Patents

Literature

1305results about "Wood heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

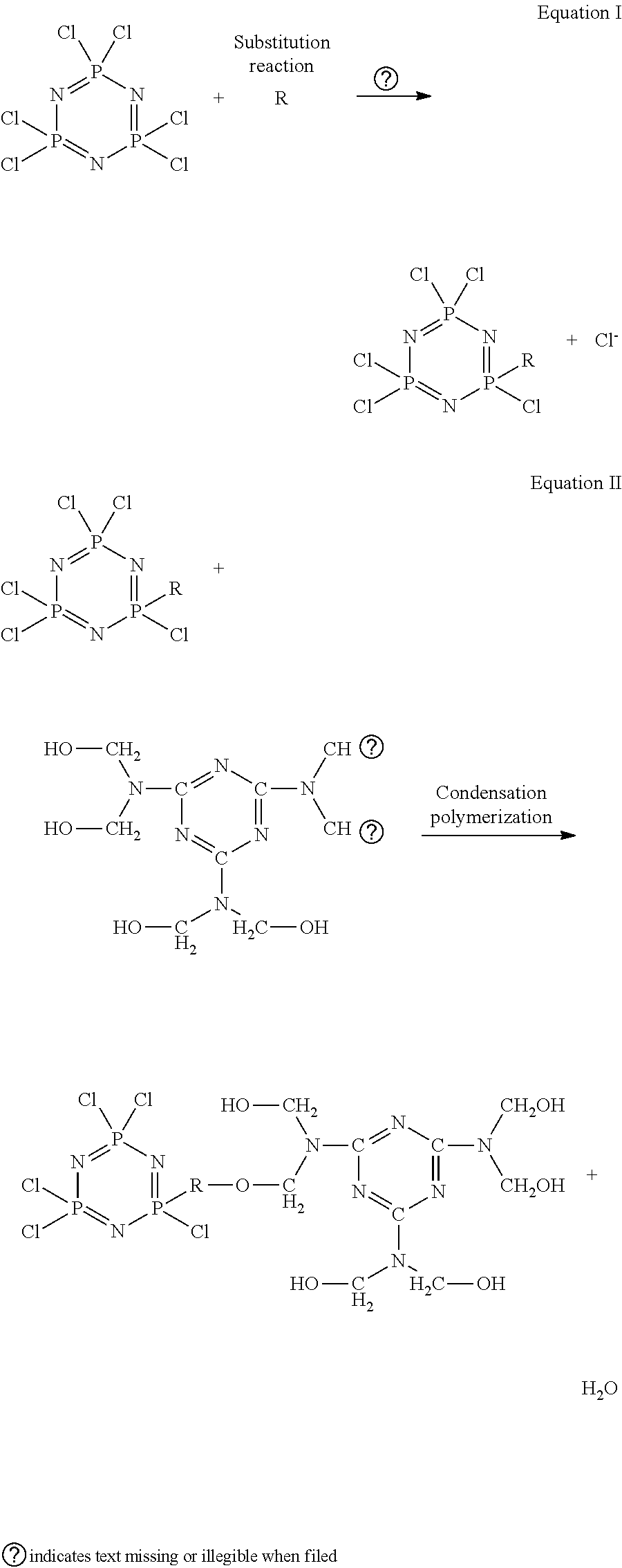

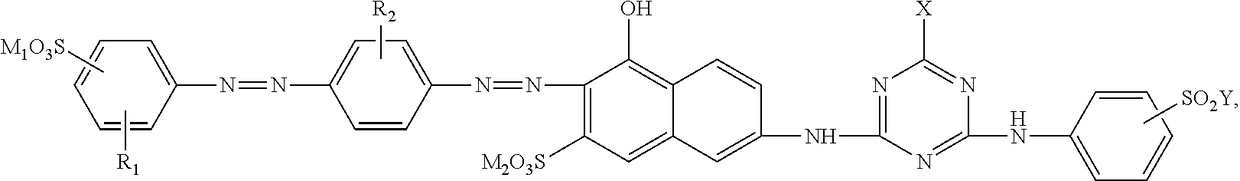

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

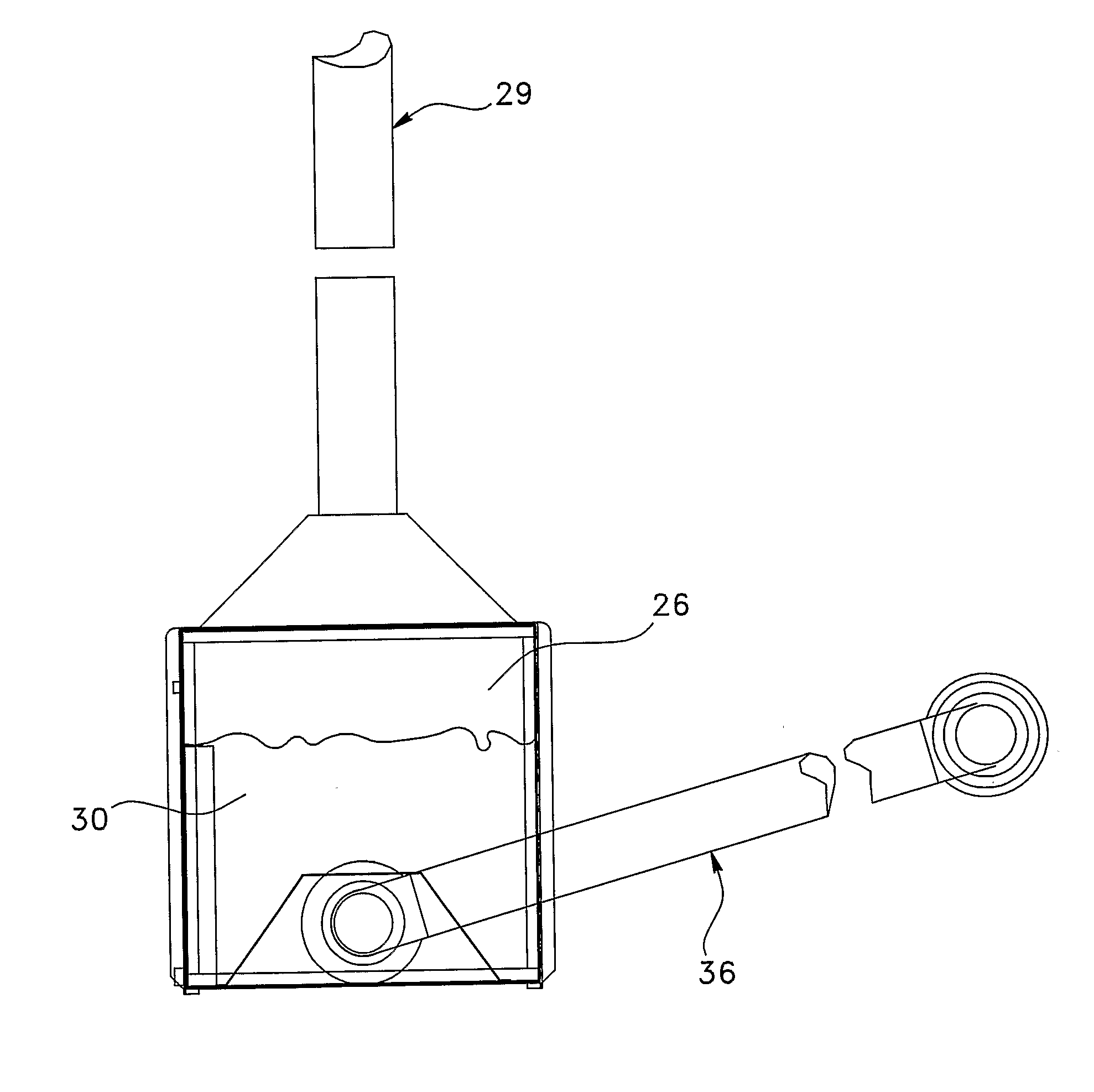

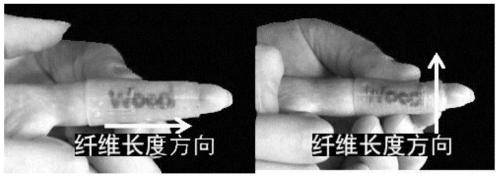

Solid wood bending technological method for curve-shaped structural member of redwood furniture

ActiveCN104802247AImprove the level of production technologyHigh strengthWood compressionWood treatment detailsSolid woodColor effect

The invention discloses a solid wood bending technological method for a curve-shaped structural member of redwood furniture. The solid wood bending technological method comprises the following steps: (1) wood type selection and lumber processing; (2) boiling or steaming for thermal treatment for softening; (3) longitudinal compression; (4) die bending forming; (5) drying sizing; (6) aging for life nourishing; (7) later processing and bending to manufacture the curve-shaped structural member of the redwood furniture. The solid wood bending technological method has the advantages that the generally conventional lineation sawing processing method can be replaced; a redwood type solid wood lumber can be directly bent into a curve-shaped part; the production technological level for the curve-shaped part of the redwood furniture can be increased, and the production technological steps can be simplified; the utilization rate of redwood type woods can be increased, the intensity of the curve-shaped part is enhanced, and the texture and color effect and the paint decoration quality on the surface of a product are guaranteed.

Owner:ZHONGSHAN TAIXING FURNITURE CO LTD

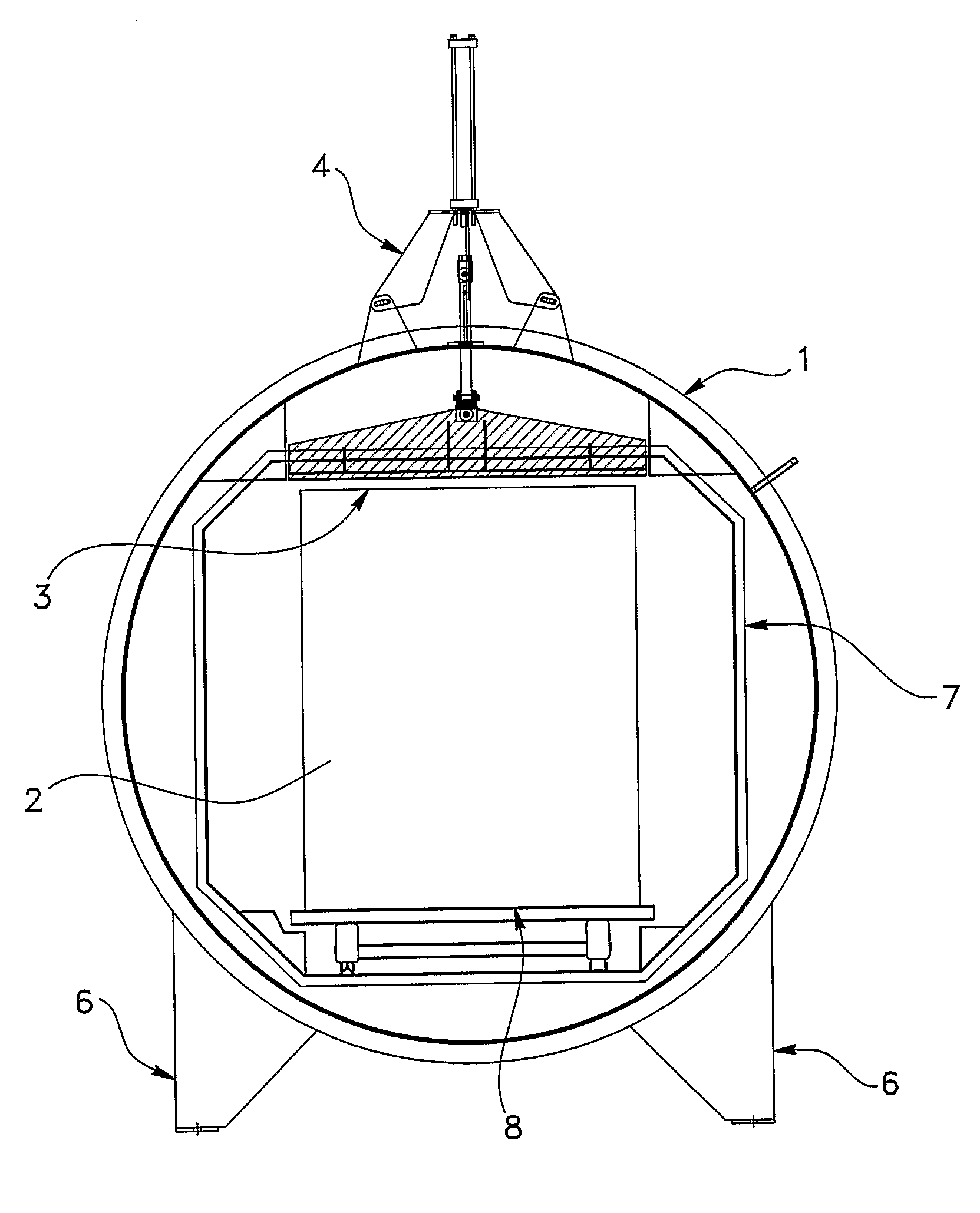

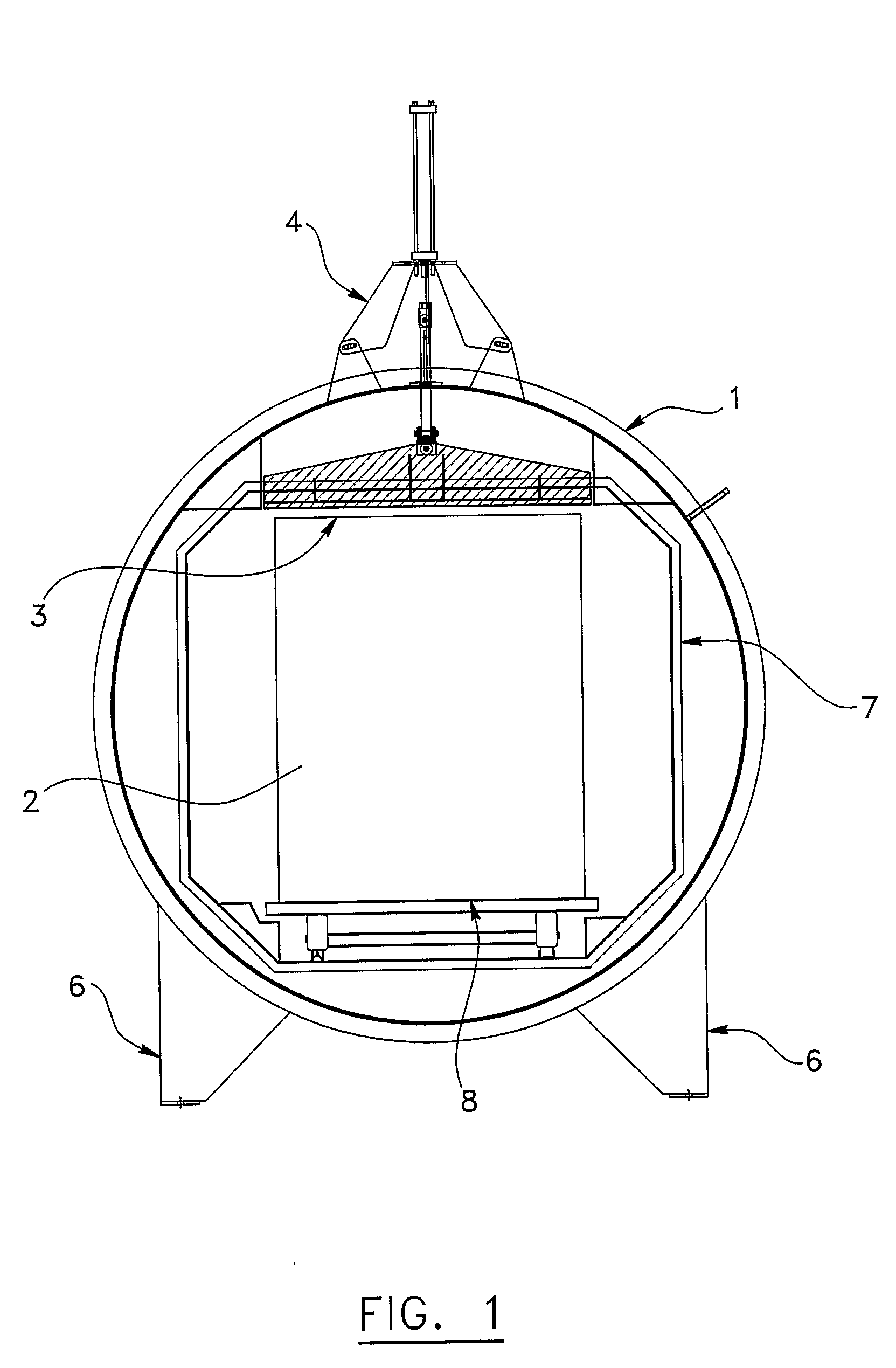

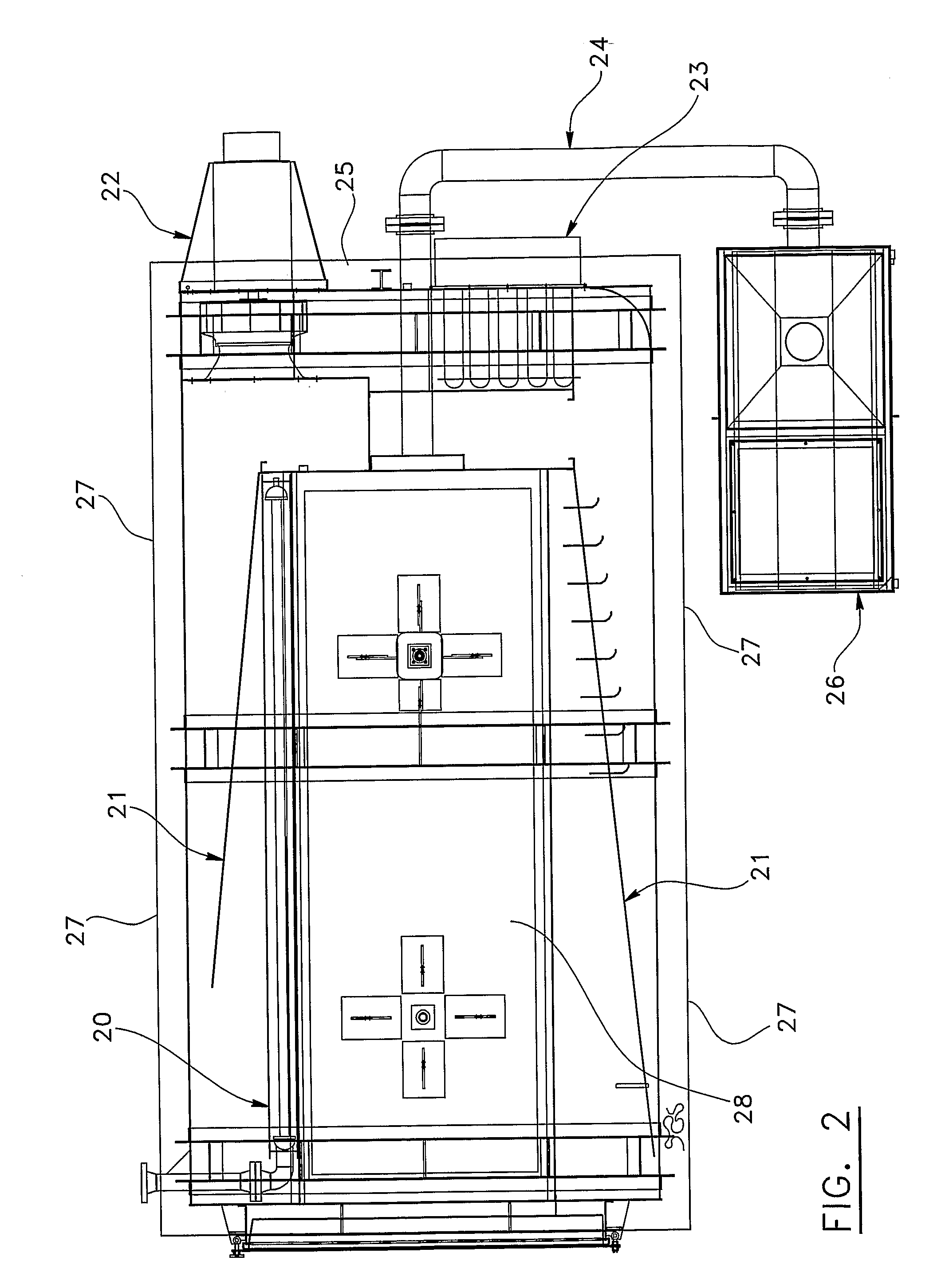

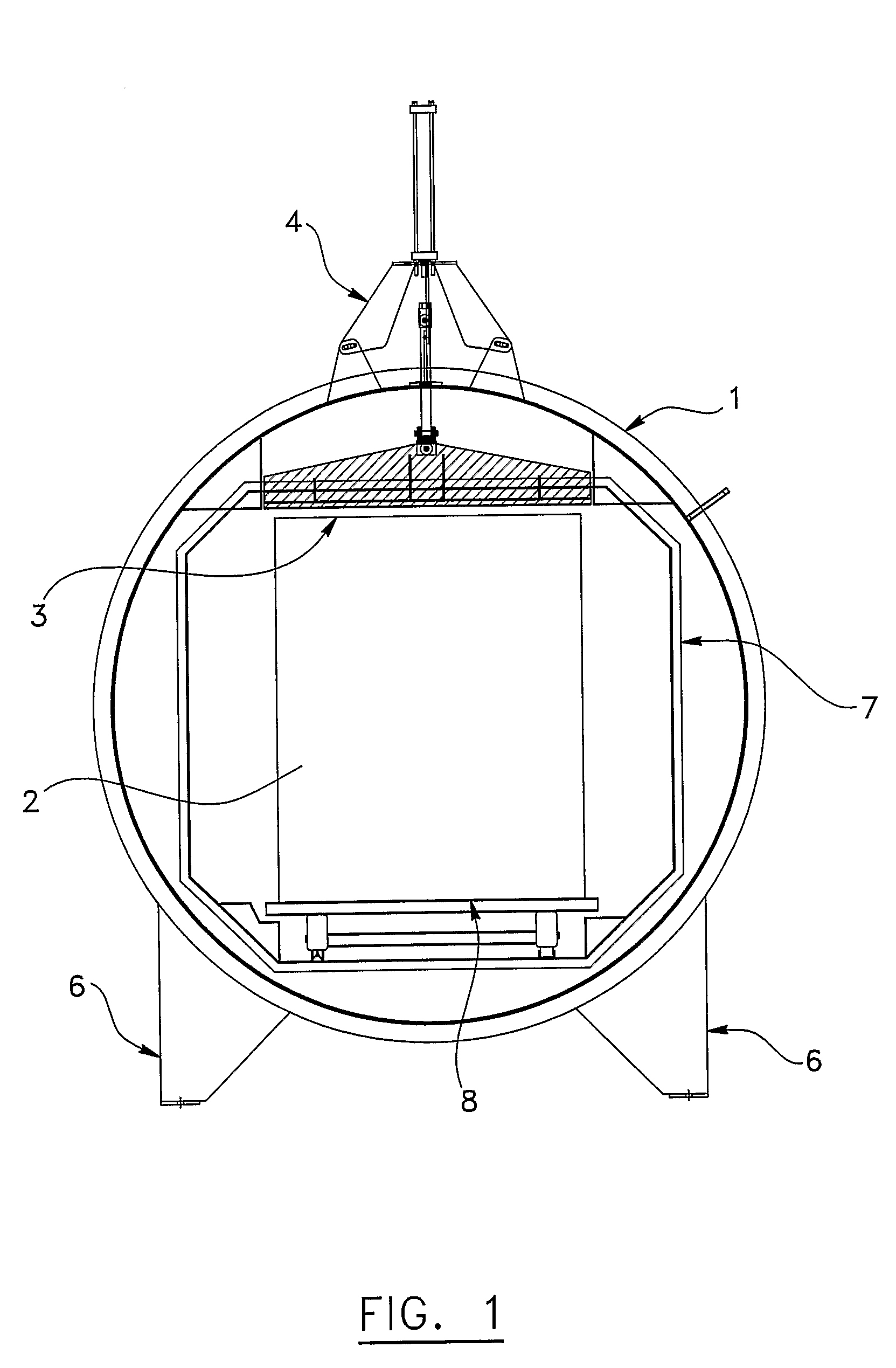

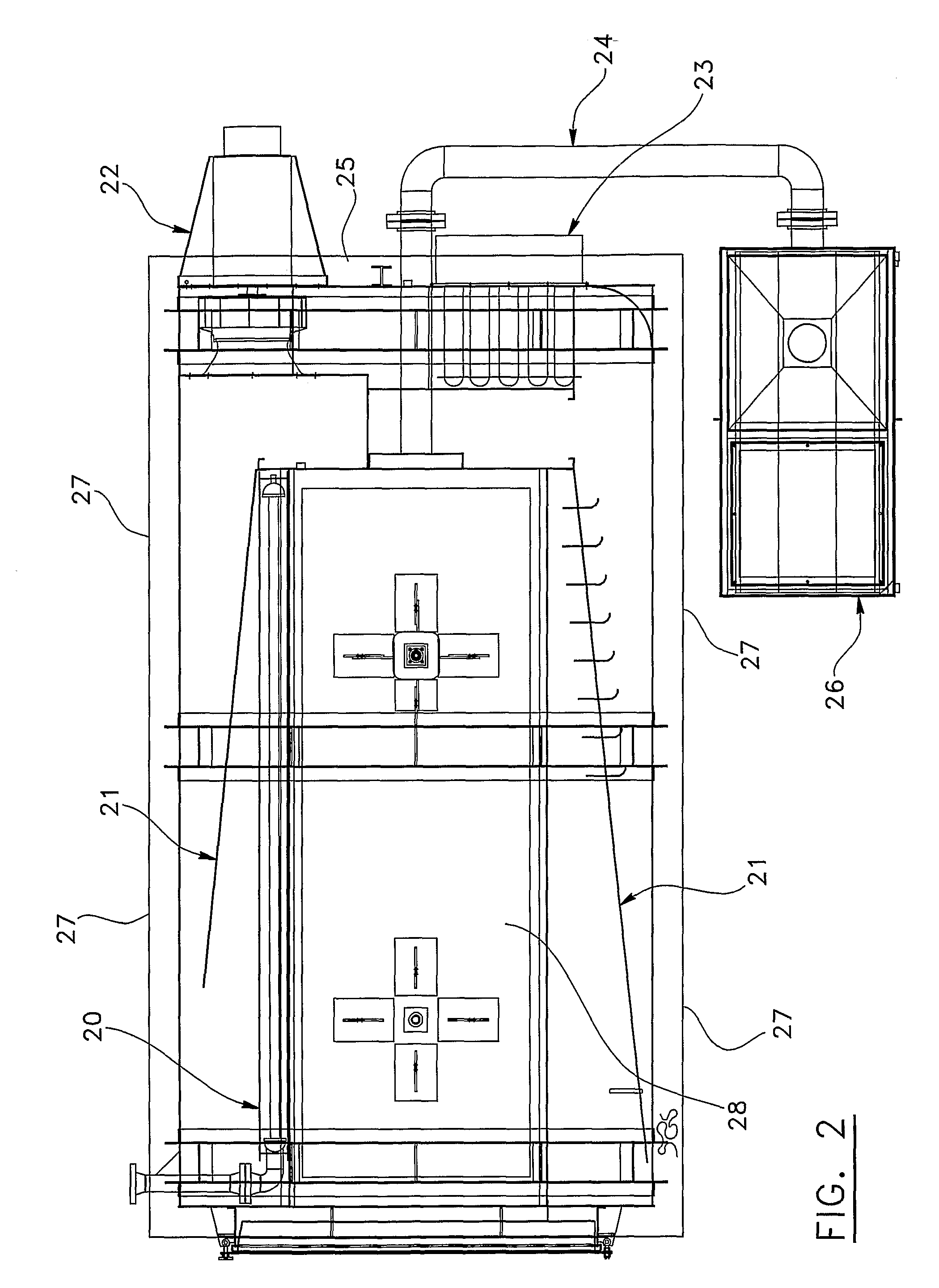

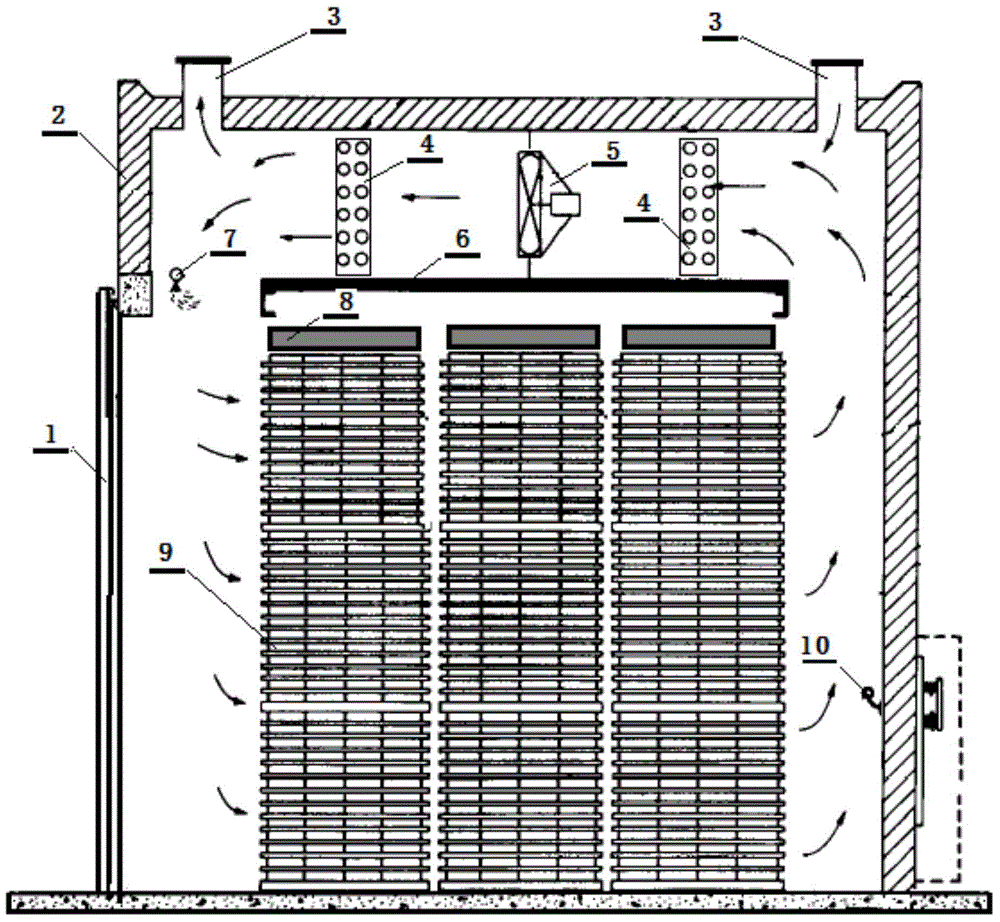

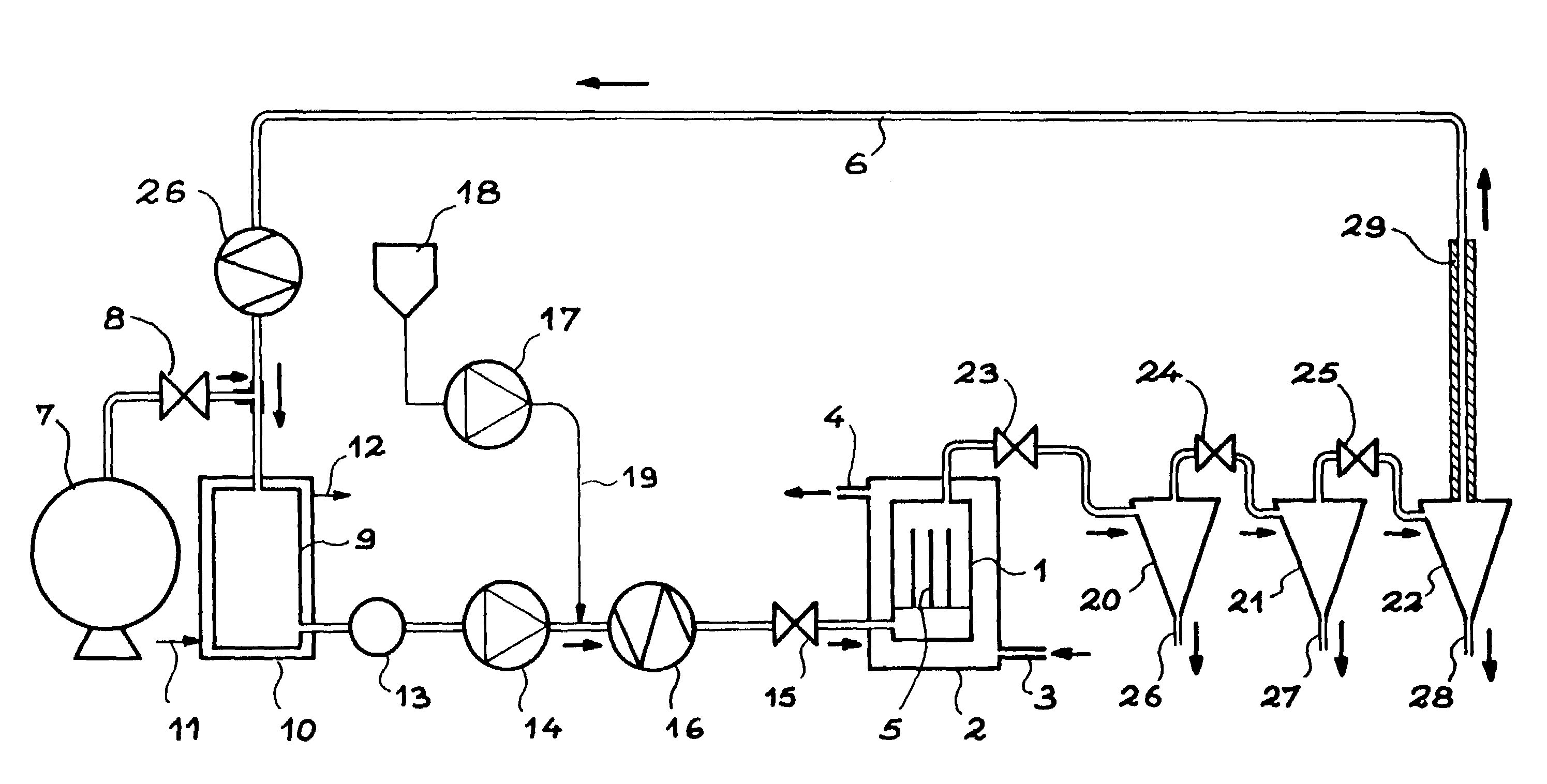

Process for Treating Lignocellulosic Material, and Apparatus for Carrying Out the Same

InactiveUS20080263891A1Satisfies needDrying using combination processesLiquid surface applicatorsCelluloseEngineering

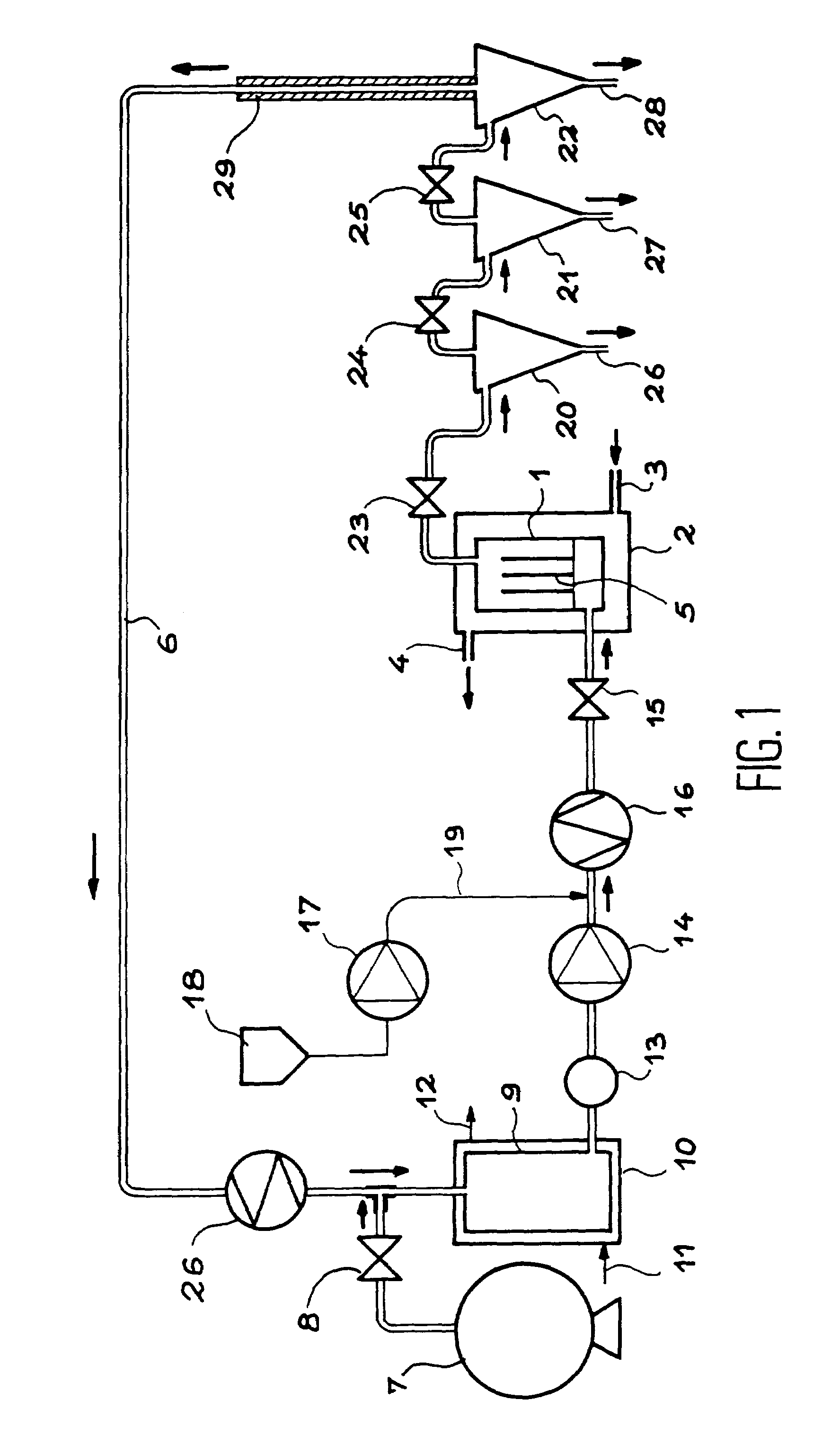

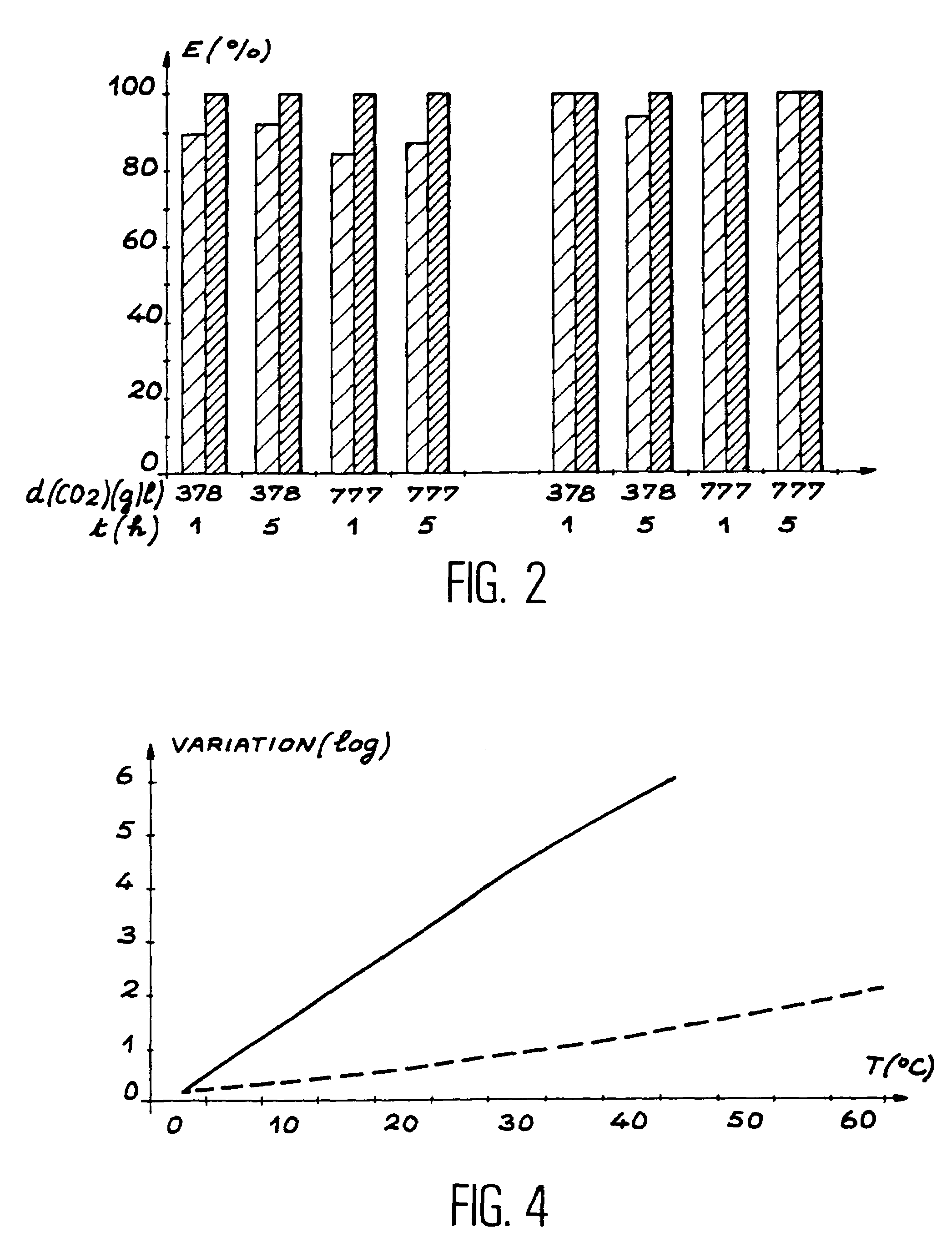

A process for treating lignocellulosic material, such as wood for example, the process including the steps of: a) providing lignocellulosic material; b) evaluating parameters of the lignocellulosic material; c) preparing the lignocellulosic material; d) heating the lignocellulosic material in a treatment chamber following a given profile based on parameters of the lignocellulosic material; e) stabilizing the lignocellulosic material; and f) cooling down the lignocellulosic material. The process enables to improve the quality of the wood being treated, while ensuring a greater repeatability and uniformity of coloring results, and overcoming drawbacks associated with conventional torrefaction methods.

Owner:9103 7366 QUEBEC

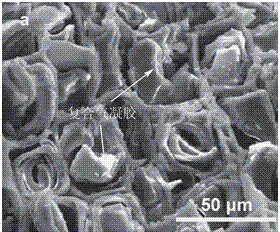

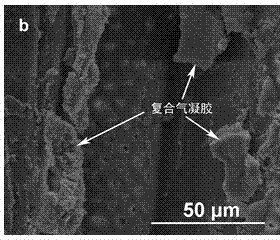

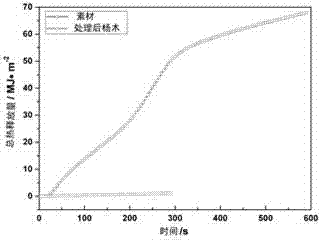

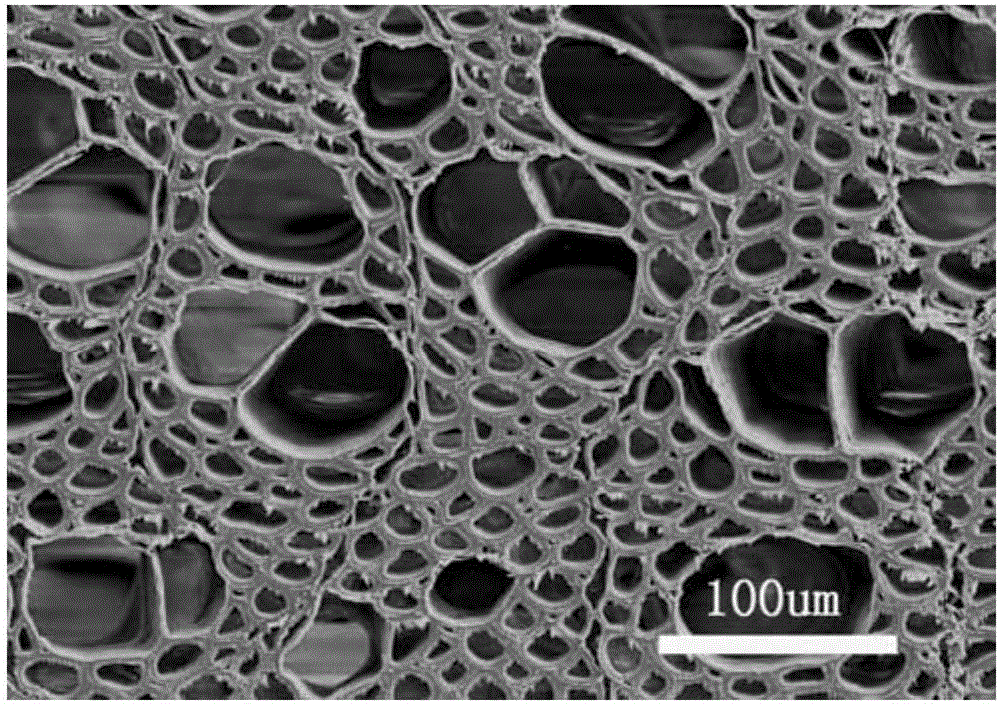

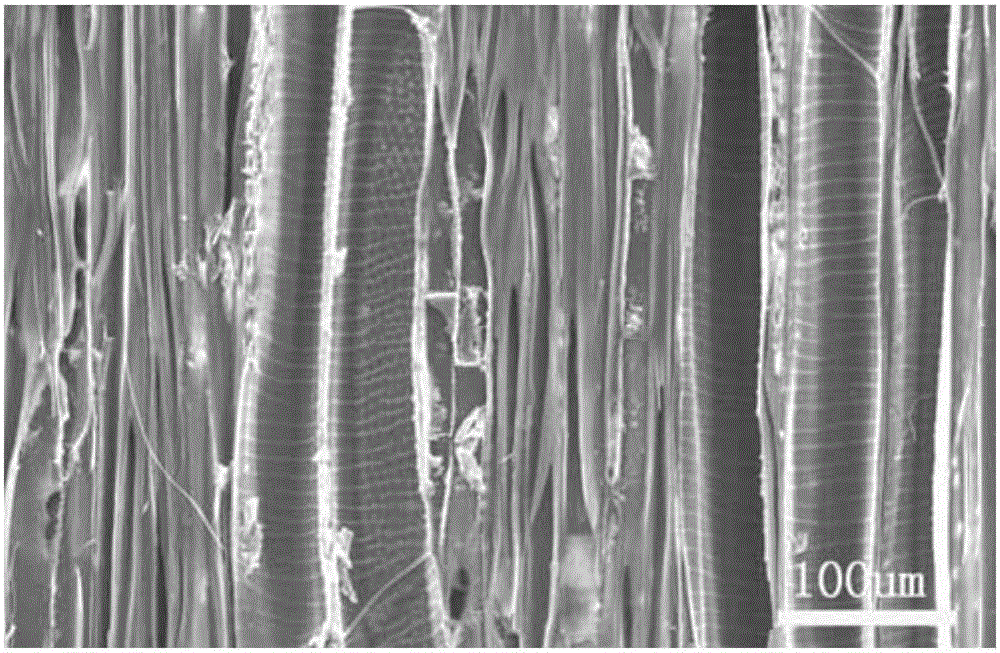

Ammonium polyphosphate/SiO2 composite aerogel flame-retardant reinforced timber and preparation method thereof

ActiveCN104760103AImprove permeabilityEvenly dispersedRadiation/waves wood treatmentWood treatment detailsSolid woodCorrosion prevention

The invention discloses an ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber which comprises a timber and an ammonium polyphosphate / SiO2 composite aerogel in timber pores. The invention also discloses a preparation method of the flame-retardant reinforced timber, which comprises the following steps: pretreating the timber with microwaves to form new flow channels in the timber, thereby enhancing the timber permeability; hydrolyzing the previously prepared ammonium polyphosphate and silicon source by pressure dipping treatment, and introducing the generated uniform sol solution into the timber; and carrying out condensation reaction and normal-pressure drying to generate the ammonium polyphosphate / SiO2 composite aerogel in the timber pore structure in situ. The ammonium polyphosphate / SiO2 composite aerogel flame-retardant reinforced timber has favorable flame-retardant and smoke-inhibition functions, and can effectively prevent the flame retardant from loss. The composite aerogel in the timber pores has the effect of enhancing wear resistance and corrosion resistance. The method can be widely used in flame retardancy, reinforcement and corrosion resistance of the solid wood or composite wood, has the advantages of feasible technical process, cheap raw materials and favorable effect, and is worthy of popularization.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

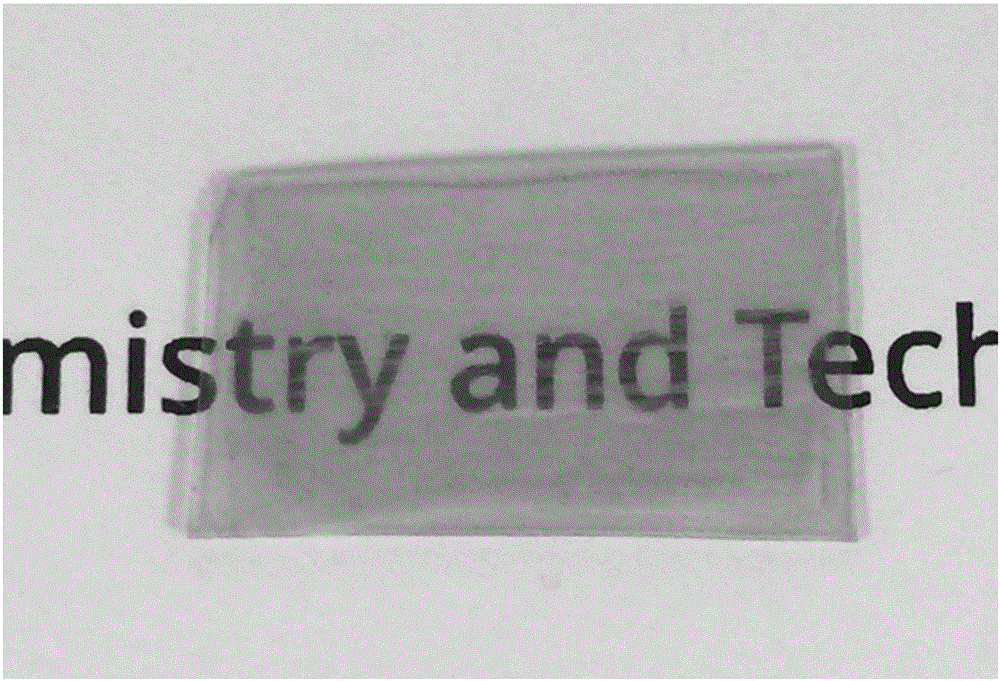

Manufacturing method for fluorescent transparent magnetic wood

InactiveCN106313221AWith transparencyAppropriate transparencyPressure wood treatmentWood treatment detailsFluorescenceMagnetite Nanoparticles

The invention relates to a manufacturing method for fluorescent transparent magnetic wood. The manufacturing method for the fluorescent transparent magnetic wood aims to solve the problems that existing wood is not transparent and does not have magnetism or the fluorescence property. The manufacturing method for the fluorescent transparent magnetic wood comprises the steps that firstly, lignin of wood is eliminated; secondly, fluorescent magnetic nanoparticles are prepared; and thirdly, the fluorescent transparent magnetic wood is manufactured and obtained. The method is used for manufacturing the fluorescent transparent magnetic wood.

Owner:NORTHEAST FORESTRY UNIVERSITY

Process for treating lignocellulosic material, and apparatus for carrying out the same

A process for treating lignocellulosic material, such as wood for example, the process including the steps of: a) providing lignocellulosic material; b) evaluating parameters of the lignocellulosic material; c) preparing the lignocellulosic material; d) heating the lignocellulosic material in a treatment chamber following a given profile based on parameters of the lignocellulosic material; e) stabilizing the lignocellulosic material; and f) cooling down the lignocellulosic material. The process enables to improve the quality of the wood being treated, while ensuring a greater repeatability and uniformity of coloring results, and overcoming drawbacks associated with conventional torrefaction methods.

Owner:9103 7366 QUEBEC

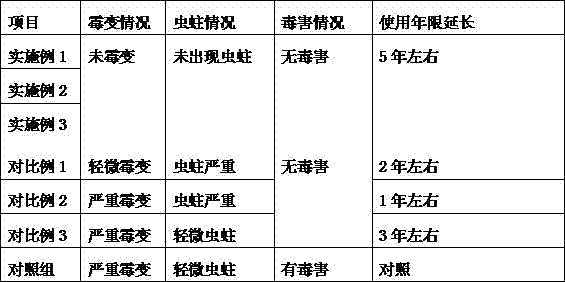

Green mould-proof insecticide for wood materials

ActiveCN106363733AWide range of raw materialsLow priceWood treatment detailsWood heatingPlant cellCorylus mandshurica

The invention relates to the technical field of wood processing and discloses a green mould-proof insecticide for wood materials. The green mould-proof insecticide is prepared from the following raw materials: cotinus coggygria leaves, Chinese pine leaves, mountain peach bark, catalpa leaves, melia azedarach leaves, paper mulberry leaves, periploca bark, corylus mandshurica, physocarpus monogynus bark, fraxinus malacophylla, clematis finetiana, edgeworthia chrysantha bark, Chinese thorowax root, butea monosperma seeds, centipedegrass, white granulated sugar, gossypol, lactic acid bacteria, wine yeasts and compound enzymes. The raw materials are rich and cheap, are simple to prepare, are green and healthy, are free of any toxic reagent, are friendly to the environment, and are harmless to the human body. Steamer water is reserved and used for extracting and can prevent mould, kill insects, increase flexibility and facilitate processing; and at the same time, water usage can be saved, the environment can be protected, and the cost can be saved by 10.2%. Through the double fermentation of the lactic acid bacteria and the wine yeasts, plant cell structures are destroyed, the extracting of effective components is promoted, small-molecular antibacterial components are increased, the mould-proof and insecticidal effect is enhanced, the antibacterial rate reaches 81.7%, and the insecticidal rate reaches 78.3%.

Owner:安徽戴家实业股份有限公司

Wicker treatment method

The invention relates to a wicker treatment method, which comprises the steps of: (1) peeling wicker, then conducting treatment in flowing air at 55DEG C and with relative humidity of 69% for 2h; (2) fumigating the wicker with sulfur under 85DEG C and relative humidity of 65% for 1h; (3) wrapping the wicker well treated in step (2) with wet river mud, and performing treatment at 18DEG C for 30h; (4) conducting heat treatment; and (5) carrying out soaking treatment on the wicker well treated in step (4) with a mixed solution for 1h, performing flushing, and then carrying out knitting. The wicker treatment method provided by the invention has a simple treatment process, the treatment raw materials are common, and the treatment can improve the toughness and strength of the wicker.

Owner:阜南佳利工艺品股份有限公司

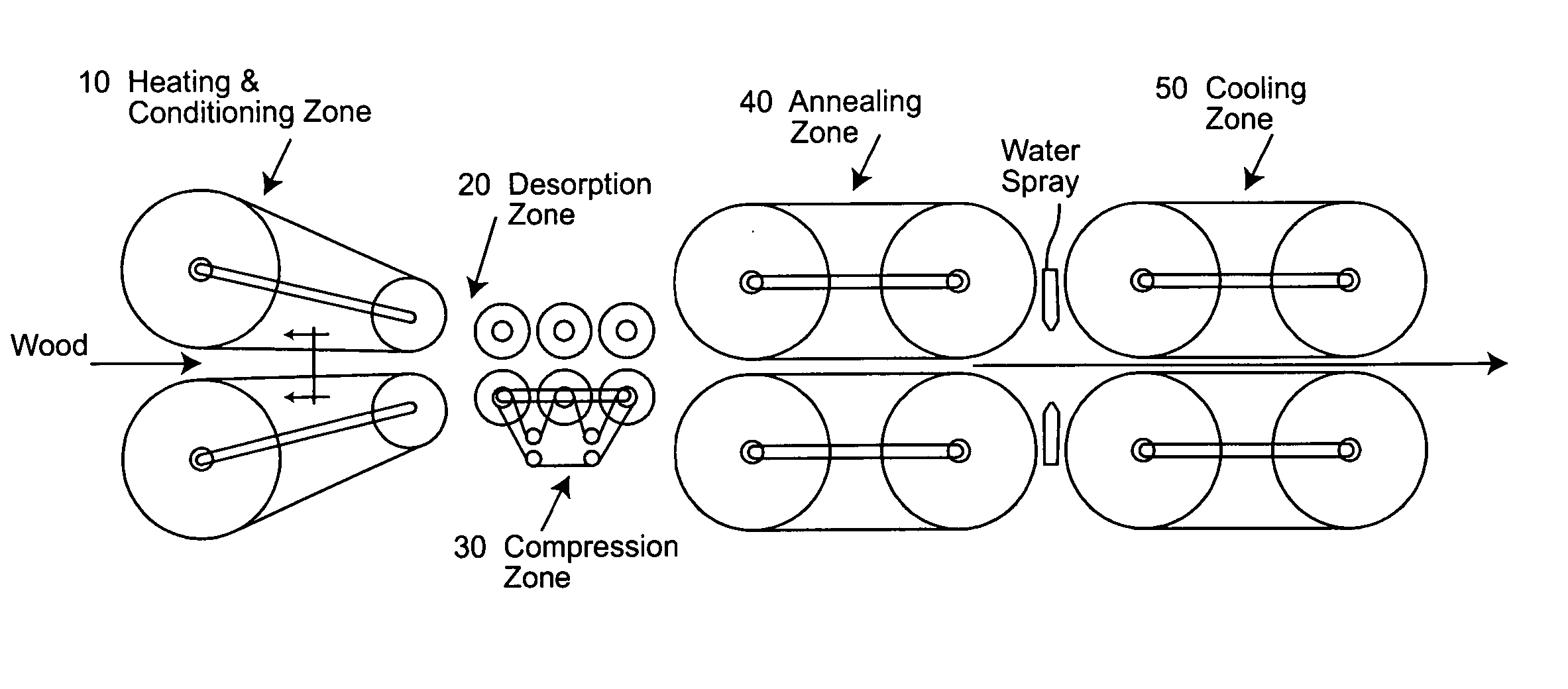

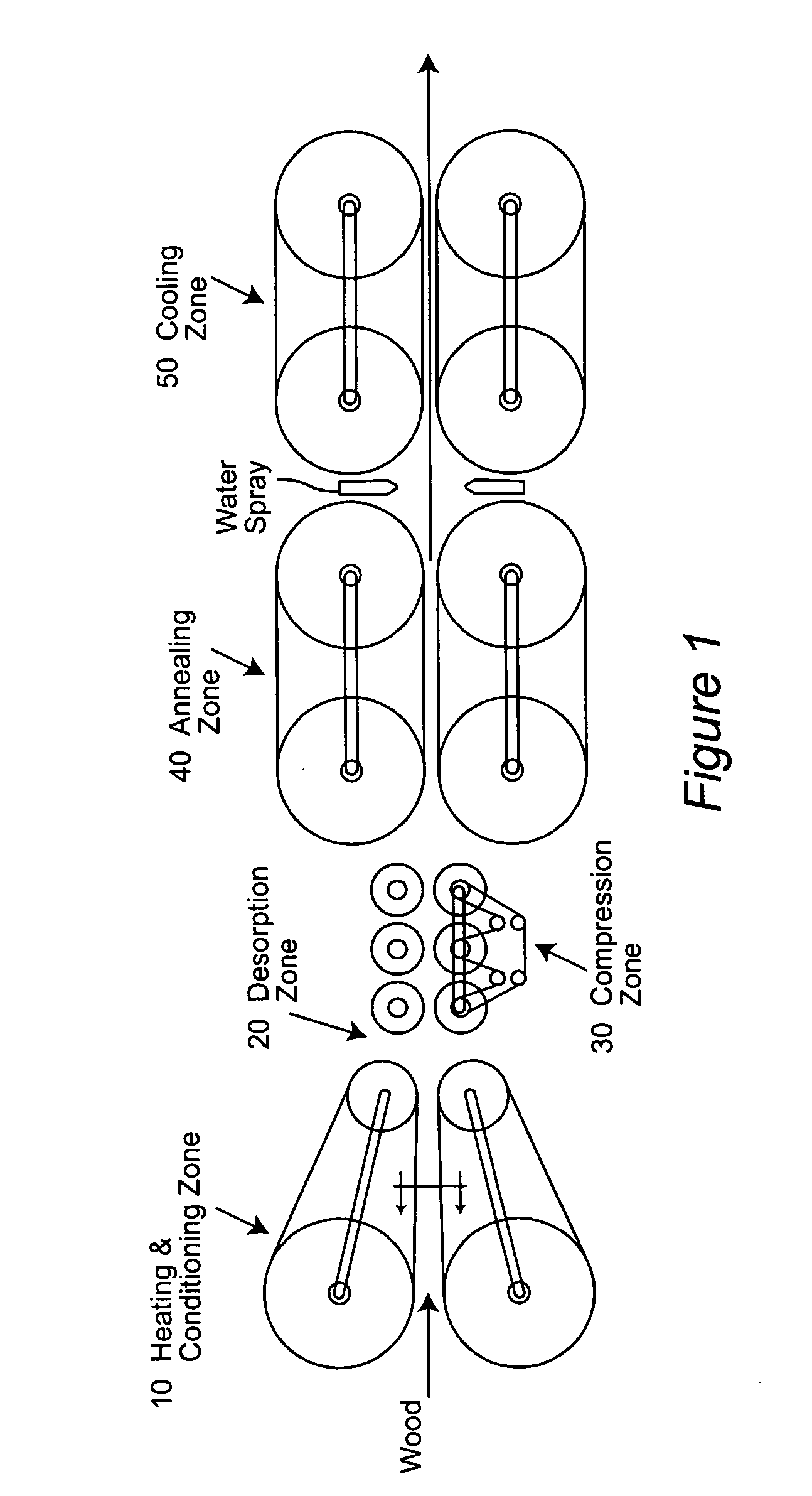

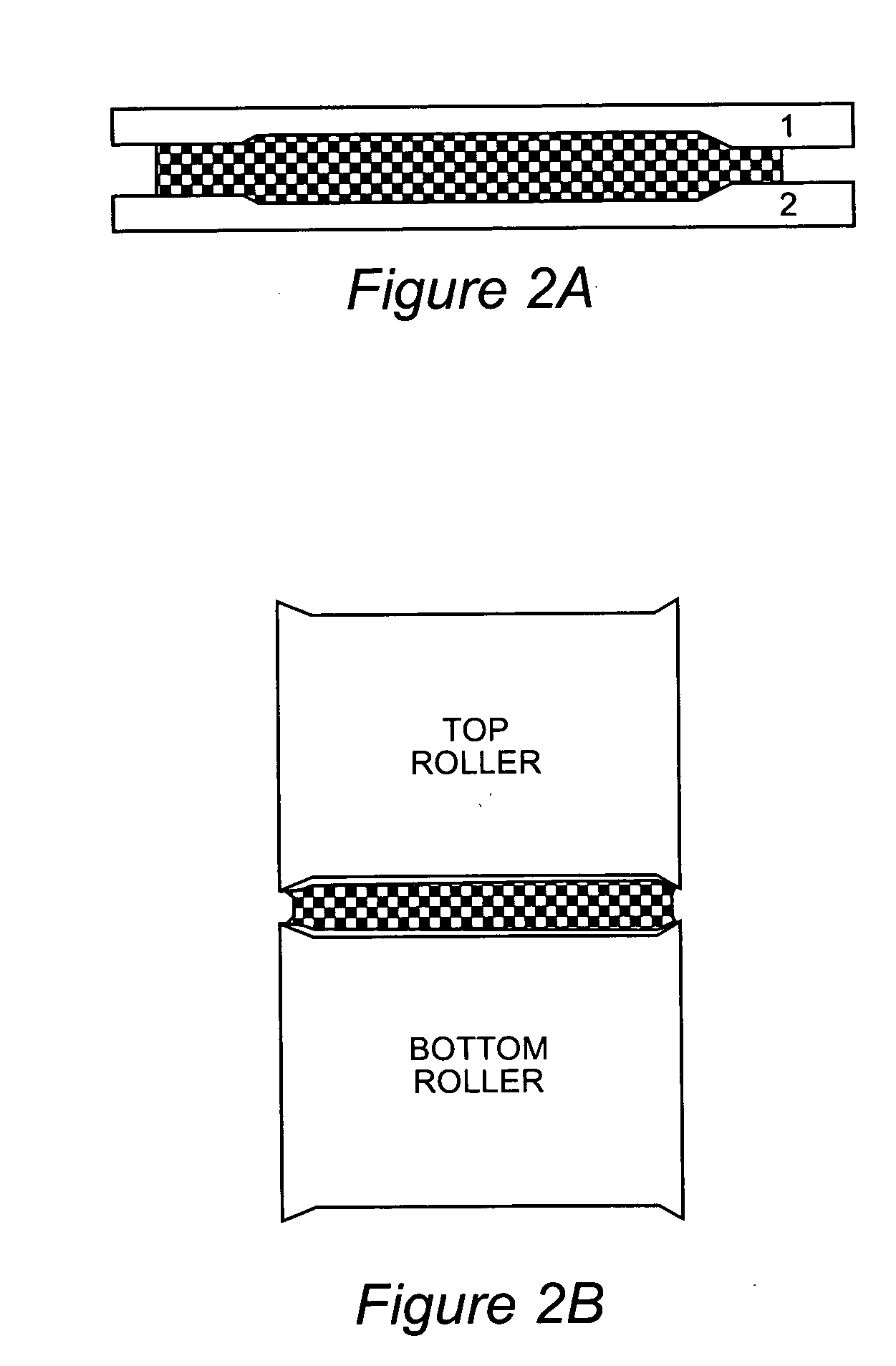

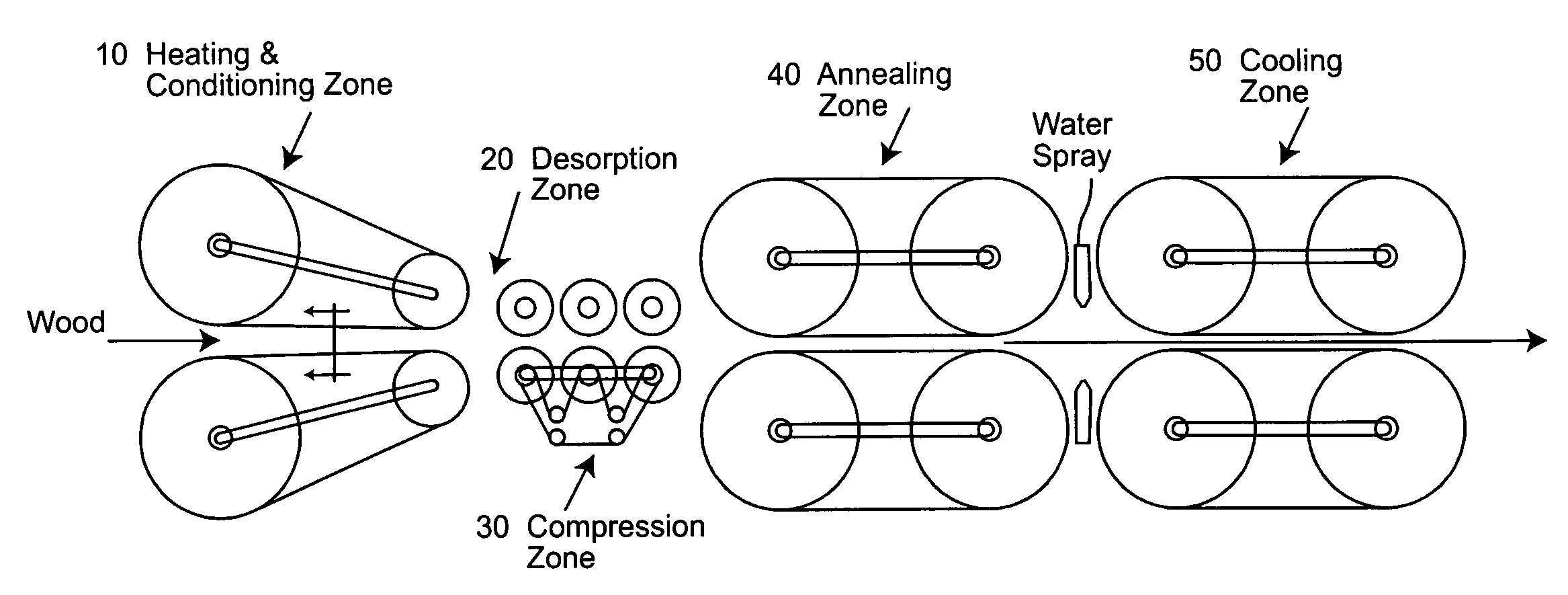

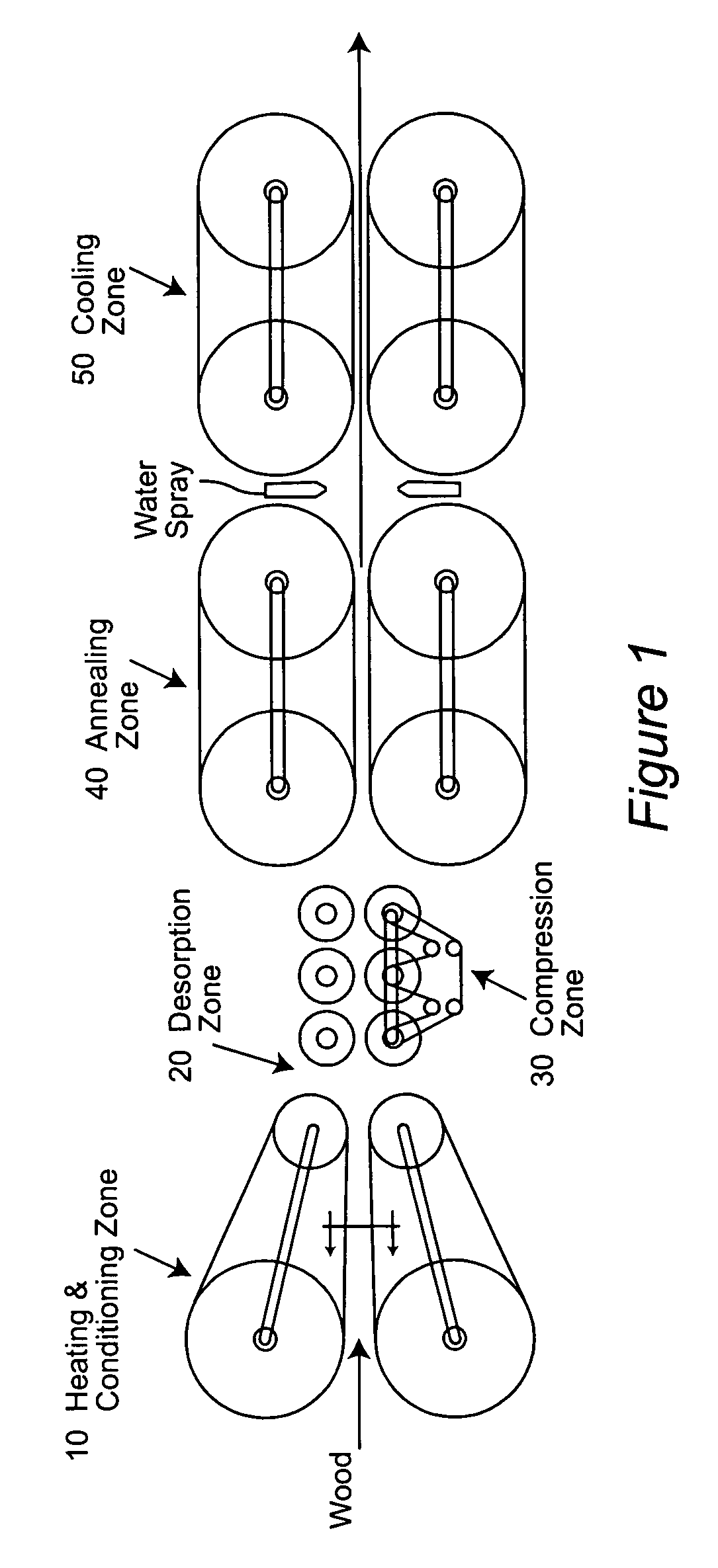

Viscoelastic thermal compression of wood

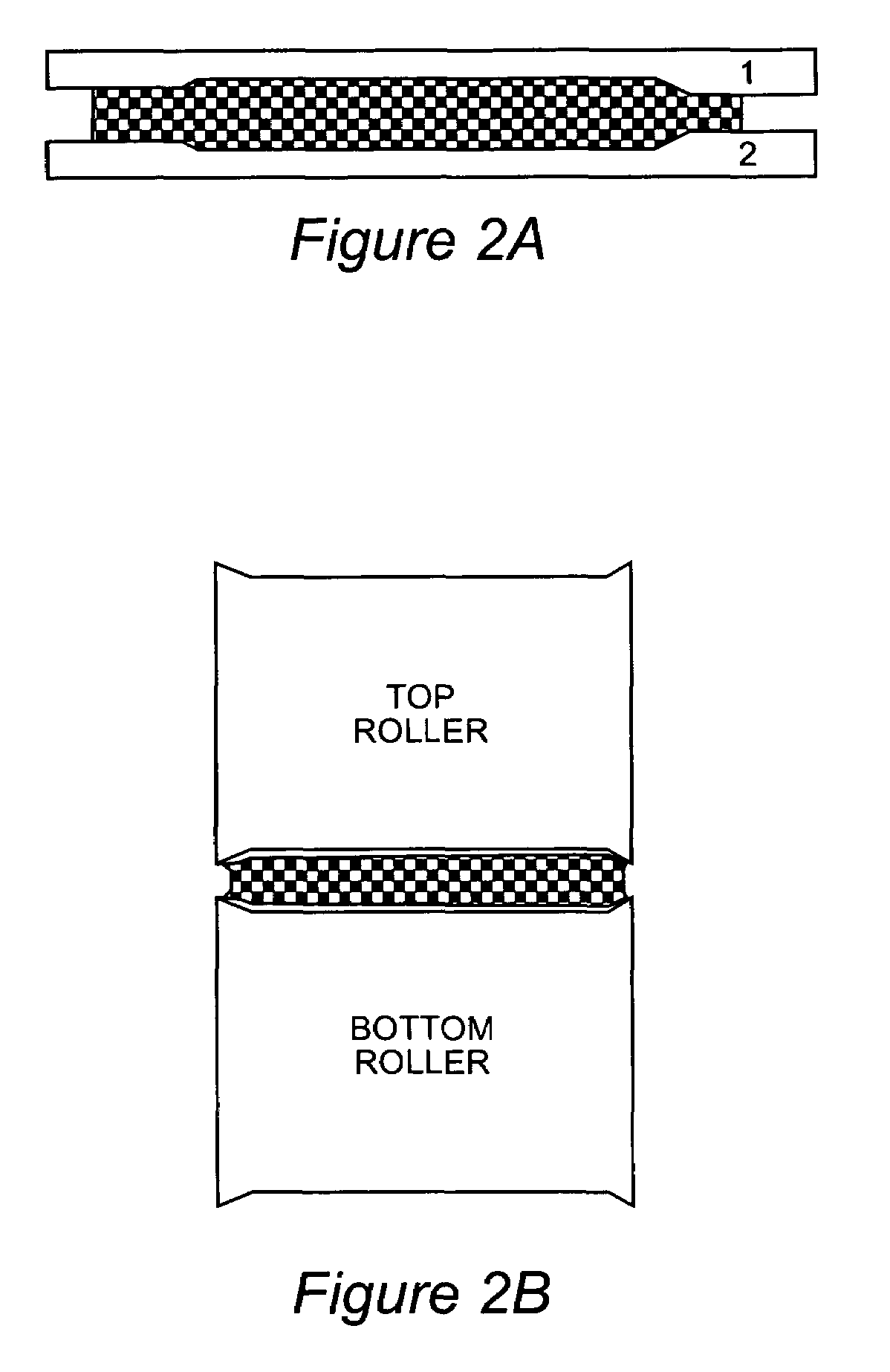

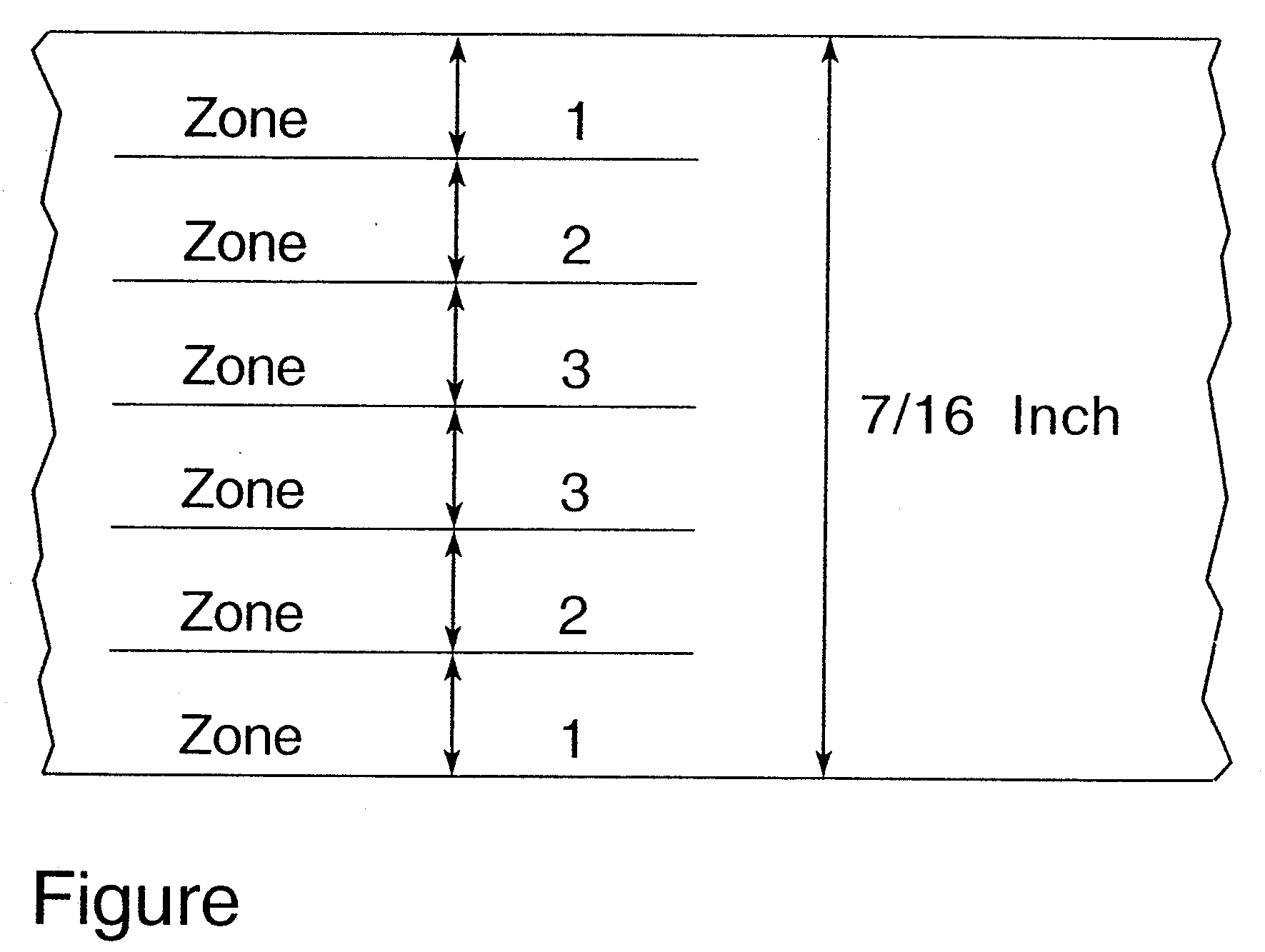

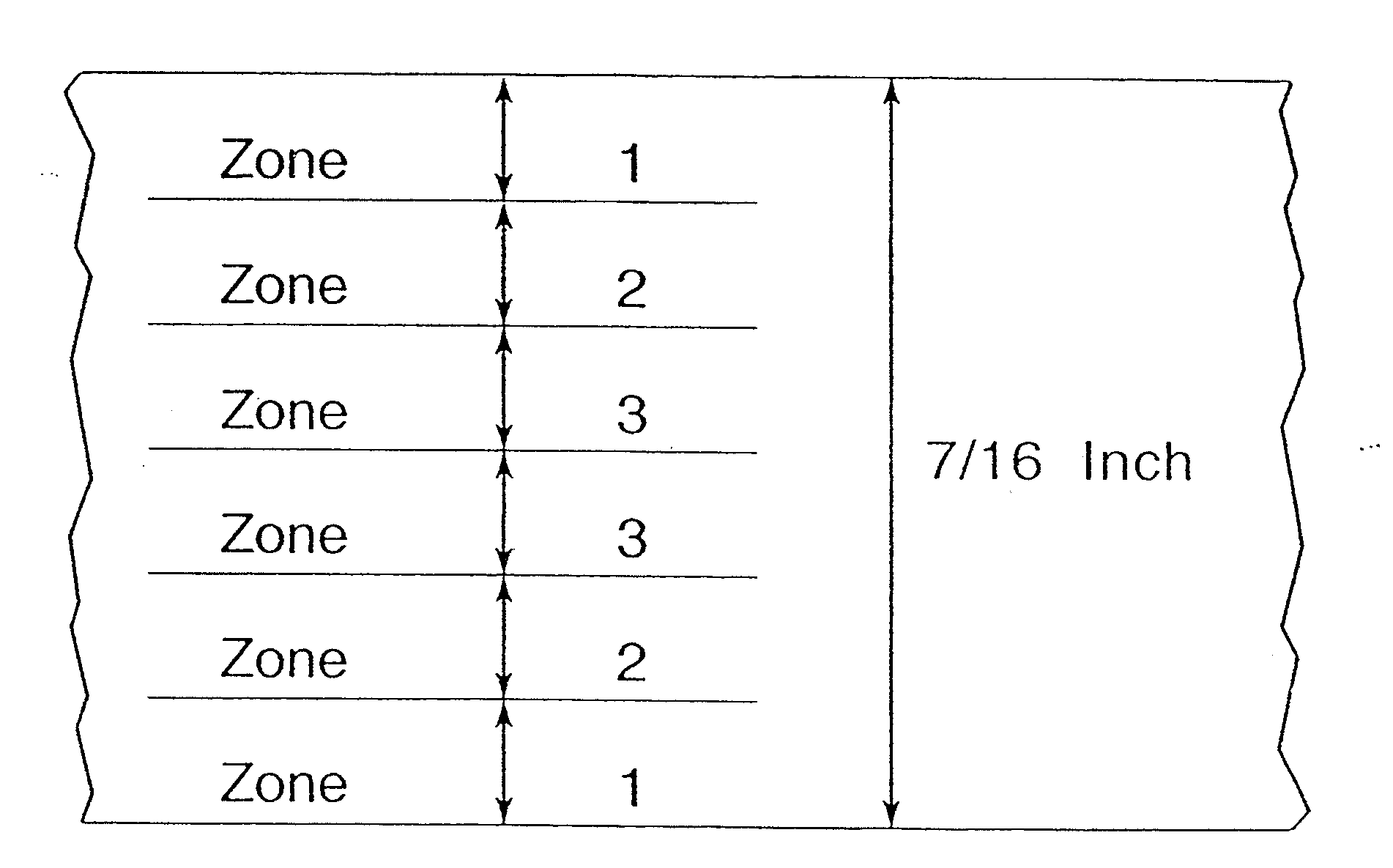

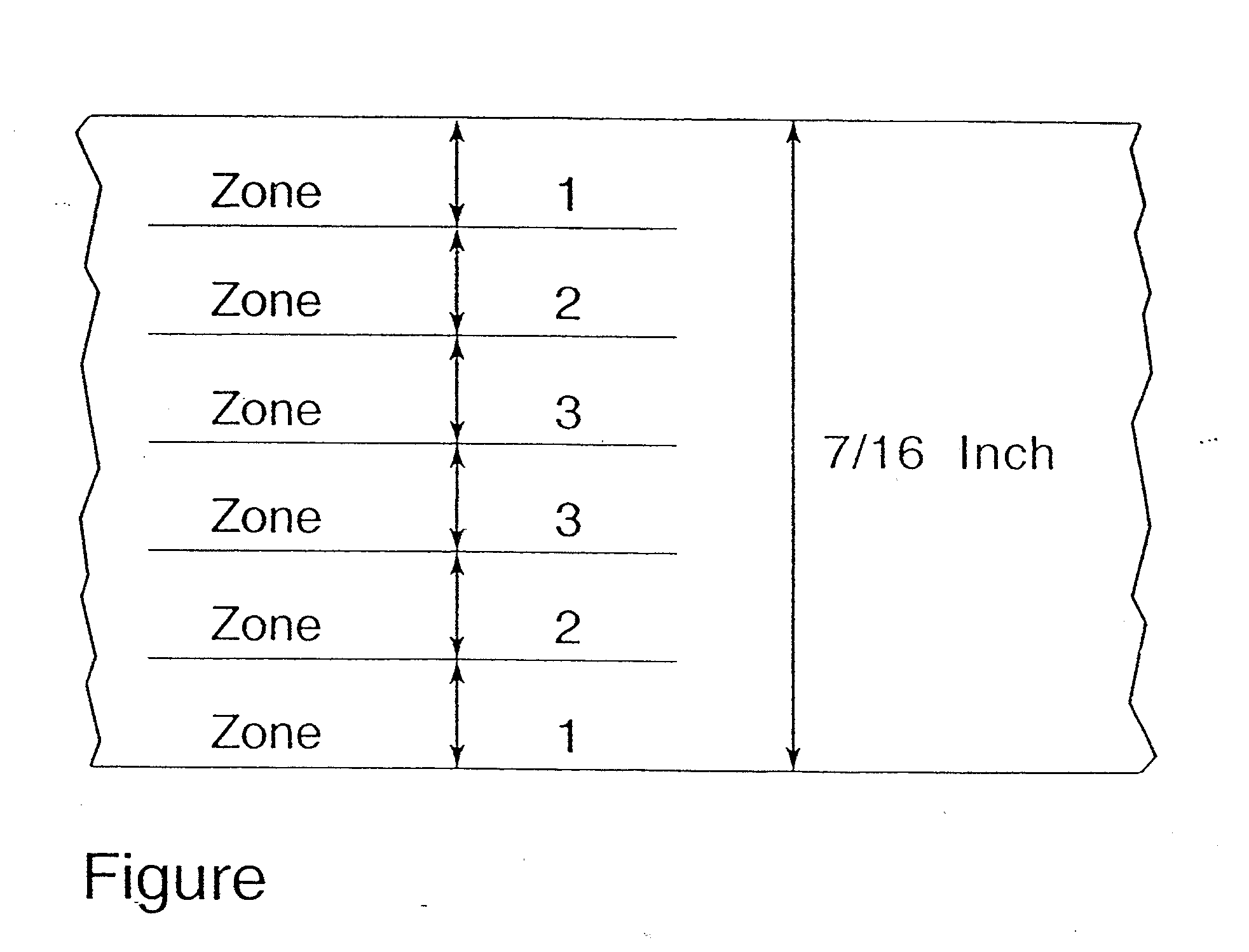

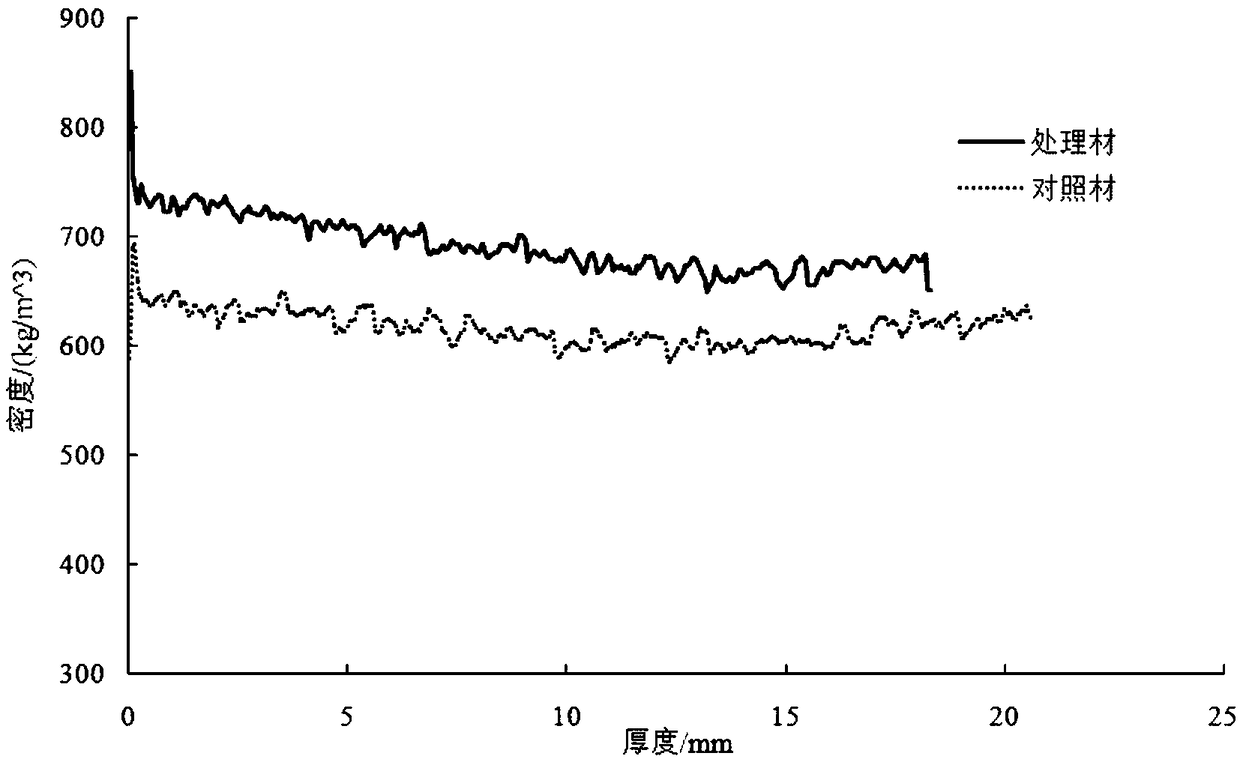

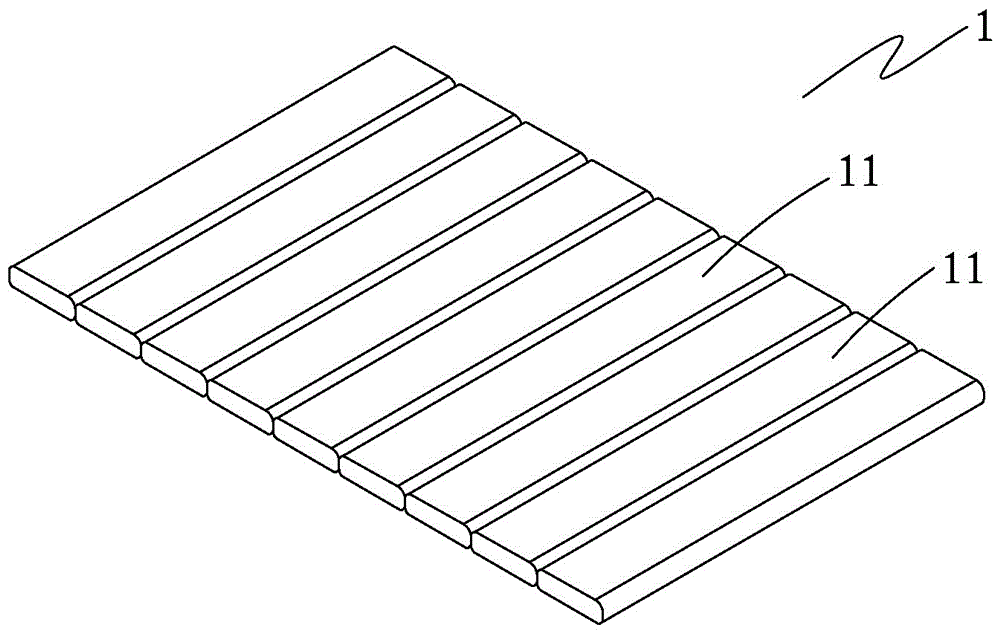

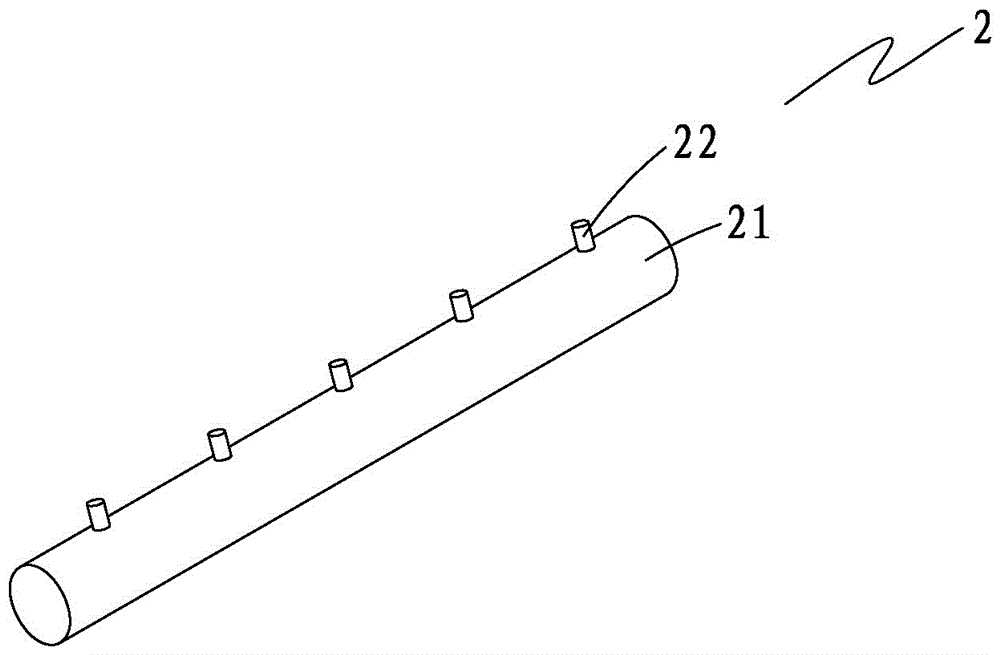

ActiveUS20050006004A1High density and strength and dimensional stabilityHigh stiffnessWood compressionWood treatment detailsHigh densityThermal compression

A high density wood product that is made from low-density wood is provided. The wood product is made using a continuous viscoelastic thermal compression (VTC) process and exhibits high density, strength and dimensional stability, compared to the lower density starting material (typically composite panels such as strand board) from which it is made.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

Viscoelastic thermal compression of wood

ActiveUS7404422B2High density and strength and dimensional stabilityHigh stiffnessWood compressionWood treatment detailsHigh densityThermal compression

A high density wood product that is made from low-density wood is provided. The wood product is made using a continuous viscoelastic thermal compression (VTC) process and exhibits high density, strength and dimensional stability, compared to the lower density starting material (typically composite panels such as strand board) from which it is made.

Owner:THE STATE OF OREGON ACTING BY & THROUGH THE OREGON STATE BOARD OF HIGHER EDUCATION ON BEHALF OF OREGON STATE UNIV

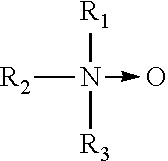

Method of Protecting Wood Through Enhanced Penetration of Wood Preservatives and a Related Solution

ActiveUS20090088481A1Improve permeabilityResists undesired grain raisingBiocideTransportation and packagingPreservativeBiological activation

A method of protecting wood through enhanced penetration of wood preservatives includes providing a solution including (a) at least one amine oxide, (b) at least one organic wood preservative and (c) a buffering agent. The solution preferably has a pH of about 7 to 10. The solution is applied to the surface of the wood after which, with or without intervening storage, the materials are activated to effect enhanced penetration of the organic wood preservative into the wood. One may effect application at a solution temperature of about 30 to 75° C. and preferably about 50 to 60° C. to effect activation at a higher temperature and high relative humidity. In a preferred practice, the wood may be heated before and / or after application of the solution. The solution is also disclosed as a product.

Owner:KOP COAT INC

Method of employing enhanced penetration of wood preservatives to protect wood and a related solution

ActiveUS20120258248A1Increase penetration depthEliminate redrying stepFireproof paintsBiocidePreservativeBiological activation

A method of protecting wood through enhanced penetration of wood preservatives includes providing a solution including (a) at least one amine oxide, (b) at least one organic wood preservative and (c) a non-borate buffering based agent. The solution has a pH of 5 to 12.4 and preferably about 7 to 10. The solution is applied to the surface of the wood after which, with or without intervening storage, the materials are activated to effect enhanced penetration of the organic wood preservative into the wood. One may effect application at a solution temperature of about 30° C. to 75° C. and preferably about 50° C. to 60° C. to effect activation at a higher temperature and high relative humidity. In a preferred practice, the wood may be heated before and / or after application of the solution. The solution is also disclosed as a product.

Owner:KOP COAT INC

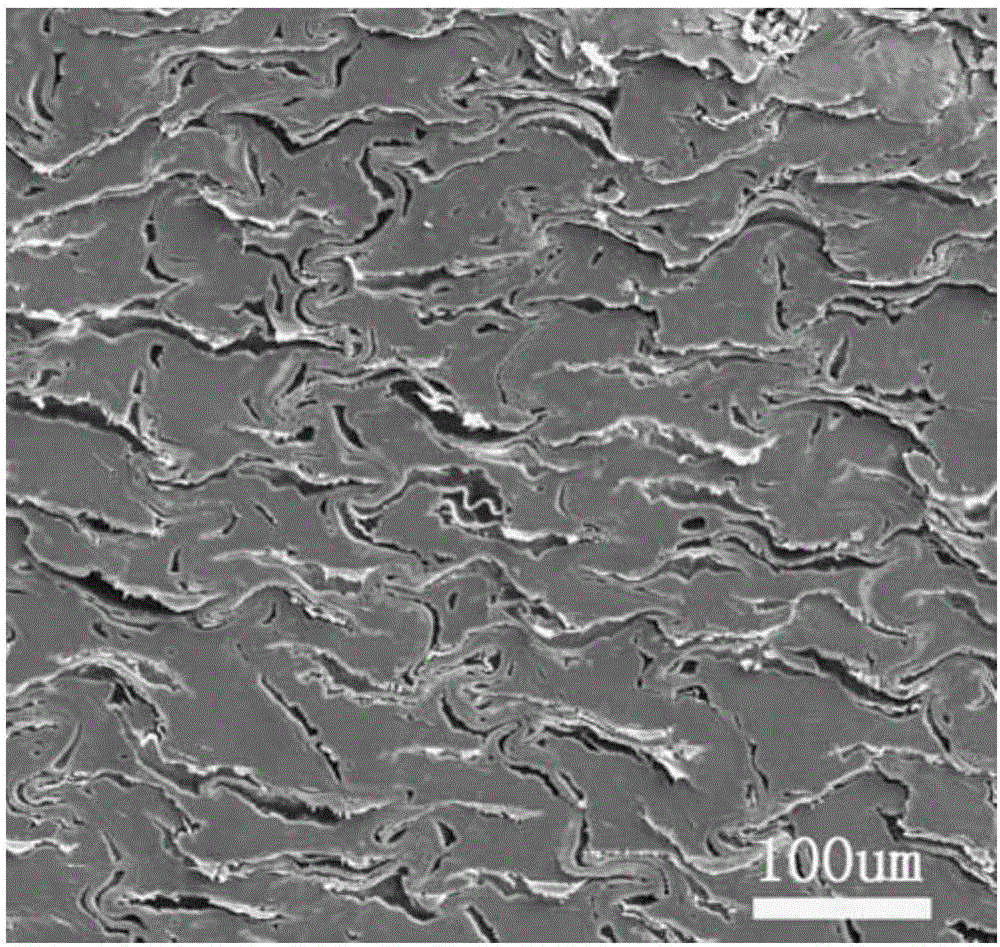

Production method of compressed compact carbonized wood

InactiveCN106493815AEasy to operateHigh strengthPressure wood treatmentWood compressionCelluloseCarbonization

A production method of compressed compact carbonized wood relates to wood modification methods and mainly solves the problem that existing wood modification methods cannot improve the mechanical strength and the waterproof dimensional stability of wood. The method comprises, I, wood softening pretreatment including immersing and heating wood in a pretreatment solution and then washing the wood to obtain softened wood, II, softened wood compression, and III, high-temperature wood carbonization. The production method of the compressed compact carbonized wood can solidify compressed deformation of wood, avoid resilience and reinforce cellulose framework structures to strengthen wood. Wood modified through the method obtains obvious enhancement in mechanical strength and dimensional stability. The production method of the compressed compact carbonized wood is applied to wood modification.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

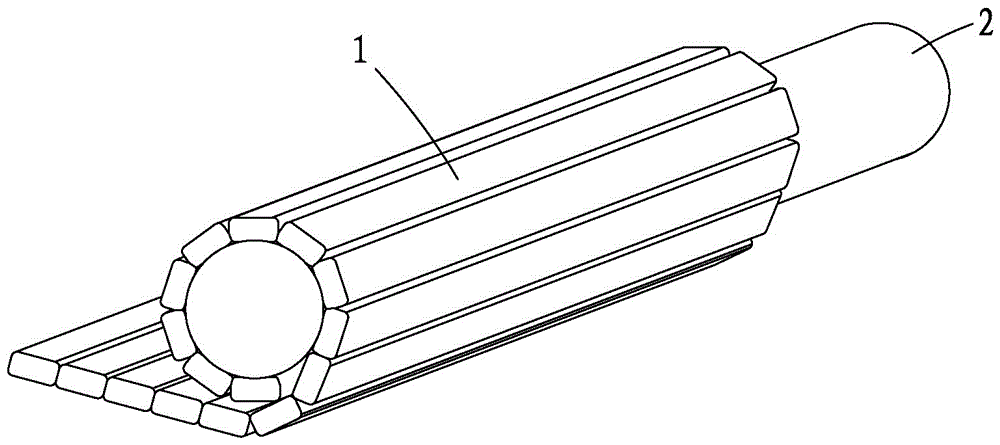

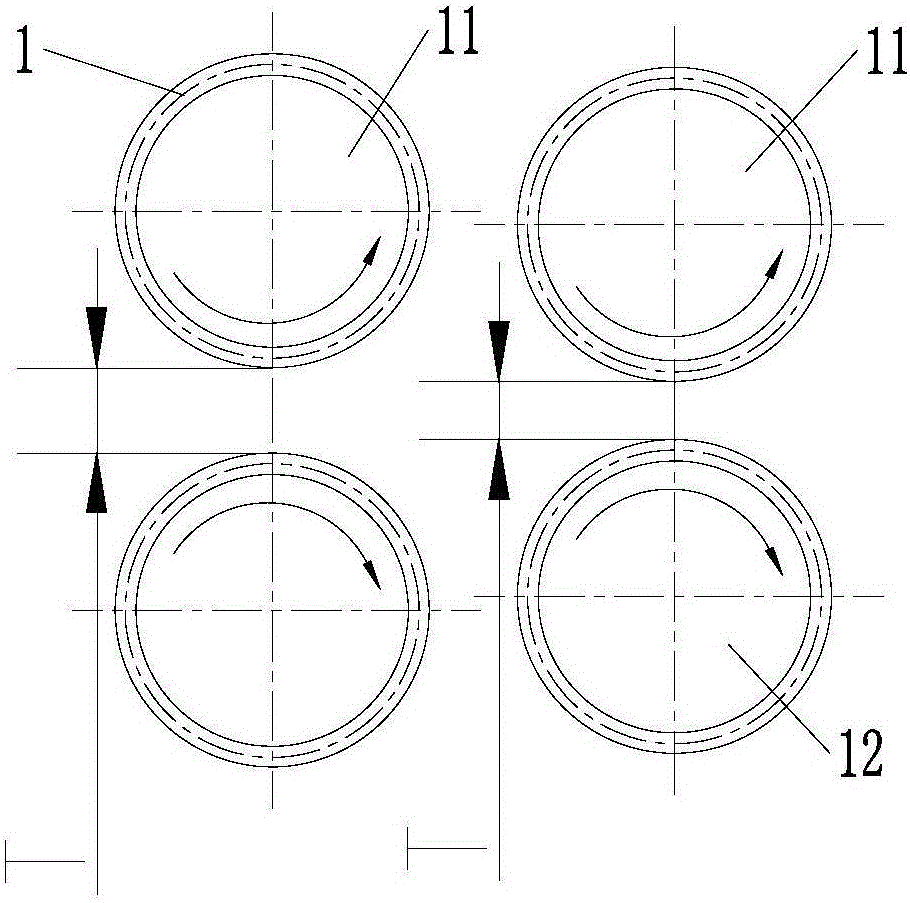

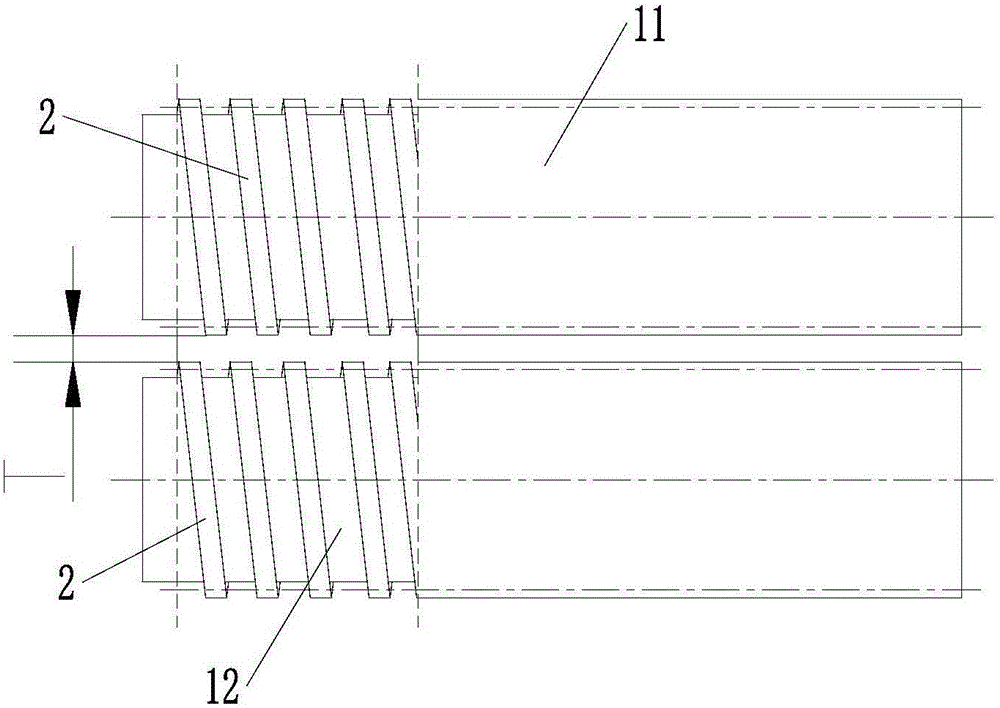

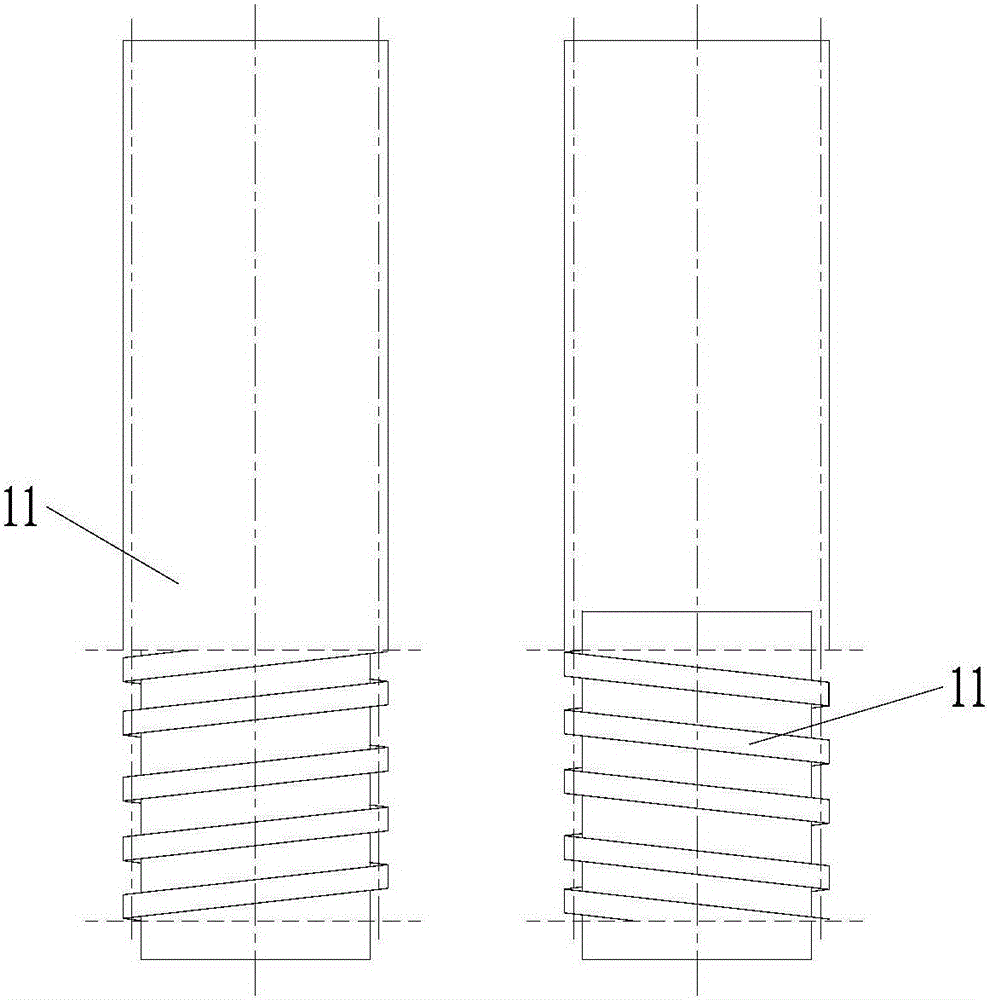

Wood compression-in-situ pressured heat treatment integrated method and compressed wood prepared through method

ActiveCN108582377AAvoid bubblingUniform temperature distributionPressure wood treatmentWood compressionPulp and paper industryDouble stage

The invention discloses a wood compression-in-situ pressured heat treatment integrated method and compressed wood prepared through the method. The method comprises the first step of the drying stage,the second step of pavement, the third step of heating, the fourth step of double-stage pressure compression treatment, the fifth step of heat treatment, the sixth step of stress relief and the seventh step of unloading. By means of the wood compression-in-situ pressured heat treatment integrated method and the compressed wood prepared through the method, the integral compression quality of the wood can be greatly improved, compression rebound of the wood can be controlled, the treated wood flatness is improved, no chemical pollution exists in the treatment process, the production cost is low,operation is simple and convenient, and the beneficial effects of high efficiency, environment friendliness and the like are achieved. Integral compression and deformation perpetual fixing of wood are achieved. By means of the method, the mechanical performance and size stability of the wood can be improved, and meanwhile the defects that anti-bending strength and screw holding force of wood subjected to heat treatment are poor are overcome.

Owner:GUANGXI NANNING QIAOSHENG WOOD

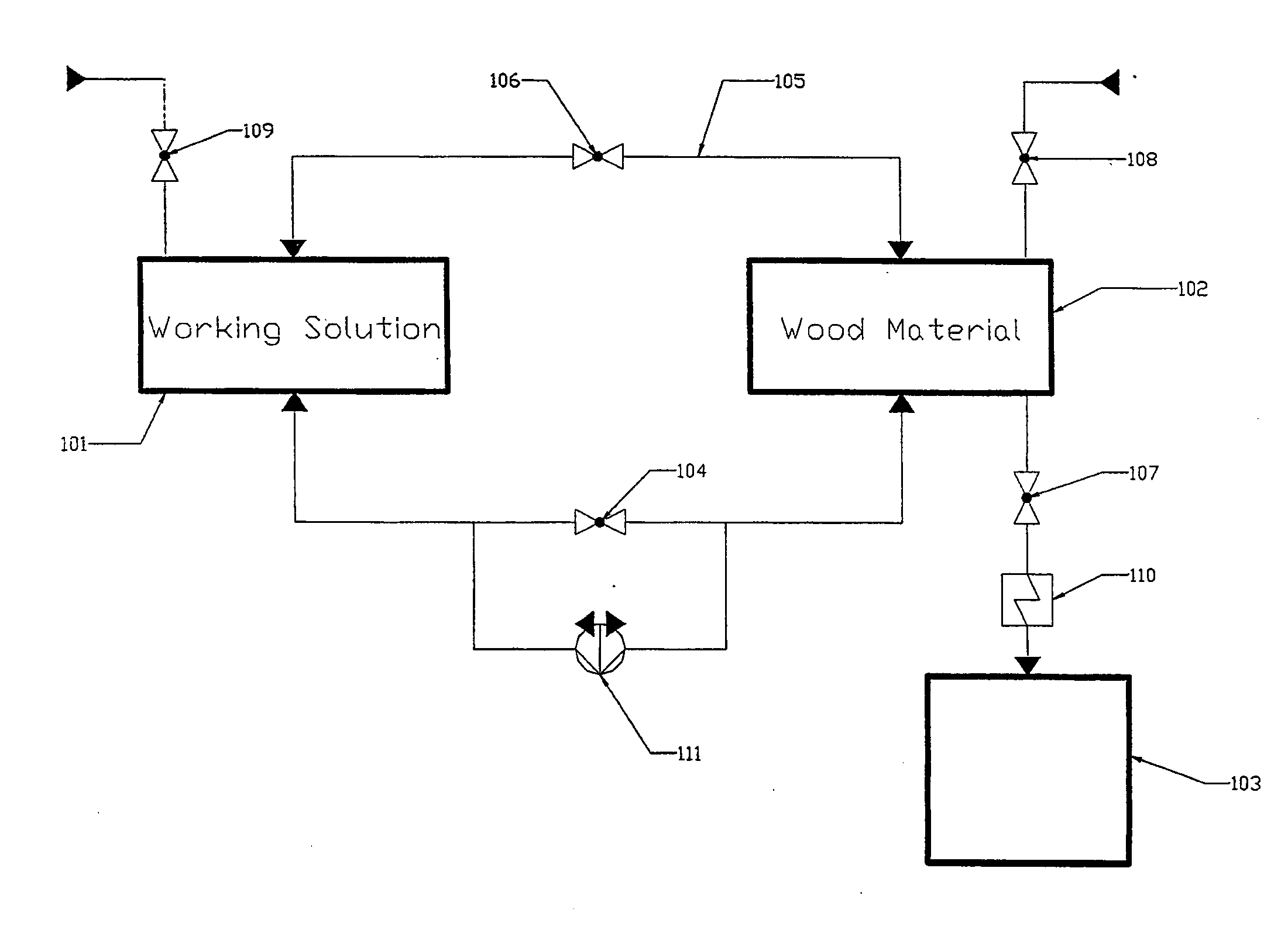

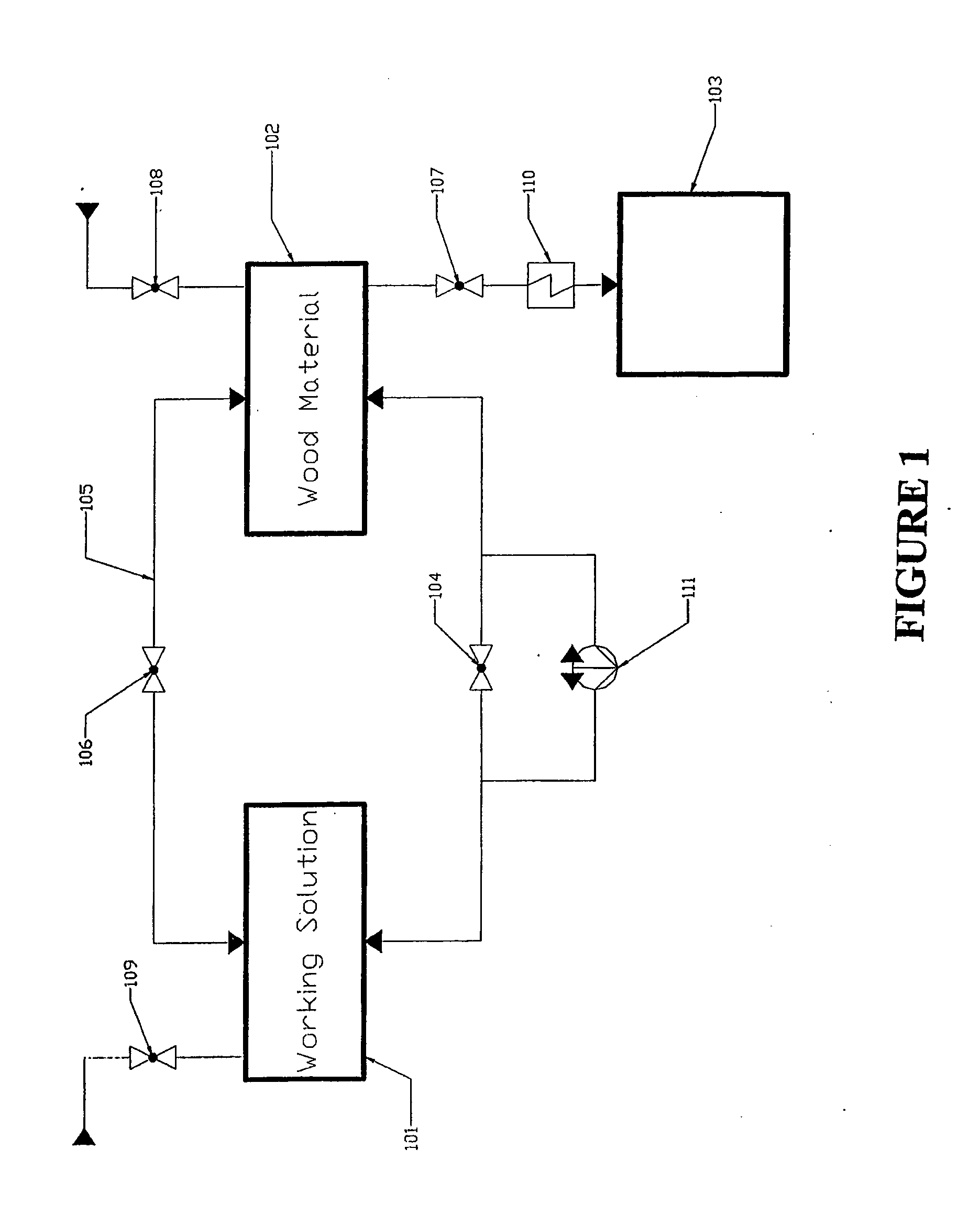

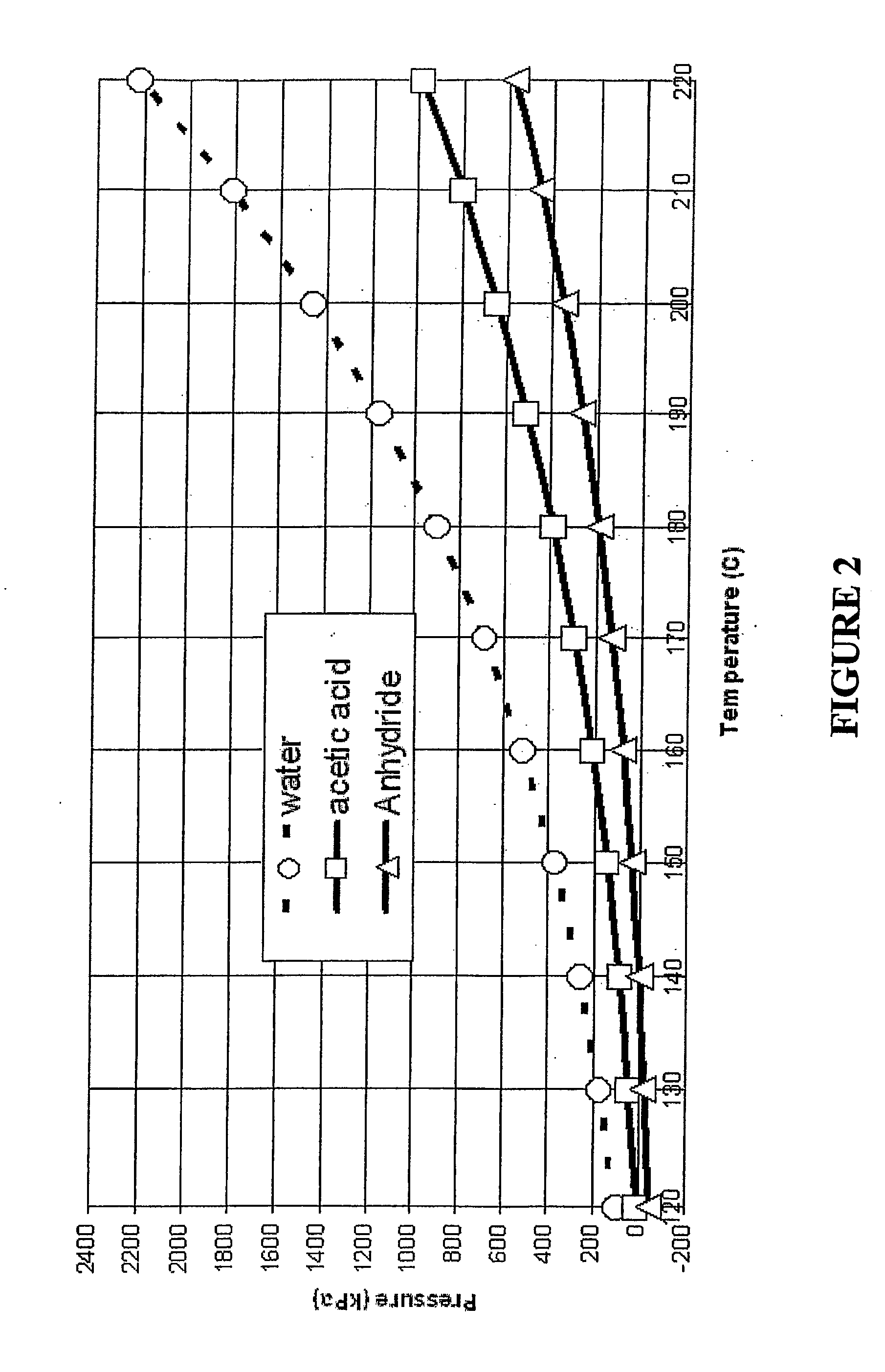

Impregnation process

ActiveUS20070128422A1Reduce pressurePromote recoveryFibreboardPretreated surfacesBoiling pointHigh pressure

The invention relates to a process for impregnating wood or wood based material. A working solution is preheated to a temperature above the atmospheric boiling point (“a super hot temperature”) above the atmospheric boiling point (“a super hot temperature”) of the working solution, at an elevated pressure sufficient to maintain the working solution in the liquid phase. The working solution is contacted with a wood or wood based material at a super hot temperature and an elevated pressure to cause impregnation of the solution into the wood or wood based material. The impregnated wood or wood based material and any remaining working solution, waste material and / or by-products are then separated.

Owner:TITAN WOOD LTD +1

Robinia pseudoacacia sawn timber drying method

InactiveCN104827534AQuick removalEvenly distributed moistureWood treatment detailsWood dampingYellow LocustMoisture distribution

The invention discloses a robinia pseudoacacia sawn timber drying method, relating to the technical field of wood processing. The robinia pseudoacacia sawn timber is stacked before being dried. The drying method comprises the following steps: a. in a pre-heating treatment stage, the dry ball temperature is controlled to be 55-65 DEG C, the dry-wet ball temperature difference is controlled to be 1-2 DEG C and the treatment time is controlled to be 3-8 hours; b, in a drying stage, the moisture content is controlled to be over 30%, the dry ball temperature is 50-60 DEG C, and the dry-wet ball temperature difference is 2-3 DEG C; a humidity-regulating treatment stage is implemented when the moisture content reaches 8-12% after drying in a staging manner, wherein the dry ball temperature is controlled to be 75-85 DEG C, the dry-wet ball temperature difference is controlled to be 3-5 DEG C, and the treatment time is controlled to be 6-12 hours; d, in a cooling stage, the sawn timber is cooled within a temperature which is higher than an outdoor temperature by 20 DEG C, and the dry-wet ball temperature difference is kept within 6-10 DEG C. According to the drying method, the dried robinia pseudoacacia sawn timber which is uniform in moisture distribution, small in residual drying stress, cannot easily deform and crack in later process and use is obtained.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

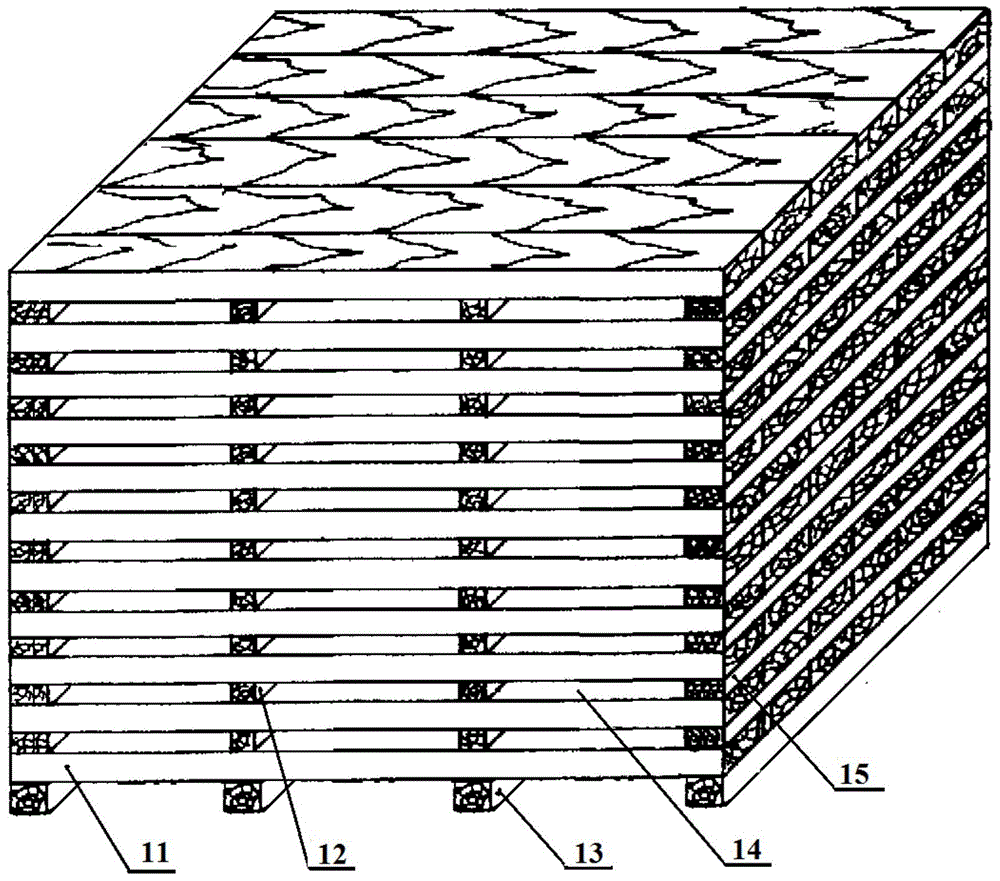

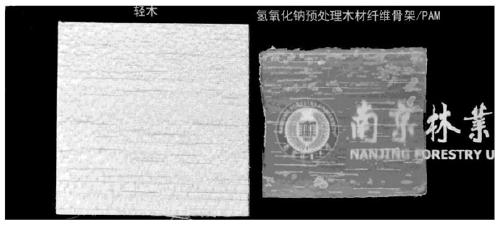

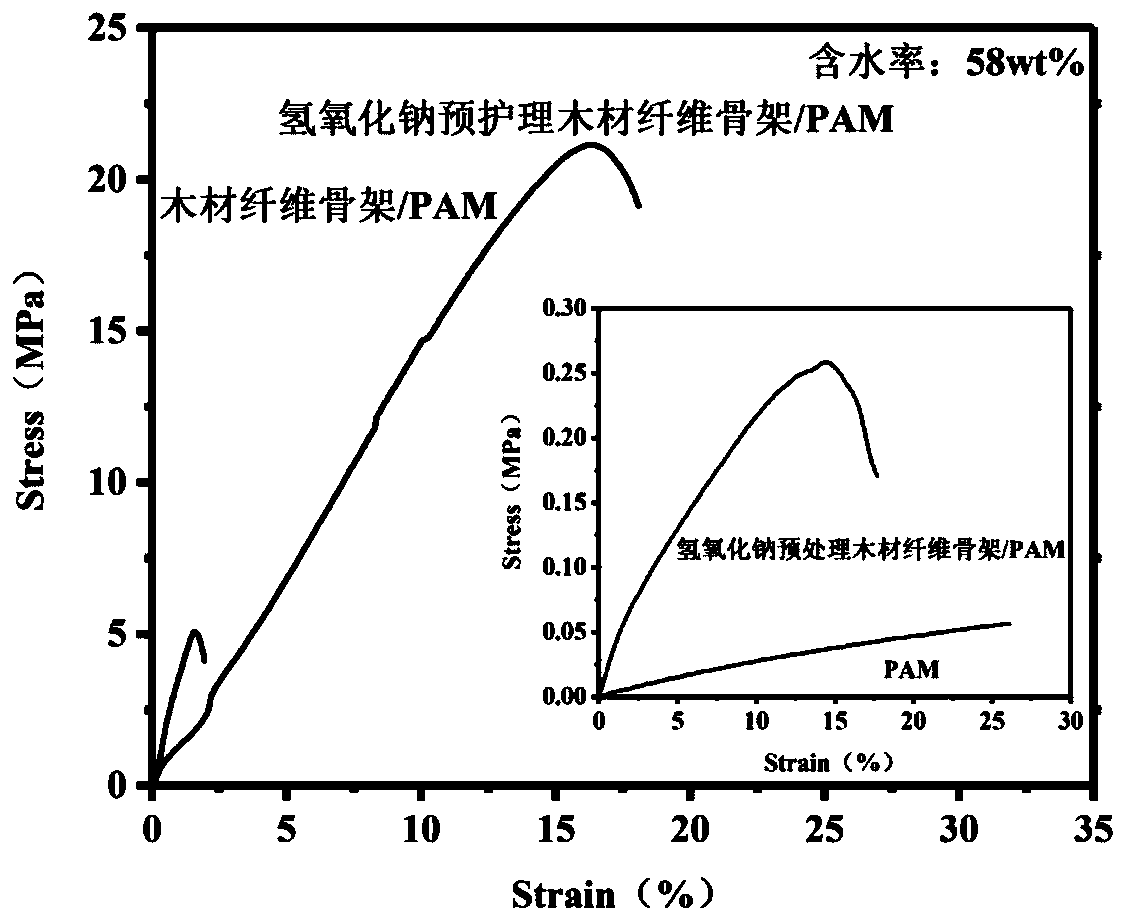

Wood-based high strength elastic composite gel and preparation method thereof

PendingCN110405882AExcellent impregnationEnhanced interface bindingWood treatment detailsOpen tank impregnationCross-linkFiber

The invention discloses a wood-based high strength elastic composite gel and a preparation method thereof. The preparation method comprises the following steps: (1) extracting a wood fiber skeleton: placing wood pieces in a sodium chlorite solution, performing heating to remove, washing the obtained wood pieces with deionized water to obtain the wood fiber skeleton, then impregnating the wood fiber skeleton in a sodium hydroxide solution, and washing the impregnated wood fiber skeleton until neutrality in order to obtain a sodium hydroxide pretreated wood fiber skeleton; (2) preparing an acrylamide solution: sequentially adding a cross-linking agent and an initiator to an aqueous acrylamide solution, and performing stirring and mixing to uniformly; and (3) preparing the composite gel: impregnating the wood fiber skeleton in the acrylamide solution at 25 DEG C, and performing heating under a vacuum condition to initiate a crosslinking reaction in order to obtain the composite gel. The preparation method of the invention can improve the interfacial bonding property between the wood fiber skeleton and the polyacrylamide, and the prepared elastic wood gel has excellent mechanical properties.

Owner:NANJING FORESTRY UNIV

Method for increasing wicker product hardness

InactiveCN106182297AImprove insect and mildew resistanceHigh strengthPressure wood treatmentWood treatment detailsHigh humidityHardness

The invention discloses a method for improving the hardness of wicker products, which comprises the following steps: (1) wicker peeling, (2) softening treatment, (3) wicker weaving, and (4) hardness treatment. The matching of each step of the method of the present invention is scientific and reasonable, and the obtained wickerwork has good insect-proof and mildew-proof effects and high surface hardness. Compared with the prior art, the surface hardness can be increased by about 25%, and the service life under normal use conditions It can be extended by about 30%, and the service life under high humidity conditions can be extended by more than 50%. It has good stability in use, strong anti-deformation ability, good corrosion resistance, and high use value.

Owner:阜南县猛发工艺品有限公司

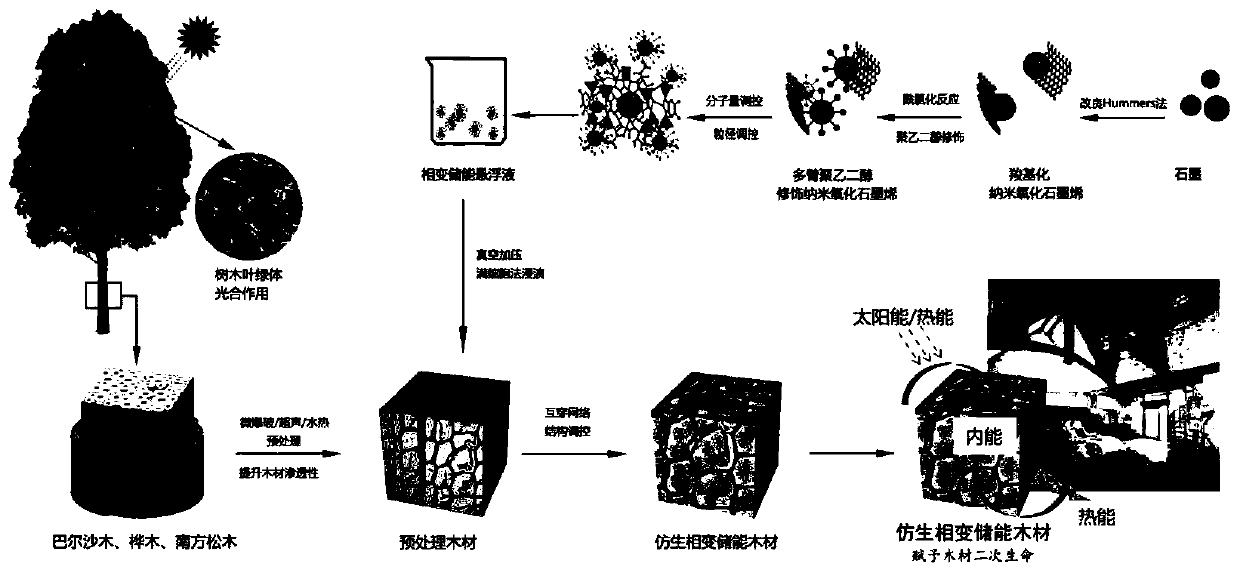

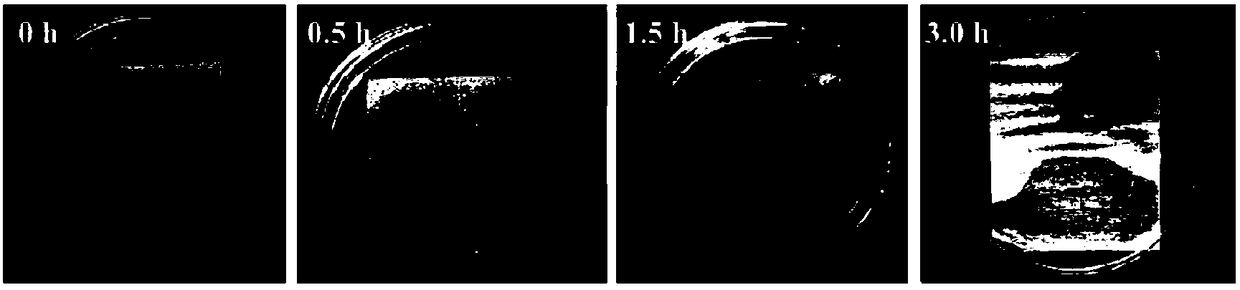

Method for preparing thermal conduction enhanced phase change energy storage wood based on photothermal response

InactiveCN110126043AImproves loss resistanceWide molecular weight rangeWood treatment detailsHeat-exchange elementsSulfite saltPolyethylene glycol

The invention discloses a method for preparing a thermal conduction enhanced phase change energy storage wood based on photothermal response. The method mainly comprises the following steps: (1) carboxylating graphene oxide to obtain carboxylated graphene oxide, performing conjugate grafting on the carboxylated graphene oxide by using ammoniated multi-arm polyethylene glycol, controlling the amount of polyethylene glycol grafted on the surface of graphene, and blending the polyethylene glycol-grafted graphene with polyethylene glycol to prepare a phase change energy storage material; and (2) preprocessing wood with a low-concentration sodium hydroxide and sodium sulfite solution, preparing a solution by using maleic anhydride as esterification agent and acetone as a solvent, impregnating the preprocessed wood in the solution, allowing the above obtained graphene / polyethylene glycol phase change energy storage suspension to infiltrate the wood by a vacuum pressurizing full-cell process,and regulating a multidimensional interpenetrating network structure to obtain the thermal conduction enhanced phase change energy storage wood. A firm amide bond can be formed between graphene and polyethylene glycol to ensure the stability of the phase change system.

Owner:BEIJING FORESTRY UNIVERSITY

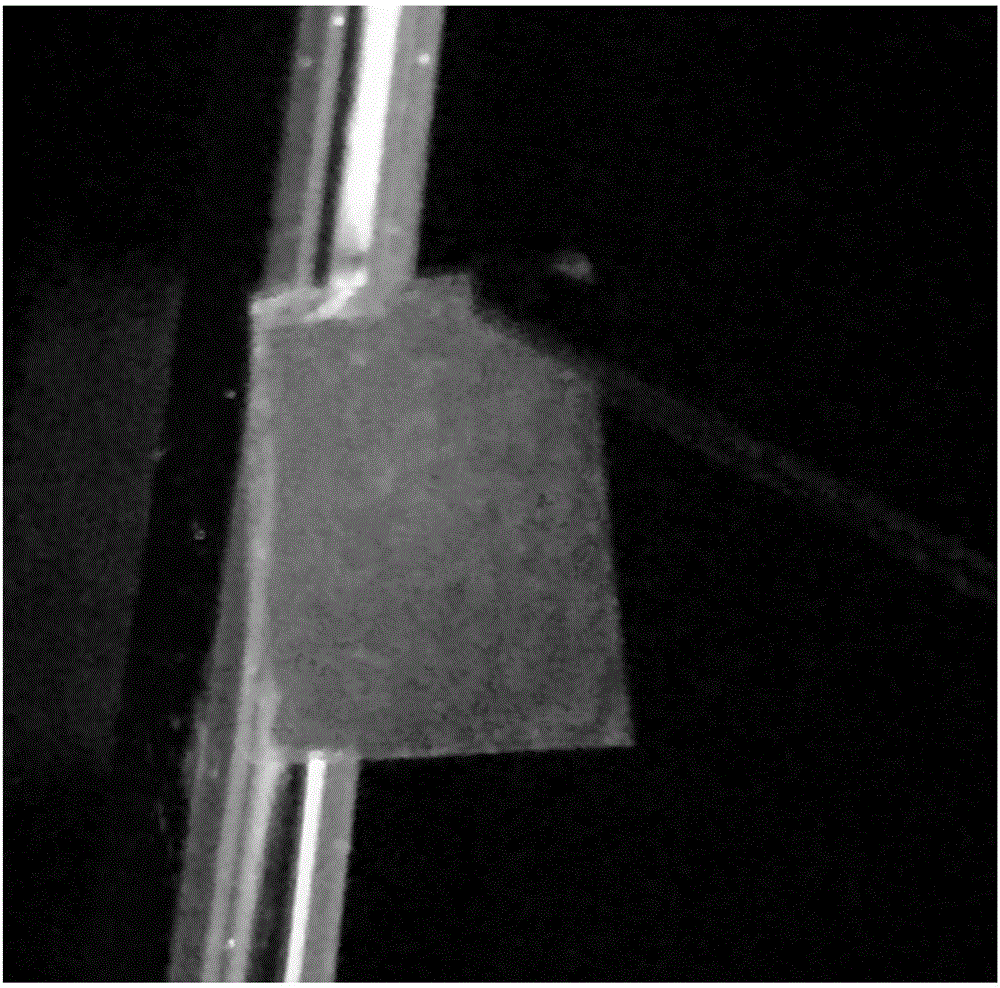

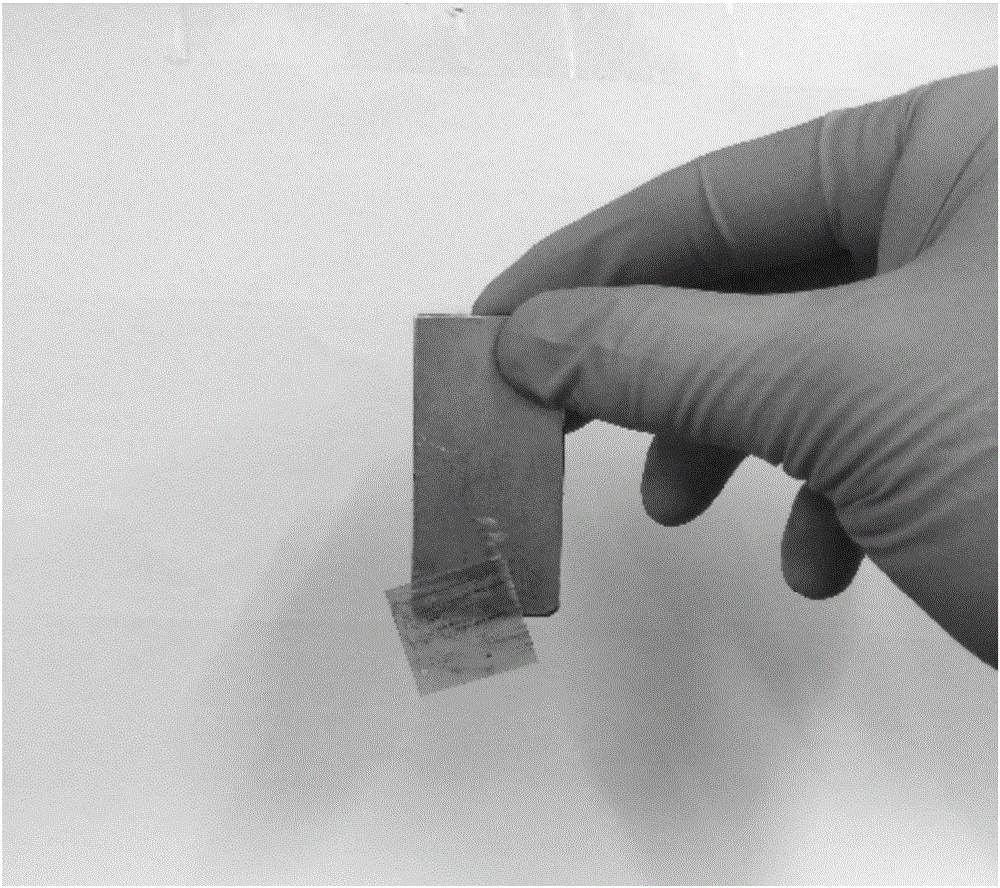

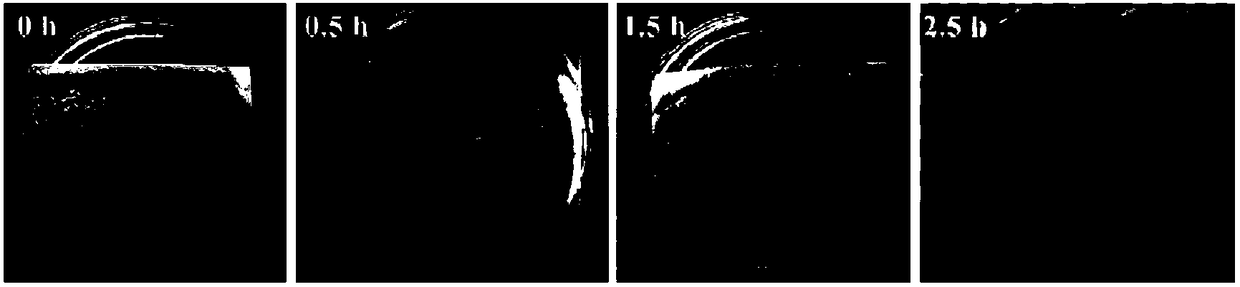

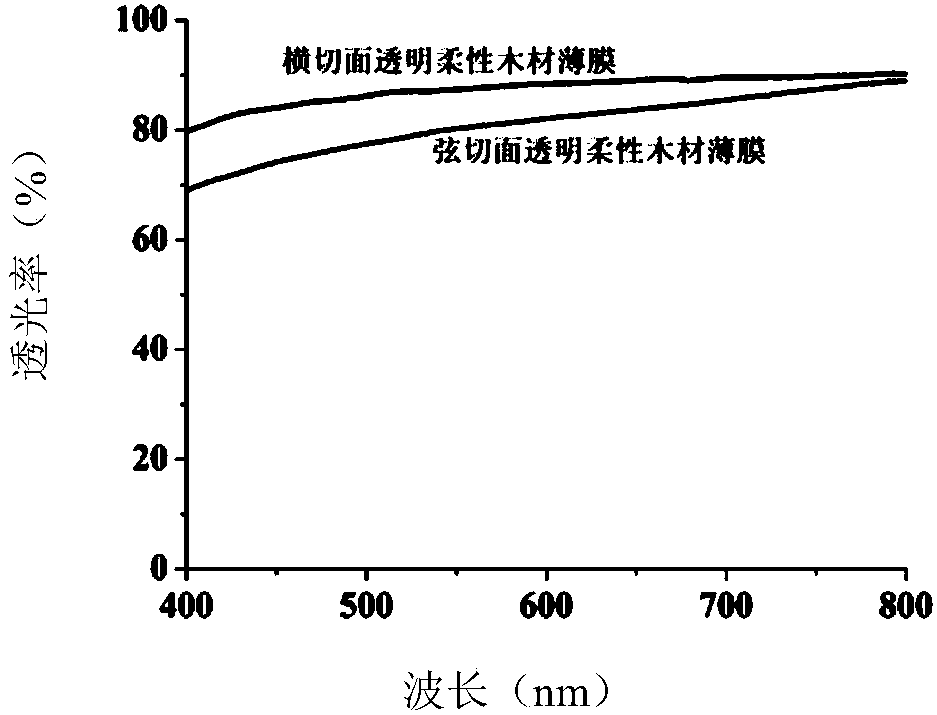

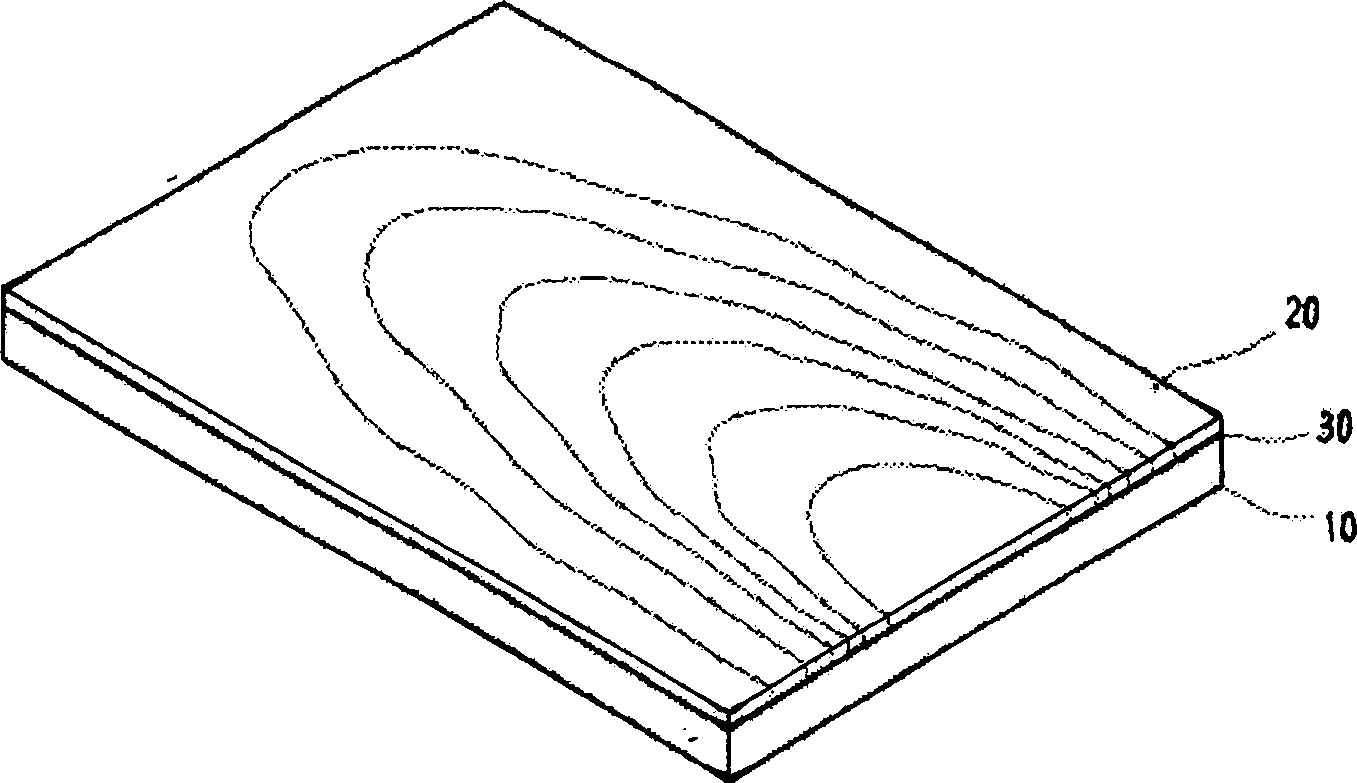

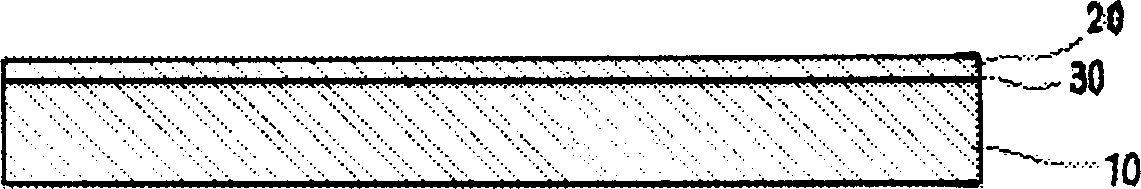

Manufacturing method for high-flexibility high-elasticity and high-transparency wood film

ActiveCN108312281AImprove flexibilityIncrease elasticityWood treatment detailsPressure impregnationEpoxyEnvironmental resistance

The invention relates to a manufacturing method for a high-flexibility high-elasticity and high-transparency wood film which belongs to the technical field of film manufacturing. The manufacturing method comprises the following steps: (1), a slicing technical step; (2), a decoloring technical step, namely a wood film is soaked in a bleaching water solution; (3), a rinsing technical step, namely atreated wood film is taken out and then placed into a mixture of an organic solvent and water for rinsing, so that remaining components and impurities in the wood film are removed clearly; and (4), apermeation curing technical step, namely polyurethane modified epoxide resin and a curing agent permeate the manufactured decolored wood film, and then the wood film is heated and subjected to curingreaction, so that the high-flexibility high-elasticity and high-transparency wood film is manufactured. The manufacturing method is simple and feasible, low in production cost and environment-friendly; and the manufactured product has good waterproofness and mechanical strength.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Manufacturing method of veneer adhibited on the top surface of floor board using chinese medicine

The invention provides a method for producing a veneer adhered to the top surface of a floor board by Chinese medicine, which comprises the following procedures: a procedure of respectively mixing szechwan lovage rhizome, lignum Santali, clove, mint, megnolia hypoleuca, muskiness, thin cinnamon bark, Chinese angelica, Chinese lizard-tail, beatamaria in catalan and oldenlandia by the weight ratio of less than 10 percent to produce a mixed herb, and putting the mixed herb with weight ratio of 20 percent to 40 percent and the water with weight ratio of 60 percent to 80 percent into a heating container to be fully heated to prepare the Chinese medicine liquid; a procedure of putting a veneer with thickness of 0.3 to 3mm and with certain width into a vacuum pot to be heated under temperature of 70 to 90 degrees; a procedure of pouring the Chinese medicine liquid into the heated vacuum pot and stewing the Chinese medicine liquid for one to four hours; a procedure of dehydrating and drying the stewed veneer taken out from the vacuum pot. The method has the advantages that the various components of the Chinese medicine are immersed on the veneer and the veneer is directly adhered to the indoor floor or the floor board on the wall, so that the floor board emits the smell of the Chinese medicines, which is good for the health of people.

Owner:WIN & WIN WOOD

Method for mould and moth preventing for bamboo product

InactiveCN107283576AEasy to useIncrease viscosityWood treatment detailsReed/straw treatmentDiseaseSludge

The invention relates to the technical field of bamboo artware processing, and discloses a method for mould and moth preventing for a bamboo product. The method comprises the following steps that firstly, newly-cut bamboo is wrapped by sludge in a pond, the sludge contains abundant nutrients suitable for growth of parasites, meanwhile, the viscous force is very large, the sludge has very strong adsorption force, disease pests and mould hidden in the bamboo are wrapped and adsorbed, and substances, causing insect damage and mould, in a bamboo body are transferred out; secondly, fumigated bamboo is placed in alums water to be immersed, alums has a very good restraining function on various gram negative and positive cocci and bacilli, Chinese herbal medicine liquid is used for fumigation after immersing, and it can be guaranteed that the bamboo product is not damaged by mould or moths for a long term through essential oil generated by the Chinese herbal medicine liquid; and thirdly, waterproof varnish is applied to the processed bamboo product, and the longer service life can be kept.

Owner:阜南县中信柳木工艺品有限公司

Drying method for wood

InactiveCN106393342AFast dryingStable Quantitative ProductionRadiation/waves wood treatmentWood treatment detailsMicrowaveWood plank

The invention discloses a drying method for wood. The drying method comprises the following steps that A, the wood is pre-planed, and the wood is cut into boards with the same size; B, the pre-planed wood is soaked with brine; C, the wood soaked with the brine is wrapped with tin foil paper and baked; D, the baked wood is coated with a wood anti-cracking agent, and then the wood is subjected to microwave and ultrasonic drying; and E, the wood obtained after microwave and ultrasonic drying is performed is subjected to thermal convection drying. By the adoption of the drying method for the wood, the moisture in the wood can be dried effectively, and the moisture content of the wood is less than 8.5% and meets the dry standard; the phenomena of cracking, deformation, bending and warping of the wood and the like can be avoided; the drying speed of the wood can be increased effectively, the time is shortened, the cost is lowered, and the stable mass production of the wood is achieved; and the quality of the obtained wood is stable, and the error between the moisture content and the target moisture content of dried products is small.

Owner:玉溪万德能源技术有限公司

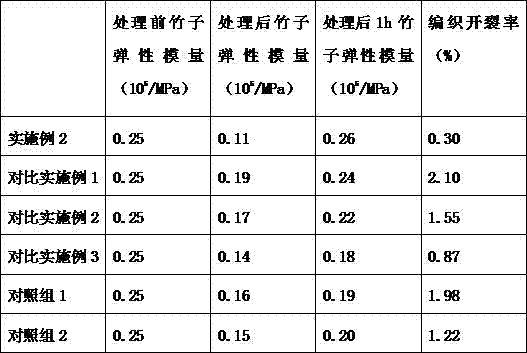

Softening treatment method for bamboo

ActiveCN107042562AGood flexibilityRigid recovery and liftingRadiation/waves wood treatmentPressure wood treatmentMedicineMegasonic cleaning

The invention discloses a softening treatment method for bamboo and belongs to the technical field of wicker processing. The softening treatment method comprises the following steps of (1) bamboo pretreatment, (2) high temperature and high pressure treatment, (3) ultrasonic cleaning treatment, (4) softening treatment fluid preparation, (5) soaking treatment and (6) dry weaving treatment. The method mainly improves softness during bamboo weaving, increases the weaving yield, also can effectively realize recovery and promotion of bamboo rigidity, improves the usage quality of a weaved product and prolongs the service life of the weaved product. Besides, bamboo after being treated in this way can be subjected to high temperature softening treatment and then deserve secondary plastic weaving, the problem that existing wickerwork cannot be effectively reused is solved, and the method has good popularization and use value.

Owner:阜南佳利工艺品股份有限公司

Method for improving corrosion resistance of wicker products

ActiveCN106182248AImprove organizational structureImprove insect and mildew resistanceRadiation/waves wood treatmentWood treatment detailsHigh humidityHardness

The invention discloses a method for improving corrosion resistance of wicker products. The method comprises the following steps: (1) skin removal of wickers, (2) softening treatment, (3) wicker weaving, and (4) anti-corrosion treatment. Various steps of the method are matched scientifically and reasonably, and the manufactured wicker products are good in insect prevention, mildew prevention and corrosion resisting effects and are high in surface hardness. Compared with the prior art, the method has the characteristics that the surface hardness of the wicker products can be improved by about 25%, the wicker products are used under the condition of high acid and alkali, the anti-corrosion time of the wicker products can be 4-5 times longer than the original anti-corrosion time, the service life can be prolonged by about 30% under the conventional using conditions, and can be prolonged by 40% or above under the condition of high humidity, use stability is good, anti-deformation ability is high, corrosion resistance is good, and use value is high.

Owner:阜南县猛发工艺品有限公司

Mould preventing treatment method for straw plaited articles

InactiveCN106182265AEnhance the effect of anti-mildew treatmentGood for protecting flexibilityRadiation/waves wood treatmentWood treatment detailsSecondary radiationMedicine

The invention discloses a mould preventing treatment method for straw plaited articles. The method comprises the first step of raw material treatment, the second step of drying treatment, the third step of radiation treatment, the fourth step of mould preventing treatment liquid preparing, the fifth step of immersing treatment, the sixth step of secondary drying treatment, the seventh step of secondary radiation treatment, the eighth step of secondary immersing treatment and the ninth step of airing weaving. Straw plaited article raw materials treated through the method have high mould preventing performance and are safe, harmless, good in flexibility and high in tensile strength and folding strength, and weaving is better facilitated.

Owner:FUNAN YONGXING ARTS & CRAFTS

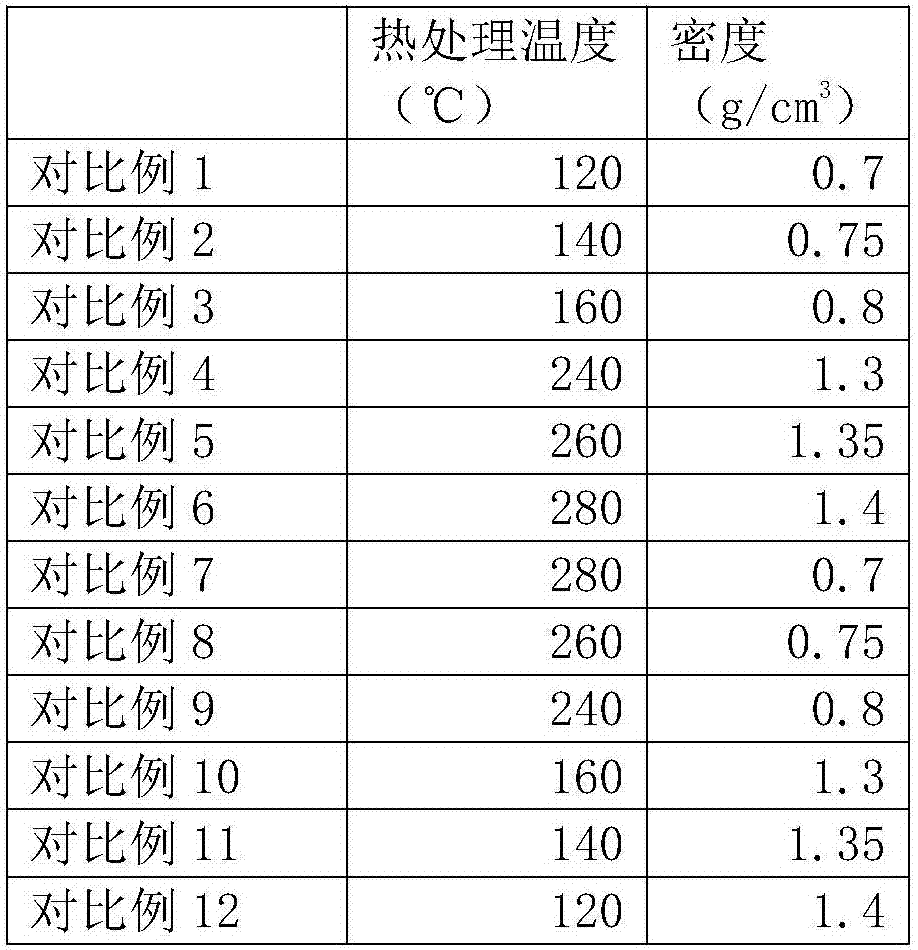

Outdoor reconsolidated bamboo product and preparation method

InactiveCN106965271AStrong light aging resistanceNo loss of sharp textureOther plywood/veneer working apparatusWood treatment detailsAging resistanceAdditional values

The invention belongs to the field of bamboo product study preparation, and particularly an outdoor reconsolidated bamboo product and a preparation method. By studying the influence of the heat treatment temperature and density on outdoor reconsolidated bamboos, the preparation method of the outdoor reconsolidated bamboos is invented, and thus the outdoor reconsolidated bamboo product is obtained. The preparation technique comprises the steps of bamboo beam unit preparation, bamboo beam heat treatment, gum dipping, assembly, hot pressing forming, saw cutting and the like, finally, the most suitable heat treatment temperature is determined to be 200 DEG C, and the most suitable density is determined to be 1.1 g / cm<3>. According to the outdoor reconsolidated bamboo product and the preparation method, light aging resistance reconsolidated bamboos obtained through development have higher light aging resistance; in outdoor use, natural clear textures of the bamboos are not damaged, the service life of the bamboo product is effectively prolonged, the product additional value is increased, and good economic, social and ecological benefits are achieved.

Owner:国家林业局竹子研究开发中心

Method for treating and extracting cork organic compounds, with a dense fluid under pressure

Process for the treatment of cork or a cork-based material particularly with a view towards extracting contaminating organic compounds, in which said cork or said cork-based material is put into contact with a dense fluid under pressure at a temperature of from 10 to 120° C. and at a pressure of from 10 to 600 bars.Manufacturing installation for parts made of cork or a cork-based material, such as bottle corks, comprising an installation for treatment or extraction by putting the said cork or the said material into contact with a dense fluid under pressure.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Method for preparing bamboo beam columns

ActiveCN106625921AMaximum environmental protectionMeet the basic requirements of beams and columnsPressure wood treatmentWood treatment detailsInternal stressBeam column

The invention provides a method for preparing bamboo beam columns. The method includes the steps that a piece of bamboo wood is selected; selected bamboo is sawed into a bamboo tube with the length being 3-8m, and then splitting is performed as required so that long-bar-shaped bamboo chips can be obtained; the long-bar-shaped bamboo chips are subjected to bamboo green and bamboo inner skin removing treatment; then the bamboo chips subjected to bamboo green and bamboo inner skin removing treatment are placed into a solution containing 0.2%-1% of hydrogen peroxide for cooking, and the bamboo chips are drained off after being cooked and placed into a drying shed to be dried; afterwards, the bamboo chips are subjected to shaping, glue dipping, blank formation and glue replenishing so that preliminarily-formed hollow bamboo columns can be obtained; the preliminarily-formed hollow bamboo columns are mold-filled, heated and cured, and the heated and cured bamboo columns are placed in a normal pressure and temperature environment for nourishing, so that internal stress is removed; then a center winding rod is drawn out of the middle part of each bamboo column; and finally, a mold is opened to take out each bamboo column, and the bamboo columns taken out refer to complete and hollow bamboo beam columns. The bamboo beam columns prepared through the method enable the environmental protection performance of the bamboo wood to be reflected maximally in construction, and meanwhile the basic requirements of large-sized housing construction beam columns can be met.

Owner:浙江业友机械有限公司

Preparing method for outdoor oil heat treatment recombined bamboo wood

ActiveCN105773755AChange performanceIncrease profitWood treatment detailsCane mechanical workingFiberSurface-active agents

The invention provides a preparing method for outdoor oil heat treatment recombined bamboo wood. The mechanical performance of the recombined bamboo wood prepared through the method is obviously improved, and the recombined bamboo wood prepared through the method has very good corrosion resisting and mold preventing properties and is good in size stability and suitable for outdoor usage. The preparing method comprises the steps that oil heat treatment is conducted, a bamboo wood sheet with the thickness ranging from 7 mm to 9 mm is immersed below the liquid level of a heat treatment tank with methylsilicone oil, the heat treatment tank is heated, the temperature of the methylsilicone oil is made to range from 145 DEG C to 200 DEG C, and insulating is conducted for 1 h-3 h; after 10 min-15 min, the methylsilicone oil in the heat treatment tank is discharged, and the sheet is taken out; grinding and fiber splitting are conducted, the sheet is ground into a bamboo bundle with the thickness ranging from 2 mm to 3 mm, the fiber of the bamboo bundle is continuous in the longitudinal direction and loose in the transverse direction to be connected in a staggered manner, and meanwhile the function of primary oil removing can be achieved; oil removing is conducted, and the bamboo bundle is subjected to further oil removing through a non-ionic surface active agent; and glue dipping, assembly and hot press are conducted, and after the bamboo bundle is immersed in glue and dried, assembly is conducted along texture, hot press is conducted, and the recombined bamboo wood is formed.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com