Patents

Literature

164results about How to "Reduce sedimentation rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

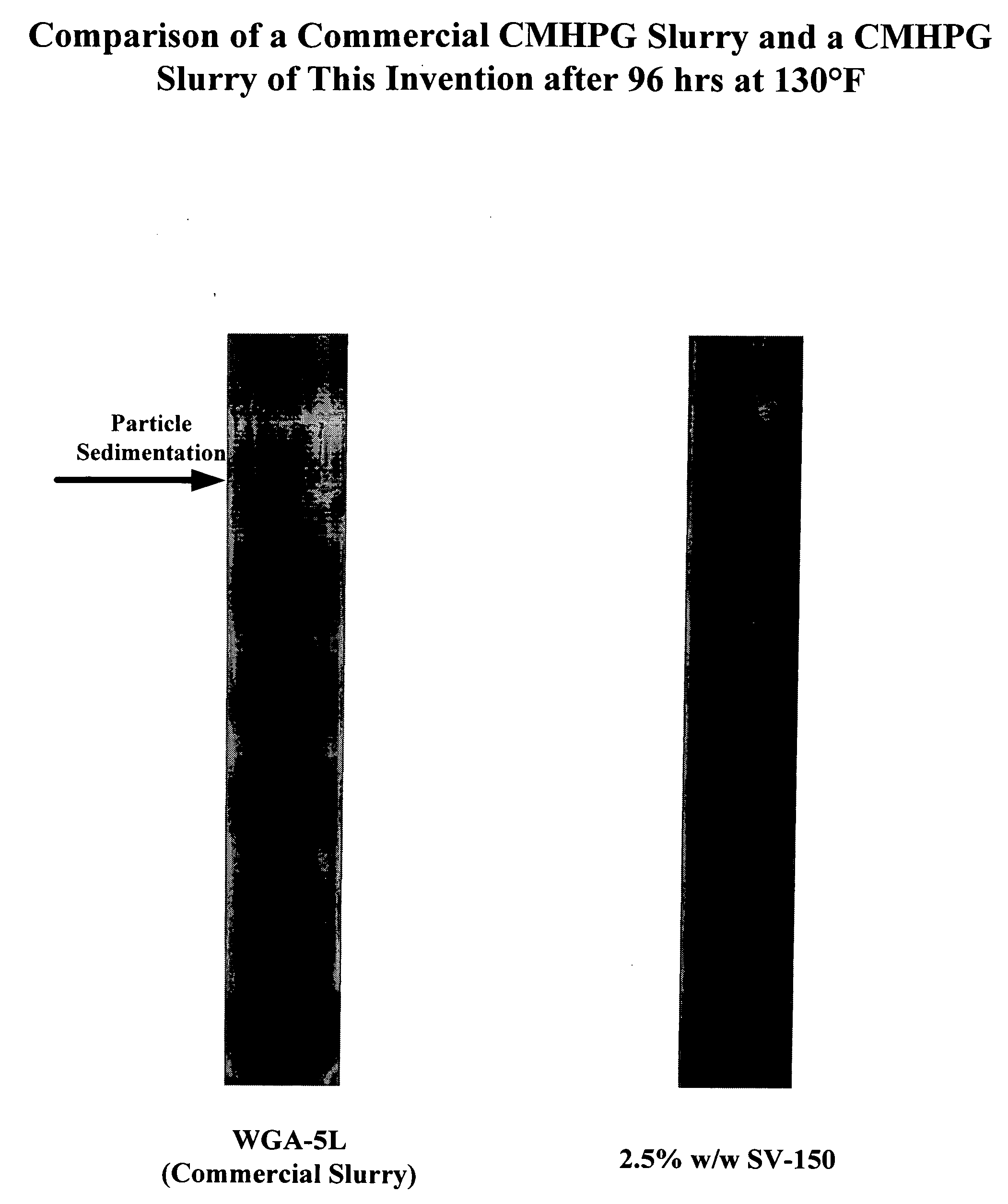

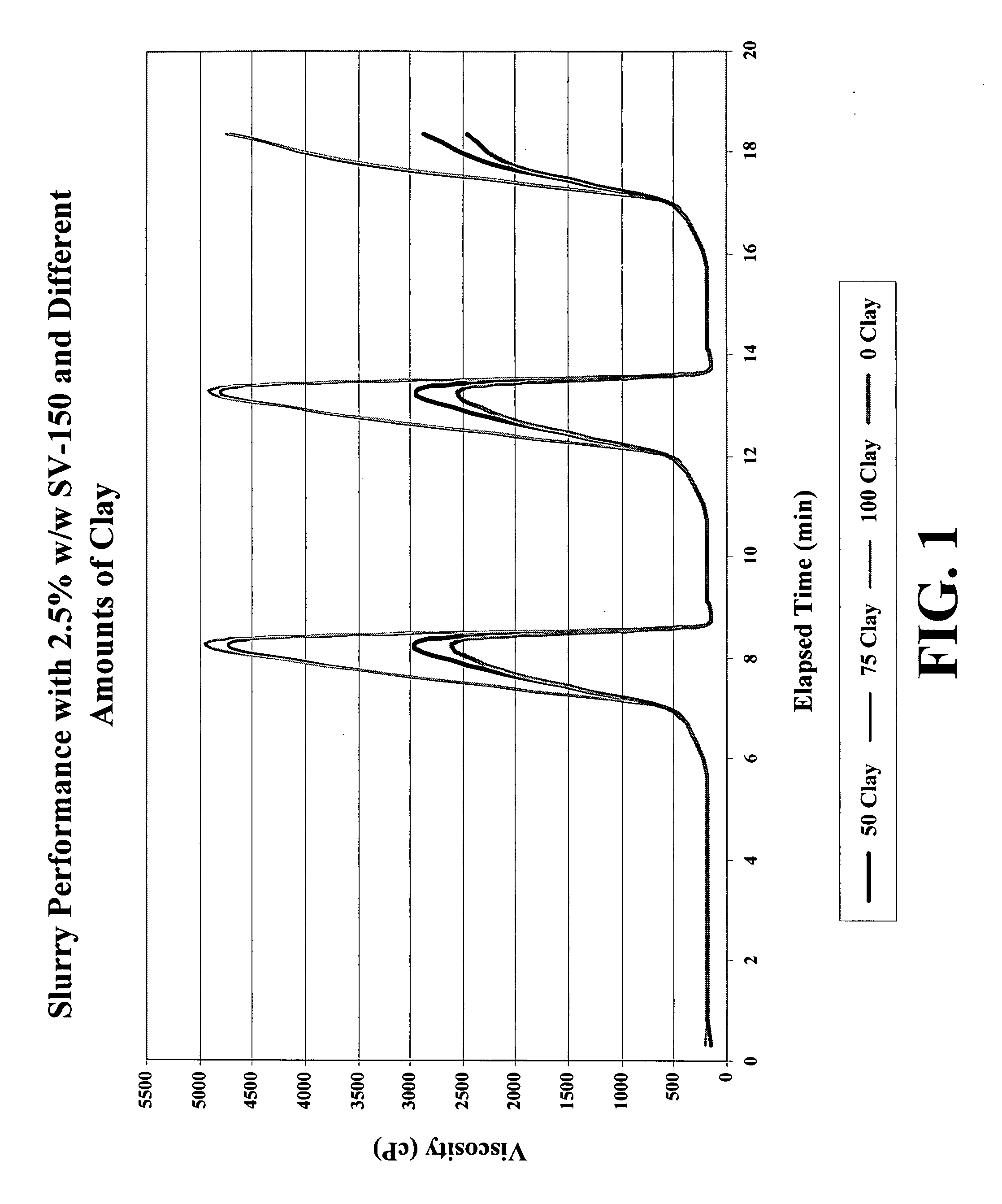

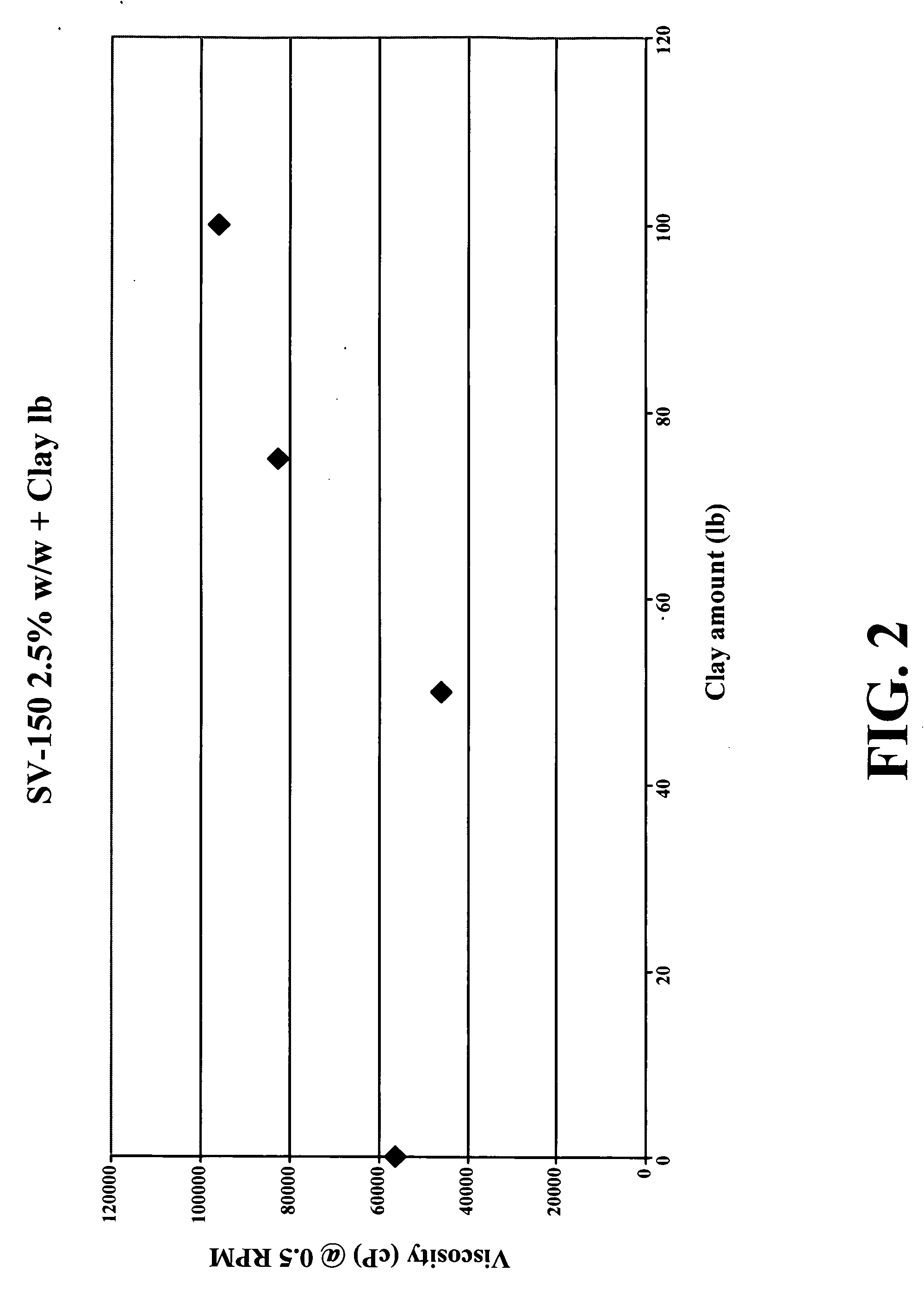

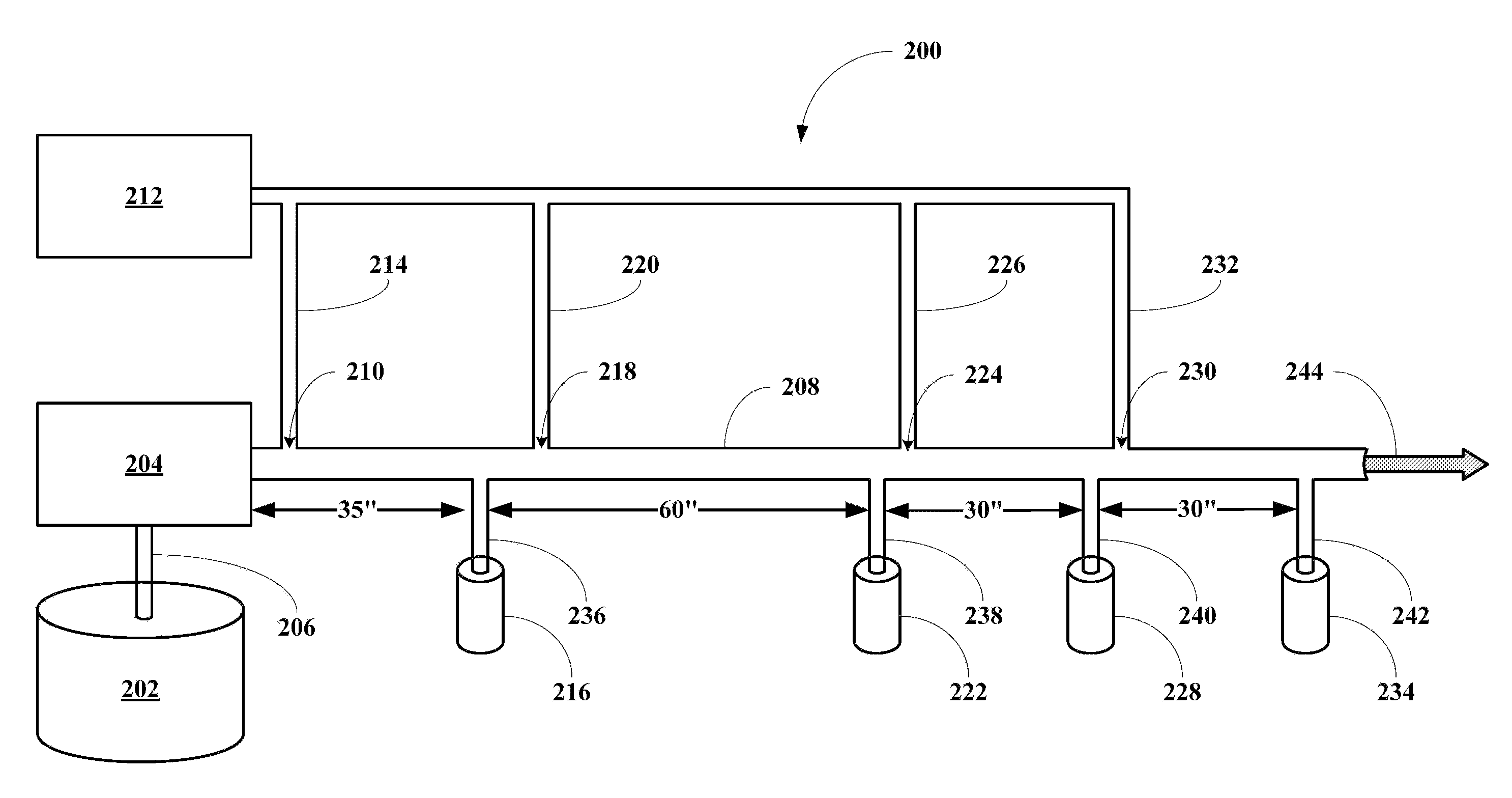

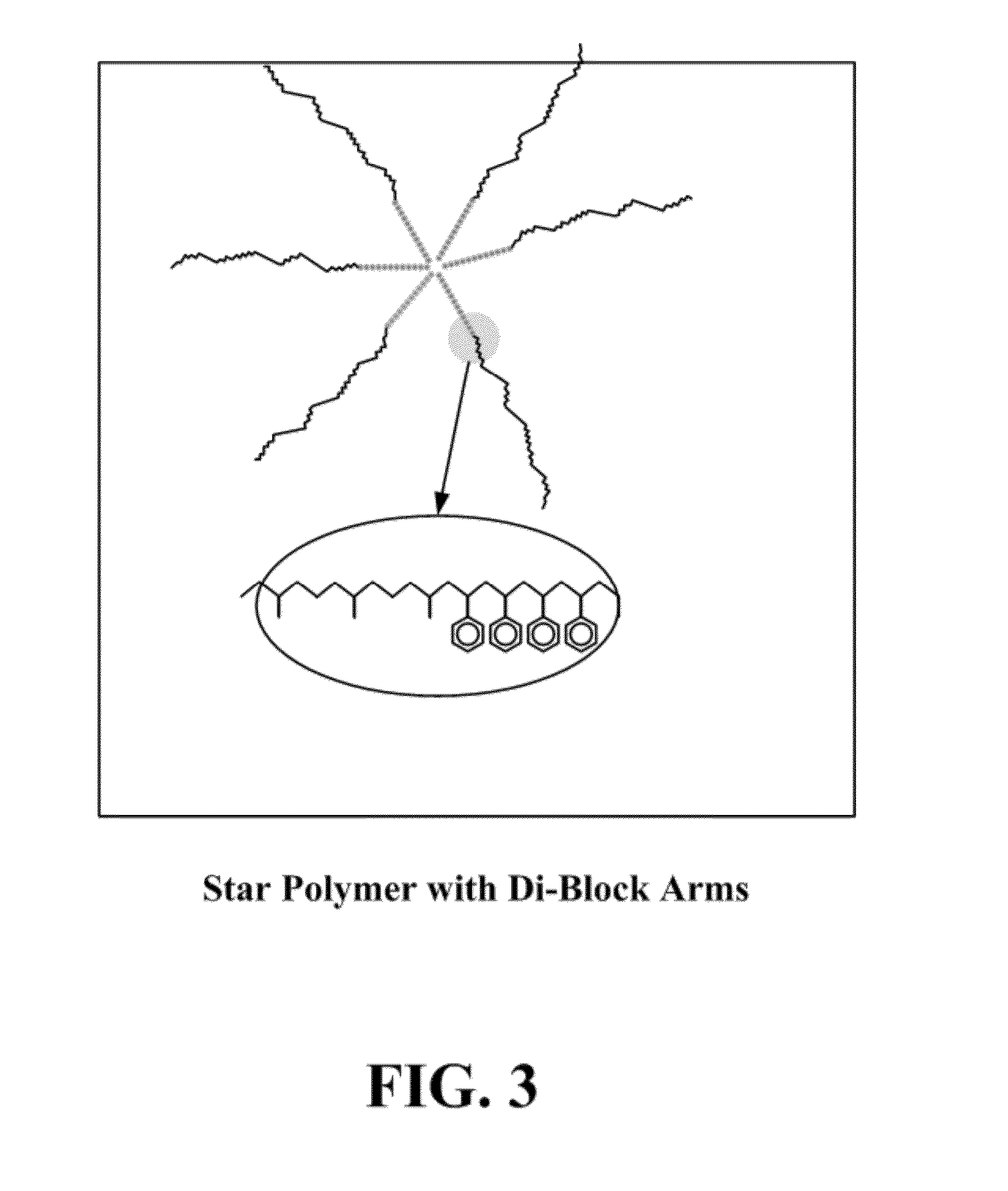

Oil based concentrated slurries and methods for making and using same

InactiveUS20080318812A1Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

Low concentrations of gas bubbles to hinder proppant settling

InactiveUS20100252262A1Low densityReduce sedimentation rateFluid removalFlushingFracturing fluidBuoyancy

Owner:CLEARWATER INT LLC

Magnetorheological fluid-based device and method for use

InactiveUS20130186473A1Reduce sedimentation rateSpringsFluid dynamicsMagnetorheological fluidEngineering

A magnetorheological fluid-based device and method may include the use of magnetorheological (MR) fluid, a primary magnetic field to control the viscosity of the fluid, and a secondary magnetic field to reduce clumping of ferromagnetic particles.

Owner:GM GLOBAL TECH OPERATIONS LLC

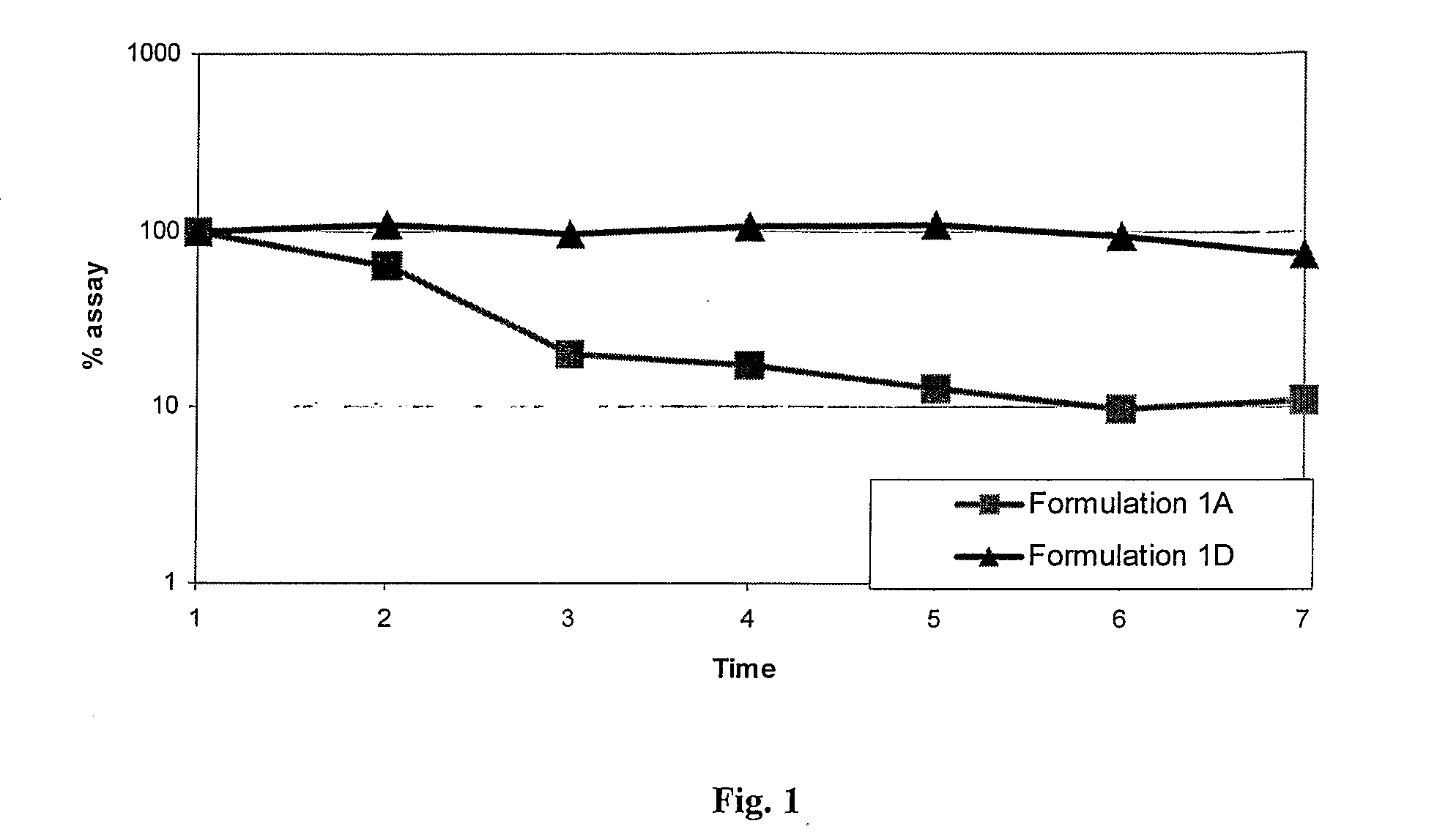

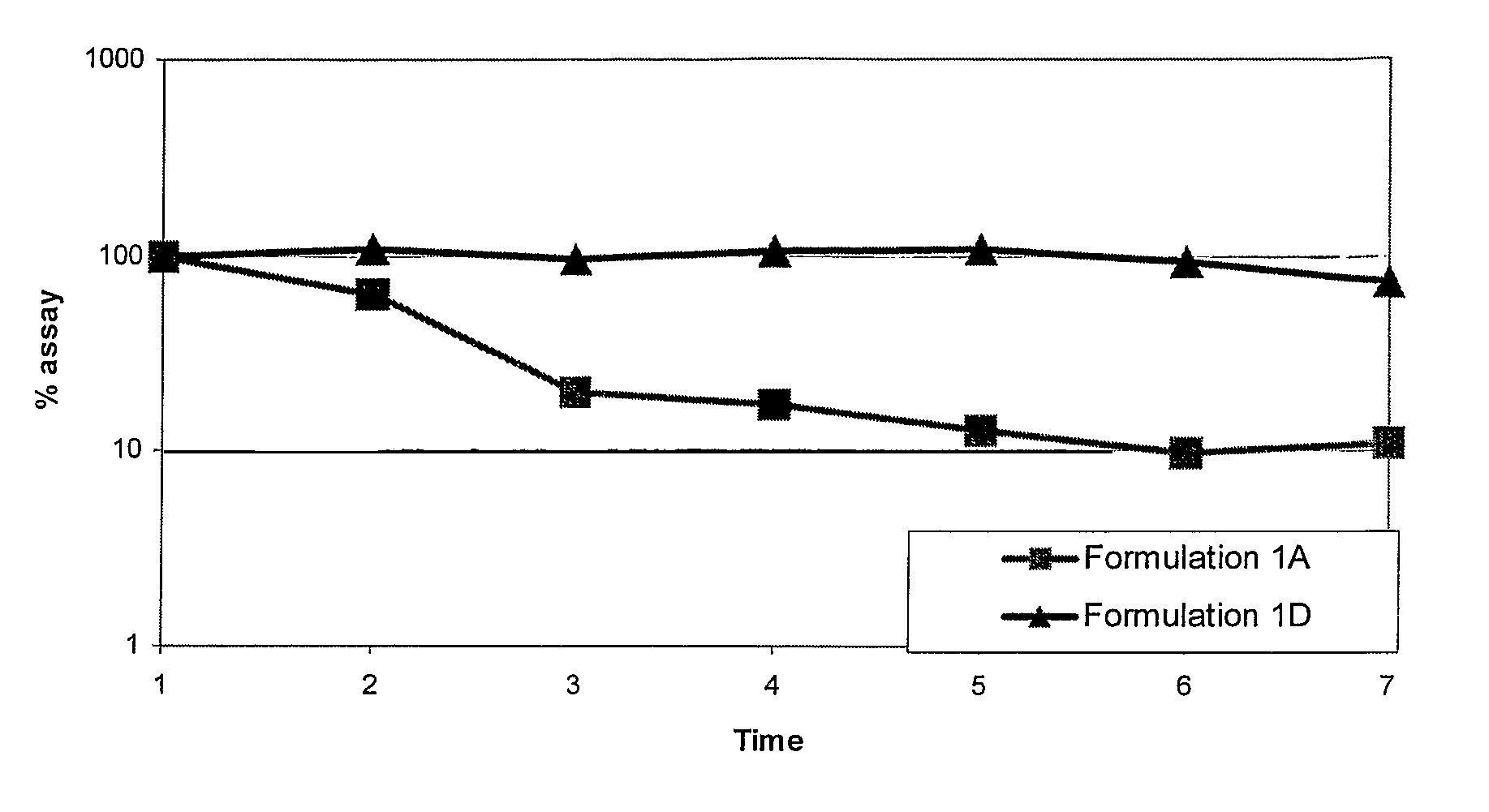

Novel Dispersible Tablet Composition

ActiveUS20080312168A1Reduce sedimentation rateDisintegrates quicklyBiocideCarbohydrate active ingredientsBULK ACTIVE INGREDIENTActive ingredient

The present invention relates to a novel dispersible tablet composition, which comprises of a pharmacologically active ingredient and at least one excipient, which reduces the sedimentation rate of active ingredient. This invention further relates to a process for the preparation of a dispersible tablet of a pharmacologically active ingredient.

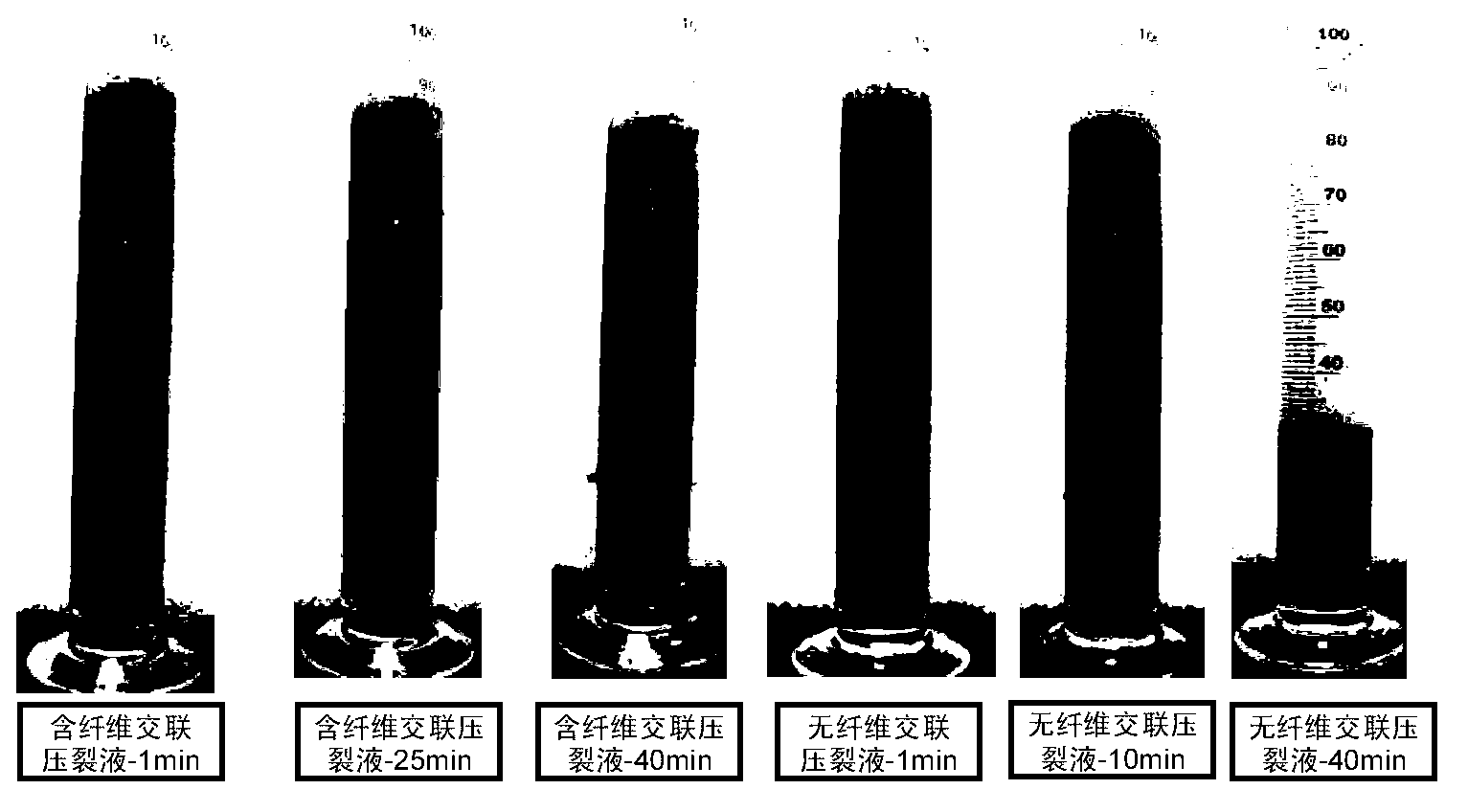

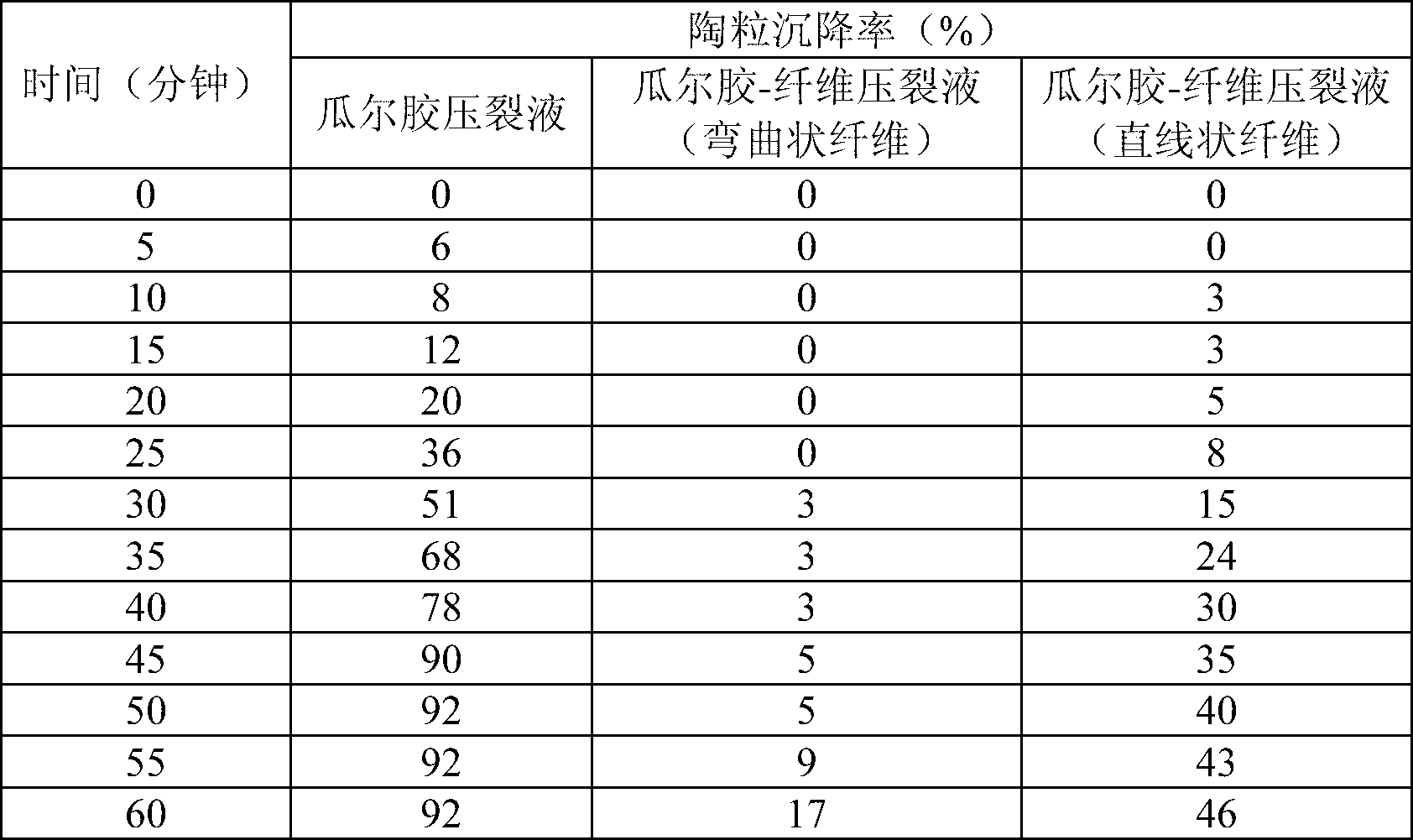

Fracturing fluid and fracturing method for increasing applicaiton efficiency of support agent in fractured cracks

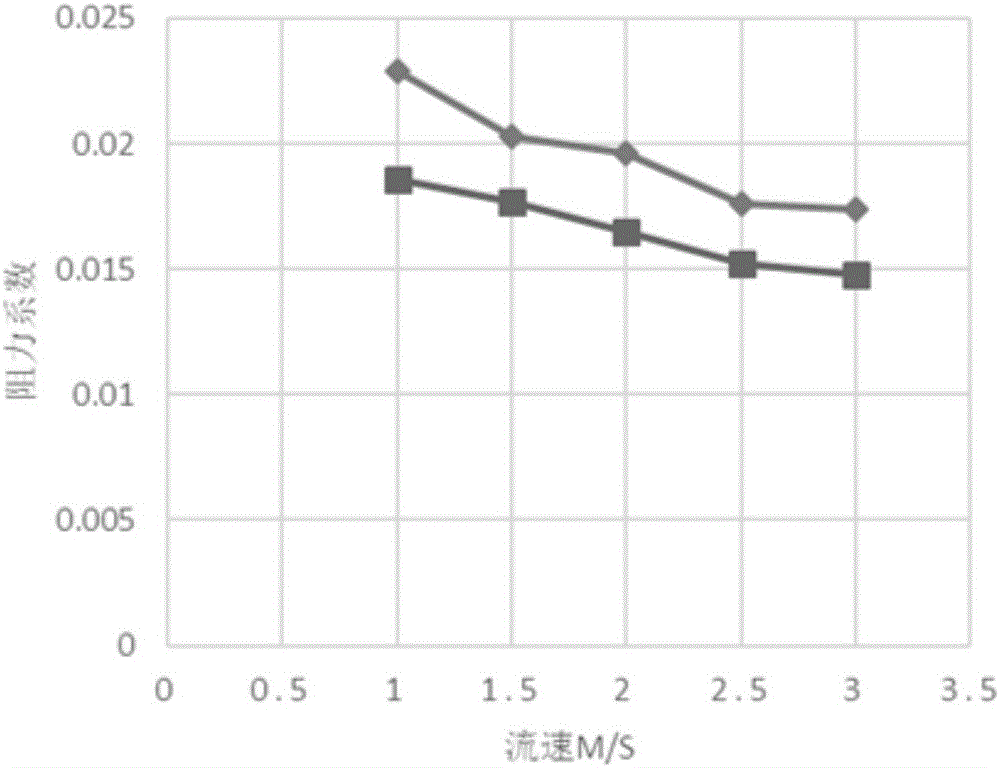

ActiveCN103013486AReduce sedimentation rateEvenly distributedFluid removalDrilling compositionGuar gumEnvironmental geology

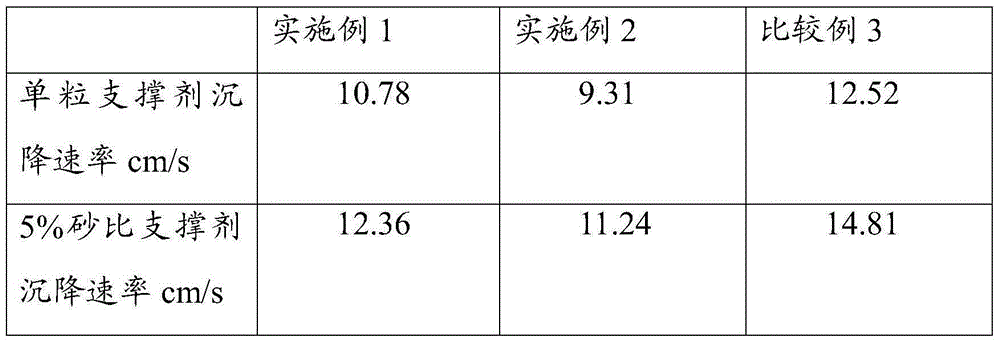

The invention relates to a fracturing fluid and fracturing method for increasing the application efficiency of a support agent in a fractured crack. The fracturing fluid is a water-based fracturing fluid and comprises sand-suspending fibers and a thickening agent, wherein the sand-suspending fibers are hydrophilic high-strength bent organic fibers or inorganic fibers. The fracturing method comprises the step of injecting the fracturing fluid serving as a sand carrying fluid into a formation crack, wherein the injection parameters of the sand-carrying fluid are as follows: the consumption is 40-3000m<3> and the injection speed is 2.0-15.0m<3> / min. The support agent is suspended by using a three-dimensional net structure formed by the sand-suspending fibers. According to the method, the content of guar gum in the sand-carrying fluid can be reduced, and the application efficiency of the support agent in a longitudinal direction is increased, and therefore, the support agent is more uniformly distributed in the longitudinal direction of a manual fractured crack, the guide performance of the crack in the whole longitudinal profile is improved, and the economic benefit of fracturing constructing is increased.

Owner:PETROCHINA CO LTD +1

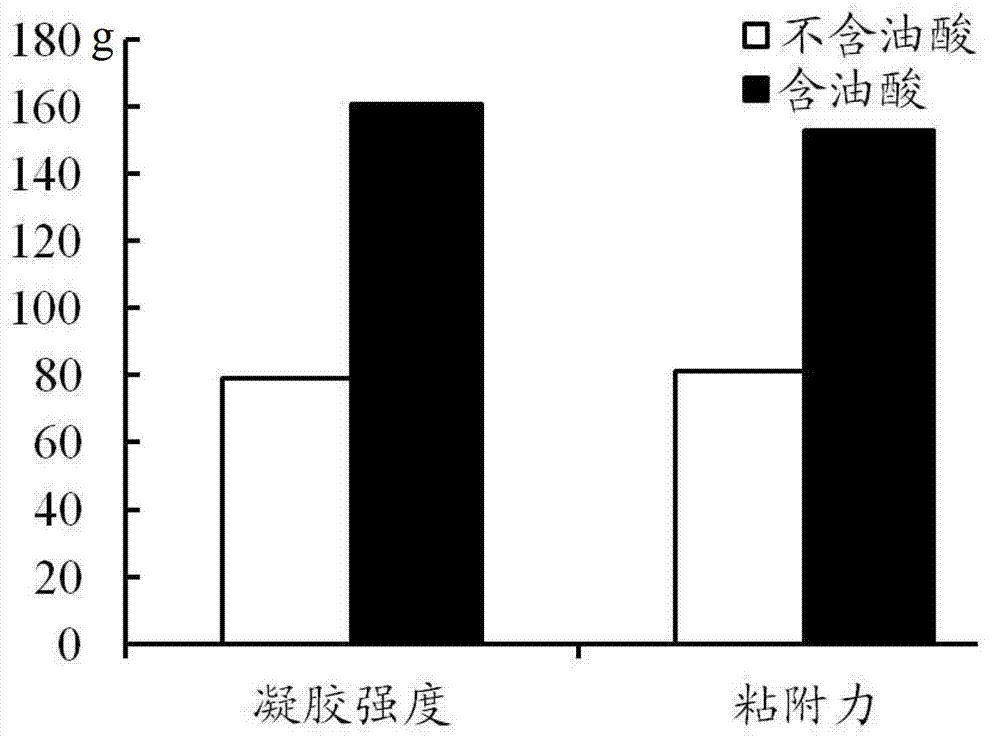

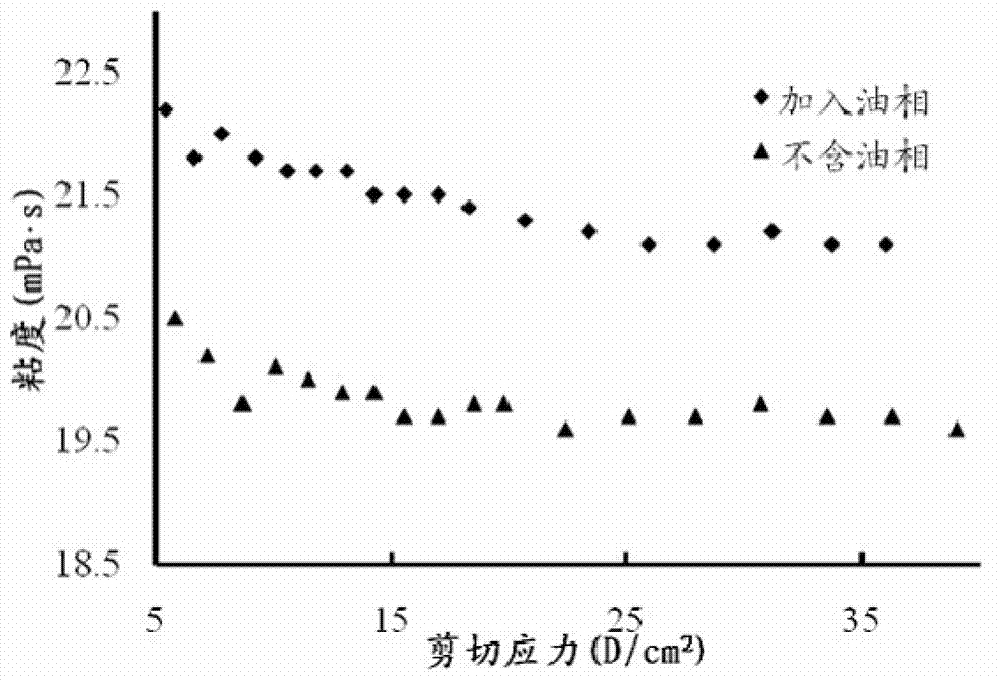

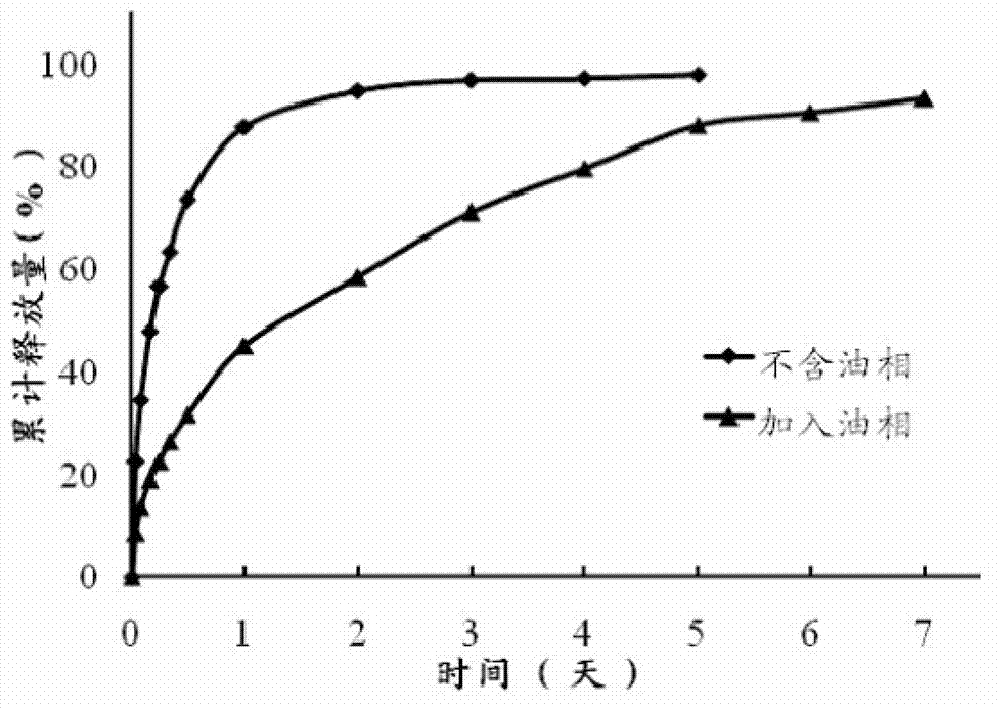

Precursor suspension of lyotropic liquid crystal and preparation method thereof

ActiveCN103040741AHigh viscosityHigh strengthSolution deliveryEmulsion deliveryOrganic solventUltimate tensile strength

The invention discloses a precursor suspension of a lyotropic liquid crystal. The precursor suspension comprises lyotropic liquid crystal material, organic solvent, oil phase and a drug, wherein the weight percentage of the oil phase in the precursor suspension is 2-50 percent, the weight percentage of the drug in the precursor suspension is 1-30 percent, and the weight ratio of the lyotropic liquid crystal material and the organic solvent in the precursor suspension is 2-9:1. According to the invention, through the adding of the oil phase into the precursor suspension, the stability of the suspension is improved, the sedimentation rate is reduced, and the strength and the adhesive force of the gel formed are enhanced at the same time; the gel formed in the body is more liable to stay at a lesion location and less liable to be relocated and the shape is less liable to be damaged by the mechanical motion of the body, so that the drug therapy can be located effectively; and the preparation technology is simple and the precursor suspension of the lyotropic liquid crystal is a partial slow-release drug delivering system provided with a favorable perspective.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

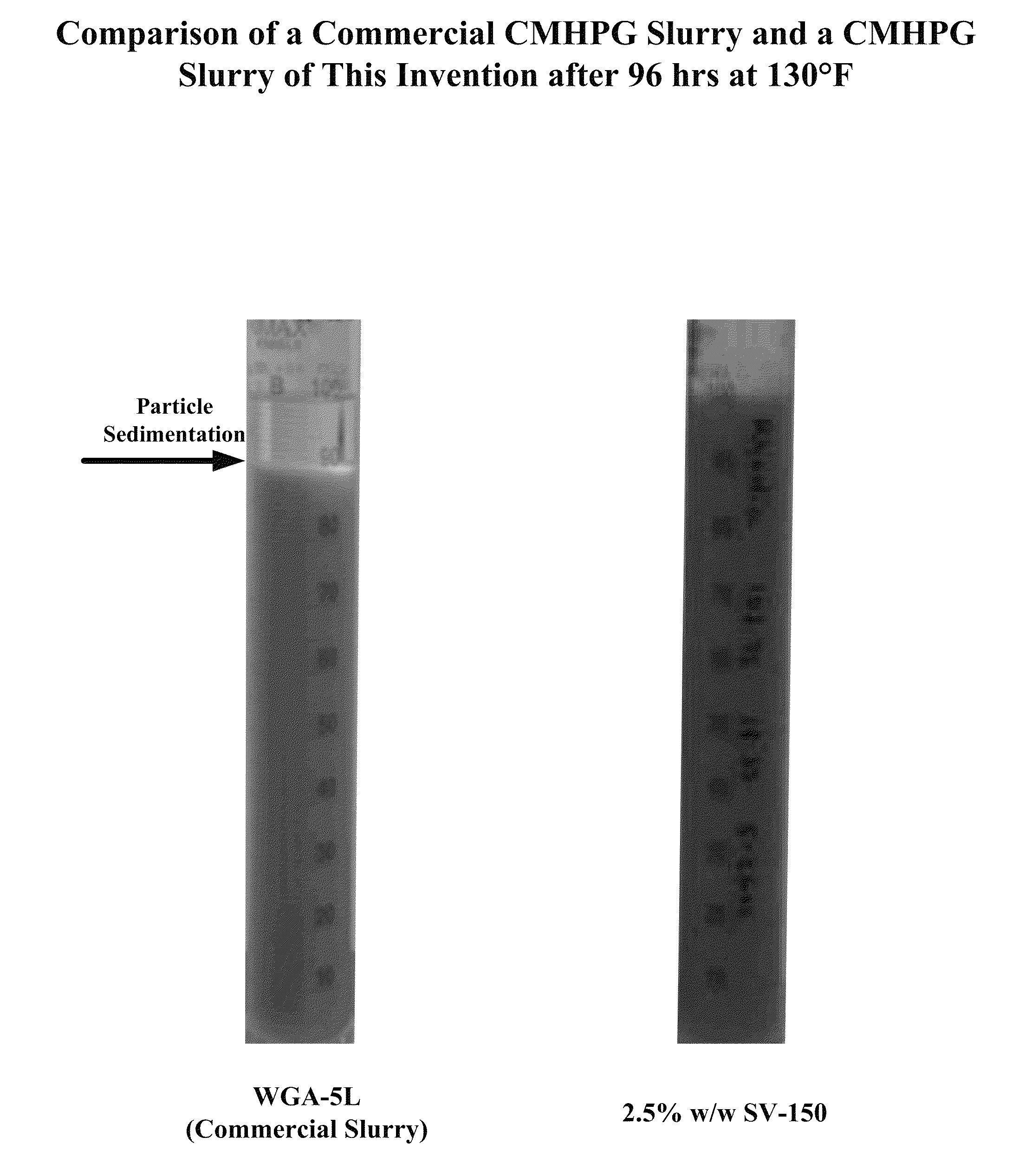

Oil based concentrated slurries and methods for making and using same

InactiveUS8728989B2Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

Oil based concentrated slurries and methods for making and using same

ActiveUS20140315763A1Reduce sedimentation rateReduce settlementFluid removalFlushingParticulatesSlurry

New hydrocarbon based slurry compositions and drilling, fracturing, completion and production fluids including the hydrocarbon based slurry composition are disclosed, where the composition includes a hydrocarbon soluble polymer adapted to decrease particle settling rates of particulate materials present in the fluids and in the case of fluids that include hydratable materials to increase hydration properties of such materials.

Owner:WEATHERFORD TECH HLDG LLC

Modified carbon black carbon black dispersion liquid and water base ink

InactiveCN1692144AReduce sedimentation rateStable storagePigmenting treatmentDuplicating/marking methodsTO-18Water based

There are provided a carbon black according to which long-term stable storage is possible, clogging is not prone to occurring, and the OD value is high and hence printing with a deep black color is possible, or a carbon black that can be used in a water-based ink that is used in ink jet printer printing, that has low settleability and can thus be stored stably for a long period, for which clogging is not prone to occurring, and for which the reflection density is high and hence printing with a high printing density and a deep black color is possible, a carbon black dispersion having the carbon black dispersed therein, and a water-based ink containing the carbon black. An embodiment of a modified carbon black of the present invention is a modified carbon black obtained by carrying out oxidation treatment on a carbon black having a primary particle diameter of 11 to 18 nm, a BET specific surface area of at least 180 m2 / g, a DBP oil absorption of at least 180 mL / 100 g, and a value of the BET specific surface area (m2 / g) divided by the DBP oil absorption (mL / 100 g) of 0.75 to 1.3, and is characterized in that at least lactone groups and carboxyl groups are introduced onto the surface thereof, and the ratio of the mean particle diameter to the primary particle diameter is at least 8.5. Moreover, a carbon black dispersion and a water-based ink of the present invention contain this modified carbon black.

Owner:SEIKO EPSON CORP +1

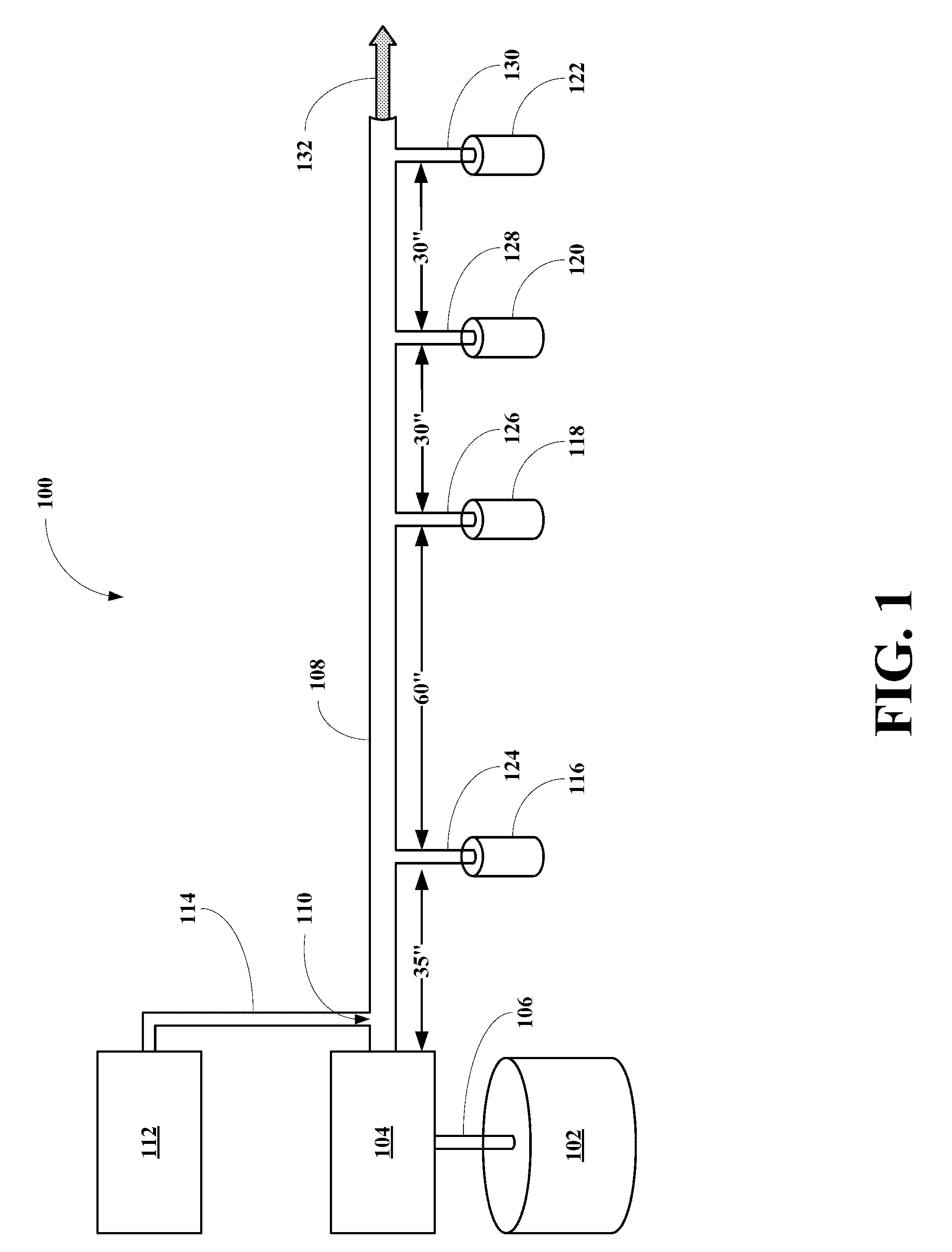

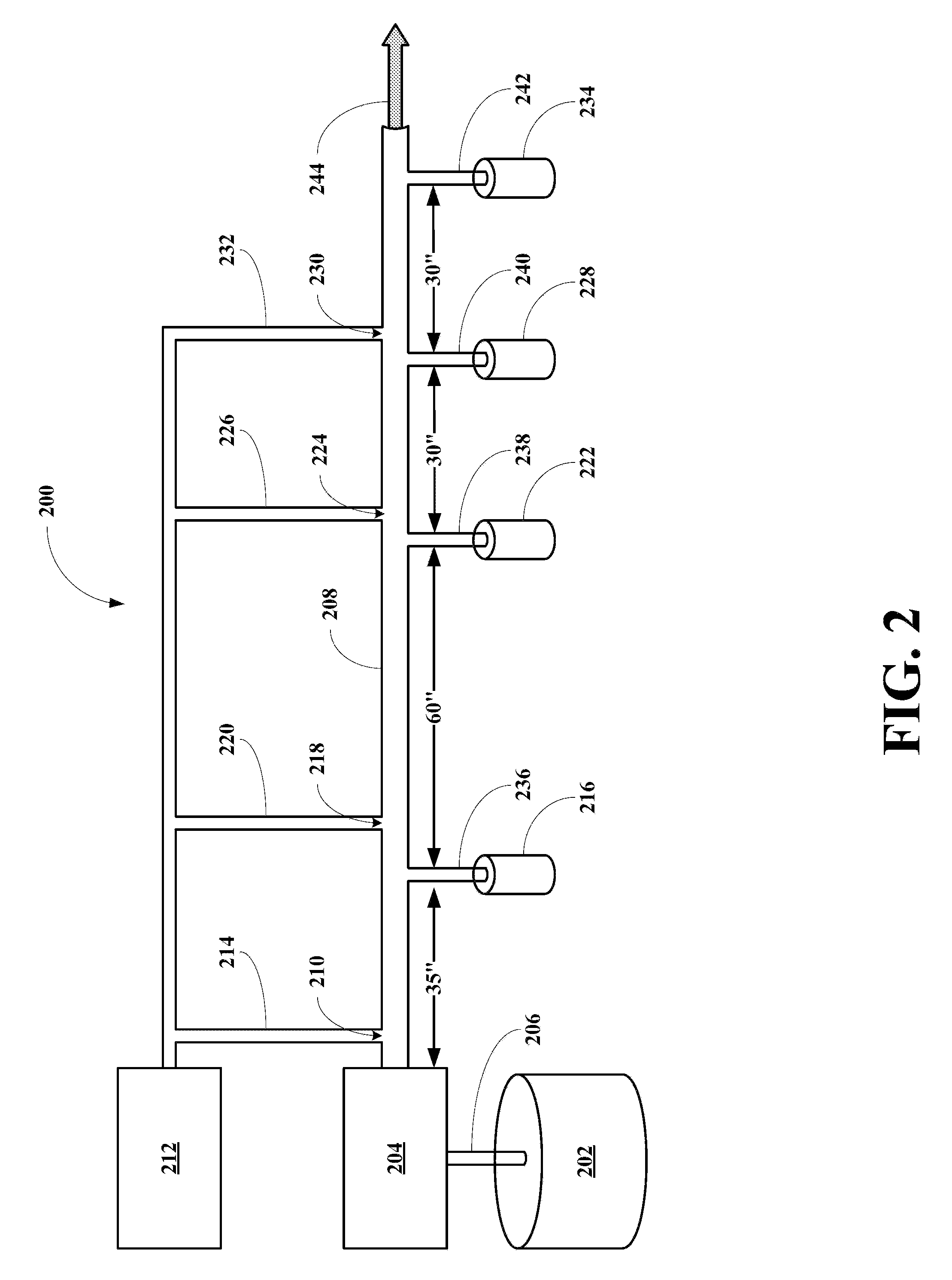

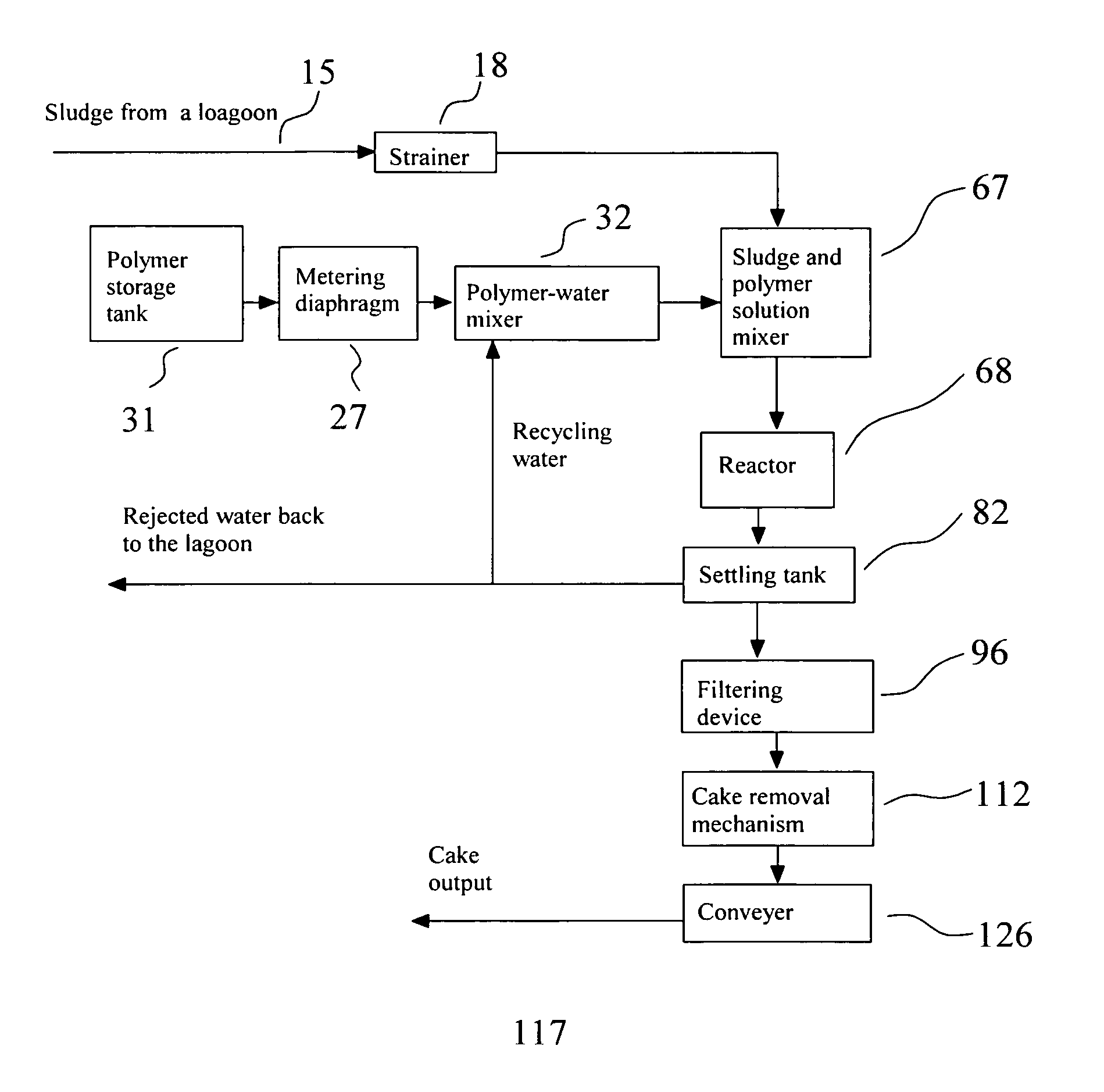

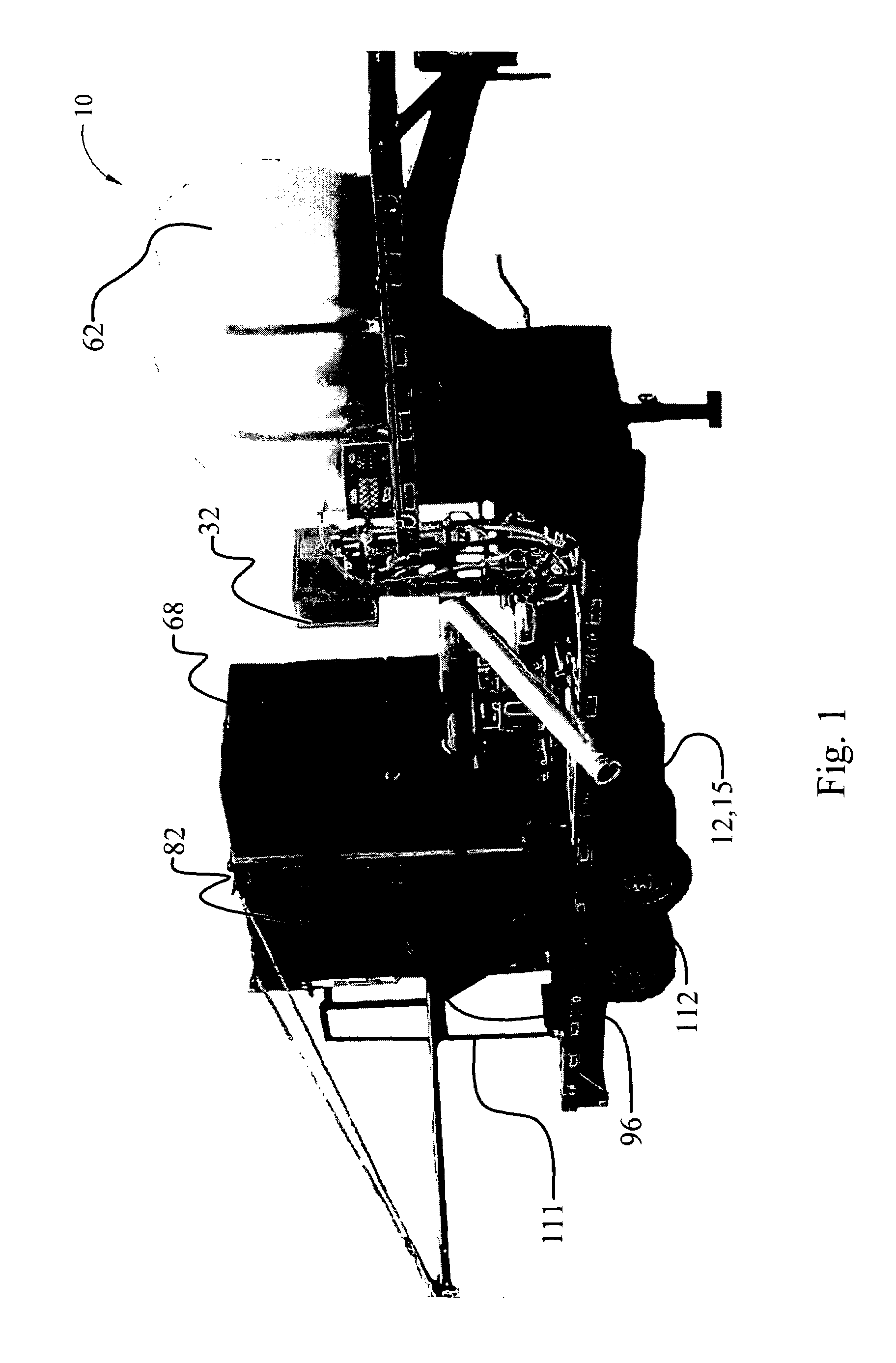

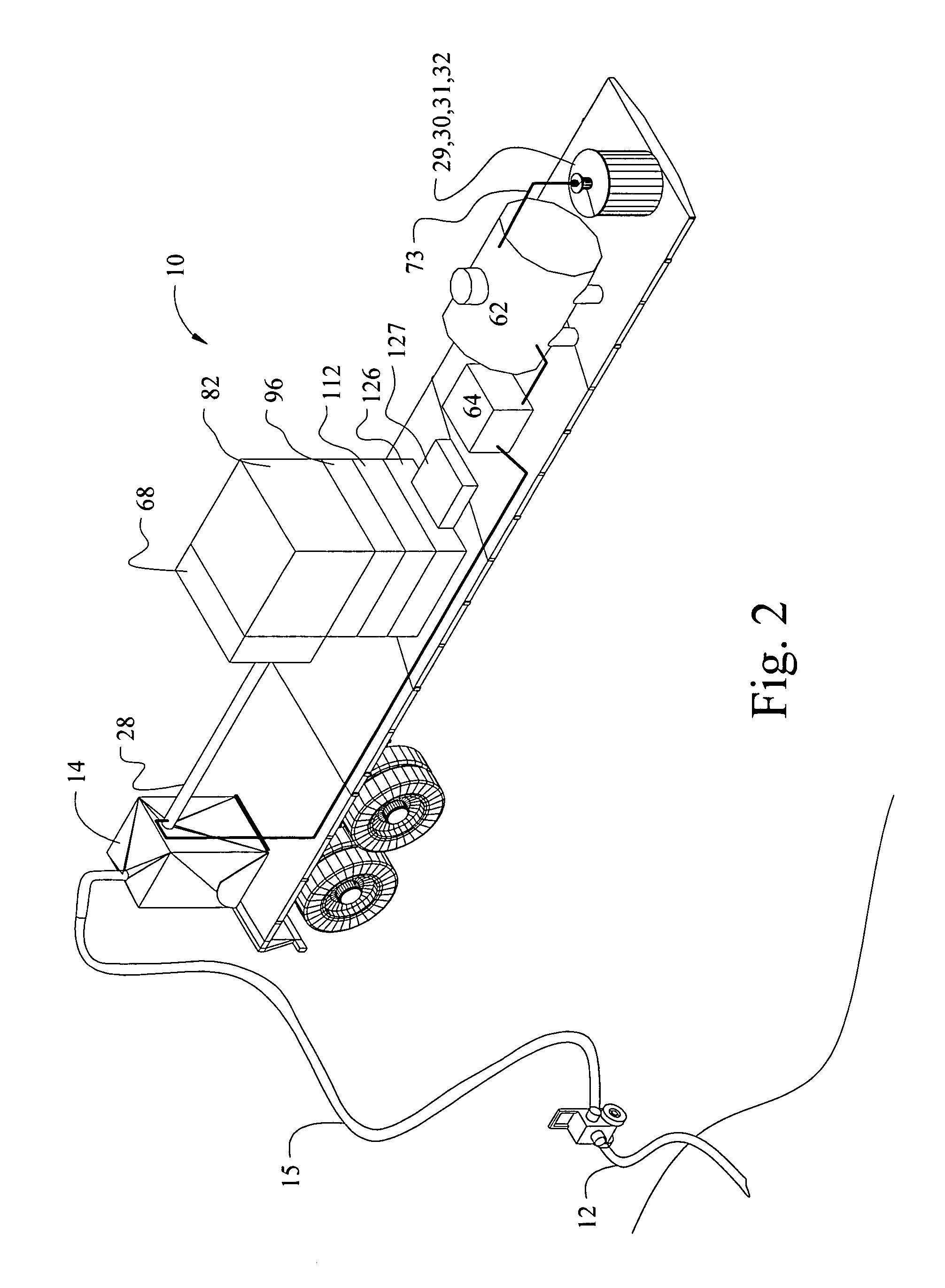

Settling grid separator

InactiveUS7276154B1Promote solid flocculationLimit transportabilityIon-exchanger regenerationSolid sorbent liquid separationFlocculationHigh density

A settling grid separator apparatus and method of use which provides deep dehydration of high flow rate sludge in an environmentally friendly and energy efficient manner. The apparatus and method comprise and utilize an efficient mixing of the sludge with a flocculating agent or polymer solution, and sludge flow quieting techniques to reduce disturbances and promote flocculation of clustered solids. Free surface liquid rejection, a series of traps, and pressurized filtering utilize gravimetric, hydrometric, and densimetric techniques to separate liquid from suspended solids. Gravitational forces are utilized throughout the apparatus and method to promote separation of higher density solids from the lower density liquid carrier. Upon separation, solids with a minimal liquid content are controllably discharged for proper disposal or recycling.

Owner:VAV TECH

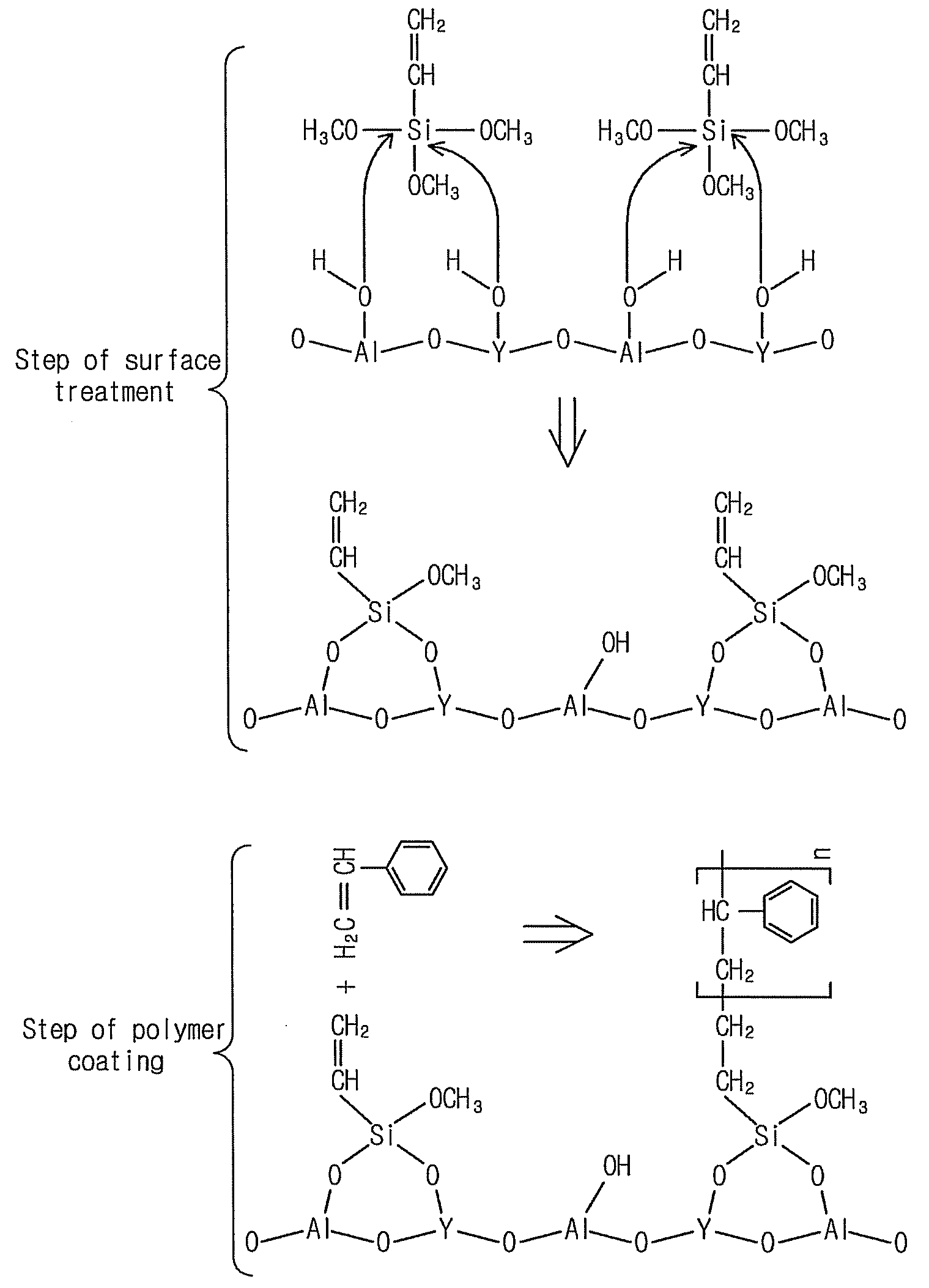

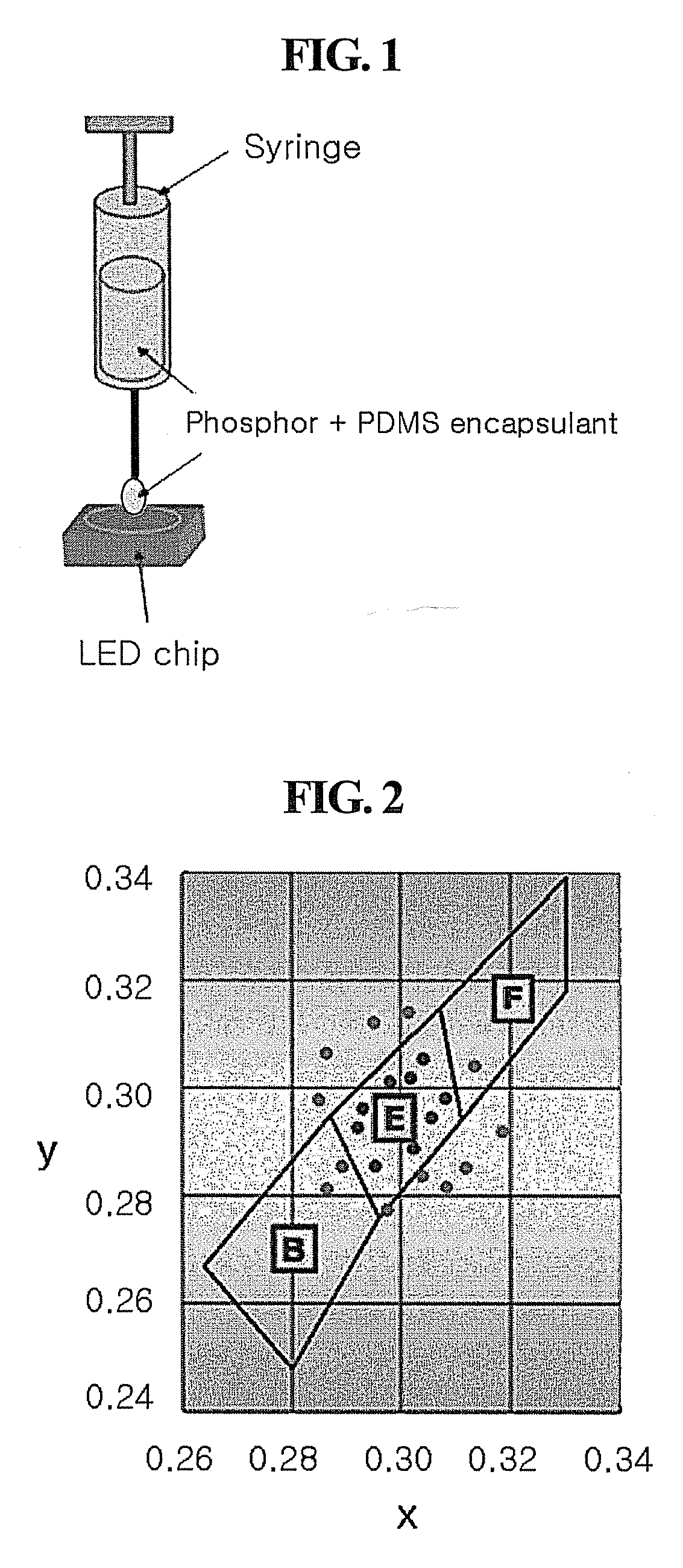

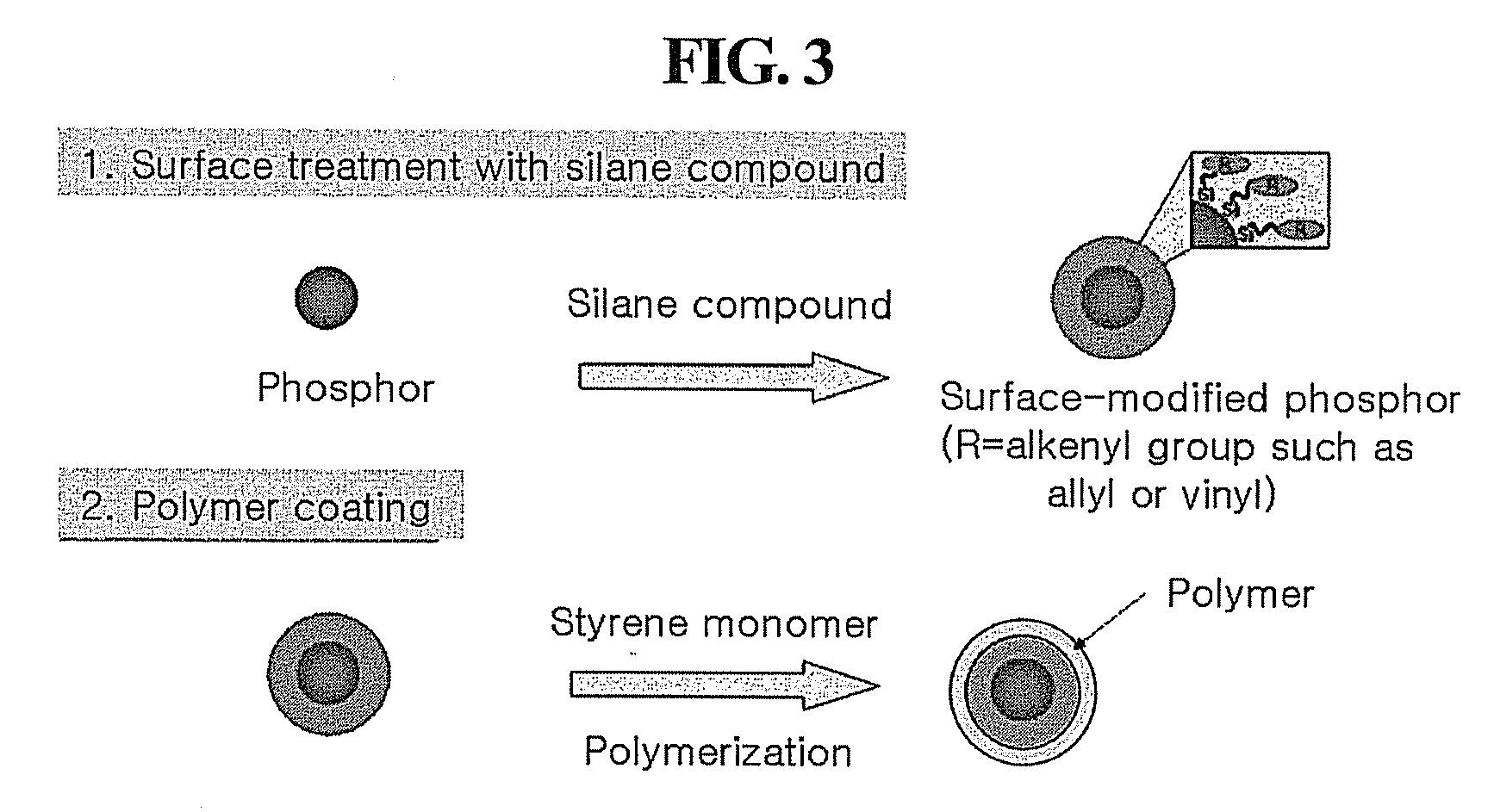

Method for Controlling Fluidity of Phosphor, Phosphor and Phosphor Paste

InactiveUS20080103276A1Improve fluidityReduced settling speedLuminescent compositionsSemiconductor devicesDouble bondMembrane configuration

Disclosed herein is a method for controlling the fluidity of a phosphor, a phosphor and a phosphor paste, the method comprising the steps of: treating the surface of a phosphor with a silane compound comprising a double bond; and polymerizing the monomer on the surface of the phosphor to form a polymer membrane thereon. The phosphor having the polymer membrane formed thereon exhibits significantly stabilized fluidity within a polymer encapsulant.

Owner:SAMSUNG ELECTRONICS CO LTD

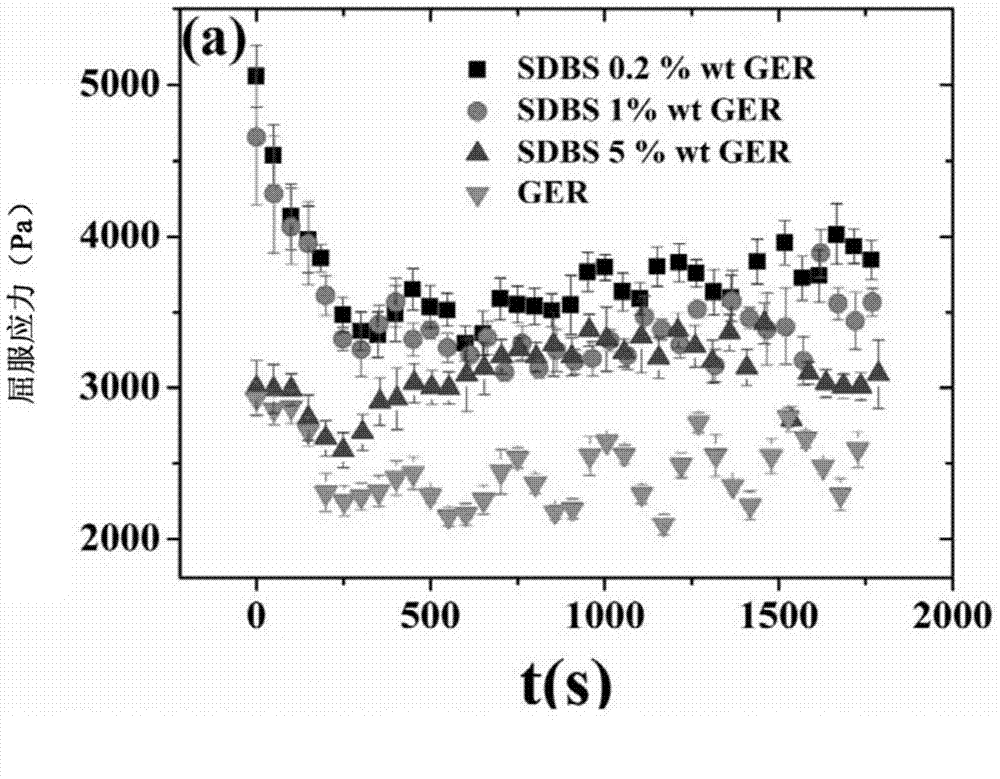

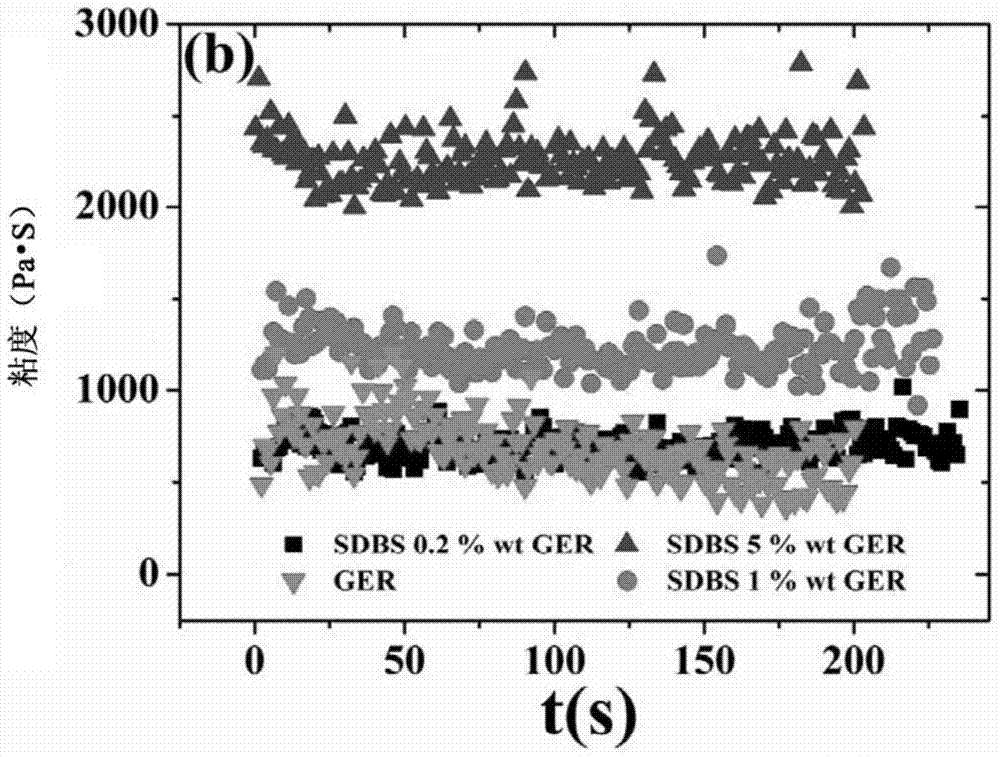

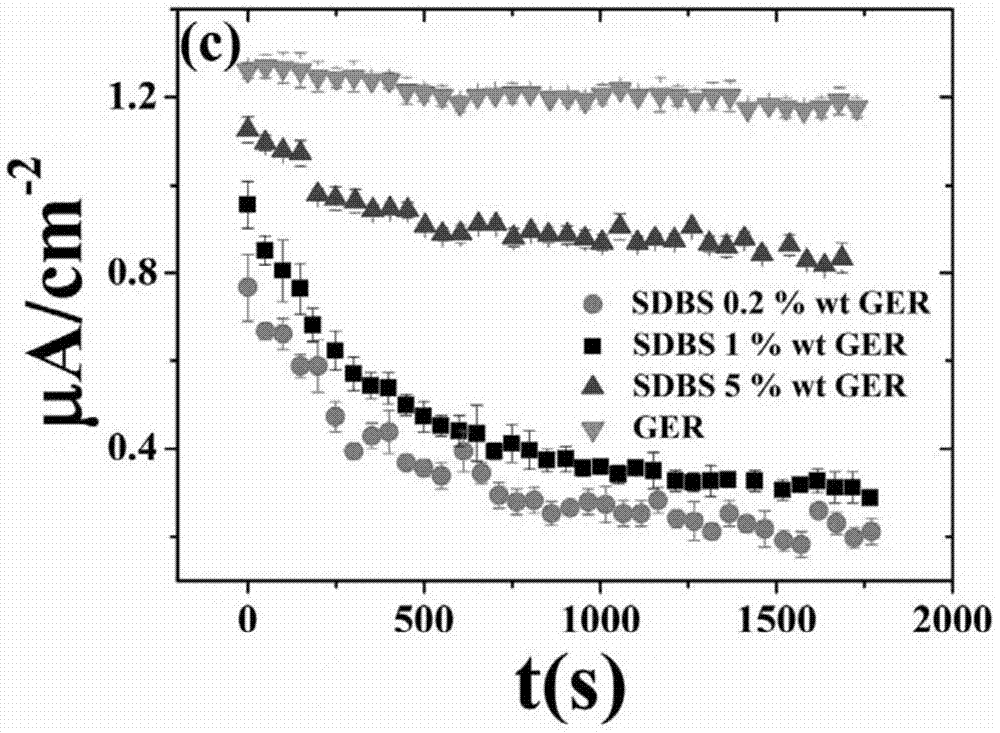

Improved giant electrorheological fluid and manufacturing method thereof

InactiveCN104774675AReduce sedimentation rateImproved redispersion propertiesAdditivesPower flowMechanical property

The invention relates to an improved giant electrorheological (GER) fluid and a manufacturing method thereof. The GER fluid comprises metal salt nano composite coated by urea, polar molecule additive and high-wettability insulating liquid, wherein the metal salt nano composite suspends in the high-wettability insulating liquid. By adding the polar molecule additive, the yield stress of the GER fluid under the electric field is increased by more than 50%, but the current density is reduced to 1 / 4 of that of the original GER fluid. The reversible response time maintains the same, and the sedimentary stability is obviously improved. The zero field viscosity of the improved GER fluid maintains the same as that of the GER fluid without the additive. The electrical and mechanical properties of the improved GER fluid are improved, and the improved GER fluid can be applied to vehicle clutches, hydraulic brakes and vehicle dampers.

Owner:THE HONG KONG UNIV OF SCI & TECH

Ceramic inkjet inks

The current document discloses an inkjet ink that is characterized by exceptionally low sedimentation rate of glass frit and pigment particles. Practically, the ink reversibly gels upon extended standing, thus preventing sedimentation entirely.

Owner:DIP TECH

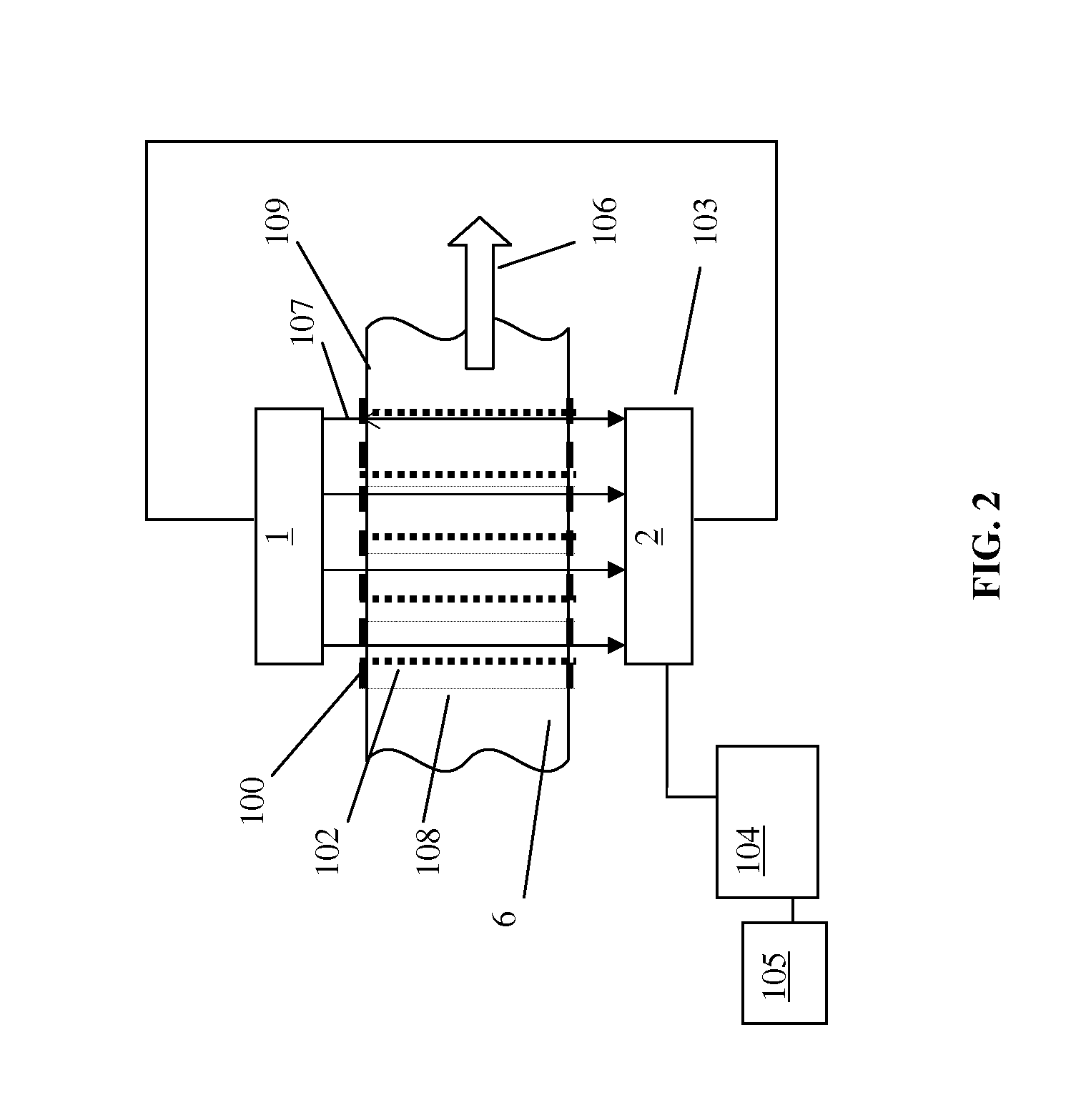

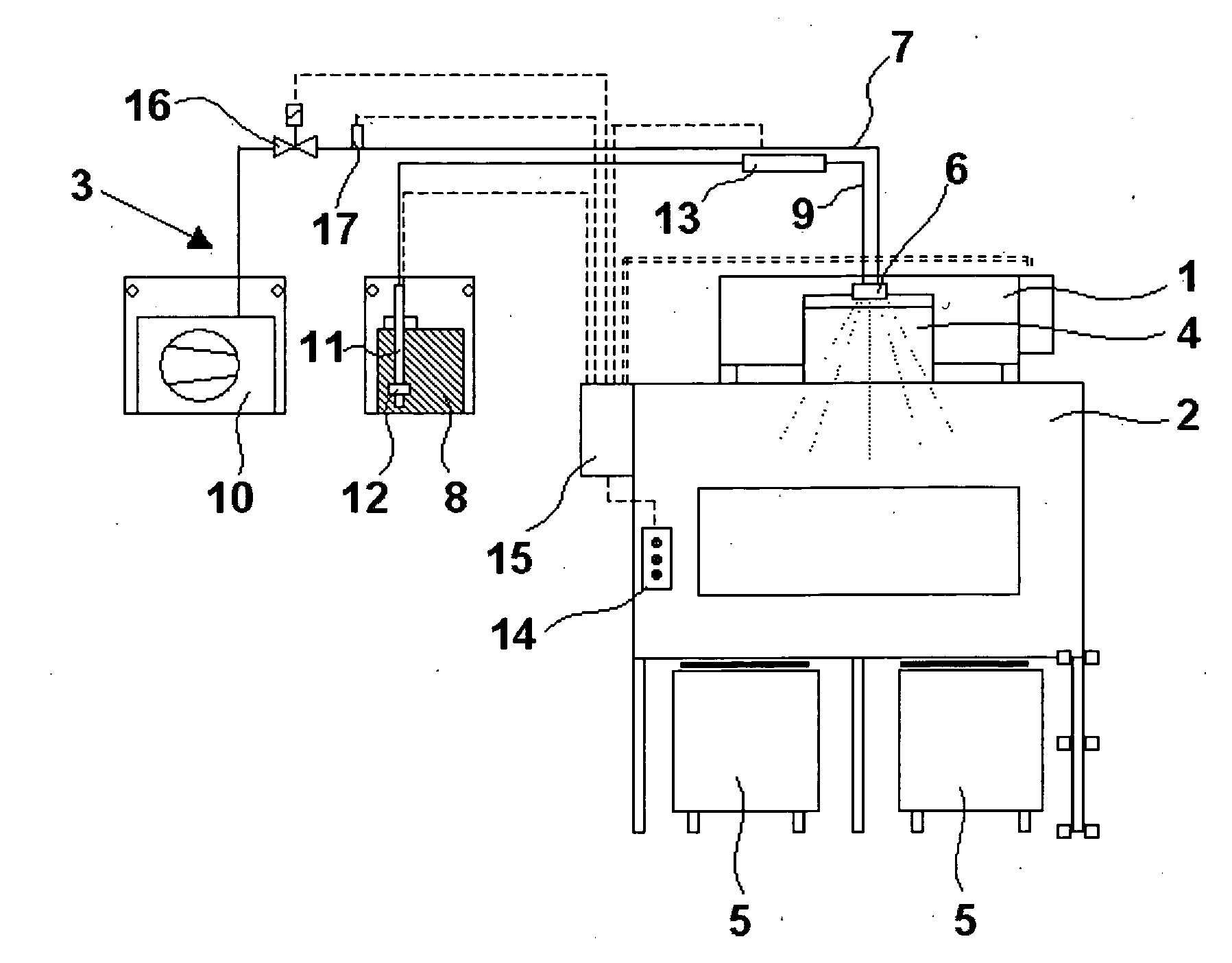

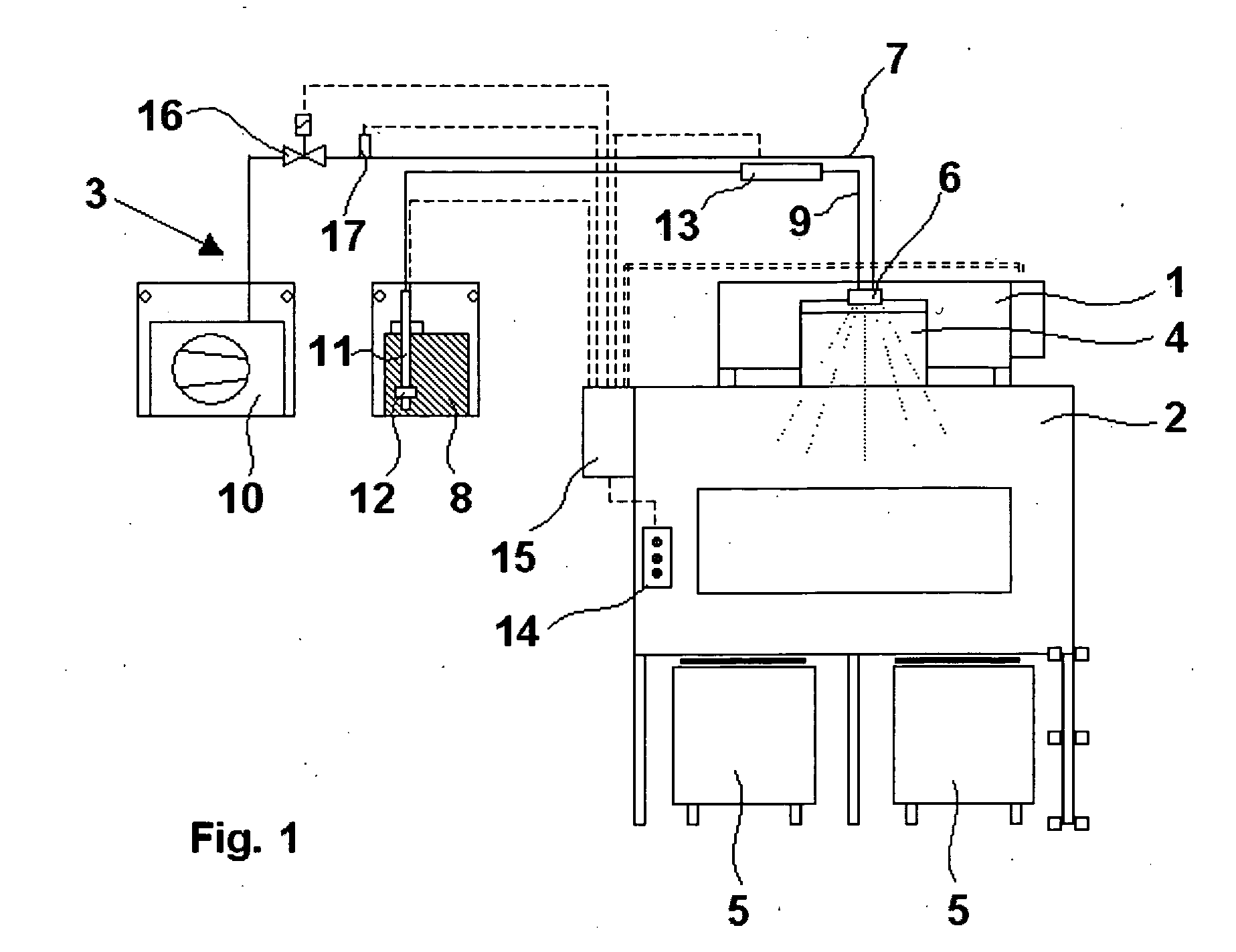

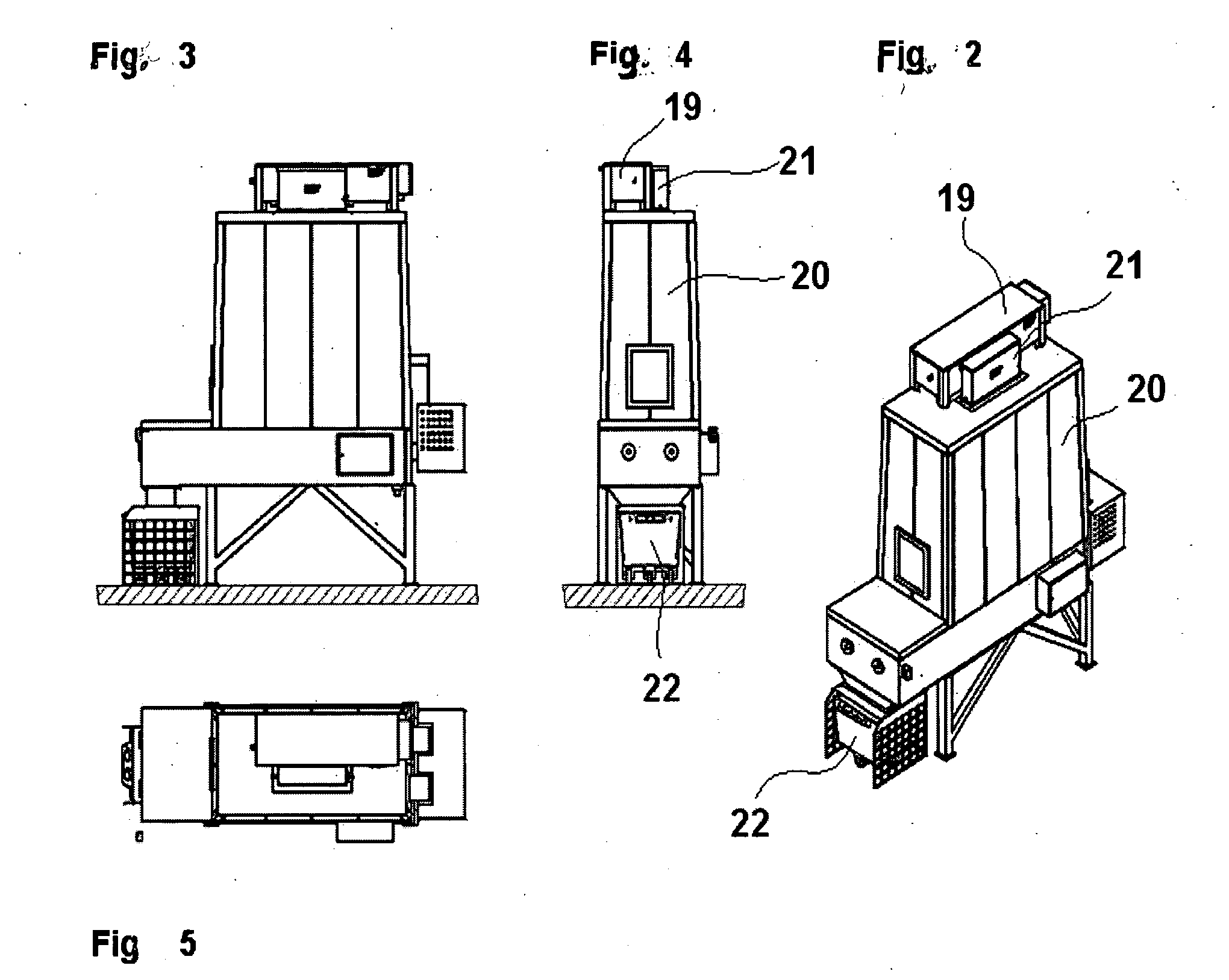

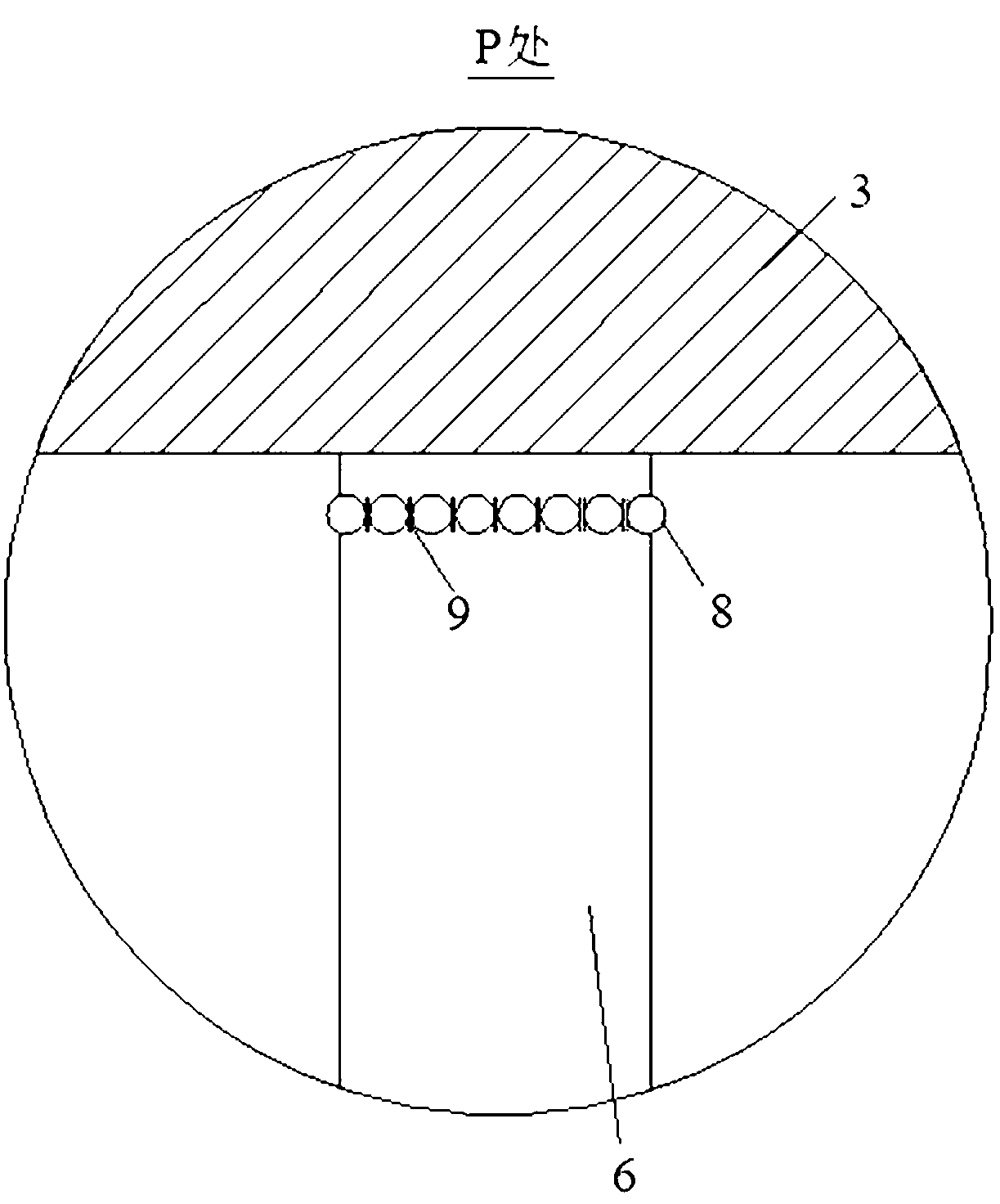

Device and method for disinfection of ice machines, ice silos and/or chutes for transport of ice

InactiveUS20090000317A1Improve efficiencyImprove disinfection efficiencyLiquid surface applicatorsIce productionNebulizerDisinfectant

Device and method for disinfection of ice machines, ice silos, and / or chutes for transport of the ice, with a storage tank (8) for holding a disinfectant, with a pressure line (7) for the supply of pressurized carrier fluid, with at least one atomizer device (6) for atomizing the disinfectant and for generating a mixture of carrier fluid and disinfectant and with an inlet for introducing the carrier fluid / disinfectant mixture into the ice machine (1, 19, 23, 28, 32), the ice silo (2, 20, 24, 33), or the ice chutes (4, 21, 29, 34).

Owner:MAJA-MASCHINENFABRIK HERMAN SCHILL KG

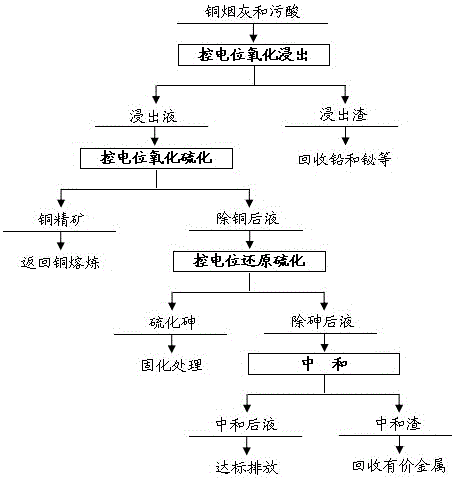

Combined treatment method for copper smelting soot and polluted acid

InactiveCN105950874AEasy to separateAvoid consumptionProcess efficiency improvementCopper sulfideSoot

The invention discloses a combined treatment method for copper smelting soot and polluted acid. The method includes the steps that after the copper smelting soot and the polluted acid are mixed for pulp conditioning, an oxidizing agent is added for controlled-potential oxidization leaching, so that copper, arsenic, zinc and other metal in the copper soot are dissolved to enter leachate, and lead, bismuth and other metal are precipitated to enter a reaching residue; then an oxidizing agent is added into the leachate so that As(III) in the solution can be completely oxidized into As(V); afterwards, sodium sulphide is added, so that the copper in the solution is precipitated in the form of copper sulphide to produce copper concentrate, and a reducing agent is added into the copper-removed solution so that the As(V) in the solution can be completely reduced into As (III); then sodium sulphide is added so that the arsenic in the solution can be precipitated in the form of arsenic sulfide; and finally the arsenic-removed solution is neutralized with alkaline and then is discharged after reaching the standard. By the adoption of the combined treatment method, controlled-potential oxidization leaching, controlled-potential oxidization sulfurization and reduction sulfurization are simultaneously combined to be used for step-by-step separation and recovery of valuable metal in the copper smelting soot and polluted acid, and therefore waste in the system can be recycled, and the purpose of using waste to treat waste is achieved.

Owner:CENT SOUTH UNIV

Isothiazolone composition and method for stabilizing isothiazolone

InactiveCN1671674AReduce sedimentation rateInhibit growthBiocideOrganic chemistryIsothiazolinoneEmulsion

The present invention relates to an isothiazolone composition and a method for stabilizing the same, and particularly to an isothiazolone composition that does not comprise alkali earth metal salt of a divalent metal such as magnesium chloride, which causes salt shock, and thus that can be stably used as a sterilizer in a dispersion or emulsion such as paint acrylate or latex, therefore effectively preventing growth of microorganisms, and that has superior storage stability due to its low precipitation formation rate because it comprises a precipitation-preventing agent, and a method for stabilizing the same.

Owner:SK CHEM CO LTD

Liquid-phase CO2 fracturing fluid

InactiveCN105131930AImprove sand carrying capacityReduce frictionDrilling compositionFiberCarbon nanotube

The invention discloses a liquid-phase CO2 fracturing fluid including a tackifying agent, an auxiliary solvent, nano coating fibers and liquid CO2, wherein the nano coating fibers particularly comprise polymer / inorganic ion nano composite fibers, polymer / carbon nano tube composite fibers, polymer / lamellar filling material composite fibers, polymer / montmorillonite nano composite fibers or polymer / graphite nano composite fibers. In the embodiment above, by means of addition of the nano coating fibers to the liquid-phase CO2 fracturing fluid, friction resistance in a constructed tubular column is reduced. In addition, the nano coating fibers can form a fiber network in the liquid-phase CO2 fracturing fluid, thereby improving sand carrying performance of the fracturing fluid, changing sedimentation manner and reducing sedimentation rate of a propping agent.

Owner:PETROCHINA CO LTD

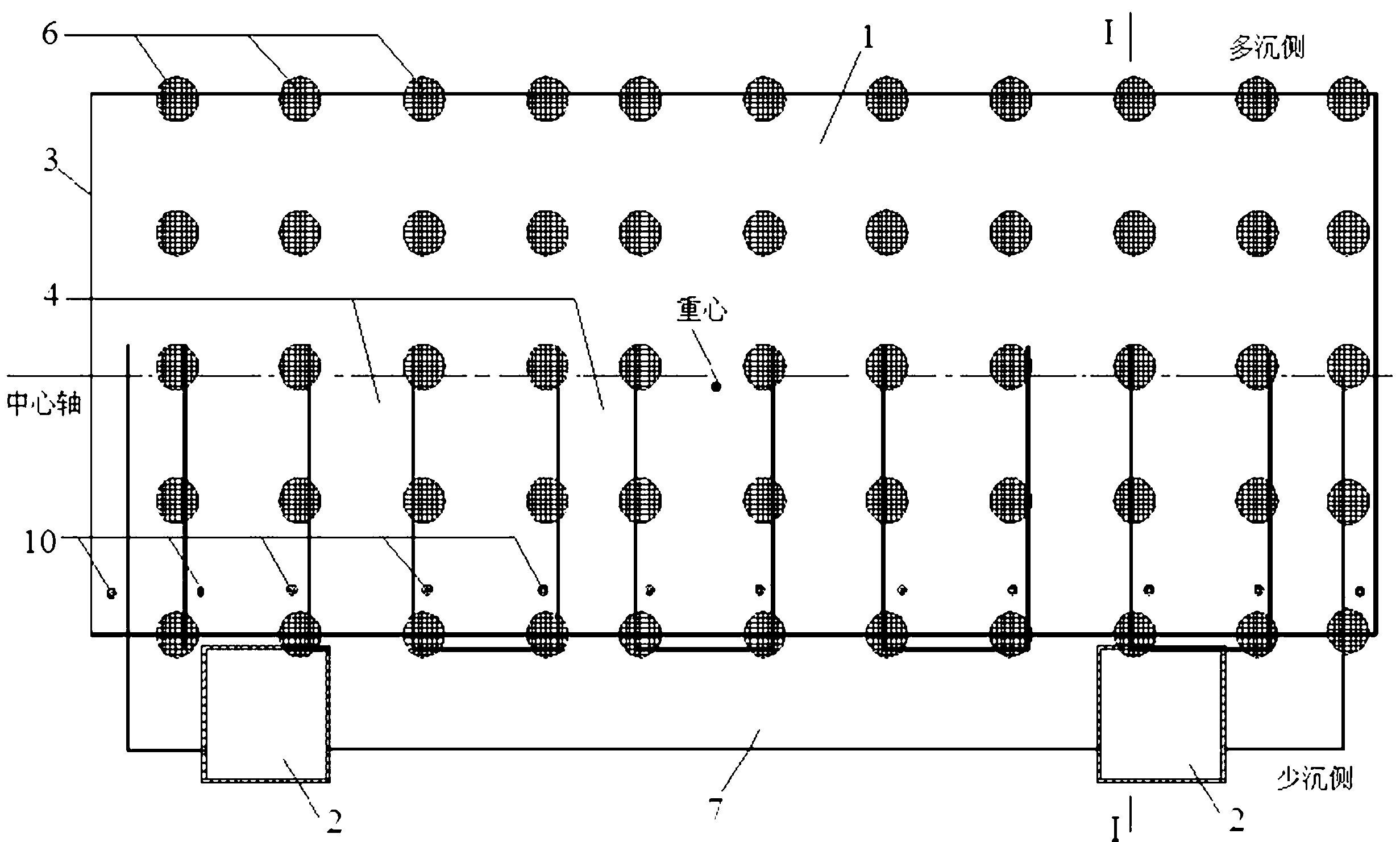

Rectifying method by drilling at intervals and pile cutting off

ActiveCN103321260ABearing area reducedAccelerated settlementFoundation engineeringStructural engineeringControllability

The invention provides a rectifying method by drilling at intervals and pile cutting off. The method includes excavating at least two constructing wells along the longitudinal direction of the light settlement side, communicating all the constructing wells, excavating a plurality of horizontal roadways, determining the pile cutting height of each concrete pile from the light settlement side to the heavy settlement side in a same row of concrete piles according to designed maximum rectifying amount by the principle of similar triangles, cutting off piles in batches, and arranging a pre-reserved stripe between two adjacent pile-cutting holes on one concrete pile; rectifying by the own weight of an inclined building and force of an anchor cable arranged at the light settlement side until a rectifying target is achieved; patching the pile-cutting hole, filling back the wells and the roadways, and finishing rectifying of the inclined building. By the aid of the method, blindness and sudden sinking effect of pile cutting off can be avoided effectively, rectifying risks are reduced, defects of poor controllability, difficulty in mastering pile cutting amount accurately and the like are overcome, controllability and security of rectifying are improved greatly, and the method can be applied in the fields of building rectifying and reinforcing.

Owner:NORTHWEST RES INST CO LTD OF C R E C

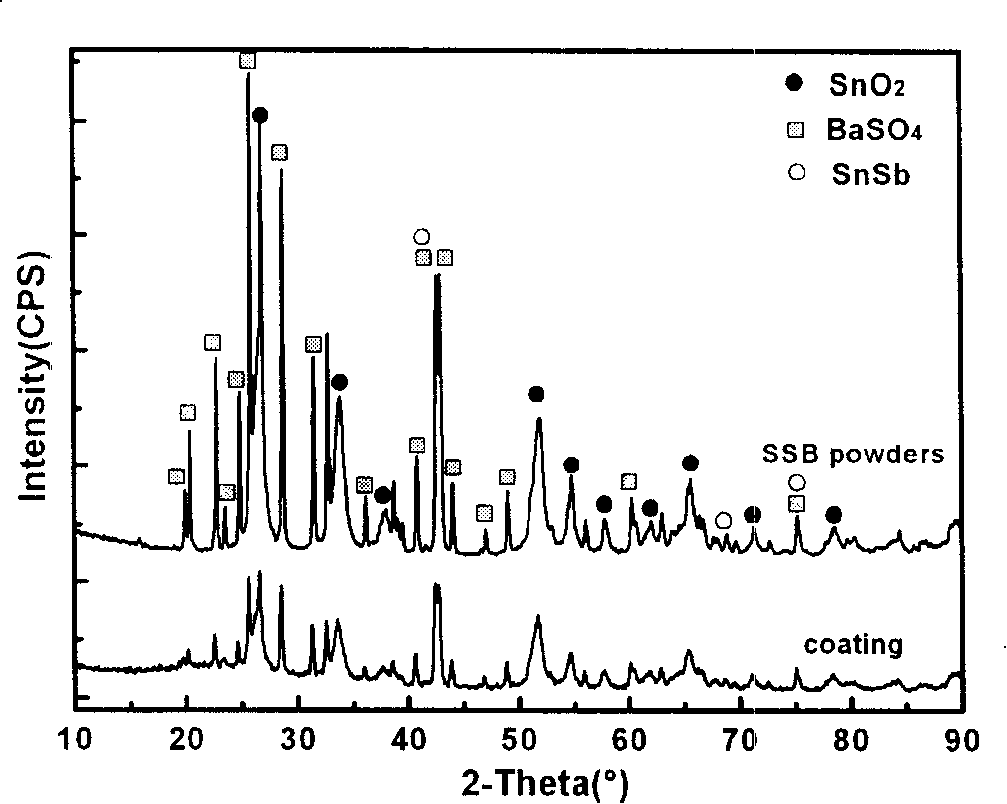

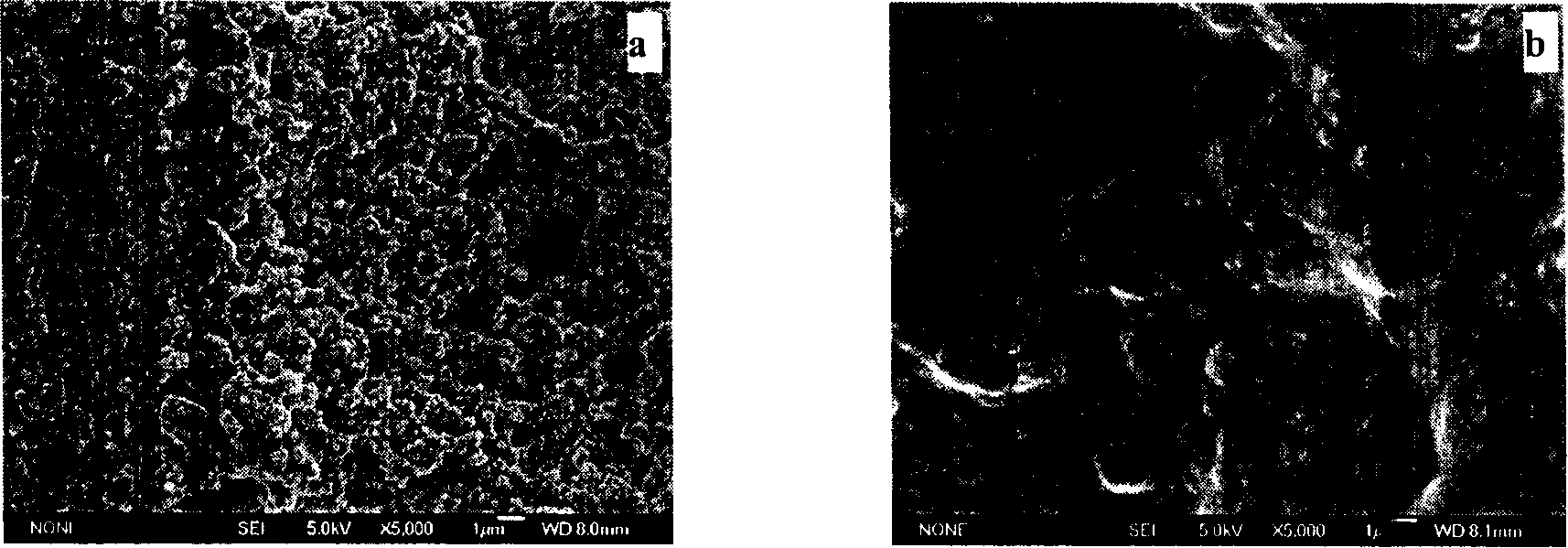

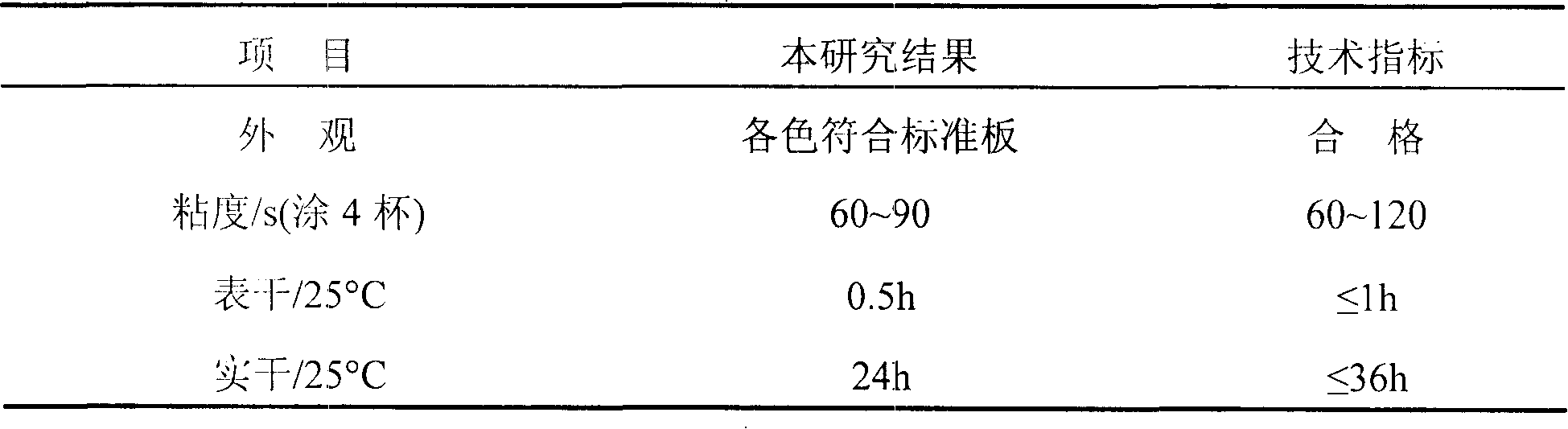

Process for producing composite electrically-conducting paint

InactiveCN101220219AGood dispersionImprove conductivityEpoxy resin coatingsElectrically-conductive paintsCoated surfaceConductive coating

The invention discloses a preparation method of a composite conductive coating. SnCl4.4H2O and SbCl3 are taken as raw materials, high-purity barite is ball milled for 1.5 hours to 7.5 hours; chemical coprecipitation method is adopted for produce a precursor SnO2BaSO4 which is intermingled with Sb; SSB composite conductive power is obtained after being baked for 1.5 hours to 2 hours at a temperature of 600 to 900 DEG C after being dried. The SSB composite conductive power is subject to surface modification with a coupling agent; film forming matter with a weight percentage of 27 to 43 percent and accessory ingredient are dispersed fully; 25 to 45 percent of the SSB composite conductive power with modification surface is added into the disperse system for stirring fully. A diluting agent is put into the mixture for mixing and then the new mixture is sand ground and dispersed for 0.5 hour to 1 hour at a high speed; after the impurity is removed, finished product of conductive coating is obtained. The composite conductive coating prepared by the novel method has the advantages of good constructive property, low sedimentation rate of coating, smooth and plane coating surface and good anti-friction and anti-impact property.

Owner:CENT SOUTH UNIV

Method to Enhance Proppant Conductivity from Hydraulically Fractured Wells

InactiveUS20080196895A1Contributing to overall effectiveness of treatmentConductivity is not affectedFluid removalDrilling compositionSlurryCarrier fluid

A method of mitigating proppant settling in a hydraulic fracture in order to better suspend the proppant as well as ensure a more uniform pack, by mixing a pre-determined volume percent of low density additive, such as glass beads or other suitable material, such as polylactic acid particles, into the fracturing slurry along with the standard high-density proppant, it is anticipated that density gradients can be induced inside the fracture. Upward movement of low density additive due to them having density lower than the carrier fluid will interfere with downward movement of high-density proppant and vice versa. This mutual interference between the two proppants confined in the narrow fracture will significantly hinder the settling / segregation of the high-density proppant. The low density material has a specific gravity of about 0.3, particle size distribution similar to that of standard proppant, and sufficient mechanical strength to survive fracture closure stress.

Owner:CSI TECH LLC A TEXAS LLC

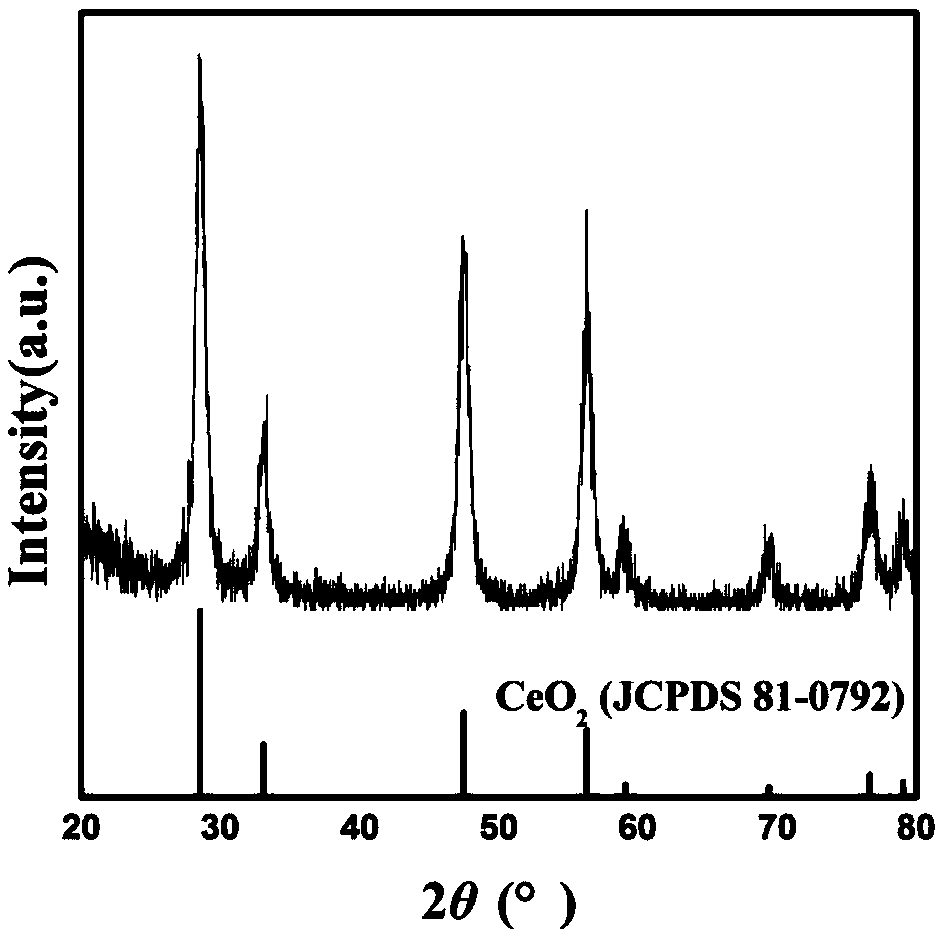

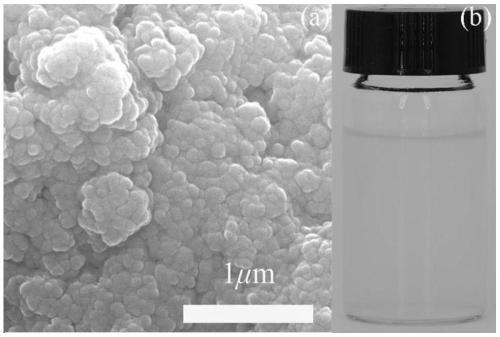

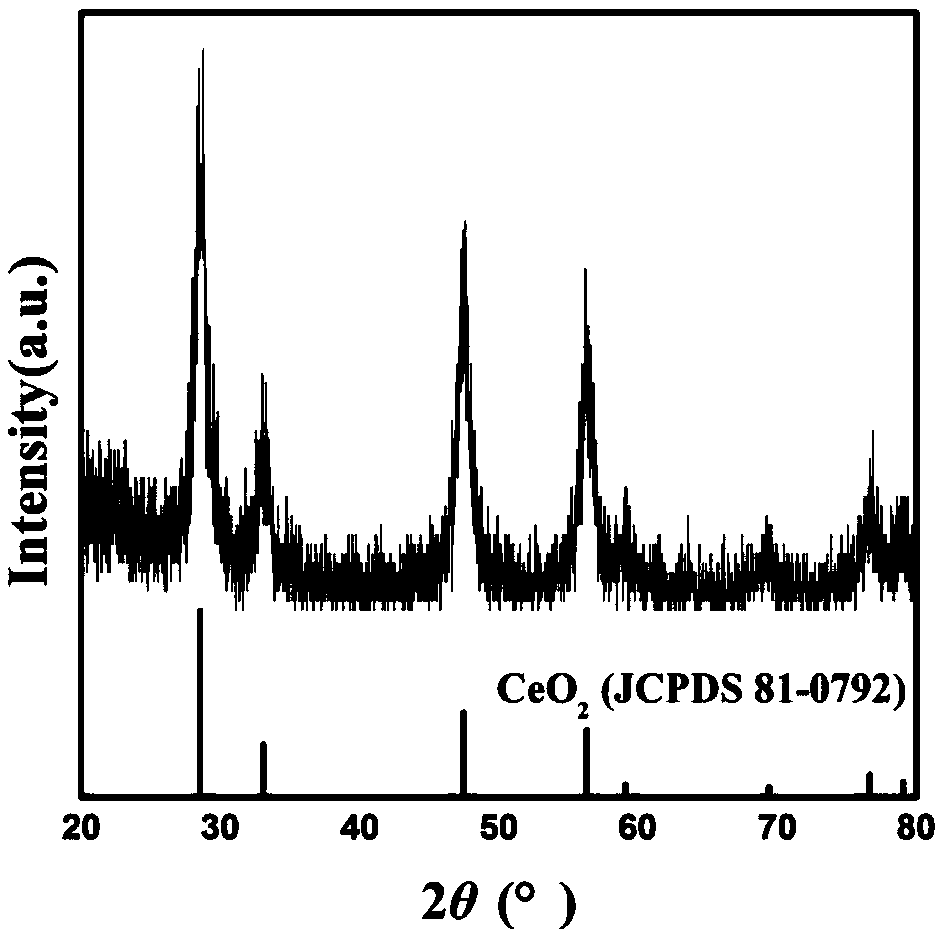

Fast preparation method of nanometer cerium dioxide dispersion liquid

InactiveCN108975380AEasy to controlReduce energy consumptionRare earth metal oxides/hydroxidesNanotechnologyCeriumUltraviolet absorption

The invention discloses a fast preparation method of nanometer cerium dioxide dispersion liquid. Ordinary pressure and low temperature water phase pyrolysis is combined with the air oxidation effect for fast preparing high-quality nanometer cerium dioxide dispersion liquid. By regulating the preparation process, the average grain diameter of cerium dioxide crystalline grains can be regulated in arange of 50 to 1000nm; the stabilization time of the dispersion liquid can reach 30 days or longer to several months. The cerium dioxide dispersion liquid can be widely applied to the fields of polishing, catalysis, luminescence, ultraviolet absorption and the like.

Owner:HEFEI UNIV OF TECH

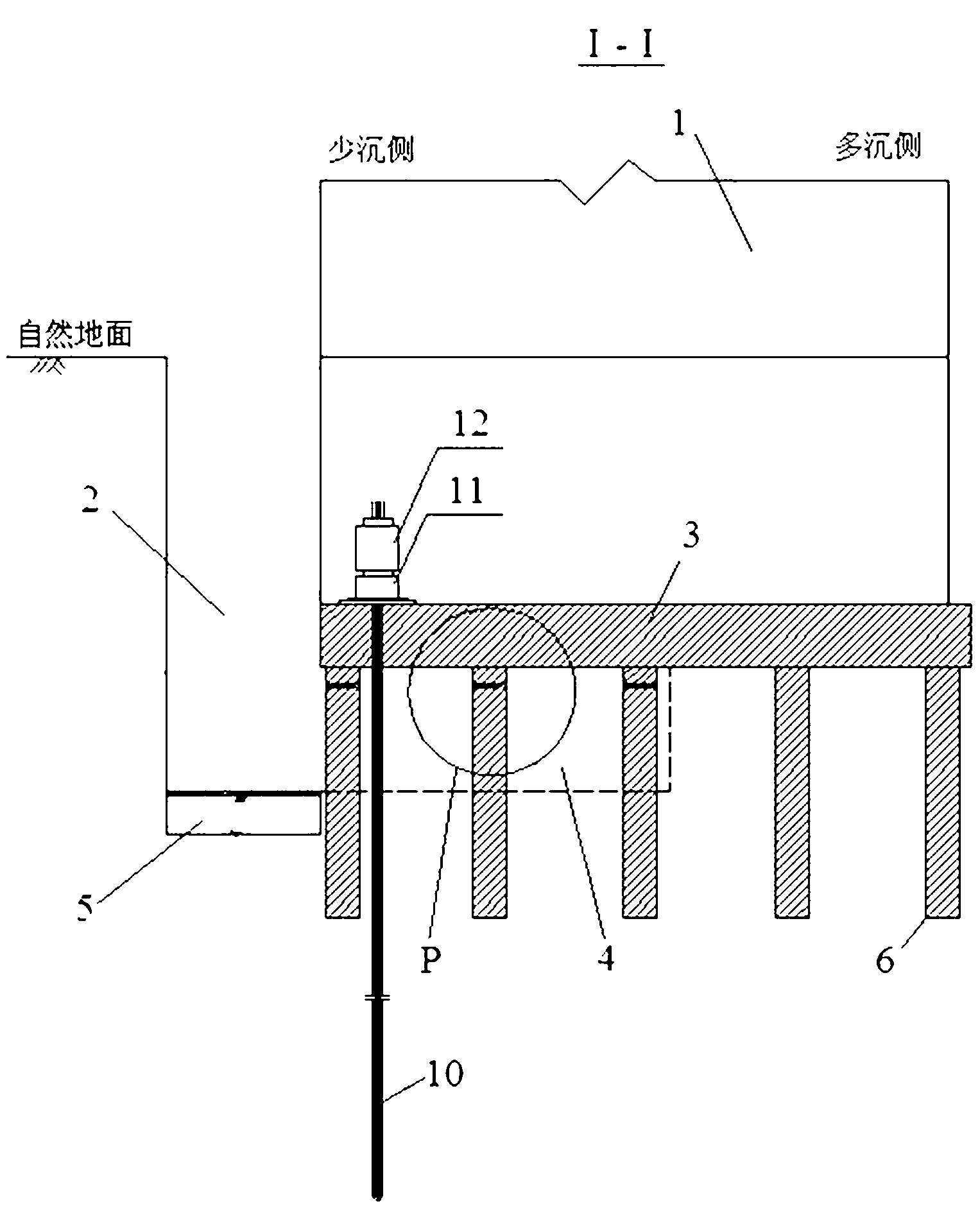

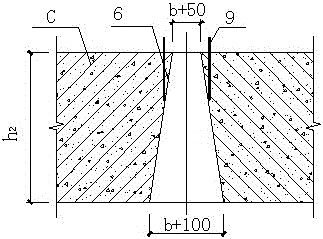

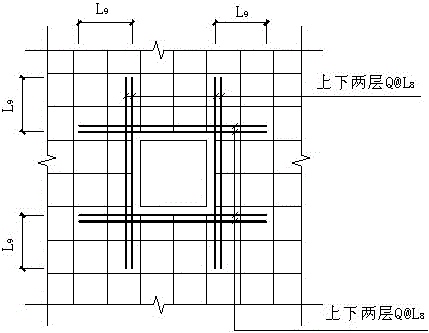

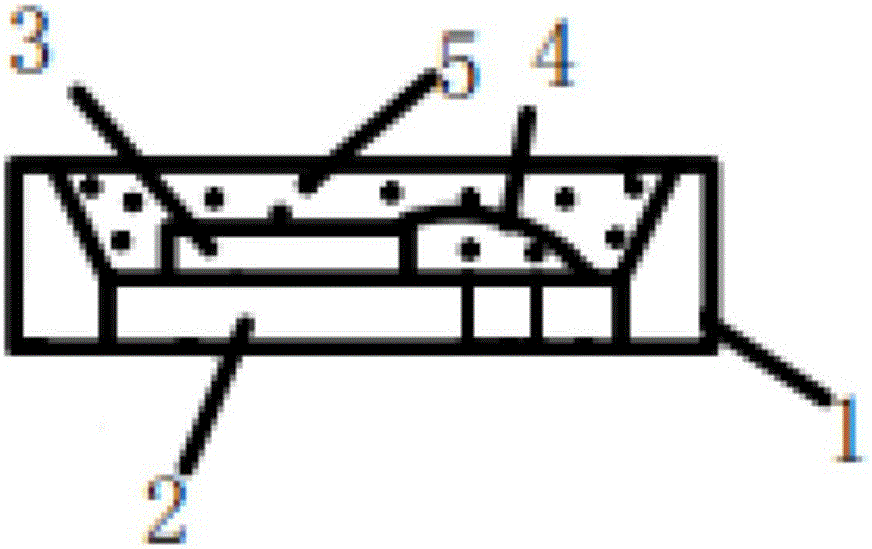

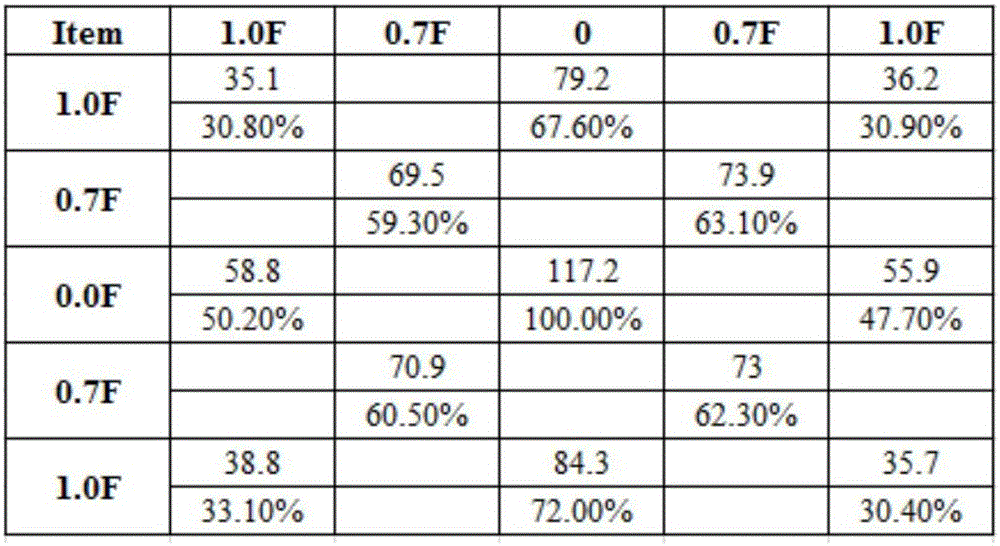

Foundation reinforcement and inclination correction method for friction piles of high-rise building

InactiveCN106436788AReduce sedimentation rateRealize the purpose of reinforcement and rectificationBuilding repairsFoundation repairHigh riseCorrection method

A foundation reinforcement and inclination correction method for friction piles of a high-rise building comprises the steps of 1, building settlement and inclination analysis, wherein (1), settlement and inclination displacement monitoring, (2), supplementary investigation of geotechnical engineering conditions and (3), determination of bearing capacity of original pile foundation are included; 2, making of an inclination correction and reinforcement scheme of the high-rise building, wherein (1), determination of a reinforcement and inclination correction idea, (2), determination of a reinforcement and inclination correction target, (3), raft supplement calculation, and (4), a principle of pile supplement are included; 3, high-rise building reinforcement construction, wherein (1), foundation excavation, (2), raff construction and determination of supplement pile positions, (3), column (wall) foot reinforcement construction, (4), static pressure pile construction, (5), press-in pile quality detection, (6), settlement of large side sealing piles, and (7), original soil compaction are included; and 4, high-rise building self-weight inclination correction construction, wherein (1), the use of high-rise building self-weight inclination correction, (2), settlement of small side sealing piles, and (3), the original soil compaction are included.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Method for recycling rhenium from tungsten-rhenium alloy waste

ActiveCN106430320AHigh energy consumptionReduced current efficiencyProcess efficiency improvementRhenium compoundsRheniumPotassium

The invention provides a method for recycling rhenium from tungsten-rhenium alloy waste. The method comprises the following steps that 1, the tungsten-rhenium alloy waste is subjected to electrochemical dissolution, and a rhenium-containing solution is obtained; 2, excessive potassium chloride is added into the rhenium-containing solution, rhenium in the rhenium-containing solution is made to perform a precipitation reaction with potassium chloride to generate KReO4 precipitations, then, the KReO4 precipitations are subjected to recrystallization, and high-purity KReO4 is obtained. The technology is simple, the problem of collecting rhenium in a comparison oxidation volatilization method does not exist, and the rhenium recovery rate is high. Due to the fact that both a traditional oxidation volatilization method and a niter fusion-ion exchange method are implemented under the high-temperature condition, comparatively, the technology is low in energy consumption.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

LED fluorescent glue and packaging method for improving luminescence uniformity, and LED

InactiveCN105845812AGood dispersionLarge specific surface areaSolid-state devicesSemiconductor devicesFluorescenceWavelength

The invention discloses an LED fluorescent glue that improves the uniformity of light emission. In parts by weight, the fluorescent glue consists of 1 part of packaging glue, 0.01-1 part of fluorescent powder, 0.01-0.1 part of silica-based inorganic nanoparticles, 0.01 part of ‑1 part silicone granules. Inorganic nanomaterials and silicone particles are mixed in the encapsulation glue, which reduces the sedimentation rate of the phosphor in the encapsulation glue, improves the uniformity of the phosphor distribution in the colloid, makes the white light spot more uniform, and improves the light diffusivity and transmittance. The light rate is maximized, and by changing the propagation path of the light, the light of various wavelengths is more fully mixed, and the spatial color uniformity of the light is further improved. It also provides an LED packaging method and LED that improve the uniformity of light emission, which improves the consistency of products, reduces the probability of uneven color distribution in space due to uneven distribution of phosphor powder, and improves product yield and product production. efficiency.

Owner:SHENZHEN JUFEI OPTOELECTRONICS CO LTD

High-temperature-resistant full-suspension low-damage fracturing fluid and preparation method thereof

The invention discloses a high-temperature-resistant full-suspension low-damage fracturing fluid, which comprises the following components in percentage by weight: 0.3-0.5% of a low-damage thickeningagent, 0.1-0.4% of a multifunctional stabilizer, 0.1-0.3% of a regulator, 0.4-0.8% of a suspension synergist and the balance of clear water or saline water; the preparation method of the fracturing fluid comprises the following steps of: 1, adding the low-damage thickening agent, the multifunctional stabilizer and the regulator into clear water or saline water under a stirring condition, uniformlystirring, and swelling for 2 to 4 hours to obtain fracturing fluid base liquid; 2, fully mixing the fracturing fluid base liquid and the suspension synergist to form the full suspension fracturing fluid with excellent sand carrying performance and temperature resistance under the combined action of physical crosslinking and chemical crosslinking. The fracturing fluid is superstrong structure fluid formed by carrying out physical crosslinking and chemical crosslinking on acrylamide polymer and suspension synergist together, and the temperature resistance can reach 150 DEG C; the sand carryingperformance is excellent, the strong spatial structure can completely suspend a proppant, and the influence of temperature is small.

Owner:SOUTHWEST PETROLEUM UNIV +2

Colorful pervious concrete and preparation method thereof

The invention relates to the technical field of pervious concrete preparation, in particular to colorful pervious concrete. Concrete in each stere is prepared from the following raw materials of, in parts by weight, 80-120 parts of coarse-diameter gravels, 9-15 parts of fine-diameter zeolite, 15-30 parts of cement, 6-8 parts of water, 4-6 parts of additives, 2-4 parts of painting and 0.5-1.5 partsof modified wood fibers. According to the technical scheme of the preparation method of the colorful pervious concrete, fine-diameter zeolite is added to increase the accumulation density of aggregates, the contact points among the aggregates are increased, accordingly the compressive strength of the prepared pervious concrete is improved, meanwhile, zeolite has a special porous structure, and thus the porosity of the pervious concrete is improved further. The modified wood fibers are added into the pervious concrete as well, so that adhesion among granules of the pervious concrete is tighter, the sedimentation rate of cement paste is lowered, meanwhile, the modified wood fibers can bear part of tensile stress, and accordingly the breaking strength of concrete is improved.

Owner:南通鸿基市政工程有限公司

Method to enhance proppant conductivity from hydraulically fractured wells

InactiveUS7708069B2Effective coverageIncrease shear rateFluid removalDrilling compositionSlurryCarrier fluid

Owner:CSI TECH LLC A TEXAS LLC

Dispersible tablet composition

ActiveUS9198862B2Disintegrates quicklyLow rate of sedimentationBiocideCarbohydrate active ingredientsBULK ACTIVE INGREDIENTActive ingredient

Disclosed herein is a dispersible tablet composition including a pharmacologically active ingredient and at least one excipient that reduces the sedimentation rate of the active ingredient and a process for preparing the same.

Owner:RUBICON RES PTY LTD

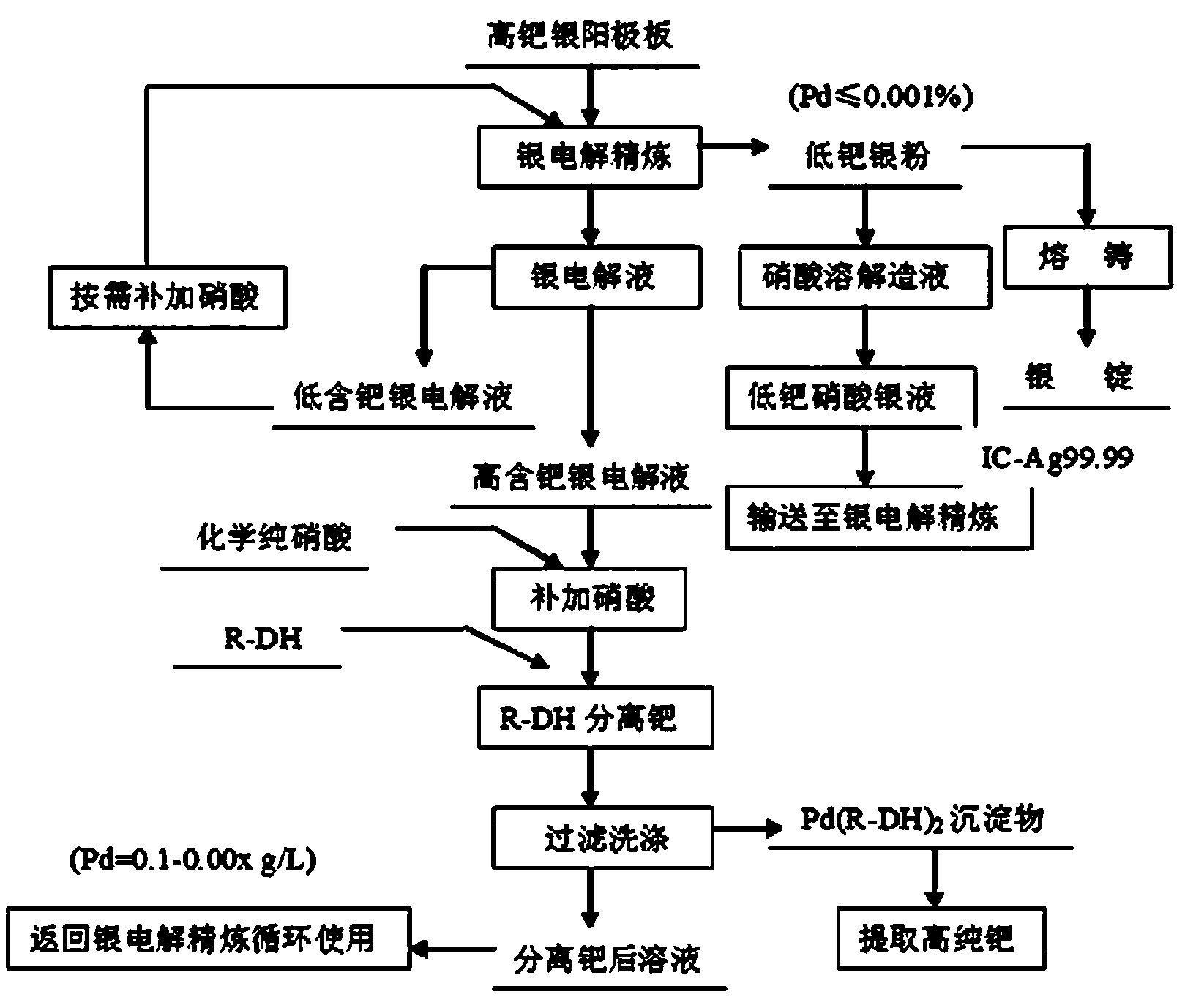

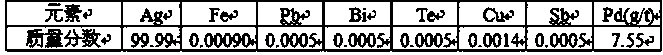

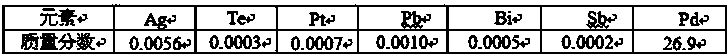

Method for high-efficiency separation of palladium from silver electrolyte

InactiveCN103526233AHigh selectivityImprove efficiencyPhotography auxillary processesProcess efficiency improvementHigh selectivityCoordination complex

The invention provides a method for high-efficiency separation of palladium from a silver electrolyte. The method comprises the following steps: allowing the mass volume concentration of free nitric acid in the silver electrolyte to accord with requirements and heating the silver electrolyte; weighing a high-efficiency palladium removing agent, adding the high-efficiency palladium removing agent into the heated silver electrolyte and successively carrying out a reaction with stirring and vacuum filtration so as to obtain a palladium-removed liquid and a palladium complex; washing the palladium complex; adding the palladium-removed liquid into a silver electrolytic tank and carrying out silver electrolysis so as to obtain silver powder; when the mass volume concentration of palladium in a solution in the silver electrolytic tank is more than or equal to 0.4 g / L, separating palladium from the solution and returning palladium-removed liquid to the procedure of silver electrolysis for refining and cyclic utilization; and when the concentrations of a variety of other impurity ions in the solution in the silver electrolytic tank exceed prescribed limits of the silver electrolyte, extracting out the silver electrolyte, separating palladium out and carrying out treatment of a waste silver electrolyte. With the method, high-efficiency high-selectivity one-step separation of palladium from a complex silver electrolyte can be realized, the deposition rates of metals like silver and copper are extremely low, properties of the solution are not destroyed, the solution can be returned to the silver electrolytic tank for cyclic utilization, and purifying and palladium removal efficiency of the electrolyte can be improved.

Owner:JINCHUAN GROUP LIMITED

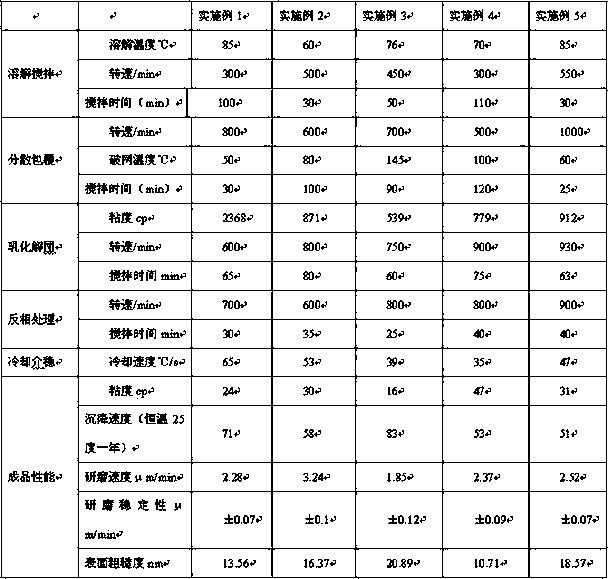

Environmental-friendly diamond grinding liquid and preparation process thereof

InactiveCN107603492AReduce sulfur contentImprove thermal stabilityPolishing compositions with abrasivesAlkaneParaffin wax

The invention relates to environmental-friendly diamond grinding liquid and a preparation process thereof. The environmental-friendly diamond grinding liquid is characterized by being prepared from the following components in percent by weight: 0.1-20wt% of grinding material, 60-99wt% of solvent, 1-20wt% of emulsifying agent, 1-20wt% of thickening agent and 1-20wt% of suspending agent, wherein thegrinding material contains at least one of polycrystalline diamond micropowder, polycrystalline-like diamond micropowder and monocrystalline diamond micropowder; the solvent contains at least one ofnaphtha, white oil, alkylbenzene and isoparaffin; the emulsifying agent contains at least one of an alkylphenol-series emulsifying agent, a benzenesulfonic-acid-series emulsifying agent, a polyoxyethylene-ether-series emulsifying agent and a sorbitol-series emulsifying agent; the thickening agent contains at least one of olefins polymer and silicon-alkane polymer; the suspending agent contains atleast one of paraffin series, epoxy resin, C9 petroleum resin and butadiene styrene rubber SBS. The environmental-friendly diamond grinding liquid is prepared by the steps of dissolving, stirring, dispersing, coating, emulsifying, disaggregating, reverse treatment, cooling and converting. The environmental-friendly diamond grinding liquid has the advantages of wide working-temperature range, longstability time and stable-controllable grinding speed and the like.

Owner:SHANDONG ZHONGSHAN PHOTOELECTRIC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com