Method for preparing bamboo beam columns

A technology of bamboo beams, columns and bamboo chips, which is applied in the directions of manufacturing tools, mechanical equipment, reed/straw treatment, etc., can solve the problems of bulky structure, poor environmental protection performance, high density of reconstituted bamboo, etc., and achieves low preparation cost, low price, easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

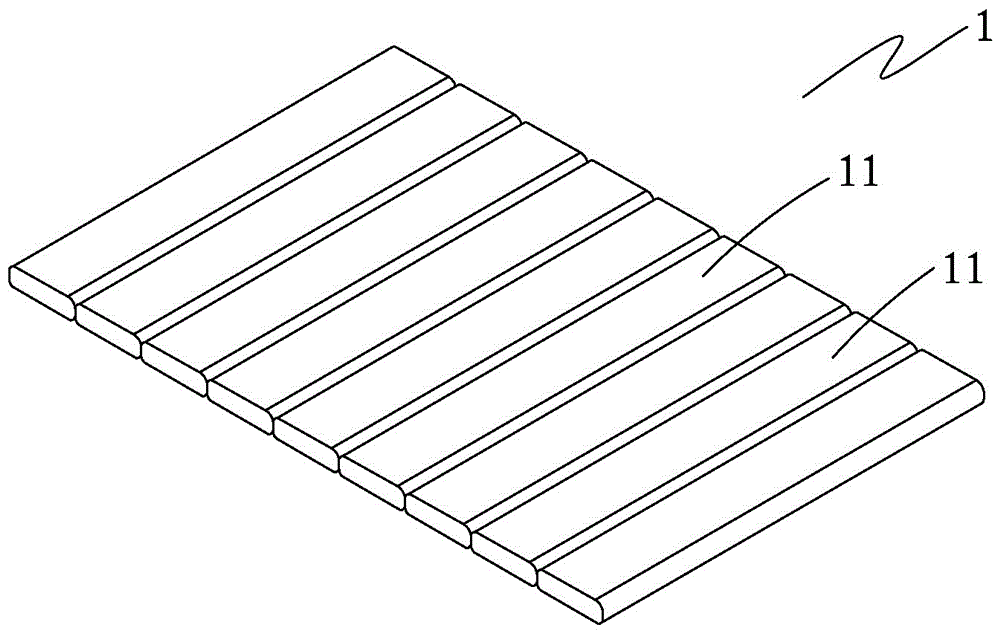

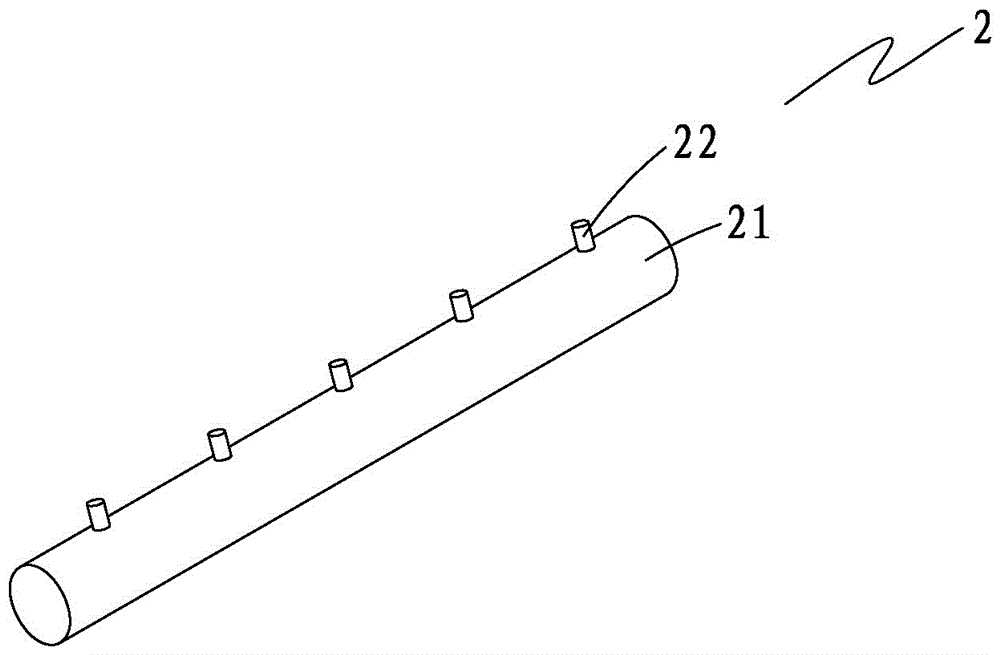

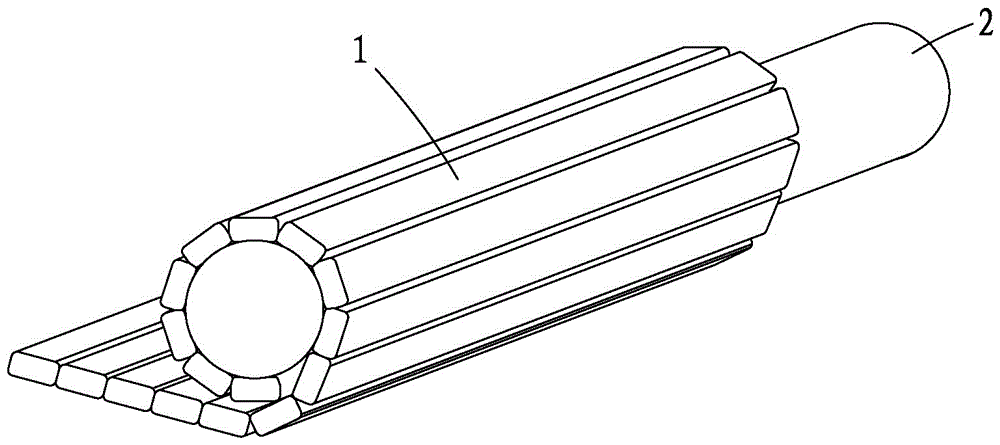

[0036] A kind of preparation method of bamboo beam column of the present invention, this preparation method specifically comprises following operation steps: (1), choose bamboo material: select 5~8 years old moso bamboo or giant dragon bamboo for use; (2), saw and cut bamboo strips: The selected bamboo is sawed and cut into bamboo tubes with a length of 3 to 8 meters, and then the bamboo tubes are sliced according to the requirements, and divided into long and wide strips of bamboo; (3), removing useless substances: the strips of bamboo obtained Remove bamboo green and bamboo yellow, and then place the bamboo slices after removing bamboo green and bamboo yellow into 0.2 to 1% hydrogen peroxide solution (that is, 0.2 to 1% hydrogen peroxide in the hydrogen peroxide solution) for cooking, and the bamboo chips and hydrogen peroxide solution The mass ratio is 1:3~5, the cooking temperature is 100℃~180℃, and the cooking pressure is 1~5kg / cm 2 , cooking time is 3~6 hours, after co...

Embodiment 1

[0040] Embodiment 1 prepares cylindrical bamboo beam column

[0041] Select 5-8 year old moso bamboo or Julong bamboo for standby; saw the selected bamboo into bamboo tubes with a length of 3-8 meters, and then slice the bamboo tubes according to the needs, and divide them into long strips of required length and width; The obtained long strips of bamboo chips are processed to remove bamboo green and bamboo yellow, and then the bamboo chips after removing bamboo green and bamboo yellow are placed in a solution containing 0.5% hydrogen peroxide for cooking, and the mass ratio of bamboo chips to hydrogen peroxide solution is 1:4, Cooking temperature 180°C, cooking pressure 3kg / cm 2 , the cooking time is 5 hours, after cooking, drain and put into a drying room to dry until the moisture content of the bamboo slices is 6%), stand-by; the cooked and dried bamboo slices are sliced into shapes that cooperate with each other, and then each bamboo slice 11 Woven into bamboo chain 1 (s...

Embodiment 2

[0042] Embodiment 2 prepares the bamboo beam column of square column shape

[0043] Select 5-8 year old moso bamboo or Julong bamboo for standby; saw the selected bamboo into bamboo tubes with a length of 3-8 meters, and then slice the bamboo tubes according to the needs, and divide them into long strips of required length and width; The obtained long strips of bamboo chips are processed to remove bamboo green and bamboo yellow, and then the bamboo chips after removing bamboo green and bamboo yellow are placed in a solution containing 0.2% hydrogen peroxide for cooking, and the mass ratio of bamboo chips to hydrogen peroxide solution is 1:5, Cooking temperature 150°C, cooking pressure 1kg / cm 2 , the cooking time is 6 hours, after cooking, drain and put it into a drying room to dry until the moisture content of the bamboo slices is 8%, and set aside; cut the steamed and dried bamboo slices into shapes that match each other, and then each bamboo slice 11 Woven into bamboo sheet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com