Patents

Literature

2332results about How to "Reduce material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

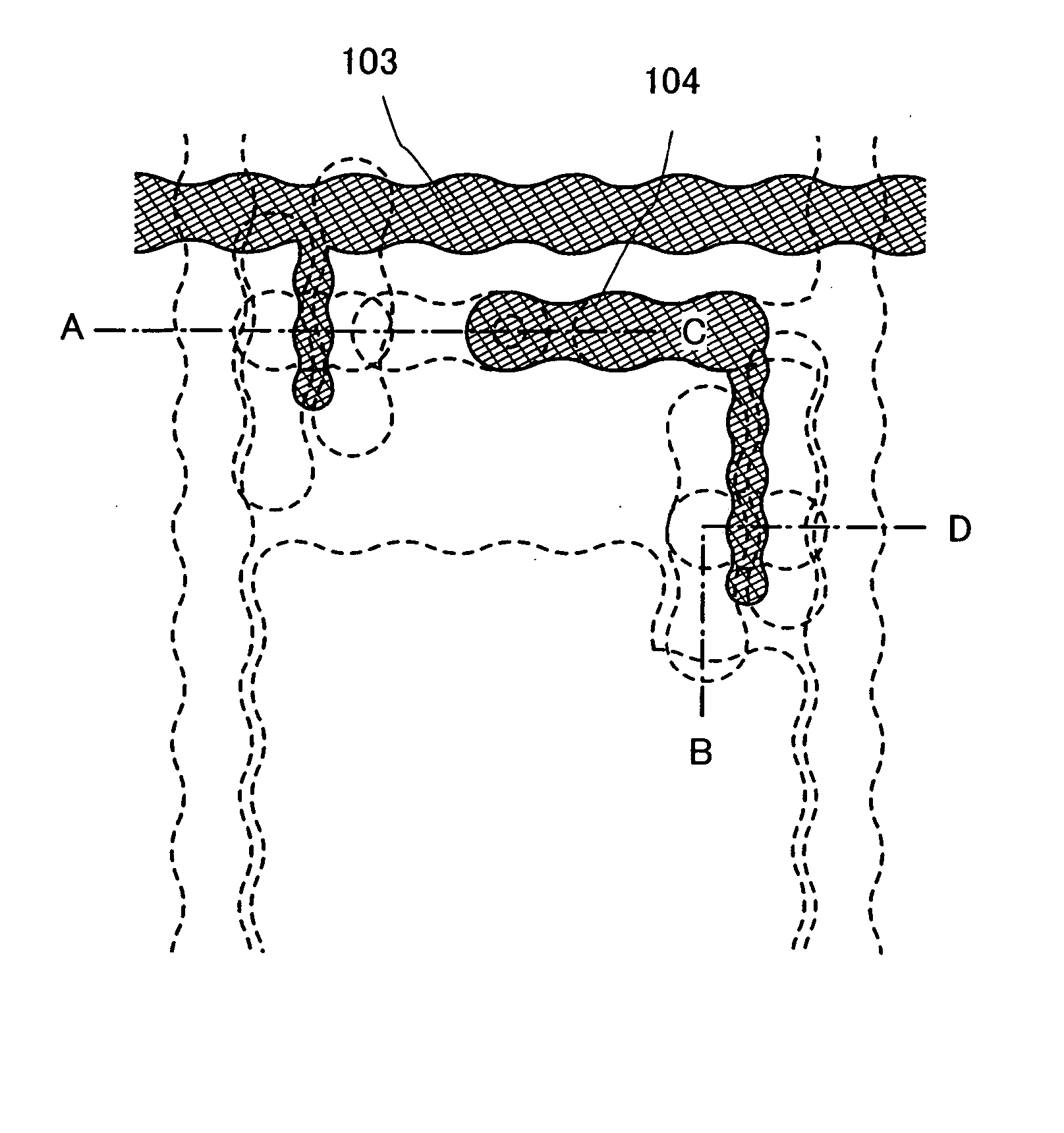

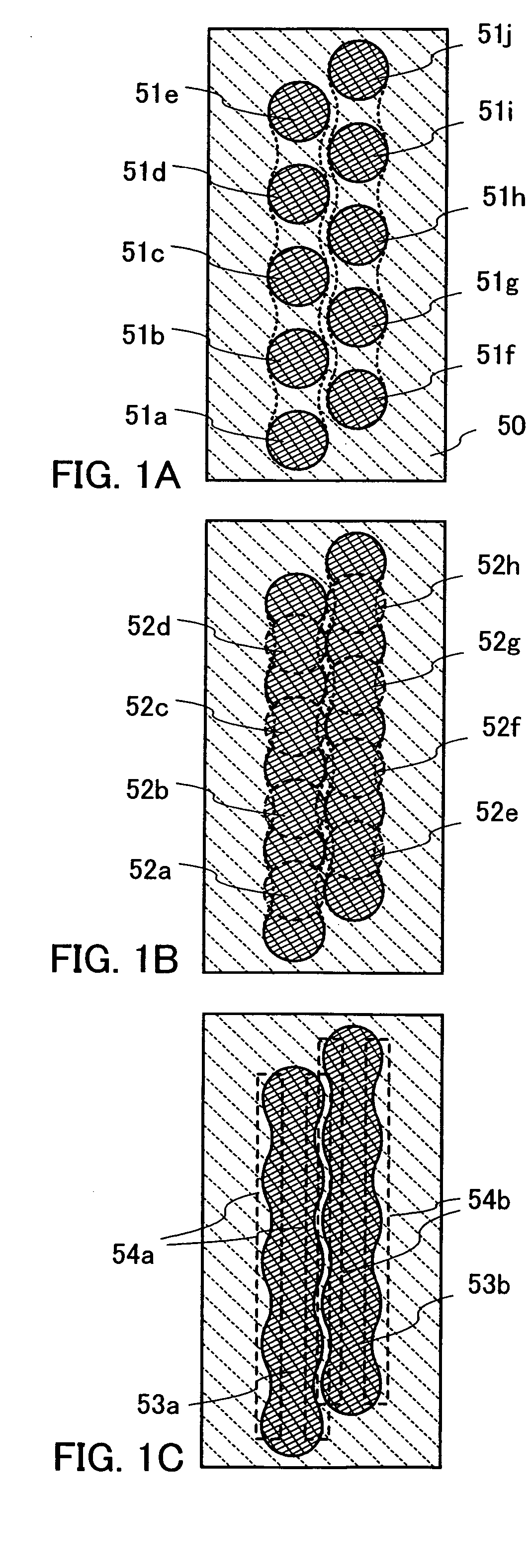

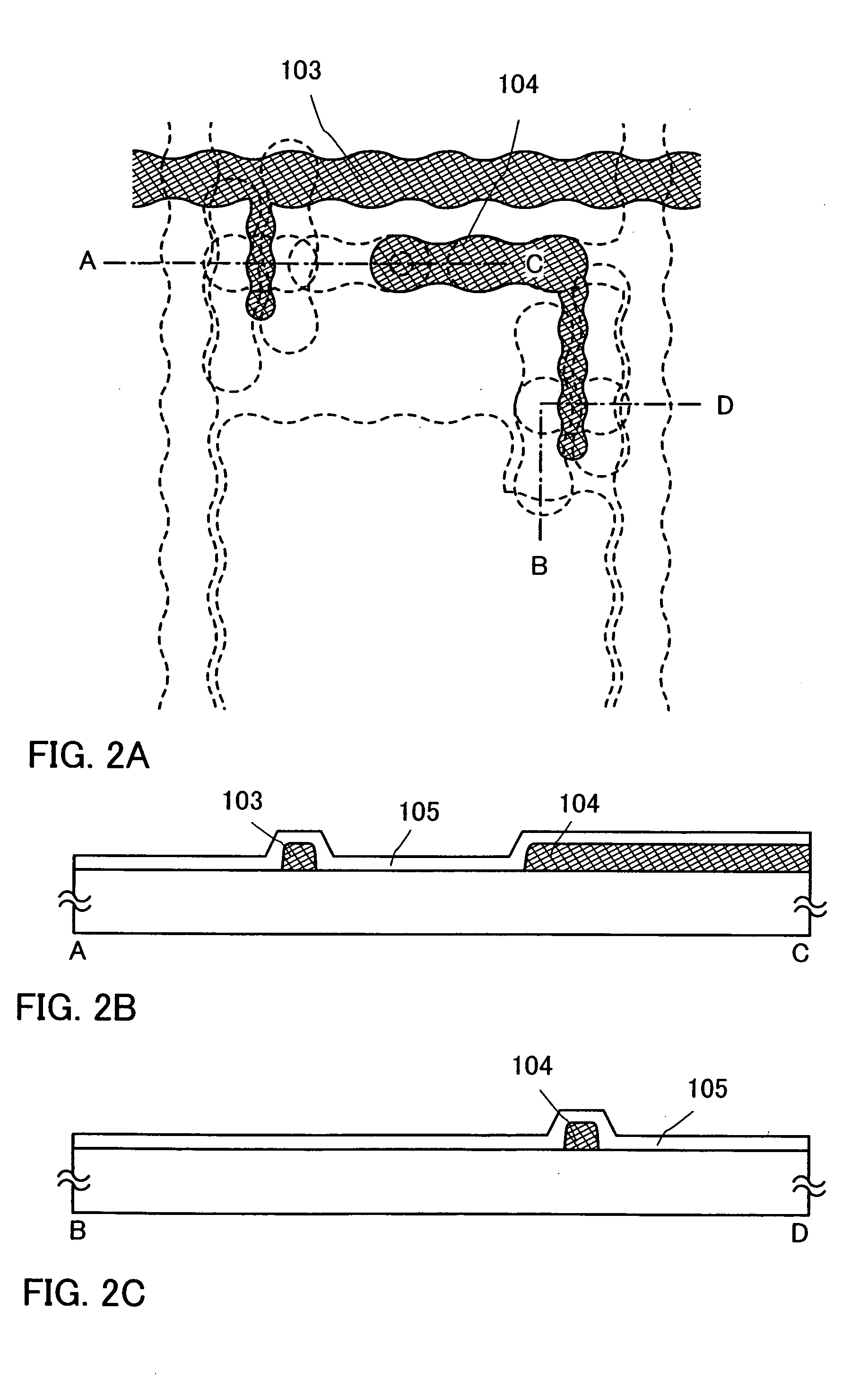

Semiconductor device, electronic device, and method of manufacturing semiconductor device

InactiveUS20060170111A1Stable formationImprove performanceSemiconductor/solid-state device detailsSolid-state devicesDevice materialShortest distance

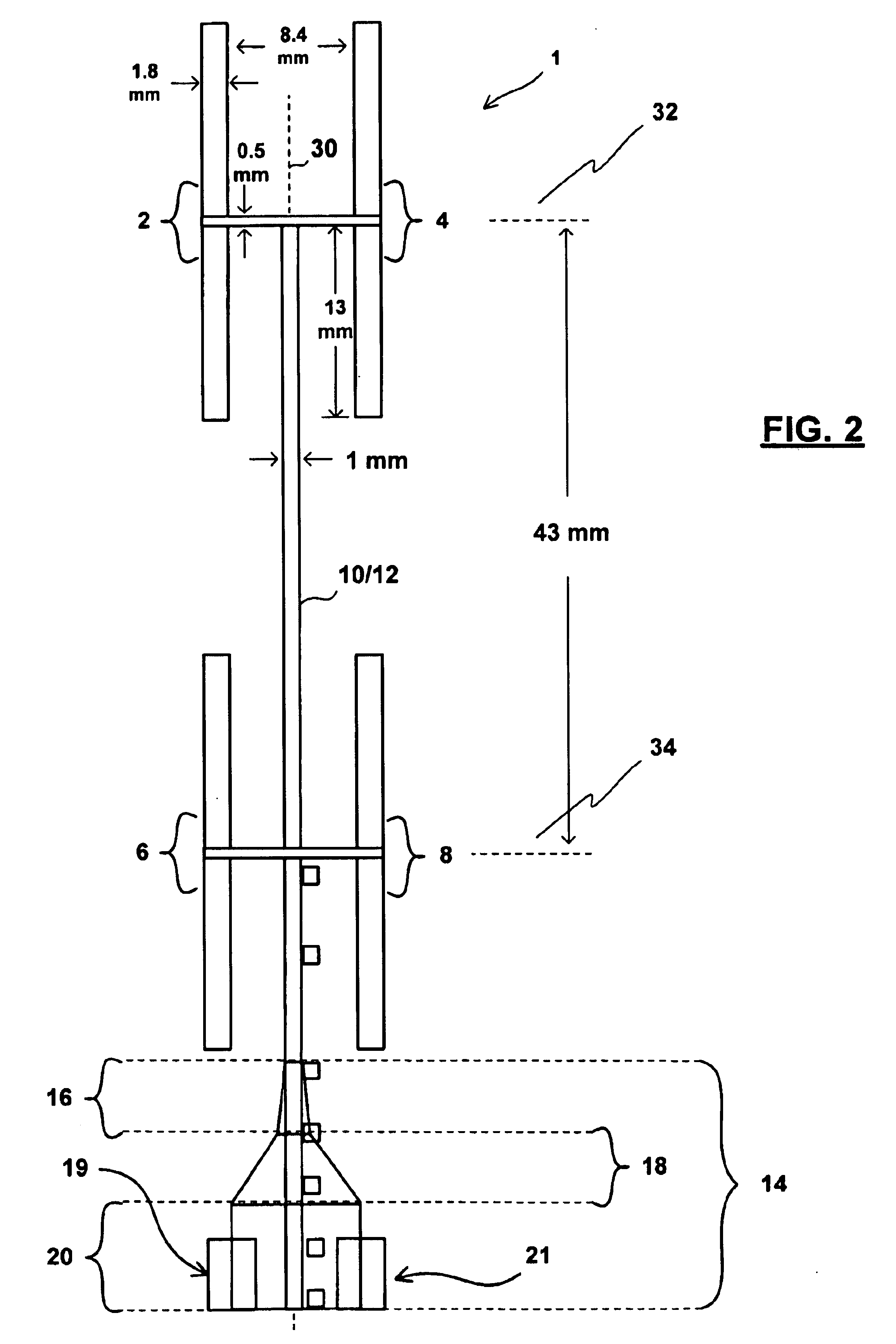

Conductive layers having knots are adjacently formed with uniform distance therebetween. Droplets of the conductive layers are discharged to stagger centers of the droplets in a length direction of wirings so that the centers of the discharged droplets are not on the same line in a line width direction between the adjacent conductive layers. Since the centers of the droplets are staggered, parts of the conductive layers each having a widest line width (the widest width of knot) are not connected to each other, and the conductive layers can be formed adjacently with a shorter distance therebetween.

Owner:SEMICON ENERGY LAB CO LTD

Carbon conductive substrate for electronic smoking article

ActiveUS20150059780A1Improve natureReduce materialSteam generation using steam absorptionTobacco pipesPorous carbonEngineering

The present disclosure provides components useful in heating, particularly heating of an aerosol precursor solution so as to vaporize the solution and form an aerosol. The disclosure particularly provides an electrically conductive, porous carbon heater. The heater may be combined with an aerosol precursor transport element that also is formed of carbon. The heater and transport element may form an atomizer that can be useful in an electronic smoking article, such as in a cartridge that is adapted for attachment to a control body. In some embodiments, the disclosure provides a cartridge of an electronic smoking article, the cartridge being formed substantially completely of carbon.

Owner:RAI STRATEGIC HLDG INC

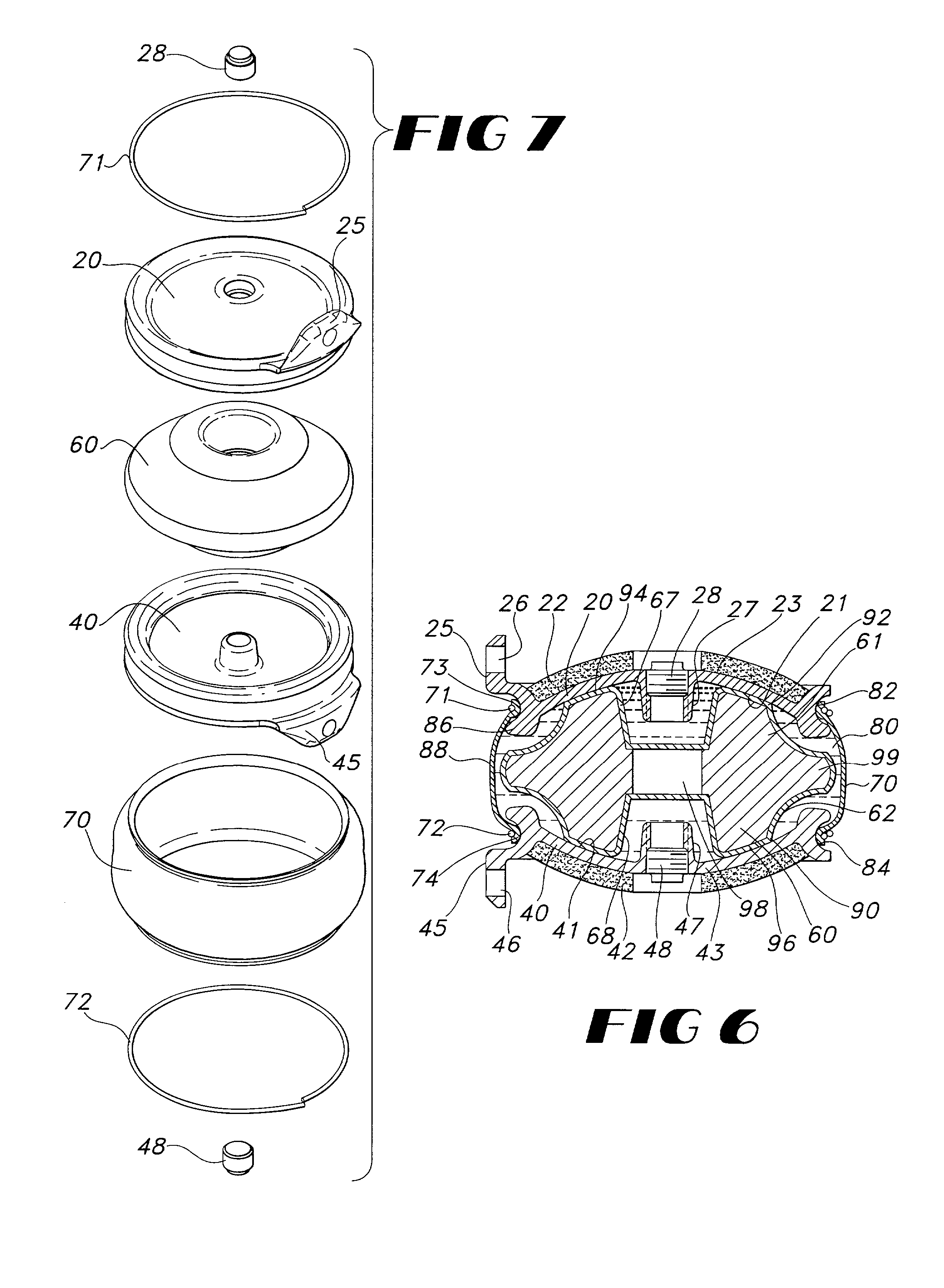

Implantable joint prosthesis

ActiveUS20020128715A1Increased durabilityImprove stabilityDiagnosticsJoint implantsIntervertebral discSurgical implant

The invention relates to a surgical implant that provides an artificial diarthroidal-like joint, suitable for use in replacing any joint, but particularly suitable for use as an intervertebral disc endoprosthesis. The invention contains two rigid opposing shells, each having an outer surface adapted to engage the surfaces of the bones of a joint in such a way that the shells are immobilized by friction between their outer surfaces and the surfaces of the bone. These outer surfaces are sufficiently rough that large frictional forces strongly resist any slippage between the outer surface and the bone surfaces in the joint. They may be convex, and when inserted into a milled concavity, are immediately mechanically stable. Desirably, the outer surfaces of the shells are adapted to allow for bony ingrowth, which further stabilizes the shells in place. The inner surfaces of the shells are relatively smooth, and adapted to slide easily across a portion of the outer surface of a central body disposed between the shells. The central body has a shape that cooperates with the shape of the inner surface of the shell so as to provide a range of motion similar to that provided by a healthy joint. A flexible sheath extends between edges of the opposing shells. The inner surface of this sheath, together with the inner surfaces of the rigid shells, defines a cavity encasing the central body. At least a portion of this cavity is filled with a fluid lubricant, further decreasing the frictional force between inner surfaces of the shell and the surface of the central body.

Owner:COMPANION SPINE LLC

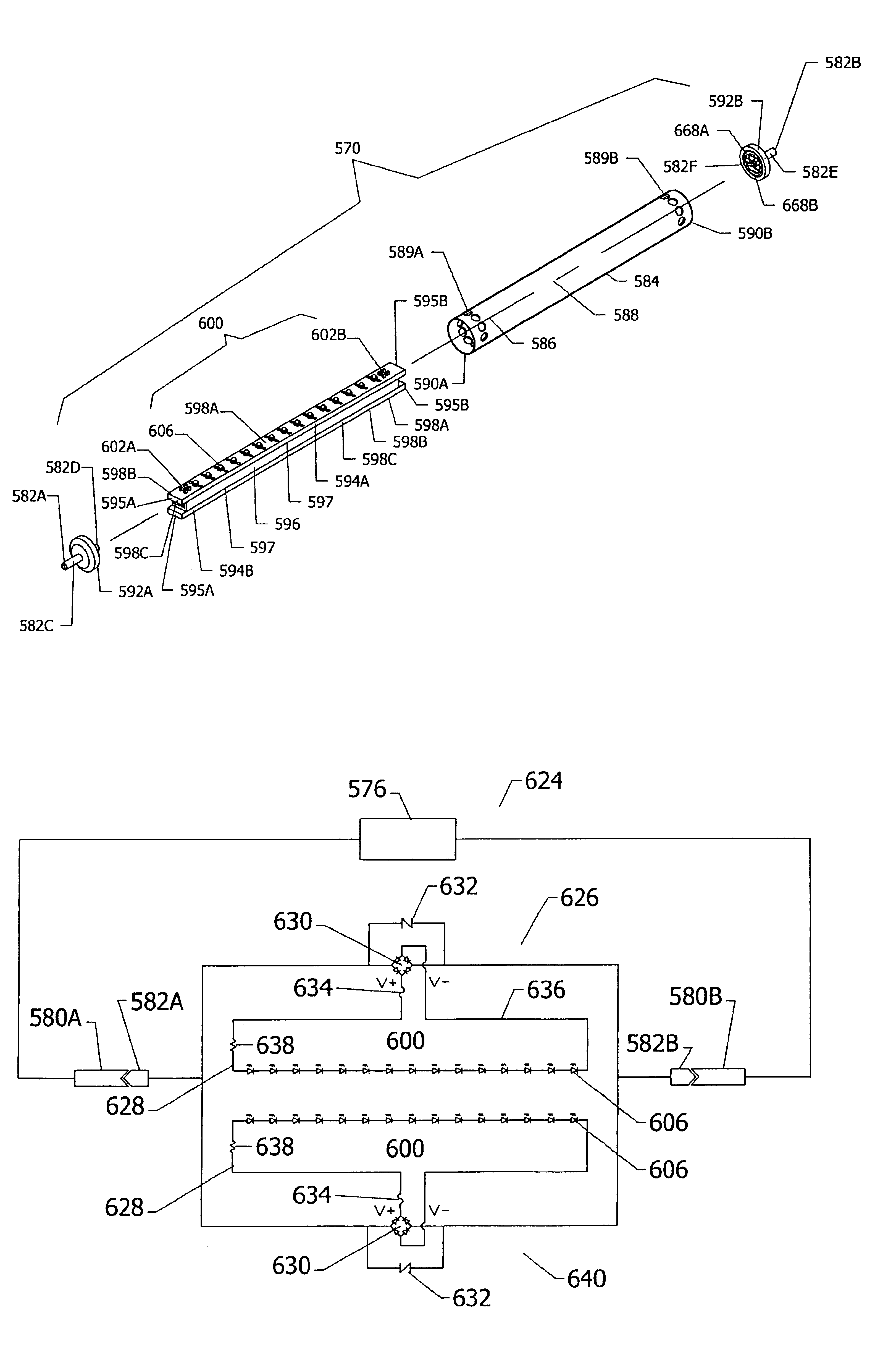

LED retrofit lamp

InactiveUS6853151B2Reduce materialReduce power consumptionPoint-like light sourceElongate light sourcesElectrical connectionLED lamp

An LED lamp for mounting to an existing fluorescent lamp fixture having a ballast assembly including ballast opposed electrical contacts, comprising a tubular wall generally circular in cross-section and having tubular wall ends with one or more LEDs positioned within the tubular wall between the tubular wall ends. An electrical circuit provides electrical power from the ballast assembly to the LED(s). The electrical circuit includes at least one metal substrate circuit board and means for electrically connecting the electrical circuit with the ballast assembly. The electrical circuit includes an LED electrical circuit including opposed electrical contacts. Each metal substrate circuit board supports and holds the one or more LEDs and the LED electrical circuit. Each metal substrate circuit board is positioned within the tubular wall between the tubular wall ends. At least one electrical string is positioned within the tubular wall and generally extends between the tubular wall ends. One or more LEDs are in electrical connection with at least one electrical string and are positioned to emit light through the tubular wall. Means for suppressing ballast voltage is included. The metal substrate circuit board includes opposed means for connecting the metal substrate circuit board to the tubular wall ends, which include means for mounting the means for connecting, and the one or more metal substrate circuit boards.

Owner:SIGNIFY HLDG BV

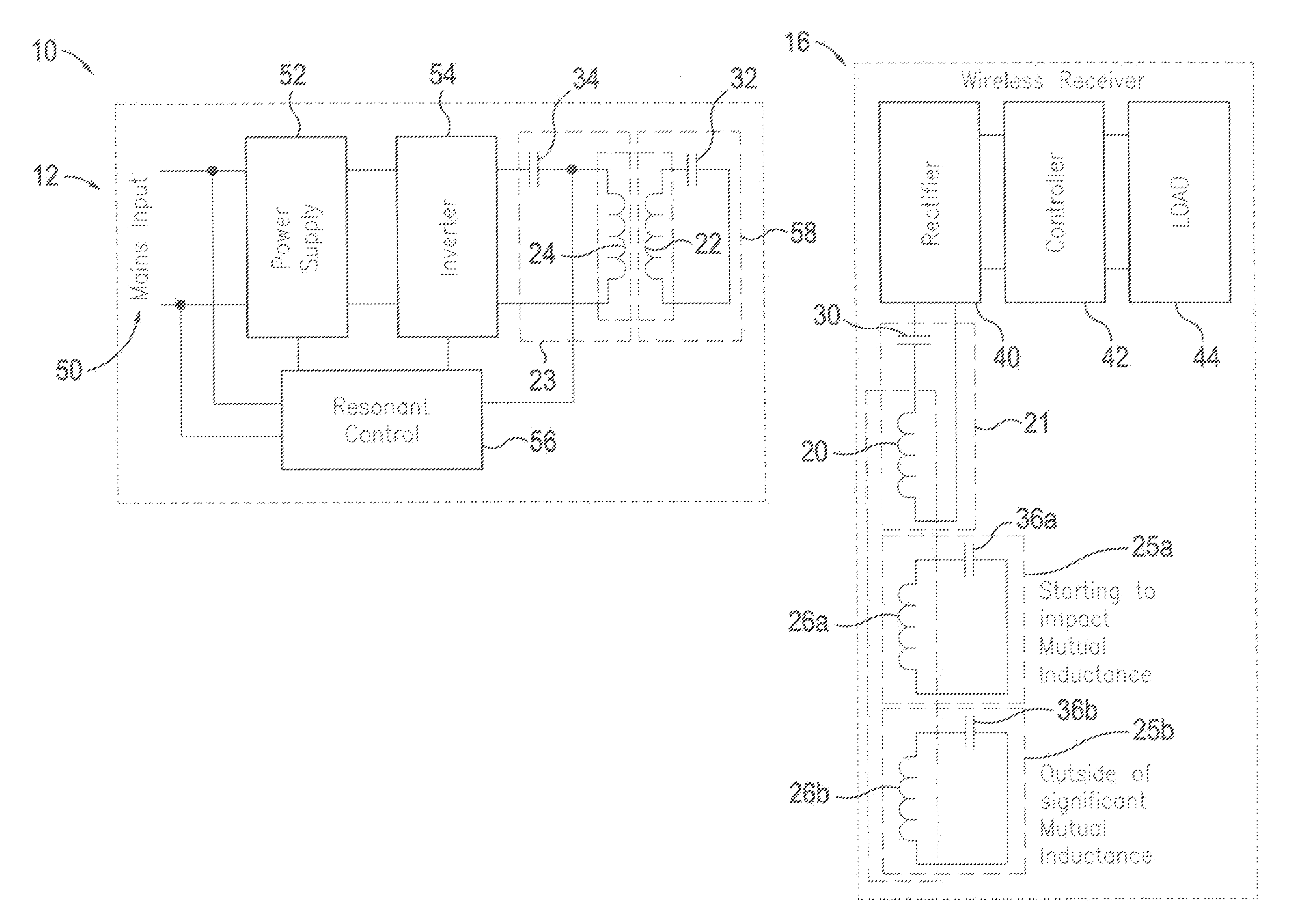

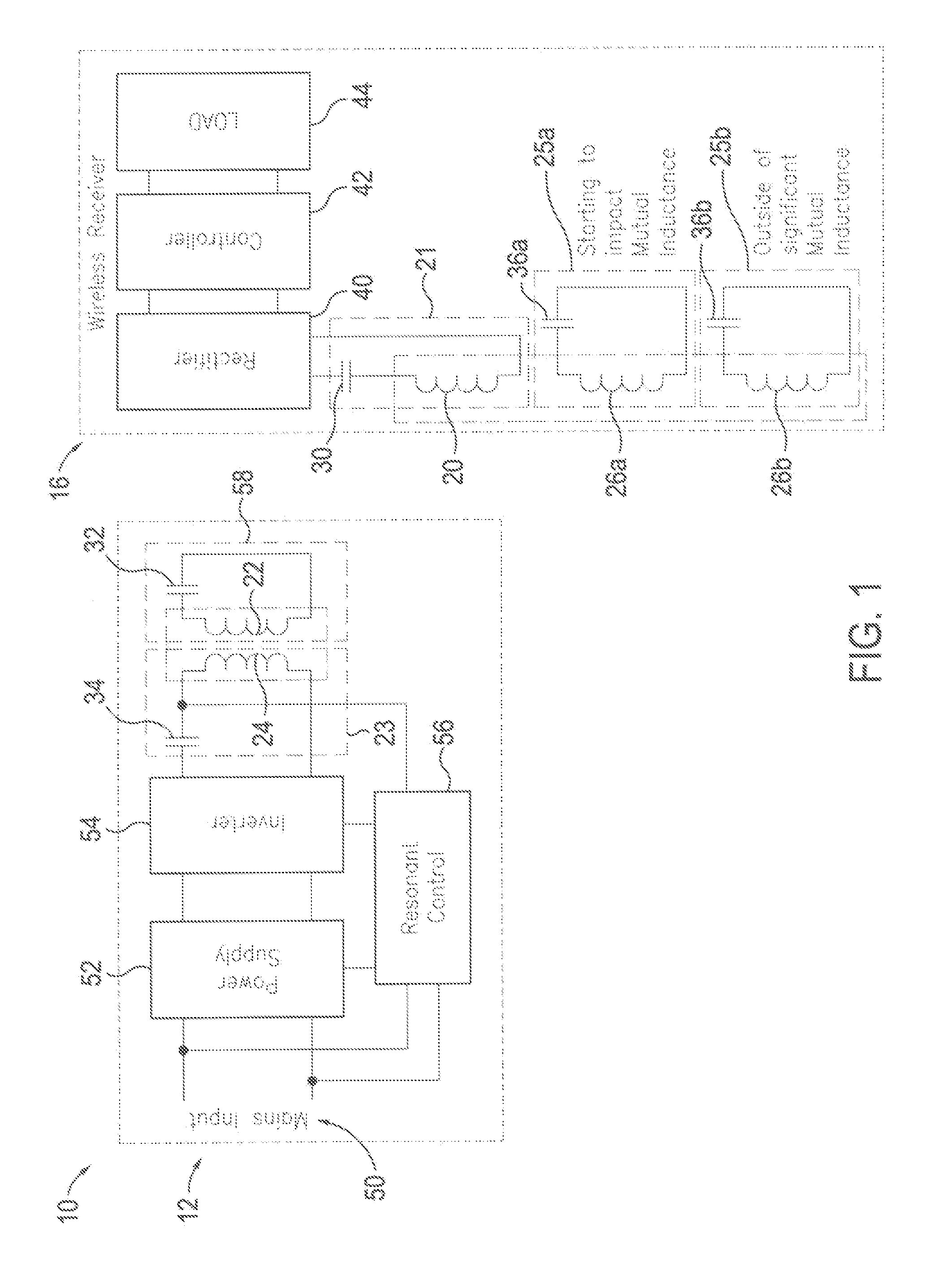

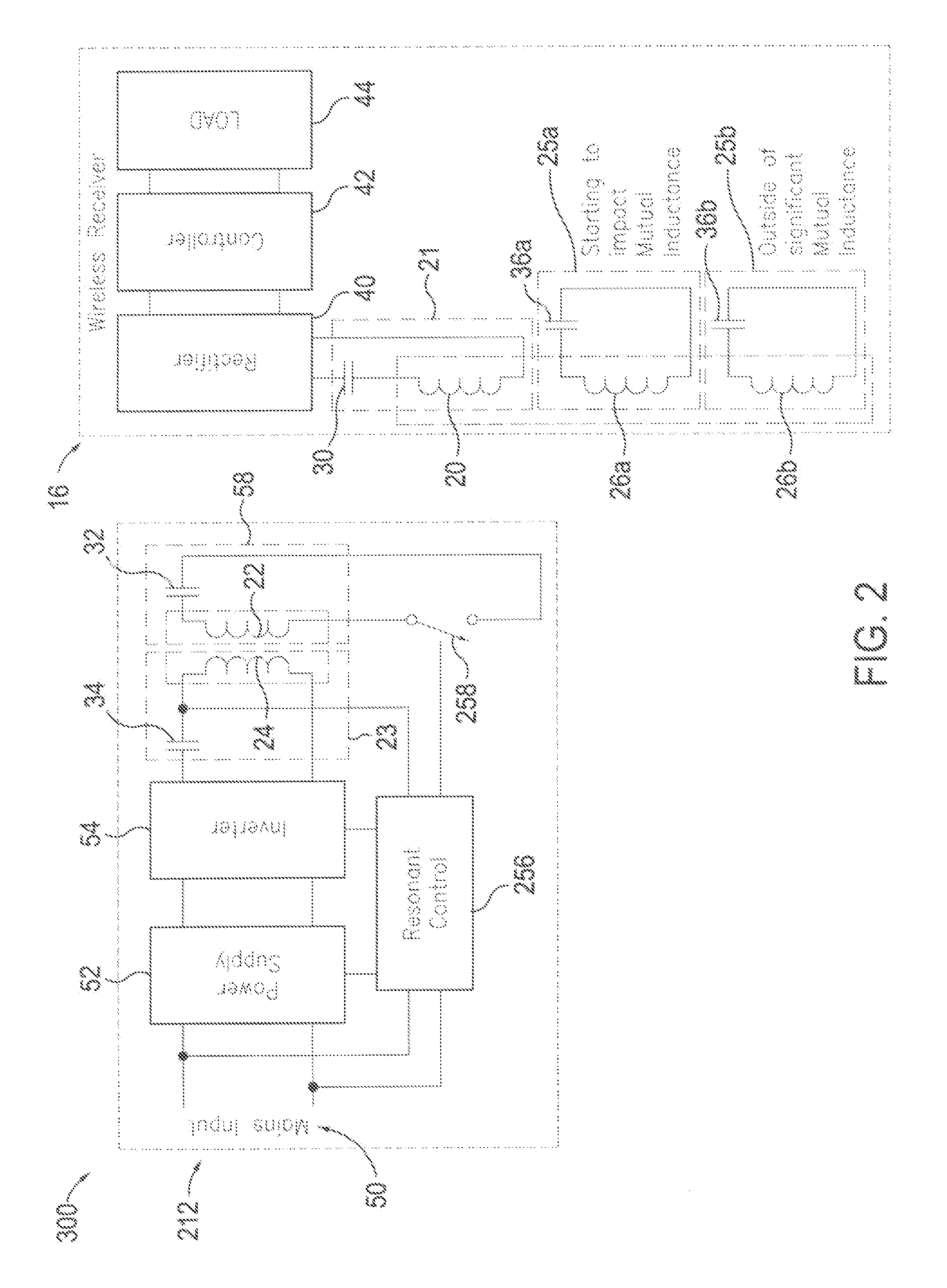

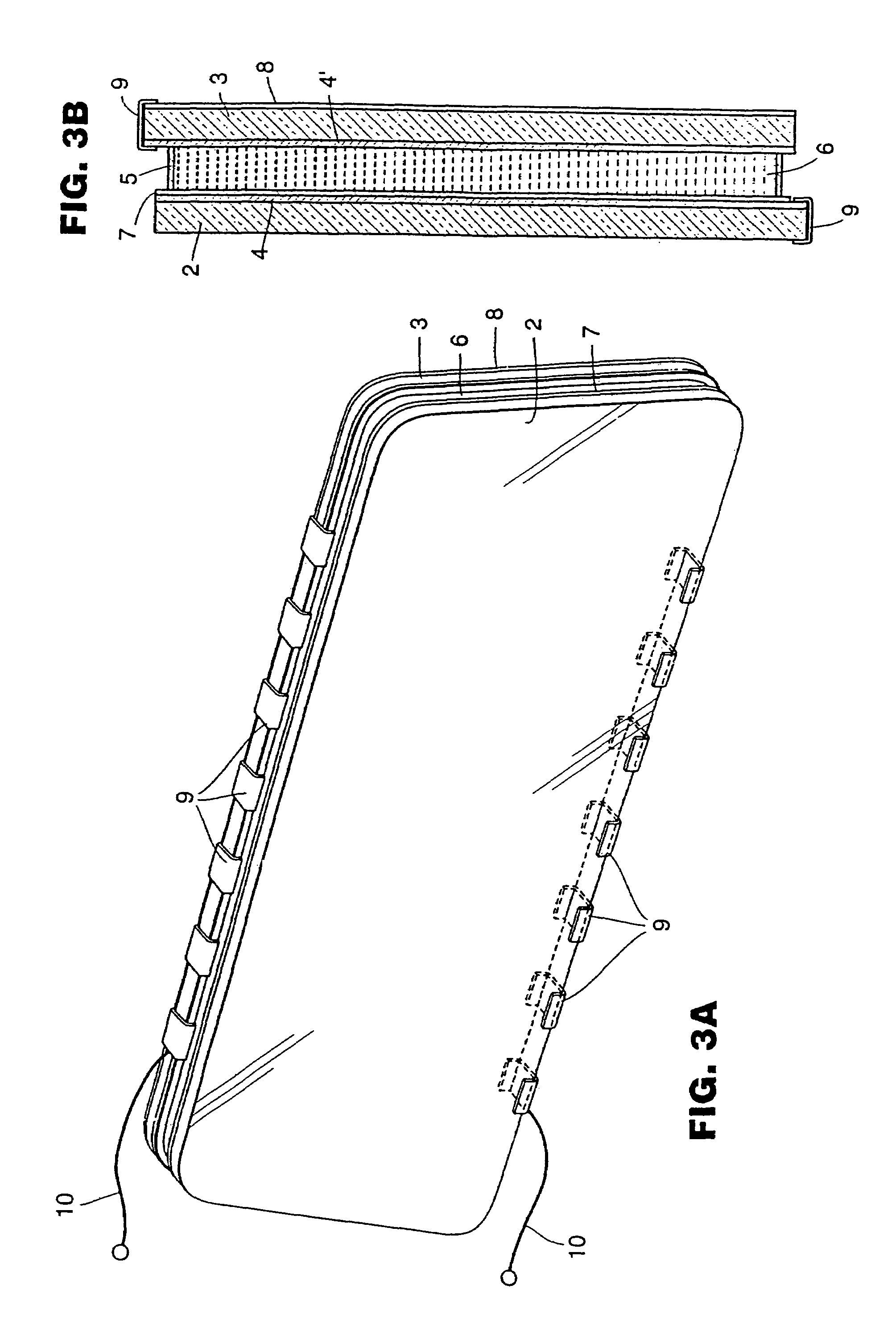

Coil configurations for inductive power transer

ActiveUS20110304216A1High power transmission efficiencyThe process is simple and effectiveNear-field transmissionElectromagnetic wave systemElectric power transmissionElectric power system

An inductive power supply system in which the receiving unit includes a secondary coil and a plurality of resonating circuits with different characteristics. Each of the resonating circuits may include a resonating coil and a resonating capacitor. The resonating coils may be inductively coupled to the secondary coil so that energy may be transferred from one or more of the resonating coils to said receiving unit. The plurality of resonating circuits are configured to provide improved power transfer efficiency or performance at different distances between the primary coil and secondary coil. The present invention may also provide a method for tuning the wireless power system including the general steps of measuring an operating characteristic in the primary unit, measuring an operating characteristic in the receiver unit and tuning one or more of the components in the primary unit and the secondary unit based on a comparison of the two measurements.

Owner:PHILIPS IP VENTURES BV

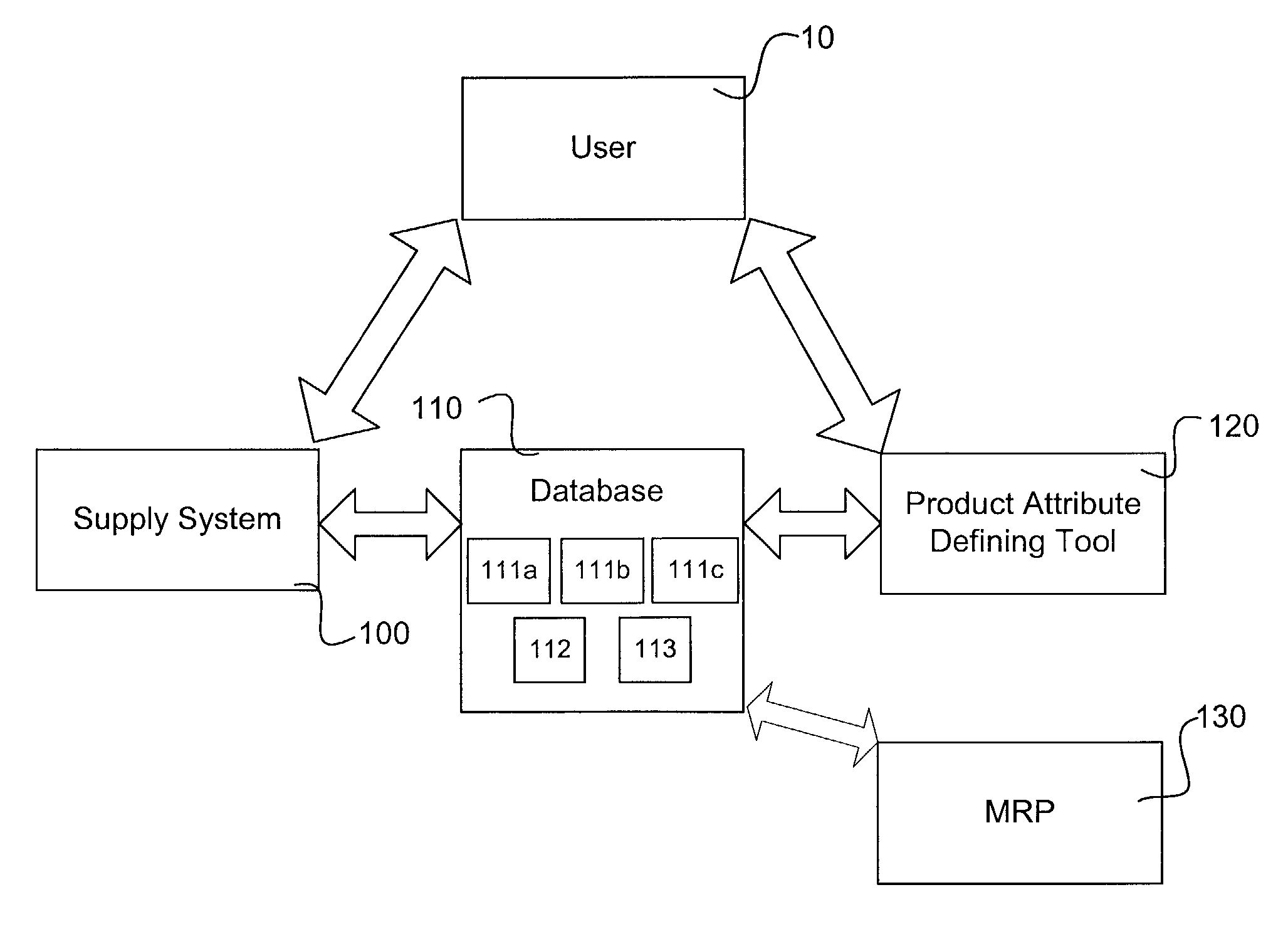

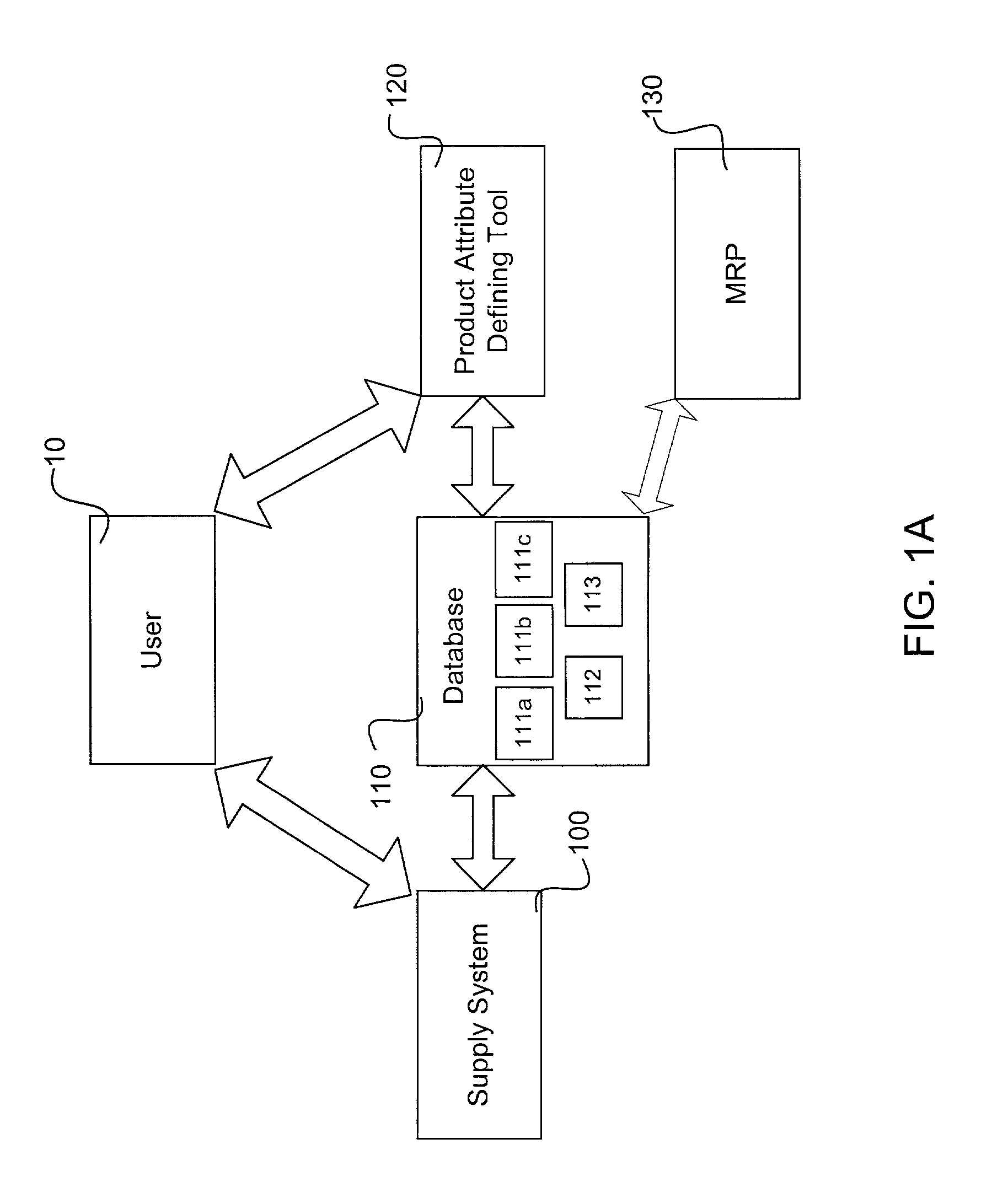

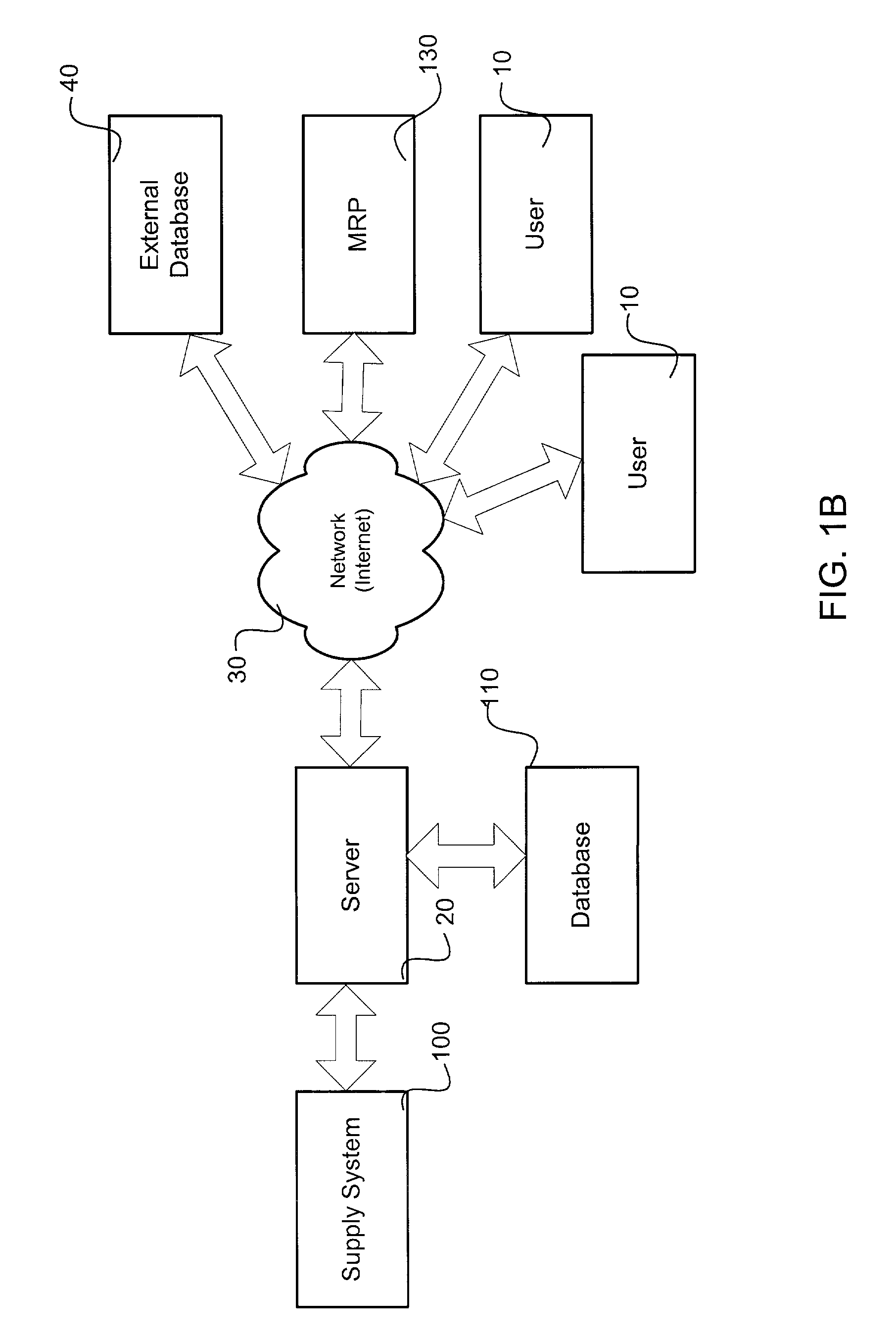

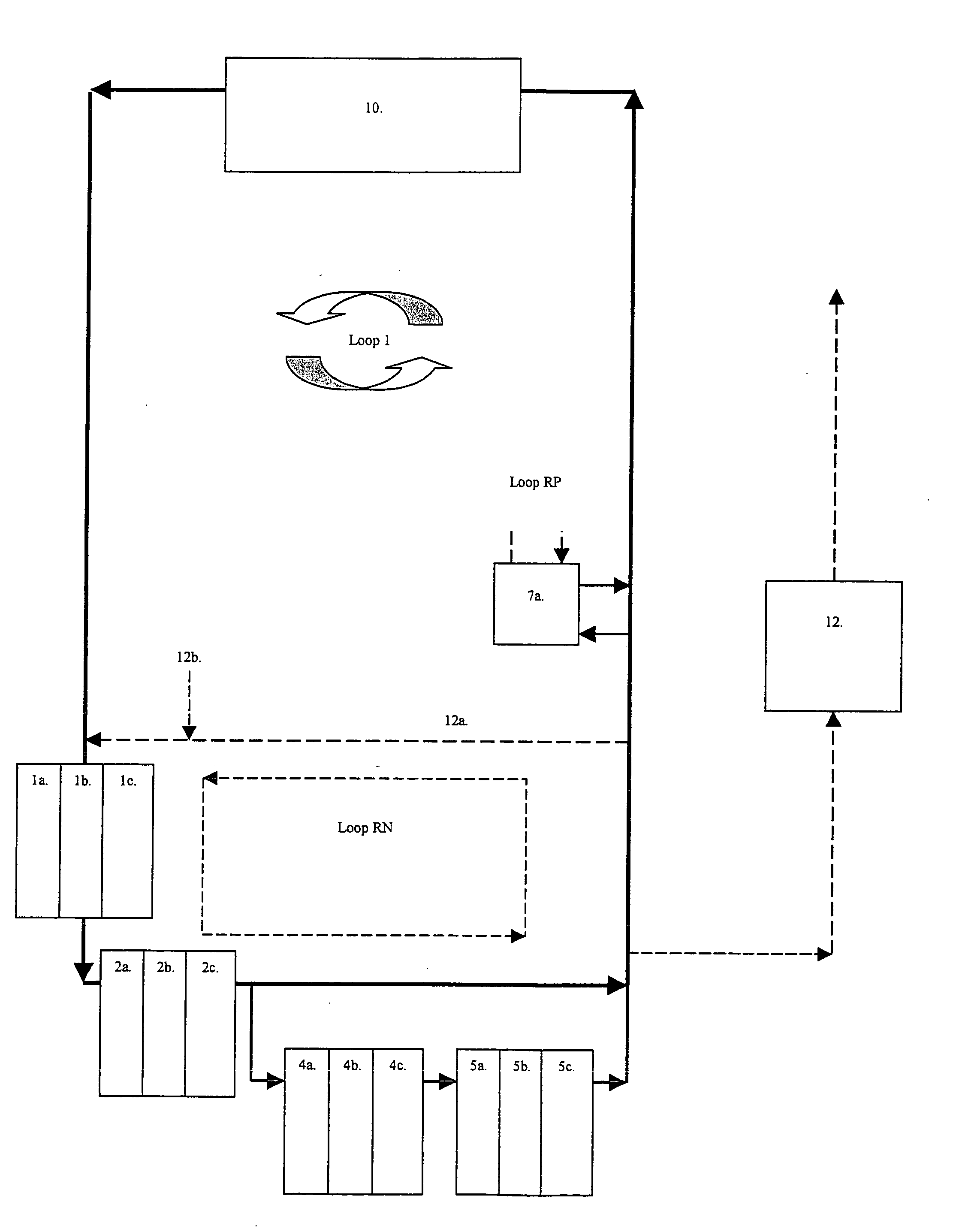

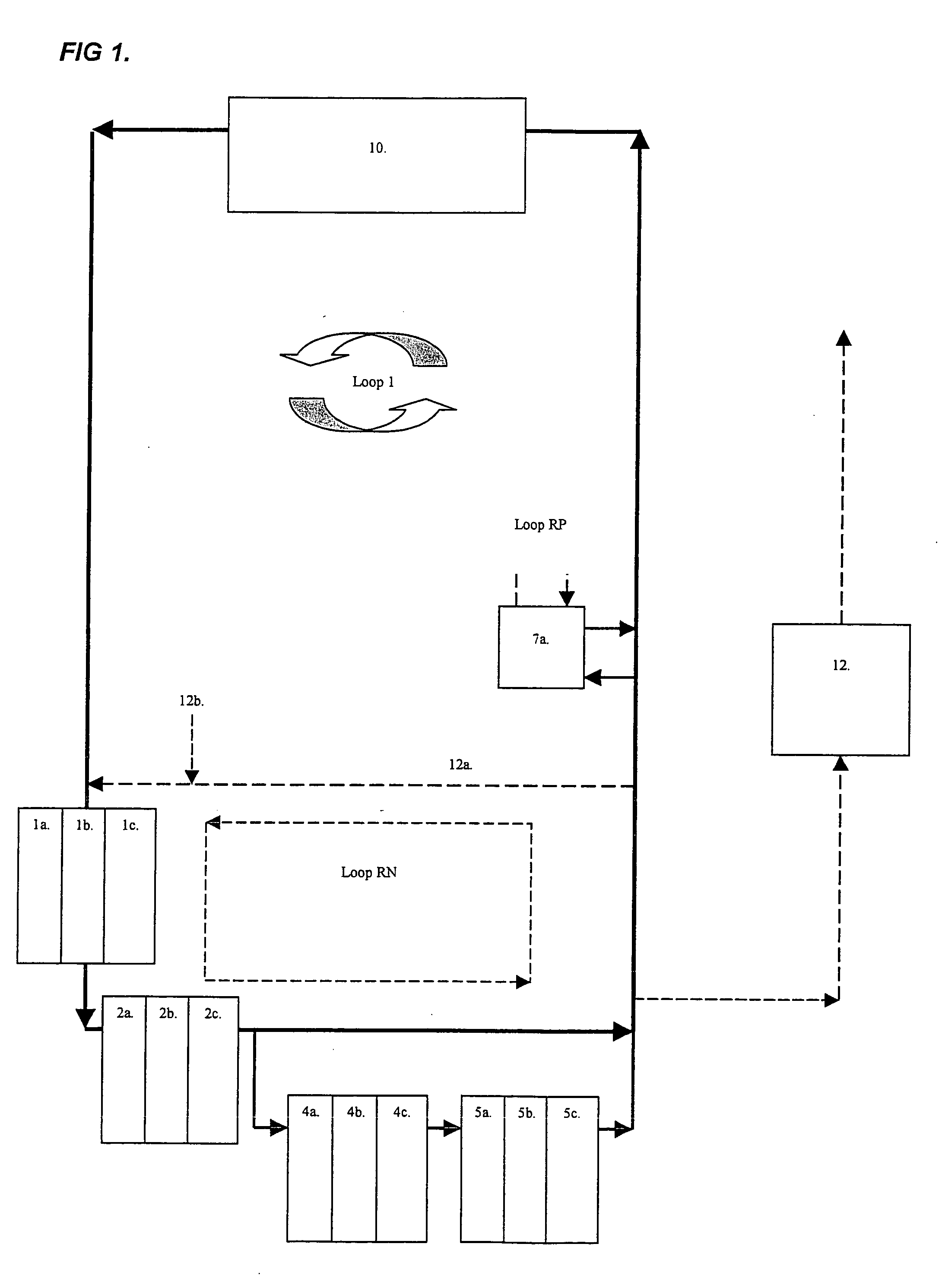

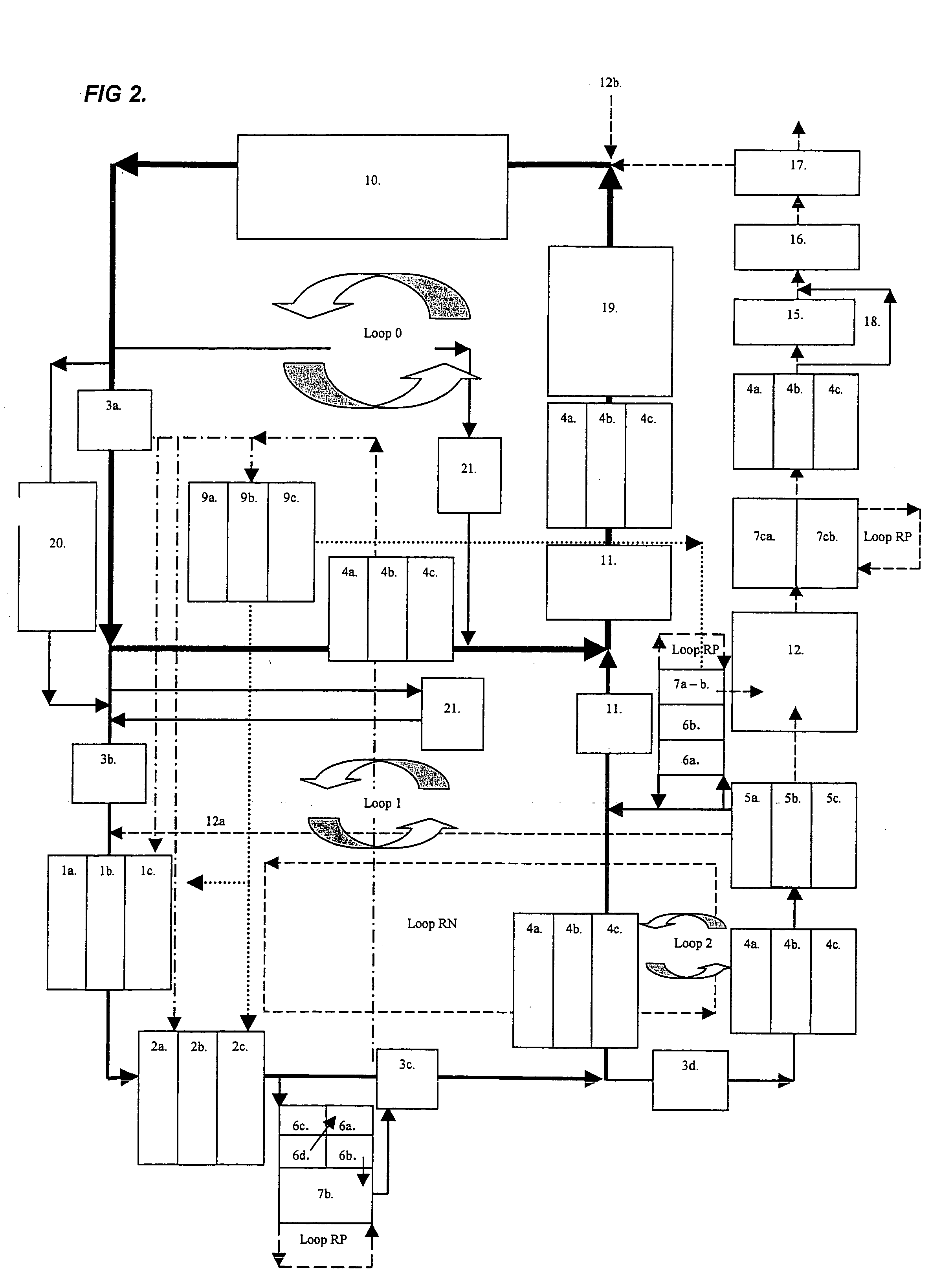

System and method for allocating the supply of critical material components and manufacturing capacity

InactiveUS7058587B1Improve responsivenessMaximize inventory useResourcesSpecific program execution arrangementsProgram planningChange analysis

The present invention allocates the supply of critical components and manufacturing capacity by optimizing critical material planning decisions and dynamically allocating constrained materials using advanced substitution logic that considers alternate suppliers and supports product life cycle from design through end-of-life. The present invention may utilize unique synchronized allocations and matched sets logic. The synchronized allocations ensure that all materials necessary for production are available in the appropriate time-phased allocation before beginning production to minimize wasted production capacity and materials. The supply system may include various combination of components, including a Supply Planner, a Resource Optimizer, a Constraint Based Master Planner, a Product Change Analyzer, a Comparer, a Resource Requirements Planner, a Finite Resource Planner, a Customer Promiser, and an Interactive Master Scheduler. Another embodiment of the supply system includes a tool that allows users to define products using engineering specifications.

Owner:BLUE YONDER GRP INC

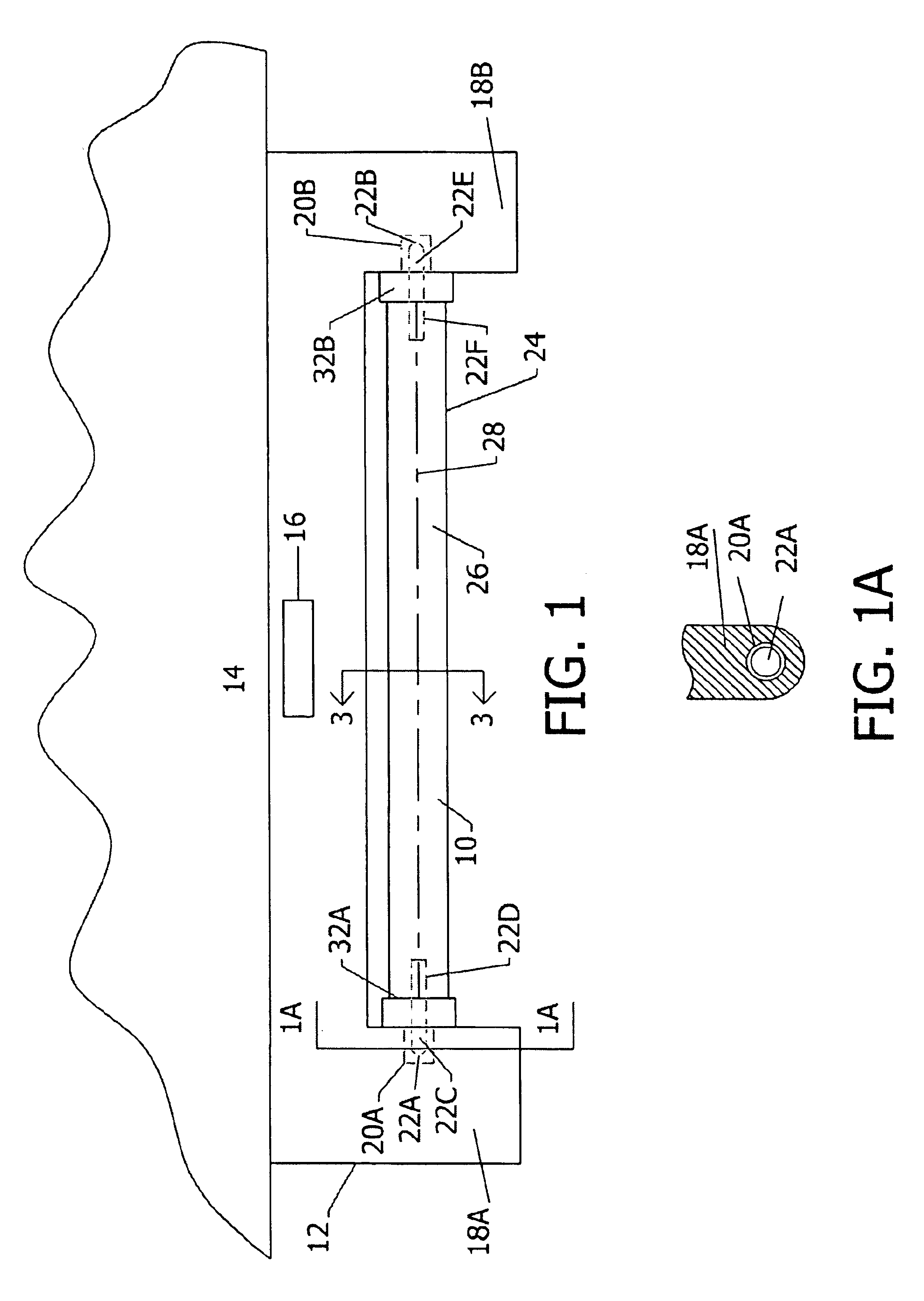

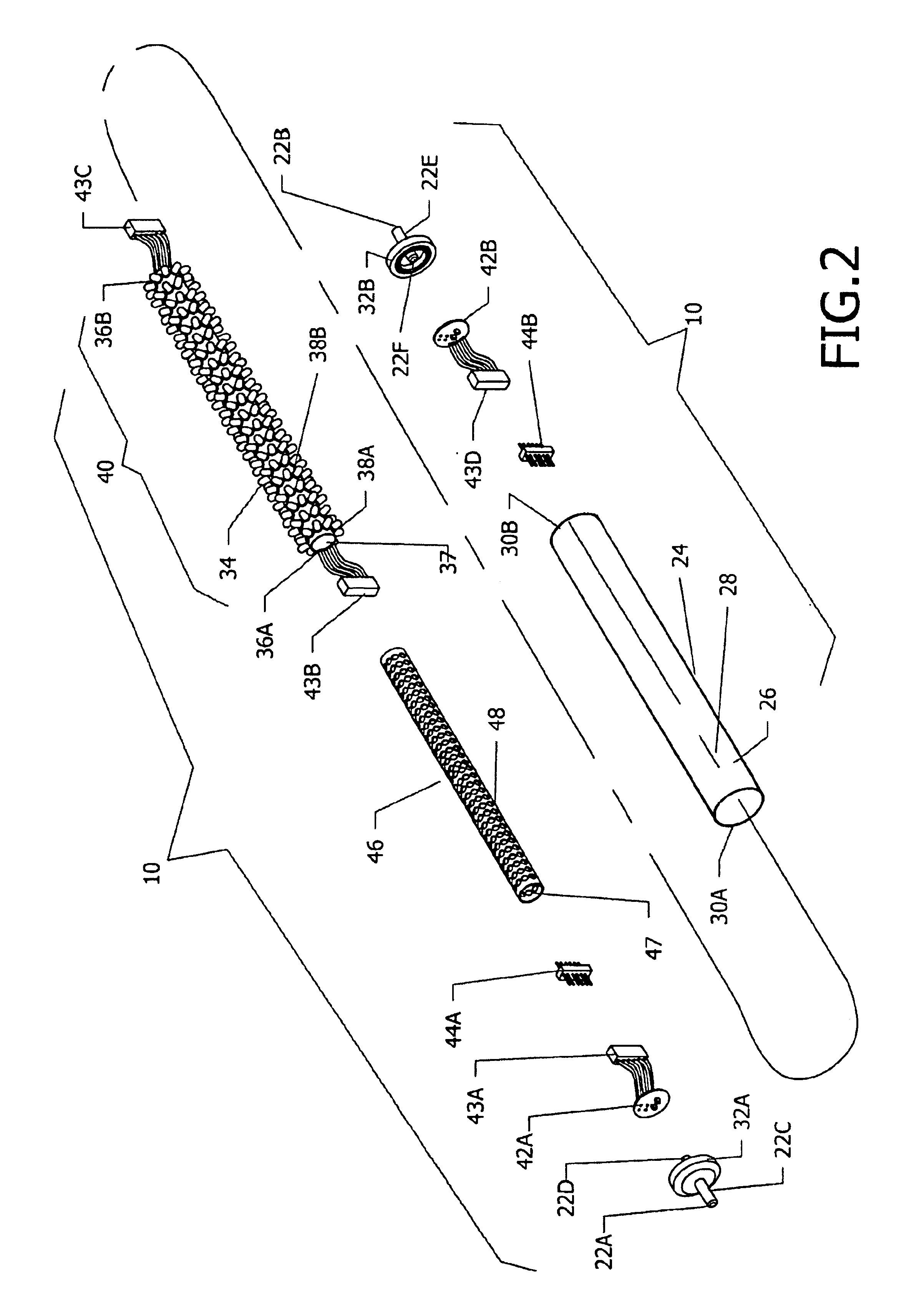

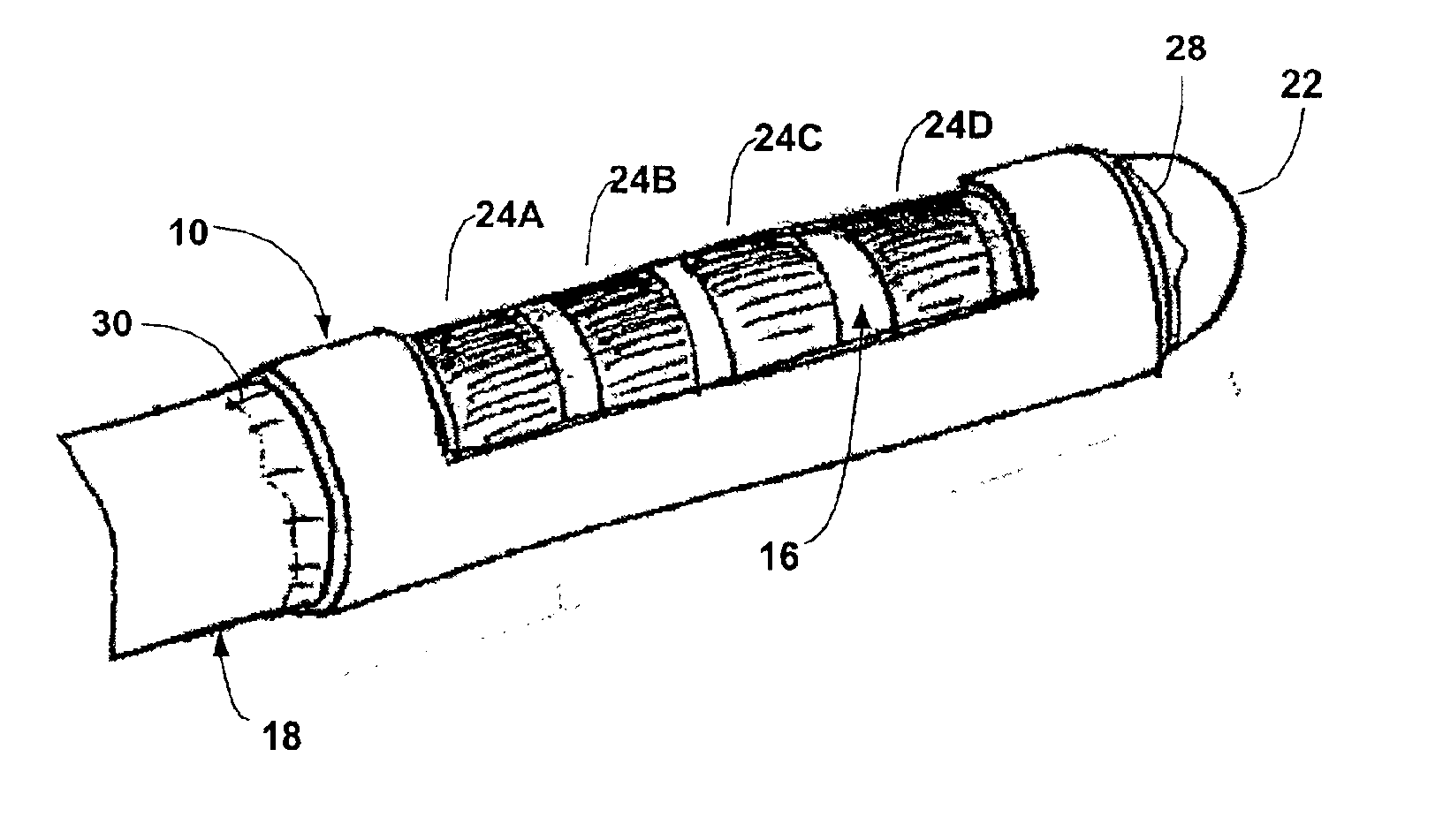

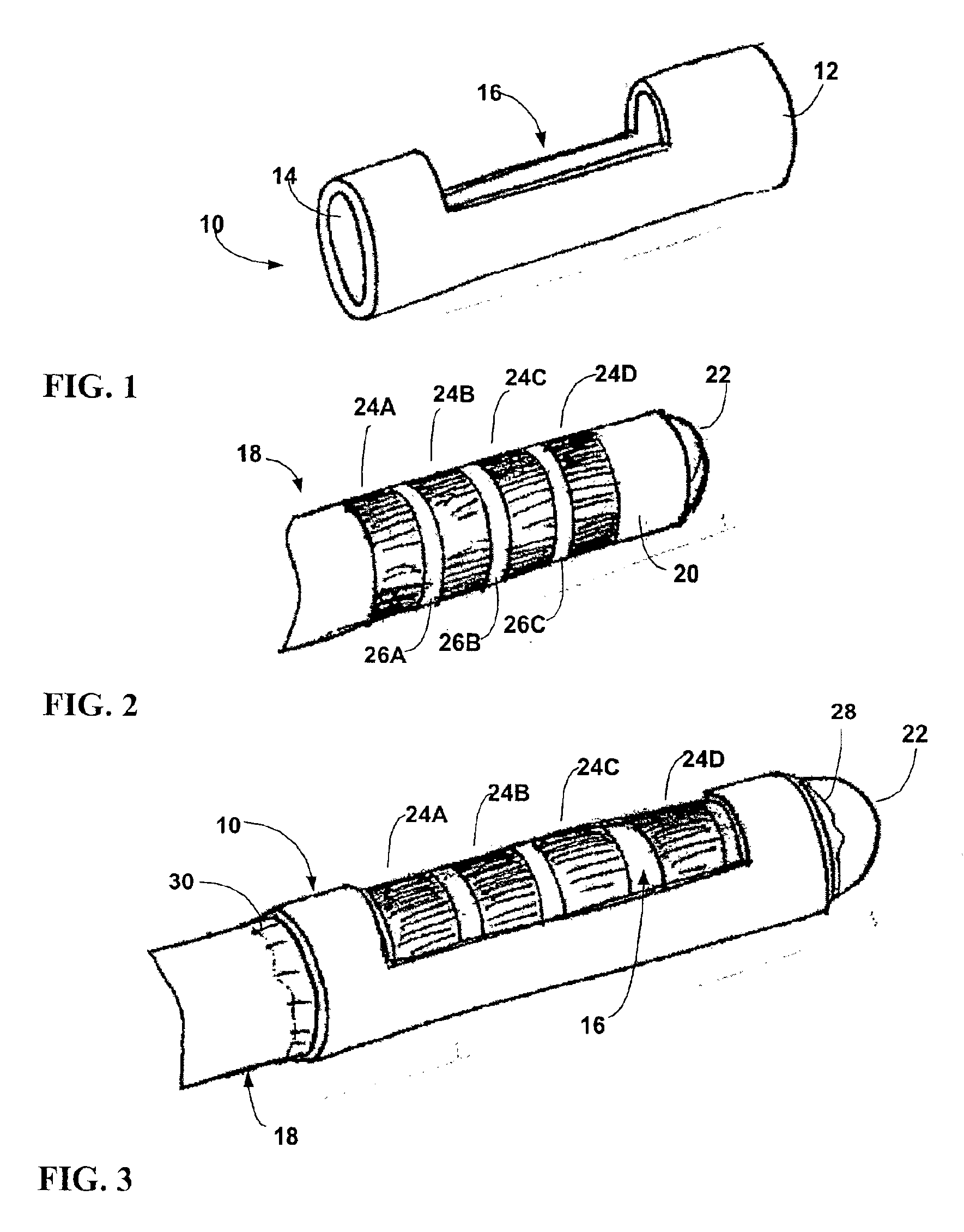

Directional brain stimulation and recording leads

InactiveUS7212867B2Improve abilitiesLess interferenceHead electrodesExternal electrodesElectricitySide effect

A directional brain stimulation lead assembly provides a lead body and an insulating member defining one or more windows that selectively expose portions of electrodes carried by the lead body to produce a directional stimulation current field. The lead assembly can achieve more effective localization of electrical stimulation to very small brain targets, and thereby reduce the incidence of material side effects caused by collateral stimulation of brain tissue adjoining a desired brain target. In addition, the directional lead can sense brain activity on a more localized basis.

Owner:MEDTRONIC INC

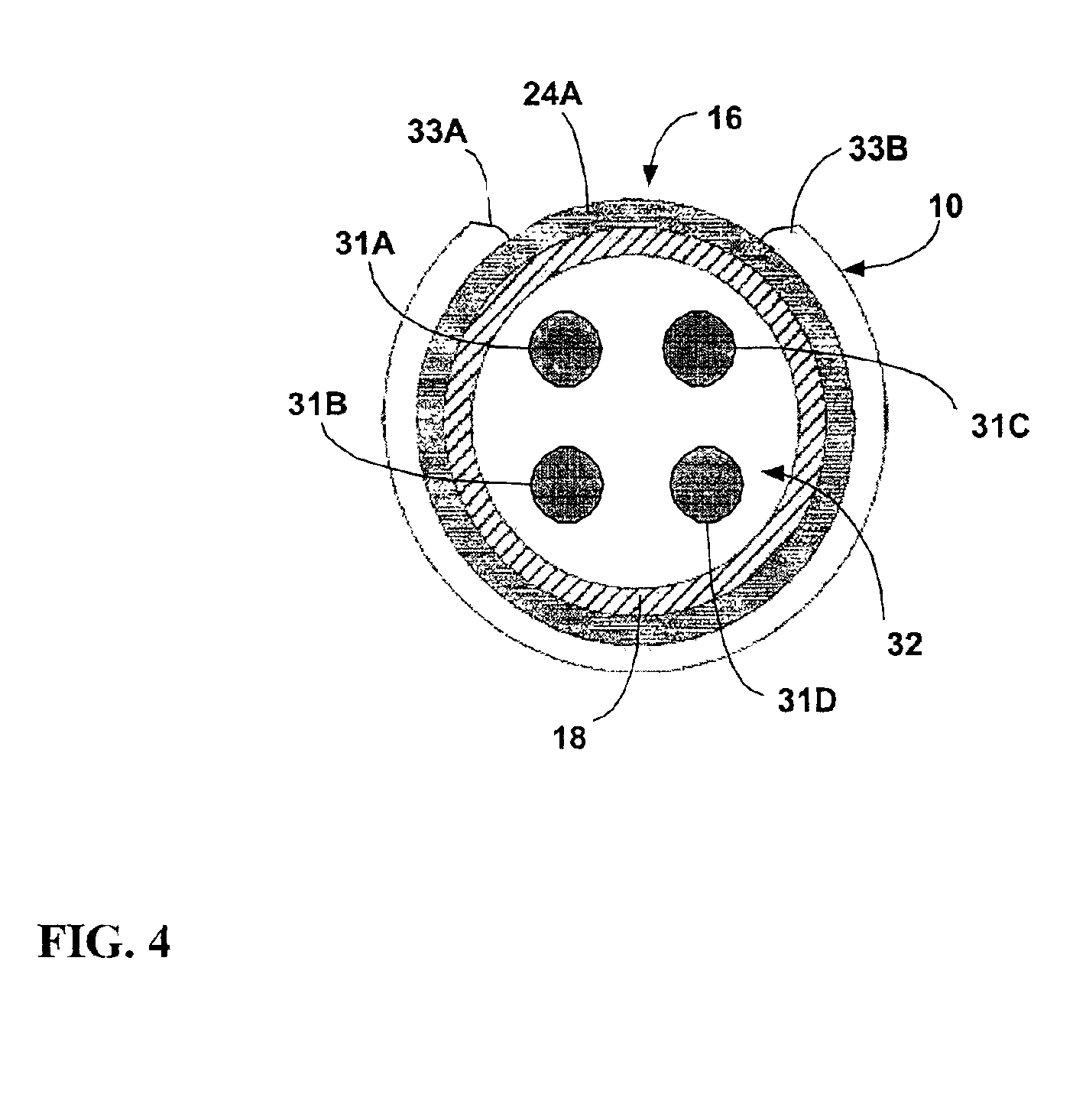

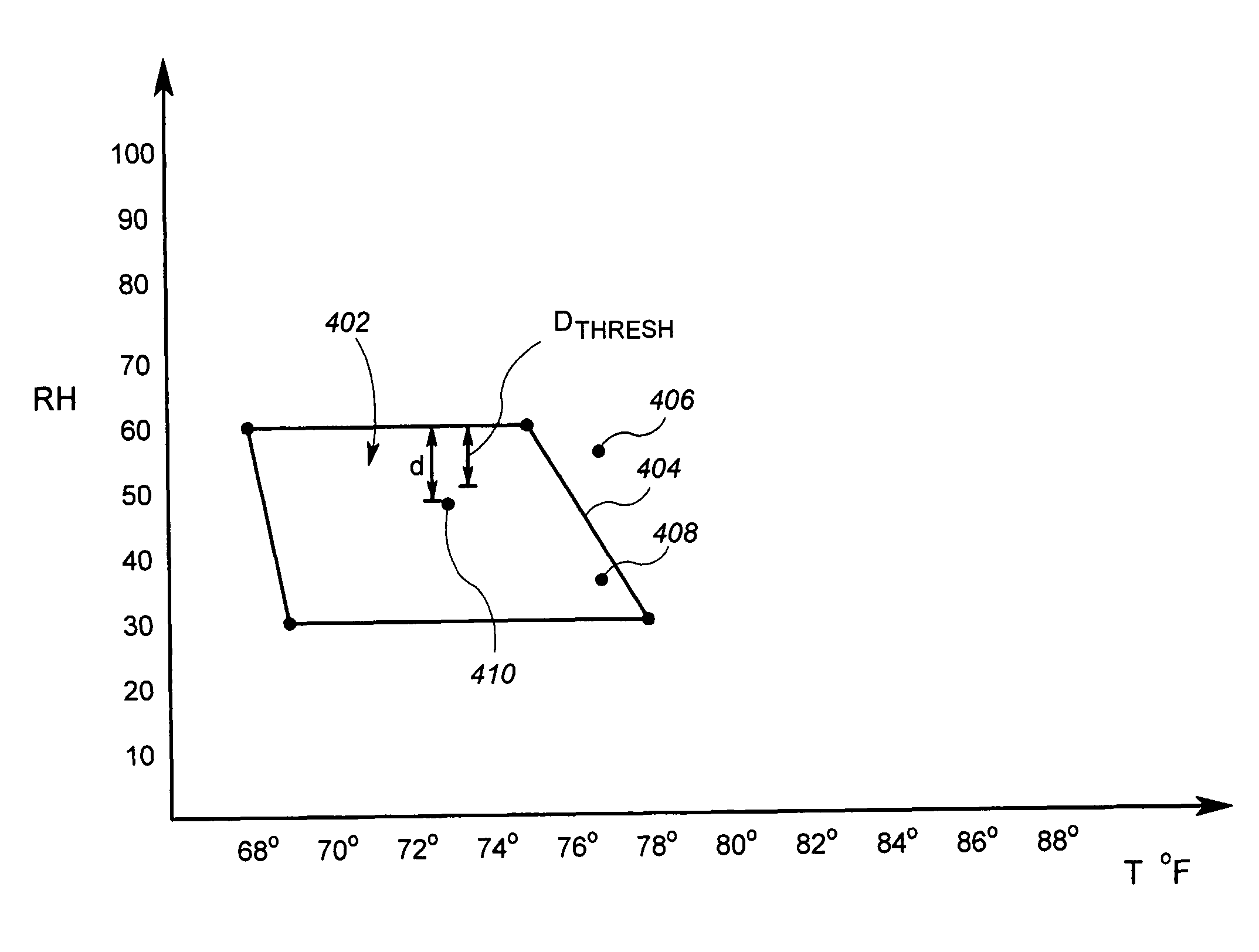

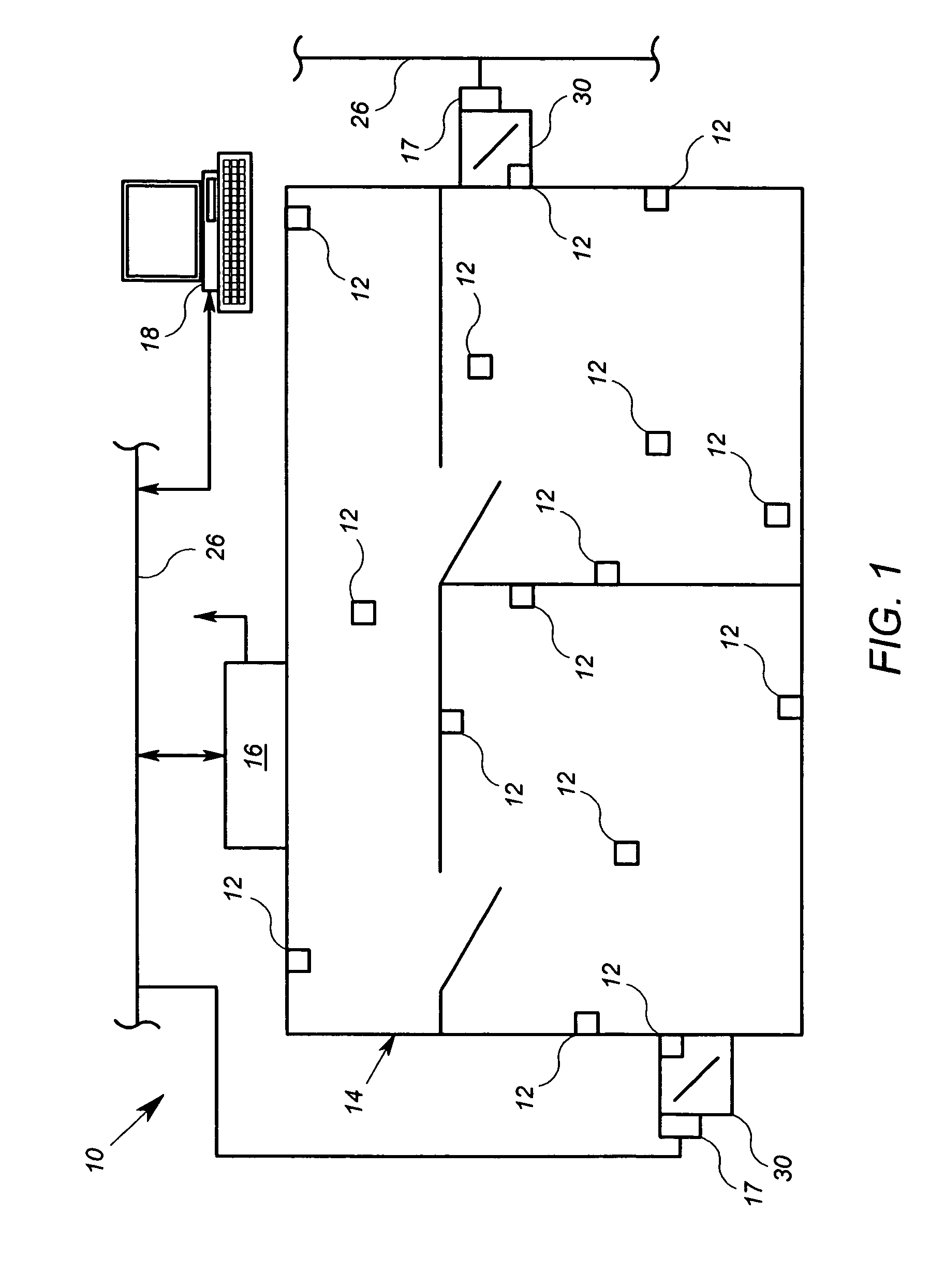

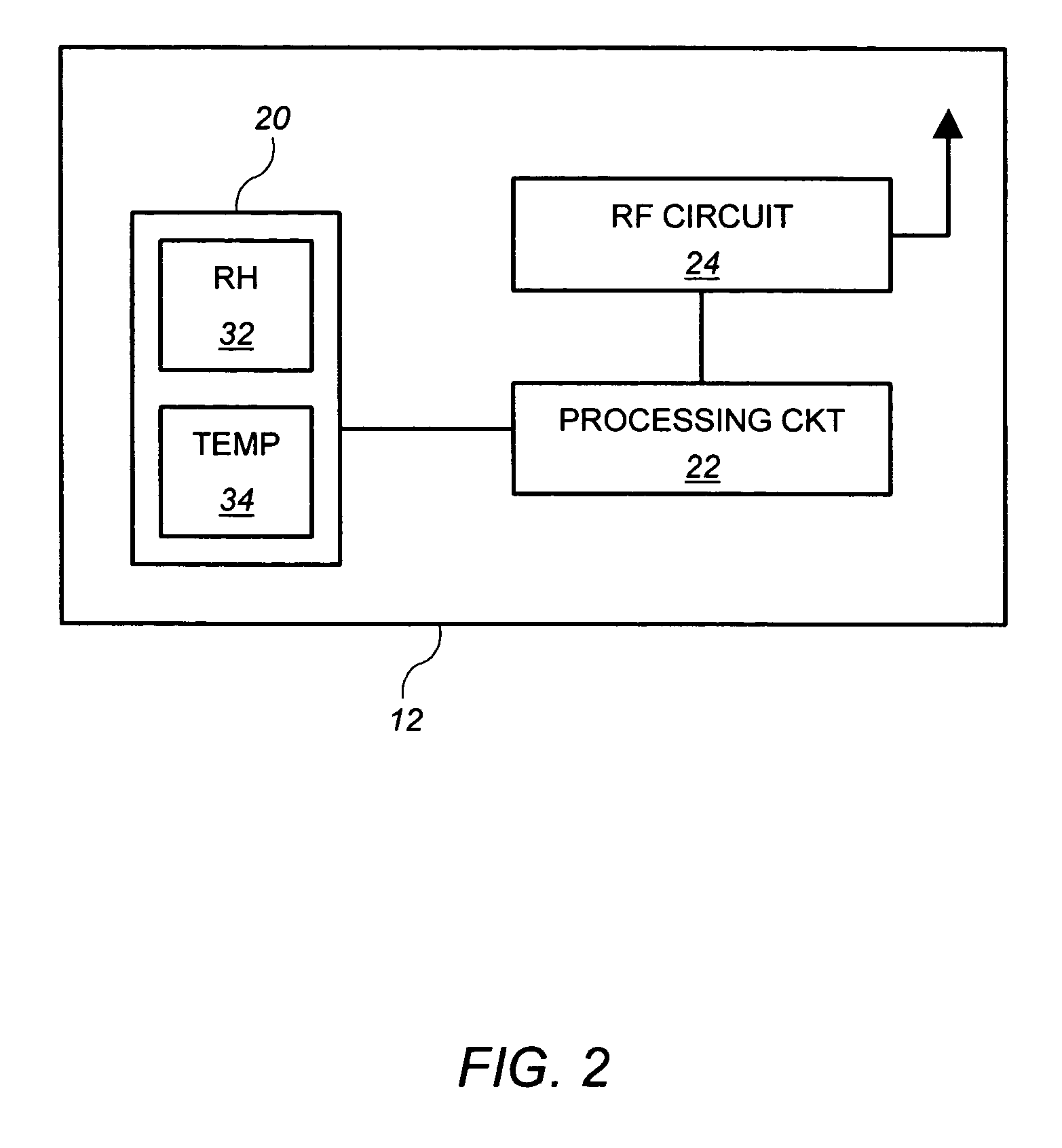

Application of microsystems for comfort control

ActiveUS7854389B2Reduce laborReduce materialMechanical apparatusTemperatue controlEngineeringRelative humidity

An arrangement includes a plurality of wireless microsystems. Each microsystem is operable to measure at least relative humidity and temperature, and to communicate temperature and relative humidity information wirelessly to a network device. The network device is operable to communicate the temperature and relative humidity information to at least a first processor configured to cause a change in a building control condition based on the information.

Owner:SIEMENS IND INC

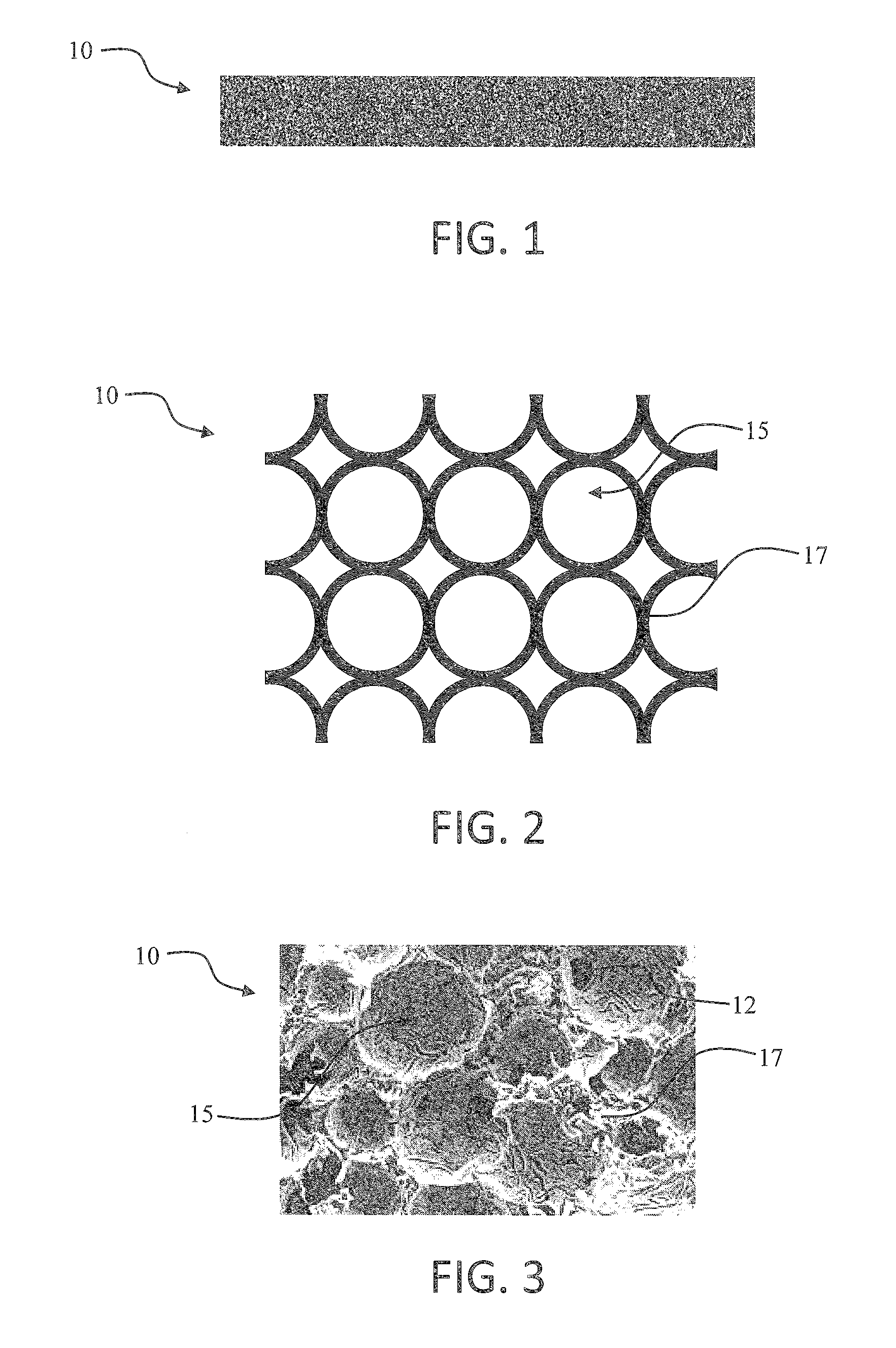

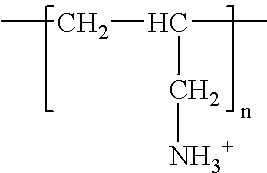

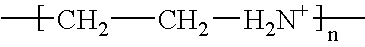

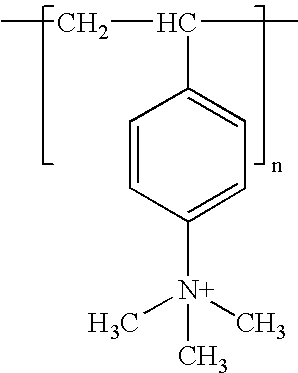

Biomedical devices having improved surface characteristics

InactiveUS7297725B2Reduce complexityHigh oxygen permeabilityOptical articlesCoatingsSpray coatingOxygen

Biomedical devices, such as ophthalmic lenses, and methods of making such devices having a surface coating including at least one polyionic layer. A preferred method involves spray coating a polycationic material onto a core lens, rinsing and drying the lens, followed by spray coating a polyanionic material, rinsing and drying. The coating process may be applied a plurality of times to achieve a multi-layer coating on the lens surface. A particularly preferred embodiment is a contact lens comprising a highly oxygen permeable hydrophobic core coated with a 5 to 20 bilayers of hydrophilic polyionic materials.

Owner:NOVARTIS AG

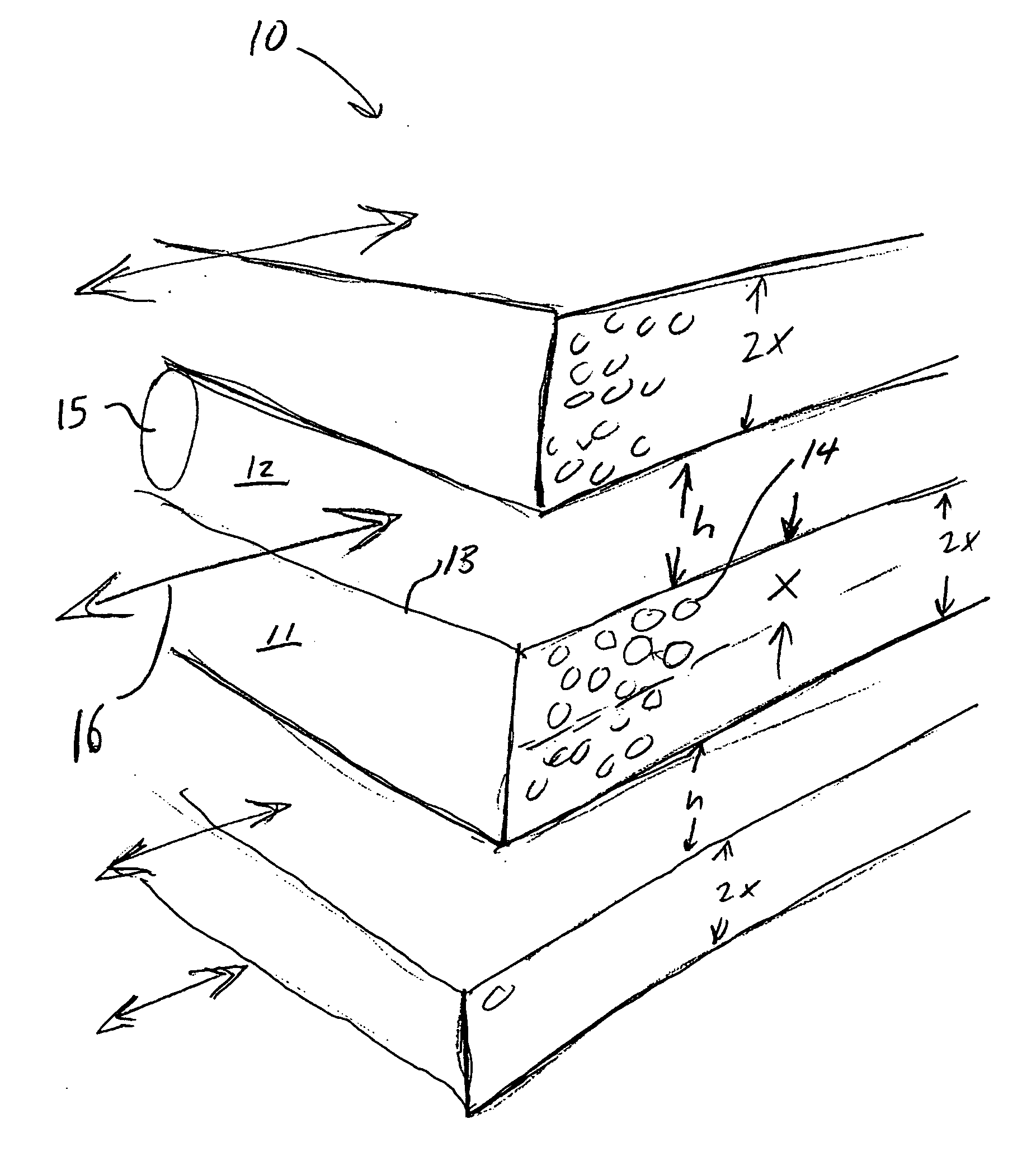

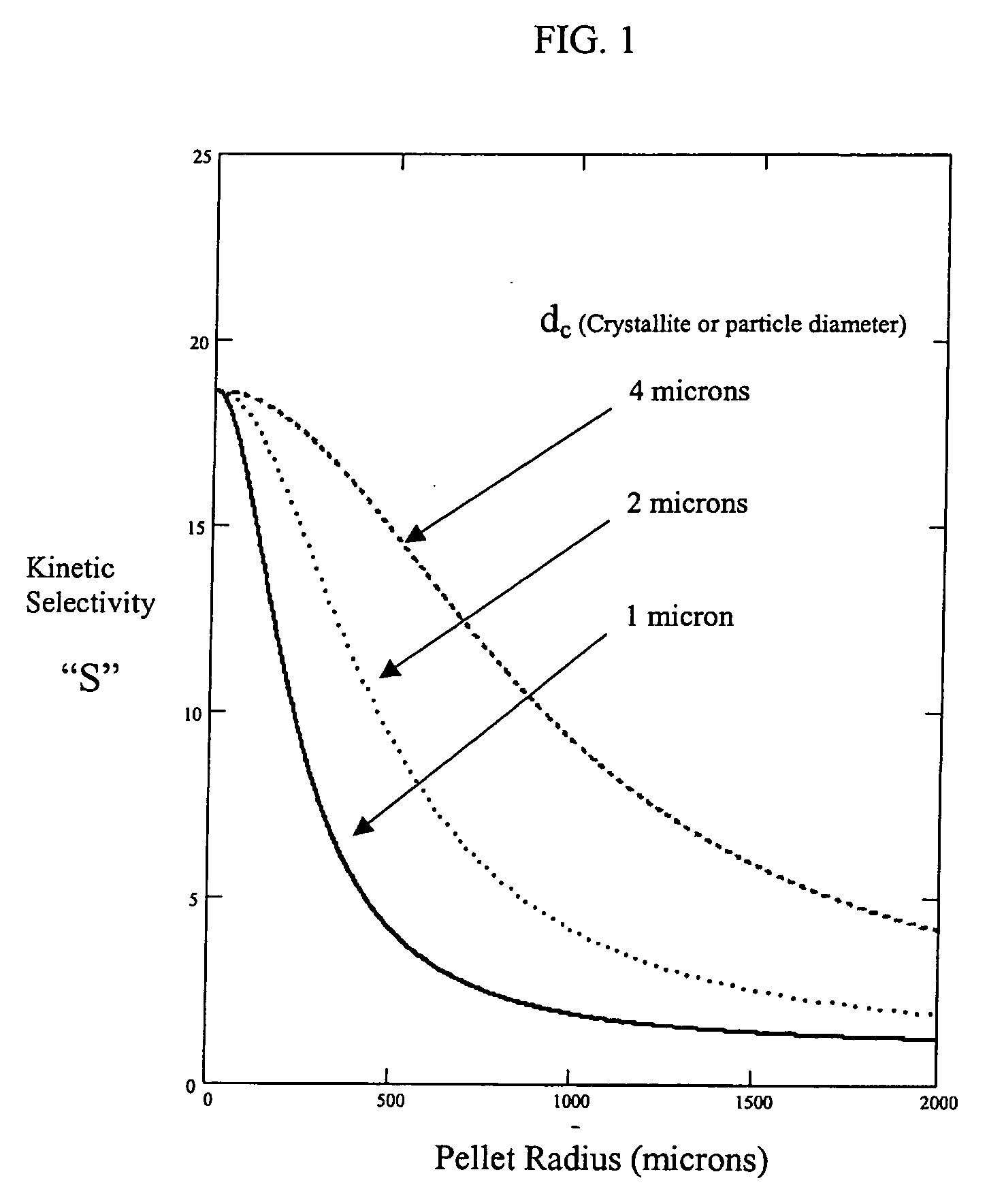

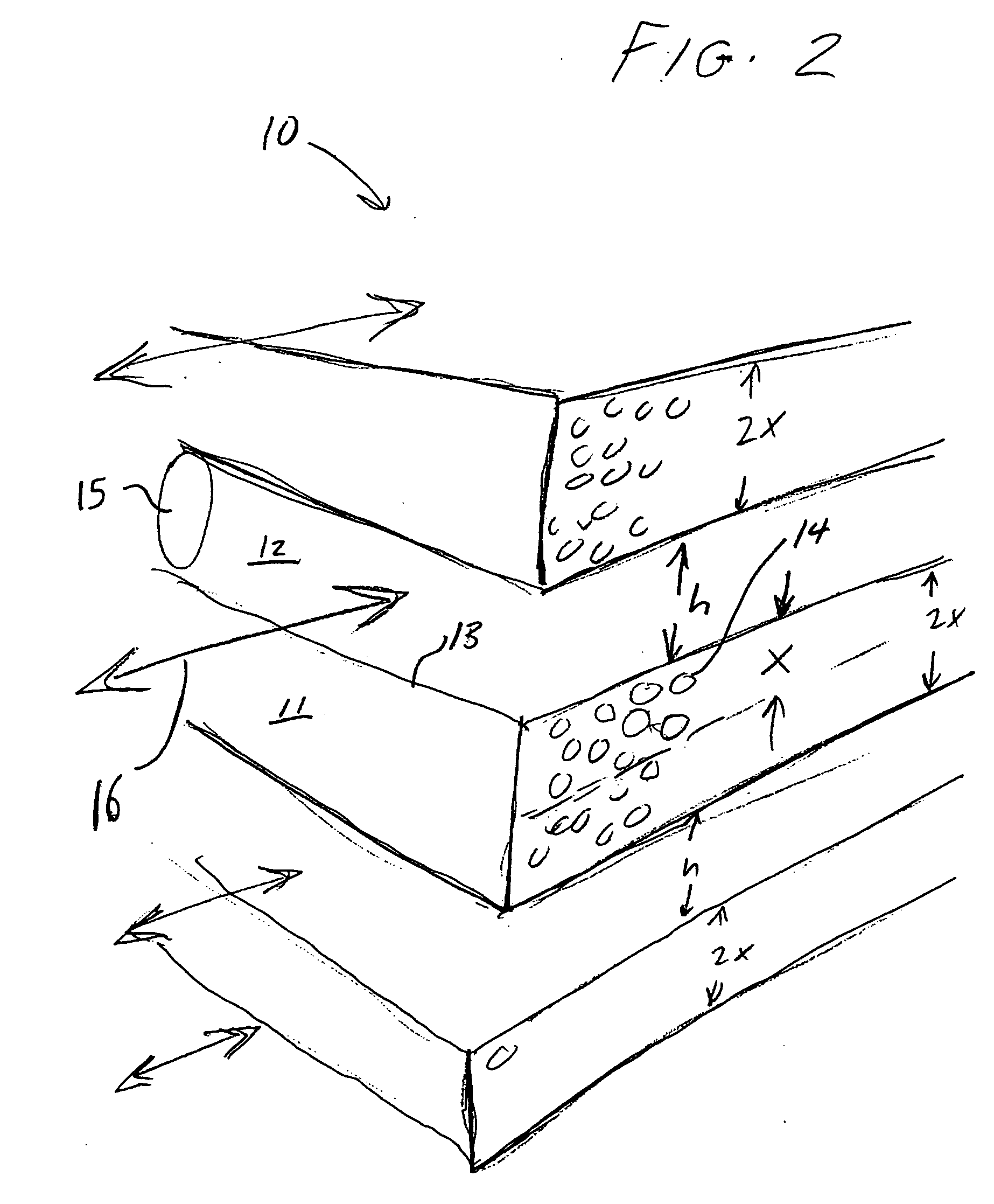

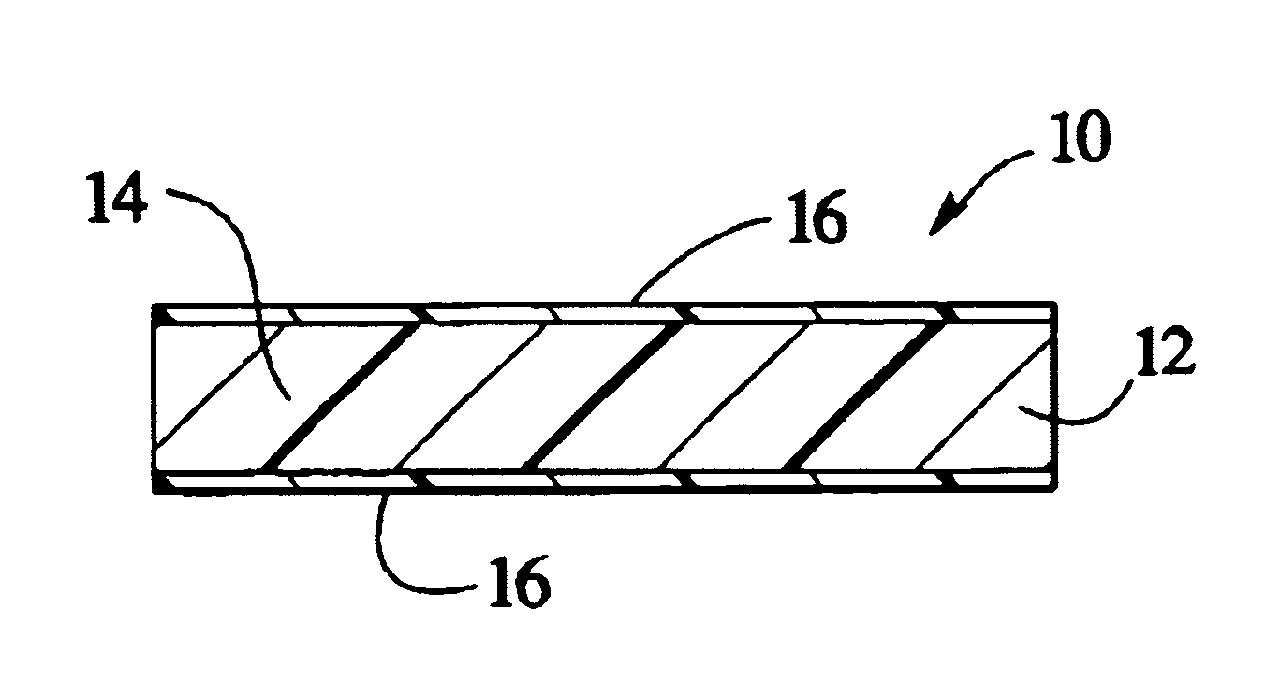

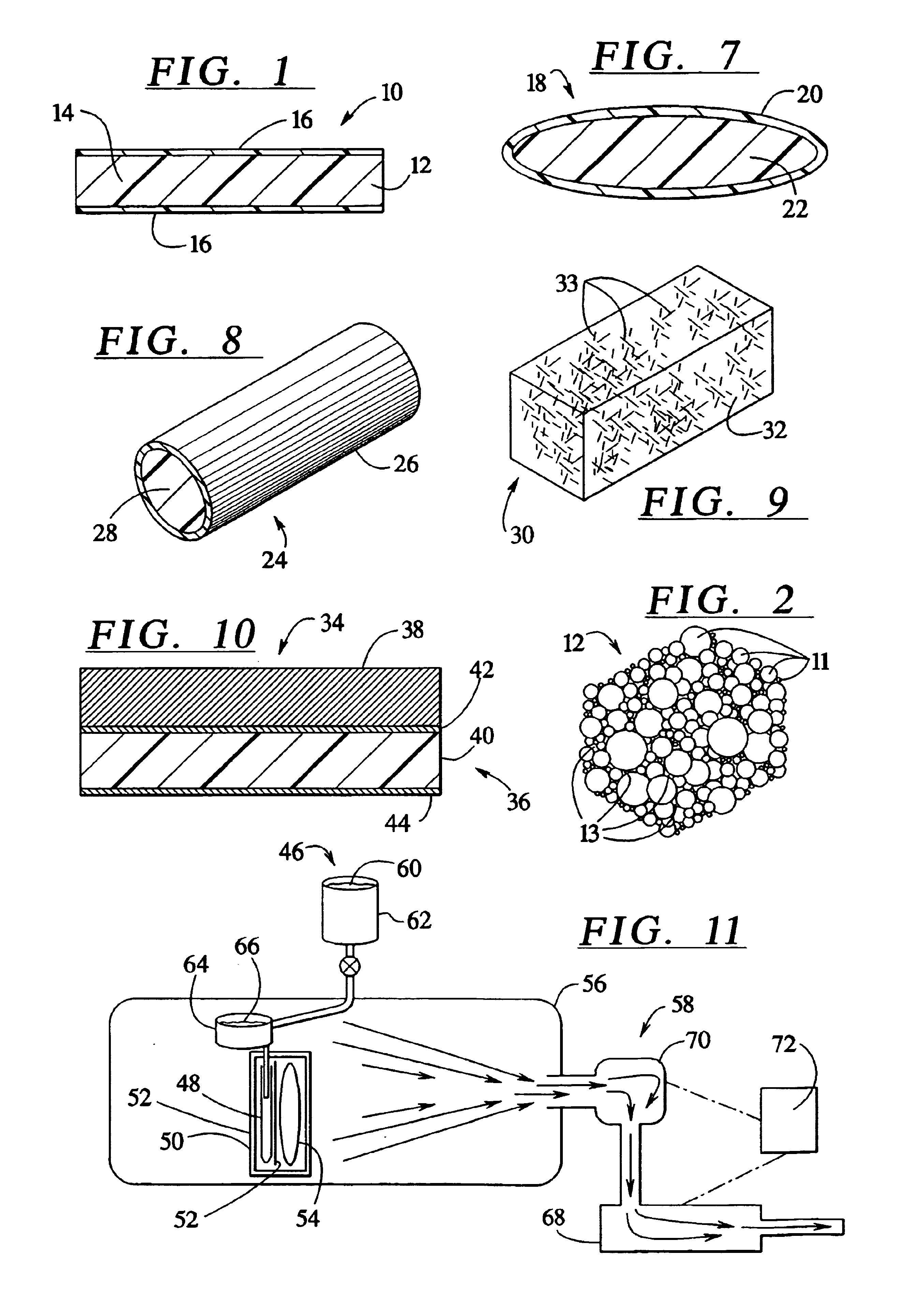

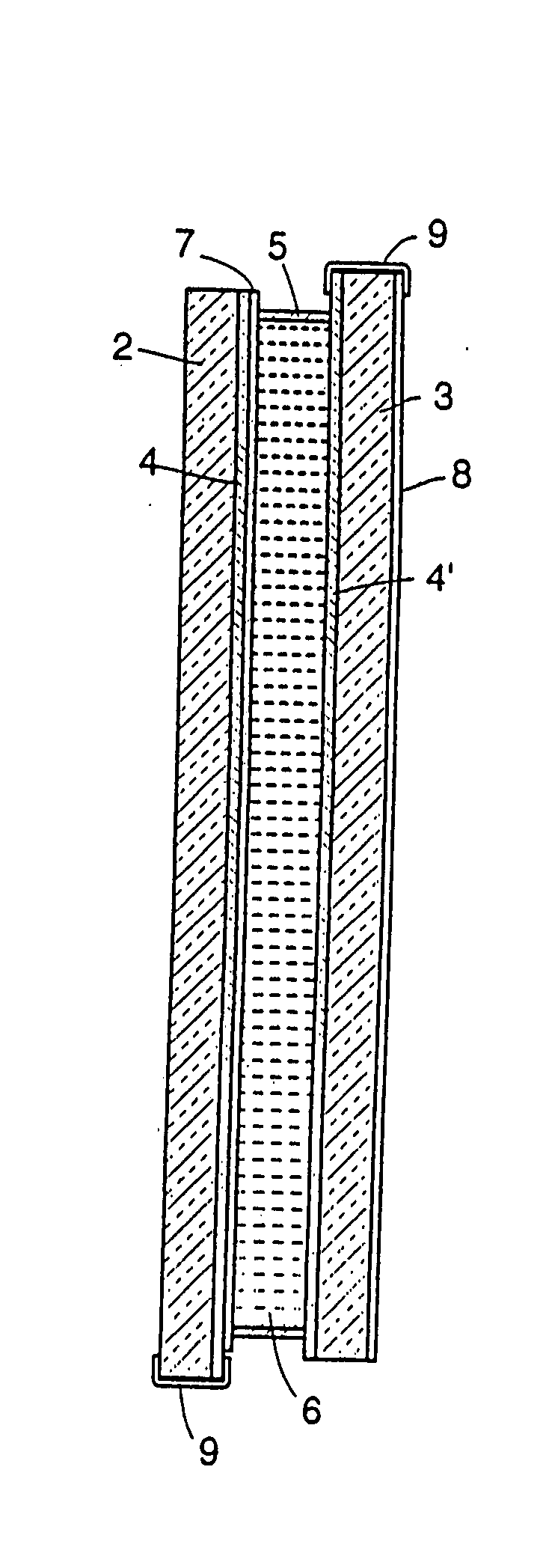

Engineered adsorbent structures for kinetic separation

ActiveUS20060169142A1Easy to controlHigh selectivityGas treatmentMethane captureProduction rateSorbent

Improved adsorbent sheet based parallel passage adsorbent structures for enhancing the kinetic selectivity of certain kinetic-controlled adsorption processes, such as PSA, TSA and PPSA processes, and combinations thereof, are provided. The enhancements in kinetic selectivity made possible through the implementation of the present inventive improved adsorbent structures may unexpectedly enable significant intensification of selected kinetic adsorption processes relative to attainable performance with conventional adsorbent materials in beaded or extruded form. Such process intensification enabled by the present inventive adsorbent structures may provide for increased adsorption cycle frequencies, and increased gas flow velocities within the adsorbent beds, which may increase the productivity and / or recovery of a kinetic adsorption system incorporating the inventive adsorbent structures.

Owner:AIR PROD & CHEM INC

Composite materials

InactiveUS7037865B1Remarkable strength and other propertyImprove material performanceSynthetic resin layered productsCellulosic plastic layered productsFiberHigh density

New composite materials having a high density of small particles, such as hollow microspheres, in a matrix material are disclosed. The microspheres are densely packed in the matrix material such that adjacent microspheres are positioned in contact with each other or very close together. Fiber flanking may be provided on the opposite sides of a layer of a core of composite material having the small particles and matrix material. Also disclosed are methods of making and using the composite materials.

Owner:JAMES HARDIE TECH LTD

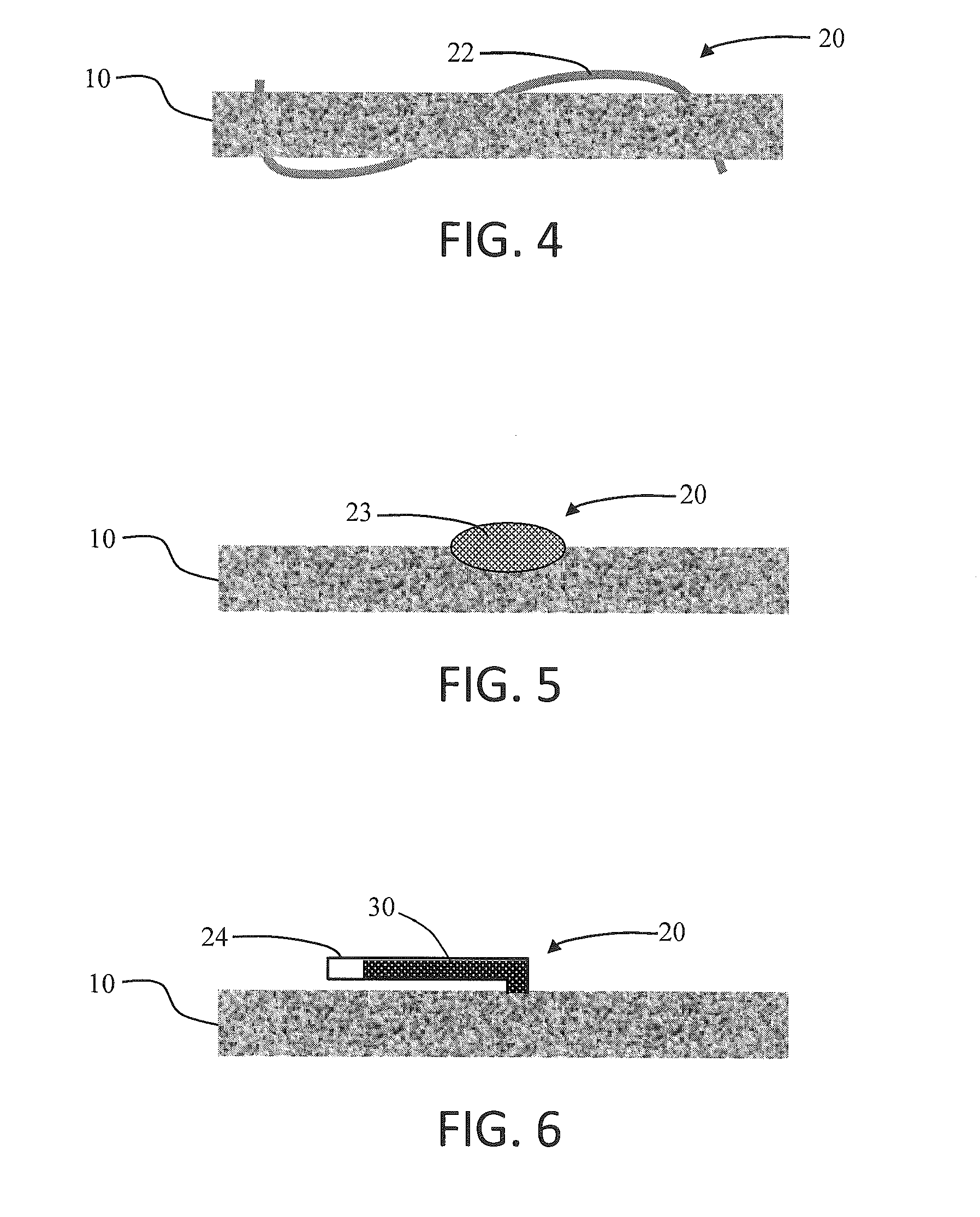

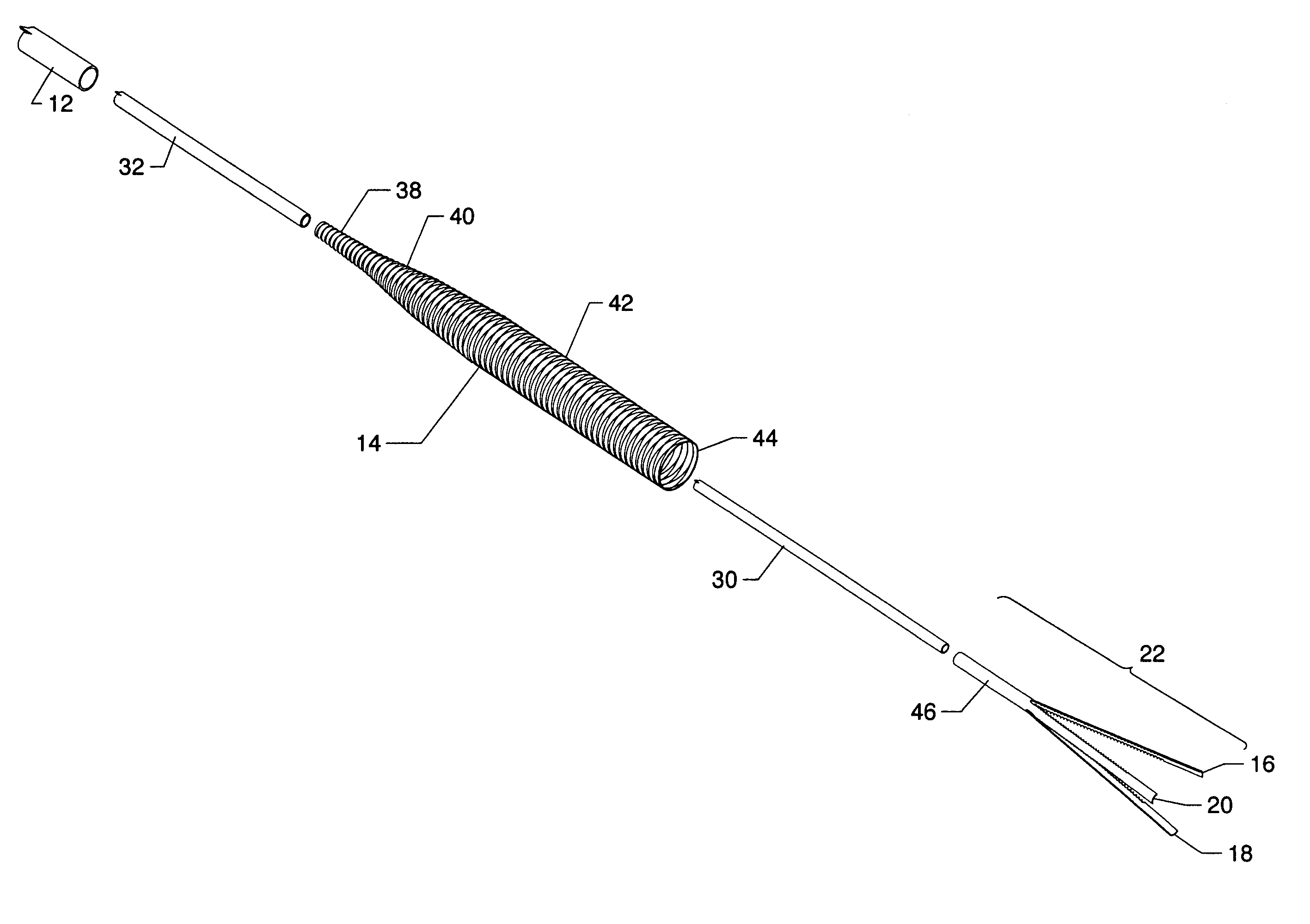

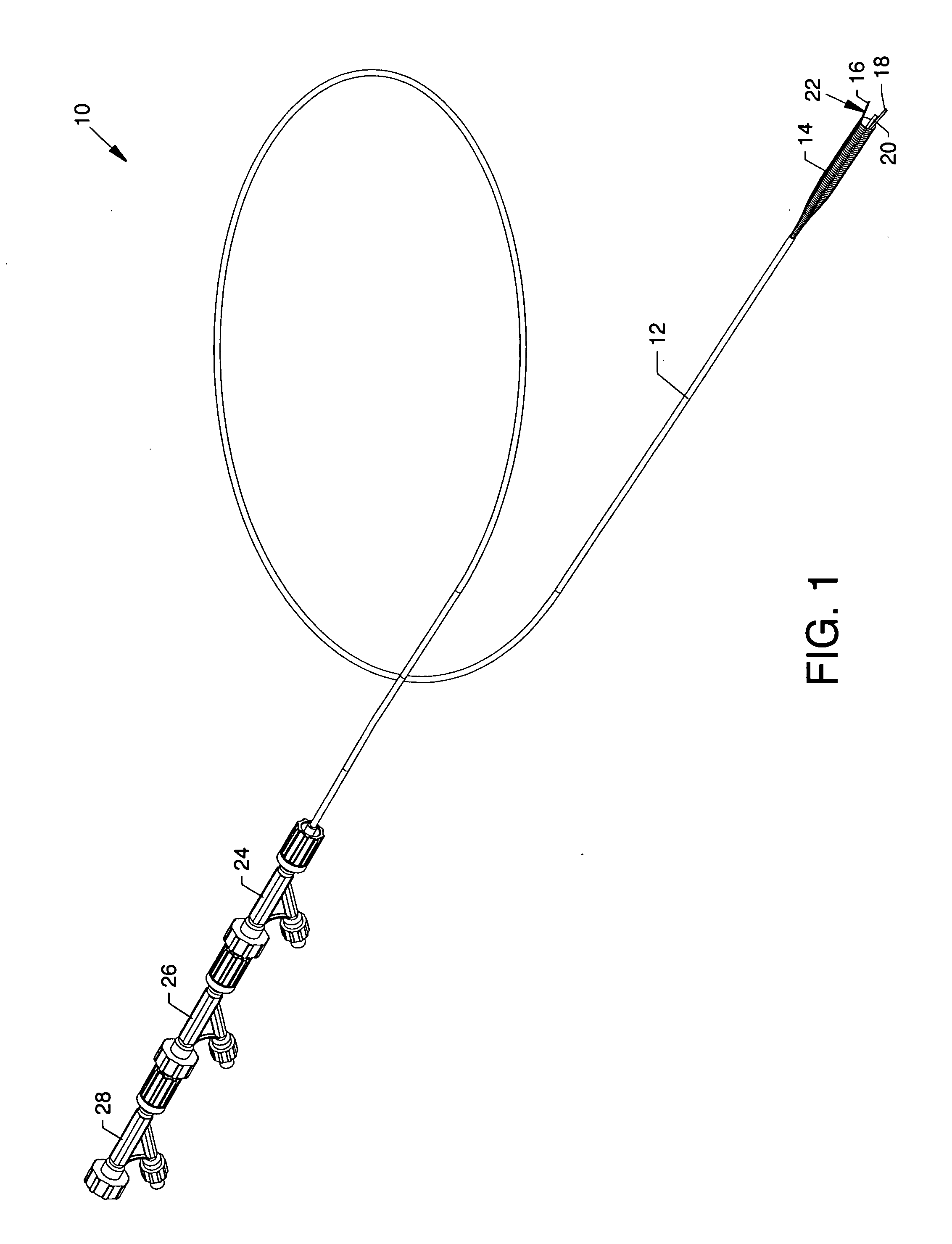

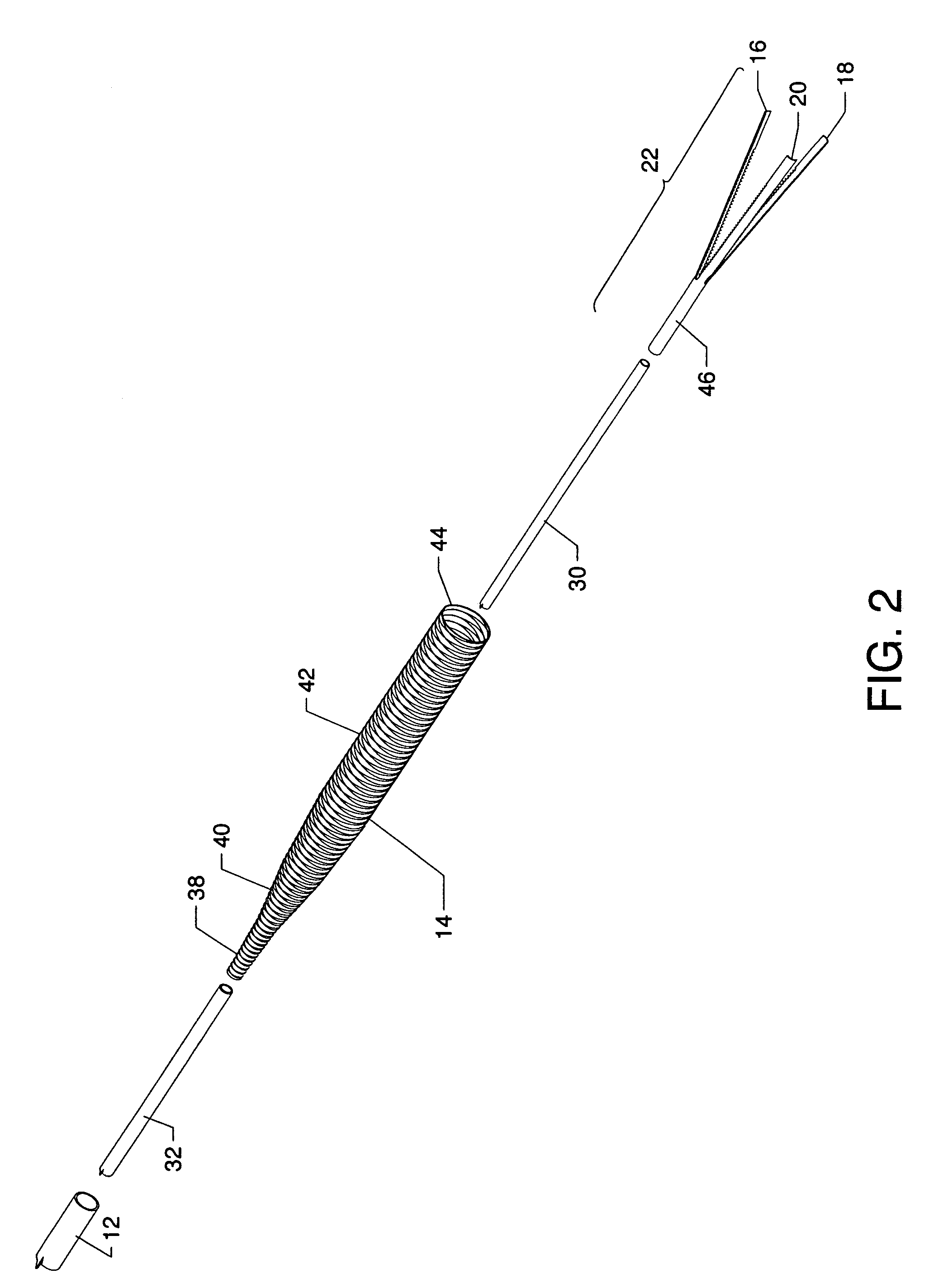

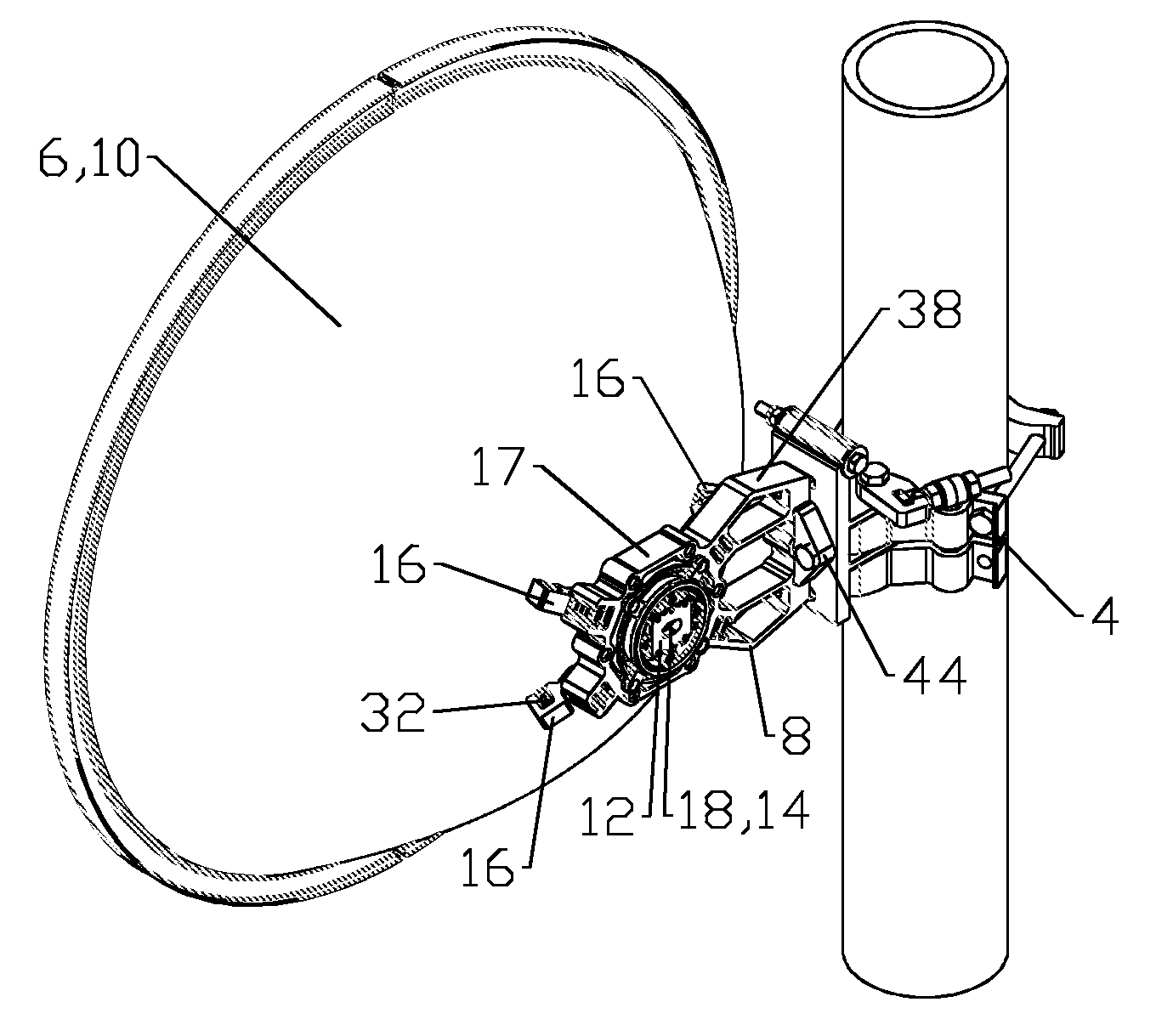

Catheter for removal of an organized embolic thrombus

The general purpose of the present invention is to provide a catheter for removal of an organized embolic thrombus, preferably in conjunction with a distal occlusion balloon guidewire. The present invention consists of three main components including a capture / delivery sheath, a capture sleeve of mesh attached to a tube and a grasping mechanism attached to another tube which is central to the other components. Operative structures in the form of manifolds are connected to such components in order to manipulate and control the relative positions of the capture / delivery sheath, the capture sleeve and the grasping mechanism. An embolic thrombus is engaged by the deployable automatically expanding serrated fingers of a grasping mechanism in combination with a deployable automatically expanding mesh capture sleeve. The capture / delivery sheath is maneuvered to cause compression of the serrated fingers and of the mesh capture sleeve for subsequent removal of the embolic thrombus.

Owner:SURMODICS MD LLC

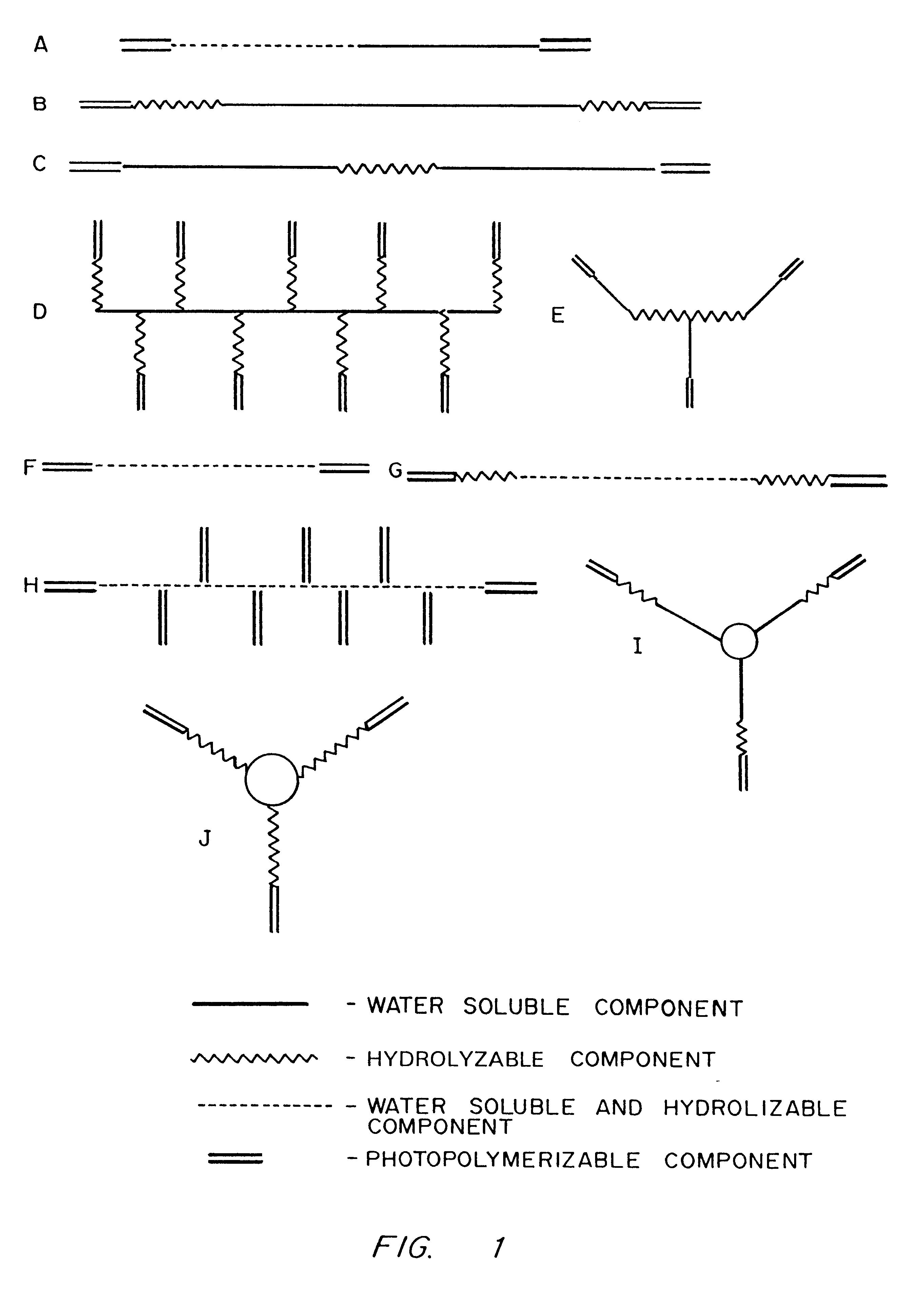

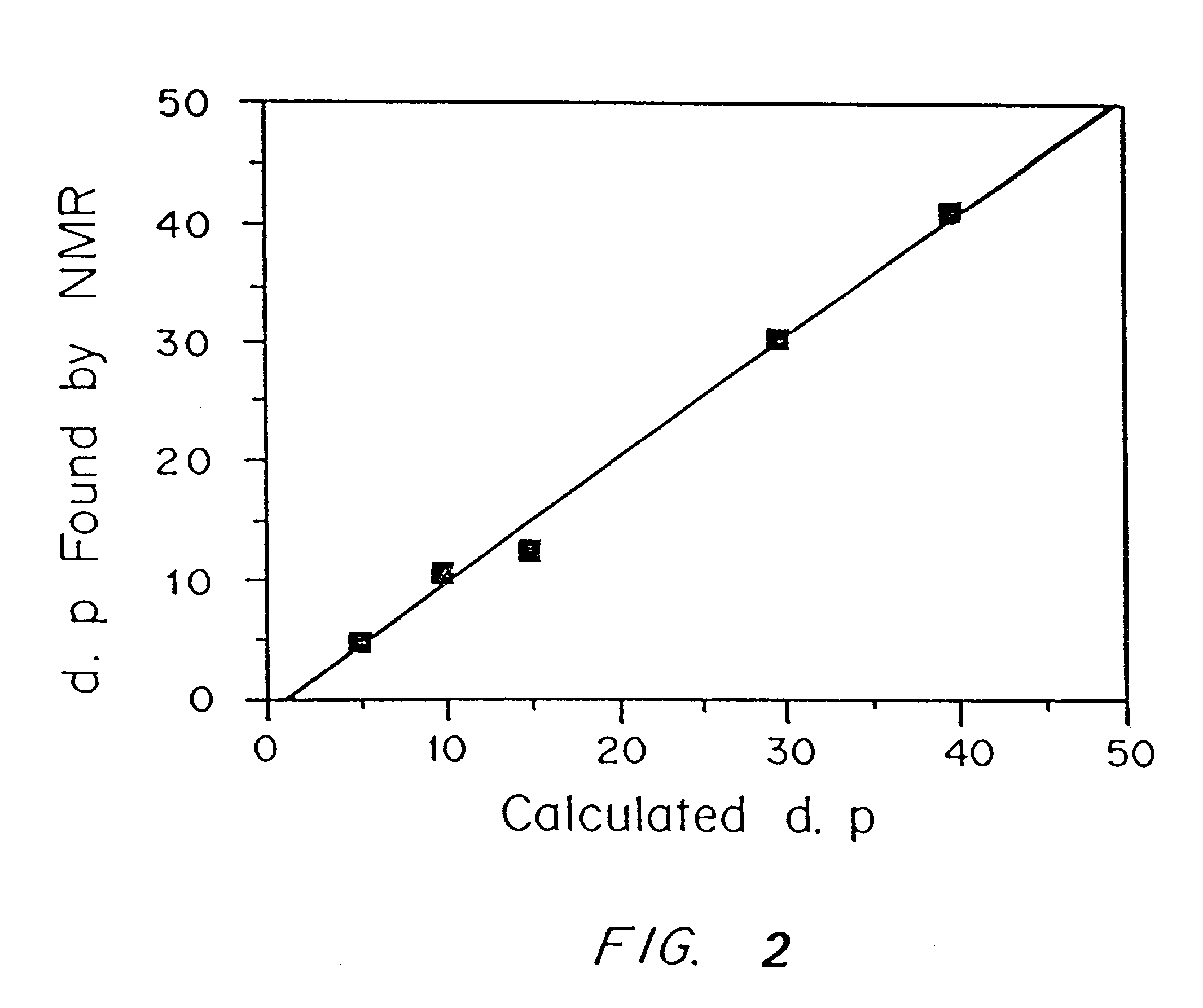

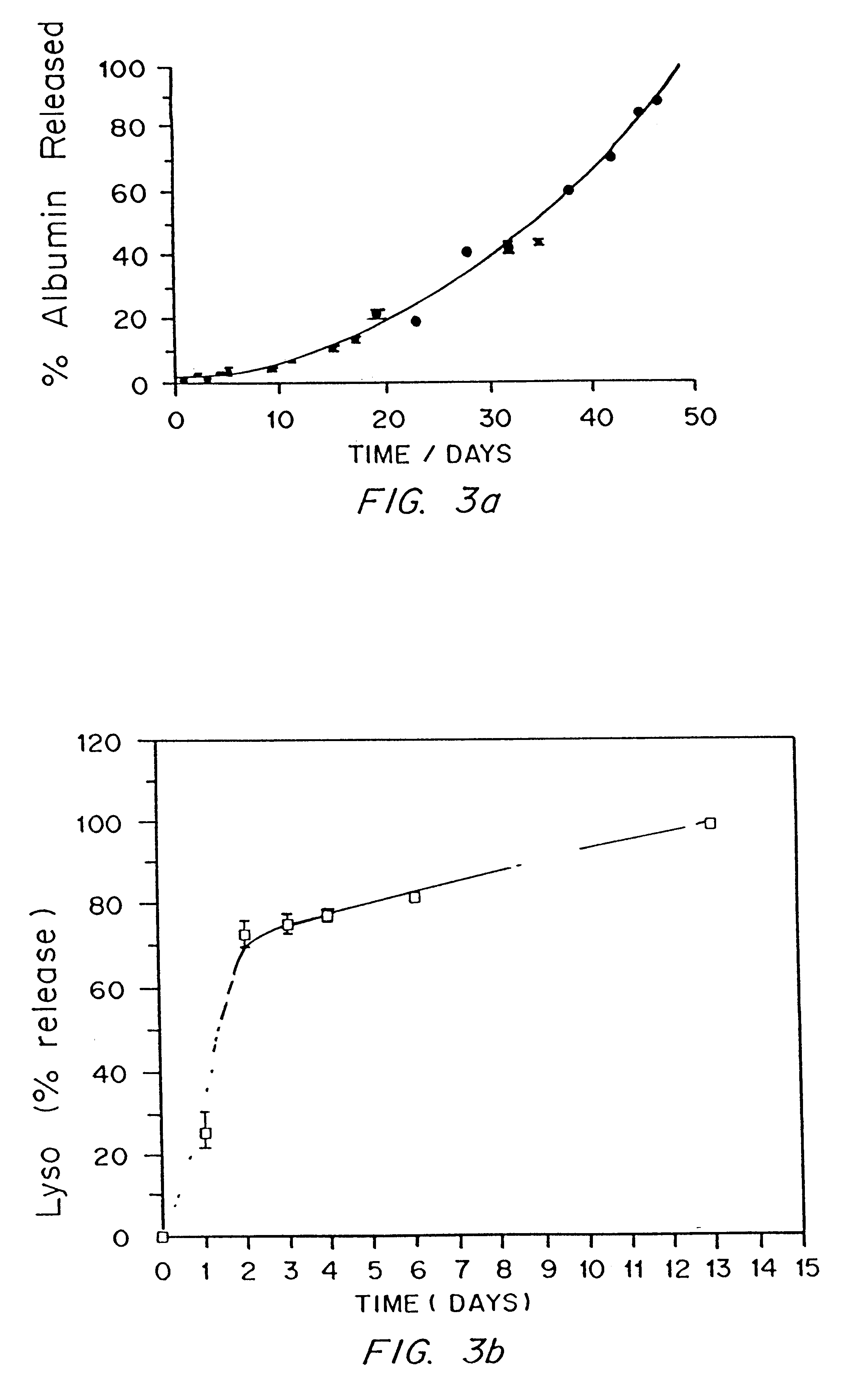

Photopolymerizable biodegradable hydrogels as tissue contacting materials and controlled-release carriers

InactiveUS6306922B1Fast gelationRapid polymerizationImmobilised enzymesPowder deliveryThermal energyUltraviolet lights

Hydrogels of polymerized and crosslinked macromers comprising hydrophilic oligomers having biodegradable monomeric or oligomeric extensions, which biodegradable extensions are terminated on free ends with end cap monomers or oligomers capable of polymerization and cross linking are described. The hydrophilic core itself may be degradable, thus combining the core and extension functions. Macromers are polymerized using free radical initiators under the influence of long wavelength ultraviolet light, visible light excitation or thermal energy. Biodegradation occurs at the linkages within the extension oligomers and results in fragments which are non-toxic and easily removed from the body. Preferred applications for the hydrogels include prevention of adhesion formation after surgical procedures, controlled release of drugs and other bioactive species, temporary protection or separation of tissue surfaces, adhering of sealing tissues together, and preventing the attachment of cells to tissue surfaces.

Owner:BOARD OF REGENTS

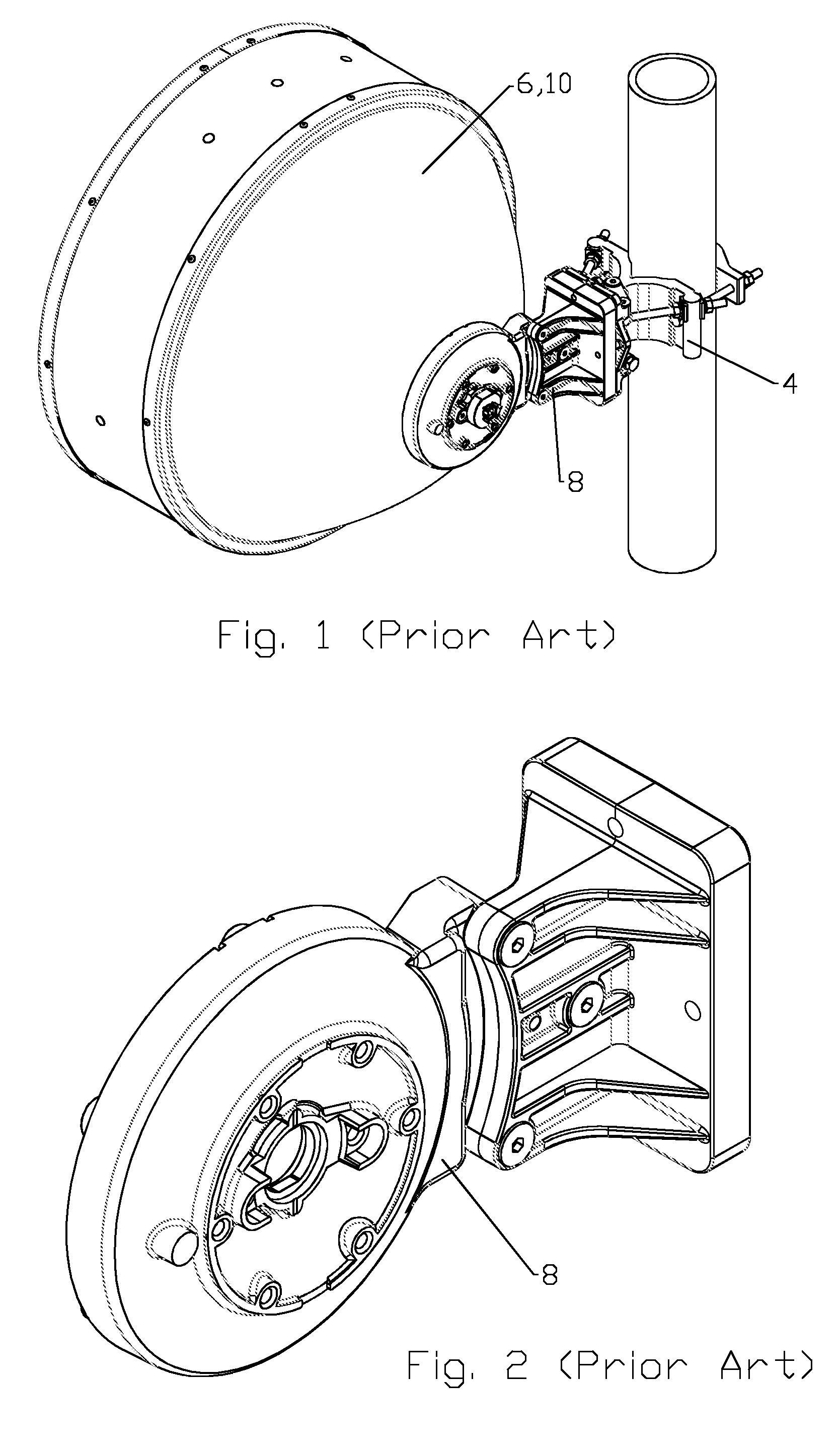

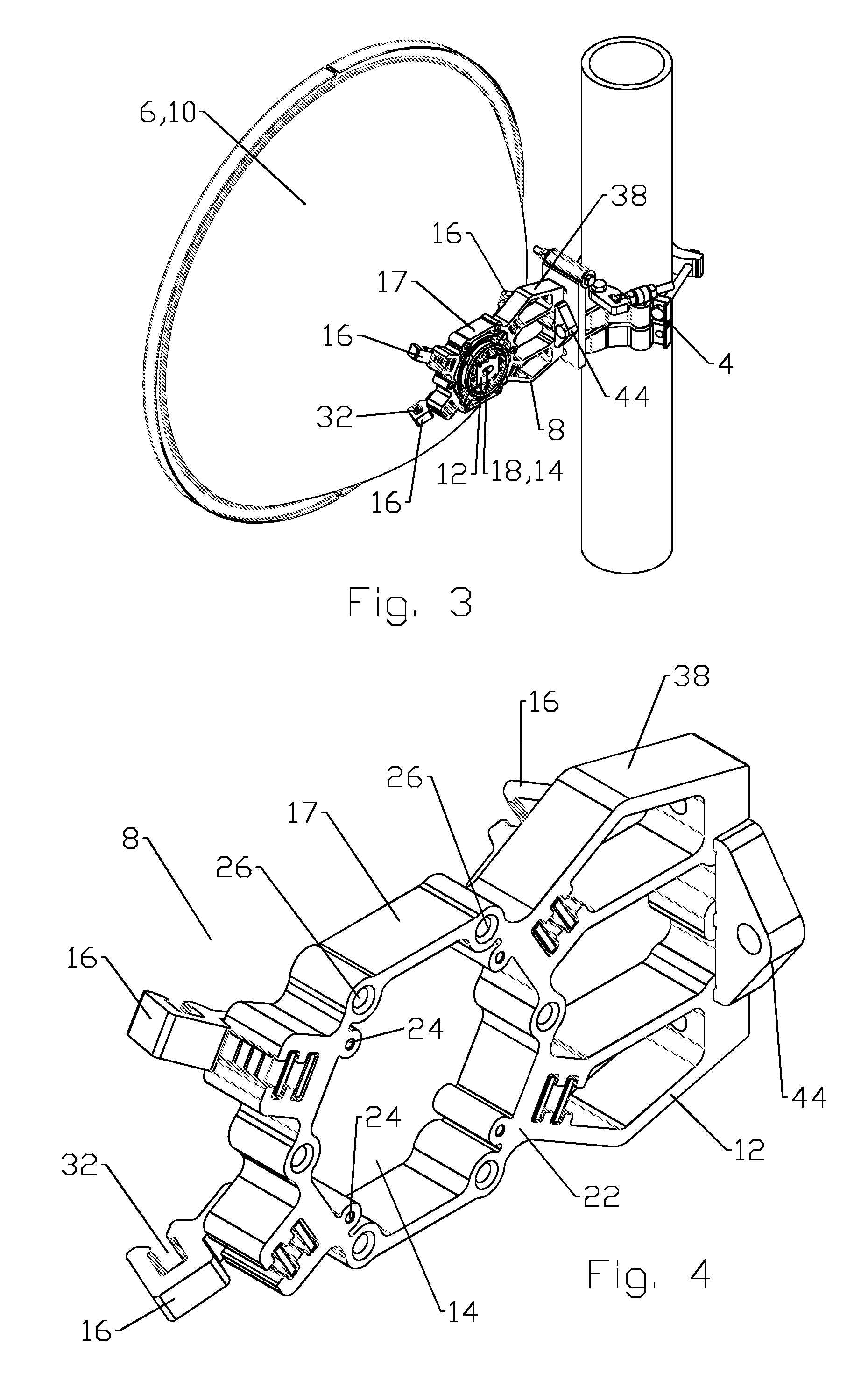

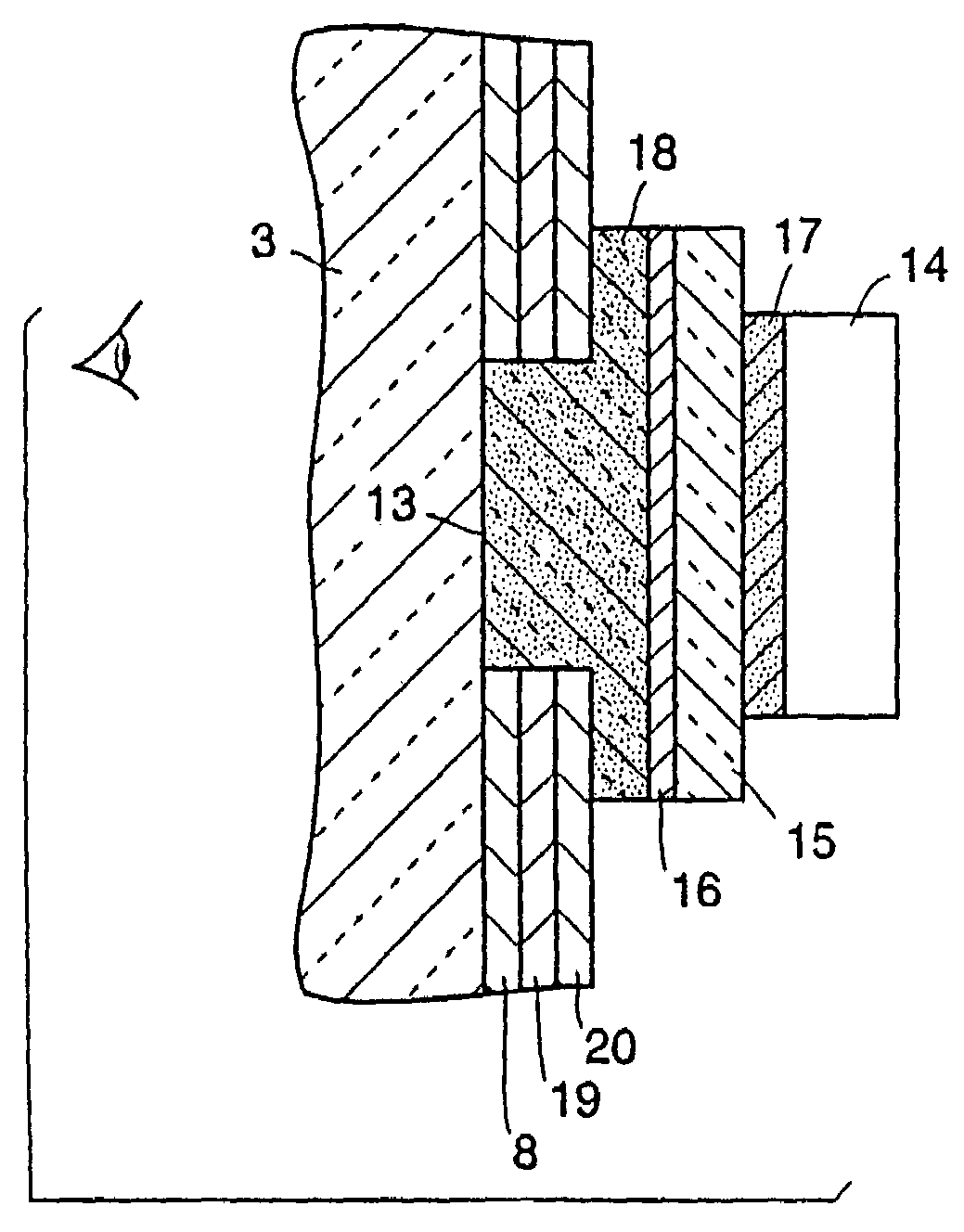

Mounting hub for antenna

ActiveUS9065172B2Low costLower manufacturing requirementsAntenna supports/mountingsEngineeringElectrical and Electronics engineering

An antenna hub for a reflector dish has a frame with a feed aperture. A plurality of feet are coupled to the frame; each of the feet provided with a dish fastener coupling axis normal to a dish surface contacting each of the feet when the reflector dish is seated upon the feet, the feed bore of the reflector dish aligned coaxial with the feed aperture. The frame and feet may be formed via extrusion.

Owner:COMMSCOPE TECH LLC

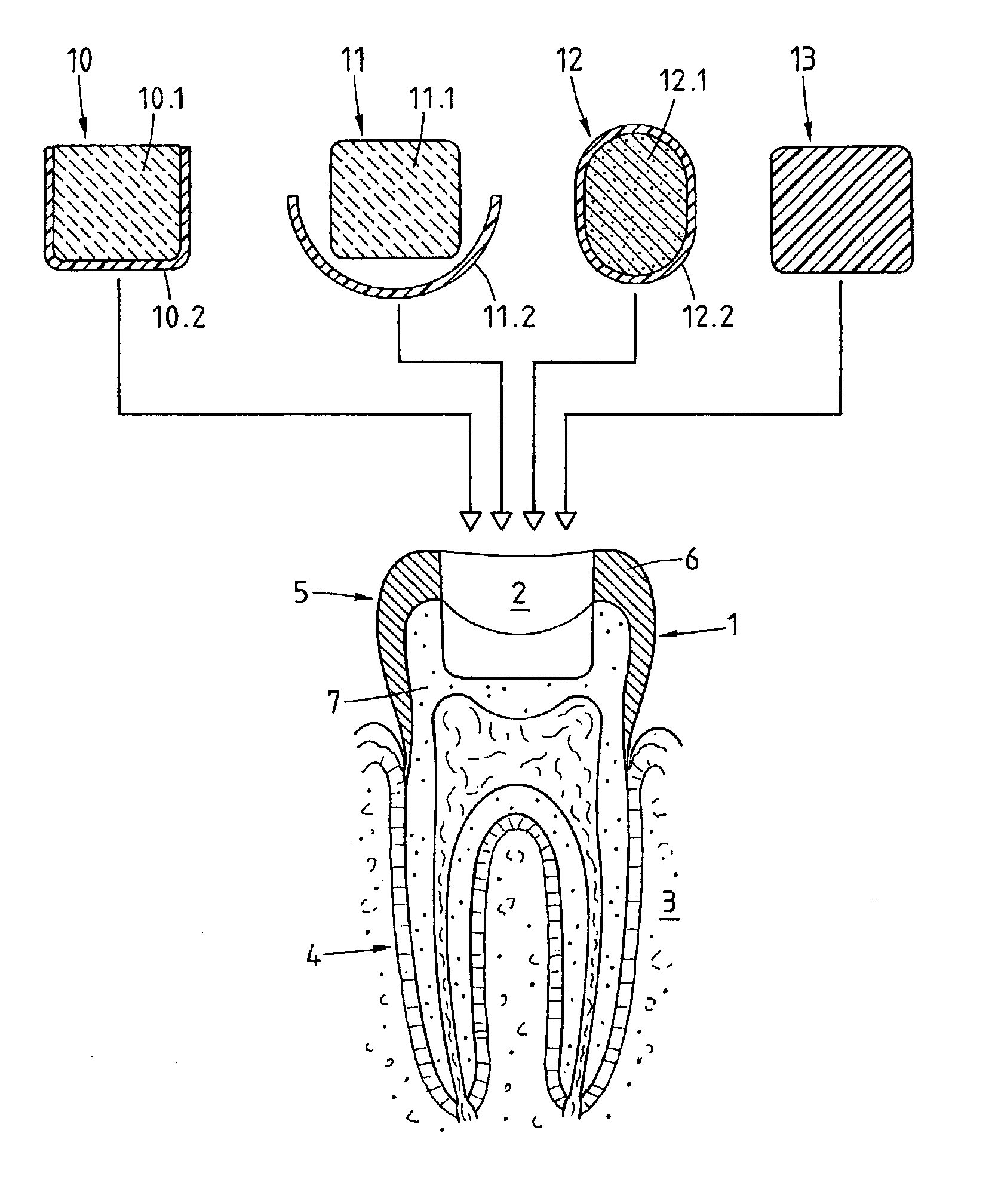

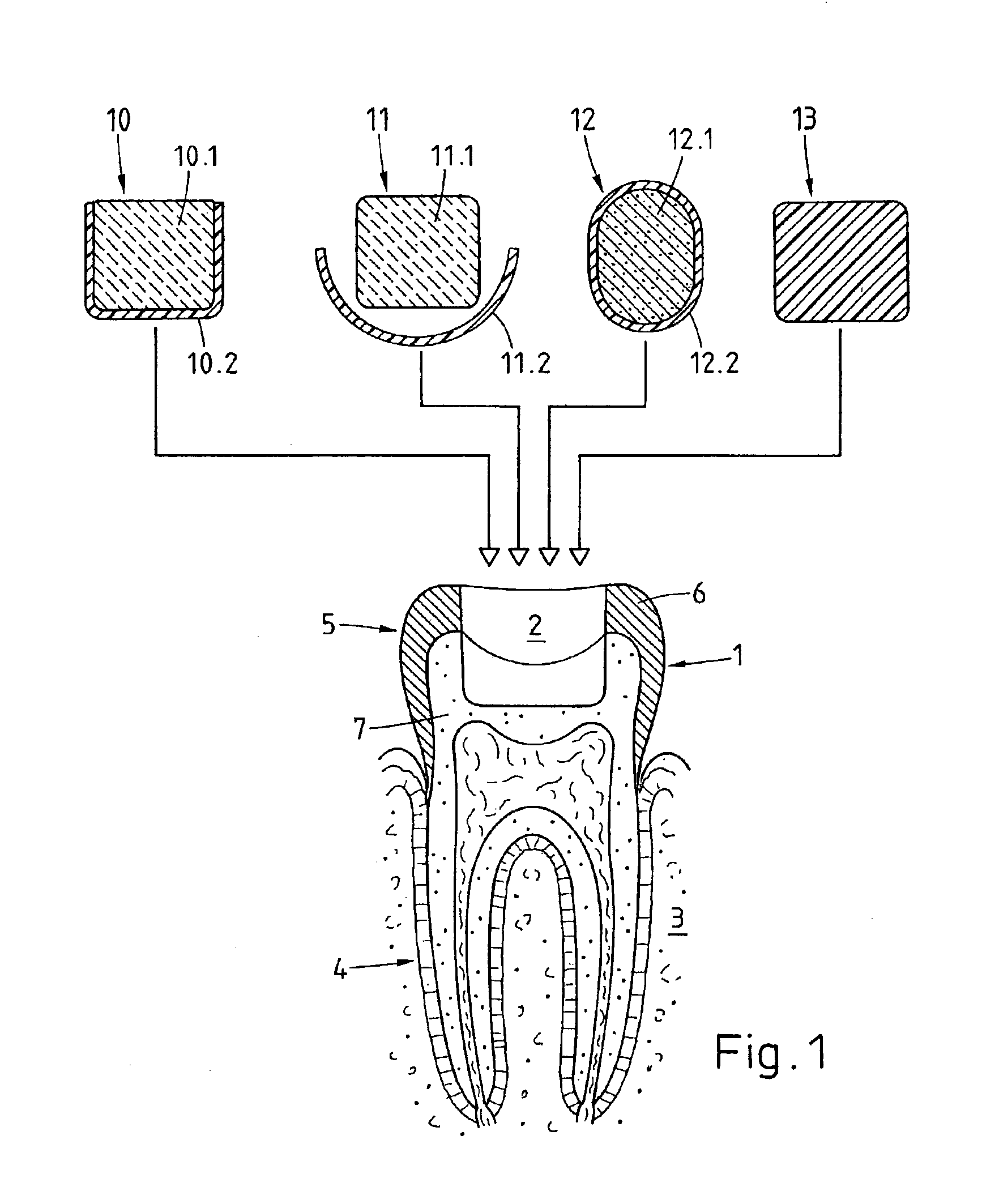

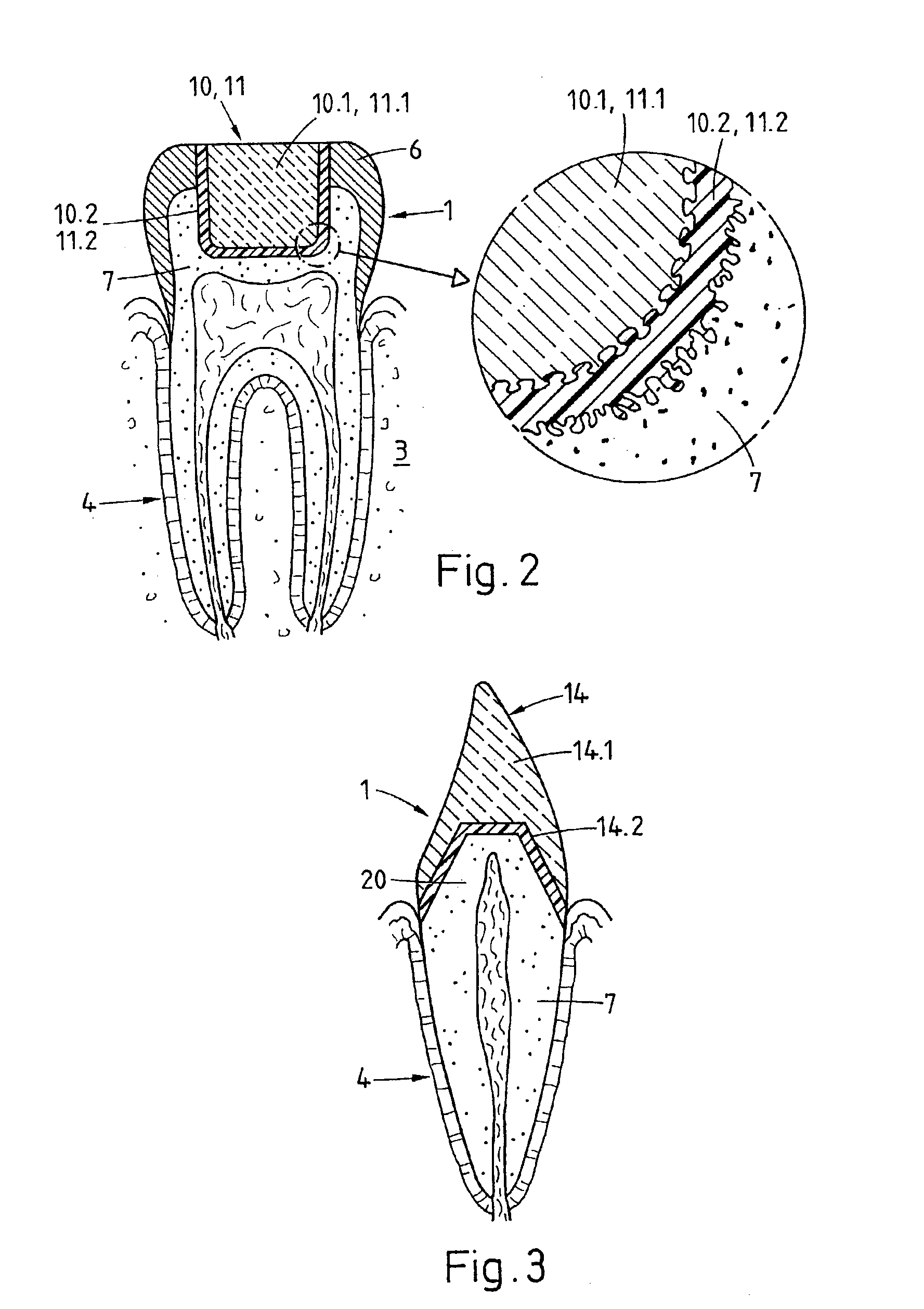

Preparation for being fastened on a natural tooth part or tooth and corresponding fastening method

ActiveUS6955540B2Reduce Shrinkage ProblemsRelieve stressDental implantsImpression capsStress concentrationNatural tooth

A preparation (10, 11,12,13) to be fixed to a natural tooth part or tooth, in particular for the replacement of a load-bearing tooth part, is for example a filling for a drilled-out tooth (1), a crown, bridge or prosthesis to be placed on a tooth stub, or a tooth pin to be fixed in a tooth root for fastening an artificial tooth, a bridge or a prosthesis. The preparation has surface regions which consist of a material with thermoplastic properties. The preparation (10, 11, 12,13) is designed in a manner such that it has oscillation properties with such low damping losses that for a liquefaction of the material with thermoplastic properties by way of oscillations there are local stress concentrations required, and in a manner such that such stress concentrations only occur in the region of the preparation surface. The preparation is positioned on a suitably prepared natural tooth part in a manner such that the material with the thermoplastic properties is in contact or may be brought into contact with the dentin surface and / or enamel surface. The preparation is then made to mechanically oscillate and is simultaneously pressed against the natural tooth part, whereby the material with the thermoplastic properties is at least partly liquefied and brought into intimate contact with the dentin or enamel surface in a manner such that after solidification it forms a positive fit and / or material fit connection. Teeth restored with such preparations have a high stability and a long life, which in particular is attributed to the fact that the thermoplastic material, in contrast to cements used for the same purpose, shrinks less and has the ability to relieve internal stress by creeping.

Owner:WOODWELDING

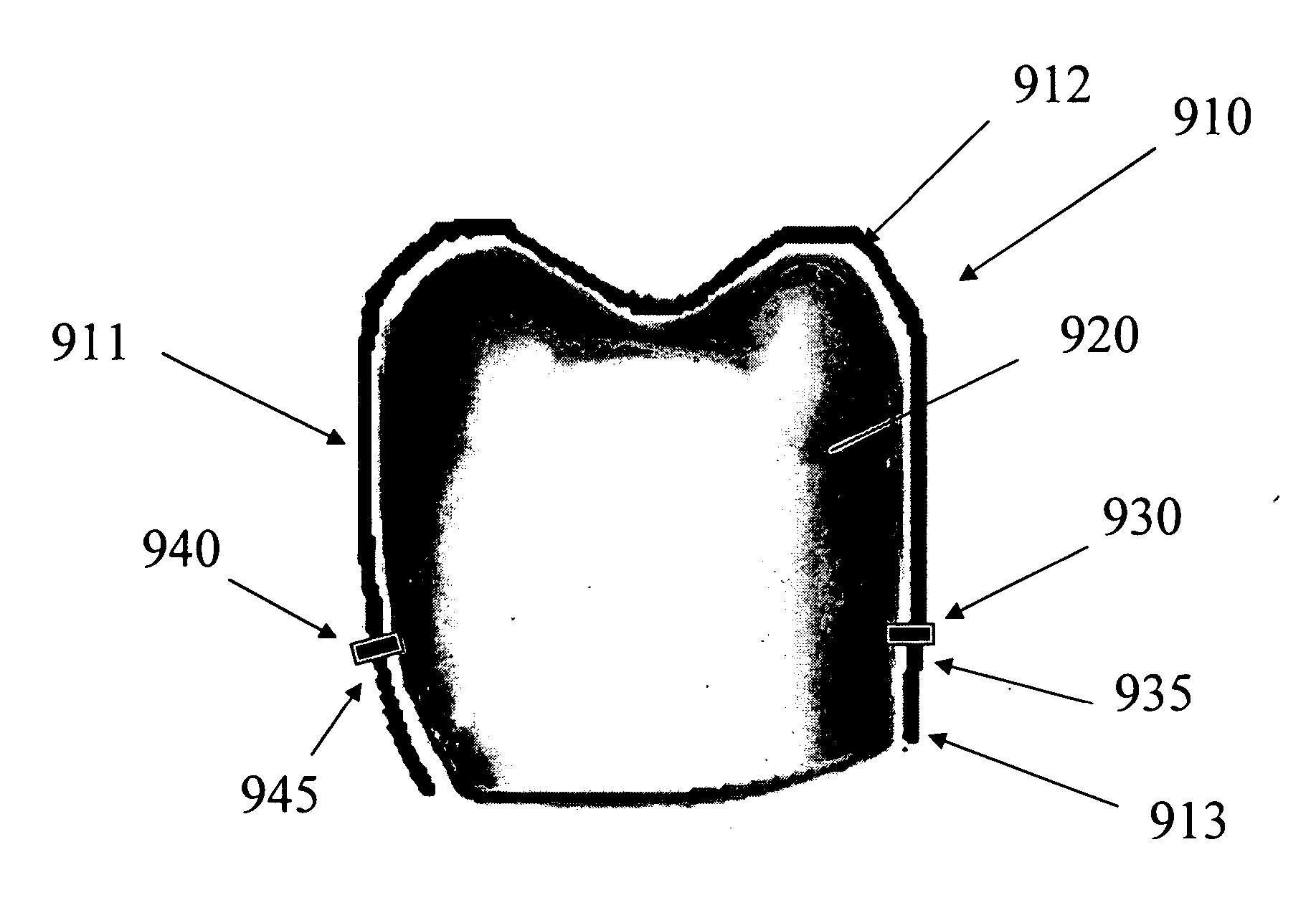

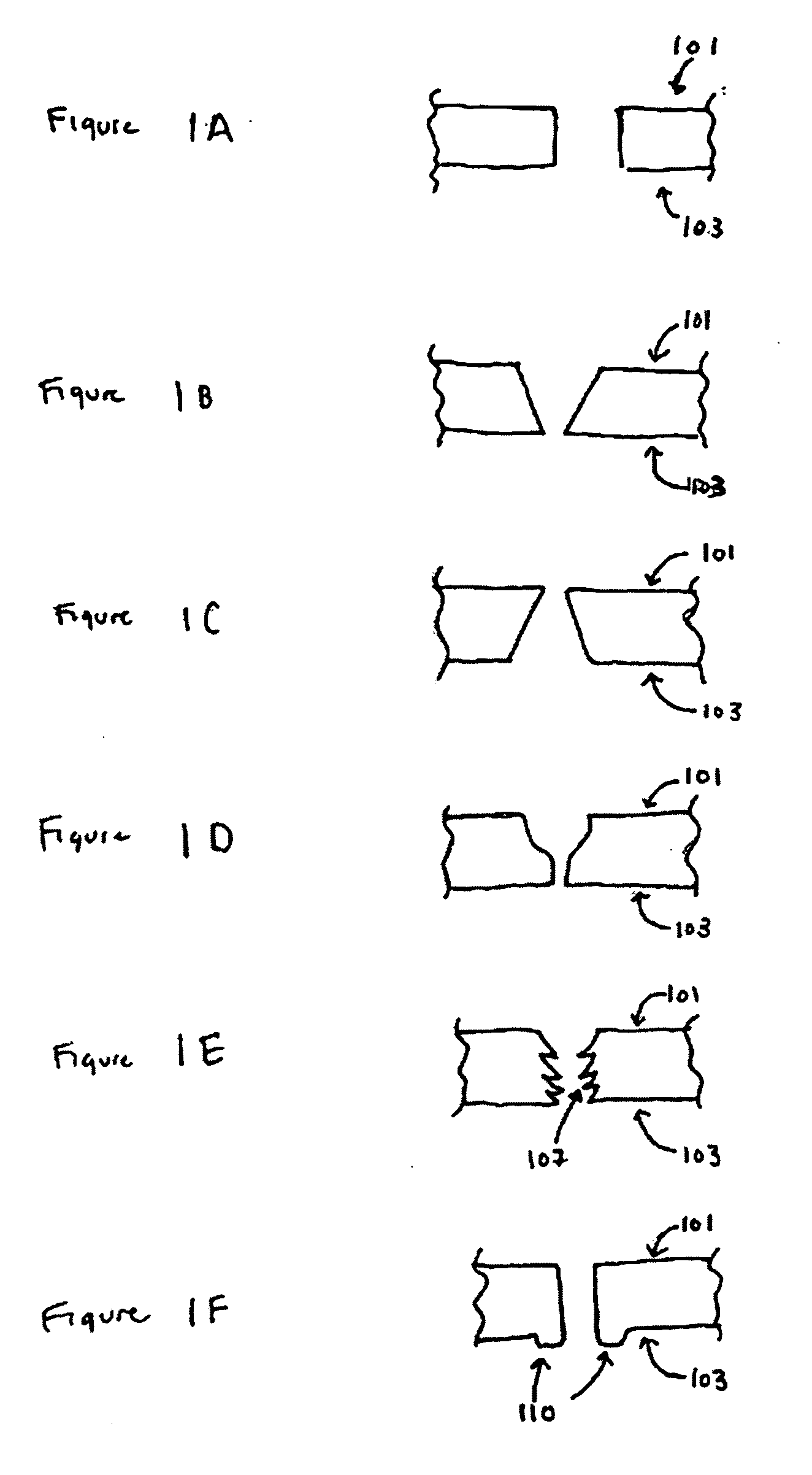

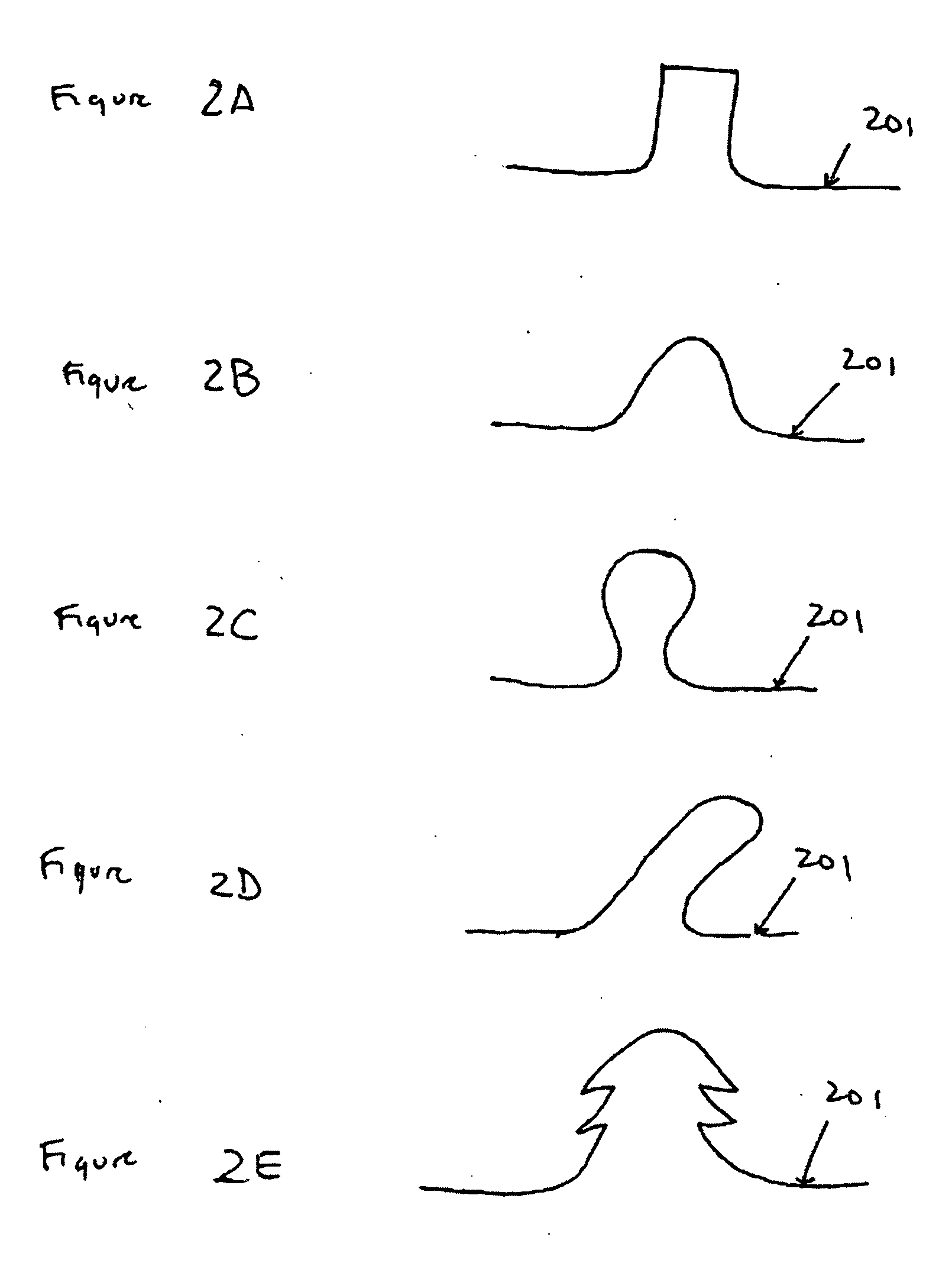

Dental aligner devices having snap-on connectors

InactiveUS20060234179A1Improve accuracy and effectivenessReduce numberOthrodonticsDental toolsOrthodontic BraceEngineering

A system for producing corrective movement in a subject's teeth includes a dental aligner device having one or more through-holes and one or more connectors fixed to the subject's teeth. The connectors can snap into the through-holes when the dental aligner is worn on the subject's teeth.

Owner:ALIGN TECH

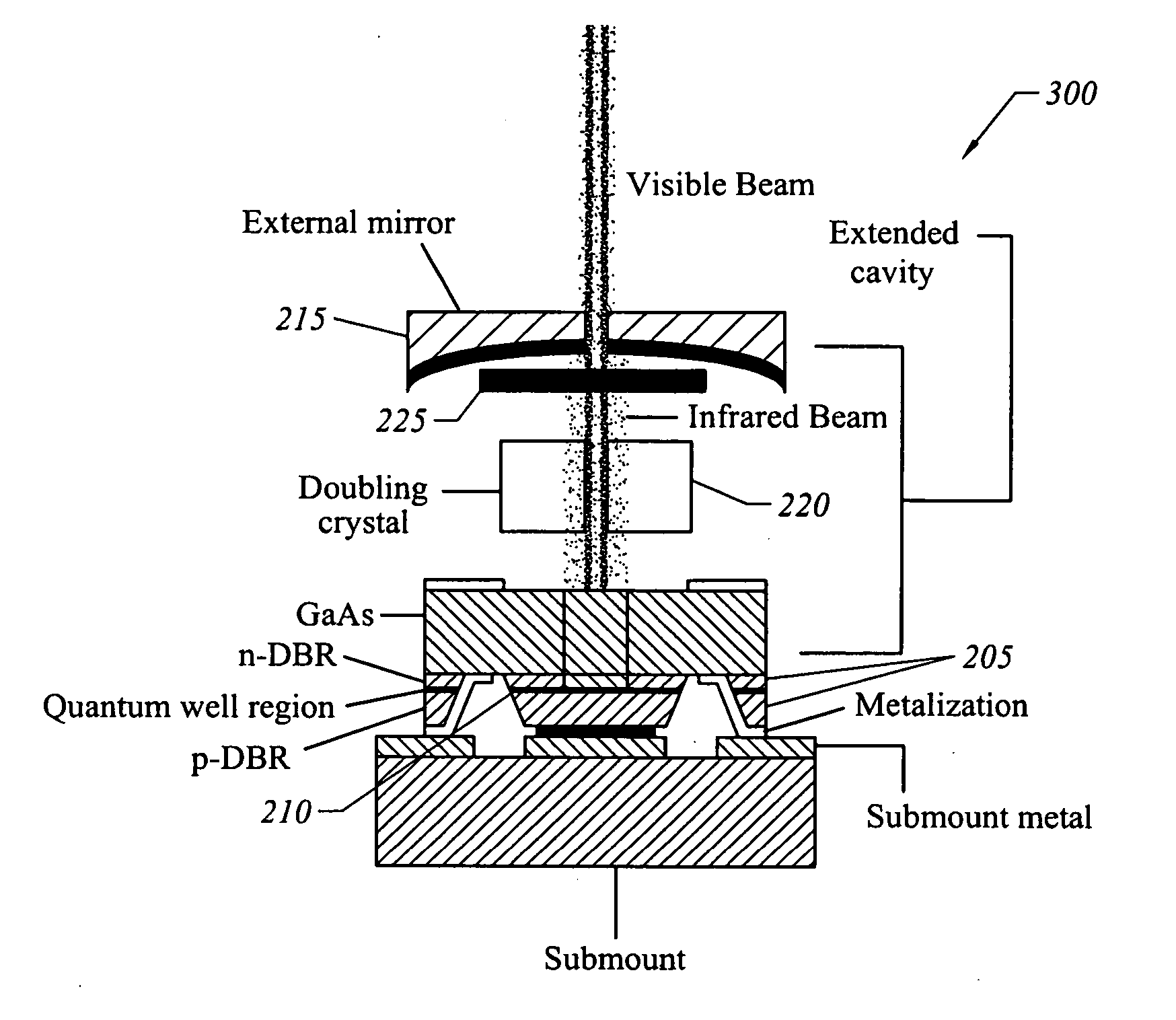

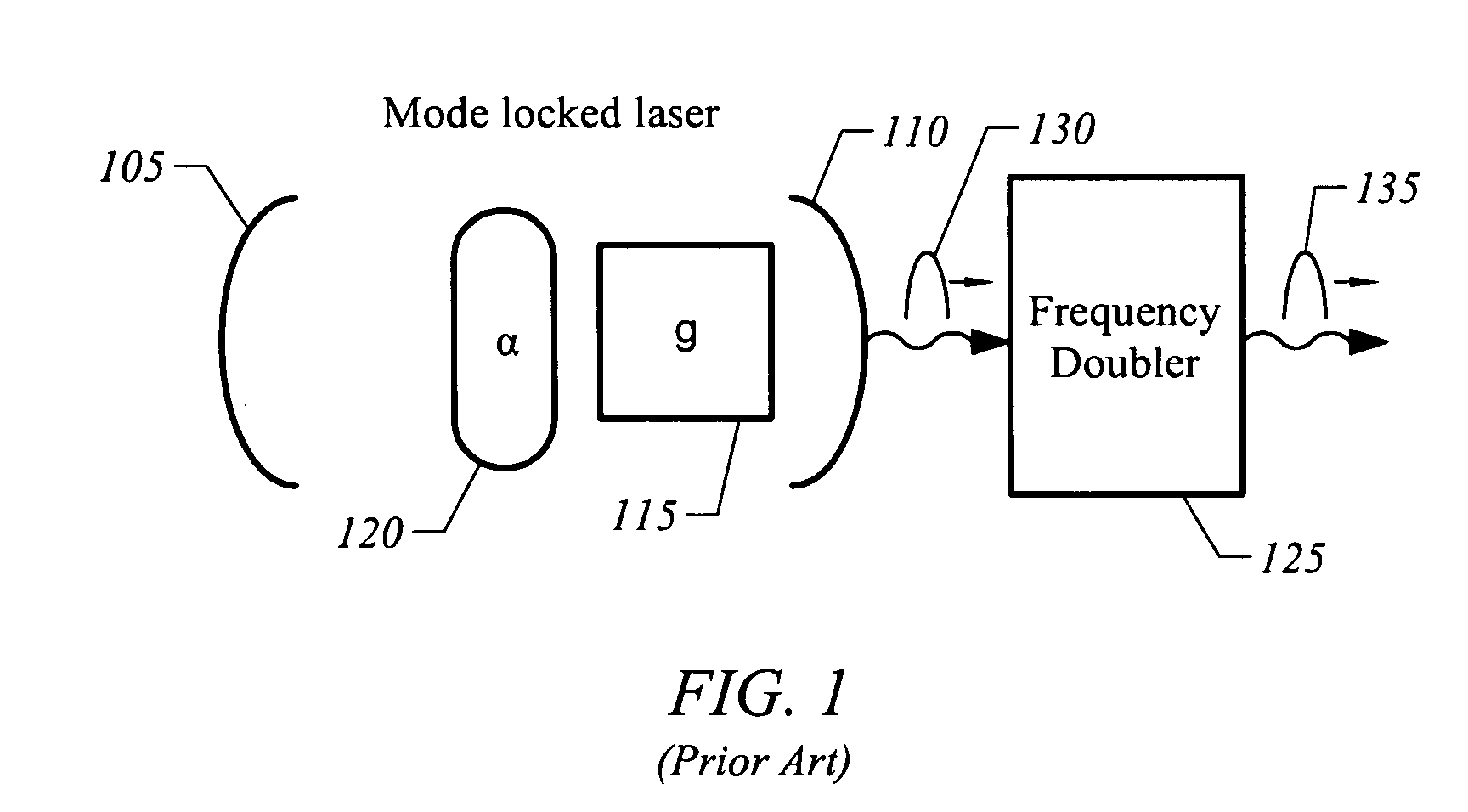

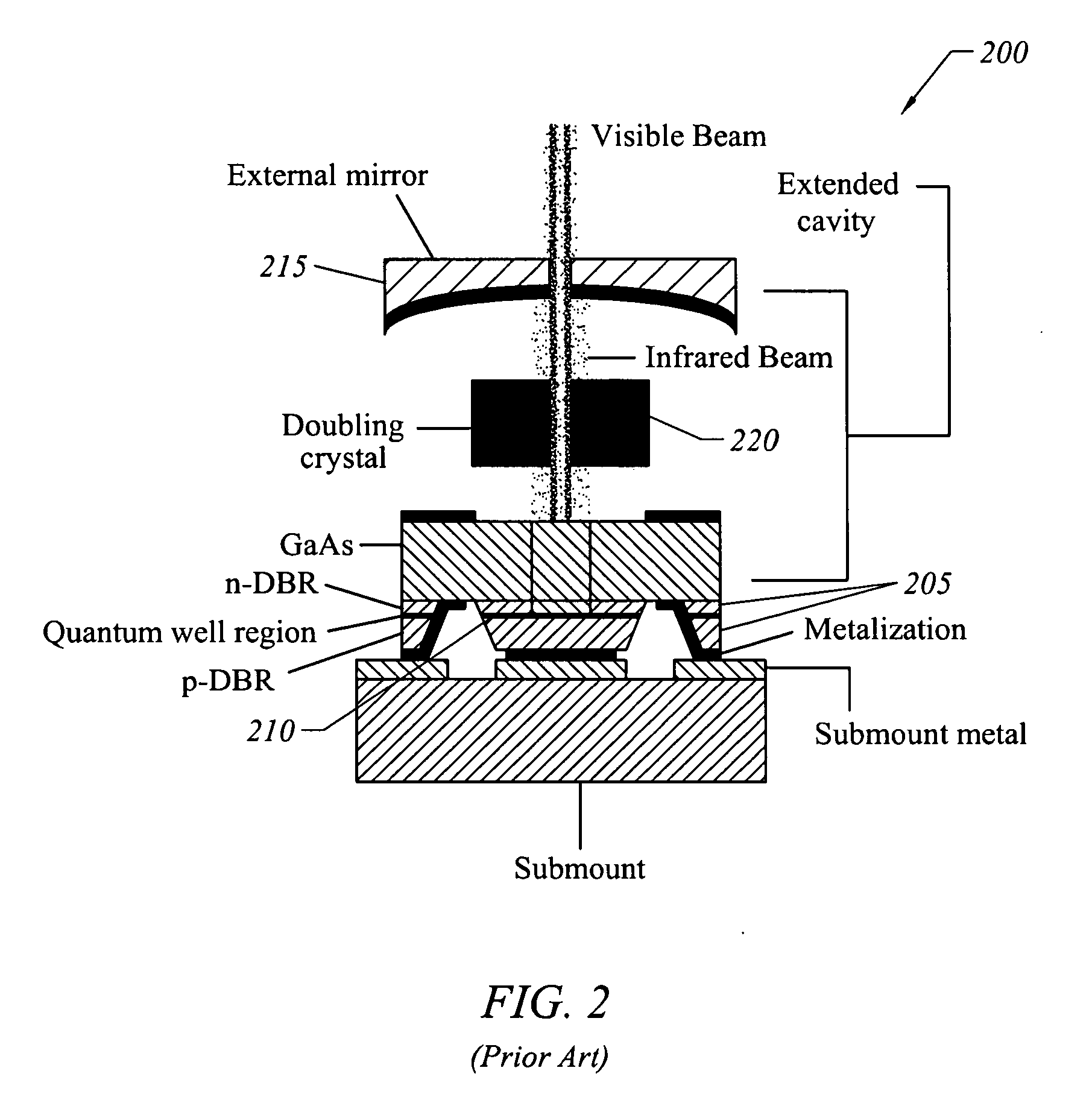

Apparatus, system, and method for wavelength conversion of mode-locked extended cavity surface emitting semiconductor lasers

InactiveUS20060023757A1Reduce polarizationReduce materialLaser detailsSemiconductor lasersFrequency conversionFundamental frequency

A mode-locked laser with intracavity frequency conversion is disclosed. In one embodiment the conversion frequency is improved by reducing the temporal, spatial, or polarization overlap between pulses at the fundamental frequency and pulses at a frequency-shifted frequency.

Owner:NECSEL INTPROP +1

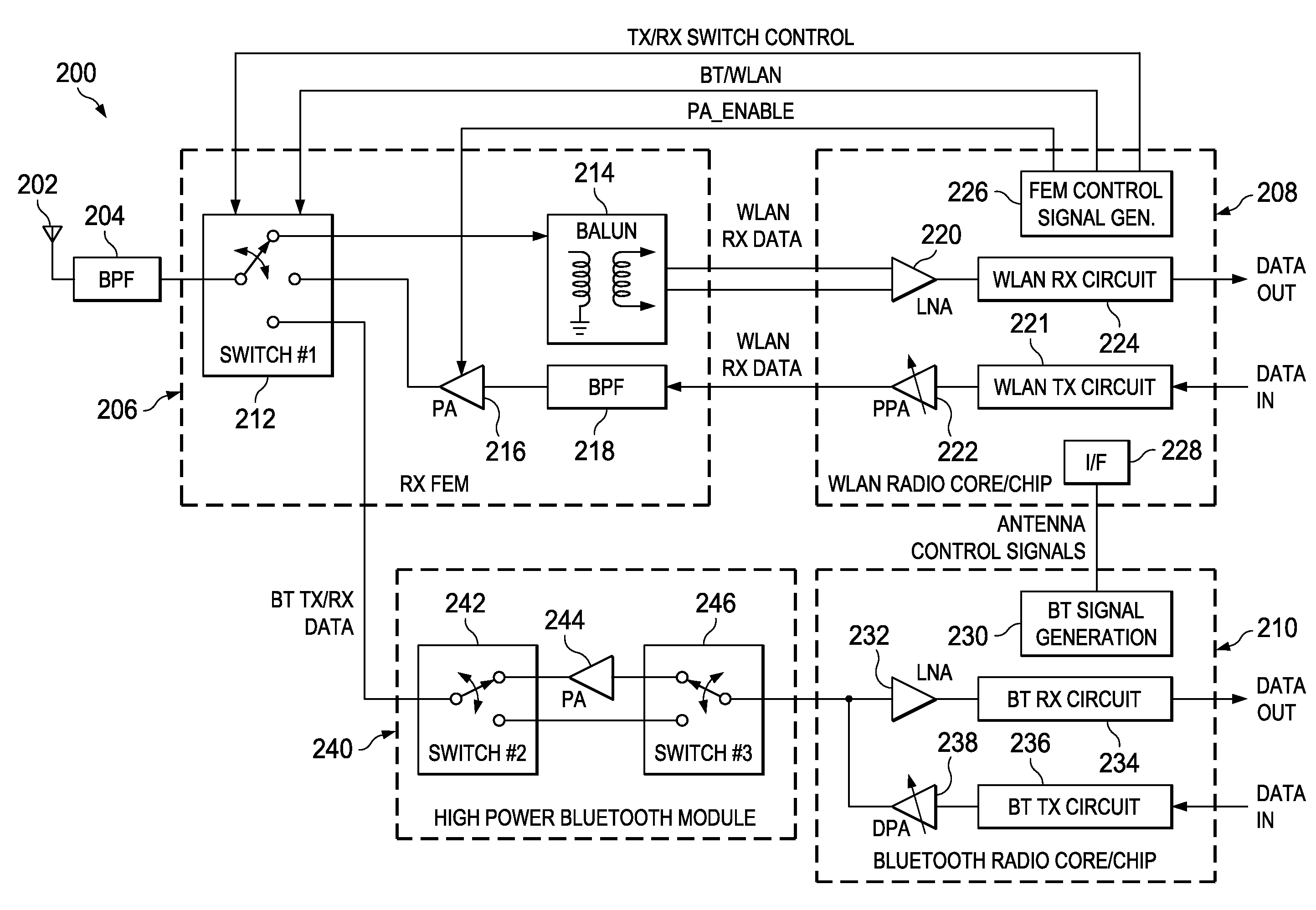

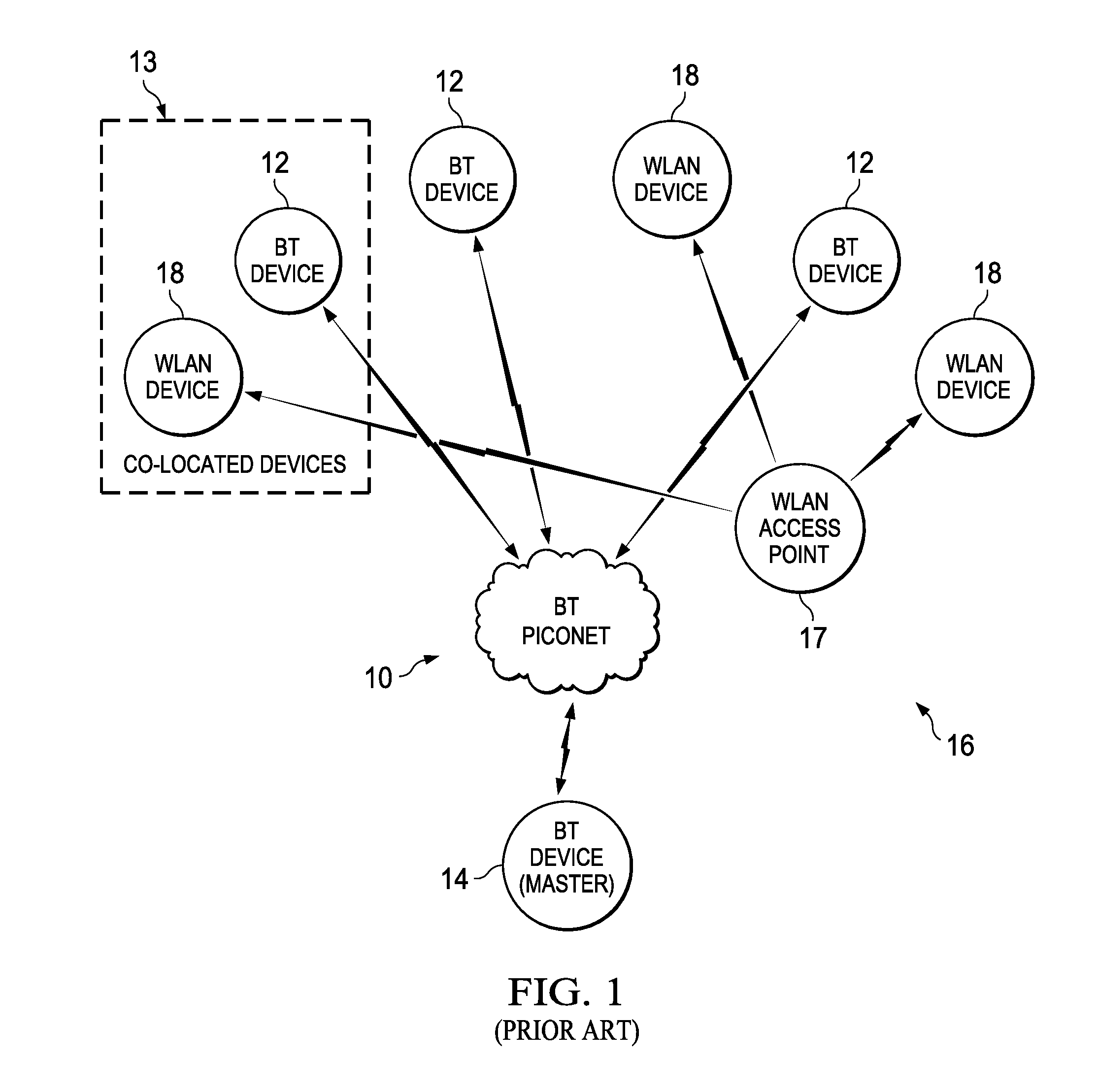

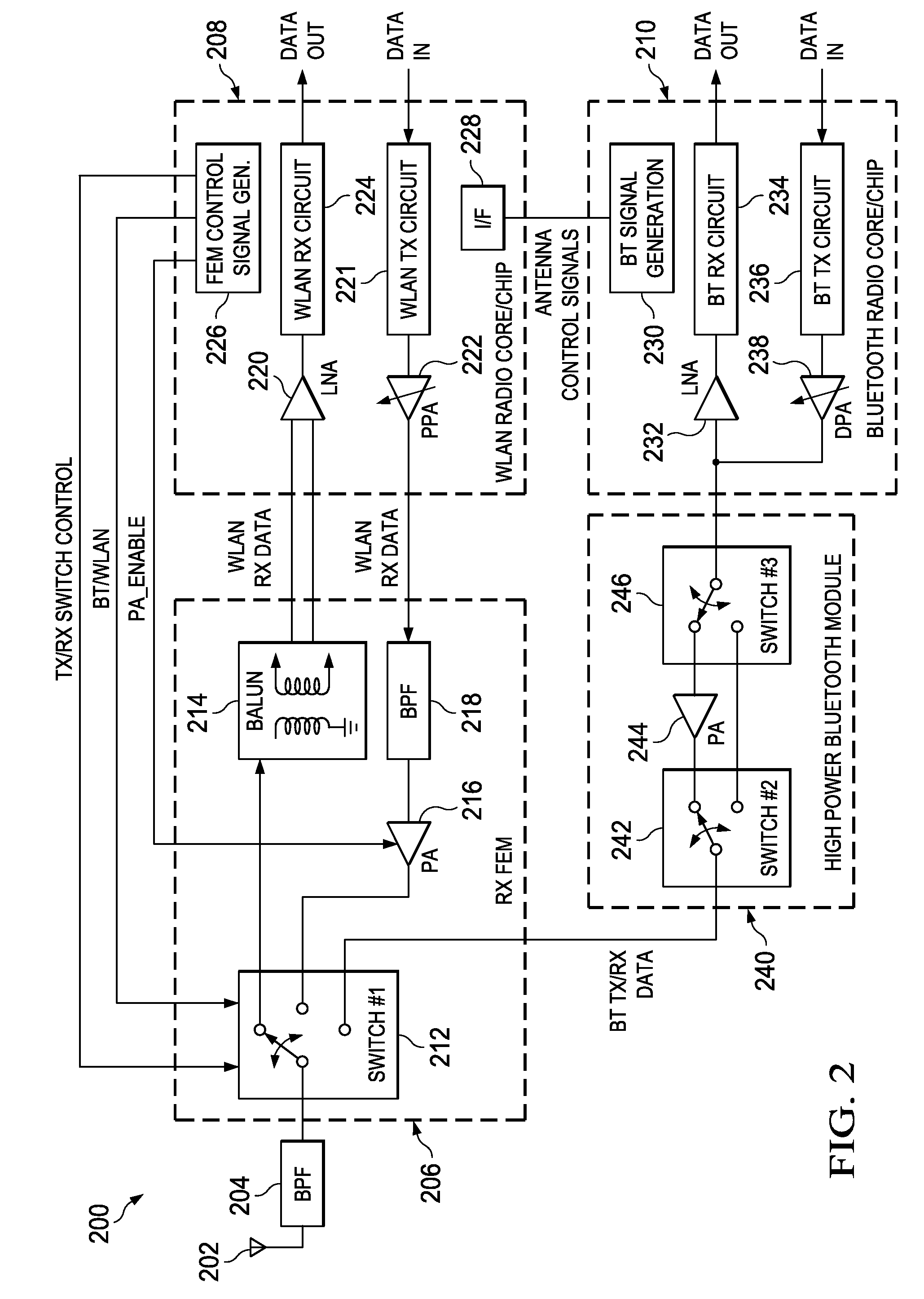

High transmission power using shared bluetooth and wireless local area network front end module

InactiveUS20100008338A1Reduce consumptionLow costRadio/inductive link selection arrangementsRadio transmissionAudio power amplifierControl signal

A novel and useful system for providing high transmission power using a shared Bluetooth and Wireless Local Area Network (WLAN) front end module (FEM). A single power amplifier in the front end module is shared between the WLAN and Bluetooth radio cores, thus providing a high power transmission option (Bluetooth class 1) for the Bluetooth core. Interface circuitry in the FEM couple either the WLAN TX output or the Bluetooth TX output to the input of the power amplifier and couple the output of the power amplifier to the external antenna. In the receive direction, the interface circuitry steers the antenna input to the respective WLAN or Bluetooth receivers in accordance with one or more control signals. Alternatively, a switch in the WLAN / Bluetooth radio chip functions to switch the Bluetooth TX output to a conventional FEM, thereby allowing the FEM power amplifier to be shared between the WLAN and Bluetooth radio cores.

Owner:TEXAS INSTR INC

Vascular graft having a chemicaly bonded electrospun fibrous layer and method for making same

InactiveUS20030100944A1Improve surface morphologyGood tissue responseNon-woven fabricsCoatingsChemical LinkageElectrospinning

A vascular graft comprising a traditional graft material and an electrospun fibrous layer. The solvent used to reduce the material for the electrospun layer is also capable of reducing the graft material to a liquid solution. The electrospun layer is chemically bonded to the graft material, without adhesives, by either spraying the graft with the solvent prior to electrospinning or by assuring that a sufficient amount of residual solvent reaches the graft while electrospinning.

Owner:DATASCOPE INVESTMENT

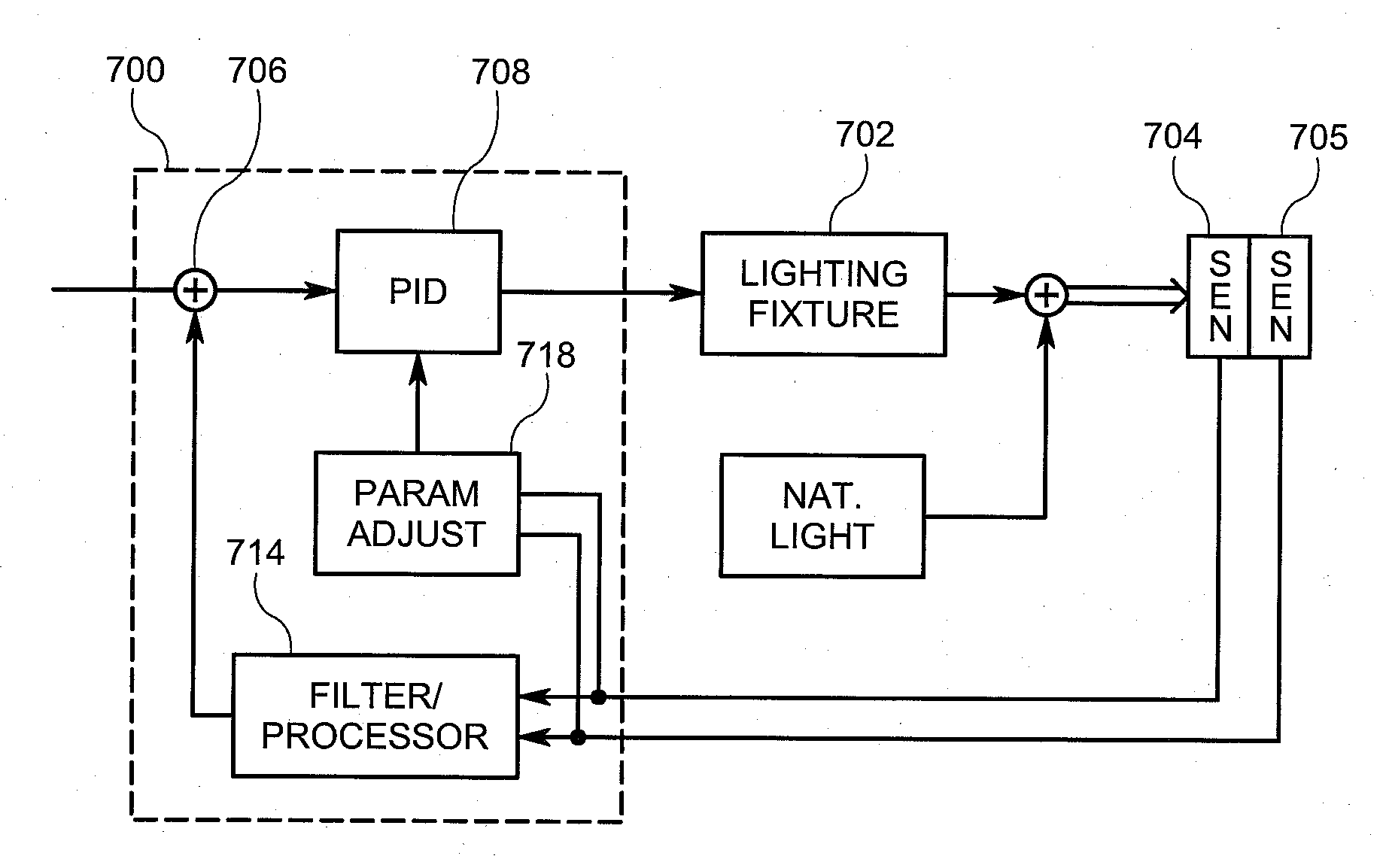

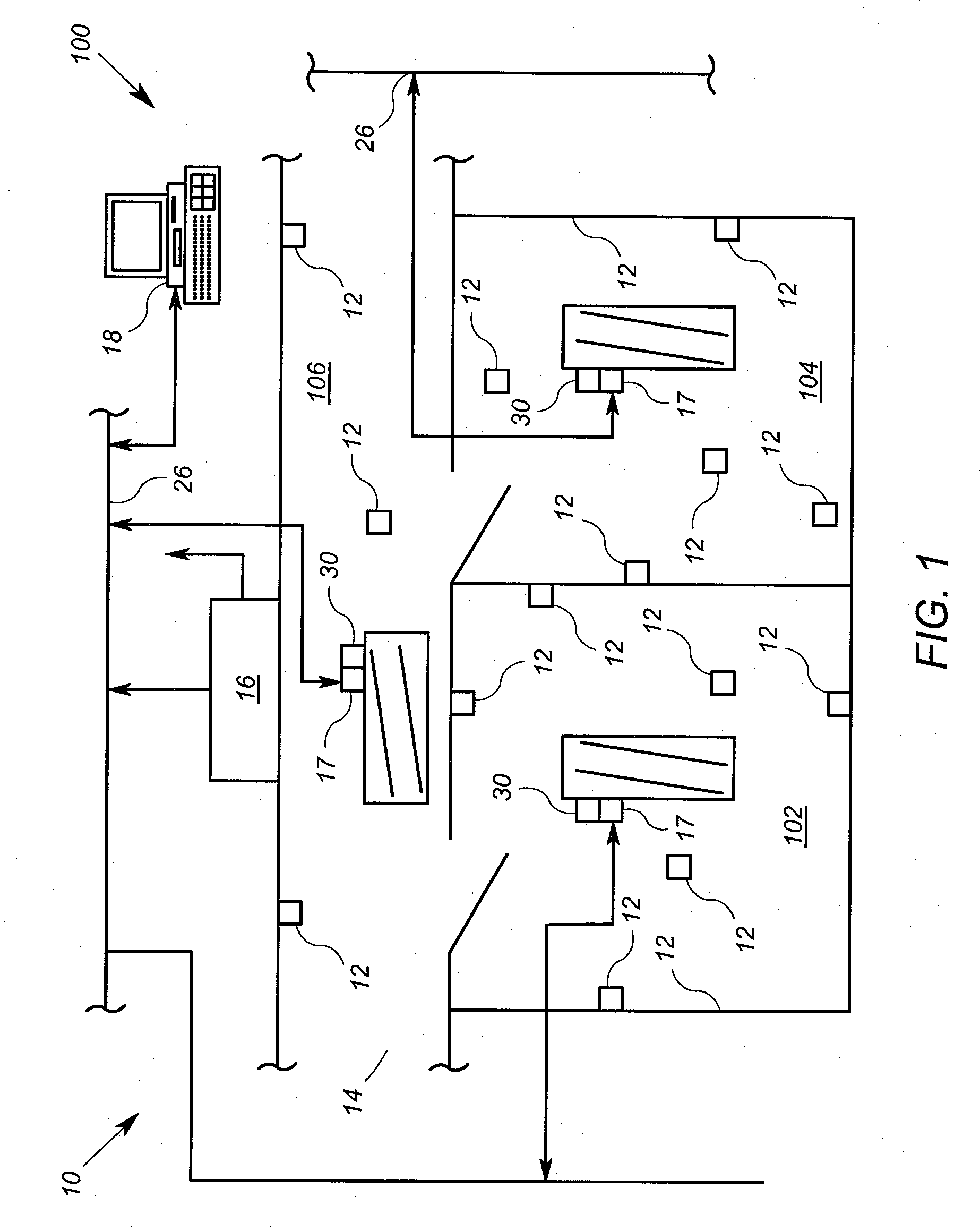

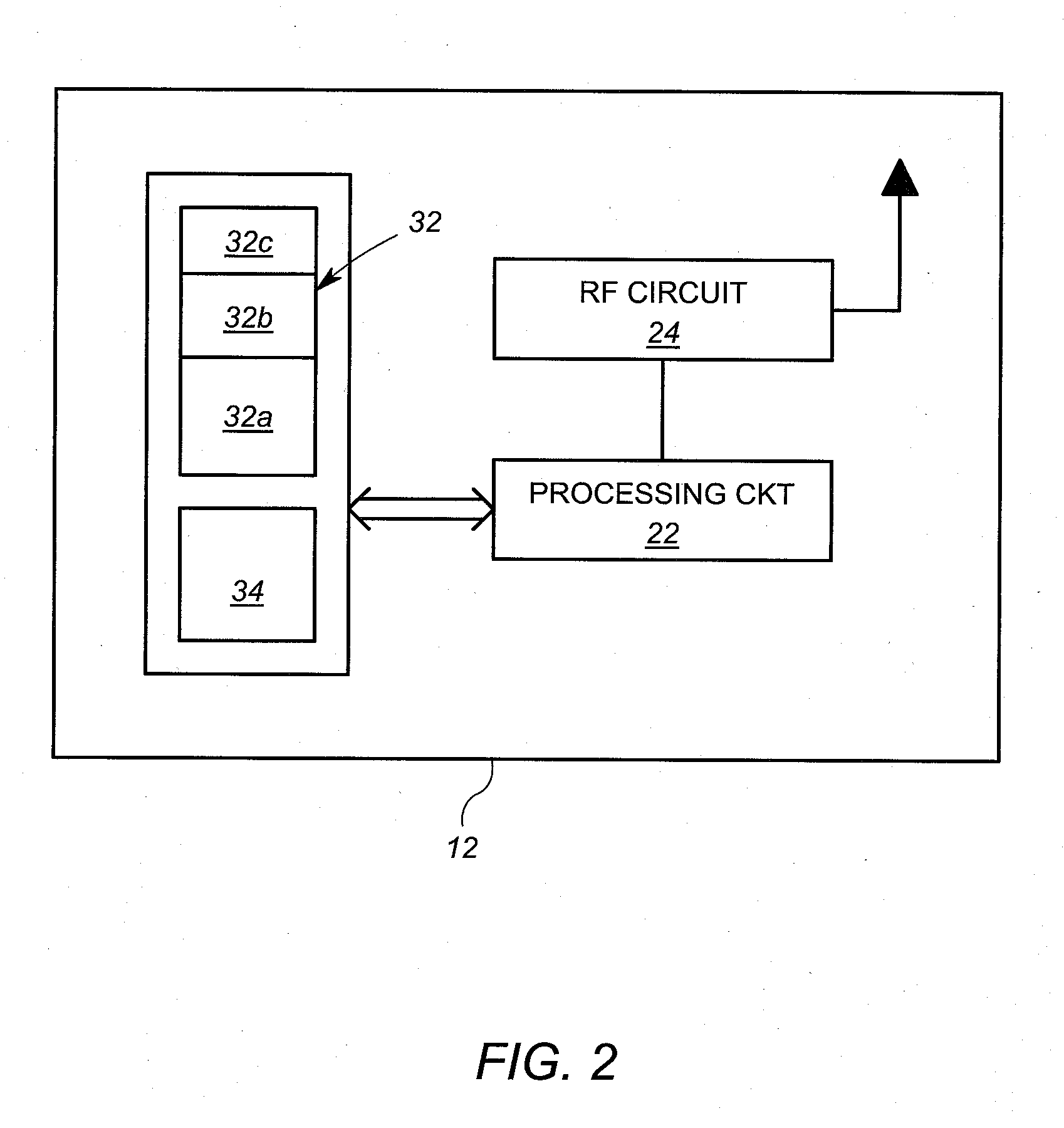

Application of Microsystems for Lighting Control

ActiveUS20080074059A1Improve efficiencyReduce laborSampled-variable control systemsElectrical apparatusEffect lightControl theory

An arrangement includes a plurality of microsystems and a controller. Each of the plurality of wireless microsystems is operable to measure at least one parameter of a space, and to transmit the at least one parameter wirelessly. The controller is operably coupled to receive the information corresponding to the at least one parameter directly or indirectly. The controller is operable to cause a change in a lighting control level based at least in part on the information. The wireless microsystems may suitably measure light levels and / or occupancy regarding the space.

Owner:SIEMENS IND INC

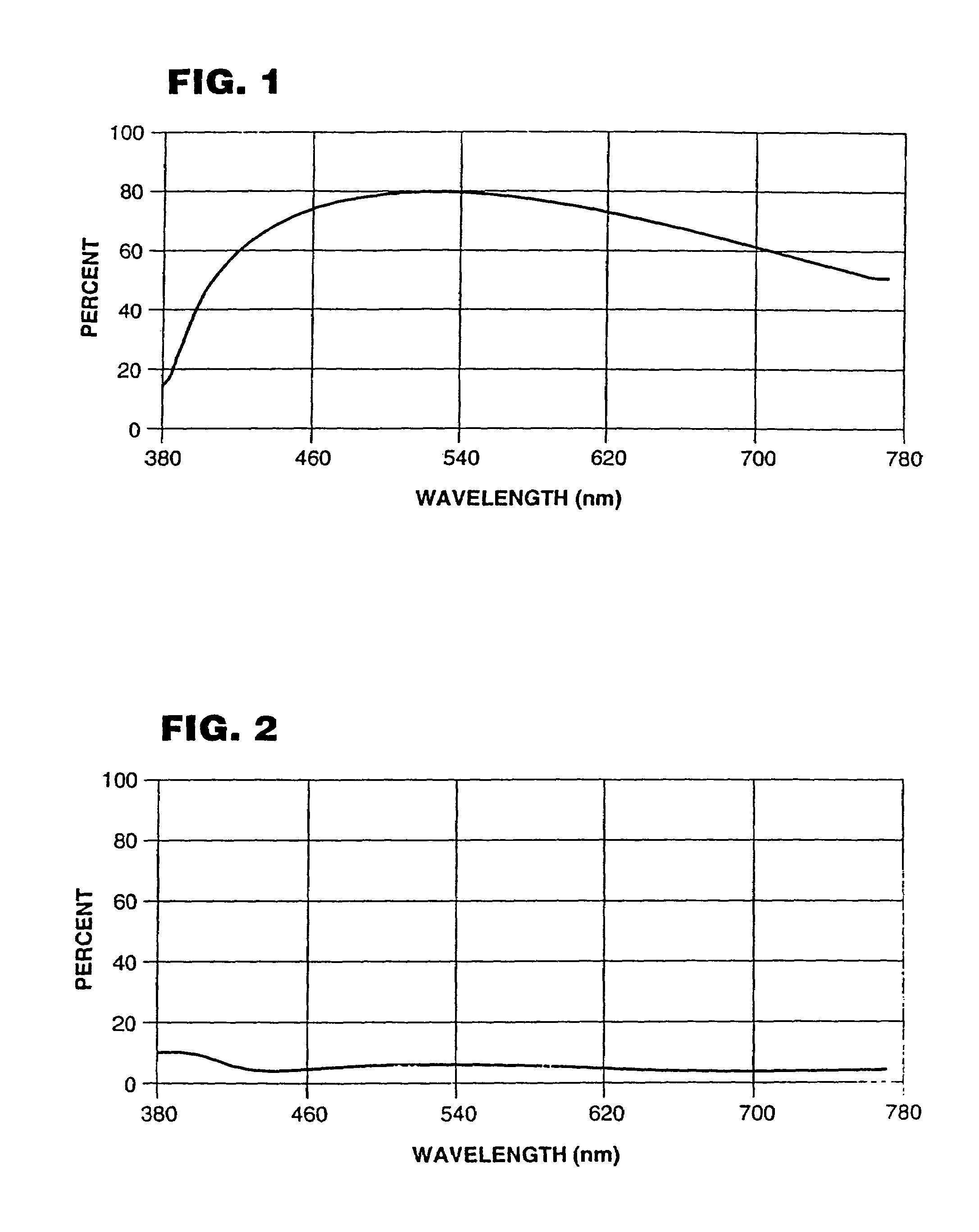

Vehicular rearview mirror element having a display-on-demand display

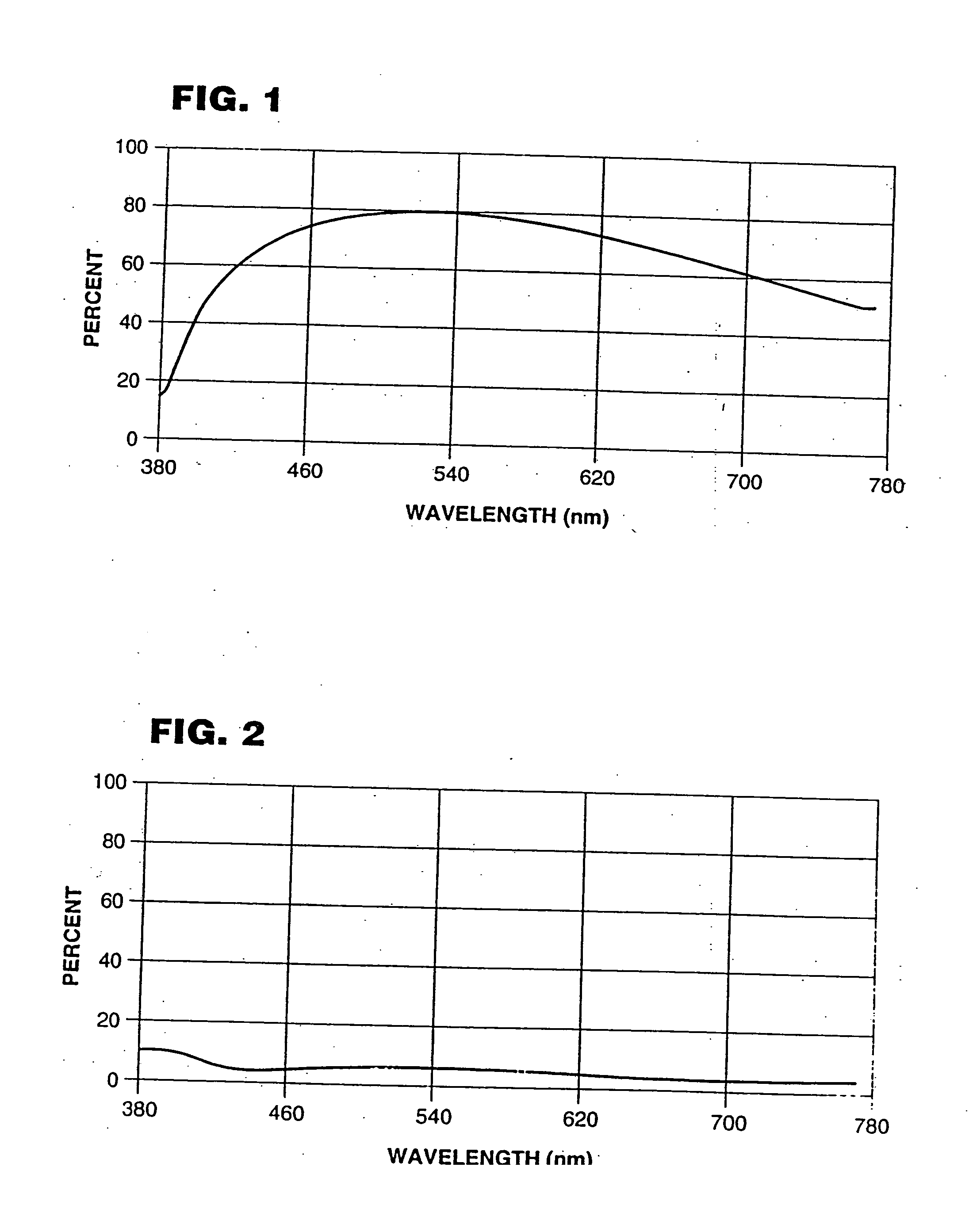

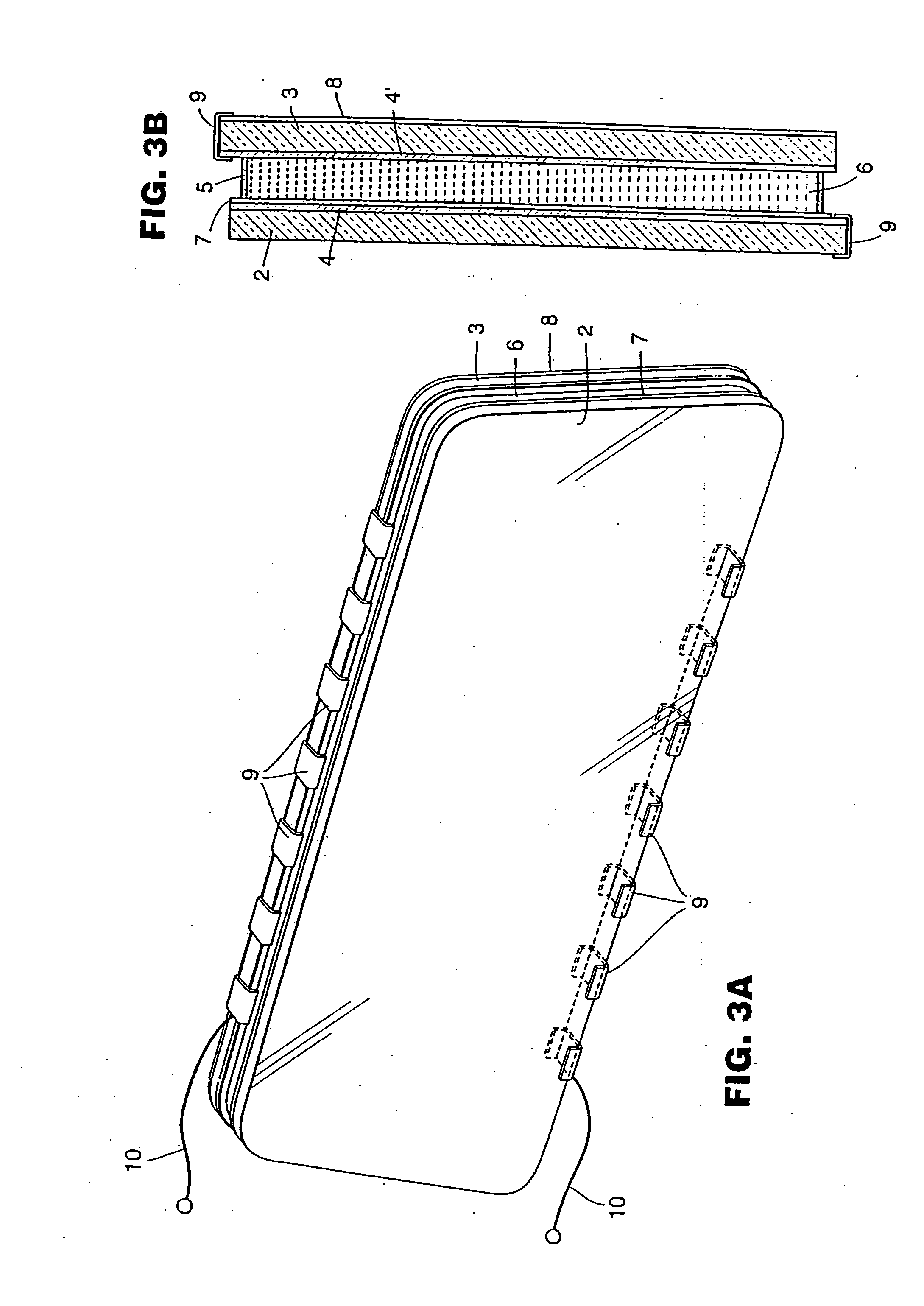

InactiveUS7543947B2Reduce material costsGood optical performanceMirrorsAntiglare equipmentDisplay deviceOptoelectronics

A rearview mirror element for a motor vehicle includes a light transmitting substrate having a visible light reflecting and visible light transmitting mirror reflector disposed on a surface thereof. A display-on-demand display device is disposed behind the substrate such that light emitted by the display device when powered passes through both the light transmitting substrate and the mirror reflector. The display device exhibits, when powered during day time driving conditions, a display luminance of at least about 60 foot lamberts. When not emitting light, the disposition of the display device to the rear of the light transmitting substrate is not substantially distinguishable to the driver of the equipped vehicle when viewing the mirror element. To the rear of the light transmitting substrate is rendered substantially opaque by a light absorbing element that is disposed at least adjacent to where, and except at where, the display device is disposed therebehind.

Owner:DONNELLY CORP

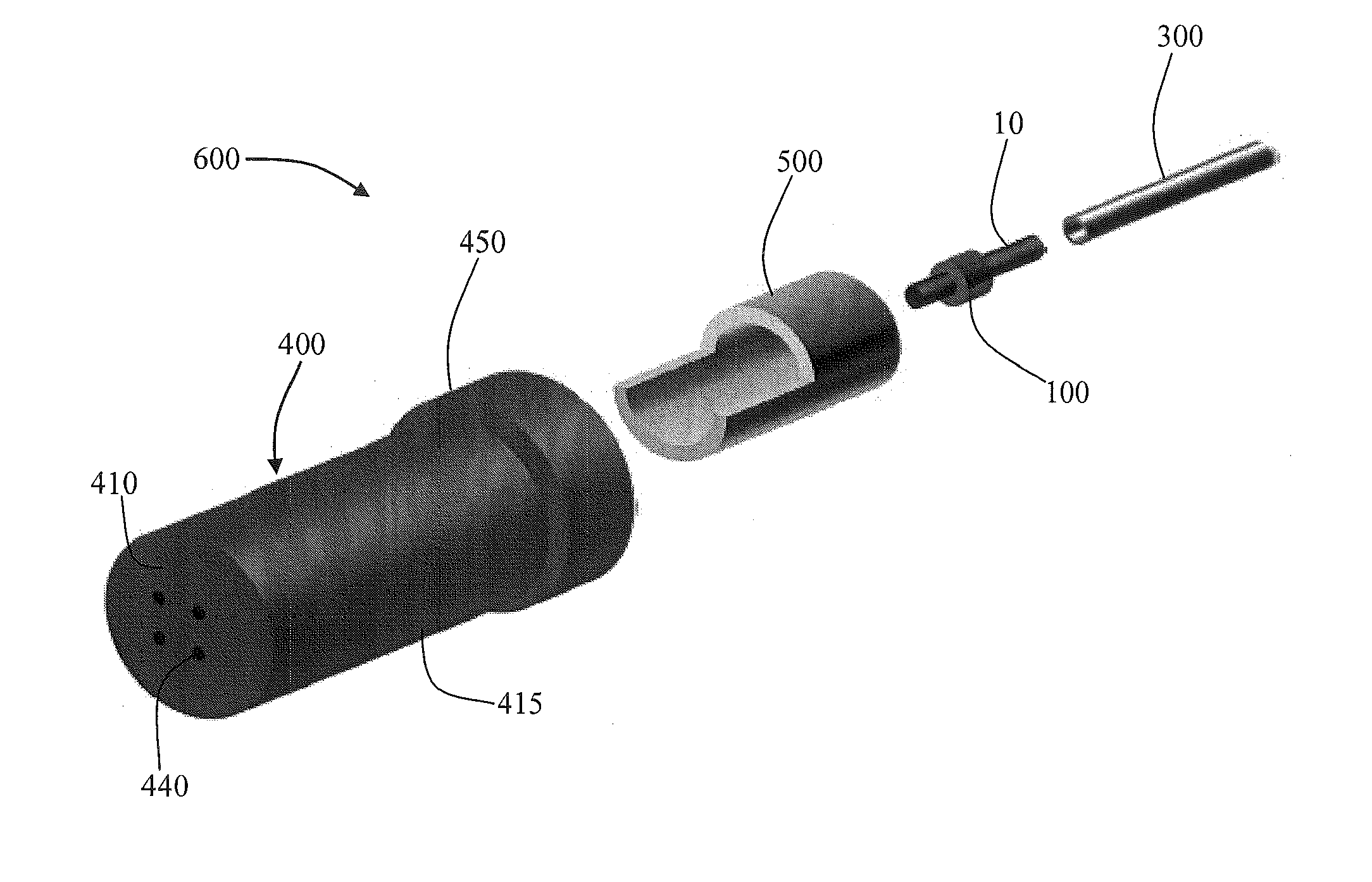

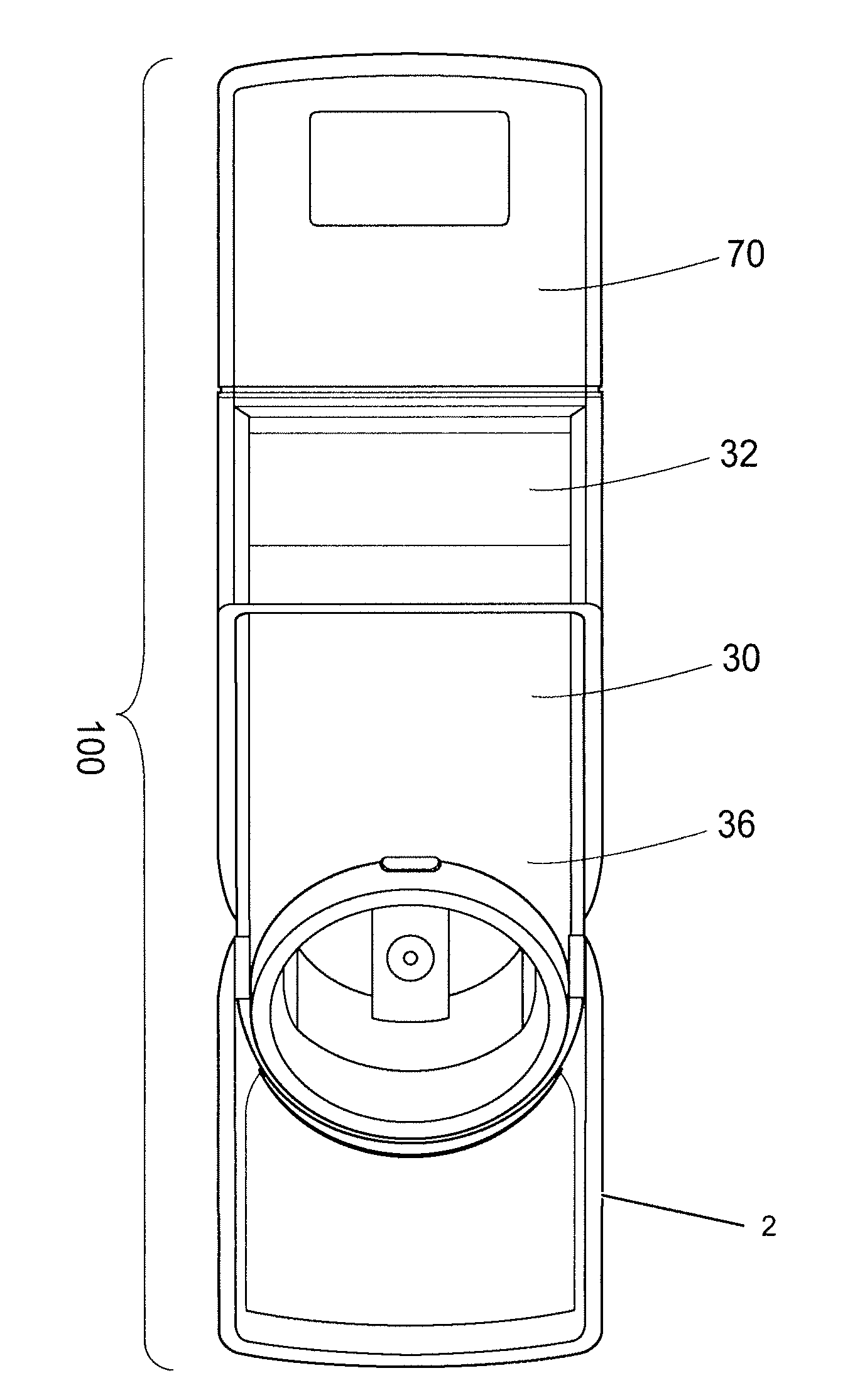

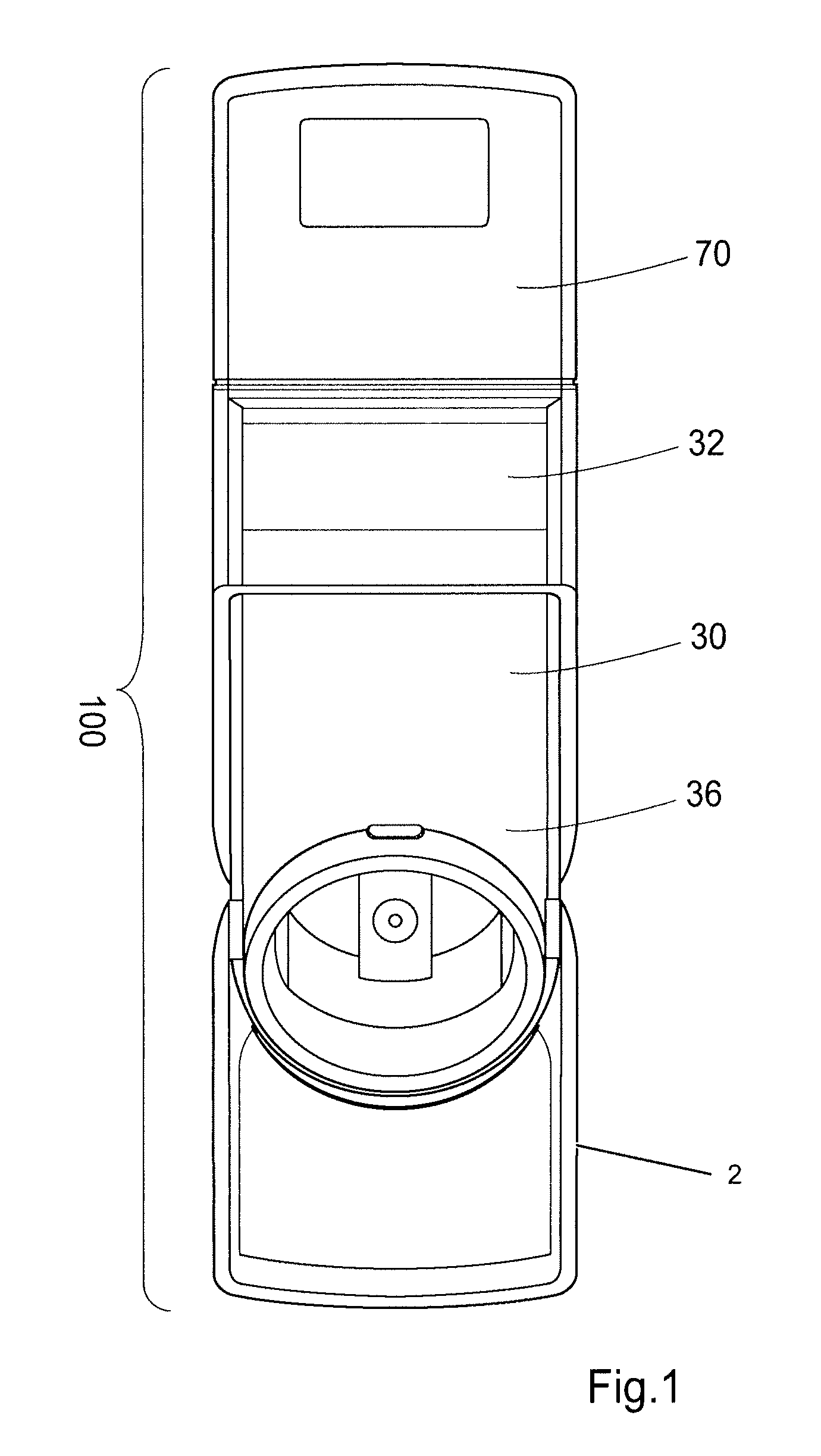

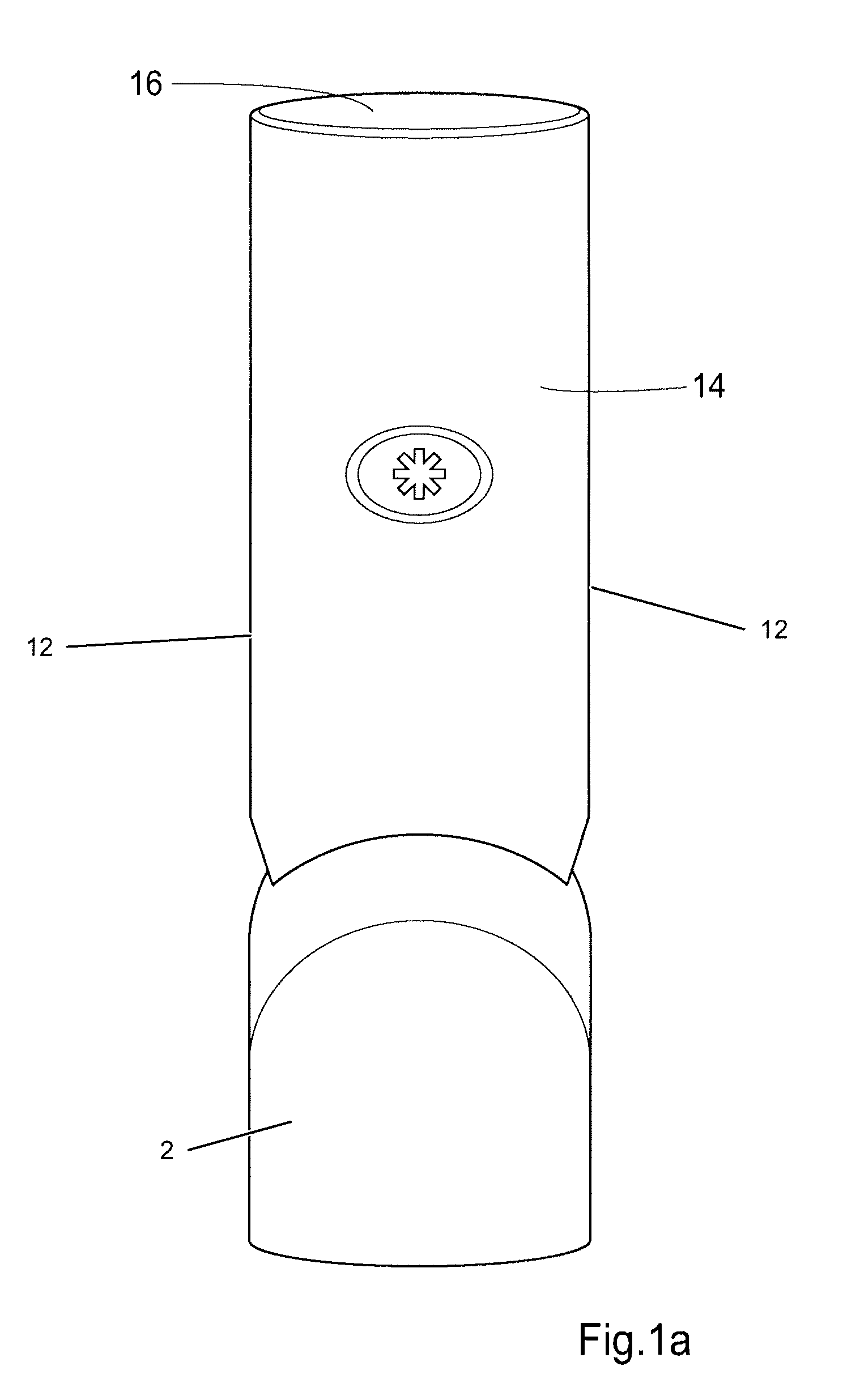

Inhaler 624

ActiveUS20080156321A1Reduce materialRespiratorsOperating means/releasing devices for valvesInhalationEngineering

The present invention relates to an Breath actuated inhaler (BAI) actuator, comprising: a loading element capable of being loaded with an actuation force, a breath actuated trigger mechanism arranged to counteract the actuation force of the loading element, and to fire the actuator by releasing the actuation force of the loading element in response to an inhalation breath, and actuation locking means moveable between a locked position wherein it relieves the actuation force from the trigger mechanism setting the trigger mechanism in a neutral position, and an armed position wherein the trigger mechanism is set in an armed position.

Owner:ASTRAZENECA AB

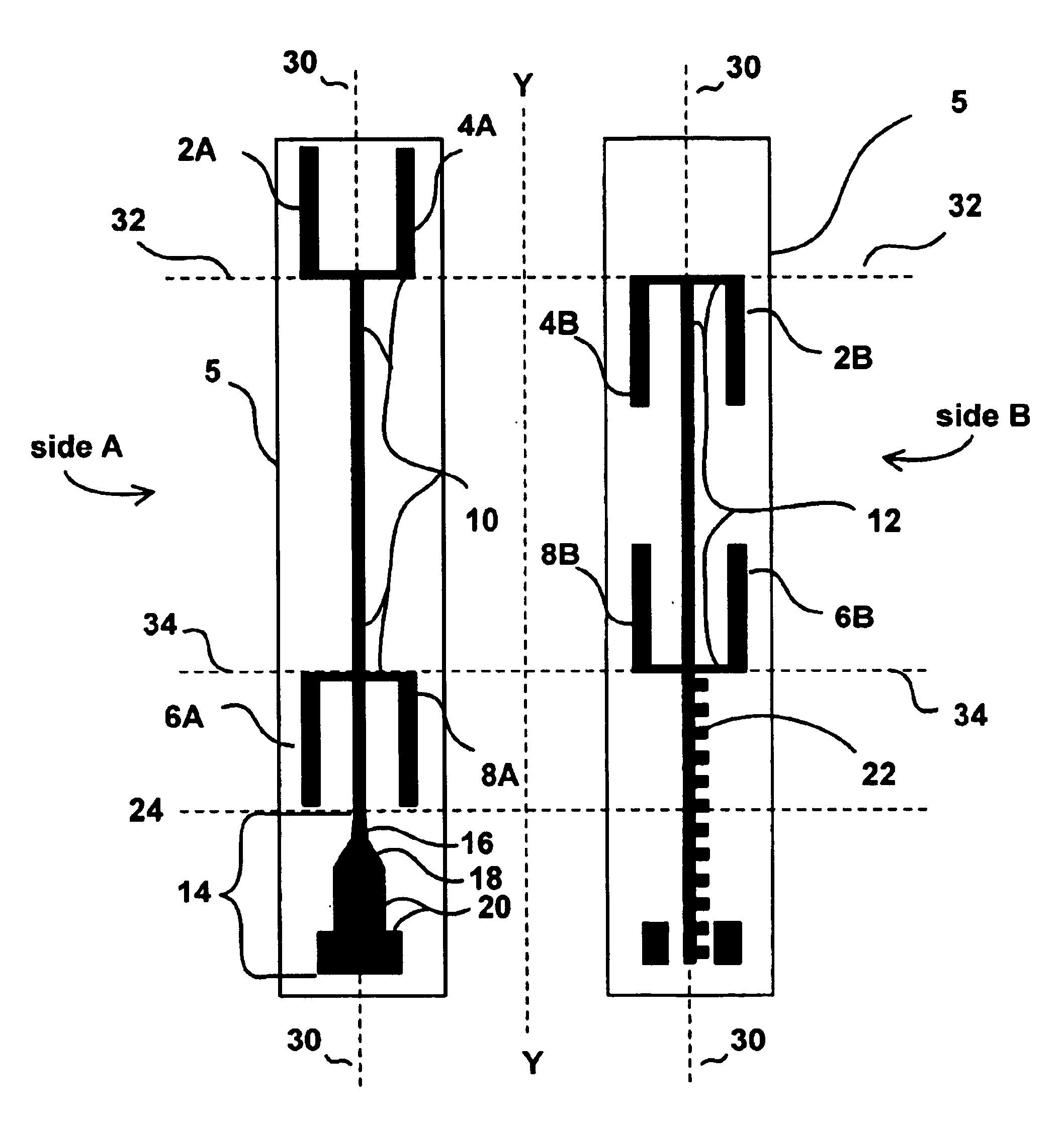

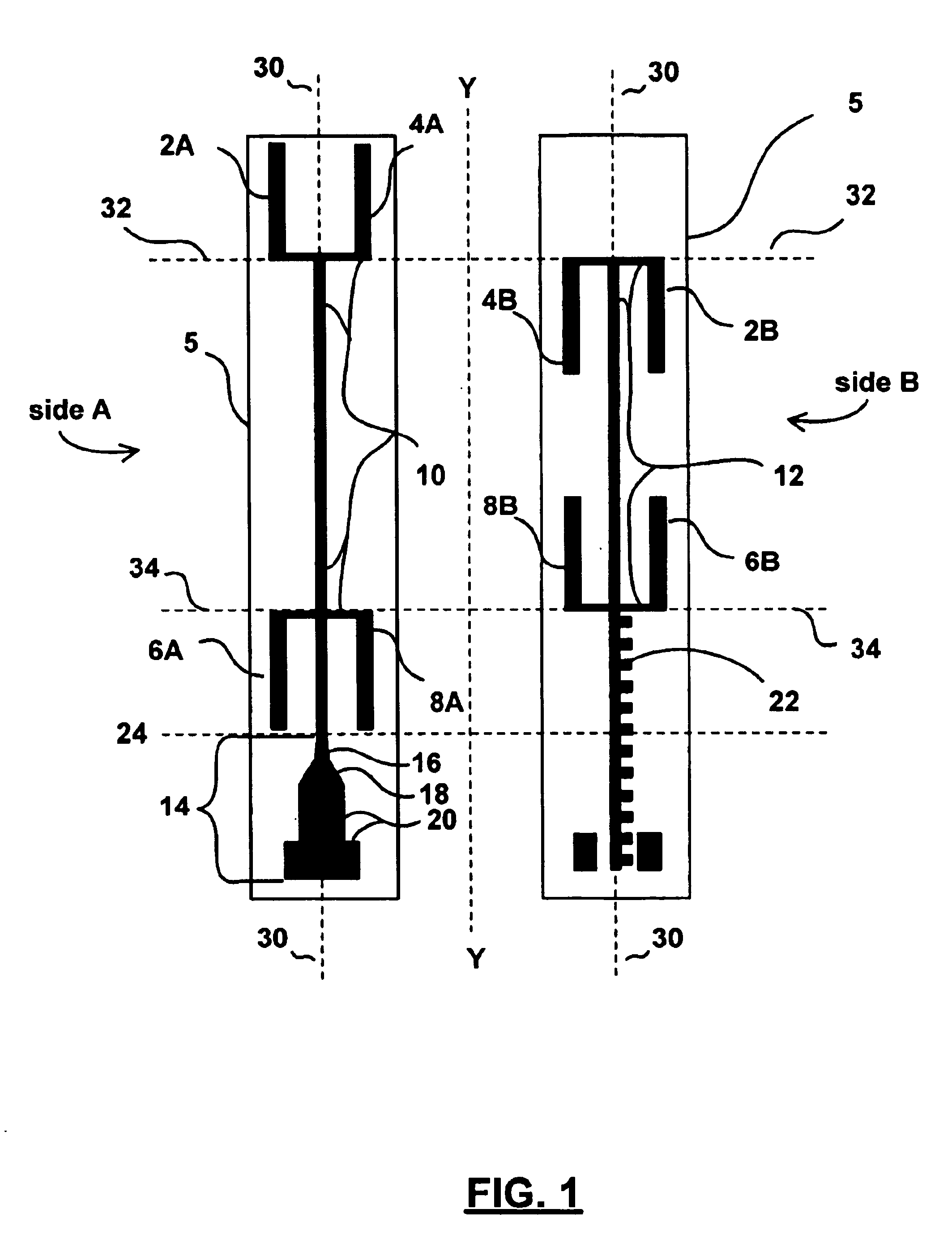

Planar high-frequency antenna

InactiveUS6747605B2High structureExcellent impedance matchingSimultaneous aerial operationsRadiating elements structural formsDipoleFeed line

The present invention provides a planar antenna having a scalable multi-dipole structure for receiving, and transmitting high-frequency signals, including a plurality of opposing layers of conducting strips disposed upon either side of an insulating (dielectric) substrate. The dipoles are bifurcated between sides of a substrate on which the dipoles are disposed. A feed line is balanced to a co-axial cable and feeds one half of the bifurcated dipoles, and an independent feed line is connected to the other half of the bifurcated dipoles. Sets of the dipoles are arranged symmetrically around a center axis of the feed lines. The sets of dipoles are in series with other sets of dipoles. The antenna is ideally suited for operation in the 5.15-5.35 GHz RF band.

Owner:QUALCOMM INC

Capacitive Sensor and Method and Apparatus for Controlling a Pump Using Same

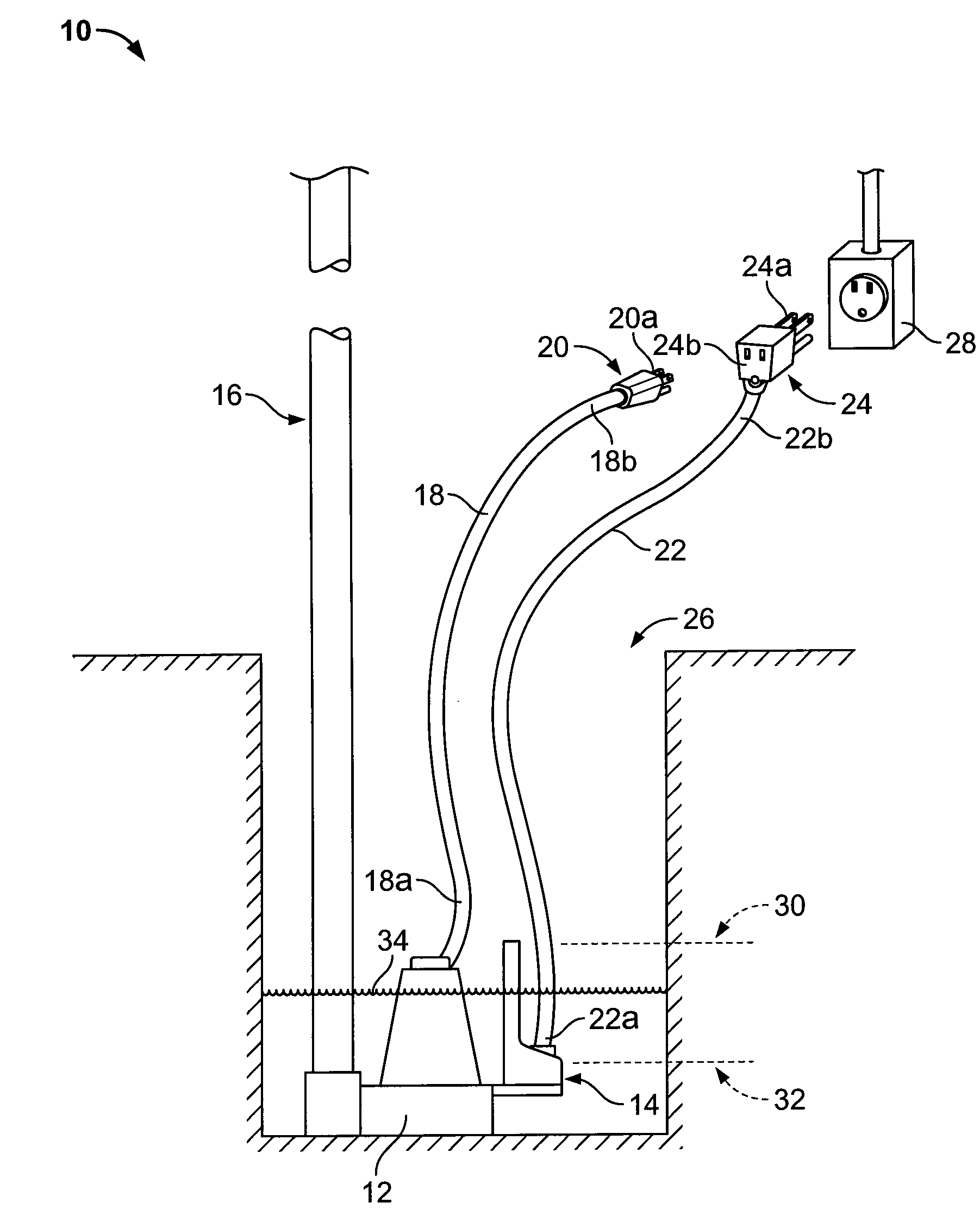

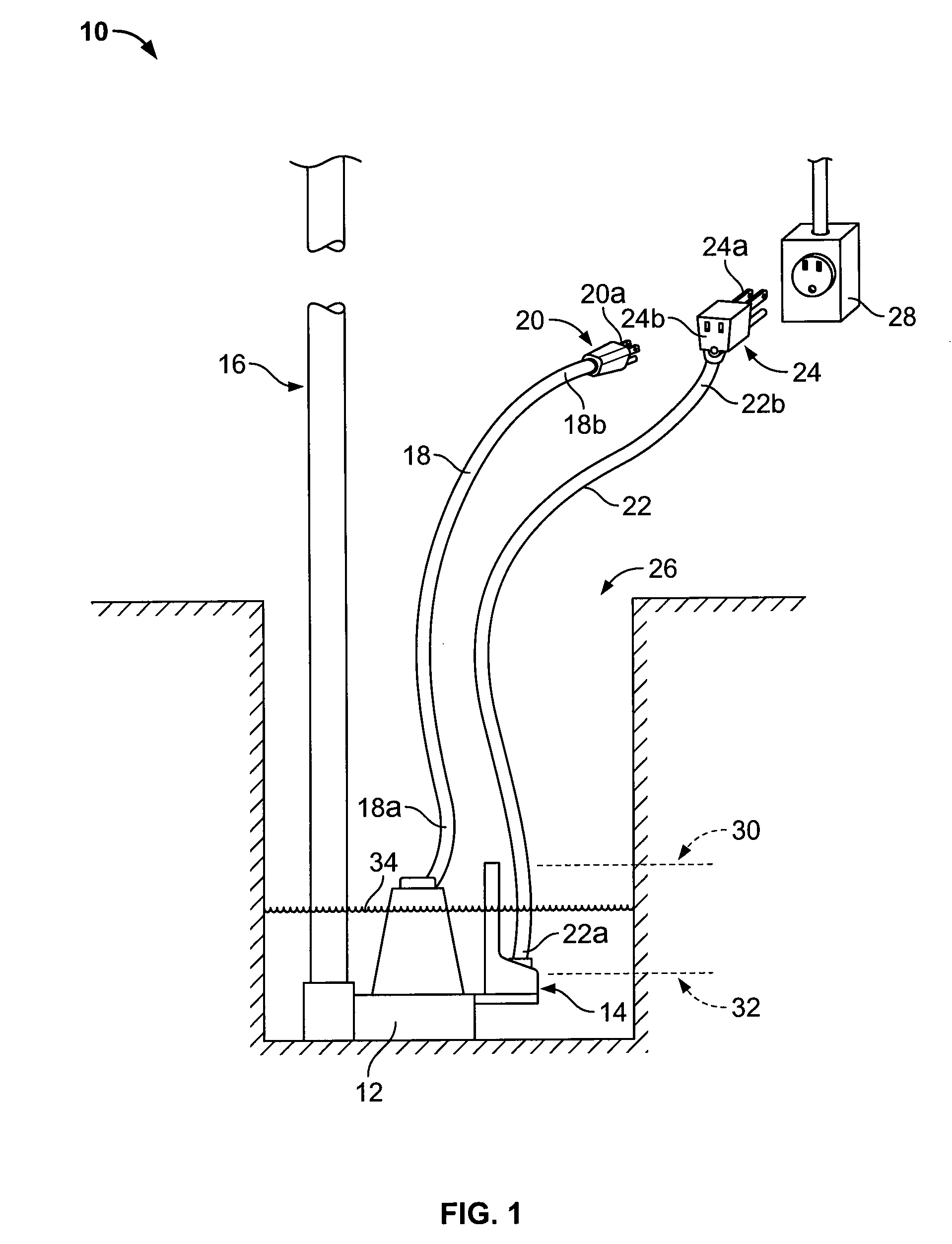

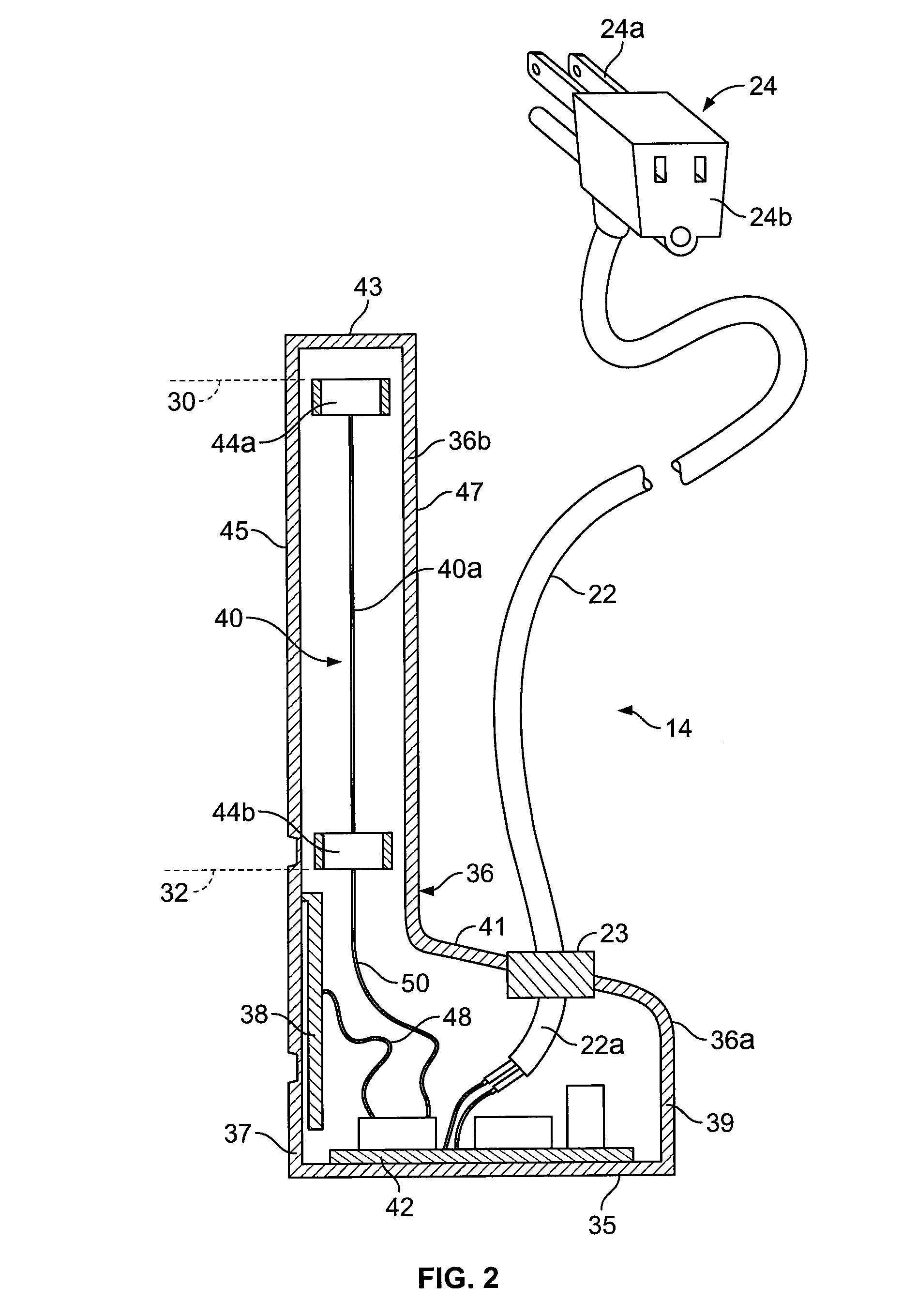

ActiveUS20080229819A1Easily assembleReduce cost associate with assembly and/or material costLevel indicators by physical variable measurementFlow controlVariable capacitorVIT signals

A variable capacitor for sensing the level of a liquid. The capacitor provides a readable capacitance that varies with respect to the level of the liquid. A pump control system implementing the capacitive sensor to control the level of a liquid by activating and deactivating the pump depending on the level of the liquid. Methods relating to varying capacitance of a capacitive sensor and controlling a pump based on the level of a liquid. A pump controller for controlling the level of a liquid in a reservoir includes a controller and a capacitor. The capacitor is adapted to provide an activation signal to the controller when the liquid in the reservoir reaches a first predetermined level relative thereto. Additionally, the capacitor is adapted to provide a trigger signal to the controller when the liquid in the reservoir reaches a second predetermined level relative thereto. Based on the trigger signal, the controller determines when to deactivate the pump.

Owner:WAYNESCOTT FETZER

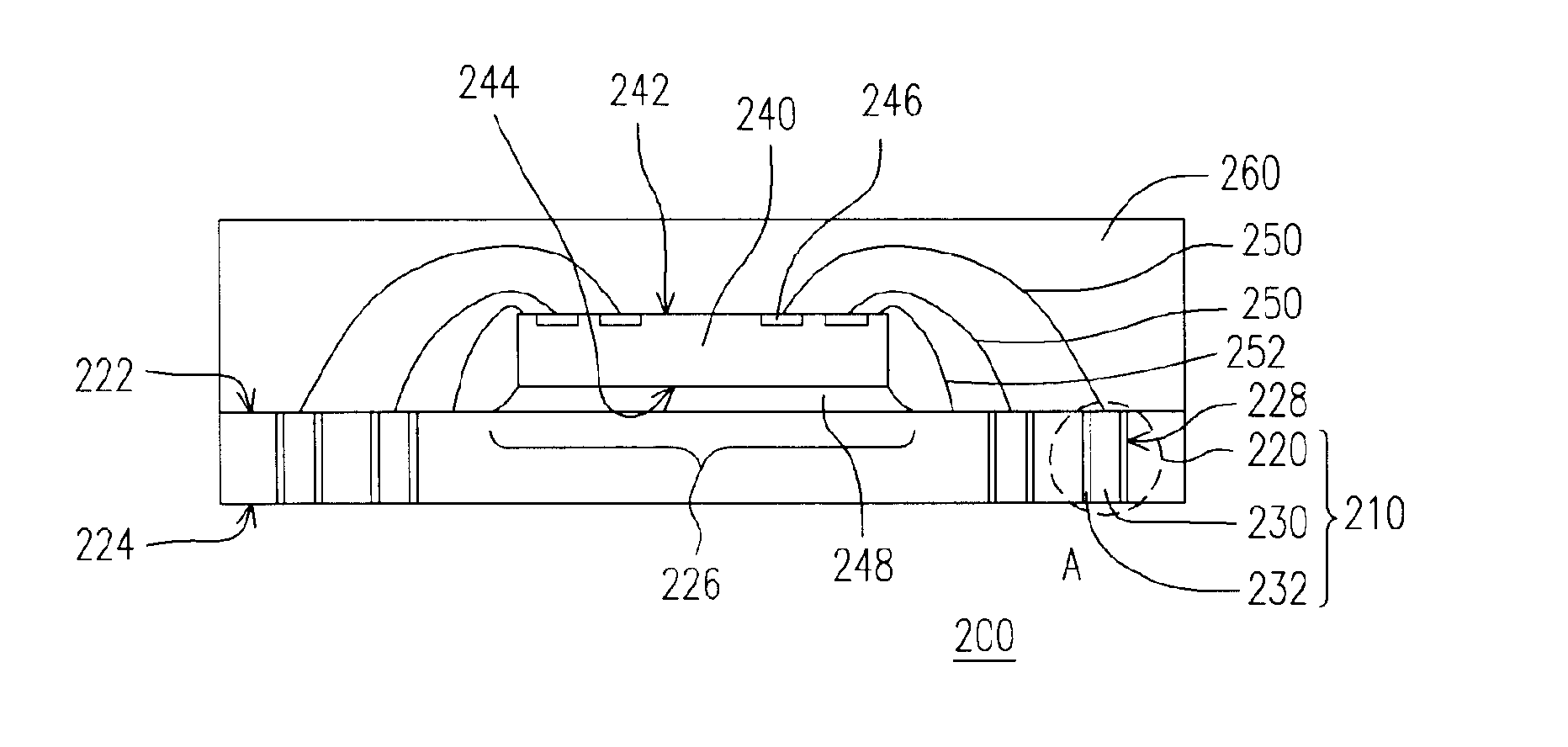

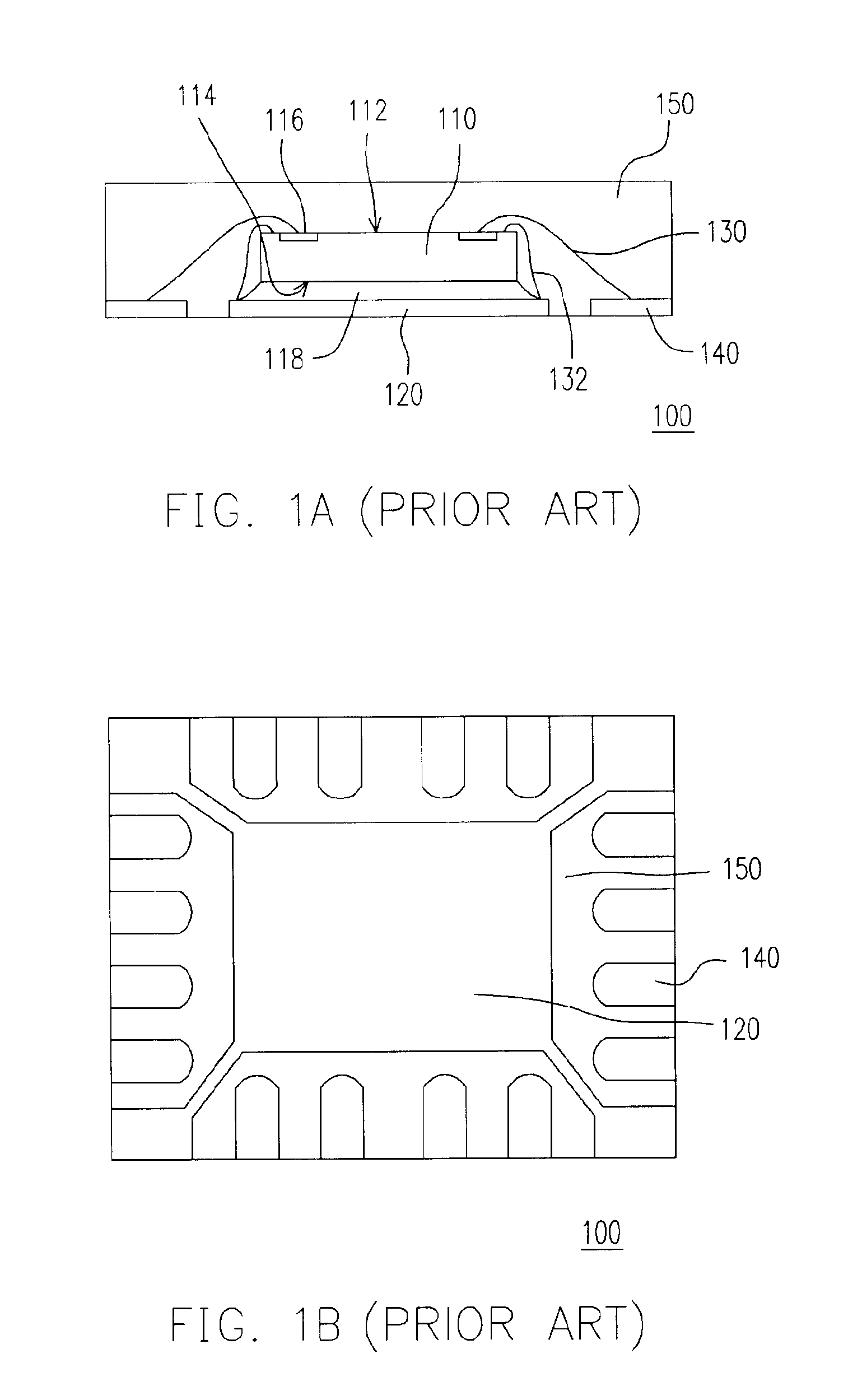

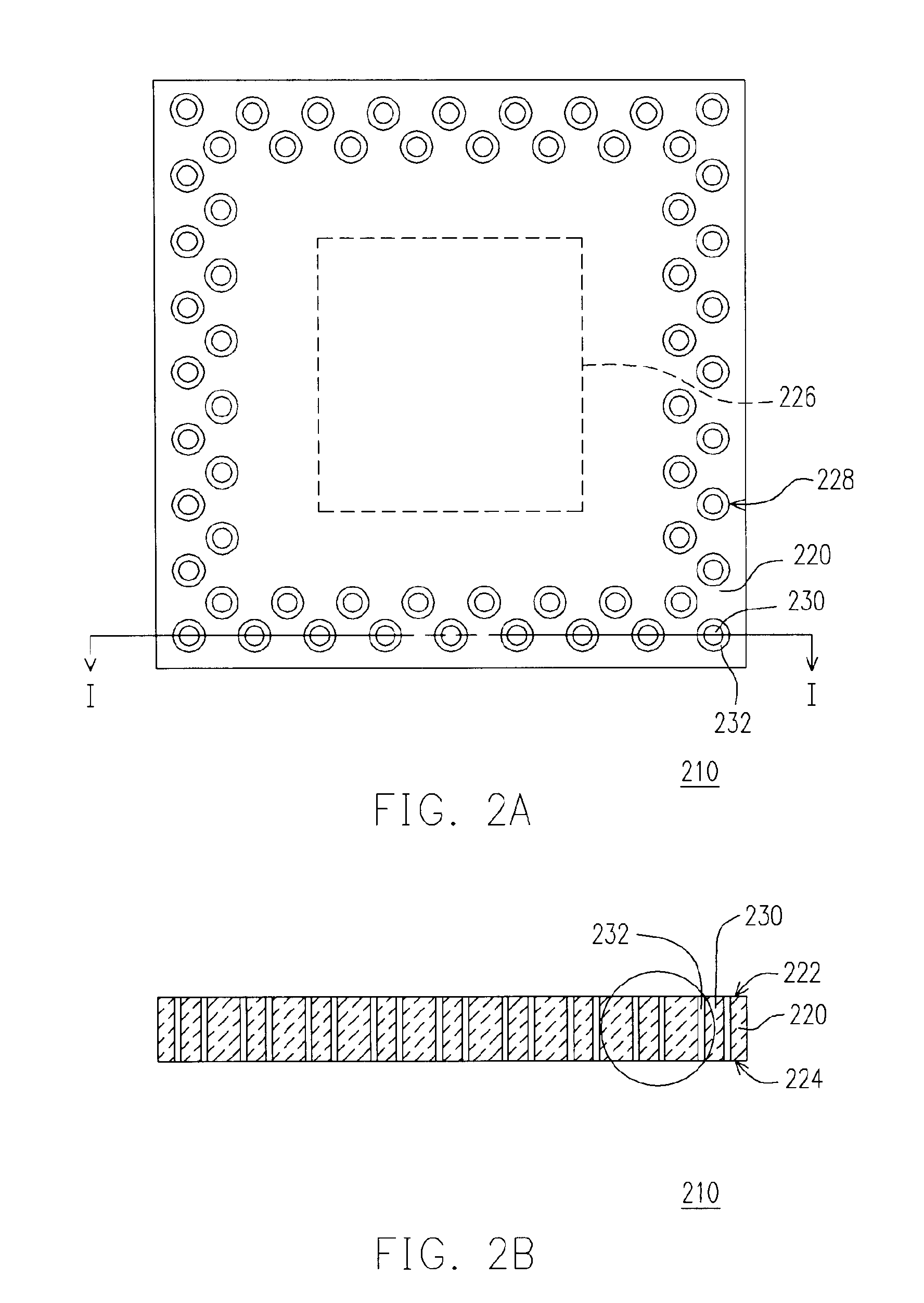

Quad flat no-lead chip carrier

ActiveUS6882057B2High I/O densityImprove chip qualitySemiconductor/solid-state device detailsSolid-state devicesLead bondingEngineering

A quad flat no-lead chip carrier for a wire-bonded chip package is provided. The chip carrier comprises a conductive plate, a plurality of conductive columns and a plurality of dielectric walls. A chip is attached to the conductive plate. The conductive plate furthermore has a plurality of columnar through holes distributed around a chip-bonding region. The conductive columns are set up within the columnar through holes. The dielectric walls are set up between the sidewall of the conductive columns and the inner surface of the columnar through holes. The chip is electrically connected to the conductive columns via conductive wires. The bottom end of the conductive columns serves as input / output contacts for connecting with external contacts. The chip carrier is able to increase overall density of the input / output contacts and improve the electrical performance of the chip package.

Owner:VIA TECH INC

Integrated closed loop system for industrial water purification

InactiveUS20050061737A1Small surface areaIncreasing biofilm thicknessTreatment using aerobic processesWater/sewage treatment by irradiationOrganic matterIndustrial water

The present invention relates to an integrated closed loop system for aquaculture in at least one culturing tank and using continuous bioreactor technology for the biological treatment and removal of organic material, nitrogen and phosphorous, comprising: an integrated, partially or wholly closed loop system for waste water treatment, where the water contains nitrogen containing compounds and / or substances, comprising at least one production unit of such nitrogen containing compounds and / or substances and using continuous bioreactor technology for the biological treatment and removal of organic matter, nitrogen and phosphorous from the said water at continuous flow, comprising: a) at least one suspended carrier bioreactor for bacterial growth under anoxic conditions to cause anaerobic denitrification, with one or several compartments, preceding b) at least one suspended-carrier bioreactor for bacterial growth under oxic conditions to cause aerobic nitrification, c) the denitrification taking place after the production unit, and d) the nitrification taking place prior to the production unit in a by-pass mode as part of the continuous flow.

Owner:GREENFISH

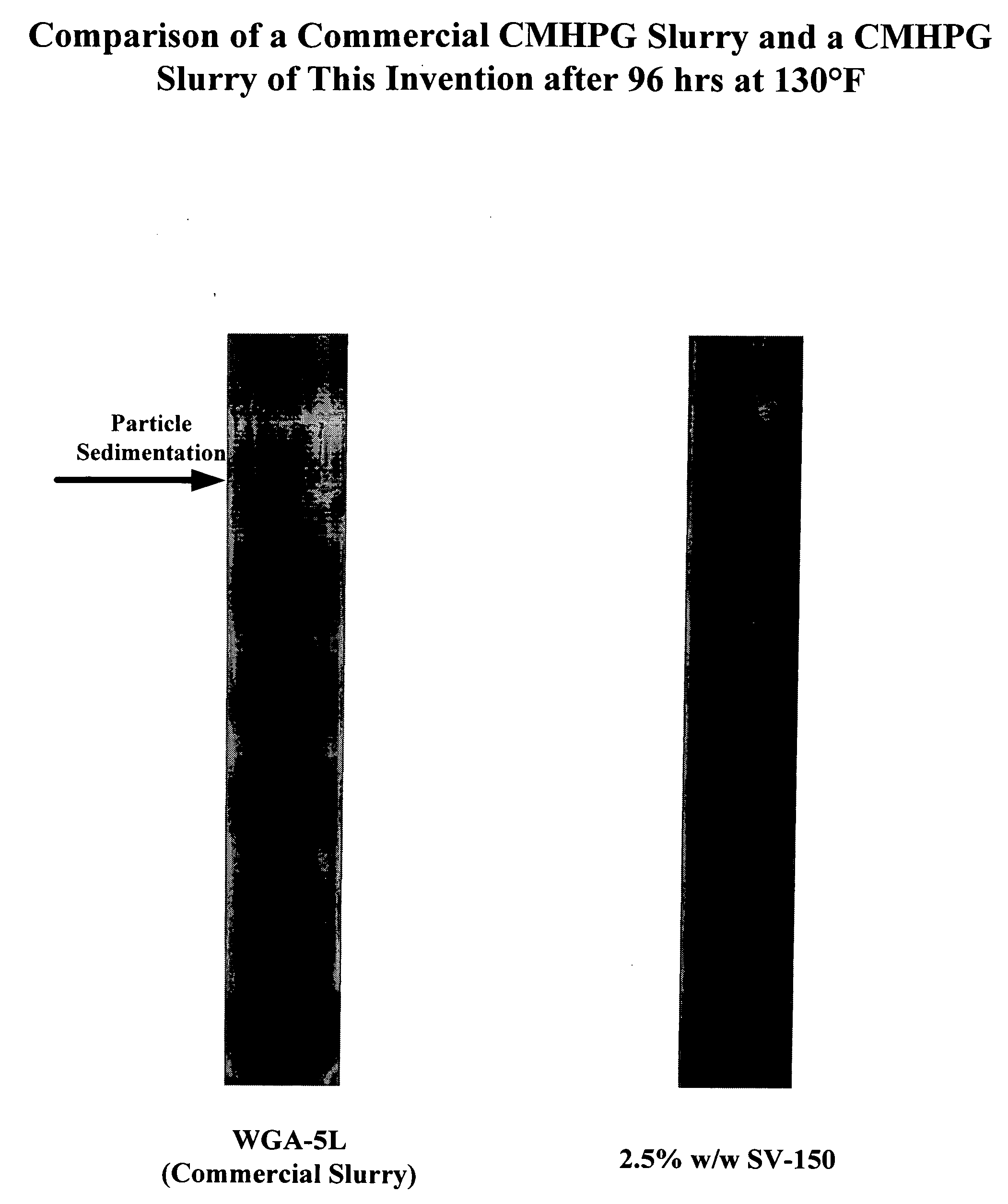

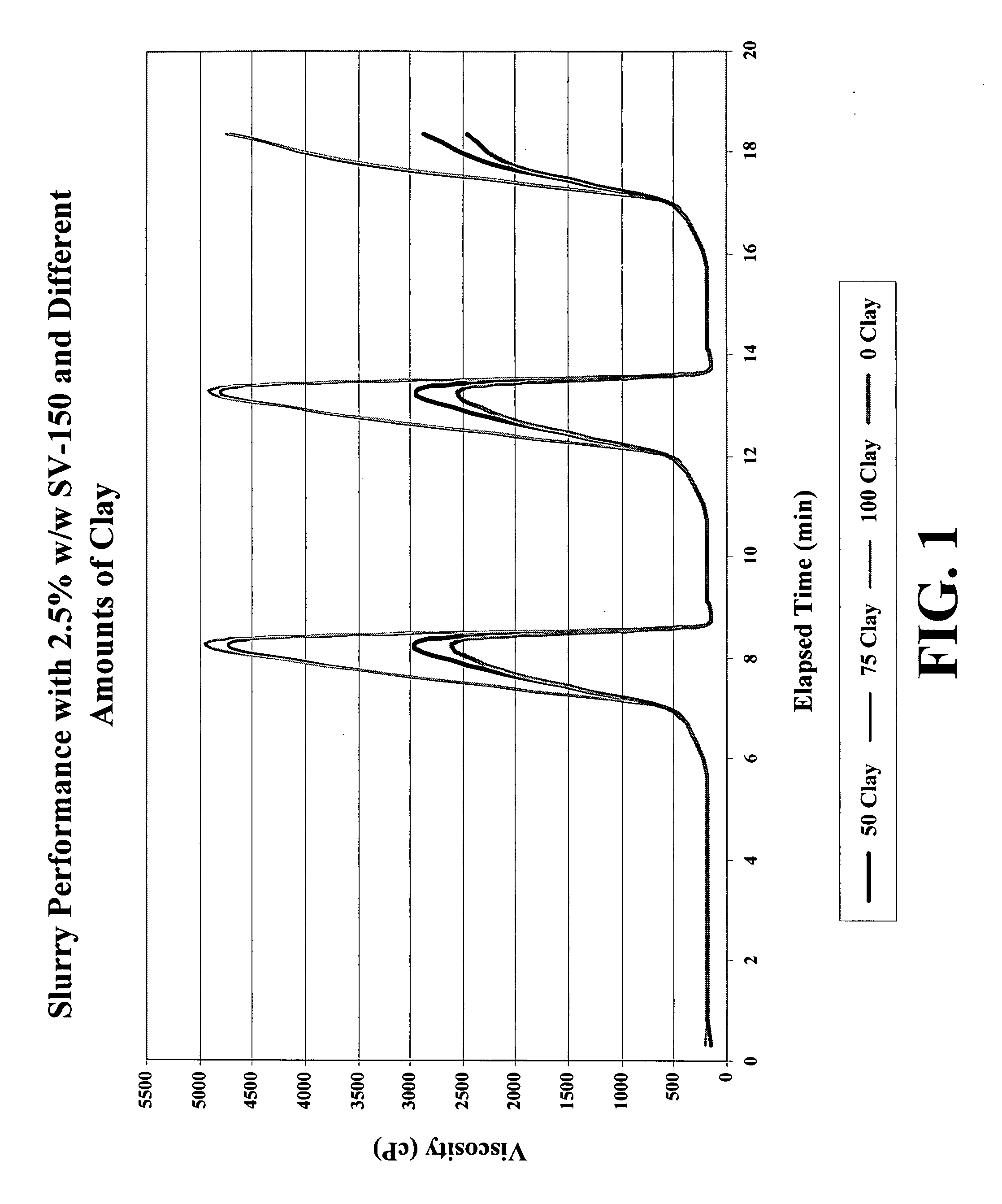

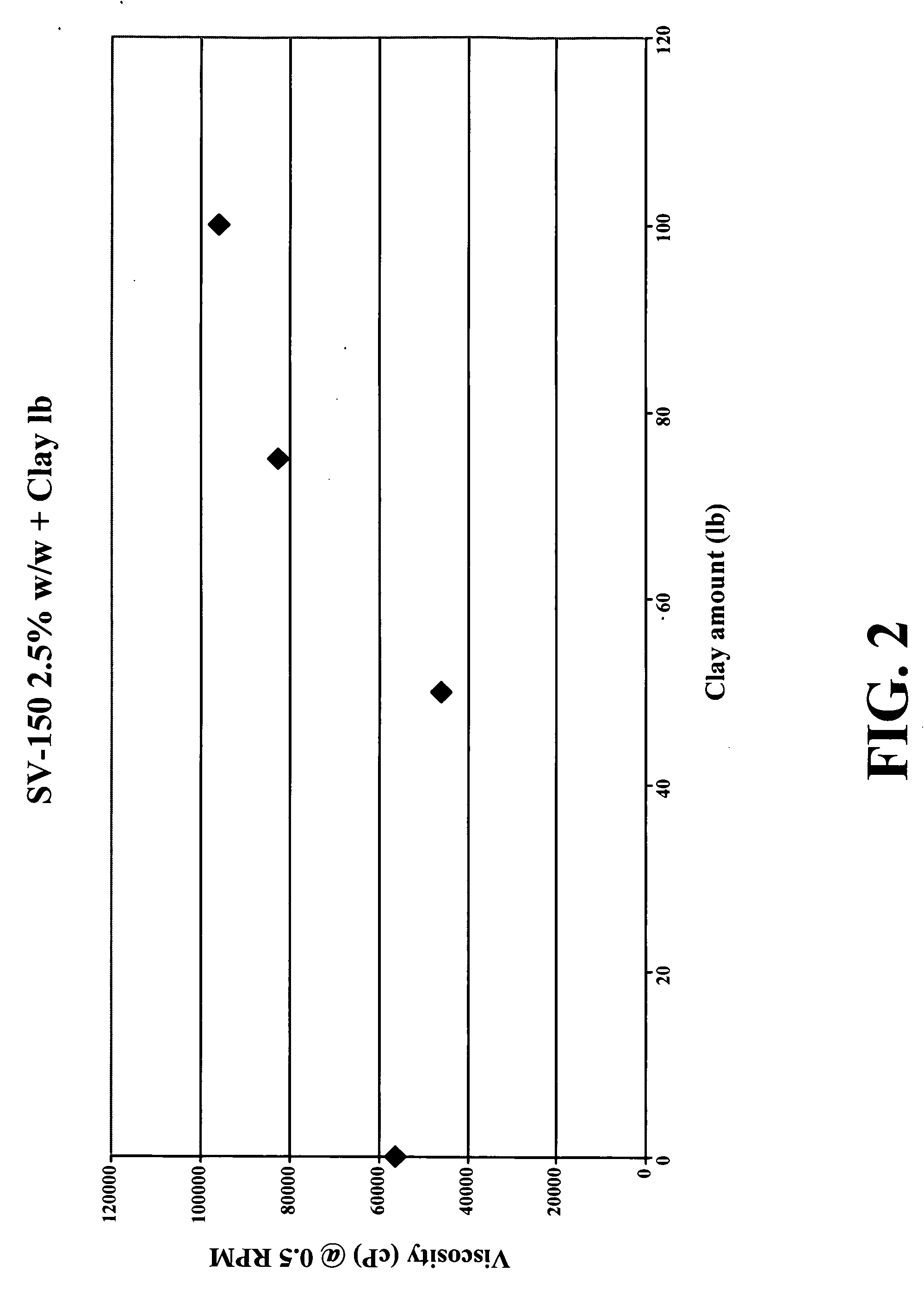

Oil based concentrated slurries and methods for making and using same

InactiveUS20080318812A1Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

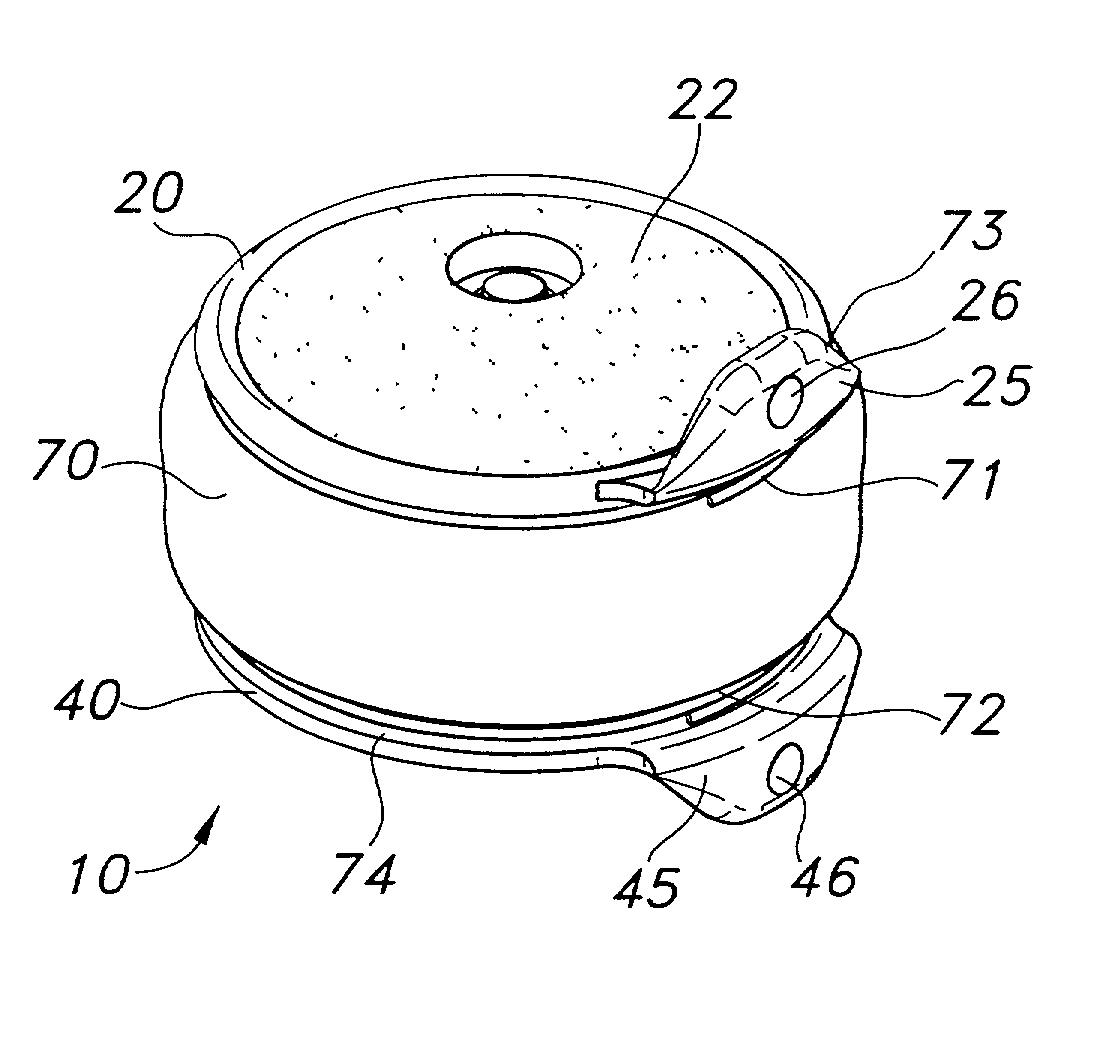

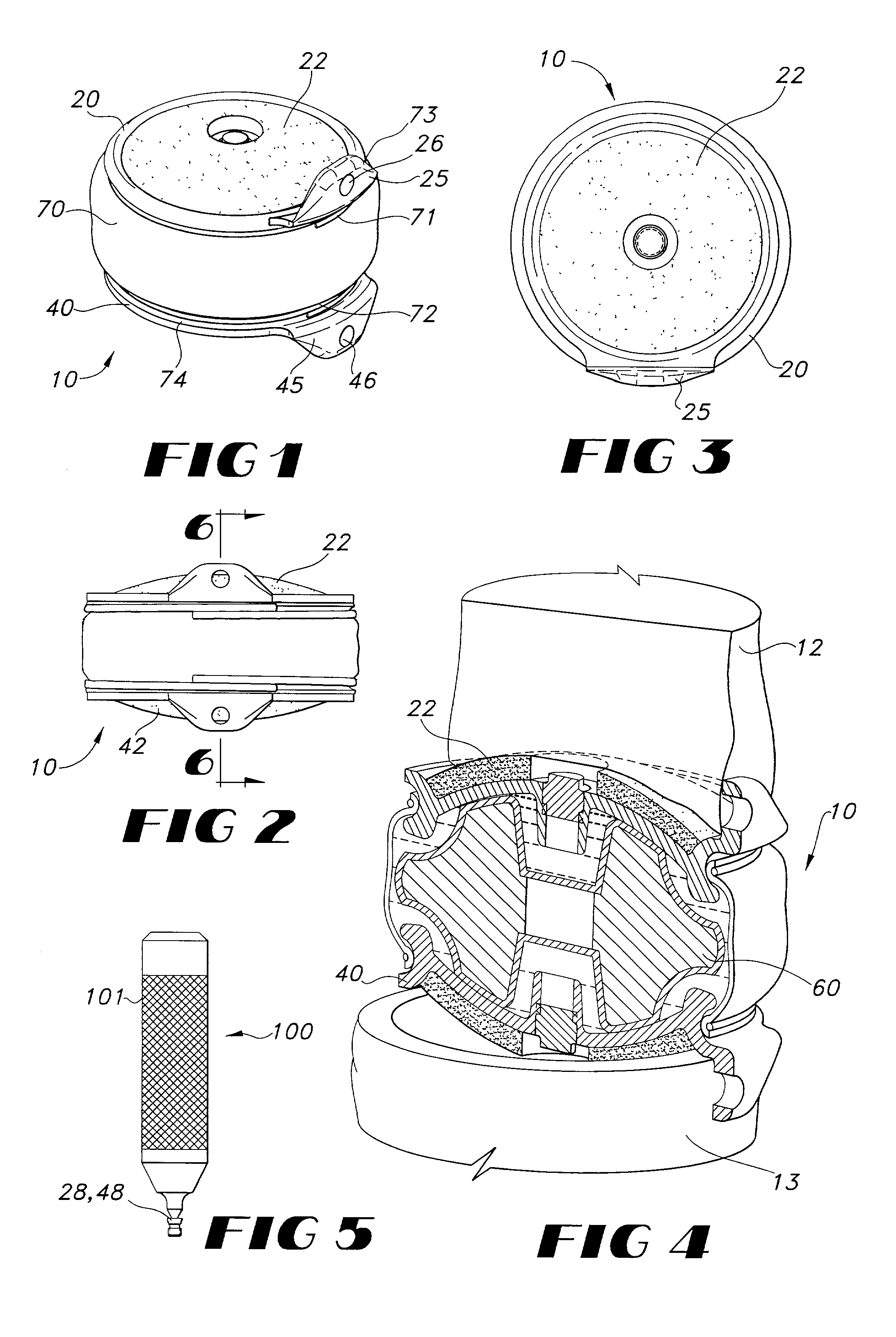

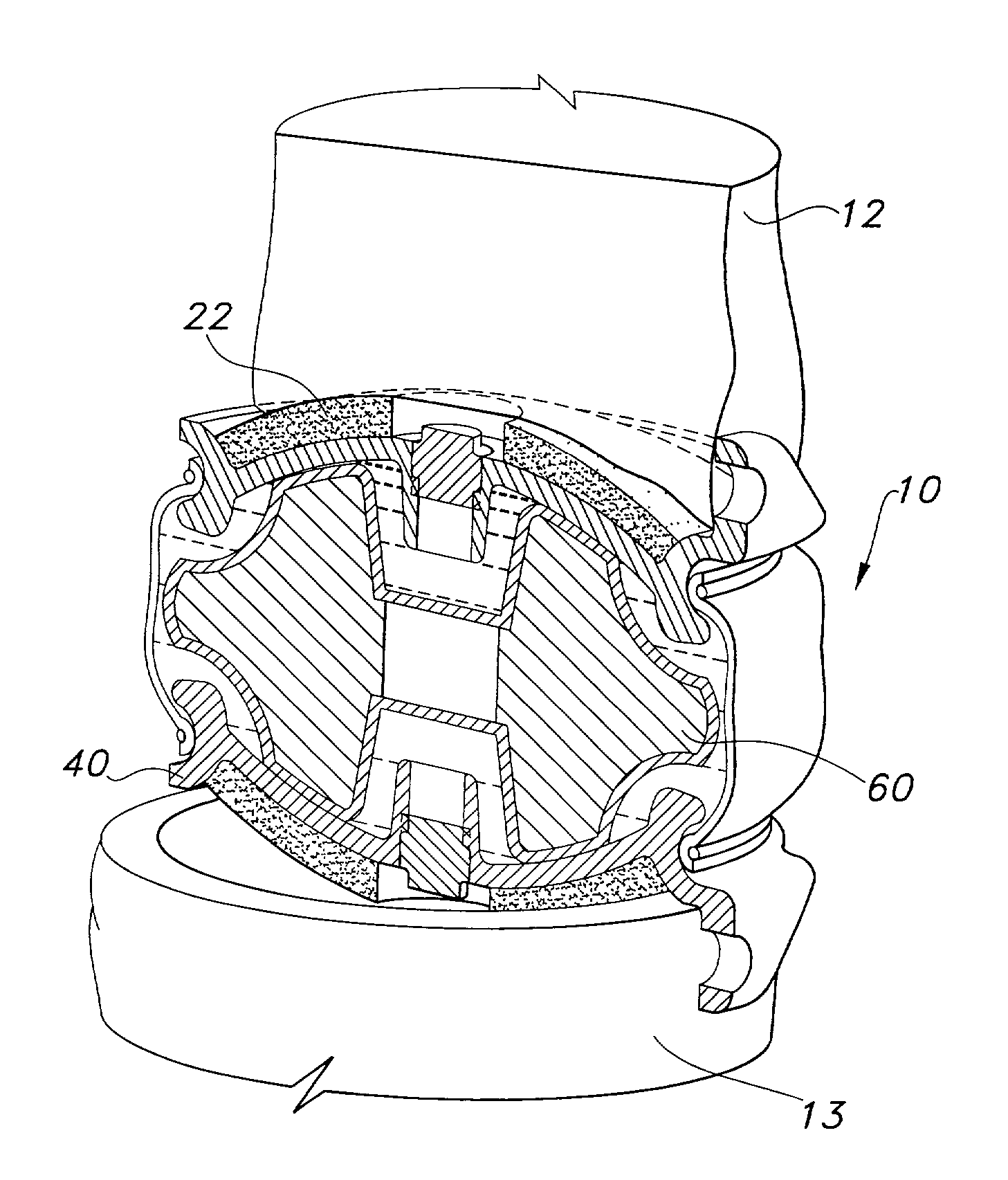

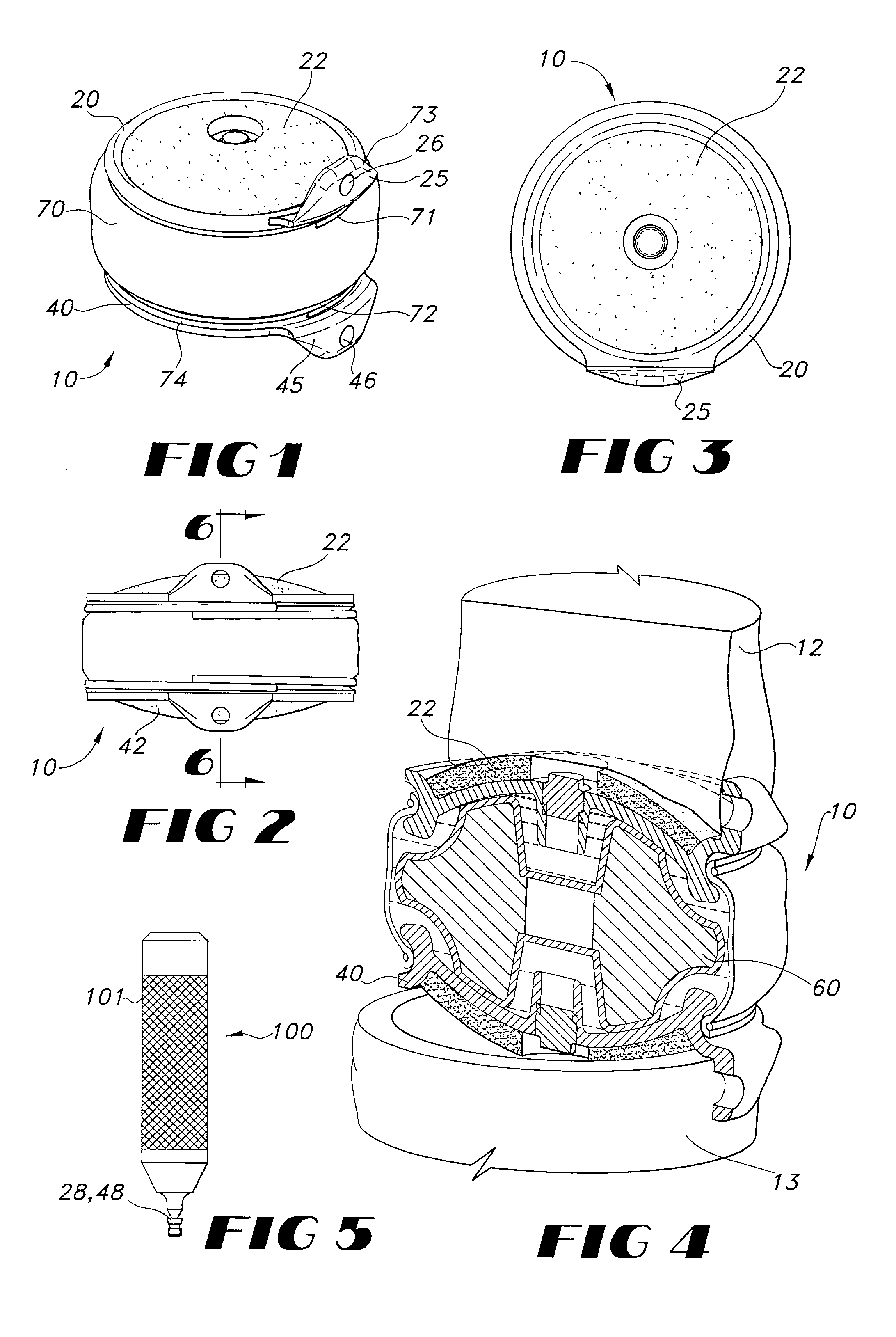

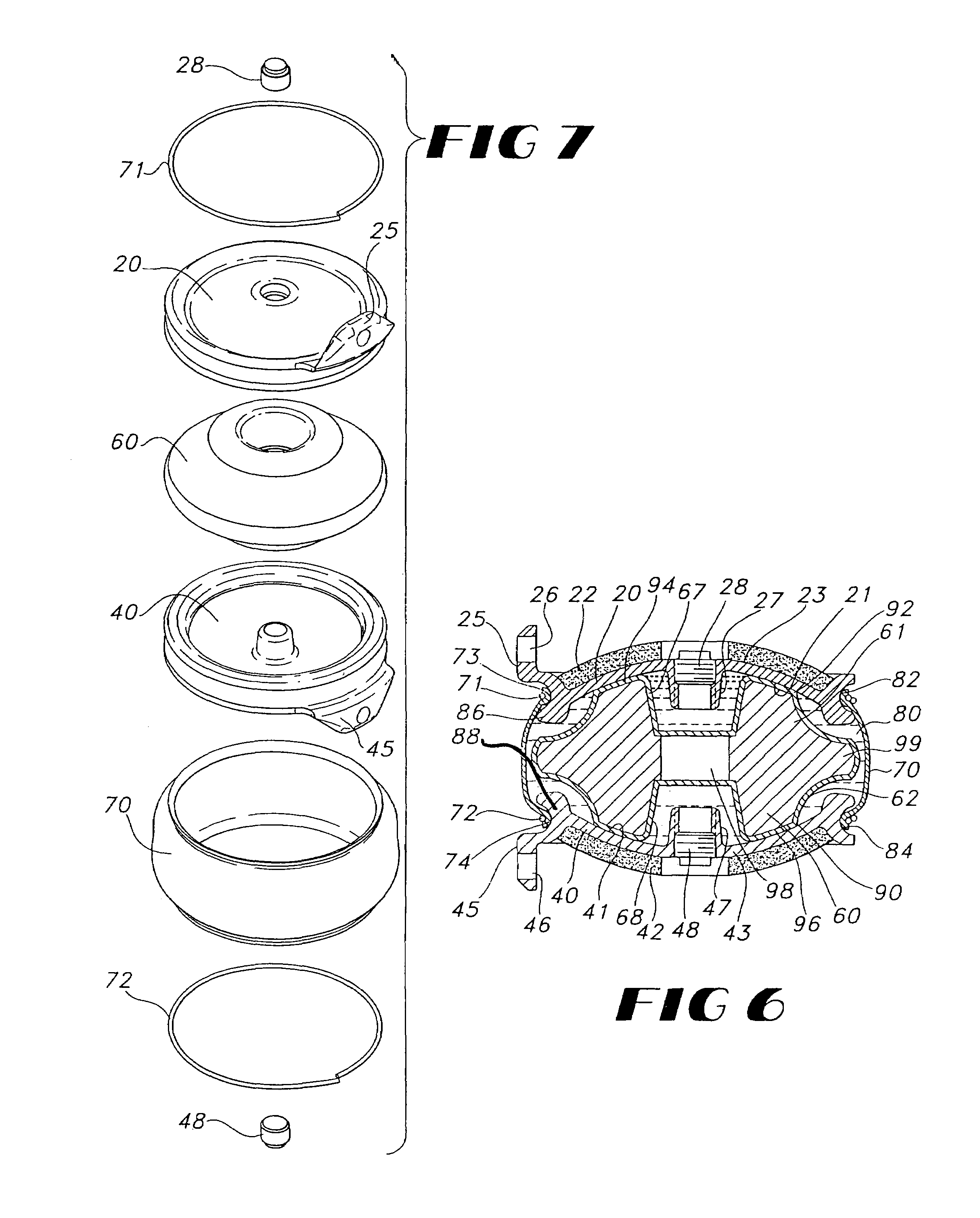

Implantable joint prosthesis

ActiveUS7641692B2Good conditionQuality improvementDiagnosticsJoint implantsRange of motionIntervertebral disc

The invention relates to a surgical implant that provides an artificial diarthroidal-like D joint, suitable for use in replacing any joint, but particularly suitable for use as an intervertebral disc endoprosthesis. The invention contains two rigid opposing shells, each having an outer surface adapted to engage the surfaces of the bones of a joint in such a way that the shells are immobilized by friction between their outer surfaces and the surfaces of the bone. These outer surfaces are sufficiently rough, while the inner surfaces of the shells are relatively smooth. The central body has a shape that cooperates with the shape of the inner surface of the shell so as to provide a range of motion similar to that provided by a healthy joint.

Owner:COMPANION SPINE LLC

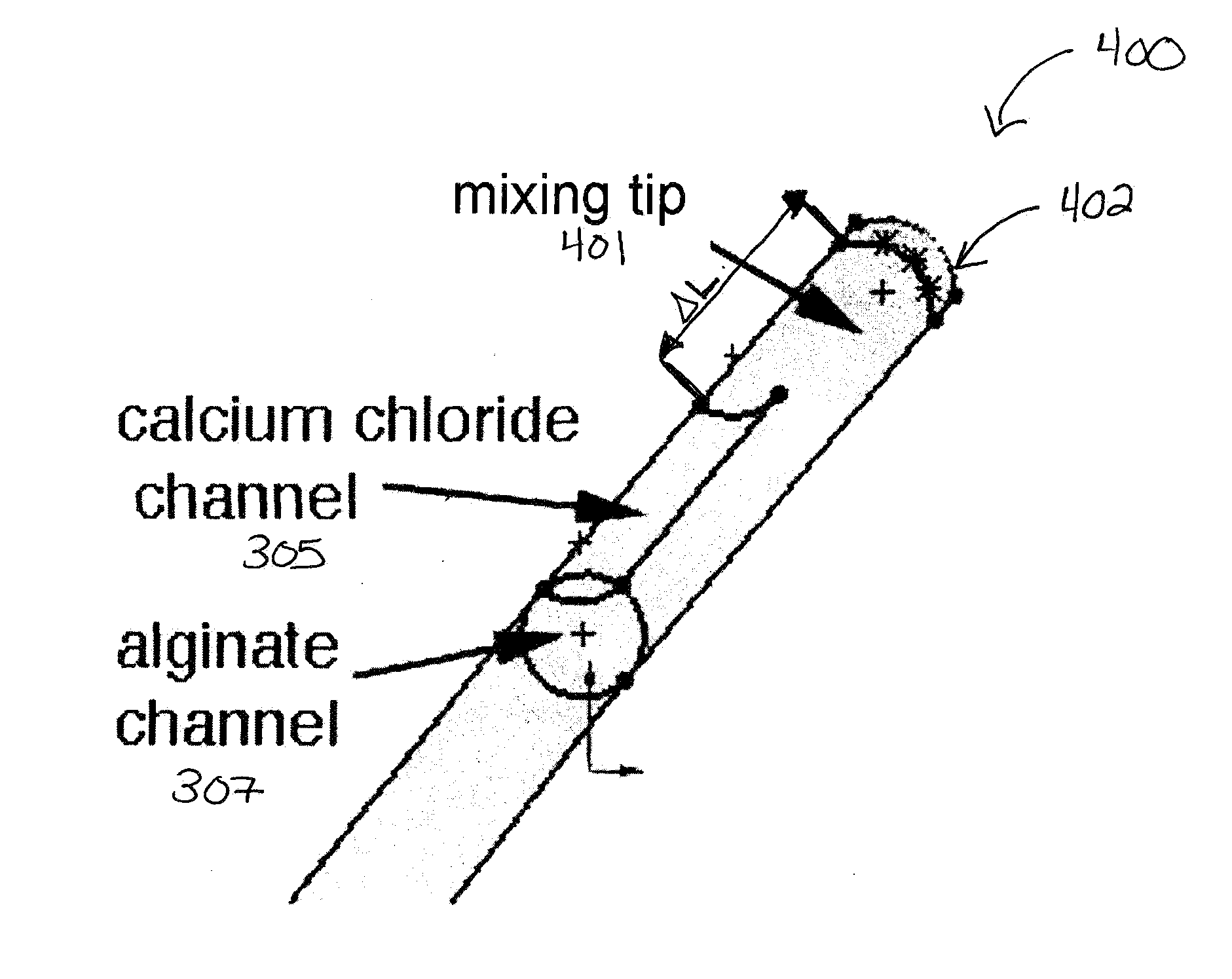

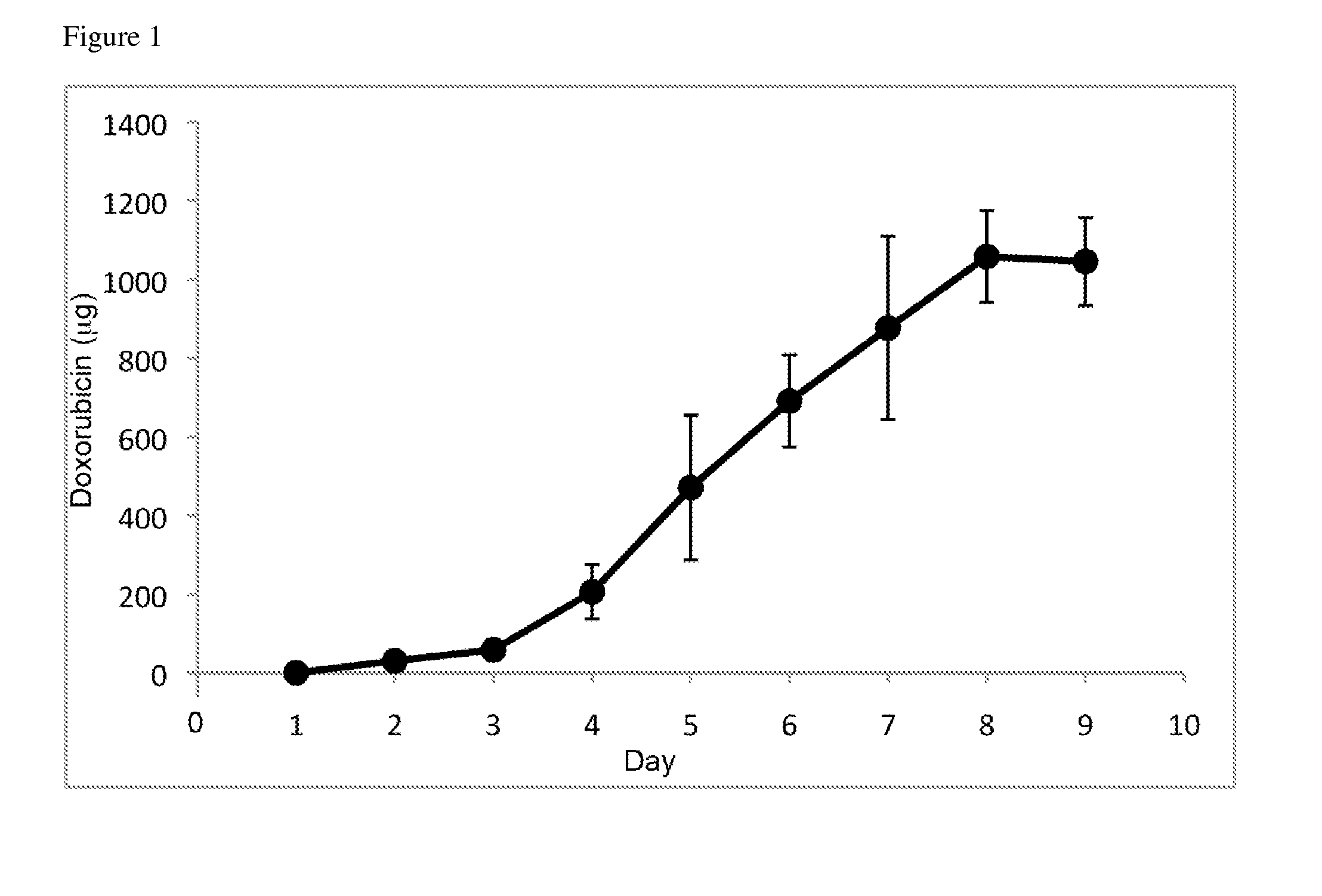

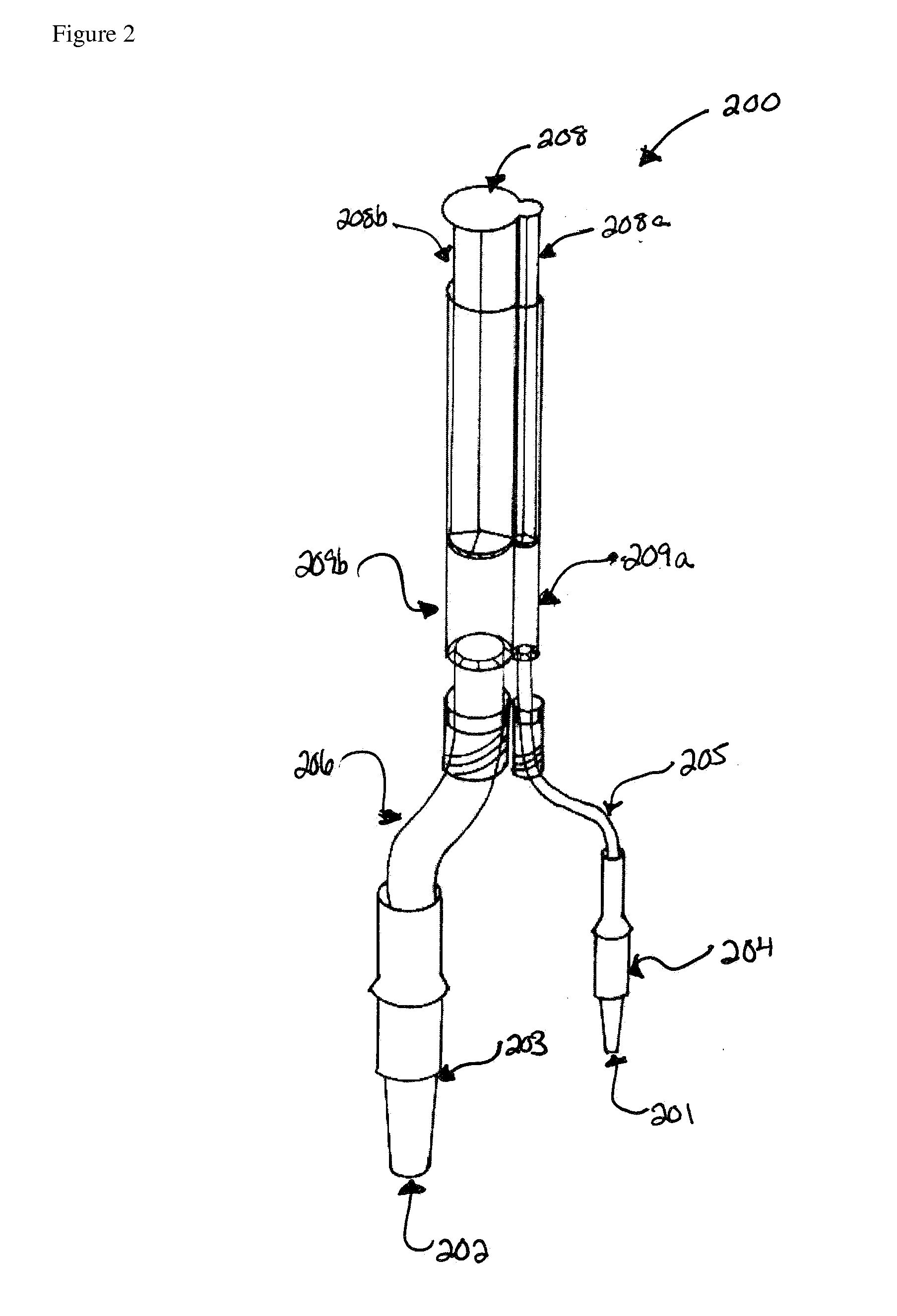

Drug eluting hydrogels for catheter delivery

InactiveUS20130211249A1Reduce materialMaximizes delivery spaceUltrasonic/sonic/infrasonic diagnosticsMulti-lumen catheterDiseaseCatheter device

The invention features catheters, hydrogel compositions, and methods that useful for the treatment of various conditions and diseases. The invention also provides kits and instructions for use.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Signal mirror system for a vehicle

InactiveUS20070183066A1Reduce material costsGood optical performanceMirrorsAntiglare equipmentDisplay deviceLight reflectance

A signal mirror system for a vehicle includes a reflective mirror element comprising a semitransparent nondichroic mirror reflector coated onto a light-transmitting substrate. The visible light transmission through the reflective mirror element is in the range of from about 1% visible light transmission to about 30% visible light transmission and the visible light reflectance is in the range from 40% visible light reflectance to 80% visible light reflectance for visible light incident upon the front side of the reflective mirror element. The reflective mirror element exhibits substantial non-spectral selectivity in its reflectance. The semitransparent nondichroic reflector comprises a metal thin film layer. A turn signal display, preferably having at least one light emitting diode, is disposed to the rear of the reflective mirror element and configured so it emits light emitted that passes through the semitransparent mirror reflector to be viewed by a viewer viewing from the front of said reflective mirror element with a display luminance of at least about 30 foot lamberts.

Owner:DONNELLY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com