Manufacturing method for high-flexibility high-elasticity and high-transparency wood film

A high-transparency, high-elasticity technology, used in wood treatment, wood heating, wood processing appliances, etc., can solve problems such as poor flexibility, and achieve the effect of promoting green development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A preparation method of highly flexible, highly elastic and highly transparent wood film, comprising the steps of:

[0044] (1) Slicing process step: get a poplar, cut out a piece of wood chip (length * width * thickness=10cm * 5cm * 0.02cm) that thickness is 200 microns from the chord section of wood;

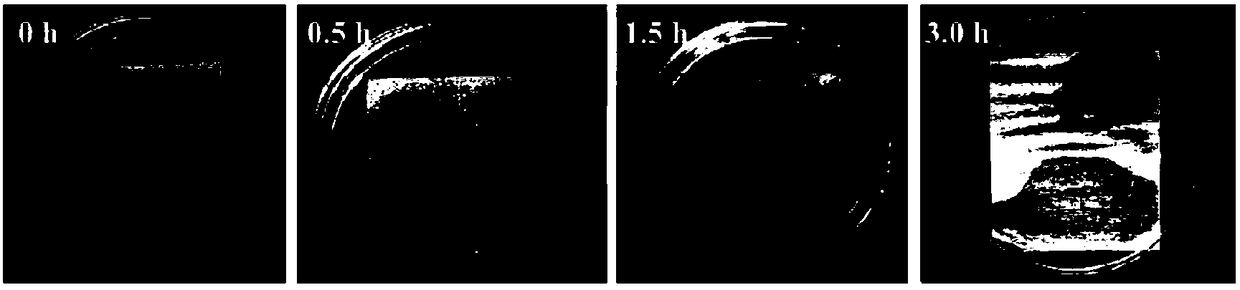

[0045] (2) decolorization process step: the wood chips prepared by step (1) are put into sodium chlorite solution (solute concentration is 2%), then the pH of the solution is adjusted to 4-5 with acetic acid, and the temperature is slowly raised to 90°C, keep it for 3 hours, the wood chips will change from natural color to pure white, such as figure 1Shown, in the embodiment of the present invention, the process diagram of the chord section wood chips from natural color to pure white;

[0046] (3) Cleaning process steps: slowly take out the wood chips in step (2), and put them into the mixed solution of ethanol and water volume ratio of 2:8, 5:5, 8:2 for cleaning in tu...

Embodiment 2

[0049] A preparation method of highly flexible, highly elastic and highly transparent wood film, comprising the steps of:

[0050] (1) Slicing process step: get a poplar, cut out a piece of wood chips with a thickness of 250 microns (length * width * thickness = 10cm * 5cm * 0.025cm) from the cross section of the wood;

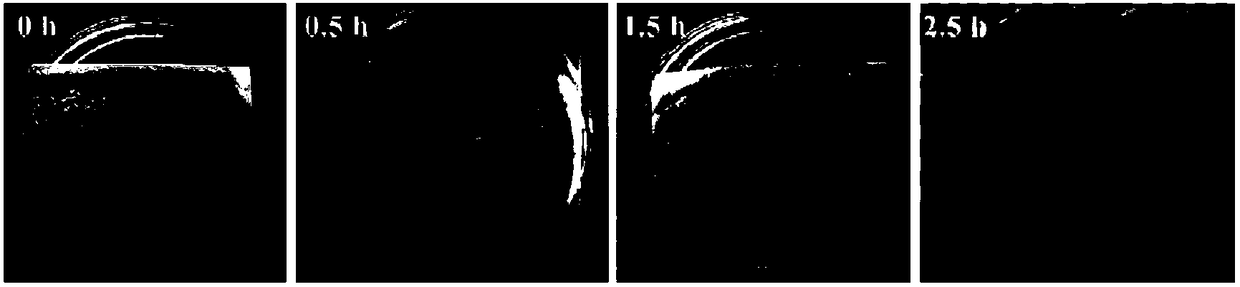

[0051] (2) Decolorization process steps: put the wood chips prepared in step (1) into sodium chlorite solution (solute concentration is 2%), then adjust the pH of the solution to 4-5, and slowly raise the temperature to 90°C , keeping for 2 hours, the wood chips change from natural color to pure white, such as figure 2 Shown, in the embodiment of the present invention, cross-section wood chip becomes the process diagram of pure white from natural color;

[0052] (3) Cleaning process steps: Take out the wood chips in step (2) slowly, put them into the mixed solution of acetone and water volume ratio of 2:8, 5:5, and 8:2 for cleaning in turn, and wait for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com