Patents

Literature

53 results about "Cone calorimeter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A cone calorimeter is a modern device used to study the fire behavior of small samples of various materials in condensed phase. It is widely used in the field of Fire Safety Engineering. It gathers data regarding the ignition time, mass loss, combustion products, heat release rate and other parameters associated with the sample's burning properties. The principle for the measurement of the heat release rate is based on the Huggett's principle that the gross heat of combustion of any organic material is directly related to the amount of oxygen required for combustion. Oxygen consumption calorimetry has made the measurement of heat release rate of a fire a routine part of fire testing for both research and for regulatory compliance. Heat release rate is a primary metric of fire size which is foundational in modern fire protection engineering. The device allows a sample to be exposed to different heat fluxes over its surface.Its name comes from the conical shape of the radiant heater that produces a nearly uniform heat flux over the surface of the sample under study.

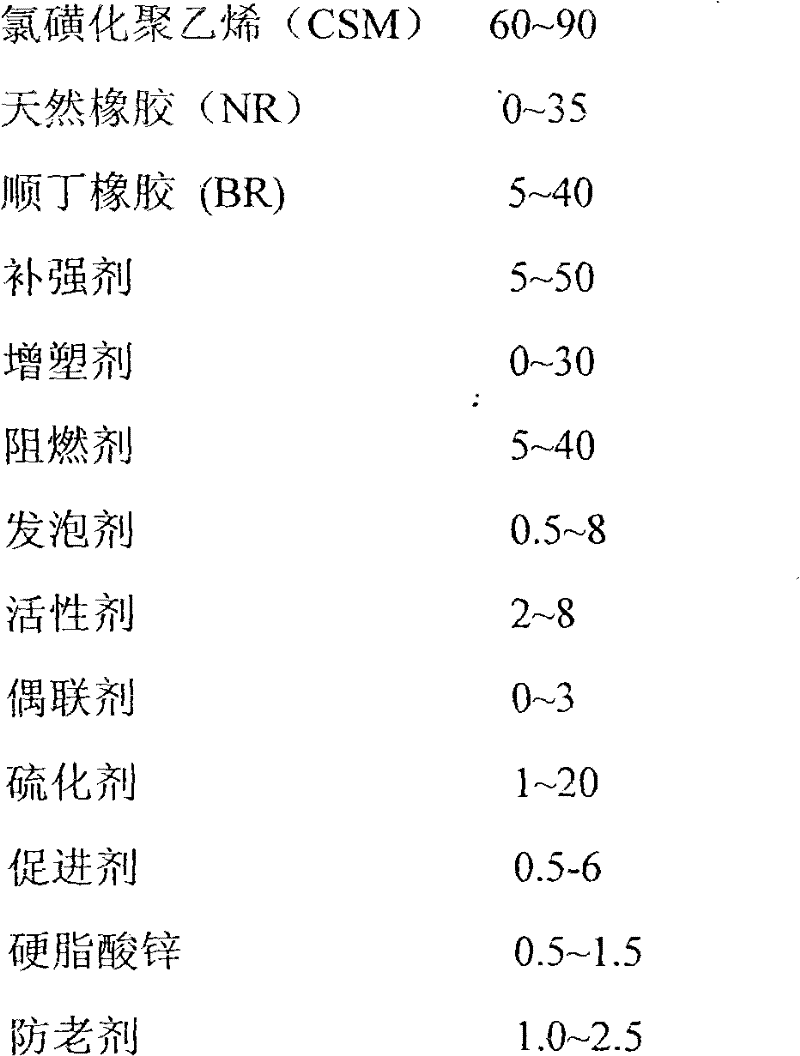

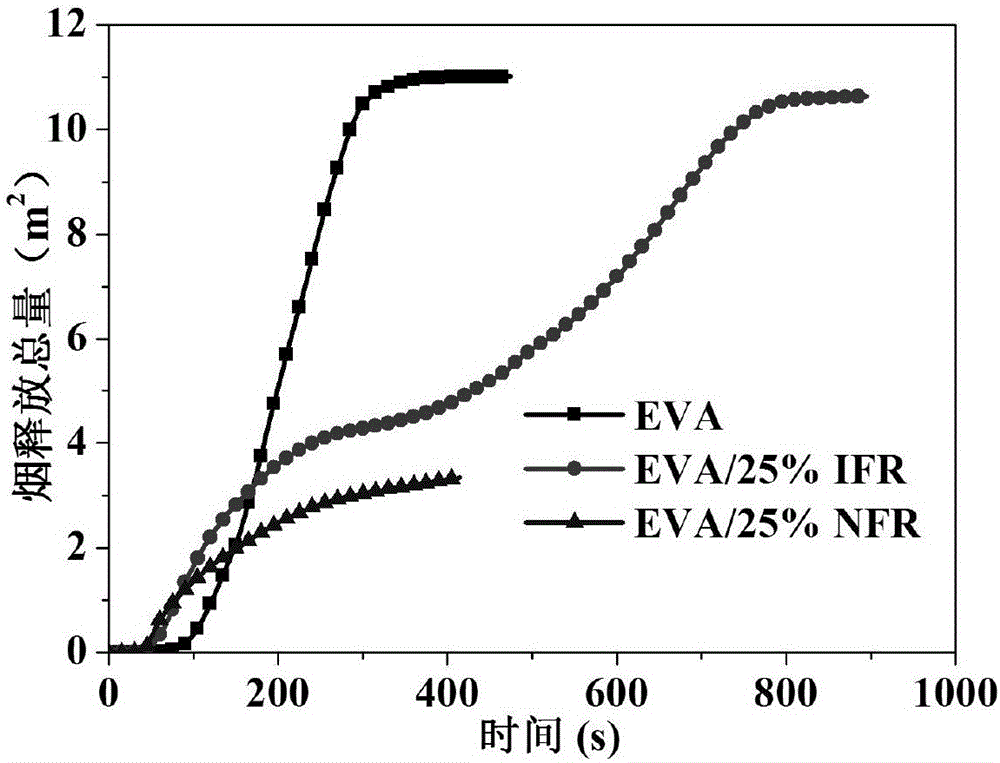

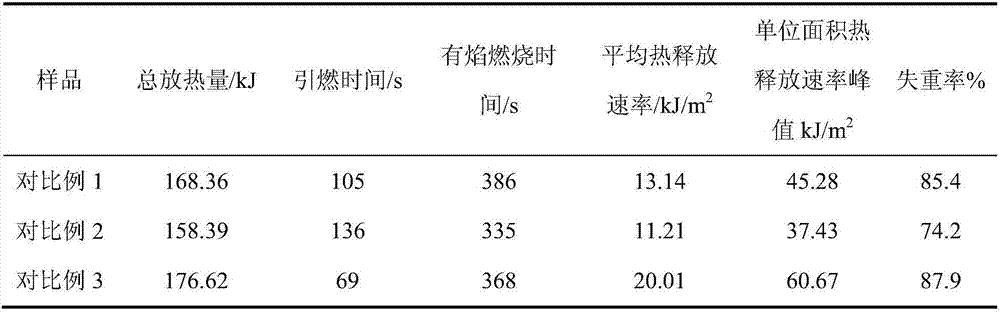

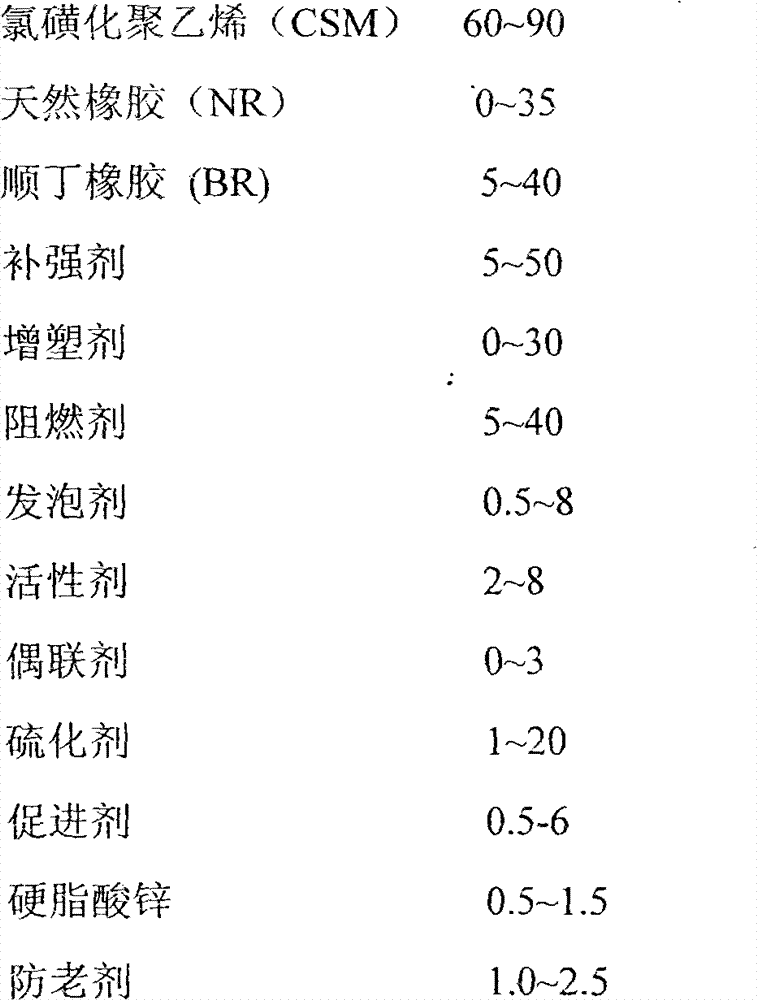

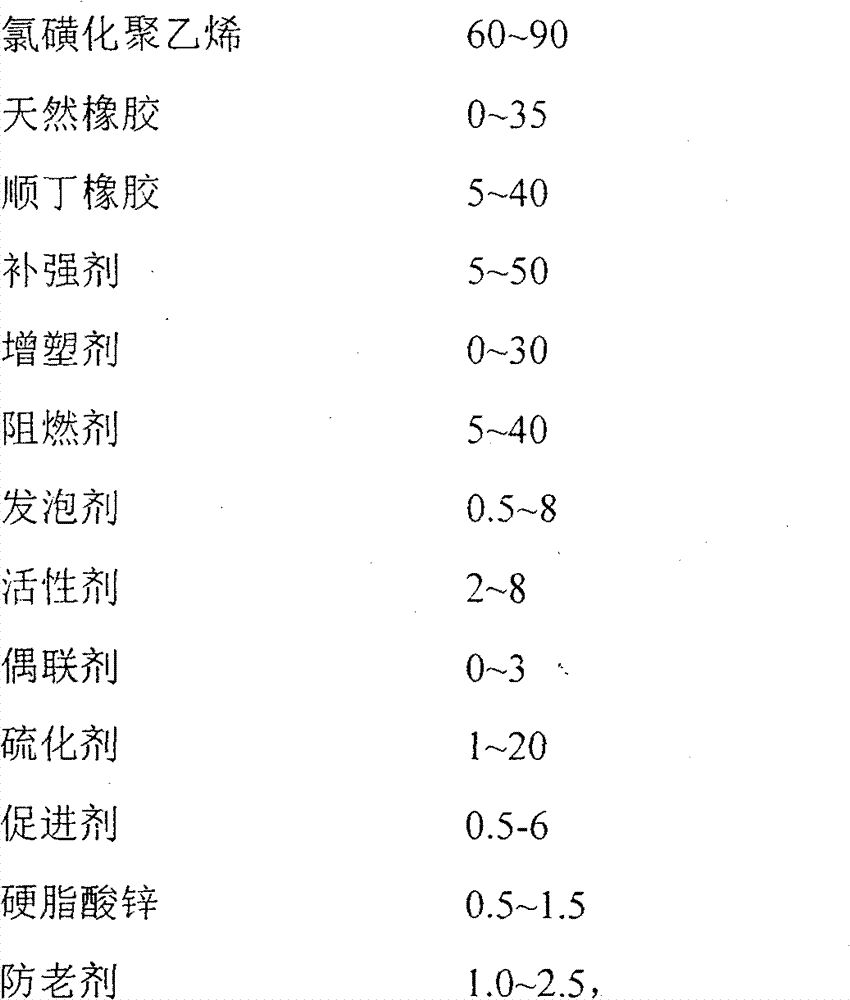

Lightweight, flame retardant and rubber foaming sole material and manufacturing method thereof

The invention relates to a rubber foaming sole material and a manufacturing method thereof, and especially relates to a manufacturing method of the sole footwear products which has high requirements on lightweighting, the flame retardation performance and the wear resistance. The material comprises the following compositions: a chlorosulfonated polyethylene rubber (CSM), a butadiene rubber (BR), a natural rubber (NR), a plasticizer, a strengthening agent, an activator, a coupling agent, a vulcanizing agent, an accelerating agent, and an antioxidant. In the invention, a series of sole materials are prepared through screening coupling agents, accelerating agents, activators, foaming agents, and fire retardants and reasonably controlling a technology on the basis of rubbers, softening oil and the strengthening agent, the lightweight and flame retardation footwear outsole material which has a density of 0.8-1.0g / cm<3> and has a maximum heat release rate of equal to or less than 110kW / m<2>and a DIN abrasion of equal to or less than 120mm<3> in tests with a tapered calorimeter is obtained through optimizing the formula and the technology. The material has the following advantages: 1, the specific gravity is light, and the flame retardation and the wear resistance are excellent; 2, the heat resistance and the light resistance are good, and the fire retardant is not easy to migrate from the surface; and 3, toxic gases of polybrominated dibenzo-p-dioxin (PBDD) and polybrominated dibenzo-furan (PBDF) are not released in combustion when a sole is discarded.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

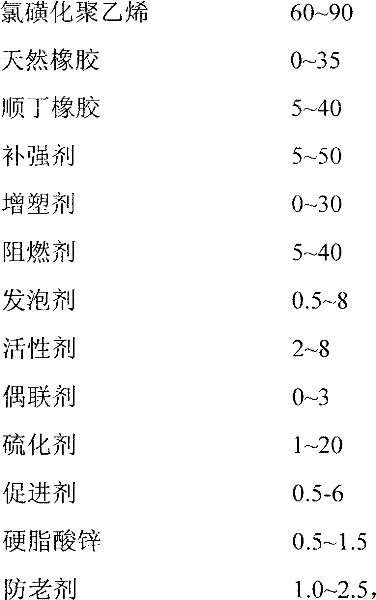

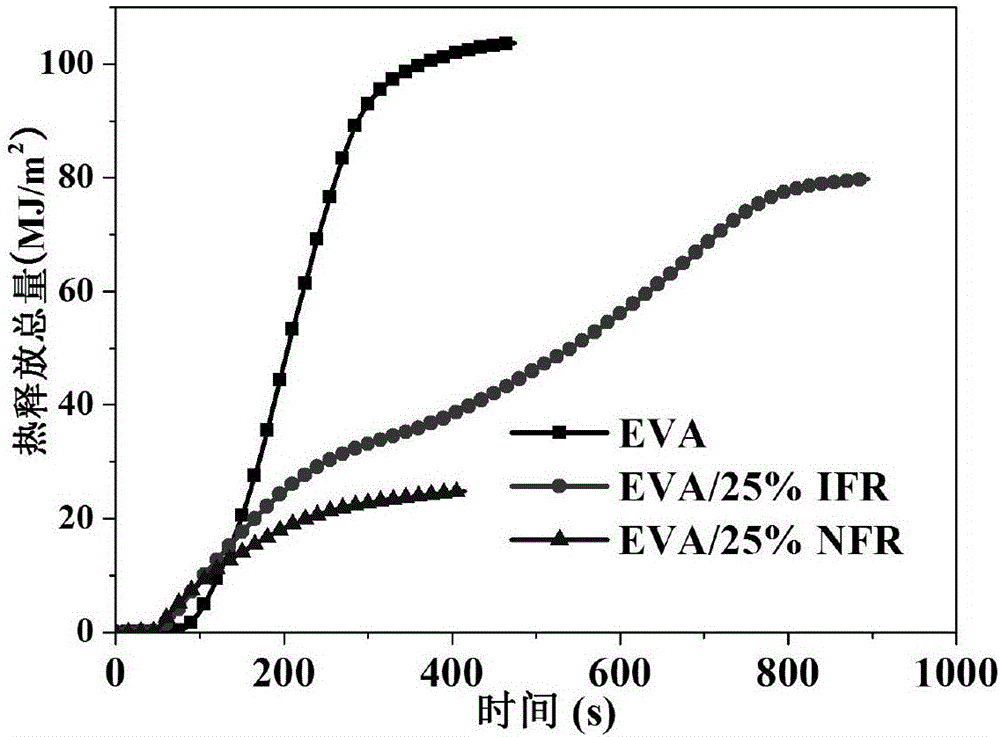

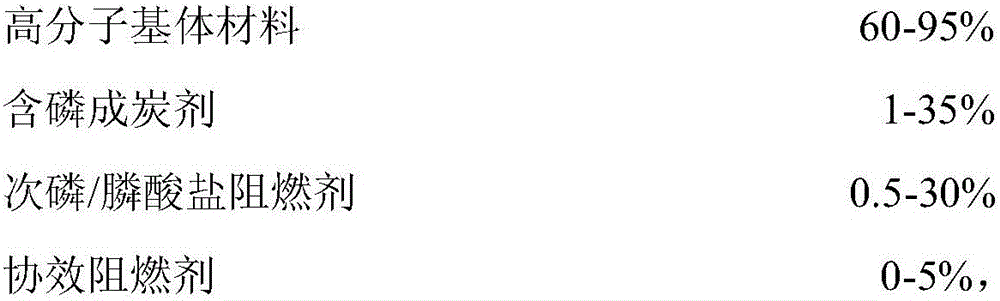

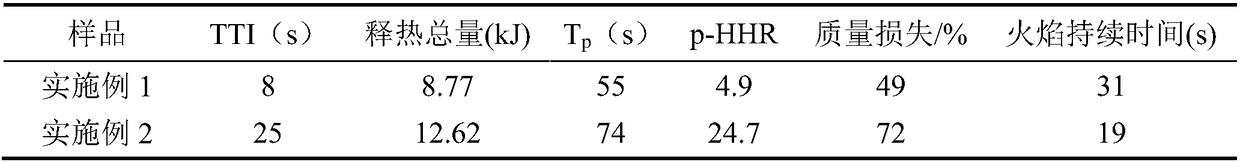

Flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite/phosphonate

ActiveCN106496729AHigh flame retardant efficiencyGood char formationPolymer scienceLimiting oxygen index

The invention discloses a flame-retardant high polymer material based on compounding of phosphorus containing char-forming agents and hypophosphite / phosphonate. The flame-retardant high polymer material is formed by blending, in weight percentage, 60-95% of high polymer base materials, 1-35% of phosphorus containing char-forming agents, 0.5-30% of hypophosphite / phosphonate and 0-5% of synergistic flame retardants. The compound main flame retardants used in the material have double char-forming functions, the material has excellent flame-retardant and smoke suppression properties, limit oxygen index reaches up to 27.0-49.5%, vertical burning test level ranges from UL-94V-1 to V-0, the total heat release of the material in cone calorimeter is reduced by 48.2-90.5% as compared with that of a pure base material, and total smoke release is reduced by 41.6-88.5%. Besides, the flame retardants used in the flame-retardant high polymer material have excellent water resistance, so that the material also has excellent water resistance, after the material is soaked in 70 DEG C for 168 hours and then dried, the vertical burning test level is unchanged, and the oxygen index is only reduced by 0-0.5%.

Owner:SICHUAN UNIV

Method for measuring combustion performance of powder or liquid sample by utilizing cone calorimeter

InactiveCN102175718AReduce dosageReduce production processMaterial heat developmentCombustionCrucible

The invention relates to a method for measuring the combustion performance of a powder or liquid sample by utilizing a cone calorimeter, disclosing a cone calorimetric testing method for a powder or liquid sample. The method provided by the invention comprises the following steps: firstly, turning on the cone calorimeter for preheating, carrying out the calibration of various indexes, and setting the needed radiation intensity; then, covering the inner wall of a crucible with an aluminum foil, placing to a sample holder, peeling, processing the sample to be processed, weighing a certain mass of the processed sample, and uniformly adding the weighed sample to the crucible; and finally, placing the crucible filled with the sample to the sample holder, performing experiments and collecting the data according to the operation specifications of the cone calorimeter. In the method provided by the invention, the manufacturing cost of the sample is effectively reduced; the sample consumption is reduced; the test time is simultaneously saved; and the application range of the cone calorimeter in the fields of the combustion performance test and combustion mechanism research of a material is enlarged.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

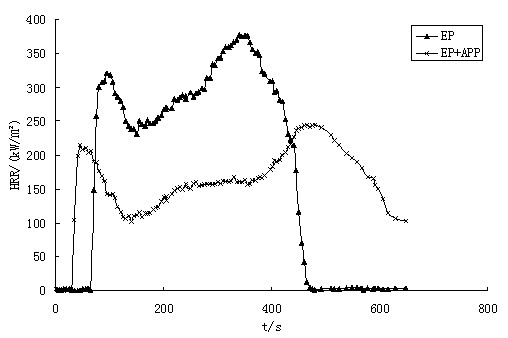

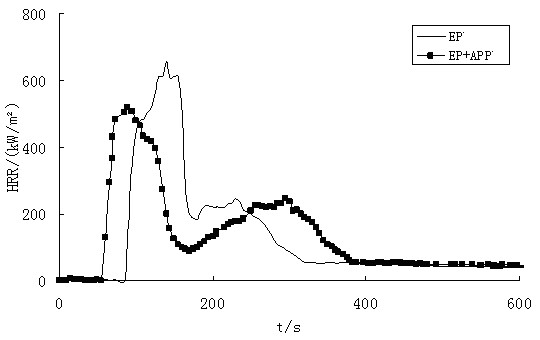

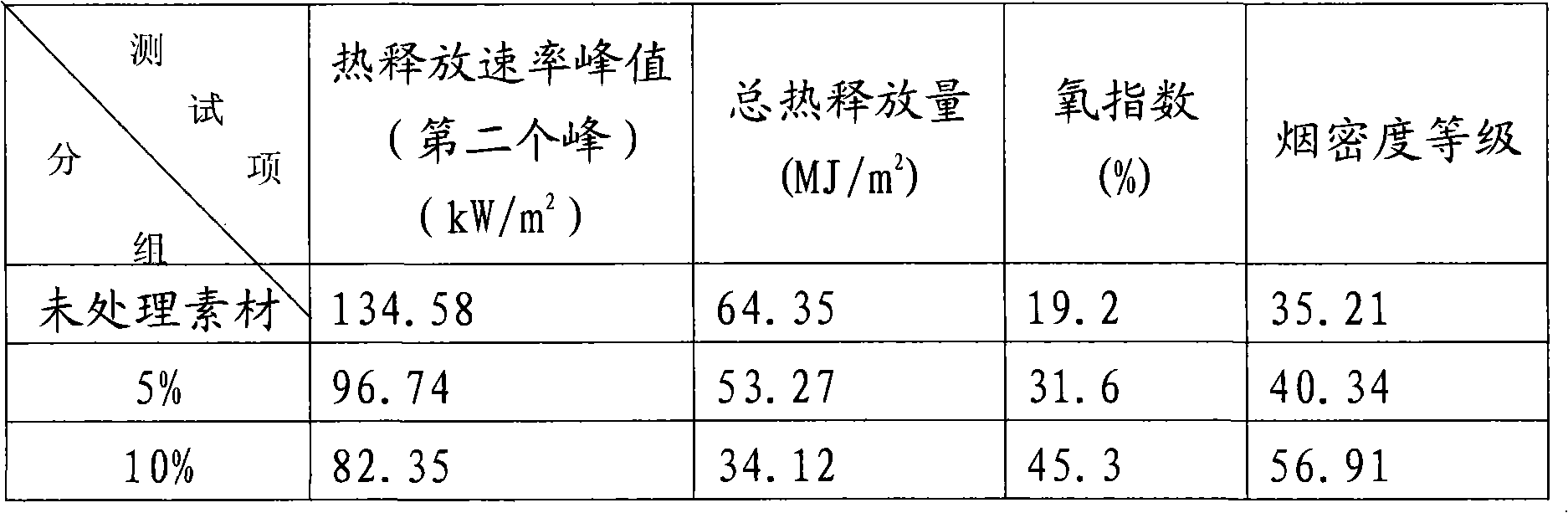

Preparation method of phosphate timber fire retardant and method for processing timber by using fire retardant

ActiveCN101982305AImprove flame retardant performancePromote expansionPressure impregnationOpen tank impregnationCarbon layerOrganic solvent

The invention provides a preparation method of phosphate timber fire retardant and a method for processing timber by using the fire retardant. The fire retardant prepared by the invention is expansible annular phosphate timber fire retardant which contains an acid source, a carbon source and a gas resource, has the advantages of good expansiveness, compact carbon layer and certain intensity, and has good antiflaming effect proved by the measurement of an oxygen index and smoke density and the analysis of a dual cone calorimeter. The fire retardant is insoluble in water but soluble in organic solvent. The method for processing timber by fire retardant has the advantages of complete dipping, large dipping depth and lasting antiflaming effect, the dipping time is shorter than common dipping time, and time is saved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

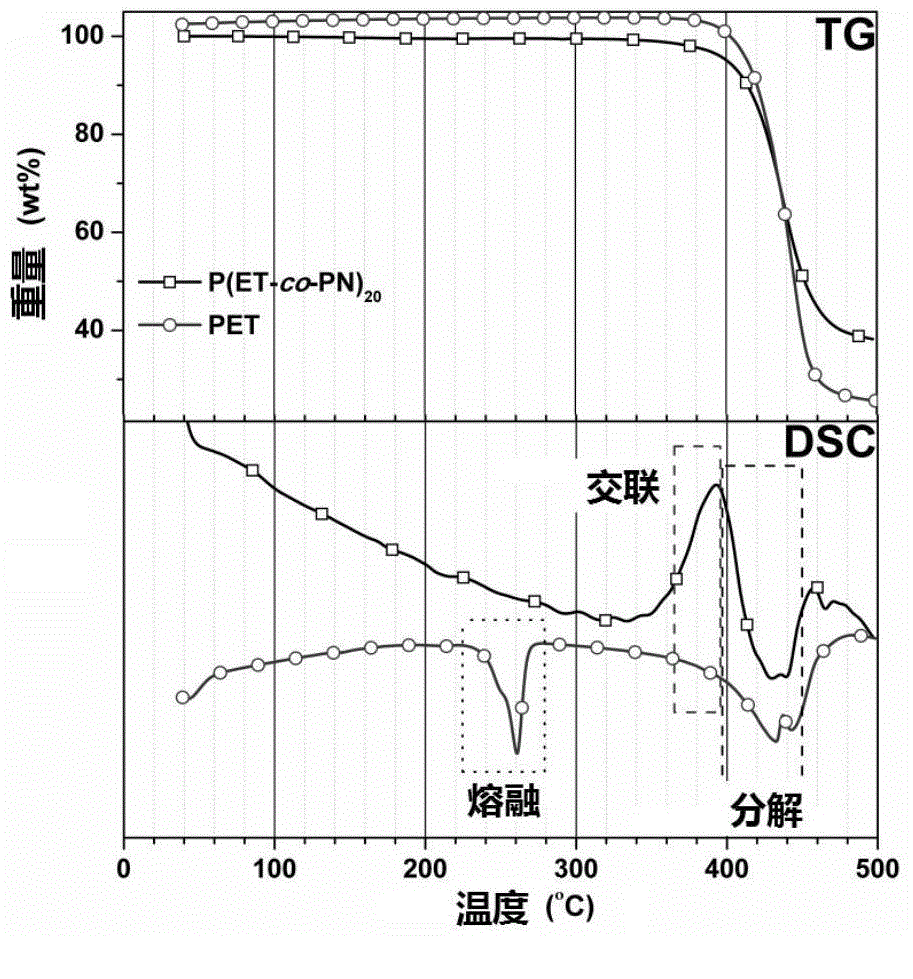

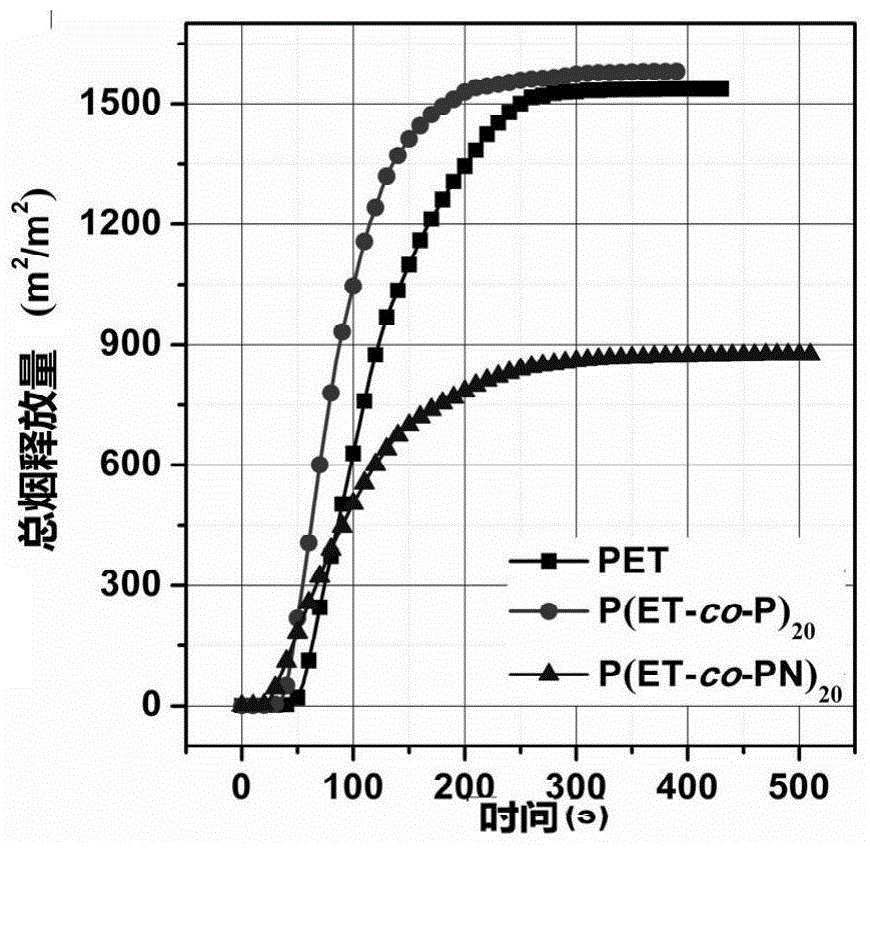

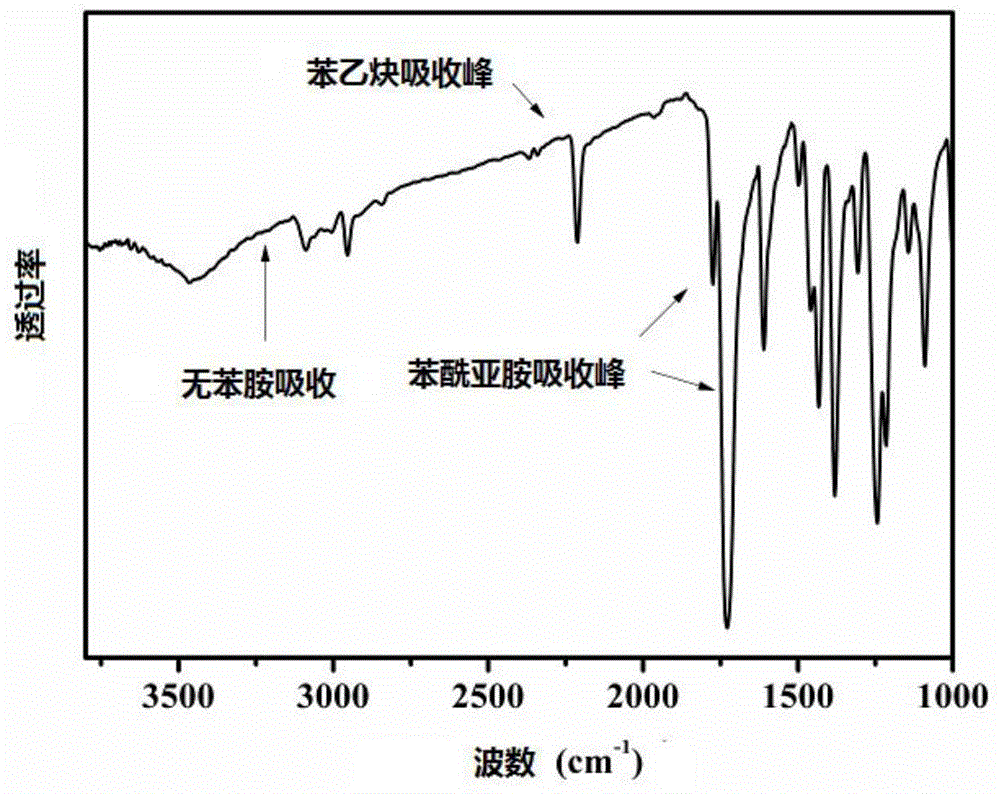

Monomer containing benzimide phenylacetylene structure, high temperature self-crosslinked copolyester and preparation method thereof

ActiveCN104592094AHigh self-crosslinking flame retardant efficiencyGood flame retardantOrganic chemistryPolymer scienceChemical reaction

The invention discloses a monomer containing a benzimide phenylacetylene structure. The monomer can enable self-crosslinking chemical reaction of a synthesized polymer under high temperature. The monomer containing a benzimide phenylacetylene structure and the structural units represented by I and II for synthesis of polyester can undergo random copolymerization to obtain high temperature self-crosslinked copolyester, and when the copolyester contains a PET structural unit, the characteristic viscosity number [eta] is 0.44-1.38dL / g, the vertical combustion UL-94 grade is from V-2 to V-0, the oxygen index LOI is 24.0-35.0%, and the cone calorimeter test peak heat release rate PHRR and the smoke release total amount are both lower than pure polyester. The invention also discloses a preparation method of the copolyester. The benzimide and phenylacetylene in the copolyester involved in the invention can generate synergistic cross-linking effect, so that the copolyester has very high flame-retardant and anti-dripping efficiency, and also the copolyester is endowed with excellent flame retardant, anti-dripping and smoke suppressing performance. The method provided by the invention is basically consistent with the synthesis method of conventional polyester, not only is mature in technology, and easy and convenient to operate, but also is easy to control and convenient for industrial production.

Owner:SICHUAN UNIV

Method for evaluating the flame-retardant effect of nano-magensium-aluminum hydrotalcite on bituminous mixture

InactiveCN109187411ALess traffic performance impactAccurate evaluation of flame retardant effectMaterial analysis by optical meansRoad surfaceFire retardant

The invention provides a method for evaluating the flame-retardant effect of nano-magensium-aluminum hydrotalcite on bituminous mixture, belongs to the technical field of bituminous mixture, and aimsto solve the problems that a current bituminous mixture flame-retardant effect evaluating method is difficult to simulate the asphalt pavement fire condition, has few testing combustion parameters, cannot comprehensively and accurately evaluate the flame-retardant effect of a flame retardant on the bituminous mixture, and has large addition amount for conventional flame retardant to impact the mixture pavement performance. The method comprises the following steps: preparing flame-retardant modified asphalt, and respectively preparing rutting plate test-pieces; cutting into conical calorimetertest-pieces, and keeping upper surfaces of original rutting plates; coating bottoms and side faces of the test-pieces with aluminum foils, keeping upper surfaces of original rutting plates upward to serve as heat faces, and simulating the pavement heated condition in a fire disaster to set a corresponding thermal radiation strength; and finally analyzing the test result to disclose influence of flame retardant on mixture combustion characteristics. According to the method, the flame retardant effect of a flame retardant on the bituminous mixture can be comprehensively and objectively evaluated, and accordance is provided to researching and developing flame retardants and improving the fire safety of asphalt pavement.

Owner:NANJING FORESTRY UNIV

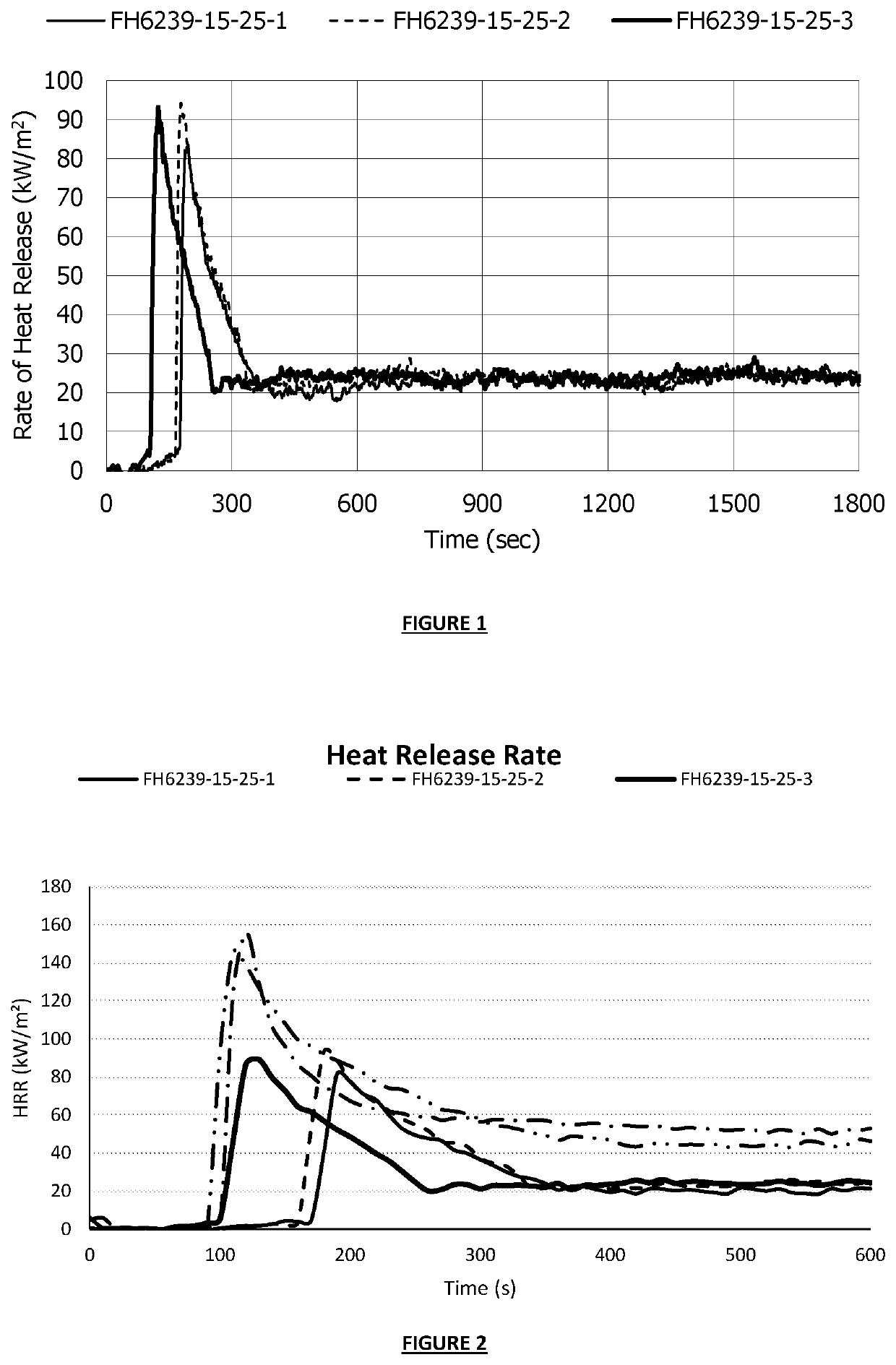

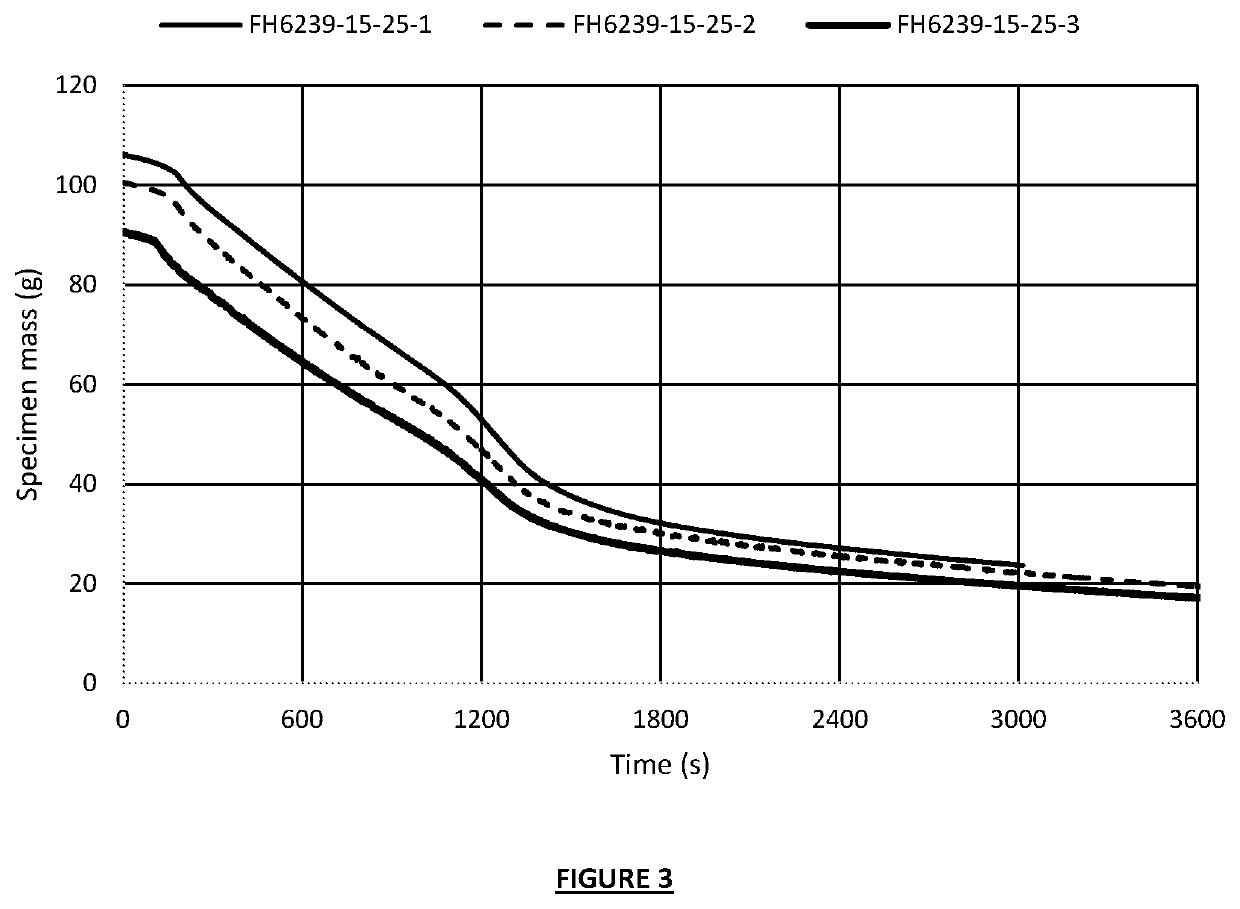

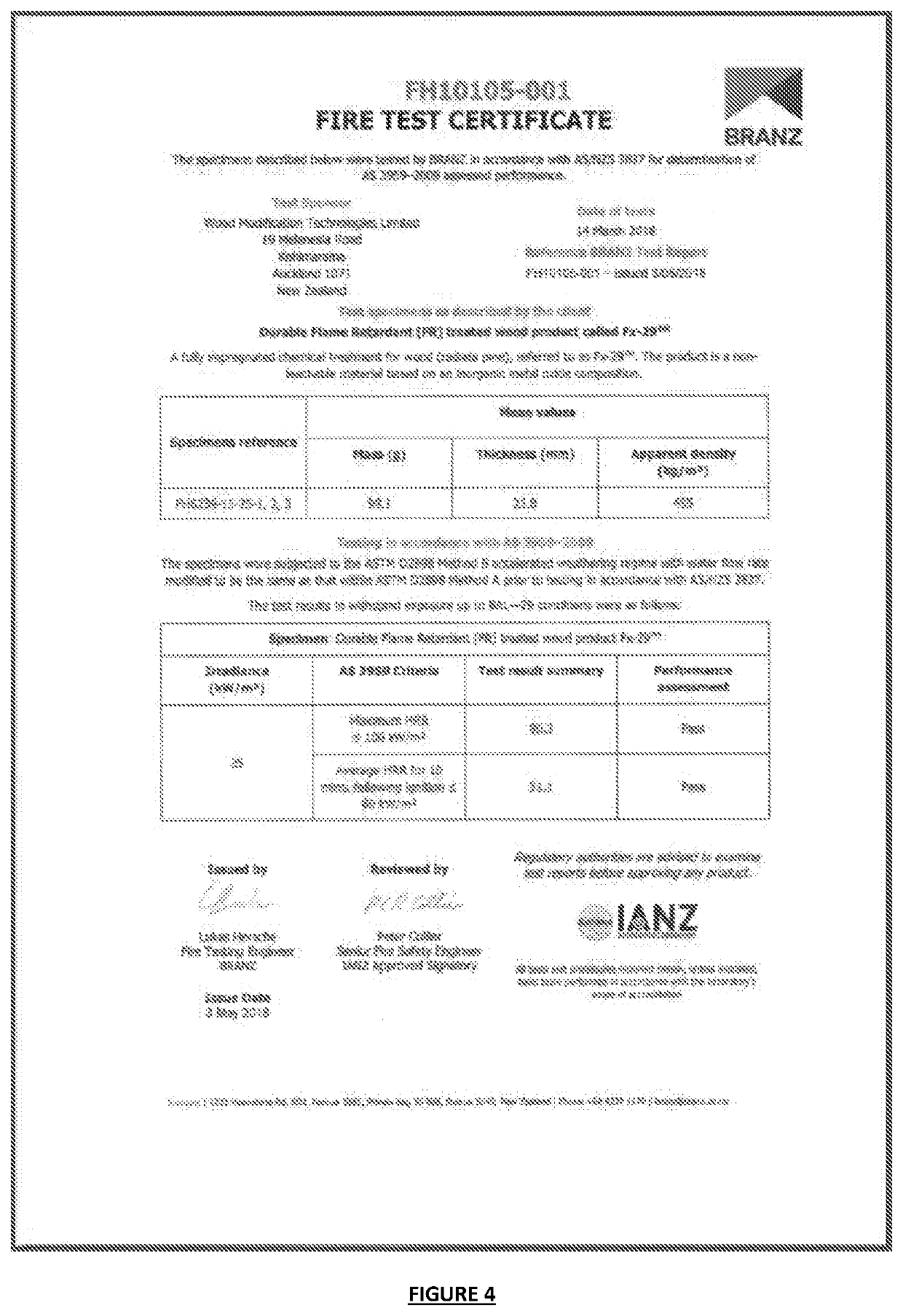

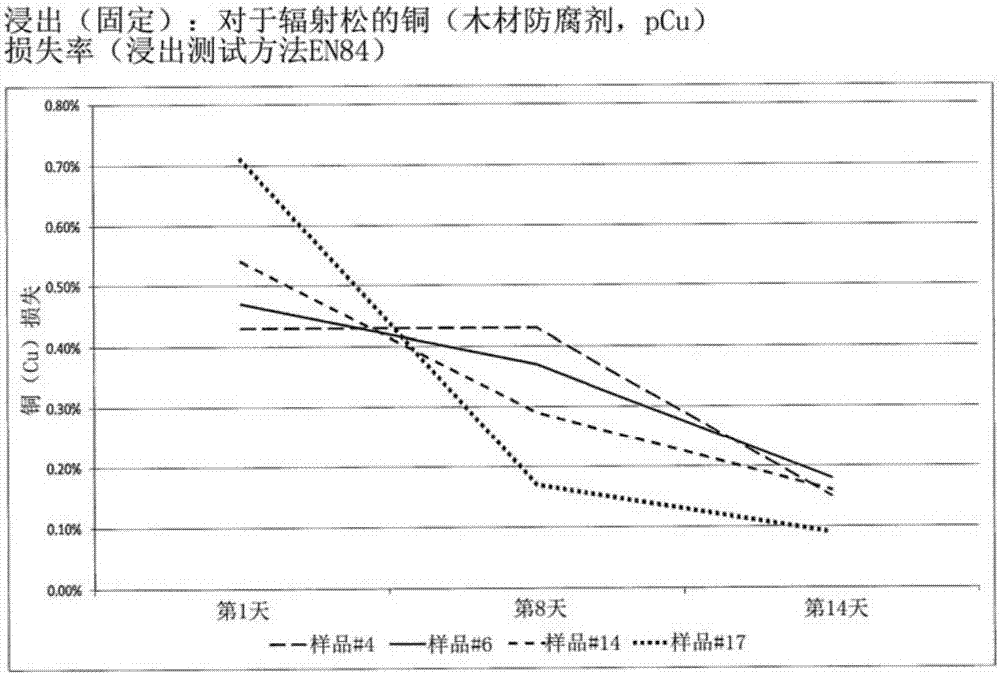

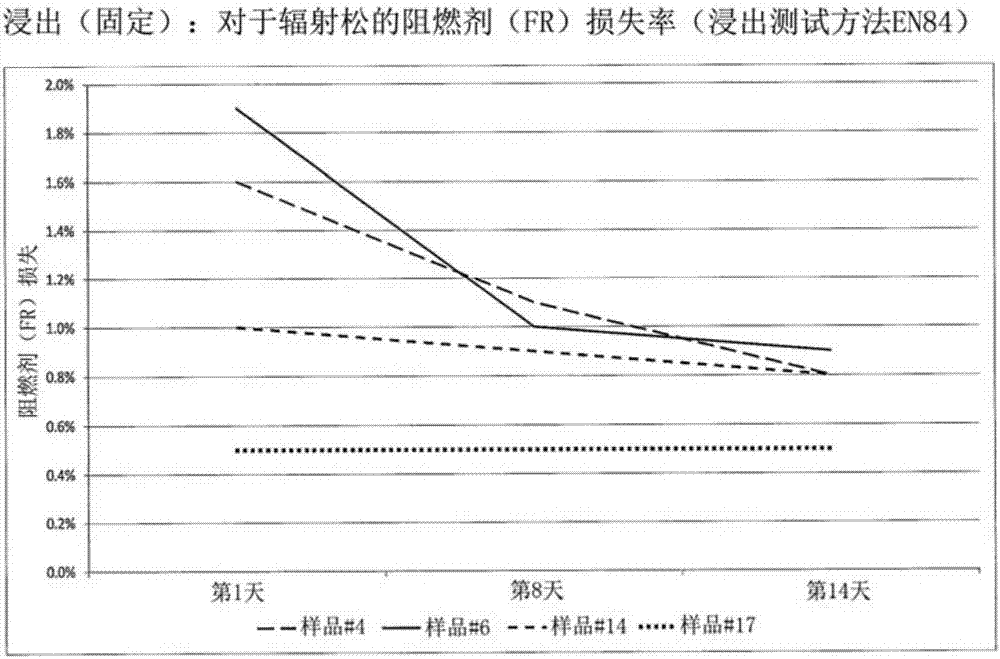

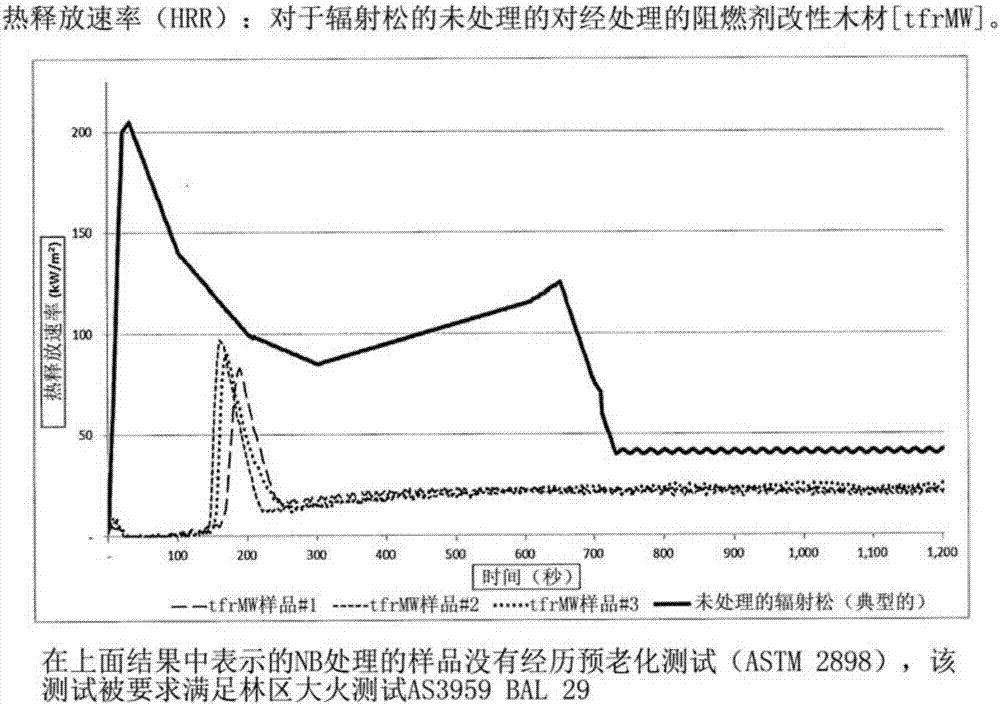

Enhanced performance of wood and engineered wood products using combined durability and flame retardancy

ActiveUS20200139574A1Increased durabilityImprove flame retardant performanceBiocideImpregnation spraying apparatusPulp and paper industryPinus radiata

A treatment process and wood products thereof including a product formulation of a single phase solution combining a wood preservative (durable component) with a Flame Retardant component (FR) to produce a durable Flame Retardant (dFR) treated wood product. The durable component comprises a range of copper based and non-copper based wood preservatives, while the FR component comprises alkali metal silicates and alkali metal aluminate compounds. The dFR working solution undergoes chemical impregnation (treatment) followed by a heat (fixation) process step that locks the chemical into the wood making it non-leachable. The dFR treated wood products are tested for their enhanced fire performance properties. When heated, wood undergoes thermal degradation and combustion producing gases, vapors, tars and chars. Using a cone calorimeter burn test method, dFR treated wood products show a significant reduction in heat release rate, mass loss rate and smoke generated values compared to untreated radiate pine.

Owner:WOOD MODIFICATION TECH LTD

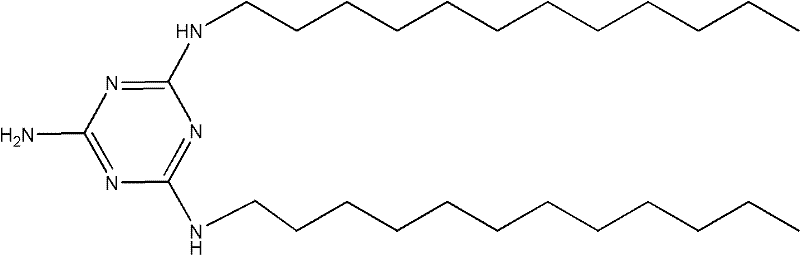

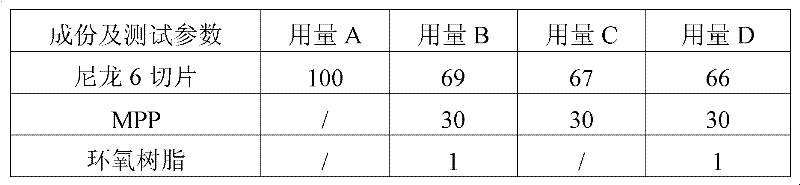

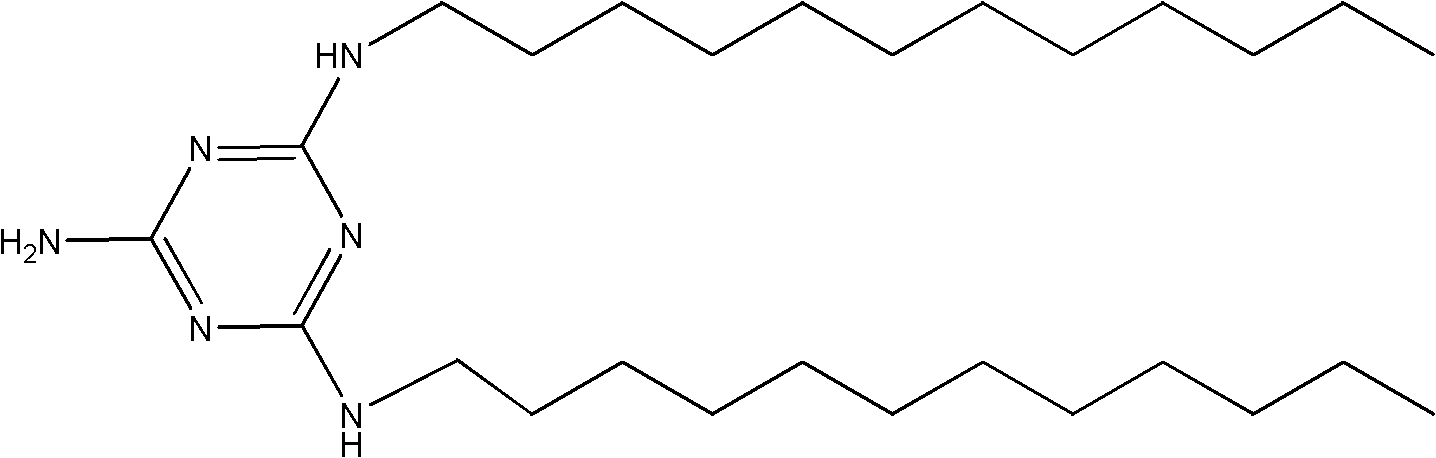

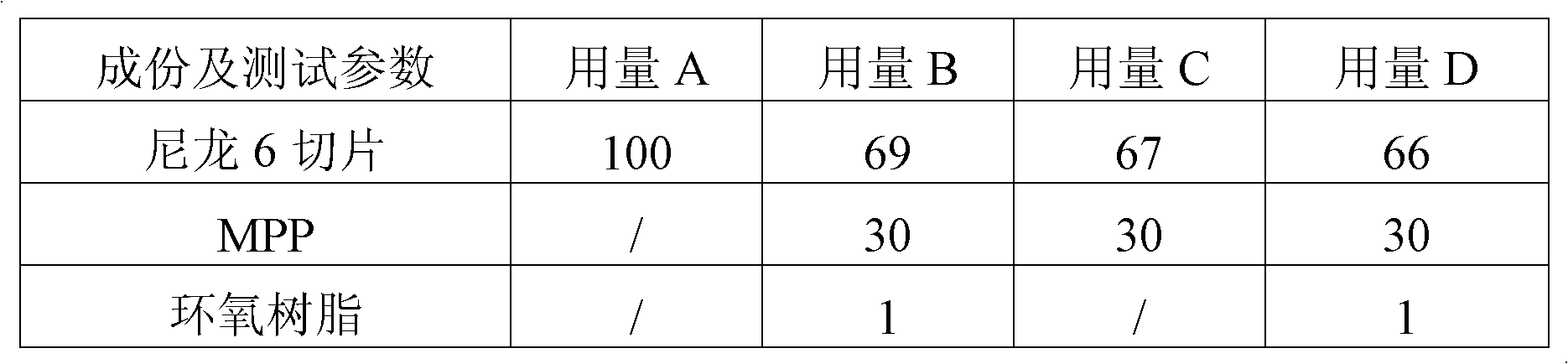

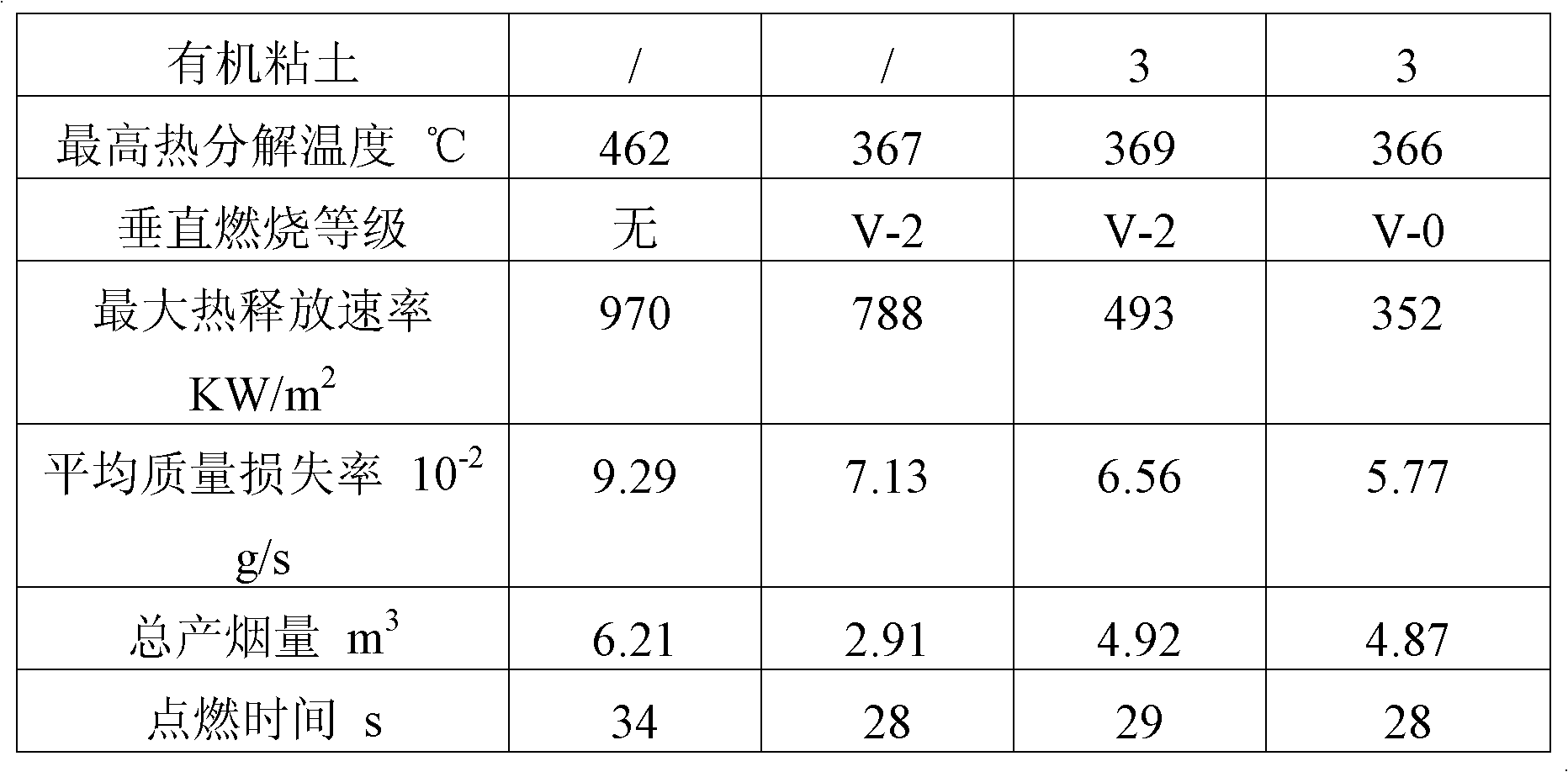

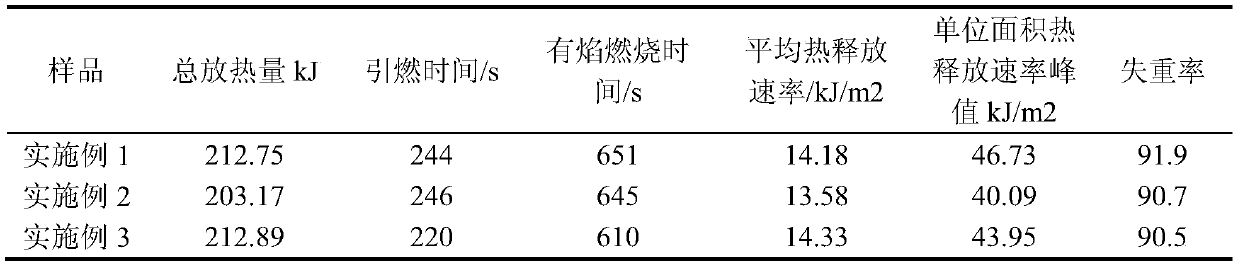

Environment-friendly flame-retardant nylon 6 nano composite material and preparation method thereof

ActiveCN102241895AImprove thermal stabilitySolve heat resistancePigment treatment with non-polymer organic compoundsEpoxyCompound a

The invention relates to an environment-friendly flame-retardant nylon 6 nano composite material and a preparation method thereof, which solve the problem of inflammability of a nylon 6 / laminated silicate nano composite material. The flame-retardant nano composite material has the main characteristic that an environment-friendly intumescent flame retardant of melamine polyphosphate (MPP) and a clay lamina retard flame in a synergic mode to achieve V-0 grades of vertical combustion. Meanwhile, a cone calorimeter test result of the flame-retardant nano composite material is obviously improved compared with that of a pure nylon 6 material. The flame-retardant nano composite material is prepared by compounding a nylon 6 monomer, MPP, epoxy resin and organic clay or clay, wherein the nylon 6 monomer, the MPP, the epoxy resin and the clay are existing materials, and the organic clay is prepared in the invention. The invention can be widely applied to fields such as automobiles, electronics,decoration and the like.

Owner:BEIJING UNIV OF CHEM TECH

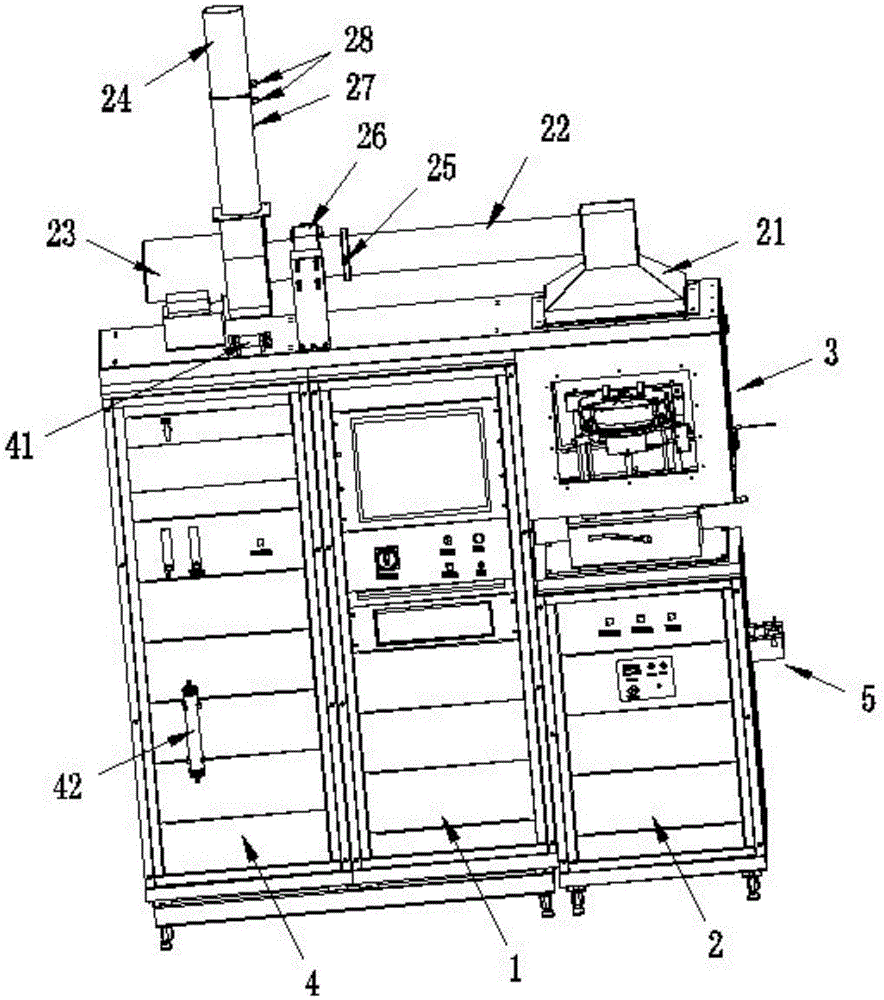

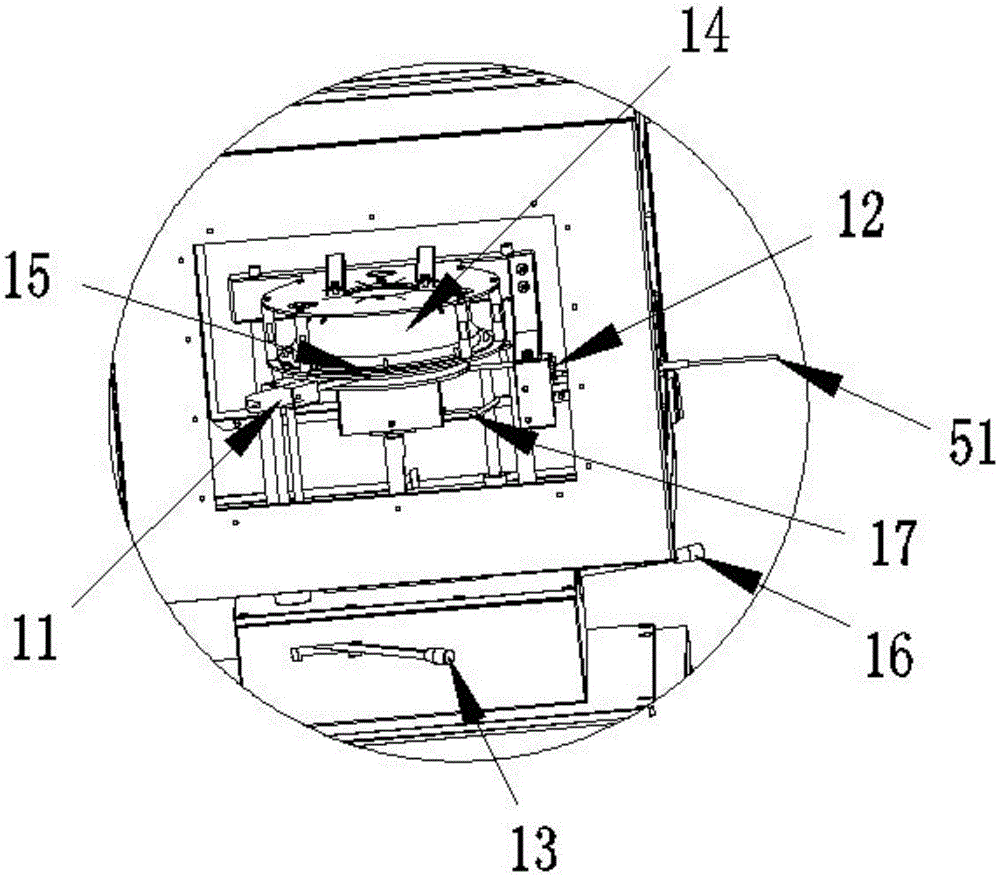

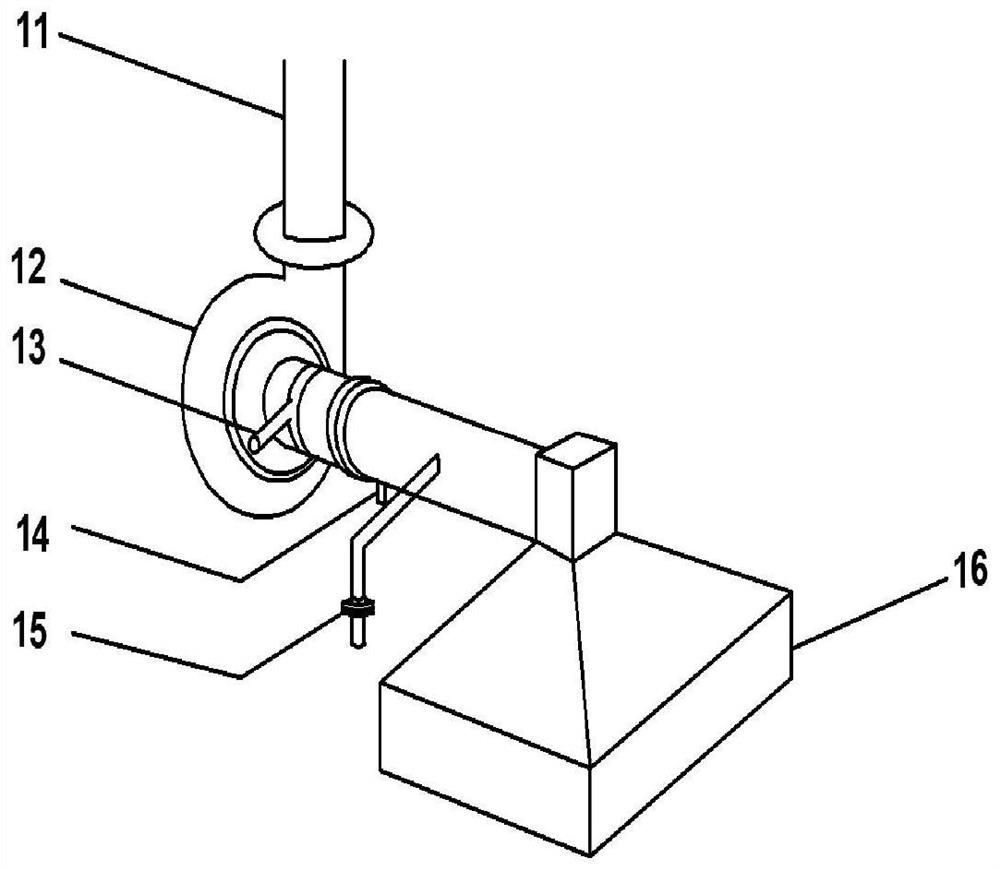

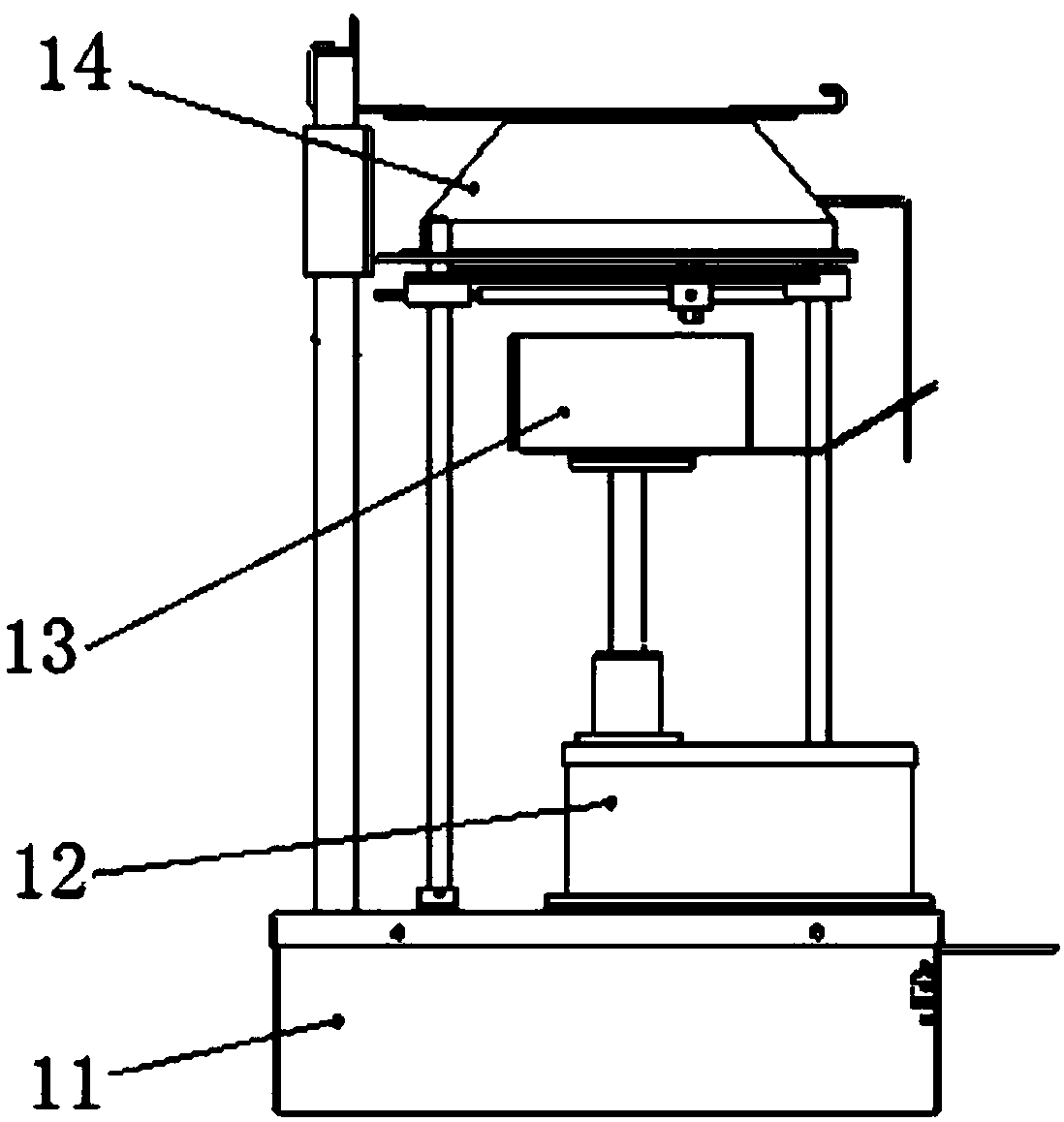

Cone calorimeter

The invention discloses a cone calorimeter. The cone calorimeter comprises a main control computer, an auxiliary control computer, a combustion and irradiation device, a smoke discharging assembly and a gas analysis device, wherein the auxiliary control computer is provided with a heat flux meter assembly and a water-cooled circulating system of the heat flux meter assembly; the combustion and irradiation device comprises an ignition assembly, a heat radiation assembly and a sampling assembly; the smoke discharging assembly is provided with a measuring assembly and is used for connecting the combustion and irradiation device with an external waste gas treatment device; the smoke discharging assembly is connected with the gas analysis device through a collecting device. In an experimental process, the main control machine is used for controlling all components and receiving a feedback signal, the auxiliary control machine is used for controlling the combustion and irradiation device to test the performance of a flame-retardant material, a generated gas can be sent from the smoke discharging assembly to the gas analysis device so as to be subjected to analysis treatment, a testing result can be obtained by the measuring assembly on the smoke discharging assembly and the gas analysis device, the needs of a test all-in-one machine used in a laboratory scale can be met, and the cone calorimeter can be widely applied to various fields.

Owner:江苏费尔曼安全科技有限公司

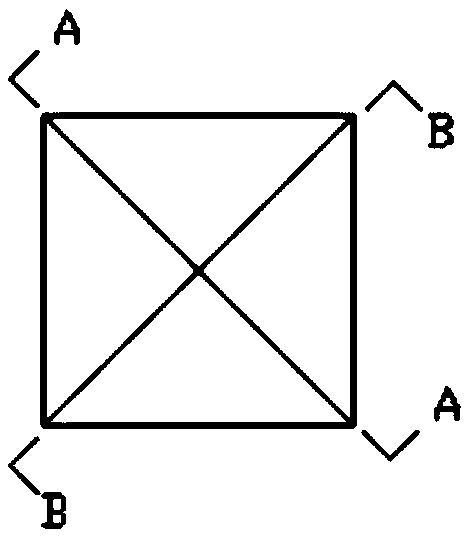

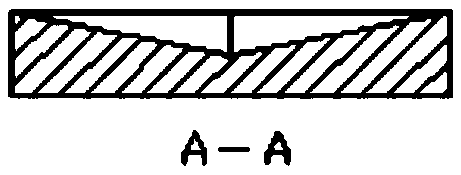

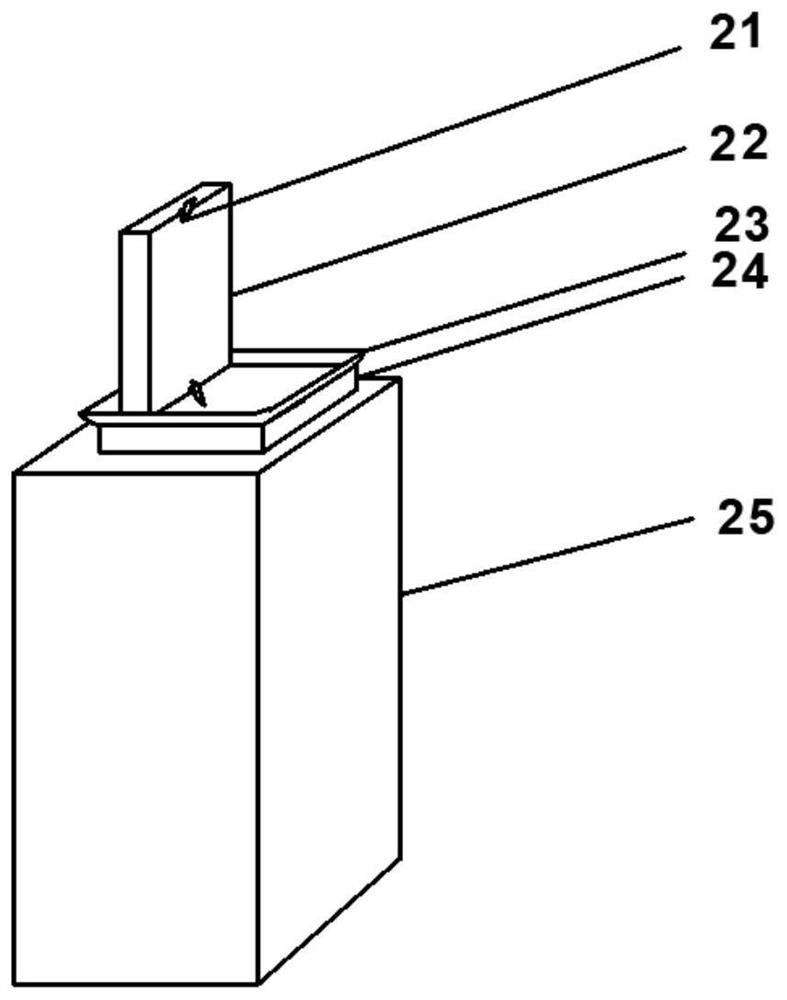

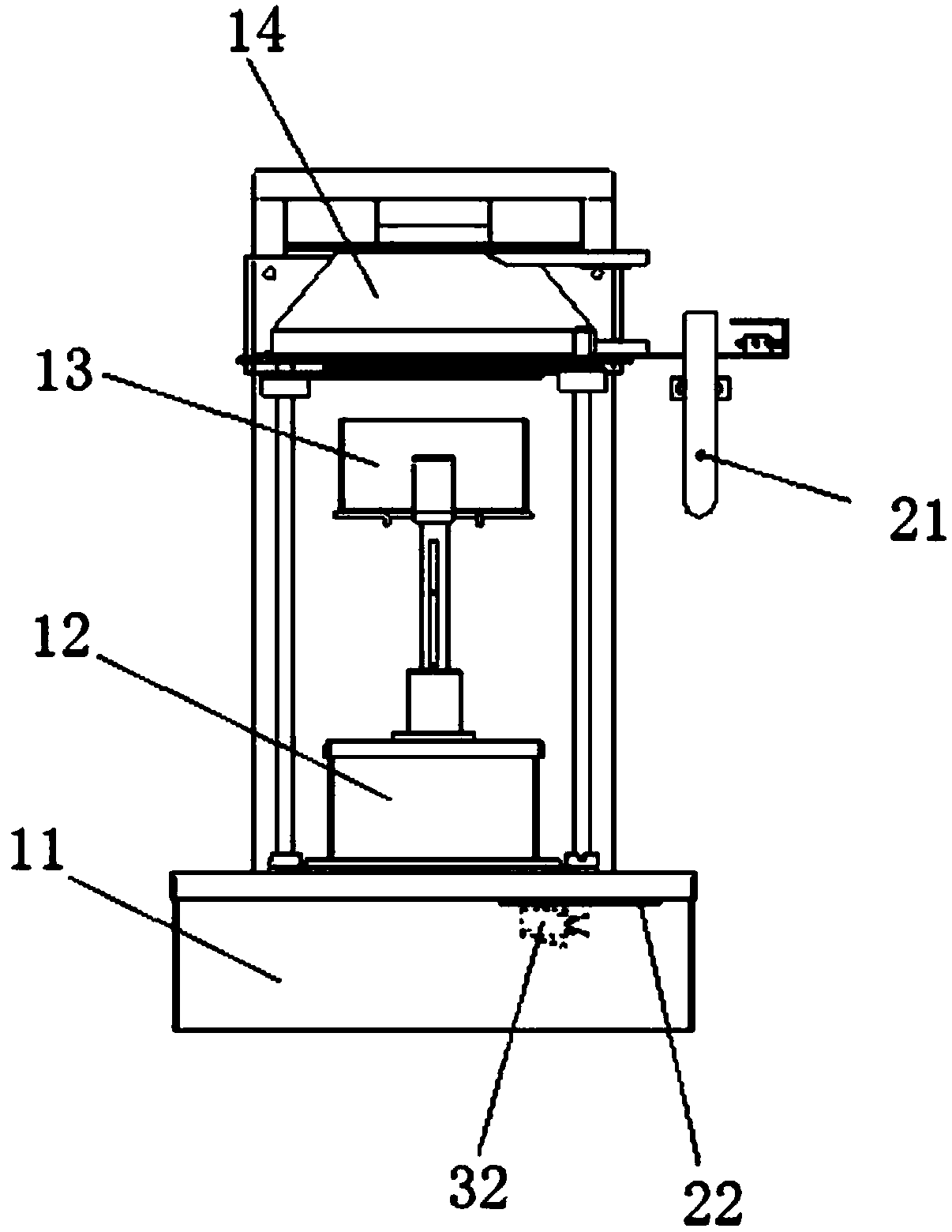

Sample containing device for cone calorimeter and test method

InactiveCN105510382AEliminate systematic errorsIn line with the real situationMaterial heat developmentInverted pyramidEngineering

The present invention provides a sample containing device for a cone calorimeter and a test method, the sample containing device comprises a sample holder and a removable grille, the upper part of the sample holder is provided with a concave part for accommodating a textile sample containing synthetic fiber, the concave part is an inverted pyramid, and the removable grille is used for covering the concave part. By use of the sample containing device, after the textile sample containing the synthetic fiber is subjected to high temperature radiation, all synthetic fiber in the sample can be heated and ignited, so that original system errors are completely eliminated, fire burning real situations can be better met, and test accuracy and repeatability can be significantly improved. In addition, the method also extends the use range of the cone calorimeter in textile materials.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY +1

Synergistic inhibition method for thermal decomposition of asphalt mixture by flame-retardant warm mixing agent

InactiveCN111925562AGood vibration dampingDriving safetyClimate change adaptationBuilding insulationsCombustionFire retardant

The invention relates to a synergistic inhibition method for thermal decomposition of an asphalt mixture by a flame-retardant warm mixing agent, belongs to the technical field of asphalt pavement firesafety, and solves the problems that the synergistic flame-retardant effect of various components of the existing composite flame retardant is poor, the whole thermal decomposition process is difficult to inhibit, and the synergistic inhibition effect of the flame-retardant warm-mixing agent on flame retardance and smoke inhibition of an asphalt mixture is difficult to accurately analyze. The method comprises the following steps: firstly, preparing a nano composite flame retardant, performing vacuum adsorption on the nano composite flame retardant and a zeolite warm-mixing agent by using a vacuum adsorption method to prepare a flame-retardant warm-mixing agent, then preparing a common asphalt mixture and a flame-retardant warm-mixing asphalt mixture, and comparing combustion behaviors ofthe two asphalt mixtures by using a cone calorimeter test; using a scanning electron microscope and an energy dispersive spectrometer to analyze the microstructure and elemental composition of residues after pyrolysis of the asphalt mixture. According to the method, all the components of the composite flame retardant can be sequentially decomposed in the heating process of the warm-mixed asphalt mixture to play flame-retardant and smoke-suppressing roles, and the synergistic flame-retardant and smoke-suppressing effects are achieved.

Owner:NANJING FORESTRY UNIV

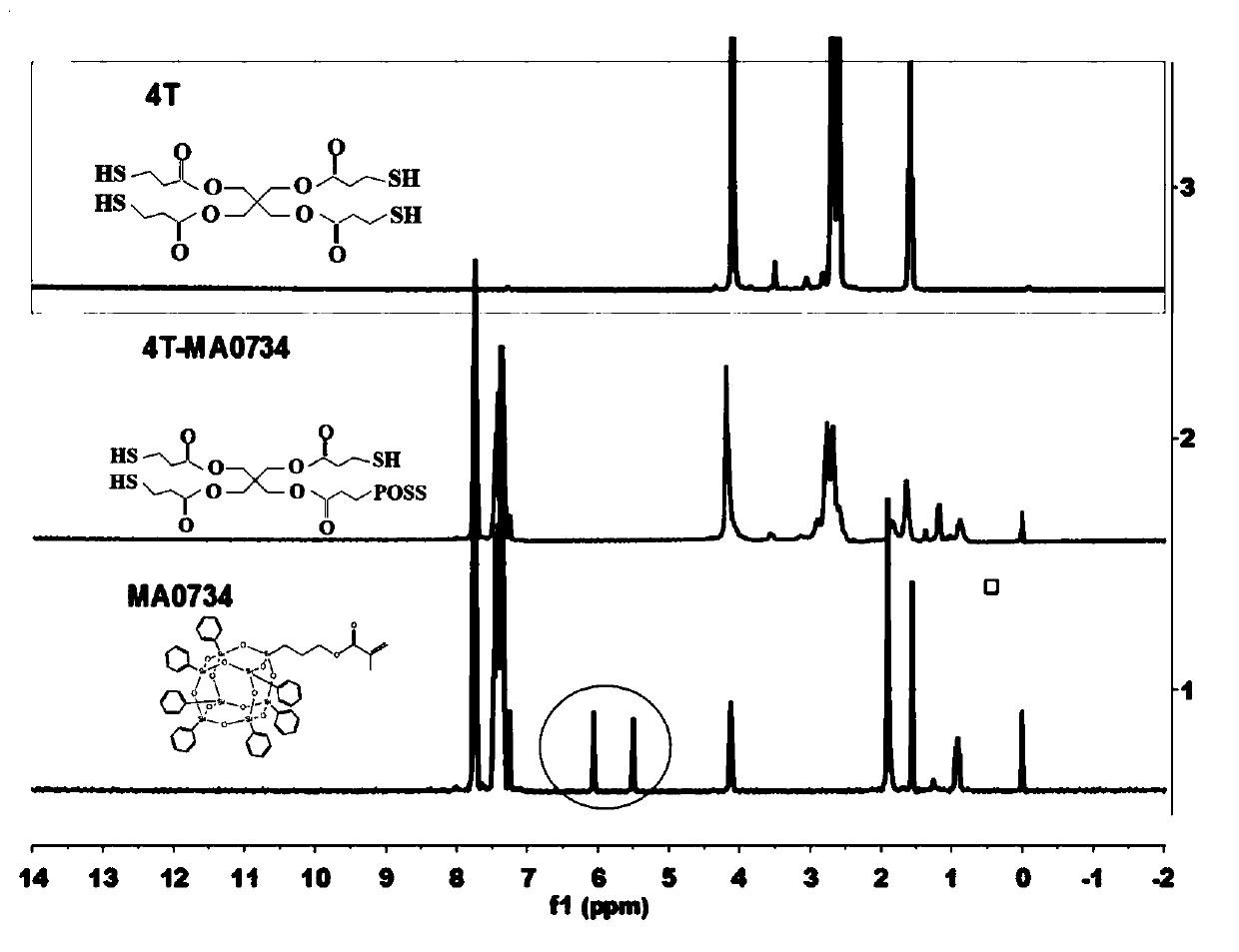

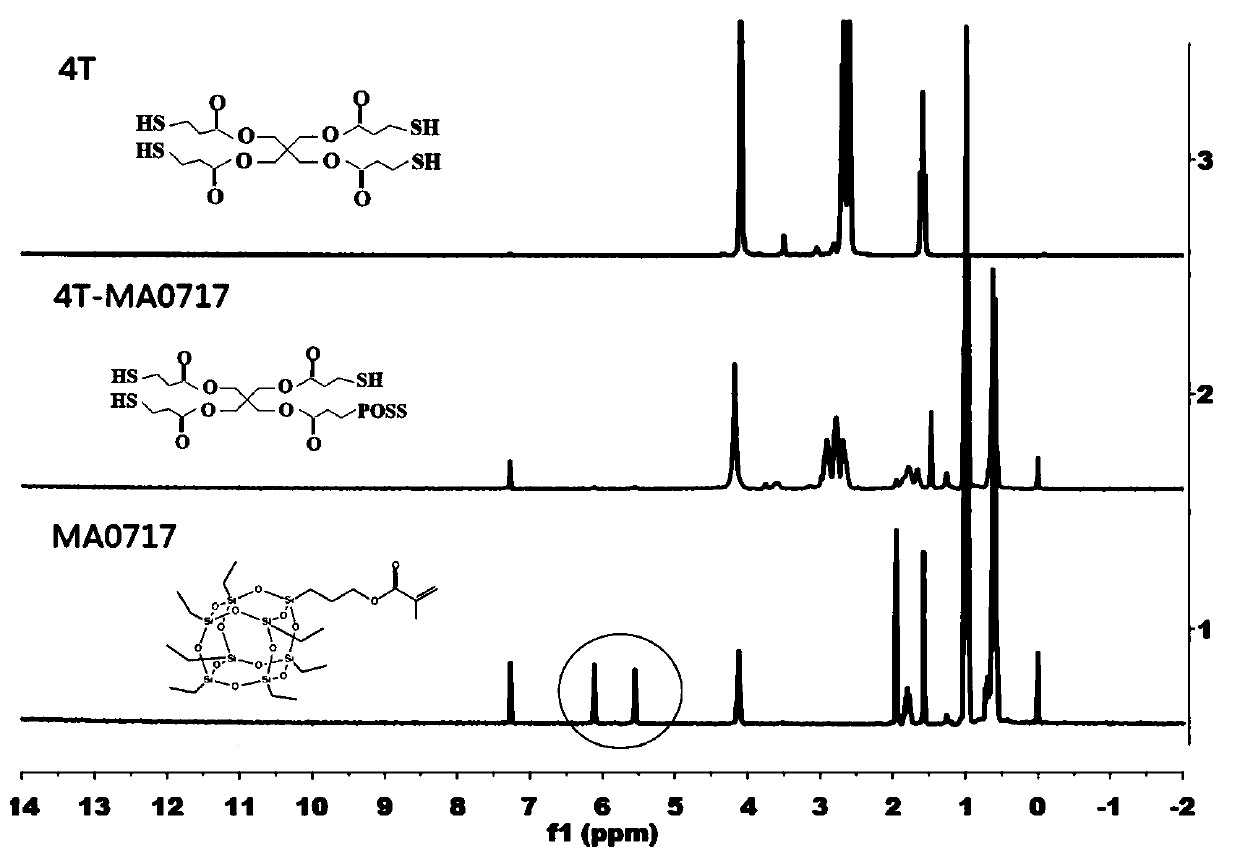

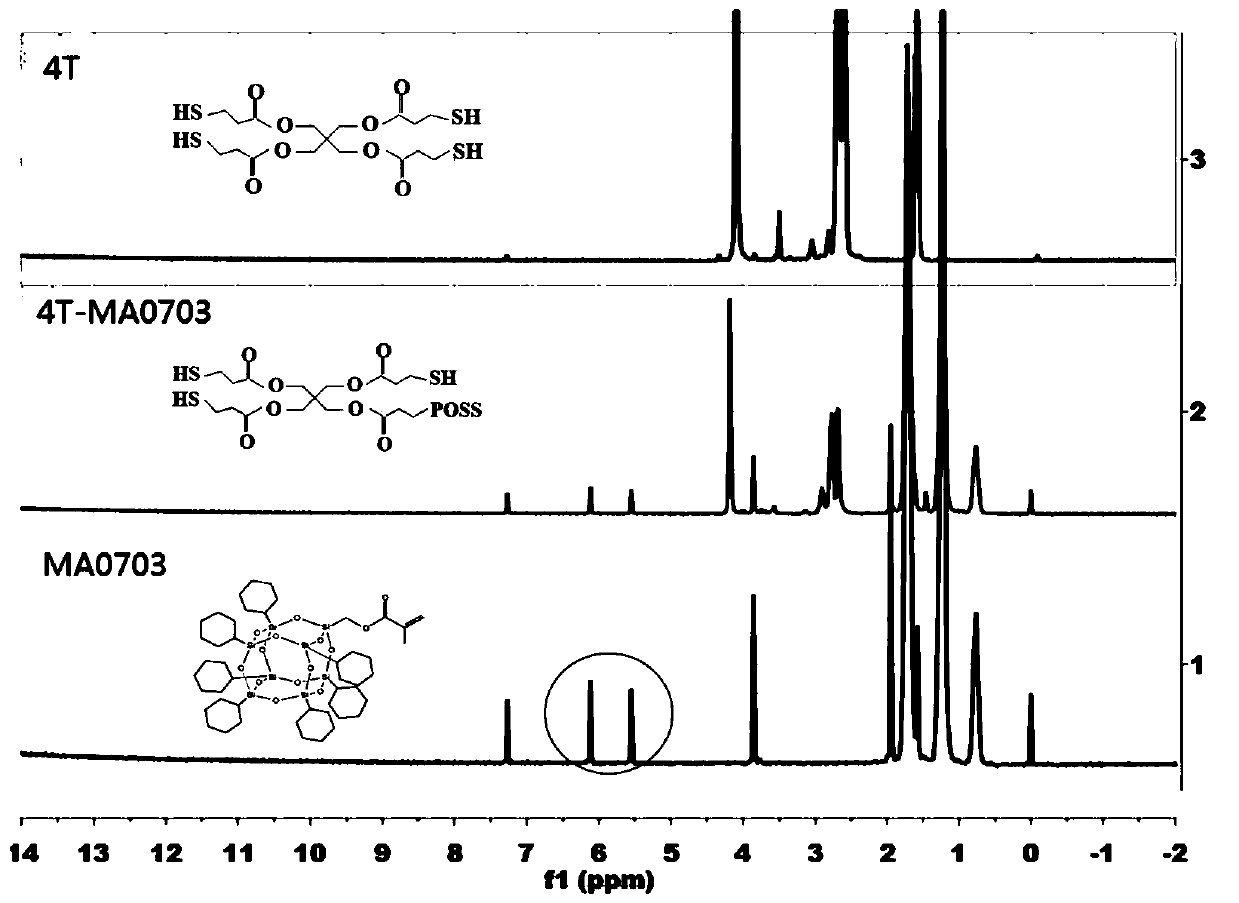

POSS modified mercapto containing pentaerythritol ester crosslinked network polymer, and preparation method and applications thereof

The invention discloses a POSS modified mercapto containing pentaerythritol ester crosslinked network polymer, and a preparation method thereof. It is confirmed by cone calorimeter method that after modification, polymer heat stability is better, and flame resistance is better. The invention also discloses applications of the POSS modified mercapto containing pentaerythritol ester crosslinked network polymer in preparation of flame retardant materials and / or flame retardant paint.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

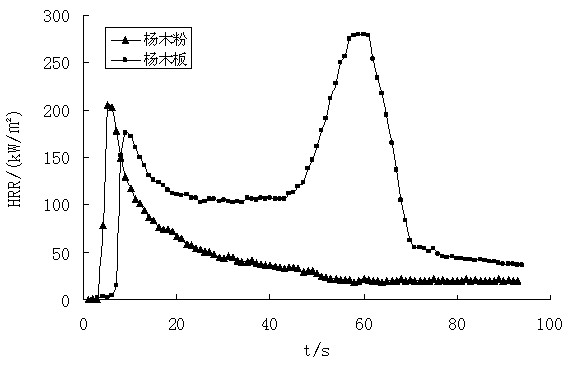

Method for preparing poplar fiber /Al2O3 nano composite material

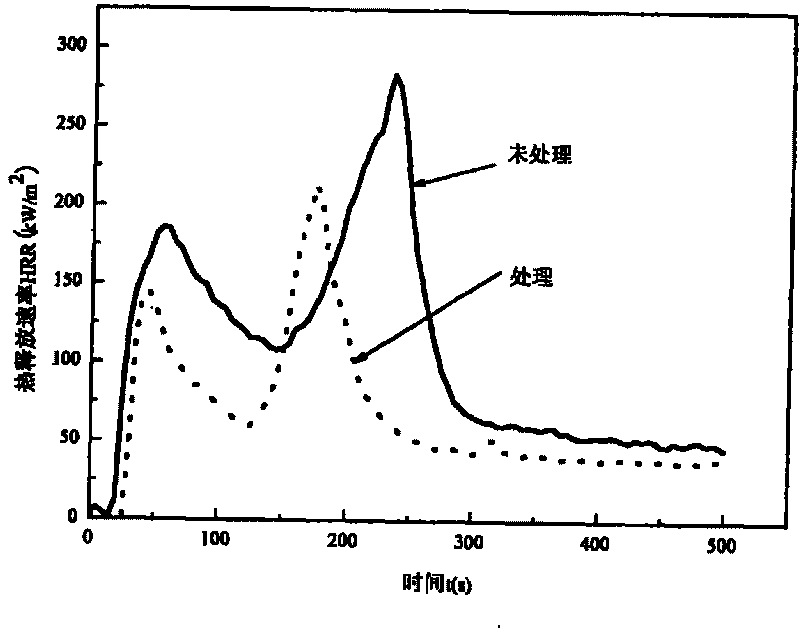

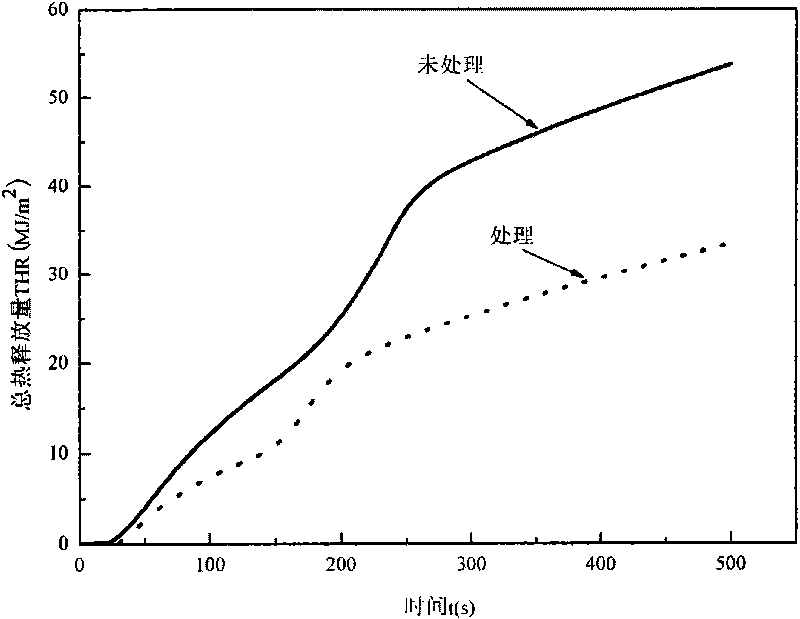

The invention relates to a method for preparing a poplar fiber / Al2O3 nano composite material. The poplar fiber / Al2O3 nano composite material is prepared by a sol-gel technique, and the heat release rate, the total heat release amount, the ignition time and the like are researched by utilizing a cone calorimeter. Experimental results show that after the nano composite material is modified by inorganic nano Al2O3, heat release peak values generated at 45s and 175s are obviously weakened, the heat release speed is obviously reduced, the average heat release speed is reduced by 38 percent, the heat release speed peak value drops by 25 percent, the total heat release is reduced by 38 percent, and the ignition time is prolonged by one time. The fire resistance of the poplar fiber / Al2O3 nano composite material is obviously improved.

Owner:NANJING FORESTRY UNIV

Method for testing heat release rate of combustible light powder

InactiveCN107271482AImprove compactnessImprove scienceMaterial heat developmentData acquisitionOperability

The invention discloses a method for testing the heat release rate of combustible light powder. After preheating, calibration and irradiation intensity setting are performed on a cone calorimeter by rule, the combustible light powder is subjected to sample pretreatment, samples are placed in a steel mold of 20*20 mm<2> and pressed through manual hydraulic forming under the pressure of 0.2-0.4 MPa, 25 samples are arranged tidily after being demolded and placed on a sample rack with the inner wall and the bottom layer covered with aluminum foil, and experiments and data acquisition are conducted according to the operation instruction of the cone calorimeter. The accuracy of determination of the heat release rate of the combustible light powder is improved, the risk of the experiment process is reduced, the pretreatment process is simple, and the method is high in operability.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

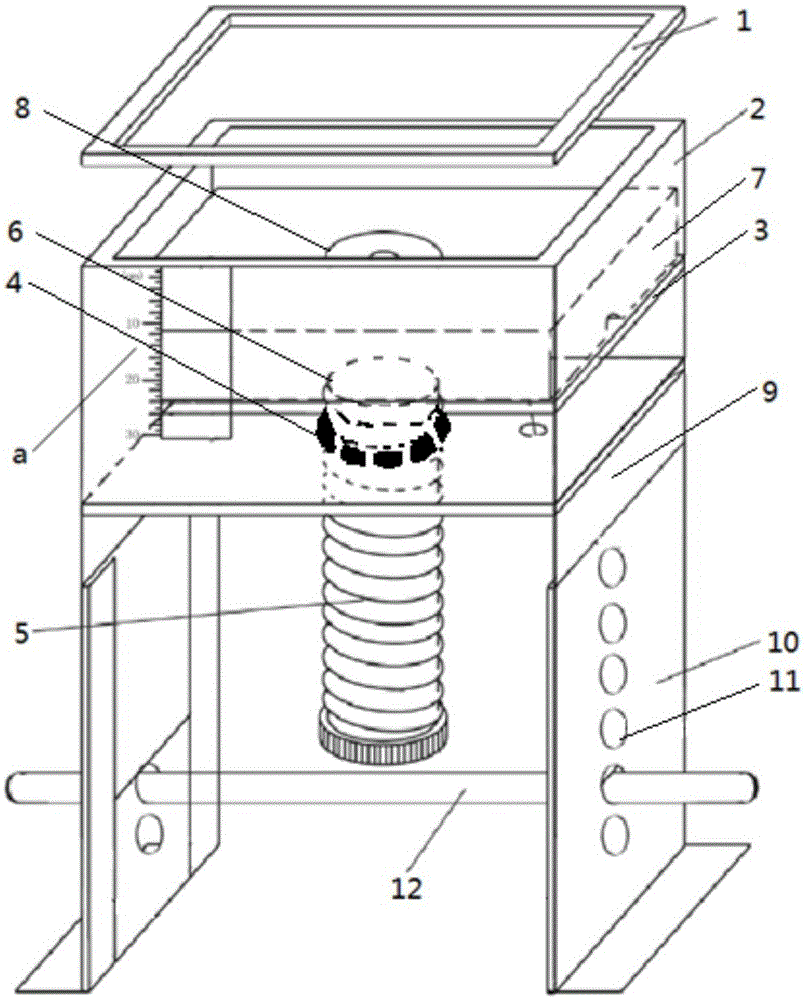

Textile material sample carrying table for cone calorimeter

InactiveCN105067665AProtection Function PredictionEffective test methodMaterial heat developmentMonitoring temperatureBrick

The invention relates to a textile material sample carrying table for a cone calorimeter. The textile material sample carrying table comprises a square box and a sample pressing frame corresponding to an upper end opening of the box. A supporting plate capable of moving vertically is arranged in the box. A screw rod is arranged in a screwed mode through a nut fixedly arranged in the center of a bottom plate of the box. The upper end of the screw rod is connected with the supporting plate through a bearing. A heat preserving brick in which a temperature sensor is embedded is arranged on the supporting plate. Inserting plates are arranged at the two sides of the bottom of the square box. The square box is inserted in a height adjusting frame through the inserting plates. A plurality of locating holes distributed vertically are formed in the height adjusting frame. By changing a clamping rod to penetrate into the different locating holes, the height distancing from a tested sample to a fire source can be adjusted; the distance between the tested sample and the temperature sensor is achieved by screwing and adjusting the screw rod. The protecting function of garment materials can be predicted by monitoring temperature changes at different distances between the tested sample and the temperature sensor. An effective test means is provided for analyzing the relation among factors influencing the protective property of shielding fabric.

Owner:JILIN UNIV

Flame-retardant smoke-suppressing enhanced polylactic acid composite fiber and preparation method thereof

InactiveCN108342788AEfficient Flame RetardancyInhibitionFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberMasterbatch

The invention discloses a flame-retardant smoke-suppressing enhanced polylactic acid composite fiber and a preparation method thereof. The polylactic acid composite fiber comprises the following threecomponents: an organic boron-nitrogen flame retardant, a flame retardant synergist and polylactic acid resin. The preparation method comprises the following steps: S1) preparing composite polylacticacid masterbatch from a certain amount of the organic boron-nitrogen flame retardant, the flame retardant synergist and the polylactic acid resin; and S2) preparing the polylactic acid composite fiberfrom a certain amount of the composite polylactic acid masterbatch and an equal amount of the polylactic acid resin. The polylactic acid composite fiber is difficult to ignite in butane gas flames under the condition of standard air, can realize self-extinguishing when take away from flames when ignited in the butane gas flames occasionally, has no obvious molten drops and does not ignite cottonflock located below the polylactic acid composite fiber. In addition, in a cone calorimeter test, the polylactic acid composite fiber has a significantly reduced smoke density in combustion compared with common phosphorus-containing flame-retardant polylactic acid fibers, recued by more than 80%.

Owner:THE HONG KONG POLYTECHNIC UNIV

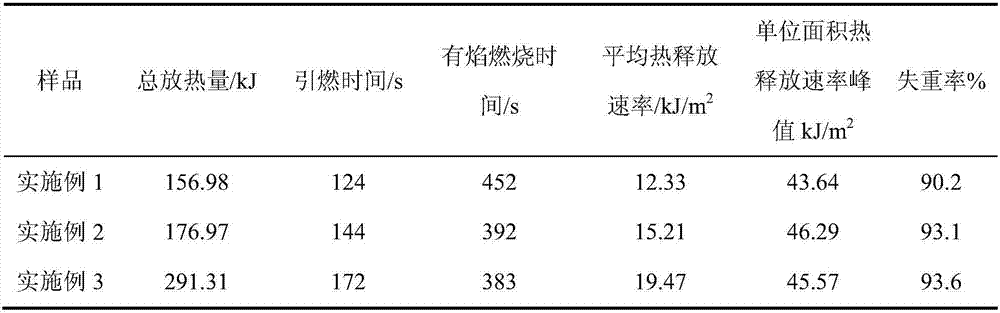

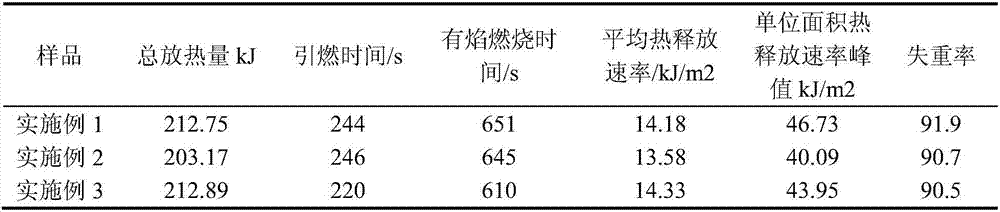

Efficient flame-retardant polyurethane rigid foam with reaction and synergistic effect and preparing method

The invention discloses efficient flame-retardant polyurethane rigid foam with a reaction and synergistic effect and a preparing method. The efficient flame-retardant polyurethane rigid foam is prepared from 20 parts of polyether polyol, 20 parts of polymethylene polyphenyl isocyanate, 5 parts of aluminum diethyl phosphinic acid, 7.5 parts of sodium alginate, 5 parts of expansible graphite, 1 partof dimethylamino ethoxyethanol and 2 parts of a modified polymerization silicon surfactant. The preparing method for the efficient flame-retardant polyurethane rigid foam includes the steps that theraw materials are fully mixed, and the mixture is put into a box of 15 cm*15 cm*15 cm under conditions of the room temperature (20 DEG C to 25 DEG C) and normal pressure, is rapidly stirred and foamedthrough an electric stirrer, is placed into a drying box of 80 DEG C and dried for 30 min after foaming is stable, and is subjected to standing for 24 hours at the room temperature, and the polyurethane-rigid-foam raw-material finished product is obtained. By means of the efficient flame-retardant polyurethane rigid foam, the flame-retardant performance of the rigid polyurethane foam can be enhanced, and through experiments of a cone calorimeter, the weight loss ratio, LOI index measurement and the like, it is verified that the flame-retardant effect of the polyurethane rigid foam is good.

Owner:SHENYANG LIGONG UNIV

Asphalt modified polymethyl methacrylate plastic and preparation method thereof

ActiveCN104098864AImprove toughnessImprove combustion performanceBuilding insulationsPolymer sciencePolymethyl methacrylate

Belonging to the technical field of high polymer materials, the invention relates to an asphalt modified polymethyl methacrylate plastic and a preparation method thereof. Methyl methacrylate is adopted as the main body, and asphalt is added as a modification additive, while improving the toughness of an organic glass main body, the material is endowed with stable combustion performance. The asphalt modified polymethyl methacrylate plastic involved in the invention is formed by bulk polymerization, the raw materials at least include: 100 parts by mass of methyl methacrylate, 0.1-12 parts by mass of refined asphalt, and 0.2-1.2 parts by mass of an initiator. The preparation method of the asphalt modified polymethyl methacrylate plastic involved in the invention consists of the processes of asphalt pretreatment, methyl methacrylate monomer pretreatment, bulk polymerization, forming and post-curing. The asphalt pretreatment adopts alkali fusion treatment. The asphalt modified polymethyl methacrylate plastic involved in the invention has enhanced toughness and stable combustion performance, is applicable to building doors and windows, building decorative plates, signboards, electrical machinery parts and the like, and is especially applicable to standard substances for laboratory cone calorimeters.

Owner:NO 53 RES INST OF CHINA NORTH IND GRP

Flame-retardant smoke-suppressing polylactic acid composite material and preparation method thereof

ActiveCN112778724AEfficient flame retardant and smoke suppression performanceEffective dissipationFlame-proof filament manufactureMonocomponent polyesters artificial filamentFiberSmoke Emission

The invention discloses a flame-retardant smoke-suppressing polylactic acid composite material and a preparation method thereof. The polylactic acid composite material comprises polylactic acid resin and a plasma-state solid material serving as a flame retardant, wherein the plasma-state solid material is a solid material with a large number of free electrons. The preparation method comprises the following steps of: S1, preparing a composite polylactic acid master batch by using a certain amount of low-dimensional plasma-state solid material and polylactic resin; and S2, preparing the polylactic acid composite material from a certain amount of the composite polylactic acid master batch and an equal amount of polylactic acid resin. Knitted fabric made of the polylactic acid composite material is difficult to ignite in butane gas flames under the standard air condition, can be self-extinguished after being occasionally ignited and away from the fire, has no obvious molten drop phenomenon, and also has no phenomenon that cotton flock on the lower side is on fire. In addition, in a cone calorimeter test, compared with common phosphorus-containing flame-retardant polylactic acid fibers, the density of smoke generated by the polylactic acid composite material in combustion is obviously reduced by more than 50%.

Owner:THE HONG KONG POLYTECHNIC UNIV

Lightweight, flame retardant and rubber foaming sole material and manufacturing method thereof

The invention relates to a rubber foaming sole material and a manufacturing method thereof, and especially relates to a manufacturing method of the sole footwear products which has high requirements on lightweighting, the flame retardation performance and the wear resistance. The material comprises the following compositions: a chlorosulfonated polyethylene rubber (CSM), a butadiene rubber (BR), a natural rubber (NR), a plasticizer, a strengthening agent, an activator, a coupling agent, a vulcanizing agent, an accelerating agent, and an antioxidant. In the invention, a series of sole materials are prepared through screening coupling agents, accelerating agents, activators, foaming agents, and fire retardants and reasonably controlling a technology on the basis of rubbers, softening oil and the strengthening agent, the lightweight and flame retardation footwear outsole material which has a density of 0.8-1.0g / cm<3> and has a maximum heat release rate of equal to or less than 110kW / m<2>and a DIN abrasion of equal to or less than 120mm<3> in tests with a tapered calorimeter is obtained through optimizing the formula and the technology. The material has the following advantages: 1, the specific gravity is light, and the flame retardation and the wear resistance are excellent; 2, the heat resistance and the light resistance are good, and the fire retardant is not easy to migrate from the surface; and 3, toxic gases of polybrominated dibenzo-p-dioxin (PBDD) and polybrominated dibenzo-furan (PBDF) are not released in combustion when a sole is discarded.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

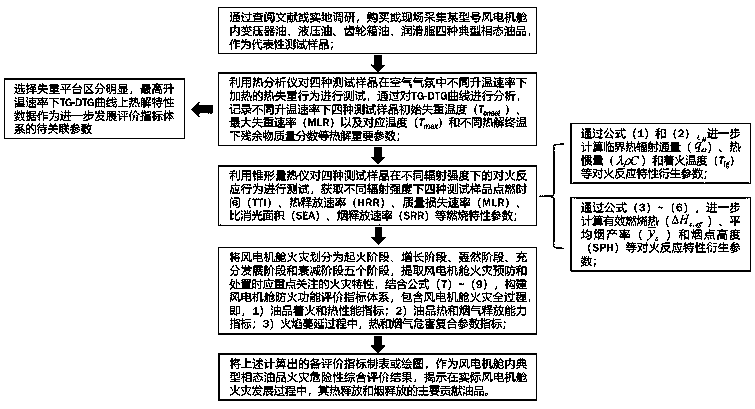

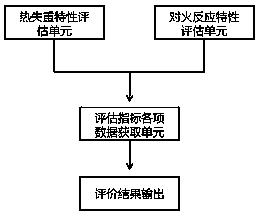

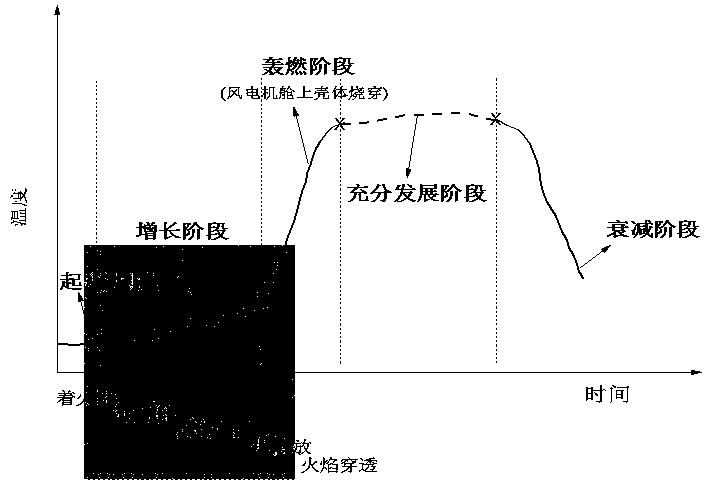

Typical oil product fire hazard evaluation system in wind turbine chamber and evaluation method thereof

PendingCN109781771AOvercome costsOvercome workloadWeighing by removing componentChemical analysis using combustionAir atmosphereNacelle

The invention relates to a typical oil product fire hazard evaluation system in a wind turbine chamber and an evaluation method thereof. A thermal gravimetric analyzer is used for acquiring key thermal decomposition characteristic parameters of a blower fan oil product in an air atmosphere in different temperature increasing speeds. A cone calorimeter is used for acquiring fire reaction characteristic parameters and derivative parameters in different radiation strengths. A fire evaluation process of the wind turbine chamber is divided into fire generating, spreading, flashover, sufficient developing and attenuating. A three-layer fire hazard evaluation structure system in which the oil product corresponds with a fire and pyrolysis characteristic, a heat and exhaust gas discharging capability and a heat and exhaust gas hazard characteristic in different stages is constructed. The system and the method have advantages of performing pyrolysis and fire reaction characteristic representation on a main fire load, performing multidimensional correlation and integrated analysis of pyrolysis and combustion, and realizing diversified evaluation to the full-process latent fire hazard of the wind turbine chamber. The system and the method further have advantages of simple operation, clear theoretical basis, reliable experiment result, and high repeatability. The system and the method provide a basis for wind turbine chamber fire application basis research and intrinsic safety treatment.

Owner:NANJING UNIV OF TECH

Method for evaluating flame retardant effect of nano composite flame retardant on pitch

InactiveCN108982285AEvaluation is scientific and accurateImprove long-term use effectWeighing by removing componentChemical analysis using combustionCombustionOxygen

The invention discloses a method for evaluating the flame retardant effect of a nano composite flame retardant on pitch, and belongs to the technical field of flame retardance. The method solves the problem that other common testing methods such as oxygen indexes, horizontal and vertical burning cannot comprehensively and objectively evaluate the flame retardant effect of the nano composite flameretardant on pitch. Firstly, the nano composite flame retardant is added according to a certain proportion to prepare pitch and a flame retardant modified pitch cone calorimeter sample; then, the bottom face and the surrounding side faces of the sample are wrapped with tin foils, and the sample is pressed by a steel mesh grid; then the combustion time, the heat releasing rate, the effective combustion heat, the mass loss rate, the fuming amount and the smoke toxicity of pitch and the modified pitch sample in which the nano composite flame retardant at different thermal irradiation powers are tested respectively; and finally, after combustion of the sample is ended, the testing results are analyzed, the influences of the nano composite flame retardant to combustion parameters of the pitch sample are compared, the flame retardant and the smoke inhibition effects of the nano composite flame retardant on pitch are evaluated, and evidences are provided for researching and developing efficient nano composite flame retardants.

Owner:NANJING FORESTRY UNIV

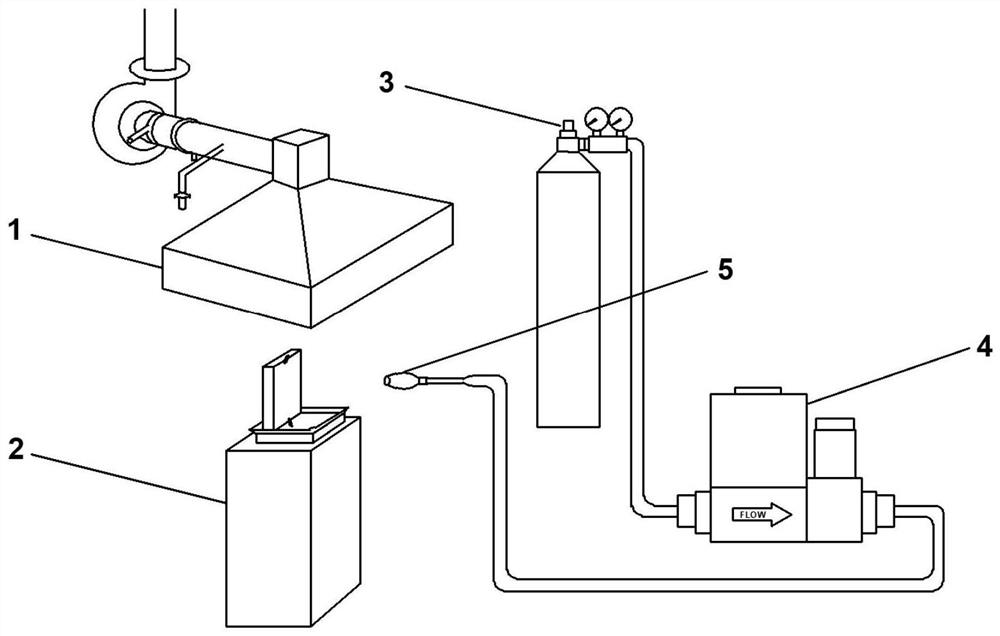

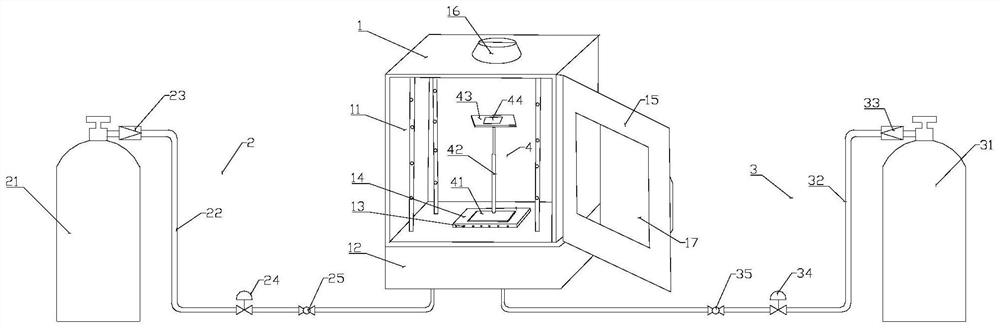

Outer flame ignition platform based on cone calorimeter

PendingCN114217007AEasy to buildEasy to operateChemical analysis using combustionMaterial heat developmentGas cylinderTest sample

The invention relates to an outer flame ignition platform based on a cone calorimeter. The outer flame ignition platform mainly utilizes flames generated after combustible gas in a propane gas cylinder is ignited to ignite a to-be-tested sample in a sample box. According to the novel outer flame ignition platform, the ignition mode of electric spark and heat radiation of a traditional cone calorimeter is expanded, fire scenes capable of being simulated by the cone calorimeter are enriched, and the novel outer flame ignition platform is more suitable for real fire. The outer flame ignition platform further has the advantages of being easy to build, low in production and use cost, easy to operate, economical, safe and the like, and is particularly suitable for fire or combustion simulation experiments in common laboratories.

Owner:WUHAN UNIV OF TECH

Method for testing heat release rate of organic dust

InactiveCN107271483ASolve densitySolve the surface prone to static electricityMaterial heat developmentEngineeringHigh pressure

The invention discloses a method for testing the heat release rate of organic dust. The method comprises steps as follows: step one, to-be-tested powder is taken, dried and sieved; step two, the sieved powder is put into a columnar mold where aluminum foil paper is laid in advance and then pressed, pressure relief and demolding are performed, and a pressed block is obtained; step three, the pressed block is packaged in an elastic bag, the elastic bag is put into a liquid high-pressure cylinder to be subjected to initial-pressure, medium-pressure and high-pressure wet-type forming pressing; step four, heat release performance of a product of the step three is tested with a conical calorimeter. The method for testing the heat release rate of the organic dust is put forward for the first time, the problems that the density of the organic dust is extremely low, static is likely to be produced on the surface, and pressure is non-uniform are solved, and the heat release rate of the organic dust can be tested with the conical calorimeter accurately.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Wood modification to enhance fire retardancy

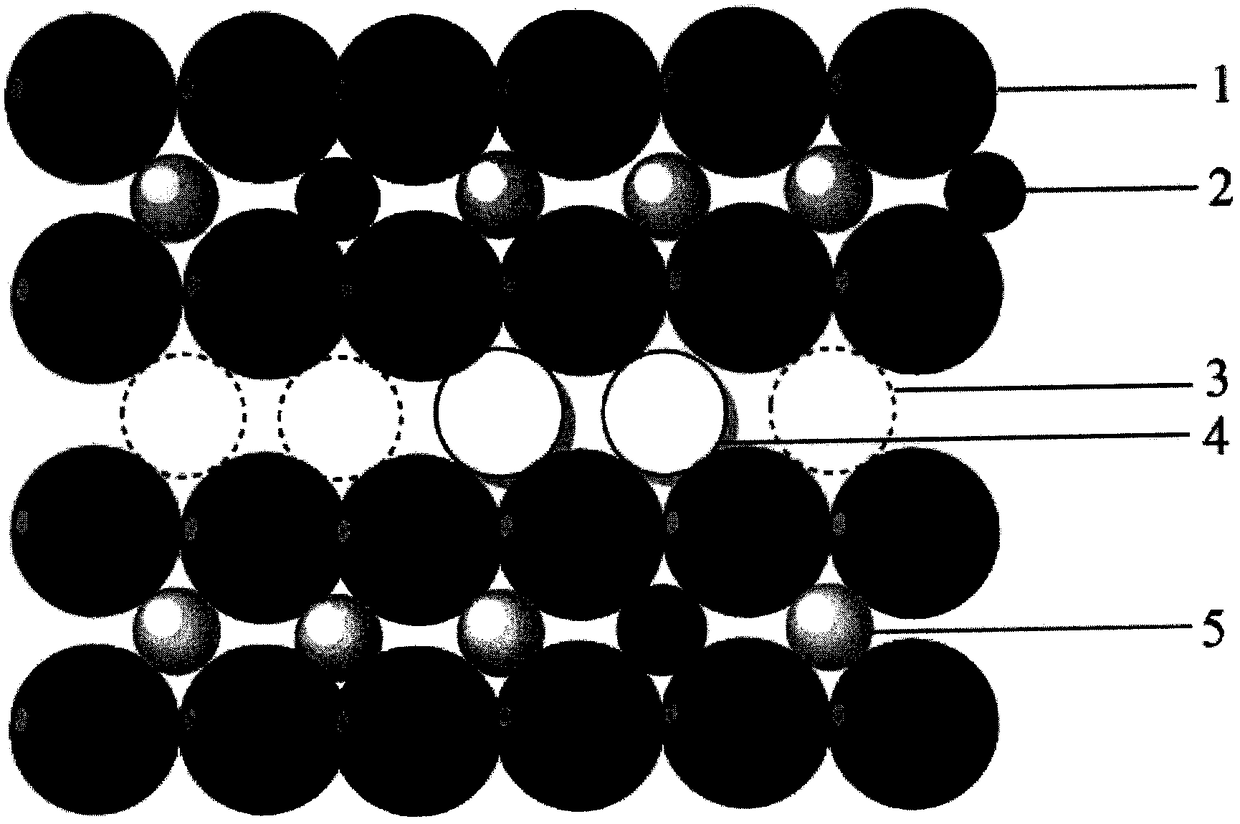

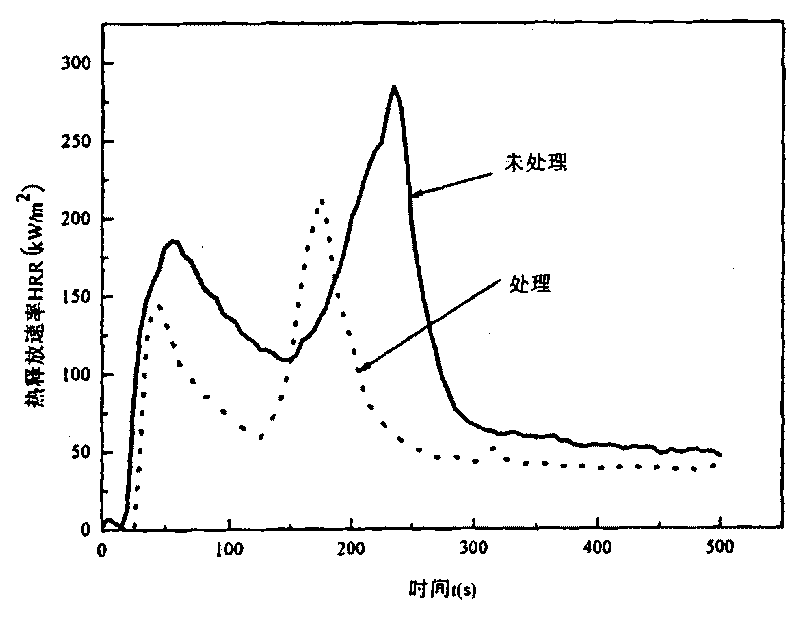

InactiveCN107206616AImprove compactnessGood dimensional stabilityWood treatment detailsThermal wood treatmentCombustionPreservative

The co-formulation of a wood preservative ('treated') with an inorganic (alkali metal silicates) based flame retardant which undergoes chemical impregnation. Once the 'treated flame retardant" working solution has fully penetrated (sapwood) into the wood, it then undergoes a heat (fixation) process using various heating schedules to achieve chemical fixation. The treated flame retardant Modified Wood [tfrMW] products are then tested for their enhanced fire performance properties. When heated, wood undergoes thermal degradation and combustion producing gases, vapours, tars & chars. Using the 'cone calorimeter' test method, the [tfrMW] products showed a significant reduction in the following parameters: heat release rate (HRR), mass loss rate (MLR) & smoke generated (SEA) values compared to untreated radiata pine.

Owner:WOOD MODIFICATION TECH LTD

Real-time measurement method and strengthening method for heat release of Ti-C igniting agent

InactiveCN108760965AVariety of heat releaseVarious temperatureChemical analysis using combustionCombustionSynthesis methods

The invention provides a real-time measurement method and strengthening method for the heat release of a Ti-C igniting agent. A cone calorimeter is adopted to monitor the heat release, temperature andquality parameters of the Ti-C igniting agent in a reaction process in real time, so that accurate and highly reliable physical and chemical parameters are provided for in-depth studying of the preparation of a composite material with a combustion synthesis method; at the same time, in order to further increase the heat release of the Ti-C igniting agent, expandable graphite is adopted to react with titanium powder, so that the heat release is increased, and the combustion reaction is more complete. On the basis of expanding the application of the cone calorimeter, the method of adopting theexpandable graphite to strengthen the heat release of the Ti-C igniting agent is disclosed for the first time, and a new way for research on the mechanism of the combustion synthesis method is openedup.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Environment-friendly flame-retardant nylon 6 nano composite material and preparation method thereof

The invention relates to an environment-friendly flame-retardant nylon 6 nano composite material and a preparation method thereof, which solve the problem of inflammability of a nylon 6 / laminated silicate nano composite material. The flame-retardant nano composite material has the main characteristic that an environment-friendly intumescent flame retardant of melamine polyphosphate (MPP) and a clay lamina retard flame in a synergic mode to achieve V-0 grades of vertical combustion. Meanwhile, a cone calorimeter test result of the flame-retardant nano composite material is obviously improved compared with that of a pure nylon 6 material. The flame-retardant nano composite material is prepared by compounding a nylon 6 monomer, MPP, epoxy resin and organic clay or clay, wherein the nylon 6 monomer, the MPP, the epoxy resin and the clay are existing materials, and the organic clay is prepared in the invention. The invention can be widely applied to fields such as automobiles, electronics,decoration and the like.

Owner:BEIJING UNIV OF CHEM TECH

A test method for heat release rate of organic dust

InactiveCN107271483BIncreased minimum ignition energyReduce the likelihood of an explosionMaterial heat developmentEngineeringHigh pressure

The invention discloses a method for testing the heat release rate of organic dust, comprising the following steps: Step 1, take the powder to be tested, and sieve it after drying; After pressing in the columnar mold, release the pressure and demould to obtain a briquette; step 3, wrap the briquette in an elastic bag, put it into a liquid high-pressure cylinder, and perform initial pressure-medium pressure-high pressure wet molding; step 4, The heat release performance of the product of step 3 is measured by using a cone calorimeter. The invention proposes a method for measuring the heat release rate of organic dust for the first time. It solves the problems of extremely low density of organic dust, easy generation of static electricity on the surface, and uneven pressure, and can accurately measure its heat release rate with a cone calorimeter.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

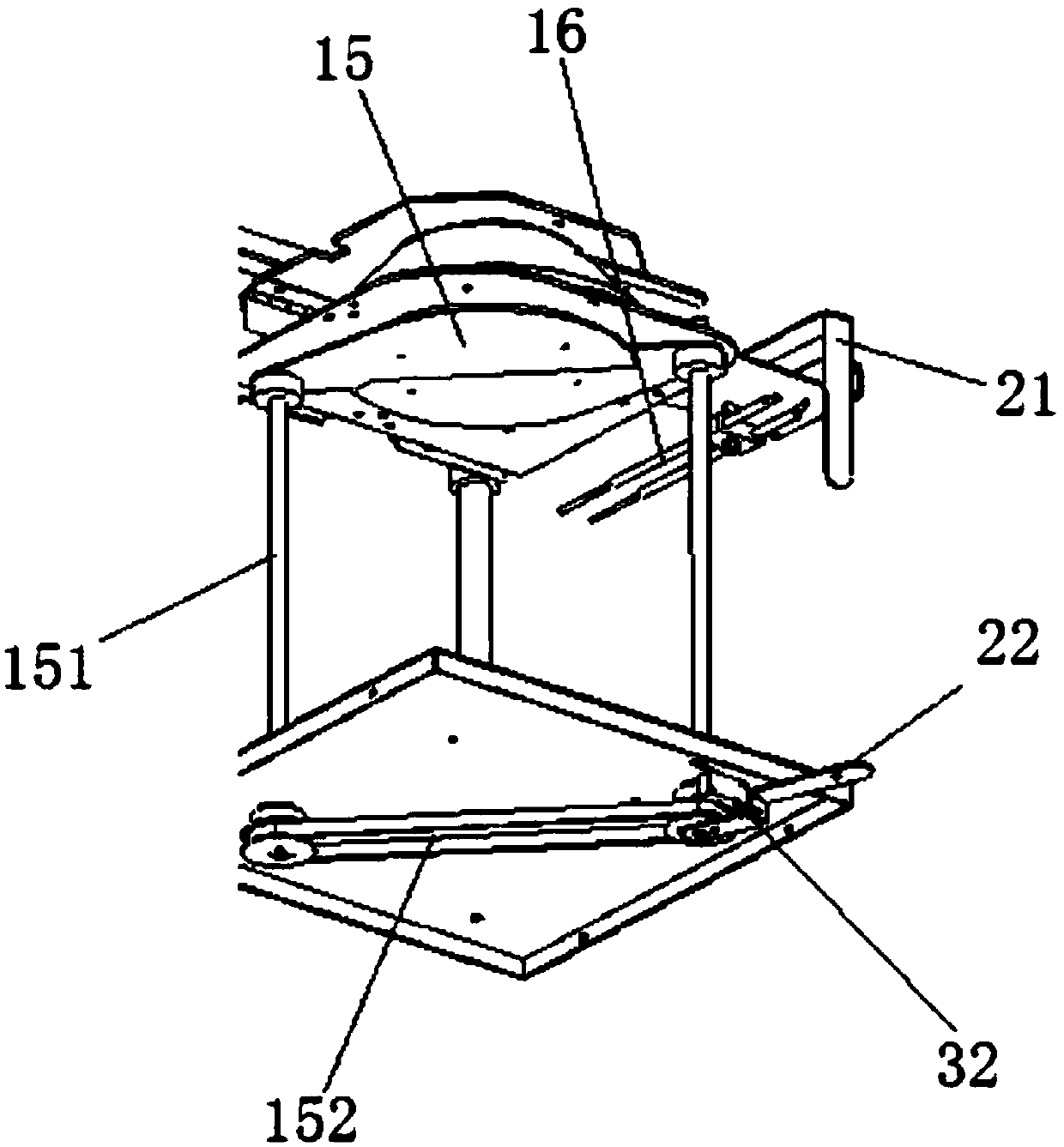

Combustion box capable of adjusting gas environment

PendingCN113588864AMeet the test requirementsImprove test accuracyChemical analysis using combustionThermodynamicsProcess engineering

The invention discloses a combustion box capable of adjusting a gas environment. And through the design of the box body, a relatively closed combustion environment can be realized. The top of the structure is provided with the exhaust port, mixed gas of nitrogen and oxygen is injected from bottom to top, and gas in the box body can be replaced in all directions before a combustion test, so that the gas environment in the combustion box meets test requirements. The gas proportion can be obtained by adjusting the nitrogen assembly and the oxygen assembly. The combustion box is suitable for combustion instruments, such as a cone calorimeter, of which the gas environment cannot be adjusted. When the combustion box is combined with a combustion instrument for use, the exhaust port can be used as an exhaust channel and can also be used as an ignition channel, and thermal load and electronic ignition of the combustion instrument can be completed through the exhaust port.

Owner:ELECTRIC POWER RES INST OF STATE GRID ANHUI ELECTRIC POWER +2

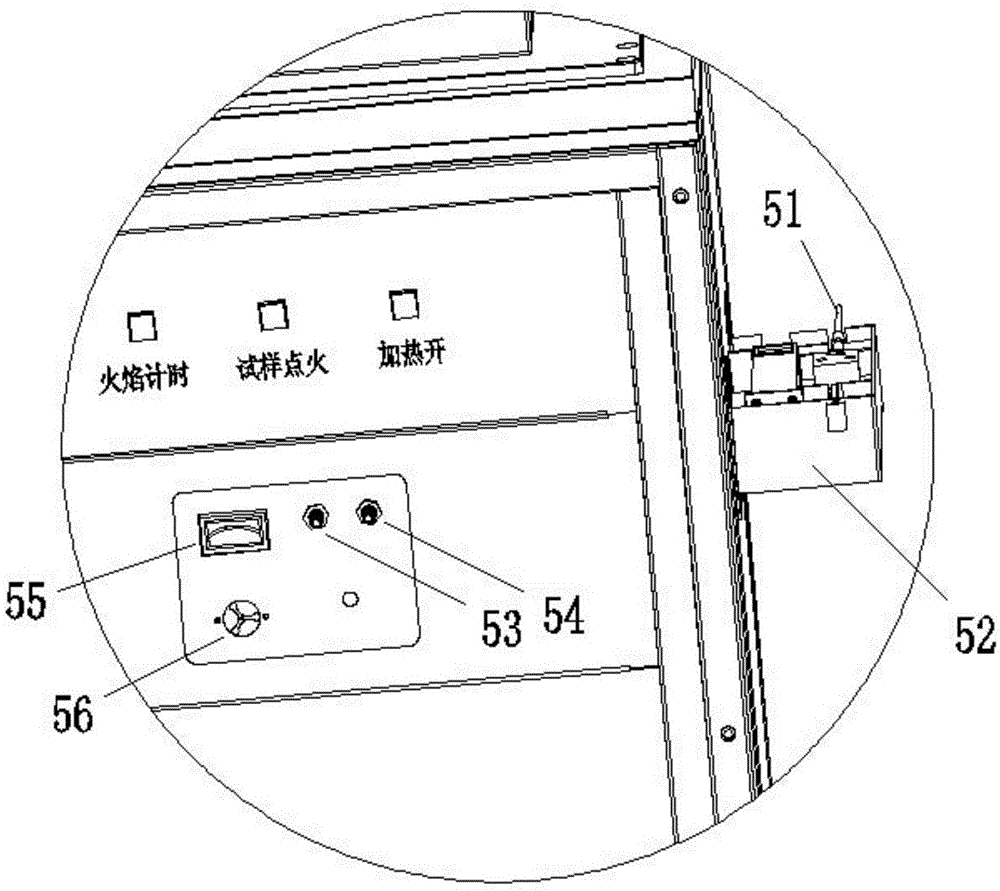

Ignition for Cone Calorimeters

ActiveCN104698031BGuaranteed reliabilityImprove accuracyMaterial heat developmentEngineeringIgnition timing

Owner:中检计量检验(深圳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com