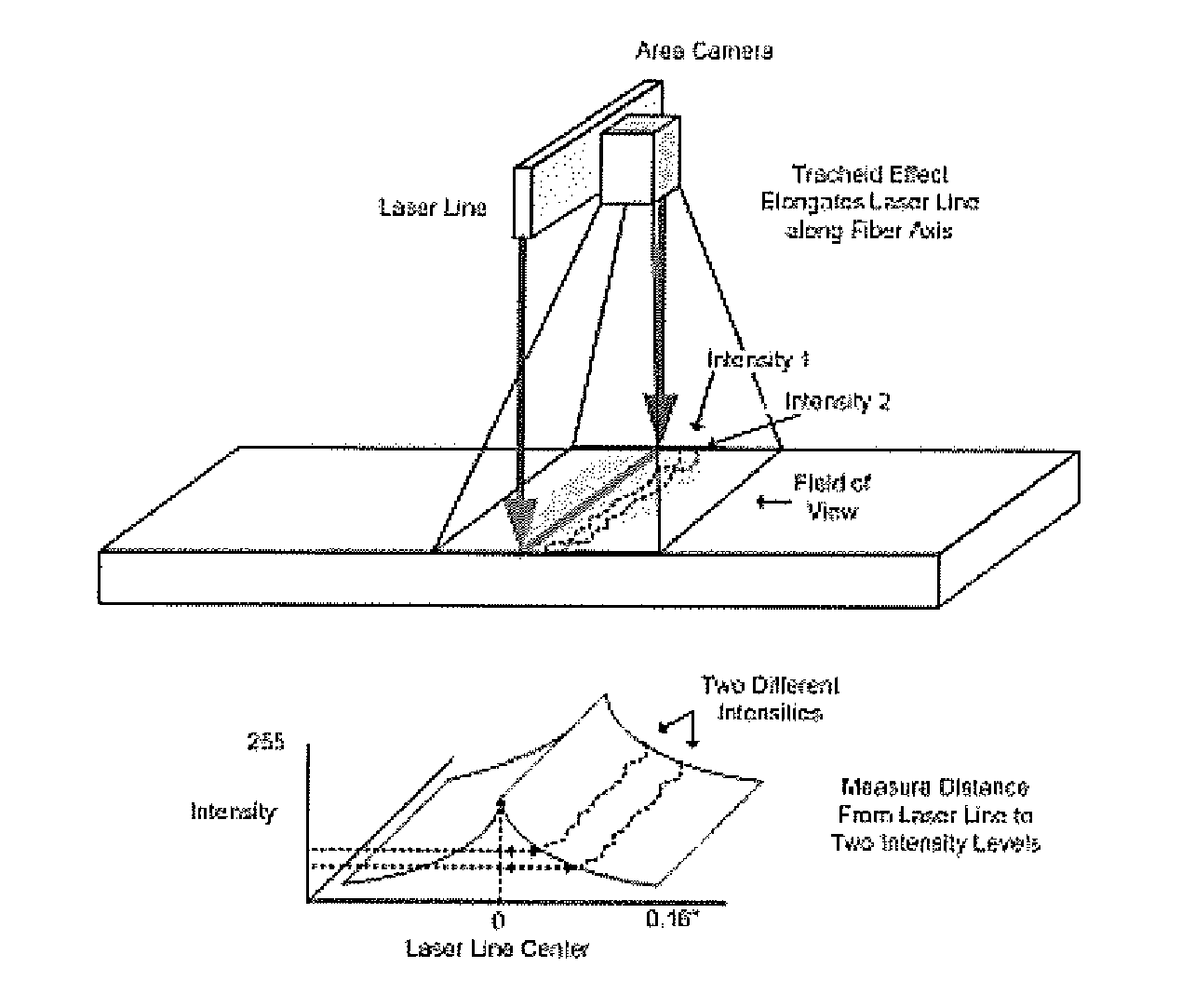

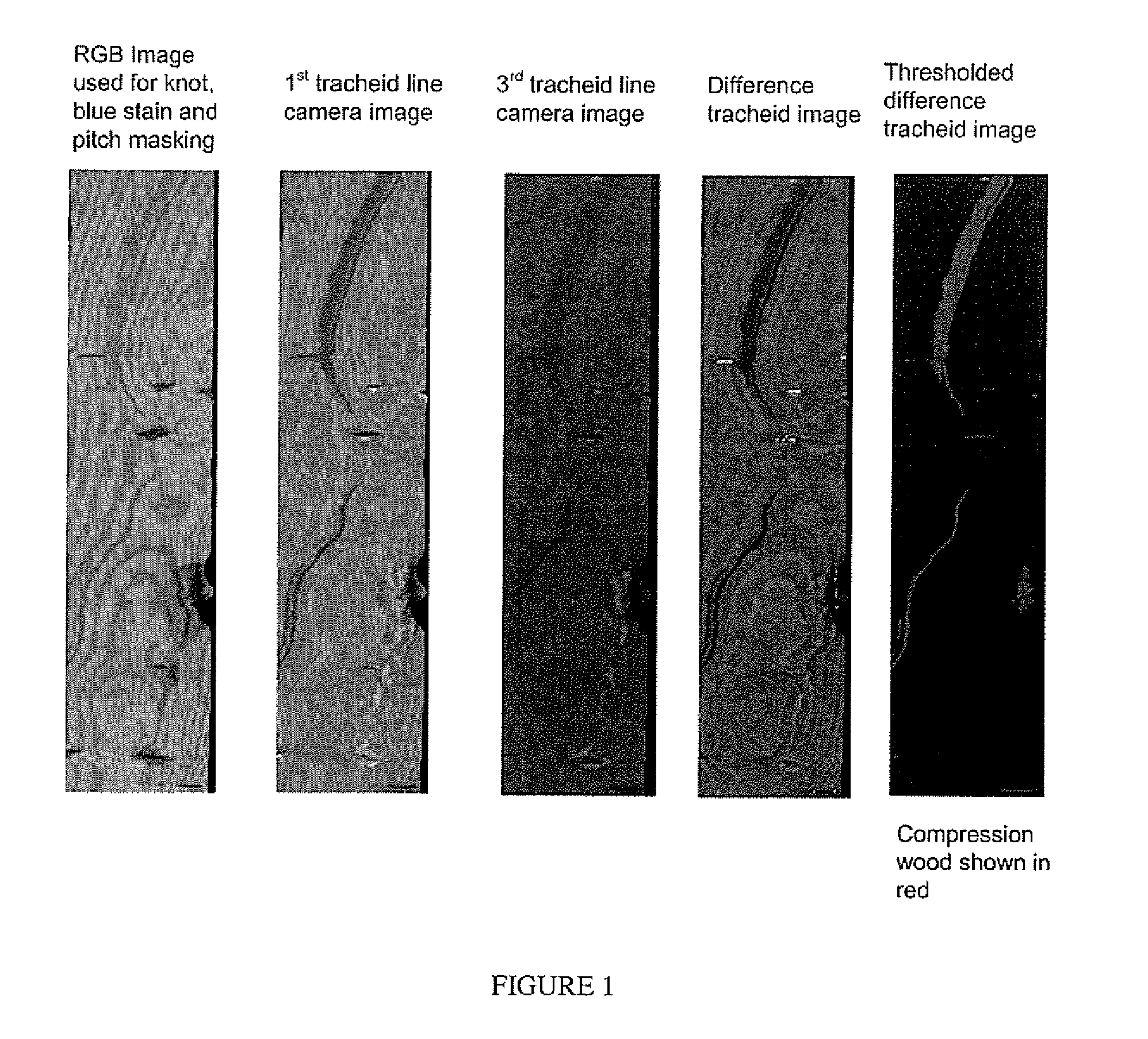

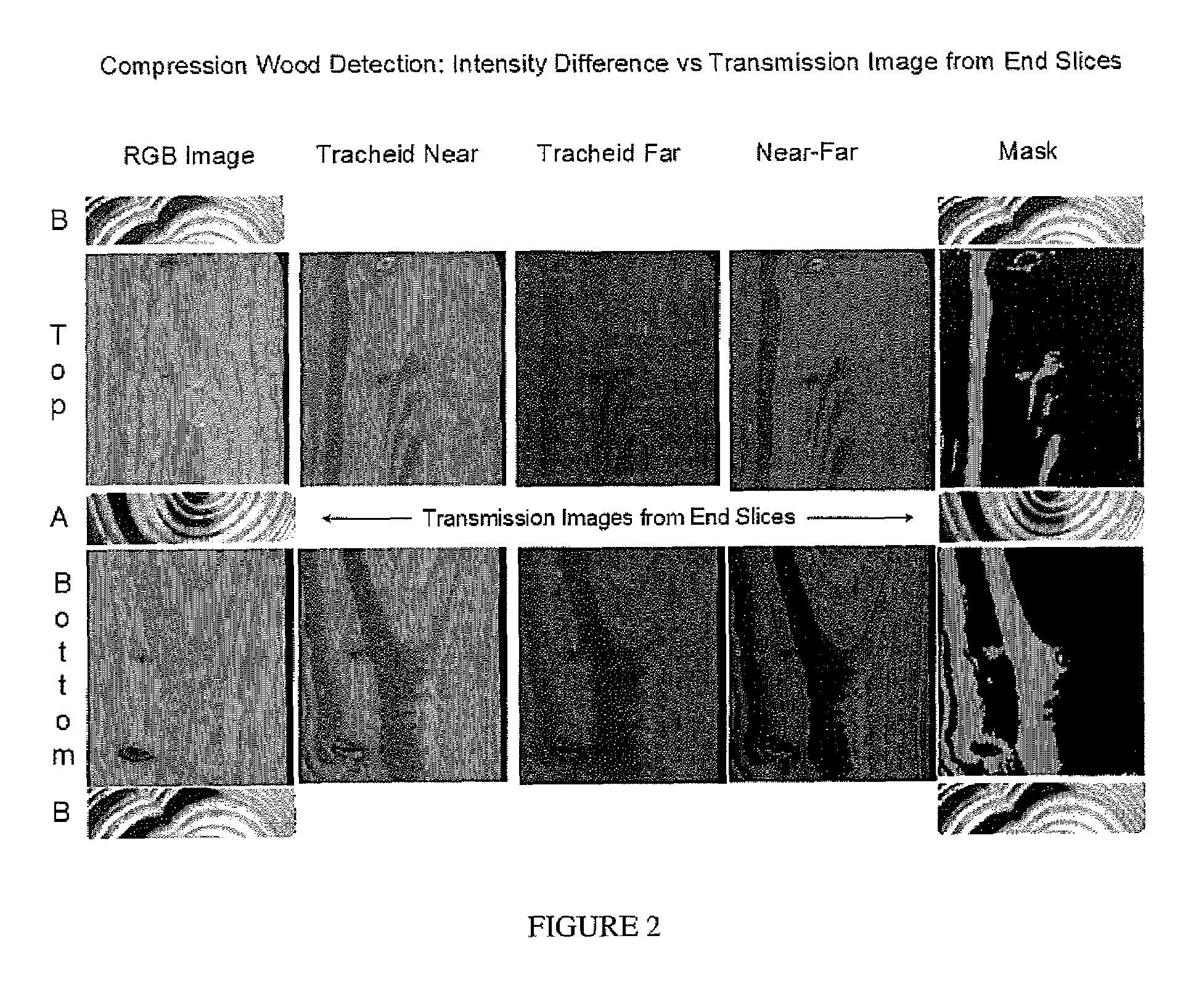

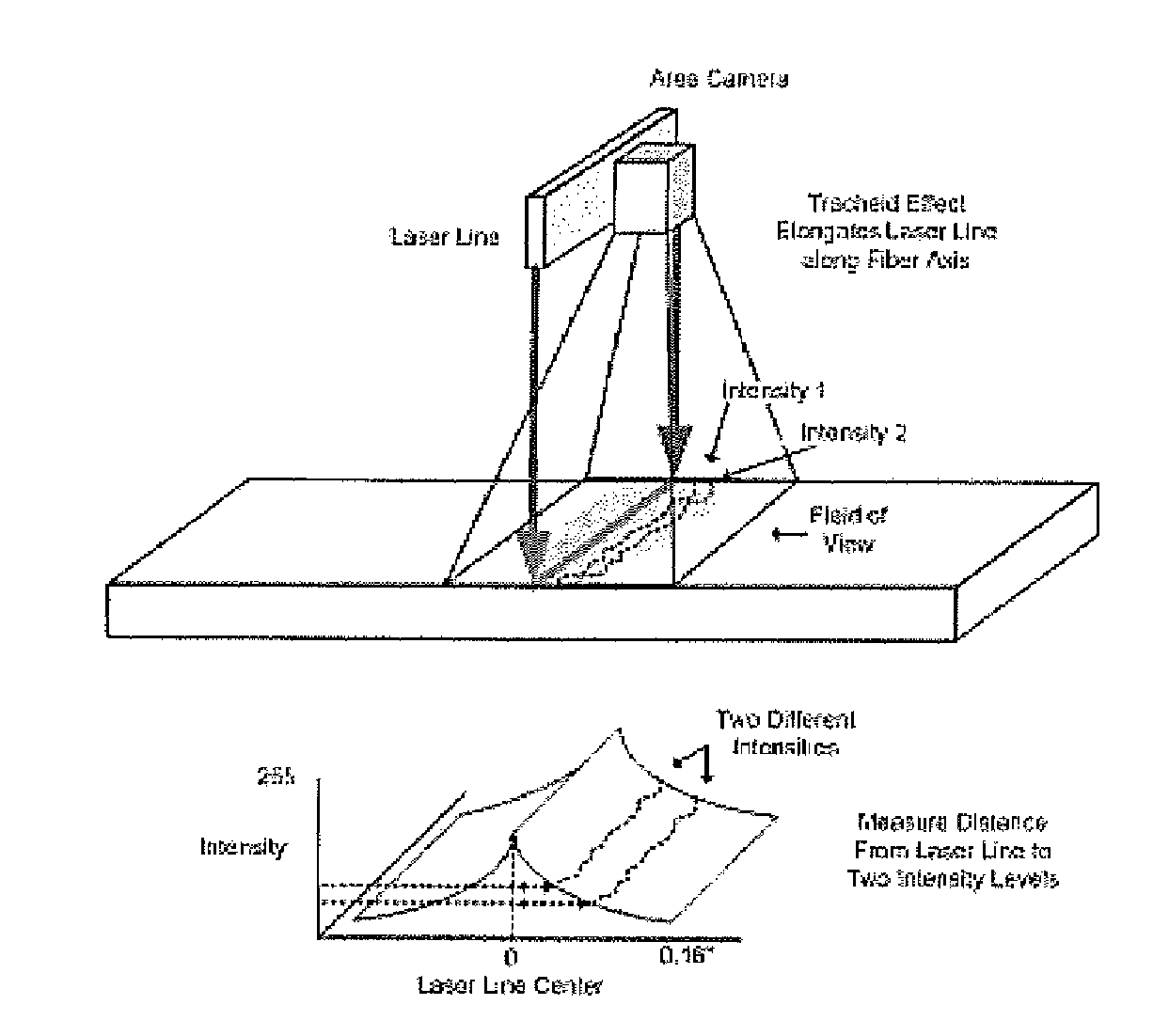

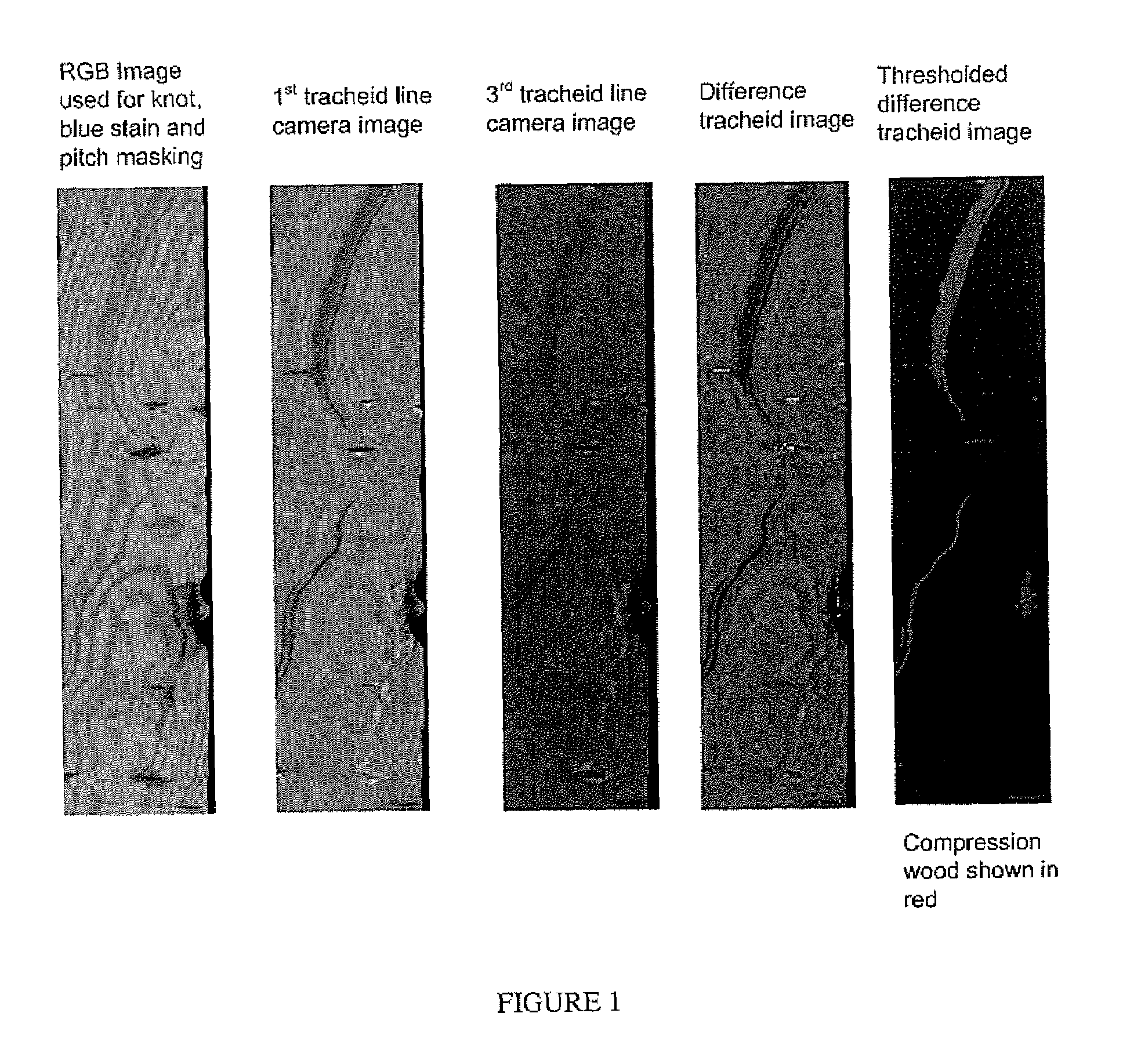

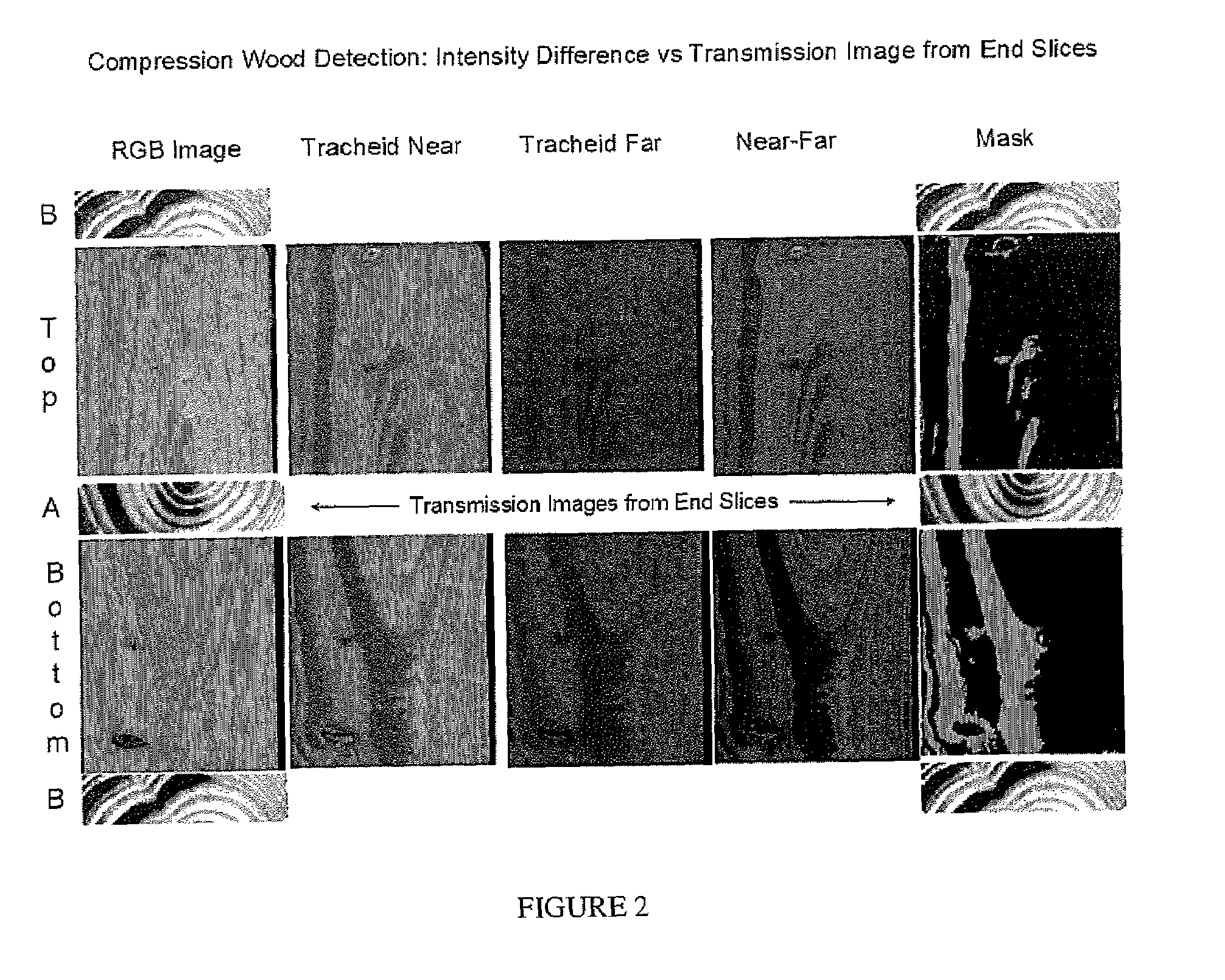

Methods are provided for detecting compression wood, blue stain, or pitch in lumber. A light beam is projected towards the wood sample. Line or area cameras acquire images of light that is reflected from the wood sample. Based on the intensity of the reflected light at one or more locations on the wood sample, compression wood, blue stain, or pitch may be detected.

Owner:WEYERHAEUSER NR CO

Methods for detecting compression wood in lumber

Methods are provided for detecting compression wood, blue stain, or pitch in lumber. A light beam is projected towards the wood sample. Line or area cameras acquire images of light that is reflected from the wood sample. Based on the intensity of the reflected light at one or more locations on the wood sample, compression wood, blue stain, or pitch may be detected.

Owner:WEYERHAEUSER NR CO

Tissue products incorporating nanoporous cellulose fiber

ActiveUS20120273147A1Increase overlapReduce the maximumNon-fibrous pulp additionPaper after-treatmentPorosityMedicine

Fibrous cellulosic products incorporating both conventional cellulosic fibers and laterally expanded cellulose fibers exhibit exceptional porosity, bulk, absorbency and resiliency properties. Typical products include absorbent tissue products, absorbent fluff products and flat papers. The laterally expanded cellulose fibers exhibit: (i) a broadened X-Ray diffraction peak for the most prominent reflection having a width at half-height, (W1 / 2h)A, of at least about 3.0° 2Θ, (ii) broad overlapping maxima in their Raman spectrum between 285 and 500 cm−1, the height of the two tallest of said maxima in said spectrum between 285 and 500 cm−1 being between 35 and 50% of the height of the peak near 1098 cm−1 and (iii) a blue stain when treated with Graff C-stain, the stain exhibiting less red than the stains exhibited with bleached hardwood kraft fibers and bleached softwood kraft fibers.

Owner:CELLLOSE SCI INT

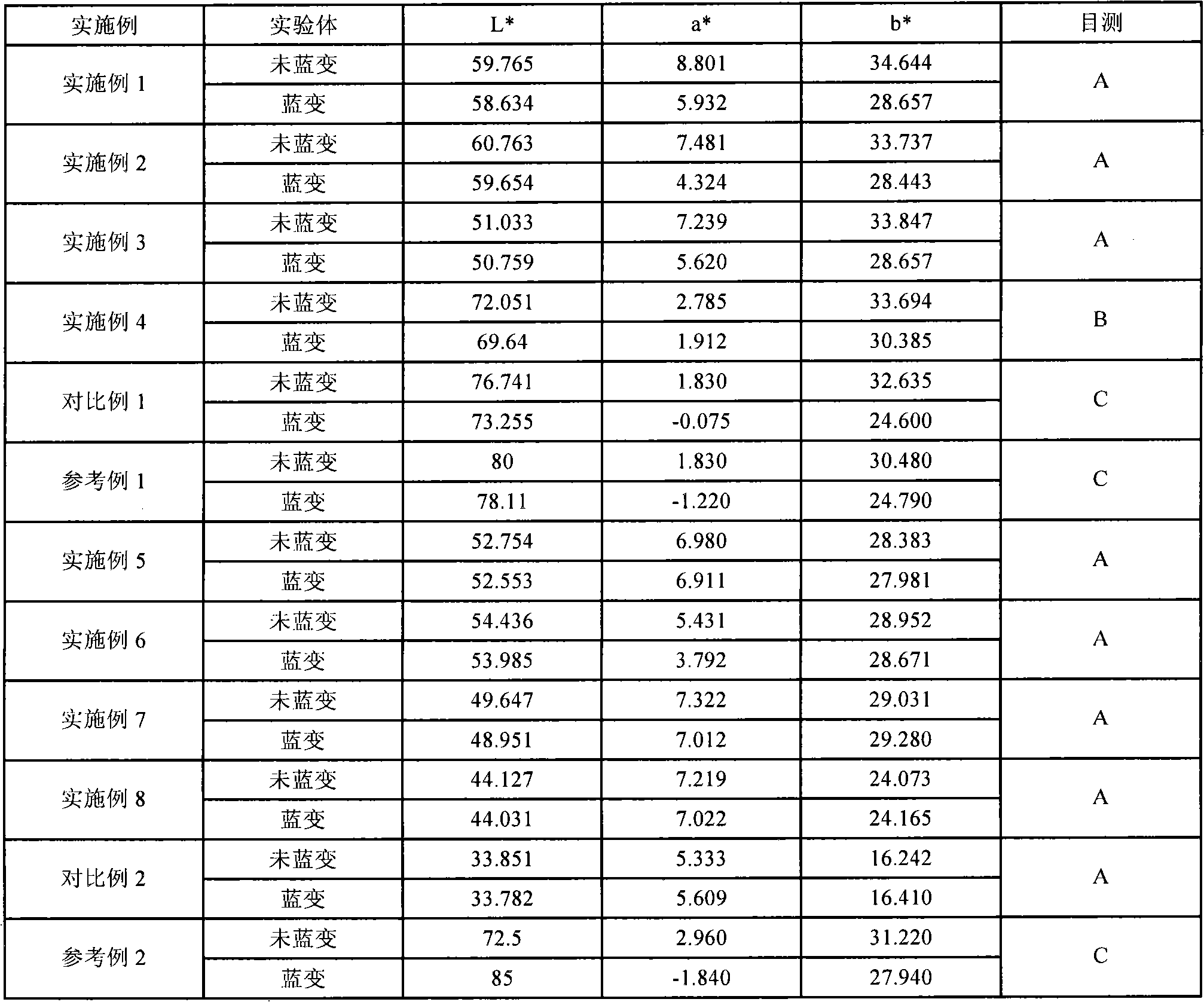

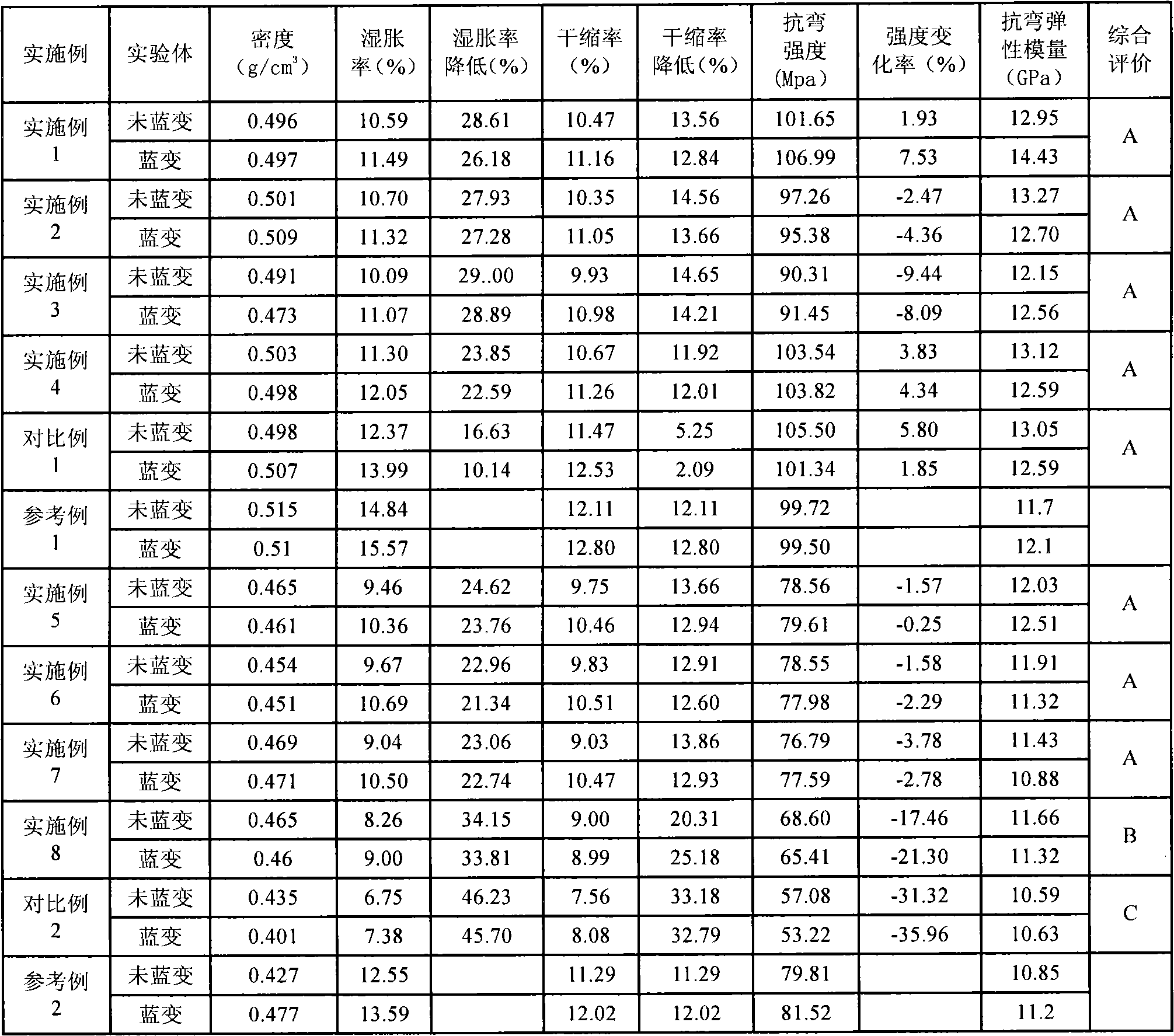

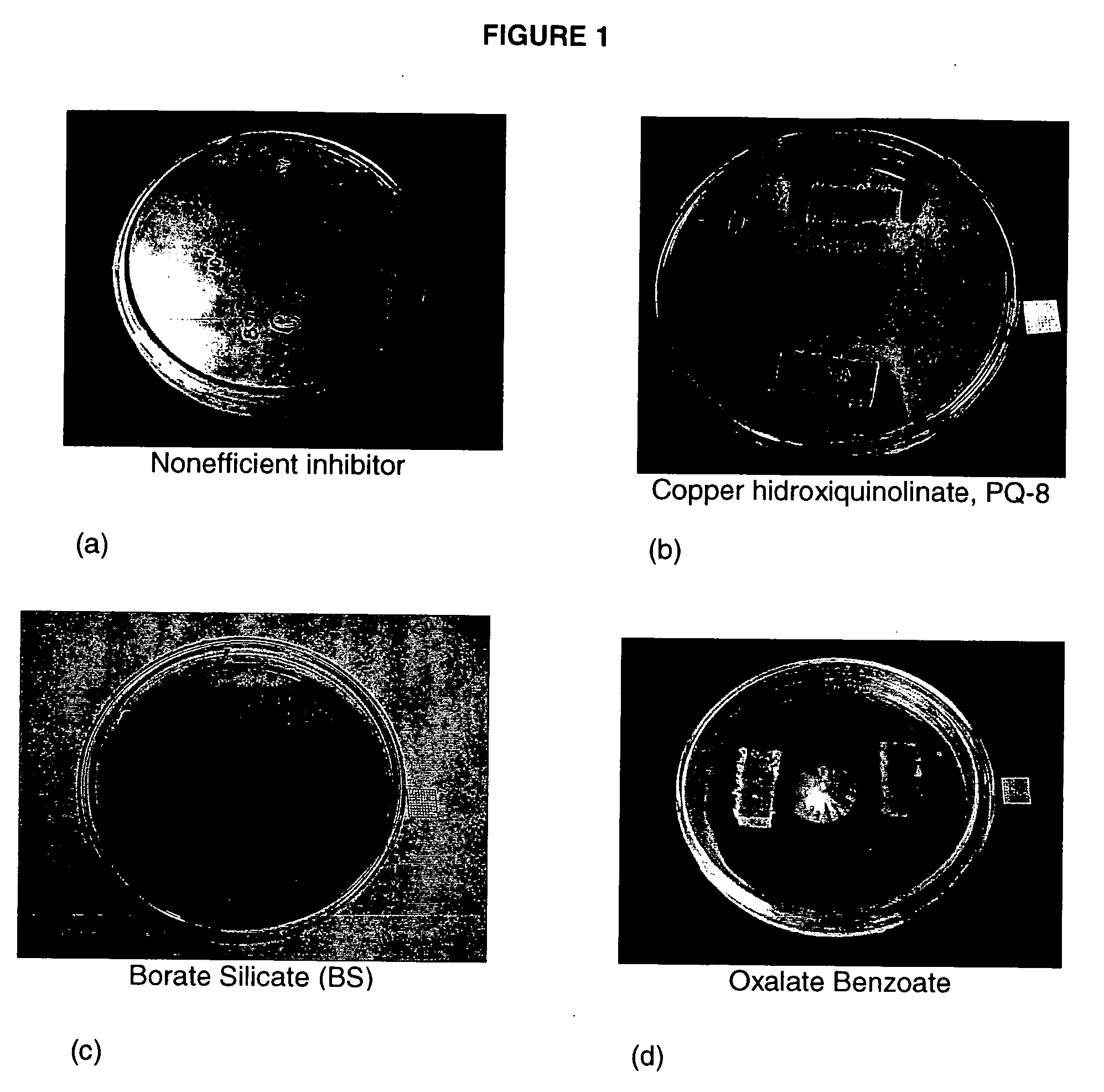

Method for processing blue-stain wood

ActiveCN102029633AImprove appearance qualityUniform colorWood treatment detailsLower gradeShielding gas

The invention provides a method for processing blue-stain wood. The method is characterized by comprising the following step of heating the blue-stain wood for 1-10 hours at the temperature of 190-230 DEG C under the atmosphere of protective gas with oxygen content being less than 3 percent by volume, wherein the water content of the blue-stain wood is 8-13 percent by weight. When the method is used for processing the blue-stain wood, the colour of the blue-stain wood and the color of non-blue-stain wood are uniform without differences by visual measurement, and therefore, the appearance quality of the blue-stain wood is greatly improved. In addition, the blue-stain wood is basically consistent with the non-blue-stain wood because of density and intensity changes after heat processing, therefore, the processed blue-stain wood can play the role of the non-blue-stain wood, the wood is transformed to a top grade from a low grade, and the application prospects and the market value of the blue-stain wood are greatly increased. The invention belongs to a wood processing technique with great prospects.

Owner:JIUSHENG WOOD

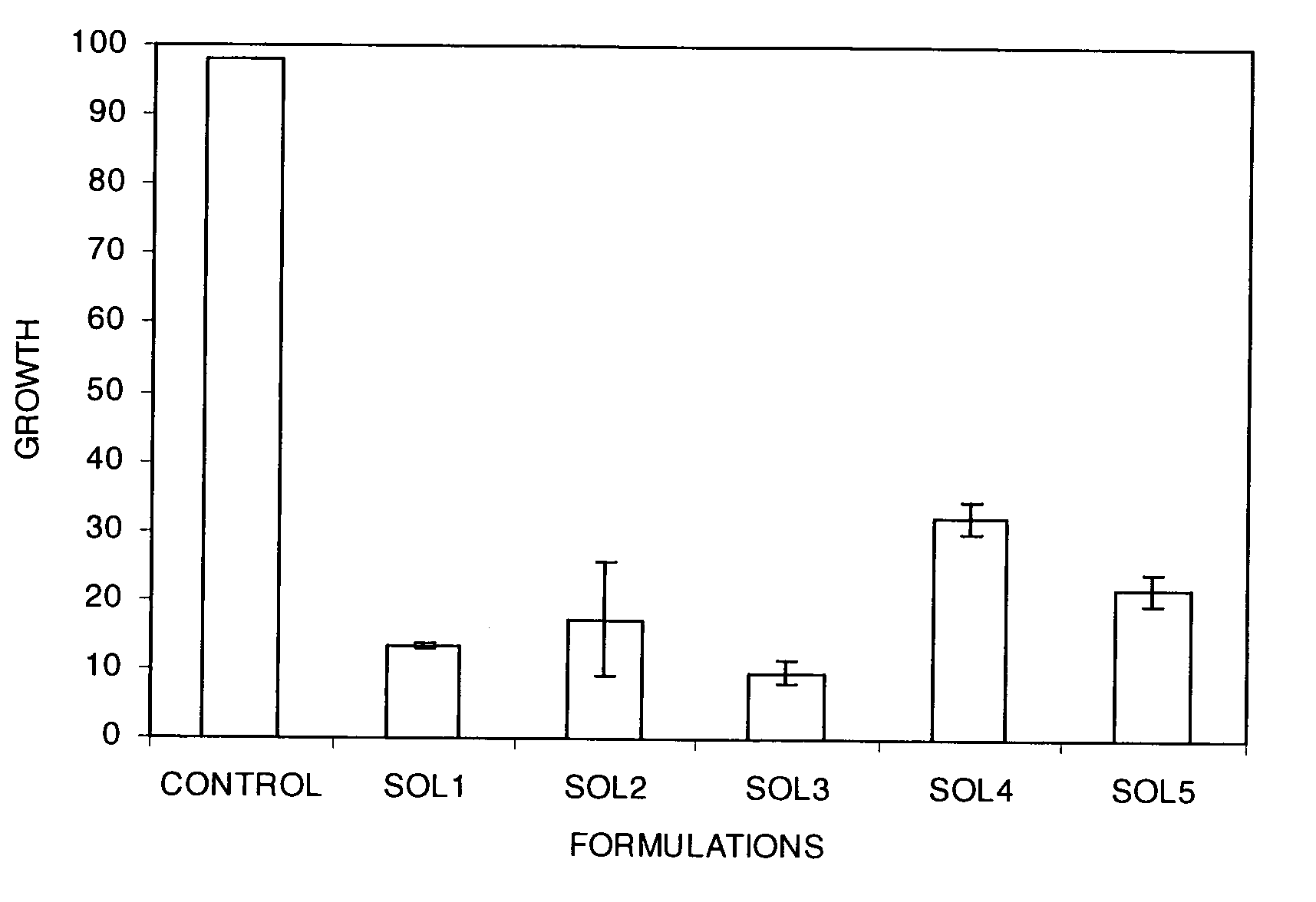

Liquor that avoids the apparition of stains produced by fungi in lignocellulosic materials such as wood

Treatment process of wood and lignocellulosic materials with an aqueous liquid that contains alkaline oxalate and benzoate, which, in contact with humid or dry wood, avoids the formation of the blue stain and stains of other colors produced by fungi. This way it avoids the strong devaluation of the stained wood and has advantages on compounds used for that aim at the present time

Owner:SEEGER BURKHARD JULIN

Field separation method for tomicus piniperda-associated bacteria

The invention discloses a field separation method for tomicus piniperda-associated bacteria. The method comprises the following steps: determining a tomicus piniperda invasion hole on a suffered pine tree in a forest, peeling off the surface bark of the mother gallery of tomicus piniperda pests along the direction of the mother gallery of the tomicus piniperda pests by taking the invasion hole as an origin, so as to expose the phloem tissues of the eaten mother gallery of the tomicus piniperda, if larvae galleries are already formed at the both sides of the mother gallery, exposing the larvae galleries, inspecting and confirming whether the spores, hyphae, perithecia and blue-stain phloem tissues of tomicus piniperda-associated bacteria exist in the various eaten galleries of the tomicus piniperda, and adopting corresponding separation measures for the tomicus piniperda-associated bacteria according to the growth and development progresses and the blue-stain phloem tissue conditions of the tomicus piniperda-associated bacteria. The method disclosed by the invention integrates field sampling with laboratory strain separation, and is simple in steps and convenient to operate; the separation obtaining success rate of the tomicus piniperda-associated bacteria is high; the many links of bringing the wood blocks infected by the associated bacteria or the phloems with galleries, and the blue-stain tissues back to a laboratory at first, and then separating are effectively simplified, the separation time for the associated bacteria is saved, the separation is accurate, and the separation efficiency is increased.

Owner:YUNNAN UNIV

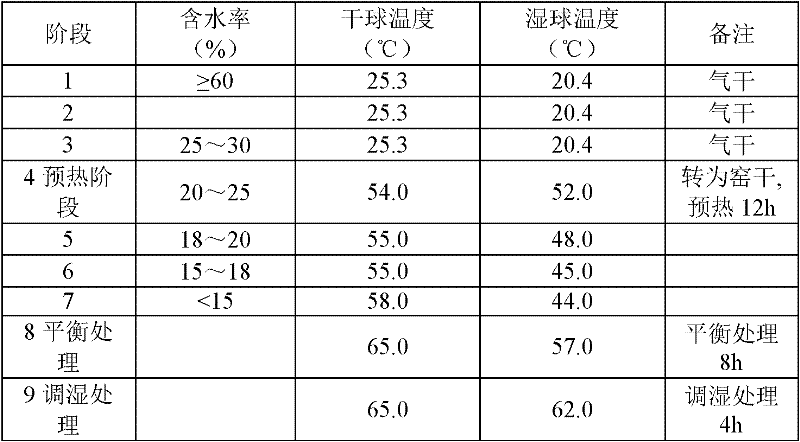

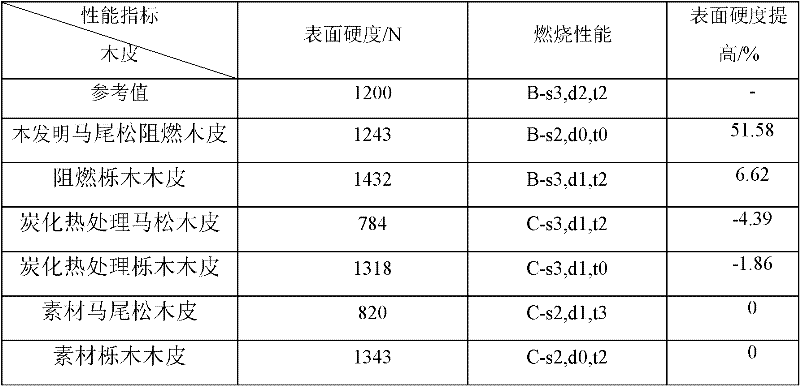

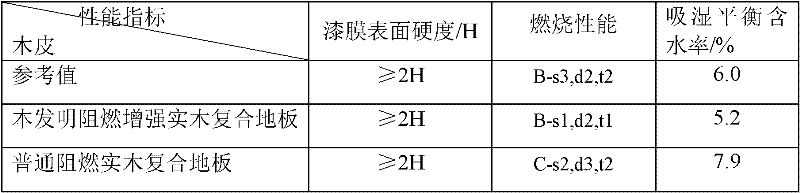

Fast-growing wood flame-retardant reinforced wood veneer and method for producing same

ActiveCN102303336AStrong corrosion and weather resistanceOvercoming the problem of not being flame retardantWood charring/burningWood veneerWeather resistance

The invention relates to wood functional improvement methods, in particular to a fast-growing wood flame-retardant reinforced wood veneer which is improved through the processes of wood charring heat treatment and flame-retardant reinforcement treatment, and a method for producing the same, belonging to the technical field of wood functional improving and wood processing. The method for producing the fast-growing wood flame-retardant reinforced wood veneer comprises the following steps of: (1) wood veneer manufacturing; (2) first-time superposing and drying; (3) charring heat treatment; (4) flame-retardant reinforcement treatment; and (5) second-time superposing and drying. The advantages of the charring heat treatment and the flame-retardant reinforcement treatment are gathered, and the defects of the charring heat treatment and the flame-retardant reinforcement treatment are overcome, so that the fast-growing wood flame-retardant reinforced wood veneer which is obtained through processing has the advantages of high dimensional stability, strong corrosion resistance and weather resistance, even penetration for flame retardant, good flame-retardant effect, high surface hardness, full color and luster for appearance of grains, simple production equipment and high out-turn percentage; and meanwhile, the defects that the traditional wood veneer is easy to be subjected to tile deformation and cracking, and the fast-growing wood veneer is easy to be subjected to mildewing, blue stain and rotting are overcome.

Owner:贵州保城新材料有限公司

Albumin-bound near-infrared fluorescent dye-maleimide conjugate

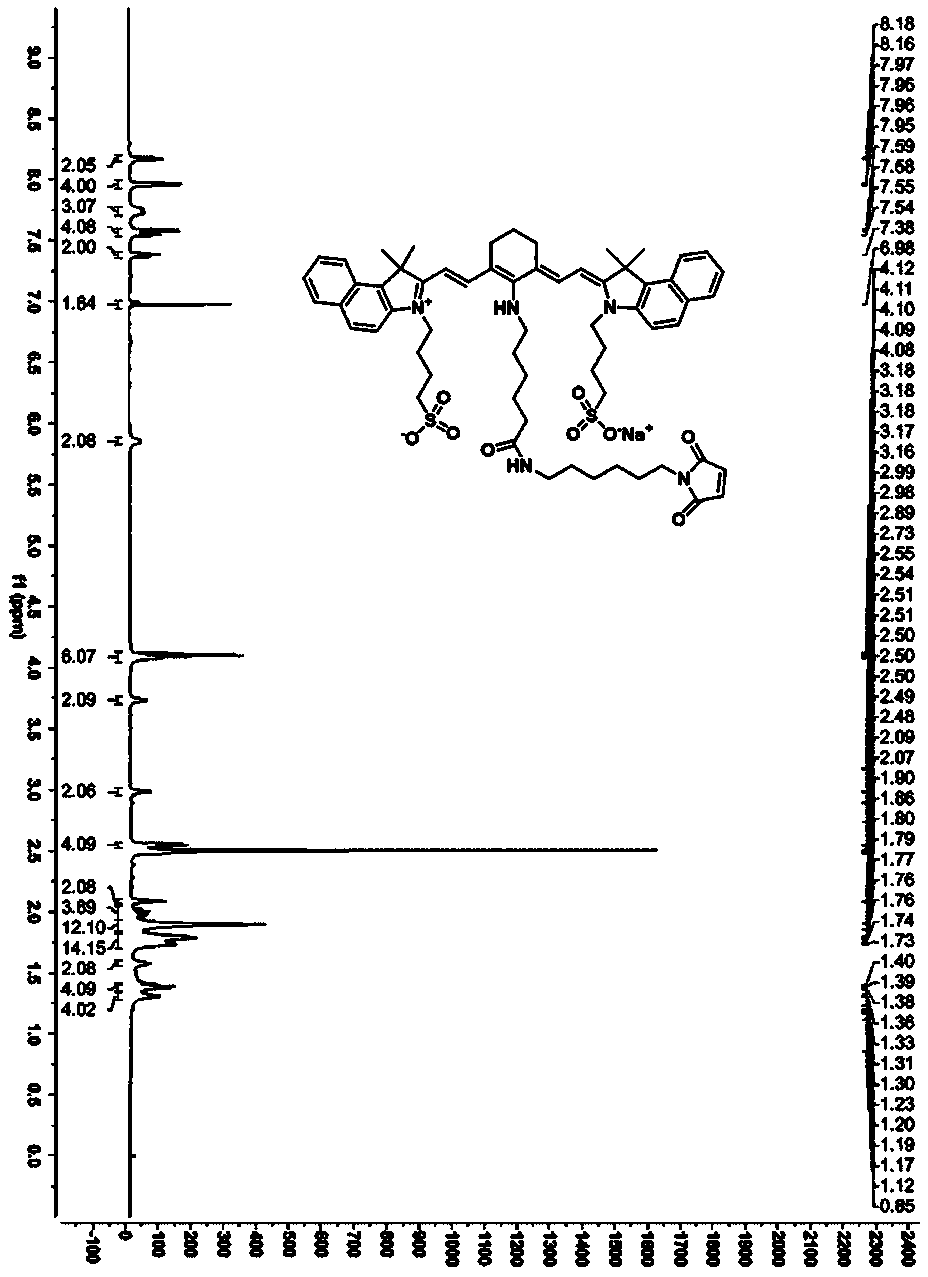

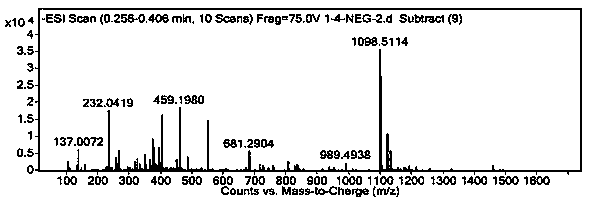

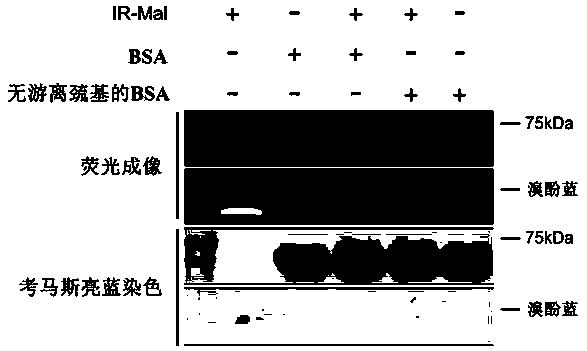

ActiveCN110201189AHas the ability to targetHave targeting abilityLuminescence/biological staining preparationGeneral/multifunctional contrast agentsDual imagingBiological imaging

The invention belongs to the technical field of medicine and relates to an albumin-bound near-infrared fluorescent dye-maleimide conjugate. The albumin-bound near-infrared fluorescent dye-maleimide conjugate specifically replaces chlorine in the conjugated chain of the cyanine dye with a group containing maleimide, and the optical properties are modified by intramolecular charge transfer effects to enable the conjugate to be used as a blue bio-dye. Secondly, the maleimide group in the conjugate can be covalently bound to a free sulfhydryl group at position 34 of cysteine on plasma albumin by aMichael addition reaction, so that the conjugate has excellent lymph node targeting. A near-infrared fluorescent biological imaging agent overcomes the defects of an imaging method used in clinical sentinel lymph node navigation surgery, and is safe, reliable, accurate in positioning, and high in imaging efficiency. The two imaging modes, blue-stained macroscopic recognition and near-infrared fluorescence imaging, are integrated to enable dual imaging function of lymph nodes in vivo.

Owner:SHENYANG PHARMA UNIVERSITY

Manufacturing method for novel recombinant wood

The invention discloses a manufacturing method for novel recombinant wood. The process steps are as follows, 1), rubber wood, cotton wood, cedar wood, ailanthus altissima and other small-diameter-grade logs easy to blue stain, brush wood, a rotary-cutting veneer processing residue and the like are used as raw materials, and undergo rolling and defibering to form wood bunches which is loose in thetransverse direction and do not crack in longitudinal direction to serve as constituent units; 2), the 0.1mol / L of the NaoH and the sodium pyrophosphate mixed solution which is diluted to reach the PHvalue of 9.0-11.0 through the deionized water is used for quenching and tempering the wood bunches; and 3), the quenched and tempered wood bunches undergo drying, glue dipping, hot pressing and otherprocesses to prepare the recombinant wood. The method has the advantages of being high in raw material utilization rate, good in impregnating effect and the like, the prepared recombinant wood has excellent mechanical properties and better dimensional stability; and in addition, the method further has the advantages of being high in production efficiency and low in energy consumption.

Owner:LIANYUNGANG NANFANG WOOD IND CO LTD

Composition and method of manufacturing the same

ActiveUS20200039106A1Maintain good propertiesEasy to keepWood treatment detailsPressure impregnationBlue stainFire retardant

Fire retardant composition for treatment of various wood products, method of producing the same and uses thereof. The compositions comprise an aqueous solution of bisphosphonate selected from 1-hydroxyethane 1,1-diphosphonic acid, an alkanol amine, and optionally an alkaline agent, the composition having a pH in the range of 4.0 to 7.0. The composition can be produced by mixing together 30 to 50 parts by weight of 1-hydroxyethane 1,1-diphosphonic acid; 1 to 10 parts by weight of an alkanol amine or mixture thereof, said alkanol amine being added in free form; and optionally 0.1 to 40 part by weight of an alkaline agent; and water. The compositions can be used for protecting wood not only against fire but also against mould, rot, blue stain, insect such as termite attacks on wood, dimensional changes, or a combination thereof due to environmental influence.

Owner:PALONOT OY

Autoclaving rapid forming production method of solid wood arc component

InactiveCN108621272AIncrease profitHigh strengthWood treatment detailsWood stock bendingSolid woodEngineering

The invention discloses an autoclaving rapid forming production method of a solid wood arc component. The method is characterized by comprising the following steps: cutting the external dimension of apanel into component dimension in a softening technology, ensuring that the reserved tolerance between the panel dimension and the component dimension is as follows: the length is 2cm, the width is 0.2cm, and the thickness is 0.1cm, putting the cut panel into a stainless steel water tank, leading saturated steam into the water tank to perform boiling, treating the panel for 15 to 40 minutes withthe saturated steam at 100 DEG C, adding an HB-60 softener into a water solution, and ensuring that the solid-containing content of the softener is 60, the PH value is 4 to 5, and the dilute concentration is 5 to 8 percent; adding 0.1 percent of oxalic acid into the water solution to prevent the phenomenon of wood blue stain during boiling. The method has the beneficial effects that the utilization rate of raw materials is high, compared with a sawing method, the utilization rate of raw materials is improved by 40 percent, the rejection rate is reduced by 15 percent, the labor efficiency is improved by 90 percent, the component strength is high, and the appearance is artistic; the boiling time is greatly shortened, the efficacy is improved, and energy is saved; the phenomenon of wood bluestain is avoided.

Owner:通化方圆木业有限公司

Pre-T vector and T vector composed of pre-T vector and application thereof

ActiveCN108588102APitfalls of Avoiding False Positive ClonesAvoid false positivesBacteriaMicroorganism based processesEnzyme digestionBlue stain

The invention belongs to the field of gene engineering and relates to a pre-T vector and a T vector composed of the pre-T vector and application thereof. The improved promoter is a recognition site for mutation from a nucleotide sequence from -35 region to -10 region in a promoter region into endonuclease. By the T vector, the problem that the product of transcription or translation of exogenous genes by a strong promoter during blue-white selection of a vector might be toxic to host and cloning will fail can be overcome, blue-white selection of a vector might be toxic to host as a strong promoter starts transcription or translation; the defect that delection of 1-2 bp at enzyme digestion site leads to lacZalpha gene frameshift mutation and false positive clones are generated can be avoided; and the false negative phenomenon that a plate is full of blue stains because exogenous DNA fragment is small and insertion of exogenous DNA does not change a reading frame of lacZalpha gene can beeliminated.

Owner:GENEWIZ INC SZ

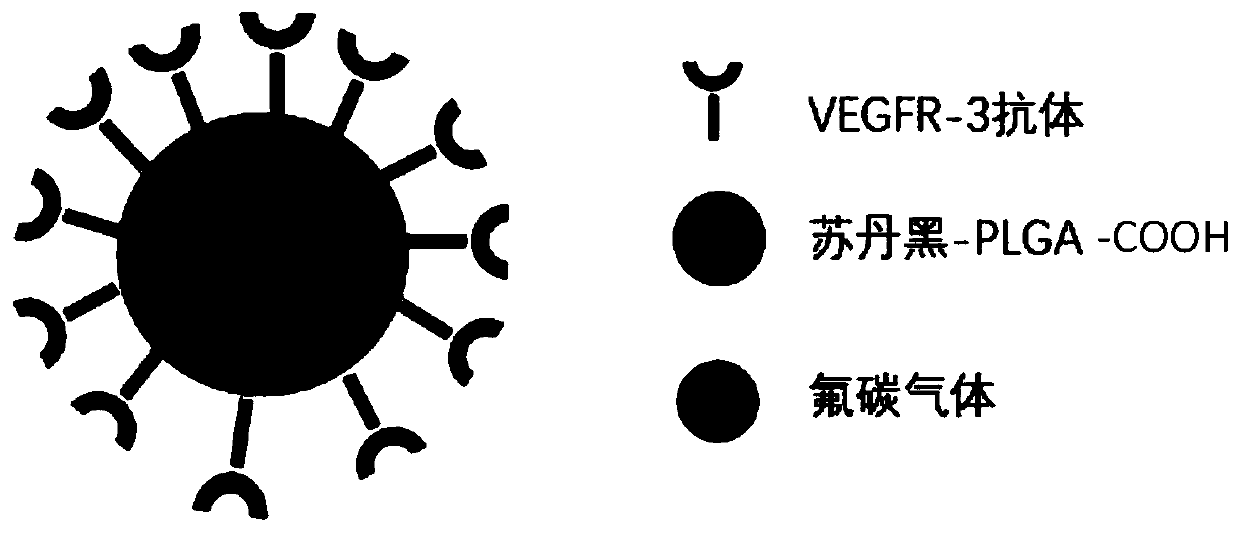

Multifunctional targeted ultrasound contrast agent and preparation method thereof

ActiveCN110327472APrecise positioningEffective positioningEchographic/ultrasound-imaging preparationsMicrocapsulesUltrasound contrast mediaMicrosphere

The invention discloses a multifunctional targeted ultrasound contrast agent. The contrast agent comprises carboxyl-terminated polylactic acid, wherein the carboxyl-terminated polylactic acid is filled with fluorocarbon gas to form carboxyl-terminated polylactic acid microspheres, the carboxyl-terminated polylactic acid loads Sudan black dye, and the carboxyl terminal of the carboxyl-terminated polylactic acid is coupled with an anti-human VEGFR-3 monoclonal antibody through a covalent bond. The contrast agent can more accurately and effectively perform positioning and be firmly combined on the surface of lymphatic endothelial cells, not only has strong target searching capability, but also has ultrasonic contrast imaging and intraoperative indication function, also has the function of preventing tumor metastasis, and is a multifunctional ultrasonic contrast agent with both blue staining trace effect and ultrasonic imaging effect and treatment. The invention also discloses a preparation method of the contrast agent, and the method utilizes a double emulsification method to prepare the ultrasonic contrast agent with the blue staining indication function, and uses EDC / NHS as a coupling activator, and covalently connects VEGFR-3 on the surface of the ultrasonic contrast agent. The method is simple and easy to operate, and is suitable for large-scale production.

Owner:THE SECOND XIANGYA HOSPITAL OF CENT SOUTH UNIV

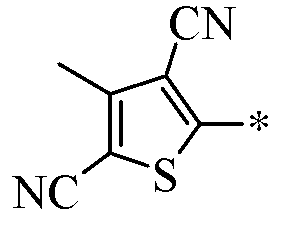

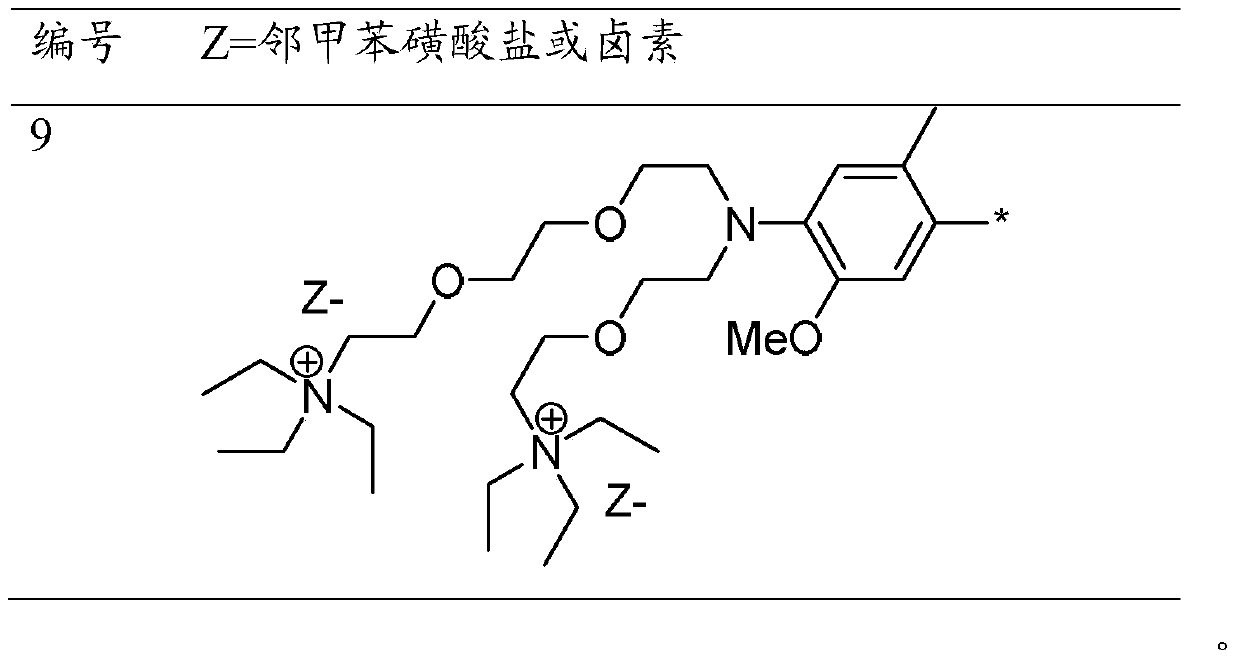

Thienylazo dye and clothes washing and caring composition with same

The invention relates to thienylazo dye, a clothes washing and caring composition with the same, and methods for manufacturing and applying the thienylazo dye and the clothes washing and caring composition. The thienylazo dye is used as a color matching agent. The thienylazo dye comprises formally electric portions and generally comprises at least two components including at least one chromophore component and at least one polymer component. The suitable chromophore component can generally emit blue, red, violet or purple fluorescence or absorb light so as to reflect blue, red, violet or purple hues when exposed in ultraviolet light. The thienylazo dye, the clothes washing and caring composition and the methods have the advantages that the thienylazo dye is favorable for realizing color matching effects such as whitening effects for fabrics, and can be prevented from being accumulated along with time, and inadvisable blue stain of the processed fabrics can be prevented; the thienylazo dye is generally stable for bleaching agents for the clothes washing and caring composition.

Owner:THE PROCTER & GAMBLE COMPANY

Method for eliminating bluing of woods

InactiveCN107225638ADoes not affect machining operationsAffect colorWood treatment detailsPretreatment apparatusScavengerBlue stain

The invention discloses a method for eliminating wood staining, which includes the following steps: (1) using a special degreasing liquid for wood to remove oil stains on the surface of wood; (2) placing the wood horizontally on the ground, and drilling the wood in the middle Small holes, and then drill holes from the middle of the wood to both ends according to the interval of 1.5-2m. The depth of each small hole is 4-8cm and the diameter is 4-6cm; (3) Fill the small holes with wood blue Remove the blue stain, and apply the wood blue stain remover on the cut surface at both ends of the wood. The method for eliminating the blue stain of wood provided by the invention has simple operation steps, and the treatment liquid is safe and environmentally friendly, will not cause harm to the health of the operator and the environment, and the treatment effect is good. The color of the treated wood is very close to that of the original wood, and it is rich in natural materials. sense, will not affect the subsequent wood processing operations.

Owner:安徽宏润工艺品有限公司

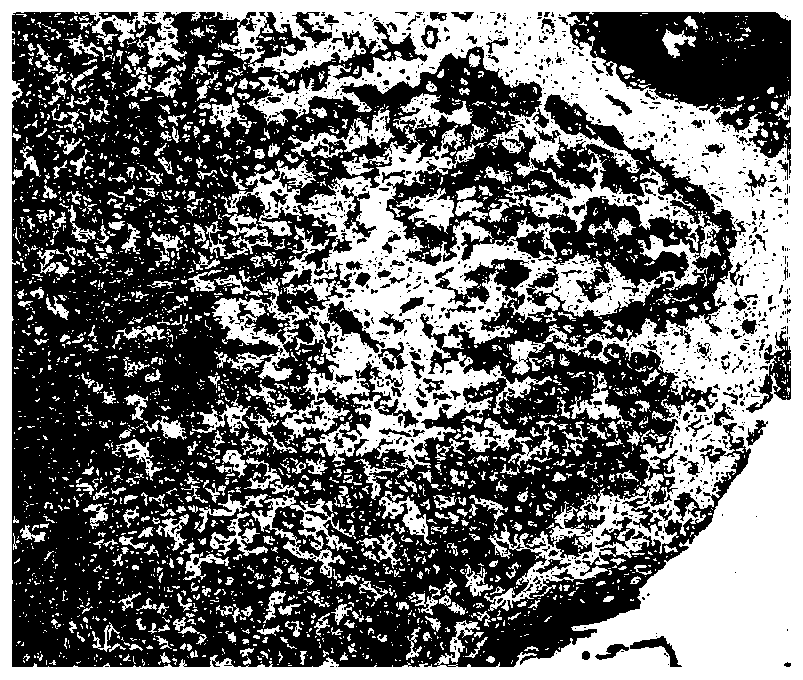

Immunohistochemical staining kit containing pigment tissues and staining method

The invention relates to an immunohistochemical staining kit containing pigment tissues and a staining method, belonging to the technical field of immunostaining. In the staining kit, a peroxidase block can block endogenous peroxidase of tissues, so as to prevent the endogenous peroxidase from affecting a staining result; a peroxidase-labeled secondary antibody polymer is based on a HRP enzyme labeling system and has high sensitivity; a blue stained substrate based on a peroxidase system and a blue stained buffer solution matching the blue stained substrate make up the blue stained color developing solution, under catalysis of the HRP enzyme, the blue stained color developing solution forms blue granular precipitates that can be observed under a microscope. The positive part of the tissuecan be positioned accurately, the signal is clear, the blue granular precipitates are in sharp contrast to color substances (melanin or carbon particles), and the immunohistochemical result is clear and distinctive. The enzyme labeling system in the invention has high sensitivity, high specificity, and has a clear staining background.

Owner:河南赛诺特生物技术有限公司

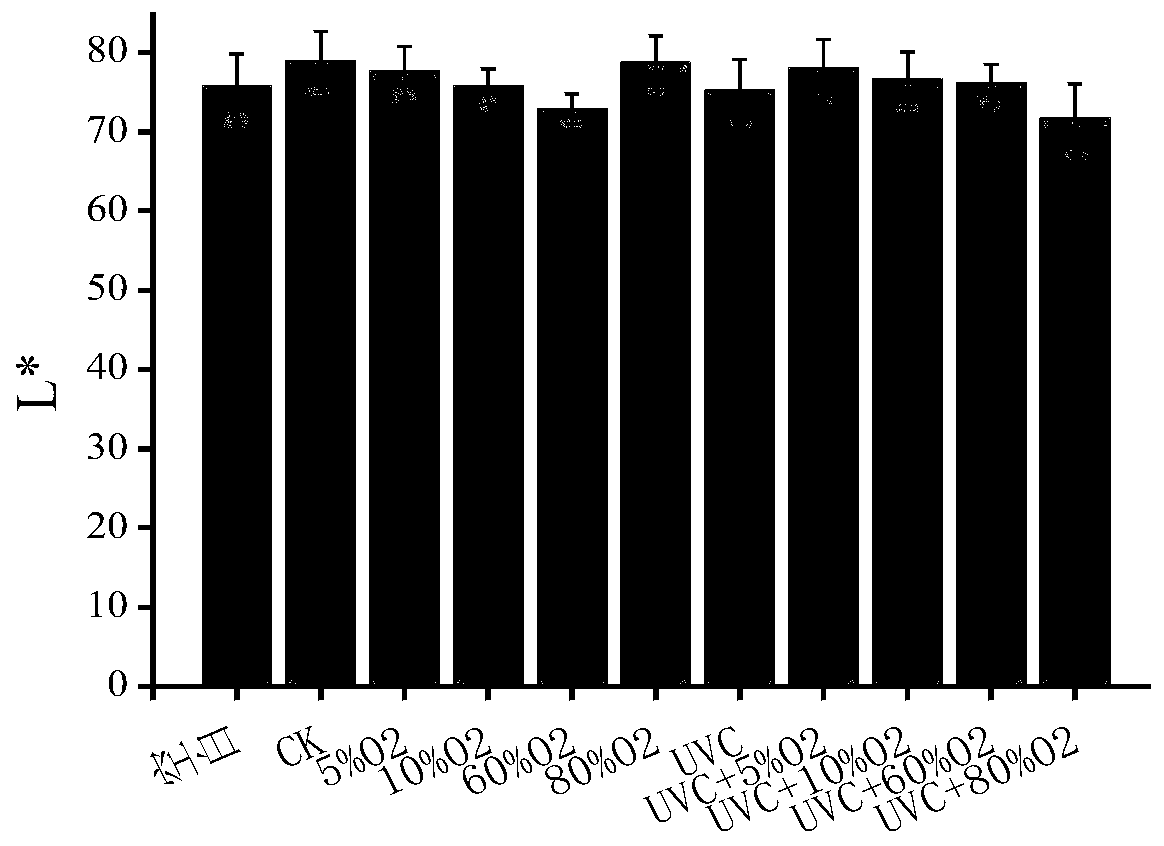

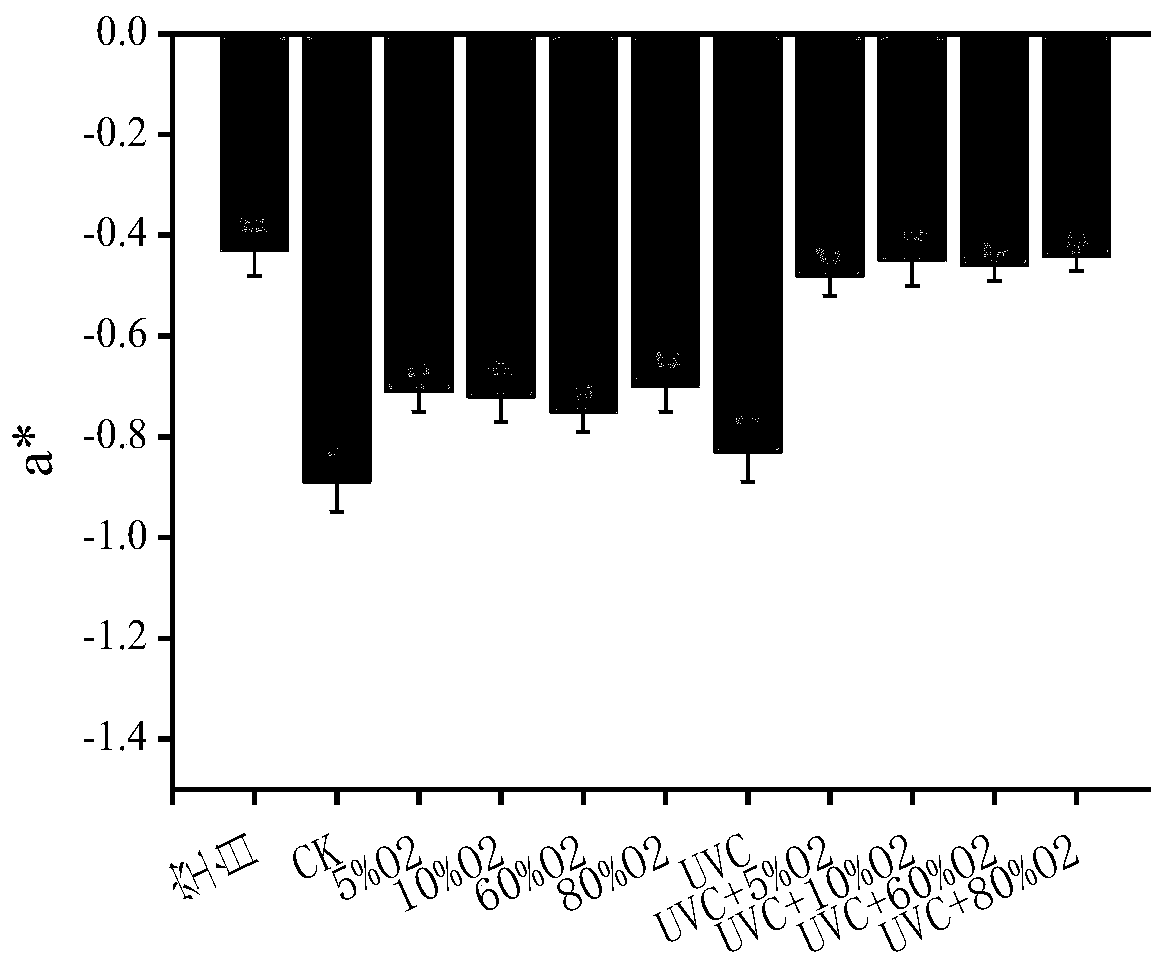

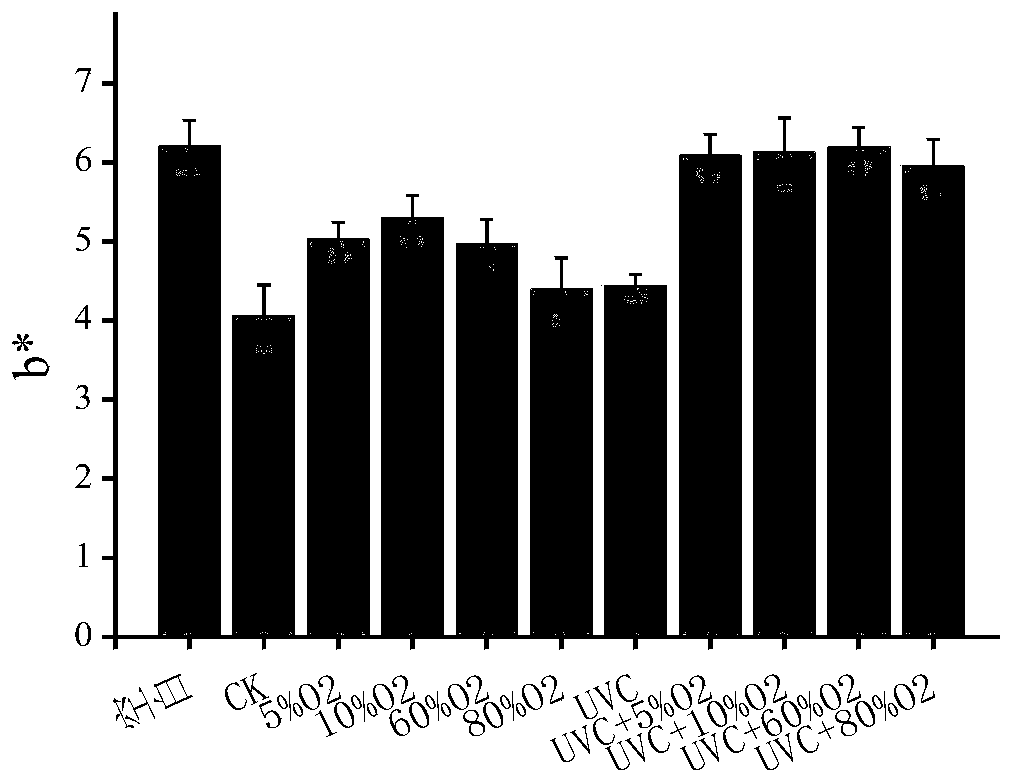

Color protecting method for inhibiting blue stain of white turnip

ActiveCN110771678AControl blue stainFruits/vegetable preservation by irradiation/electric treatmentPhysiologyNitrogen gas

The invention discloses a color protecting method for inhibiting blue stain of a white turnip. The color protecting method comprises the following steps that UVC is adopted to irradiate the white turnip, and then oxygen-containing gas is adopted to conduct gas flush packaging treatment on the white turnip; after gas flush packaging treatment, the oxygen-containing gas is released, and then storageis conducted; and the oxygen-containing gas is mixed gas of oxygen and nitrogen. The white turnip is synergistically treated through UVC irradiation and oxygen, then storage is conducted under the normal condition, thus the blue stain phenomenon of the white turnip can be effectively controlled, for example, the white turnip is stored under the normal temperature condition (the temperature is 23-28 DEG C, and the relative humidity is 30-40%) for 5 days, then the treated white turnip is longitudinally cut for observation of color change, and it is found that blue stain does not occur.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

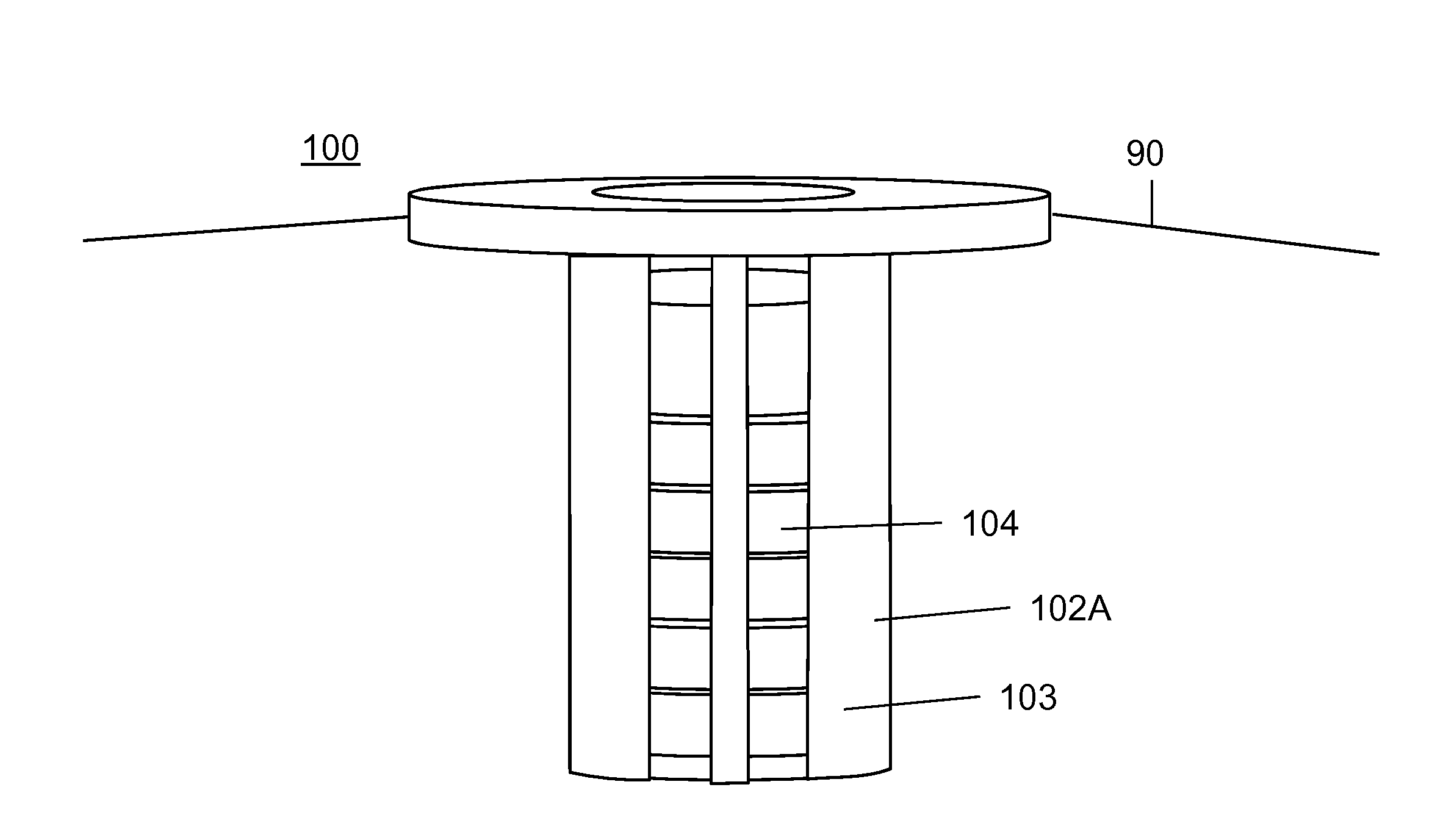

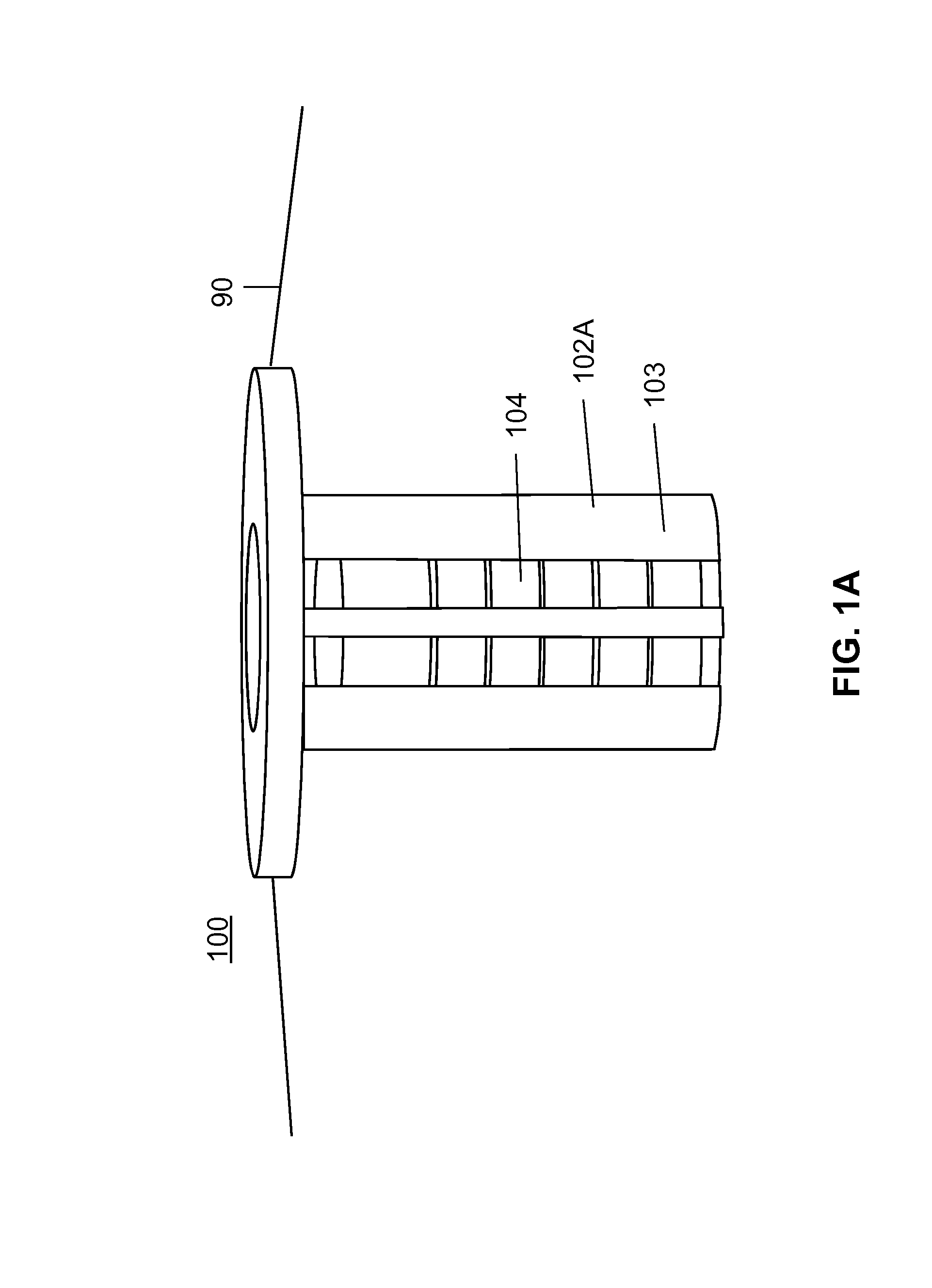

System and methods for pest reduction

The present invention includes a new type of bait for wood-targeting pest baiting systems and methods of obtaining the bait. Certain embodiments of the present invention include a blue-stained wood either treated with a solution that includes blue-stain fungi or wood naturally infected with blue-stain fungi. Additional embodiments of the present invention include a blue-stained solution that may be applied to a wood substrate or to a non-wood bait matrix.

Owner:MISSISSIPPI STATE UNIVERSITY

Methods for detecting compression wood in lumber

Owner:WEYERHAEUSER NR CO

Methods for detecting pitch in lumber

ActiveUS7679752B2Scattering properties measurementsOptically investigating flaws/contaminationLight beamBlue stain

Methods are provided for detecting compression wood, blue stain, or pitch in lumber. A light beam is projected towards the wood sample. Line or area cameras acquire images of light that is reflected from the wood sample. Based on the intensity of the reflected light at one or more locations on the wood sample, compression wood, blue stain, or pitch may be detected.

Owner:WEYERHAEUSER NR CO

Printing and dyeing method for controlling reactive brilliant blue staining dyeing-defect phenomena

The invention relates to a printing and dyeing method for controlling reactive brilliant blue staining dyeing-defect phenomena. The method includes the following steps that step one, a fabric is taken and undergoes pretreatment; step two, the temperature in a constant-temperature dye vat is adjusted to be 30-38 DEG C and then alkali is added; reactive brilliant blue is added after 10-15 minutes; heating is performed to reach the temperature of 60-70 DEG C, and the fabric is put into the dye vat to undergo dip dyeing for 20-30 minutes; then, heating is performed to reach the temperature of 80-90 DEG C, and dip dyeing is performed for 20-30 minutes; cooling is performed to reach the temperature of 75-85 DEG C, and heat preservation is performed for 10-20 minutes; step three, the dip-dyed fabric is taken out to undergo washing, color fixation and drying. By the adoption of the printing and dyeing method, the sensitivity of the reactive brilliant blue to the dyeing conditions can be effectively reduced, the dyeing-defect problems easily produced by using the reactive brilliant blue can be effective solved, the dyeing effect of the reactive brilliant blue and the production efficiency are greatly improved, and the printing and dyeing method has very good practical production and application value.

Owner:NANTONG XIANLE DYED CO LTD

Maple wood board degreasing method

InactiveCN108943236APrevent blue stainPrevent heat discolorationWood treatment detailsWood impregnation detailsPentachlorophenolSulfite salt

The invention discloses a maple wood board degreasing method. The maple wood board degreasing method comprises the following steps that A, the maple wood board surface is sprayed utilizing a pentachlorophenol sodium solution with the concentration being 1-3% and placed for 0.5-1 h to obtain a product A; B, the product A surface is sprayed utilizing a sodium sulfite solution with the concentrationbeing 2-5% and placed for 0.5-1 h to obtain a product B; C, the product A is subjected to suffocating in steam with the temperature being 180-220 DEG C, the suffocating time is 1-2 h, and a product Cis obtained; D, the product C is placed into a container to be subjected to stewing utilizing an alcoholic solution with the concentration being 50-60%, the stewing time is 4-6 h, and a product D is obtained; E, the product D is dried with the temperature being 120-150 DEG C till the water containing rate of a maple wood board is 12-16%, and the maple wood board is cooled to 20-30 DEG C to obtaina finished product. The maple wood board degreasing method has the characteristics that no blue stain is generated, and the degreasing efficiency is high.

Owner:湖州亨力木业有限公司

Composition and method of manufacturing the same

ActiveCN110612183AImprove fire resistanceImprove stabilityWood treatment detailsPressure impregnationEngineeringFire retardant

A fire retardant composition for treatment of various wood products, a method of producing the same and uses therof. The composition comprises an aqueous solution of bisphosphonate selected from 1-hydroxy ethane 1,1-diphosphonic acid, an alkanol amine, and optionally an alkaline agent, the composition having a pH in the range of 4.0 to 7.0. The composition can be produced by mixing together 30 to50 parts by weight of 1-hydroxyethane 1, 1-diphosphonic acid; 1 to 10 parts by weight of an alkanol amine or mixture thereof, said alkanol amine being added in free form; and optionally 0.1 to 40 partby weight of an alkaline agent; and water. The compositions can be used for protecting wood not only against fire but also against mould, rot, blue stain, insect such as termite attacks on wood, dimensional changes, or a combination thereof due to environmental influence.

Owner:PALONOT OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com