Accurate calibration method for MWD (measurement while drilling) system and application of accurate calibration method

A calibration method and precise technology, applied in the calibration field, can solve problems such as large fluctuations in the calculation results of inclination angle and azimuth angle, and the inability to fundamentally achieve the purpose of accurate calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Embodiment of the present invention: the accurate calibration method of MWD system comprises the following steps:

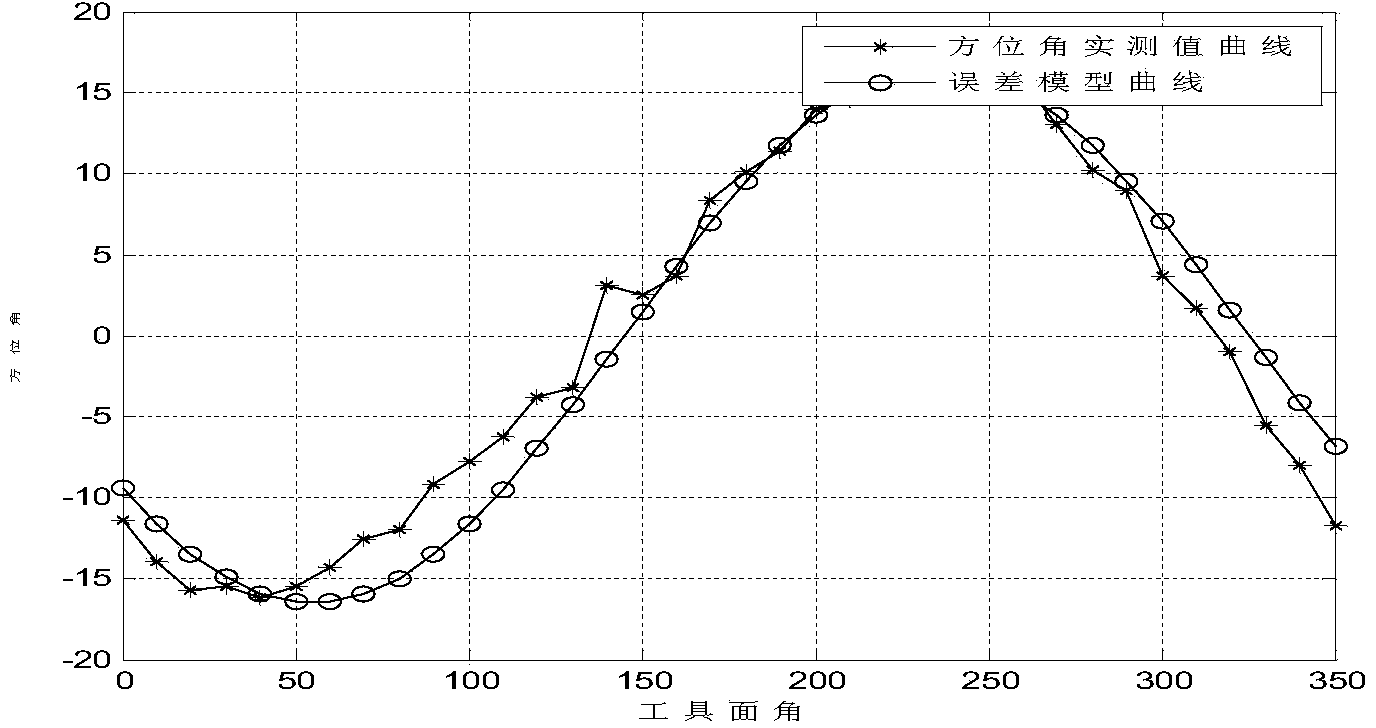

[0072] a. Look up the table according to the real-time calculation results of MWD system inclination and azimuth to obtain the error model curve coefficient;

[0073] b. Construct the error model curve through the coefficients of the error model curve, and use the error model curve to calibrate the inclination and azimuth calculation results of the MWD system to obtain the accurately calibrated inclination and azimuth.

[0074] Wherein, the error model curve coefficient described in the step a is constructed by the following method:

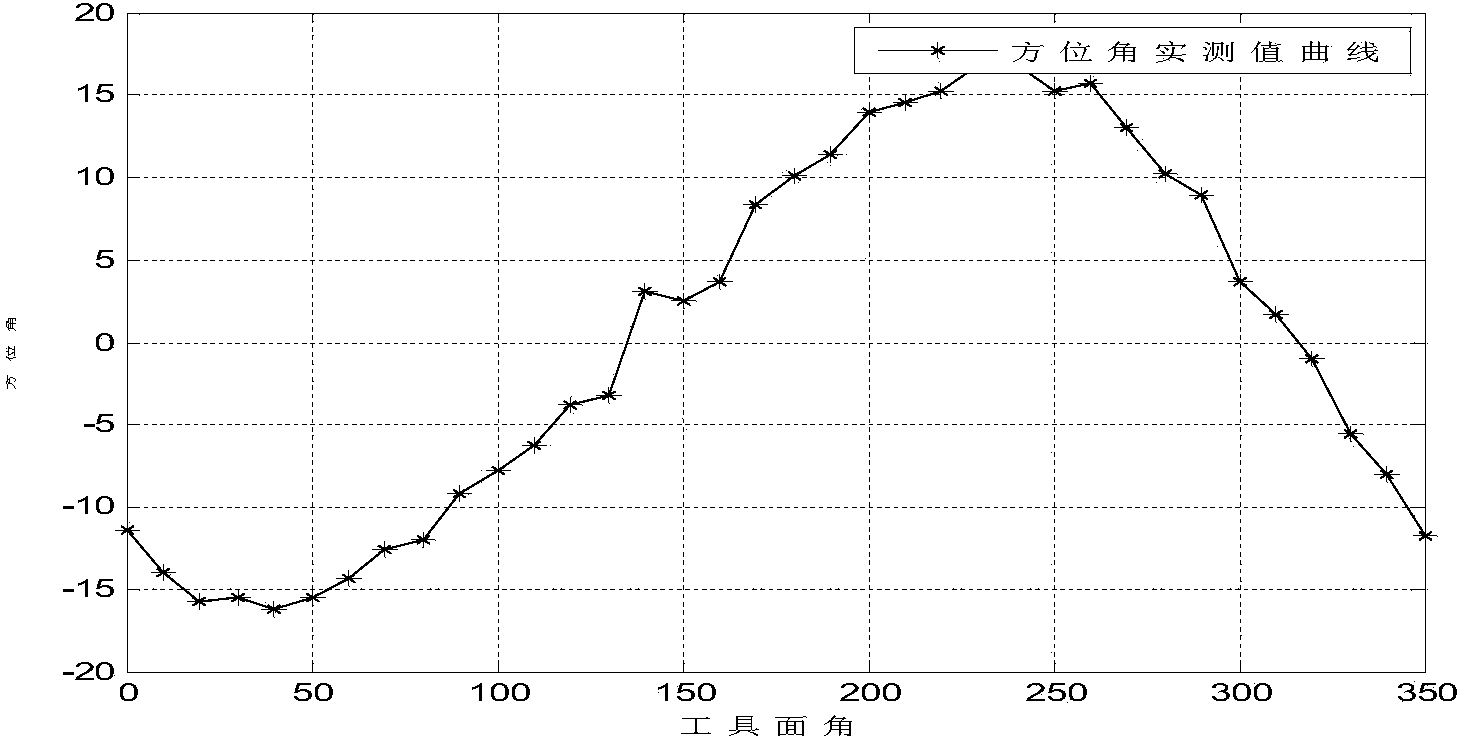

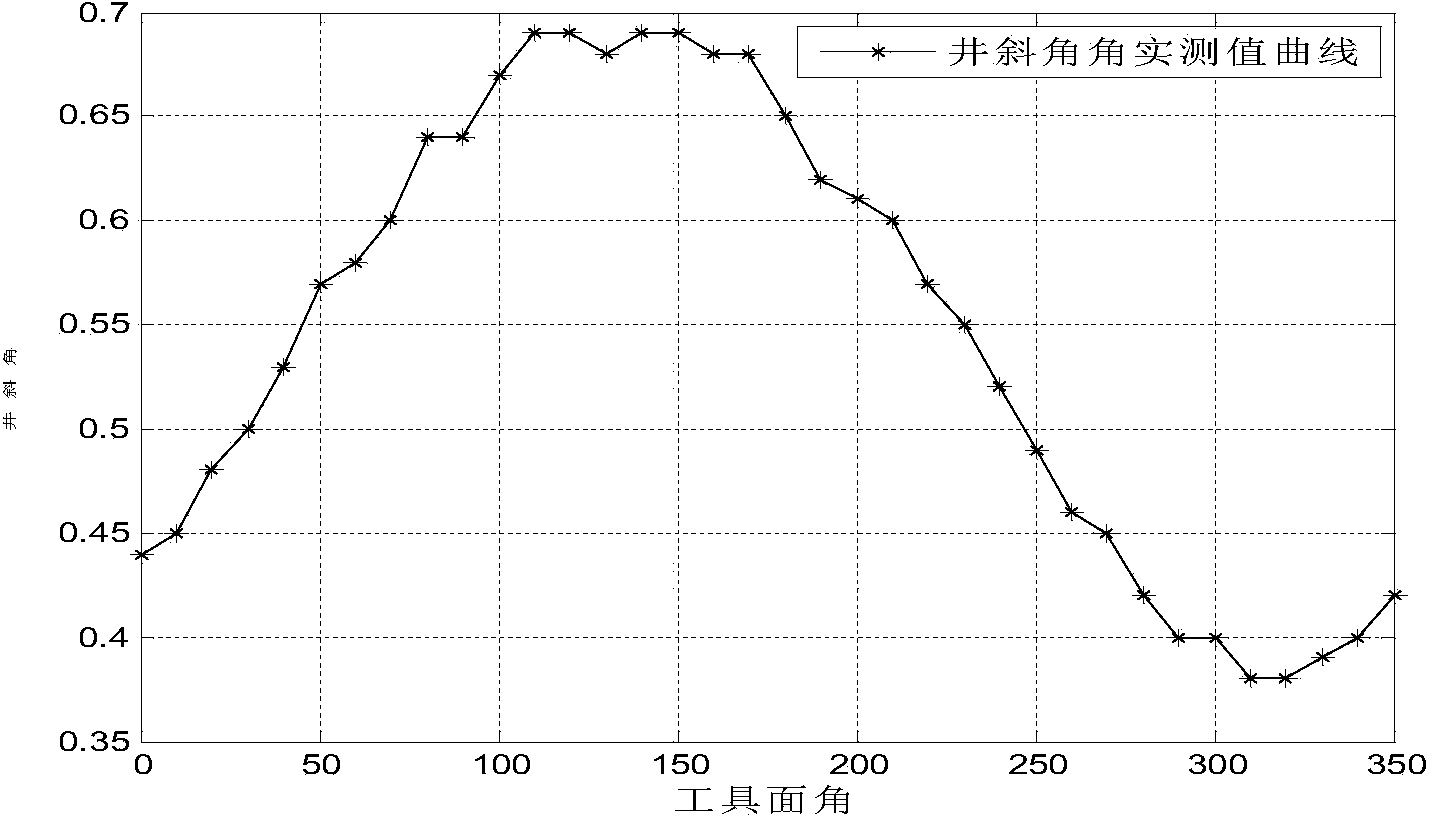

[0075] S1. Under the condition of the set attitude (the inclination angle and azimuth angle are set to a fixed value, and the tool face angle changes from 0 to 350 degrees at the same time), use the three-axis turntable to measure the inclination angle and azimuth angle of the MWD system, and obtain The output of acceleromet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com