Compositions and methods for treating cellulose-based materials with micronized additives

a technology of additives and cellulose, applied in the field of compositions and methods for treating cellulose-based materials with micronized additives, can solve the problems of environmental damage, leaching additives, residue bleeding, etc., and achieve the effects of reducing cost, reducing cost, and reducing cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Six hundred grams of red iron oxide, 400 g yellow iron oxide and 10 g carbon black are added to a container containing 2850.0 g of water and 150 g of a commercially available dispersant. The mixture is mechanically stirred for about 20 minutes and then added to a grinding mill. The sample is ground for about 1 hour and a stable dispersion is obtained. The particle size of the dispersed product can be analyzed by Horiba LA-910 Particle Size Distribution Analyzer (PSDA). The average particle size is preferably 0.3 microns with a distribution range of 0.04 um to 1.5 um.

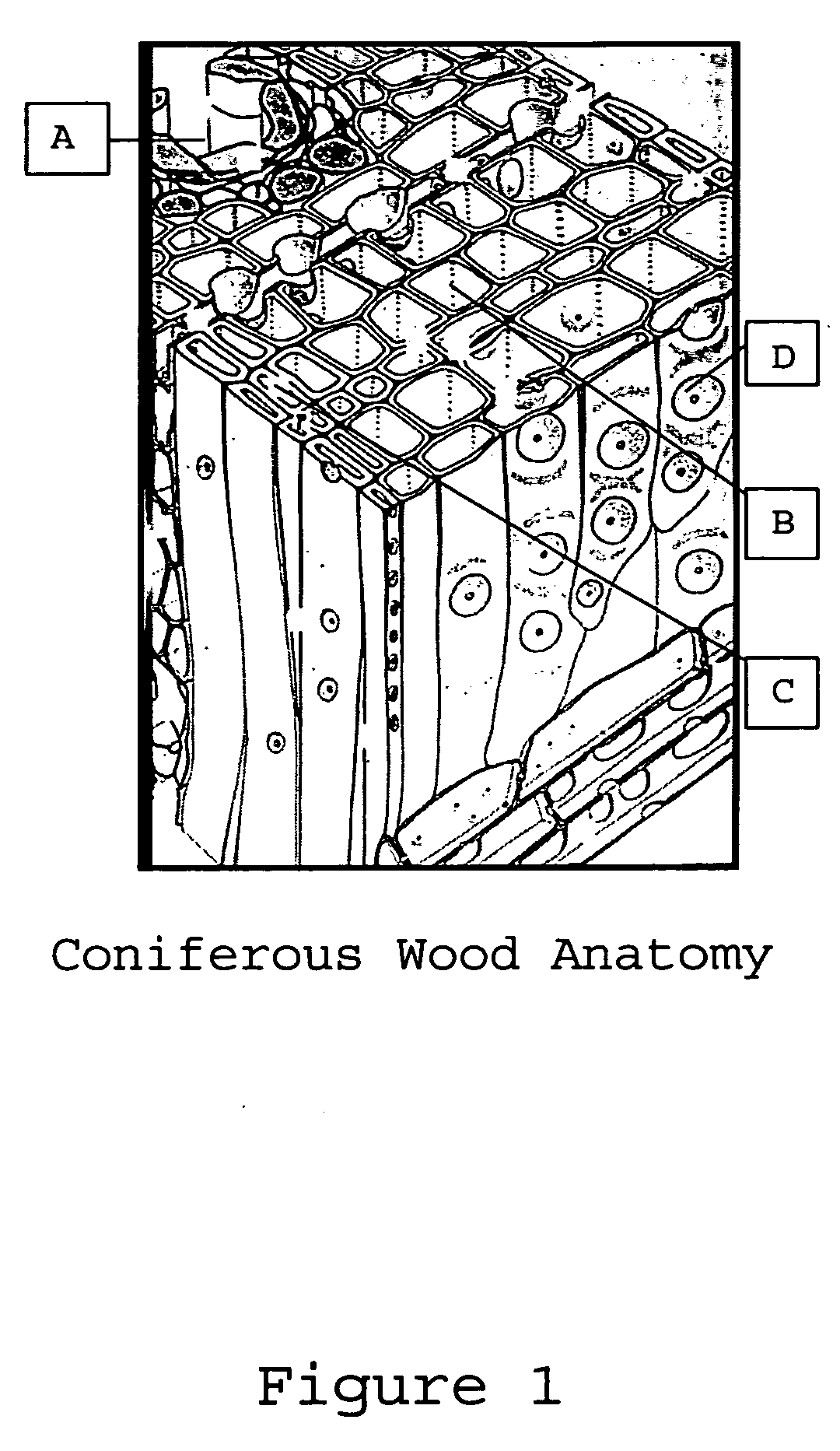

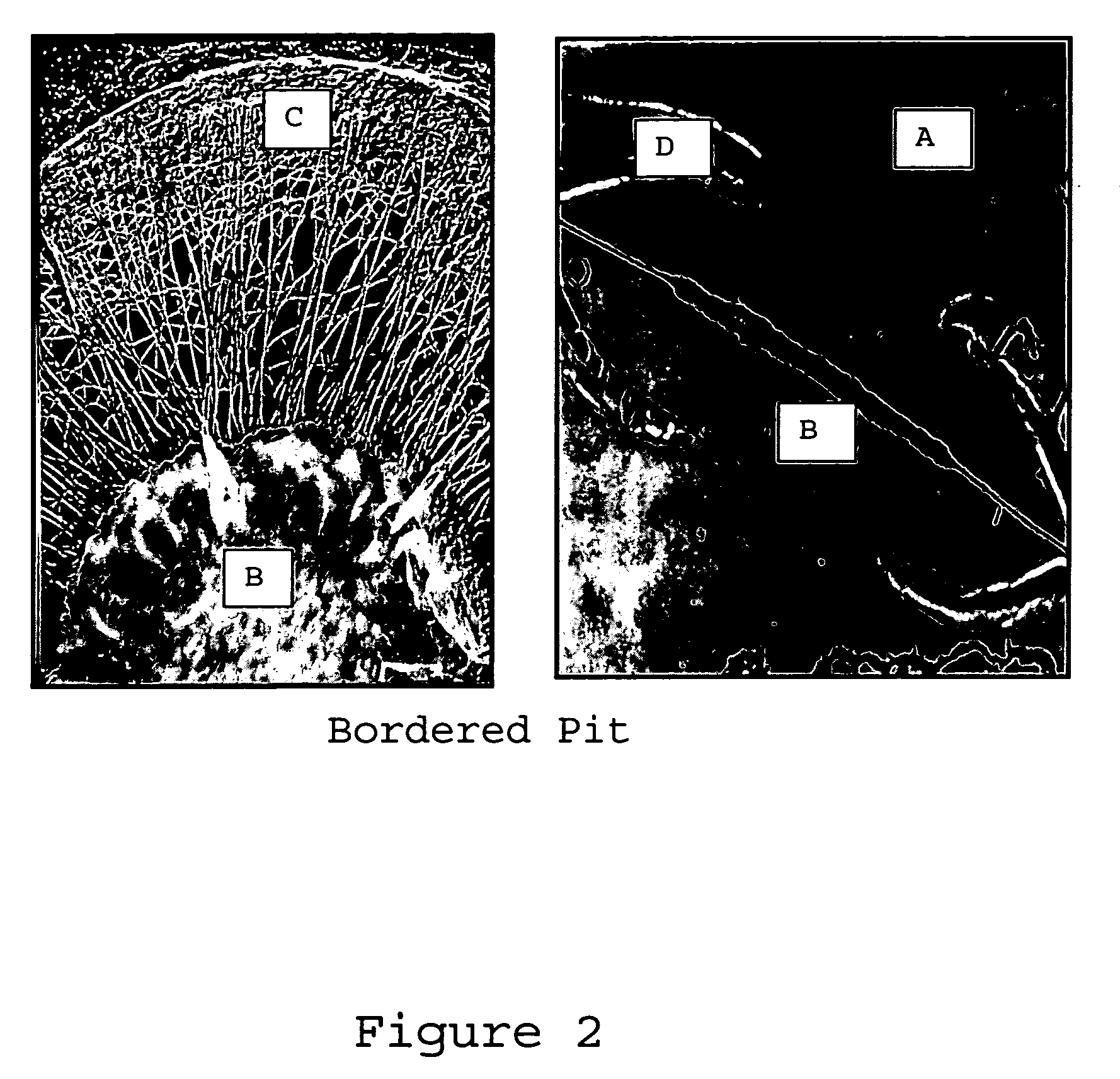

[0043] The resulting brown iron oxide dispersion can be diluted with water to make a treating fluid containing 1.0% iron oxide. The treating fluid can be used to treat southern pine samples using a full cell process. The treated samples can be oven dried and tested to check uniform distribution of iron oxide throughout the cross sections and for the presence of a uniform brown color.

example 2

[0044] Nine hundred grams of red iron oxide and 100 g yellow iron oxide are added to a container containing 1550 g of water and 150 g of a commercially available dispersant. The mixture is mechanically stirred for about 20 minutes and then added to a grinding mill. The sample is ground for about 1 hour and a stable dispersion is obtained. The particle size of the dispersed product can be analyzed by Horiba LA-910 Particle Size Distribution Analyzer (PSDA). The average particle size is preferably 0.3 microns with a distribution range of 0.005 um to 1.5 um.

[0045] The resulting dispersion can be diluted with water to make a treating fluid containing 0.5% total iron oxides. The treating fluid can be used to treat southern pine samples using a full cell process. The treated samples can be oven dried and tested to check uniform distribution of iron oxide throughout the cross sections and for the presence of a uniform color.

example 3

[0046] Seven hundred grams of red iron oxide, 200 g yellow iron oxide and 5 g black iron oxide are added to a container containing 2050 g of water and 180 g of a commercially available dispersant. The mixture is mechanically stirred for about 20 minutes and then added to a grinding mill. The sample is ground for about 1 hour and a stable dispersion is obtained. The particle size of the dispersed product can be analyzed by Horiba LA-910 Particle Size Distribution Analyzer (PSDA). The average particle size is preferably 0.35 microns with a distribution range of 0.005 um to 2.0 um.

[0047] The resulting dispersion can be diluted with water to make a treating fluid containing 0.5% total iron oxides. The treating fluid can be used to treat southern pine samples using a full cell process. The treated samples can be oven dried and tested to check uniform distribution of iron oxide throughout the cross sections and for the presence of a uniform color.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com