Combined treatment method for copper smelting soot and polluted acid

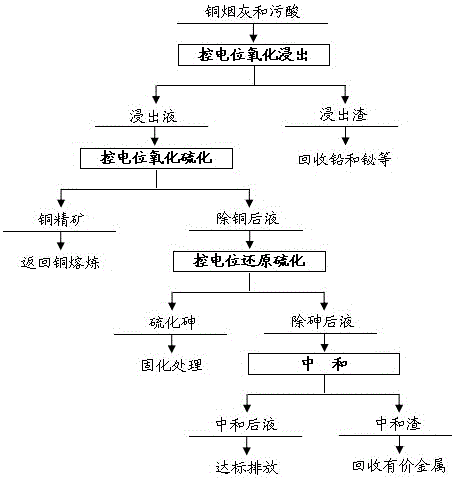

A copper smelting soot and combined treatment technology, applied in the direction of improving process efficiency, can solve the problems of increasing waste slag stacking and processing difficulty, heavy metal precipitation into gypsum slag, incomplete removal of valuable metals, etc., and achieves good metal separation effect , Prevent the precipitation of arsenic, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The soot and polluted acid produced during the smelting process of a copper concentrate oxygen-enriched bottom blowing furnace in a domestic enterprise, the main components of copper soot are calculated as mass percentages (%): Cu15.8, Pb22.5, As9.8, Zn1 .6, Bi2.9 and S10.4, the main components of dirty acid are (g / L): Cu4.2, As12.4, Bi0.8 and Zn1.5. The mass percentage of industrial grade hydrogen peroxide is not less than 27.5%, the mass percentage of industrial grade sodium sulfite is not less than 95.0%, and the mass percentage of industrial grade sodium sulfide is not less than 60.0%.

[0042] Copper smelting sewage acid and soot are mixed according to the liquid-solid ratio (ratio of liquid volume L to solid weight Kg) of 7:1, and the temperature of the mixed slurry is kept at 88°C, and an oxidant is added to oxidize and dissolve, so as to control the metal ion mixed potential of the entire slurry relative to The calomel electrode is 510mV. After the potential val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com