Composition and method of manufacturing the same

A technology of composition and mixture, applied in the direction of chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve the problems of increasing processing costs, etc., and achieve cost-effective, excellent wood permeability, and excellent fire resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0061] Alternatively, when the alkaline agent is ammonia, the bisphosphonic acid may be incorporated, or at least partially incorporated, in the form of a bisphosphonate, as described above. Therefore, according to some embodiments of the invention, the composition comprises:

[0062] - 0.1-70 wt%, preferably 1.0-60 wt%, for example 20-50 wt% of 1-hydroxyethane 1,1-diphosphonic acid or 1-hydroxyethane 1,1 in the form of a basic reagent salt such as ammonium salt - mixtures of diphosphonic acids and other bisphosphonic acids or bisphosphonates and / or other organic phosphonates, based on the amount of dissolved ingredients in the composition; and

[0063] - 1-30% by weight of alkanolamine or mixture of alkanolamines, based on the amount of dissolved ingredients in the composition.

[0064] Adding ammonia in the form of a bisphosphonate as an alkaline agent reduces the amount of free ammonia in the final solution, thereby reducing the ammonia odor and preventing discoloration of...

Embodiment 1

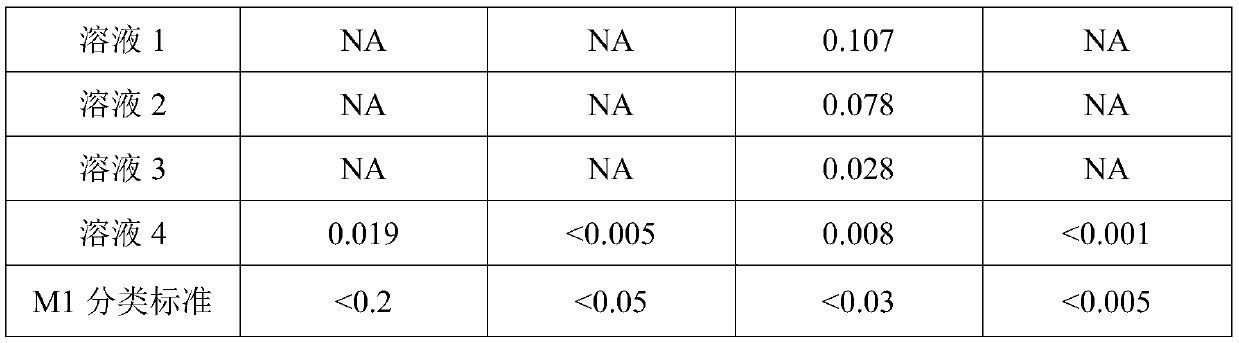

[0184] Example 1 - Emission measurement [research report NO.VTT-S-00351-17 and Report 338763]

[0185] Guideline:

[0186] 1. Chemical and sensory testing procedures for building materials. Version 22.1.2015 (www.rts.fi)

[0187] 2. SFS-EN SIO 16000-9 Determination of Emissions of Volatile Organic Compounds in Building Products and Furniture. Emission test chamber method.

[0188] 3. ISO 16000-6 Determination of volatile organic compounds in indoor and laboratory air by active sampling on a Texax-TA sorbent, thermal desorption, and gas chromatography using MS or MS-FID.

[0189] 4. EN 717-1 Wood-based panels - Determination of formaldehyde emission - Part 1: Determination of formaldehyde emission by combustion chamber method, October 2004.

[0190] 5. In-laboratory methods. Formaldehyde was determined using the spectroscopic acetylacetone method.

[0191] 6. In-laboratory methods. Determination of ammonium concentration (VTT) in room air.

[0192] 7. In-laboratory Me...

Embodiment 2

[0200] Example 2 - Fire resistance test according to EN-ISO 5660-1:2002

[0201] Before testing, the sample was adjusted to a constant volume under the conditions of room temperature 23°C and relative humidity 50%. Table 2 lists the 50kW / m 2 The ignition time and maximum heat release rate of the sample in the cone calorimeter test under the irradiance of .

[0202] Table 2 Test results according to EN-ISO 5660-1:2002

[0203] ignition time, s Maximum heat release rate, kW / m 2

[0204] Solution 3 according to the invention significantly increased the fire resistance of the treated plywood.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com