Patents

Literature

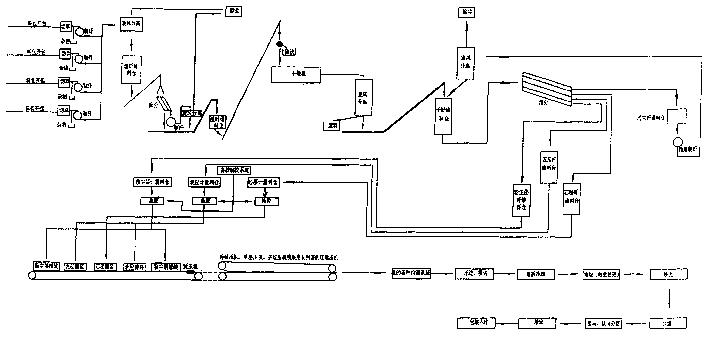

335results about "Open tank impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Phase-change energy storage heat-insulation solid wood and manufacturing method thereof

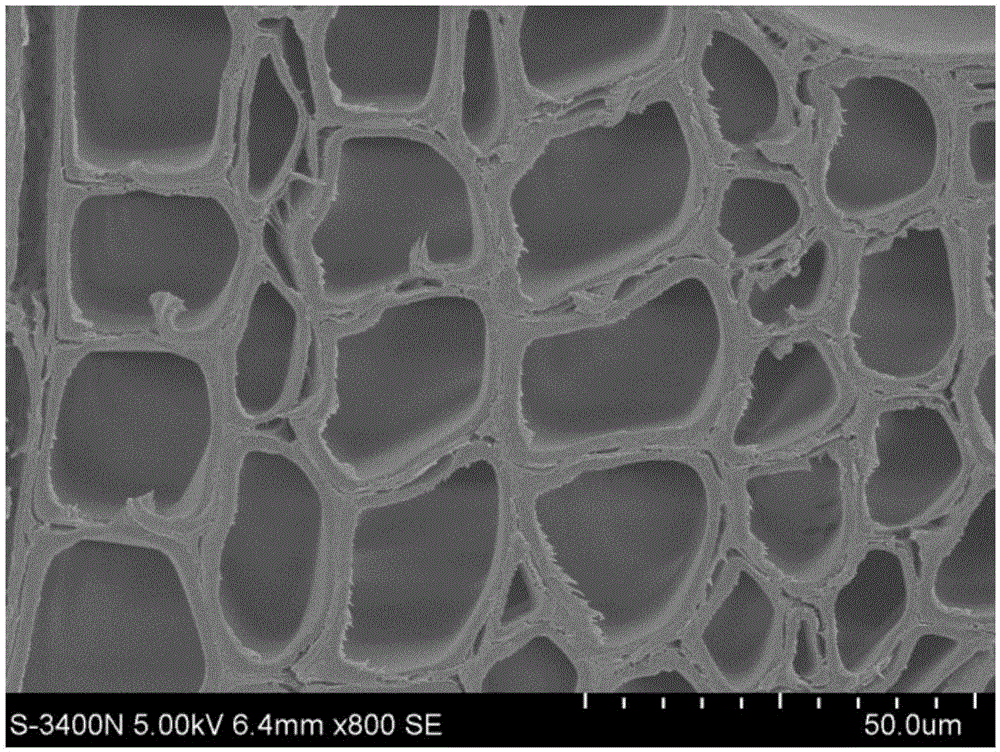

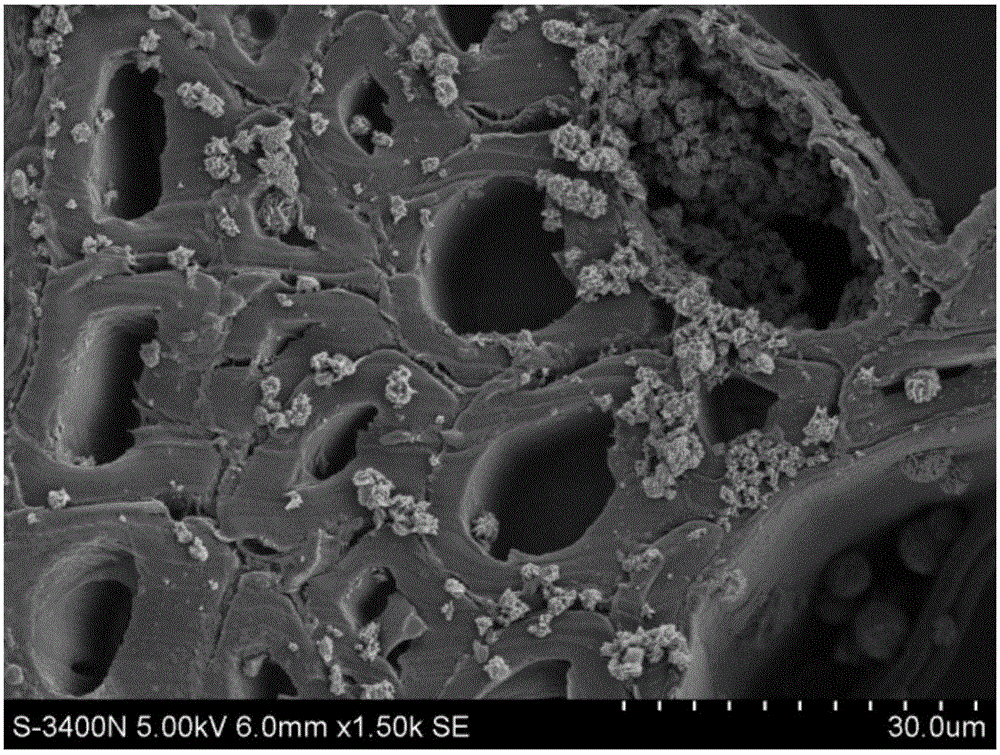

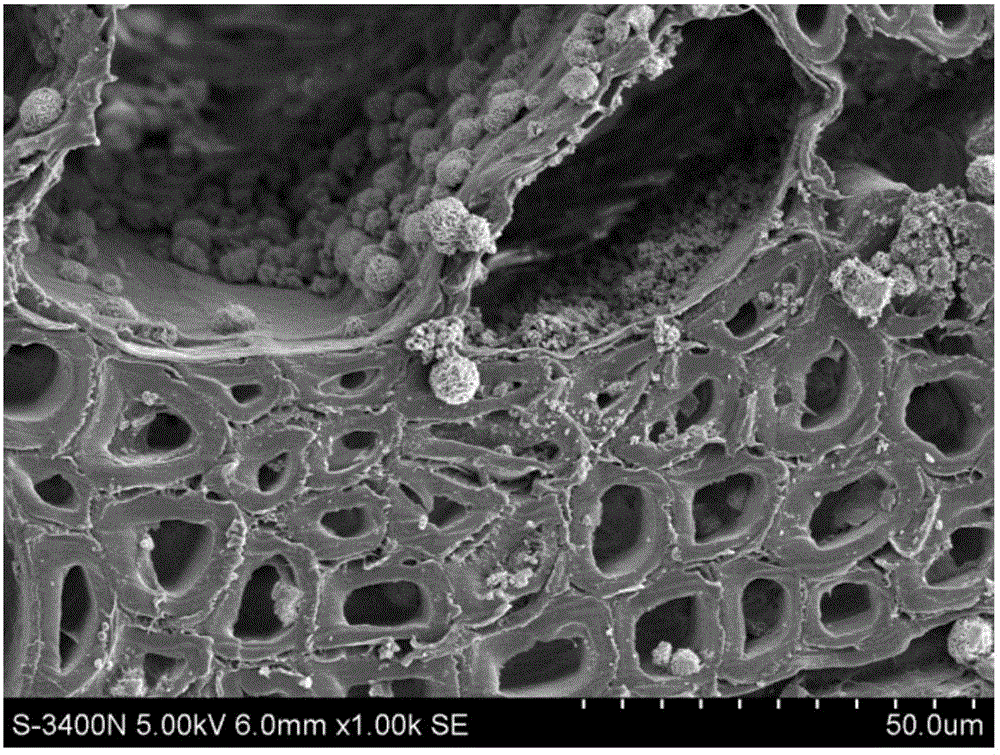

ActiveCN106625930ALow viscosityFacilitated Diffusion MigrationPressure wood treatmentWood treatment detailsSolid woodCell cavity

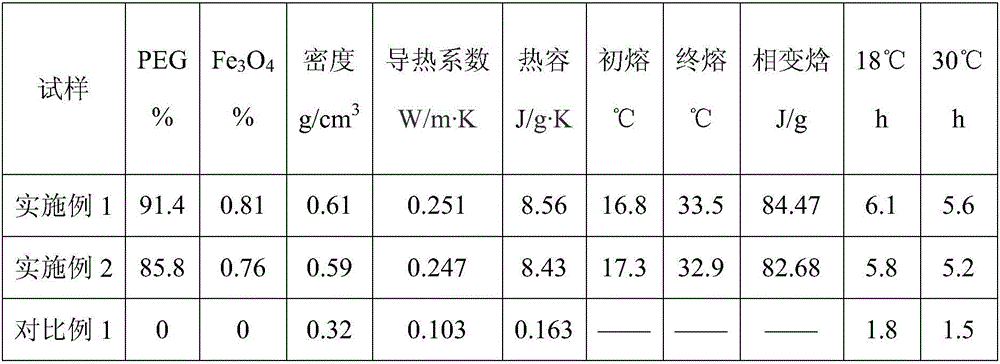

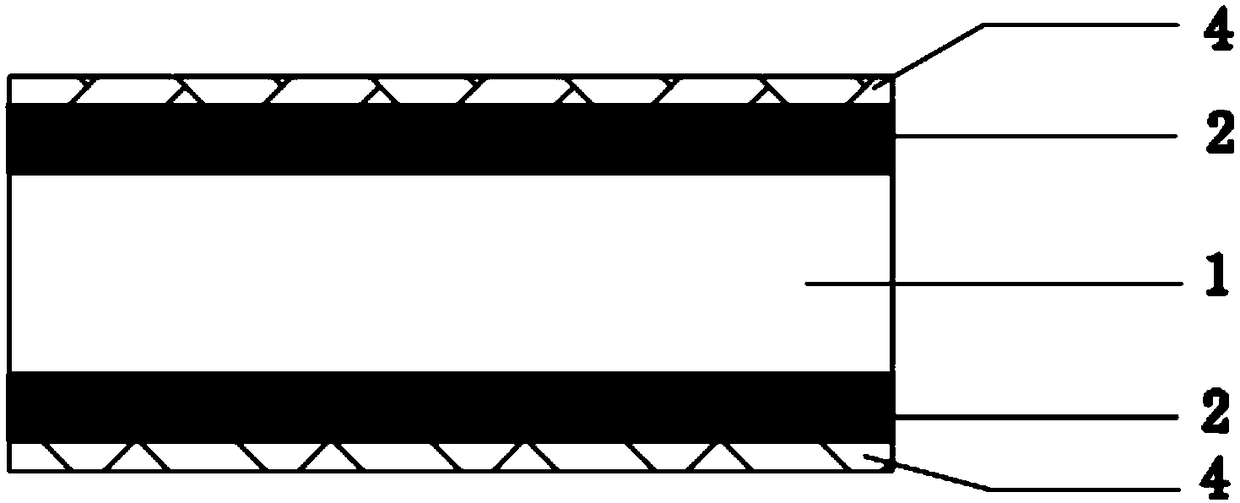

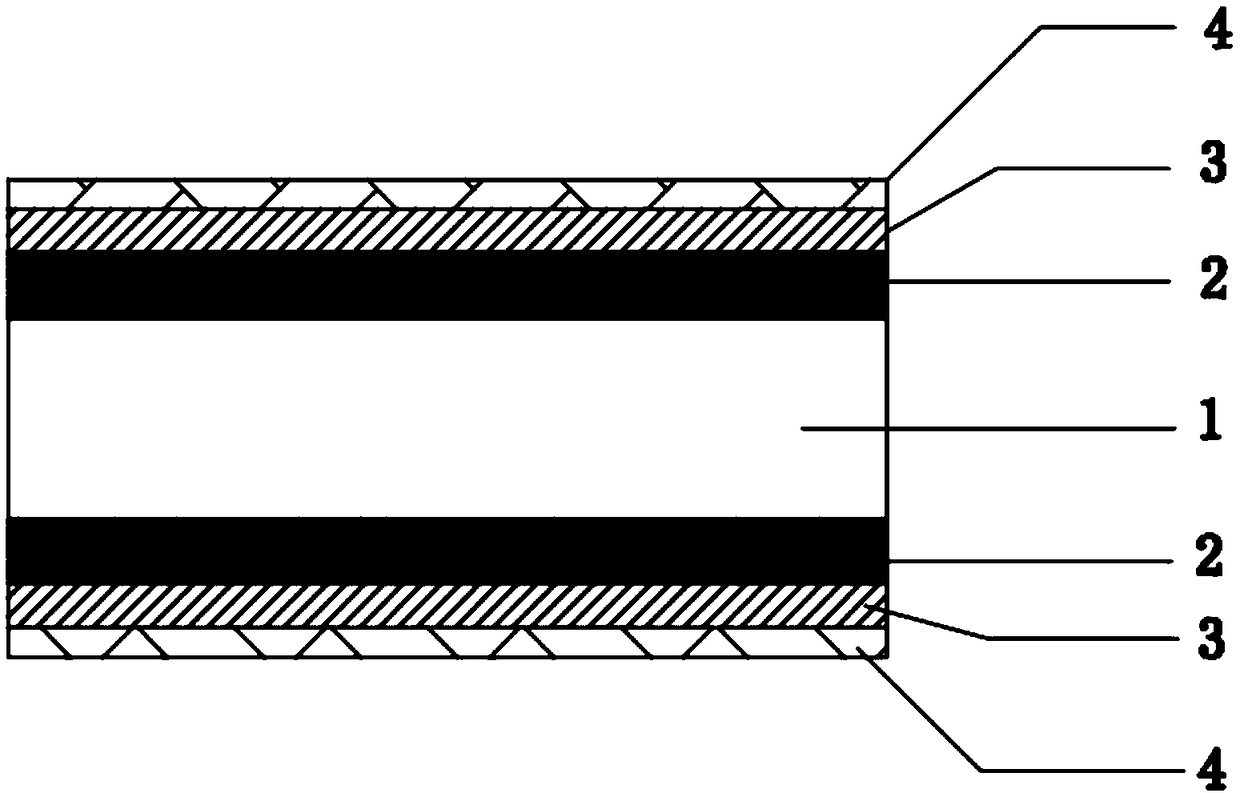

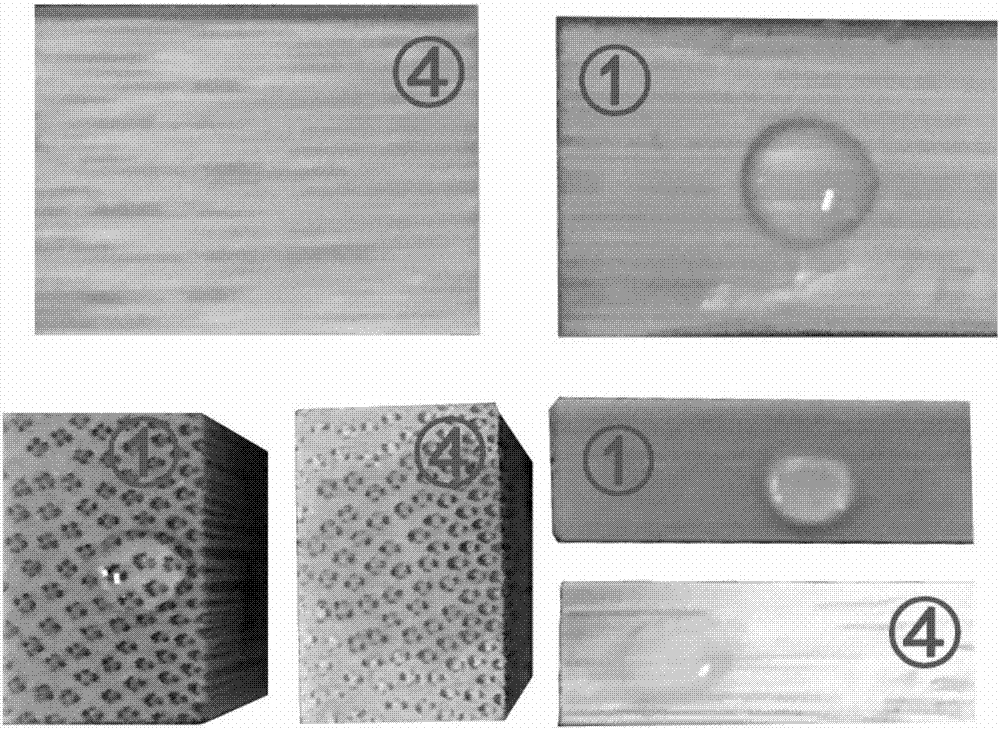

The invention provides phase-change energy storage heat-insulation solid wood. The wood comprises a solid wood component, wherein magnetic Fe3O4 nanoparticles are formed in a conduit and a cell cavity of the solid wood component through in-situ attached growth, and the conduit and the cell cavity are filled with composite phase-change energy storage materials of polyethylene glycol 600 and polyethylene glycol 800; and a protective coating is painted on the surface of the heat-insulation solid wood. The heat-insulation solid wood is capable of absorbing heat to withstand excessive rise of an indoor temperature during the day, releasing phase-change latent heat for thermal retention and cold dispelling during the night, and maintaining a human body within a comfort temperature range. The invention further provides a manufacturing method of the heat-insulation solid wood. The method comprises the steps of firstly processing the solid wood component according to the required dimension; carrying out degreasing and drying pretreatment on the solid wood component, forming the magnetic Fe3O4 nanoparticles in the solid wood component through in-situ attached growth and then impregnating and filling the composite phase-change energy storage material of the polyethylene glycol 600 and the polyethylene glycol 800; and finally carrying out sanding shaping and painting the protecting coating. According to the manufacturing method, the process is simple and the cost is low.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Flame-retardant impregnated film adhesive facing artificial board and manufacturing method thereof

InactiveCN108656250AIncreasing the thicknessQuality improvementWood treatment detailsPaper/cardboard layered productsWood veneerAdhesive

The invention discloses a flame-retardant impregnated film adhesive facing artificial board and a manufacturing method thereof. The flame-retardant impregnated film adhesive facing artificial board mainly comprises a flame-retardant core board, flame-retardant middle boards and an impregnated film adhesive layer; the upper surface and the lower surface of the flame-retardant core board are bondedwith the flame-retardant middle boards through glue, after the flame-retardant core board and the flame-retardant middle boards are pressed, a flame-retardant base material layer is obtained, the upper surface and the lower surface of the flame-retardant base material layer are bonded with impregnated film adhesive layers through glue, and after the flame-retardant base material layer and the impregnated film adhesive layers are subjected to pressing, compounding, edge aligning, a finished product is obtained. In addition, flame-retardant wood veneer layers are included and adhere to the uppersurfaces and the lower surfaces of the flame-retardant middle boards so that the thickness and / or the flatness of the base material layer can be adjusted. The flame-retardant impregnated film adhesive facing artificial board and the manufacturing method thereof have the beneficial effects that a flame-retardant impregnating method and a flame-retardant adhesive agent method are suitable for various wood boards, independent using and combined using can be achieved, and the general applicability is high; and in addition, the method operation process is simple, the treatment cost is low, large-size equipment does not need to be additionally arranged, and the product appearance effect cannot be influenced.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Medium and high density artificial board of stalk and producing process and use

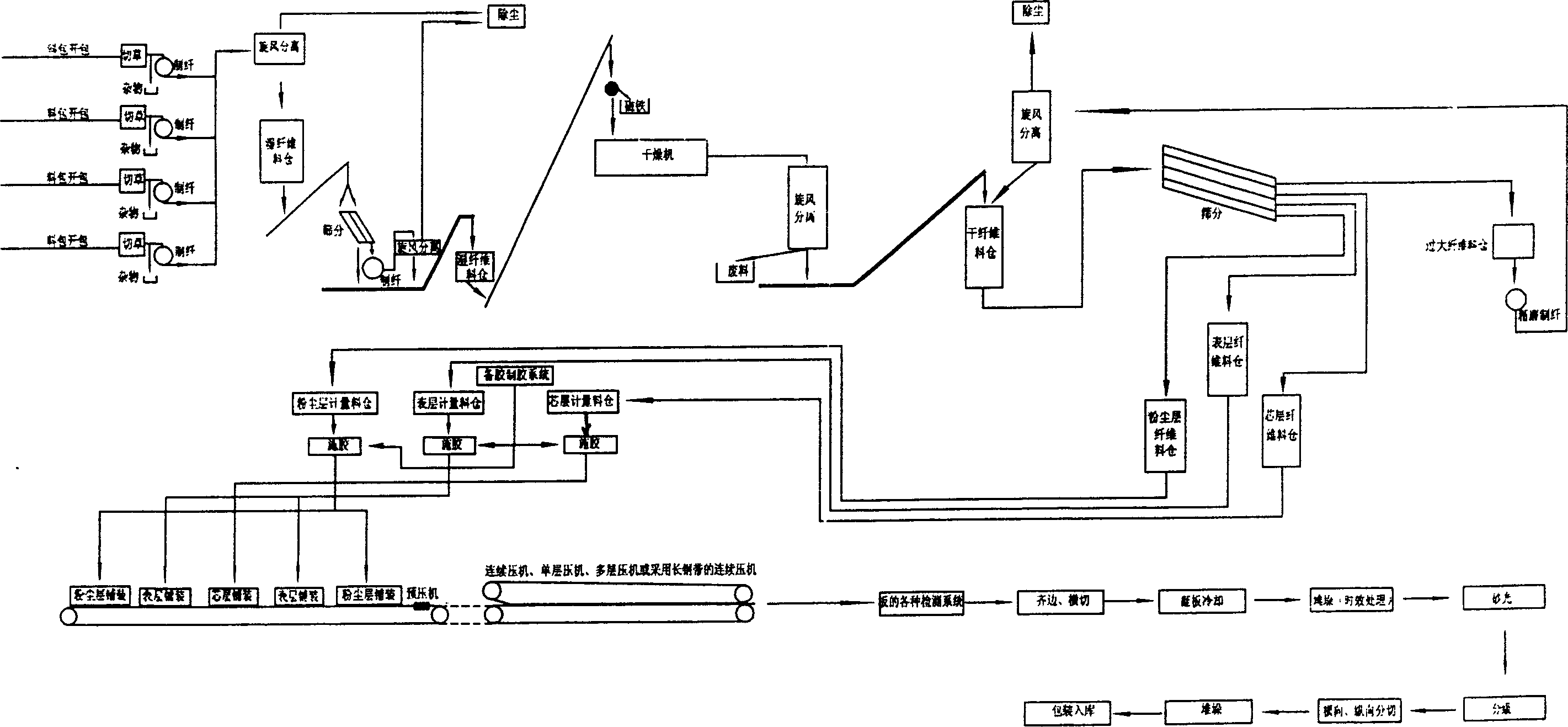

Medium and high density artificial board is produced with wheat straw, rice straw, etc as main material; and the production process includes the steps of: wet fiber preparation, dry fiber preparation, mixing with glue, spreading, demolding, pre-pressing, hot pressing, board blank treatment, grinding and others. The medium and high density straw board may be further produced into facing board, reinforced floor board, etc. The medium and high density straw board may have performance similar to that of wooden fiber board, and is non-toxic and waterproof.

Owner:正源控股股份有限公司

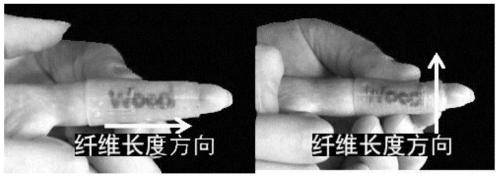

Softener and application method thereof in slicing bamboo wood

InactiveCN101733801AMaintain structureMaintain colorOpen tank impregnationWood impregnation detailsAlcoholGlycerol

The invention discloses a softener and an application method thereof in slicing bamboo wood. The softener is composed of the following components by weight percentage: 20-30% of sodium carbonate, 20-40% of glycerol, 35-45% of alcohol and 4-6% of sodium fluoride. The application method comprises the following steps: adding the softener at the ratio of 8-12% into pool water to be prepared into softening liquid; putting a bamboo board blank to be softened into the pool; after dipping for 24-48 hours at normal temperature, increasing the temperature to 55 DEG C by boosting two DEG C per hour; keeping for 60-72 hours, and stopping boosting the temperature; and when temperature is lowered to 28-30 DEG C, taking out the bamboo board blank; and entering the next working procedure. The invention has the beneficial effect that the softener has minimum damage on bamboo wood and adhesive layers, has no harm and toxicity and has obvious softening effect, short softening period, small energy consumption, easy operation and low cost; slicing yield is above 90%, and slicing thickness can reach 10-12 decimillimetres.

Owner:FUJIAN JIAYI BAMBOO PRODS DEV

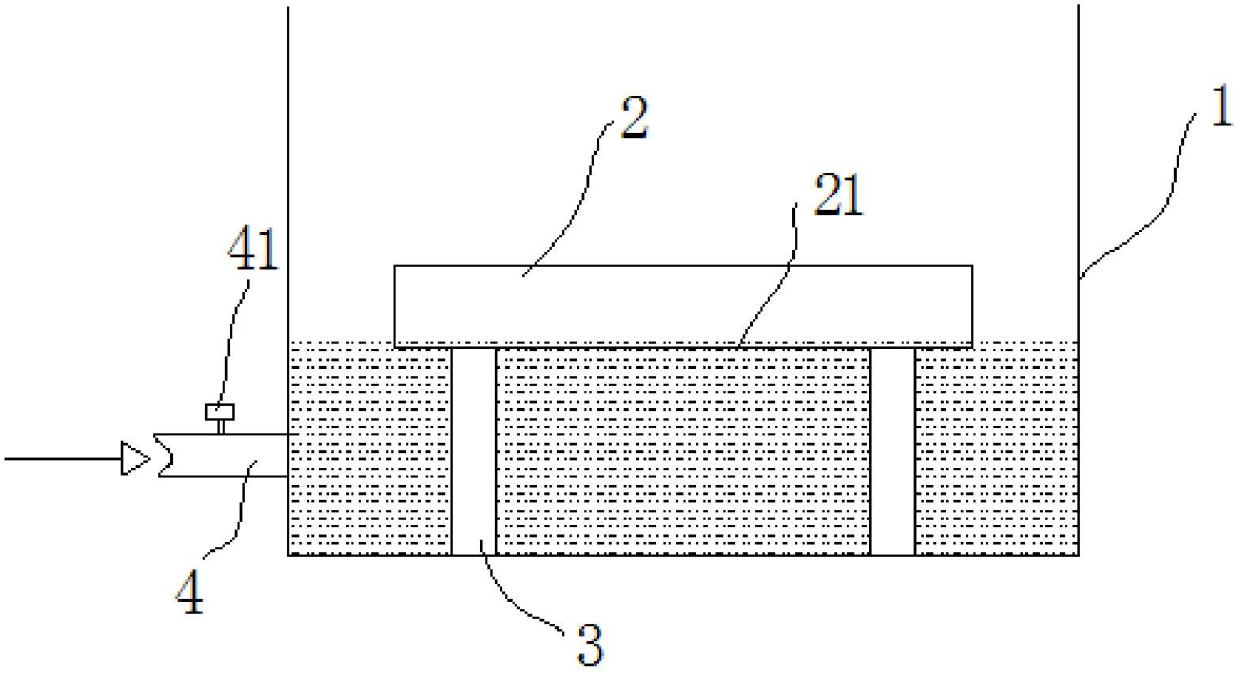

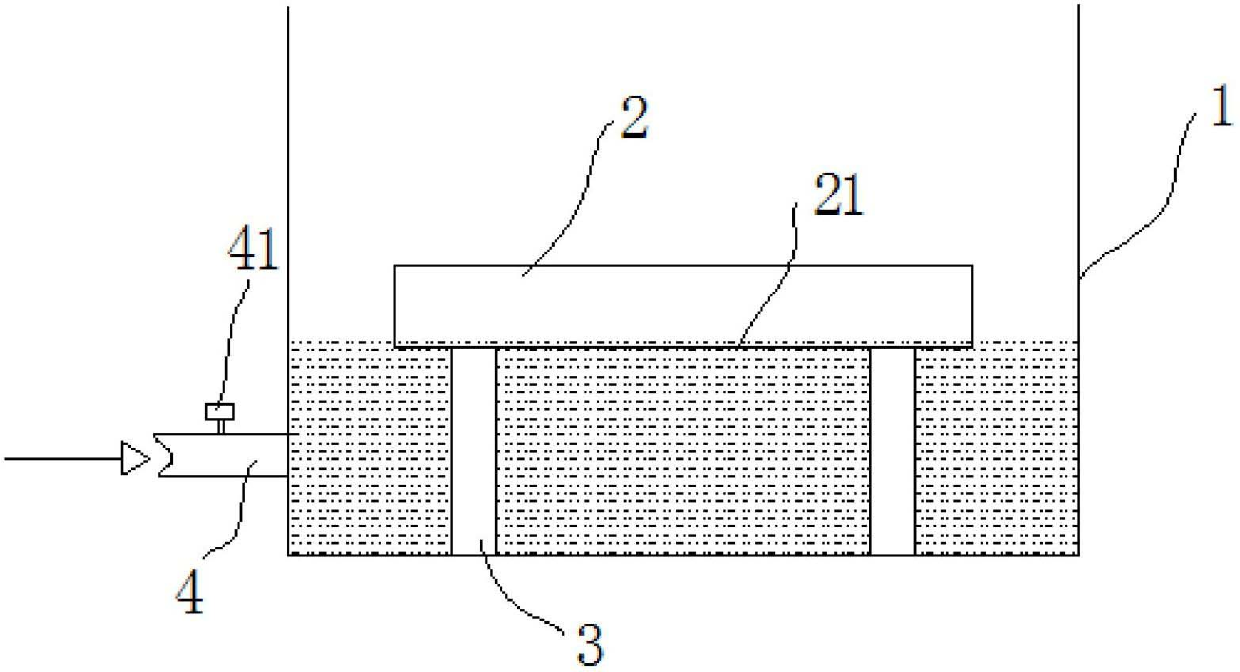

Single-side surface layer densification processing method and product for wood

InactiveCN102672771AReduce manufacturing costReduce drying stepsWood compressionOpen tank impregnationSurface layerMaterials science

The invention discloses a single-side surface layer densification processing method and a product for wood. The method includes dipping treatment; a dried board base material is dipped into a dipping tank filled with agents, the dipping thickness of the surface of the board base material is controlled through control of the dipping depth of the board base material into the liquid level of the agents, the agents include urea resin and nano calcium carbonate granules, and the nano calcium carbonate granules enter the pores of the board base material during the dipping. A floorboard produced through the processing method is composed of a densification layer and the board base material, and the lower surface of the densification layer is connected with the upper surface of the board base material. According to the processing method, the dipping thickness of the floorboard is controlled through the increase and decrease of the liquid level height of the agents, only the surface of the floorboard contacts with the agents, therefore the agents are saved; drying after dipping is not needed, and quality problems caused by the dipping and drying can be avoided, processing steps are reduced, and outturn percentage is improved.

Owner:ZHEJIANG LINTAN WOOD SCI & TECH +1

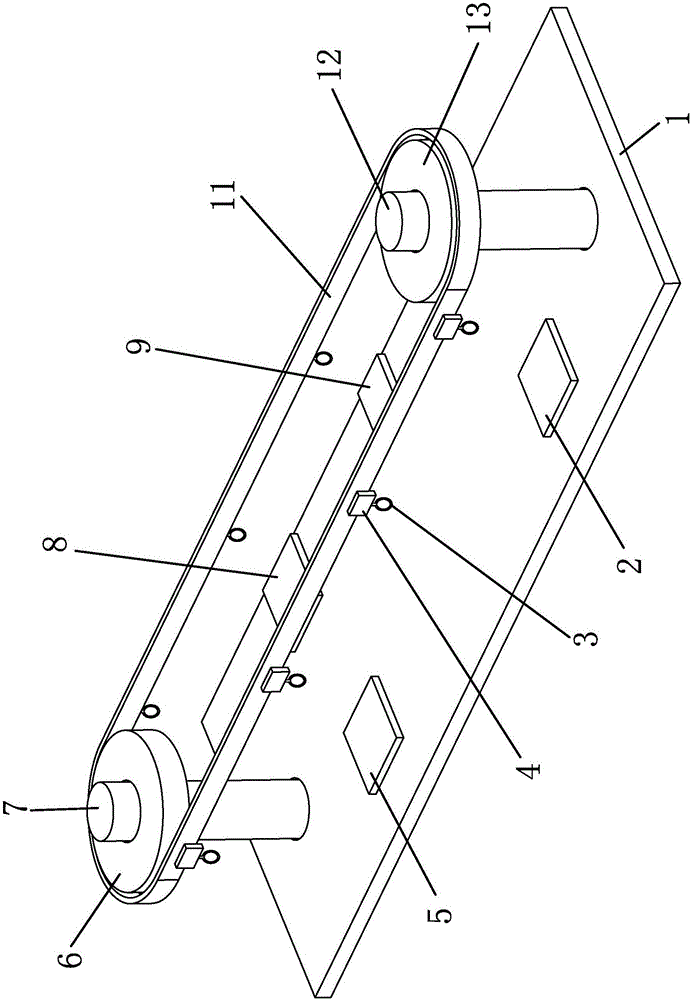

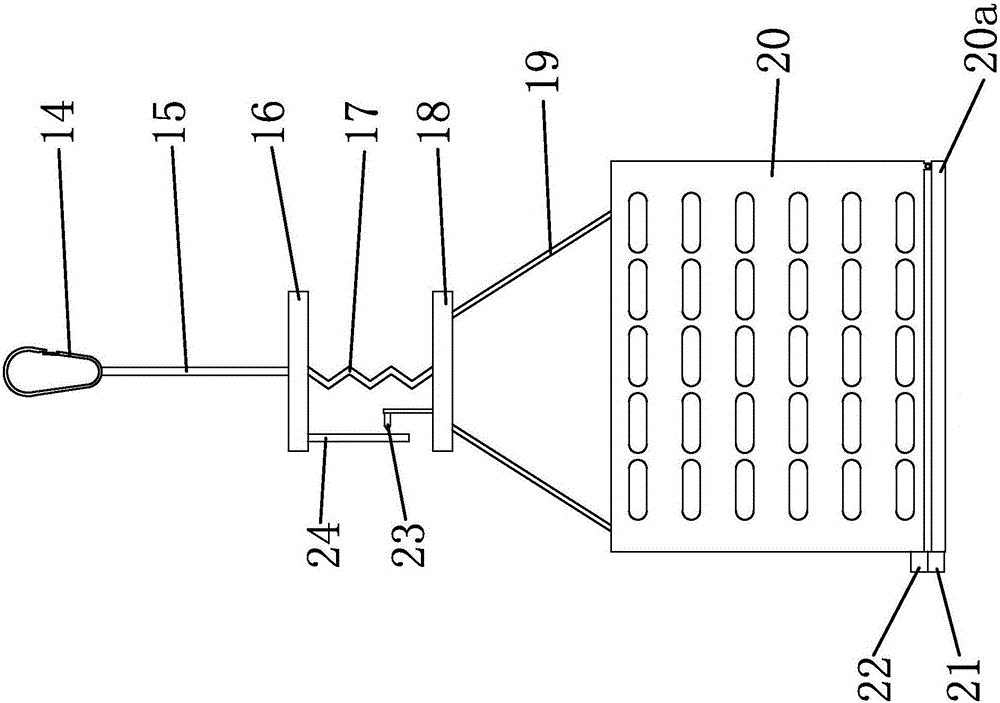

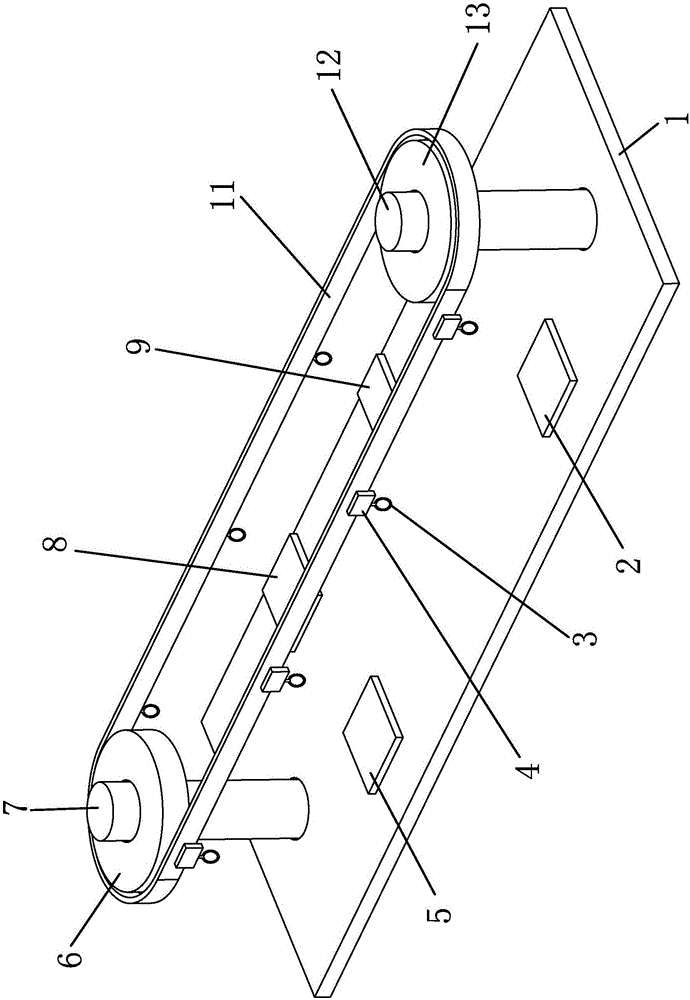

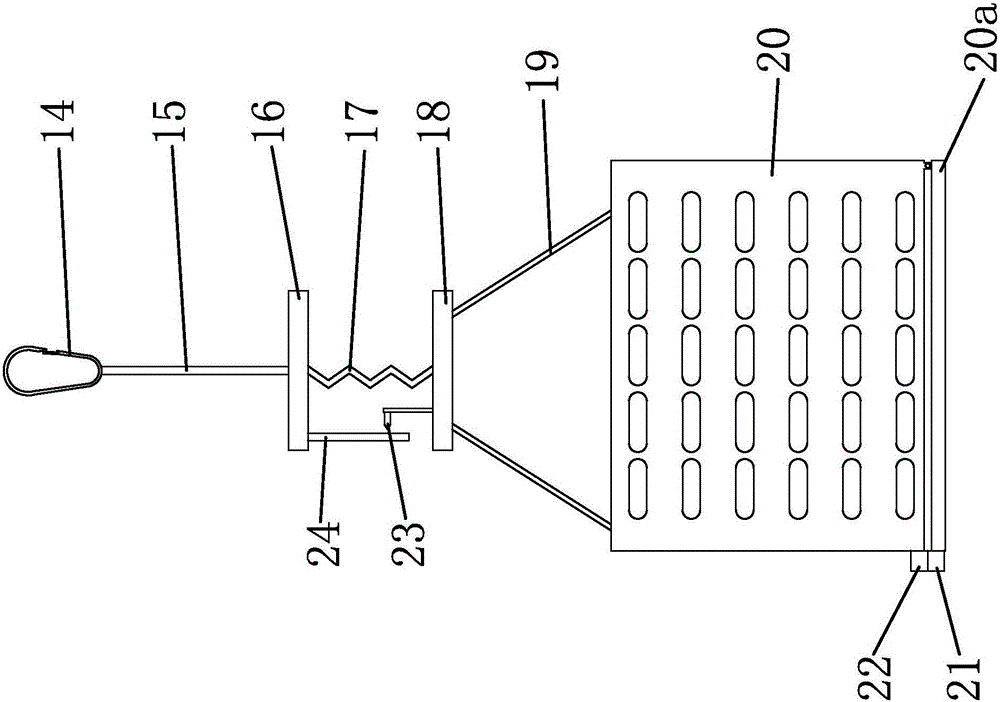

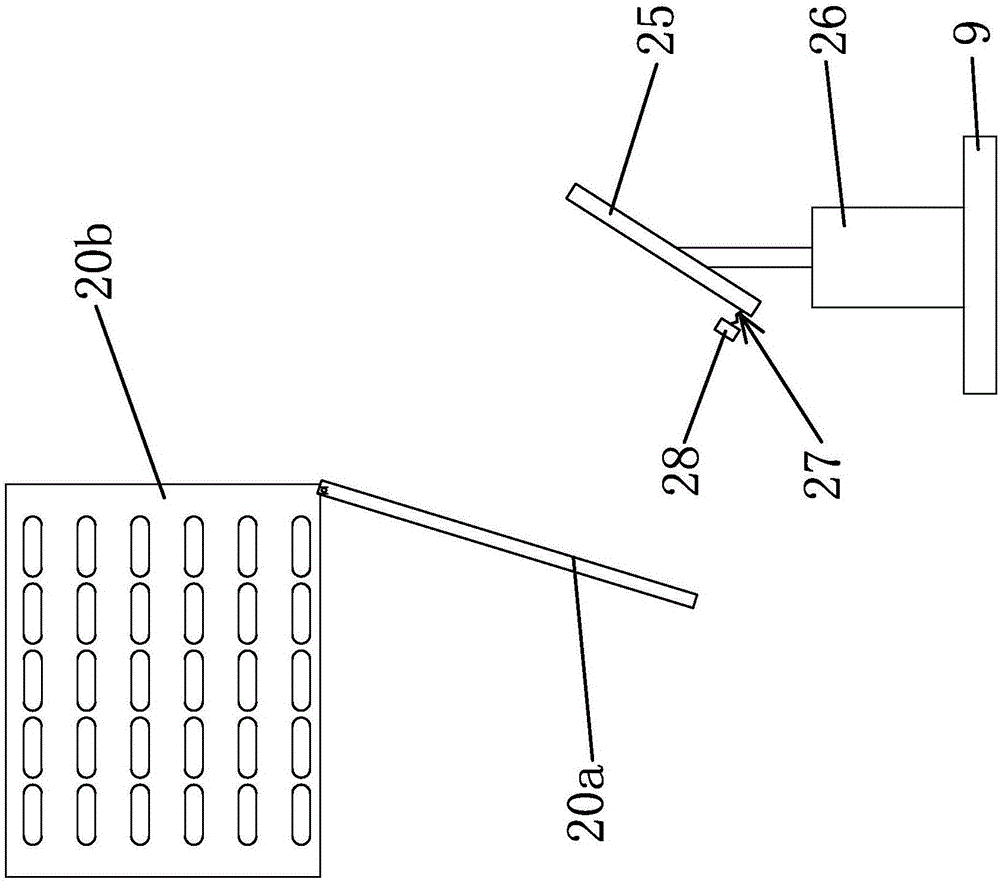

Treatment system for cabinet-wood corrosion prevention

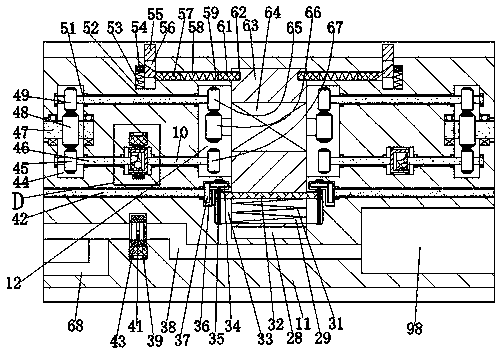

ActiveCN106182254AExtended service lifeExtended use timeWood treatment detailsOpen tank impregnationTransmission beltDrive shaft

The invention provides a treatment system for cabinet-wood corrosion prevention. The technical problems that existing treatment equipment is too simple in structure, is provided with no blanking device, needs to be manually operated and low in treatment speed are solved. The treatment system for cabinet-wood corrosion prevention comprises a rack, a driving shaft and a driven shaft are vertically arranged at the two ends of the rack correspondingly, the driving shaft is connected with a power mechanism capable of driving the driving shaft to rotate, and a diving chain wheel is fixedly arranged on the driving shaft; a driven chain wheel corresponding to the driving chain wheel is fixedly arranged on the driven shaft, a transmission belt is arranged between the driving chain wheel and the driven chain wheel, and a plurality of mounting blocks are fixedly arranged on the transmission belt; and fixed rings are fixed to the mounting blocks, storage mechanisms for storing wood are detachably arranged on the fixed rings, and a soaking device, a shaking device and a blanking device are further arranged on the rack in sequence. The treatment system has the beneficial effect of being high in treatment speed.

Owner:海宁恒森家具有限公司

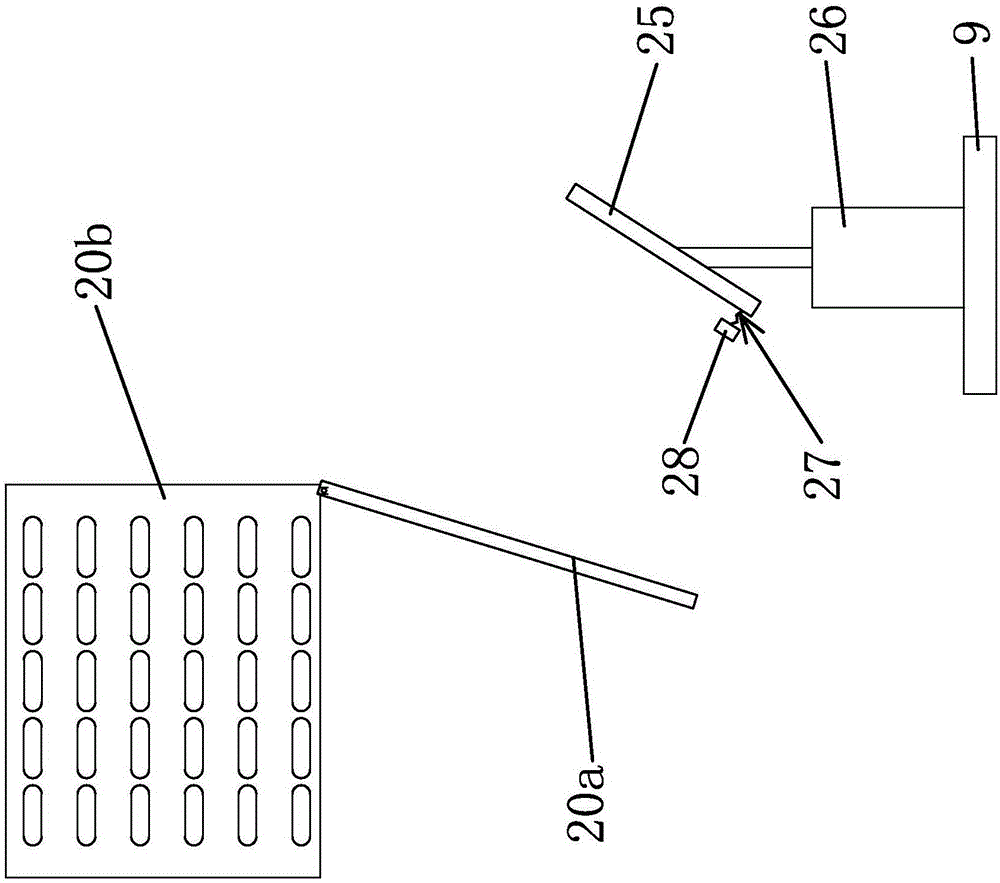

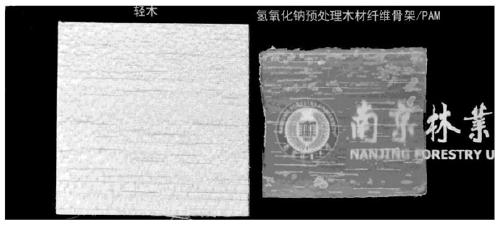

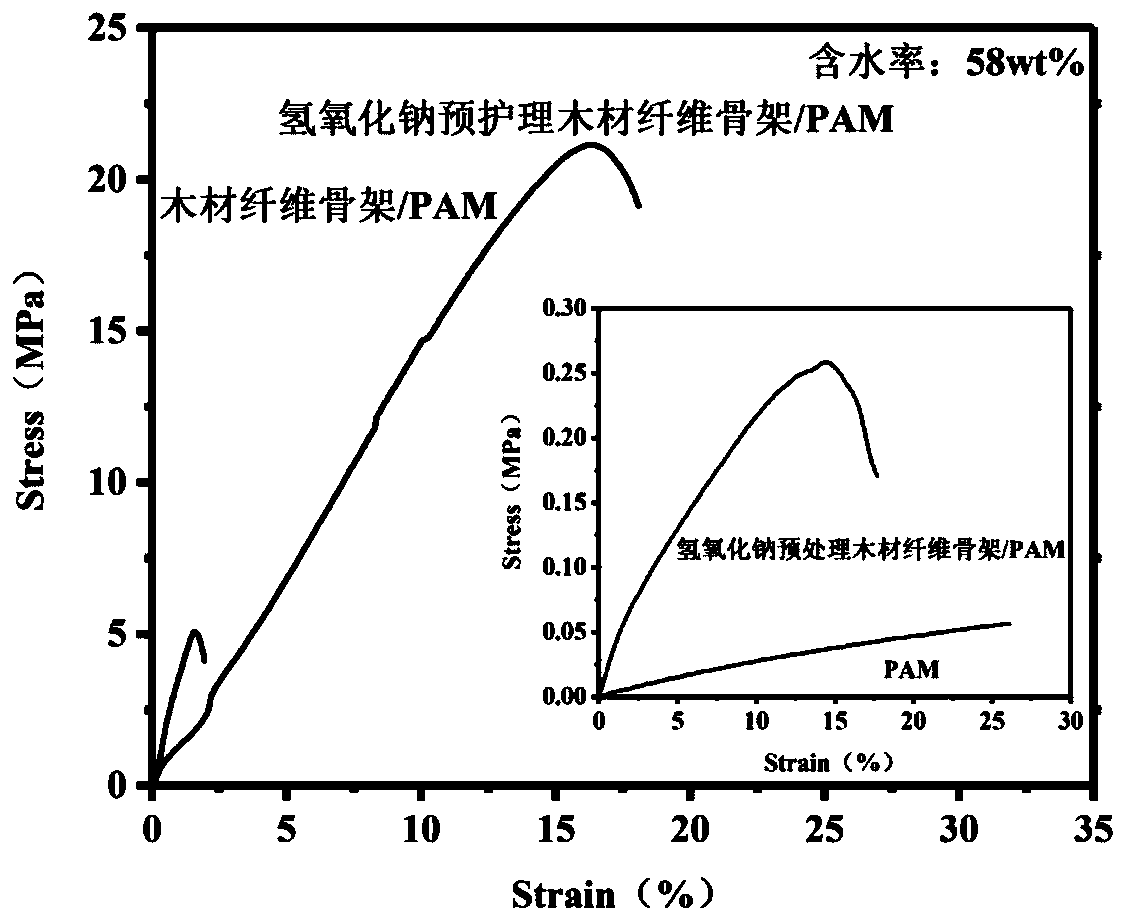

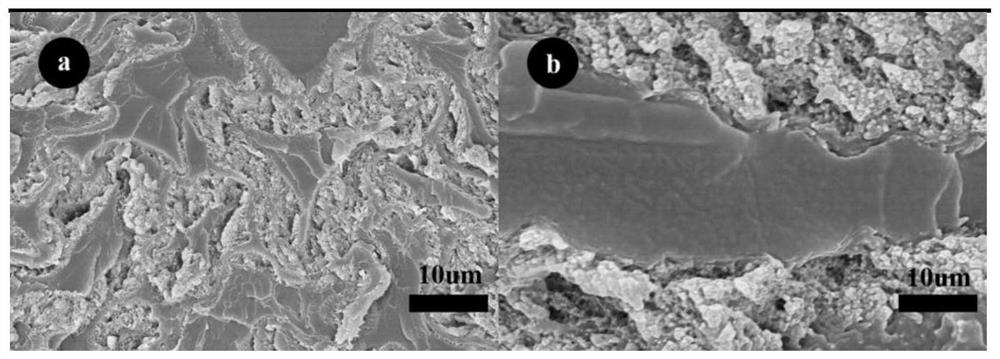

Wood-based high strength elastic composite gel and preparation method thereof

PendingCN110405882AExcellent impregnationEnhanced interface bindingWood treatment detailsOpen tank impregnationCross-linkFiber

The invention discloses a wood-based high strength elastic composite gel and a preparation method thereof. The preparation method comprises the following steps: (1) extracting a wood fiber skeleton: placing wood pieces in a sodium chlorite solution, performing heating to remove, washing the obtained wood pieces with deionized water to obtain the wood fiber skeleton, then impregnating the wood fiber skeleton in a sodium hydroxide solution, and washing the impregnated wood fiber skeleton until neutrality in order to obtain a sodium hydroxide pretreated wood fiber skeleton; (2) preparing an acrylamide solution: sequentially adding a cross-linking agent and an initiator to an aqueous acrylamide solution, and performing stirring and mixing to uniformly; and (3) preparing the composite gel: impregnating the wood fiber skeleton in the acrylamide solution at 25 DEG C, and performing heating under a vacuum condition to initiate a crosslinking reaction in order to obtain the composite gel. The preparation method of the invention can improve the interfacial bonding property between the wood fiber skeleton and the polyacrylamide, and the prepared elastic wood gel has excellent mechanical properties.

Owner:NANJING FORESTRY UNIV

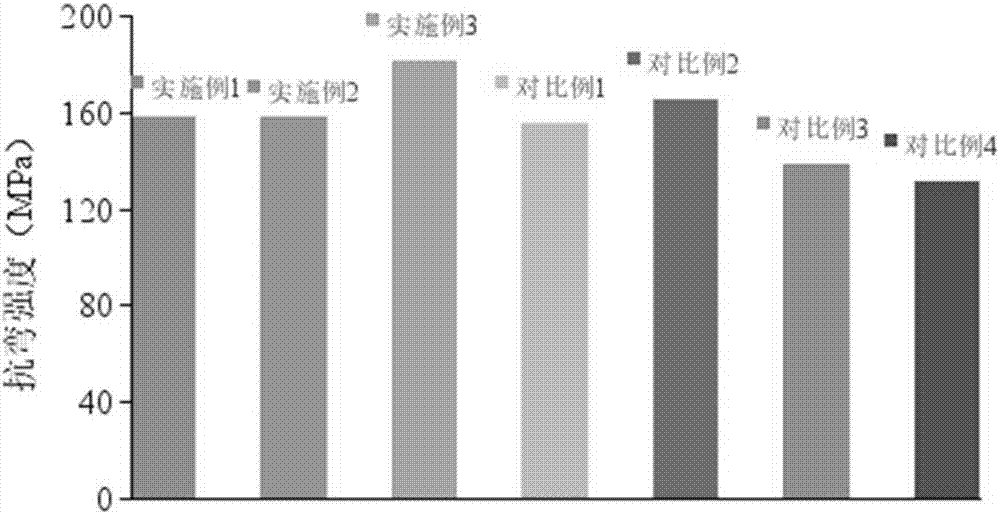

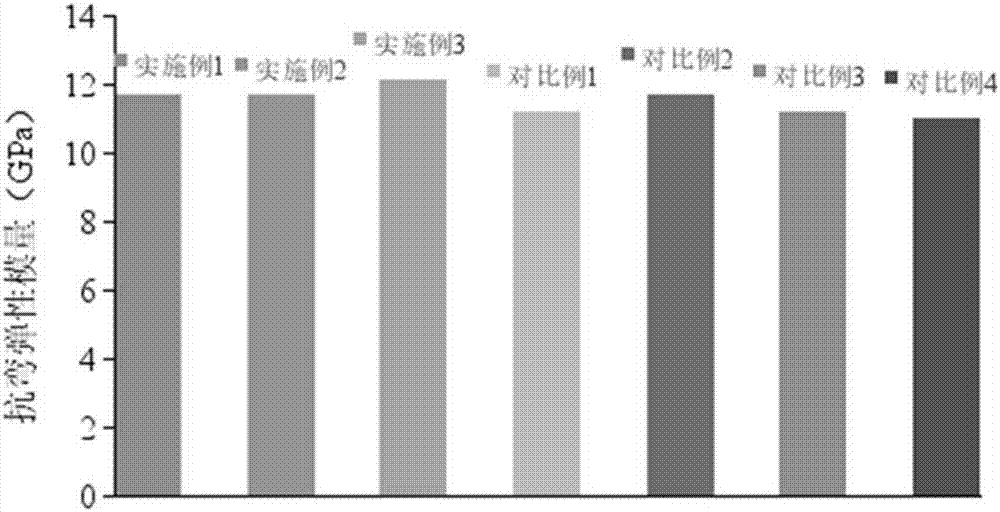

Method for manufacturing high intensity plywood for engineering structure by utilizing fast growing wood

InactiveCN103991113AHigh static bending strengthIncrease elasticityWood treatment detailsWood veneer joiningWeather resistanceSingle plate

The invention provides a method for manufacturing high intensity plywood for an engineering structure by utilizing fast growing wood. The method comprises the following steps of (1) single plate rotary cutting, (2) modified liquid preparation, (3) single plate reinforced processing, (4) gluing assembly prepressing, (5) plate blank hot press forming, and (6) veneering or film covering processing. The method for manufacturing the high intensity plywood for the engineering structure by utilizing the fast growing wood has the advantages that firstly modified liquid reinforced processing is carried out on the single plates of the fast growing wood, the intensity of the single plates of each layer is improved to a large extent, the reinforcing degree of the single plates can be adjusted through the weight gain rate of the single plates, and the weight gain rate of the reinforced single plates can be reduced from outside to inside in a graded mode to save cost and fully perform the intensity performance of single plates of all layers; thus, plywood products gain extremely high static bending intensity, elasticity modulus and surface hardness under the condition of a low compression rate, the thickness swelling rate of the products is small, the dimensional stability of the products is good, and reinforcer gives the products good rotproofness and weather resistance at the same time.

Owner:NANJING FORESTRY UNIV +1

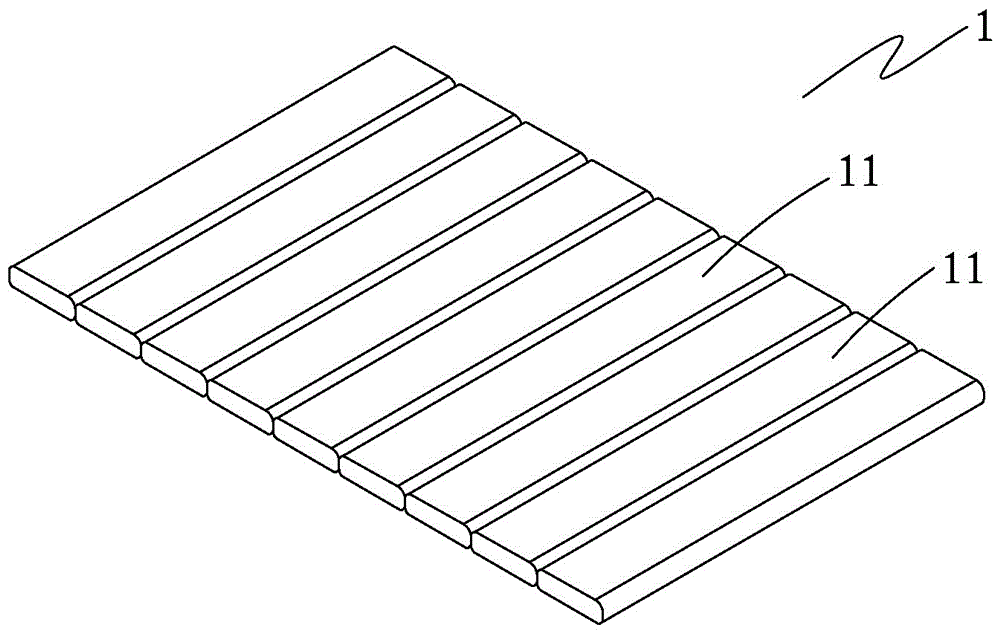

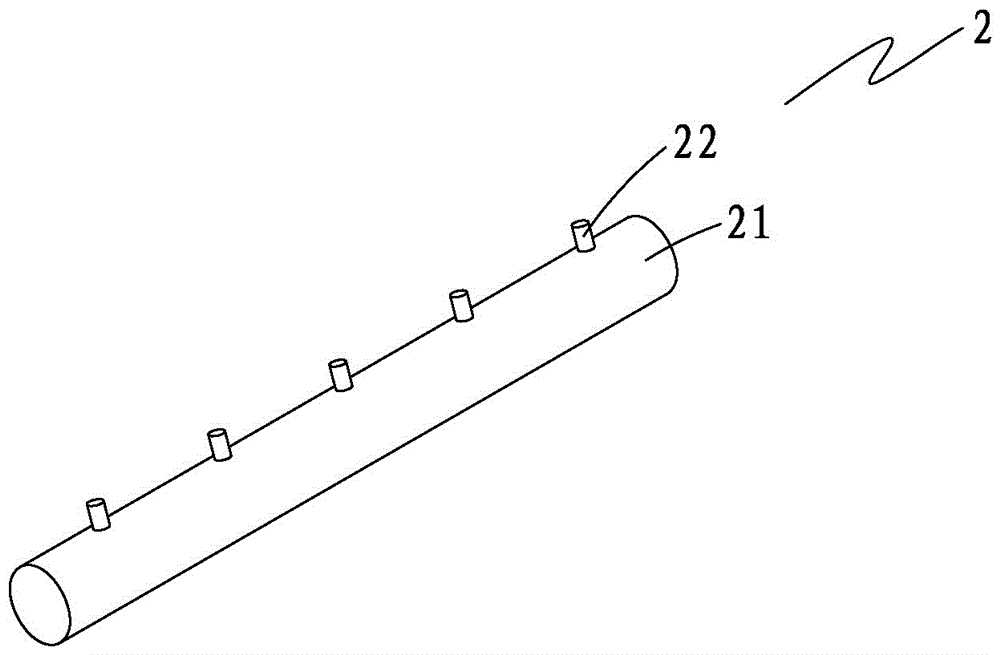

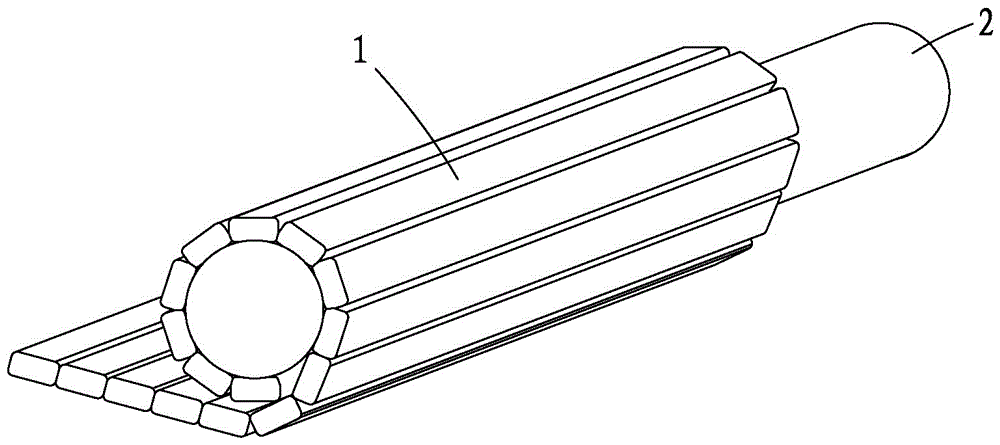

Method for preparing bamboo beam columns

ActiveCN106625921AMaximum environmental protectionMeet the basic requirements of beams and columnsPressure wood treatmentWood treatment detailsInternal stressBeam column

The invention provides a method for preparing bamboo beam columns. The method includes the steps that a piece of bamboo wood is selected; selected bamboo is sawed into a bamboo tube with the length being 3-8m, and then splitting is performed as required so that long-bar-shaped bamboo chips can be obtained; the long-bar-shaped bamboo chips are subjected to bamboo green and bamboo inner skin removing treatment; then the bamboo chips subjected to bamboo green and bamboo inner skin removing treatment are placed into a solution containing 0.2%-1% of hydrogen peroxide for cooking, and the bamboo chips are drained off after being cooked and placed into a drying shed to be dried; afterwards, the bamboo chips are subjected to shaping, glue dipping, blank formation and glue replenishing so that preliminarily-formed hollow bamboo columns can be obtained; the preliminarily-formed hollow bamboo columns are mold-filled, heated and cured, and the heated and cured bamboo columns are placed in a normal pressure and temperature environment for nourishing, so that internal stress is removed; then a center winding rod is drawn out of the middle part of each bamboo column; and finally, a mold is opened to take out each bamboo column, and the bamboo columns taken out refer to complete and hollow bamboo beam columns. The bamboo beam columns prepared through the method enable the environmental protection performance of the bamboo wood to be reflected maximally in construction, and meanwhile the basic requirements of large-sized housing construction beam columns can be met.

Owner:浙江业友机械有限公司

Method for impregnation of wood component with solid paraffin wax, apparatus therefor and wood component so impregnated

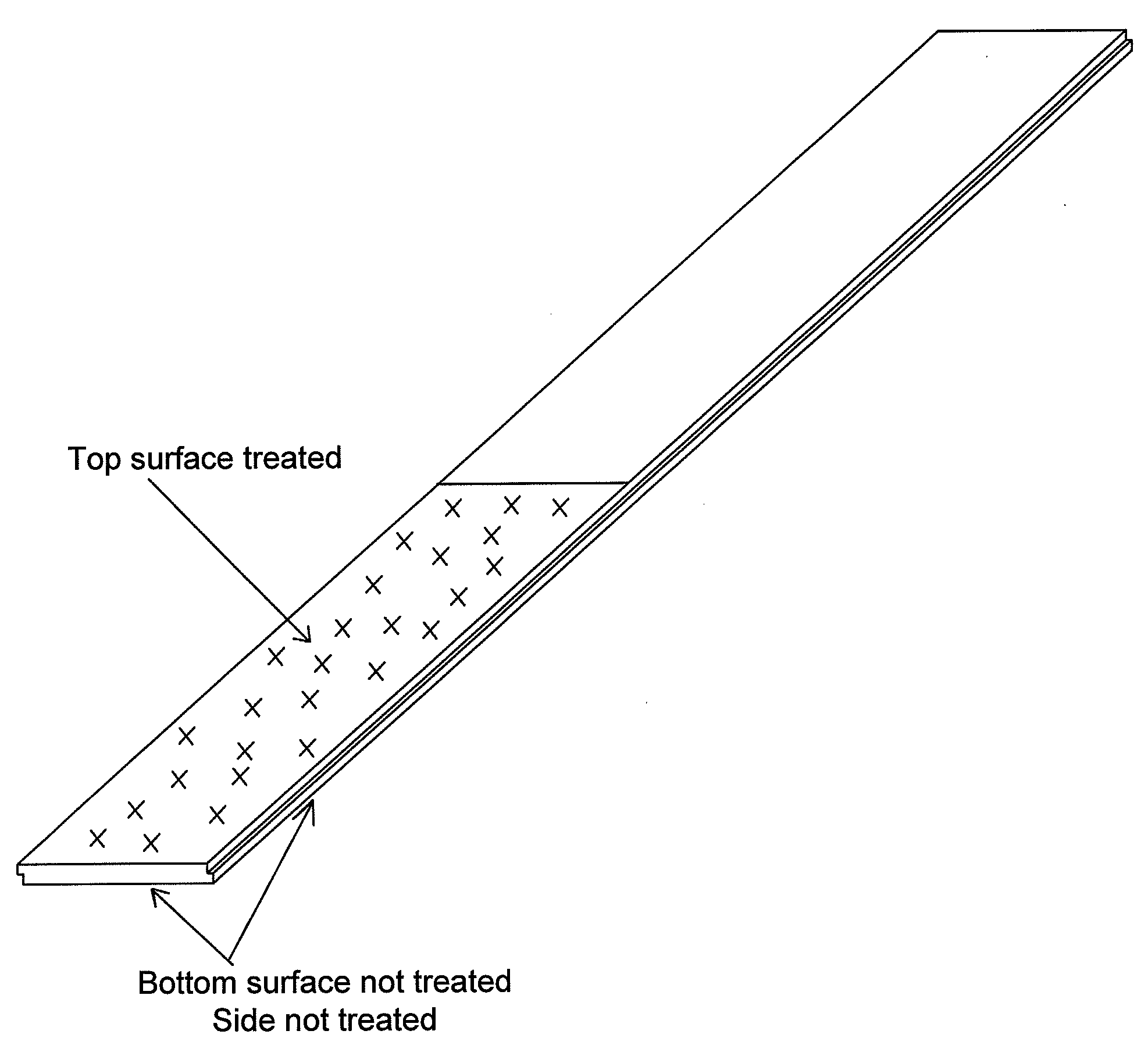

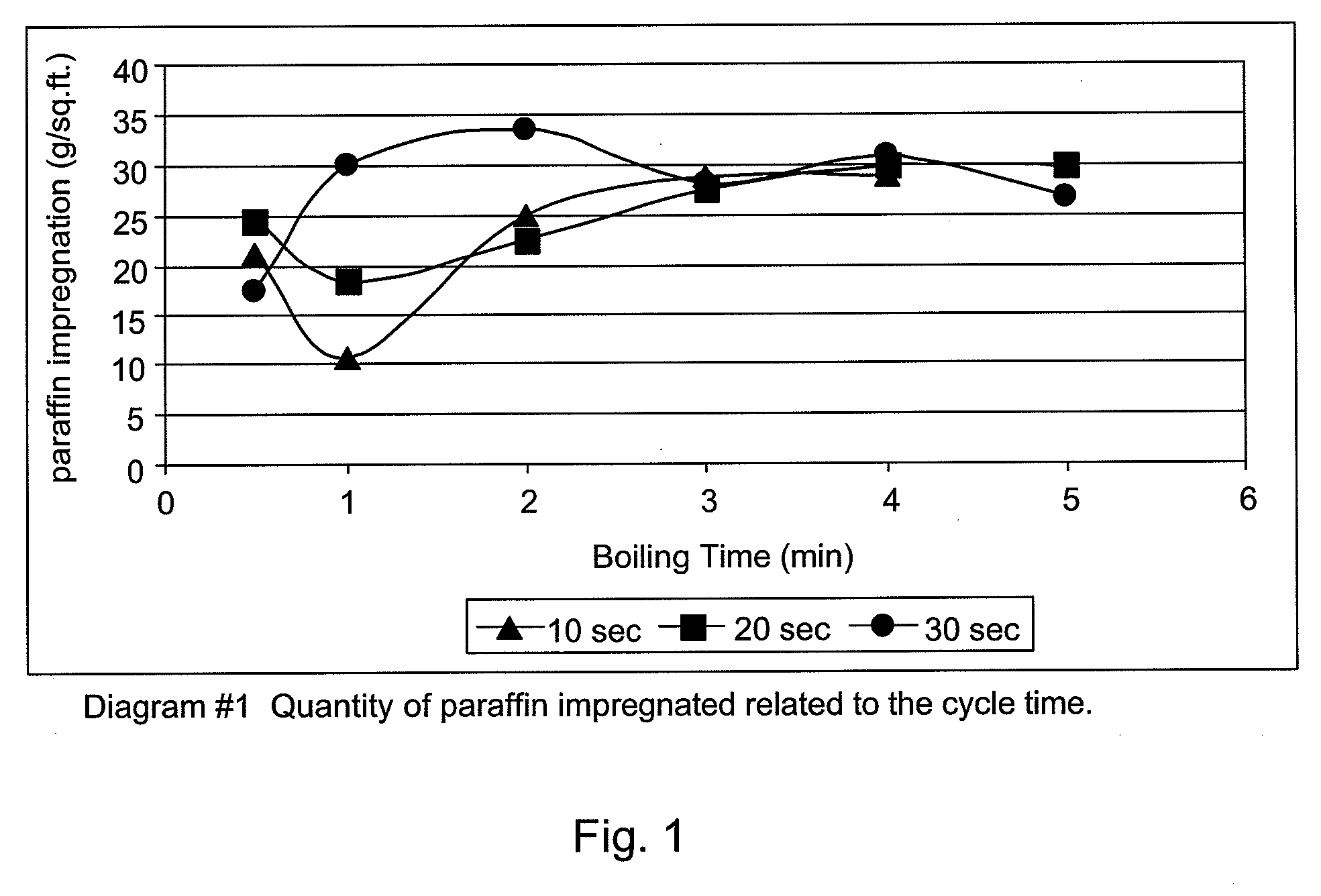

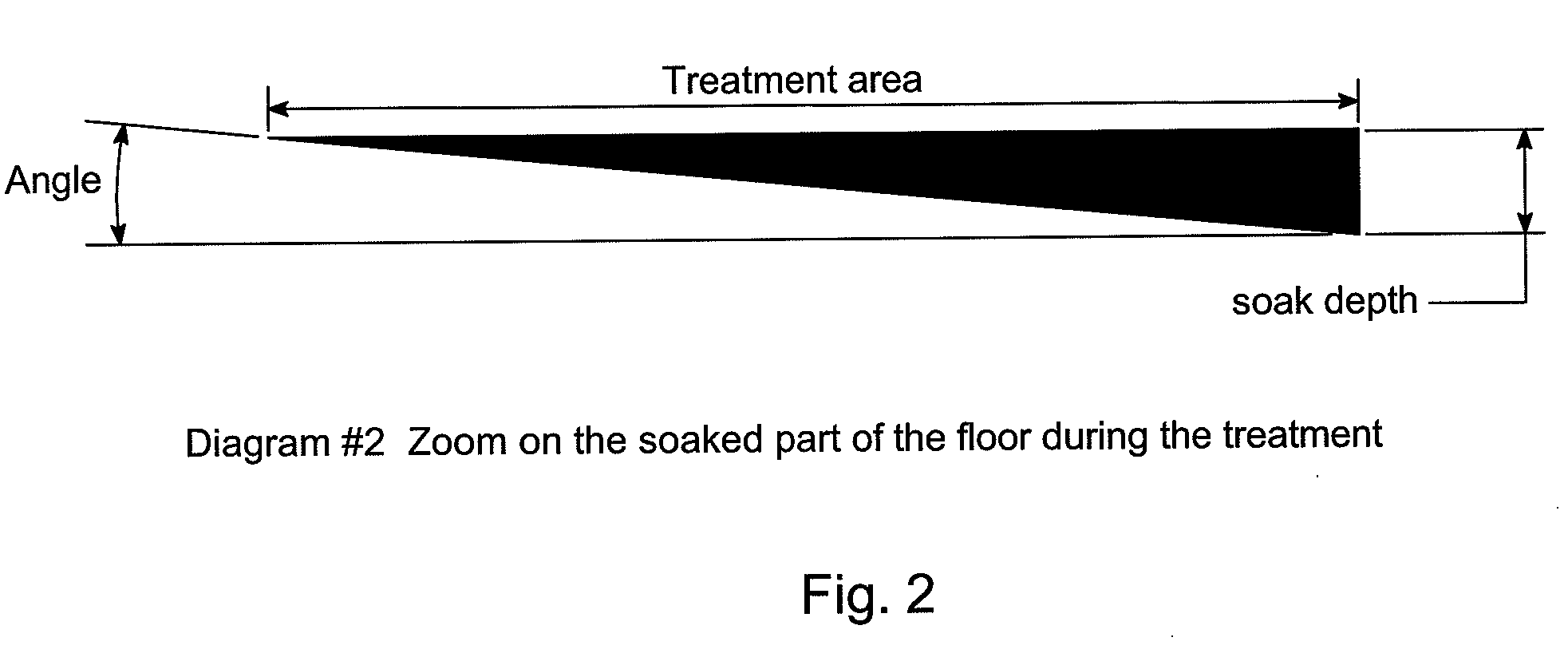

ActiveUS20090280346A1Good effectEffective waterproofPretreated surfacesCoatingsParaffin waxPulp and paper industry

A method for treating a piece of wood impregnates the piece of wood with a water repellent, wherein the water repellent is solid at ambient temperatures. The method includes the steps of providing a piece of wood to be treated; heating the piece of wood for a predetermined period of time, the piece of wood being heated at a temperature A; subsequently immersing at least a portion of the piece of wood in a bath of liquefied water repellent, the bath being at a temperature B, for a predetermined period of time. Thereafter the piece of wood is removed from the bath and allowed to cool. The temperature A is above 100° C. and the temperature B is below 100° C. but above a liquefying point for the water repellent, and a differential between temperatures A and B is at least 60° C.

Owner:PROLAM SOC & COMMANDITE

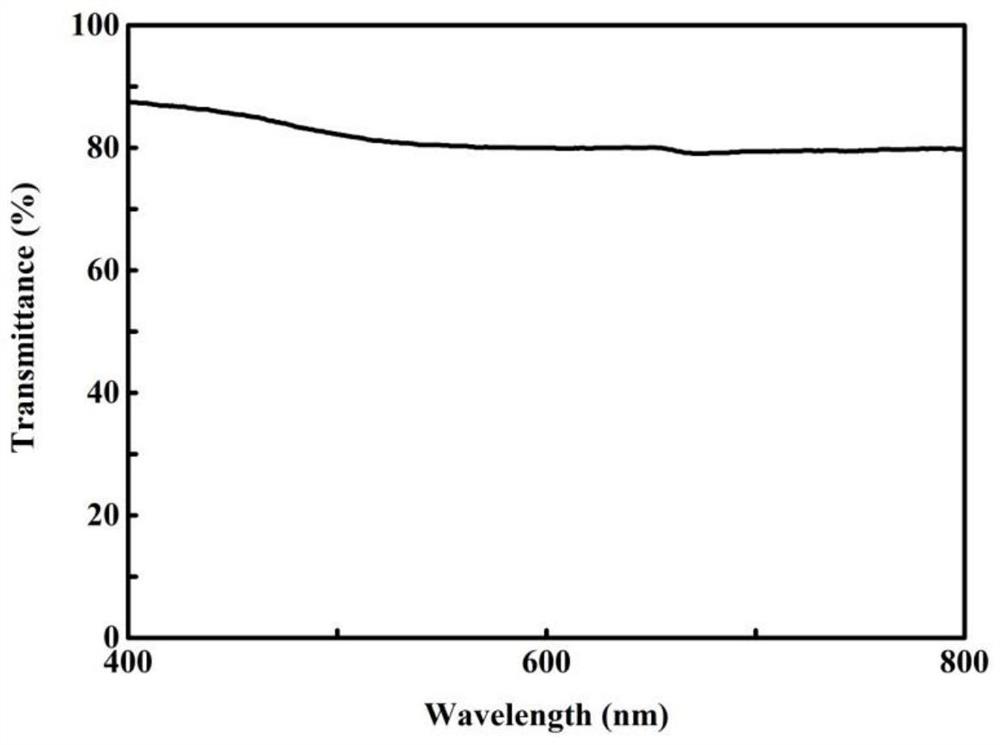

Preparation method for self-illumination wood capable of simultaneously storing heat energy and light energy

ActiveCN108724384AWide variety of sourcesLow costWood treatment detailsHeat-exchange elementsSulfite saltLight energy

The invention discloses a preparation method for self-illumination wood capable of simultaneously storing heat energy and light energy, relates to a preparation method for the energy-storage self-illumination wood, and aims to solve the problem that the wood capable of simultaneously storing heat energy and light energy cannot be prepared at present. The method comprises the following steps: 1, dipping the wood into mixed solution of sodium hydroxide and sodium sulfite, heating to the boiling point, and washing to obtain delignify wood; 2, dipping the delignify wood into hydrogen peroxide solution to be bleached to obtain the bleached wood; 3, mixing rare earth aluminate illumination materials with a molten phase change material to obtain the mixture of the rare earth aluminate illumination material and the phase change material, dipping the bleached wood into the mixture of the rare earth aluminate illumination material and the phase change material to be kept, and obtaining the self-illumination wood capable of simultaneously storing heat energy and light energy. The invention discloses the preparation method for the self-illumination wood capable of simultaneously storing the heat energy and the light energy.

Owner:NORTHEAST FORESTRY UNIVERSITY

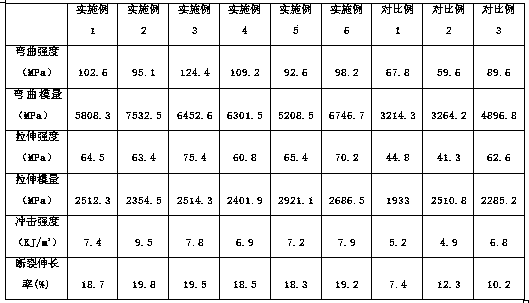

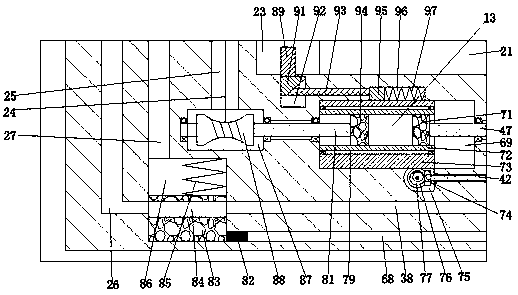

Polylactic acid wood plastic composite material used for 3D printing musical instrument and preparation method and application thereof

InactiveCN108641319AHigh tensile strengthImprove bending strengthAdditive manufacturing apparatusWood treatment details3d printerLubricant

The invention discloses a polylactic acid wood plastic composite material used for a 3D printing musical instrument and a preparation method and an application thereof. The polylactic acid wood plastic composite material comprises the following components by mass percentage: 5-30 wt% of modified wood powder, 62-86 wt% of polylactic acid, 5-10 wt% of a flexibilizer, 2-5 wt% of a nano inorganic filling material, and 1-3 wt% of a lubricant. The polylactic acid wood plastic composite material has the excellent characteristics of stretching resistance, bending resistance, and impact resistance, theimpact resistance can be tested through a FDM-type 3D printer, the surface of the composite material is polished and varnished, and the polylactic acid wood plastic composite material is completely suitable for the 3D printing musical instrument.

Owner:SOUTH CHINA AGRI UNIV +1

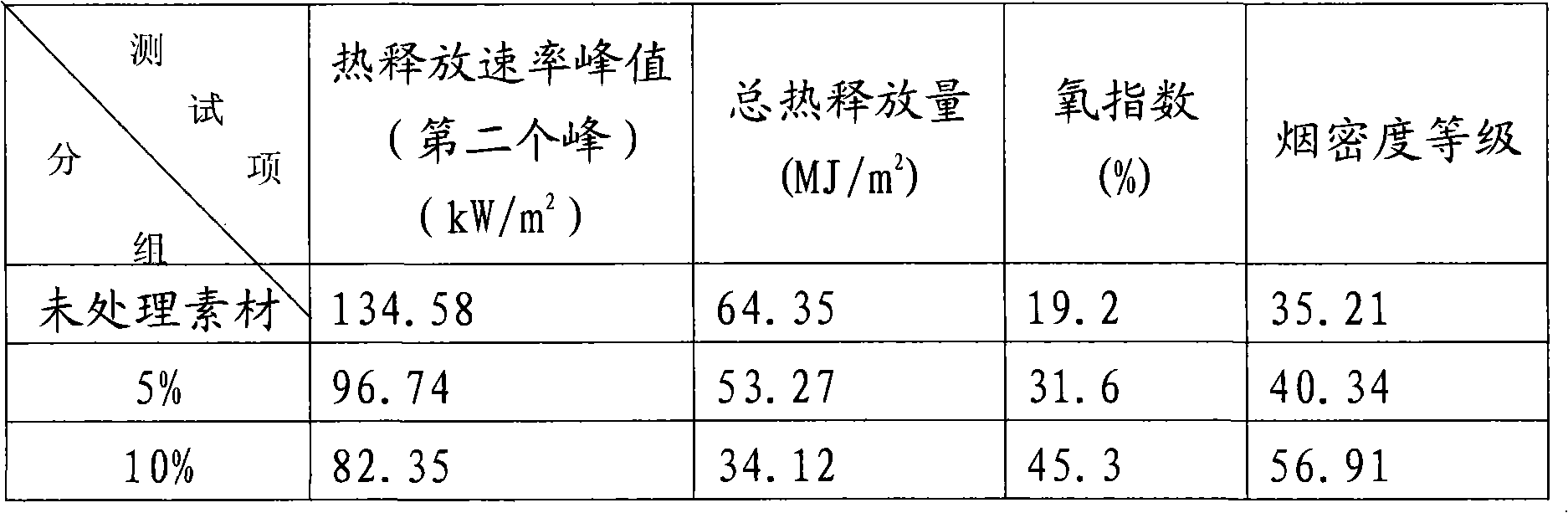

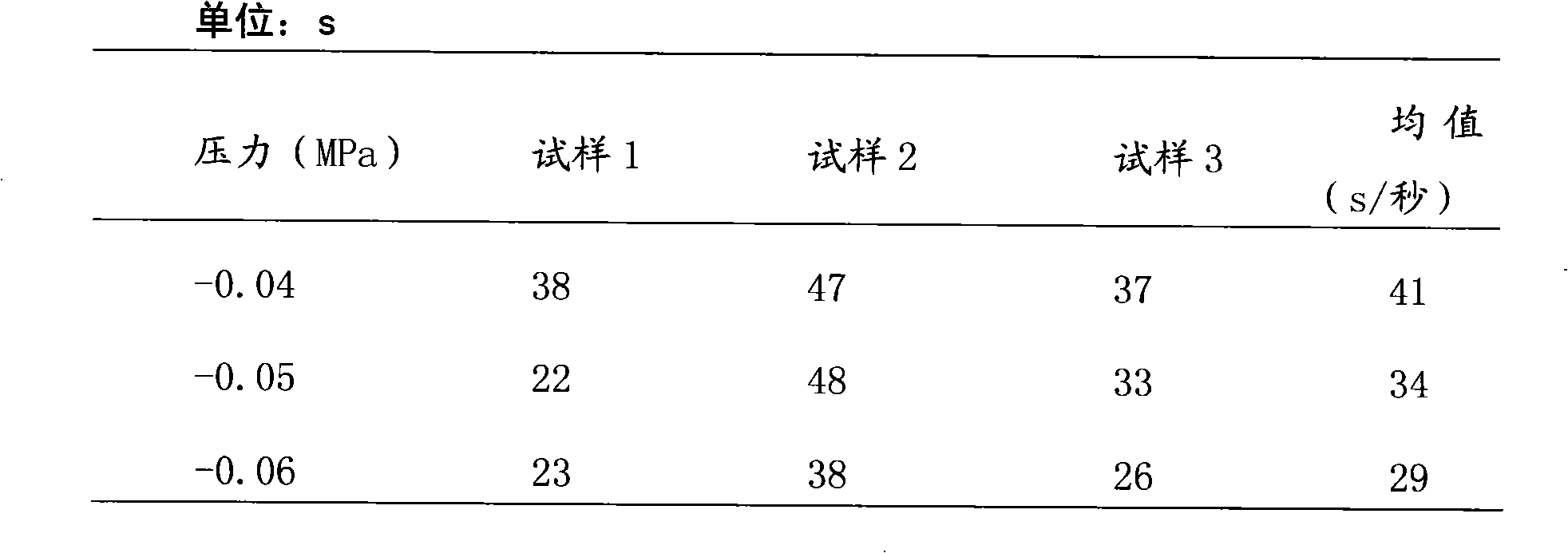

Preparation method of phosphate timber fire retardant and method for processing timber by using fire retardant

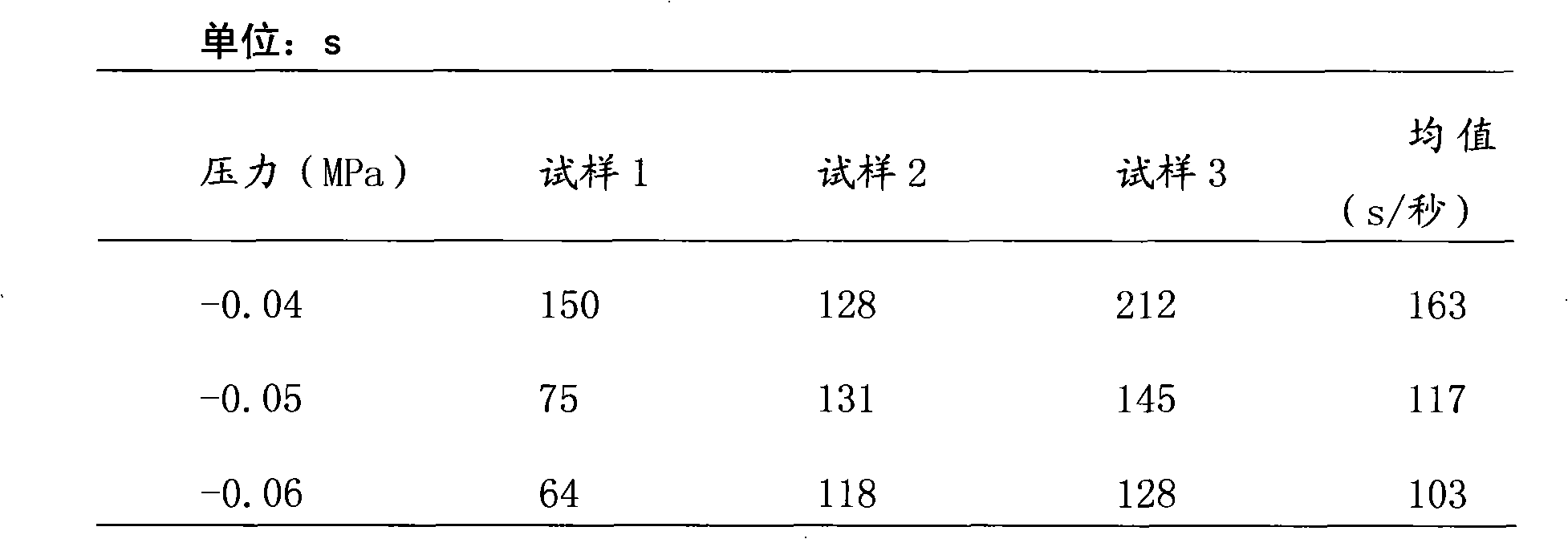

ActiveCN101982305AImprove flame retardant performancePromote expansionPressure impregnationOpen tank impregnationCarbon layerOrganic solvent

The invention provides a preparation method of phosphate timber fire retardant and a method for processing timber by using the fire retardant. The fire retardant prepared by the invention is expansible annular phosphate timber fire retardant which contains an acid source, a carbon source and a gas resource, has the advantages of good expansiveness, compact carbon layer and certain intensity, and has good antiflaming effect proved by the measurement of an oxygen index and smoke density and the analysis of a dual cone calorimeter. The fire retardant is insoluble in water but soluble in organic solvent. The method for processing timber by fire retardant has the advantages of complete dipping, large dipping depth and lasting antiflaming effect, the dipping time is shorter than common dipping time, and time is saved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

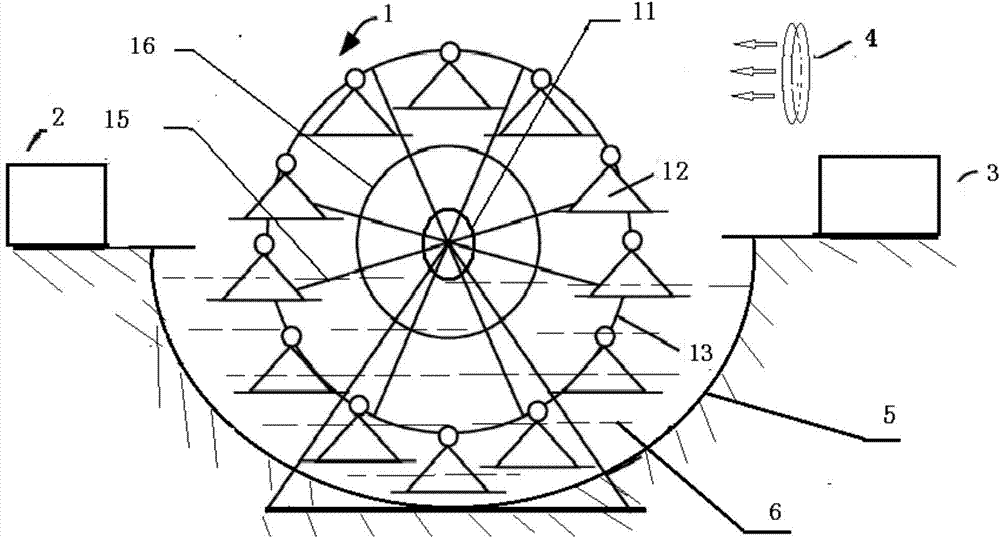

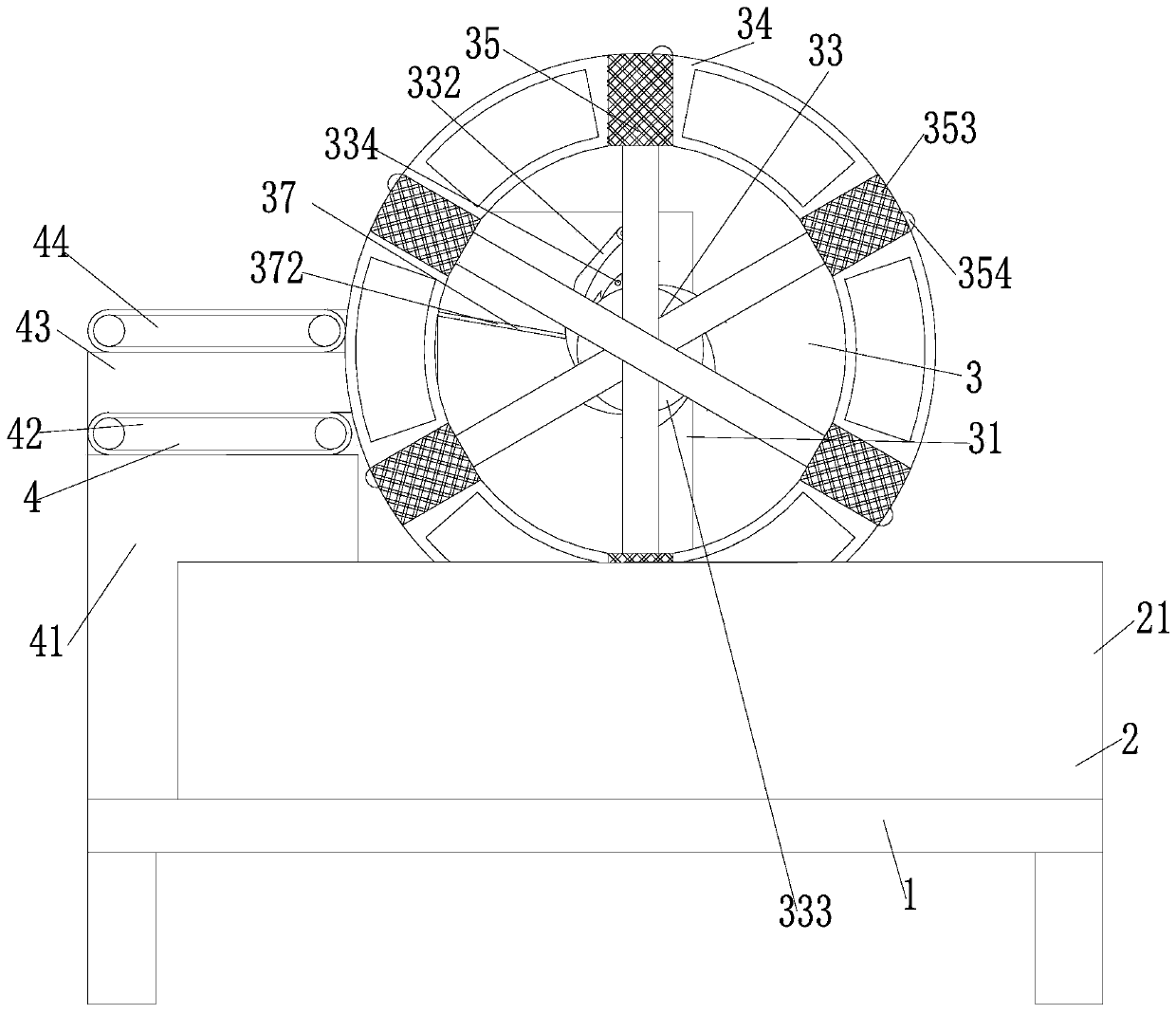

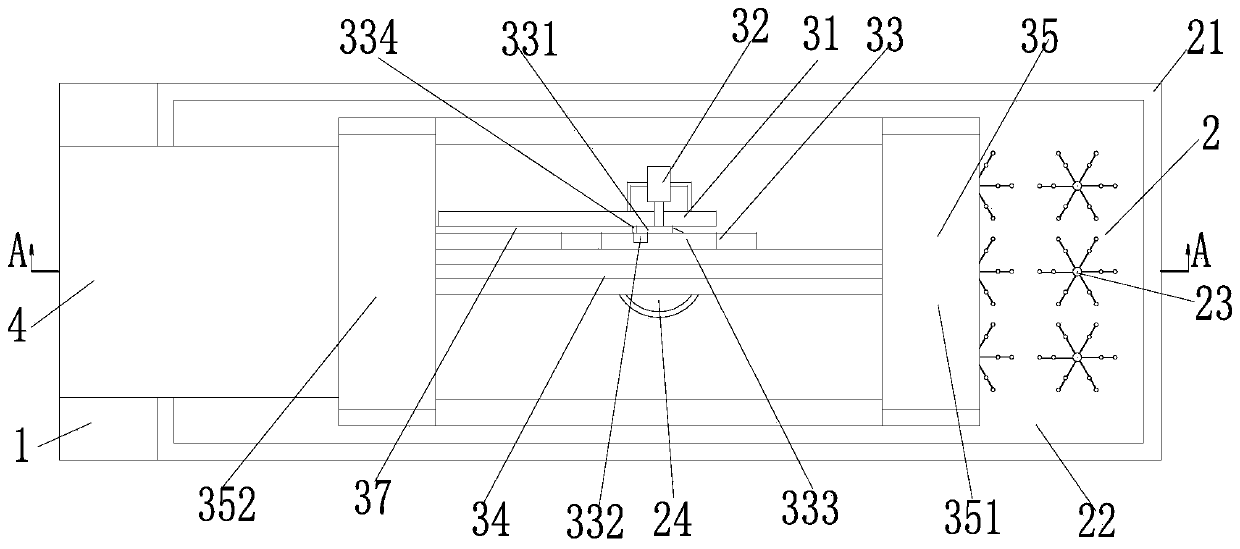

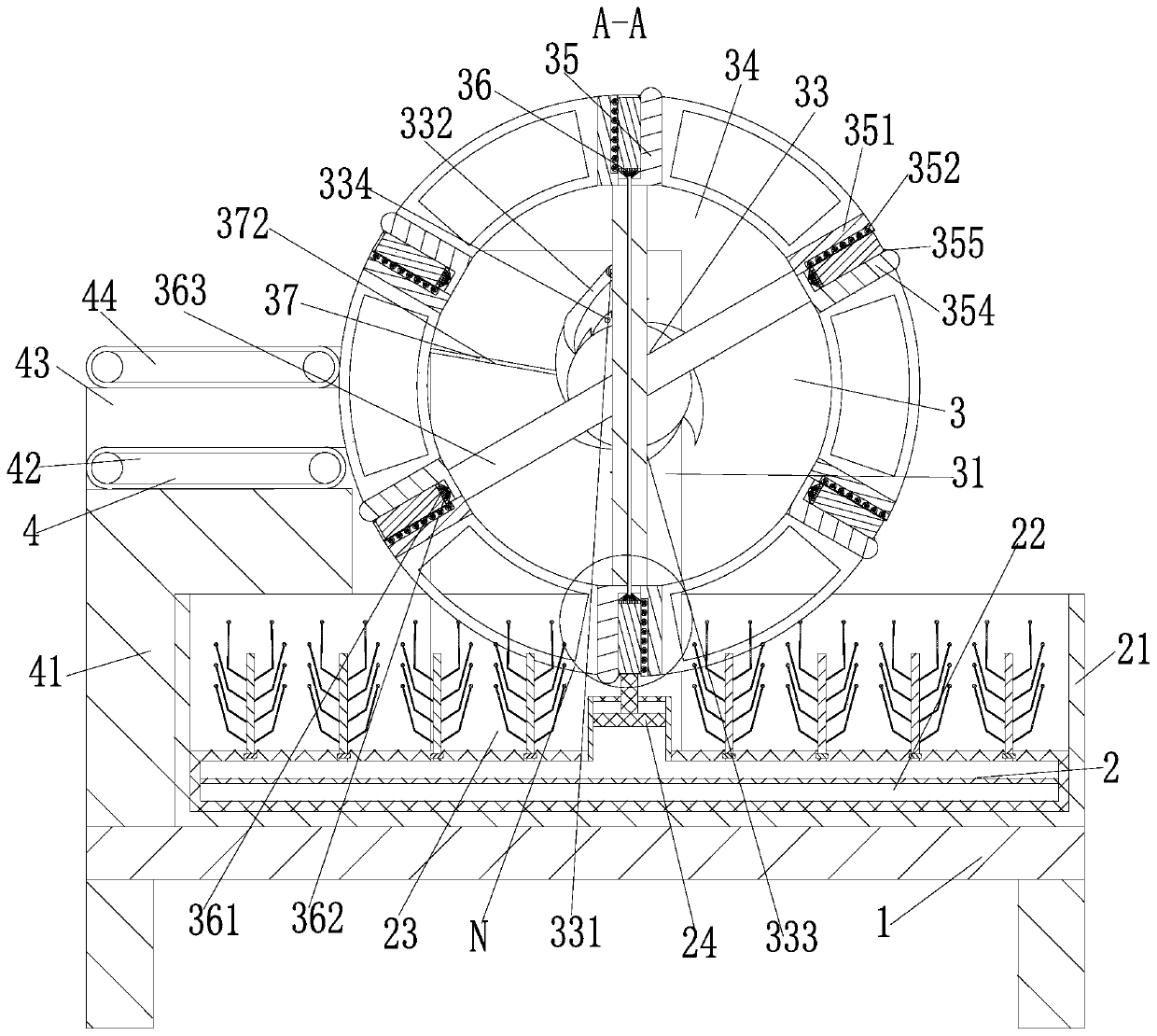

Anticorrosive treatment apparatus of furniture sheets

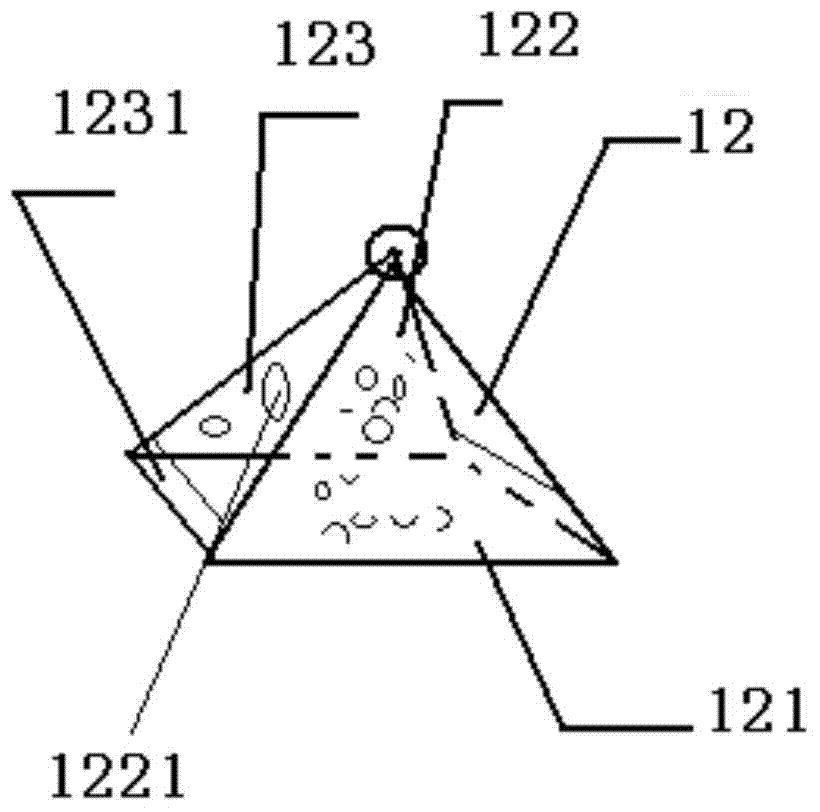

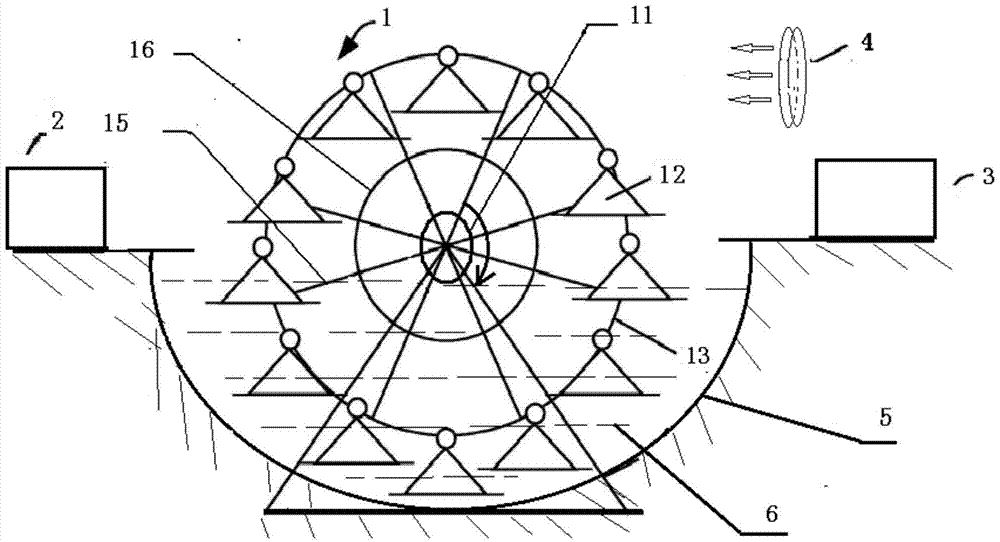

InactiveCN104708696AIncrease productivitySmall footprintWood treatment detailsOpen tank impregnationEngineeringSpoke

The invention relates to an anticorrosive treatment apparatus of furniture sheets. The apparatus comprises a sky wheel body and a support, a concave pool is arranged in an anticorrosive workshop, an anticorrosive solution is stored in the concave pool, the sky wheel body is arranged in the concave pool, the sky wheel body is vertically arranged on the bottom of the concave pool through the support, the sky wheel body comprises an outer wheel rim, a plurality of spoke sticks and a plurality of anticorrosive boxes, the spoke sticks are arranged between the circular center of a sky wheel and the outer wheel rim, the anticorrosive boxes are arranged on the outer wheel ring, the circular center of the sky wheel is provided with a driving device, and the driving device drives the outer wheel rim to rotate, and drives the furniture sheets in the anticorrosive boxes to enter the concave pool, to be immersed in the anticorrosive solution, to move to a position above the level of the anticorrosive solution, to be dried, to rotate to a loading and unloading platform and to be unloaded. The apparatus has the advantages of simple structure, simultaneous completion of anticorrosion and drying, and high efficiency.

Owner:TIANJIN BAISHENGLIHENG STEEL & WOOD FURNITURE

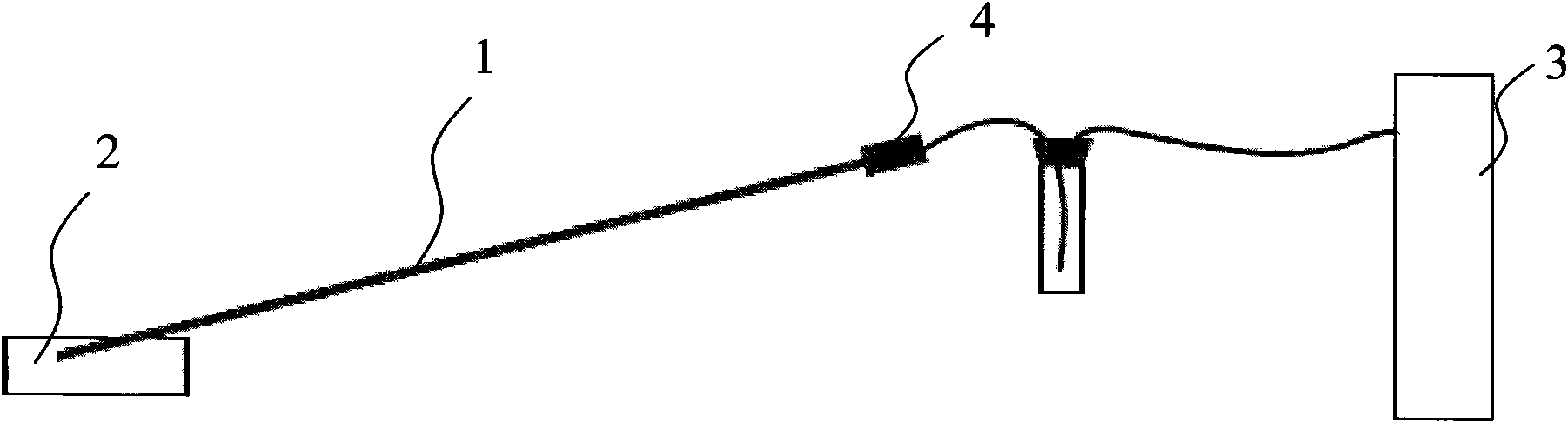

Dyeing preservative treatment method for rattan

InactiveCN101934543AReduce processing timeImprove anti-corrosion performanceWood treatment detailsOpen tank impregnationEngineeringSolution flow

The invention discloses a dyeing preservative treatment method for a rattan. The method comprises the following steps of: soaking one end of the rattan into the solution of a container for accommodating treatment solution, and sucking the other end of the rattan through a vacuum device so that the treatment solution flows to the other end from one end of the rattan through an inner hole extending along the length of the rattan and dyeing and / or preservative treatment are performed on the rattan. The suction is performed by adopting the vacuum device so that the treatment solution flows to the other end from one end of the rattan through the inner hole extending along the length of the rattan, and the whole rattan contains the treatment solution; therefore, not only the treatment time can be greatly shortened, but also the preservative effect or the dyeing effect is very good.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Preparation method for garden outdoor preservative wood

ActiveCN106217535AConsistent colorBeautiful lusterWood treatment detailsOpen tank impregnationMagnesium saltCarbonization

The invention discloses a preparation method for garden outdoor preservative wood and belongs to the technical field of garden greening. The preparation method comprises the steps that poplar which is cheap and easy to get serves as a raw material, and the poplar is soaked with a tetrabutyl titanate ethanol solution after being naturally dried in the air, so that the solution is absorbed by cells, in the program warming and carbonization processes, nutritional components inside the poplar are carbonized, ethanol is volatilized, and tetrabutyl titanate is hydrolyzed into titanium dioxide which serves as an antibiotic component and is dispersed into wood fibers; the pretreated poplar is then soaked with magnesium sulfate and subjected to liquid nitrogen freezing and soaking unfreezing, so that the solution fully enters the wood fibers; the poplar is then fumigated with high-pressure ammonia, so that magnesium salt crystal whiskers are formed inside the wood fibers, and the purpose of improving the wood strength is achieved; and the garden outdoor preservative wood is finally obtained through drying. The garden outdoor preservative wood obtained through the preparation method is free of pollution to water and soil in the using process, excellent in preservative performance and capable of effectively resisting encroachment of fungi, bacteria and moths, is a safe, natural and environment-friendly preservative and moth-proof building material and can be widely applied and popularized.

Owner:珠海经济特区园海绿化工程有限公司

Anti-corrosion and mothproof treatment method for artificial board blanks after molding

ActiveCN110722651AReduce energy consumptionPrevent lateral movementWood treatment detailsOpen tank impregnationRatchetElectric machinery

The invention relates to an anti-corrosion and mothproof treatment method for artificial board blanks after molding. An adopted device comprises a workbench, a solvent tank, a rotating device and a conveying device; the solvent tank is fixedly mounted on the middle upper end surface of the workbench; the rotating device is fixedly mounted on the middle upper end surface of the solvent tank; the conveying device is fixedly installed on the left upper end face of the workbench; the rotating device comprises a fixing plate, a motor, a ratchet wheel frame, a rotating frame, a fixing frame, a flowguide frame and a pushing frame. The artificial board blanks are conveyed to the rotating device in sequence through the conveying device; the artificial board blanks are impregnated, drained and conveyed to the conveying device at the same time by using the rotating device, the purpose that redundant solvents on the surfaces of the artificial board blanks do not drop to the surface of equipment and the ground of a workshop is achieved, only one motor is needed to drive the rotating device in the whole process, and equipment energy consumption is reduced.

Owner:蒙山县永昌木业有限公司

Method for preparing insect-resistant damp-proof wood veneer

InactiveCN109135179AIncrease elasticityImprove toughnessPlastic/resin/waxes insulatorsWood treatment detailsAdhesiveNano al2o3

The invention discloses a method for preparing insect-resistant damp-proof wood veneer. The method includes steps of A, grinding pine bark to obtain pine powder; B, grinding beech shavings to obtain beech powder; C, placing the pine powder and the beech powder into stirring barrels, uniformly mixing the pine powder and the beech powder with each other to obtain first mixtures, adding distilled water into the first mixtures, stirring the distilled water and the first mixtures, and sequentially adding camphor wood powder, mica powder, nanometer aluminum oxide powder and glass fibers into the distilled water and the first mixtures in stirring procedures to obtain second mixtures; D, sequentially adding flame retardants, adhesive and drying agents into the stirring barrels, stirring the flameretardants, the adhesive, the drying agents and the second mixtures and filling the stirring barrels with nitrogen in stirring procedures; E, pouring materials obtained at the step D into molds, carrying out compression molding by the aid of molding machines and carrying out mold release to obtain wood veneer semi-finished products; F, placing the wood veneer semi-finished products obtained at thestep E into drying ovens and carrying out drying treatment to obtain wood veneer finished products. The method has the advantage that excellent insect-resistant effects and excellent damp-proof effects can be realized by the insect-resistant damp-proof wood veneer prepared by the aid of the method.

Owner:湖州韵高木业有限公司

Moth-proofing method for wicker weaved product

InactiveCN107662260AImprove insect repellent effectGood anti-aging performanceWood treatment detailsPretreatment apparatusCold airSeepage force

The invention discloses a moth-proofing method for a wicker weaved product. The method comprises the following steps: adopting a pre-treating solution for soaking the wicker weaved products, thereby achieving a softening function, wherein the pre-treating solution is capable of permeating into the wickers so that the wicker weaved product has higher toughness; putting the wicker weaved product into a moth-proofing solution and braising; braising twice for different times at different temperatures, thereby making the moth-proofing solution fully enter into the wickers and achieving a better moth-proofing effect of the wicker weaved product; drying in two different airing manners of hot air and cold air, thereby achieving a better anti-ageing effect of the wicker weaved product; and coatinga moth-proofing coating, thereby achieving higher surface hydrophobicity and anti-scraping property of the wicker weaved product. The moth-proofing coating is in scientific formula, high in seepage force and excellent in sealing property. A coating is compact and tight, is non-cracking and non-swelling and has high waterproof property, high moth-proofing property, powerful adhesive force, ultrahigh hardness and anti-scraping property.

Owner:FUNAN NATURE ARTS & CRAFTS

Preparation method of glue-free mould pressing artificial board

The invention discloses a preparation method of a glue-free mould pressing artificial board. The method comprises the following steps: S1, straw pretreatment: pulverizing plant straws, and carrying out two-step impregnation by using a cellulase and pectinase mixed solution and alkali liquor; S2, wood pretreatment, specifically, smashing wood waste for use; S3, high-temperature treatment, namely performing high-temperature treatment on the raw materials in the step S2 and the step S1, and drying the materials for later use; S4, pre-pressing forming, specifically, adding the mixture obtained inthe step S3 into a pre-pressed plate blank; and S5, hot-pressing board forming, specifically, hot-pressing the board blank in the step S4 into the glue-free template artificial board. According to themethod, straw treated by alkali liquor is used as an adhesive, cellulose and lignin in wood are used as a framework, and the adhesive-free mould pressing artificial board is prepared through high-temperature extrusion. No adhesive is used in the process, the preparation process is environmentally friendly, the prepared artificial board does not contain formaldehyde, and the requirements of modernpeople for health and environmental protection are met.

Owner:NANJING FORESTRY UNIV

Outdoor bamboo wood natural mould-proof corrosion-proof agent and preparation and treatment methods thereof

InactiveCN108818829ANo pollution in the processReceptive to penetrationWood treatment detailsReed/straw treatmentVascular bundleParenchyma

The invention relates to the technical field of bamboo wood mould proofing and corrosion proofing, in particular to an outdoor bamboo wood natural mould-proof corrosion-proof agent and preparation andtreatment methods thereof. The bamboo wood natural mould-proof corrosion-proof agent is prepared from the following components in percentage by weight: 30-40% of industrial wastewater after stevia rebaudiana is processed to prepare stevioside, 5-10% of soapberry fruit, 20-30% of melia azedarach leaf, 10-15% of folium coptis chinensis and 10-20% of folium isatidis. According to the preparation method of the bamboo wood natural mould-proof corrosion-proof agent, conventional decoction or alcohol extraction is adopted; the method for treating bamboo wood by means of the bamboo wood natural mould-proof corrosion-proof agent comprises the steps that after the bamboo wood is placed in hot water for soaking treatment or placed in an ethyl alcohol solution for soaking treatment, the bamboo wood natural mould-proof corrosion-proof agent is used for treatment. The outdoor bamboo wood natural mould-proof corrosion-proof agent and the preparation and treatment methods thereof have the beneficialeffects that firstly, the bamboo wood is placed in the alcohol solution for soaking to make large amounts of starch, sugar, protein and other salt substances in bamboo wood tissues are extracted through alcohol; therefore, the condition that the natural organic mould-proof corrosion-proof agent penetrates through parenchyma cells and vascular bundles of the internal tissues of the bamboo wood is more easy; the mould-proof corrosion-proof agent is prepared from the natural organic extracts and do not have any toxicity or cause pollution problems to the environment.

Owner:涂世红

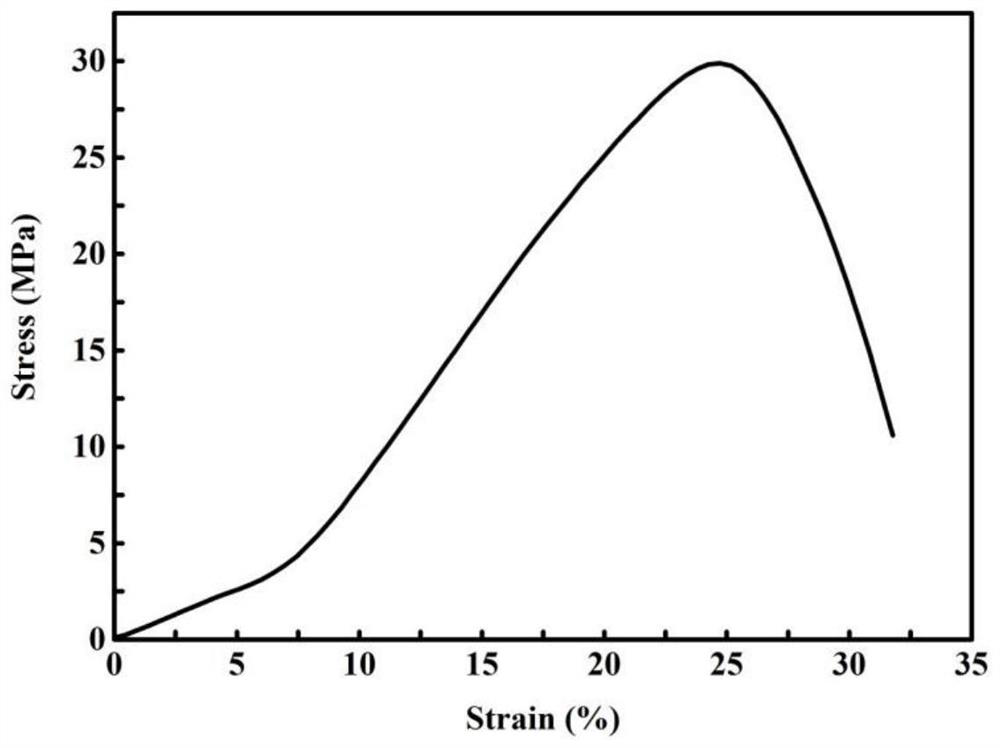

Method for preparing elastic wood based on ultraviolet light initiated graft polymerization

ActiveCN111978490APrevent crushingGuaranteed natural mechanical propertiesOpen tank impregnationFiberPolymer science

The invention discloses a method for preparing elastic wood based on ultraviolet light initiated graft polymerization. The method comprises the following steps: by using balsa wood as a raw material,carrying out mild delignification treatment by using an acidic sodium chlorite solution to obtain a complete wood fiber skeleton; treating the obtained product with a sodium hydroxide alkaline solution; preparing a mixed solution of an acrylamide monomer and a cross-linking agent, and regulating the mixing ratio of the acrylamide monomer and the cross-linking agent; fully mixing the obtained product with an acrylamide monomer through an impregnation method; and putting the obtained product into a mold, and initiating a grafting cross-linking reaction through ultraviolet light with the wavelength of 320-380 nm to obtain polyacrylamide / wood fiber skeleton composite gel, namely the elastic wood. According to the method, the elastic wood can be prepared under the condition that a chemical initiator is not used, and due to the fact that the elastic wood has high biocompatibility, excellent mechanical performance and excellent light transmission performance, the elastic wood has potential application value in the fields of artificial skin, biosensors, soft tissue engineering materials, wearable flexible electronic base materials, stimulus response soft robots and the like.

Owner:NANJING FORESTRY UNIV

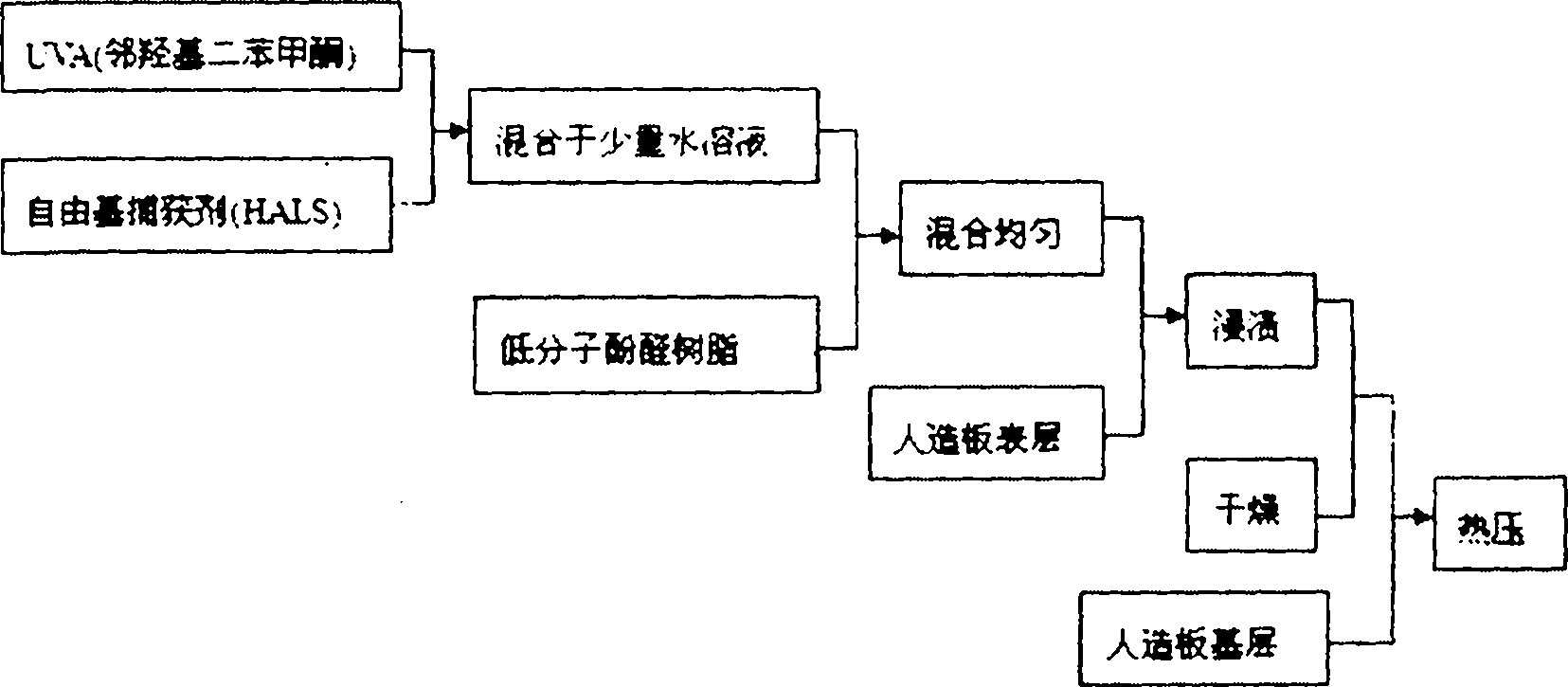

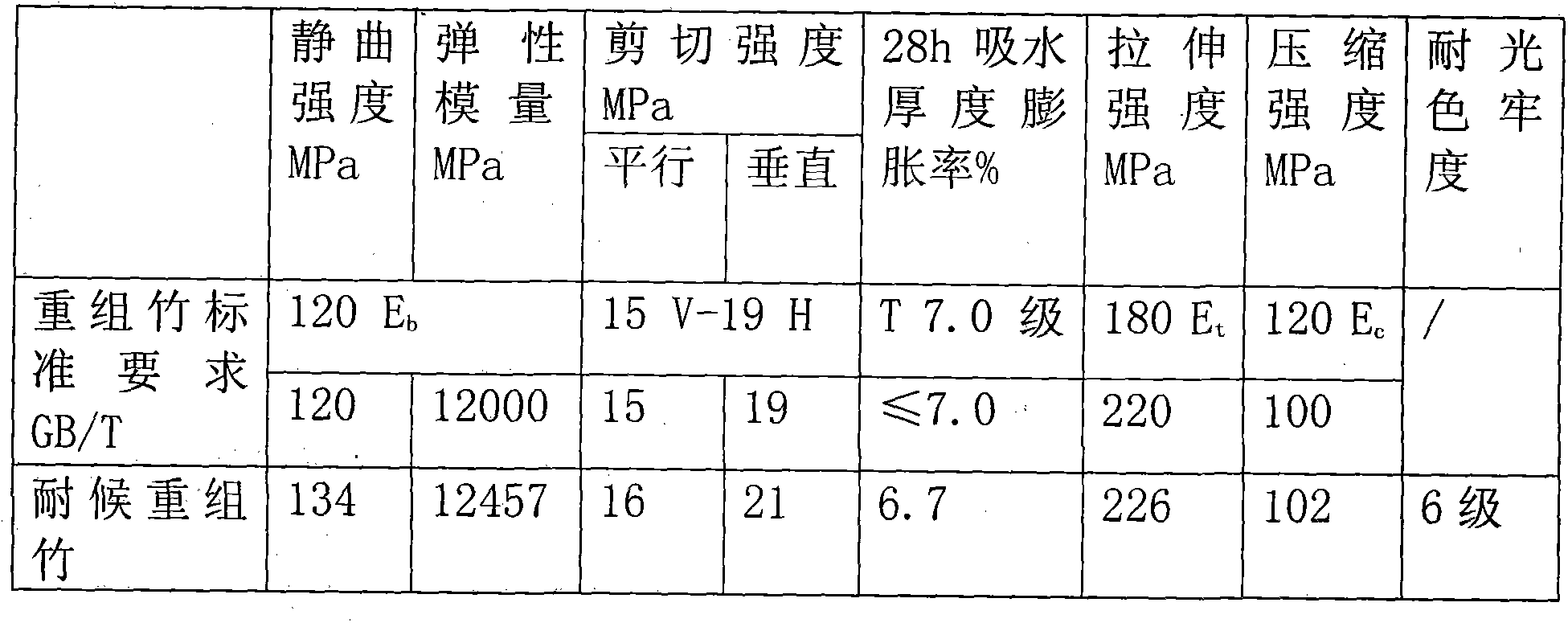

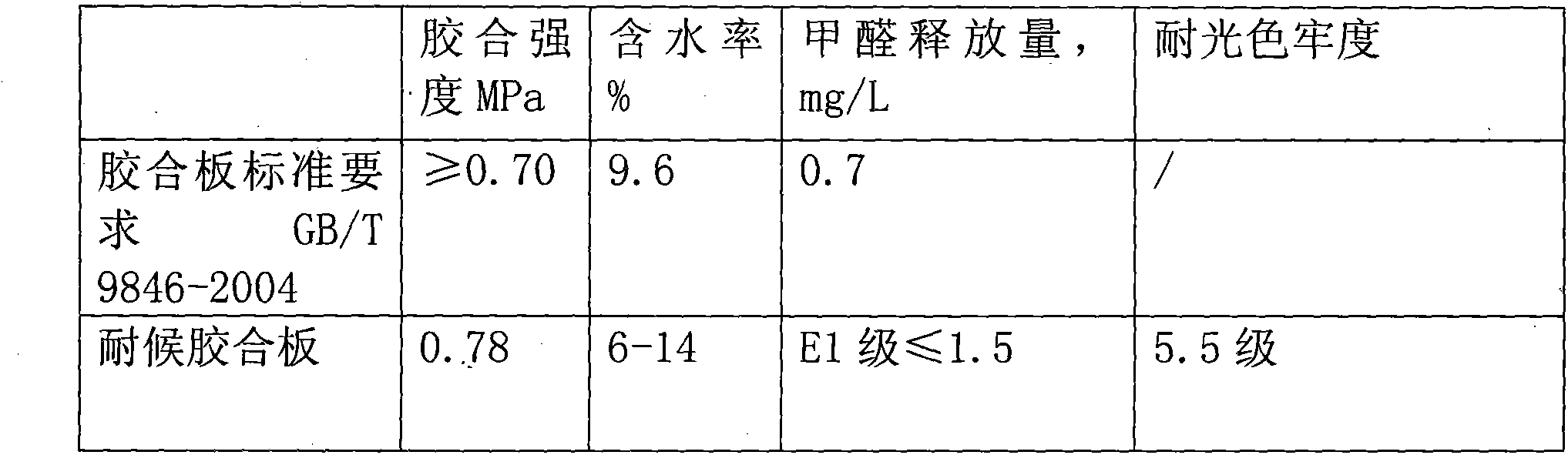

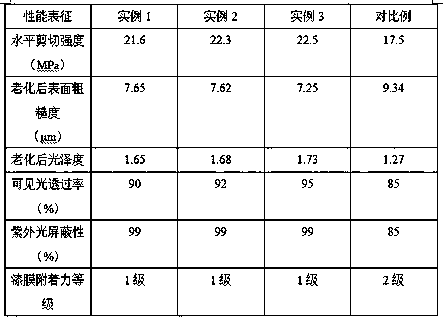

Weather-resistant artificial bamboo and wooden board and manufacturing method thereof

InactiveCN103552140APlay a protective effectStop the aging processWood veneer joiningOpen tank impregnationCell cavitySurface layer

The invention discloses a weather-resistant artificial bamboo and wooden board and a manufacturing method thereof. The method comprises the following steps of mixing and dissolving 0.5 to 1.5 percent of a ultraviolet absorber and 0.8 to 2.0 percent of a free radical capturer by a small amount of distilled water, adding low-molecular-weight phenolic resin according to a ratio, and stirring and uniformly mixing the phenolic resin with a mixture of the ultraviolet absorber and the free radical capturer to obtain a solvent A; placing an artificial board surface layer material into the solvent A, completely soaking for 2h to 6h under the normal temperature and the normal pressure, and drying the soaked artificial board surface layer material under the normal temperature until the moisture content is 7 to 11 percent; assembling the artificial board surface layer obtained in step 2 and an artificial board base layer blank, thermally rolling, disassembling, and trimming to obtain a finished product. By soaking the outdoor artificial board surface layer, the light stabilizer and the antioxidant are permeated into cell cavities, even the cell walls, along the glue-water and then are assembled and thermally pressed with a core layer, so that the surface ultraviolet aging process can be slowed down in the application process, and the surface of the artificial board can be protected.

Owner:浙江省林产品质量检测站

Technique for manufacturing middle/high-density pressed-fibre board for direct printing

ActiveCN101269504AImprove surface finishImprove printing effectPressure impregnationWood dampingParaffin waxFiber

The invention relates to a production technology of a medium and high density fibre panel, wherein, the medium and high density fibre panel can be used for direct printing, and the surface thereof is glabrous. The production technology has the working procedures of wood chip screening and washing, stewing, hot grinding, glue blending and spreading, drying, paving and molding, heat pressing, and cooling. The steam pressure when in stewing ranges from 0.70 to 0.80MPa, and the time is 2 to 5 minutes; molten refined wax, the quality of which is 0.9 to 1.1 percent of absolute dry fiber, is added when in hot grinding defibrination; the pressure in a grinding chamber is lower than the pressure in a stewing cylinder, wherein, the pressure of the stewing cylinder is 0.01 to 0.04MPa; in the work procedure of glue blending and spreading, urea-formaldehyde resin modified by polyvinyl alcohol and firming agent are added into the fibre; after the fibre is dried, the water ratio thereof ranges from 8 percent to 12 percent; before entering into a hot-press, parting medium which is 1ml to 2ml is sprayed onto the upper surface and the lower surface of a plate blank. The production technology has the advantages that by utilizing the technology to produce the fibre panel, the surface texture and the hydrolytic resistance of a plank stuff are improved, the surface processability of the fibre panel is increased, the printing effect of the fibre panel when in direct printing is increased, and the production cost of printing process is lowered.

Owner:DONGYING ZHENGHE WOOD IND

Wicker processing method for wickerwork manufacturing

InactiveCN107379166ADamaged will notIncrease moisture contentWood treatment detailsReed/straw treatmentDiseaseCelsius Degree

The invention discloses a wicker processing method for wickerwork manufacturing. The wicker processing method comprises the following steps that (1) wickers which are uniform in thickness, no diseases and insect pests, non-bifurcate and good in smoothness are harvested, the wickers are paved horizontally and sun-cured, and until the leaf water content is less than 3%, leaves are removed; (2) the wickers without the leaves are washed cleanly by using clear water and then placed in a pretreatment liquid of 50 degrees celsius to be soaked for 20 minutes, willowpelts are stripped after the soaked wickers are taken out, and the wickers are washed cleanly; (3) the wickers after being processed in the step (2) are dried by using hot wind until the wicker water content is less than 30%; (4) the wickers are soaked for four hours by using a softening fluid again, then washed cleanly and dried by using the hot wind until the wicker water content is less than 20%; and (5) the wickers are fumigated for half hour by using steam, the temperature is naturally lowered to normal temperature after the wickers are taken out, and the wickers can be directly used for wickerwork. The wicker processing method is simple, the wickers can be softened before weaving, the weaving difficulty is reduced, wicker fracture is prevented in the weaving process, the quality of products is high, and the processed wickers have mould-proof and insect-proof functions.

Owner:阜南县铭钰柳木工艺品有限公司

Wood modifying method

The invention discloses a wood modifying method. The wood modifying method comprises a device body, and a permeation device arranged in the device body; the permeation device comprises a first cavityformed in the device body; a first slide block capable of sliding up and down is arranged in the first cavity; a second cavity communicates into the inner walls on the left and right sides of the first cavity; the left and right side end surfaces of the first slide block are fixedly connected with second slide blocks extending into the second cavity; first pull wires are fixedly connected to the upper side end surfaces of the second slide blocks; a third cavity is formed in the inner wall of the side, far from the first cavity, of the second cavity; and the upper end of the third cavity communicates with an opening at the upper end of the second cavity. The invention aims to design a device and a method for modifying woods through filling leaching liquid in inner wall gaps of the woods toimprove the wood hardness and to kill ovum in the woods.

Owner:陈佳佳

Low-temperature oil-heat bamboo modifying processing method

ActiveCN107443518AGood dimensional stabilityQuick dipWood treatment detailsReed/straw treatmentApplication areasMechanical property

The invention discloses a low-temperature oil-heat bamboo modifying processing method. By means of the method, the mechanical property of bamboo can be improved, the waterproof effect of the bamboo can be better, the anti-corrosive durability is improved, and therefore the application field of the bamboo is widened. The method comprises the following steps of (1) drying the bamboo, (2) adding a coupling agent into oil for preparing an oil solution, (3) heating the oil solution, (4) immersing the bamboo into constant-temperature heated oil for treatment, (5) conducting surface treatment and (6) conducting end-capping treatment. The dimensional stability of the bamboo treated according to the method is improved, the anti-corrosion, mold-proof and waterproof properties of products are improved, and the mechanical property does not decline. After the cross section of the bamboo is subjected to end-capping treatment, the loss of a modifying agent can be effectively reduced, and the protecting effect is more lasting.

Owner:INT CENT FOR BAMBOO & RATTAN

Preparing method for antibacterial and ultraviolet-resisting wood and obtained product

InactiveCN106003309AImprove thermal stabilityHas broad-spectrum antibacterial propertiesWood treatment detailsPressure impregnationNanoparticleUltraviolet

The invention provides a method for preparing antibacterial and anti-ultraviolet wood, comprising sequentially using wood impregnating solution A and wood impregnating solution B to impregnate wood, wherein the wood impregnating solution A is an aqueous solution of zinc salt, and the wood impregnating solution B Aqueous solution of alkali. The invention also proposes the material prepared by the preparation method. The wood treatment process proposed by the present invention uses a wet chemical method to generate nano-zinc oxide in situ inside the wood. The binding force between the nano-particles and wood components is strong, it is not easy to be lost, and the modification effect is long-lasting. The wood treatment method can not only endow the wood with excellent antibacterial properties and anti-ultraviolet properties, but also has good thermal stability.

Owner:BEIJING FORESTRY UNIVERSITY

Preparation method of light aging-resistant outdoor recombinant bamboo wood board

InactiveCN108214751ALong-term bacteriostasisImprove water resistanceWood treatment detailsCane mechanical workingFiberAging resistance

The invention relates to a preparation method of a light aging-resistant outdoor recombinant bamboo wood board and belongs to the technical field of bamboo products. By fumigating bamboo bundles, lignin is cracked and crosslinked to form a more stable structure and generate many phenol components and antioxidant components, absorption of ultraviolet light is reduced obviously, and the light aging-resistance of the material is improved. Meanwhile, pores generated by cracking and crosslinking lignin cure and lock camphor oil in the bamboo bundles to achieve the purpose of continuously releasingthe camphor oil; the camphor oil and the generated many phenol components and antioxidant components form a barrier to coat the bamboo bundles to hinder permeation of water, so that the water resistance and the durability of the bamboo bundles are improved. By veneering the surfaces of the recombinant bamboos with fiber cloth layers, an ultraviolet shielding system suitable for the recombinant bamboos is constructed, and is high in ultraviolet shielding property and high in visible light transmittance. The light aging-resistant outdoor recombinant bamboo wood board also has a good protective effect to the shielding system while protecting a base material, and the color and luster of the recombinant bamboos can be protected effectively.

Owner:汪逸凡

Manufacturing technology for wood sooting and dyeing

ActiveCN106217528ASimplify production stepsShorten the timeDrying solid materials without heatWood treatment detailsManufacturing technologySulfate

The invention provides a manufacturing technology for wood sooting and dyeing. The manufacturing technology solves the technical problems that according to an existing dyeing method, steps are too complex, and a large amount of time needs to be spent. The manufacturing technology for wood sooting and dyeing includes the following steps that a, metal ion sulfate dyeing liquid is prepared, wood is put into the metal ion sulfate dyeing liquid to be cooked for 1.2 h to 1.5 h, the cooking temperature ranges from 92 DEG C to 98 DEG C, and the wood is cleaned through clean water and is cleaned 2 times to 3 times; b, the wood is subjected to cold leaching treatment for 16 min to 20 min in a shikonin vegetable dye extracting solution under the normal temperature and the normal pressure through processing equipment; and c, the processed wood is cleaned again through clean water and is naturally dried. The manufacturing technology has the beneficial effect of being simple.

Owner:海宁恒森家具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com