Sample containing device for cone calorimeter and test method

A cone calorimeter and holding device technology, applied in the direction of material thermal development, can solve problems such as offset, use limitation, thin and light sample warping, etc., to expand the use range, eliminate system errors, improve accuracy and reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

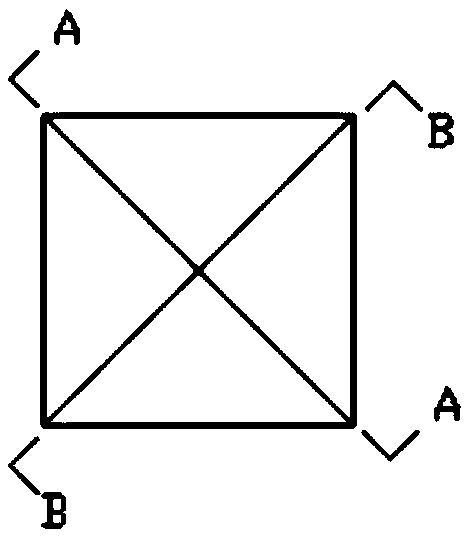

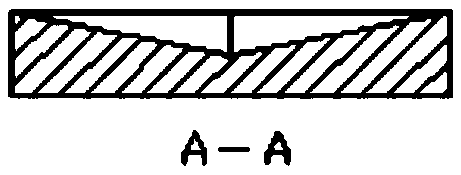

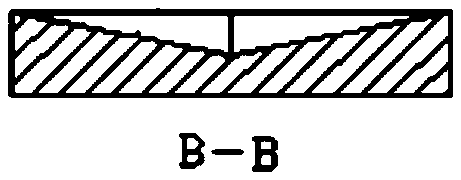

[0023] According to a preferred embodiment of the present invention, the structure of the sample holder is as Figure 1a-Figure 1c shown. The accompanying drawing shows that the sample holder is a cuboid with the recess formed on the top, wherein the bottom surface of the sample holder is square, the recess is an inverted regular pyramid, and the bottom area of the regular pyramid is equal to the area of the bottom surface of the sample holder.

[0024] According to the sample holding device of the present invention, the material of the sample rack can be selected with reference to the prior art, for example, it can be selected from heat insulating materials that can withstand 1000°C. From the viewpoint of easy availability of materials, it is preferable that the material of the sample holder is selected from ceramics or corundum.

[0025] In the present invention, the grid is used to cover the recess, and this structure can ensure that the synthetic fiber-containing texti...

Embodiment 1

[0040] This embodiment is used to illustrate the sample holding device and test method for the cone calorimeter of the present invention.

[0041] The sample holding device used in this embodiment is specifically as follows: the structure of the sample rack is as follows: Figure 1a-Figure 1c As shown, the material of the sample holder is ceramic, and the height of the sample holder is 27mm; the slope of the conical surface of the concave part is 1:5. The grid is welded by 6 vertical and 6 horizontal stainless steel wires, the length of each stainless steel wire is 10mm, and the diameter is 2mm.

[0042] The test method of the present embodiment is carried out according to the following steps:

[0043] (1) Accurately cut 10cm×10cm to be tested 210g / m 2 Several pieces of pure polyester woven fabric samples;

[0044] (2) Place the sample to be tested in an oven at 100°C and dry to constant weight;

[0045] (3) Stack the samples to be tested in 3 layers and wrap them with alum...

Embodiment 2

[0056] This embodiment is used to illustrate the sample holding device and test method for the cone calorimeter of the present invention.

[0057] The sample holding device used in this embodiment is specifically as follows: the structure of the sample rack is as follows: Figure 1a-Figure 1c As shown, the material of the sample holder is ceramic, and the height is 27mm; the slope of the conical surface of the concave part is 1:57. The grid is welded by 6 vertical and 6 horizontal stainless steel wires, the length of each stainless steel wire is 10mm, and the diameter is 2mm.

[0058] The test method of the present embodiment is carried out according to the following steps:

[0059] (1) Accurately cut 10cm×10cm to be tested 160g / m 2 Several pieces of nylon / spandex blended textile samples;

[0060] (2) Place the sample to be tested in an oven at 100°C and dry to constant weight;

[0061] (3) Stack the samples to be tested in 6 layers and wrap them in aluminum foil;

[0062]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com