Patents

Literature

511results about "Polymerisation impregnation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

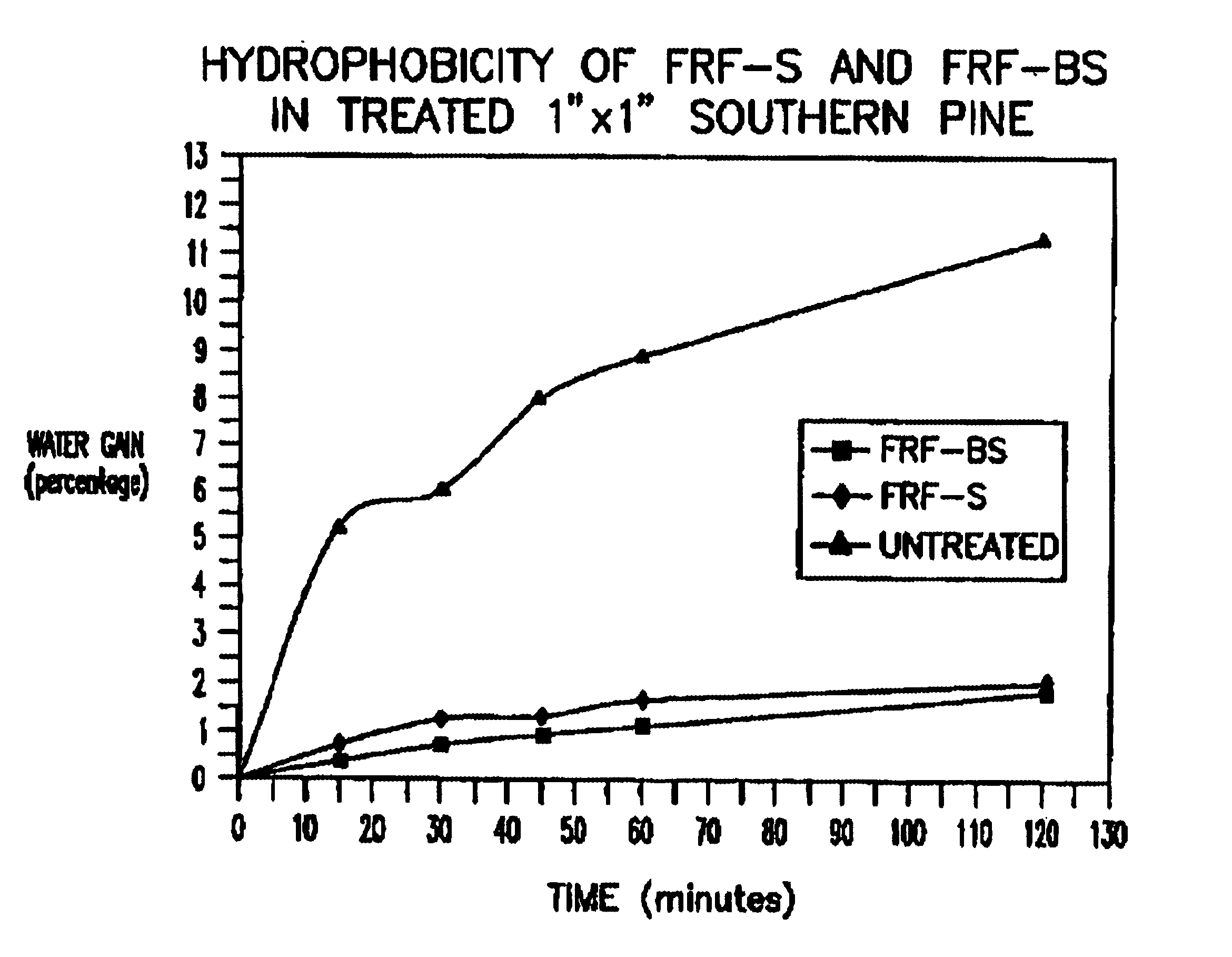

Fire retardant compositions and methods for preserving wood products

Wood preservative compositions are disclosed. Treatment of lumber, plywood, and other wood products with a novel composition comprising the boron source composition, a melamine binder resin, and a urea casein activator resin protects lumber, plywood, and other wood products from attack by termites, fungi, fire and flame. The preservative can be formed by combining a source of boron such as boric acid and the water-soluble salts thereof, a melamine binder resin, and a urea casein resin. A wood preservative is characterized by a weight ratio of the urea casing activator resin to the melamine binder resin ranging from about 1:20 to 1:4 and a weight ratio of the boron source composition to the melamine binder resin ranging from about 1.3:1 to 9.6:1.

Owner:LOPEZ RICHARD A

Systems and method for forming a servo pattern on a magnetic tape

InactiveUS7153366B1Maintain alignmentLiquid surface applicatorsAlignment for track following on tapesMagnetic tapeEngineering

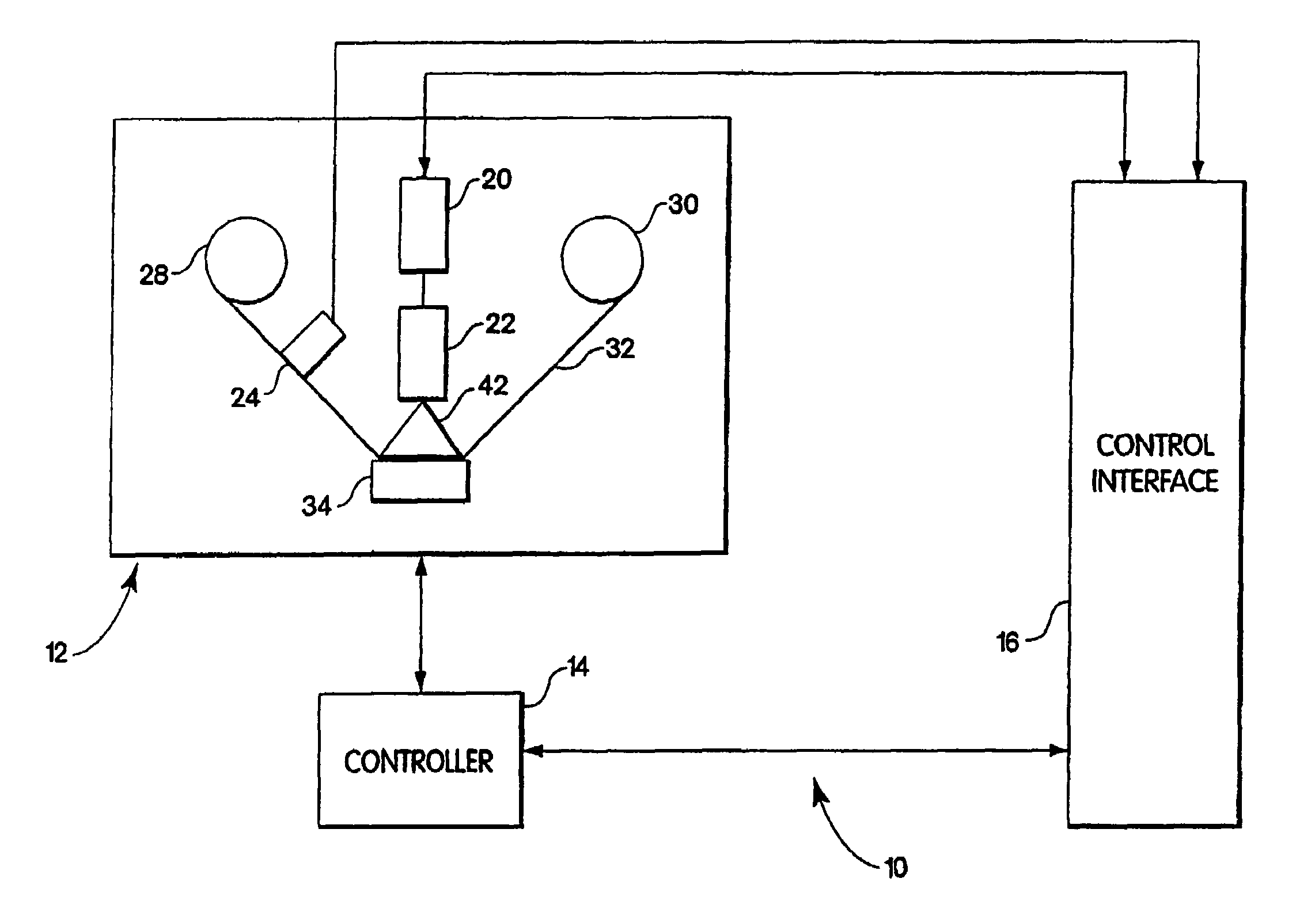

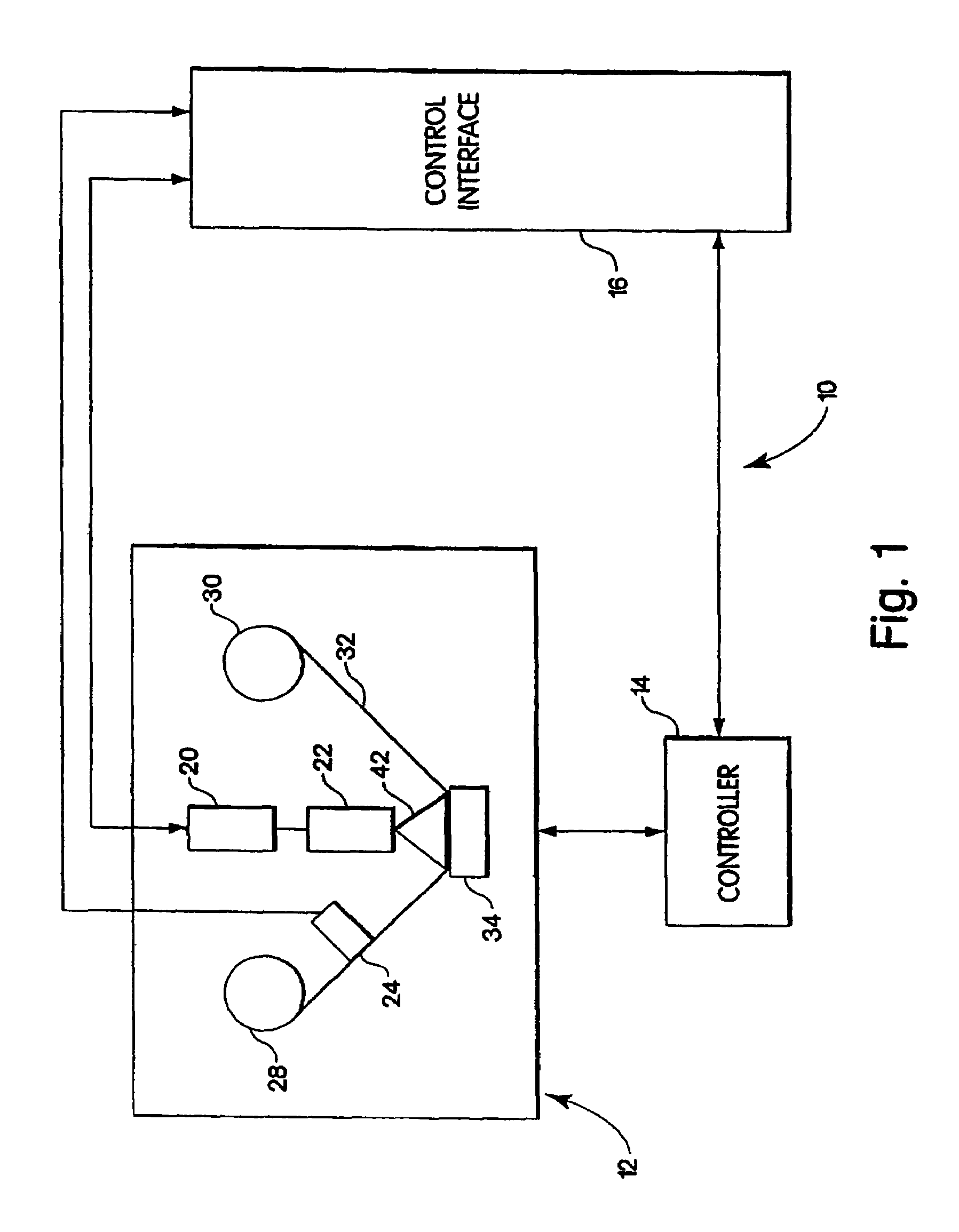

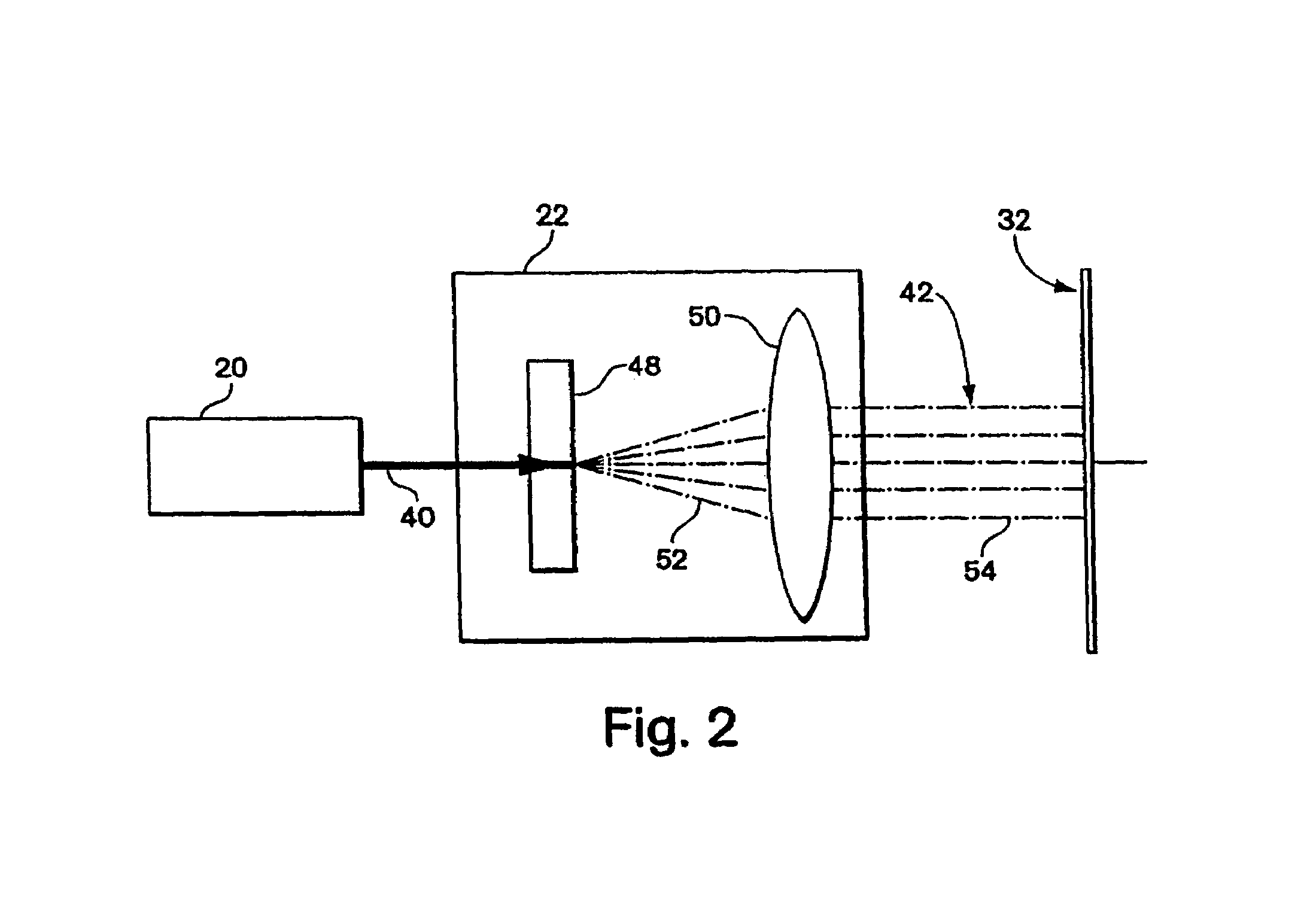

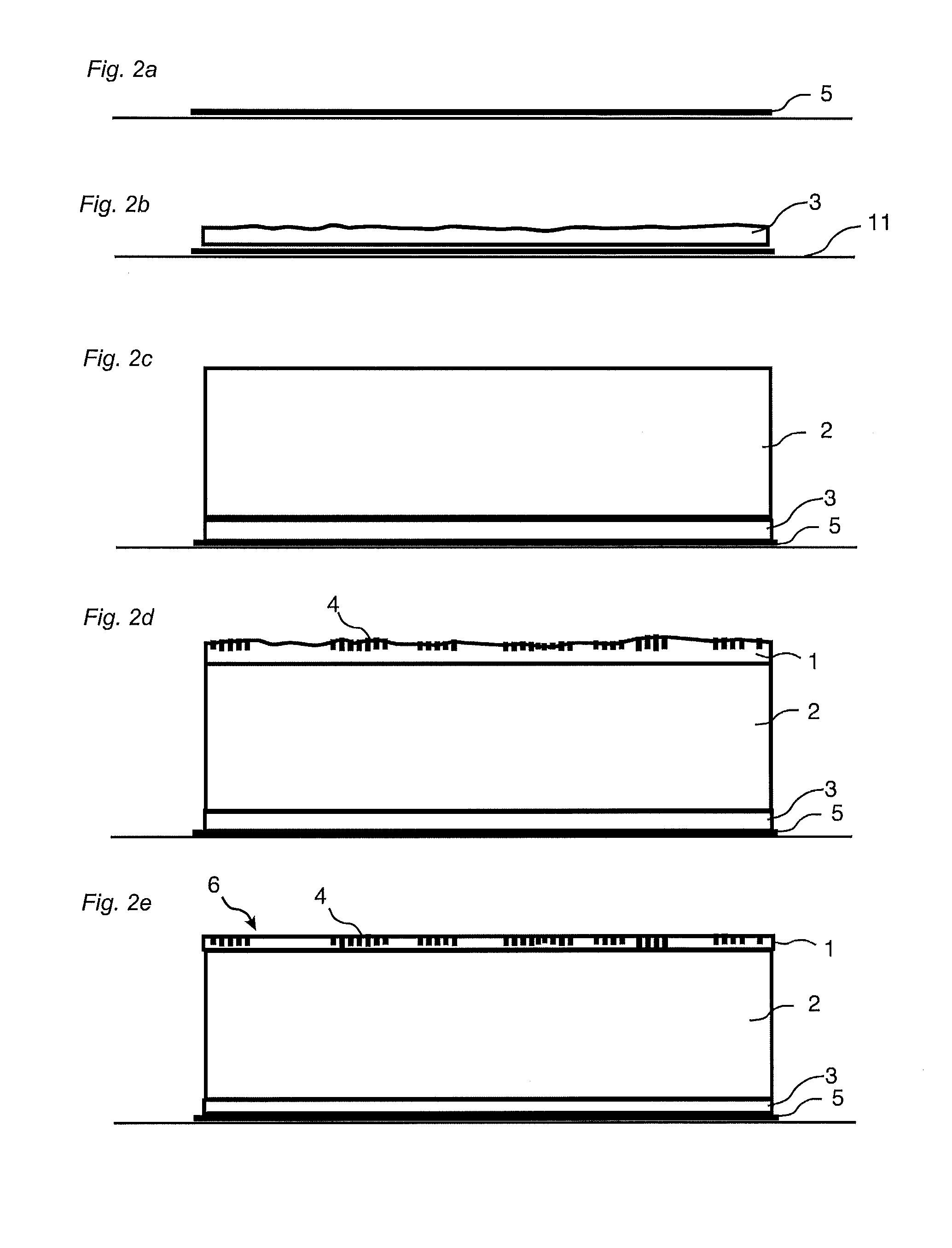

The systems, methods and products of the invention include systems and methods for manufacturing servo tracks on a magnetic tape. In one aspect, the invention includes systems for manufacturing magnetic tapes having servo tracks thereon wherein the servo tracks are optically detectable and are capable of being processed by a servo control system for maintaining alignment of a magnetic recording head with the data tracks on the recording side of the magnetic tape. In one practice, the manufacturing systems described herein engrave the servo tracks onto the non-recording side of a magnetic tape by directing a laser beam at the non- recording side of the magnetic tape. In another practice, the manufacturing systems described herein engrave the servo tracks onto the magnetic side of a magnetic tape by directing a laser beam at the magnetic side of the magnetic tape. Such engraved patterns can act as optical servo tracks for maintaining alignment of the recording head with the data tracks on the magnetic tape.

Owner:QUANTUM CORP

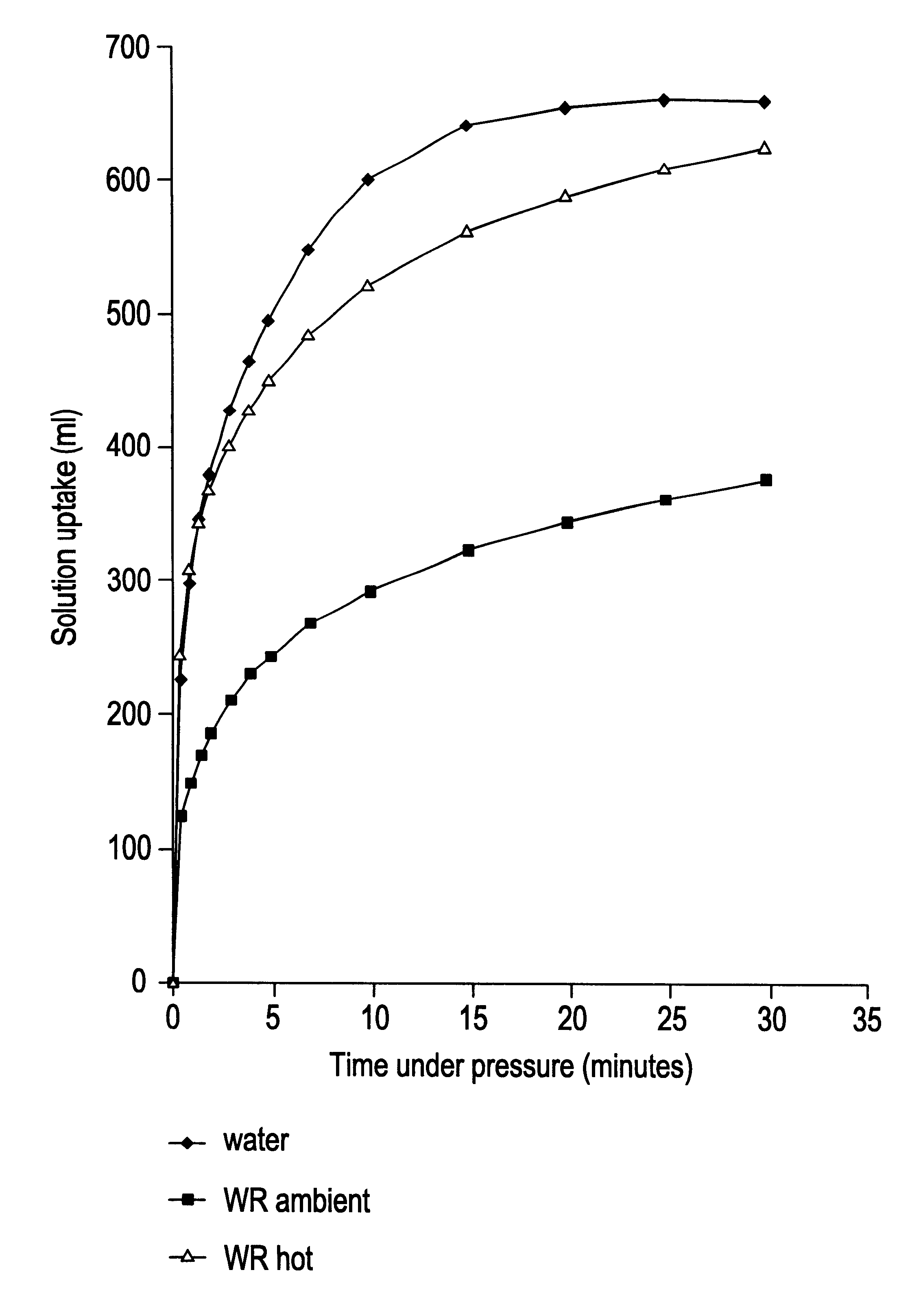

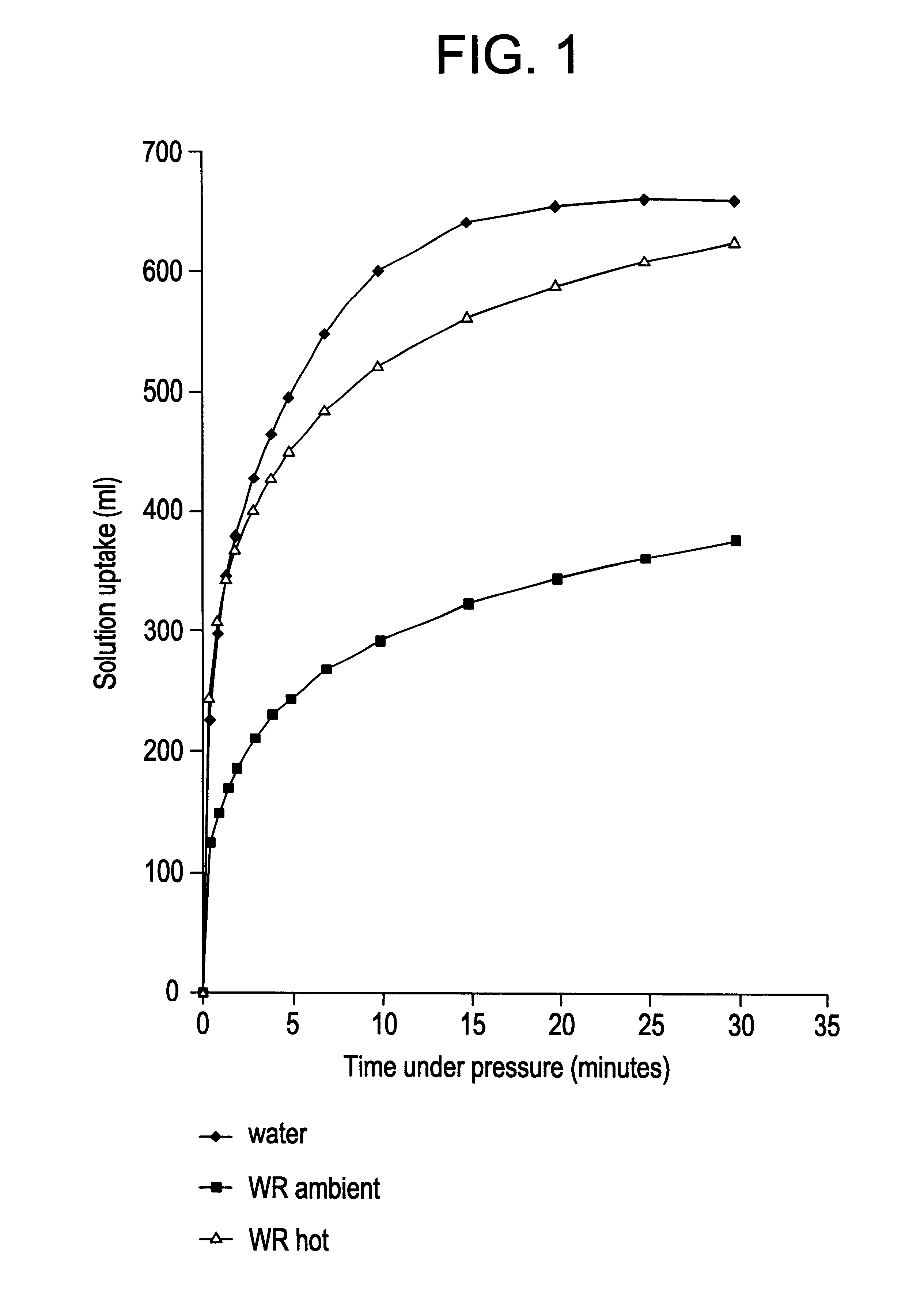

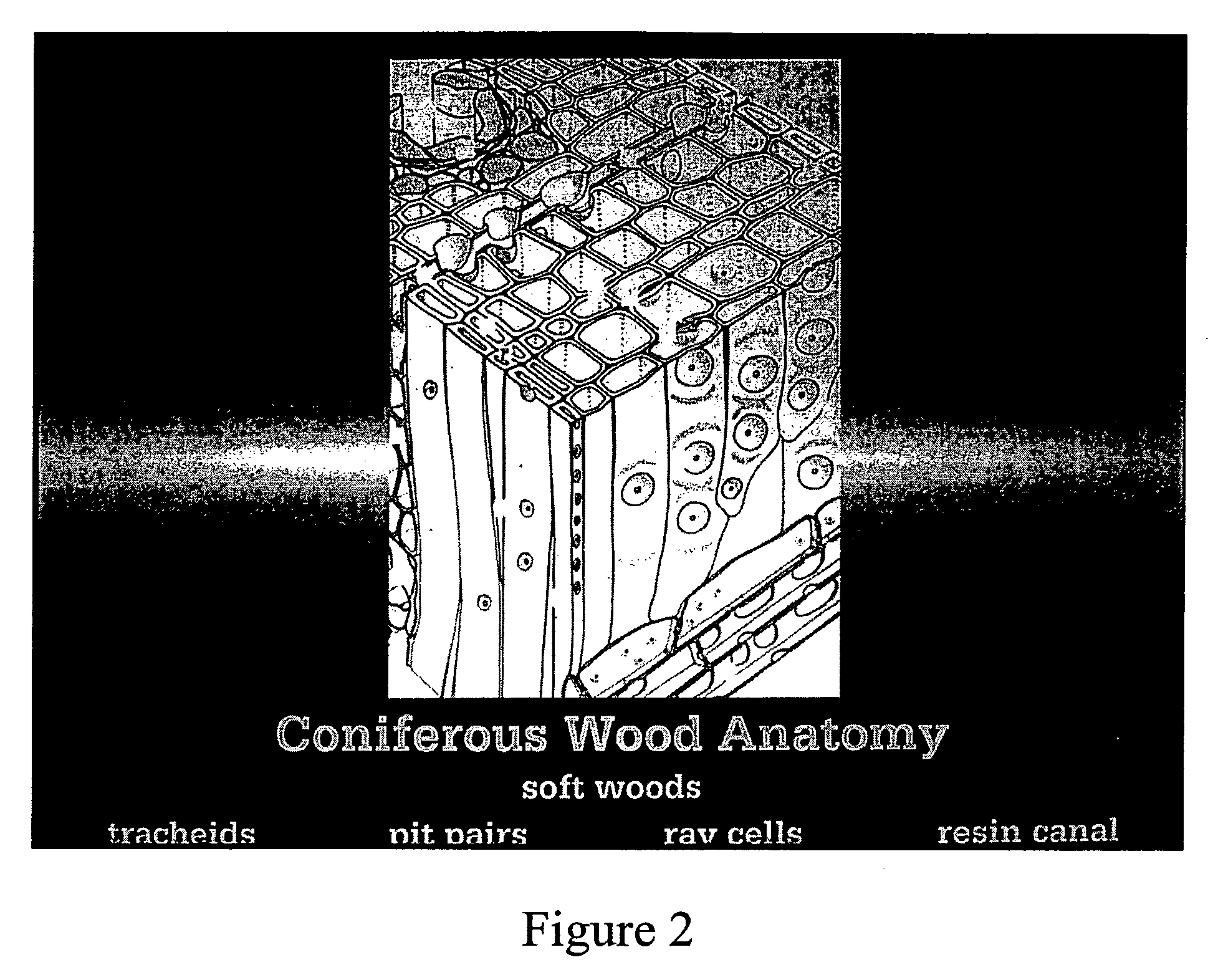

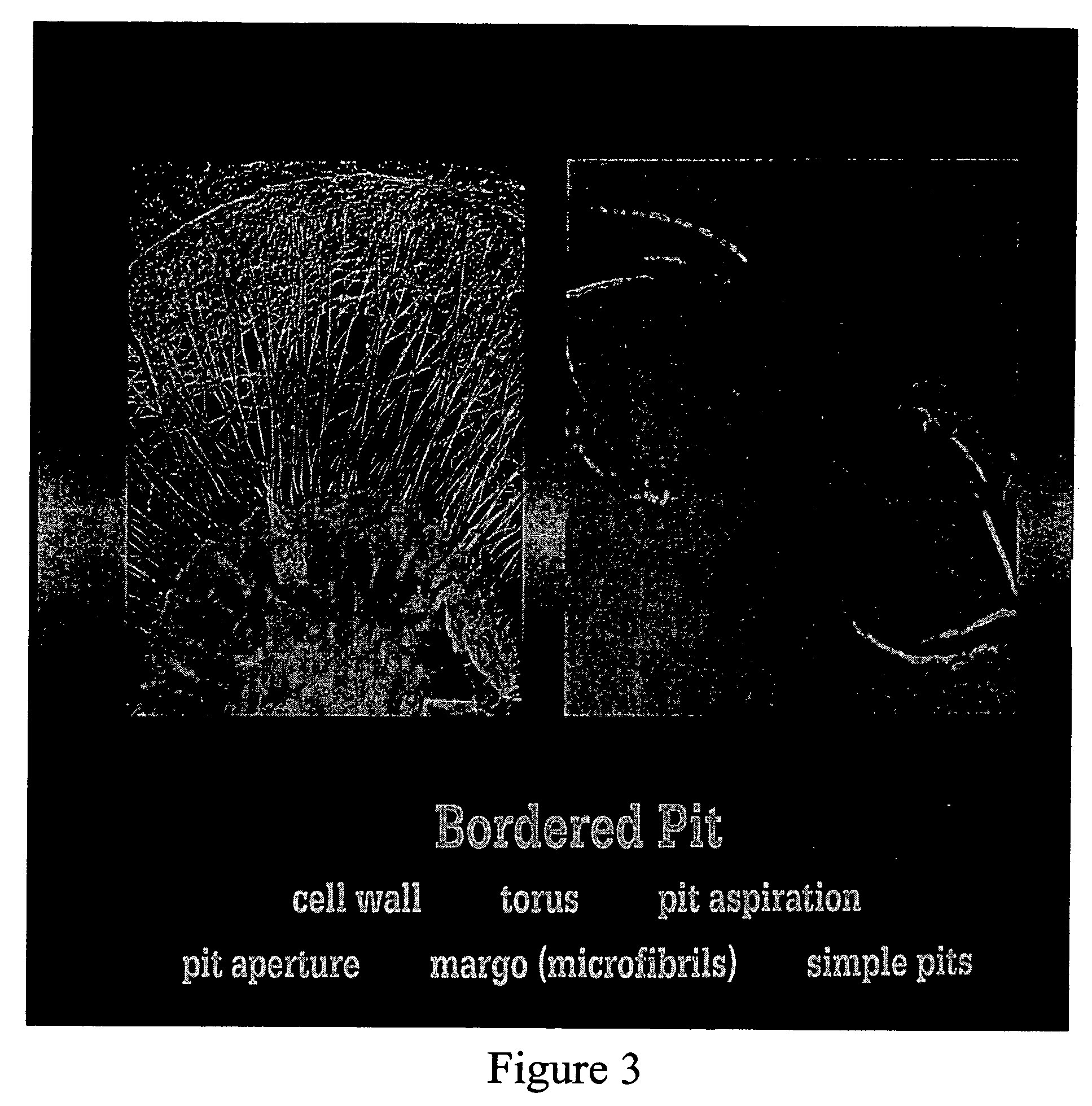

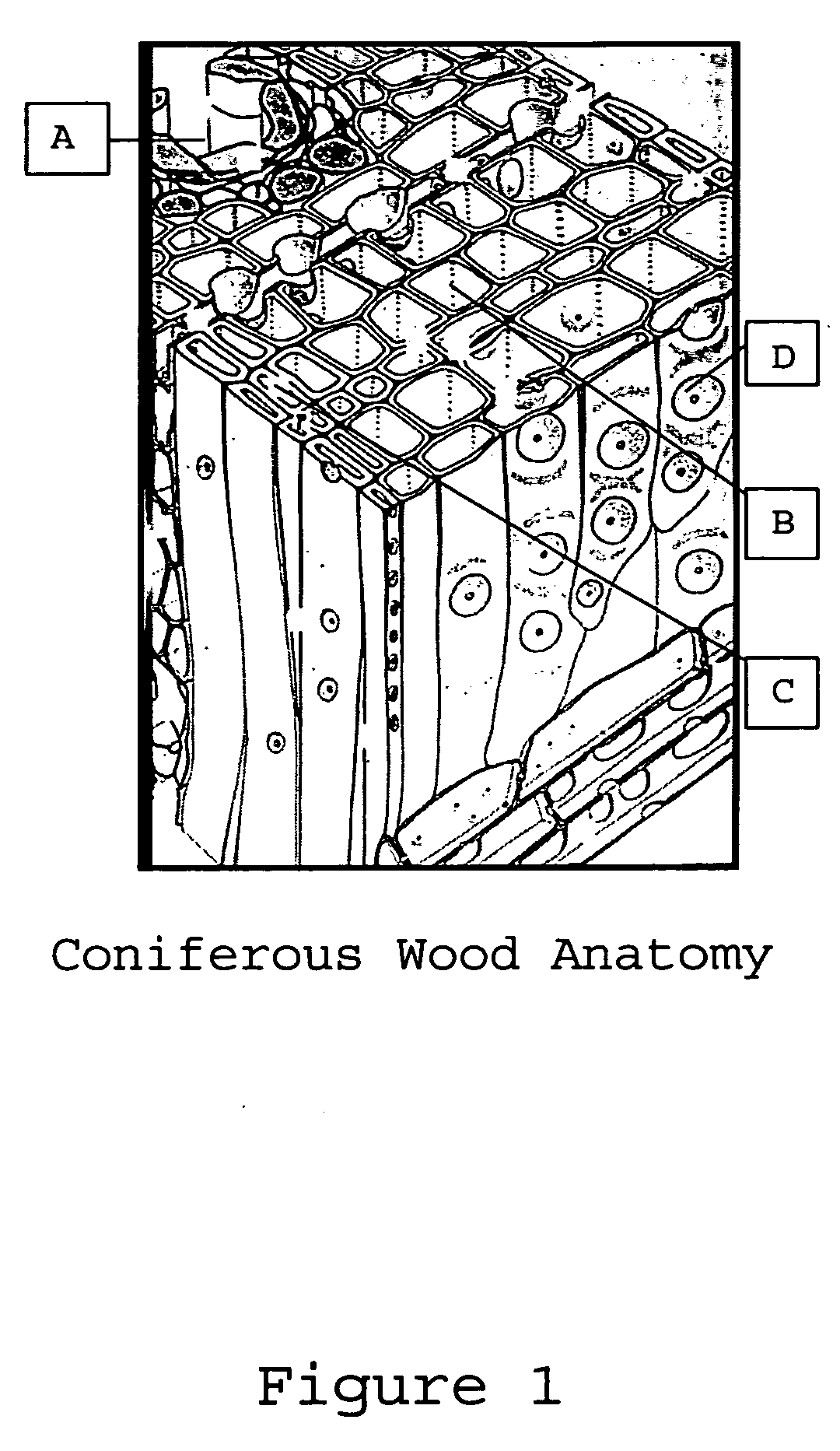

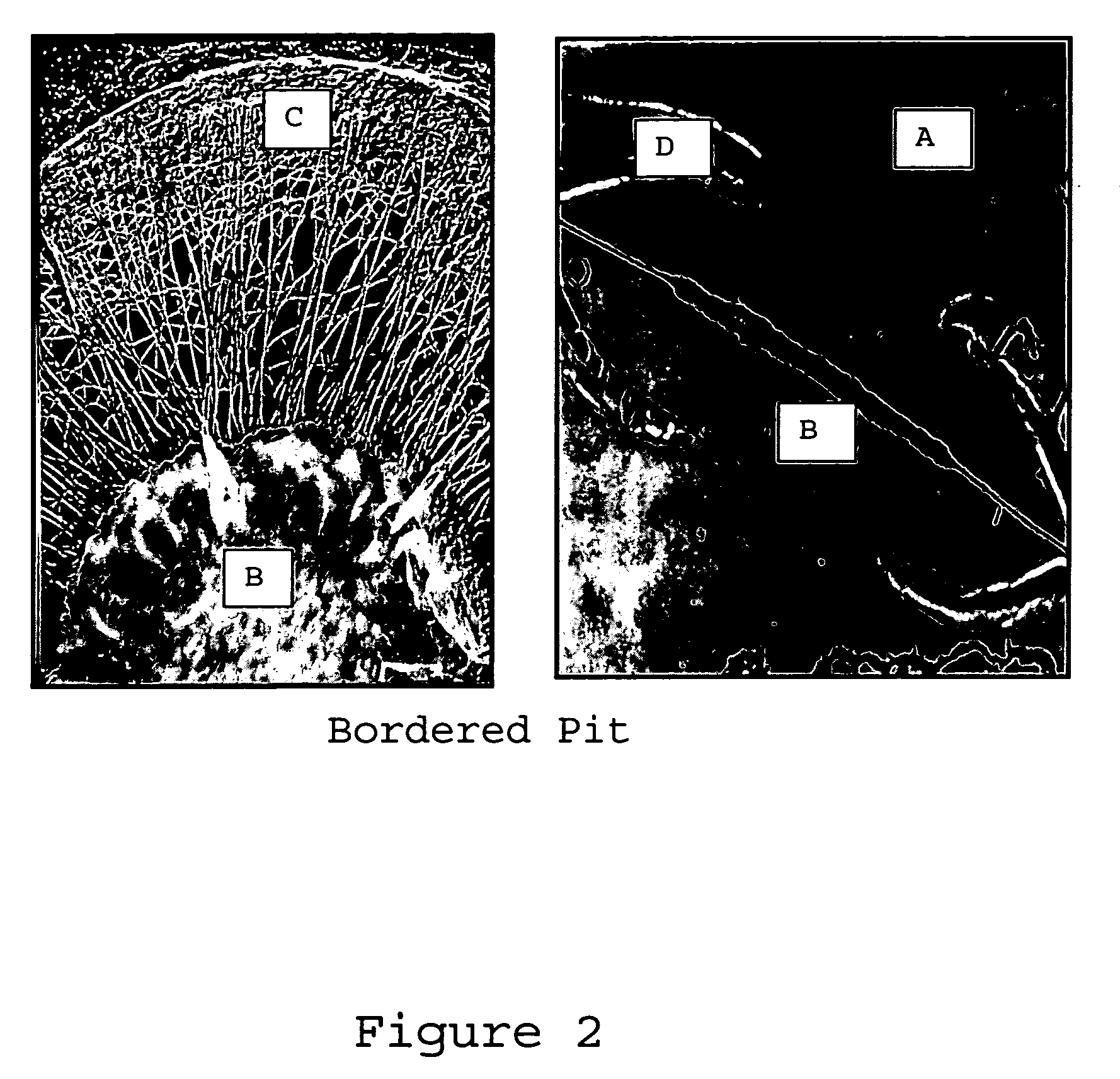

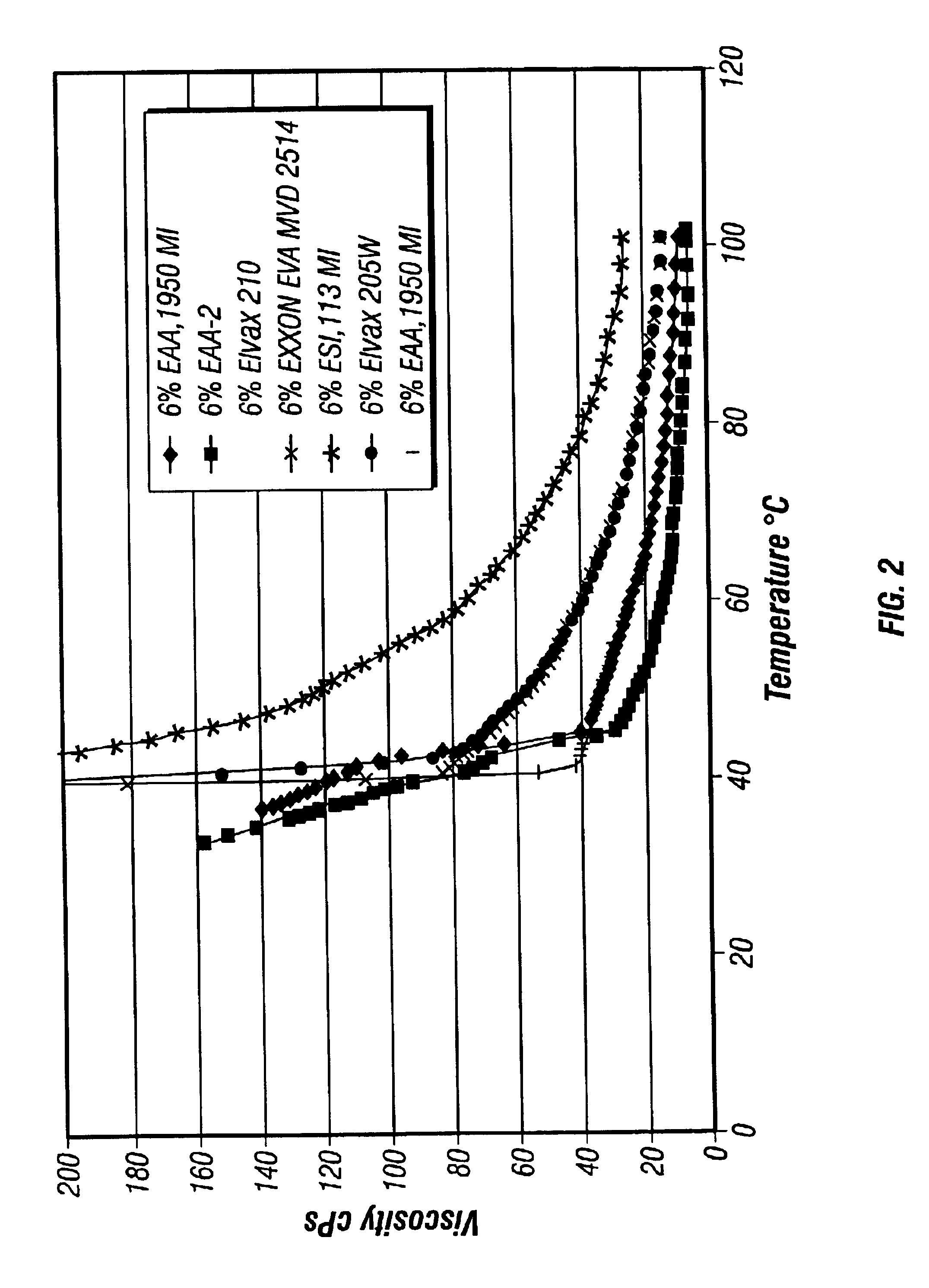

Wood treatment process

InactiveUS6274199B1High shear stabilityImprove permeabilityWood treatment detailsPretreated surfacesWater basedMolten state

A process for treating a wood substrate with a water-based formulation containing a wax in order to confer water repellency to the substrate comprising the steps of:(a) placing the substrate in a treatment vessel and reducing the pressure in the vessel to remove air in the pores of the substrate;(b) contacting the substrate in the vessel, while reduced pressure is present in the vessel, with the formulation to allow the formulation to flow into said pores, said contacting being carried out at a temperature at or above that required to cause the wax to change into a molten state;(c) applying a positive pressure to the vessel to force the formulation into said pores; and(d) releasing the pressure in the vessel and removing the resultant wood substrate from the vessel.

Owner:VIANCE

Use and production of coated filaments for extrusion-based 3D printing processes

ActiveUS20140134335A1Additive manufacturing apparatusFilament manufacturePolymer sciencePrinting press

Owner:EVONIK OPERATIONS GMBH

Method for treating wood with a metal-containing treating agent and wood treated thereby

InactiveUS6541038B1Reduce leachingEasy to fixBiocideHeavy metal active ingredientsLignosulfonatesMetal

A method for treating wood, characterized by impregnating wood with a metal-containing treating agent containing lignin and / or lignin derivatives and a metal, a metal compound, and / or a metal ion and oxidizing and / or macromolecularizing of the lignin and / or lignin derivatives in the wood to fix the metal component in the wood, and wood and woody materials obtained by the treating method. According to the method of the present invention, while effectively utilizing lignins, lignosulfonic acids, or lignosulfonic acid salts, leaching of the metal component can be suppressed to a low level to thereby retain the effects due to the incorporation of the metal components for a prolonged period.

Owner:SDS BIOTECH CO LTD

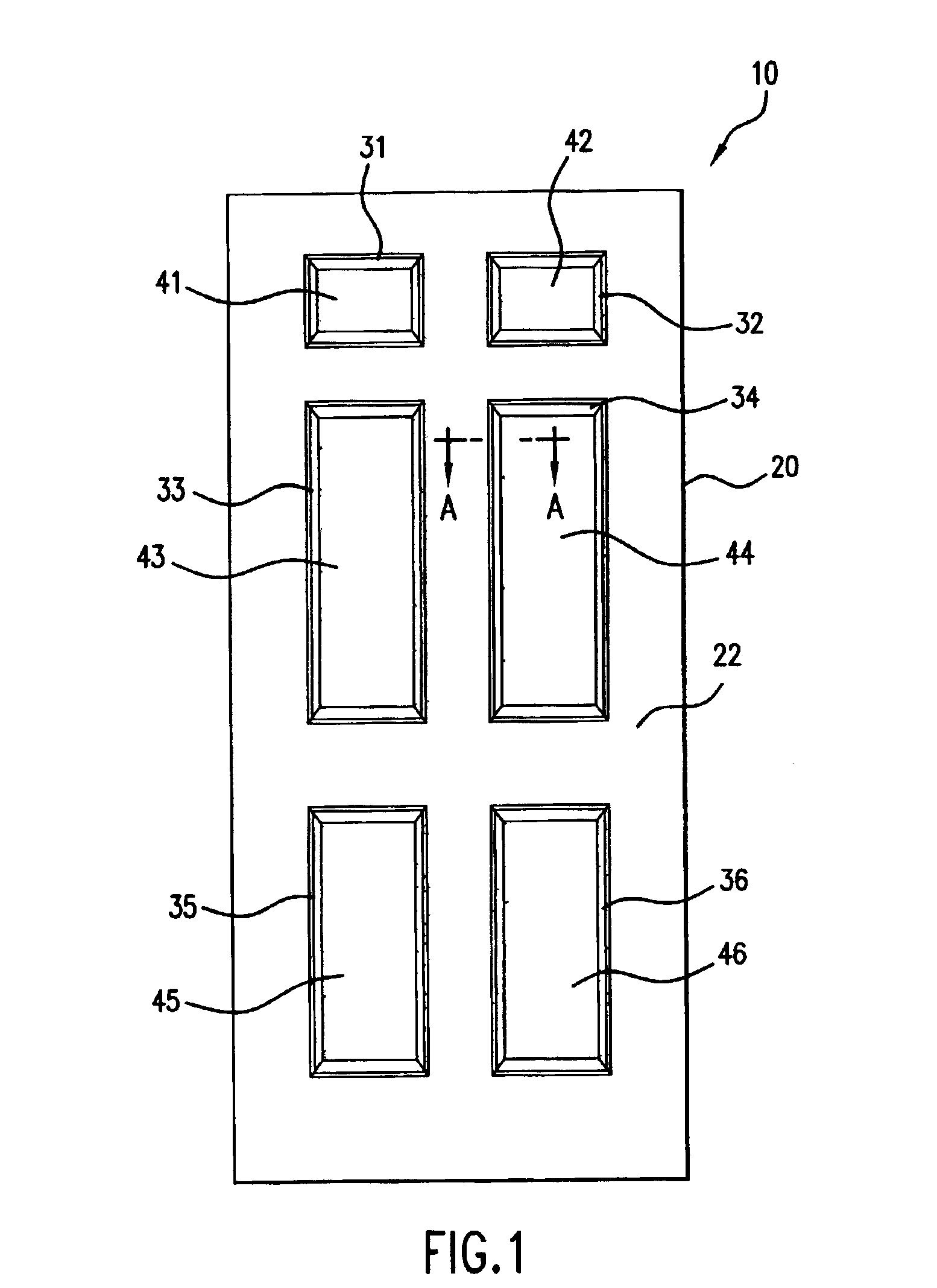

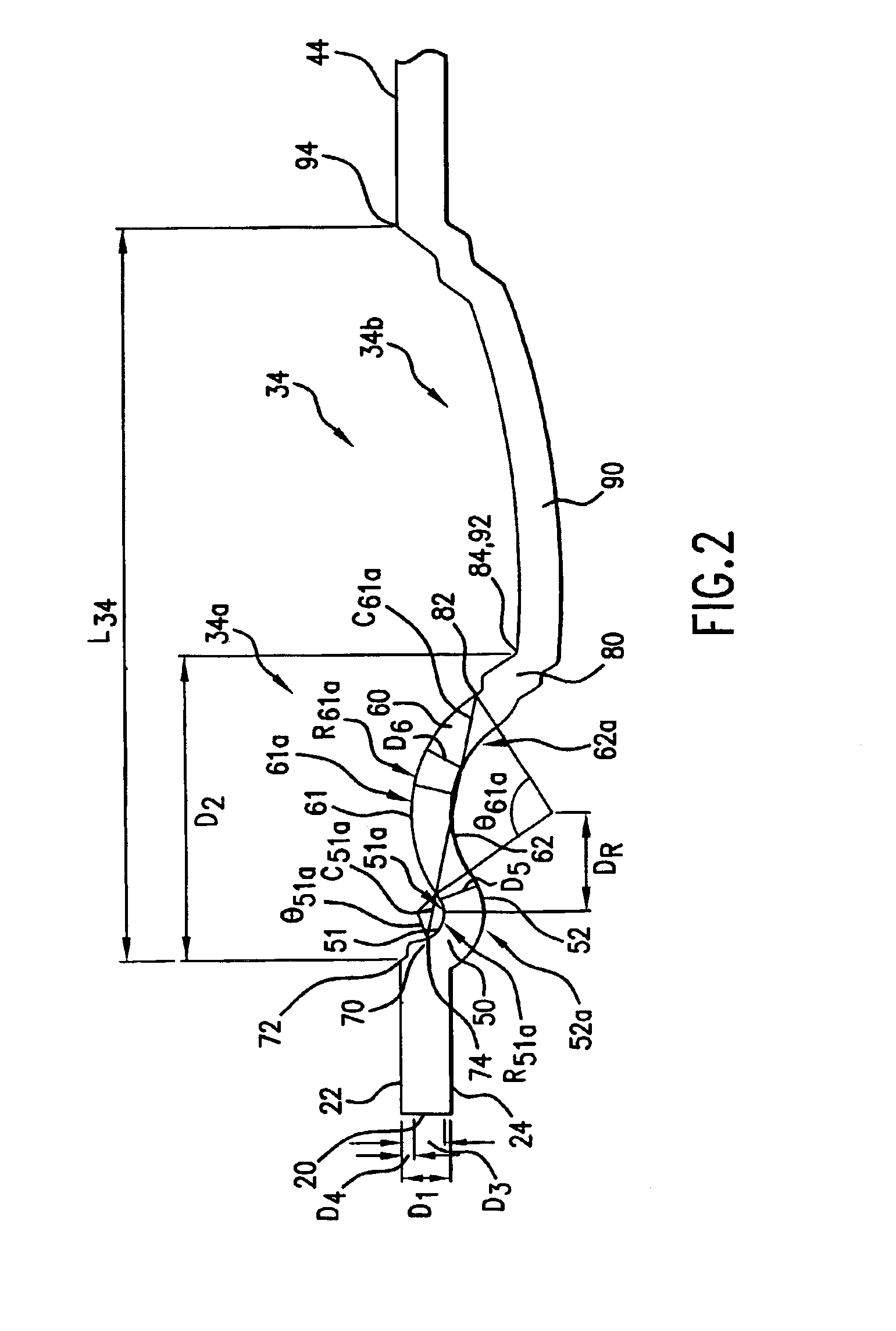

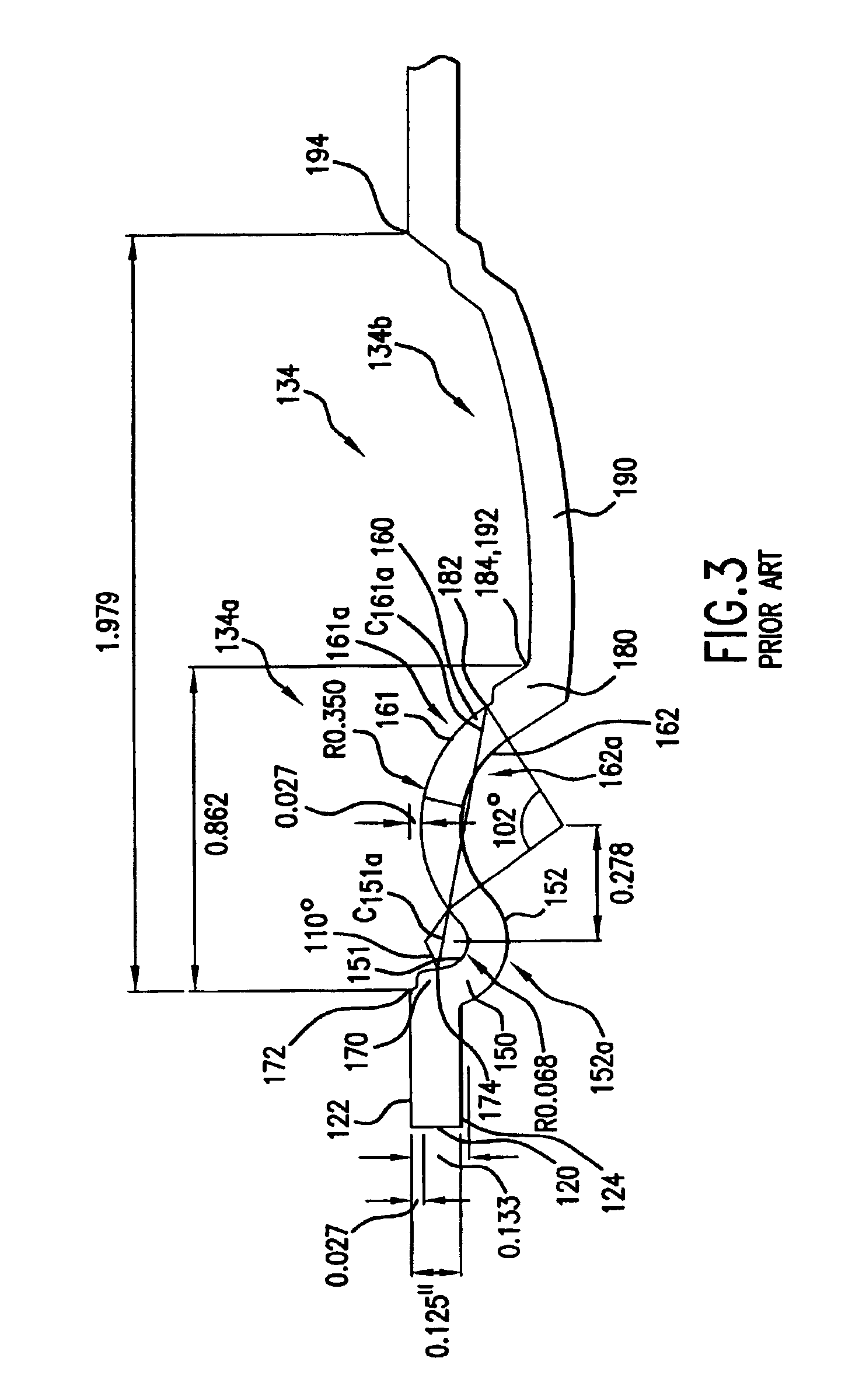

Molded skin with curvature

InactiveUS7022414B2Density is accurateUniform appearanceCeramic shaping apparatusWood layered productsEngineeringSheet material

Molded skins and methods of making molded skins are disclosed. An embodiment of a skin includes a sheet having first and second surfaces, a first arcuate portion integral with the sheet, and a second arcuate portion integral with the sheet and adjacent to the first arcuate portion. The sheet includes a cellulosic material. The first arcuate portion includes a first surface and a second surface, each having an arc. The second arcuate portion includes a first surface and a second surface, each having an arc. An angle forming the arc of the first surface of the first arcuate portion is greater than 110 degrees and an angle forming the arc of the first surface of the second arcuate portion is less than 102 degrees.

Owner:JELD-WEN

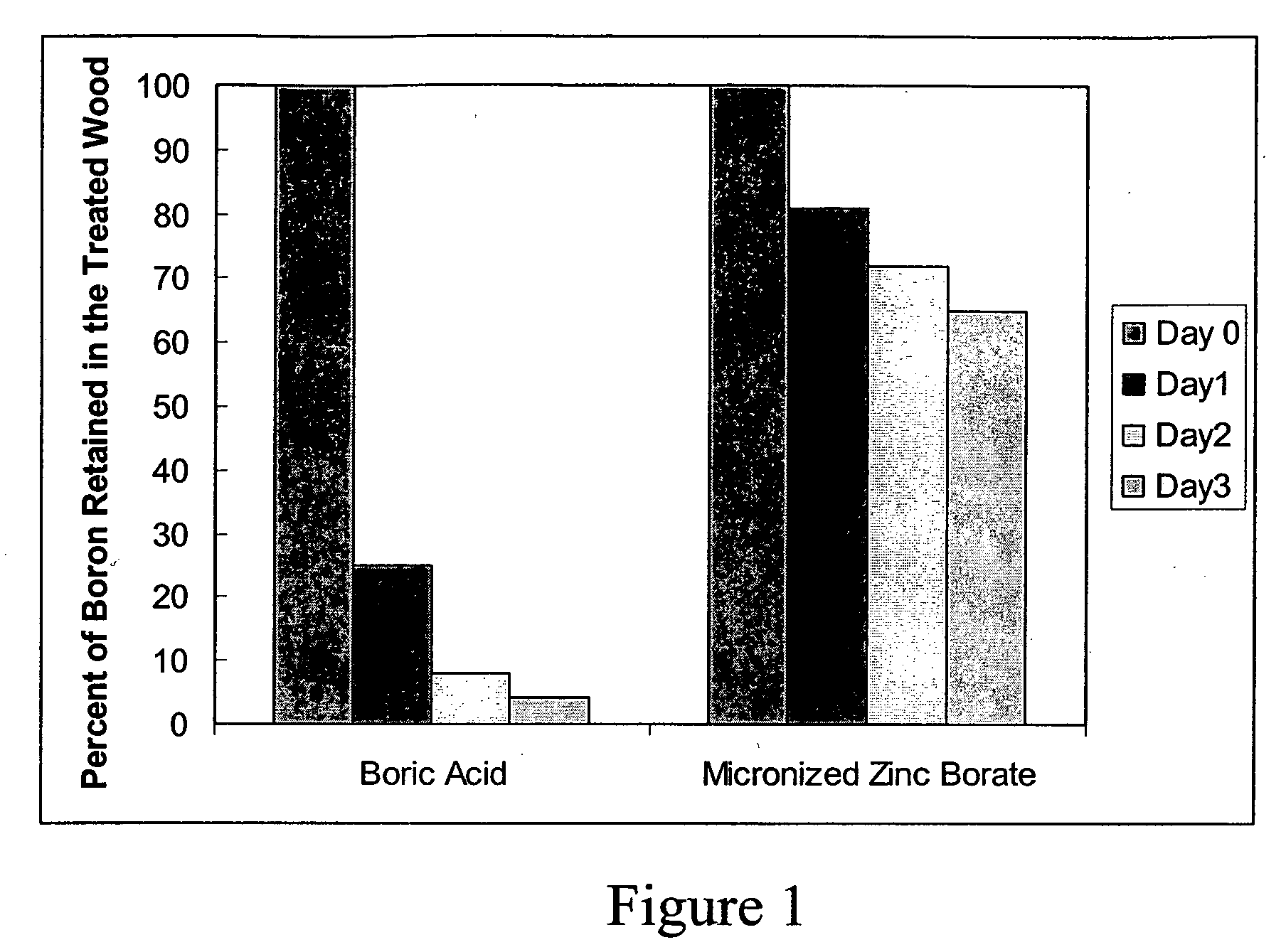

Micronized wood preservative formulations comprising boron compounds

InactiveUS20060257578A1Improving decay- and insect and fire-resistanceAccelerated decayFireproof paintsAntifouling/underwater paintsPreservativeFire retardant

The present invention provides wood preservative and flame retardant compositions having low leachability comprising micronized boron compounds and, optionally, one or more organic biocides which may be micronized. Also provided is a method for applying the composition to wood and wood products comprising impregnating the wood with the composition.

Owner:OSMOSE

Water repellent compositions for wood preservatives

InactiveUS7264886B2Improve permeabilityImprove waterproof performanceFireproof paintsWax coatingsWaxWater based

Water-based wax emulsions, optionally for use in conjunction with alkaline copper and / or quaternary ammonium based preservatives systems, are described. These emulsions are comprised of natural or synthetic wax, nonionic surfactants having HL B values greater than 11, anionic surfactants, and water. Certain emulsion compositions as described in this specification posses the unique property of maintaining emulsion stability in wood preservatives during extended use in typical wood treatment processes. Water-repellant wood treated with the wax emulsions are described. A method of treating wood, comprising providing wood and treating the wood with the wax emulsion under conditions effective to increase its water repellency is also disclosed.

Owner:VIANCE

Adhesive system and method of producing a wood based product

InactiveUS20070298274A1Suitable for useSufficient qualityAdhesive processesWood layered productsPolymerAdhesive system

The invention relates to a method of producing a wood based product, comprising applying an adhesive system onto one or more pieces of a wood-based material, and joining the one or more pieces with one or more further pieces of a material, the adhesive system comprises one component comprising starch and another component comprising one or more polymers (P) containing an amine group or an amide group. The present invention also relates to an adhesive system comprising one component comprising starch and another component comprising one or more polymers (P) containing an amine group or an amide group, the two components being present as unmixed separate components. The invention further relates to a wood based product.

Owner:AKZO NOBEL COATINGS INT BV

Compositions and methods for treating cellulose-based materials with micronized additives

InactiveUS20050265893A1Increase costIncrease residueBiocideDrying using combination processesCelluloseMaterials science

Owner:OSMOSE +1

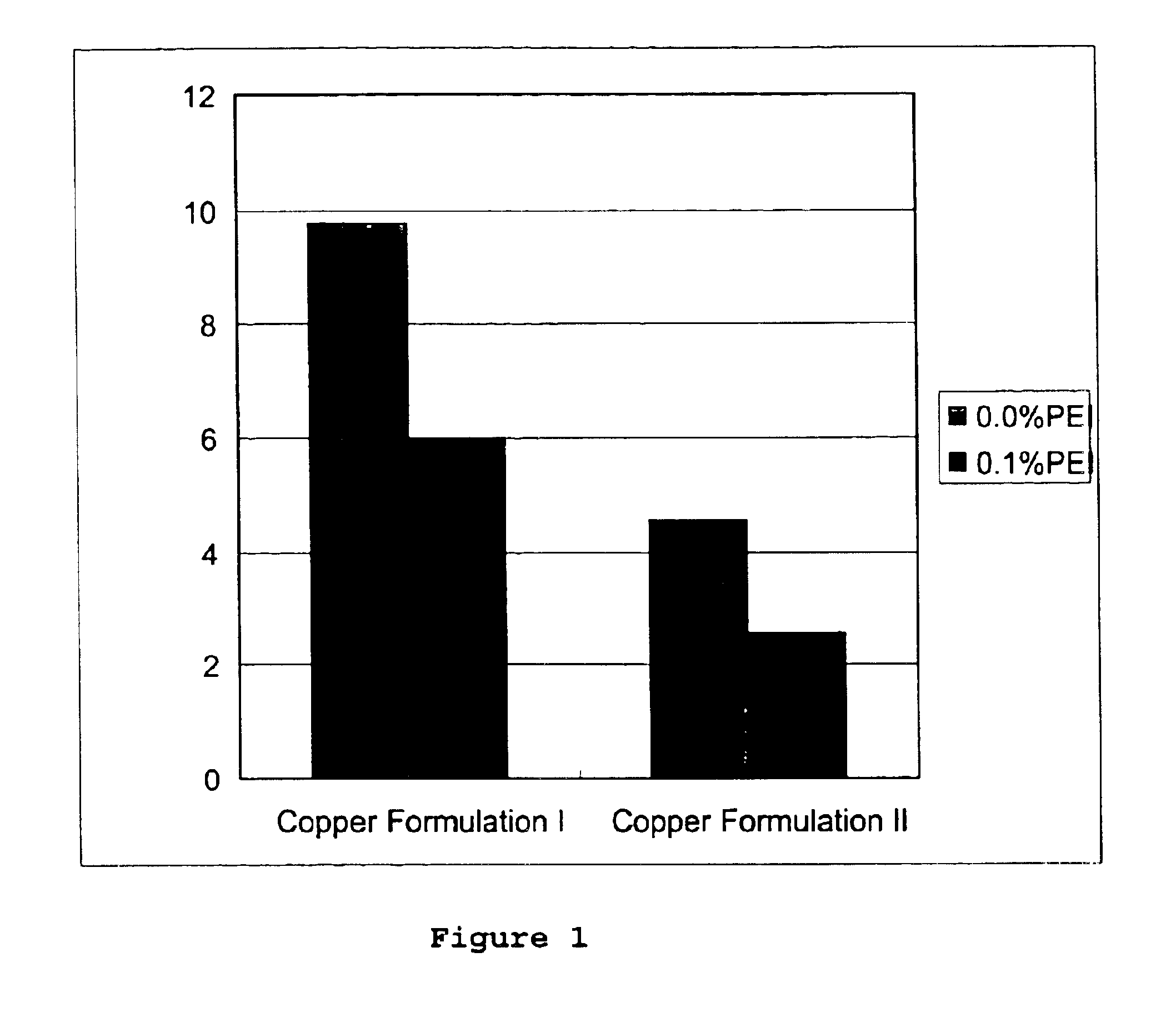

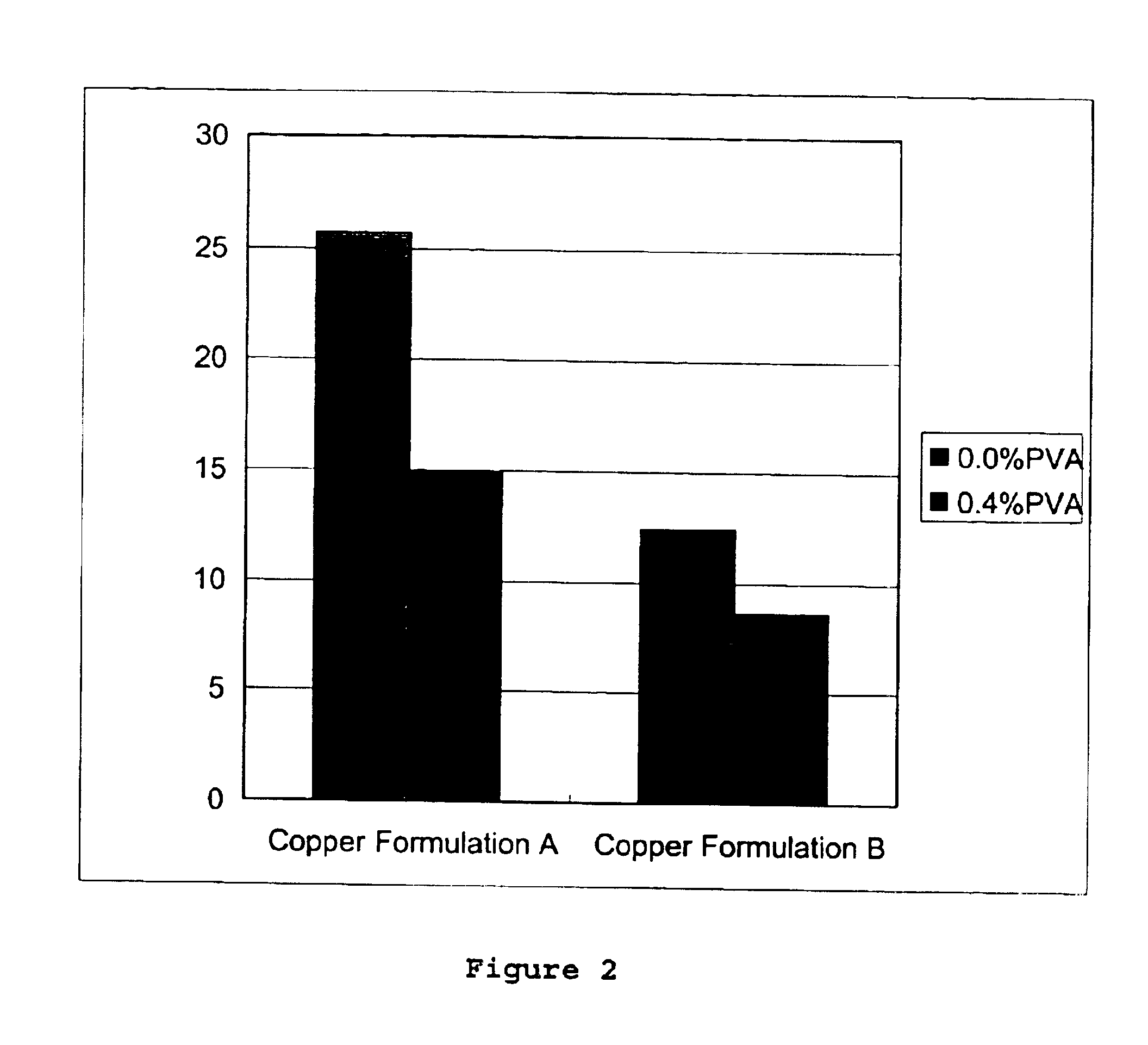

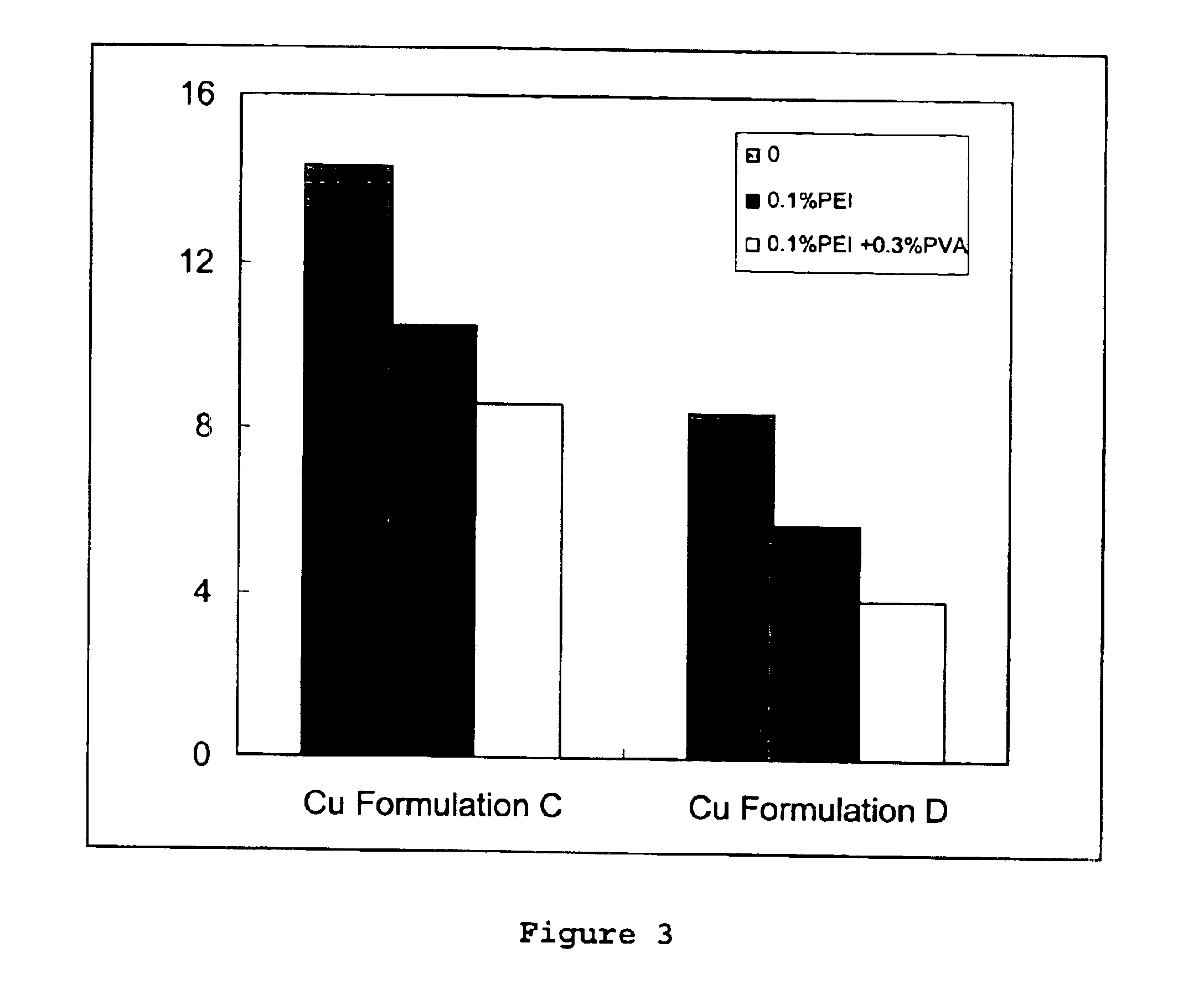

Polymeric wood preservative compositions

The present invention relates to a method and a wood preserving composition which comprises mixtures of a metal compound, complexing agents selected from ethanolamines, polyethylenimine, ammonia or a mixture of these compounds, and a vinyl based polymer selected from poly(vinyl alcohol) (PVA), poly(acrylamide) (PA), poly(N-vinyl pyrrolidone) (PVP) and poly(N-isopropyl acrylamide) (PNIPAM). The resulting metal amine solution can then be used to formulate a variety of metal-based cellulosic material preserving products.

Owner:OSMOSE

Wood composites, methods of production, and methods of manufacture thereof

ActiveUS20070020476A1Monocarboxylic acid ester polymer adhesivesProtein adhesivesMethods of productionOrganic chemistry

An adhesive binder comprising a phenol-formaldehyde resin, polyvinyl ester resin, and a protein is disclosed. The adhesive binder is useful for preparing wood composites.

Owner:HEXION INC

Method For Preparing Functional Engineered Wood

ActiveUS20170239836A1Improve permeabilityWell mixedLiquid surface applicatorsPressure wood treatmentFire retardantEngineered wood

The present invention relates to furniture panels, and more particularly, to a method for preparing functional engineered wood. It includes the following steps: make veneer blanks by rotary cutting or splicing, and cut the veneer blanks into desired dimensions to obtain veneers A. Soak the veneers A in a ternary mixed solution of a biomass nanocellulose solubilizer, a fire retardant and an acid dye for toughening, fire retardation and dyeing to obtain veneers B. Add a formaldehyde decomposing powder into a modified MUF adhesive, mix them up, coat the veneers B with the mixture to obtain veneers C. Assemble and cold-press the veneers C to obtain flitches D, and saw the flitches D into desired patterns and dimensions to obtain finished products.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Water repellent composition for improving wood product dimensional stability

InactiveUS20070037001A1Increased swelling resistanceImprove material stabilityWax coatingsOther chemical processesWaxWater repellent

Provided are compositions for improving the water-resistance and dimensional stability of wood and wood products. The compositions comprises wax and oil components, and can be applied as liquid compositions comprising little or no water. Also provided are methods for the application of the compositions to wood.

Owner:OSMOSE

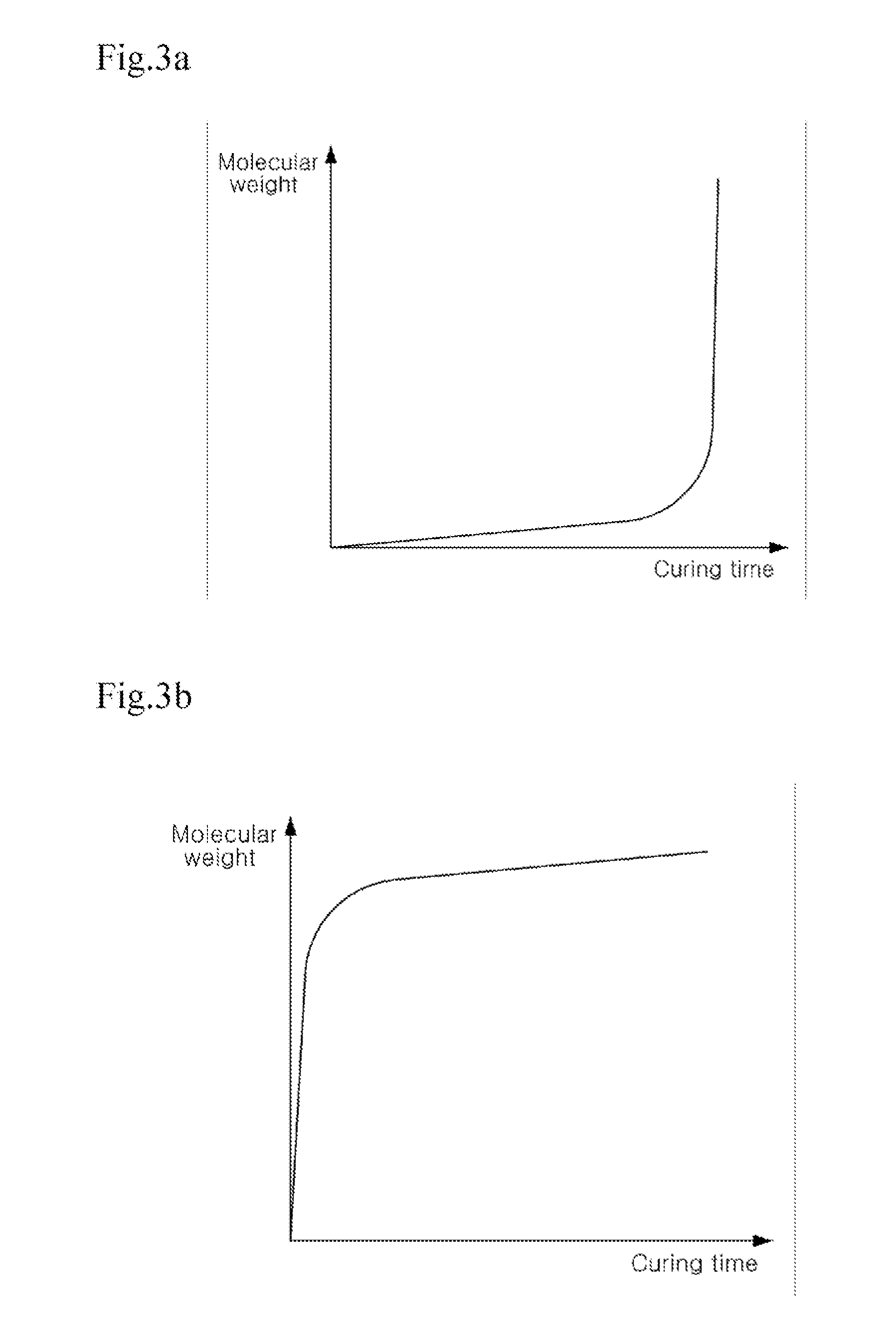

Process for macromolecularizing phenolic compounds etc. and use thereof

InactiveUS20010007762A1Prevent rustLoss of strengthAntibacterial agentsOrganic active ingredientsPoulticeAdhesive

A process for macromolecularizing phenolic compounds or aromatic amine compounds by the action of a catalyst comprising an enzyme having a polyphenol oxidizing activity in the alkali region; applications of the compounds obtained by the above process to thickeners, stabilizers, coagulants, emulsifiers, dispersants, water retainers, antioxidants, adhesives, concrete admixtures, dyes, coating materials, petroleum recovering agent, soil conditioner, a blow-applied seed bearing surface soil stabilizer, deodorants, smell eliminators, agricultural chemical spreaders, feeding stuff binders, bactericides, antimicrobial agents, viral infection inhibitors, bioadhesion preventives, biotic repellents, insecticides, poultices, ink bases or wood treating agents; and method of waste water disposal, a method of deoxygenation and a method of treating wood, concrete or soil in which use is made of the above reaction.

Owner:SDS BIOTECH CO LTD

Preparation of water-soluble organic silicon compounds

Water-soluble organic silicon compounds are prepared by effecting co-hydrolysis of (A) 1-30 parts of an alkyltrialkoxysilane of R1Si(OR2)3 or a partial hydrolyzate thereof, (B) 70-90 parts of an alkoxy-containing siloxane of R3a(OR2)bSiO(4-a-b) / 2, and (C) 1-20 parts of an amino-containing alkoxysilane of R4R5NR6-SiR7n(OR2)3-n or a partial hydrolyzate thereof in the presence of an organic or inorganic acid. R1 is a C7-C18 alkyl group, R2 is a C1-C4 alkyl group, R3 is a C1-C6 alkyl group, R4 and R5 are a hydrogen atom, C1-C15 alkyl or aminoalkyl group, R6 is a divalent C1-C18 hydrocarbon group, and R7 is a C1-C4 alkyl group. Letters a and b are 0.75< / =a< / =1.5, 0.2< / =b< / =2, and 0.95<a+b<3.4. These water-soluble organic silicon compounds are fully water soluble and shelf stable and can be used as an agent for preventing porous materials from water absorption simply after dilution with water. Porous materials are coated or impregnated with the compounds so that they are given excellent water repellency and water absorption-preventing effect.

Owner:SHIN ETSU CHEM IND CO LTD

Powder based balancing layer

A method to produce a building panel comprising a decorative surface layer, a core and a balancing and / or protective layer is disclosed.

Owner:VÄLINGE INNOVATION AB

Layered wood composites

ActiveUS7544423B2Liquid surface applicatorsAdhesive processes with surface pretreatmentCelluloseMaterials science

A method for the preparation of a composite product, as well as the composite product. The composite product comprises at least two layers. At least one of the layers is of wood or another cellulose-containing material. The process comprises differentially treating the layers prior to, during, or after the lamination of the layers into a composite product.

Owner:KOPPERS PERFORMANCE CHEM

Preservative compositions for wood products

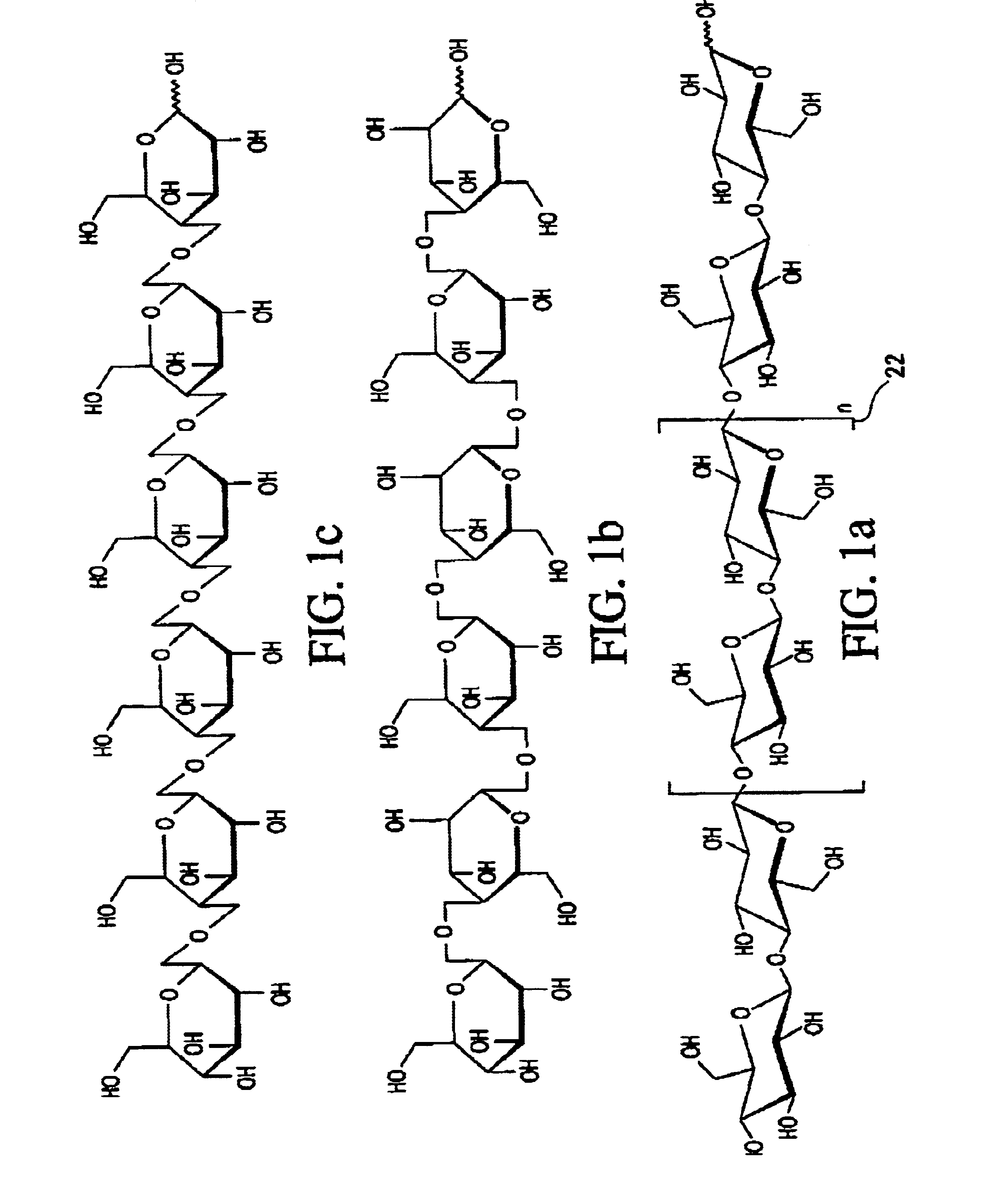

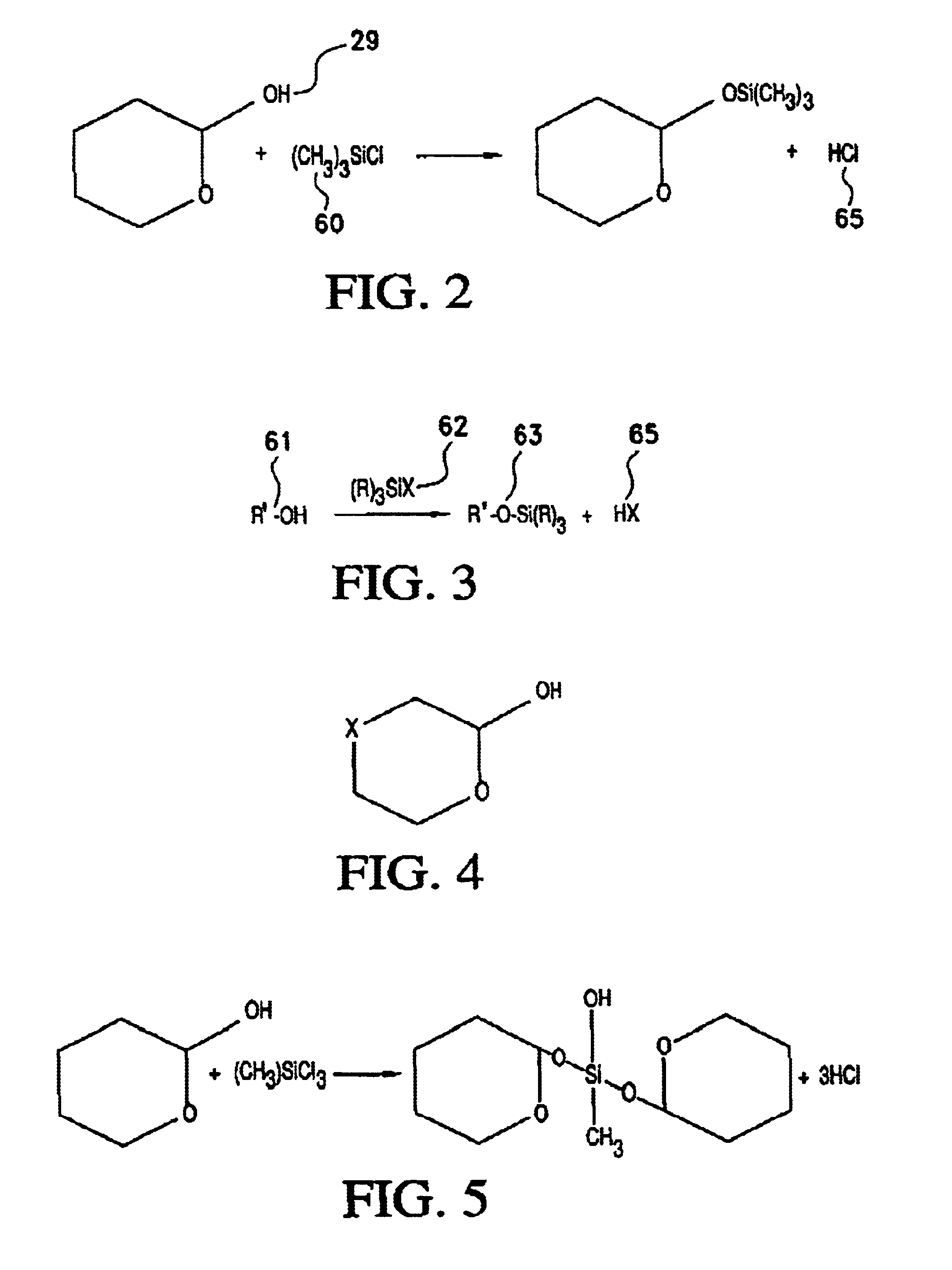

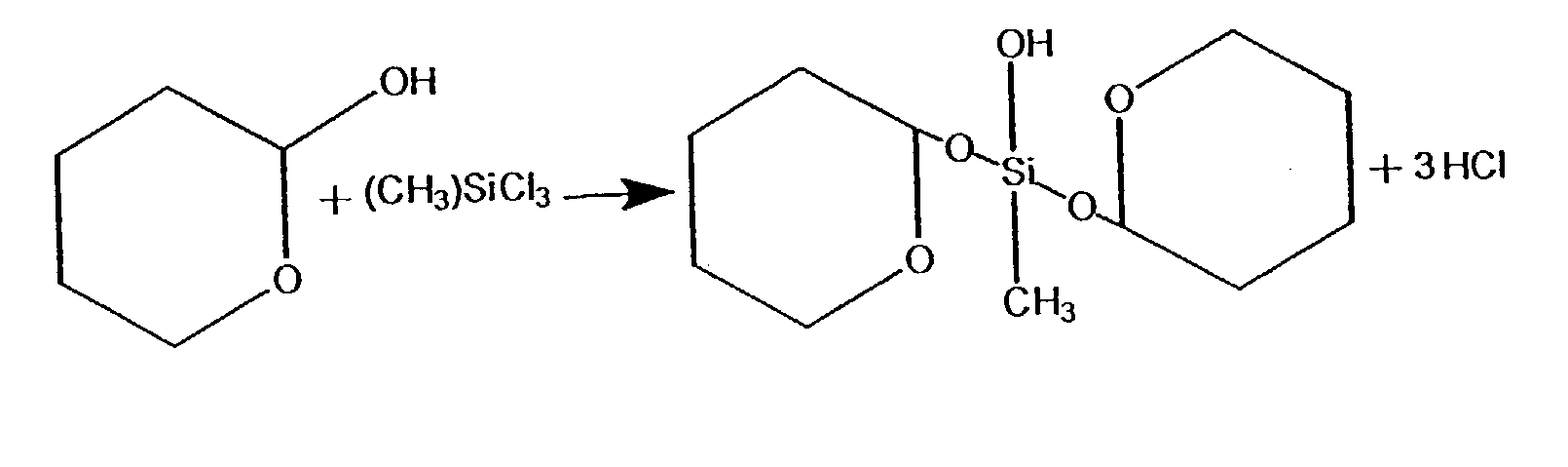

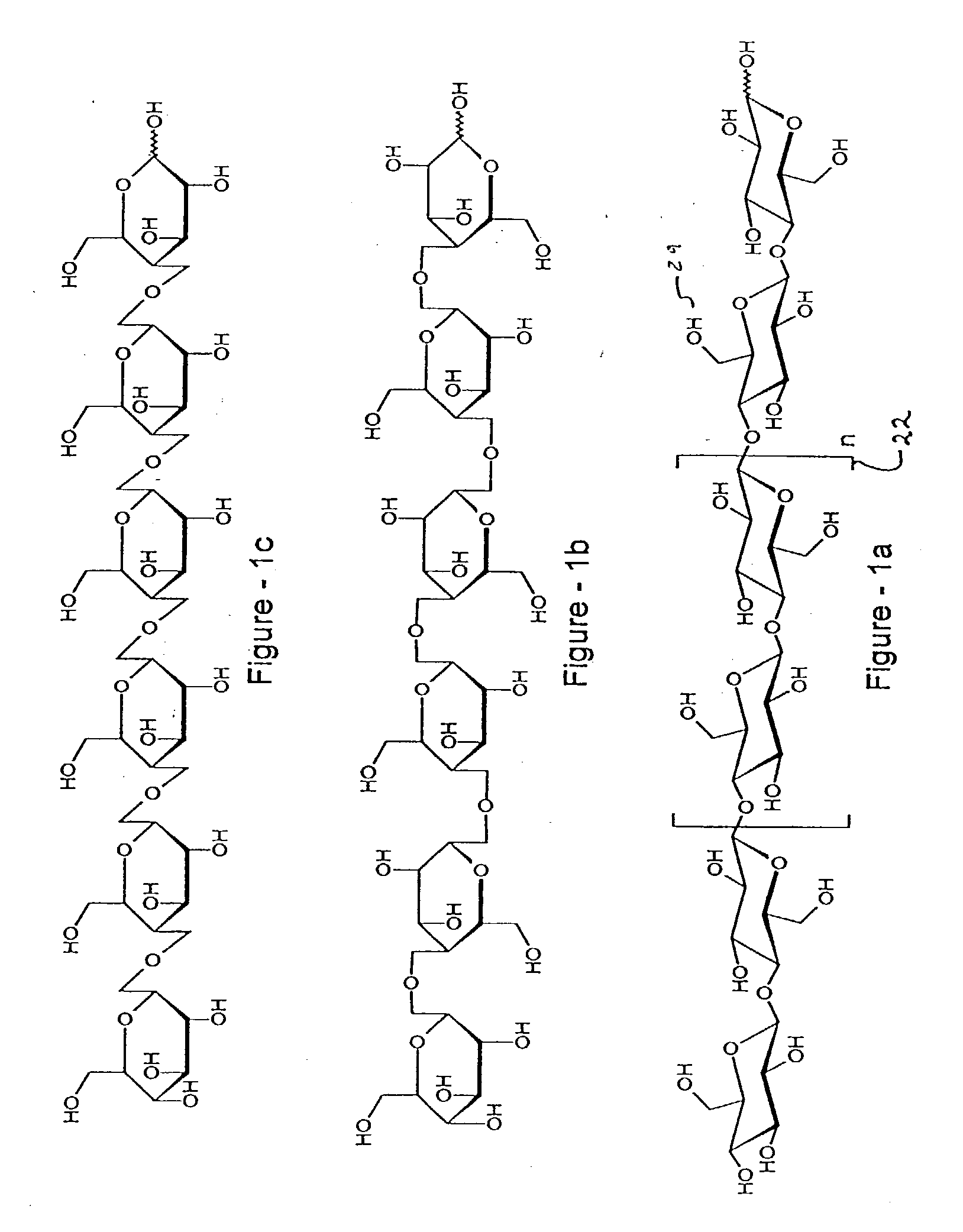

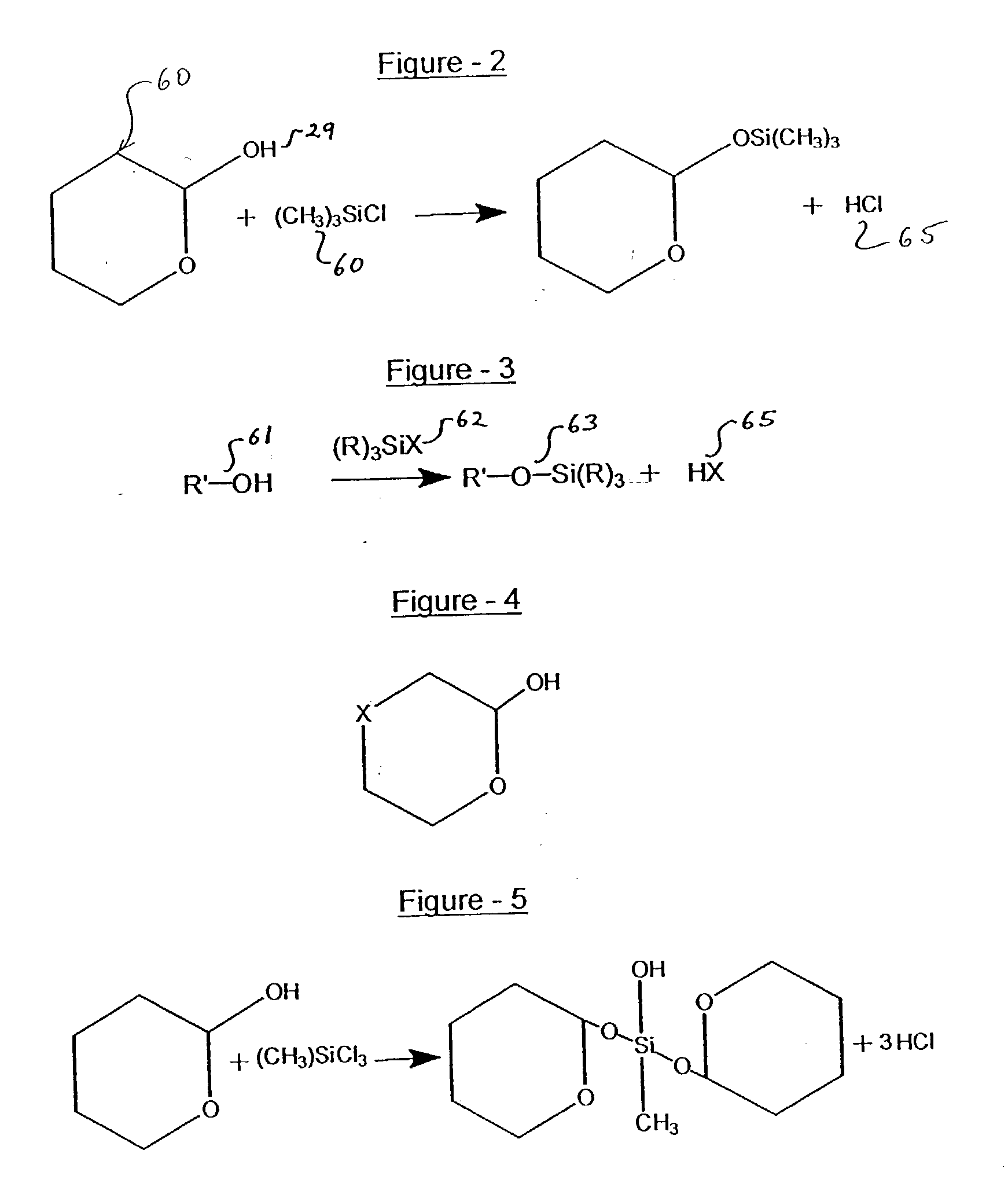

Preservative compositions for wood products is described. The compositions include at least one boron-containing material, such as but not limited to boric anhydride, and at least one silane-containing material, such as but not limited to methyltrichlorosilane. Optionally, at least one solvent, such as tetrahydrofuran, pentane, or water, may also be employed in the compositions. The compositions impart protection to the treated wood products, especially damage caused by exposure to water and insects.

Owner:PETRA INT HLDG

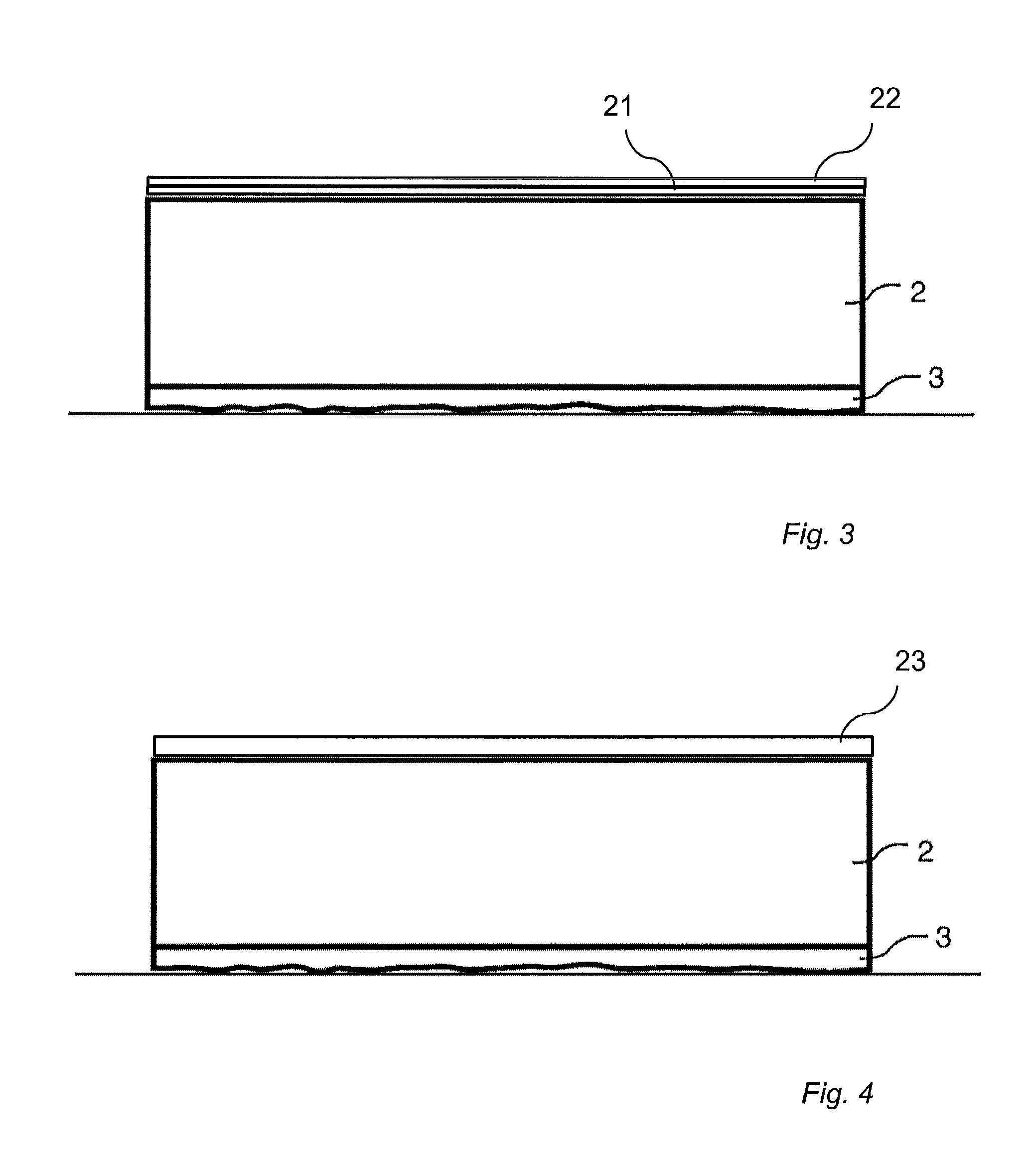

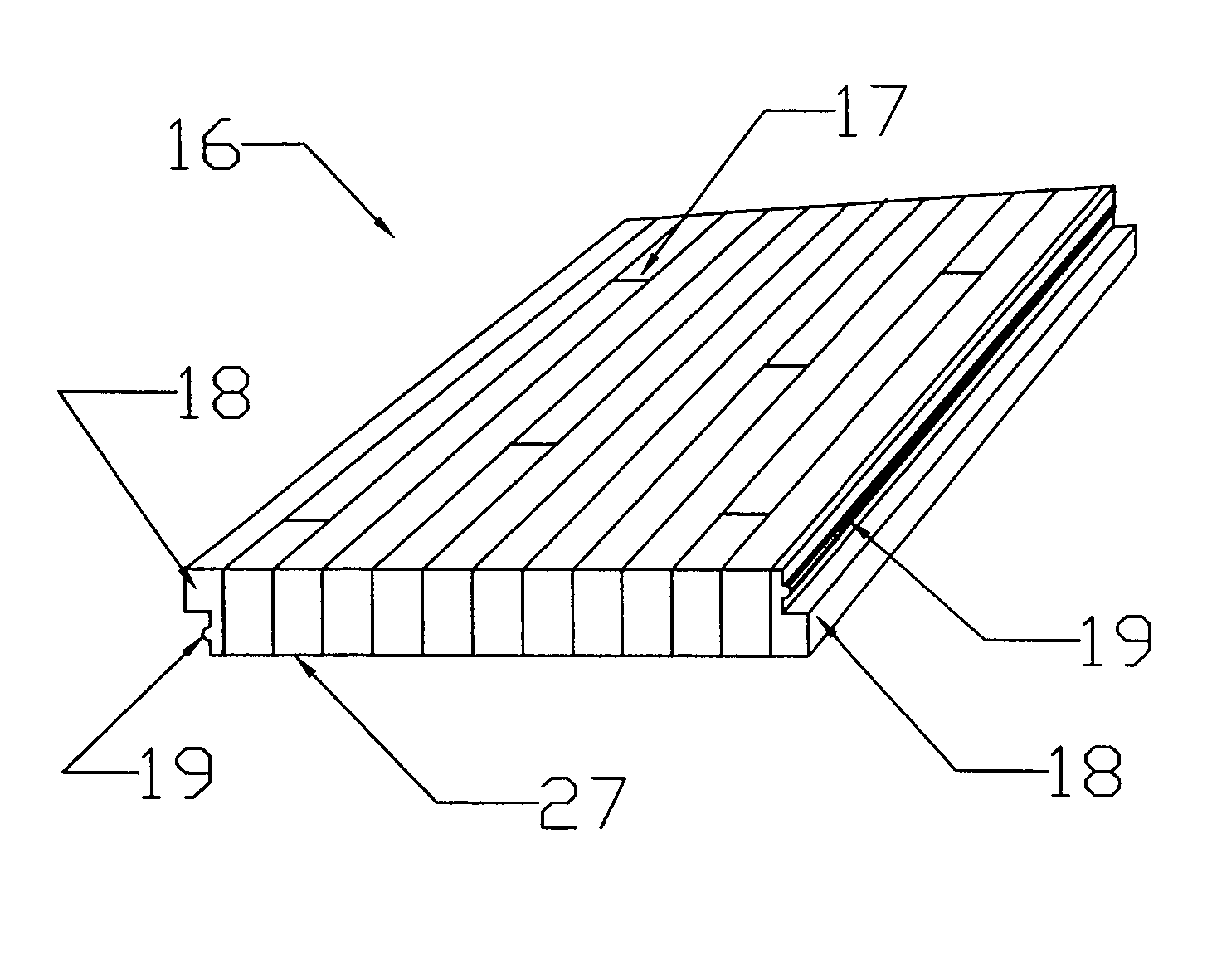

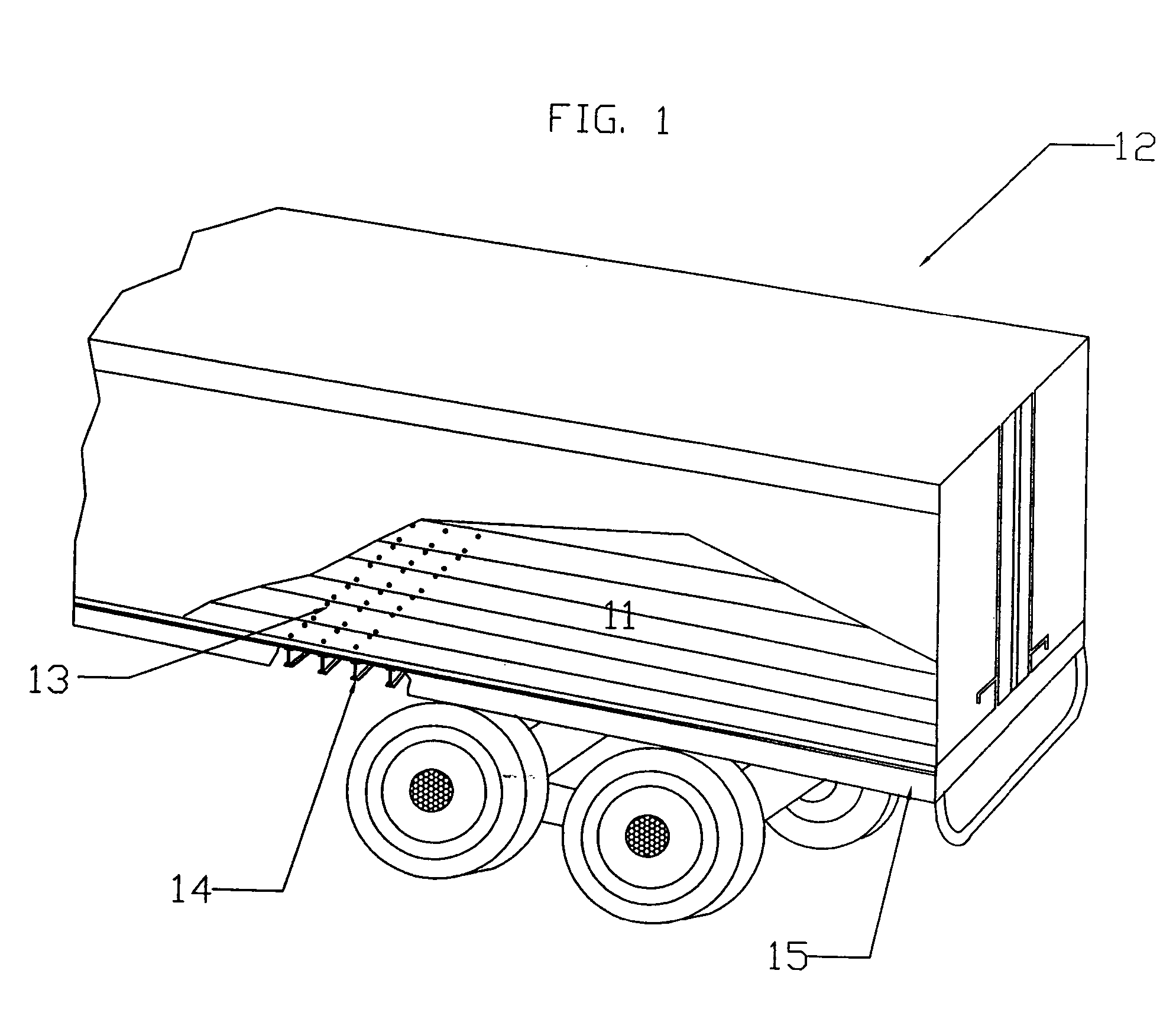

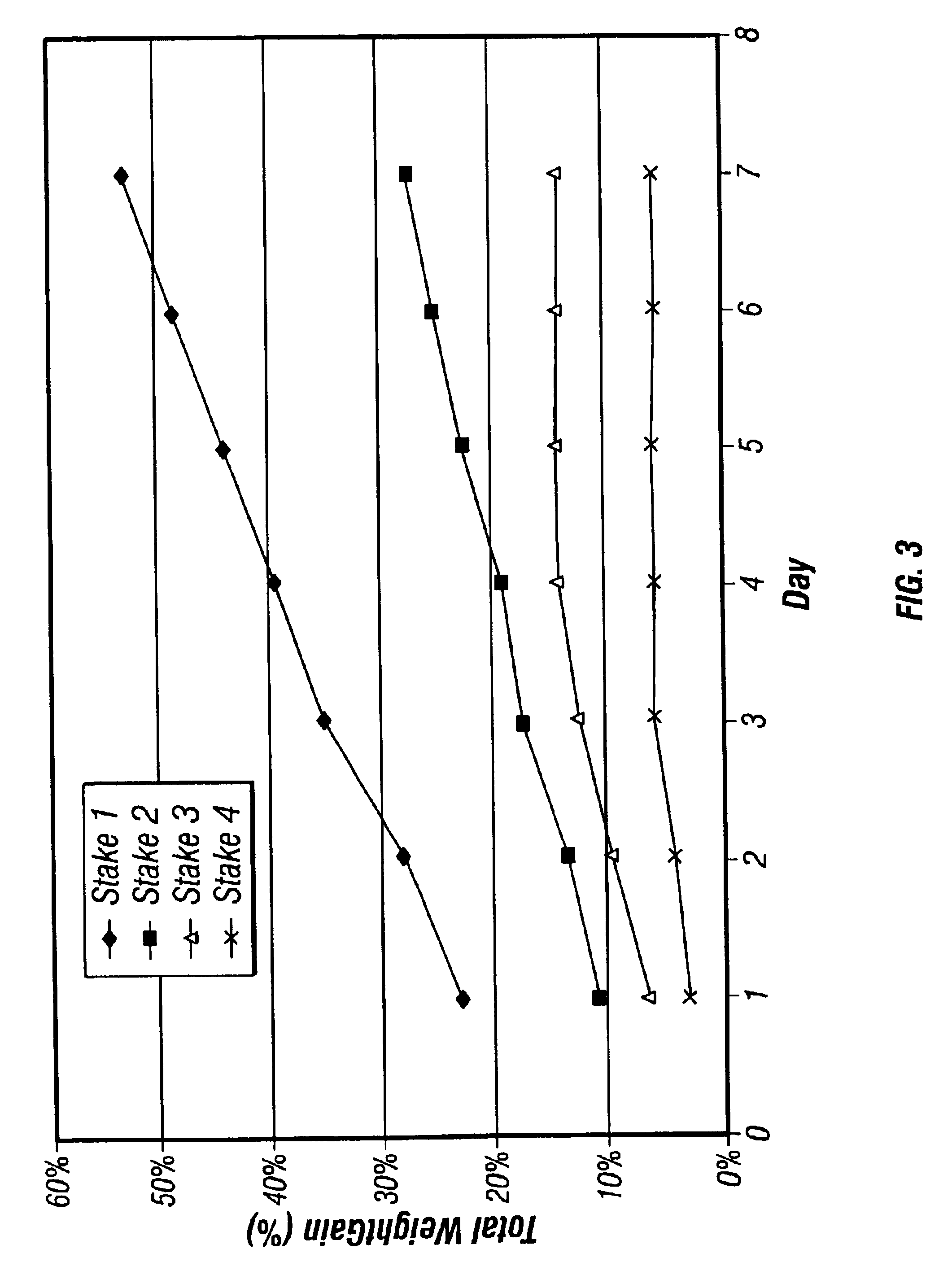

Trailer flooring with hotmelt coating

ActiveUS20050266200A1Broaden applicationBonding is affectedLiquid surface applicatorsSynthetic resin layered productsSolid woodHot melt

A coated wood board flooring having improved moisture protection, the flooring comprising: a plurality of solid wood components which together form the wood board, such that the wood board has a first surface and a second surface; and a coating substantially free of water and solvents, wherein the coating is applied to at least one of the first and second surfaces of the wood board.

Owner:HAVCO WOOD PRODS

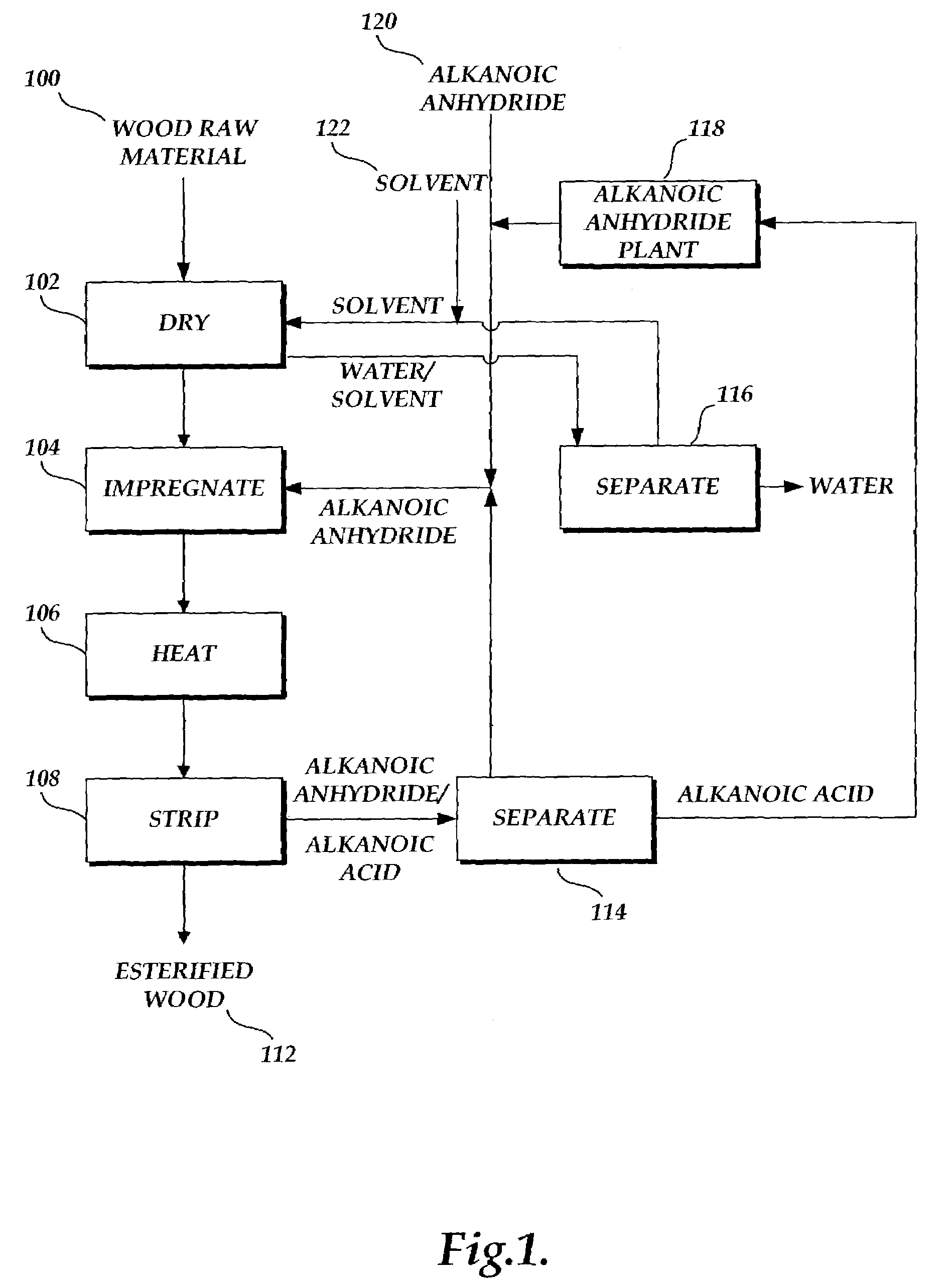

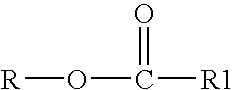

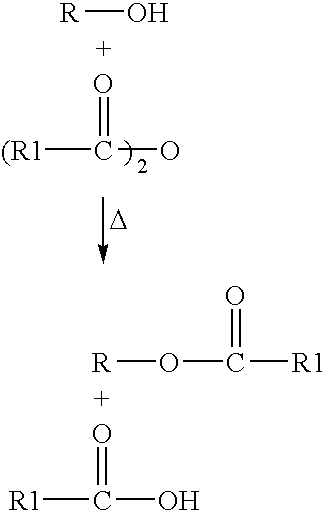

Methods for esterifying hydroxyl groups in wood

ActiveUS7300705B2Cheap methodIncreased durabilityFibre treatmentCellulosic plastic layered productsMicrowaveElectromagnetic radiation

Methods for esterifying hydroxyl groups in cellulose, hemicellulose, and lignin in wood are described, wherein the wood is chosen from loblolly, slash, shortleaf, longleaf or radiata pines. Methods can include solvent drying techniques and heating provided by electromagnetic radiation, such as microwave, and radiofrequency. Products made from the methods are described that have greater decay resistance and dimensional stability as compared with non-esterified wood products.

Owner:TITAN WOOD LTD

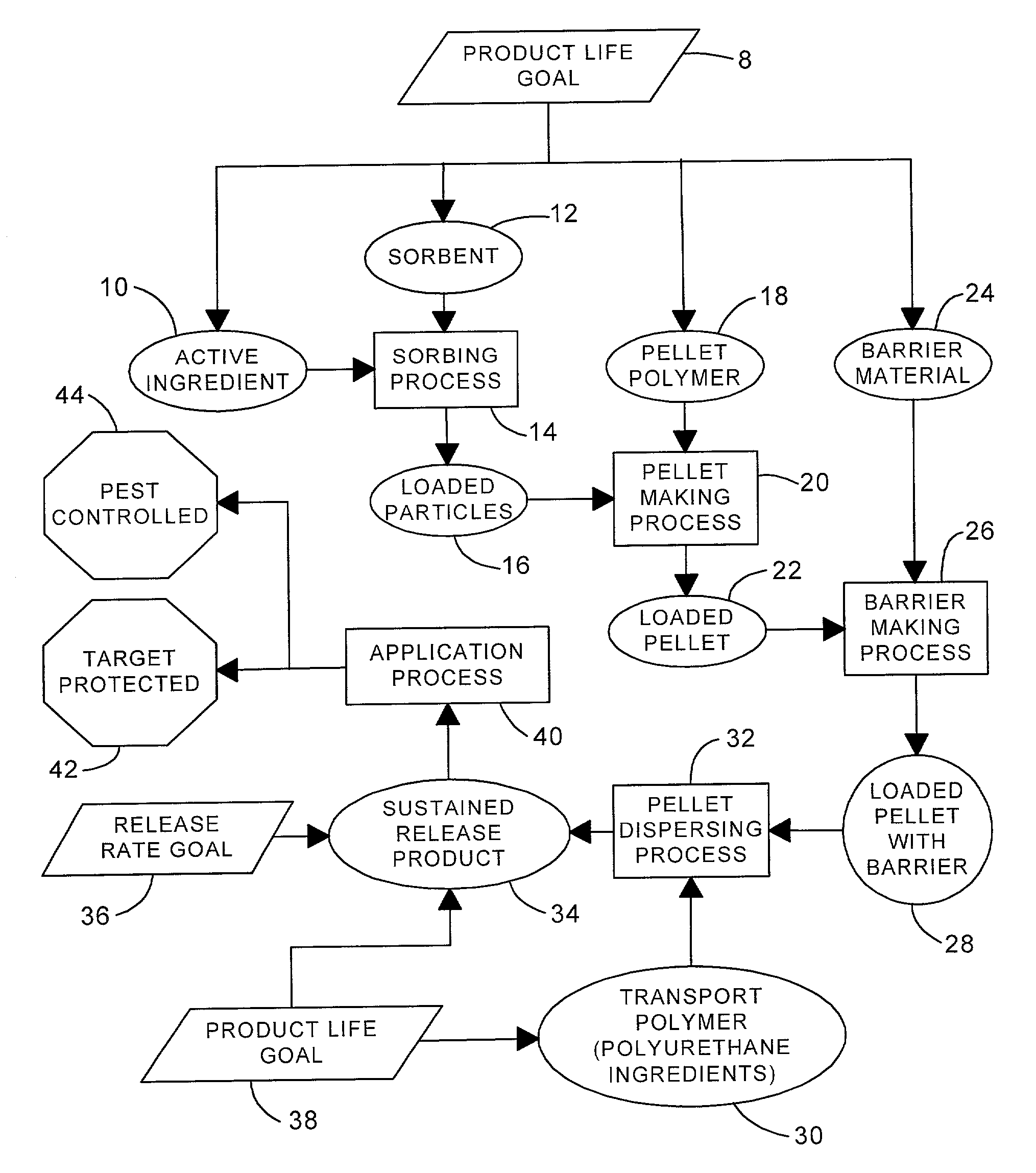

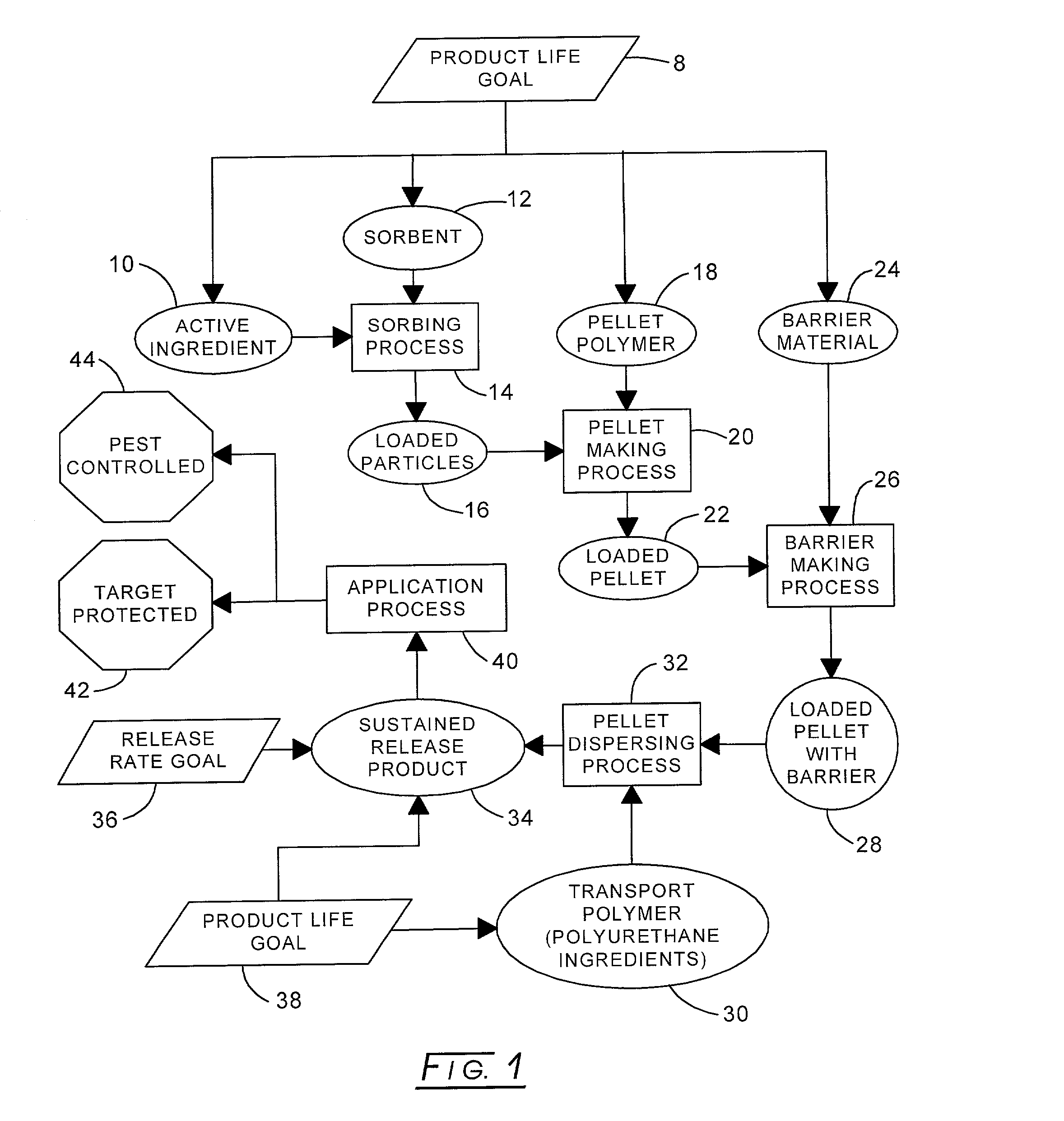

Sustained release pest control products and their applications

InactiveUS7056522B2Convenient and inexpensive methodReadily apparentBiocideLiquid surface applicatorsPolymer scienceSorbent

A method for applying a barrier to structures to prevent the infiltration of pest species (unwanted organisms) uses a (e.g., coating) composition formed from a polyurethane (e.g., film-forming) polymer system and a pellet comprising a pesticide incorporated into a sorbent and dispersed in the polyurethane polymer system. The composition protects the structure by application either to the structure or to a pathway that leads to the structure. Advantageous polymer systems include polyurethanes rich in urea linkages and predominating in aliphatic and alicyclic backbones.

Owner:BIOGUARD TECH

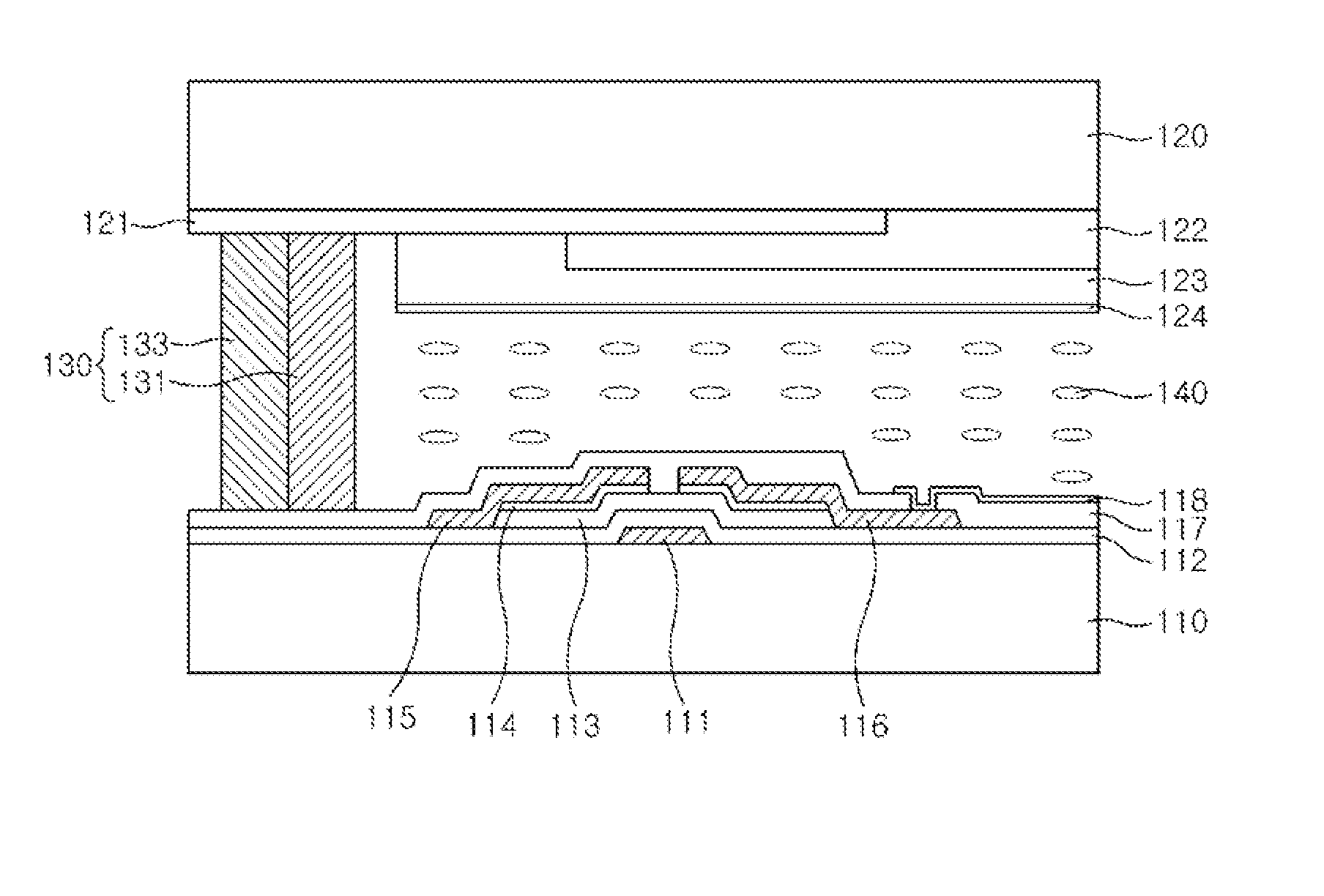

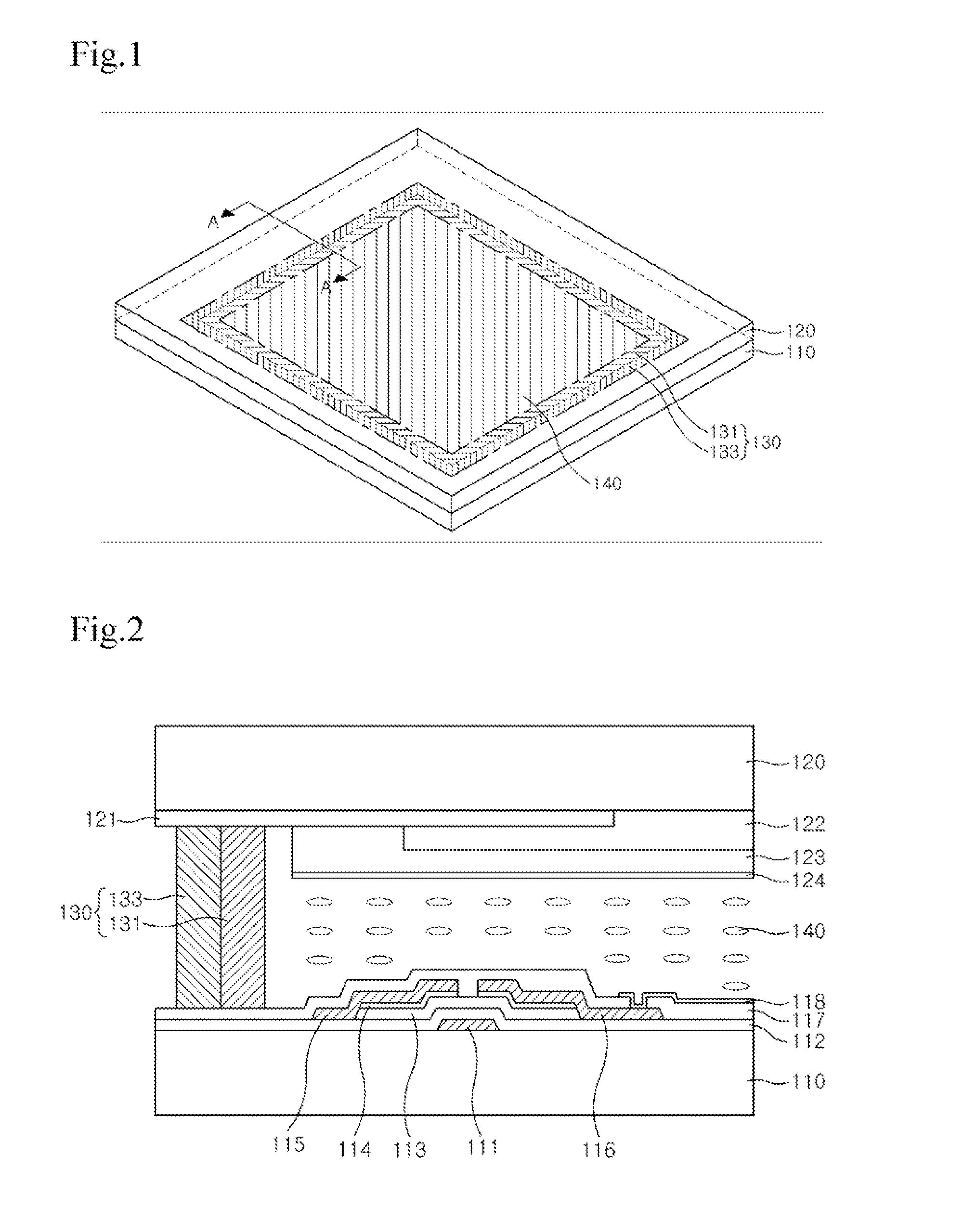

Sealant dispensing apparatus, liquid crystal display panel manufactured using the same and method of manufacturing liquid crystal display panel

InactiveUS20070095468A1Prevent bursting of liquid crystal dropping the liquid crystalAvoid it happening againLiquid crystal compositionsLiquid surface applicatorsInjection pressureLiquid-crystal display

The present invention relates to a sealant dispensing apparatus, a liquid crystal display panel manufactured using the sealant dispensing apparatus, and a method of fabricating the liquid display panel. The sealant dispensing apparatus. Comprises a body having an injection nozzle, a partition plate for dividing the interior of the body, into at least two spaces, and an injection pressure application section for applying an injection pressure to the spaces divided by the partition plate. A liquid crystal display panel manufactured using the sealant dispensing apparatus, comprises upper and lover substrates, a sealing pattern formed along edges of opposite upper and lower substrates, and liquid crystal interposed inward of the sealing pattern, wherein the sealing pattern comprises at least two kinds of sealants whose mixing ratio is changed along a widthwise direction of the sealing pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Process for treating wood and products from treated wood

InactiveUS6902767B2Increased durabilityHigh strengthMaterial nanotechnologyPretreated surfacesCelluloseAnti-degradant

Wood cellulose is treated with a reactive silicate. The reaction is done to cellulose within the wood and may be catalyzed with acid or base catalysts or a carbon silicon halogen combination which produces in situ acid catalysts or a different combination to produce an in situ base catalyst which replaces some of the molecules or atoms within the cellulose structure with silicon, boron or other hydrophobic or anti-degrading agents. Preferably an organic solvent, such as alcohol is used to accelerate the reaction with the water in the wood. Here, the hydroxyl (OH) group on some or all of the cellulose molecules is partially replaced with silicon or an alternative atom or molecule to changes the character of the wood. The process may be modified to insert a preliminary step of adding a reactive agent to be locked into the wood. Manufacturing techniques to enhance the process using ultrasound or other wave generating techniques are also taught.

Owner:D & L +1

Sustained release pest control products and their applications

InactiveUS20060127435A1Convenient and inexpensive methodSlow release rateBiocideLiquid surface applicatorsPest controlColloid

A method for applying a barrier to a structure to prevent the infiltration of pest species includes providing a composition and associating the coating composition with the structure. The composition is formed from a polymer component having dispersed therein beads formed from colloidal clay and adsorbed pest control agent. Colloidal clays (e.g., nano-clays) adsorb more pest control agent that do standard clays and releases the adsorbed pest control agent at a slower rate than do standard clays.

Owner:BIOGUARD TECH

Process for treating wood and products from treated wood

Wood cellulose is treated with a reactive silicate. The reaction is done to cellulose within the wood and may be catalyzed with acid or base catalysts or a carbon silicon halogen combination which produces in situ acid catalysts or a different combination to produce an in situ base catalyst which replaces some of the molecules or atoms within the cellulose structure with silicon, boron or other hydrophobic or anti-degrading agents. Preferably an organic solvent, such as alcohol is used to accelerate the reaction with the water in the wood. Here, the hydroxyl (OH) group on some or all of the cellulose molecules is partially replaced with silicon or an alternative atom or molecule to changes the character of the wood. The process may be modified to insert a preliminary step of adding a reactive agent to be locked into the wood. Manufacturing techniques to enhance the process using ultrasound or other wave generating techniques are also taught.

Owner:D & L +1

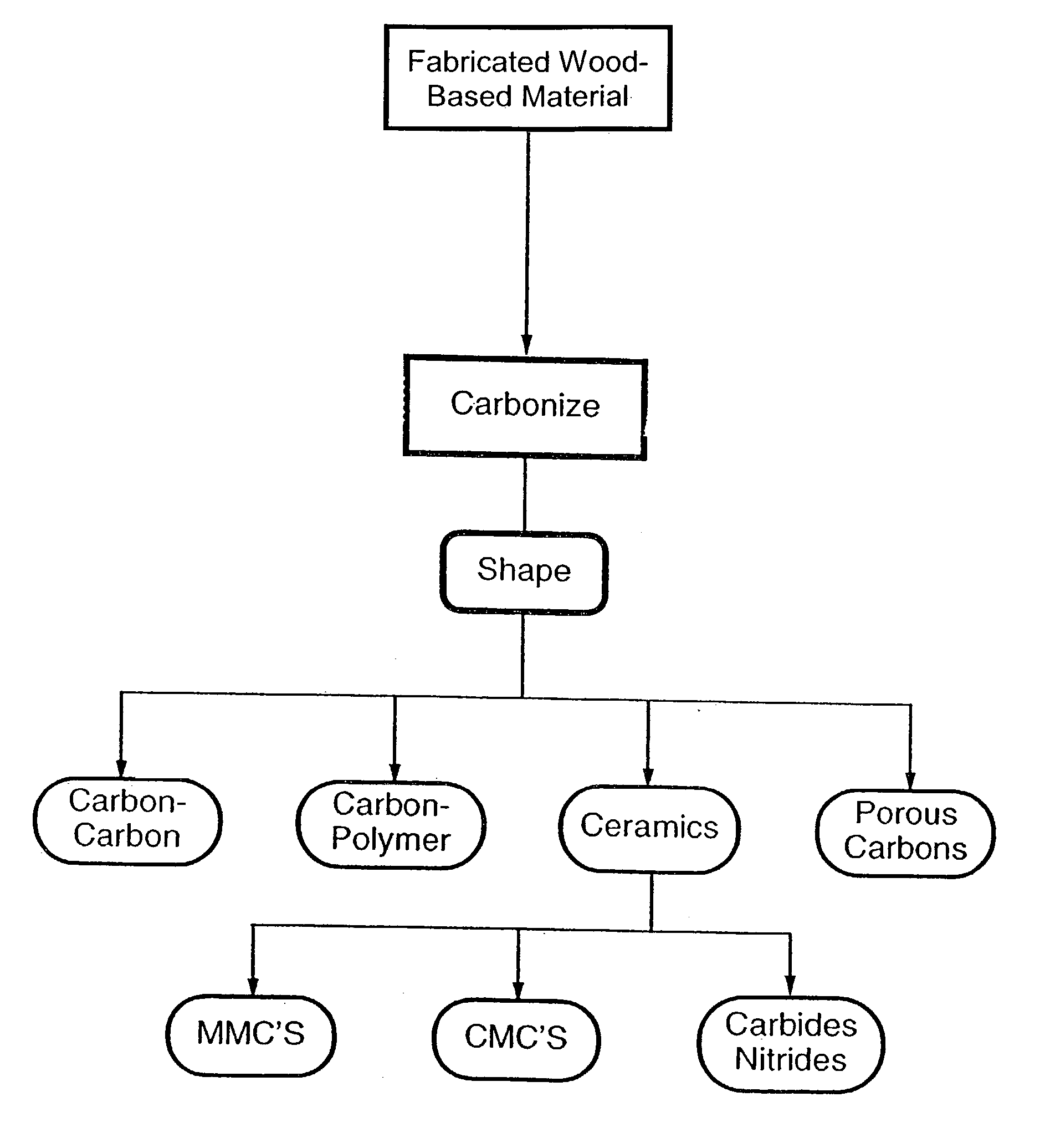

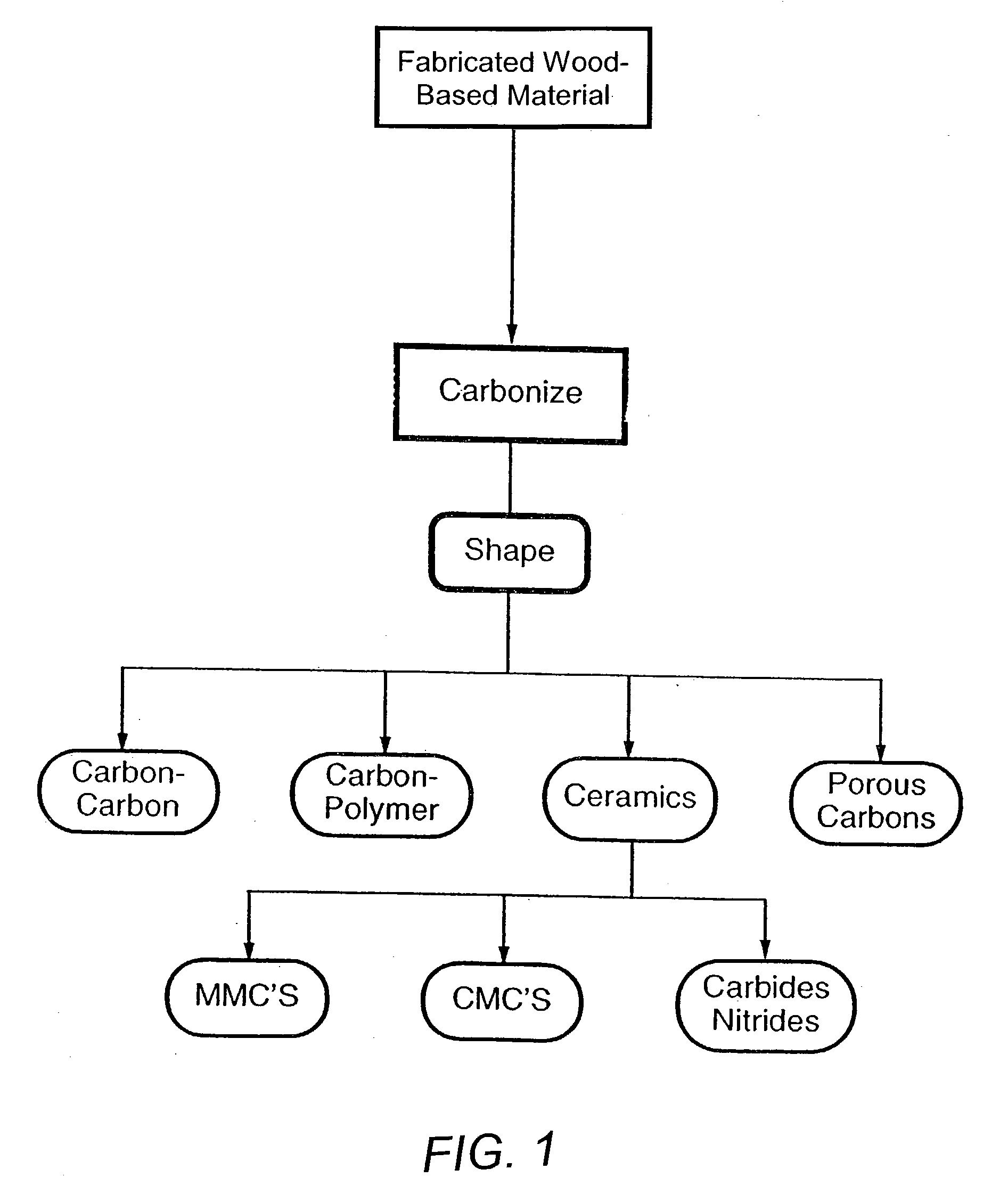

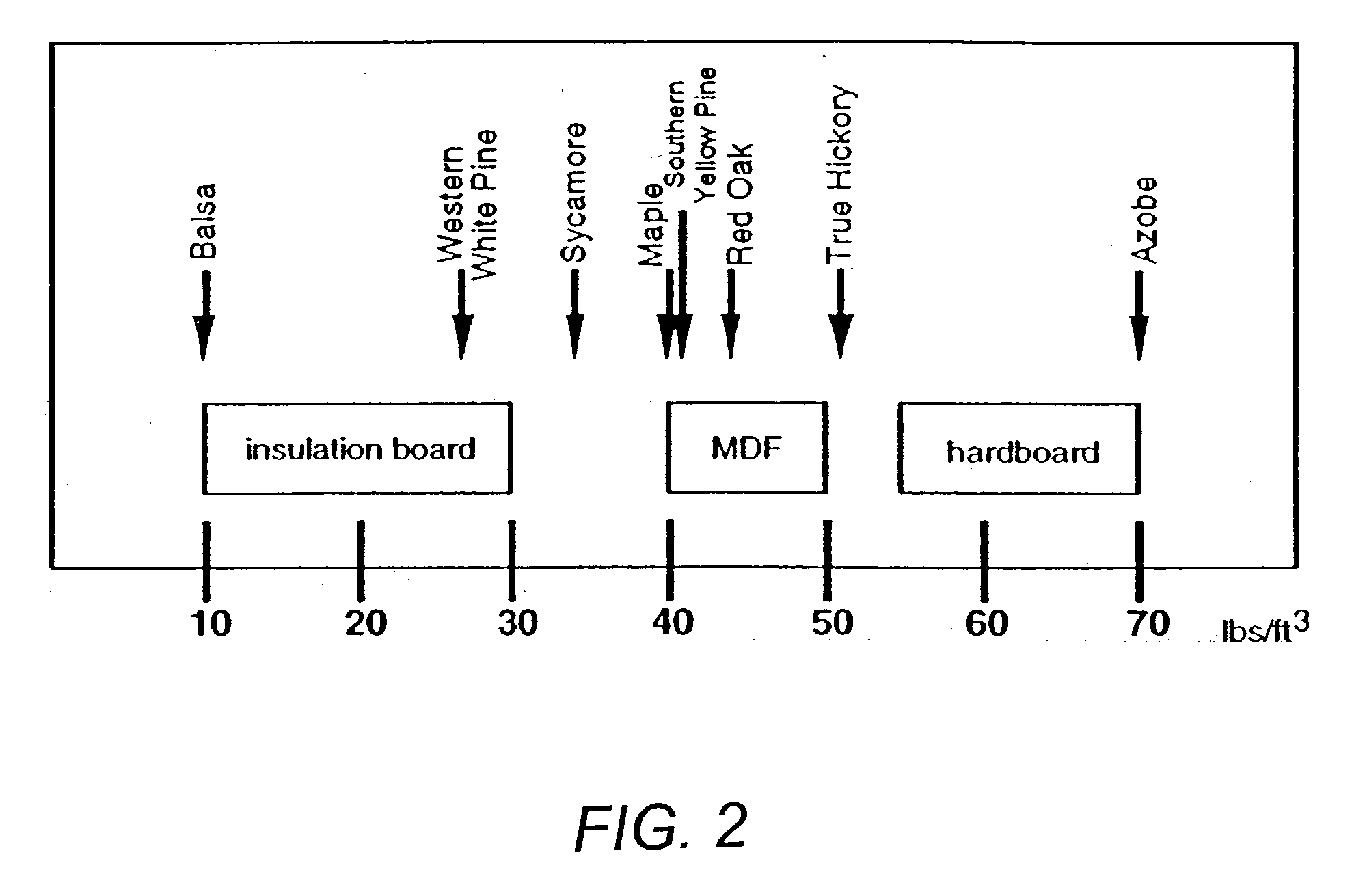

Carbonized wood-based materials

A method of carbonizing fabricated wood-based materials, such as wood composition board, is disclosed. Fabricated wood-based material is used as a precursor material, which is carbonized under controlled temperature and atmosphere conditions to produce a porous carbon product having substantially the same cellular structure as the precursor fabricated wood-based material. The porous carbonized product may be used for various applications such as filters, fuel cell gas separators, and battery electrodes, or may be further processed to form carbon-polymer or carbon-carbon composites. The carbonized product may also be converted to a ceramic such as silicon carbide. Additional processing may be used to form ceramic-metal or ceramic-ceramic composites.

Owner:NAGLE DENNIS C +1

Wood composites, methods of production, and methods of manufacture thereof

ActiveUS7803855B2Monocarboxylic acid ester polymer adhesivesProtein adhesivesOrganic chemistryAdhesive bonding

An adhesive binder comprising a phenol-formaldehyde resin, polyvinyl ester resin, and a protein is disclosed. The adhesive binder is useful for preparing wood composites.

Owner:HEXION INC

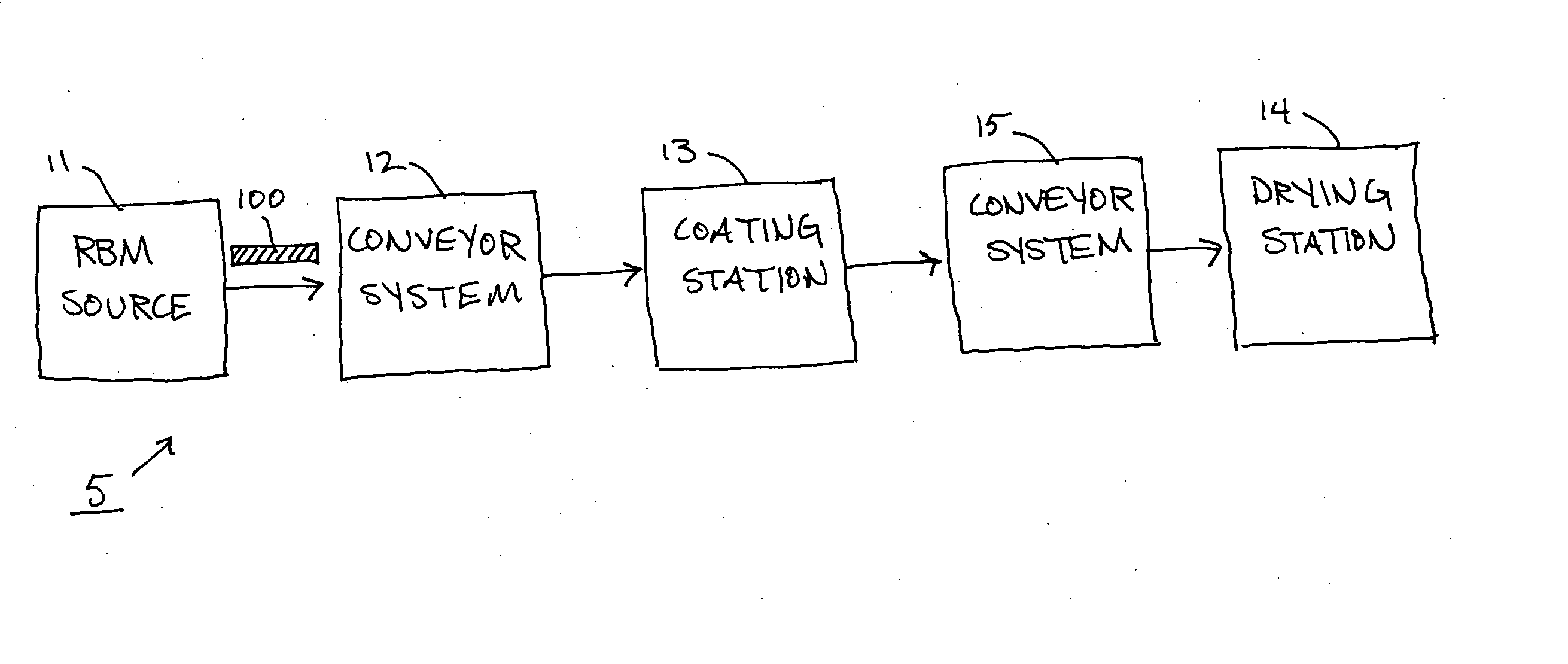

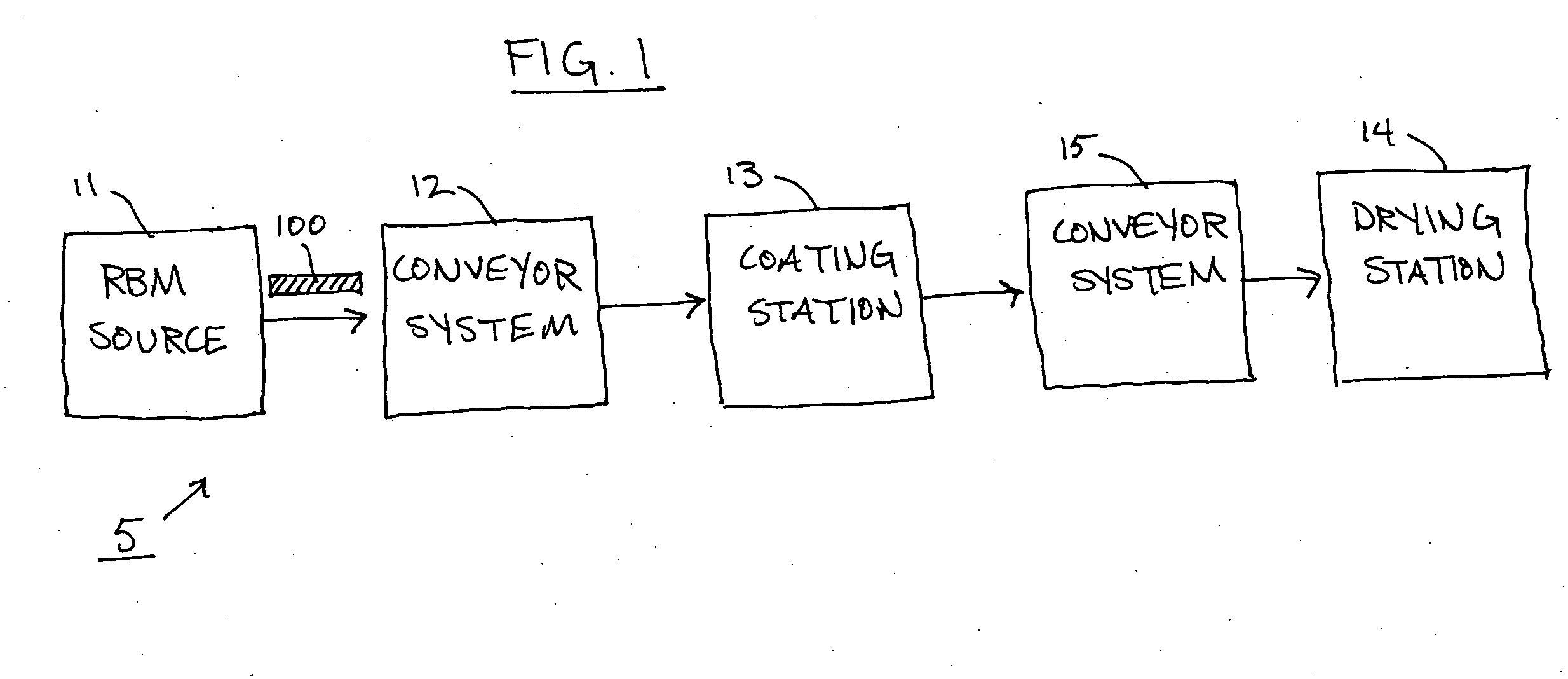

Systems and methods for manufacturing, treating, and selling raw building materials

InactiveUS20050053797A1Facilitate pre-coatingPrevent and impede fungal growthPretreated surfacesCoatingsRaw materialCoating

A method and apparatus for applying a UV-curable, anti-fungal coating to raw building materials, and a business method for selling said coated raw building materials is described. The method may include supplying a volume of raw building materials to a conveyor system that conveys the raw building materials through a coating station wherein a UV-curable, anti-fungal coating is applied to the raw building materials. The conveyor system then conveys the coated raw building materials through a drying station, wherein a source of radiation, such as UV lamps, irradiate the raw building material to cure the coating. In addition to its anti-fungal properties, the coating, when dry, may mask cosmetic irregularities and provide a uniform appearance to the raw building materials, while allowing lumber grade stamps to remain visible.

Owner:RUMPH SCOTT W +1

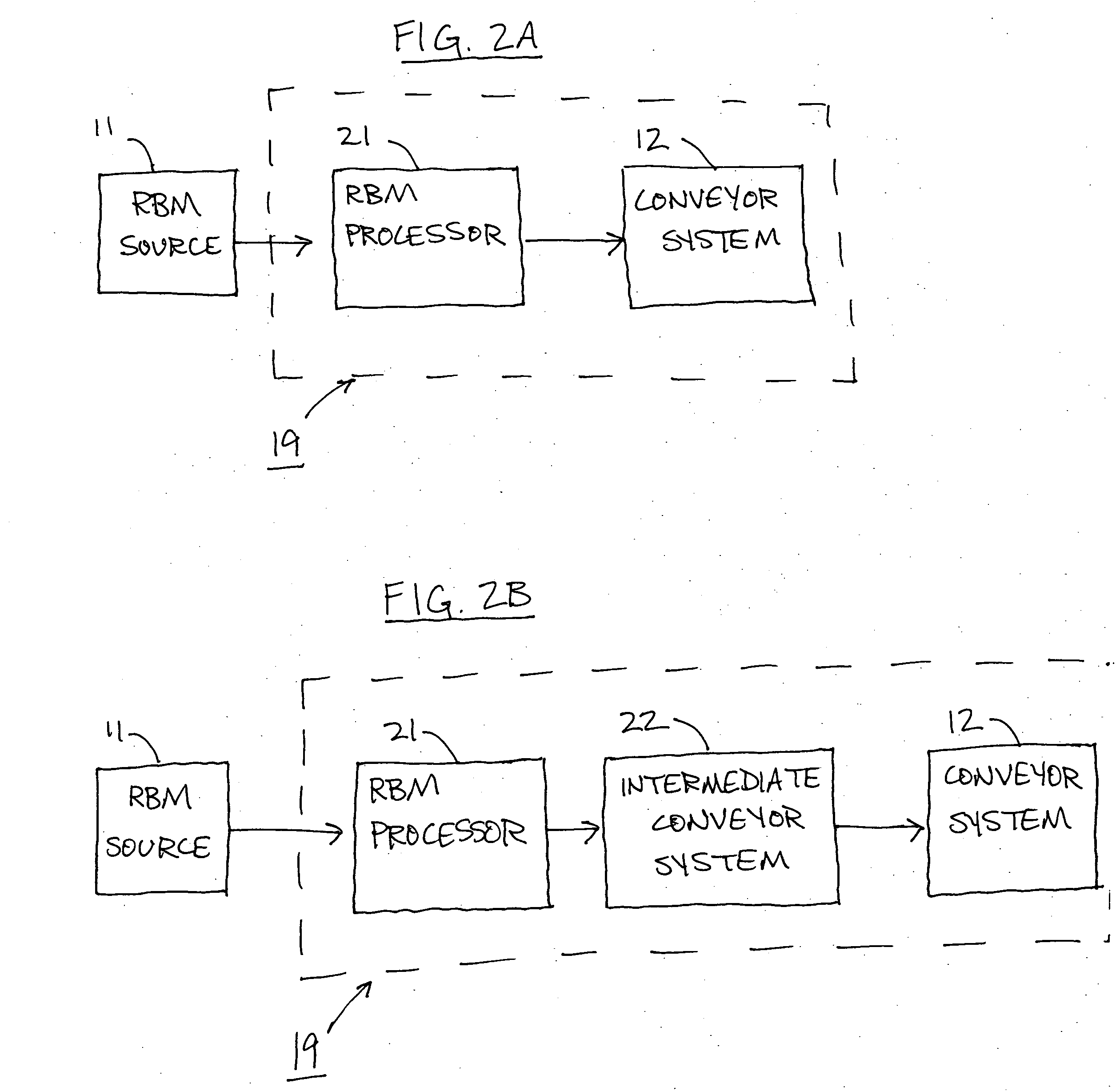

Wood treatment composition and method of use

A wood treatment composition for the preservation of wood comprises a mixture of creosote and a polymer which is miscible with the creosote at about 200° F. and does not substantially phase-separate when the wood treatment composition is under ambient conditions. The polymer may include, but is not limited to, ethylene vinyl acetate copolymers, ethylene methyl acrylate copolymers, ethylene ethyl acrylate copolymers, ethylene butyl acrylate copolymers, ethylene acrylic acid copolymers, ethylene methacrylic acid copolymers, ethylene methyl methacrylic acid copolymers, ethylene styrene interpolymers, styrene acrylic acid copolymers, styrene methacrylic acid copolymers, styrene methyl acrylate copolymers, styrene butadiene styrene block copolymers, styrene ethylene butylene styrene block copolymers, or a blend thereof. Preferably, the creosote is present in an amount of at least 50 percent by weight of the composition. Such compositions can be used to treat wood surfaces to prolong the service life of the wood.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com